Abstract

This paper investigates the bearing behavior of squeezed branch piles and straight-shaft piles under uplift and combined horizontal–uplift loading in silty clay strata. Utilizing a combined approach of laboratory model tests and numerical simulation, the influence of key parameters, such as the depth of the first branch and branch spacing, on the bearing capacity was systematically analyzed. The results demonstrate that under combined loading, the bearing capacity of squeezed branch piles is significantly superior to that of straight-shaft piles, with double-branch piles outperforming single-branch piles. The bearing capacity increases with the depth of the first branch and the branch spacing, reaching its optimum when the first branch is buried at a depth of 6 d (where d is the straight-shaft pile diameter). This study also reveals a unique mechanical response under combined loading: the load–displacement curves exhibit a “smoothed” characteristic, rendering the traditional inflection point method unsuitable for determining the ultimate bearing capacity. Furthermore, a significant coupled weakening effect exists between horizontal and uplift forces. However, increasing the depth of the first branch (to 6 d) and the branch spacing can effectively mitigate this effect, enhancing the pile’s stability under complex loading conditions. This research provides a crucial basis for the optimized design and application of squeezed branch piles in complex loading environments.

1. Introduction

In recent years, the increasing complexity of structural loads has driven a continuous advancement in pile foundation technologies. Squeezed branch piles [1], as a representative innovation, utilize branch-forming techniques [2,3,4] to create variable cross-sections along the shaft, significantly enhancing bearing capacity [5,6,7] and optimizing pile–soil interactions [8,9,10]. These advantages have led to their widespread use in high-rise buildings and transmission tower foundations [11,12,13]. The improved performance stems from two primary mechanisms: the enlarged bearing area provided by the branch plates and the compaction effect that strengthens the surrounding soil [14,15,16].

However, most existing studies focus on single-load conditions [17,18,19]—such as vertical compression or pure uplift—while the mechanical behavior under combined horizontal and uplift loads remains insufficiently explored [20,21]. This gap is particularly notable given that many real-world structures, including offshore platforms, high-voltage transmission towers, and wind turbine foundations, are subjected to such combined loading conditions in service. Furthermore, while squeezed branch piles are frequently applied in silty clay [22] strata common in alluvial and coastal regions, their performance in such soils under complex loading has not been systematically investigated.

To address these research needs, this study employs laboratory model tests and numerical simulations to systematically analyze the failure mechanisms [23,24] and bearing behavior [25] of squeezed branch piles under combined horizontal-uplift loading. Emphasis is placed on the influence of branch spacing and the embedment depth of the first plate, with the tests conducted in typical silty clay to better represent practical engineering conditions. The results are intended to provide design references for pile foundations under similar complex loading patterns in soft soil areas.

2. Materials and Methods

2.1. Laboratory Model Test

To gain deeper insights into the mechanical behavior of squeezed branch piles under combined horizontal–uplift loading, this study designed a laboratory model test program based on similitude theory. The laboratory model test design draws upon established methodologies from prior research [26], with the model geometry and scaling principles carefully calibrated against the well-documented prototype test in Ref. [27]. This ensured adherence to key similitude criteria—geometric, elastic, strength, and stress similarity—thereby guaranteeing that the laboratory model tests accurately replicated the mechanical response of a full-scale prototype.

2.1.1. Model Materials and Testing Parameters

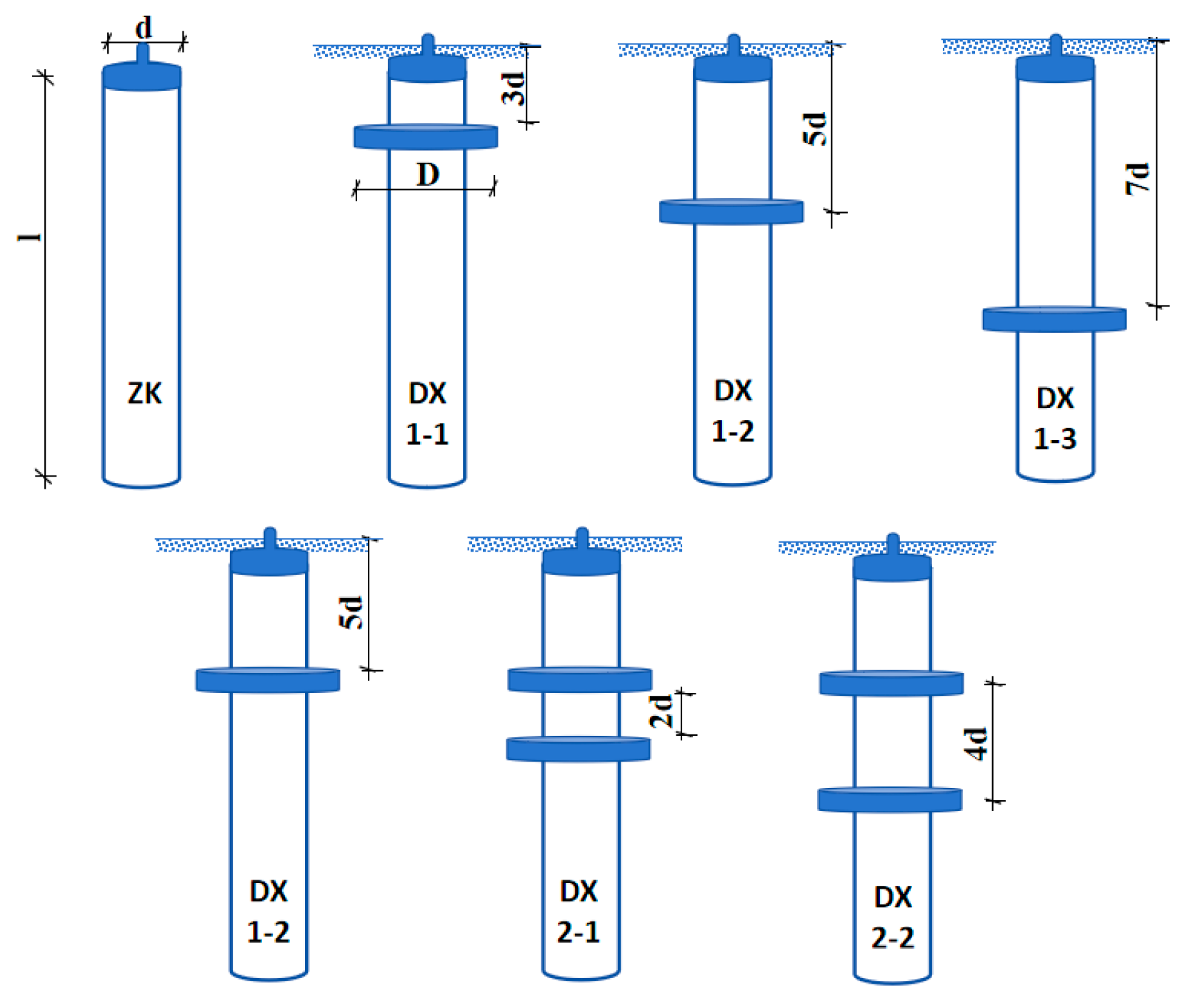

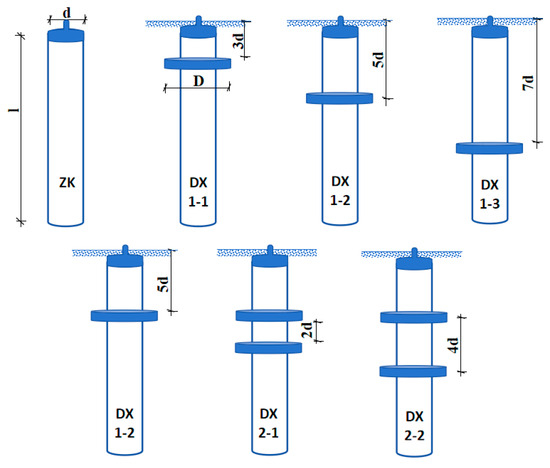

The laboratory model test program included six pile configurations with distinct geometries, each having a design length of 1200 mm. To ensure data reliability and account for experimental variability, each configuration was tested under three identical replicates under uplift loading and combined horizontal–uplift loading. The investigation focused on the pile head load–displacement response, with the detailed test arrangements summarized in Table 1 and illustrated in Figure 1.

Table 1.

Dimensional details of model piles.

Figure 1.

Diagram of model piles.

The foundation soil material used in this experiment was homogeneous silty clay. The basic geotechnical parameters of the soil obtained through laboratory tests are presented in Table 2.

Table 2.

Geotechnical parameters of silty clay.

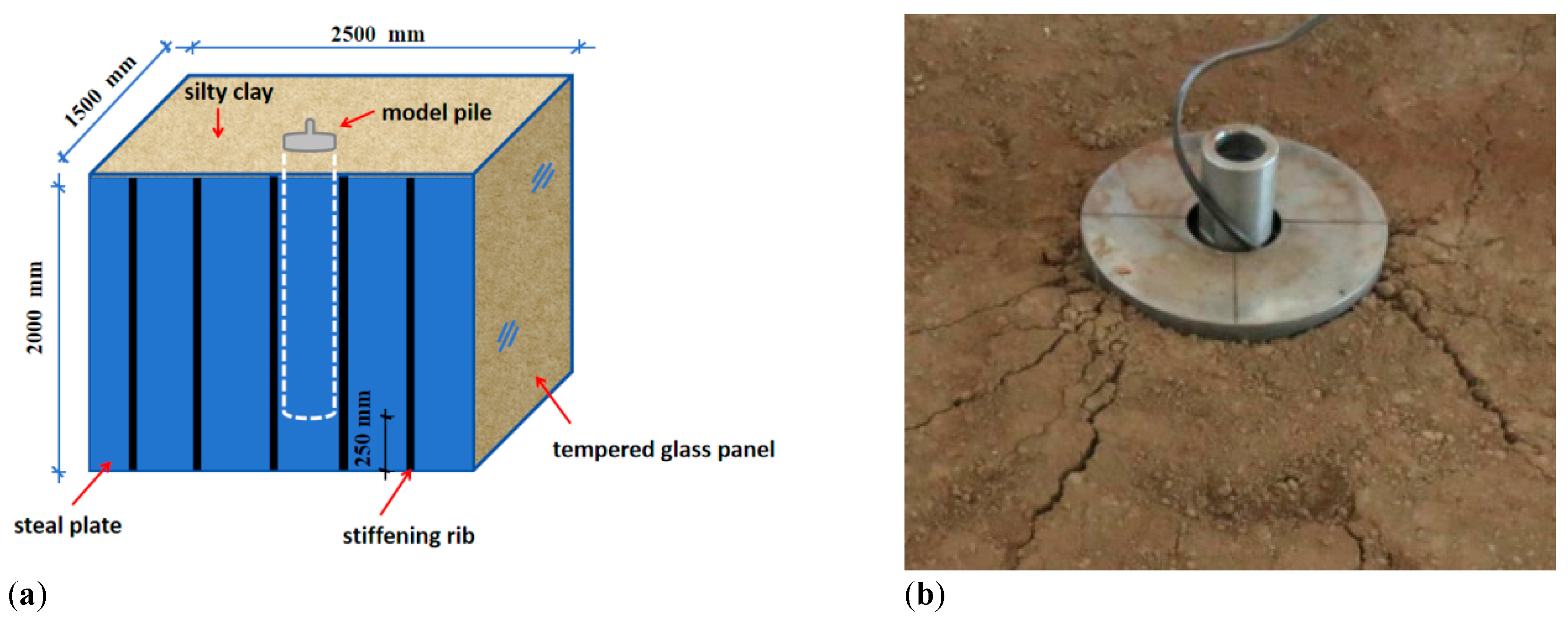

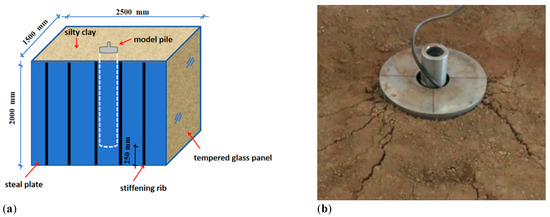

A dedicated laboratory model test chamber with internal dimensions of 2.5 m (L) × 1.5 m (W) × 2 m (H) was constructed to contain the soil specimen. The main structure was fabricated from 10 mm thick steel plates, reinforced with stiffening ribs for enhanced rigidity. One side of the box was fitted with a 10 mm thick tempered glass panel, facilitating visual observation throughout the testing process. The design drawings of the model chamber are provided in Figure 2.

Figure 2.

Schematic of the model chamber and pile embedment. (a) Diagram of laboratory model test chamber; (b) pile embedment.

2.1.2. Testing Methods

The specimen surfaces were abraded with fine sand to enhance roughness and ensure full mobilization of shaft friction. After securely installing the test pile in the laboratory model test chamber, the soil was compacted in layers using a self-made rammer. The system was then allowed to stand for 24 h before conducting horizontal–uplift loading tests.

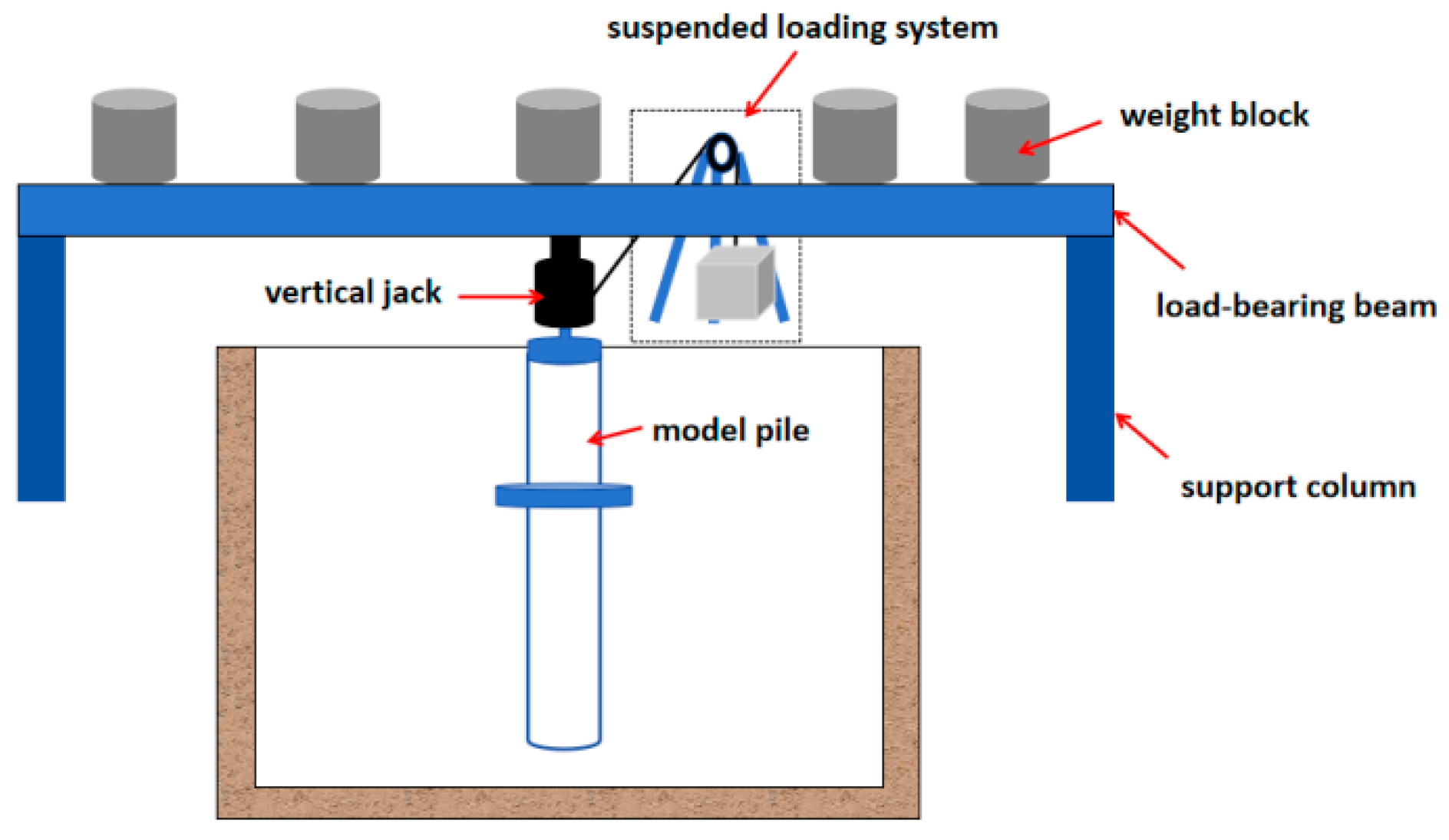

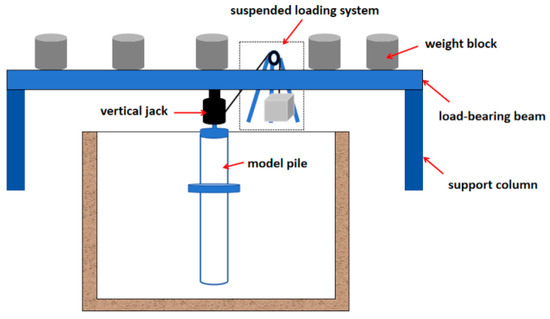

The laboratory model tests adopted the “slow maintained load method [28,29].” Vertical load was applied through a hydraulic jack, while horizontal load was implemented via a suspended loading system, with a vertical-to-horizontal load ratio of 5:1 [30]. The pile head load was measured using tension load cells, and the vertical displacement at the pile head was monitored by dial gauges mounted on a rigid beam. The loading system schematic diagram is shown in Figure 3.

Figure 3.

Loading system schematic diagram.

Specific Loading Procedure: Each load stage was set at 1/10 of the estimated ultimate capacity. After applying each stage, readings were taken at 5, 10, and 15 min, then every 15 min thereafter. After cumulative loading reached 1 h, readings were taken every 30 min. All measured values were recorded in the test log. The pile was considered to have reached relative stability when the settlement per hour did not exceed 0.1 mm and this condition was met twice consecutively (as determined from three consecutive readings within a 1.5 h period). Once stability was achieved, the next load stage was applied. Loading was terminated when an abrupt change in displacement was observed, and the load was gradually reduced to zero in stages.

2.2. Numerical Simulation

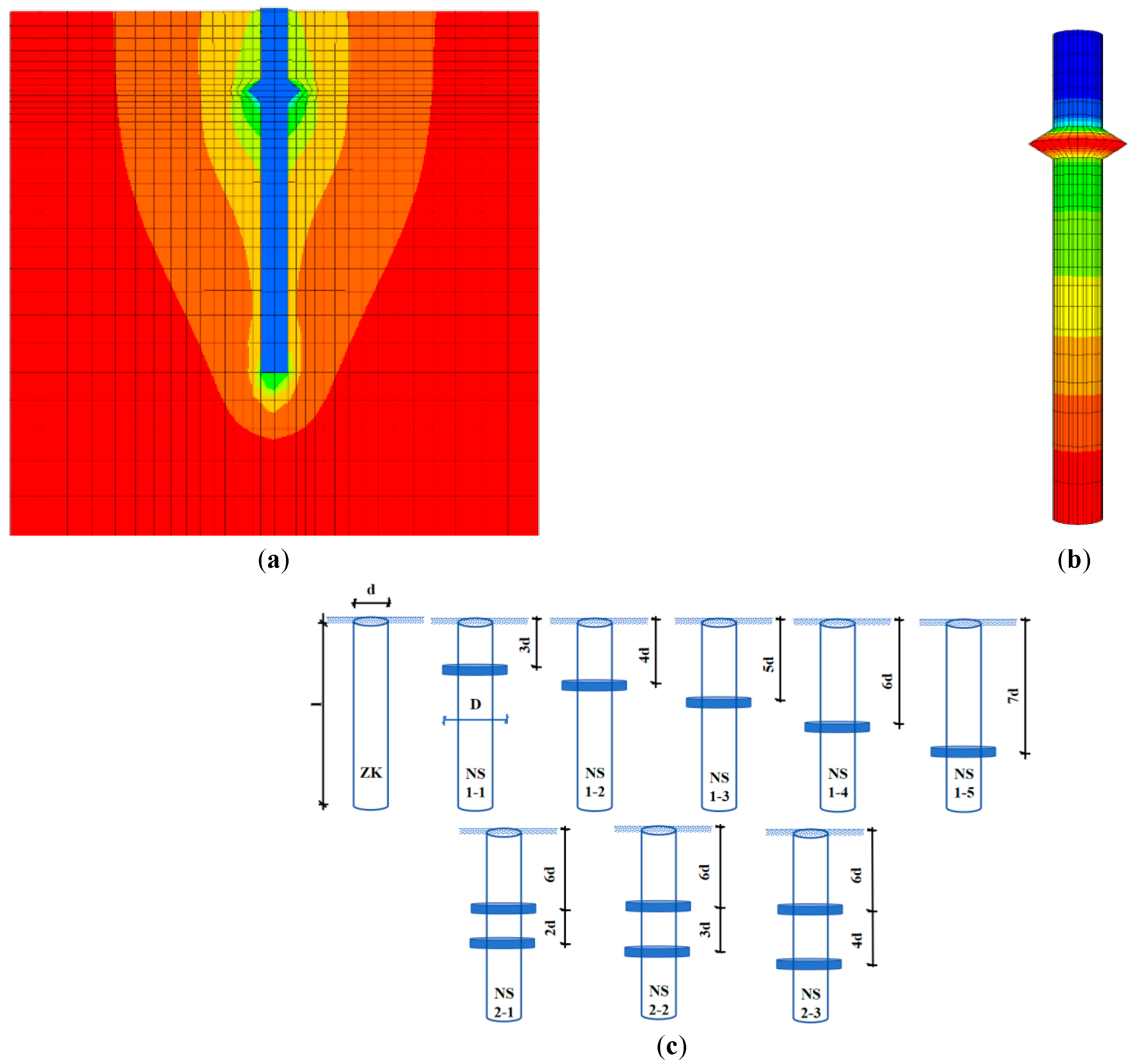

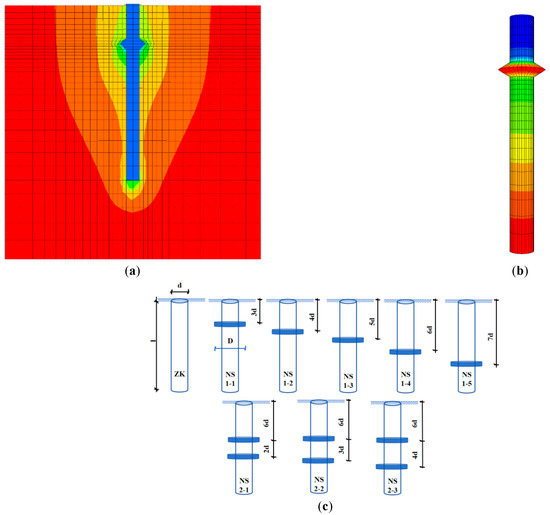

To validate against physical laboratory model test results and precisely characterize the bearing behavior of squeezed branch piles under combined horizontal load, this study developed numerical models for both single-plate and double-plate pile configurations. The models were constructed with the following geometric parameters: pile diameter d = 800 mm, pile length l = 12,000 mm, bearing plate height h = 700 mm, and plate diameter D = 1600 mm. Numerical simulations were conducted following the methodology outlined in Table 3 and Figure 4c.

Table 3.

Numerical model computation scheme.

Figure 4.

Figures of numerical model piles; (a) pile–soil mesh diagram; (b) pile mesh; (c) schematics of various pile types.

The numerical simulation was established using the Finite Difference Method. The pile and soil were discretized into quadrilateral elements, with interface elements inserted at their contact. The pile–soil interface parameters are illustrated in Table 4. The analysis adopted the Mohr–Coulomb constitutive model and simulated a homogeneous silty clay deposit, neglecting the influence of groundwater. The material parameters for the soil and pile, detailed in Table 5 [31], were assigned accordingly. The model was first subjected to different horizontal forces, followed by the progressive application of vertical loads to simulate combined loading conditions, while the response of the surrounding ground strata was monitored.

Table 4.

Pile–soil interface parameter table.

Table 5.

Pile and soil parameter table.

3. Results and Discussion

This section systematically compares physical laboratory model test results with numerical simulations to elucidate the load-bearing characteristics and deformation patterns of squeezed branch piles under combined horizontal and uplift loading. The study not only validates the reliability of the numerical model but, more importantly, leverages the mutual verification between both approaches to deepen the understanding of pile–soil interaction mechanisms. It further clarifies the influence of key parameters, such as bearing plates and embedment depth, on the overall performance of the pile foundation.

3.1. Results of Laboratory Model Test

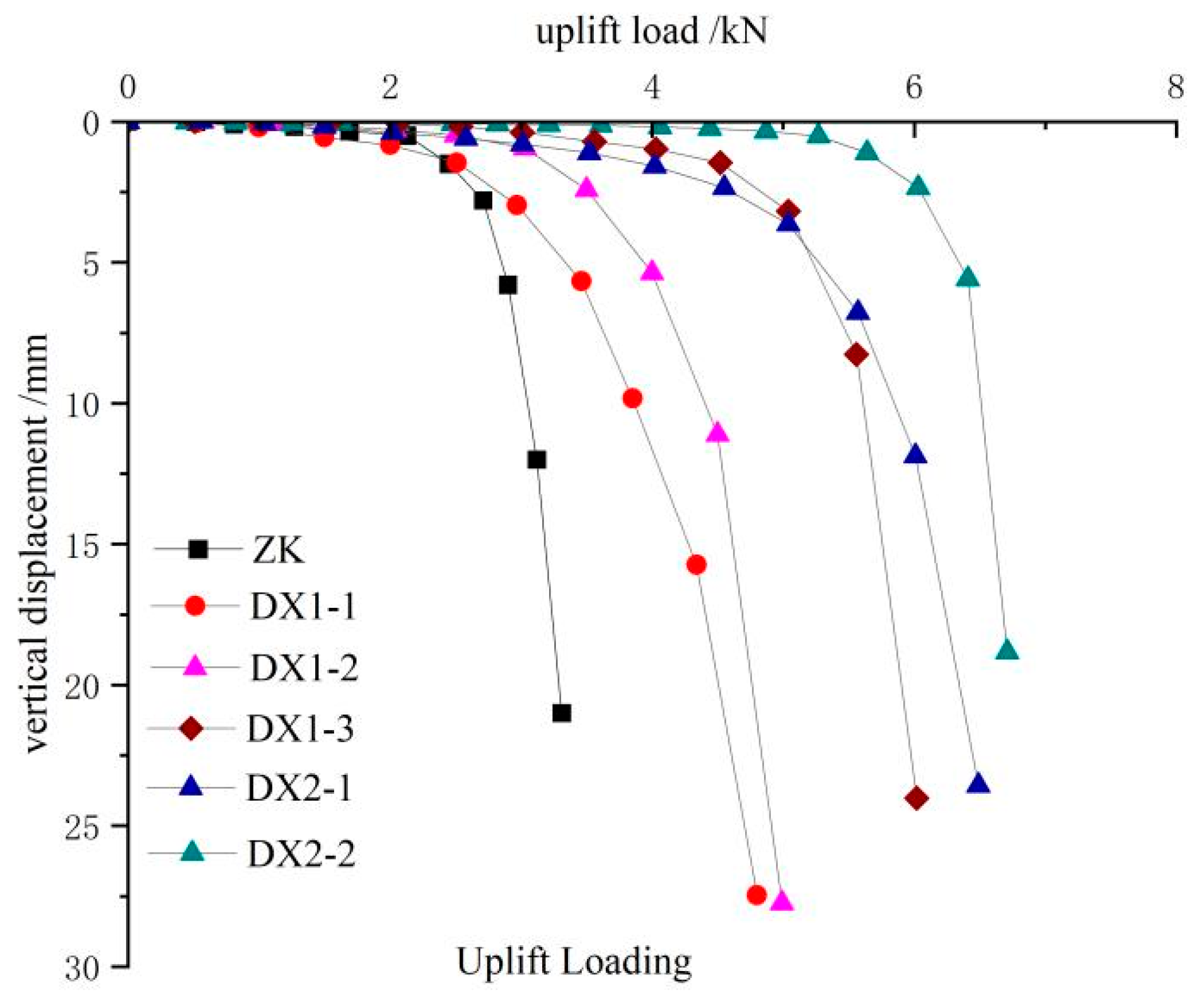

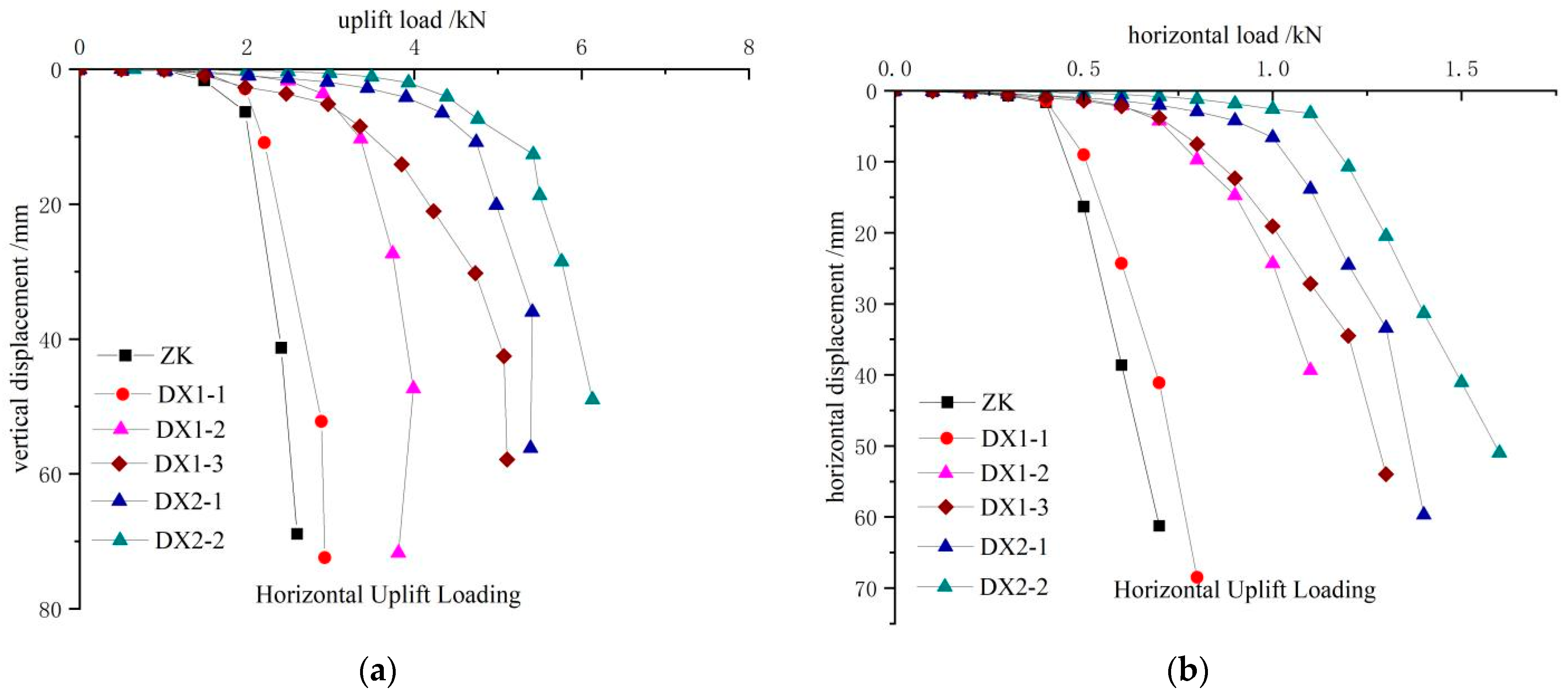

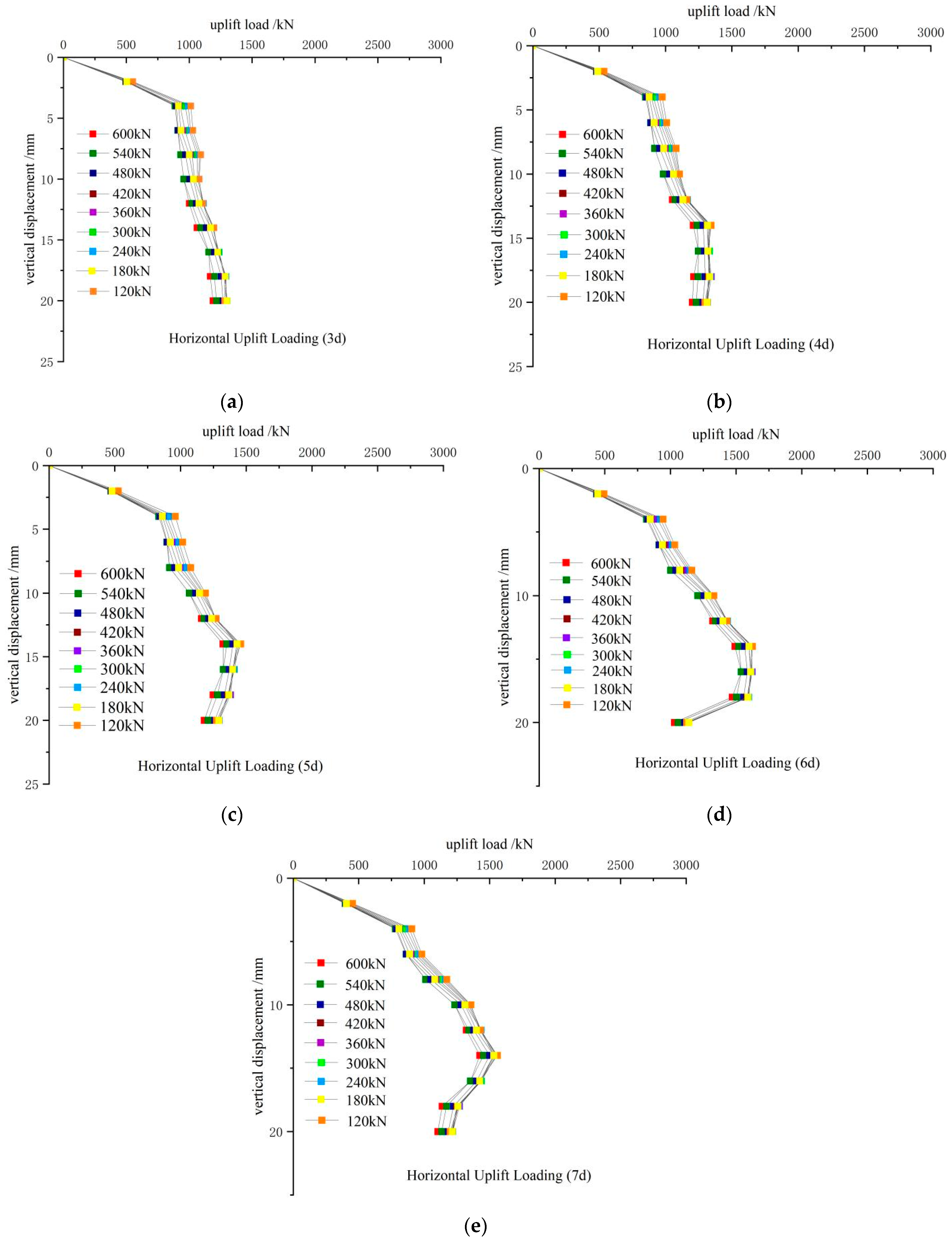

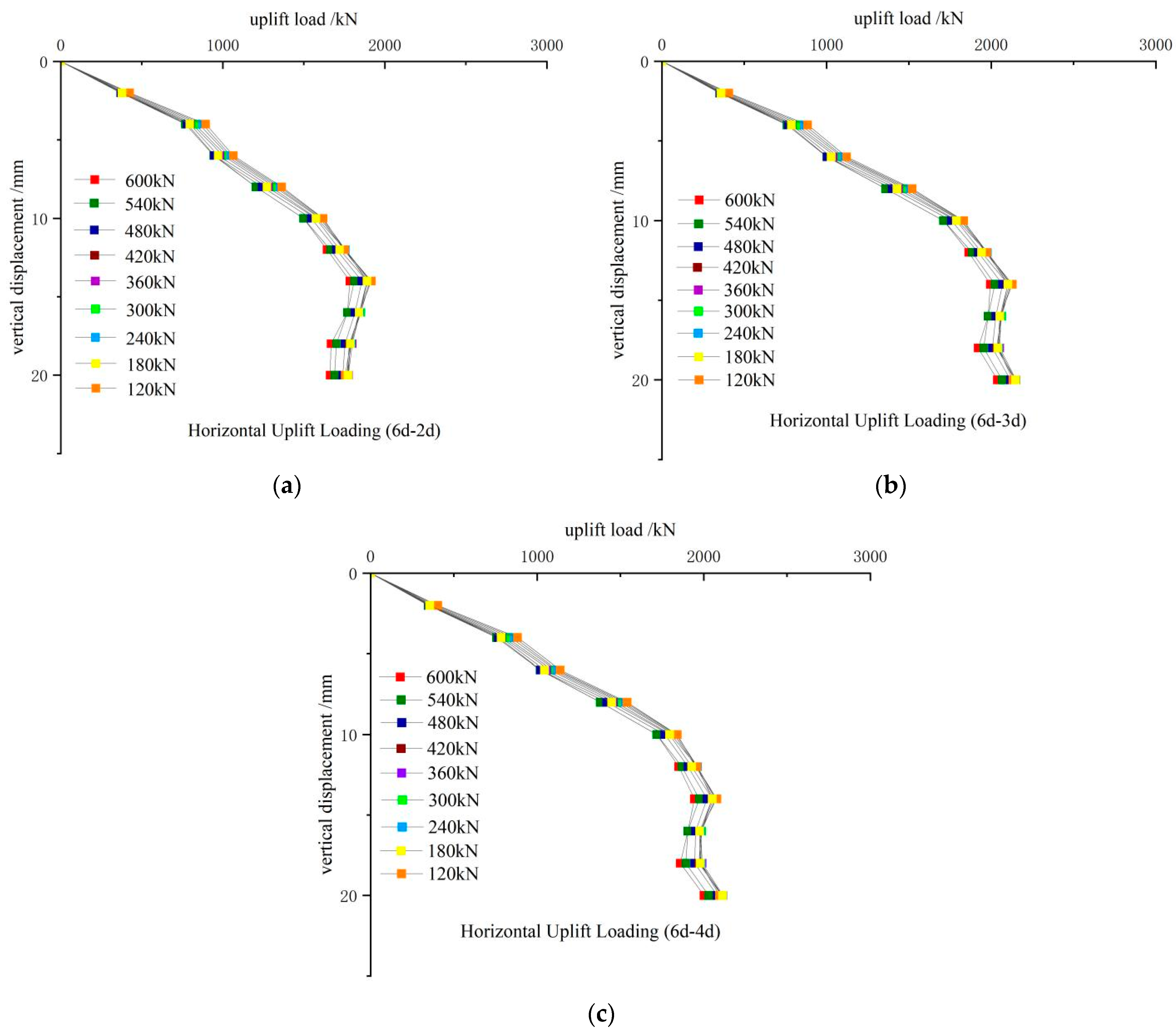

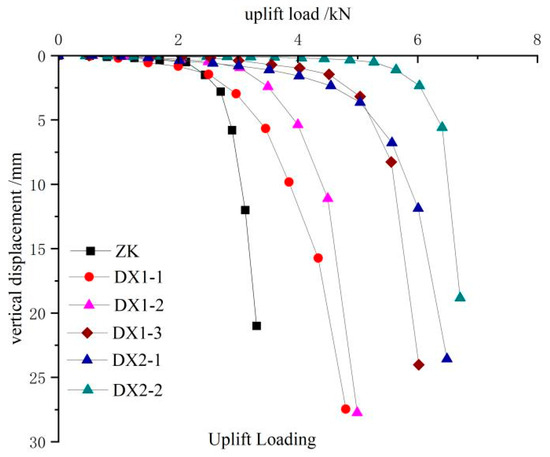

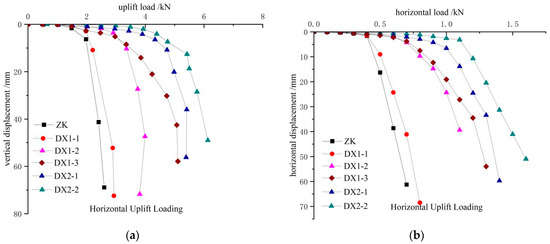

The test data after consolidation reveal the displacement curve under uplift loading, as shown in Figure 5, and the load–displacement curve under horizontal–uplift loading, as illustrated in Figure 6.

Figure 5.

Load–displacement curve under uplift loading.

Figure 6.

Load–displacement curve under horizontal + uplift loading. (a) Uplift load–displacement curve; (b) horizontal load–displacement curve.

As shown in Figure 5 and Figure 6, the presence of horizontal load reduces the vertical bearing capacity of the pile. The ultimate load of each pile type is determined using the rate of settlement method [32], revealing that the deformation behavior under combined loading is consistent with that under single loading conditions. In all cases, the squeezed branch pile demonstrates superior bearing capacity compared to the straight-shaft pile.

Specifically, under pure uplift loading, the uplift capacity of the single-branch pile is 45–82% higher than that of the straight-shaft pile, while the double-plate pile shows an improvement of 96–103%. Under combined loading, the improvements are 37–156% for the single-plate pile and 173–191% for the double-plate pile.

Moreover, the vertical capacity of the straight-shaft pile decreases by approximately 40% due to the horizontal load. For squeezed branch piles, the reduction in vertical capacity ranges between 14% and 40%. Further analysis indicates that as the burial depth of the branches increases, both the uplift and horizontal bearing capacities of the squeezed branch piles improve. Additionally, under the same burial depth conditions, a larger plate spacing enhances the uplift capacity. These observations confirm that the behavior of squeezed branch piles under combined loading remains consistent with that under single loading conditions.

3.2. Results of Numerical Simulation

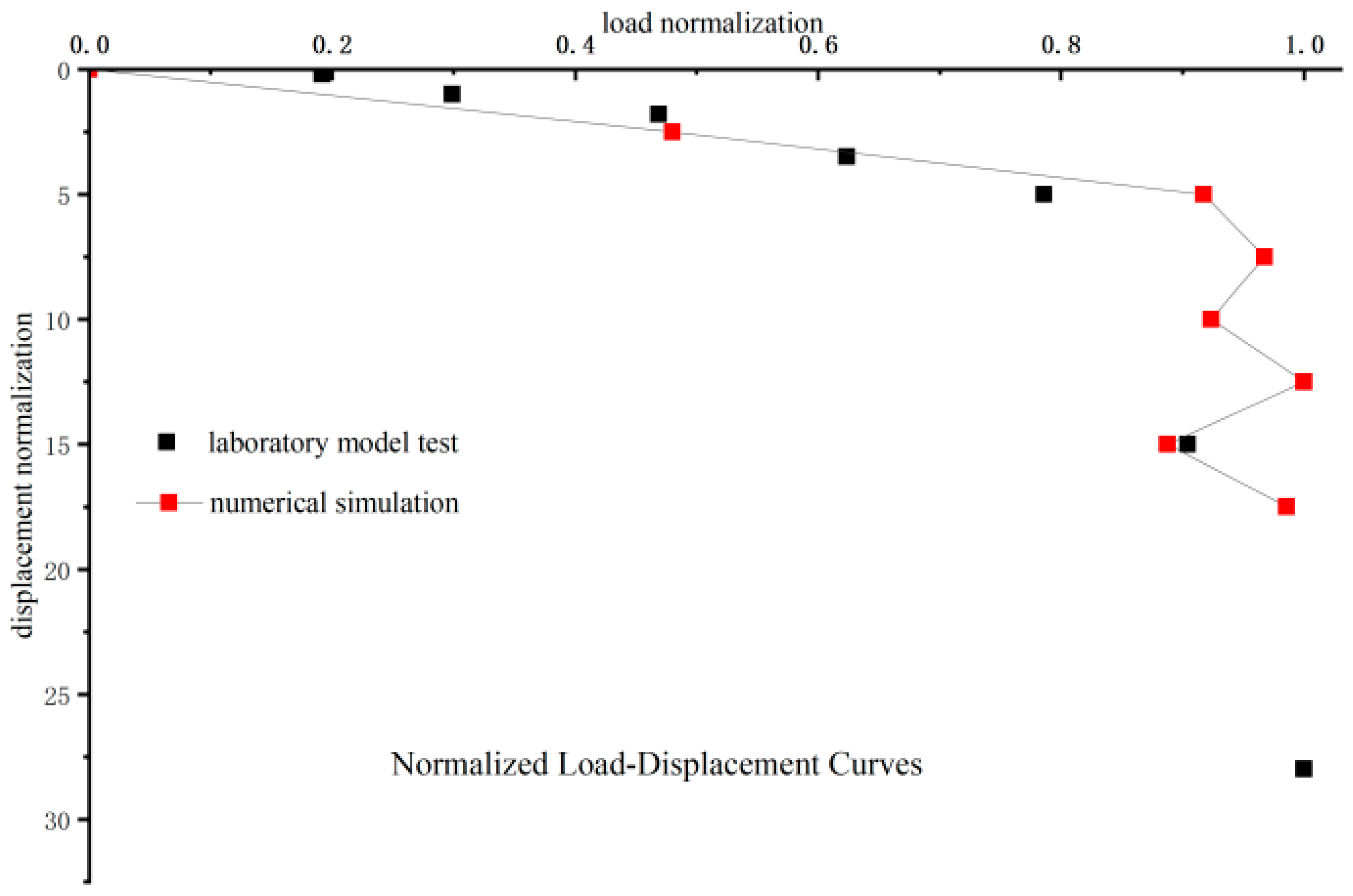

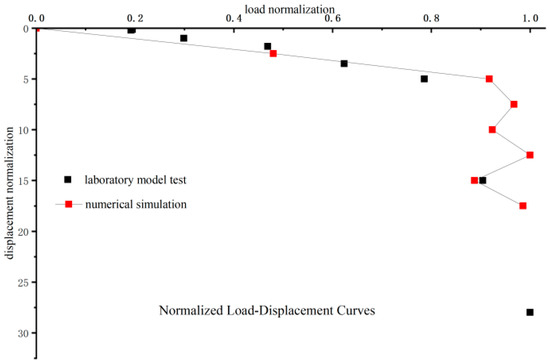

To validate the reliability of the laboratory model test and numerical simulation results, experimental and simulation data of straight-shaft piles under uplift loading were selected. To eliminate the influence of scale effects, the data were normalized: the load was converted into a dimensionless parameter by dividing it by the ultimate load, while the displacement was standardized by dividing it by the pile diameter. The normalized load–displacement curves from both approaches were compared, as shown in Figure 7. The comparative analysis indicates that within the ultimate bearing capacity range, the normalized numerical simulation curves agree well with the experimental curves. Although certain discrepancies exist between the numerical simulation conditions and the actual field conditions and testing environment, the comparison results still demonstrate the rationality and applicability of the numerical model adopted in this study.

Figure 7.

Comparison of load–displacement curves from finite element analysis and laboratory model test.

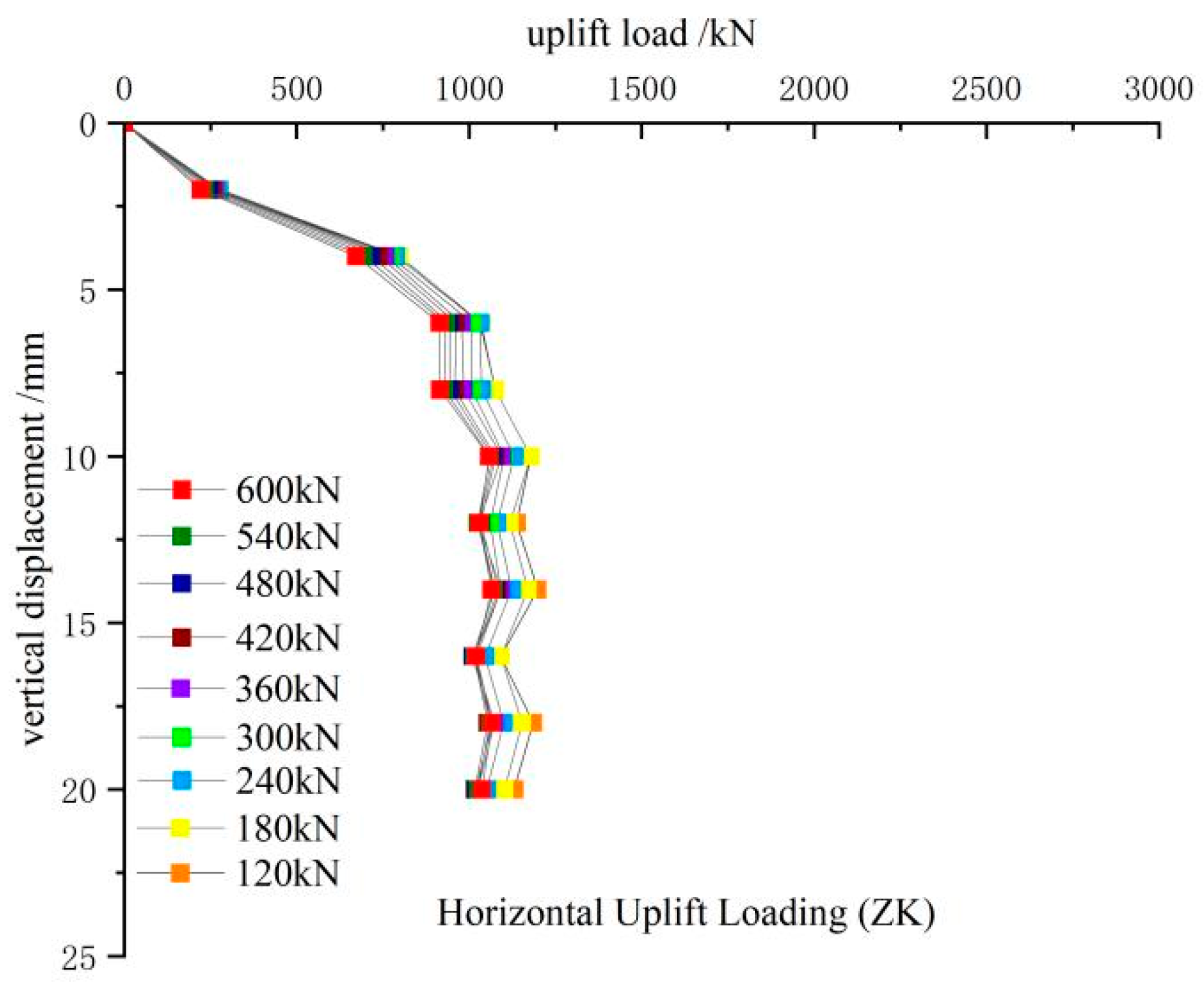

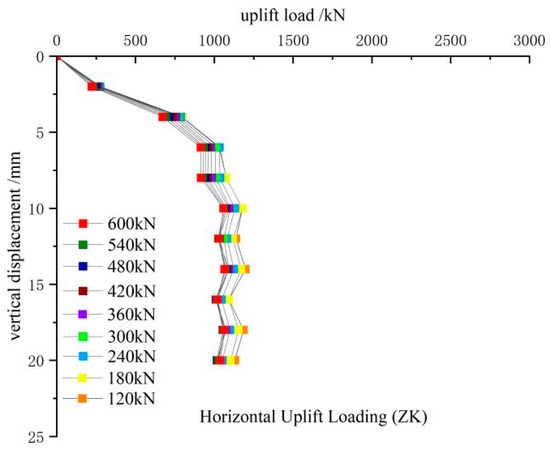

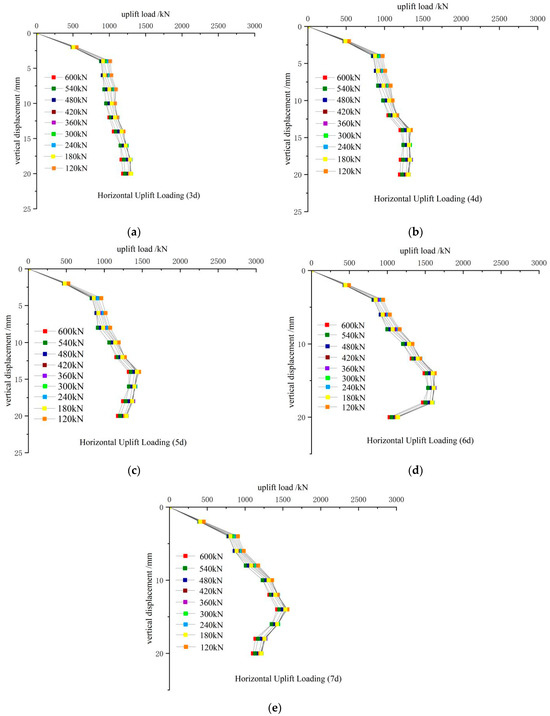

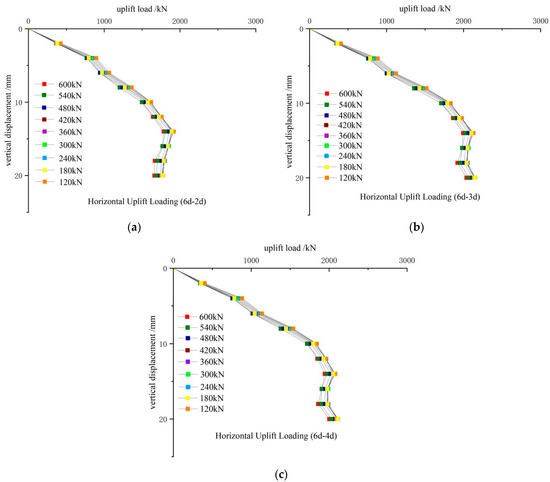

The figures below (Figure 8, Figure 9 and Figure 10) present the numerical simulation results of different pile types (including straight-shaft piles, single-plate piles, and double-plate piles) under composite loading conditions. As shown in the figure, the bearing behavior of the piles under combined loading is generally consistent with that under single loading conditions: the overall bearing capacity of branched piles is significantly superior to that of straight-shaft piles, while the bearing performance of double-plate piles exceeds that of single-plate piles. Further analysis indicates that the bearing capacity of branched piles gradually increases with the embedment depth of the first plate, reaching its maximum value at a depth of 6 times the straight-shaft pile diameter (6 d). Similarly, for double-plate piles, the bearing capacity also shows an increasing trend with larger plate spacing.

Figure 8.

Load–displacement curve of ZK under horizontal + uplift loading.

Figure 9.

Load–displacement curve under horizontal + uplift loading. (a) Load–displacement curve of NS1-1; (b) load–displacement curve of NS1-2; (c) load–displacement curve of NS1-3; (d) load–displacement curve of NS1-4; (e) load–displacement curve of NS1-5.

Figure 10.

Load–displacement curve under horizontal + uplift loading. (a) Load–displacement curve of NS2-1; (b) load–displacement curve of NS2-2; (c) load–displacement curve of NS2-3.

Table 6 further lists the ultimate bearing capacities of various pile types under different horizontal loads. Analysis reveals a clear trend in the influence of horizontal load on the vertical bearing performance of the piles: the greater the horizontal load, the more significant the reduction in uplift bearing capacity. At the same time, squeezed branched piles exhibit a certain resistance to interference, as the rate of bearing capacity reduction gradually decreases with increasing embedment depth, also reaching an optimal resistance state at 6 d. Additionally, double-plate piles demonstrate greater stability throughout the loading process, with an overall lower rate of bearing capacity reduction compared to single-plate piles.

Table 6.

Uplift bearing capacity of piles under different horizontal loads.

These results systematically verify the significant bearing advantages of branched piles, particularly double-plate piles, under complex loading conditions.

3.3. Comparison with Similar Results

To contextualize this research within a broader academic framework, a comparative analysis was conducted with selected representative studies covering typical pile types and research methodologies. Given the variations in soil conditions and geometric parameters, direct comparison of absolute bearing capacity values offers limited insight. Therefore, this section focuses on comparing the overall evolutionary patterns of the load–displacement curves and the influence mechanisms of horizontal loads on vertical bearing capacity. This approach serves to validate the reliability of the model used in this study and highlight its distinctive value in elucidating the underlying bearing mechanisms.

3.3.1. The Overall Shape of the Load–Displacement Curve

According to [33], “Analysis of the Response of Squeezed Branched Piles Under Inclined Uplift Loading,” the load–displacement curve corresponding to a first disc embedment depth of 6d and a disc spacing of 4d shows that, compared to the curve under pure uplift loading, the inflection point under combined horizontal–uplift loading is significantly less pronounced—a trend consistent with the curve results obtained in this study. The underlying reason is that the presence of horizontal load alters the soil–pile interaction mechanism, shifting the failure mode from shear failure to a ductile and progressive failure. This also indicates that the ultimate load of the pile under combined loading cannot be accurately determined by the simple inflection point method.

3.3.2. The Influence Mechanisms of Horizontal Loads on Vertical Bearing Capacity

According to the in-depth analysis in the same study, a significant load coupling effect is observed in piles under combined horizontal–uplift loading. Specifically, an increase in the horizontal load component systematically reduces the uplift capacity of the pile, and this reduction becomes more pronounced with greater horizontal loads. The pattern revealed in that study aligns closely with the conclusions drawn in this study, thereby providing independent validation of the reliability and generalizability of the findings presented here.

4. Conclusions

This paper systematically investigates the bearing characteristics of squeezed branch piles and straight-shaft piles in silty clay strata under complex loading conditions through model tests and numerical simulations. The following innovative conclusions are drawn:

- Superiority of Bearing Mechanism

Squeezed branch piles maintain their advantage over straight-shaft piles of the same diameter, demonstrating significantly higher bearing capacity. Their load-bearing mechanism shifts from the pure shaft friction reliance of straight-shaft piles to a composite mechanism involving both branch bearing pressure and shaft friction. This results in higher bearing efficiency and stability.

- Optimization Law of Key Design Parameters

This study clarifies the quantitative relationship between key design parameters of branch piles and their bearing performance under combined loading.

Optimal Depth of the First Branch: The depth of the first branch significantly influences the bearing capacity, with an optimal value existing. Under the conditions of this study, the vertical bearing capacity peaks when the depth is 6 d (where d is the straight-shaft pile diameter). At this depth, the weakening effect of horizontal load on the bearing capacity is minimized.

Positive Effect of Branch Spacing: For squeezed branch piles, increasing the spacing between branches effectively enhances the bearing capacity and significantly reduces the decay rate of capacity due to load coupling under combined loading. This proves that rationally configuring multiple branches fully utilizes their spatial synergistic effect.

- Unique Response and Shift in Failure Mode Under Combined Loading

This research reveals fundamental behavioral changes in branch piles under combined loading.

“Smoothing” of Load–Displacement Curves: Unlike the distinct inflection point observed at the ultimate load under single loading conditions, the load–displacement curves under combined loading exhibit a smoother transition. This indicates that the traditional “inflection point method” is no longer suitable for determining the ultimate bearing capacity under combined horizontal–uplift loading.

Quantification of Load-Coupling Effects: A significant coupled weakening effect exists between horizontal and uplift forces. Straight-shaft piles are most sensitive to this, with a maximum reduction in bearing capacity reaching 20%. However, by optimizing the depth of the first branch (e.g., to 6 d) and increasing the branch spacing, squeezed branch piles can effectively mitigate this coupled weakening effect, minimizing the reduction rate and highlighting their robust performance against complex loading.

In summary, this study not only verifies the superior performance of squeezed branch piles in resisting combined horizontal–uplift loads but also, more importantly, by revealing their “smoothed” mechanical response, the limitations of traditional evaluation methods, and the optimization mechanisms of key design parameters (first branch depth, branch spacing), provides a crucial theoretical basis and design guidance for the scientific design and application of squeezed branch piles under complex loading conditions.

Author Contributions

Conceptualization, T.D., K.P. and Z.H.; methodology, T.D., K.P. and Z.H.; software, T.D., K.P., Z.H. and P.H.; validation, T.D., K.P. and Z.H.; formal analysis, T.D., K.P., P.H. and Z.H.; investigation, T.D., K.P., P.H. and Z.H.; resources, T.D., K.P. and Z.H.; data curation, T.D., K.P. and P.H.; writing—original draft preparation, T.D., K.P., P.H. and Z.H.; visualization, T.D., K.P., P.H. and Z.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquires can be directed to the corresponding author.

Conflicts of Interest

Author Kun Peng is employed by the Powerchina Jiangxi Electric Power Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Gao, X.J.; Zhu, X.R. Theory Research and Engineering Application of Branched Piles; Science Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Pu, C.P.; He, W.B.; He, Z.Y.; Li, H.Z. Correlation Analysis Between Extrusion and Expansion Pressure and Influence Factors. Highw. Eng. 2025, 50, 246–253. [Google Scholar]

- Wang, X.F. Analysis of Vertical Bearing Capacity and Design and Construction Points of Squeezed Expansion Branch Pile. Mod. Eng. Technol. 2024, 3, 61–64. (In Chinese) [Google Scholar]

- Loseva, E.; Lozovsky, I.; Zhostkov, R. Refining Low Strain Pile Integrity Testing for Minor Flaw Detection with Complex Wavelet Transform. Civ. Eng. J. 2024, 10, 3194–3207. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Song, M.; Zhao, J.; Bai, J. Uplift Bearing Capacity of Squeezed Branch Pile Group. Geotech. Geol. Eng. 2022, 41, 283–293. [Google Scholar] [CrossRef]

- Li, X.; Li, G.W.; Zhou, Y.; He, G.J. Experimental and Analytical Investigation of the Bearing Capacity of Bulbs for Squeezed Branch Piles. Int. J. Geomech. 2023, 23, 1–10. [Google Scholar]

- Wang, D.H.; Ju, Y.Z.; Zhao, X.P.; Bai, J.F. Field Test and Numerical Simulation on Bearing Capacity of Squeezed Branch Pile in Transmission Line. Mechanika 2017, 23, 762–768. [Google Scholar] [CrossRef]

- Qian, Y.M.; Zhang, J.Y.; Wang, R.Z.; Tian, W. Experimental study on influence of disc number on soil failure state of concrete expanded-plate pile under horizontal force in oceanographic engineering. J. Coast. Res. 2020, 106, 660–663. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, H.; Hu, Z.; Wang, L.; Chen, X. The Calculation Method for the Horizontal Bearing Capacity of Squeezed Branch Piles Considering the Plate-Soil Nonlinear Interaction. Appl. Sci. 2023, 13, 13229. [Google Scholar] [CrossRef]

- Qian, Y.; Qi, D.; Mou, Y.; Wang, X.; Wang, Z.; Sun, L.; Ma, Z. Analysis of the Influence of Bearing Plate Position on the Uplift Bearing Capacity of Low-Header CEP Single-Pile Foundations. Buildings 2025, 15, 1353. [Google Scholar] [CrossRef]

- Qian, Y.M.; Fang, B.H.; Jin, Y.J.; Wang, R.Z. Experimental study on effect of disc spacing on soil failure state of expanded pile under the action of horizontal force and application in oceanographic engineering. J. Coast. Res. 2020, 36, 283–287. [Google Scholar] [CrossRef]

- Qian, D.L.; Tang, H.M. Pile-made Mechanism and Practical Prospects of Squeezed Branch Pile. Bull. Geol. Sci. Technol. 2000, 19, 89–92. [Google Scholar]

- Pan, C.S. The Application and Research of Squeezed Branch Pile in Collapsible Loess Area. Shaanxi Archit. 2025, 25–33. [Google Scholar]

- Zhang, M.X.; Xu, P.; Cui, W.J.; Gao, Y.B. Bearing Behavior and Failure Mechanism of Squeezed Branch Piles. J. Rock Mech. Geotech. Eng. 2018, 10, 935–946. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Y.; Chen, Y.; Qiu, S.; Yi, H.; Yang, J. Investigation of the Axial-Bearing Mechanism of Single and Group Squeezed Branch Piles in Soft Soil Combining Field Measurements and Numerical Modeling. Int. J. Geomech. 2025, 25, 04025225. [Google Scholar] [CrossRef]

- Lin, C.; Wang, R.; Huang, M.; Huang, L.; Tan, Q. Study on Disturbance Mechanism of Squeezed and Non-Squeezed Soil Piles on Soft Soil Foundation. Appl. Sci. 2023, 13, 7757. [Google Scholar] [CrossRef]

- Zhang, M.X.; Cui, W.J.; Xu, P.; Niu, Y.J. Research on Soil Displacement Field around the Squeezed Branch Pile under Vertical Load. Chin. J. Rock Mech. Eng. 2017, 36, 3569–3577. [Google Scholar]

- Xie, H.; Wang, M.; Tian, Y.; Ren, Y.; Zhou, Z. Numerical Analysis of Bearing and Settlement Characteristics of Squeezed Branch Piles. J. Archit. Civ. Eng. 2025, 42, 197–206. [Google Scholar]

- Yu, H.; Qian, Y.M.; Niu, L.; Li, Z.J. Research on Influence of Disc Cantilever Diameter on Pullout Bearing Capacity of Concrete Expanded-plate Double Piles. Build. Struct. 2023, 53, 147–151. [Google Scholar]

- Li, Y.H.; Gao, X.J.; Zhong, G.H. Model Test and Finite Element Analysis of Squeezed and Branch Pile Bared Vertical and Horizontal Loads. Appl. Mech. Mater. 2013, 470, 1101–1104. [Google Scholar] [CrossRef]

- Ghalib, Z.H.; Mahmood, M.R. The Behavior of Enlarged Base Pile Under Compression and Uplift Loading in Partially Saturated Sand. Civ. Eng. J. 2024, 10, 3240–3252. [Google Scholar] [CrossRef]

- Ali, M.M.; Abrar, M.M.; Abiduzzaman, M.; Deb Nath, S. Numerical Analysis of Soil-Pile Interface Properties of Bored Pile Embedded in Silty Clay Soils. Baiust Acad. J. 2023. [Google Scholar] [CrossRef]

- Bhujade, R.P.; Dhatrak, A.I.; Thakare, S.W. Numerical Assessment of Squeezed Branch Pile in Silty Clay Soil. Int. J. Eng. Adv. Technol. 2020, 9, 2210–2216. [Google Scholar] [CrossRef]

- Gao, X.J.; Wang, J.C.; Zhu, X.R. Static load test and load transfer mechanism study of squeezed branch and plate pile in collapsible loess foundation. J. Zhejiang Univ.-Sci. 2007, 8, 1110–1117. [Google Scholar] [CrossRef]

- Han, W.F.; Feng, B.B.; Zhou, J.; Lu, C.Y. The study on the engineering properties of squeezed branch piles under combined load. Adv. Civ. Ind. Eng. IV 2014, 580–583, 371. [Google Scholar] [CrossRef]

- Lu, C.Y.; Meng, F.L.; Wang, L. Model Test Study on Squeezed Branch Piles. Rock Soil Mech. 2004, 11, 1809–1813. [Google Scholar]

- He, L.; Ma, Q.S. Discussion on the Uplift Failure Mode and Calculation Formula of the Cast-in-place Pile with Expanded Bells. Build. Struct. 2019, 49, 841–845. [Google Scholar]

- JGJ 94-2008; Technical Code for Building Pile Foundations. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2008.

- JGJ 106-2014; Technical Code for Testing of Building Foundation Piles. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2014.

- DL/T 5219-2005; Technical Regulation for Designing Foundation of Overhead Transmission Line. National Energy Administration: Beijing, China, 2005.

- Wang, X.B.; Wen, S.L.; Xu, W.Q. Sensitivity Analysis of Interface Parameters of Large-diameter Long Pile. J. Yangtze River Sci. Res. Inst. 2011, 2, 38–44,55. [Google Scholar]

- Xu, Z.L. Design and Construction of Squeezed Branch Piles; China Standard Press: Beijing, China, 2011. [Google Scholar]

- Kong, L.; Jiang, L.; Chen, R.; Fan, J.; Lin, G.; Chen, Y. Analysis of the Response of Squeezed Branched Piles Under Inclined Uplift Loading. Chin. J. Appl. Mech. 2013, 30, 228–233. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).