Bending Test and FE Analysis of Novel Grouted Plug-in Connection for Prefabricated Assembled Raft Foundation

Abstract

1. Introduction

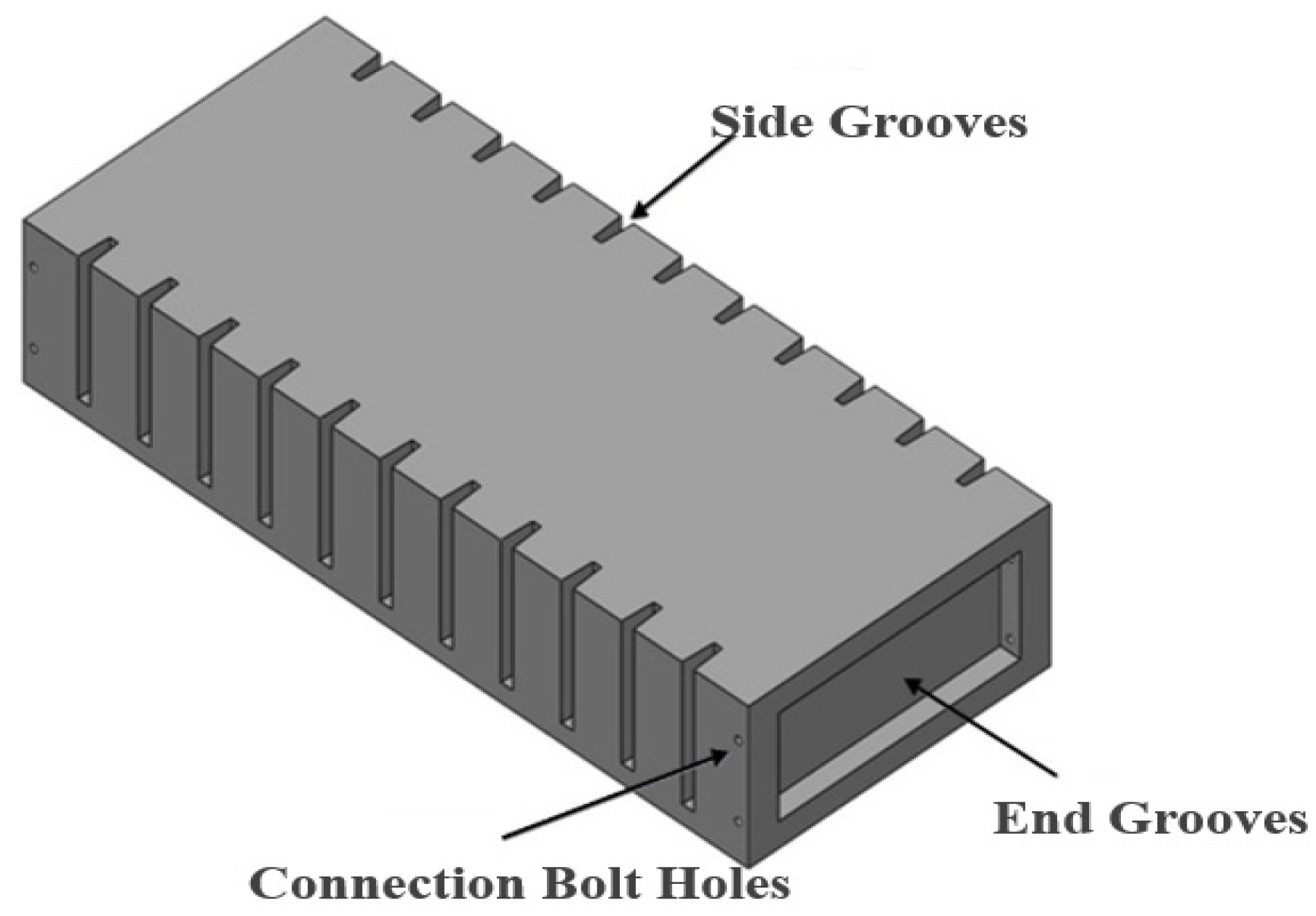

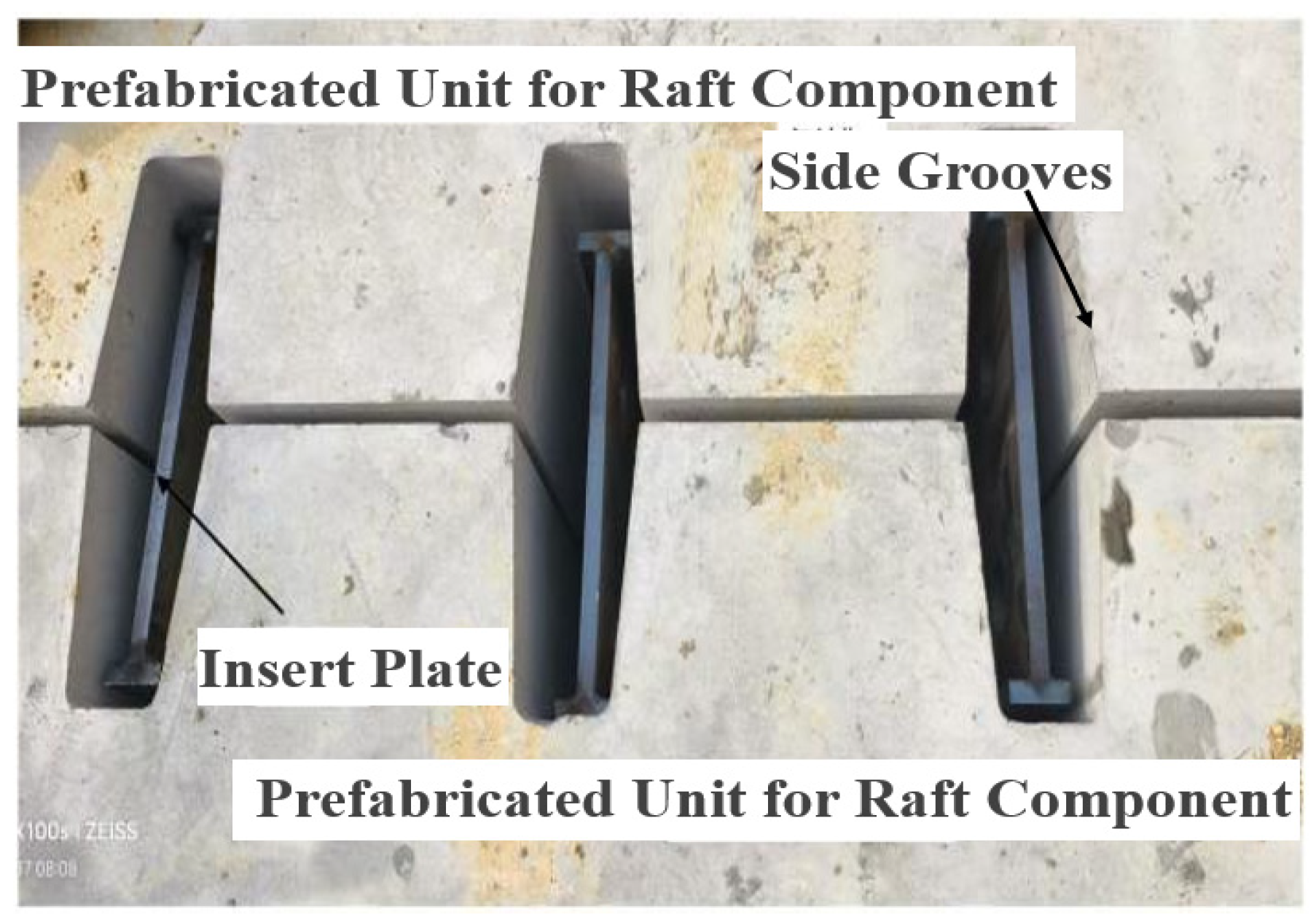

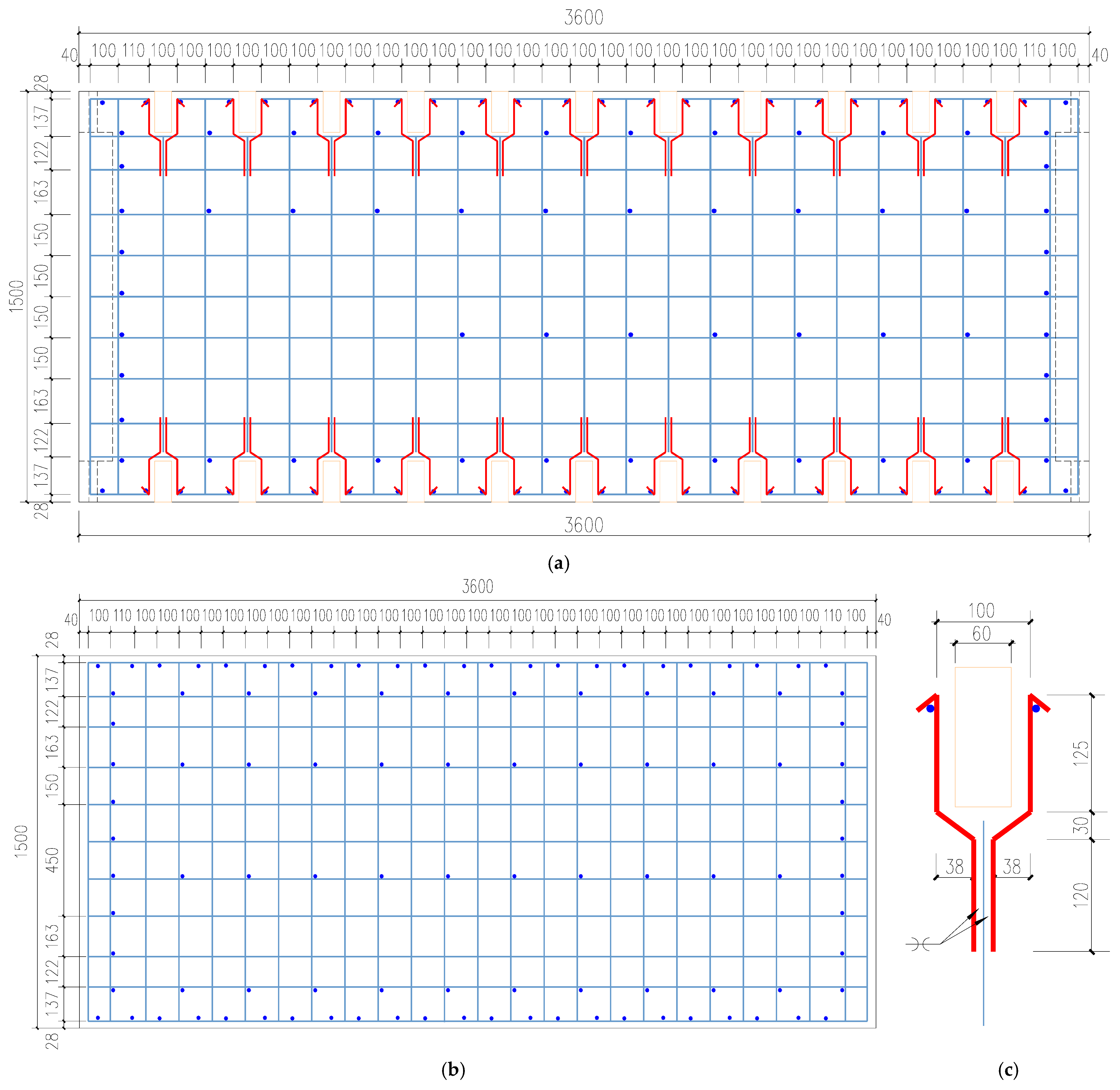

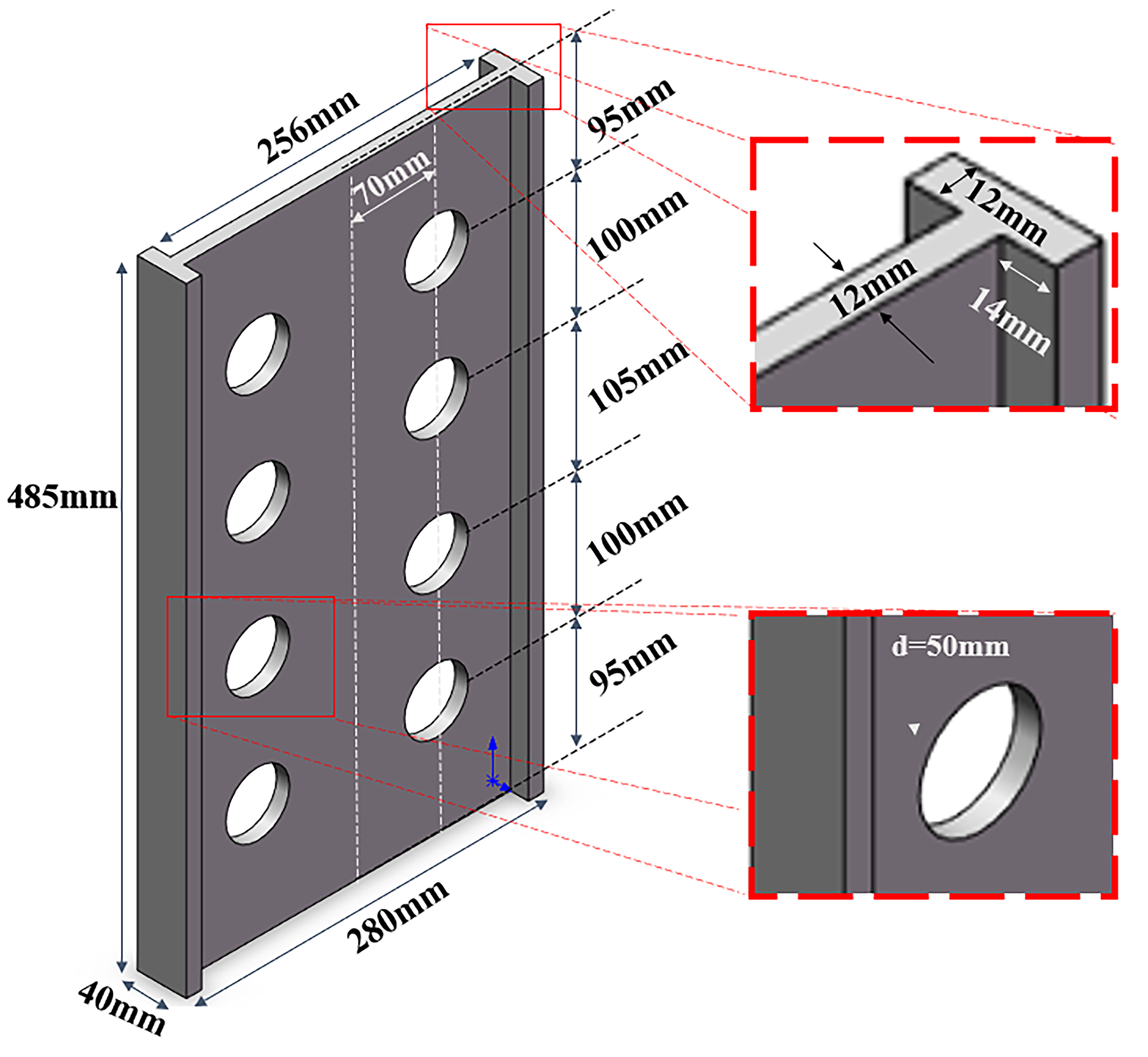

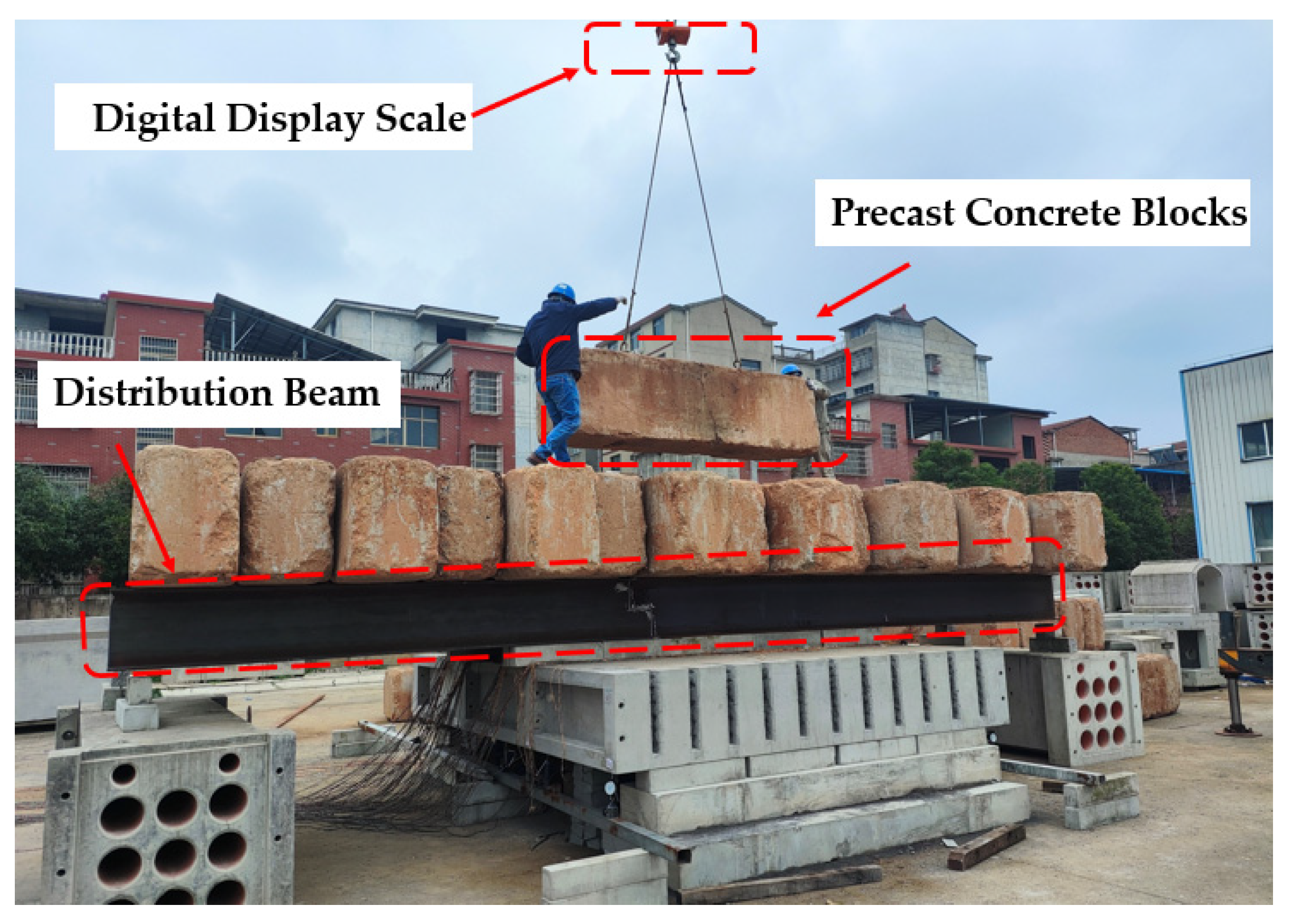

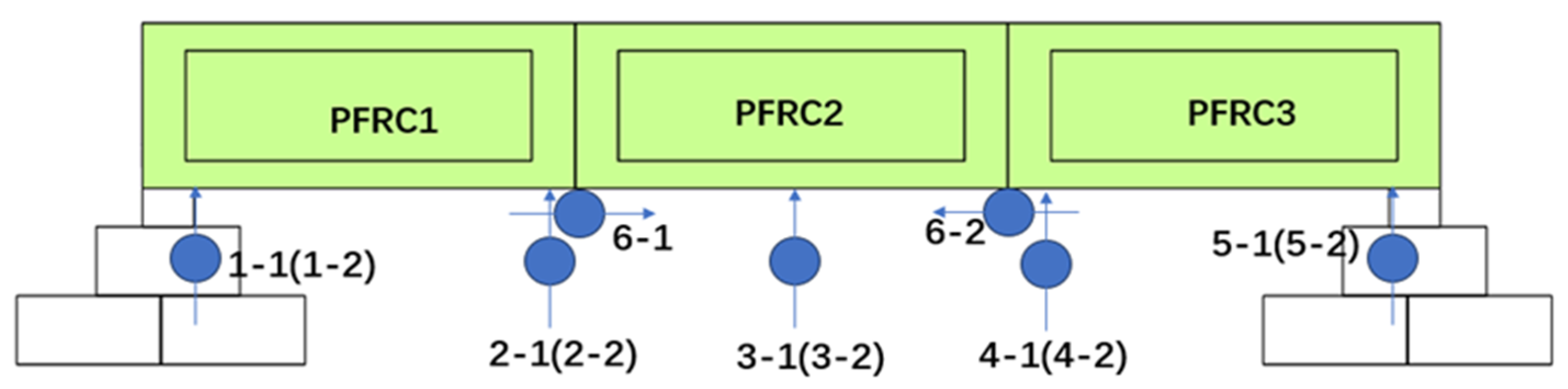

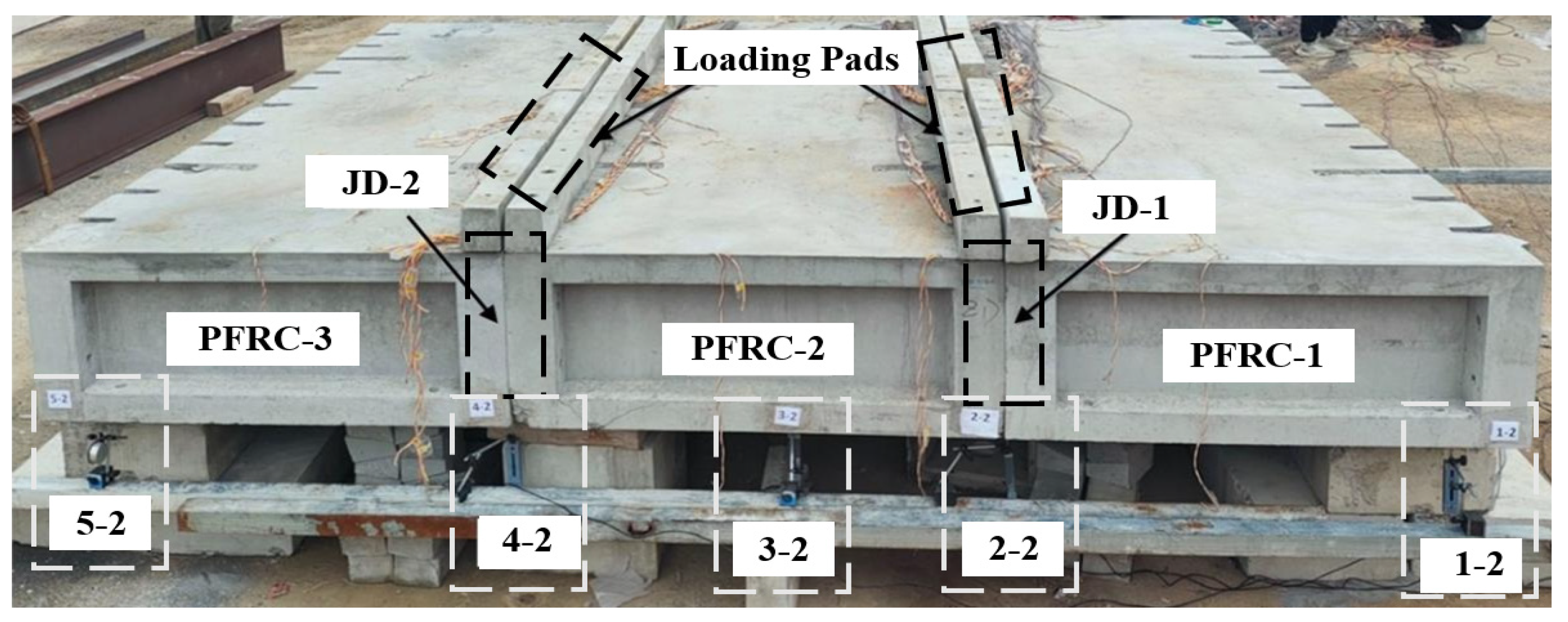

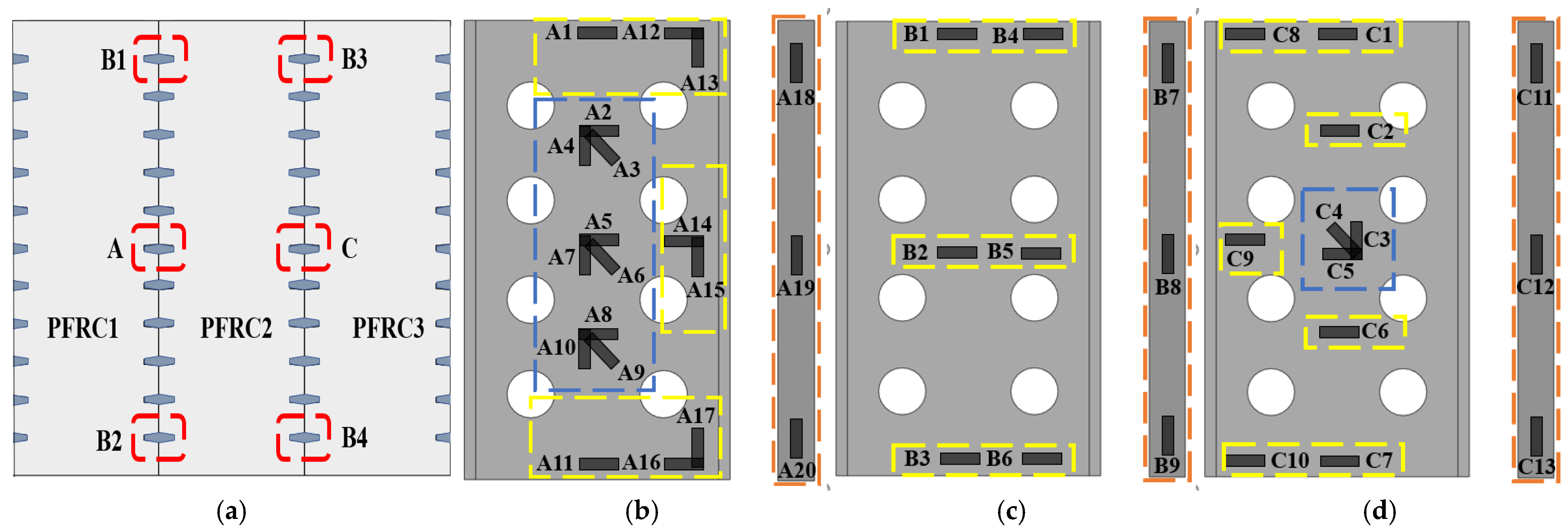

2. Testing Specimen

3. Flexural Testing Procedure

4. Experimental Observations and Material Property Test Results

4.1. Material Property Test Results

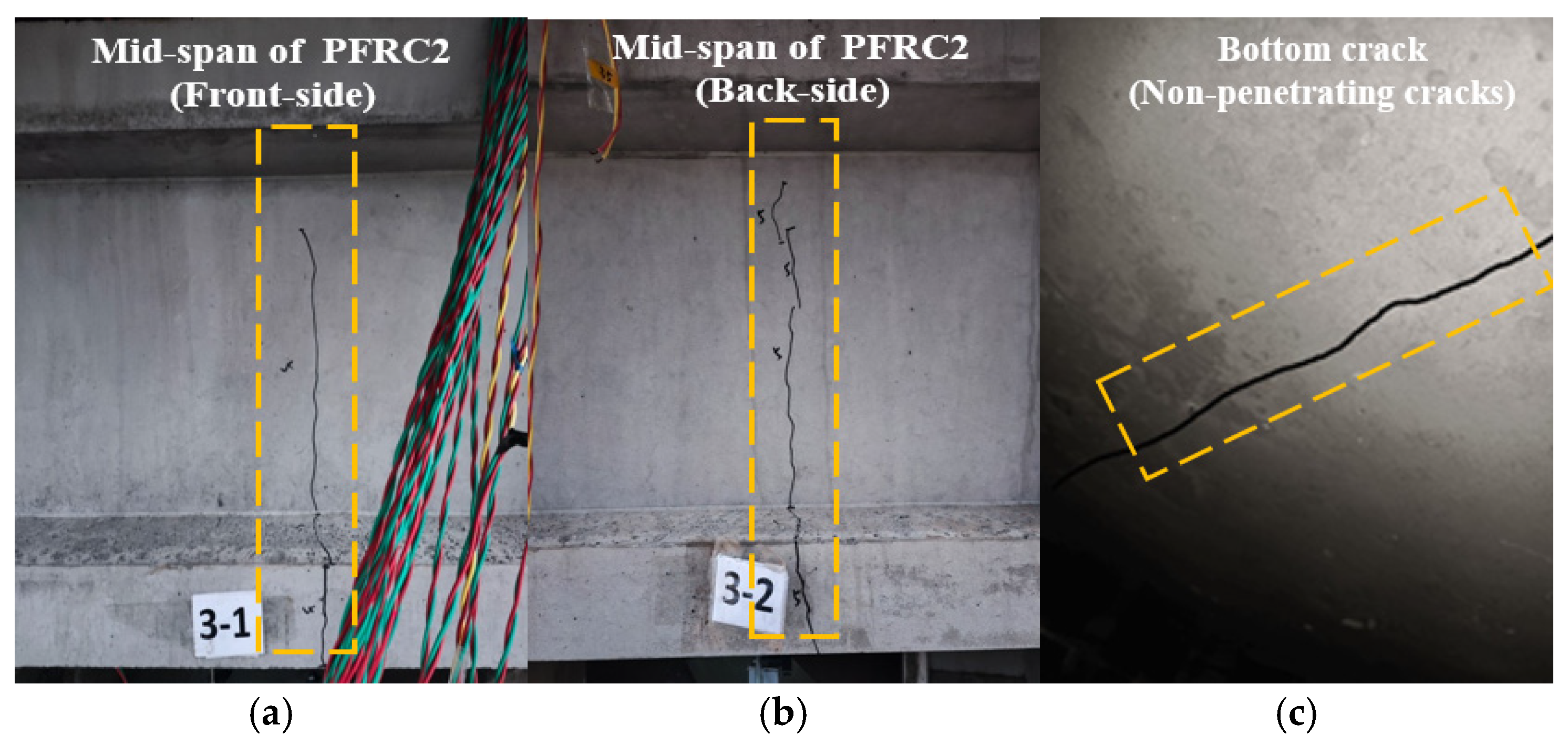

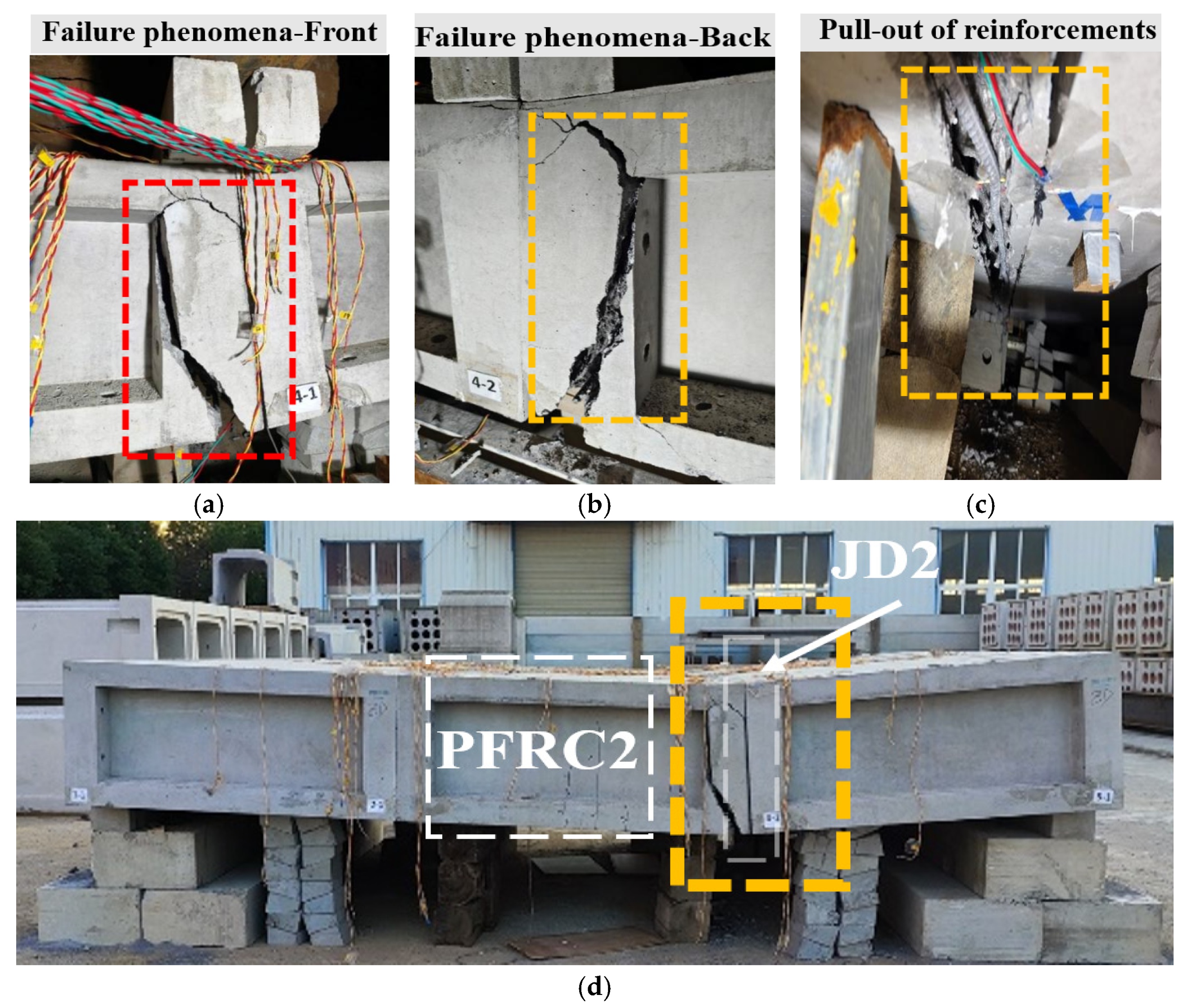

4.2. Experimental Observations

5. Finite Element Analysis and Comparative Study

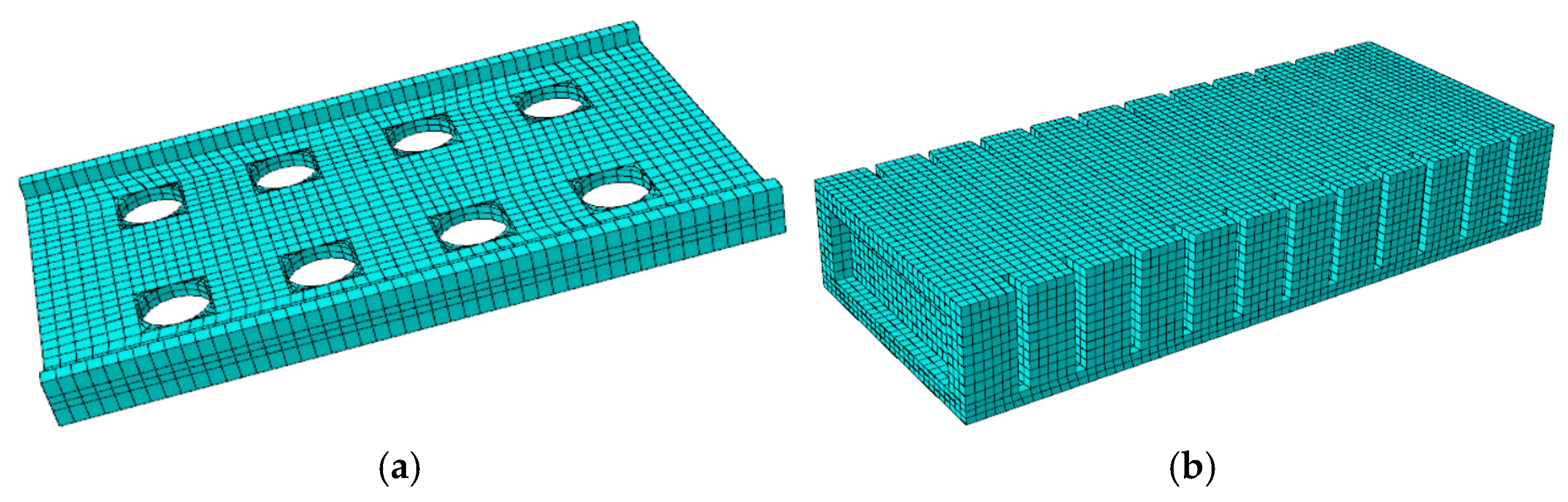

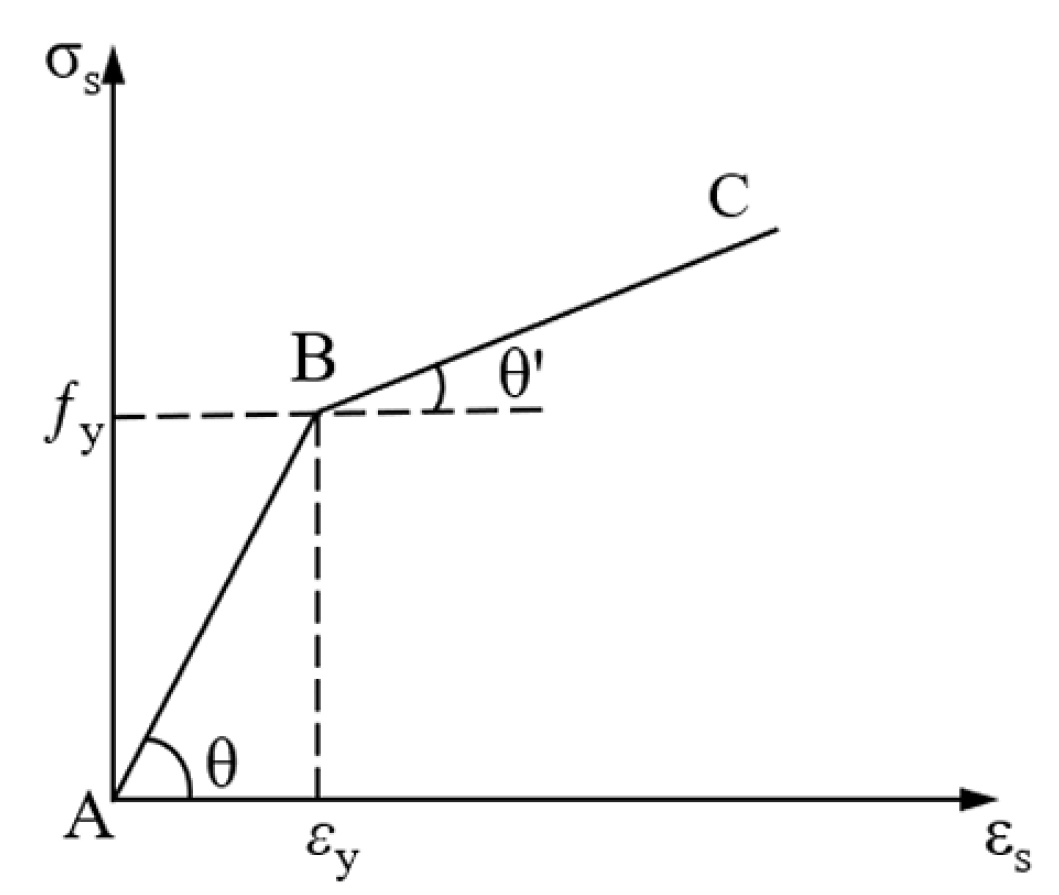

5.1. Finite Element Modeling

5.2. Finite Element Analysis Results

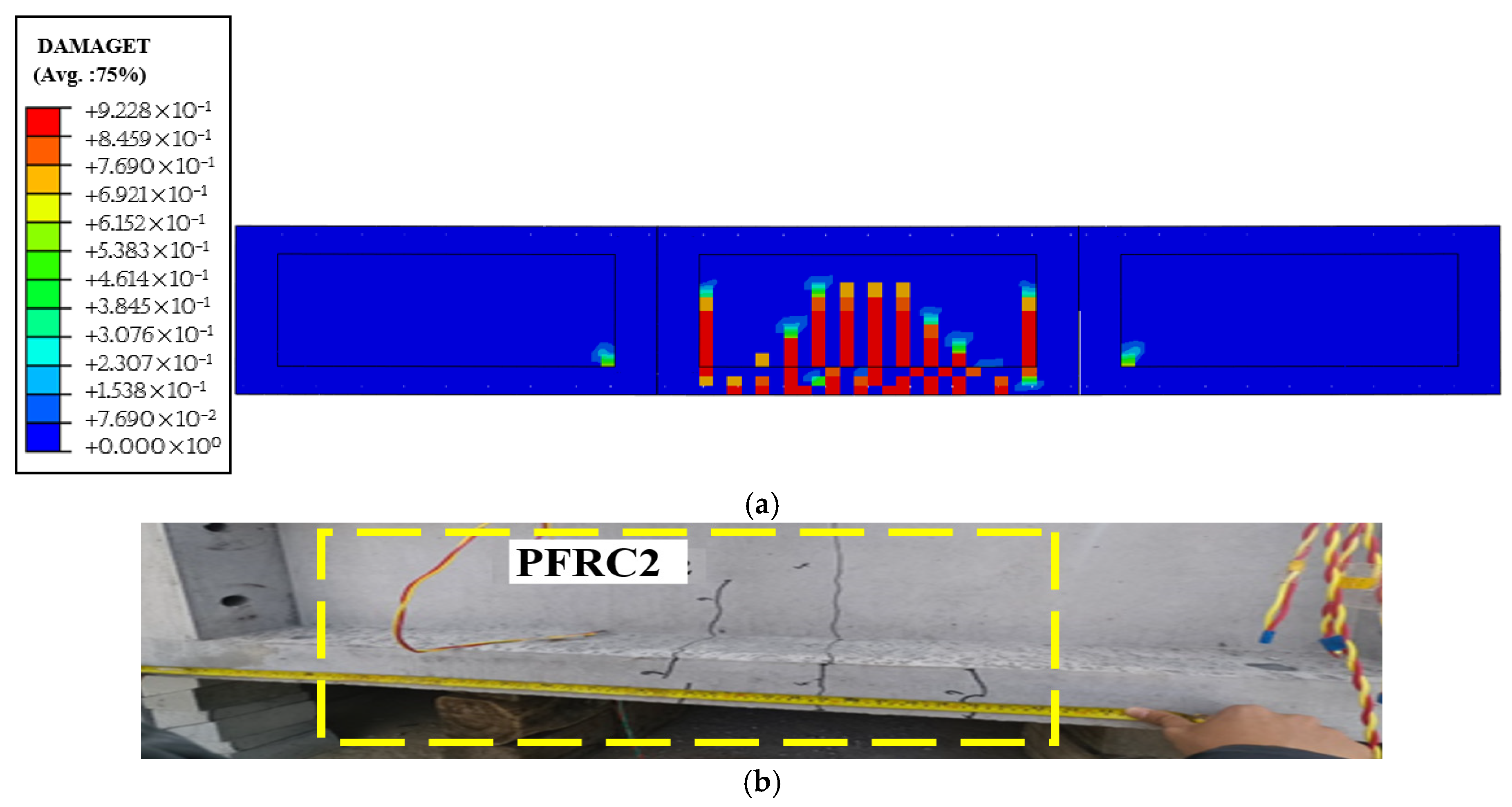

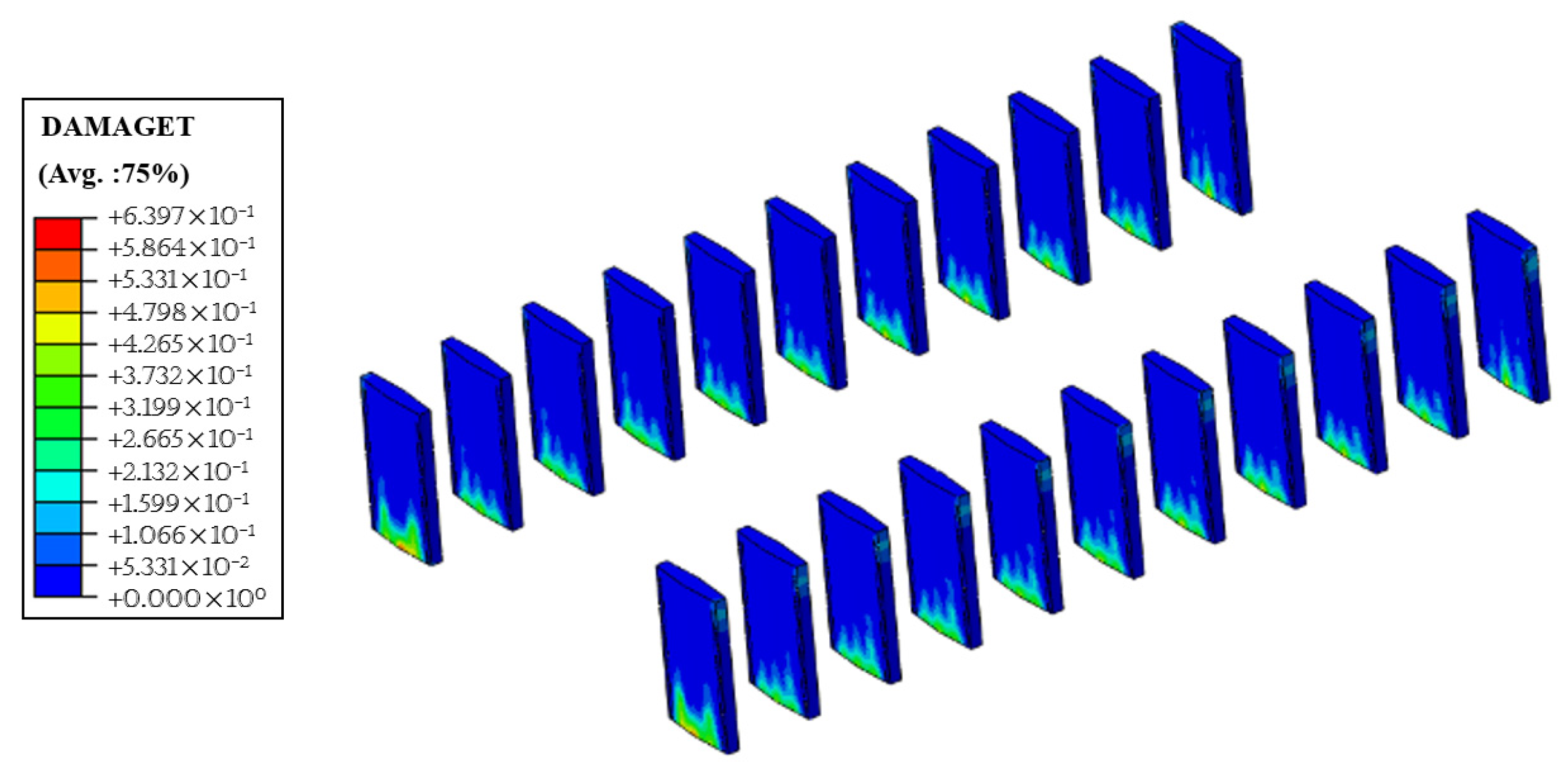

5.2.1. Comparison of Failure Phenomena

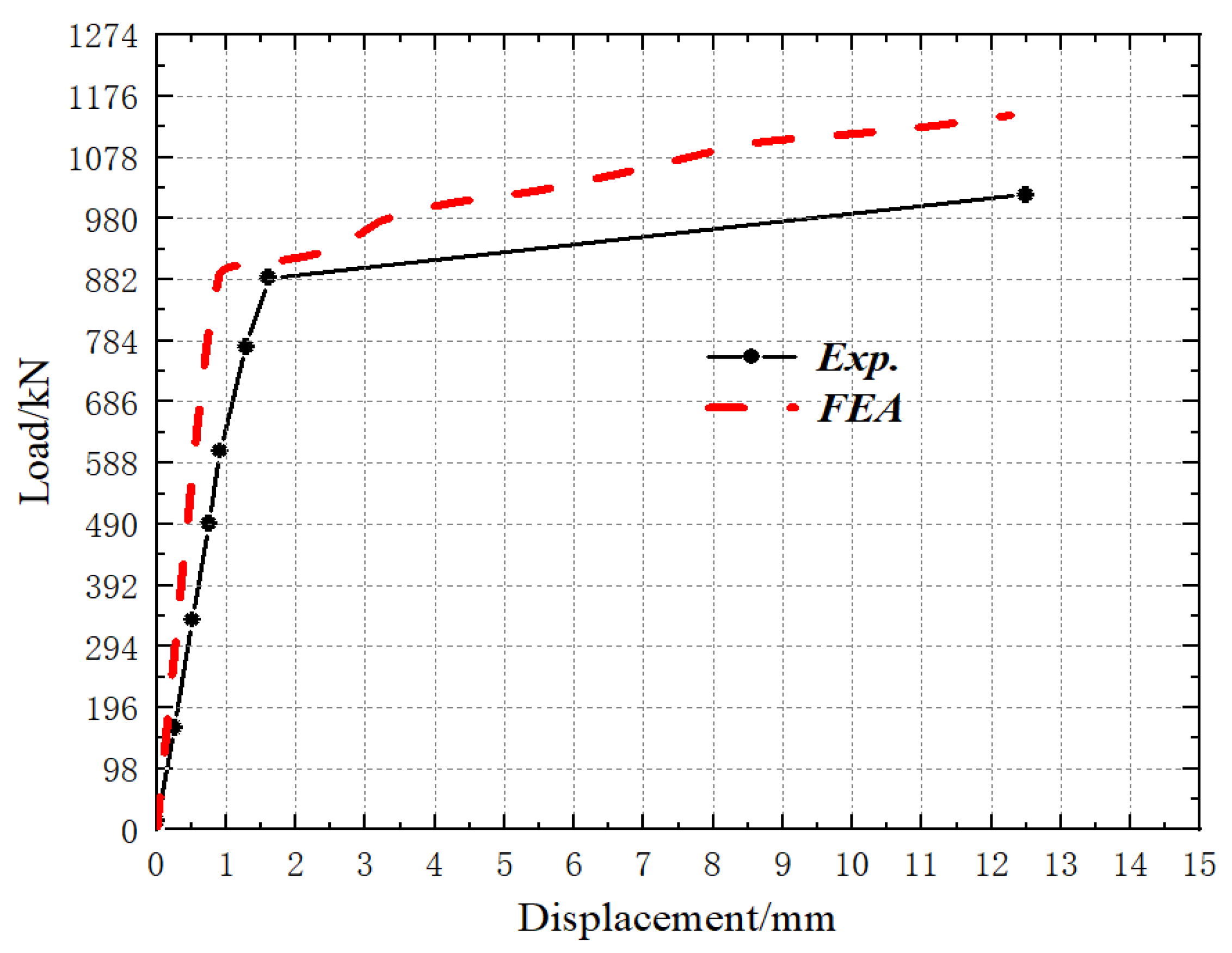

5.2.2. Load–Displacement Behavior

6. Conclusions

- (1)

- Upon reaching the ultimate load, there was no obvious damage at the inserted plate joints, while pronounced flexural failure occurred near the inserted plate joints of the specimen. Therefore, the connection joints possess sufficient strength, and the configuration of the steel reinforcement cages in the prefabricated units needs to be optimized to improve their flexural resistance.

- (2)

- In the elastic phase, the slopes of the experimental and numerical load–displacement curves are 549.8 kN/mm and 945.7 kN/mm, respectively, indicating that the numerical model has greater bending stiffness. Material parameters or contact settings in the finite element modeling have increased the model stiffness to a certain extent, thereby enhancing its bending stiffness. The ultimate bending moments obtained from the test and simulation are 736.5 kN·m and 859.5 kN·m (ratio: 0.86, discrepancy: 14%), respectively, reflecting the difference between the two. All data demonstrate that the prefabricated raft foundation specimens possess qualified bending stiffness and exhibit good load-bearing capacity.

- (3)

- Excluding upper-layer reinforcement, the theoretical cross-section flexural bearing capacity of a single prefabricated unit is 892.8 kN·m. The experimental ultimate moment reaches 0.83 times this value, demonstrating that grouted plug-in connections enable prefabricated raft foundations to achieve good load-bearing performance, with favorable overall performance that can meet the load requirements of HGIS equipment.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shao, G.; Liu, J.; Zou, J.; Zhao, G.; Zheng, T.; Meng, X.; Tian, L.; Liu, J. Experimental Study on the Bearing Performance of Segmented Prestressed Assembled Foundation with Full-Scale Testing. ACT 2025, 23, 123–137. [Google Scholar] [CrossRef]

- Zhang, W.; Ding, Z.; Kang, H.; Lin, P.; Wen, G.; Yong, D.; Lu, C.; Wang, J.; Meng, X.; Rong, K.; et al. Research on Bearing Capacity of a Novel Prestressed Concrete Prefabricated Foundation with High Uplift Resistance Characteristic. Buildings 2024, 14, 3743. [Google Scholar] [CrossRef]

- Wang, W.; Gao, Y.; Wang, Z.; Zhang, L.; An, Z.; Shao, S. An Experimental Study on Plate Splicing of Prefabricated Plate Foundation. Buildings 2023, 13, 2114. [Google Scholar] [CrossRef]

- Wang, W.; Ma, H.; Shao, S.; Wang, Z.; Gao, Y.; Zheng, X.; Zhang, Z. An Experimental Study on Plate Splicing of a New Prefabricated Plate-Type Foundation. KSCE J. Civ. Eng. 2025, in press. [Google Scholar] [CrossRef]

- Li, X.; Hao, H.; Wang, H.; Zhang, L.; Guo, Y.; Lian, J.; Du, Y.; Wang, X.; Zeng, C. Design and Analysis of a New Prefabricated Foundation for Onshore Wind Turbines. Buildings 2024, 14, 193. [Google Scholar] [CrossRef]

- Wang, H.; Liu, C.; Guo, Y.; Hao, H.; Zhang, L. Experimental Study on the Mechanical Characteristics of Prefabricated Dense Ribs Foundation for Onshore Wind Turbines. Structures 2025, 73, 108273. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, X.; Wang, Y.; Ke, K. Axial Compression Behavior of Steel-UHPC Grouted Connections for Offshore Wind Turbines. J. Constr. Steel Res. 2025, 235, 109831. [Google Scholar] [CrossRef]

- Li, L.; Yan, N.; Liu, Z.; Wu, W.; Jiang, G.; Chen, L.; Liu, H. Investigation on the Cyclic Laterally-Loaded Response of Pile-Bucket Foundation with Grouted Connection. Mar. Struct. 2025, 103, 103808. [Google Scholar] [CrossRef]

- Tian, W.; Li, Z.; Wan, H. Design and Analysis of a Novel Prefabricated Foundation for Substation Buildings. Buildings 2024, 14, 4073. [Google Scholar] [CrossRef]

- Pul, S.; Senturk, M.; Ilki, A.; Hajirasouliha, I. Experimental and Numerical Investigation of a Proposed Monolithic-like Precast Concrete Column-Foundation Connection. Eng. Struct. 2021, 246, 113090. [Google Scholar] [CrossRef]

- Zhou, X.; Ding, R.; Guo, B.; Nie, X.; Fan, J. Connections between Precast Hollow Concrete Columns and Foundations Using UHPC and Rebar Lap Splices. Eng. Struct. 2024, 321, 118982. [Google Scholar] [CrossRef]

- Fan, J.-J.; Feng, D.-C.; Wu, G.; Hou, S.; Lu, Y. Experimental Study of Prefabricated RC Column-Foundation Assemblies with Two Different Connection Methods and Using Large-Diameter Reinforcing Bars. Eng. Struct. 2020, 205, 110075. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, L.; Sun, H.; Feng, M.; Dou, K. Side Shear Strength and Load-Transfer Mechanism of Corrugated Steel Column–Foundation Socket Connection. Case Stud. Constr. Mater. 2022, 17, e01377. [Google Scholar] [CrossRef]

- Cao, J.; Wang, X.; Yang, L.; Chen, C. Finite Element Analysis and Failure Modes of CFST Pier-to-Foundation Connection with Tubed RC Encasement. Structures 2025, 80, 109994. [Google Scholar] [CrossRef]

- Cogurcu, M.T.; Uzun, M. Experimental Investigation of a New Precast Column-Foundation Connection under Cyclic Loading. J. Build. Eng. 2022, 50, 104245. [Google Scholar] [CrossRef]

- Qi, J.; Ye, Y.; Jiang, L.; Lü, W.; Lu, B.; Wu, J. A Study on the Mechanical Behavior of a Wind Turbine Foundation with a Constrained Structural Shear Connector. Buildings 2024, 14, 3162. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Z.; Liu, H. Shear Performance of Assembled Bamboo–Concrete Composite Structures Featuring Perforated Steel Plate Connectors. Buildings 2025, 15, 1376. [Google Scholar] [CrossRef]

- Di, J.; Liao, X.; Huang, X.; Wu, M.; Zhao, Y.; Guo, N. Experimental Study and Numerical Simulation of the Mechanical Behaviour of a Bamboo Scrimber Beam–Column Connected to a Concrete Joint Embedded with Steel-Reinforcing Bars. Structures 2025, 81, 110321. [Google Scholar] [CrossRef]

- Xiong, X.; Wei, Z.; Zhang, D.; Liu, J.; Xie, Y.; He, L. An Experimental Study on the Seismic Performance of New Precast Prestressed Concrete Exterior Joints Based on UHPC Connection. Buildings 2025, 15, 729. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, C.; Zhu, Z.; Xu, L.; Han, Q.; Zhou, L.; Xu, S.; Du, X. Investigation on Socket Depth of Prefabricated Assembly CFST Column-Beam Joints by Cyclic Load Test. J. Build. Eng. 2025, 112, 113884. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, Z.; Miao, X.; Chen, Z. Research on Grouting Connection Technology in PHC Pipe Piles and Bearing Platform Integration. J. Build. Eng. 2025, 106, 112633. [Google Scholar] [CrossRef]

- Bai, J.; Yang, J.; Liang, T.; Jin, S. Seismic Performance of Novel Modular Steel Structural Joint with Shear Key Double-Layer Grouting Connection. J. Constr. Steel Res. 2025, 232, 109640. [Google Scholar] [CrossRef]

- Zhu, G.; Zhou, M.; Song, J.; Tian, X. Seismic Performance of the Precast Segmental Hollow Section Bridge Columns with UHPC Wet Joint Connections and UHPC Grouted Duct Connections. Structures 2025, 71, 108009. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, T.; Xie, Z. Seismic Experimental Study on a Precast Concrete Beam-Column Connection with Grout Sleeves. Eng. Struct. 2018, 155, 330–344. [Google Scholar] [CrossRef]

- Qu, X.; Yang, J.; Yan, J. Study on the Eccentric Load-Bearing Performance of Prefabricated Concrete-Filled Steel Tube Columns with “Inner Tube-Flange-Grouting” Connections. Structures 2025, 80, 110043. [Google Scholar] [CrossRef]

- Li, M.; Meng, F.; Zhang, L.; Wu, Q. Experimental and Numerical Study on Flexural Behavior of Prefabricated Bottom Slabs with Rabbeted Grouting Splicing Joints. Structures 2024, 70, 107755. [Google Scholar] [CrossRef]

- Wu, X.; Lu, L.; Jin, J.; Liu, C.; Ding, Z.; Ji, P. Study on Seismic Response of a Novel Prefabricated Box Culvert with Split Components Based on Shaking Table Test. J. Build. Eng. 2024, 84, 108548. [Google Scholar] [CrossRef]

- Zhao, P.; Chen, C.; Shao, X.; Rong, X. Shear Stress at Joint of Prefabricated-Composite Box Girders with Corrugated Steel Webs. J. Constr. Steel Res. 2024, 212, 108307. [Google Scholar] [CrossRef]

- GB/T 228.1-2010; Metallic Materials-Tensile Testing-Part 1: Method of Test at Ambient Temperature. China Architecture & Building Press: Beijing, China, 2010.

- GB/T 50081-2019; Standard for Test Methods of Mechanical Properties of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2019.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). China Standards Press: Beijing, China, 2021.

- Saiidi, M. Hysteresis Models for Reinforced Concrete. ASCE J. Struct. Div. 1982, 108, 1077–1087. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A Plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structure. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- Zhang, J. Research on Mechanical Performance of New Prefabricated Plate Assembly Joint. Master’s Thesis, Jiangsu University, Zhenjiang, China, April 2023. [Google Scholar]

| Case No. | Number of Loading Blocks | Load Per Case (kN) | Cumulative Load (kN) |

|---|---|---|---|

| JZ-1 | 5 | 163.7 | 163.7 |

| JZ-2 | 6 | 171.5 | 335.2 |

| JZ-3 | 4 | 119.6 | 454.7 |

| JZ-4 | 5 | 147.0 | 601.7 |

| JZ-5 | 5 | 147.0 | 748.7 |

| JZ-6 | 5 | 147.0 | 896.7 |

| JZ-7 | 3 | 85.3 | 982.0 |

| Specimen ID | Yield Strength (MPa) | Ultimate Strength (MPa) | Elastic Modulus (MPa) | Elongation After Fracture (%) |

|---|---|---|---|---|

| 1 | 445 | 580 | 206,433 | 16.9 |

| 2 | 460 | 595 | 226,682 | 14.5 |

| 3 | 430 | 600 | 214,569 | 12.7 |

| Avg. | 445 | 592 | 215,895 | 14.7 |

| Specimen Type | Specimen ID | Cross-Section Dimensions (mm) | Failure Load (kN) | Compressive Strength (MPa) |

|---|---|---|---|---|

| Cube compressive strength 1 | 1 | 150.30 × 150.50 × 150.00 | 1066.8 | 47.2 |

| 2 | 150.60 × 149.30 × 150.00 | 1103.4 | 49.1 | |

| 3 | 150.10 × 150.80 × 150.00 | 1088.1 | 48.1 | |

| Avg. | - | 1086.1 | 48.1 | |

| Cylinder compressive strength 2 | 1 | 150.30 × 149.50 × 300.00 | 886.5 | 39.5 |

| 2 | 149.60 × 150.40 × 300.00 | 900.6 | 40.0 | |

| 3 | 149.50 × 150.70 × 300.00 | 915.1 | 40.6 | |

| Avg. | - | 900.7 | 40.0 |

| Specimen ID | Cross-Section Dimensions (mm) | Compressive Strength (MPa) | Ec (MPa) |

|---|---|---|---|

| 1 | 151.30 × 150.50 × 300.00 | 39.6 | 35,898 |

| 2 | 149.70 × 150.80 × 300.00 | 39.4 | 34,903 |

| 3 | 150.50 × 150.90 × 300.00 | 40.3 | 32,892 |

| Avg. | - | 39.8 | 34,564 |

| Specimen ID | Yield Strength (MPa) | Ultimate Strength (MPa) | Elastic Modulus (MPa) | Elongation (%) |

|---|---|---|---|---|

| 1 | 325 | 465 | 203,355 | 12.9 |

| 2 | 315 | 465 | 203,341 | 14.8 |

| 3 | 305 | 445 | 203,359 | 13.3 |

| Avg. | 315 | 458.3 | 203,351.7 | 13.7 |

| Specimen ID | Cross-Section Dimensions (mm) | Flexural Failure Load (kN) | Flexural Strength 1 (MPa) | Compressive Failure Load (kN) | Compressive Strength (MPa) |

|---|---|---|---|---|---|

| 1 | 39.80 × 40.10 × 160.00 | 3.9 | 9.0 | 132.9 | 82.3 |

| 2 | 39.90 × 40.00 × 160.00 | 3.8 | 9.1 | 127.8 | 80.5 |

| 3 | 40.00 × 40.10 × 160.00 | 3.9 | 9.0 | 130.5 | 79.8 |

| Avg. | - | - | 9.0 | - | 80.9 |

| /° 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| 38 | 0.1 | 1.16 | 0.6667 | 0.005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, H.; Zhang, K.; Wang, X.; Tang, Y.; Huo, X.; Jiang, W.; He, S.; Li, T.; Tong, X. Bending Test and FE Analysis of Novel Grouted Plug-in Connection for Prefabricated Assembled Raft Foundation. Buildings 2025, 15, 3931. https://doi.org/10.3390/buildings15213931

Ju H, Zhang K, Wang X, Tang Y, Huo X, Jiang W, He S, Li T, Tong X. Bending Test and FE Analysis of Novel Grouted Plug-in Connection for Prefabricated Assembled Raft Foundation. Buildings. 2025; 15(21):3931. https://doi.org/10.3390/buildings15213931

Chicago/Turabian StyleJu, Hongtao, Kai Zhang, Xiaoping Wang, Yu Tang, Xinggang Huo, Wen Jiang, Shizhe He, Tao Li, and Xin Tong. 2025. "Bending Test and FE Analysis of Novel Grouted Plug-in Connection for Prefabricated Assembled Raft Foundation" Buildings 15, no. 21: 3931. https://doi.org/10.3390/buildings15213931

APA StyleJu, H., Zhang, K., Wang, X., Tang, Y., Huo, X., Jiang, W., He, S., Li, T., & Tong, X. (2025). Bending Test and FE Analysis of Novel Grouted Plug-in Connection for Prefabricated Assembled Raft Foundation. Buildings, 15(21), 3931. https://doi.org/10.3390/buildings15213931