Affordable Housing in Developing Regions: A Systematic Review of Materials, Methods and Critical Success Factors with Case Insights

Abstract

1. Introduction

1.1. Background

1.2. Related Review

1.3. Objectives and Research Questions

- Q1: What locally available and innovative materials are used for affordable housing?

- Q2: What innovative construction approaches have been applied in successful affordable housing projects?

- Q3: Are there successful examples of affordable housing projects in developing countries that could inform best practices for materials, construction methods and policy?

- Q4: What are the CSFs for constructing affordable housing in developing countries?

2. Methodology

2.1. Review Design and Protocol

2.2. Classification Framework for Analysis

2.3. Finding Relevant Studies

2.4. Study Selection

3. Research Trends and Distributions

3.1. Research Trend by Year and Regions

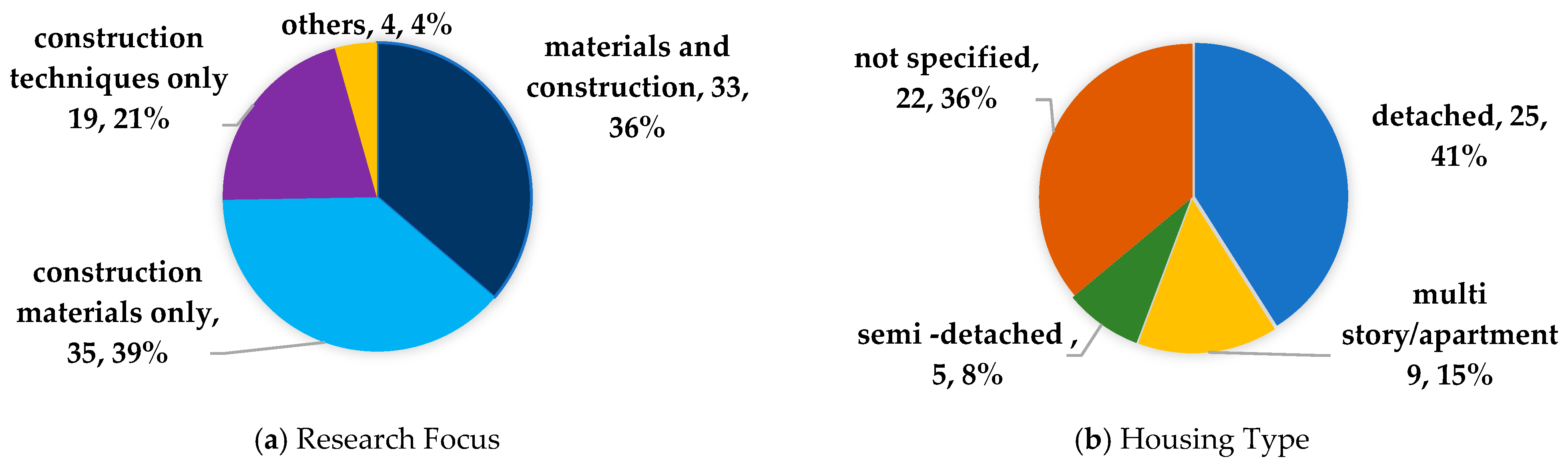

3.2. Research Trend by Focus Area and Building Type

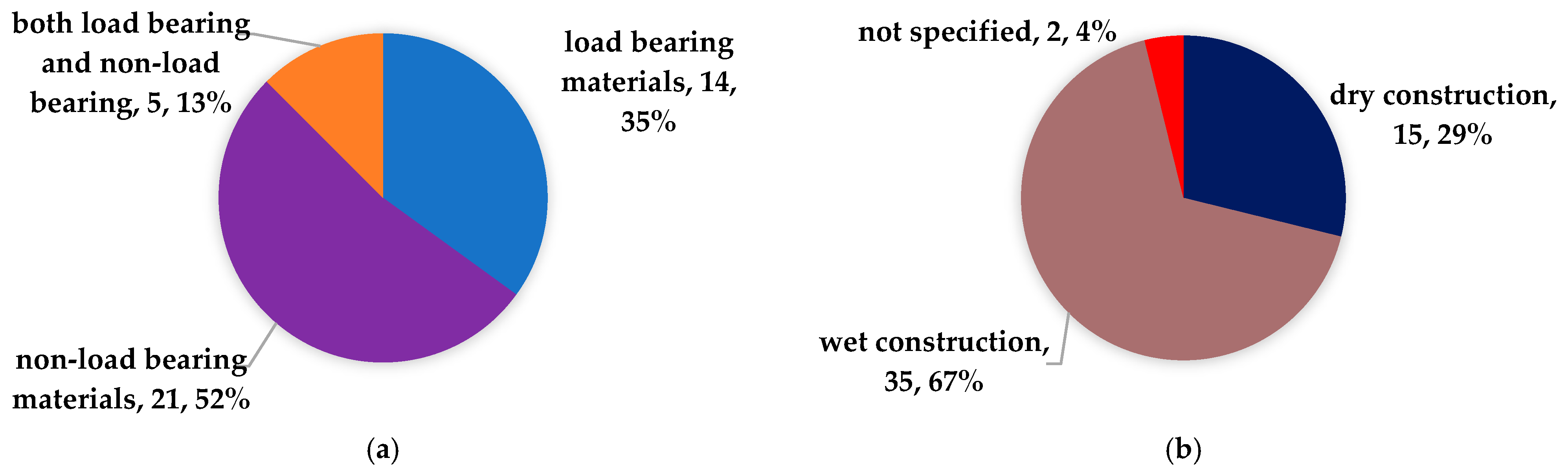

3.3. Distribution of Studies by Materials and Construction Method

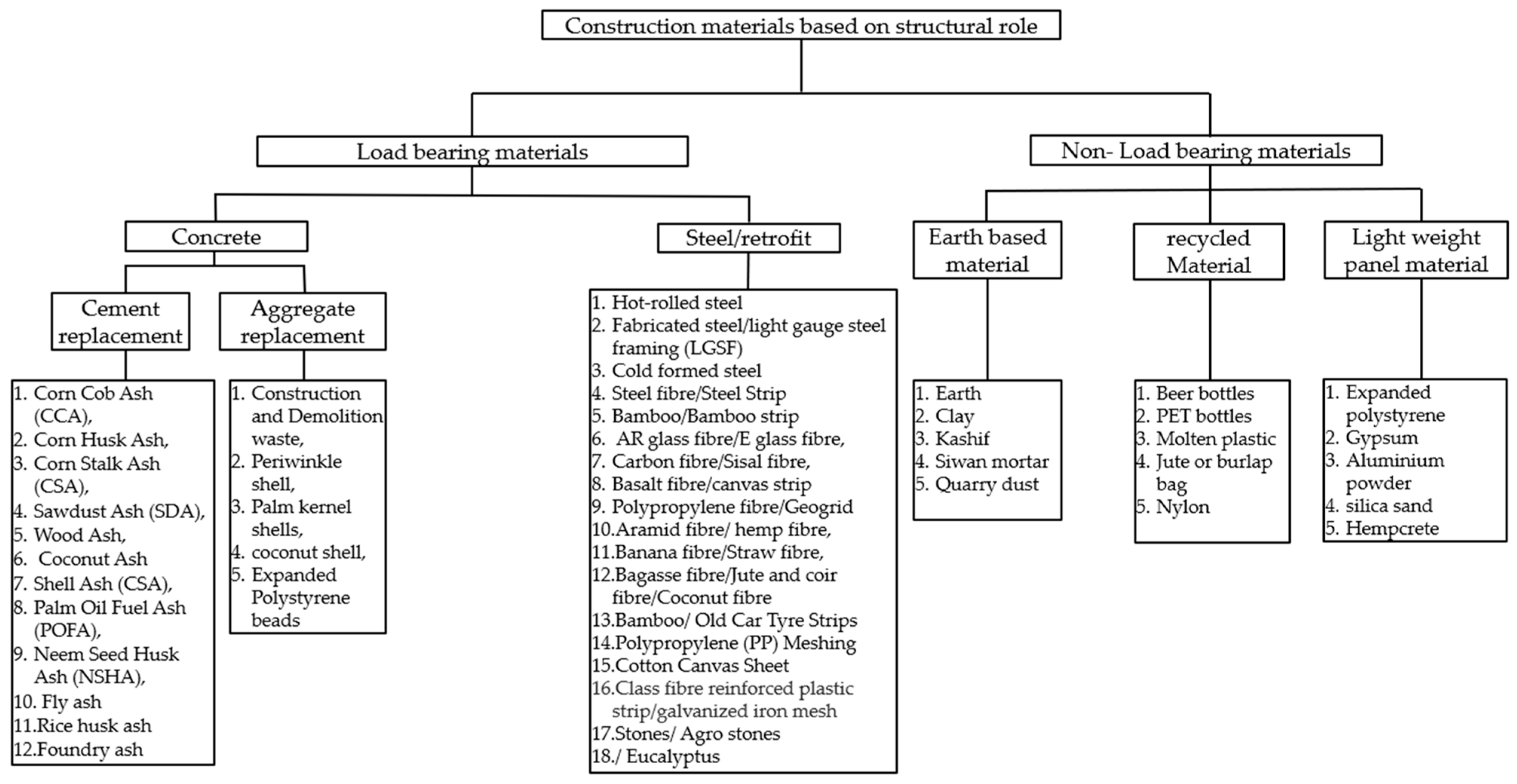

4. Construction Materials for Affordable Housing

4.1. Load Bearing Materials

4.1.1. Concrete and Its Supplementary Materials (SCMs)

4.1.2. Steel and Its Supplementary Materials (SCMs)

4.2. Non-Load-Bearing Materials

4.2.1. Earth Based Materials

4.2.2. Lightweight Panel Materials

4.2.3. Recycled Plastic Materials

5. Construction Approaches for Affordable Housing

5.1. Wet Construction

5.1.1. Masonry Construction

5.1.2. Cast-Situ Construction

5.2. Dry Construction

6. Successful Implementation

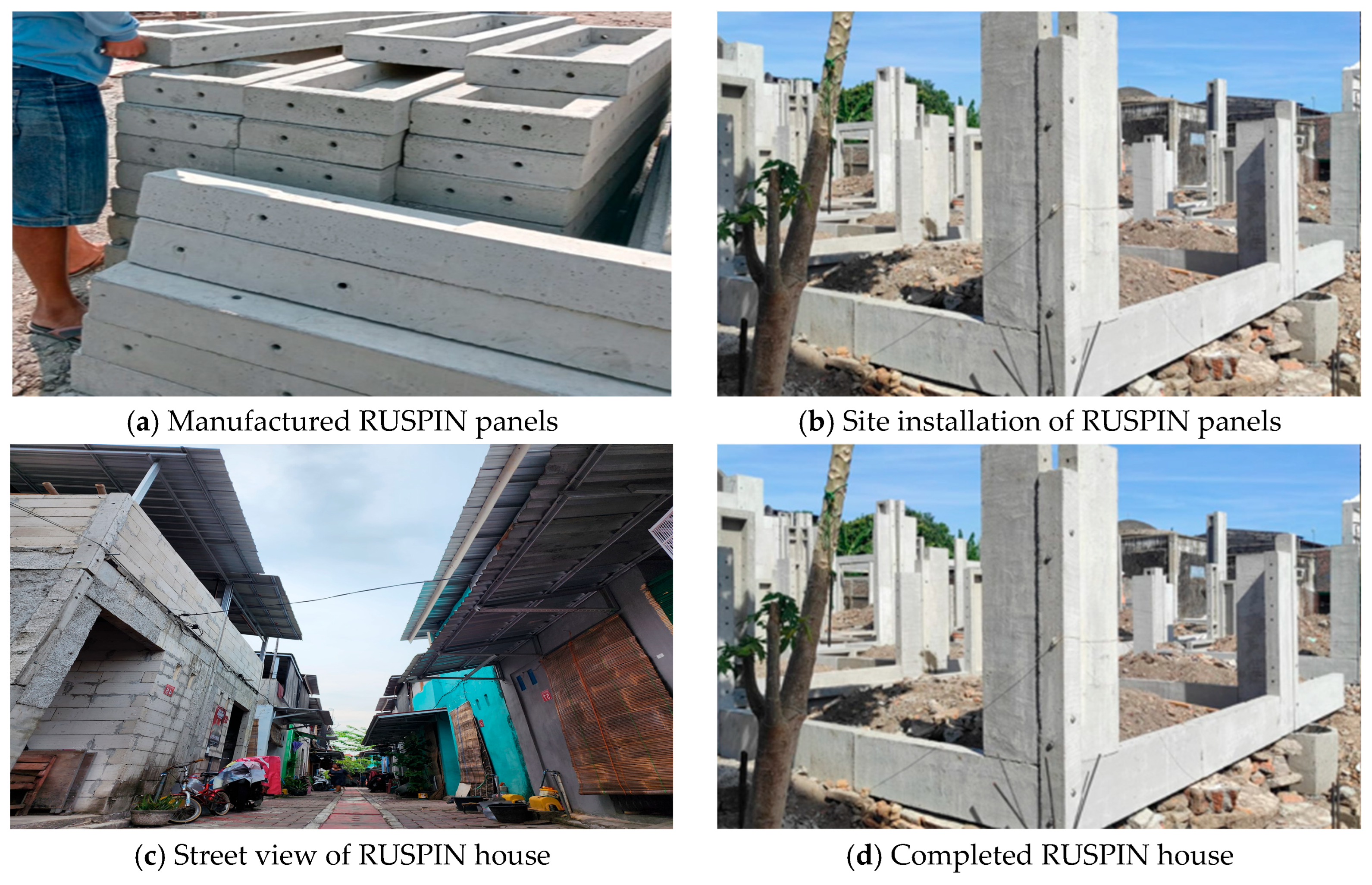

6.1. RUSPIN Construction Method

6.2. Reusable Polymer Formwork (RPF) Construction System

6.3. Critical Success Factors of RUSPIN and RPF Construction System

6.3.1. Local Adaptability of the Construction Methods

6.3.2. Supply Chain Independence

6.3.3. Cost Efficiency of the Construction Method

6.3.4. Integration with Human Resource Development

6.4. Evolution and Regulatory Compliance of RUSPIN and RPF Construction Systems

6.5. Implications and Future Potential of RUSPIN and RPF Construction System

6.6. Scalability and Technological Transfer of RUSPIN and RPF Method

7. Conclusions

7.1. Key Findings

7.2. Contributions to Literature

7.3. Future Research Directions

- Material and technology Innovation

- Policy Implications

- Recycled Materials for Insulation Applications

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Structural Purpose | Joining Process | Construction Technique/Method | Primary Materials | Joining Material | Ref. |

|---|---|---|---|---|---|

| Load bearing | dry | Precast concrete panel-(offsite) | reinforcement, concrete | Mechanical fasteners, | [77,90] |

| Load bearing | dry | Assam-type houses | Timber, Bamboo, reed, plaster, Corrugated iron sheets, thatch, Clay, mud, cow dung, lime | Mechanical fasteners, rope | [55] |

| Load bearing frame | dry | Lightweight steel framing | Lightweight steel, cold-formed steel fame- | Screw, bolt and nut, rivet, welding Adhesives | [52,53] |

| Load bearing | Wet | Tunnel system | reinforcement, concrete | Cast-in-place concrete, Shotcrete | [77] |

| Load bearing | Wet | RPF system | Plastic formwork | Sand, cement, Admixture | [86,104,105] |

| Load bearing | Wet | Flat slab | reinforcement, concrete | Cast-in-place concrete, Shotcrete | [77,89] |

| Load bearing | Wet | Wobo shelter construction (On-site) | Beer bottles, cement mortar | Cement, fine aggregates, coarse aggregates | [72] |

| Load bearing | wet | Bamboo reinforced prefabricated wall panels (Off-site) | Bamboo strip, lime, epoxy, sand, bitumen, cement mortar | Reinforcing bars, steel wires, high strength grout | [97] |

| Load bearing | wet | Masonry construction(on site) | Brick, concrete, wood, bamboo, cement | Cement mortar, mechanical Fateners. Adhesives and Glues | [28] |

| Load bearing | wet | 3D Construction Technology | Concrete, earth-based mixes, cob, hempcrete | Cement Mortar | [55,63] |

| Non-Load bearing | dry | Bamboo micro housing, woven bamboo house (On-site) | Bamboo | rope, nut, and bolt, | [58,60,98] |

| Non-load bearing | dry | Coconut fiber reinforced concrete (On-site) | fibers, concrete. | Interlocking, coconut rope | [100] |

| Non-load bearing | dry | Wire Mesh Panels with Integrated C&D Wastes (Off-site) | Wire mesh, fry ash, coarse aggregate, C&D waste, sand/quarry dust | Mechanical fastener | [48] |

| Non-load bearing | dry | Building boards/panels, (Off-site) | Straw fiber, Bagasse fiber, Jute and coir fiber Coconut fiber | cement, lime, gypsum, Epoxy, Adhesive | [54] |

| Non-load bearing | wet | Hempcrete panel/block | Hemp fiber, lime, alluminium powder, cement, fly ash, Cand D waste | Cement mortar | [39,111] |

| Non-load bearing | Wet | Autoclave aerated concrete block (On-site)/Panel (Off-site) | Cement, lime, aluminum powder, water, steel mesh | Cement mortar | [39,92,111] |

| Non-load bearing | wet | Reinforced soil block (On-site) | Soil, AR glass, polypropylene, banana and jute fiber. | Cement mortar | [112] |

| Non-load bearing | wet | hollow concrete block (HCB) /brick (On-site) | Cement, fine aggregate, coarse aggregate, water, addition or additives, Stones masonry | Cement mortar, (mud + straw + water) | [33,113] |

| Non-load bearing | wet | Palm Kernel Shell Solid Concrete Masonry Block(On-site) | Palm Kernel Shell, coarse aggregate, metakaoloin | Cement mortar | [114] |

| Non-load bearing | wet | Fly Ash bricks (On-site). | dolomitic waste (DW), silica fume (SF), and river sand (RS),/Earth | Cement mortar | [35,38,115] |

| Non-load bearing | Wet | PET bottle brick/bottle brick mansonry (On-site) | PET bottle, crushed recycled aggregate (RA)/Soil, PET bottles, Nylon, Water, Cement | Soil, Water, Cement mortar, rope, clay | [73,74,75,116] |

| Non-load bearing | Wet | Eucalyptus construction (On-site) | Stones, Eucalyptus frame, cow dung screed, plastic sheet carpet, | ‘Chiqa’ (mud + straw+ water) | [113] |

| Non-load bearing | dry/wet | Expanded polystyrene panel (Off-site) | Polystyrene foam, outer facing, wire mesh, Adhesive/coconut shell, Foundry sand and Fly ash | Cement Mortar or Adhesive Bonding, Mechanical Fastening with Screws and Anchors | [117,118] |

| Load-bearing/non-load bearing | dry | Sandbag construction (On-site) | Bag (Burlap jute) and sand | Barbed wire, mortar | [65] |

| Load-bearing/non-load bearing | dry | ISSB (On-site) | Earth | Interlocking system | [64] |

| Load-bearing/non-load bearing | dry | Gypsum Prefabricated wall panel systems | Glass Fiber Reinforced Gypsum (GFRG) wall, dry wall | Reinforced concrete infill, rebars, grout, and mortar/screw, nails, adhesives | [42,119] |

| Load-bearing/non-load bearing | Wet | CEB, CSEB (On-site) | Earth | Siwan mortar, Cement-based or lime-based mortar | [16,38,66] |

References

- UN Habitant. World Cities Report: Envisaging the Future of Cities. United Nations Human Settlements Programme. 2022. Available online: http://unhabitat.org/sites/default/files/2022/06/wcr_2022.pdf (accessed on 3 September 2025).

- United Nations. New Urban Agenda-A/RES/71/256. 2017. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_71_256.pdf (accessed on 11 September 2025).

- Nzau, B.; Trillo, C. Affordable housing provision in informal settlements through land value capture and inclusionary housing. Sustainability 2020, 12, 5975. [Google Scholar] [CrossRef]

- Uddin, N. Assessing urban sustainability of slum settlements in bangladesh: Evidence from chittagong city. J. Urban Manag. 2018, 7, 32–42. [Google Scholar] [CrossRef]

- Satoto, E.B. Boosting homeownership affordability for low-income communities in indonesia. Int. J. Sustain. Dev. Plan. 2023, 18, 1365–1376. [Google Scholar] [CrossRef]

- World Health Organization. WHO Housing and Health Guidelines; World Health Organization: Geneva, Switzerland, 2018; ISBN 978-92-4-155037-6.

- Kyprianou, I.; Artopoulos, G.; Bonomolo, A.; Brownlee, T.; Cachado, R.Á.; Camaioni, C.; Đokić, V.; D’Onofrio, R.; Đukanović, Z.; Fasola, S.; et al. Mitigation and adaptation strategies to offset the impacts of climate change on urban health: A european perspective. Build. Environ. 2023, 238, 110226. [Google Scholar] [CrossRef]

- Sustainable and Affordable Housing Report. Available online: https://worldgbc.org/article/sustainable-and-affordable-housing/ (accessed on 19 October 2024).

- UN-Habitat. SDG 11 Synthesis Report: United Nations Human Settlements Programme Executive Summary. High-Level Political Forum. 2023. Available online: https://unhabitat.org/sites/default/files/2023/11/sdg_11_synthesis_report_2023_executive_summary_2023.pdf (accessed on 3 November 2025).

- World Bank. Global Facility for Disaster Reduction and Recovery. In Building Regulation for Resilience: Managing Risks for Safer Cities; World Bank: Washington, DC, USA, 2016. Available online: https://www.gfdrr.org/sites/default/files/publication/Building_Regulation_for_Resilience_Managing_Risks_for_Safer_Cities.pdf (accessed on 12 October 2025).

- Ahsan, M. Making unaffordable to affordable: Looking into affordable housing issues and its remedies. Archit. Urban Plan. 2019, 15, 22–29. [Google Scholar] [CrossRef]

- Festus, I.A.; Amos, I.O. Housing policy in Nigeria: An overview. Am. Int. J. Contemp. Res. 2015, 5, 53–59. [Google Scholar]

- Wakely, P. Reflections on urban public housing paradigms, policies, programmes and projects in developing countries. Int. J. Urban Sustain. Dev. 2016, 8, 10–24. [Google Scholar] [CrossRef]

- Omer, K. Transforming slums through urban intensification. World J. Sci. Technol. Sustain. Dev. (WJSTSD) 2022, 19, 55–66. [Google Scholar] [CrossRef]

- Montfort, S.; Fesenfeld, L.; Stadelmann-Steffen, I.; Ingold, K. Policy sequencing can increase public support for ambitious climate policy. Policy Soc. 2023, 42, 454–477. [Google Scholar] [CrossRef]

- Ugochukwu, I.B.; Chioma, M.I.B. Local building materials: Affordable strategy for housing the urban poor in Nigeria. Procedia Eng. 2015, 118, 42–49. [Google Scholar] [CrossRef]

- Ramesh, C.P. Affordable self sustaining housing in developing countries of composite climate region: A case study in Afghanistan. Int. J. Innov. Res. Technol. 2018, 5, 323–339. [Google Scholar]

- Moghayedi, A.; Awuzie, B.; Omotayo, T.; Le Jeune, K.; Massyn, M.; Ekpo, C.O.; Braune, M.; Byron, P. A Critical success factor framework for implementing sustainable innovative and affordable housing: A systematic review and bibliometric analysis. Buildings 2021, 11, 317. [Google Scholar] [CrossRef]

- Bredenoord, J.; Kulshreshtha, Y. Compressed stabilized earthen blocks and their use in low-cost social housing. Sustainability 2023, 15, 5295. [Google Scholar] [CrossRef]

- Adegun, O.B.; Adedeji, Y.M.D. Review of economic and environmental benefits of earthen materials for housing in Africa. Front. Archit. Res. 2017, 6, 519–528. [Google Scholar] [CrossRef]

- Schmidt, W.; Otieno, M.; Olonade, K.; Radebe, N.; Van-Damme, H.; Tunji-Olayeni, P.; Kenai, S.; Tetteh Tawiah, A.; Manful, K.; Akinwale, A.; et al. Innovation potentials for construction materials with specific focus on the challenges in Africa. RILEM Tech. Lett. 2020, 5, 63–74. [Google Scholar] [CrossRef]

- Retno, D.P.; Harmiyati, H. The construction of affordable housing in developing countries: A scientometric review. J. Appl. Eng. Technol. Sci. (JAETS) 2023, 5, 291–304. [Google Scholar] [CrossRef]

- Haboubi, C.; Elabdouni, A.; Haboubi, K.; El Hammoudani, Y.; Bohout, S.; Dimane, F. A systematic analysis on the applications of local materials in civil engineering. BIO Web Conf. 2024, 109, 01008. [Google Scholar] [CrossRef]

- Ray, P.; Ismail, M.; Thapa, P.; Ghosh, A.; Saha, J.K. Inclusive disaster-resistant housing policy: Integrating traditional knowledge with modern construction techniques. Res. Rev. Int. J. Multidiscip. 2025, 10, 45–53. [Google Scholar] [CrossRef]

- Shaqour, A.; Hagishima, A. Systematic Review on Deep Reinforcement Learning-Based Energy Management for Different Building Types. Energies 2022, 15, 8663. [Google Scholar] [CrossRef]

- Ashiru, A.R.; Anifowose, K.J. An investigation into application of dry construction technique in providing low-cost housing for Nigerians. Civ. Eng. Archit. 2021, 9, 206–213. [Google Scholar] [CrossRef]

- Alomari, O.M.; Albtoush, A.M.F.; Al-Rawashdeh, M. Useful strategies for low-cost construction. Archit. Eng. 2023, 8, 44–50. [Google Scholar] [CrossRef]

- Adamy, A.; Meillyta, M.; Maharani, L.; Aidina, F.; Aini, Q. Disaster vulnerability assessment of low-cost houses in java island. J. Contemp. Urban Aff. 2023, 7, 20–37. [Google Scholar] [CrossRef]

- Osuizugbo, I.C.; Uhunmwangho, E.E. Factors affecting steel structure erection in developing countries: A case study of Nigerian construction industry. Niger. J. Technol. 2022, 40, 771–778. [Google Scholar] [CrossRef]

- Spišáková, M.; Mačková, D. The use potential of traditional building materials for the realization of structures by modern methods of construction. Sel. Sci. Pap.-J. Civ. Eng. 2015, 10, 127–138. [Google Scholar] [CrossRef]

- Maduabum, A.; Munonye, C. An overview of affordable low cost housing in Nigeria; a case for stabilised compressed earth block (sceb). Int. J. Innov. Sci. Res. Technol. 2020, 5, 1023–1028. [Google Scholar] [CrossRef]

- Ahammed, M.R.; Mia, M.B.; Raihan, M.A.; Hossain, M.N.; Hossen, M.; Md Hasan, S. An overview of conventional construction materials and their characteristics. N. Am. Acad. Res. 2024, 7, 1–13. [Google Scholar] [CrossRef]

- Unni, A.; Anjali, G. Cost-benefit analysis of conventional and modern building materials for sustainable development of social housing. Mater. Today Proc. 2022, 51, 1649–1657. [Google Scholar] [CrossRef]

- Soliman, A.; Hafeez, G.; Erkmen, E.; Ganesan, R.; Ouf, M.; Hammad, A.; Eicker, U.; Moselhi, O. Innovative construction material technologies for sustainable and resilient civil infrastructure. Mater. Today Proc. 2022, 60, 365–372. [Google Scholar] [CrossRef]

- Aneke, F.I.; Awuzie, B. Conversion of industrial wastes into marginal construction materials. Acta Structilia 2018, 25, 119–137. [Google Scholar] [CrossRef]

- Marut, J.J.; Alaezi, J.O.; Obeka, I.C. A review of alternative building materials for sustainable construction towards sustainable development. J. Mod. Mater. 2020, 7, 68–78. [Google Scholar] [CrossRef]

- Chowdhury, S.; Roy, S. Prospects of Low Cost Housing in India. Geomaterials 2013, 3, 60–65. [Google Scholar] [CrossRef]

- Jena, J.; Sahoo, C.; Singh, K.S. Fly-ash enriched earthen un-burnt bricks for low-cost housing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 970, 012003. [Google Scholar] [CrossRef]

- Geetha, S.; Selvakumar, M. Properties of aerated hempcrete as a potential sustainable building material. IOP Conf. Ser. Mater. Sci. Eng. 2019, 577, 012074. [Google Scholar] [CrossRef]

- Shinde, S.S.; Karankal, A.B. Affordable housing materials & techniques for urban poor’s. Int. J. Sci. Res. (IJSR) 2013, 1, 30–36. [Google Scholar]

- Cherian, P.; Menon, D.; Prasad, A.M. Use of glass fibre reinforced gypsum panels with reinforced concrete infills for construction of walls and slabs. Indian Concr. J. 2016, 90, 19–32. [Google Scholar]

- Krishna, J.G.; Roshan, R.; Vinothni, S.N.; Sivapriya, S.V. Glass fibre reinforced gypsum (gfrg) as an emerging technology. In Sustainable Practices and Innovations in Civil Engineering; Lecture Notes in Civil Engineering; Springer: Singapore, 2021; Volume 79, pp. 309–324. ISBN 978-981-15-5100-0. Available online: https://www.researchgate.net/publication/343969105 (accessed on 3 November 2025).

- Jittin, V.; Bahurudeen, A.; Ajinkya, S.D. Utilisation of rice husk ash for cleaner production of different construction products. J. Clean. Prod. 2020, 263, 121578. [Google Scholar] [CrossRef]

- Habeeb, G.A.; Mahmud, H.B. Study on properties of rice husk ash and its use as cement replacement material. Mater. Res. 2010, 13, 185–190. [Google Scholar] [CrossRef]

- Raj, P.V.; Teja, P.S.; Siddhartha, K.S.; Rama, J.K. Housing with low-cost materials and techniques for a sustainable construction in India—A review. Mater. Today Proc. 2021, 43, 1850–1855. [Google Scholar] [CrossRef]

- Raheem, A.A.; Ikotun, B.D. Incorporation of agricultural residues as partial substitution for cement in concrete and mortar—A review. J. Build. Eng. 2020, 31, 101428. [Google Scholar] [CrossRef]

- Janani, S.; Kulanthaivel, P.; Sowndarya, G.; Srivishnu, H.; Shanjayvel, P.G. Study of coconut shell as coarse aggregate in light weight concrete—A review. Mater. Today Proc. 2022, 65, 2003–2006. [Google Scholar] [CrossRef]

- Varalakshmi, V.; Mohanbabu, M.; Babu, P.M. Cost-effective and sustainable construction: Mechanical strength behavior of wire mesh panels with integrated c&d wastes. SSRG Int. J. Civ. Eng. 2024, 11, 37–40. [Google Scholar] [CrossRef]

- Ogundipe, K.E.; Ogunbayo, B.F.; Olofinnade, O.M.; Amusan, L.M.; Aigbavboa, C.O. Affordable housing issue: Experimental investigation on properties of eco-friendly lightweight concrete produced from incorporating periwinkle and palm kernel shells. Results Eng. 2021, 9, 100193. [Google Scholar] [CrossRef]

- Yang, S.; Zhu, J. Research on steel structure system of assembled building and its mechanical performance analysis. Appl. Math. Nonlinear Sci. 2024, 9, 20230864. [Google Scholar] [CrossRef]

- Surya, K.P.; Balakrishnama, N.V. An Analysis of Indian steel industry. J. Int. Acad. Res. Multidiscip. 2013, 1, 3. [Google Scholar]

- Sutarja, I.N.; Ardana, M.D.W.; Putra, I.D.G.A.D. The post-disaster house: Simple instant house using lightweight steel structure, bracing, and local wood wall. Int. J. Eng. Trans. B Appl. 2021, 34, 348–354. [Google Scholar] [CrossRef]

- Amalia, A.R.; Iranata, D. Alternative design of post-earthquake temporary housing in Indonesia. Civ. Eng. Archit. 2020, 8, 289–296. [Google Scholar] [CrossRef]

- Srivastava, M.; Kumar, V. The methods of using low cost housing techniques in India. J. Build. Eng. 2018, 15, 102–108. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Adak, D.; Marthong, C.; Forth, J. Sustainable solutions for low-cost building: Material innovations for assam-type house in north-east India. Case Stud. Constr. Mater. 2025, 22, e04461. [Google Scholar] [CrossRef]

- Immanuel, S.; Baskar, K. A State-of-the-art review on sustainable low-cost housing and application of textile reinforced concrete. Innov. Infrastruct. Solut. 2023, 8, 39. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Zamani-Ahari, G.; Naka, R.; Hanazato, T. Classification and effects of strengthening and retrofitting techniques for unreinforced masonry structures. Bull. N. Z. Soc. Earthq. Eng. 2016, 29, 242–255. [Google Scholar] [CrossRef]

- Dey, A.; Chetia, N. Experimental study of bamboo reinforced concrete beams having various frictional properties. Mater. Today Proc. 2018, 5, 436–444. [Google Scholar] [CrossRef]

- Mehra, A.S.; Ganguly, R.; Gupta, A.K.; Singh, L.; Shukla, A. Performance and durability evaluation of bamboo reinforced cement concrete beams. Int. J. Eng. Technol. 2016, 8, 1138–1161. [Google Scholar]

- Dalbiso, A.D.; Nuramo, D.A. Ethiopian Vernacular Bamboo Architecture and Its Potentials for Adaptation in Modern Urban Housing: A Case Study. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies (SCMT5), London, UK, 15–17 July 2019; pp. 364–374. Available online: https://www-scopus-com.ezproxy.lib.kyushu-u.ac.jp/record/display.uri?eid=2-s2.0-85071122037&origin=inward&txGid=a2dc0bb9ea245b8a5b3e978f0239f091 (accessed on 15 September 2025).

- Adeniyi, S.M.; Mohamed, S.F. Prospects and challenges of green materials for construction low-cost building in Nigeria. IOP Conf. Ser. Mater. Sci. Eng. 2020, 884, 012048. [Google Scholar] [CrossRef]

- Baja, E.; Teklay, R.; Elshadai, B. Local Construction Materials for Affordable Housing: The Case of Gereb Giba, Mekelle. Bachelor’s Thesis, Mekelle University, Mekele, Ethiopia, 2017. Unpublished Undergraduate Thesis. [Google Scholar]

- De Souza, E.A.; Borges, P.H.R.; Stengel, T.; Nematollahi, B.; Bos, F.P. 3D Printed sustainable low-cost materials for construction of affordable social housing in Brazil: Potential, challenges, and research needs. J. Build. Eng. 2024, 87, 108985. [Google Scholar] [CrossRef]

- Gohnert, M.; Bulovic, I.; Bradley, R. A low-cost housing solution: Earth block catenary vaults. Structures 2018, 15, 270–278. [Google Scholar] [CrossRef]

- Adetooto, J.; Windapo, A.; Pomponi, F. The use of alternative building technologies as a sustainable affordable housing solution: Perspectives from south Africa. J. Eng. Des. Technol. 2024, 22, 1447–1463. [Google Scholar] [CrossRef]

- Mohamed, A.F. Comparative study of traditional and modern building techniques in Siwa oasis, Egypt: Case study: Affordable residential building using appropriate building technique. Case Stud. Constr. Mater. 2020, 12, e00311. [Google Scholar] [CrossRef]

- Khursheed, S.; Paul, V.K.; Akbari, M.A. Cost feasibility and performance assessment of expanded polystyrene sheet over conventional method: A case study in Bhubaneswar. Asian J. Civ. Eng. 2019, 20, 659–667. [Google Scholar] [CrossRef]

- Ede, A.N.; Abimbola, O. Thermal behaviour and admissible compressive strength of expanded polystyrene wall panelsof varying thickness. Curr. Trends Technol. Sci. 2014, 3, 110–117. [Google Scholar]

- Wayal, A.; Kumthekar, M.B. Aerocon blocks and panels: Sustainable and cost effective material for speedy construction. In Proceedings of the Sustainable Infrastructure Development & Management (SIDM) 2019, Online, 22 February 2019; p. 6. [Google Scholar] [CrossRef]

- Saiyed, F.M.; Makwana, A.H.; Pitroda, J.; Vyas, C.M. Aerated autoclaved concrete (aac) blocks: Novel material for construction industry. Int. J. Adv. Res. Eng. Sci. Manag. 2014, 1, 21–32. [Google Scholar]

- Mansir, D.; Muhammad, M.G.; Faiza, H.Y.; Kabir, F.A. Factors affecting the use of expanded polystyrene (eps) for sustainable housing construction in nigeria. In Proceedings of the WABER 2019 Conference, Accra, Ghana, 5–7 August 2019; WABER: Quebec, QC, Canada, 2019. ISBN 978-9988-2-6010-1. [Google Scholar] [CrossRef]

- Sebastian, A.W. Design and building of energy efficient, eco-friendly and economical wobo shelter. Civ. Eng. Archit. 2024, 12, 1436–1446. [Google Scholar] [CrossRef]

- Pradeep, L.; Dash, S.P.; Pati, D.J.; Boby, N.M. Determining the feasibility of using pet bottles as construction material in urban context. Mater. Today Proc. 2022, 60, 384–393. [Google Scholar] [CrossRef]

- Kim, B.; Wisniewski, J.; Baker, T.; Oyinlola, M. Behaviour of sand-filled plastic bottled clay panels for sustainable homes. J. Build. Eng. 2019, 26, 100895. [Google Scholar] [CrossRef]

- Kavyashree; Bhagyashree. Harnessing waste bottles for sustainable housing solutions: From the perspective of developing an innovative and affordable approach. Environ. Ecol. Res. 2024, 12, 537–546. [Google Scholar] [CrossRef]

- Yadav, A.; Chandra, A.; Singh, S. Study on application of waste plastic in the construction industry. Mater. Today Proc. 2022, 64, 1455–1458. [Google Scholar] [CrossRef]

- Abdullah, D.S.; Al-Nuamman, R.S.A. Impact of construction systems on project timelines: A case study of multi-floor affordable residential buildings. Int. J. Sustain. Dev. Plan. 2023, 18, 3025–3036. [Google Scholar] [CrossRef]

- Anchliya, A.S.; Chaurasia, A. Latest construction techniques adopted in disaster-resilient architecture. Int. J. Sci. Res. Eng. Manag. 2024, 8, 1–5. [Google Scholar] [CrossRef]

- Mohamed, N.A.G.; Mahmoud, I.A.E. Cost-effectiveness and affordability evaluation of a residential prototype built with compressed earth bricks, hybrid roofs and palm midribs. Front. Built Environ. 2023, 9, 1058782. [Google Scholar] [CrossRef]

- Onyenokporo, N.C.; Beizaee, A.; Adekeye, O.F.; Oyinlola, M.A. The bottle house: Upcycling plastic bottles to improve the thermal performance of low-cost homes. Sustainability 2024, 16, 1360. [Google Scholar] [CrossRef]

- Mehtab, T.; Agrawal, R.; Kamal, M.A. Technological appraisal of prefabricated glass fibre reinforced gypsum (gfrg) panels in building construction system. Archit. Eng. Sci. 2023, 4, 154. [Google Scholar] [CrossRef]

- Raj, D.; Nautiyal, V. Cost effective construction techniques. J. Civ. Eng. Environ. Technol. 2017, 4, 358–361. [Google Scholar]

- Işık, E.; Avcil, F.; Büyüksaraç, A.; İzol, R.; Hakan Arslan, M.; Aksoylu, C.; Harirchian, E.; Eyisüren, O.; Arkan, E.; Güngür, M.Ş.; et al. Structural damages in masonry buildings in Adıyaman during the Kahramanmaraş (Turkiye) earthquakes (mw 7.7 and mw 7.6) on 06 February 2023. Eng. Fail. Anal. 2023, 151, 107405. [Google Scholar] [CrossRef]

- Kadam, S.B.; Singh, Y.; Li, B. Strengthening of unreinforced masonry using welded wire mesh and micro-concrete–behaviour under in-plane action. Constr. Build. Mater. 2014, 54, 247–257. [Google Scholar] [CrossRef]

- Yavartanoo, F.; Kang, T.H.-K. Retrofitting of unreinforced masonry structures and considerations for heritage-sensitive constructions. J. Build. Eng. 2022, 49, 103993. [Google Scholar] [CrossRef]

- Kabundu, E.; Mbanga, S.; Botha, B.; Crafford, G. Housing quantum and innovative building systems in south Africa—The affordability perspective for 2020. Crit. Hous. Anal. 2022, 9, 18–29. [Google Scholar] [CrossRef]

- Shalgar, A.M.; Aradhye, D.T. Introduction to advanced tunnel formwork system: Case study of ‘rohan-abhilasha’. Int. Res. J. Eng. Technol. 2017, 4, 2395-0072. [Google Scholar]

- Khan, K.M.; Jeelani, M. Analysis and design of flat slabs in commercial building by using etabs software. Int. Res. J. Eng. Technol. 2018, 5, 998–1002. [Google Scholar]

- Ibrahim, S.; Ostovar Ravari, S.; Resatoglu, R. Comparative study of analysis and cost of flat slab and conventional slab structures in somalia-mogadishu. Eurasia Proc. Sci. Technol. Eng. Math. 2022, 21, 228–236. [Google Scholar] [CrossRef]

- Holly, I.; Abrahoim, I. Connections and joints in precast concrete structures. Slovak J. Civ. Eng. 2020, 28, 49–56. [Google Scholar] [CrossRef]

- Agrawal, A.; Sanghai, S.S.; Dabhekar, K. A review on analysis and design of precast structures. Int. J. Sci. Res. Sci. Eng. Technol. 2021, 8, 345–350. [Google Scholar] [CrossRef]

- Kumar, R.; Aggarwal, V.; Gupta, S.M. Recent developments in affordable high-rise buildings—A case study. SSRG Int. J. Civ. Eng. 2024, 11, 18–23. [Google Scholar] [CrossRef]

- Farooqui, R.U.; Shabbir, M. Affordable housing in developing countries. In Proceedings of the Eighth International Conference on Construction in the 21st Century (CITC-VIII), Thessaloniki, Greece, 27–30 May 2015; pp. 517–523. Available online: https://www.academia.edu/90875278/affordable_housing_in_developing_countries (accessed on 6 September 2025).

- Mahecha, R.E.G.; Caldas, L.R.; Garaffa, R.; Lucena, A.F.P.; Szklo, A.; Filho, R.D.T. Constructive systems for social housing deployment in developing countries: A case study using dynamic life cycle carbon assessment and cost analysis in Brazil. Energy Build. 2020, 227, 110395. [Google Scholar] [CrossRef]

- Agustiningtyas, R.S.; Takaguchi, H.; Prasetya, A.B.; Kubota, T. Embodied energy and carbon assessment of existing affordable apartments in Indonesia. J. Asian Archit. Build. Eng. 2024, 23, 2057–2070. [Google Scholar] [CrossRef]

- Marlon, C.S. Development of affordable and disaster-resistant housing initiative. Int. J. Adv. Res. Sci. Commun. Technol. 2023, 3, 987–995. [Google Scholar] [CrossRef]

- Puri, V.; Chakrabortty, P.; Anand, S.; Majumdar, S. Bamboo reinforced prefabricated wall panels for low cost housing. J. Build. Eng. 2017, 9, 52–59. [Google Scholar] [CrossRef]

- Nareswarananindya; Laksono, S.H.; Ramadhani, A.N.; Budianto, A.; Komara, I.; Syafiarti, A.I.D. The design concept of bamboo in micro housing as a sustainable self-building material. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1010, 012026. [Google Scholar] [CrossRef]

- Bredenoord, J.; Kokkamhaeng, W.; Janbunjong, P.; Nualplod, O.; Thongnoy, S.; Khongwong, W.; Ngernchuklin, P.; Mahakhant, A. Interlocking block masonry (issb) for sustainable housing purposes in Thailand, with additional examples from Cambodia and Nepal. Eng. Manag. Res. 2019, 8, 42. [Google Scholar] [CrossRef]

- Ali, M. Use of Coconut fibre reinforced concrete and coconut-fibre ropes for seismic-resistant construction. Mater. Constr. 2016, 66, e073. [Google Scholar] [CrossRef]

- Mohamed, N.A.G.; Moustafa, A.; Darwish, E.A. Structural, acoustical, and thermal evaluation of an experimental house built with reinforced/hollow interlocking compressed stabilized earth brick-masonry. J. Build. Eng. 2024, 86, 108790. [Google Scholar] [CrossRef]

- Ibrahim, D.; Bankole, O.C.; Ma’aji, S.A.; Ohize, E.J.; Abdul, B.K. Assessment of the strength properties of polystyrene material used in building construction in mbora district of abuja, nigeria. Int. J. Eng. Res. Dev. 2013, 6, 80–84. [Google Scholar]

- Teknologi Pracetak untuk Rumah Sederhana Tahan Gempa. Available online: https://www.suara.com/bisnis/2021/10/23/080000/teknologi-pracetak-untuk-rumah-sederhana-tahan-gempa (accessed on 21 January 2025).

- Sodeinde, A.H. Stimulus Plan for Affordable Housing Solutions in Emerging Nations. Master’s Thesis, Johns Hopkins University, Baltimore, MD, USA, 2011. Available online: https://jscholarship.library.jhu.edu/server/api/core/bitstreams/6412f485-aaa5-4cb0-a5ee-a6c9272c783f/content (accessed on 25 August 2025).

- Prajapati, R.; Pitroda, J.; Bhavsar, J.J. Plastic formwork: New era for construction secto. In Proceedings of the National Conference on: Trends and Challenges of Civil Engineering in Today’s Transforming World, Umrakh, India, 29 March 2014; Available online: https://www.researchgate.net/publication/281493419 (accessed on 4 September 2025).

- Hennie. Low-Cost Housing. Image. Wikimedia Commons. 2012. Available online: https://commons.wikimedia.org/wiki/File:Low_cost_housing.JPG (accessed on 16 October 2025).

- Belani, D.; Pitroda, J.; Bhavsar, J.J. Impact of plastic formwork over conventional formwork. Int. J. Sci. Eng. Res. 2017, 5, 136–141. [Google Scholar] [CrossRef]

- Kavishe, N.; Chileshe, N. Critical success factors in public-private partnerships (ppps) on affordable housing schemes delivery in tanzania: A qualitative study. J. Facil. Manag. 2019, 17, 188–207. [Google Scholar] [CrossRef]

- Pramitaningrum, E.; Nugraha, D.H. Market and industrialization opportunities of rumah unggul sistem panel instan (ruspin) technology using business model canvas. Spek Ind. 2023, 21, 52–61. [Google Scholar] [CrossRef]

- Bredenoord, J. Sustainable building materials for low-cost housing and the challenges facing their technological developments: Examples and lessons regarding bamboo, earth-block technologies, building blocks of recycled materials, and improved concrete panels. J. Archit. Eng. Tech. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Parashar, A.; Sistla, V.K.; Sudarsan, J.S.; Kore, S. Hempcrete as a sustainable building material: A viable alternative to conventional concrete. In Proceedings of the 2ND International Conference on Mathematical Techniques and Applications: ICMTA20212022, Kattankulathur, India, 24–26 March 2021; p. 260003. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Devi, S.S. Reinforced soil blocks: Viable option for low cost building units. Constr. Build. Mater. 2018, 189, 1124–1133. [Google Scholar] [CrossRef]

- Feleke, F.H. Incremental Housing for Rapidly Urbanizing Small Towns of Ethiopia, the Case of Gashena Town, North Wollo. Master’s Thesis, Addis Ababa University, Addis Ababa, Ethiopia, 2019. Available online: https://www.researchgate.net/publication/338655831 (accessed on 18 August 2025).

- John, N.; Shanthi, R.M.; Tensing, D. Prospects of metakaolin admixed palm kernel shell solid concrete masonry block: A review. Civ. Eng. Archit. 2022, 10, 1354–1372. [Google Scholar] [CrossRef]

- Janani, R.; Chakravarthy, P.R.K.; Ilango, T. Budget houses for low-income people. Int. J. Mech. Eng. Technol. 2018, 9, 109–117. [Google Scholar]

- Oyinlola, M.; Whitehead, T.; Abuzeinab, A.; Adefila, A.; Akinola, Y.; Anafi, F.; Farukh, F.; Jegede, O.; Kandan, K.; Kim, B.; et al. Bottle House: A case study of transdisciplinary research for tackling global challenges. Habitat Int. 2018, 79, 18–29. [Google Scholar] [CrossRef]

- Munmulla, T.; Hidallana-Gamage, H.; Navaratnam, S.; Ponnampalam, T.; Zhang, G.; Jayasinghe, T. Suitability of modular technology for house construction in Sri Lanka: A survey and a case study. Buildings 2023, 13, 2592. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban Poverty Alleviation; CSIR—Central Building Research Institute (CSIR-CBRI). Manual for Expanded Polystyrene (EPS) Core Panel System and Its Field Application; CSIR-CBRI Report No.: S.E(G)/0605; CSIR—Central Building Research Institute (CSIR-CBRI): Roorkee, India, 2017; Available online: https://www.bmtpc.org/datafiles/cms/file/pdf_files/manual_eps.pdf (accessed on 17 July 2025).

- Patil, D.; Bukhari, S.A.; Minde, P.R.; Kulkarni, M.S. Review on comparative study of diverse wall materials for affordable housing. Mater. Today Proc. 2023, 77, 823–831. [Google Scholar] [CrossRef]

| Reference | Year | Focus Area | Geographic Scope |

|---|---|---|---|

| [19] | 2013 | Earth blocks in social housing | Africa, Asia, Latin America |

| [20] | 2017 | Earthen materials and technologies in housing projects | Africa |

| [21] | 2020 | Local innovation potentials for concrete materials derived from indigenous materials. | Africa |

| [18] | 2021 | SIAH Critical Success Factor Framework | South Africa |

| [22] | 2023 | Scientometric analysis of affordable housing construction in developing countries | Developing countries |

| [23] | 2024 | Potential of local materials for sustainable constructions | Morocco |

| [24] | 2025 | Integrating traditional knowledge with modern construction techniques | India |

| PICO Element | Description |

|---|---|

| Population | Low-income households in developing countries, particularly in urban informal settlements and rural areas |

| Intervention | Locally available and alternative construction materials and methods |

| Comparison | Standard construction practices currently used in developed regions |

| Outcome | Critical success factor for affordable housing case study implementation |

| Search Query | Search Database | Total Number of Studies |

|---|---|---|

| (TITLE-ABS-KEY ((low-cost housing) OR (affordable housing) OR (cost efficient housing)) AND ((Material) OR (alternative material) OR (locally available material)) AND ((construction) OR (alternative construction))) | Scopus | 1094 |

| TITLE-ABS KEY (((Affordable-Building) OR (Affordable-Housing) OR (Affordable-Dwelling)) AND ((Materials AND case-study) OR (Construction AND case-study) OR (Policy AND case-study) OR (thermal comfort AND case-study))) | Scopus | 462 |

| “Affordable housing” AND “material” AND “construction techniques” AND “residential building” AND “housing policy” | Google scholar | 246 |

| Feature | RUSPIN System (Rumah Unggul Sistem Panel Instant) | RPF System |

|---|---|---|

| Origin | Indonesia | South Africa |

| Main developer | Government Initiative | Private developer |

| Design Initiatives | Developed to address local constraints using lightweight, human-portable panels that do not require heavy machinery for transport or assembly | Designed to integrate with readily available local materials, reducing transportation costs and environmental impact |

| Core Technology | Two types of standardized precast concrete panels and wall infill | Reusable plastic formwork for monolithic concrete structure |

| Primary Material | Concrete, reinforcement | Cement mortar, reinforcement. |

| Joining Method | Bolt–nut connection for prefabricated panels (dry construction) | In situ cast (wet construction) |

| Labor and training Requirement | Requires skilled labor, though training needs are minimal | Requires unskilled or semi-skilled labor with limited training |

| Cost per unit house | Approx. USD 2454.94 for a 36 m2 unit | Approx. USD 6037 for a 40 m2 unit |

| Construction Time | 1–3 weeks per unit | Around 1 week per unit |

| Key Advantage | Portable panels, rapid installation, cost-effectiveness, and earthquake resilience | High construction speed, cost-effectiveness, durability, and earthquake resistance |

| Portability | Panels are human-portable and manually transportable | Lightweight formwork easily transported to remote areas |

| Scalability potential | Currently implemented in Indonesia with strong potential for adoption in other developing regions | Used for decades and adopted in multiple developing countries across Asia, Africa and Latin America |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhammed, F.Z.; Yamaguchi, K.; Handayani, K.N.; Hagishima, A. Affordable Housing in Developing Regions: A Systematic Review of Materials, Methods and Critical Success Factors with Case Insights. Buildings 2025, 15, 4015. https://doi.org/10.3390/buildings15224015

Muhammed FZ, Yamaguchi K, Handayani KN, Hagishima A. Affordable Housing in Developing Regions: A Systematic Review of Materials, Methods and Critical Success Factors with Case Insights. Buildings. 2025; 15(22):4015. https://doi.org/10.3390/buildings15224015

Chicago/Turabian StyleMuhammed, Fatimah Z., Kentaro Yamaguchi, Kusumaningdyah Nurul Handayani, and Aya Hagishima. 2025. "Affordable Housing in Developing Regions: A Systematic Review of Materials, Methods and Critical Success Factors with Case Insights" Buildings 15, no. 22: 4015. https://doi.org/10.3390/buildings15224015

APA StyleMuhammed, F. Z., Yamaguchi, K., Handayani, K. N., & Hagishima, A. (2025). Affordable Housing in Developing Regions: A Systematic Review of Materials, Methods and Critical Success Factors with Case Insights. Buildings, 15(22), 4015. https://doi.org/10.3390/buildings15224015