Electromechanical and Rheological Properties of Self-Sensing Mortars Containing Red Mud for Concrete Beam Monitoring †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Self-Sensing Cementitious Composites (SSCC)

2.2.2. Rheological Behavior Assessment

Rotational Rheometry Test

Mini-Flow Test

2.2.3. Compressive Strength Test

2.2.4. Electrical Resistivity Test

2.2.5. Evaluation of the Piezoresistive Behavior

2.2.6. Case Study: Concrete Beam Containing SSCC Under Dynamic Loading

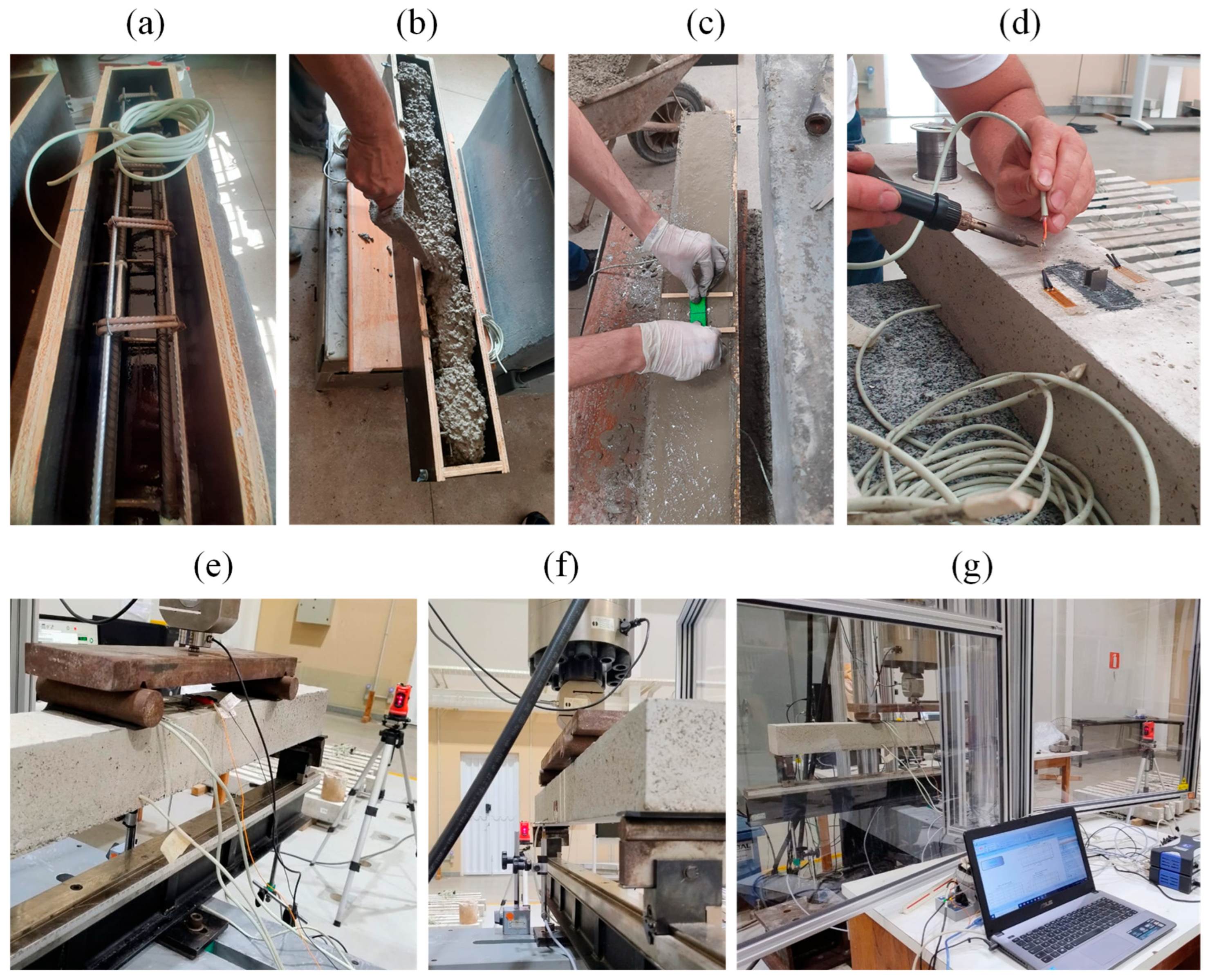

SSCC Embedded in the Concrete Beam

Concrete Mix Proportions

Steel Reinforcement

RC Beam Production

Experimental Setup of Dynamic Bending Tests

Loading History

3. Results and Discussion

3.1. SSCC Investigations

3.1.1. Rheological Behavior

Rotational Rheometry Results

Consistency Index

3.1.2. Compressive Strength

3.1.3. Electrical Resistivity

3.1.4. Piezoresistive Behavior

3.2. Investigations on RC Beam Containing SSCC

4. Conclusions

- The incorporation of RM into the cementitious matrix resulted in an increase in the plastic viscosity and yield stress of the sensing mortars, while reducing the consistency index, as the substitution level of natural aggregates in the REF series (25% RM) was raised to 100% RM. This behavior can be attributed to the high water absorption and fine particle size of RM compared to sand particles.

- The replacement of natural aggregates with RM also altered the electrical resistivity of the cementitious composites. While mortars produced with a 25% replacement level exhibited the typical behavior of insulating materials, composites with replacement levels of 50%, 75%, and 100% displayed high electrical conductivity. This behavior may be associated with the presence of conductive particles in RM, which promoted a greater refinement of the electronic conduction network within the cementitious matrix.

- Piezoresistive tests indicated that only mortars with 50%, 75%, and 100% replacement levels exhibited consistent and reversible variations in electrical resistivity under mechanical loading cycles. Increasing the aggregate replacement level with RM from 50% to 100% enhanced the self-sensing capability of the composites, as evidenced by an approximate 23% increase in the GF.

- For dynamic tests involving up to 100 loading cycles on an RC beam, conducted within the elastic regime, the SSCC exhibited satisfactory sensing behavior. The FCR values of the sensing composite showed reversible behavior throughout the loading/unloading cycles, with a cyclic pattern consistent with the deformations recorded by conventional electrical strain gauges attached to the structural element. However, a moderate hysteresis was observed in the electrical signal at the end of the dynamic analysis test.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, Y.; Su, Y.; Lu, N.; Shah, S. Meta Concrete: Exploring Novel Functionality of Concrete Using Nanotechnology. Eng. Sci. 2020, 8, 1–10. [Google Scholar] [CrossRef]

- Chung, D.D.L. Self-Sensing Concrete: From Resistance-Based Sensing to Capacitance-Based Sensing. Int. J. Smart Nano Mater. 2021, 12, 1–19. [Google Scholar] [CrossRef]

- Ubertini, F.; D’Alessandro, A. Concrete with Self-Sensing Properties. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Elsevier: Amsterdam, The Netherlands, 2018; pp. 501–530. [Google Scholar]

- Chung, D.D.L. A Critical Review of Piezoresistivity and Its Application in Electrical-Resistance-Based Strain Sensing. J. Mater. Sci. 2020, 55, 15367–15396. [Google Scholar] [CrossRef]

- Dinesh, A.; Indhumathi, S.; Pichumani, M. Self-Sensing Cement Composites for Structural Health Monitoring: From Know-How to Do-How. Autom. Constr. 2024, 160, 105304. [Google Scholar] [CrossRef]

- Kang, Z.; Aslani, F.; Han, B. Prediction of Mechanical and Electrical Properties of Carbon Fibre-Reinforced Self-Sensing Cementitious Composites. Case Stud. Constr. Mater. 2024, 20, e02716. [Google Scholar] [CrossRef]

- Jiang, X.; Lu, D.; Yin, B.; Leng, Z. Advancing Carbon Nanomaterials-Engineered Self-Sensing Cement Composites for Structural Health Monitoring: A State-of-the-Art Review. J. Build. Eng. 2024, 87, 109129. [Google Scholar] [CrossRef]

- Elseady, A.A.E.; Zhuge, Y.; Ma, X.; Chow, C.W.K.; Lee, I.; Zeng, J.; Gorjian, N. Development of Self-Sensing Cementitious Composites by Incorporating a Two-Dimensional Carbon-Fibre Textile Network for Structural Health Monitoring. Constr. Build. Mater. 2024, 415, 135049. [Google Scholar] [CrossRef]

- Bekzhanova, Z.; Memon, S.A.; Kim, J.R. Self-Sensing Cementitious Composites: Review and Perspective. Nanomaterials 2021, 11, 2355. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Guo, Y.; He, X.; Sheng, D. Effects of Silica Fume on Physicochemical Properties and Piezoresistivity of Intelligent Carbon Black-Cementitious Composites. Constr. Build. Mater. 2020, 259, 120399. [Google Scholar] [CrossRef]

- Tian, Z.; Li, Y.; Zheng, J.; Wang, S. A State-of-the-Art on Self-Sensing Concrete: Materials, Fabrication and Properties. Compos. Part B Eng. 2019, 177, 107437. [Google Scholar] [CrossRef]

- Lima, G.; Nalon, G.; Santos, R.F.; Ribeiro, J.C.L.; Franco de Carvalho, J.M.; Pedroti, L.G.; de Araújo, E.N.D. Microstructural Investigation of the Effects of Carbon Black Nanoparticles on Hydration Mechanisms, Mechanical and Piezoresistive Properties of Cement Mortars. Mater. Res. 2020, 24, e20200539. [Google Scholar] [CrossRef]

- Nalon, G.H.; Ribeiro, J.C.L.; Pedroti, L.G.; da Silva, R.M.; de Araújo, E.N.D. Behavior of Self-Sensing Masonry Structures Exposed to High Temperatures and Rehydration. Structures 2024, 68, 107083. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Self-Sensing Concrete in Smart Structures; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780128005170. [Google Scholar]

- Kim, T.U.; Kim, M.K.; Park, J.W.; Kim, D.J. Effects of Temperature and Humidity on Self-Stress Sensing Capacity of Smart Concrete Blocks. J. Build. Eng. 2023, 69, 106227. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.; Ou, J. Electrical Property of Cement-Based Composites Filled with Carbon Black under Long-Term Wet and Loading Condition. Compos. Sci. Technol. 2008, 68, 2114–2119. [Google Scholar] [CrossRef]

- Xiao, H.; Li, H.; Ou, J. Strain Sensing Properties of Cement-Based Sensors Embedded at Various Stress Zones in a Bending Concrete Beam. Sens. Actuators A Phys. 2011, 167, 581–587. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic Self-Sensing Concrete and Structures: A Review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Horňáková, M.; Lehner, P. Relationship of Surface and Bulk Resistivity in the Case of Mechanically Damaged Fibre Reinforced Red Ceramic Waste Aggregate Concrete. Materials 2020, 13, 5501. [Google Scholar] [CrossRef]

- Dogra, A.; Hazim, S.; Goyal, A.; Bhatia, A.; Sharma, S. Developing Embeddable Self-Sensing Cementitious Composite Sensor Incorporating Carbon Based Materials for Smart Structural Health Monitoring. J. Build. Eng. 2025, 111, 113278. [Google Scholar] [CrossRef]

- Han, J.; Pan, J.; Xu, L.; Cai, J.; Li, X.; Meng, L.; Li, N. Development of Self-Sensing Engineered Cementitious Composite Sensors for Monitoring Flexural Performance of Reinforced Concrete Beam. Dev. Built Environ. 2024, 18, 100407. [Google Scholar] [CrossRef]

- Dong, W.; Ahmed, A.H.; Liebscher, M.; Li, H.; Guo, Y.; Pang, B.; Adresi, M.; Li, W.; Mechtcherine, V. Electrical Resistivity and Self-Sensing Properties of Low-Cement Limestone Calcined Clay Cement (LC3) Mortar. Mater. Des. 2025, 252, 113790. [Google Scholar] [CrossRef]

- Guo, Y.; Qu, F.; Dong, W.; Wang, Y.; Yoo, D.-Y.; Maruyama, I.; Li, W. Self-Sensing Performance of Nanoengineered One-Part Alkali-Activated Materials-Based Sensors after Exposure to Elevated Temperature. Cem. Concr. Compos. 2025, 164, 106257. [Google Scholar] [CrossRef]

- Kang, Z.; Zhang, J.; Li, N.; Yang, Y.; Lv, T.; Lu, J. Development of Self-Sensing Cement Composites by Incorporating Hybrid Biochar and Nano Carbon Black. Cem. Concr. Compos. 2024, 153, 105708. [Google Scholar] [CrossRef]

- Haque, M.I.; Khan, R.I.; Ashraf, W.; Pendse, H. Production of Sustainable, Low-Permeable and Self-Sensing Cementitious Composites Using Biochar. Sustain. Mater. Technol. 2021, 28, e00279. [Google Scholar] [CrossRef]

- Zhao, Y.; Xiang, J.; Qiang, S.; Lu, H. Study on the Optimization of Electromechanical Properties and Fiber Dispersion Mechanisms in Red Mud-Carbon Fiber-Cement Ternary Composites. Constr. Build. Mater. 2025, 490, 142527. [Google Scholar] [CrossRef]

- Dong, W.; Guo, Y.; Sun, Z.; Tao, Z.; Li, W. Development of Piezoresistive Cement-Based Sensor Using Recycled Waste Glass Cullets Coated with Carbon Nanotubes. J. Clean. Prod. 2021, 314, 127968. [Google Scholar] [CrossRef]

- Li, G.; Liu, M.; Rao, M.; Jiang, T.; Zhuang, J.; Zhang, Y. Stepwise Extraction of Valuable Components from Red Mud Based on Reductive Roasting with Sodium Salts. J. Hazard. Mater. 2014, 280, 774–780. [Google Scholar] [CrossRef]

- Liu, X.; Han, Y.; He, F.; Gao, P.; Yuan, S. Characteristic, Hazard and Iron Recovery Technology of Red Mud—A Critical Review. J. Hazard. Mater. 2021, 420, 126542. [Google Scholar] [CrossRef]

- Pan, X.; Wu, H.; Lv, Z.; Yu, H.; Tu, G. Recovery of Valuable Metals from Red Mud: A Comprehensive Review. Sci. Total Environ. 2023, 904, 166686. [Google Scholar] [CrossRef]

- Li, S.; Pan, J.; Zhu, D.; Guo, Z.; Shi, Y.; Dong, T.; Lu, S.; Tian, H. A New Route for Separation and Recovery of Fe, Al and Ti from Red Mud. Resour. Conserv. Recycl. 2021, 168, 105314. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiang, S. Exploring the Potential of Bayer Red Mud: Toward Self-Sensing Cementitious Composites. Constr. Build. Mater. 2025, 460, 139850. [Google Scholar] [CrossRef]

- Raghu Babu, U.; Kondraivendhan, B. Influence of Bauxite Residue (Red Mud) on Corrosion of Rebar in Concrete. Innov. Infrastruct. Solut. 2020, 5, 108. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Labrincha, J.A.; Morelli, M.R. Chloride Diffusivity in Red Mud-Ordinary Portland Cement Concrete Determined by Migration Tests. Mater. Res. 2011, 14, 227–234. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Labrincha, J.A.; Morelli, M.R. Effect of the Addition of Red Mud on the Corrosion Parameters of Reinforced Concrete. Cem. Concr. Res. 2012, 42, 124–133. [Google Scholar] [CrossRef]

- Konkanov, M.; Salem, T.; Jiao, P.; Niyazbekova, R.; Lajnef, N. Environment-Friendly, Self-Sensing Concrete Blended with Byproduct Wastes. Sensors 2020, 20, 1925. [Google Scholar] [CrossRef]

- Salih, W.T.; Yu, W.; Dong, X.; Hao, W. Study on Stress-Strain-Resistivity and Microscopic Mechanism of Red Mud Waste Modified by Desulphurization Gypsum-Fly Ash under Drying-Wetting Cycles. Constr. Build. Mater. 2020, 249, 118772. [Google Scholar] [CrossRef]

- Nalon, G.H.; Santos, R.F.; Lima, G.E.S.d.; Andrade, I.K.R.; Pedroti, L.G.; Ribeiro, J.C.L.; Franco de Carvalho, J.M. Recycling Waste Materials to Produce Self-Sensing Concretes for Smart and Sustainable Structures: A Review. Constr. Build. Mater. 2022, 325, 126658. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM: West Conshohocken, PA, USA, 2024.

- Oliveira, H.R.; Nalon, G.H.; de Lima, G.E.S.; Pedroti, L.G.; Ribeiro, J.C.L.; de Carvalho, J.M.F.; Ferreira, F.A. Effects of Red Mud on the Mechanical and Piezoresistive Properties of Mortars. In Proceedings of the Characterization of Minerals, Metals, and Materials (TMS 2025), Las Vegas, NV, USA, 23–27 March 2025; pp. 345–356. [Google Scholar]

- Rai, S.; Lataye, D.H.; Chaddha, M.J.; Mishra, R.S.; Mahendiran, P.; Mukhopadhyay, J.; Yoo, C.; Wasewar, K.L. An Alternative to Clay in Building Materials: Red Mud Sintering Using Fly Ash via Taguchi’s Methodology. Adv. Mater. Sci. Eng. 2013, 2013, 757923. [Google Scholar] [CrossRef]

- Ma, M.; Wang, G.; Yang, Z.; Huang, S.; Guo, W.; Shen, Y. Preparation, Characterization, and Photocatalytic Properties of Modified Red Mud. Adv. Mater. Sci. Eng. 2015, 2015, 907539. [Google Scholar] [CrossRef]

- Ridaoui, H.; Jada, A.; Vidal, L.; Donnet, J.-B. Effect of Cationic Surfactant and Block Copolymer on Carbon Black Particle Surface Charge and Size. Colloids Surf. A Physicochem. Eng. Asp. 2006, 278, 149–159. [Google Scholar] [CrossRef]

- Soares de Lima, G.E.; Nalon, G.H.; Santos, R.F.; Pedroti, L.G.; Lopes Ribeiro, J.C.; Franco de Carvalho, J.M.; Duarte de Araújo, E.N.; Garcez de Azevedo, A.R. Evaluation of the Effects of Sonication Energy on the Dispersion of Carbon Black Nanoparticles (CBN) and Properties of Self-Sensing Cementitious Composites. J. Mater. Res. Technol. 2025, 36, 1283–1293. [Google Scholar] [CrossRef]

- Wang, H.; Shi, F.; Shen, J.; Zhang, A.; Zhang, L.; Huang, H.; Liu, J.; Jin, K.; Feng, L.; Tang, Z. Research on the Self-Sensing and Mechanical Properties of Aligned Stainless Steel Fiber-Reinforced Reactive Powder Concrete. Cem. Concr. Compos. 2021, 119, 104001. [Google Scholar] [CrossRef]

- Han, J.; Cai, J.; Pan, J.; Sun, Y. Study on the Conductivity of Carbon Fiber Self-Sensing High Ductility Cementitious Composite. J. Build. Eng. 2021, 43, 103125. [Google Scholar] [CrossRef]

- Shi, Y.; Han, L.; Wu, P.; Dai, K.; Liu, Z.; Wu, C. Design of 3D Printing Green Ultra-High Performance Concrete Based on Binder System Optimization. Case Stud. Constr. Mater. 2025, 22, e04625. [Google Scholar] [CrossRef]

- Franco de Carvalho, J.M.; Schmidt, W.; Kühne, H.-C.; Peixoto, R.A.F. Influence of High-Charge and Low-Charge PCE-Based Superplasticizers on Portland Cement Pastes Containing Particle-Size Designed Recycled Mineral Admixtures. J. Build. Eng. 2020, 32, 101515. [Google Scholar] [CrossRef]

- Schmidt, W. Design Concepts for the Robustness Improvement of Self Compacting Concrete: Effects of Admixtures and Mixture Components on the Rheology and Early Hydration at Varying Temperatures. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2014. [Google Scholar]

- Vasiliou, E.; Schmidt, W.; Stefanidou, M.; Kühne, H.-C.; Rogge, A. Effectiveness of Starch Ethers as Rheology Modifying Admixture for Cement Based Systems. Acad. J. Civ. Eng. 2017, 35, 81–85. [Google Scholar] [CrossRef]

- Downey, A.; D’Alessandro, A.; Ubertini, F.; Laflamme, S.; Geiger, R. Biphasic DC Measurement Approach for Enhanced Measurement Stability and Multi-Channel Sampling of Self-Sensing Multi-Functional Structural Materials Doped with Carbon-Based Additives. Smart Mater. Struct. 2017, 26, 065008. [Google Scholar] [CrossRef]

- Downey, A.; Garcia-Macias, E.; D’Alessandro, A.; Laflamme, S.; Castro-Triguero, R.; Ubertini, F. Continuous and Embedded Solutions for SHM of Concrete Structures Using Changing Electrical Potential in Self-Sensing Cement-Based Composites. Proc. SPIE 2017, 10169, 101691G. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Labrincha, J.A. Effect of Red Mud Addition on the Rheological Behaviour and on Hardened State Characteristics of Cement Mortars. Constr. Build. Mater. 2011, 25, 163–170. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Morelli, M.R. Use of Red Mud as Addition for Portland Cement Mortars; Associacao Brasileira de Ceramica (ABC): Sao Paulo, Brazil, 2010. [Google Scholar]

- Liu, L.; Xu, J.; Yin, T.; Wang, Y.; Chu, H. Improving Electrical and Piezoresistive Properties of Cement-Based Composites by Combined Addition of Nano Carbon Black and Nickel Nanofiber. J. Build. Eng. 2022, 51, 104312. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; You, I.; Lee, S.-J. Electrical Properties of Cement-Based Composites with Carbon Nanotubes, Graphene, and Graphite Nanofibers. Sensors 2017, 17, 1064. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Labrincha, J.A.; Morelli, M.R. Effect of Red Mud Addition on the Corrosion Parameters of Reinforced Concrete Evaluated by Electrochemical Methods. Rev. IBRACON Estrut. E Mater. 2012, 5, 451–467. [Google Scholar] [CrossRef][Green Version]

- Dong, W.; Li, W.; Tao, Z.; Wang, K. Piezoresistive Properties of Cement-Based Sensors: Review and Perspective. Constr. Build. Mater. 2019, 203, 146–163. [Google Scholar] [CrossRef]

| Oxides | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | SO3 | TiO2 | Others |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 68.15 | 16.94 | 5.16 | 3.44 | 0.53 | 0.85 | 3.89 | 0.27 | 0.77 |

| Red Mud | 0.26 | 31.53 | 44.47 | 21.53 | 0.00 | 0.23 | 0.19 | 1.44 | 0.36 |

| Natural sand | 0.50 | 88.94 | 7.31 | 1.31 | 0.37 | 0.84 | 0.04 | 0.30 | 0.41 |

| Series | Mixture Proportions (by Volume) | CBN-to-Cement Ratio (by Mass) | Superplasticizer-to-Cement Ratio (by Mass) | |||

|---|---|---|---|---|---|---|

| Cement | Sand | Red Mud | Water | |||

| REF | 1.000 | 0.563 | 0.188 | 2.130 | 0.125 | 0.0625 |

| 50%RM | 1.000 | 0.375 | 0.375 | 2.130 | 0.125 | 0.0625 |

| 75%RM | 1.000 | 0.188 | 0.563 | 2.130 | 0.125 | 0.0625 |

| 100%RM | 1.000 | 0.000 | 0.750 | 2.130 | 0.125 | 0.0625 |

| Cement | Fine Aggregate | Coarse Aggregate | Water | Plasticizer | Slump (mm) |

|---|---|---|---|---|---|

| 306.00 | 835.00 | 964.00 | 214.00 | 2.14 | 185.00 |

| Diameter (mm) | Type | Yield Stress (MPa) | Ultimate Stress (MPa) |

|---|---|---|---|

| 5.0 | CA-60 | 655.0 | 732.0 |

| 10.0 | CA-50 | 570.0 | 654.0 |

| Property | Series |

|---|---|

| Highest flowability | REF |

| Highest compressive strength | 100%RM |

| Highest electrical conductivity | 100%RM |

| Highest gauge factor (strain sensitivity) | 100%RM |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, H.R.; Nalon, G.H.; de Lima, G.E.S.; Pedroti, L.G.; Ribeiro, J.C.L.; Franco de Carvalho, J.M.; Ferreira, F.A.; Miranda de Souza, A.; Peixoto, R.A.F.; de Oliveira, D.S. Electromechanical and Rheological Properties of Self-Sensing Mortars Containing Red Mud for Concrete Beam Monitoring. Buildings 2025, 15, 4085. https://doi.org/10.3390/buildings15224085

Oliveira HR, Nalon GH, de Lima GES, Pedroti LG, Ribeiro JCL, Franco de Carvalho JM, Ferreira FA, Miranda de Souza A, Peixoto RAF, de Oliveira DS. Electromechanical and Rheological Properties of Self-Sensing Mortars Containing Red Mud for Concrete Beam Monitoring. Buildings. 2025; 15(22):4085. https://doi.org/10.3390/buildings15224085

Chicago/Turabian StyleOliveira, Henrique Ribeiro, Gustavo Henrique Nalon, Gustavo Emilio Soares de Lima, Leonardo Gonçalves Pedroti, José Carlos Lopes Ribeiro, José Maria Franco de Carvalho, Flávio Antônio Ferreira, Ariel Miranda de Souza, Ricardo André Fiorotti Peixoto, and Diôgo Silva de Oliveira. 2025. "Electromechanical and Rheological Properties of Self-Sensing Mortars Containing Red Mud for Concrete Beam Monitoring" Buildings 15, no. 22: 4085. https://doi.org/10.3390/buildings15224085

APA StyleOliveira, H. R., Nalon, G. H., de Lima, G. E. S., Pedroti, L. G., Ribeiro, J. C. L., Franco de Carvalho, J. M., Ferreira, F. A., Miranda de Souza, A., Peixoto, R. A. F., & de Oliveira, D. S. (2025). Electromechanical and Rheological Properties of Self-Sensing Mortars Containing Red Mud for Concrete Beam Monitoring. Buildings, 15(22), 4085. https://doi.org/10.3390/buildings15224085