Bending Characteristics of Hybrid Fiber Concrete Beams Reinforced with Steel–GFRP Hybrid Rebars

Abstract

1. Introduction

2. Experimental Procedure

2.1. Concrete and Mixtures

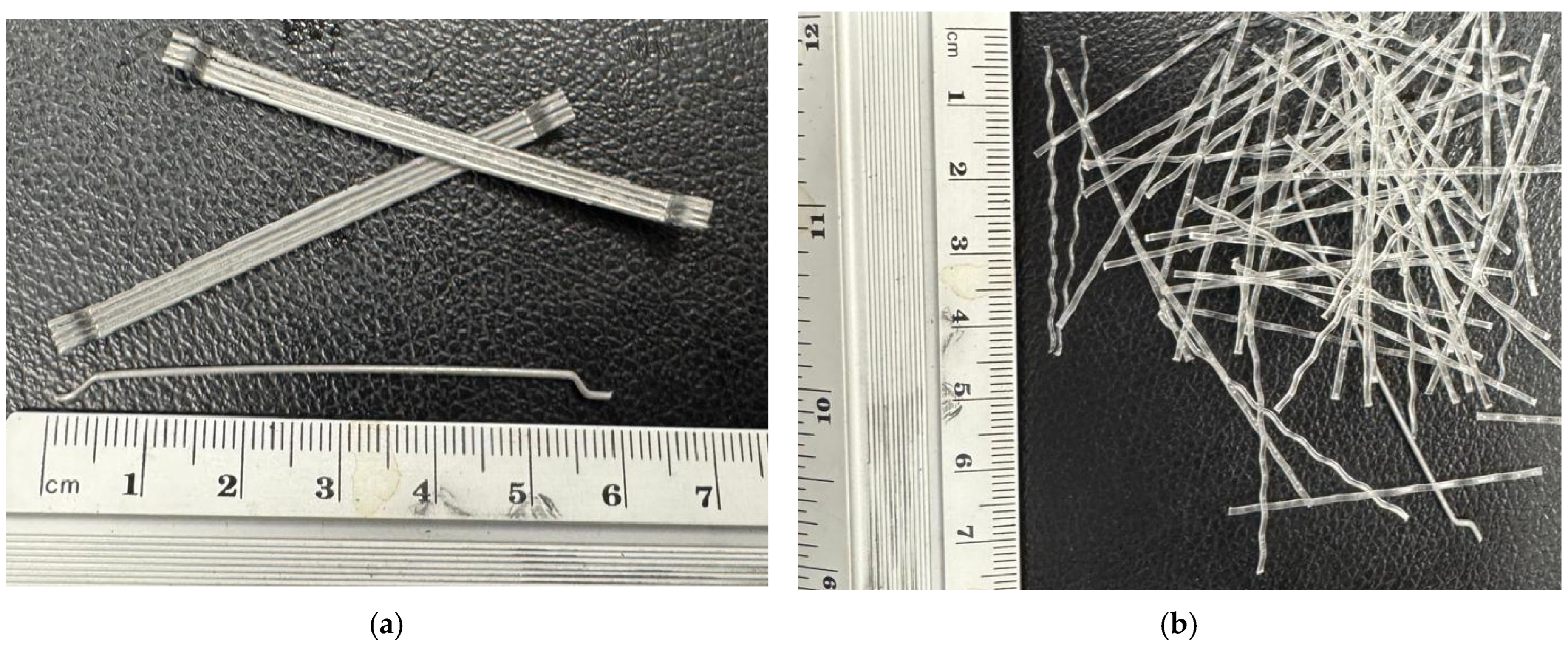

2.2. GFRP and Steel Bars

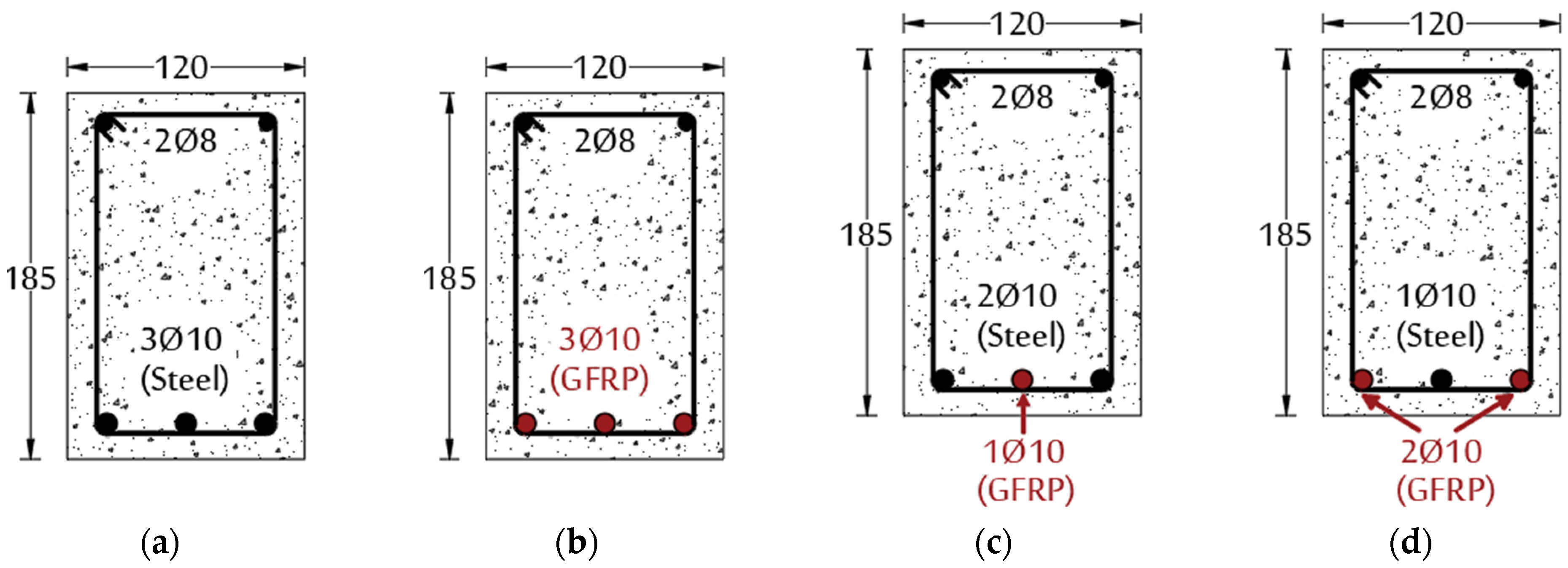

2.3. Test Specimens

2.4. Specimen Preparation

2.5. Test Setup and Procedures

3. Results and Discussion

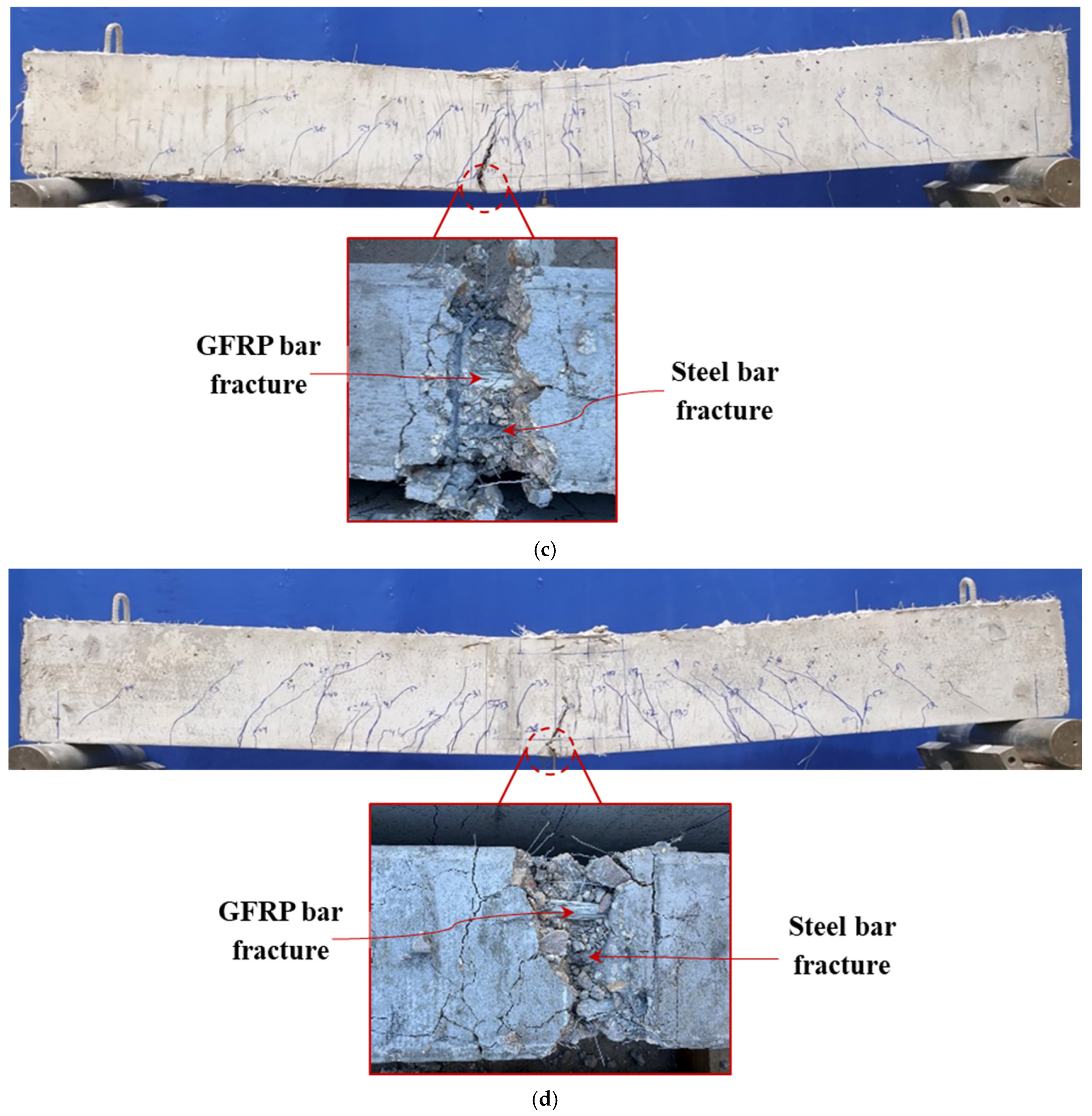

3.1. Failure Patterns

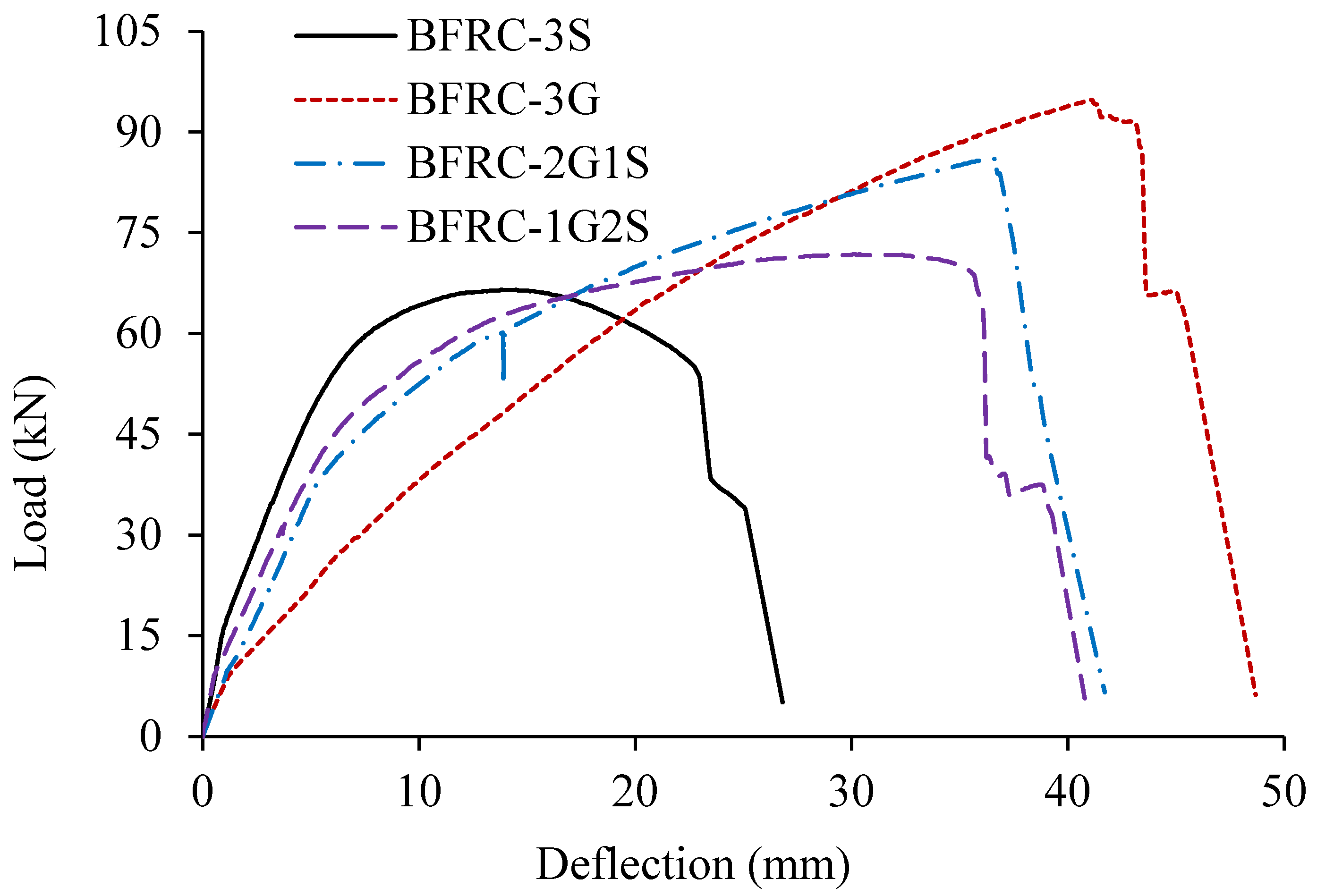

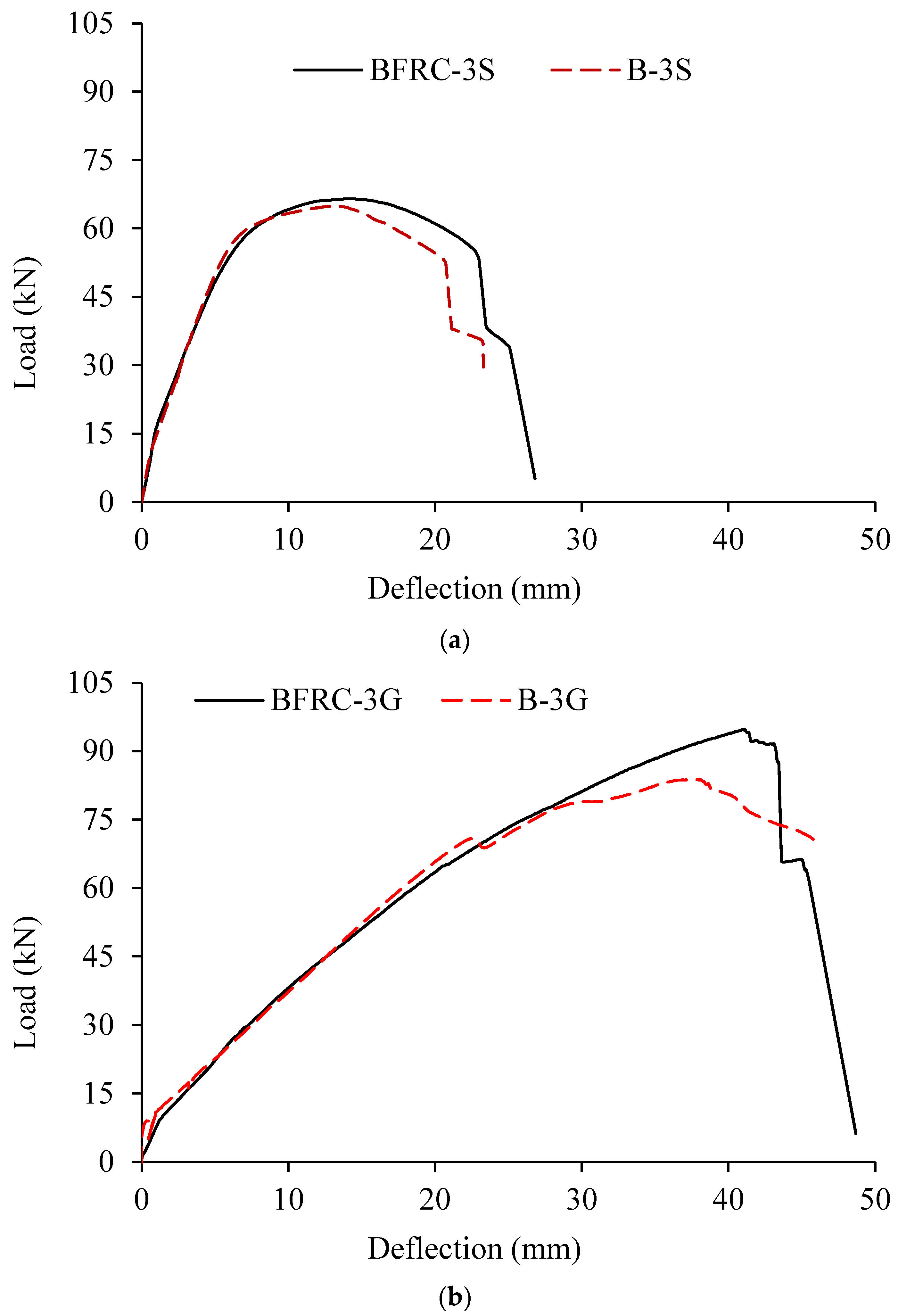

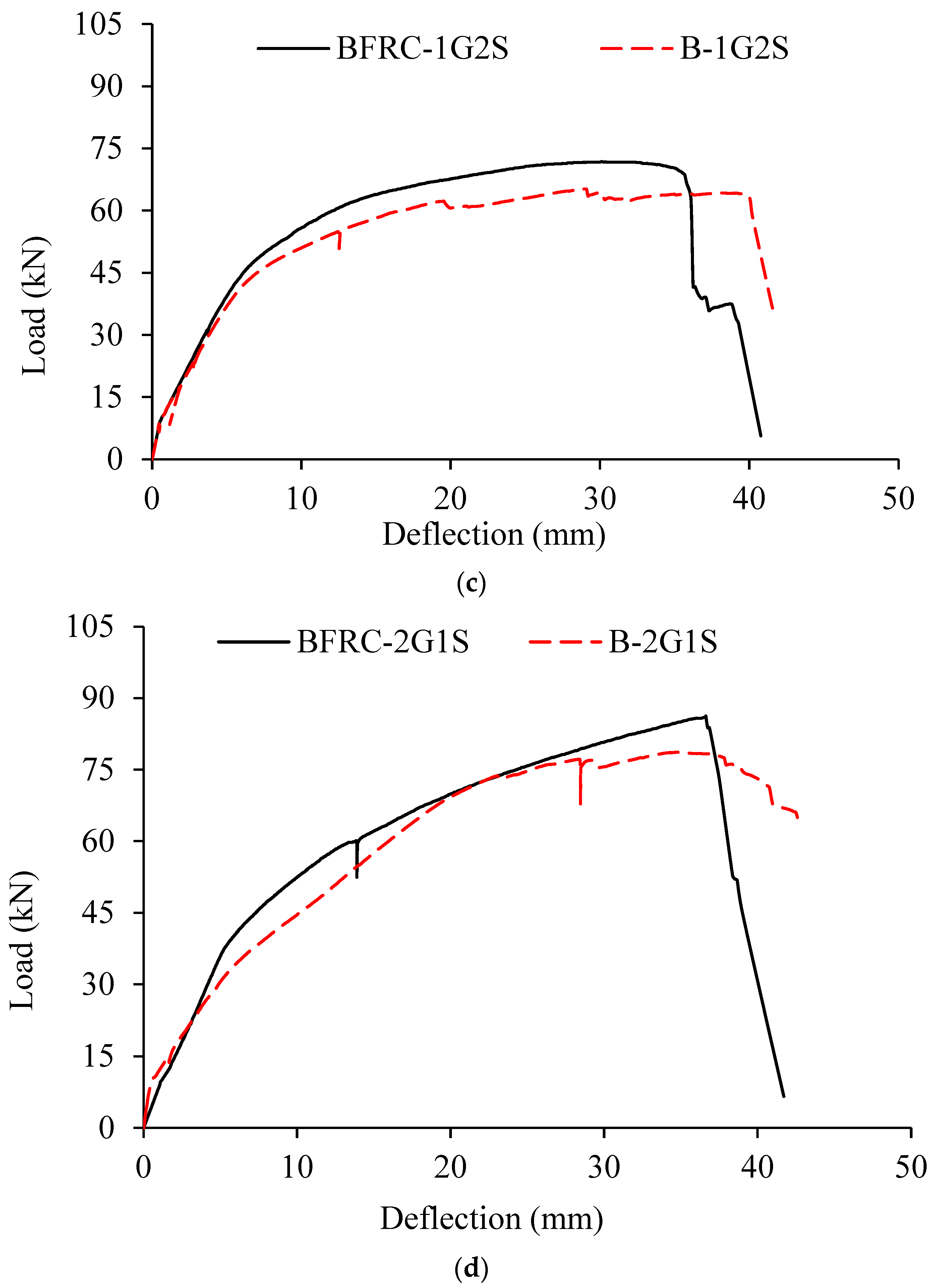

3.2. Load–Deflection Response

3.3. Load–Strain Response of the Bars

3.4. Ultimate Bending Moment

3.5. Moment–Curvature Relationship

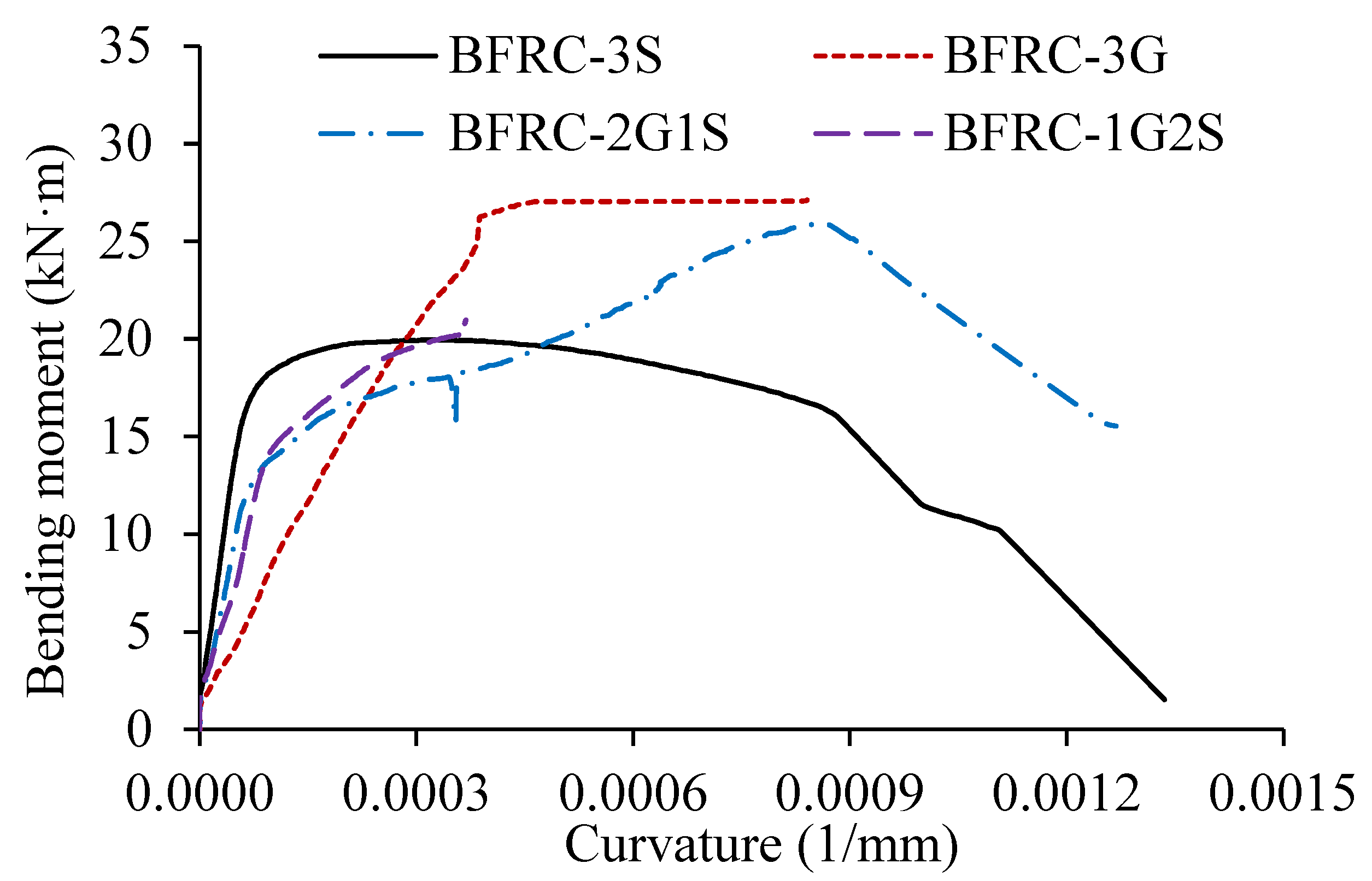

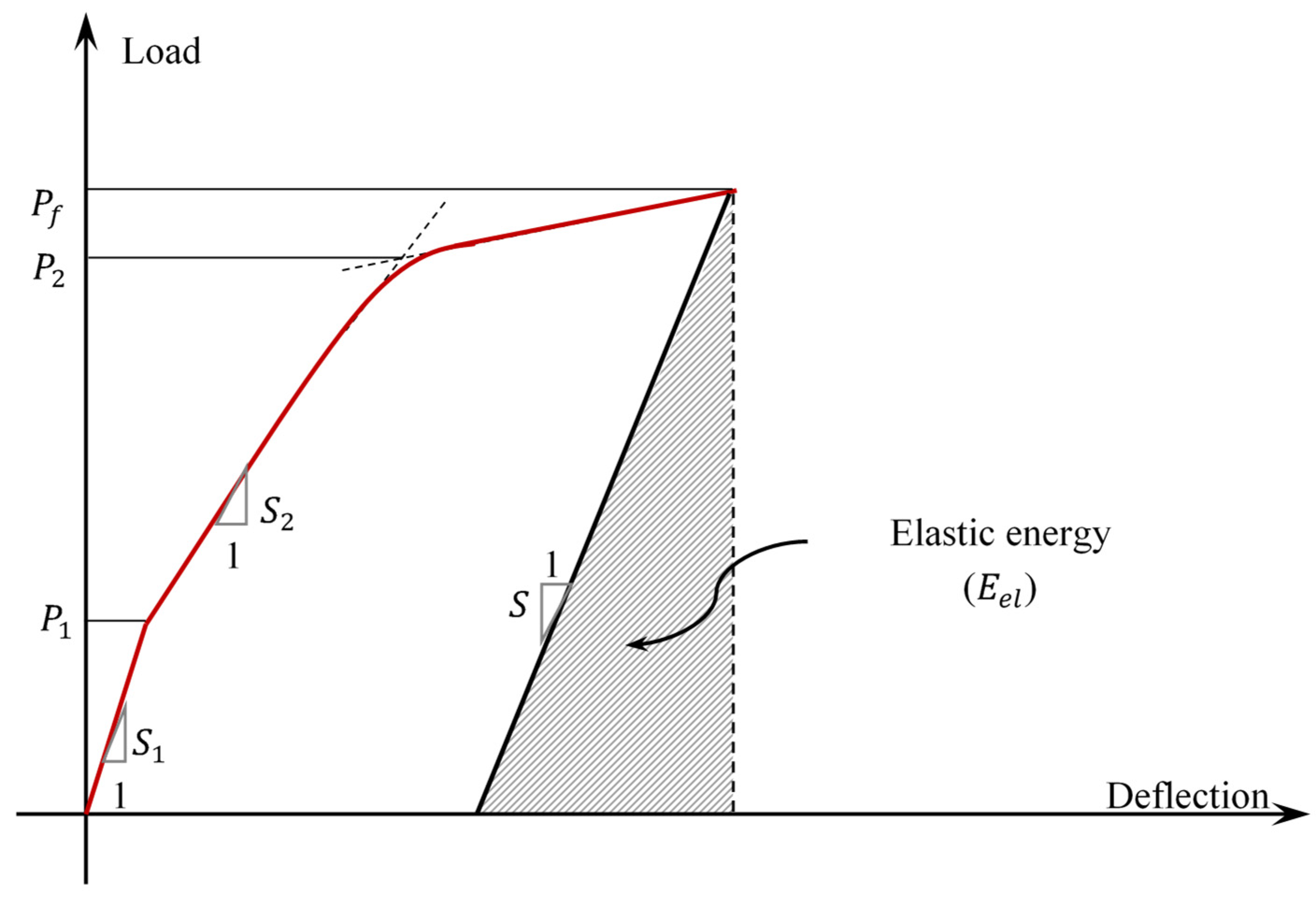

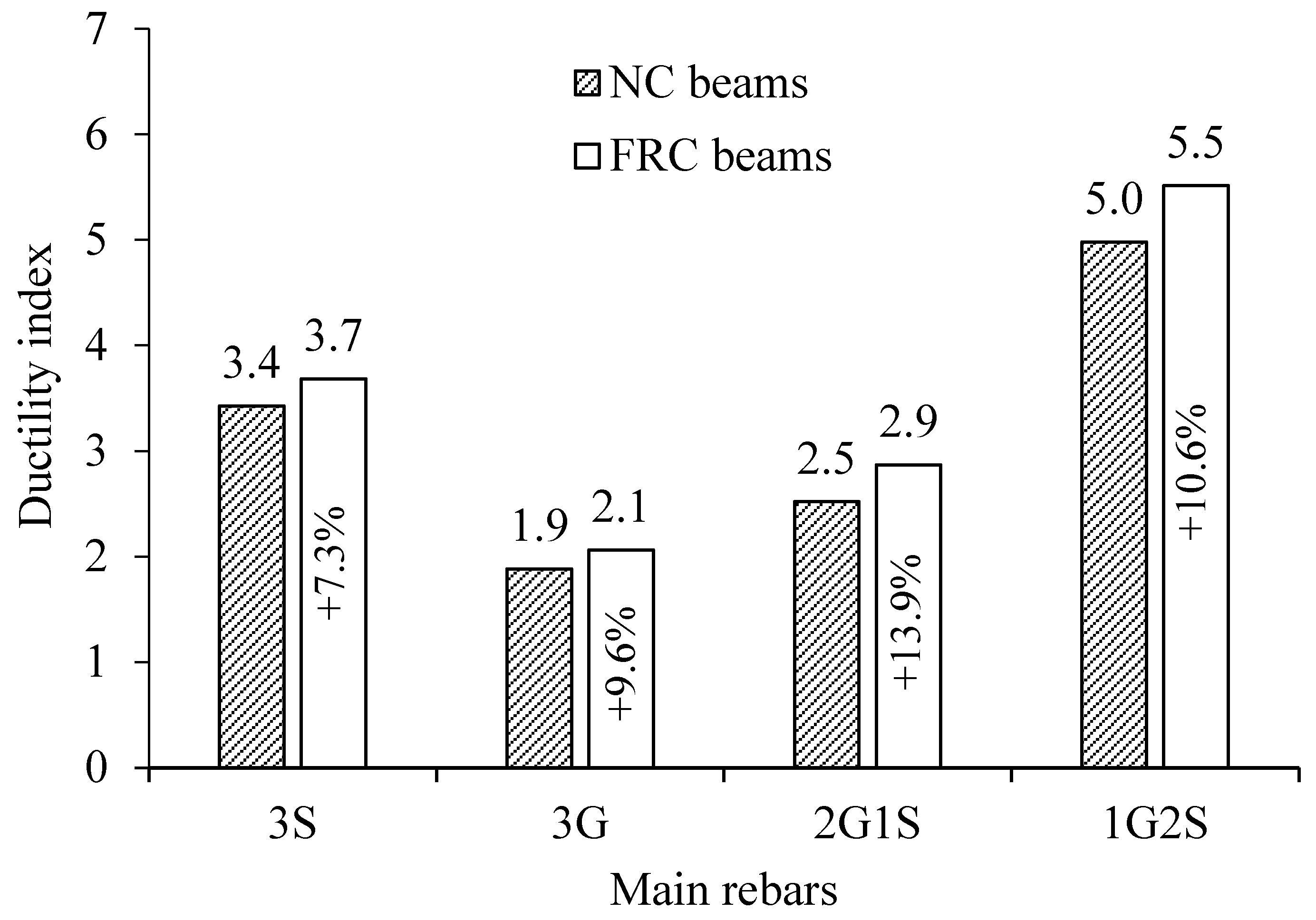

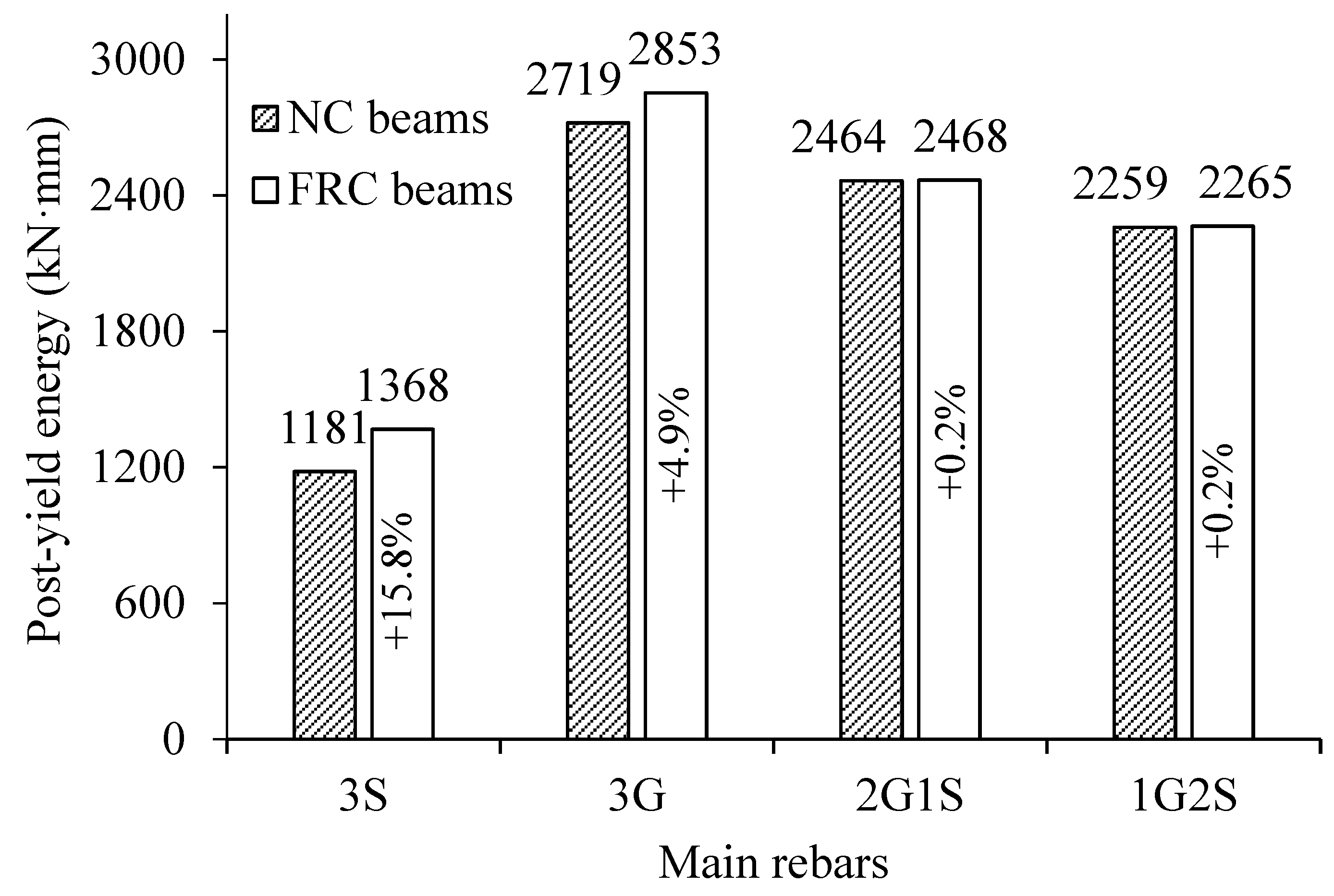

3.6. Ductility

4. Conclusions

- All beams failed in flexural tension mode as designed, with yielding of steel bars and fracture of GFRP reinforcement at ultimate strain, accompanied by major crack widening before rupture.

- Incorporating hybrid fibers into concrete improved its toughness and ductility, transforming brittle failure into ductile behavior and reducing concrete crushing in the compression zone.

- Hybrid FRC beams exhibited a clear horizontal plateau between yielding and ultimate load, reflecting enhanced ductility that increased with the steel reinforcement ratio.

- Hybrid fibers effectively delayed crack initiation, restricted crack widening and propagation, and increased load capacity by up to 13.2% compared to normal concrete beams.

- The stiffness of the hybrid FRC beams was positioned between that of the corresponding steel FRC beam and the GFRP-FRC beam. It is observed that a higher ratio of steel-to-GFRP bars correlates with an increase in stiffness. It is recommended to increase the steel bars to mitigate the risk of excessive deformation, which may lead to brittle rupture of GFRP bars.

- The findings indicate that the energy-based ductility index () of the hybrid FRC beams generally rises with an increase in the number of steel bars. The use of GFRP bars reduced beam ductility, with BFRC-3G exhibiting a 44% drop in compared to BFRC-3S. Introducing steel into hybrid beams improved ductility substantially: replacing one GFRP bar increased by 39.1%, while replacing two bars enhanced it by 167.1%, making BFRC-1G2S 92.2% more ductile than BFRC-2G1S. In addition, the values for the FRC beams show a clear superiority compared to the NC beams, with an increase of up to 13.9%.

- This study provides practical insights into the performance of FRC beams with hybrid steel–GFRP reinforcement. The results show that partial replacement of steel with GFRP bars enhances ductility and energy absorption, while fibers further improve crack control and toughness. These findings support the broader adoption of hybrid reinforcement systems for durable, corrosion-resistant, and ductile concrete structures.

- Future studies are recommended to explore the influence of varying proportions and types of FRP and steel reinforcement, including configurations with FRP bars placed in the bottom layer and steel bars positioned in the upper layer to enhance corrosion resistance. Additionally, investigating different hybrid combinations of fibers within the concrete matrix could further optimize the mechanical performance and durability of hybrid FRC beams reinforced with hybrid rebars.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hosseinzadehfard, E.; Mobaraki, B. Corrosion performance and strain behavior of reinforced concrete: Effect of natural pozzolan as partial substitute for microsilica in concrete mixtures. Structures 2025, 79, 109397. [Google Scholar] [CrossRef]

- Yan, L.; Deng, W.; Wang, N.; Xue, X.; Hua, J.; Chen, Z. Anti-corrosion reinforcements using coating technologies—A review. Polymers 2022, 14, 4782. [Google Scholar] [CrossRef]

- Abbas, H.; Elsanadedy, H.; Alaoud, L.; Almusallam, T.; Al-Salloum, Y. Effect of confining stirrups and bar gap in improving bond behavior of glass fiber reinforced polymer (GFRP) bar lap splices in RC beams. Constr. Build. Mater. 2023, 365, 129943. [Google Scholar] [CrossRef]

- Wei, B.; He, X.; Zhou, M.; Wang, H.; He, J. Experimental study on flexural behaviors of FRP and steel bars hybrid reinforced concrete beams. Case Stud. Constr. Mater. 2024, 20, e02759. [Google Scholar] [CrossRef]

- Tomlinson, D.; Fam, A. Performance of Concrete Beams Reinforced with Basalt FRP for Flexure and Shear. J. Compos. Constr. 2015, 19, 04014036. [Google Scholar] [CrossRef]

- Soric, Z.; Kisicek, T.; Galic, J. Deflections of concrete beams reinforced with FRP bars. Mater. Struct. 2010, 43, 73–90. [Google Scholar] [CrossRef]

- Adam, M.A.; Said, M.; Mahmoud, A.A.; Shanour, A.S. Analytical and experimental flexural behavior of concrete beams reinforced with glass fiber reinforced polymers bars. Constr. Build. Mater. 2015, 84, 354–366. [Google Scholar] [CrossRef]

- Pawłowski, D.; Szumigała, M. Flexural Behaviour of Full-scale Basalt FRP RC Beams—Experimental and Numerical Studies. Procedia Eng. 2015, 108, 518–525. [Google Scholar] [CrossRef]

- Abadel, A.A. Flexural behaviour of RC beams with a UHPFRC top layer and hybrid reinforcement of steel and glass fiber reinforced polymer bars. Case Stud. Constr. Mater. 2024, 21, e04017. [Google Scholar] [CrossRef]

- Said, M.; Shanour, A.S.; Mustafa, T.S.; Abdel-Kareem, A.H.; Khalil, M.M. Experimental flexural performance of concrete beams reinforced with an innovative hybrid bars. Eng. Struct. 2021, 226, 111348. [Google Scholar] [CrossRef]

- Dong, H.-L.; Zhou, W.; Wang, Z. Flexural performance of concrete beams reinforced with FRP bars grouted in corrugated sleeves. Compos. Struct. 2019, 215, 49–59. [Google Scholar] [CrossRef]

- Said, M.; Adam, M.A.; Mahmoud, A.A.; Shanour, A.S. Experimental and analytical shear evaluation of concrete beams reinforced with glass fiber reinforced polymers bars. Constr. Build. Mater. 2016, 102, 574–591. [Google Scholar] [CrossRef]

- Habeeb, M.N.; Ashour, A.F. Flexural Behavior of Continuous GFRP Reinforced Concrete Beams. J. Compos. Constr. 2008, 12, 115–124. [Google Scholar] [CrossRef]

- Pecce, M.; Manfredi, G.; Cosenza, E. Experimental Response and Code Modelsof GFRP RC Beams in Bending. J. Compos. Constr. 2000, 4, 182–190. [Google Scholar] [CrossRef]

- El Refai, A.; Abed, F.; Al-Rahmani, A. Structural performance and serviceability of concrete beams reinforced with hybrid (GFRP and steel) bars. Constr. Build. Mater. 2015, 96, 518–529. [Google Scholar] [CrossRef]

- Sun, Z.; Fu, L.; Feng, D.-C.; Vatuloka, A.R.; Wei, Y.; Wu, G. Experimental study on the flexural behavior of concrete beams reinforced with bundled hybrid steel/FRP bars. Eng. Struct. 2019, 197, 109443. [Google Scholar] [CrossRef]

- Ge, W.; Zhang, J.; Cao, D.; Tu, Y. Flexural behaviors of hybrid concrete beams reinforced with BFRP bars and steel bars. Constr. Build. Mater. 2015, 87, 28–37. [Google Scholar] [CrossRef]

- Safan, M.A. Flexural behavior and design of steel-GFRP reinforced concrete beams. ACI Mater. J. 2013, 110, 677. [Google Scholar] [CrossRef]

- Kara, I.F.; Ashour, A.F.; Köroğlu, M.A. Flexural behavior of hybrid FRP/steel reinforced concrete beams. Compos. Struct. 2015, 129, 111–121. [Google Scholar] [CrossRef]

- Lau, D.; Pam, H.J. Experimental study of hybrid FRP reinforced concrete beams. Eng. Struct. 2010, 32, 3857–3865. [Google Scholar] [CrossRef]

- Aiello, M.A.; Ombres, L. Structural Performances of Concrete Beams with Hybrid (Fiber-Reinforced Polymer-Steel) Reinforcements. J. Compos. Constr. 2002, 6, 133–140. [Google Scholar] [CrossRef]

- Yoon, Y.-S.; Yang, J.-M.; Min, K.-H.; Shin, H.-O. Flexural strength and deflection characteristics of high-strength concrete beams with hybrid FRP and steel bar reinforcement. Spec. Publ. 2011, 275, 1–22. [Google Scholar]

- Thamrin, R.; Zaidir, Z.; Iwanda, D. Ductility Estimation for Flexural Concrete Beams Longitudinally Reinforced with Hybrid FRP–Steel Bars. Polymers 2022, 14, 1017. [Google Scholar] [CrossRef] [PubMed]

- Pang, L.; Qu, W.; Zhu, P.; Xu, J. Design Propositions for Hybrid FRP-Steel Reinforced Concrete Beams. J. Compos. Constr. 2015, 20, 04015086. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, Z.-Y.; Wu, G.; Cao, D.-F.; Zhang, Z.-Q. Flexural capacity and design of hybrid FRP-steel-reinforced concrete beams. Adv. Struct. Eng. 2019, 23, 1290–1304. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, Z.; Wu, G.; Cao, D.-F.; Pan, D. Experimental study of concrete beams reinforced with hybrid bars (SFCBs and BFRP bars). Mater. Struct. 2020, 53, 77. [Google Scholar] [CrossRef]

- Lu, C.H.; Li, H.; Xu, K.; Xuan, G.Y.; Abdullah, W. Experimental study of flexural behavior and serviceability of hybrid concrete beams reinforced by steel and G/BFRP bars. IOP. Conf. Ser. Mater. Sci. Eng. 2020, 770, 12007. [Google Scholar] [CrossRef]

- Ruan, X.; Lu, C.; Xu, K.; Xuan, G.; Ni, M. Flexural behavior and serviceability of concrete beams hybrid-reinforced with GFRP bars and steel bars. Compos. Struct. 2020, 235, 111772. [Google Scholar] [CrossRef]

- Qin, R.; Zhou, A.; Lau, D. Effect of reinforcement ratio on the flexural performance of hybrid FRP reinforced concrete beams. Compos. B Eng. 2017, 108, 200–209. [Google Scholar] [CrossRef]

- Abbas, H.; Abadel, A.; Almusallam, T.; Al-Salloum, Y. Experimental and analytical study of flexural performance of concrete beams reinforced with hybrid of GFRP and steel rebars. Eng. Fail. Anal. 2022, 138, 106397. [Google Scholar] [CrossRef]

- Alwesabi, E.A.; Bakar, B.H.A.; Alshaikh, I.M.H.; Akil, H.M. Impact resistance of plain and rubberized concrete containing steel and polypropylene hybrid fiber. Mater. Today Commun. 2020, 25, 101640. [Google Scholar] [CrossRef]

- Alwesabi, E.A.H.; Bakar, B.H.A.; Alshaikh, I.M.H.; Akil, H.M. Experimental investigation on mechanical properties of plain and rubberised concretes with steel–polypropylene hybrid fibre. Constr. Build. Mater. 2020, 233, 117194. [Google Scholar] [CrossRef]

- Abadel, A.A.; Abbas, H.; Alshaikh, I.M.H.; Tuladhar, R.; Altheeb, A.; Alamri, M. Experimental study on the effects of external strengthening and elevated temperature on the shear behavior of ultra-high-performance fiber-reinforced concrete deep beams. In Structures; Elsevier: Amsterdam, The Netherlands, 2023; pp. 943–957. [Google Scholar]

- Abdullah, G.M.S.; Alshaikh, I.M.H.; Zeyad, A.M.; Magbool, H.M.; Bakar, B.H.A. The effect of openings on the performance of self-compacting concrete with volcanic pumice powder and different steel fibers. Case Stud. Constr. Mater. 2022, 17, e01148. [Google Scholar] [CrossRef]

- Alshaikh, I.M.H.; Bakar, B.H.A.; Alwesabi, E.A.H.; Abadel, A.A.; Alghamdi, H.; Wasim, M. An experimental study on enhancing progressive collapse resistance using a steel fiber–reinforced concrete frame. J. Struct. Eng. 2022, 148, 04022087. [Google Scholar] [CrossRef]

- ASTM C150-24; Standard Test Method for Portland Cement. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2024.

- ASTM A370-24a; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2024.

- ASTM D7205/D7205M-21; Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- ACI. Guide to External Curing of Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2016. [Google Scholar]

- Zhao, S.; Liu, J.; Liu, R. Steel/plastic-steel hybrid fiber UHPC dynamic tensile performance: An experimental and numerical simulation study. J. Build. Eng. 2024, 92, 109706. [Google Scholar] [CrossRef]

- Li, J.; Luo, J.; Chen, L.; Fan, X.; Zhu, Y.; Wang, X.; Guo, J. Research on mechanical properties of steel-polypropylene fiber concrete and application of beam structure. Front. Mater. 2024, 11, 1440466. [Google Scholar] [CrossRef]

- Shaaban, I.G.; Said, M.; Khan, S.U.; Eissa, M.; Elrashidy, K. Experimental and theoretical behaviour of reinforced concrete beams containing hybrid fibres. Structures 2021, 32, 2143–2160. [Google Scholar] [CrossRef]

- El Bakzawy, A.; Makhlouf, M.H.; Mustafa, T.S.; Adam, M. Experimental investigation on the flexural behavior of SFRC beams reinforced with hybrid reinforcement schemes. Eng. Struct. 2024, 309, 118054. [Google Scholar] [CrossRef]

- De Maio, U.; Gaetano, D.; Greco, F.; Lonetti, P.; Pranno, A. An adaptive cohesive interface model for fracture propagation analysis in heterogeneous media. Eng. Fract. Mech. 2025, 325, 111330. [Google Scholar] [CrossRef]

- Faron, A.; Rombach, G.A. Simulation of crack growth in reinforced concrete beams using extended finite element method. Eng. Fail. Anal. 2020, 116, 104698. [Google Scholar] [CrossRef]

- Abdel-Karim, A.H.; Khalil, G.I.; Ewis, A.E.; Makhlouf, M.H. Impact of developed hybrid polypropylene fiber inclusion on the flexural performance of concrete beams reinforced with innovative hybrid bars. Constr. Build. Mater. 2023, 409, 134113. [Google Scholar] [CrossRef]

- Abbas, H.; Almusallam, T.; Abadel, A.; Alenzi, S.; Al-Salloum, Y. Shear Strength of Functionally Graded Self-Compacting Concrete Deep Beams Reinforced with Steel and GFRP Bars. Case Stud. Constr. Mater. 2023, 18, e01872. [Google Scholar] [CrossRef]

- Abadel, A.; Alenzi, S.; Almusallam, T.; Abbas, H.; Al-Salloum, Y. Shear behavior of self-consolidating concrete deep beams reinforced with hybrid of steel and GFRP bars. Ain. Shams. Eng. J. 2023, 14, 102136. [Google Scholar] [CrossRef]

- ACI 440.2R-17; Guide for the Design Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2017.

- Naaman, M.; Jeong, A.E. Structural Ductility of Concrete Beams Prestressed with FRP Tendons. In Non-Metallic (FRP) Reinforcement for Concrete Structures: Proceedings of the Second International RILEM Symposium; CRC Press: Boca Raton, FL, USA, 1995; p. 379. [Google Scholar]

- Grace, N.F.; Soliman, A.K.; Abdel-Sayed, G.; Saleh, K.R. Behavior and ductility of simple and continuous FRP reinforced beams. J. Compos. Constr. 1998, 2, 186–194. [Google Scholar] [CrossRef]

- Fouad, R.; Aboubeah, A.S.; Hussein, A.; Zaher, A.; Said, H. Flexural behavior of RC continuous beams having hybrid reinforcement of steel and GFRP bars. J. Reinf. Plast. Compos. 2023, 42, 1289–1302. [Google Scholar] [CrossRef]

| Cement (C) | White Sand | Crushed Sand | Coarse Aggregates | Fibers | Super-Plasticizer | Water (W) | W/C Ratio | ||

|---|---|---|---|---|---|---|---|---|---|

| 10 mm | 20 mm | SF | PP | ||||||

| 350 | 470 | 310 | 210 | 840 | 58.9 | 19.6 | 1.815 | 190.5 | 0.54 |

| Specimen ID | Concrete Mix | Top Reinforcement | Bottom Reinforcement | |

|---|---|---|---|---|

| Steel Bars | GFRP Bars | |||

| B-3S | NC * | 28 (0.45%) | 310 (1.23%) | - |

| B-3G | - | 310 (1.23%) | ||

| B-1G2S | 210 (0.82%) | 110 (0.41%) | ||

| B-2G1S | 110 (0.41%) | 210 (0.82%) | ||

| BFRC-3S | FRC | 28 (0.45%) | 310 (1.23%) | - |

| BFRC-3G | - | 310 (1.23%) | ||

| BFRC-1G2S | 210 (0.82%) | 110 (0.41%) | ||

| BFRC-2G1S | 110 (0.41%) | 210 (0.82%) | ||

| Specimens ID | First-Crack Load (kN) | (kN) | (kN·m) | (kN·m) | ||

|---|---|---|---|---|---|---|

| B-3S * | 15 | 64.9 | 19.5 | 15.4 | 1.26 | 3.43 |

| BFRC-3S | 24 | 66.5 | 20.0 | 20.0 | 1.00 | 3.68 |

| B-3G * | 10 | 83.8 | 25.1 | 23.7 | 1.06 | 1.88 |

| BFRC-3G | 17 | 94.8 | 28.4 | 30.4 | 0.94 | 2.06 |

| B-2G1S * | 12 | 78.7 | 23.6 | 22.9 | 1.03 | 2.52 |

| BFRC-2G1S | 19 | 86.3 | 25.9 | 27.2 | 0.95 | 2.87 |

| B-1G2S * | 14 | 65.2 | 19.6 | 18.5 | 1.06 | 4.98 |

| BFRC-1G2S | 20 | 71.8 | 21.5 | 23.7 | 0.91 | 5.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abadel, A.; Abbas, H.; Elsanadedy, H.; Almusallam, T.; Mourad, S.; Al-Salloum, Y. Bending Characteristics of Hybrid Fiber Concrete Beams Reinforced with Steel–GFRP Hybrid Rebars. Buildings 2025, 15, 4146. https://doi.org/10.3390/buildings15224146

Abadel A, Abbas H, Elsanadedy H, Almusallam T, Mourad S, Al-Salloum Y. Bending Characteristics of Hybrid Fiber Concrete Beams Reinforced with Steel–GFRP Hybrid Rebars. Buildings. 2025; 15(22):4146. https://doi.org/10.3390/buildings15224146

Chicago/Turabian StyleAbadel, Aref, Husain Abbas, Hussein Elsanadedy, Tarek Almusallam, Shehab Mourad, and Yousef Al-Salloum. 2025. "Bending Characteristics of Hybrid Fiber Concrete Beams Reinforced with Steel–GFRP Hybrid Rebars" Buildings 15, no. 22: 4146. https://doi.org/10.3390/buildings15224146

APA StyleAbadel, A., Abbas, H., Elsanadedy, H., Almusallam, T., Mourad, S., & Al-Salloum, Y. (2025). Bending Characteristics of Hybrid Fiber Concrete Beams Reinforced with Steel–GFRP Hybrid Rebars. Buildings, 15(22), 4146. https://doi.org/10.3390/buildings15224146