Study on the Effects of Nozzle Proximal Carbonation Mixing and Vacuum Dewatering on the Printability and Mechanical Properties of the 3D Printed Construction Mortar

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

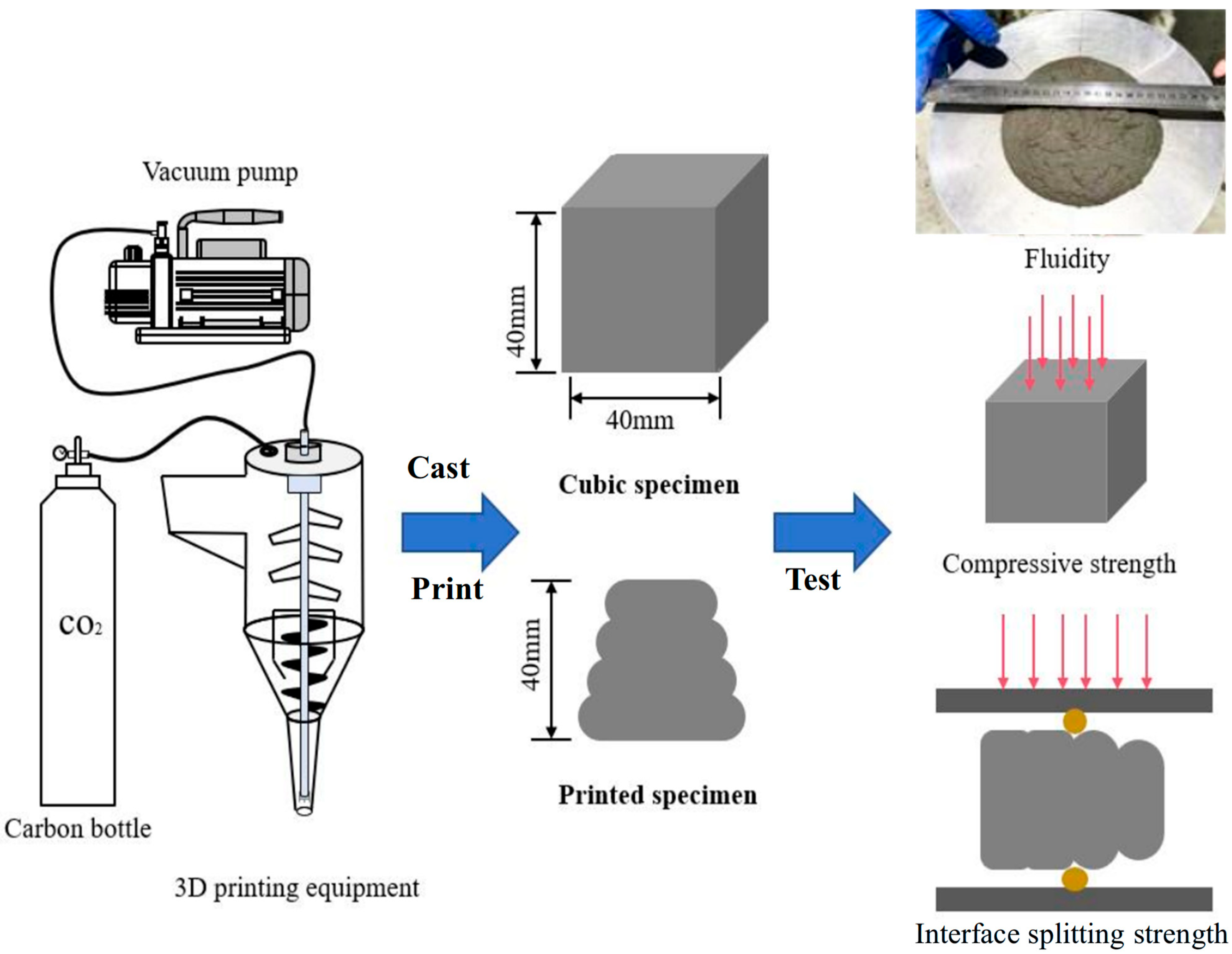

2.2. Three-Dimensional Printing and Specimen Preparation

2.3. Printability Test

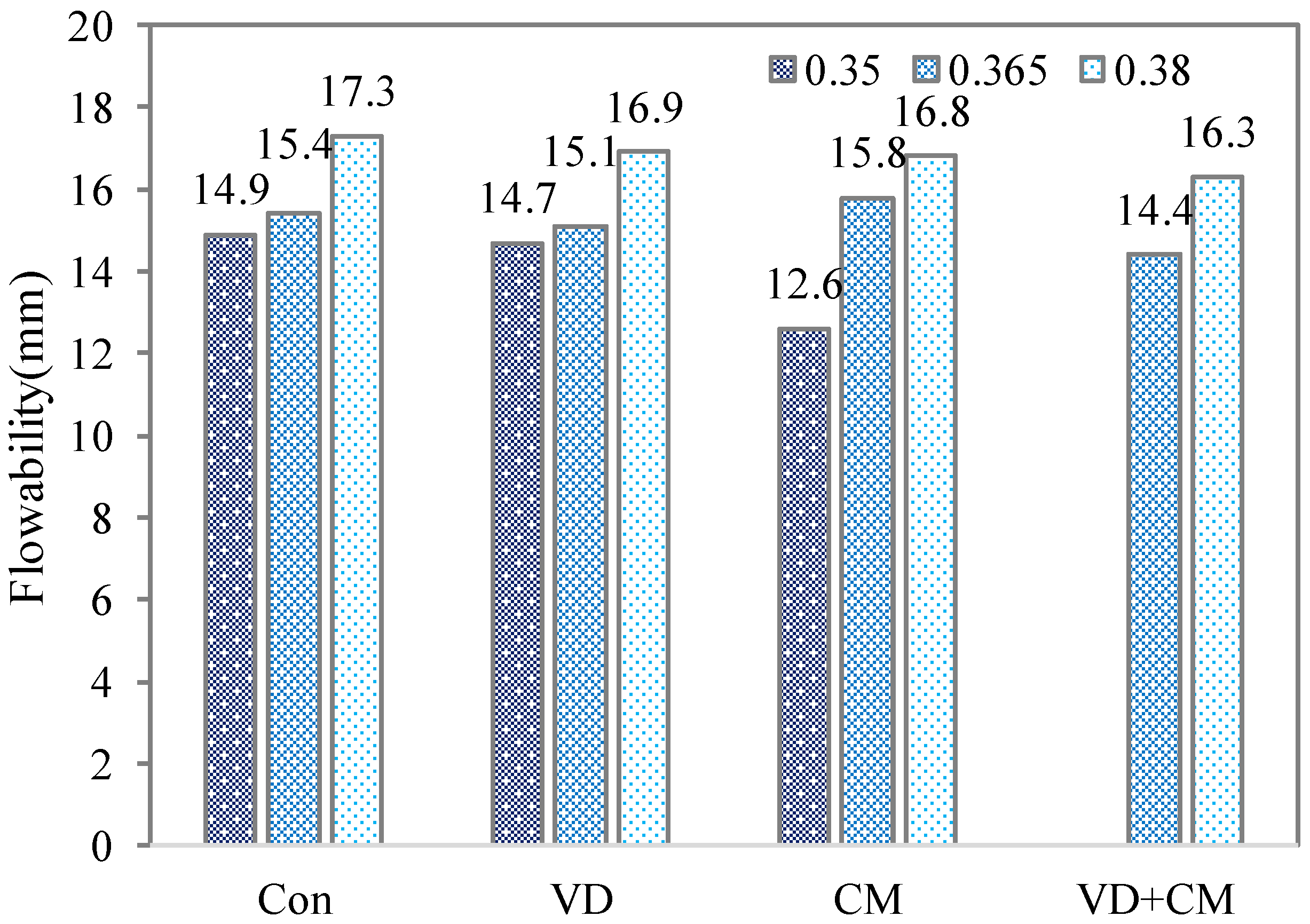

2.3.1. Flowability Test

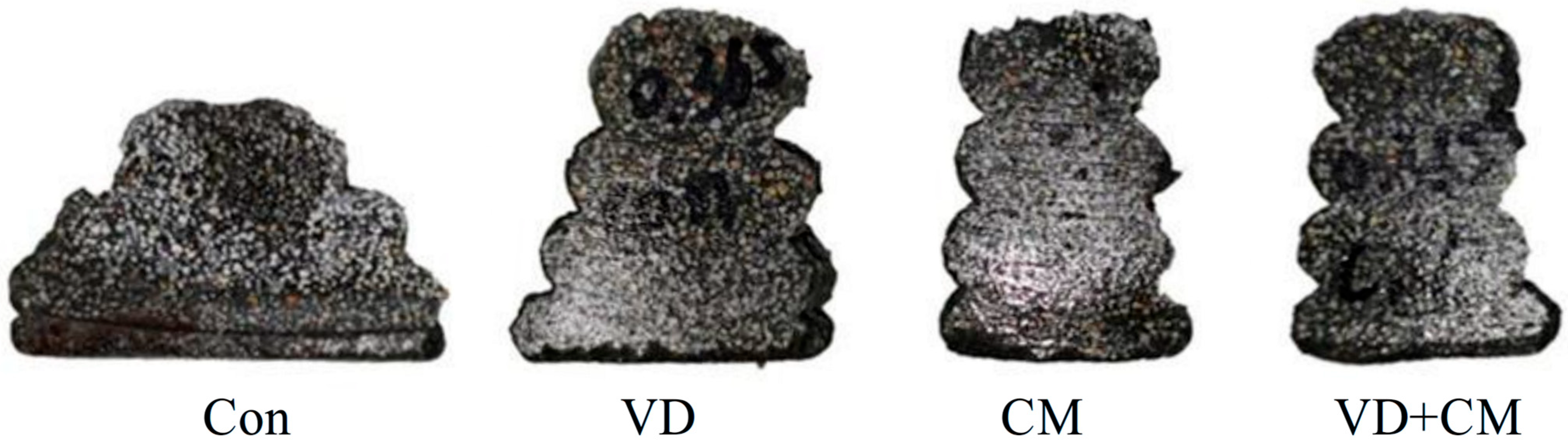

2.3.2. Extrudability Test

2.3.3. Buildability Test

2.4. Experimental Test

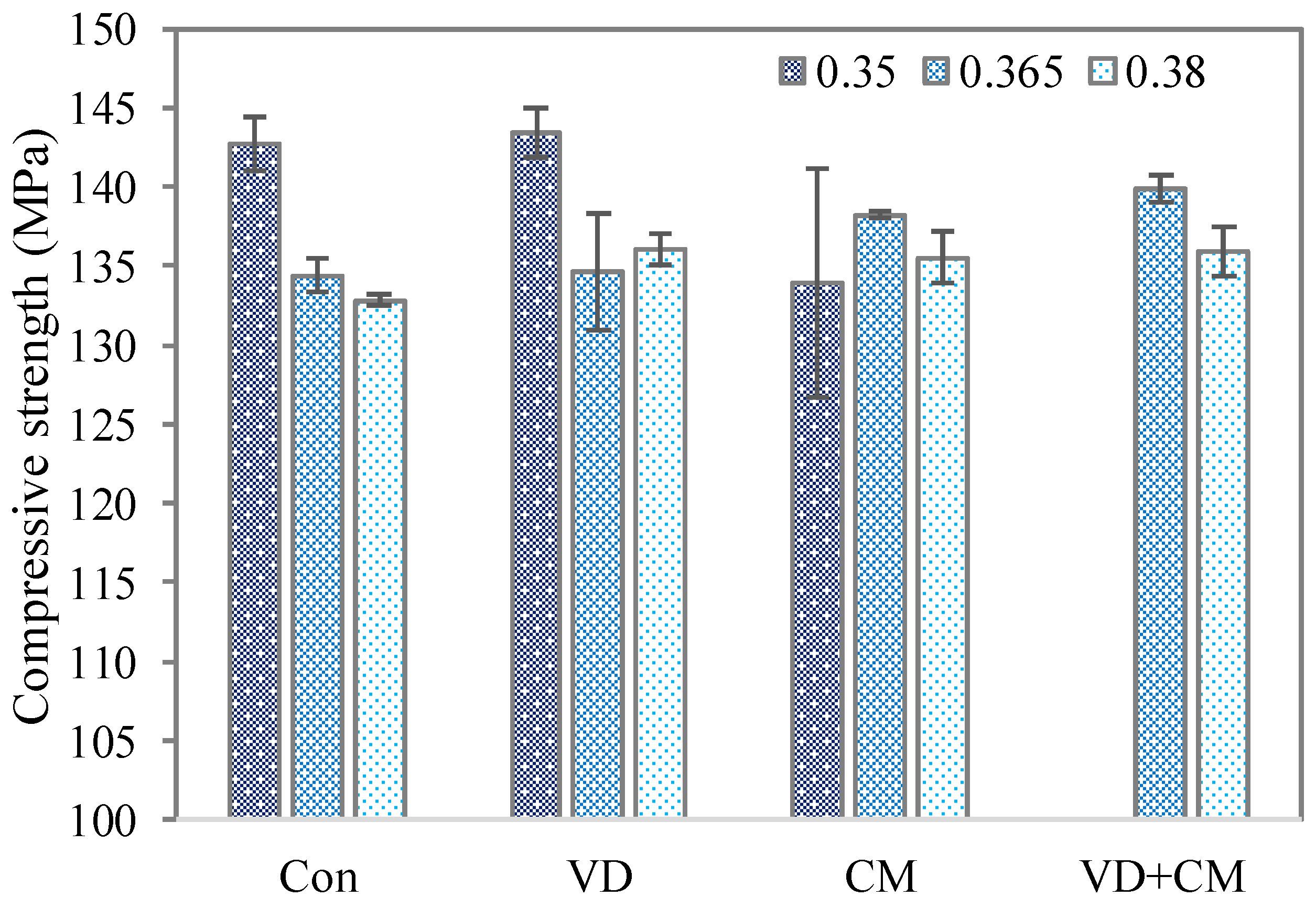

2.4.1. Compressive Strength Test

2.4.2. Interfacial Bonding Strength Test

2.4.3. Microstructure Test with SEM

3. Results and Discussion

3.1. Printability

3.1.1. Flowability

3.1.2. Extrudability

3.1.3. Buildability

3.2. Mechanical Properties

3.2.1. Compressive Strength

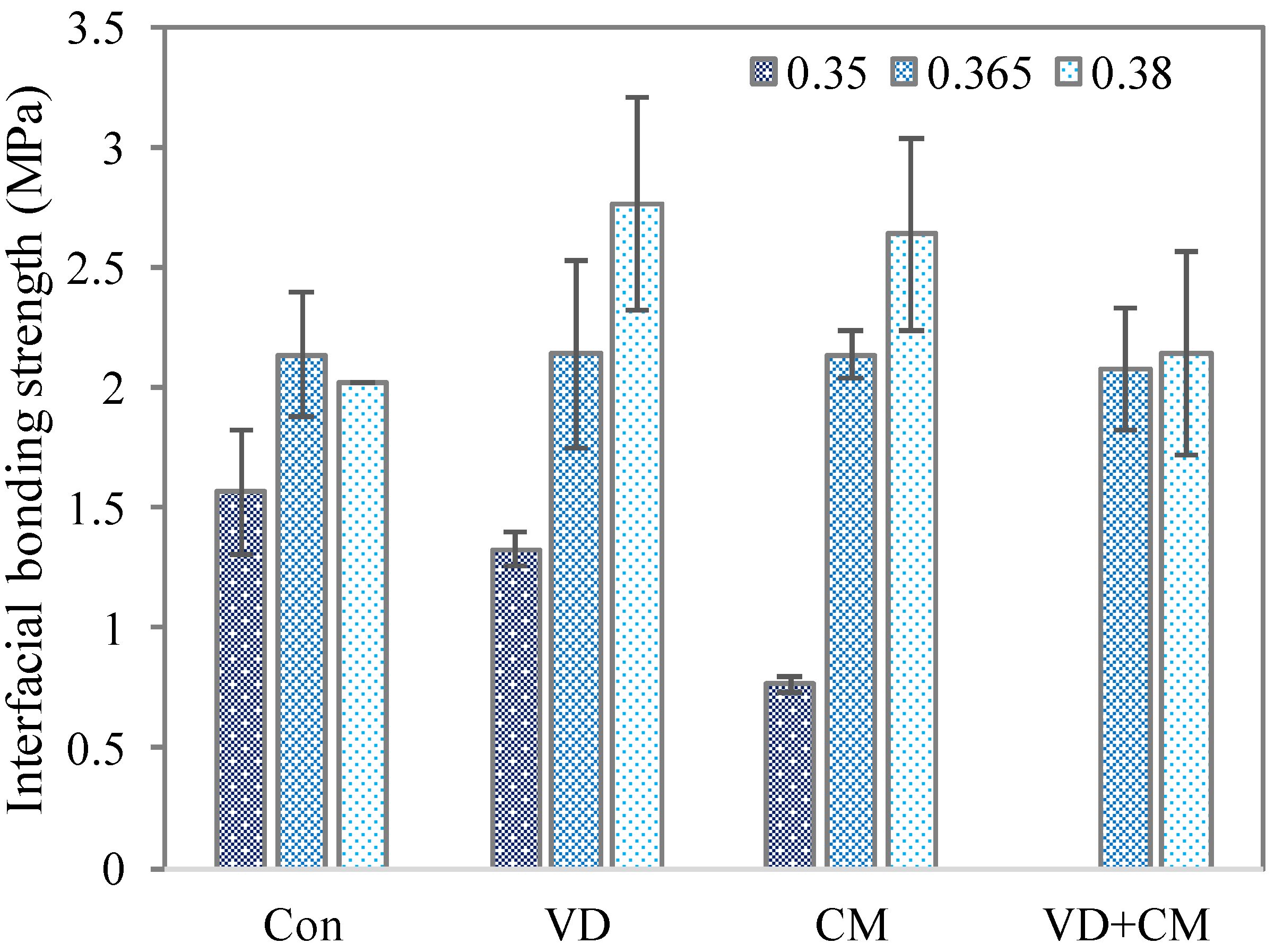

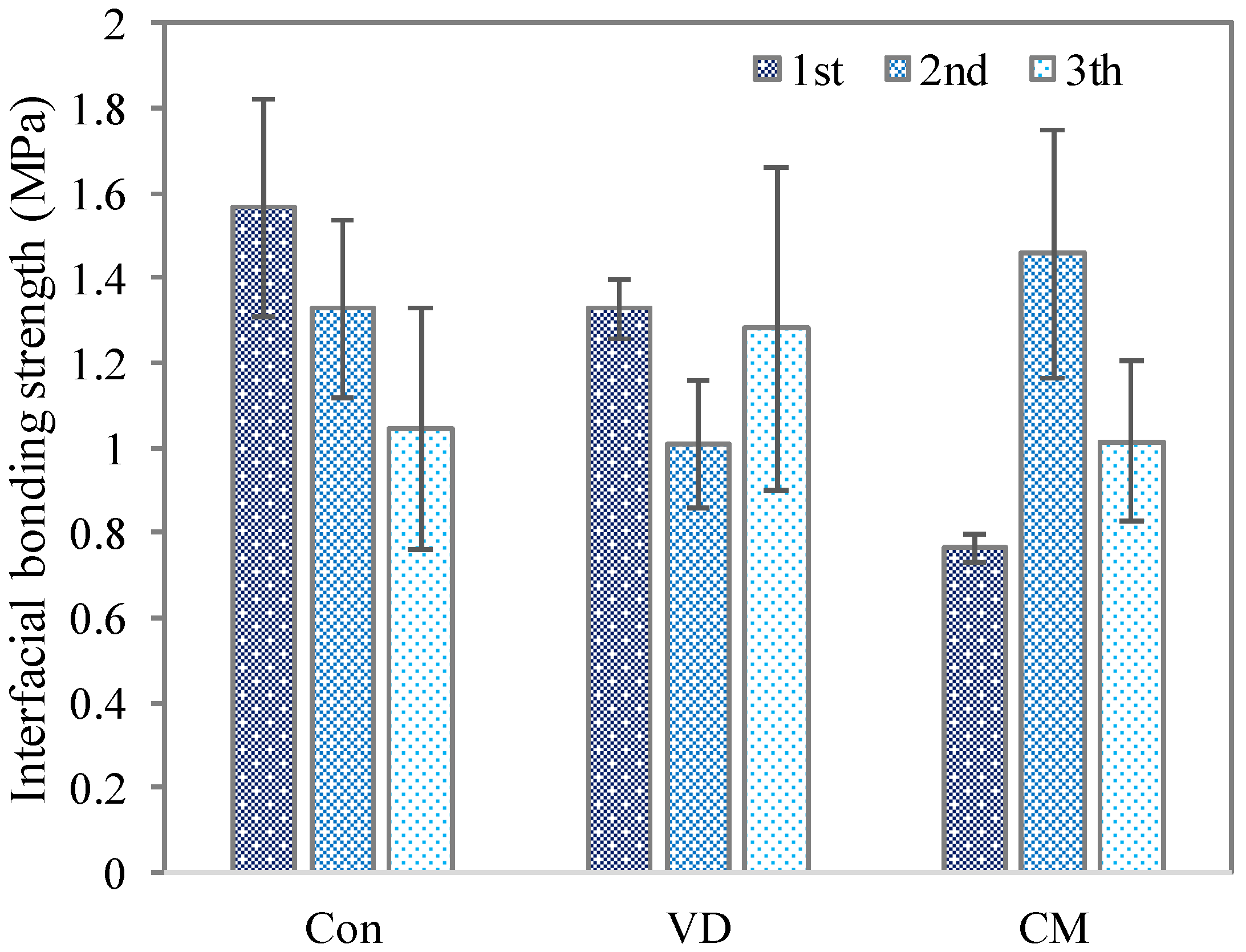

3.2.2. Interfacial Bonding Strength

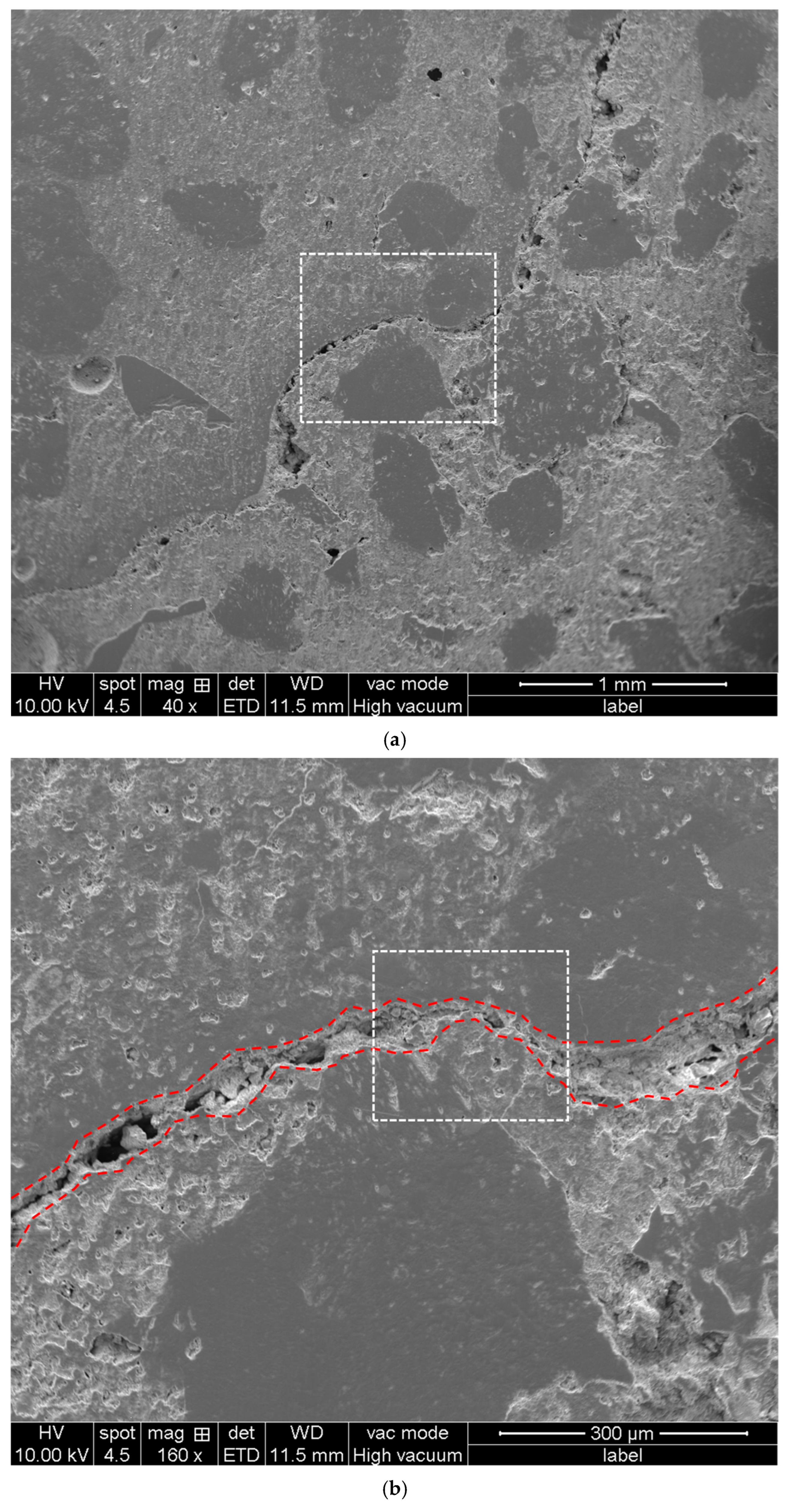

3.3. Microstructure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3DPCM | 3D-printed construction mortar |

| VD | Vacuum dewater |

| CM | Carbonation mixing |

| RFA | Recycled fine aggregate |

| SF | Silica fume |

| SP | Superplasticizer |

| NC | Nano-clay |

| HPMC | Hydroxypropyl methyl cellulose |

| SG | Sodium gluconate |

| DF | Defoamer |

| ITZ | Interfacial transition zone |

References

- Beltrami, M.; Orzes, G.; Sarkis, J.; Sartor, M. Industry 4.0 and sustainability: Towards conceptualization and theory. J. Clean. Prod. 2021, 312, 127733. [Google Scholar] [CrossRef]

- Ahmed, G.H. A review of “3D concrete printing”: Materials and process characterization, economic considerations and environmental sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Chen, K.; Liu, Q.; Chen, B.; Zhang, S.; Ferrara, L.; Li, W. Effect of raw materials on the performance of 3D printing geopolymer: A review. J. Build. Eng. 2024, 84, 108501. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía de Gutiérrez, R.; Villaquirán-Caicedo, M.A.; Delvasto Arjona, S. 3D printing with cementitious materials: Challenges and opportunities for the construction sector. Autom. Constr. 2023, 146, 104693. [Google Scholar] [CrossRef]

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D concrete printing for sustainable and economical construction: A comparative study. Autom. Constr. 2022, 134, 104087. [Google Scholar] [CrossRef]

- Ma, G.; Salman, N.M.; Wang, L.; Wang, F. A novel additive mortar leveraging internal curing for enhancing interlayer bonding of cementitious composite for 3D printing. Constr. Build. Mater. 2020, 244, 118305. [Google Scholar] [CrossRef]

- Kristombu Baduge, S.; Navaratnam, S.; Abu-Zidan, Y.; McCormack, T.; Nguyen, K.; Mendis, P.; Zhang, G.; Aye, L. Improving Performance of Additive Manufactured (3D Printed) Concrete: A Review on Material Mix Design, Processing, Interlayer Bonding, and Reinforcing Methods. Structures 2021, 29, 1597–1609. [Google Scholar] [CrossRef]

- Huang, G.; Pudasainee, D.; Gupta, R.; Liu, W.V. Extending blending proportions of ordinary Portland cement and calcium sulfoaluminate cement blends: Its effects on setting, workability, and strength development. Front. Struct. Civ. Eng. 2021, 15, 1249–1260. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, V.; Joshi, Y.M.; Singh, M.K. Nano-silica based aqueous colloidal gels as eco-friendly thixotropic lubricant. J. Colloid Interface Sci. 2025, 700, 138486. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Y.; Pan, T.; Yin, K. The Synergistic Effect of Ester-Ether Copolymerization Thixo-Tropic Superplasticizer and Nano-Clay on the Buildability of 3D Printable Cementitious Materials. Materials 2021, 14, 4622. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, M.; Wang, Y.; Zhang, M. Roles of carbonated recycled fines and aggregates in hydration, microstructure and mechanical properties of concrete: A critical review. Cem. Concr. Compos. 2023, 138, 104994. [Google Scholar] [CrossRef]

- Liang, C.; Pan, B.; Ma, Z.; He, Z.; Duan, Z. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Monkman, S.; Sargam, Y.; Naboka, O.; Lothenbach, B. Early age impacts of CO2 activation on the tricalcium silicate and cement systems. J. CO2 Util. 2022, 65, 102254. [Google Scholar] [CrossRef]

- Monkman, S.; Hwang, S.D.; Khayat, K. Rheology modification of flowable mortar with CO2. Cem. Concr. Compos. 2024, 151, 105584. [Google Scholar] [CrossRef]

- Monkman, S.; Lee, B.E.J.; Grandfield, K.; MacDonald, M.; Raki, L. The impacts of in-situ carbonate seeding on the early hydration of tricalcium silicate. Cem. Concr. Res. 2020, 136, 106179. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Dongxu, L.; Xuequan, W. A study on the application of vacuum microwave composite dewatering technnique in concrete engineering. Cem. Concr. Res. 1994, 24, 159–164. [Google Scholar] [CrossRef]

- Sancak, E. Effect of Vacuum Dewatering Application on the Chemical Corrosion and Mechanical Properties of Concrete. Asian J. Appl. Sci. 2008, 1, 79–86. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Shahzad, Q.; Wang, X.; Wang, W.; Wan, Y.; Li, G.; Ren, C.; Mao, Y. Coordinated adjustment and optimization of setting time, flowability, and mechanical strength for construction 3D printing material derived from solid waste. Constr. Build. Mater. 2020, 259, 119854. [Google Scholar] [CrossRef]

- Korpa, A.; Trettin, R. The influence of different drying methods on cement paste microstructures as reflected by gas adsorption: Comparison between freeze-drying (F-drying), D-drying, P-drying and oven-drying methods. Cem. Concr. Res. 2006, 36, 634–649. [Google Scholar] [CrossRef]

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020.

- Liu, Q.; Cheng, S.; Sun, C.; Chen, K.; Singh, A.; Bai, T.; Bai, Y. Effects of varied building solid wastes, particle sizes and substitution ratios on the performance and impedance spectrum of recycled fine aggregate mortar and the feasibility of developing a prediction method. J. Build. Eng. 2024, 83, 108310. [Google Scholar] [CrossRef]

- Liu, Q.; Cheng, A.; Singh, A.; Tam, V.W.Y. Performance enhancement of recycled concrete through carbonation during ready-mix and curing. Constr. Build. Mater. 2025, 458, 139665. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Zhang, D.; Tan, M.J.; Qian, S. Investigation of interlayer adhesion of 3D printable cementitious material from the aspect of printing process. Cem. Concr. Res. 2021, 143, 106386. [Google Scholar] [CrossRef]

- Yu, K.; McGee, W.; Ng, T.Y.; Zhu, H.; Li, V.C. 3D-printable engineered cementitious composites (3DP-ECC): Fresh and hardened properties. Cem. Concr. Res. 2021, 143, 106388. [Google Scholar] [CrossRef]

- Aslani, F.; Dale, R.; Hamidi, F.; Valizadeh, A. Mechanical and shrinkage performance of 3D-printed rubberised engineered cementitious composites. Constr. Build. Mater. 2022, 339, 127665. [Google Scholar] [CrossRef]

- Moelich, G.M.; Kruger, J.; Combrinck, R. Modeling the interlayer bond strength of 3D printed concrete with surface moisture. Cem. Concr. Res. 2021, 150, 106559. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

| Cao | SiO2 | Fe2O3 | Al2O3 | Na2O | MgO | K2O | SO3 |

|---|---|---|---|---|---|---|---|

| 63.80 | 20.78 | 3.99 | 3.57 | 0.26 | 1.72 | 0.75 | 3.82 |

| 1.18–0.6 mm | 0.6–0.3 mm | 0.3–0.15 mm | 0.15–0.075 mm | <0.075 mm |

|---|---|---|---|---|

| 34.42 | 32.48 | 22.20 | 9.50 | 0.98 |

| Cement | Water | RFA | SF | SP | NC | HPMC | SG | DF |

|---|---|---|---|---|---|---|---|---|

| 1000 | 350 | 1000 | 50 | 0.5 | 5 | 1.3 | 0.7 | 0.5 |

| 1000 | 365 | 1000 | 50 | 0.5 | 5 | 1.3 | 0.7 | 0.5 |

| 1000 | 380 | 1000 | 50 | 0.5 | 5 | 1.3 | 0.7 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Q.; Zhou, G.; Bao, H.; Liu, Q. Study on the Effects of Nozzle Proximal Carbonation Mixing and Vacuum Dewatering on the Printability and Mechanical Properties of the 3D Printed Construction Mortar. Buildings 2025, 15, 4036. https://doi.org/10.3390/buildings15224036

Song Q, Zhou G, Bao H, Liu Q. Study on the Effects of Nozzle Proximal Carbonation Mixing and Vacuum Dewatering on the Printability and Mechanical Properties of the 3D Printed Construction Mortar. Buildings. 2025; 15(22):4036. https://doi.org/10.3390/buildings15224036

Chicago/Turabian StyleSong, Qiang, Guangyu Zhou, Hailing Bao, and Qiong Liu. 2025. "Study on the Effects of Nozzle Proximal Carbonation Mixing and Vacuum Dewatering on the Printability and Mechanical Properties of the 3D Printed Construction Mortar" Buildings 15, no. 22: 4036. https://doi.org/10.3390/buildings15224036

APA StyleSong, Q., Zhou, G., Bao, H., & Liu, Q. (2025). Study on the Effects of Nozzle Proximal Carbonation Mixing and Vacuum Dewatering on the Printability and Mechanical Properties of the 3D Printed Construction Mortar. Buildings, 15(22), 4036. https://doi.org/10.3390/buildings15224036