Optimization of Mechanical Properties and Shrinkage Resistance of Ternary-Hybrid-Fiber-Reinforced Geopolymer Concrete Using Simplex-Centroid Design

Abstract

1. Introduction

2. Experimental Program

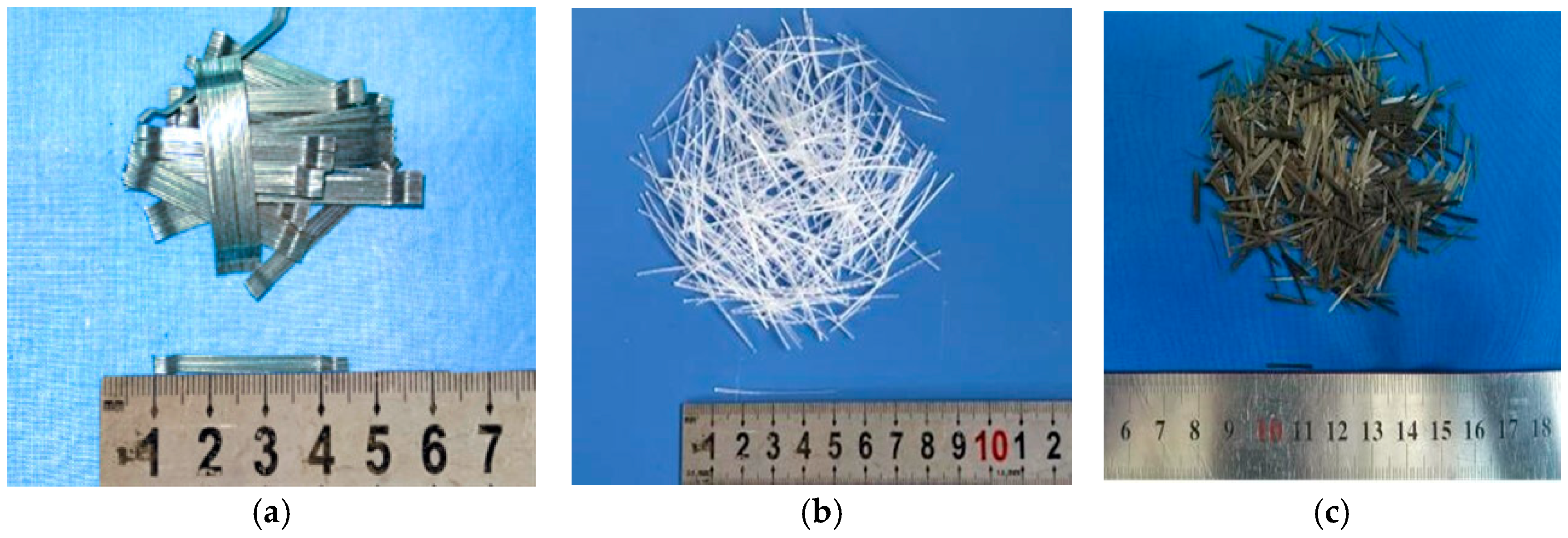

2.1. Materials

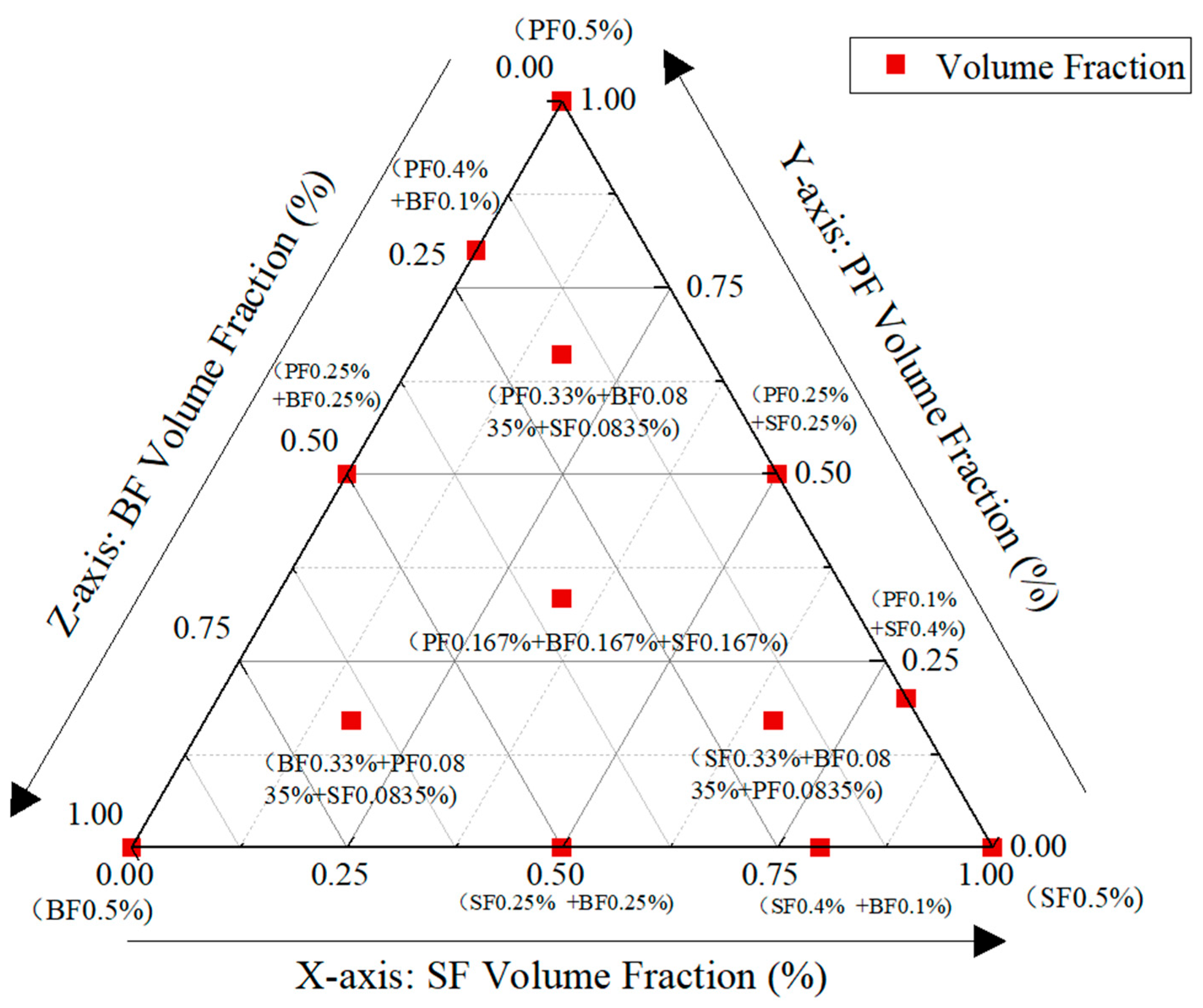

2.2. Specimen Preparation

2.3. Test Methods

2.3.1. Compressive Strength Test

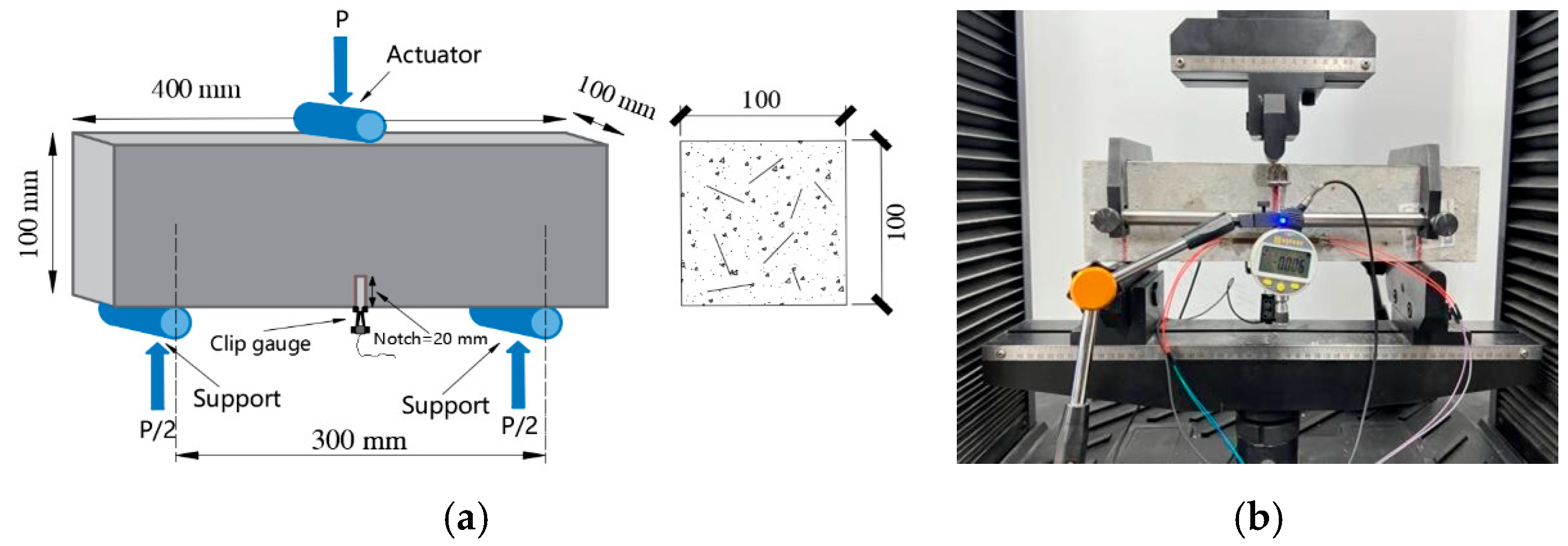

2.3.2. Three-Point Bending Test

2.3.3. Early-Age Shrinkage Test

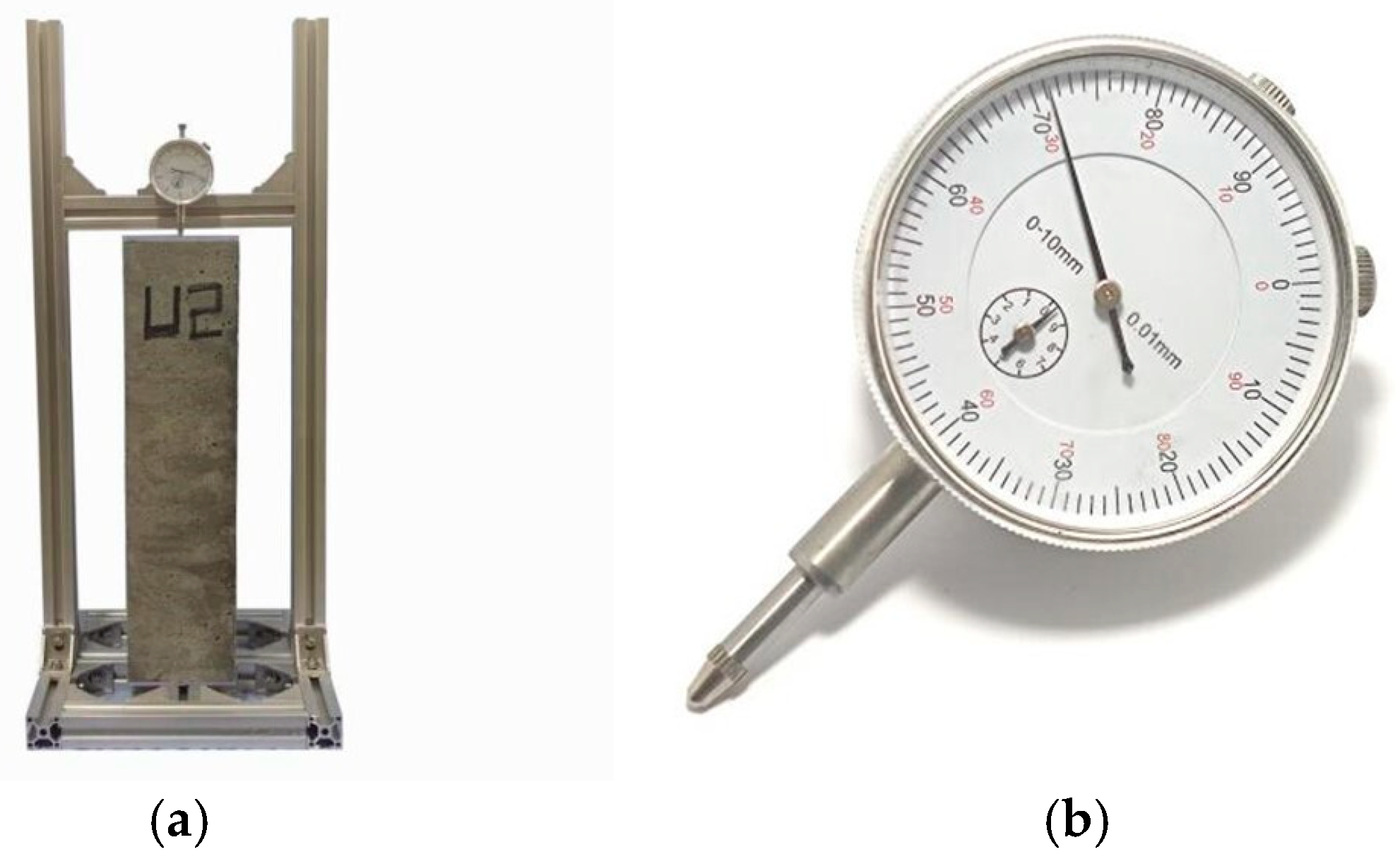

2.3.4. SEM Microstructural Analysis

3. Results and Discussion

3.1. Analysis of Compressive Strength in FRGPC

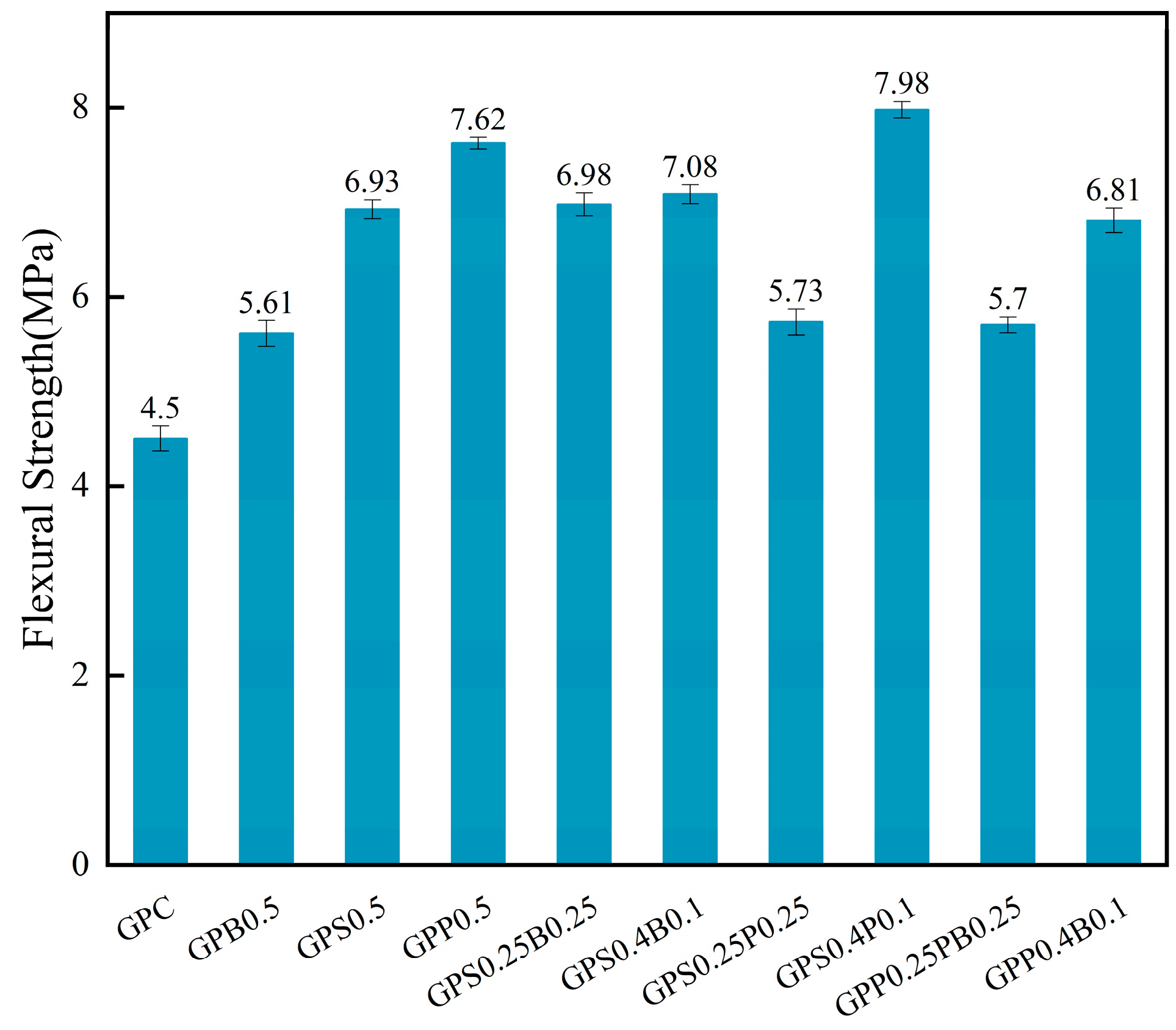

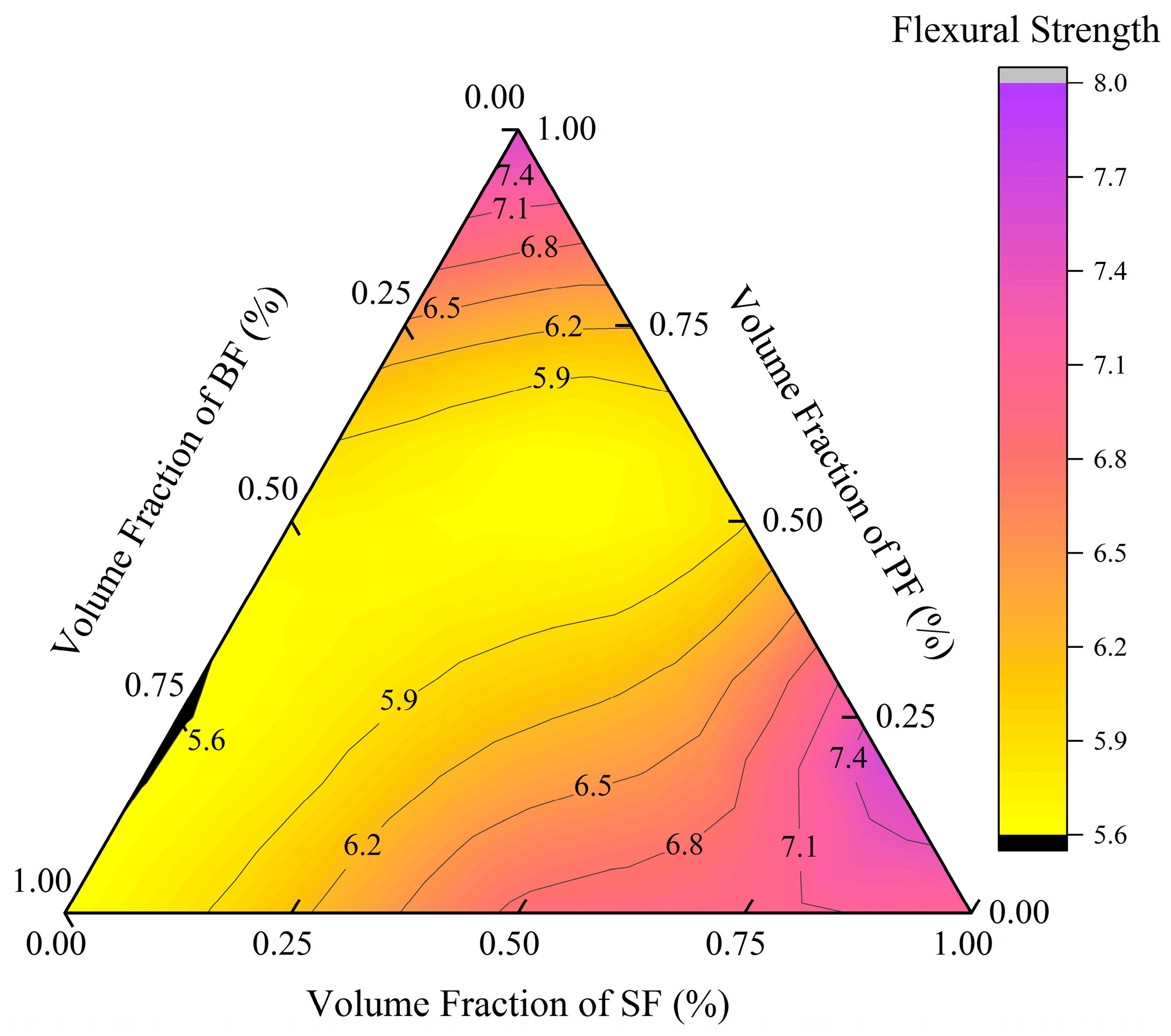

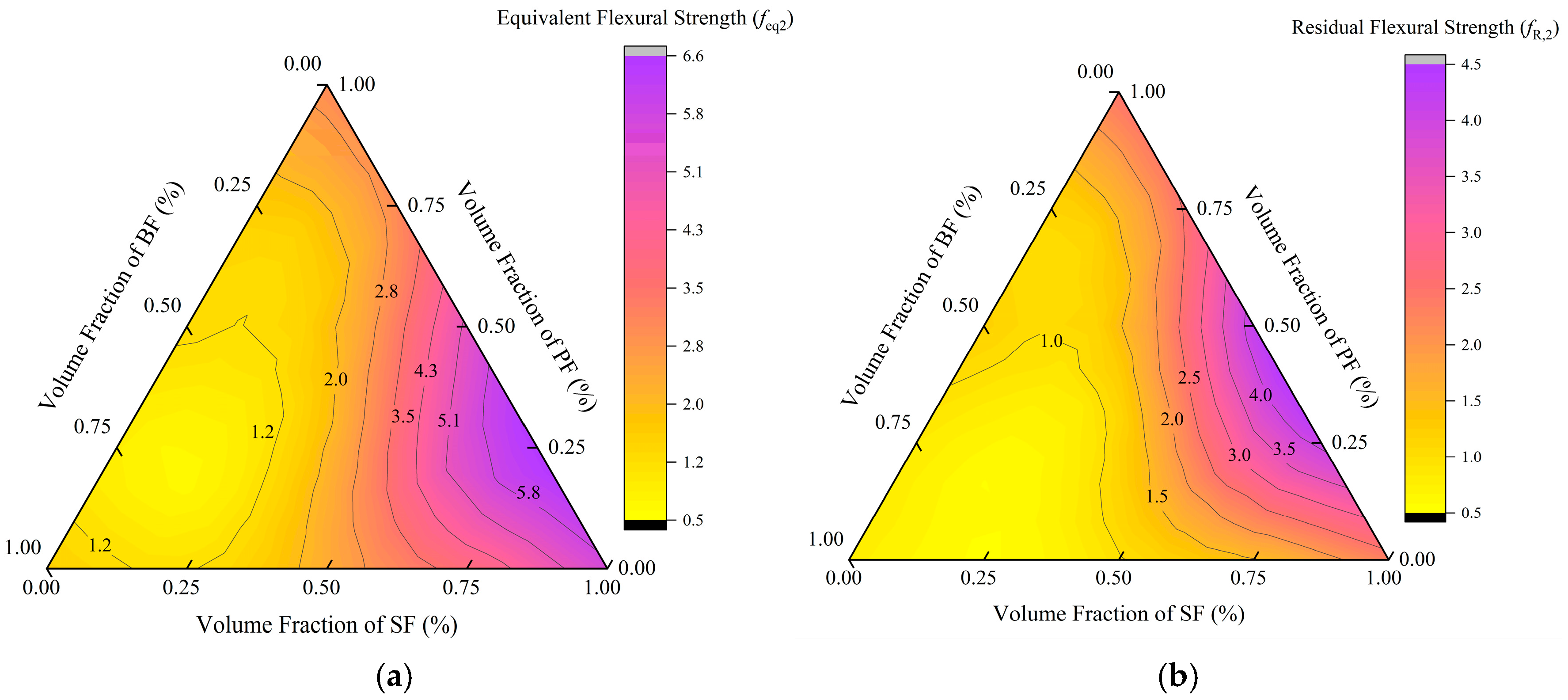

3.2. Effect of Fibers on the Flexural Strength of GPC

3.3. Effect of Fibers on the Load–Deflection Curve of GPC

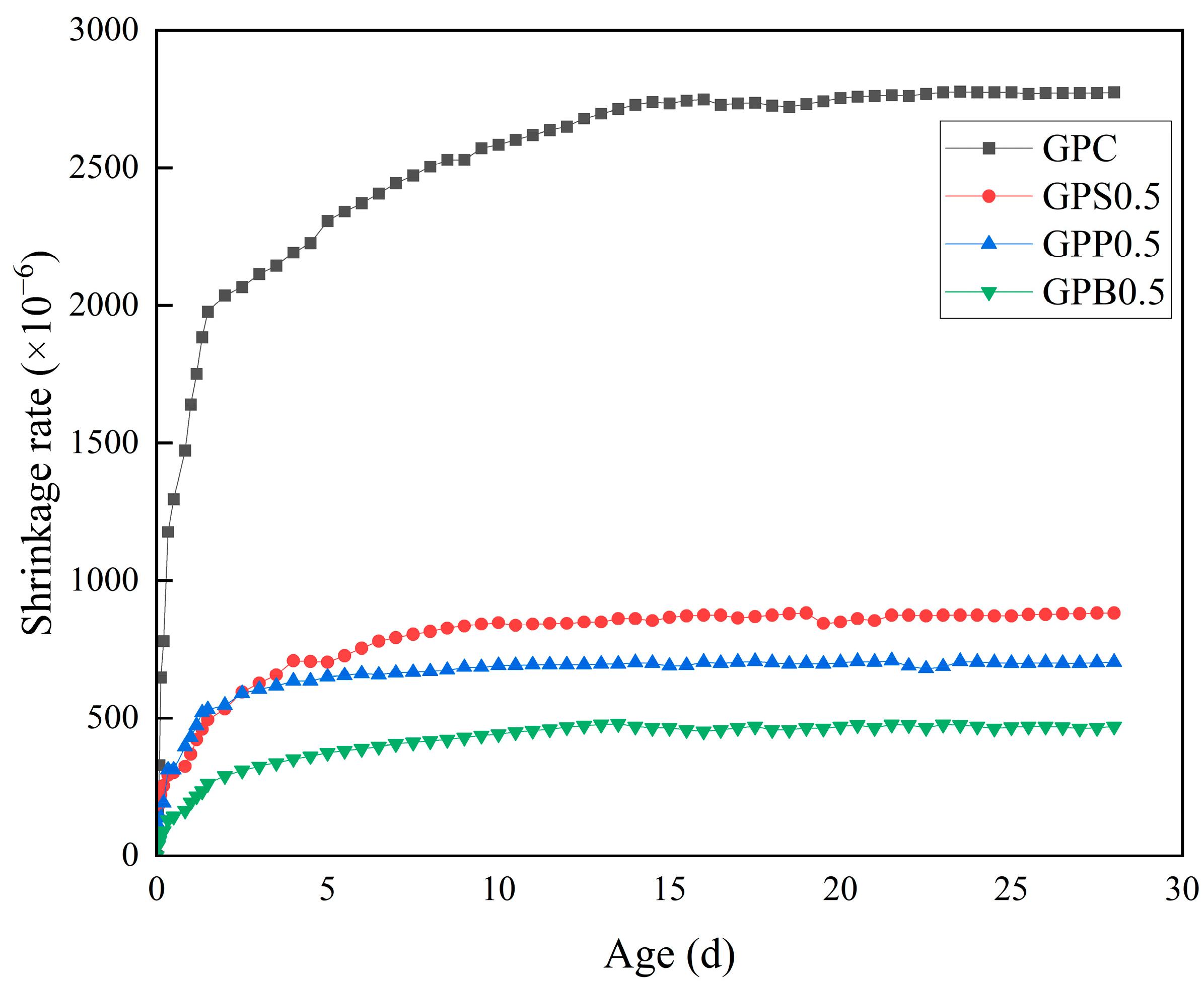

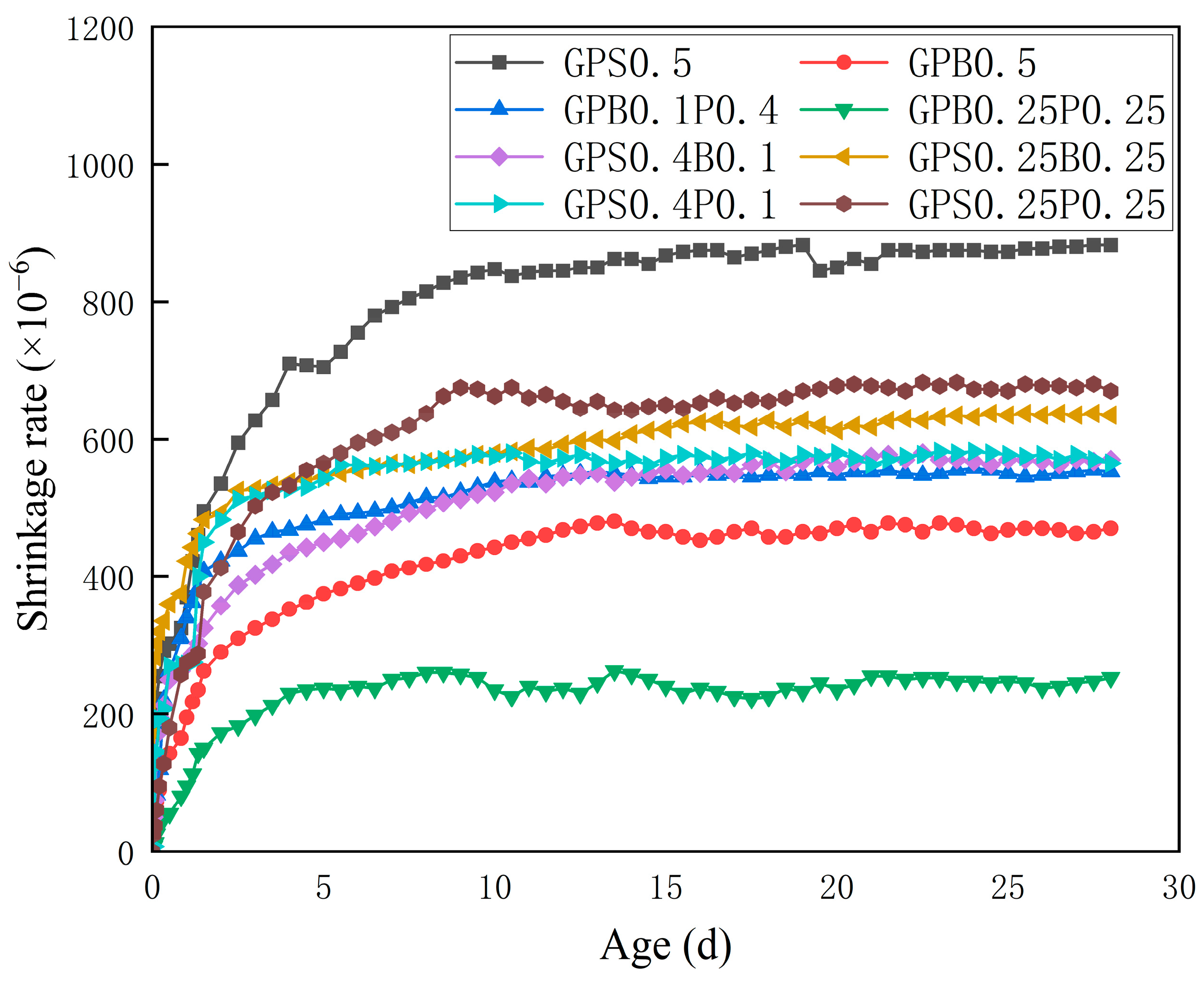

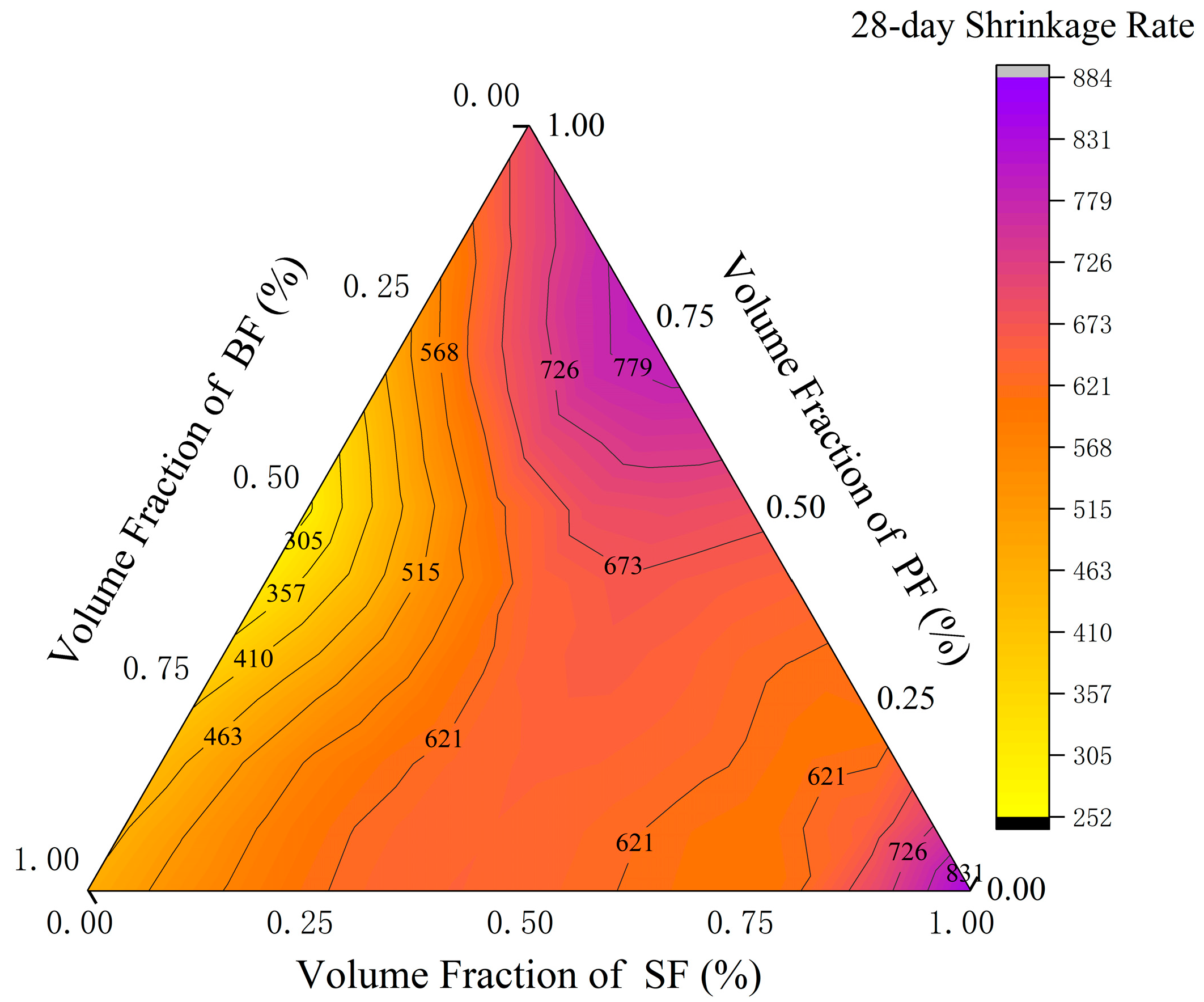

3.4. Effect of Fibers on Early-Age Shrinkage of GPC

3.5. Fiber Microscopic Reinforcement Mechanism

3.6. Determination of the Optimal Mix Proportion

4. Conclusions

- The hybrid-fiber system demonstrated a significant positive synergistic effect. The binary SF-PF combination yielded the most comprehensive improvement, with the optimal specimen (GPS0.4P0.1) achieving a 36.8% increase in compressive strength and a 77.3% increase in flexural strength; this composite also exhibited superior flexural toughness.

- All the fibers studied effectively inhibited early-age shrinkage in geopolymer concrete. Among them, the PF-BF binary system demonstrated the best inhibition effect through a synergistic “rigid–flexible composite restraint” mechanism, reducing the shrinkage rate by 90.9%. The optimized ternary hybrid formulation successfully achieved a balance between good mechanical performance and significant shrinkage suppression.

- Quantitative regression models reveal the interactions among SF, PF, and BF, as well as their influence on material properties. The combination of SF and PF shows a positive synergistic effect, improving mechanical strength and toughness, whereas combining PF and BF results in a negative synergistic effect.

- Microscopic analysis revealed that the synergy stems from complementary, stage-specific mechanisms—BF bridges microcracks, PF enhances toughness through plastic deformation after fracture, and SF resists macrocrack propagation through pull-out—collectively improving the overall durability and toughness of GPC.

- Contour overlay analysis identified the optimal formulation range, i.e., satisfying all target properties, for the ternary fiber composite. The recommended fiber volume fractions are steel fiber ≥55%, polypropylene fiber 13–46%, and basalt fiber 25–68%. Within this range, the fibers work synergistically, leading to a composite characterized by high strength, high toughness, and low shrinkage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Del Rio, D.D.F.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the cement and concrete industry: A systematic review of socio-technical systems, technological innovations, and policy options. Renew. Sustain. Energy Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Xu, J.; Guan, Y.; Oldfield, J.; Guan, D.; Shan, Y. China carbon emission accounts 2020–2021. Appl. Energy 2024, 360, 122837. [Google Scholar] [CrossRef]

- Han, X.; Zhang, P.; Zheng, Y.; Wang, J. Utilization of municipal solid waste incineration fly ash with coal fly ash/metakaolin for geopolymer composites preparation. Constr. Build. Mater. 2023, 403, 133060. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Das, S.; Saha, P.; Jena, S.P.; Panda, P. Geopolymer concrete: Sustainable green concrete for reduced greenhouse gas emission–A review. Mater. Today Proc. 2022, 60, 62–71. [Google Scholar] [CrossRef]

- Van Deventer, J.S.J.; Provis, J.L.; Duxson, P. Technical and commercial progress in the adoption of geopolymer cement. Miner. Eng. 2012, 29, 89–104. [Google Scholar] [CrossRef]

- Zhou, X.; Shen, J. Micromorphology and microstructure of coal fly ash and furnace bottom slag based light-weight geopolymer. Constr. Build. Mater. 2020, 242, 118168. [Google Scholar] [CrossRef]

- Su, L.; Fu, G.; Liang, B.; Sun, Q.; Zhang, X. Mechanical properties and microstructure evaluation of fly ash-Slag geopolymer foaming materials. Ceram. Int. 2022, 48, 18224–18237. [Google Scholar] [CrossRef]

- Oderji, S.Y.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: Effect of slag and alkali activators. J. Clean. Prod. 2019, 225, 1–10. [Google Scholar] [CrossRef]

- Thunuguntla, C.S.; Rao, T.G. Effect of mix design parameters on mechanical and durability properties of alkali activated slag concrete. Constr. Build. Mater. 2018, 193, 173–188. [Google Scholar] [CrossRef]

- Abdellatief, M.; Abd Elrahman, M.; Abadel, A.A.; Wasim, M.; Tahwia, A. Ultra-high performance concrete versus ultra-high performance geopolymer concrete: Mechanical performance, microstructure, and ecological assessment. J. Build. Eng. 2023, 79, 107835. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Ghiassi, B.; Yin, S.; Ye, G. Fracture properties and microstructure formation of hardened alkali-activated slag/fly ash pastes. Cem. Concr. Res. 2021, 144, 106447. [Google Scholar] [CrossRef]

- Maganty, S.T.; Subramaniam, K.V. Efficiency of Steel Fibers in Geopolymer and Portland Cement Concrete: Comparative Evaluation of Fiber Bonding and Crack Bridging Stress. Cem. Concr. Compos. 2025, 159, 105988. [Google Scholar] [CrossRef]

- Xing, X.; Wang, B.; Luo, S.; Lin, F.; Wei, J.; Xu, W.; Hu, J.; Yu, Q. Preparation and formation mechanism of high-toughness organic polymers modified geopolymers. Cem. Concr. Compos. 2024, 150, 105578. [Google Scholar] [CrossRef]

- Khan, S.U.; Ayub, T. PET fiber–reinforced engineered geopolymer and cementitious composites. J. Mater. Civ. Eng. 2022, 34, 06021010. [Google Scholar] [CrossRef]

- Wallah, S.; Rangan, B.V. Low-Calcium Fly Ash-Based Geopolymer Concrete: Long-Term Properties; Curtin University of Technology: Bentley, Australia, 2006; p. 108. [Google Scholar]

- Collins, F.; Sanjayan, J.G. Effect of pore size distribution on drying shrinking of alkali-activated slag concrete. Cem. Concr. Res. 2000, 30, 1401–1406. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Ye, G. Drying Shrinkage of Alkali-Activated Slag and Fly Ash Concrete; A Comparative Study with Ordinary Portland Cement Concrete. Available online: https://repository.tudelft.nl/record/uuid:a3dd27c0-6815-4307-b6f6-527e4eeea83d (accessed on 1 February 2019).

- Bernal, S.A.; Provis, J.L.; Brice, D.G.; Kilcullen, A.; Duxson, P.; Van Deventer, J.S. Accelerated carbonation testing of alkali-activated binders significantly underestimates service life: The role of pore solution chemistry. Cem. Concr. Res. 2012, 42, 1317–1326. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Luo, W.; Zhou, W. Effects of adding nano-TiO2 on compressive strength, drying shrinkage, carbonation and microstructure of fluidized bed fly ash based geopolymer paste. Constr. Build. Mater. 2016, 106, 115–125. [Google Scholar] [CrossRef]

- Zhang, W.; Xue, M.; Lin, H.; Duan, X.; Jin, Y.; Su, F. Effect of polyether shrinkage reducing admixture on the drying shrinkage properties of alkali-activated slag. Cem. Concr. Compos. 2023, 136, 104865. [Google Scholar] [CrossRef]

- Zhang, L.V.; Suleiman, A.R.; Allaf, M.M.; Marani, A.; Tuyan, M.; Nehdi, M.L. Crack self-healing in alkali-activated slag composites incorporating immobilized bacteria. Constr. Build. Mater. 2022, 326, 126842. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Corrosion performance and strain behavior of reinforced concrete: Effect of natural pozzolan as partial substitute for microsilica in concrete mixtures. Structures 2025, 79, 109397. [Google Scholar] [CrossRef]

- Kasaniya, M.; Thomas, M.D.A.; Moffatt, E.G. Pozzolanic reactivity of natural pozzolans, ground glasses and coal bottom ashes and implication of their incorporation on the chloride permeability of concrete. Cem. Concr. Res. 2021, 139, 106259. [Google Scholar] [CrossRef]

- Ganesh, A.C.; Muthukannan, M. Development of high performance sustainable optimized fiber reinforced geopolymer concrete and prediction of compressive strength. J. Clean. Prod. 2021, 282, 124543. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jyothsna, G.; Sofi, A.; Shanmugam, V.; Thomas, B. A comprehensive review on the use of natural fibers in cement/geopolymer concrete: A step towards sustainability. Case Stud. Constr. Mater. 2023, 19, e02244. [Google Scholar] [CrossRef]

- Ansari, M.A.; Shariq, M.; Mahdi, F. Influence of fibres characteristics on the engineering properties of geopolymer concrete-a review. Mater. Today Proc. 2023, 93, 12–19. [Google Scholar] [CrossRef]

- Ma, J.; Yuan, H.; Zhang, J.; Zhang, P. Enhancing concrete performance: A comprehensive review of hybrid fiber reinforced concrete. Structures 2024, 64, 106560. [Google Scholar] [CrossRef]

- Zhang, H.; Sarker, P.K.; Wang, Q.; He, B.; Jiang, Z. Comparative fracture properties of ambient-cured geopolymer concrete containing four different fibers in mono and hybrid combinations using digital image correlation. J. Build. Eng. 2024, 89, 109288. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Akhmetov, D.; Akhazhanov, S.; Jetpisbayeva, A.; Pukharenko, Y.; Root, Y.; Utepov, Y.; Akhmetov, A. Effect of low-modulus polypropylene fiber on physical and mechanical properties of self-compacting concrete. Case Stud. Constr. Mater. 2022, 16, e00814. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, K.; Lin, B.; Yao, Y. The enhancement mechanism of modified basalt fiber on the performance of geopolymer concrete. Constr. Build. Mater. 2024, 417, 135123. [Google Scholar] [CrossRef]

- Xu, J.; Kang, A.; Wu, Z.; Xiao, P.; Gong, Y. Effect of high-calcium basalt fiber on the workability, mechanical properties and microstructure of slag-fly ash geopolymer grouting material. Constr. Build. Mater. 2021, 302, 124089. [Google Scholar] [CrossRef]

- Li, L.; Shu, W.; Xu, H.; Rui, X.; Wang, Z.; Zeng, Y.; Jia, S.; Chen, T.; Zhu, Z. Experimental study on flexural toughness of fiber reinforced concrete beams: Effects of cellulose, polyvinyl alcohol and polyolefin fibers. J. Build. Eng. 2024, 81, 108144. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pongsopha, P.; Chindaprasirt, P.; Songpiriyakij, S. Flexural performance and toughness of hybrid steel and polypropylene fibre reinforced geopolymer. Constr. Build. Mater. 2018, 161, 37–44. [Google Scholar] [CrossRef]

- Smarzewski, P.; Barnat-Hunek, D. Property assessment of hybrid fiber-reinforced ultra-high-performance concrete. Int. J. Civ. Eng. 2018, 16, 593–606. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Zhang, Z.; Zhu, D.; Hwang, H.-J.; Zhu, Y.; Sun, T. A mixture proportioning method for the development of performance-based alkali-activated slag-based concrete. Cem. Concr. Compos. 2018, 93, 163–174. [Google Scholar] [CrossRef]

- Scheffe, H. The simplex-centroid design for experiments with mixtures. J. R. Stat. Soc. Ser. B (Methodol.) 1963, 25, 235–251. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, P.; Sha, F.; He, S.; Lu, G.; Yu, Z.; Chen, H. Preparation and performance of the ultra-high performance mortar based on simplex-centroid design method. J. Mater. Res. Technol. 2021, 15, 3060–3077. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y. Mixture design of concrete using simplex centroid design method. Cem. Concr. Compos. 2018, 89, 76–88. [Google Scholar] [CrossRef]

- GB/T50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- CECS:13-2009; Standard test methods for fiber reinforced concrete. China Planning Press: Beijing, China, 2010. (In Chinese)

- Vandewalle, L.; Nemegeer, D.; Balázs, G.L.; Barr, B. RILEM TC 162-TDF: Test and design methods for steel fibre reinforced concrete: Bending test. Mater. Struct. 2000, 33, 3–5. [Google Scholar]

- Yassin, A.M.; Mohie Eldin, M.; Hafez, M.A.; Elnaggar, M.A. The Flexural Behavior and Mechanical Properties of Super High-Performance Concrete (SHPC) Reinforced Using the Hybridization of Micro Polypropylene and Macro Steel Fibers. Buildings 2024, 14, 1887. [Google Scholar] [CrossRef]

- Xu, J.; Pi, Z.; Huang, S.; Liu, Y.; Chen, Z.; Shen, Y. Hybrid Effect of Basalt and Polyacrylonitrile Fibers on Physico-Mechanical Properties of Tailing Mortar. Buildings 2024, 14, 639. [Google Scholar] [CrossRef]

- Ma, L.; Zhen, C.; Zeng, Q.; Li, B. Experimental Investigation on the Mechanical Properties of Geopolymer Recycled Aggregate Concrete Reinforced with Steel-Polypropylene Hybrid Fiber. Buildings 2025, 15, 1723. [Google Scholar] [CrossRef]

- Liang, N.; Hu, G.; Zhou, K.; Liu, X.; Zhou, X. Study on early-age cracking resistance of multi-scale polypropylene fiber reinforced concrete in restrained ring tests. J. Sustain. Cem.-Based Mater. 2024, 13, 1050–1062. [Google Scholar] [CrossRef]

- Liu, R.; Zhao, S.; Sun, S.; Cui, Y. Experimental study of the mechanical properties and microstructure of basalt fiber-reinforced concrete. J. Mater. Civ. Eng. 2023, 35, 04023205. [Google Scholar] [CrossRef]

- Ren, G.; Gao, X.; Zhang, H. Utilization of hybrid sisal and steel fibers to improve elevated temperature resistance of ultra-high performance concrete. Cem. Concr. Compos. 2022, 130, 104555. [Google Scholar] [CrossRef]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Naaman, A.E.; Wongtanakitcharoen, T.; Hauser, G. Influence of different fibers on plastic shrinkage cracking of concrete. ACI Mater. J. 2005, 102, 49–58. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Compos. Part B Eng. 2019, 174, 107021. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Teng, S. Experiments on drying shrinkage and creep of high performance hybrid-fiber-reinforced concrete. Cem. Concr. Compos. 2020, 106, 103481. [Google Scholar] [CrossRef]

- Shen, Y.; Li, Q.; Huang, B.; Liu, X.; Xu, S. Effects of PVA fibers on microstructures and hydration products of cementitious composites with and without fly ash. Constr. Build. Mater. 2022, 360, 129533. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, P.; Sha, F.; Yu, Z.; He, S.; Xu, W.; Lv, M. Effects of Type and Content of Fibers, Water-to-Cement Ratio, and Cementitious Materials on the Shrinkage and Creep of Ultra-High Performance Concrete. Polymers 2022, 14, 1956. [Google Scholar] [CrossRef]

- Mashrei, M.; Sultan, A.M.; Mahdi, A. Effects of polypropylene fibers on compressive and flexural strength of concrete material. Int. J. Civ. Eng. Technol. 2018, 9, 2208–2217. [Google Scholar]

- Alhozaimy, A.M.; Soroushian, P.; Mirza, F. Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cem. Concr. Compos. 1996, 18, 85–92. [Google Scholar] [CrossRef]

- Lee, J.-H. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Qureshi, L.A.; Sheikh, M.I.; Sultan, T. Effect of Mixing Fiber Cocktail on Flexural Strength of Concrete. Procedia Eng. 2013, 54, 711–719. [Google Scholar] [CrossRef][Green Version]

- He, P.; Zhang, B.; Lu, J.-X.; Poon, C.S. A ternary optimization of alkali-activated cement mortars incorporating glass powder, slag and calcium aluminate cement. Constr. Build. Mater. 2020, 240, 117983. [Google Scholar] [CrossRef]

- Shi, C.; Jiao, D.; Zhang, J.; Wang, D.; Zhang, Y.; Farzadnia, N.; Hu, X. Design of high performance concrete with multiple performance requirements for #2 Dongting Lake Bridge. Constr. Build. Mater. 2018, 165, 825–832. [Google Scholar] [CrossRef]

- T/CCES49-2024; Standard for Design of Macro Fiber Reinforced Concrete Structures (In Chinese). China Architecture & Building Press: Beijing, China, 2024.

- Li, Z.; Liu, X.; Sun, G. Pore structure of fiber-reinforced geopolymer recycled concrete: Effects on mechanical properties and drying shrinkage. J. Build. Eng. 2025, 111, 112990. [Google Scholar] [CrossRef]

- Liu, Y.; Ren, Y.; Li, Q.; Shi, C. Influence of steel fiber hybridization on the static mechanical performance of ultra-high performance geopolymer concrete (UHPGC). Cem. Concr. Compos. 2025, 160, 106064. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | MgO | K2O | SO3 |

|---|---|---|---|---|---|---|---|---|

| FA | 62.04 | 25.50 | 4.28 | 4.01 | 0.46 | 1.27 | 2.04 | — |

| SL | 34.50 | 15.35 | 0.83 | 35.99 | — | 6.58 | 0.62 | 2.50 |

| Fiber Type | Length (mm) | Equivalent Diameter (mm) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| Hooked-end SF | 35 | 0.75 | 7.85 | 1100 | 200 |

| Textile-grade PF | 40 | 0.22 | 0.92 | 650 | 5 |

| Chopped BF | 12 | 0.0165 | 2.66 | 1140 | 93.1 |

| SL | FA | Sand | Coarse Aggregate | Sodium Silicate Solution | NaOH | Water |

|---|---|---|---|---|---|---|

| 400 | 100 | 660 | 1077 | 151.8 | 21.6 | 96.7 |

| Group ID | SF | BF | PF | Total Fiber |

|---|---|---|---|---|

| GPC | 0 | 0 | 0 | 0 |

| GPS0.5 | 39.25 | 0 | 0 | 39.25 |

| GPP0.5 | 0 | 0 | 4.65 | 4.65 |

| GPB0.5 | 0 | 13.30 | 0 | 13.30 |

| GPS0.25B0.25 | 19.63 | 6.65 | 0 | 26.28 |

| GPS0.4B0.1 | 31.40 | 2.66 | 0 | 34.06 |

| GPS0.25P0.25 | 19.63 | 0 | 2.33 | 21.96 |

| GPS0.4P0.1 | 31.40 | 0 | 0.93 | 32.33 |

| GPP0.25B0.25 | 0 | 6.65 | 5.81 | 12.46 |

| GPP0.4B0.1 | 0 | 2.66 | 3.72 | 6.38 |

| GPS0.33BP | 25.91 | 2.26 | 0.82 | 28.98 |

| GPSB0.33P | 6.67 | 0.79 | 8.78 | 16.24 |

| GPSBP0.33 | 6.67 | 2.26 | 3.07 | 12.00 |

| GPSBP0.167 | 13.11 | 4.44 | 1.55 | 19.10 |

| Specification Item | Technical Parameter |

|---|---|

| Maximum Rated Force (kN) | 100 |

| Minimum Test Speed (mm/min) | 0.001 |

| Position Resolution (mm) | 0.000017 |

| Maximum Specimen Length (mm) | 600 |

| Matrix ID | Compressive Strength (MPa) | Improvement Rate (%) | Matrix ID | Compressive Strength (MPa) | Improvement Rate (%) |

|---|---|---|---|---|---|

| GPC | 54.2 | 0 | GPS0.4P0.1 | 74.13 | 36.77 |

| GPS0.5 | 67.55 | 24.63 | GPP0.4B0.1 | 57.75 | 6.55 |

| GPP0.5 | 63.80 | 17.71 | GPP0.25B0.25 | 61.84 | 14.10 |

| GPB0.5 | 59.46 | 9.70 | GPS0.33BP | 68.30 | 26.01 |

| GPS0.25B0.25 | 69.34 | 27.93 | GPSB0.33P | 61.89 | 14.19 |

| GPS0.4B0.1 | 70.13 | 29.39 | GPSBP0.33 | 72.87 | 34.45 |

| GPS0.25P0.25 | 71.48 | 31.88 | GPSBP0.167 | 72.51 | 33.78 |

| Matrix ID | fL | fu | Df,2 | Df,3 | feq,2 | feq,3 | fR,2 | fR,3 |

|---|---|---|---|---|---|---|---|---|

| /MPa | /MPa | /kN·mm | /kN·mm | /MPa | /MPa | /MPa | /MPa | |

| GPC | 4.50 | 4.50 | — | — | — | — | — | — |

| GPS0.5 | 6.51 | 6.93 | 4.05 | 10.05 | 5.70 | 2.83 | 2.24 | 1.17 |

| GPB0.5 | 5.61 | 5.61 | 1.19 | 2.80 | 1.67 | 0.79 | 0.81 | — |

| GPP0.5 | 6.89 | 7.62 | 2.16 | 9.51 | 3.04 | 2.68 | 2.49 | 2.71 |

| GPS0.25B0.25 | 6.89 | 6.98 | 1.72 | 4.16 | 2.42 | 1.17 | 1.03 | 0.42 |

| GPS0.4B0.1 | 6.96 | 7.08 | 2.61 | 5.72 | 3.67 | 1.61 | 1.31 | 0.96 |

| GPS0.25P0.25 | 5.71 | 5.73 | 3.84 | 15.18 | 5.40 | 4.27 | 4.50 | 3.67 |

| GPS0.4P0.1 | 7.69 | 7.98 | 4.68 | 13.68 | 6.59 | 3.85 | 3.94 | 1.78 |

| GPP0.25B0.25 | 5.28 | 5.70 | 1.11 | 4.49 | 1.57 | 1.26 | 1.38 | 1.28 |

| GPP0.4B0.1 | 5.86 | 6.81 | 1.45 | 3.81 | 2.03 | 1.07 | 1.26 | — |

| GPSPB0.33 | 5.01 | 5.77 | 0.34 | 0.84 | 0.48 | 0.24 | 0.46 | — |

| GPS0.33PB | 6.49 | 6.52 | 4.18 | 10.32 | 5.87 | 2.90 | 3.14 | 0.99 |

| GPSP0.33B | 5.67 | 5.67 | 0.86 | 1.92 | 1.21 | 0.54 | 0.95 | — |

| GPSPB0.167 | 6.02 | 6.02 | 1.08 | 3.02 | 1.52 | 0.85 | 0.78 | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Ning, X.; Li, L.; Li, Y.; Jin, J.; Li, J.; Sun, R.; Ilunga wa Ngoy, T. Optimization of Mechanical Properties and Shrinkage Resistance of Ternary-Hybrid-Fiber-Reinforced Geopolymer Concrete Using Simplex-Centroid Design. Buildings 2025, 15, 3901. https://doi.org/10.3390/buildings15213901

Liu Z, Ning X, Li L, Li Y, Jin J, Li J, Sun R, Ilunga wa Ngoy T. Optimization of Mechanical Properties and Shrinkage Resistance of Ternary-Hybrid-Fiber-Reinforced Geopolymer Concrete Using Simplex-Centroid Design. Buildings. 2025; 15(21):3901. https://doi.org/10.3390/buildings15213901

Chicago/Turabian StyleLiu, Zhenyv, Xiliang Ning, Long Li, Yuanyuan Li, Jiahui Jin, Jianfeng Li, Ruiyang Sun, and Tracey Ilunga wa Ngoy. 2025. "Optimization of Mechanical Properties and Shrinkage Resistance of Ternary-Hybrid-Fiber-Reinforced Geopolymer Concrete Using Simplex-Centroid Design" Buildings 15, no. 21: 3901. https://doi.org/10.3390/buildings15213901

APA StyleLiu, Z., Ning, X., Li, L., Li, Y., Jin, J., Li, J., Sun, R., & Ilunga wa Ngoy, T. (2025). Optimization of Mechanical Properties and Shrinkage Resistance of Ternary-Hybrid-Fiber-Reinforced Geopolymer Concrete Using Simplex-Centroid Design. Buildings, 15(21), 3901. https://doi.org/10.3390/buildings15213901