Abstract

This study examines the potential of 3D printing to improve the energy efficiency of housing in hot arid climates such as the UAE. Using a case study of a typical Emirati residence, twenty-four wall configurations were simulated, varying by material (standard vs. sulfur concrete), thickness (4 cm, 8 cm, 10 cm), and insulation level (0%, 25%, 50%, 100%). Results show that eleven configurations met the U-value requirement, six achieved cooling loads below the benchmark, and twelve reduced overall energy use, with only four meeting all criteria simultaneously. Standard concrete proved more versatile across performance conditions, while sulfur concrete with full insulation achieved the lowest energy consumption, underscoring its potential as a sustainable material. These findings demonstrate the value of 3D printing in advancing the UAE’s green building standards and environmental goals, while offering practical strategies for delivering more energy-efficient housing in hot arid regions.

1. Introduction

Over the past few years, there has been growing interest in the application of 3D concrete printing (3DCP) in building construction. This technology offers several potential advantages, such as reduced construction time and cost, reduced waste, water, and material use, and reduced labor [1,2,3]. Many countries are racing to implement this technology at a large scale, motivated by sustainability goals and industrial innovation strategies [4,5,6]. The United Arab Emirates (UAE)—particularly the emirates of Dubai and Sharjah—has positioned itself at the forefront of this transformation, demonstrating the first successful regional applications of 3D-printed buildings. The scale and function of completed projects vary, but the residential sector seems to be especially keen on implementing 3D printing, especially for the development of national housing programs [7].

Yet, the widespread adoption of 3DCP faces numerous challenges. Key obstacles to implementation include regulatory compliance, public acceptance, durability and long-term performance, adaptability to local climatic conditions, and integration with existing structural, electrical, and plumbing systems. Equally important are concerns over material availability, supply-chain logistics, and the embodied energy and cost associated with specialized cementitious mixes. Understanding and optimizing these factors are crucial if 3DCP is to evolve from experimental practice to mainstream construction.

3DCP technologies can be broadly classified into robotic-arm and gantry-based systems. Robotic-arm printers, resembling articulated human arms, employ sensors and actuators to deposit material layer by layer according to a digital model. They are valued for their accuracy and mobility, especially in prefabrication facilities, but their limited reach (approximately 3 m) constrains large-scale, on-site use. Gantry systems, by contrast, employ three-axis motion control to guide the extrusion nozzle along programmed paths, making them ideal for additive manufacturing of entire structures. Commercial gantry printers now achieve spans up to 12 m in width and 9 m in height, enabling the construction of single-story dwellings and façade systems. Further, the use of 3D printing for building construction can be implemented as on-site casting systems, as well as in the prefabrication of building components, with the latter being the more cost-effective option for smaller-scale projects [8]. Wall printing, interior and exterior, and building envelope construction are where the application of 3DCP is most prominent.

The printable materials used in these systems vary widely and are selected according to structural, thermal, and economic requirements. Most mixes are cement-based, but geopolymer, fiber-reinforced, and polymer-modified composites are increasingly investigated for improved rheology and sustainability, while experimental cases have tested local clays and muds [9,10]. Additives such as superplasticizers and accelerators control flowability and setting time, ensuring geometric stability during deposition. Researchers have explored incorporating industrial by-products (fly ash, slag) and natural fibers to enhance strength and durability while reducing cement content and embodied energy, as this latter aspect remains one of the largest environmental burdens of concrete [11,12,13].

A major research focus has been the thermal and energy performance of 3D-printed walls. This issue is particularly pressing in hot, arid climates such as those of the Gulf Cooperation Council (GCC) region, where high cooling loads dominate operational energy consumption. In the UAE, the “Dubai 3D Printing Strategy” explicitly targets large-scale adoption noting that “25 per cent of buildings in Dubai to be based on 3D printing technology by 2030”, linking technological innovation to sustainable housing production [14]. These objectives must, of course, meet current and future thermal performance standards and regulations: Dubai’s Building Code mandates a maximum wall transmittance of 0.57 W/m2 K [15], whereas Abu Dhabi’s “Estidama Pearl Rating System” requires a stricter 0.29 W/m2 K for external walls [16]. Meeting or surpassing such limits is fundamental for achieving net-zero-energy-building (NZEB) standards in the Gulf’s extreme environment.

Extensive literature underscores the importance of wall insulation for reducing energy demand and greenhouse gas emissions. Studies consistently show that insulated walls significantly lower heating and cooling loads [17,18,19]. The optimal insulation thickness varies across climate zones, and material choice strongly influences life-cycle savings [20]. Advanced design techniques, including optimized insulation ratios and thermal-bridge mitigation, further enhance envelope performance [21,22]. Beyond energy conservation, insulation improves indoor environmental quality and occupant comfort, as verified by life-cycle assessments of eco-friendly materials [23,24].

When combined with building-integrated photovoltaics (BIPV), well-insulated envelopes can produce or offset their own energy consumption, realizing the NZEB concept [25]. Regulatory frameworks in multiple countries—including the UK and the UAE—encourage such high-performance construction [26,27], while economic analyses indicate potential energy-cost savings of up to 80% compared with uninsulated walls [23,28].

Within this context, numerous studies have examined the thermal behavior, U-values, and energy modeling of 3DCP wall systems. Comparative analyses between 3DCP and conventional systems such as wood-frame and concrete-masonry-unit (CMU) construction reveal that printed concrete walls are prone to thermal bridging due to the high conductivity of concrete and embedded reinforcement. Yet, when such bridges are mitigated and insulation is incorporated, 3DCP walls can achieve R-values comparable to traditional assemblies [29,30]. The U.S. National Renewable Energy Laboratory (NREL) proposed a numerical framework comparing 3DCP, WFC, and CMU walls across eight U.S. climate zones, demonstrating competitive performance but not isolating the influence of thermal mass, which is significant in concrete walls [31].

Building on this foundation, subsequent research has investigated wall-cavity geometries, material compositions, and insulation strategies using both experimental and numerical methods. Studies exploring sulfur-, cork-, and silica-enhanced mixes found that the optimum configuration depends heavily on climatic conditions [32,33,34]. Finite-Element Method (FEM) analyses further confirmed that wall geometry and thickness exert strong control over U-values, with diamond and triangular cavities yielding the best thermal resistance [35,36]. Investigations in Poland and Italy demonstrated that unfilled cavities alone fail to meet national energy standards, emphasizing the necessity of insulation infill. The integration of recycled or cellulose-based materials improved both thermal performance and environmental outcomes [37,38]. Material innovation has also focused on alternative binders such as magnesium–potassium–phosphate cement (MKPC), which exhibits favorable thermal conductivity and mechanical strength in prefabricated 3D-printed panels [39]. Recent work on multi-layer or sandwich wall systems has advanced performance further: complex gyroid infills produced through additive manufacturing have achieved enhanced insulation and energy efficiency [40].

Collectively, these findings highlight the interdependence between material selection, cavity geometry, and insulation configuration in determining the thermal performance of 3D-printed walls. While the existing body of research provides valuable insights, most investigations have been conducted in temperate or cold climates, leaving limited data for hot, arid regions such as the UAE. The present study addresses this gap by focusing on operational energy modeling of 3D-printed wall systems under the UAE’s climatic conditions, providing a benchmark for their thermal and energy performance.

Accordingly, the study examines the thermal transmittance (U-values) and energy performance of both conventional and 3D-printed wall assemblies representative of Emirati residential buildings. Using DesignBuilder 6.1 and OPAQ 3.0, various concrete mix designs and insulation configurations are simulated to quantify their impact on building envelope efficiency. The results aim to inform the design of energy-efficient, regulation-compliant, and cost-effective 3D-printed envelopes, directly supporting the UAE’s 3D-printing initiative and its broader ambition toward sustainable, low-carbon, and net-zero-energy development. The approach established in this work also provides a framework for future studies to extend the analysis toward life-cycle and embodied-energy evaluations, thereby strengthening the overall understanding of 3DCP’s sustainability potential.

2. Case Study and Methods

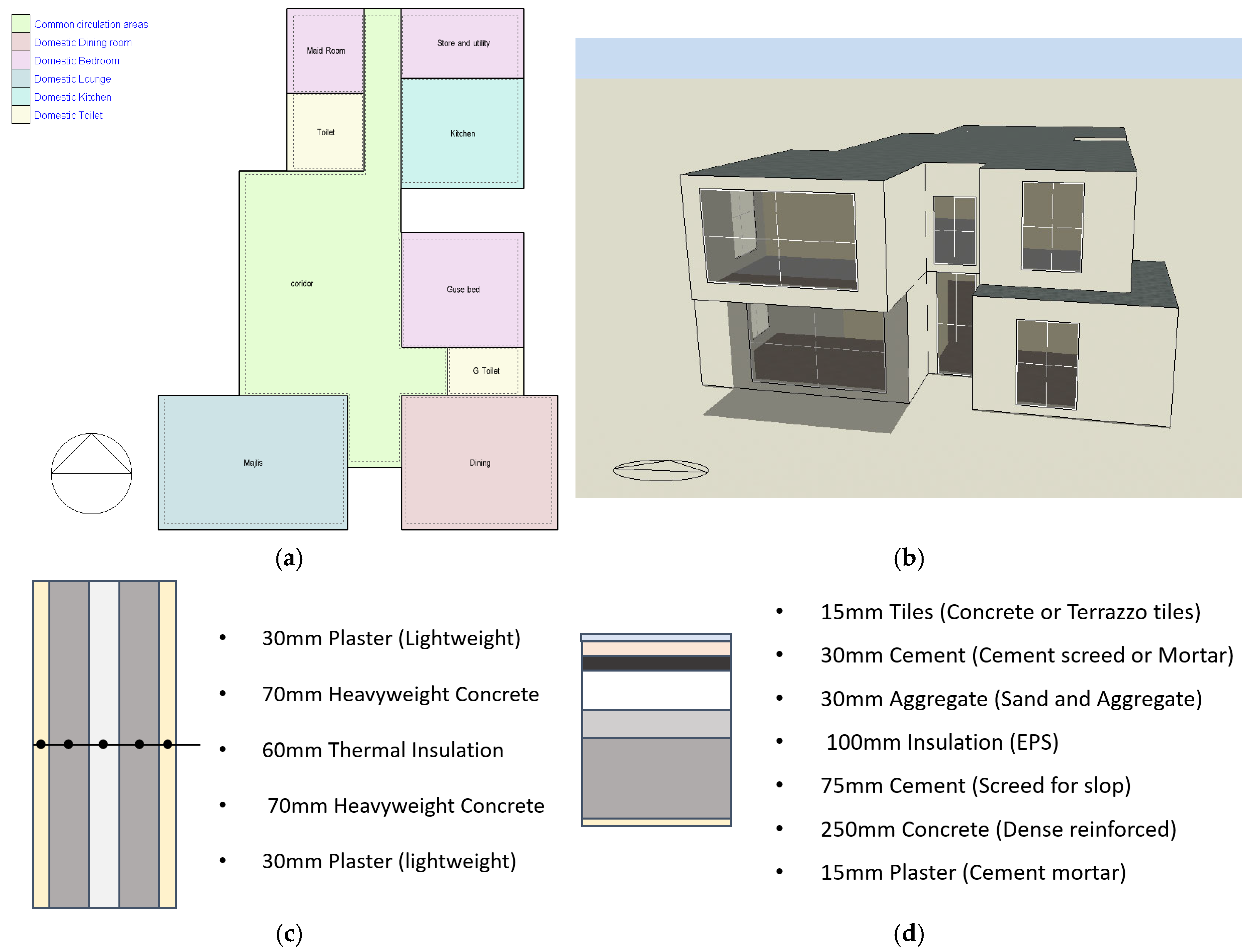

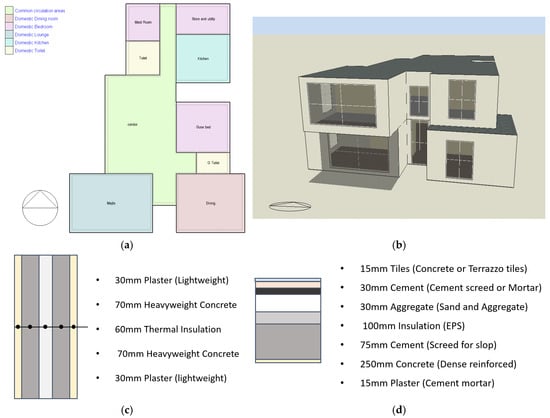

The building studied in this paper is a standard-size Emirati National Housing Program Villa, as developed by the Abu Dhabi Housing Authority (ADHA). This is a freestanding house that has a total area of 478 m2, distributed over two stories of 239 m2 each, including the stairs. The total height of this building, from the ground floor finished-floor-level (FFL) to the roof FFL is 8.76 m. In the ground floor layout, it has the majlis, dining and family room, as well as kitchen and service areas. The second floor includes all five bedrooms, each with its own bathroom. Figure 1 shows the ground floor plan (Figure 1a) and 3D image of the villa’s south façade (Figure 1b).

Figure 1.

Case study villa floors and construction details. (a) DesignBuilder Model Ground Floor Plan. (b) DesignBuilder Model South Elevation. (c) External wall detail. (d) Roof detail.

Wall construction consists primarily of walls built using CMU blocks with insulation. These have two exterior layers of 70 mm concrete, with an insulation insert of 60 mm, resulting in a U-value of 0.466 W/m2 K (Figure 1c). This wall is plastered on both sides with a 30 mm finishing layer. The studied villa has concrete flat roofs, which are built in the following configuration: reinforced concrete slab 250 mm, cement screed for slope 75 mm, polystyrene insulation 100 mm, sand/aggregate 30 mm, cement screed 30 mm, finished with concrete or terrazzo tiles 15 mm. The interior face is finished with cement mortar plaster (15 mm), giving the whole roof a thickness of 515 mm (Figure 1d).

Simulation Scenarios

In this study, the dynamic simulation software used is DesignBuilder Version 6.1, which integrates EnergyPlus Version 8.9. This software complies with ASHRAE Standard 140 required by the U.S. Department of Energy (DOE), enabling three-dimensional simulation of HVAC system loads, energy costs, and CO2 emissions based on building operations. Additionally, it supports computational fluid dynamics (CFD), design and system optimization, and thermal comfort analysis. For opaque surfaces such as walls or roofs, OPAQ 3.0 was used to calculate U-values, time lag, and decrement factors for single- or multi-layer configurations. This allows for calculating heat gains or losses through opaque surfaces. The baseline models created with DesignBuilder and OPAQ were validated based on the input data shown in Table 1. The actual building’s input data was provided by the Abu Dhabi government, and conforms to approved typical villa requirements [41].

Table 1.

Validation of the baseline model’s input data for the DesignBuilder model.

Based on this model, simulations were conducted for three configurations or scenarios (Table 2) to assess changes in thermal conductivity (U-value), cooling load, and cooling energy consumption in unit area.

Table 2.

Summary of simulation scenarios.

- Scenario 1 involved altering the type and thickness of the 3D-printed concrete layers. Two types of concrete mix were tested, conventional concrete and sulfur concrete, with specifications provided in Table 3. The sulfur concrete mix followed the formulation proposed by Bretz [42] and recently applied in 3D-printed wall simulation research [32]. Additionally, the size of the printing nozzle was assumed to be the standard 4 cm, 8 cm, and 10 cm, the type of printing concrete was varied, and the size of the internal cavity was adjusted to 18 cm, 10 cm, and 6 cm, respectively. The total wall thickness was thus 26 cm, which matches the case study villa’s actual external wall thickness (Figure 1c).

- Scenario 2 examined various filling levels of insulation for each of the internal cavities that were outlined in Scenario 1, and insulation fill was set to 25%, 50%, and 100% of the cavity space.

Table 3.

Specifications of 3D-printed concrete and expanded polystyrene (EPS) insulation.

Table 3.

Specifications of 3D-printed concrete and expanded polystyrene (EPS) insulation.

| 3D Material Specifications | Density (kg/m3) | Thermal Conductivity (W/m·K) | Specific Heat (J/g·K) |

|---|---|---|---|

| General Concrete Mix (C) | 2240 | 1.95 | 0.900 |

| Sulfur Concrete Mix (SC) | 1.254 | 0.367 | 0.803 |

| Expanded Polystyrene (EPS) | 15 | 0.04 | 1.45 |

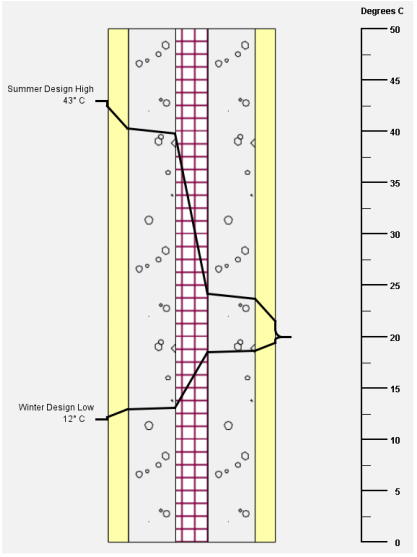

A material sensitivity study was conducted using Opaque 3.0 software to examine how material substitution and wall configuration influence thermal performance. Three 260 mm wall types were modeled: ① a baseline wall, ② a baseline with sulfur concrete wall, and ③ a 3D-printed sulfur concrete wall (4 cm SC + 6 cm EPS + 12 cm air cavity + 4 cm SC). As summarized in Table 4, replacing conventional concrete with sulfur concrete increased the R-value from 1.77 to 2.37 m2K/W and decreased the U-value from 0.57 to 0.421 W/m2 K, yielding roughly a 26% improvement in insulation. In contrast, the 3D sulfur concrete wall achieved an intermediate performance with an R-value of 2.03 m2K/W and a U-value of 0.493 W/m2 K, suggesting better insulation than the baseline but lower than the full sulfur concrete wall.

Table 4.

Using Opaque 3.0 to calculate the concrete materials’ sensitivity.

Time-lag analysis revealed that the baseline wall maintained the highest thermal inertia (−9.84 h), while the sulfur and 3D sulfur walls showed reduced lag (−1.69 h and −0.15 h, respectively). These results confirm that although sulfur concrete enhances steady-state insulation, the layered 3D configuration still limits heat-storage capacity, requiring geometric and density optimization for improved transient thermal performance.

3. Results

This study investigates the impact of varying external wall thickness and insulation levels on the thermal performance and energy consumption of a baseline case study building. The baseline wall thickness of 26 cm was used as the reference, while the basic wall thickness for 3D printing was set at 4 cm, a common standard. Simulations were conducted to analyze the changes in U-value of the external wall, cooling load, and energy consumption per unit area as the wall thickness increased from 4 cm to 8 cm and 10 cm. Additionally, the effects of incorporating insulation at 25%, 50%, and 100% of the wall cavity were evaluated.

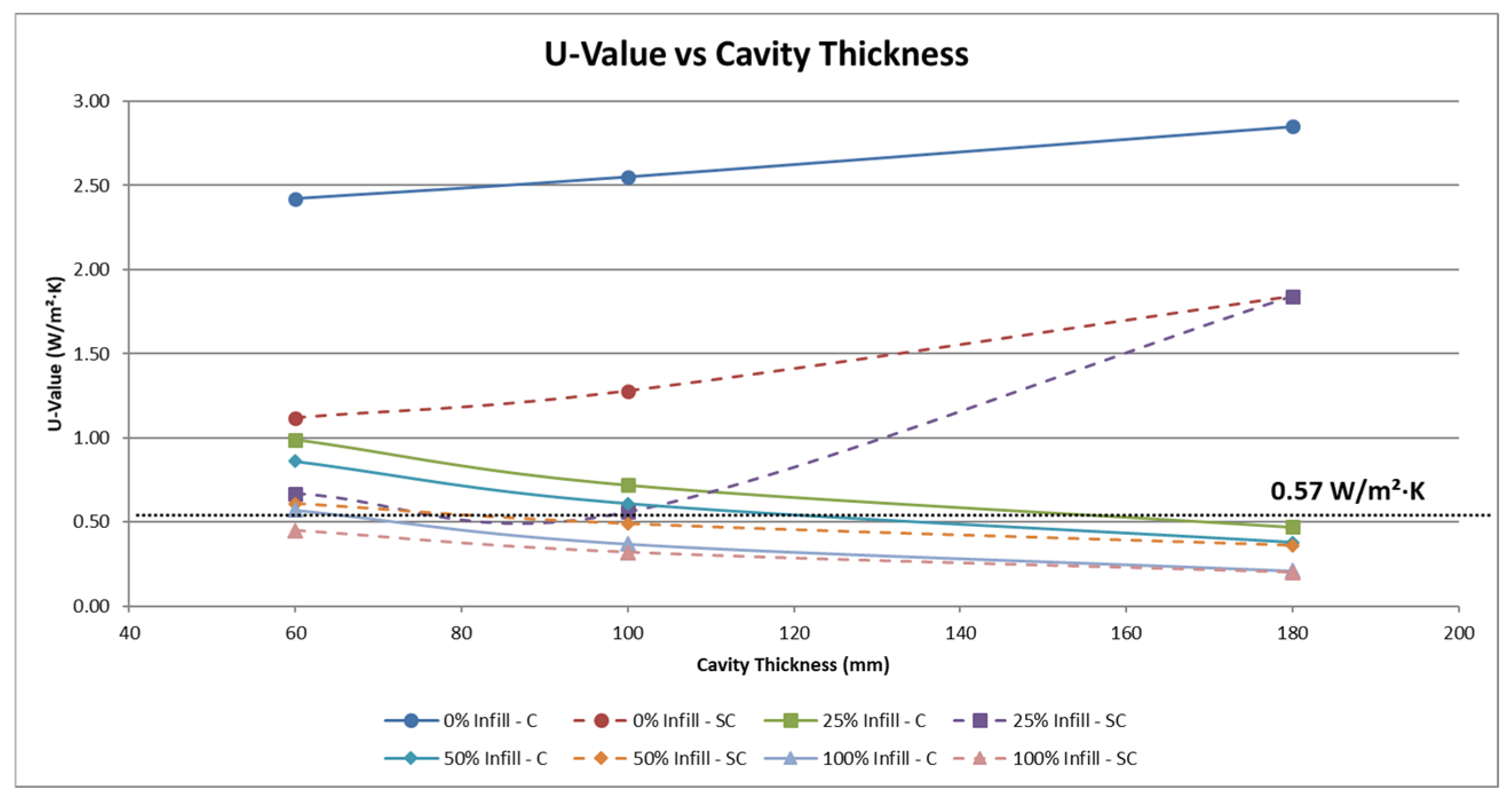

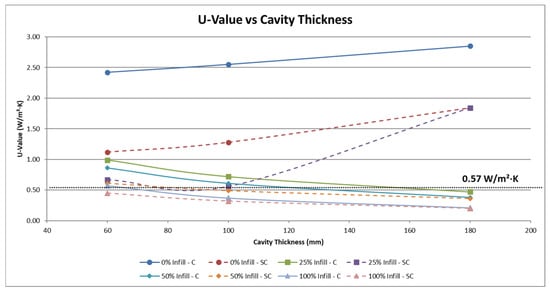

3.1. Analysis of U-Value Variations Based on 3D Printing Materials and Insulation Levels

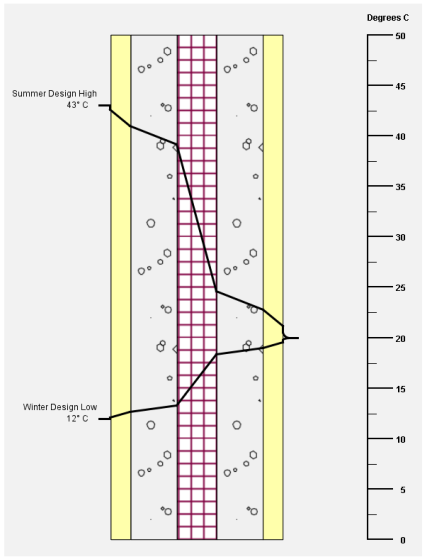

The study analyzed the U-value performance of two commonly used 3D printing materials—standard concrete mix and sulfur concrete mix—combined with varying insulation levels. The goal was to determine configurations that meet the baseline requirement of 0.57 W/m2 K for the external wall. Results showed that all 11 tested configurations achieved the target U-value under specific material and insulation conditions.

Based on Table 2 scenarios and Figure 2 below, when the standard concrete mix was used as the 3D printing material, the following configurations met the target U-value: 4 cm wall thickness achieved the requirement with 25%, 50%, and 100% insulation filling of the cavity, 8 cm wall thickness met the requirement with 100% insulation filling, and 10 cm wall thickness achieved the requirement with 100% cavity insulation filling.

Figure 2.

Different insulation levels impact external wall U-value.

For walls using a sulfur concrete mix, the configurations that satisfied the U-value requirement were as follows: 4 cm wall thickness achieved the requirement with 25%, 50%, 100% insulation filling, 8 cm wall thickness met the requirement with 25%, 50%, and 100% cavity insulation filling, and 10 cm wall thickness achieved it with 100% insulation filling.

The findings highlight the influence of both material selection and insulation levels on achieving thermal performance standards. While the standard concrete mix required higher insulation levels for thicker walls to meet the U-value threshold, sulfur concrete mix demonstrated greater flexibility in achieving compliance across a wider range of insulation levels and wall thicknesses. These results underscore the potential of sulfur concrete as an alternative material for thermally efficient 3D-printed structures.

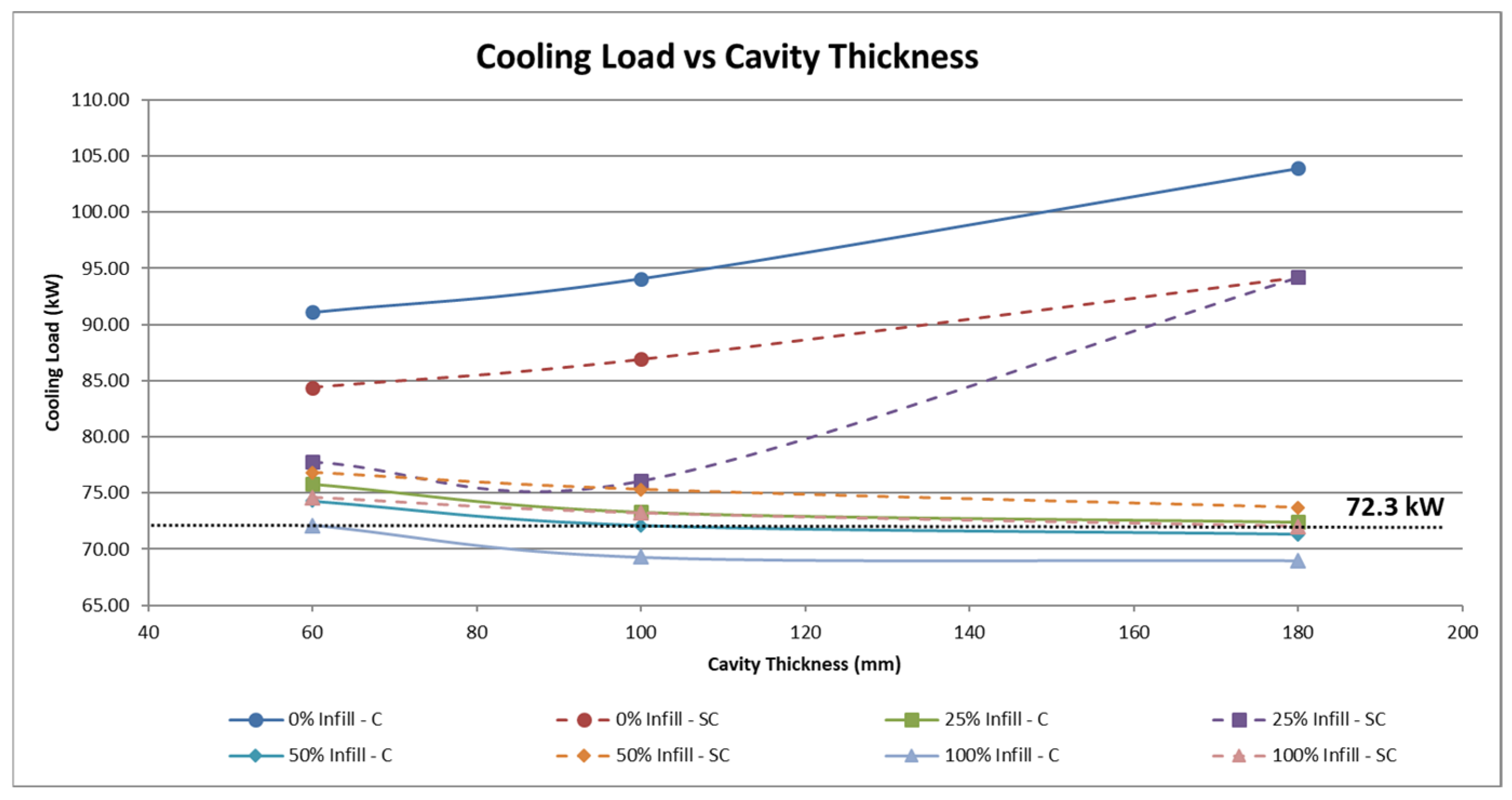

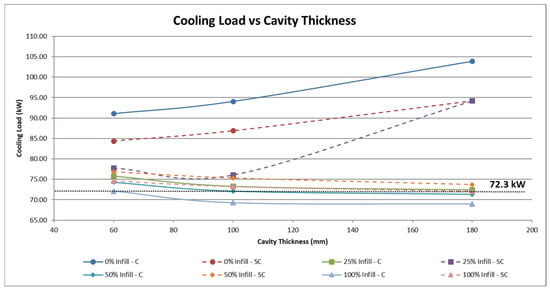

3.2. Cooling Load Analysis for 3D Printing Materials and Insulation Levels

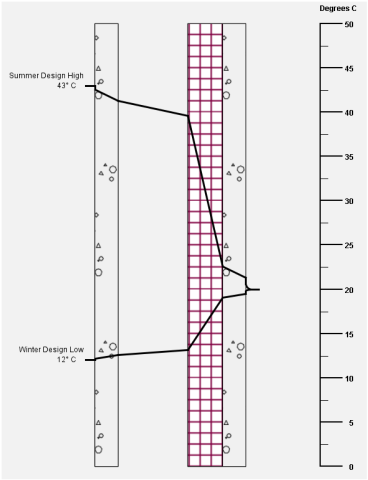

To evaluate the cooling load (kW) performance of walls constructed with two 3D-printed materials, standard concrete mix and sulfur concrete mix were studied under varying insulation levels. The baseline cooling load requirement of 72.3 kW was used as the reference. Out of 24 total simulations, only 6 configurations achieved cooling loads lower than the baseline.

For walls made with the standard concrete mix, 4 cm and 8 cm wall thickness achieved the requirement with 50% and 100% insulation filling, and 10 cm wall thickness met the cooling load requirement only with 100% insulation filling. For walls using sulfur concrete mix, the only configuration that satisfied the cooling load requirement was 4 cm wall thickness with 100% insulation filling.

The results indicate that while the standard concrete mix provided more flexibility in meeting the cooling load requirement at various thicknesses and insulation levels, sulfur concrete mix achieved compliance only in a highly insulated configuration (100% insulation at 4 cm thickness). These results are presented in Figure 3.

Figure 3.

Different insulation levels impact cooling load.

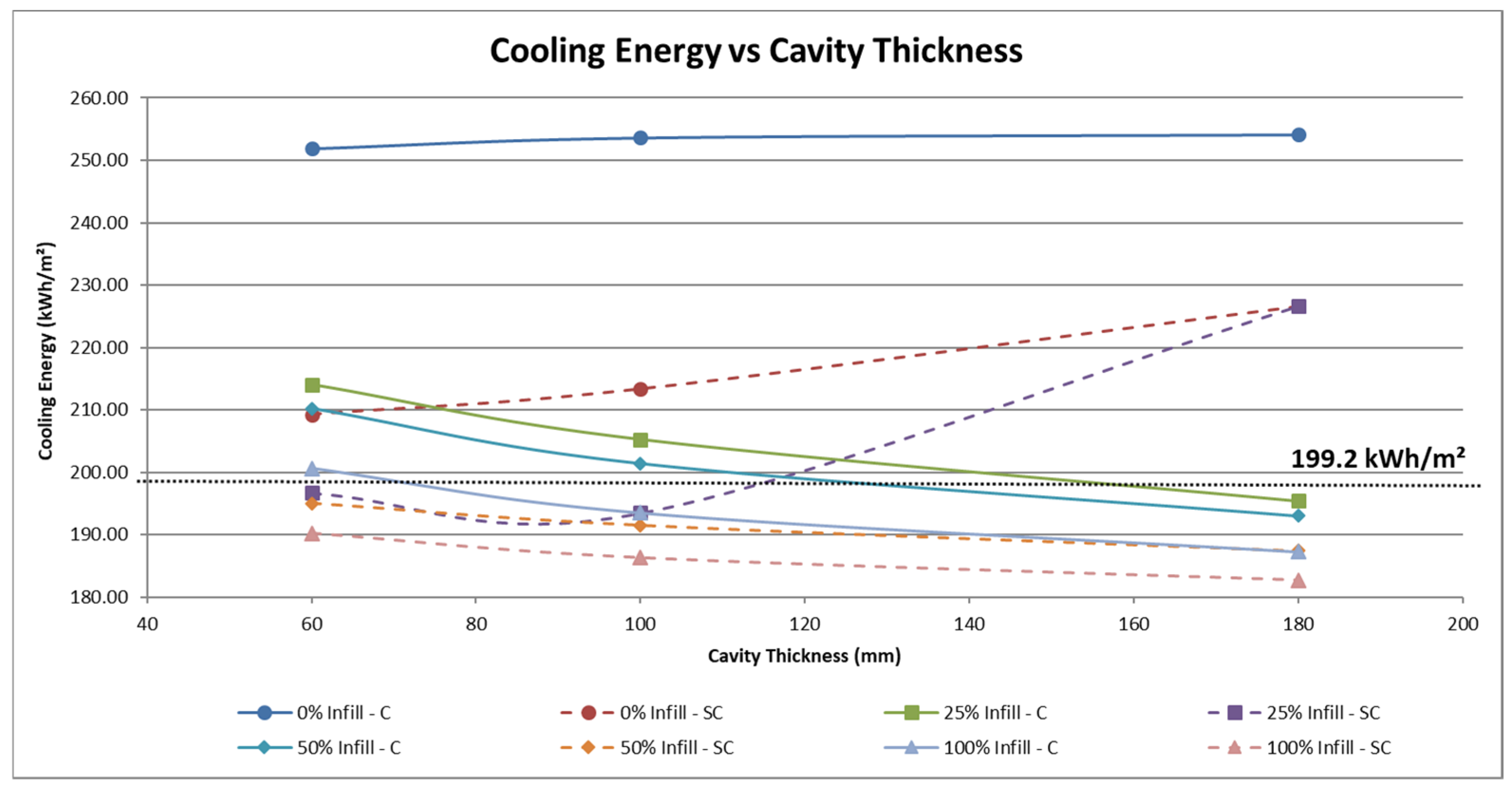

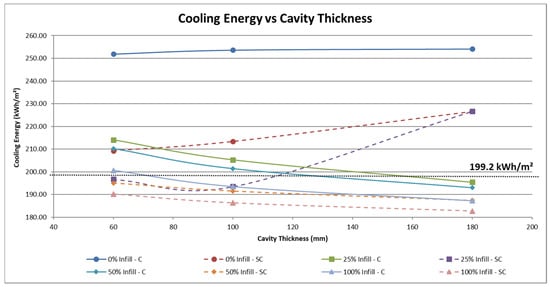

3.3. Cooling Energy Consumption Analysis for 3D-Printed Materials and Insulation Levels

This study also analyzed the energy consumption per unit area (kWh/m2) for walls constructed with standard concrete mix and sulfur concrete mix under varying insulation levels. The baseline energy consumption requirement was set at 199.2 kWh/m2. Out of all simulations, 12 configurations met this requirement.

The majority of configurations that satisfied the energy consumption criterion aligned with the findings from the U-value study. However, notable discrepancies were observed, which were as follows: 10 cm standard concrete mix with 100% insulation filling did not meet the energy consumption requirement, despite satisfying the U-value criterion, and 10 cm sulfur concrete mix with 25% and 50% insulation filling met the energy consumption requirement, even though these configurations did not satisfy the U-value threshold.

The results, shown in Figure 4, highlight sulfur concrete mix as a more favorable material for energy-efficient building envelopes, providing a broader range of compliant configurations. This finding underscores the importance of material selection in optimizing energy performance, as sulfur concrete mix proved advantageous even in scenarios where U-value thresholds were not met.

Figure 4.

Different insulation levels’ impact on cooling energy consumption per unit area.

3.4. Optimal Selections for Satisfying the Baseline Condition

Among the 24 simulated scenarios, only 4 configurations met all three baseline requirements—0.57 W/m2 K for the external wall, 72.3 kW for the cooling load, and 199.2 kWh/m2 for energy consumption. These configurations are ① the 4 cm standard concrete mix walls with 50% and 100% insulation filling, ② the 8 cm standard concrete mix wall with 100% insulation filling, and ③ the 4 cm sulfur concrete mix wall with 100% insulation filling (Table 5). This indicates that while standard concrete allows for more varied combinations to meet the requirements, sulfur concrete paired with 100% insulation filling is more advantageous in terms of reducing energy consumption.

Table 5.

Simulation results and cases meeting the baseline condition.

3.5. Overall Simulation Results and Discussion

Table 6 presents the results of a comprehensive material sensitivity analysis performed using Opaque 3.0 and DesignBuilder to evaluate the influence of cavity thickness and infill ratio on the thermal behavior of multi-layer wall systems composed of both conventional concrete and sulfur concrete. The study considered cavity depths of 60 mm, 100 mm, and 180 mm combined with infill densities of 0%, 25%, 50%, and 100%. Across all configurations, sulfur concrete walls demonstrated superior thermal insulation and lower cooling demand compared to conventional concrete counterparts, confirming the material’s potential for energy-efficient 3D-printed wall design.

Table 6.

Overall simulation results.

As shown in Table 6, the highest U-values and energy consumption occurred in walls with the largest cavity (180 mm) and no infill. The baseline 4C wall recorded a U-value of 2.85 W/m2 K, a cooling load of 103.9 kW, and a unit cooling energy of 254.1 kWh/m2, while the 4SC sulfur concrete wall under identical conditions improved performance to 1.84 W/m2 K, 94.2 kW, and 226.6 kWh/m2, respectively. Increasing the infill density and reducing cavity thickness led to a marked reduction in heat transfer and cooling energy. At 100% infill, sulfur concrete walls achieved minimum U-values of 0.20–0.45 W/m2 K, with corresponding cooling loads between 69 and 75 kW and unit energy demands of 182–190 kWh/m2, reflecting an overall 25–30% enhancement in energy performance relative to the baseline (4SC).

These outcomes reveal two key trends. First, material composition plays a decisive role—sulfur concrete’s lower thermal conductivity directly improves resistance to heat flow. Second, geometric configuration and infill density substantially govern transient heat transfer, where reduced cavity size and higher infill enhance conductive continuity and thermal mass, yielding lower overall cooling requirements. The optimal configuration therefore combines moderate cavity depth and high infill density using sulfur concrete, balancing structural stability with superior insulation performance.

4. Conclusions

Over the past decade, the construction industry has shown growing interest in adopting 3D concrete printing (3DCP) as a transformative technology to achieve faster, more cost-effective, and environmentally responsible building practices. However, its successful integration into large-scale housing programs—particularly in hot and arid regions such as the United Arab Emirates (UAE)—requires a comprehensive understanding of how 3D-printed wall systems perform thermally compared with conventional construction methods.

This study addressed this gap by evaluating the thermal behavior and energy performance of conventional concrete and 3D-printed sulfur concrete wall systems under various insulation and cavity configurations. Using DesignBuilder 6.1 and Opaque 3.0, a series of simulations were performed on a representative Emirati residential unit to assess U-values, cooling loads, and energy consumption across multiple wall designs. The analysis aimed to identify configurations capable of meeting UAE building code requirements and to establish a benchmark for future 3DCP-based construction in the region.

The results showed that sulfur concrete walls exhibited significantly improved thermal resistance, achieving approximately 26% lower U-values than conventional concrete under comparable conditions. Optimized insulation ratios and cavity infills led to substantial reductions in cooling energy demand, confirming the potential of 3DCP for energy-efficient applications in hot climates. Nevertheless, achieving full compliance with all thermal performance benchmarks (U-value, cooling load, and total energy consumption) remains challenging. Only four configurations met all criteria, with the 4 cm sulfur concrete wall with 100% insulation performing best. These results demonstrate that while 3DCP offers distinct material and construction advantages, its geometric configuration and internal layering still require further optimization to enhance transient thermal behavior.

It should also be acknowledged that this study focused solely on operational energy performance. Factors such as embodied energy, life-cycle environmental impacts, and economic costs—including material production, printing logistics, and equipment operation—were beyond its scope. These aspects remain essential for a comprehensive sustainability assessment and should be addressed in future work through life-cycle assessment (LCA) and techno-economic analysis to complement the operational findings presented here.

From a broader perspective, the findings underscore the importance of insulation strategy, material selection, and cavity design in developing high-performance, low-energy wall systems. The growing national and international interest in 3D building innovation makes it essential that such technologies comply with Dubai’s and Abu Dhabi’s energy codes to ensure both environmental and economic viability. The integration of advanced thermal design approaches, potentially combined with renewable energy systems, could enable future 3D-printed housing projects to meet net-zero-energy-building (NZEB) standards.

In summary, this research provides one of the first systematic benchmarks comparing conventional and 3D-printed sulfur concrete wall systems under UAE climatic conditions. The outcomes support the development of design standards, policy frameworks, and performance criteria for energy-efficient 3D-printed construction, advancing both regional and global goals for sustainable building innovation.

Author Contributions

Conceptualization, Y.K.K., M.S. and M.H.; methodology, Y.K.K.; software, Y.K.K.; validation, Y.K.K.; formal analysis, Y.K.K.; investigation, Y.K.K., M.S. and M.H.; resources, M.S.; data curation, M.H.; writing—original draft, Y.K.K., M.S. and M.H.; writing—review and editing, Y.K.K., M.S. and M.H.; project administration, M.S.; funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by a grant. The research was supported by the United Arab Emirates University UPAR Grant G00004641.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

We gratefully acknowledge Shouq Al Qarni, Noura Al Bloushi, Jaber Al Ali and Khalifa Alblooshi from the ARCH590 Capstone Engineering Design Project for their valuable contributions to architectural drafting and data collection during the Spring 2025 semester.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tu, H.; Wei, Z.; Bahrami, A.; Ben Kahla, N.; Ahmad, A.; Özkılıç, Y.O. Recent advancements and future trends in 3D concrete printing using waste materials. Dev. Built Environ. 2023, 16, 100187. [Google Scholar] [CrossRef]

- Kreiger, M.; Kreiger, E.; Mansour, S.; Monkman, S.; Delavar, M.A.; Sideris, P.; Roberts, C.; Friedell, M.; Platt, S.; Jones, S. Additive construction in practice—Realities of acceptance criteria. Cem. Concr. Res. 2024, 186, 107652. [Google Scholar] [CrossRef]

- Habibi, A.; Buswell, R.; Osmani, M.; Aziminezhad, M. Sustainability principles in 3D concrete printing: Analysing trends, classifying strategies, and future directions. J. Build. Eng. 2024, 98, 111354. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive manufacturing: Technology, applications, markets, and opportunities for the built environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Lee, D.; Kim, H.; Sim, J.; Lee, D.; Cho, H.; Hong, D. Trends in 3D Printing Technology for Construction Automation Using Text Mining. Int. J. Precis. Eng. Manuf. 2019, 20, 871–882. [Google Scholar] [CrossRef]

- Aghimien, D.; Aigbavboa, C.; Aghimien, L.; Thwala, W.D.; Ndlovu, L. Making a case for 3D printing for housing delivery in South Africa. Int. J. Hous. Mark. Anal. 2020, 13, 565–581. [Google Scholar] [CrossRef]

- Raza, M.H.; Besklubova, S.; Zhong, R.Y. Economic analysis of offsite and onsite 3D construction printing techniques for low-rise buildings: A comparative value stream assessment. Addit. Manuf. 2024, 89, 104292. [Google Scholar] [CrossRef]

- Es-Sebyty, H.; Igouzal, M.; Ferretti, E. Improving stability of an ecological 3D-printed house -a case study in Italy. J. Achiev. Mater. Manuf. Eng. 2022, 111, 18–25. [Google Scholar] [CrossRef]

- Giacomobono, L.; Argenti, M.; Ferretti, E.; Paparella, G. Three-Dimensional Printing with Earthen Materials: A Settlement-Scale Design Experience. Buildings 2024, 14, 2721. [Google Scholar] [CrossRef]

- De Rubeis, T.; Ciccozzi, A.; Giusti, L.; Ambrosini, D. On the use of 3D printing to enhance the thermal performance of building envelope—A review. J. Build. Eng. 2024, 95, 110284. [Google Scholar] [CrossRef]

- Rahemipoor, S.; Hasany, M.; Mehrali, M.; Almdal, K.; Ranjbar, N.; Mehrali, M. Phase change materials incorporation into 3D printed geopolymer cement: A sustainable approach to enhance the comfort and energy efficiency of buildings. J. Clean. Prod. 2023, 417, 138005. [Google Scholar] [CrossRef]

- Capêto, A.P.; Jesus, M.; Uribe, B.E.B.; Guimarães, A.S.; Oliveira, A.L.S. Building a Greener Future: Advancing Concrete Production Sustainability and the Thermal Properties of 3D-Printed Mortars. Buildings 2024, 14, 1323. [Google Scholar] [CrossRef]

- Government of the United Arab Emirates. Dubai 3D Printing Strategy; Government of the United Arab Emirates: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- Dubai Municipality. Dubai Green Building Regulations and Specifications (GBRS): Energy—Thermal Transmittance Requirements for External Walls; Dubai Municipality: Dubai, United Arab Emirates, 2014. [Google Scholar]

- Abu Dhabi Urban Plnning Council. The Pearl Rating System for Estidama Public Realm Rating System Design & Construction; Abu Dhabi Urban Plnning Council: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- Harold, J.; Lyons, S.; Cullinan, J. The determinants of residential gas demand in Ireland. Energy Econ. 2015, 51, 475–483. [Google Scholar] [CrossRef]

- Rasuli, M.A.; Torii, S. Energy consumption comparison at various insulation scenarios: Mid-rise residential buildings, Kabul city. E3S Web Conf. 2023, 405, 02001. [Google Scholar] [CrossRef]

- Fang, M.; Fang, T.; Chen, J.; Yu, Z. Impact Analysis of the Thickness of Wall Insulation on Indoor Comfort in Hot Summer and Cold Winter Area. Appl. Mech. Mater. 2012, 193–194, 1069–1074. [Google Scholar] [CrossRef]

- Kabundu, E.; Mbanga, S.; Botha, B.; Ayesu-Koranteng, E. Relative comparison of the benefits of wall envelope insulation materials in the South African energy zones, subject to the new national building energy efficiency standards. Front. Built Environ. 2023, 9, 1305029. [Google Scholar] [CrossRef]

- Chandrasiri, D.; Gatheeshgar, P.; Ahmadi, H.M.; Simwanda, L. Numerical Study of Thermal Efficiency in Light-Gauge Steel Panels Designed with Varying Insulation Ratios. Buildings 2024, 14, 300. [Google Scholar] [CrossRef]

- Martins, C.; Santos, P.; Da Silva, L.S. Lightweight steel-framed thermal bridges mitigation strategies: A parametric study. J. Build. Phys. 2016, 39, 342–372. [Google Scholar] [CrossRef]

- Bodalal, A.; Mashite, S.; Aladouli, O.; Ihdash, A. Calculation of Annual Heating and Cooling Energy Requirements for Residential Building in Different Climate Zones in Libya. Innov. Energy Res. 2017, 6, 161. [Google Scholar] [CrossRef]

- Mitterpach, J.; Hroncová, E.; Ladomerskỳ, J.; Štefko, J. Quantification of Improvement in Environmental Quality for Old Residential Buildings Using Life Cycle Assessment. Sustainability 2016, 8, 1303. [Google Scholar] [CrossRef]

- Kuan, S.-C.; Chan, C.-C.; Shu, C.-M. A study of BIPV net-zero energy building. Int. J. Smart Grid Clean Energy 2014, 3, 64–69. [Google Scholar] [CrossRef][Green Version]

- Petrou, G.; Hutchinson, E.; Mavrogianni, A.; Milner, J.; Macintyre, H.; Phalkey, R.; Hsu, S.C.; Symonds, P.; Davies, M.; Wilkinson, P. Home energy efficiency under net zero: Time to monitor UK indoor air. BMJ 2022, 377, e069435. [Google Scholar] [CrossRef]

- Lingard, J. Residential retrofit in the UK: The optimum retrofit measures necessary for effective heat pump use. Build. Serv. Eng. Res. Technol. 2021, 42, 279–292. [Google Scholar] [CrossRef]

- Wang, X.; Lin, Q.; Li, J. Energy saving technology of wall insulation of harbor building based on energy cost analysis. Therm. Sci. 2021, 25, 4003–4010. [Google Scholar] [CrossRef]

- Wu, C.; Evans, P. An Integrated System for Improving 3D Concrete Printing Process. In Proceedings of the Eleventh National Conference of IBPSA-USA, Denver, CO, USA, 21–23 May 2024. [Google Scholar]

- Abouzeid, T.M.; Tarek, Z.M.; Sayad, E.L.; Ragheb, R.A. 3D Printing Technology as a Sustainable Solution for Mitigation of Energy Consumption in the Face of the Climate Crisis. In Proceedings of the IASTEM International Conference, Dubai, United Arab Emirates, 26–27 February 2024; pp. 2394–2827. [Google Scholar]

- Torcellini, P.; Pless, S.; Deru, M.; Crawley, D. Zero Energy Buildings: A Critical Look at the Definition. In Proceedings of the ACEEE Summer Study Pacific Grove, Pacific Grove, CA, USA, 14−18 August 2006. [Google Scholar]

- Alkhalidi, A.; Hatuqay, D. Energy efficient 3D printed buildings: Material and techniques selection worldwide study. J. Build. Eng. 2020, 30, 101286. [Google Scholar] [CrossRef]

- Chamatete, K.; Yalçınkaya, Ç. Numerical Evaluation on Thermal Performance of 3D Printed Concrete Walls: The Effects of Lattice Type, Filament Width and Granular Filling Material. Buildings 2024, 14, 926. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef] [PubMed]

- AlZahrani, A.A.; Alghamdi, A.A.; Basalah, A.A. Computational optimization of 3D-printed concrete walls for improved building thermal performance. Buildings 2022, 12, 2267. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Upasiri, I.; Gatheeshgar, P.; Poologanathan, K.; Nagaratnam, B.; Santos, P.; Rajanayagam, H. Energy Performance of 3D-Printed Concrete Walls: A Numerical Study. Buildings 2021, 11, 432. [Google Scholar] [CrossRef]

- Dziura, P.; Maroszek, M.; Góra, M.; Rudziewicz, M.; Pławecka, K.; Hebda, M. Influence of the In-Fill Pattern of the 3D Printed Building Wall on Its Thermal Insulation. Materials 2023, 16, 5772. [Google Scholar] [CrossRef]

- Pessoa, S.; Jesus, M.; Rangel, C.; Guimarães, A.S.; Lucas, S.S.; Simões, N. Preliminary study of the application of thermal mortar in 3D printed concrete walls. J. Phys. Conf. Ser. 2023, 2654, 012081. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building Envelope Prefabricated with 3D Printing Technology. Sustainability 2021, 13, 8923. [Google Scholar] [CrossRef]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P.; Baryś, M. The Potential of 3D Printing in Thermal Insulating Composite Materials—Experimental Determination of the Impact of the Geometry on Thermal Resistance. Materials 2024, 17, 1202. [Google Scholar] [CrossRef] [PubMed]

- Department of Municipal Affairs. Abu Dhabi International Energy Conservation Code (ADIECC); Government of Abu Dhabi: Abu Dhabi, United Arab Emirates, 2013. [Google Scholar]

- Bretz, T.J. Properties of Sulfur Concrete; U.S. Bureau of Mines: Washington, DC, USA, 1979. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).