Heating Performance and Flexural Strength of Steel Fiber–Carbon Nanotube Cement Composites for Black Ice Prevention

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Overview

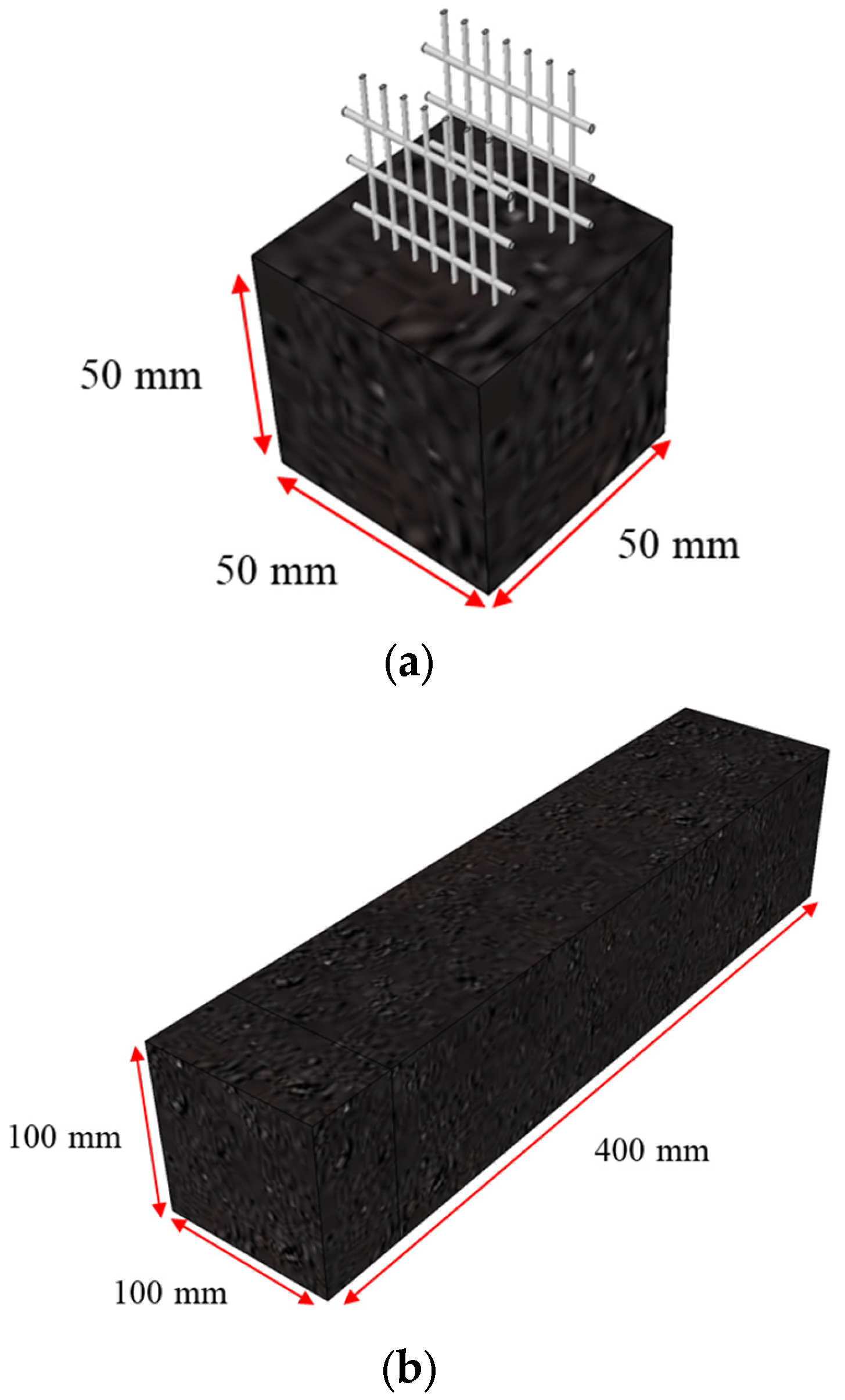

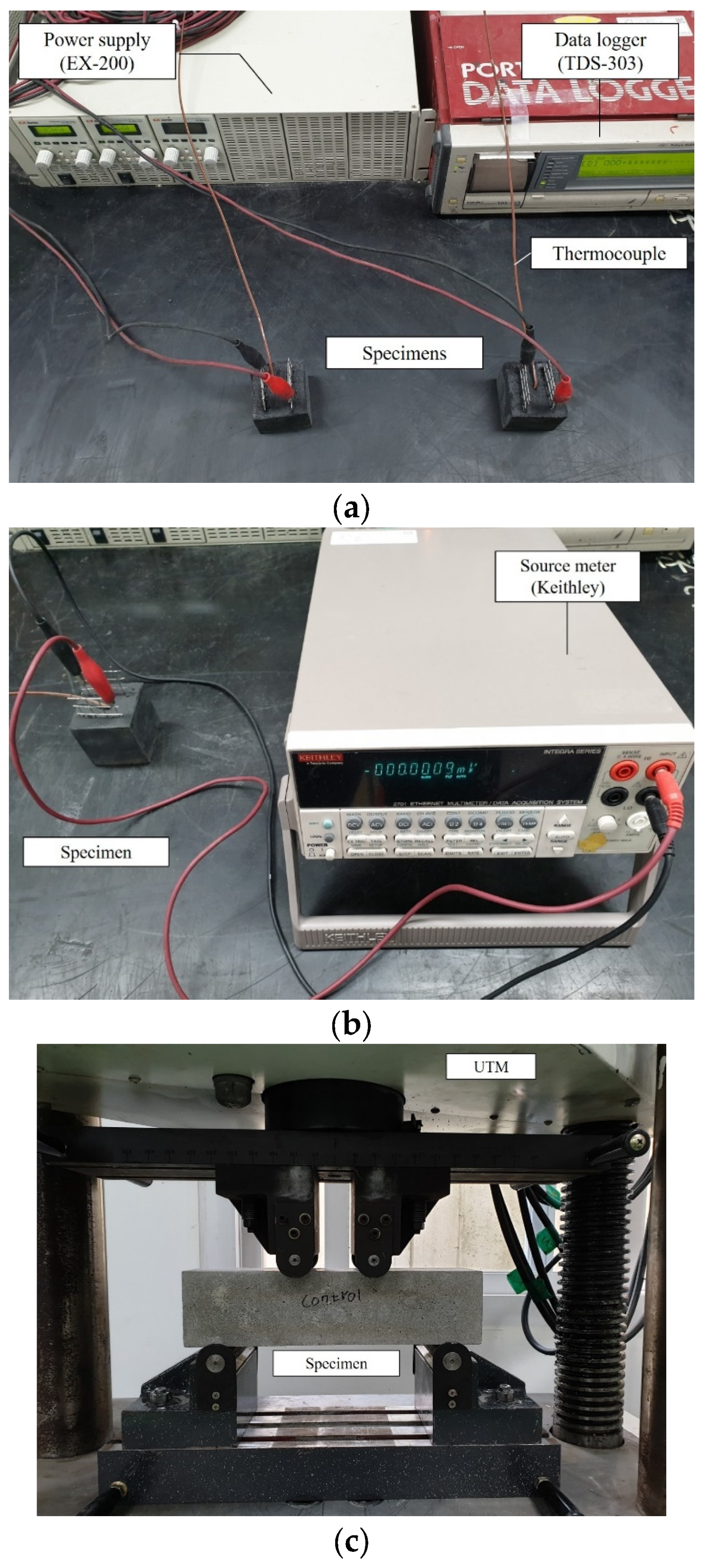

2.1.1. Heating and Electrical Resistance Tests

2.1.2. Flexural Strength Test

2.1.3. Internal Microstructural Analysis

2.2. Specimen Fabrication and Experimental Procedure

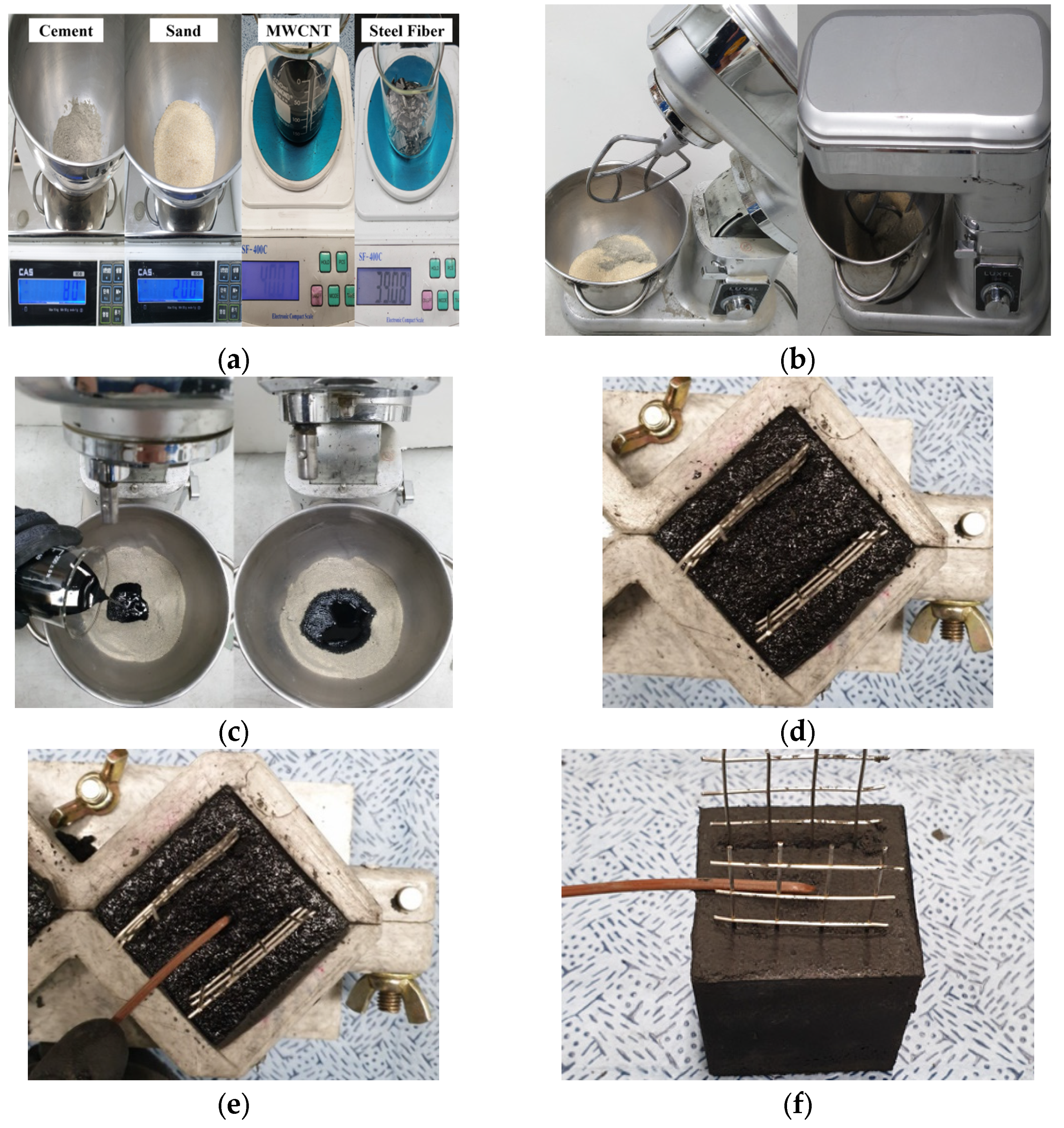

2.2.1. Heating and Electrical Resistance Test

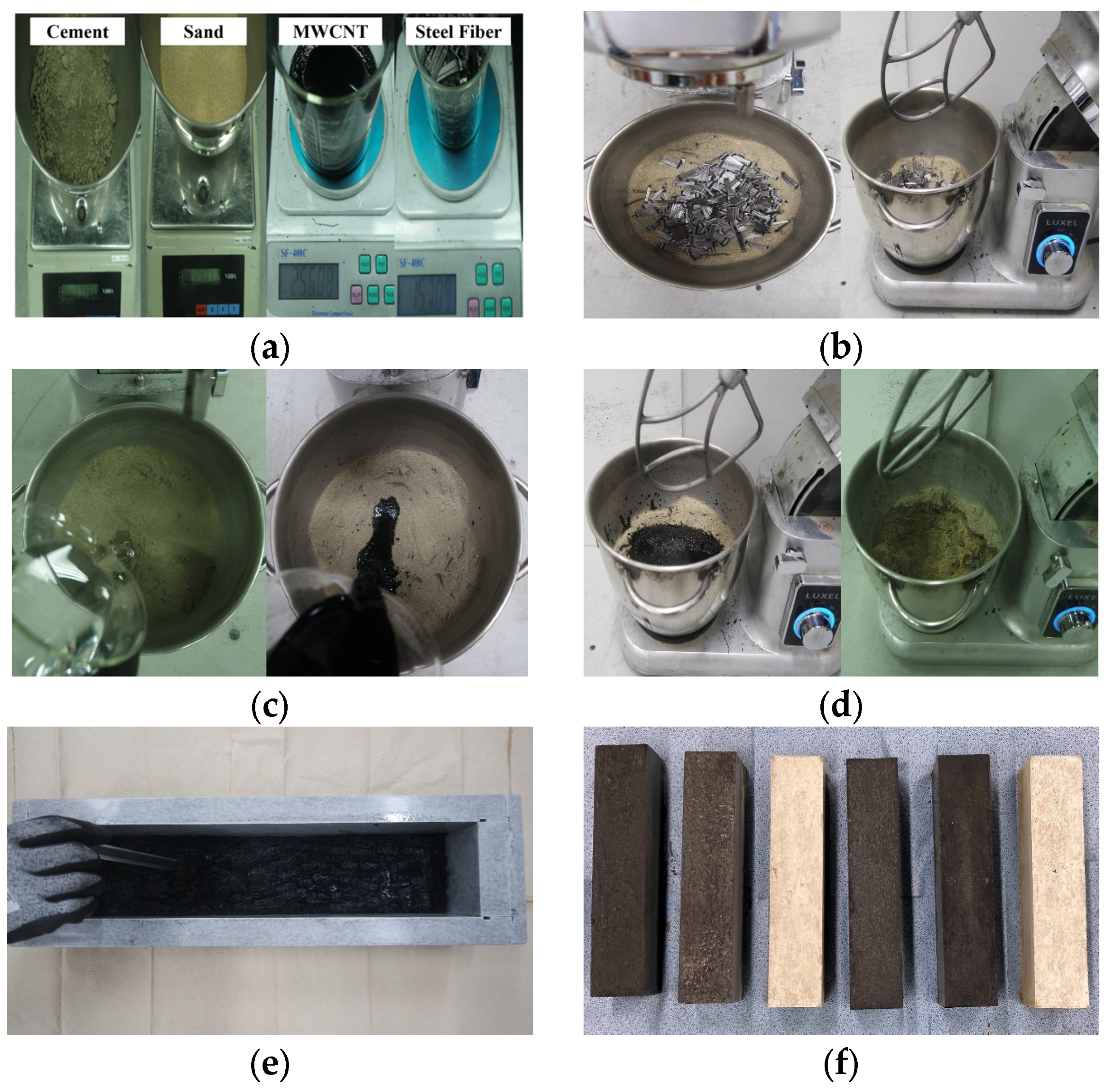

2.2.2. Flexural Strength Test

2.2.3. Internal Microstructure Analysis

3. Results

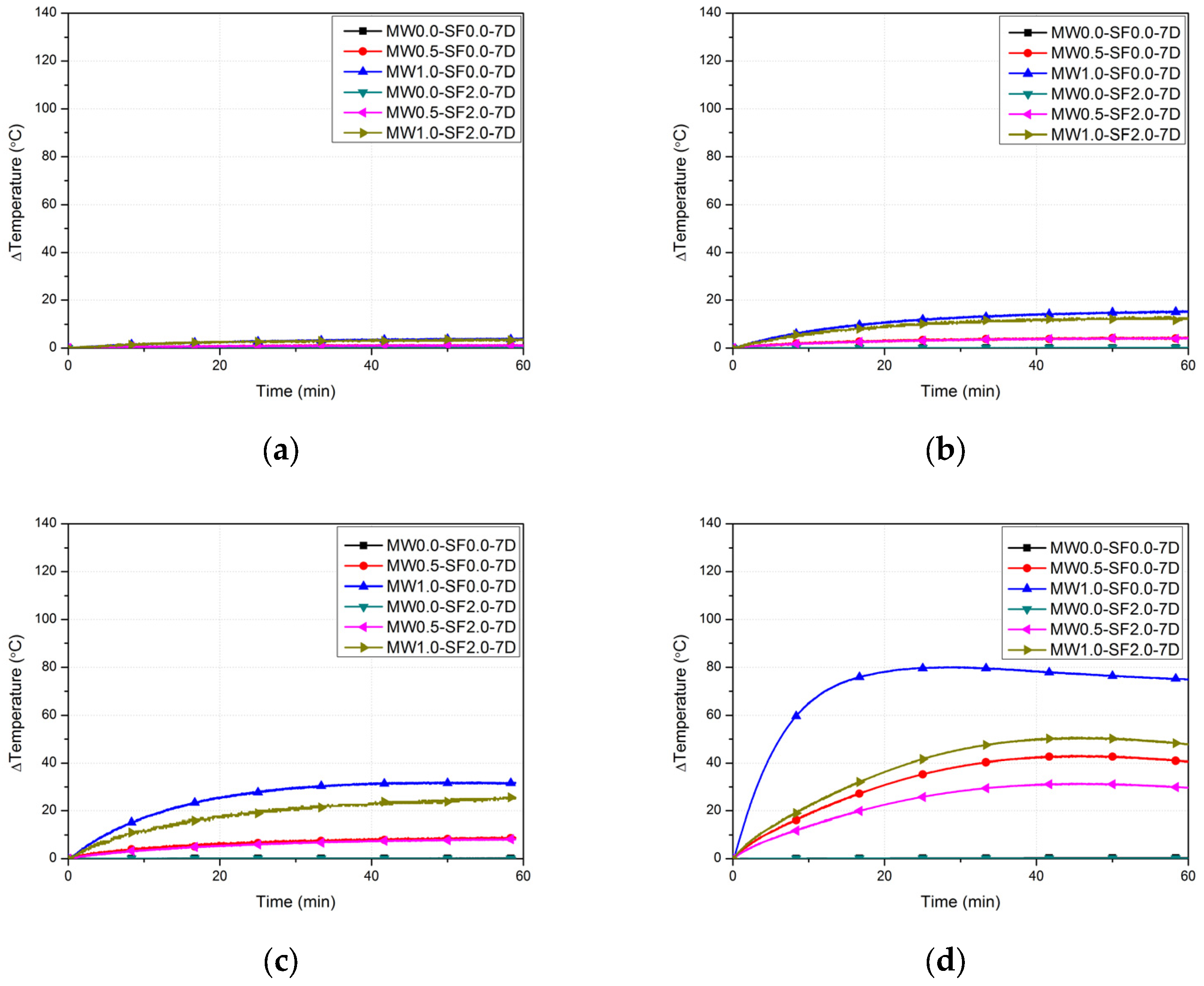

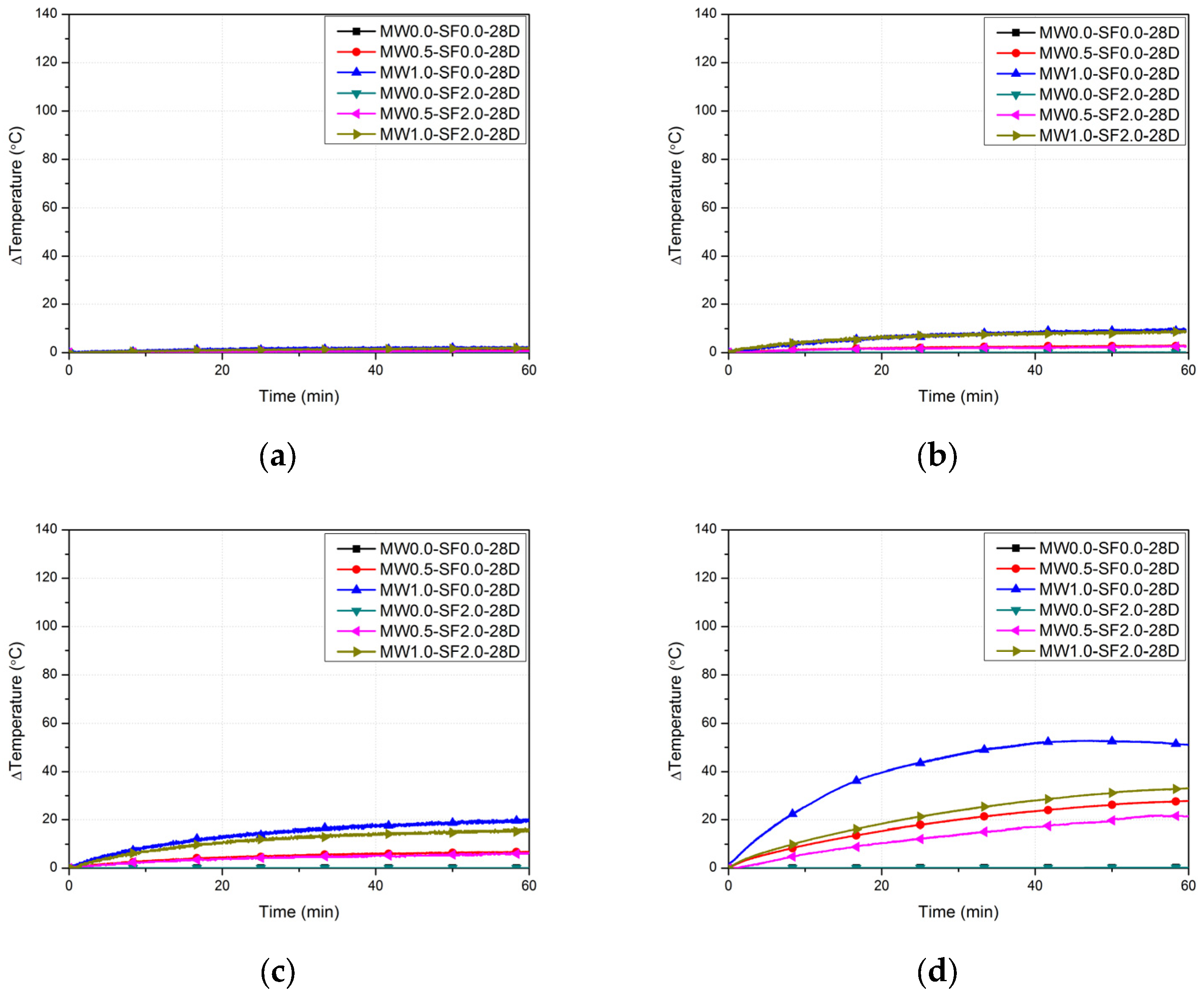

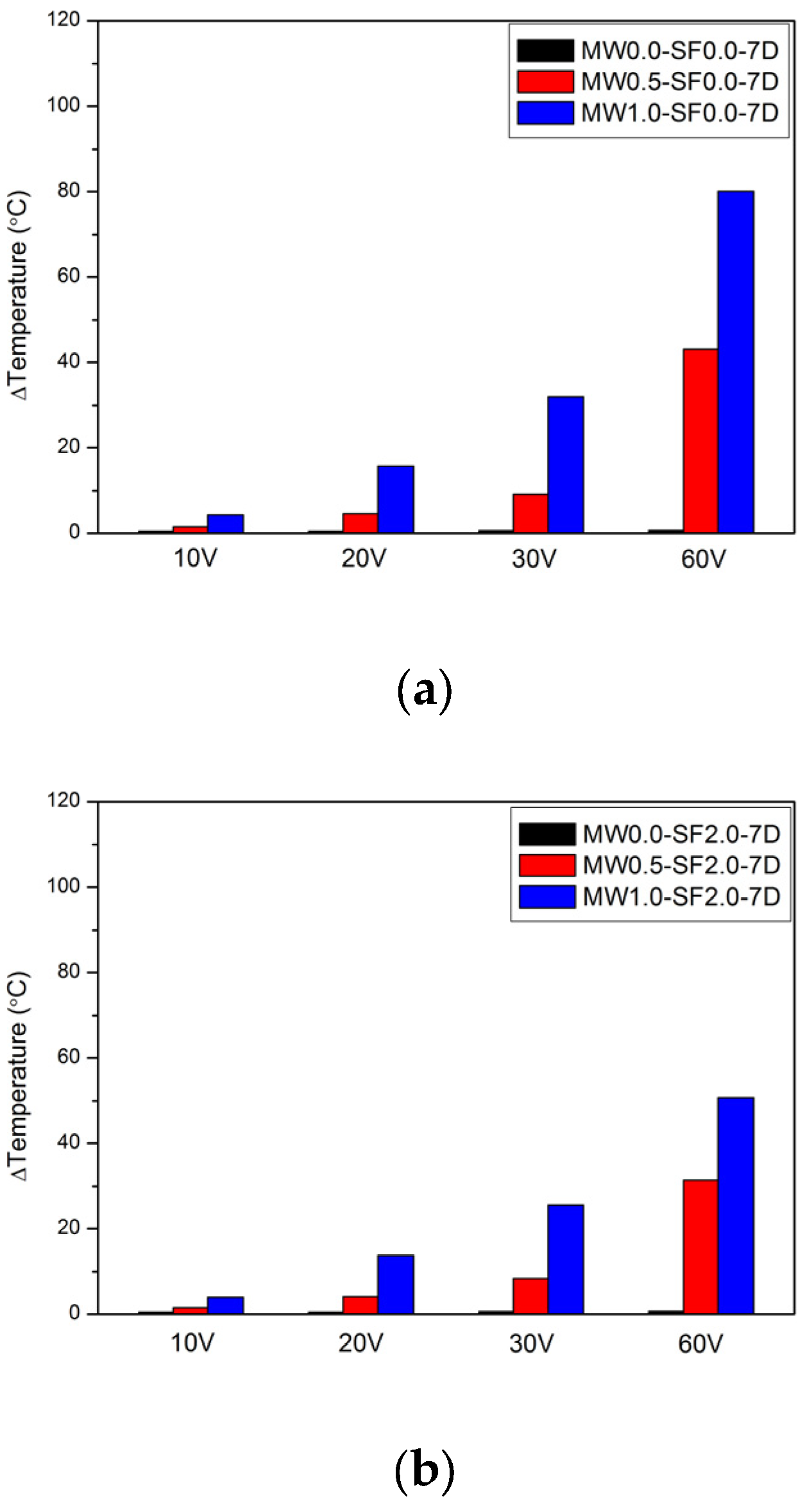

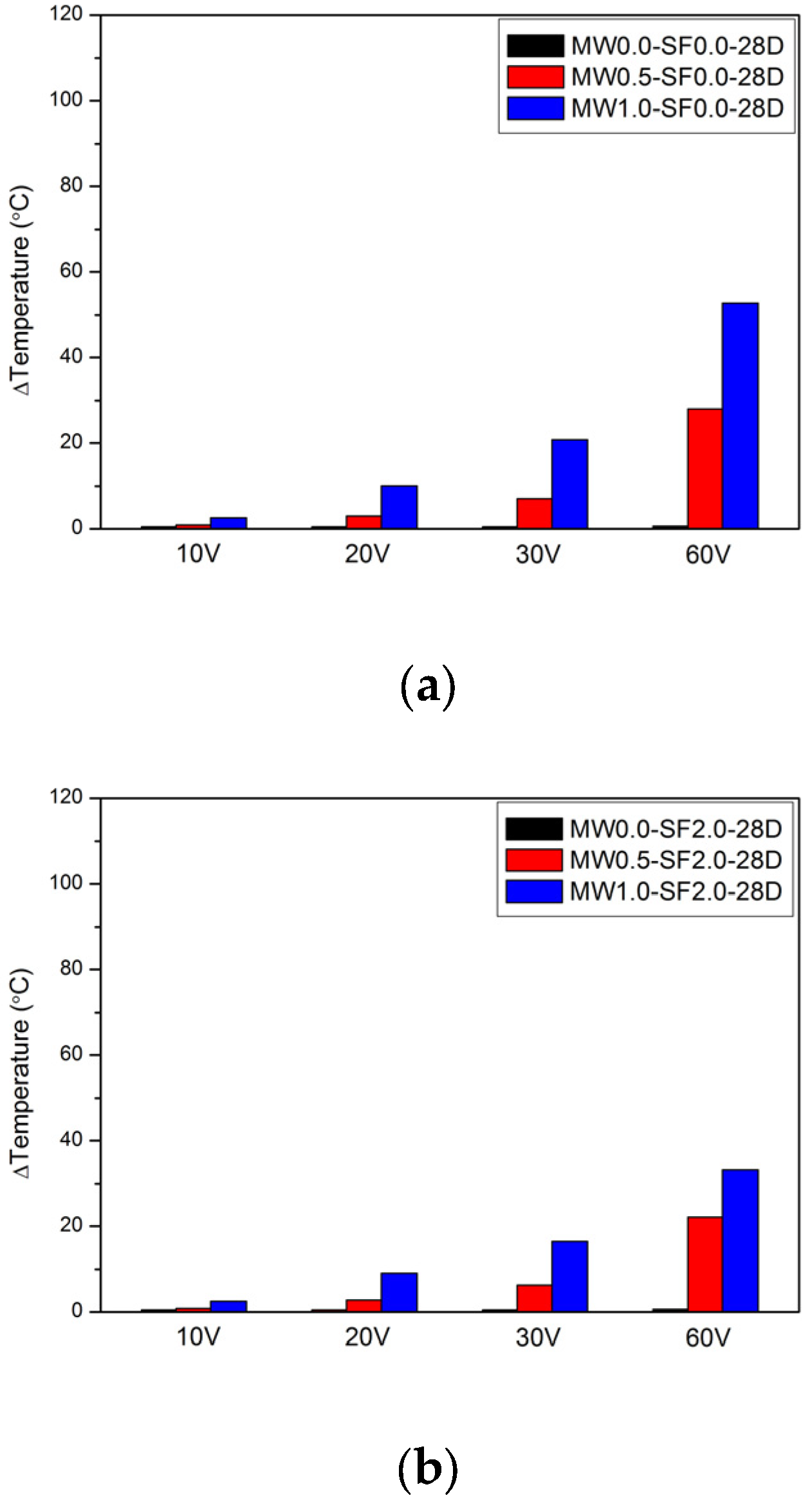

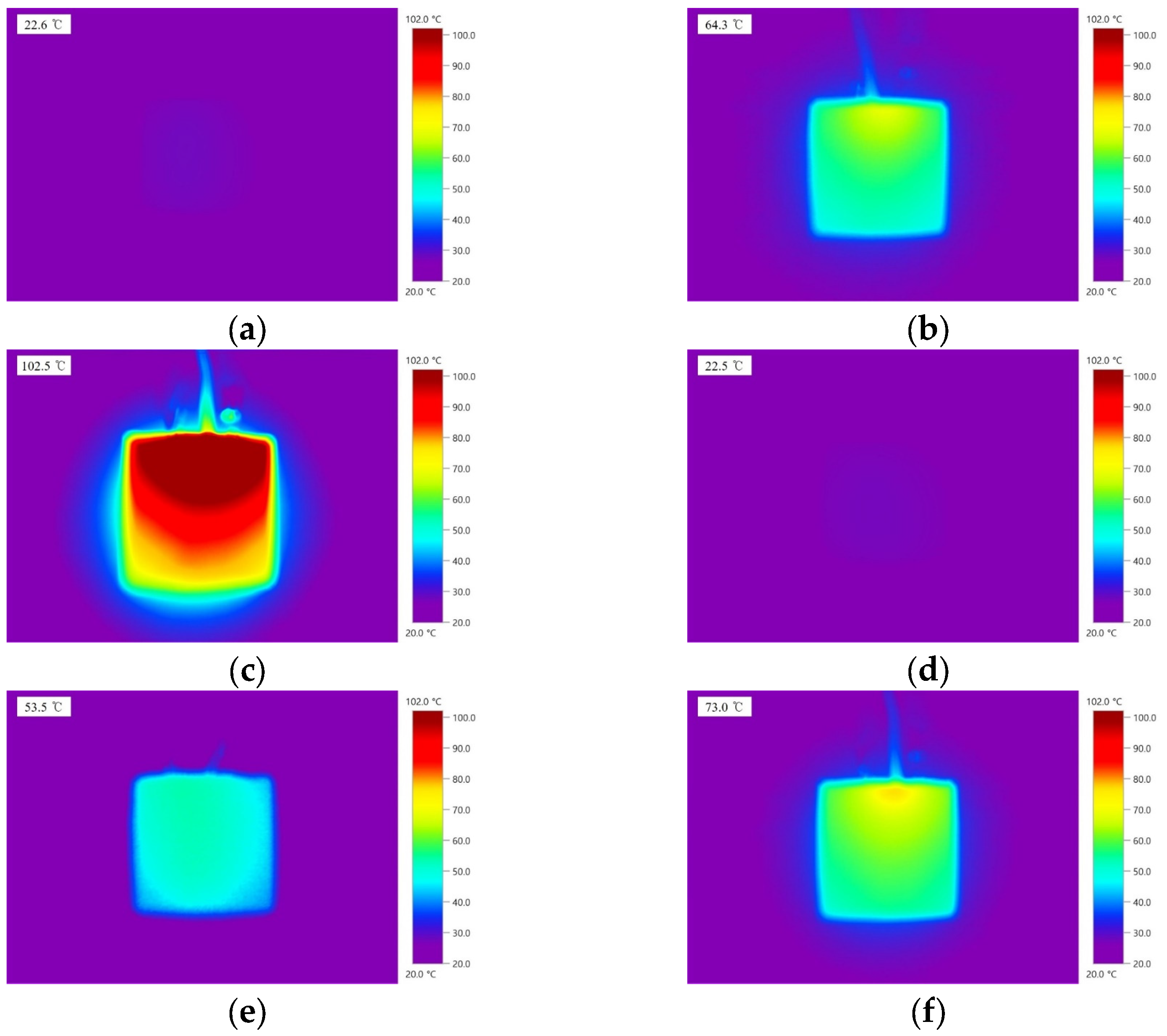

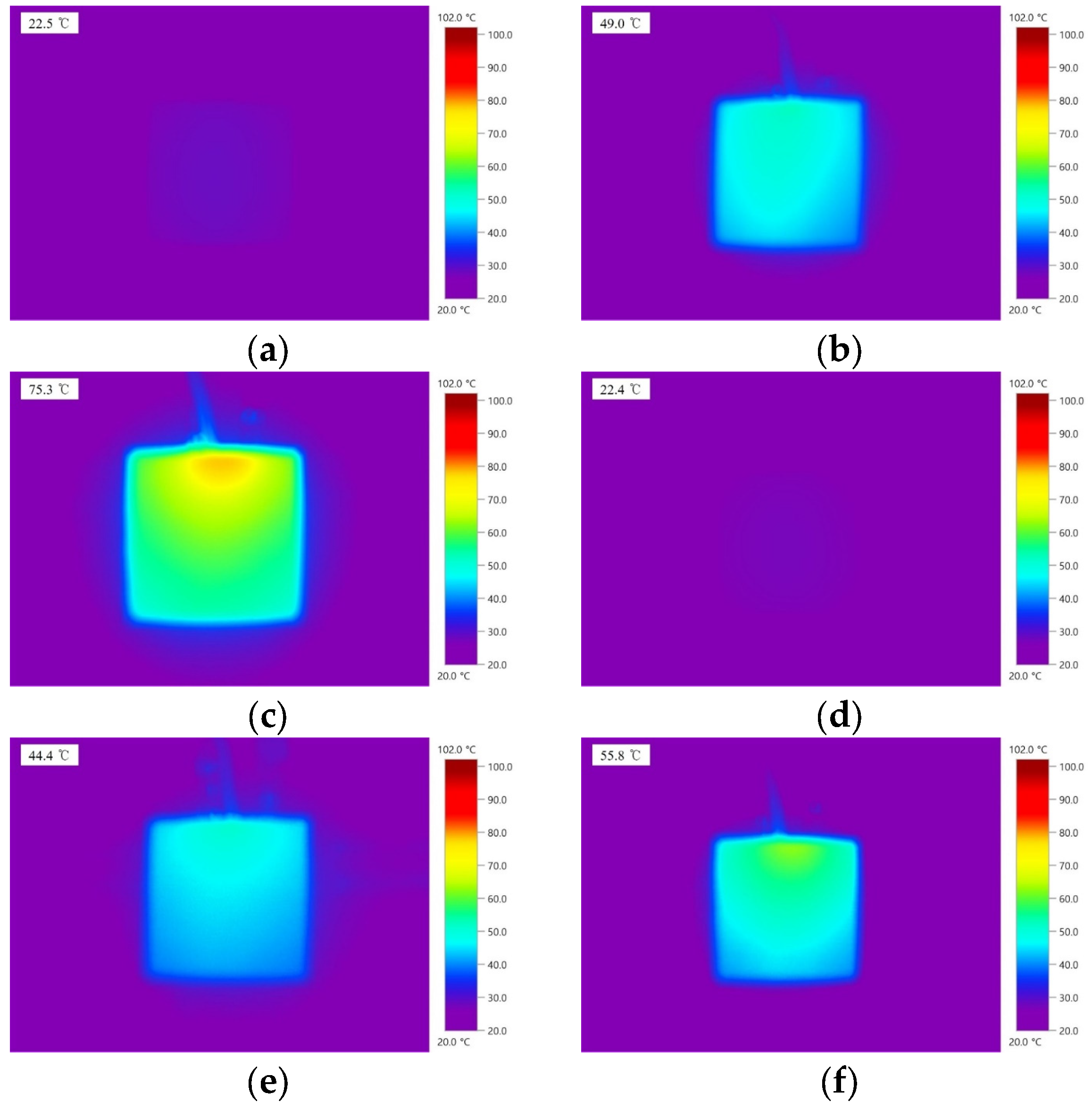

3.1. Heating Performance Test Results

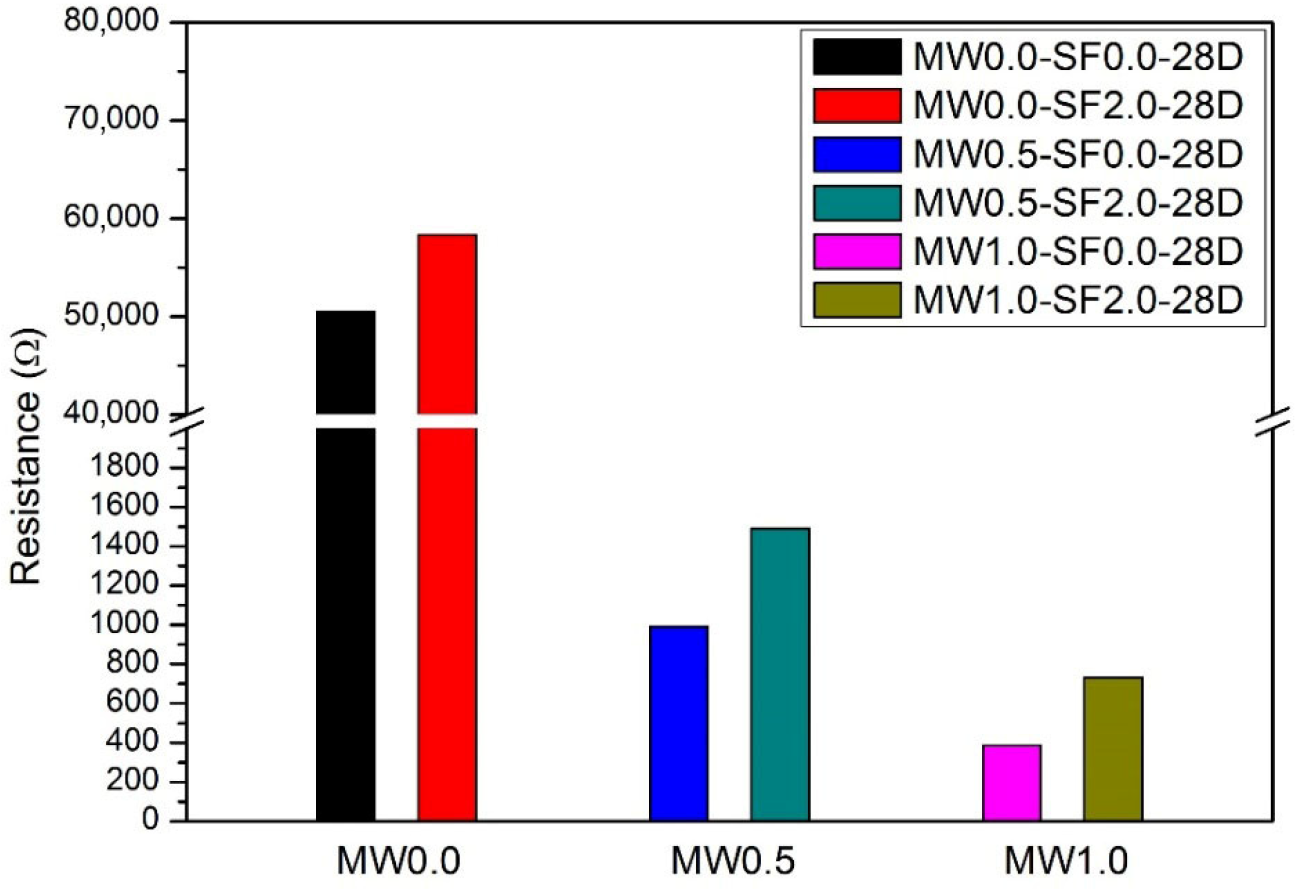

3.2. Electrical Resistance Test Results

3.3. Flexural Strength Test Results

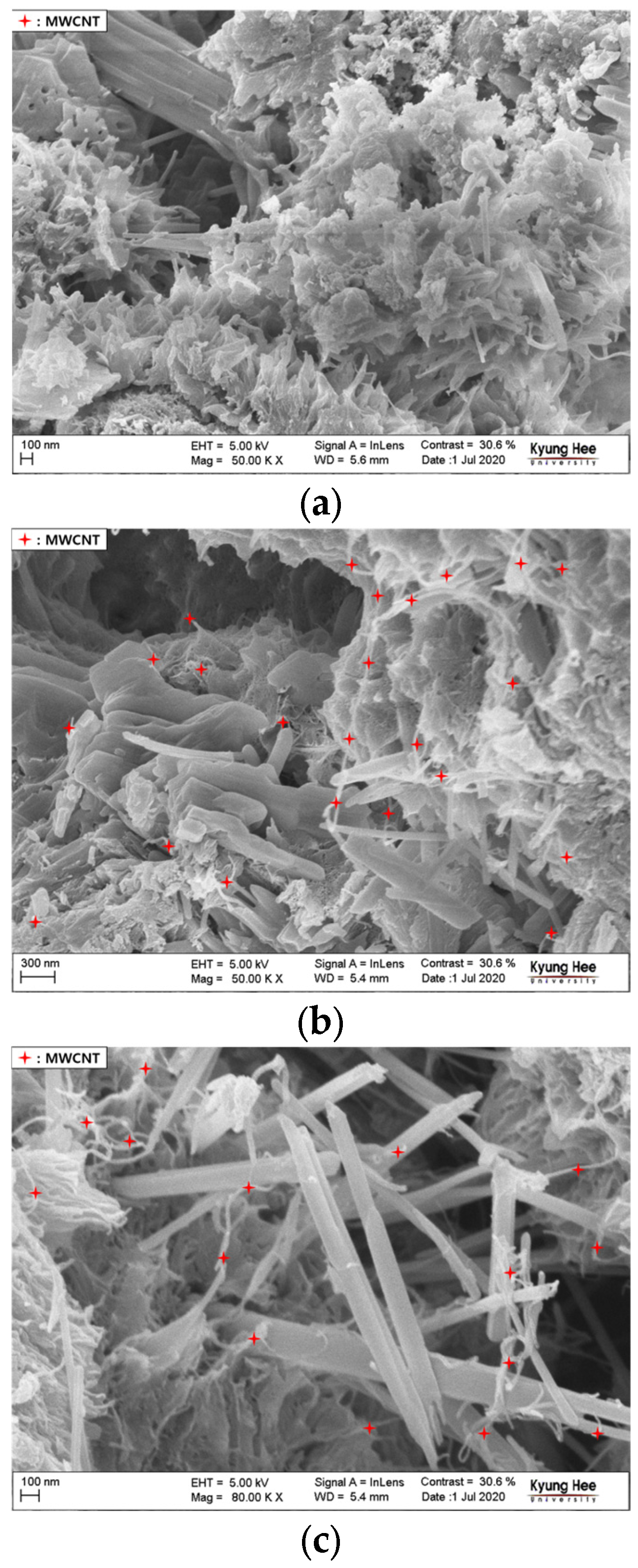

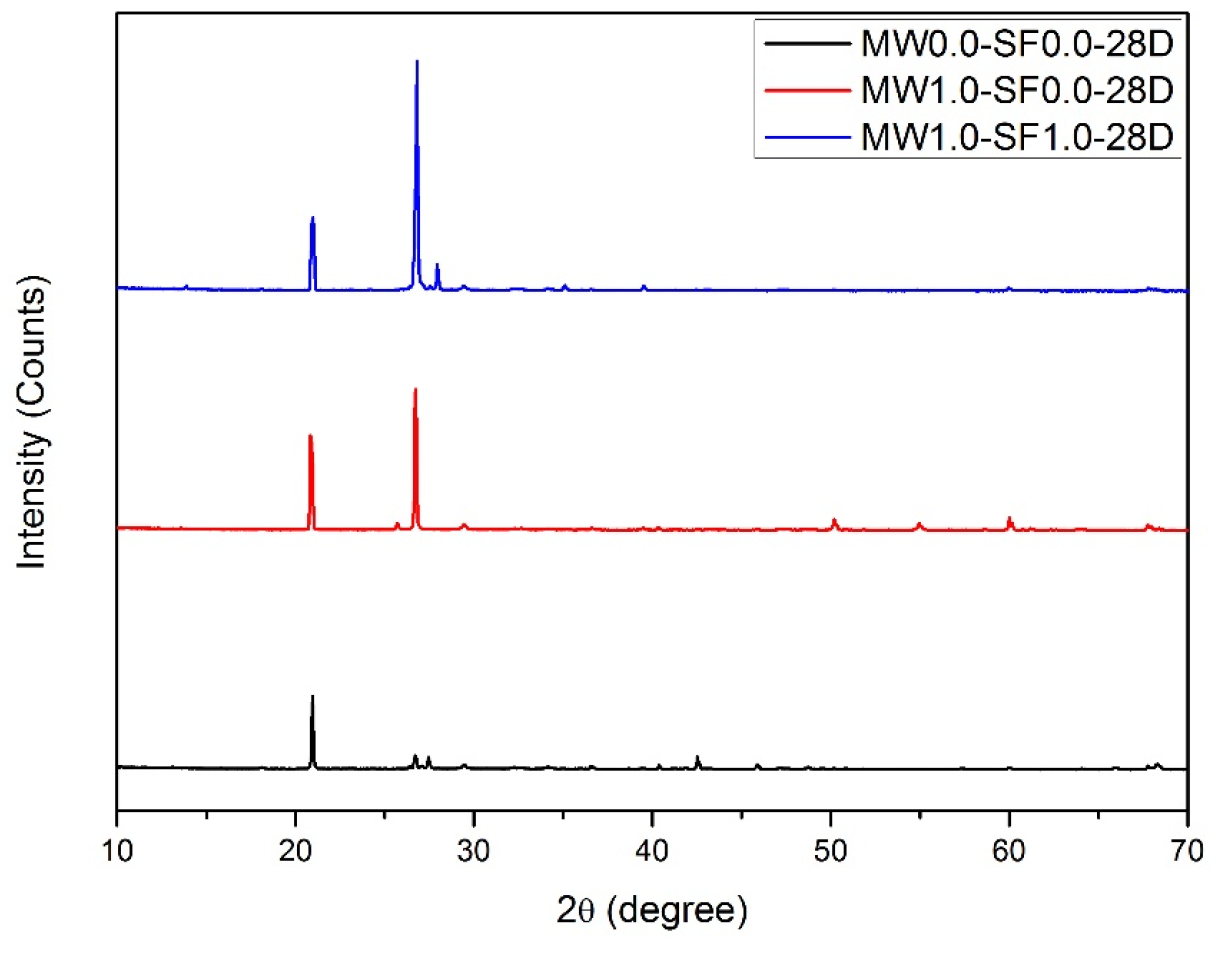

3.4. Internal Microstructure Analysis Results

4. Conclusions

- The heating performance of steel fiber–carbon nano cementitious composites increased with higher MWCNT concentration. Specimen MW1.0-SF0.0-7D exhibited the best heating performance among all parameters, with a 10 min temperature rise of 65.0 °C and a maximum heating value of 80.1 °C. MWCNTs formed CNT networks between the hydration products. As the MWCNT concentration increased, the number of CNT networks also increased, resulting in improved 10 min temperature rise and maximum heating values.

- The heating performance decreased with longer curing duration. The heating value of 7-day cured specimens was approximately 50% higher than that of 28-day cured specimens. The residual moisture in the early curing stage increased the current flow through specimens, thereby enhancing the heating performance. As curing progressed, hydration consumed the moisture, diminishing the effect of residual water and reducing the heating performance.

- The maximum heating value and 10 min temperature rise decreased with the incorporation of steel fibers. Among fiber-reinforced specimens, MW1.0-SF2.0-7D showed the best heating performance, with values of 21.8 °C and 50.8 °C for the 10 min temperature rise and maximum heating value, respectively. These values were approximately 70% and 37% lower than those of MW1.0-SF0.0-7D with identical MWCNT concentration. The reduction in the heating performance was attributable to the increase in the steel fiber resistance at higher temperatures. However, compared to the values for specimens without MWCNT, the 10 min temperature rise and maximum heating value increased by approximately 21.7 °C and 50.5 °C, respectively, demonstrating superior heating performance relative to conventional construction materials.

- Electrical resistance decreased with higher MWCNT concentration. Increased incorporation of highly conductive MWCNTs promoted the formation of extensive CNT networks, thereby reducing the resistance. Electrical resistance increased with steel fiber incorporation. Steel fibers influenced the workability of fresh mortar; reduced workability hindered the dispersion of MWCNTs, leading to increased resistance.

- Flexural strength improved with MWCNT incorporation. MWCNTs, possessing high tensile strength, formed CNT networks within specimens, which enhanced their flexural strength. Steel fibers exerted a pronounced reinforcing effect; the flexural strength of fiber-reinforced specimens exceeded that of specimens without steel fiber by more than threefold. In addition to enhancing the flexural strength, steel fibers mitigated microcracking, thereby improving the durability of steel fiber–carbon nano cementitious composites.

- FE-SEM imaging confirmed that MWCNTs were dispersed within steel fiber–carbon nano cementitious composites and formed CNT networks. These CNT networks improved the heating performance of the specimens and reduced their electrical resistance. XRD and TGA analyses verified that hydration products identical to those observed in ordinary mortar were generated in steel fiber–carbon nano cementitious composites. MWCNT incorporation did not alter the cement hydration reactions.

- Steel fiber–carbon nano cementitious composites demonstrated adequate heating performance for black ice prevention. Steel fiber incorporation contributed to the adjustment of thermal gradients and enhancement of durability. In addition, the marked improvement in flexural strength supports the application of these composites as self-heating construction materials with both functional and structural advantages.

- Laboratory-scale experiments verified the enhanced heating and mechanical performance of steel fiber–MWCNT cementitious composites. The results provide a basis for large-scale validation and long-term durability evaluation under real environmental conditions. Further research will focus on optimizing energy efficiency and assessing life-cycle sustainability. Experimental data and procedures are available upon reasonable request to ensure reproducibility.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Konsta-Gdoutos, M.S.; Aza, C.A. Self-sensing carbon nanotube and nanofiber cementitious composites for real-time damage assessment in smart structures. Cem. Concr. Compos. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.G.; Ou, J.P. Effect of compressive strain on electrical resistivity of carbon black-filled cement-based composites. Cem. Concr. Compos. 2006, 28, 824–828. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S. Study on the graphite and carbon fiber modified asphalt concrete. Constr. Build. Mater. 2011, 25, 1807–1811. [Google Scholar] [CrossRef]

- Monteiro, A.O.; Cachim, P.B.; Costa, P.M.F.J. Electrical properties of cement-based composites containing carbon black particles. Mater. Today Proc. 2015, 2, 193–199. [Google Scholar] [CrossRef]

- Rao, R.; Fu, J.; Chan, Y.; Tuan, C.Y.; Liu, C. Steel fiber confined graphite concrete for pavement deicing. Compos. Part B Eng. 2018, 155, 187–196. [Google Scholar] [CrossRef]

- Richardson, D.N.; Whitwell, B.A. Concrete production plant variables affecting flexural strength relative to compressive strength. J. Mater. Civ. Eng. 2014, 26, 04014032. [Google Scholar] [CrossRef]

- Gražulytė, J.; Šernas, O.; Karbočius, M.; Mickevič, R. Concrete modular pavement structures with optimized thickness based on high-performance concrete mixtures. Materials 2021, 14, 3423. [Google Scholar] [CrossRef]

- Ahmed, M.; El Hadi, K.M.; Hasan, M.A.; Mallick, J. Evaluating the co-relationship between concrete flexural tensile strength and compressive strength. Int. J. Struct. Eng. 2014, 5, 115–131. [Google Scholar] [CrossRef]

- ACI 318-14; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- ASTM C78/C78M; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2022.

- EN 13877-2; Concrete Pavements–Part 2: Functional Requirements for Rigid Pavements. European Committee for Standardization: Brussels, Belgium, 2013.

- Federal Highway Administration. FHWA Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; U.S. Department of Transportation: Washington, DC, USA, 2001. [Google Scholar]

- ACI PRC-325.9-15; Guide for Construction of Concrete Pavements. American Concrete Institute: Farmington Hills, MI, USA, 2015.

- KCS 44 50 15; Cement Concrete Pavement Work. Korea Construction Standards Center: Seoul, Republic of Korea, 2019.

- Zhang, Q.; Li, H. Experimental investigation on the ice/snow melting performance of CNFP & MWCNT/cement-based deicing system. In Proceedings of the 6th International Workshop on Advanced Smart Materials and Smart Structures Technology, Dalian, China, 25–26 July 2011. [Google Scholar]

- Li, H.; Zhang, Q.; Xiao, H. Self-deicing road system with a CNFP high-efficiency thermal source and MWCNT/cement-based high-thermal conductive composites. Cold Reg. Sci. Technol. 2013, 86, 22–35. [Google Scholar] [CrossRef]

- Gomis, J.; Galao, O.; Gomis, V.; Zornoza, E.; Garcés, P. Self-heating and deicing conductive cement: Experimental study and modeling. Constr. Build. Mater. 2015, 75, 442–449. [Google Scholar] [CrossRef]

- Kim, G.M.; Naeem, F.; Kim, H.K.; Lee, H.K. Heating and heat-dependent mechanical characteristics of CNT-embedded cementitious composites. Compos. Struct. 2016, 136, 162–170. [Google Scholar] [CrossRef]

- Lee, H.; Song, Y.M.; Loh, K.J.; Chung, W. Thermal response characterization and comparison of carbon nanotube-enhanced cementitious composites. Compos. Struct. 2018, 202, 1042–1050. [Google Scholar] [CrossRef]

- Lee, H.; Seong, J.; Chung, W. Correlation analysis of heat curing and compressive strength of carbon nanotube–cement mortar composites at sub-zero temperatures. Crystals 2021, 11, 1182. [Google Scholar] [CrossRef]

- Lee, H.; Park, S.; Cho, S.; Chung, W. Correlation analysis of heating performance and electrical energy of multi-walled carbon nanotubes cementitious composites at sub-zero temperatures. Compos. Struct. 2020, 238, 111977. [Google Scholar] [CrossRef]

- Lee, H.; Seong, J.; Chung, W. Effect of curing time on thermal response characterization of carbon-nano cementitious composites. Compos. Struct. 2021, 265, 113781. [Google Scholar] [CrossRef]

- Wei, J.; Fan, Y.; Zhao, L.; Xue, F.; Hao, L.; Zhang, Q. Thermoelectric properties of carbon nanotube reinforced cement-based composites fabricated by compression shear. Ceram. Int. 2018, 44, 5829–5833. [Google Scholar] [CrossRef]

- Farcas, C.; Galao, O.; Navarro, R.; Zornoza, E.; Baeza, F.J.; del Moral, B.E.; Garcés, P. Heating and de-icing function in conductive concrete and cement paste with the hybrid addition of carbon nanotubes and graphite products. Smart Mater. Struct. 2021, 30, 095014. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

- Yu, X.; Kwon, E. A carbon nanotube/cement composite with piezoresistive properties. Smart Mater. Struct. 2009, 18, 055010. [Google Scholar] [CrossRef]

- Gong, H.; Zhang, Y.; Quan, J.; Che, S. Preparation and properties of cement based piezoelectric composites modified by CNTs. Curr. Appl. Phys. 2011, 11, 653–656. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E.; Ou, J. Effects of CNT concentration level and water/cement ratio on the piezoresistivity of CNT/cement composites. J. Compos. Mater. 2012, 46, 19–25. [Google Scholar] [CrossRef]

- Kim, H.K.; Park, I.S.; Lee, H.K. Improved piezoresistive sensitivity and stability of CNT/cement mortar composites with low water–binder ratio. Compos. Struct. 2014, 116, 713–719. [Google Scholar] [CrossRef]

- Jang, S.H.; Hochstein, D.P.; Kawashima, S.; Yin, H. Experiments and micromechanical modeling of electrical conductivity of carbon nanotube/cement composites with moisture. Cem. Concr. Compos. 2017, 77, 49–59. [Google Scholar] [CrossRef]

- Park, H.M.; Kim, G.M.; Lee, S.Y.; Jeon, H.; Kim, S.Y.; Kim, M.; Yang, B.J. Electrical resistivity reduction with pitch-based carbon fiber into multi-walled carbon nanotube (MWCNT)-embedded cement composites. Constr. Build. Mater. 2018, 165, 484–493. [Google Scholar] [CrossRef]

- Yoo, D.Y.; You, I.; Youn, H.; Lee, S.J. Electrical and piezoresistive properties of cement composites with carbon nanomaterials. J. Compos. Mater. 2018, 52, 3325–3340. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Kumar, S.; Kolay, P.; Malla, S.; Mishra, S. Effect of multiwalled carbon nanotubes on mechanical strength of cement paste. J. Mater. Civ. Eng. 2012, 24, 84–91. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Taha, R.; Taqa, A.A.; Shaat, A. Optimum carbon nanotubes’ content for improving flexural and compressive strength of cement paste. Constr. Build. Mater. 2017, 150, 395–403. [Google Scholar] [CrossRef]

- Zhou, C.; Li, F.; Hu, J.; Ren, M.; Wei, J.; Yu, Q. Enhanced mechanical properties of cement paste by hybrid graphene oxide/carbon nanotubes. Constr. Build. Mater. 2017, 134, 336–345. [Google Scholar] [CrossRef]

- Hassan, A.; Galal, S.; Hassan, A.; Salman, A. Utilization of carbon nanotubes and steel fibers to improve the mechanical properties of concrete pavement. Beni-Suef Univ. J. Basic. Appl. Sci. 2022, 11, 121. [Google Scholar] [CrossRef]

- Park, Y.J.; Lee, H.S.; Seo, T.S. Experimental study on properties of graphene and hollow glass powder-added ultra-high strength concrete. Int. J. Concr. Struct. Mater. 2024, 18, 47. [Google Scholar] [CrossRef]

- Salman, A.; Hassan, A.; Ahmed, H.I. Effects of steel fibers and carbon nanotubes on the flexural behavior of hybrid GFRP/steel reinforced concrete beams. Beni-Suef Univ. J. Basic. Appl. Sci. 2024, 13, 127. [Google Scholar] [CrossRef]

- Jaramillo, L.J.; Kalfat, R. Evaluation of mechanical properties and water resistance performance of concrete modified with graphene nanoplatelets (GNP). Int. J. Concr. Struct. Mater. 2025, 19, 39. [Google Scholar] [CrossRef]

- Sičáková, A.; Kim, J.; Bálintová, M.; Eštoková, A.; Junáková, N.; Orolin, P.; Ubysz, A. Contribution to the prediction of the recycling potential of recycled concrete as a cement admixture based on the compressive strength of the parent concrete. Int. J. Concr. Struct. Mater. 2024, 18, 80. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Mechanical and damping properties of CNT-reinforced cementitious composites. Compos. Struct. 2017, 160, 81–88. [Google Scholar] [CrossRef]

- Domínguez-Santos, D.; Muñoz, P.; Morales-Ferreiro, J.O.; Acuña, C.; Diaz-Droguett, D.E.; Villaro, E. Reinforced concrete with graphene oxide: Techno-economic feasibility for reduced cement usage and CO2 emissions. Int. J. Concr. Struct. Mater. 2025, 19, 52. [Google Scholar] [CrossRef]

- Sindu, B.S.; Sasmal, S. Properties of carbon nanotube reinforced cement composite synthesized using different types of surfactants. Constr. Build. Mater. 2017, 155, 389–399. [Google Scholar] [CrossRef]

- Nasehi Ghashouieh, M.; Malekinejad, M.; Amiri, M. Microstructural analysis of the effect of using nano-silica on the mechanical properties of cement–sand mortar under the effect of heat. Int. J. Concr. Struct. Mater. 2024, 18, 74. [Google Scholar] [CrossRef]

- KSD 24 12 21; Bridge Design Load (Limit State Design Method). Korean Design Standard: Seoul, Republic of Korea, 2021.

- [Standard 1] KSL ISO 679; Methods of Testing Cements—Determination of Strength. Korean Agency for Technology and Standards: Seoul, Republic of Korea, 2022.

- KS F 2408; Standard Test Method for Flexural Strength of Concrete. Korean Agency for Technology and Standards: Seoul, Republic of Korea, 2016.

- KS F 2566; Standard Test Method for Flexural Performance of Fiber Reinforced Concrete. Korea Agency for Technology and Standards: Seoul, Republic of Korea, 2014.

| Specimen Name | MWCNT Concentration (wt%) | Steel Fiber Content (vol%) | Curing Days (Day) |

|---|---|---|---|

| MW0.0-SF0.0-7D | 0.0 | 0.0 | 7 |

| MW0.5-SF0.0-7D | 0.5 | ||

| MW1.0-SF0.0-7D | 1.0 | ||

| MW0.0-SF2.0-7D | 0.0 | 2.0 | |

| MW0.5-SF2.0-7D | 0.5 | ||

| MW1.0-SF2.0-7D | 1.0 | ||

| MW0.0-SF0.0-28D | 0.0 | 0.0 | 28 |

| MW0.5-SF0.0-28D | 0.5 | ||

| MW1.0-SF0.0-28D | 1.0 | ||

| MW0.0-SF2.0-28D | 0.0 | 2.0 | |

| MW0.5-SF2.0-28D | 0.5 | ||

| MW1.0-SF2.0-28D | 1.0 |

| Specimen Name | MWCNT (g) | Steel Fiber (g) |

|---|---|---|

| MW0.0-SF0.0-7D | 0 | 0 |

| MW0.5-SF0.0-7D | 0.4 | |

| MW1.0-SF0.0-7D | 0.8 | |

| MW0.0-SF2.0-7D | 0 | 19.6 |

| MW0.5-SF2.0-7D | 0.4 | |

| MW1.0-SF2.0-7D | 0.8 | |

| MW0.0-SF0.0-28D | 0 | 0 |

| MW0.5-SF0.0-28D | 0.4 | |

| MW1.0-SF0.0-28D | 0.8 | |

| MW0.0-SF2.0-28D | 0 | 19.6 |

| MW0.5-SF2.0-28D | 0.4 | |

| MW1.0-SF2.0-28D | 0.8 |

| Specimen Name | Maximum Temperature Variation | |||

|---|---|---|---|---|

| 10 V | 20 V | 30 V | 60 V | |

| MW0.0-SF0.0-7D | ||||

| MW0.5-SF0.0-7D | ||||

| MW1.0-SF0.0-7D | ||||

| MW0.0-SF2.0-7D | ||||

| MW0.5-SF2.0-7D | ||||

| MW1.0-SF2.0-7D | ||||

| MW0.0-SF0.0-28D | ||||

| MW0.5-SF0.0-28D | ||||

| MW1.0-SF0.0-28D | ||||

| MW0.0-SF2.0-28D | ||||

| MW0.5-SF2.0-28D | ||||

| MW1.0-SF2.0-28D | ||||

| Specimen Name | Steel Fiber Content (vol%) | MWCNT Content (wt%) | Electrical Resistance (Ω) |

|---|---|---|---|

| MW0.0-SF0.0-28D | 0.0 | 0.0 | |

| MW0.5-SF0.0-28D | 0.5 | ||

| MW1.0-SF0.0-28D | 1.0 | ||

| MW0.0-SF2.0-28D | 2.0 | 0.0 | |

| MW0.5-SF2.0-28D | 0.5 | ||

| MW1.0-SF2.0-28D | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Kim, D.; Cho, S.; Chung, W. Heating Performance and Flexural Strength of Steel Fiber–Carbon Nanotube Cement Composites for Black Ice Prevention. Buildings 2025, 15, 4144. https://doi.org/10.3390/buildings15224144

Lee H, Kim D, Cho S, Chung W. Heating Performance and Flexural Strength of Steel Fiber–Carbon Nanotube Cement Composites for Black Ice Prevention. Buildings. 2025; 15(22):4144. https://doi.org/10.3390/buildings15224144

Chicago/Turabian StyleLee, Heeyoung, Donghwi Kim, Sanghyeon Cho, and Wonseok Chung. 2025. "Heating Performance and Flexural Strength of Steel Fiber–Carbon Nanotube Cement Composites for Black Ice Prevention" Buildings 15, no. 22: 4144. https://doi.org/10.3390/buildings15224144

APA StyleLee, H., Kim, D., Cho, S., & Chung, W. (2025). Heating Performance and Flexural Strength of Steel Fiber–Carbon Nanotube Cement Composites for Black Ice Prevention. Buildings, 15(22), 4144. https://doi.org/10.3390/buildings15224144