Abstract

The growing demand for sustainable construction materials has intensified efforts to reduce the environmental impact of Portland cement. This study investigates the effect of partial substitution of cement with metakaolin (MK, 5–15 wt.%) and biosilica (BS, 5 wt.%) on the physical, mechanical, and microstructural properties of cementitious mortars. The influence of a polycarboxylate ether-based superplasticizer (Mf) and ultrasonic treatment (ULT) was also evaluated. The mortars were characterized through setting time, density, water absorption, flexural and compressive strength tests, as well as FTIR and SEM analyses. Water absorption decreased from 12.21% to 9.8%, indicating improved pore refinement and densification. Flexural strength of all modified mortars exceeded that of the control mix: from 10.0% to 89.9% at 7 days, and from 4.7% to 50.4% at 28 days. The compressive strength improved markedly with MK and BS incorporation, from 20.8% to 51.3% at 7 days and from 9.7% to 35.2% at 28 days compared to the control sample. FTIR and SEM results confirmed enhanced pozzolanic activity and formation of C–S–H gel. The synergistic use of MK, BS, and Mf—especially with ultrasonic dispersion—yielded denser, stronger, and more sustainable cementitious composites.

1. Introduction

Cement-based materials are fundamental to modern infrastructure; however, their environmental impact, particularly the significant CO2 emissions associated with Portland cement production, has led to extensive research into more sustainable alternatives [1,2,3]. Finding a substitute binding substance to replace Portland cement and enhance sustainability in construction is increasingly crucial as the demand for building materials continues to escalate. Research has been conducted to explore novel materials that could serve as alternatives to Portland cement aiming to reduce its usage in light of the considerable exploitation of natural resources and emissions involved in its production [4,5,6]. Supplementary cementitious materials (SCMs) are extensively utilized to address this issue while simultaneously enhancing the performance of cementitious composites [7]. Among these materials, metakaolin (MK), a thermally activated aluminosilicate, is noted for its high pozzolanic reactivity and its ability to enhance the mechanical strength, durability, and microstructure of mortars and concrete [8]. In recent years, blast furnace slag (BS) has emerged as a sustainable and effective additive for cement-based systems. BS, derived from biological or agricultural waste sources such as rice husk ash or diatoms, contains highly reactive amorphous silica that facilitates the formation of secondary C-S-H. When processed to the micro- or nanoscale, BS demonstrates a significant filler effect and pozzolanic behavior, which enhances the densification of the microstructure, refines pores, and improves the interfacial transition zone (ITZ) [9,10]. The combined use of MK and BS offers a synergistic approach to enhancing mortar performance. While MK contributes to strength development and durability through its pozzolanic and micro-filling properties, BS can further refine the pore structure and accelerate the formation of calcium silicate hydrate (C-S-H) gel [11]. Despite their benefits, few studies have systematically investigated the simultaneous incorporation of these two materials and their integrated effects on the microstructure, mechanical properties, and overall sustainability [12,13,14]. The MK reaction is predicated on the development of insoluble CSH/CAH (Calcium Aluminate Hydrate) when Ca(OH)2 activates the amorphous phases. The pozzolanic reaction is a gradual process that positively influences the long-term mechanical and durability properties, as well as the progression of hydration heat. Numerous historical monuments provide evidence of the utilization of pozzolanic materials in construction [15]. Compared to other SCMs, metakaolin (MK) demonstrates higher reactivity [16]. While the distribution of particle sizes and mineralogical composition influence reactivity, the smallest particles tend to cause aggregation [17]. The fine particles and porous nature of these supplementary materials enhance water adsorption within the cement matrix, acting as internal reservoirs that facilitate hydration of the cement. This effect is particularly beneficial during the early hydration stages, where water availability at the particle surface promotes the formation of additional calcium silicate hydrate (C–S–H) gel.

In addition to being retained in capillary pores, the adsorbed water is also held in other types of pores. This enhanced pore structure reduces permeability and bolsters resistance to environmental threats such as chloride ingress and sulfate attack. The combined influence of MK and BS on water adsorption thus promotes extended hydration, improves packing density, and ultimately enhances the mechanical performance and durability of hardened mortar [18,19].

While extensive research has been conducted on individual supplementary cementitious materials, the combined use of metakaolin and BS within cementitious systems remains underexplored. Previous studies have demonstrated that metakaolin enhances pozzolanic reactivity and durability, whereas BS contributes to pore refinement and the formation of additional C–S–H [3,5,7].

The objective of this study is to examine the impact of incorporating blended metakaolin and BS on the compressive strength, microstructural development, and durability-related properties of mortar. The innovation of this research lies in the combined utilization of two highly reactive and sustainable pozzolans as partial replacements for cement, presenting a promising approach to enhance mechanical performance while simultaneously reducing the environmental impact of cement-based materials.

2. Materials and Methods

2.1. Materials

2.1.1. Fine Aggregate (Sand)

River sand was used in the preparation of the mortar. Its primary physical properties are presented in Table 1. The sand was pre-dried at (105 ± 5) °C for 24 h, ensuring that the difference between initial and final weightings did not exceed 0.2%, in accordance with the standard presented in [20].

Table 1.

Physical properties of sand.

2.1.2. Ordinary Portland Cement

Ordinary Portland cement of class CEM I 52.5 N, manufactured by “Shincement” LLC, Ararat, Armenia, was used as a binder. The physical and mechanical properties were determined according to EN 196-3-2002 [21] and EN 196-1-2002 [22], while its chemical composition complies with EN 196-2-2002 [23], as presented in Table 2.

Table 2.

Physical and mechanical properties, chemical composition of cement.

2.1.3. Metakaolin

Metakaolin significantly enhances concrete properties by augmenting its strength and durability, reducing permeability, and increasing resistance to aggressive substances. Additionally, it improves workability and early-age strength development. These advantages render metakaolin a valuable additive for producing high-performance, durable concrete suitable for various construction projects. Consequently, we produce metakaolin from kaolin [24,25,26], which was sourced from Esco-pharm Ltd., Hong Kong, China, The chemical composition of kaolin was approximated to be as follows: 46.5% SiO2, 39.5% Al2O3, and 13% H2O [24]. Metakaolin (MK) was produced by calcining kaolin at 750 °C, resulting in an amorphous aluminosilicate with cementitious pozzolanic activity [25]. This process consumes less energy and emits less CO2 than traditional cement production [27,28].

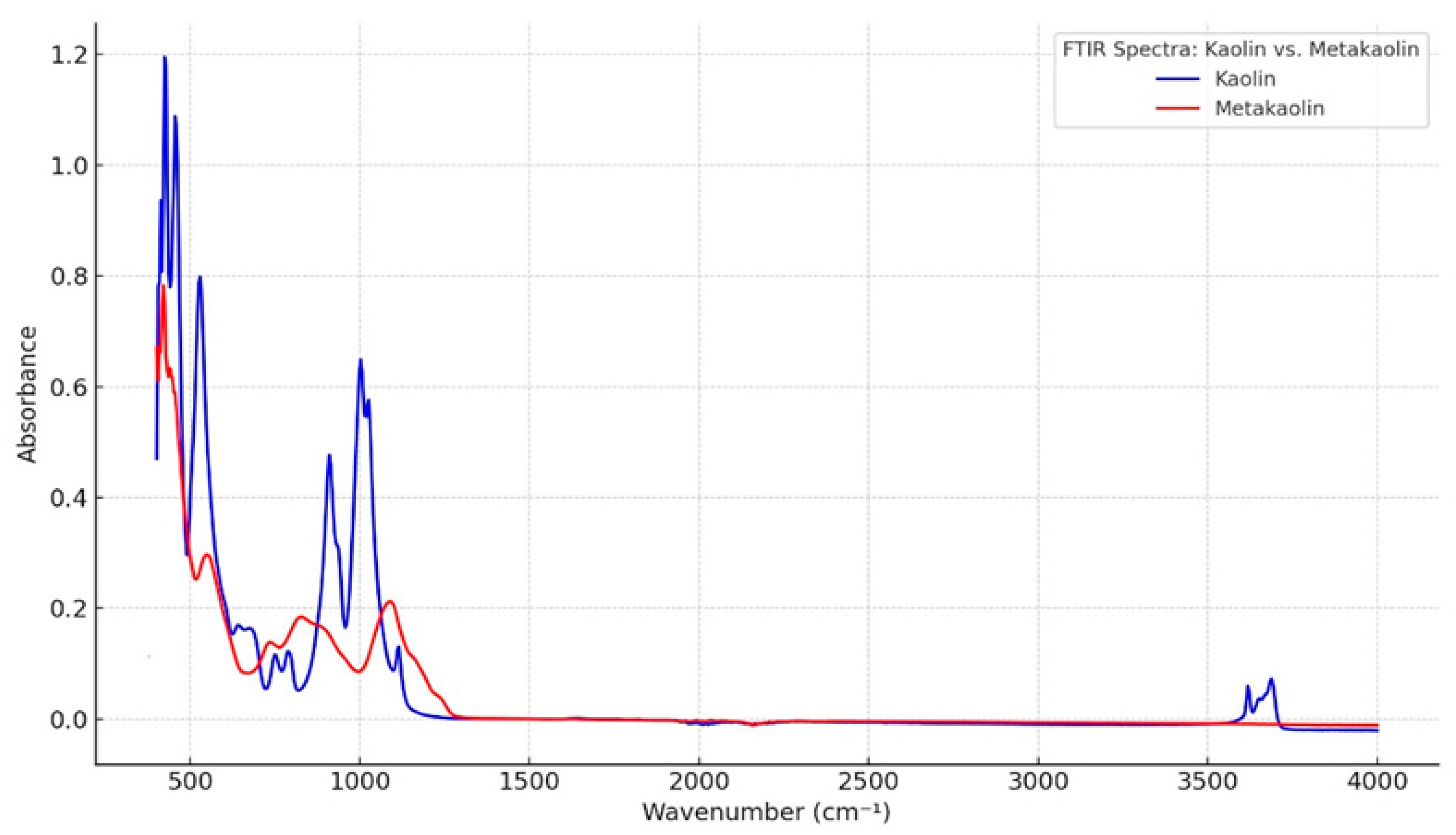

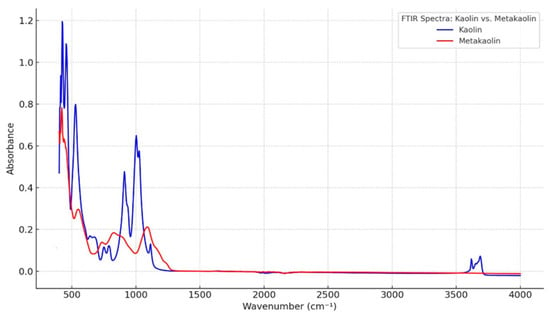

The transformation of kaolin into metakaolin was confirmed by significant changes in the FTIR spectra (Figure 1), particularly in the regions associated with the hydroxyl groups and Si–O/Al–O bonding environments. In kaolin, strong absorption bands in the 3600–3700 cm−1 range correspond to O–H stretching vibrations from hydroxyl groups (inner and inner-surface OH). Upon calcination to form metakaolin, these peaks disappeared or significantly diminished, indicating dehydroxylation. Kaolin exhibits well-defined peaks in the 1000–1100 cm−1 range due to Si–O stretching vibrations. In MK, these bands became broader and shifted, reflecting the amorphization of the crystalline structure and disruption of the orderly Si–O and Al–O frameworks. Peaks associated with Al–O bending in the 400–600 cm−1 range shifted and decreased in intensity, signifying structural reorganization [29].

Figure 1.

FTIR analysis of MK.

2.1.4. Biosilica (BS)

The BS (Effect group, Yerevan, Armenia) used as an additive in these mortars is an amorphous silica of biogenic origin that resulted in the combined activation of the natural diatomite. It is characterized by a high surface area, porous structure, and excellent biocompatibility, making it suitable for a wide range of applications [11,30,31]. The physical and chemical properties of the materials are listed in Table 3.

Table 3.

Physical properties and chemical composition of BS.

2.1.5. Superplasticizer

A polycarboxylate-based superplasticizer Melflux (Mf) is utilized as a dispersant during the sonication of MK. This superplasticizer is a yellowish powder with a bulk density of (450 ± 20) kg/m3 at 20 °C. The recommended dosage ranges from 0.05% to 1.00% of the weight of the binder. According to the Technical Data Sheet, the product has a maximum drying loss of 2.00% and a pH value between 5.5 and 8.5 at 20 °C.

2.2. Mix Design

For the MK-modified mortars, the mixing procedure was as follows: cement and MK were dry-mixed for 150 s. Water was then added, and mixing continued for an additional 30 s using a mortar mixer in slow mode. To ensure homogeneity and avoid the accumulation of material on the container walls, mixing was paused for 15 s to manually clean the sides. The process was then resumed at a higher speed for 60 s (140 and 285 rpm; E095 Mortar Mixer, Matest, Brugherio, Italy).

The procedure was adapted accordingly for mixtures containing BS. Cement and BS were first mixed for 120 s, after which MK was introduced and mixed for another 120 s. Water was subsequently added over a 30-s interval, followed by 60 s of continued mixing. A 15-s pause was incorporated mid-process to clean the walls of the mixing container, after which high-speed mixing was resumed for an additional 60 s.

For mortars incorporating ultrasonic treatment (ULT), a solution of water, MK, and Mf was subjected to ultrasonic irradiation for 30 min (Ultrasonic machine UP400St, 400 W, 24 kHz Hielscher digital sonicator, Teltow, Germany). The treated solution was then added to the cement, and the mixing process continued as described above. The same quantity of superplasticizer (0.44% by weight of binder) was utilized in the 10MK + Mf, 10MK + Mf + ULT, 10MK5BS + Mf, and 10MK5BS + Mf + ULT compositions to enable a proper comparison of the final results.

For each mortar composition, six prismatic specimens measuring 40 × 40 × 160 mm were cast to be tested after 7 and 28 days of curing. Specimens were cast in two layers and compacted using a laboratory vibrating table (C278 Vibrating Table, Matest, Brugherio, Italy). After placing and compacting the first layer, the remaining mortar was added, leveled with a trowel, and compacted again. The total compaction time per specimen was 30 s. In this study, eleven cement mortar compositions were developed, as detailed in Table 4.

Table 4.

The mix proportions for mortars incorporating partial replacements with MK and BS.

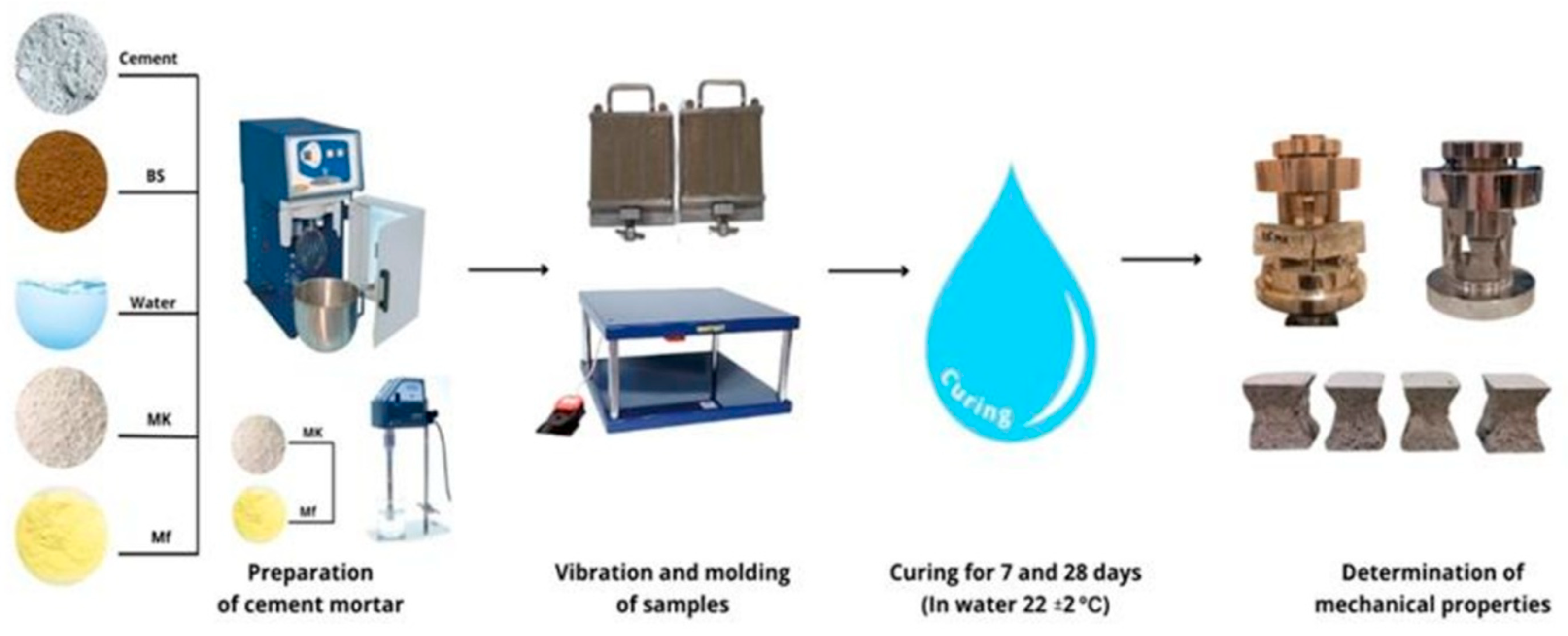

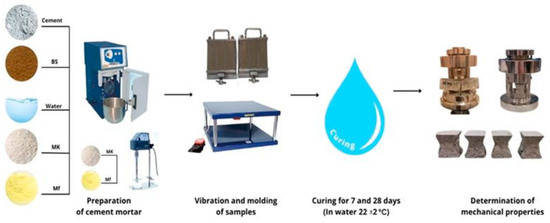

Figure 2 illustrates the processes of preparing mixtures, forming test specimens, storing and testing. The specimens were initially stored under ambient air conditions for (24 ± 1) h, after which they were demolded and placed horizontally on a grid inside a curing tank filled with water (C302-10, Matest; 550 L capacity). The curing environment was maintained at (20 ± 1) °C with a relative humidity of (95 ± 2)%.

Figure 2.

The work processes flowchart.

2.3. Analytical Methods

2.3.1. Particle Size

The particle size distributions of materials were measured using Dynamic Light Scattering (Litesizer 500, Anton Paar, Graz, Austria). A color laser with a wavelength of 658 nm was used during the measurement to ensure high measurement accuracy.

2.3.2. Fourier Transform Infrared Spectroscopy (FTIR)

FTIR spectra of mortars were recorded using Shimadzu IRTracer 100 spectrometer (Shimadzu, Kyoto, Japan).

2.3.3. Scanning Electron Microscope (SEM)

Surface morphology was analyzed using a Prisma E SEM (Thermo Fisher Scientific, Waltham, MA, USA). Samples were mounted on silicon wafers, dried at ambient temperature, and sputter-coated with a 5–10 nm gold layer using an Agar Sputter Coater under vacuum (Thermo Fisher Scientific, Waltham, MA, USA).

2.3.4. Setting Time

The setting time of the cement pastes was evaluated using the Vicat needle apparatus (Matest S.p.A., Treviolo, Italy) in accordance with EN 196-3-2002 [21]. The influence of MK, BS, and MF on the setting time of cementitious systems was investigated. A total of eleven paste formulations were prepared, each with a water-to-binder (w/b) ratio of 0.47.

The Vicat test was used to determine both the initial and final setting times. A plunger with a diameter of (1.13 ± 0.05) mm, subjected to a constant load of 300 g, was employed to assess the penetration depth into the cement paste. The initial setting time corresponds to the point at which the paste begins to lose its plasticity and transition into a rigid state. According to the standard, this is defined by a penetration depth of (6 ± 2) mm. The final setting time is determined when the paste is considered fully set, indicated by a penetration depth of 0.5 mm from the surface, or 39.5 mm from the bottom of the mold. These values were recorded to assess the influence of the various additives on the setting behavior of the cement pastes.

2.3.5. Water Absorption and Density

Water absorption tests were conducted in accordance with BS EN 772-11:2011 [32]. The specimens were fully submerged in a water-filled container, and the water level was maintained at approximately 50 mm above the top surface of the samples. The water temperature was maintained at (20 ± 2) °C throughout the test.

The samples were weighed at 24 h intervals using an analytical balance with an accuracy of 0.1%. Before each weighing, the specimens were carefully removed from the water and gently wiped with a damp, well-wrung cloth to remove any surface moisture. Notably, any water draining from the pores of the specimen onto the scale pan was considered to be part of the saturated mass. Weighing continued until the difference between two successive measurements did not exceed 0.1%, indicating that the samples had saturated. All specimens were tested in their dry state before immersion to allow for accurate determination of water absorption. The density of the test specimens was determined in accordance with EN 1015-2 [33]. To determine the density in the dry state, the samples were first dried to a constant mass, as specified in Section 8.5.1 of the standard specification. The volume of each specimen was calculated based on its geometric dimensions, which were measured using a dial caliper with a maximum permissible error of 0.1 mm. The masses of the dried specimens were recorded using a balance with an accuracy of no more than 0.1%. The density (ρ) of the hardened mortar was then calculated, with the measurement uncertainty not exceeding ±1 kg/m3.

2.3.6. Flexural Strength Test

Samples measuring 40 × 40 × 160 mm underwent flexural strength testing with the “Unitronic 50 kN” apparatus. The loading rates are 0.1 mm/min and (0.05 ± 0.01) kN/s, respectively, according to the GOST EN 196-1-2002 standard, point 9.2 [23].

2.3.7. Compressive Strength Test

The compressive strength was determined for samples with dimensions of 40 × 40 × 40 mm using a Compression machine 2000 kN automatic (Matest S.p.A., Treviolo, Italy), Servo-Plus Progress hydraulic press. The loading rates are 0.1 mm/min and (2.4 ± 0.2) kN/s, respectively, according to the EN 196-1-2002 standard, point 9.3 [23].

3. Results

Through the use of these supplemental cementitious materials (SCMs), this study aims to enhance pozzolanic reactivity, minimize the environmental impact of cement manufacture, and optimize the microstructure of mortar for use in modern and eco-friendly construction practices. Table 5 presents the physical and mechanical properties of mortars with partial replacement of cement with MK and BS.

Table 5.

Physical and mechanical properties of mortars with partial replacement of cement by MK and BS.

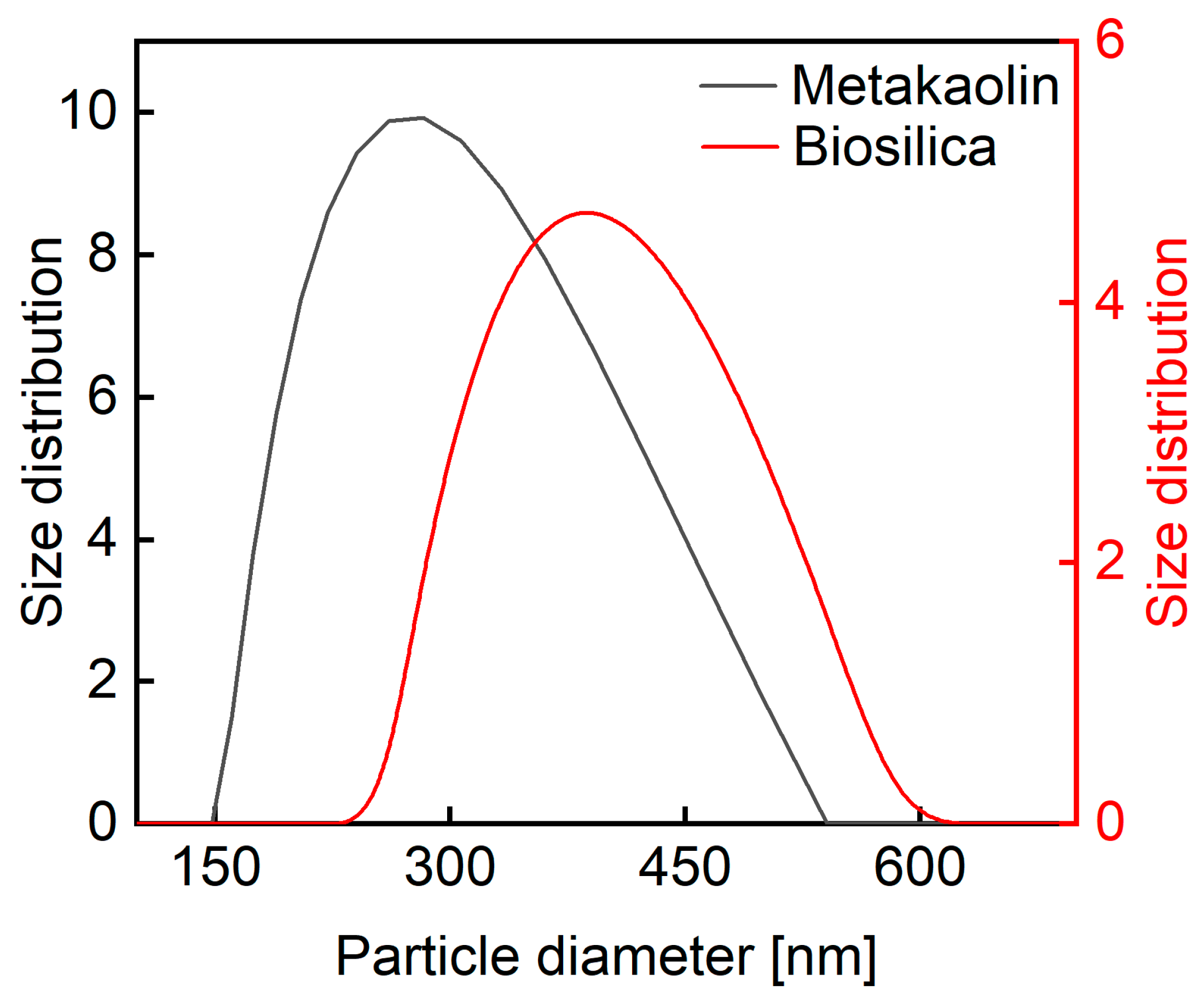

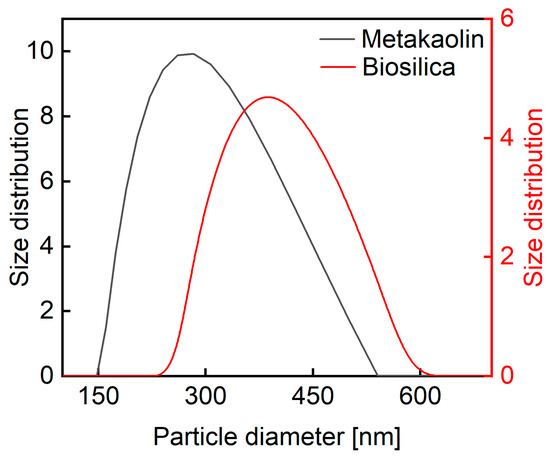

3.1. Particle Size Distribution of MK and BS

Dynamic light scattering (DLS) was employed to determine the particle size distributions of MK and BS. Measurements were conducted at a scattering angle of 90° using a refractive index value of 1.3. The results are presented in Figure 3. For MK, the hydrodynamic diameters ranged from approximately 150 nm to 539 nm, with a mean value of 277 nm. The intensity-weighted distribution yielded a polydispersity index (PDI) of 0.27, indicating moderate heterogeneity in particle size. In the case of BS, the particle sizes were distributed between ~234.6 nm and 603 nm, with an average hydrodynamic diameter of approximately 391 nm and a PDI of 0.25.

Figure 3.

Particle size distribution curves of MK and BS.

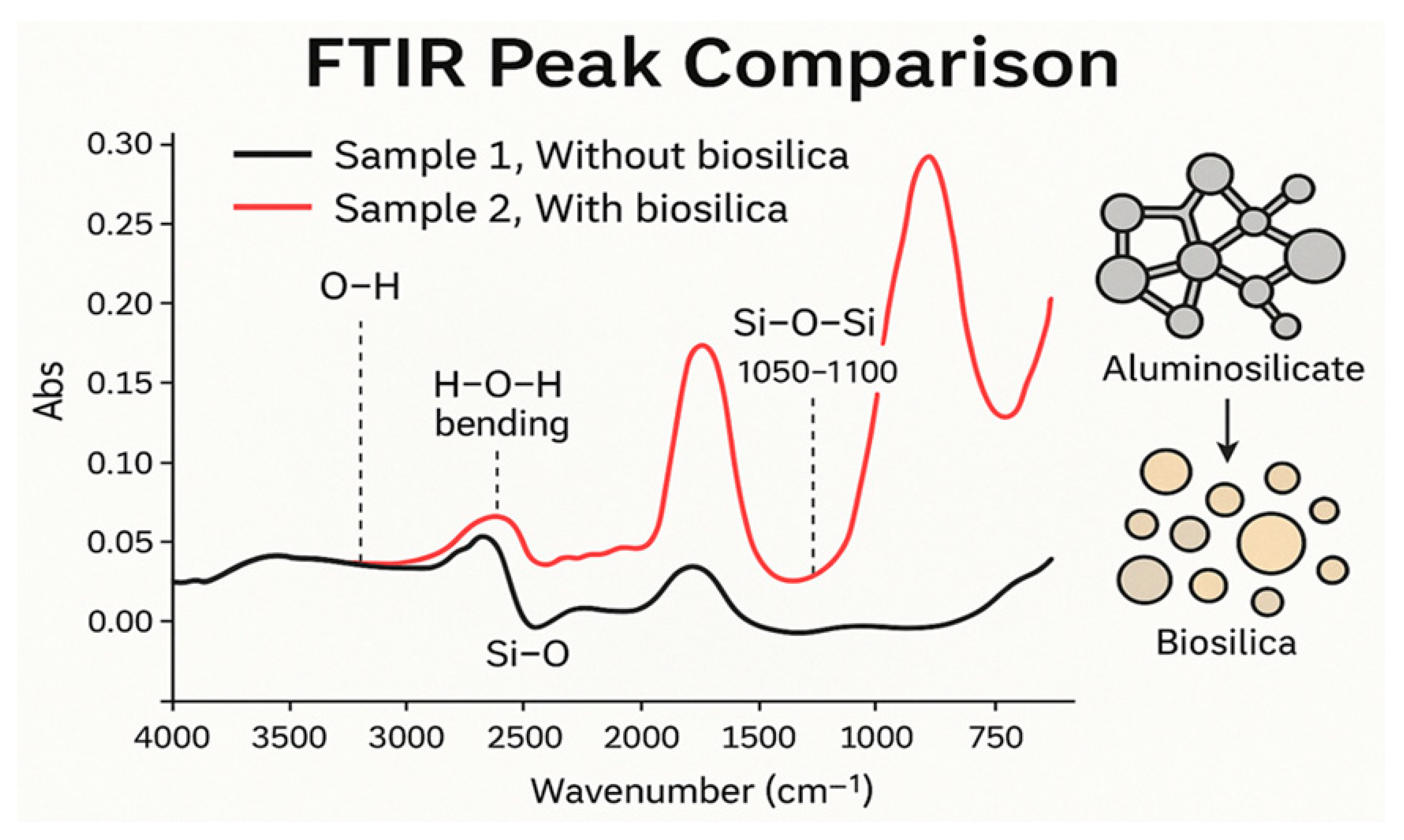

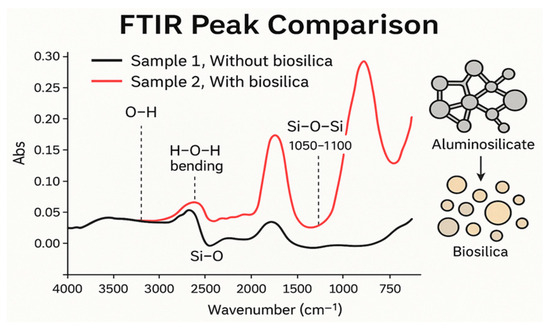

3.2. FTIR Analysis of Cement Mortars Partially Replaced with MK and BS

FTIR spectra of the hardened mortars were used to identify the main hydration products and investigate the influence of MK, BS, and Mf on the microstructure (Figure 4).

Figure 4.

FTIR analysis for samples with BS and without BS.

The key spectral features observed include

1. Si–O stretching (1000–1100 cm−1): This represents a broad and intense band corresponding to silicate phases such as calcium silicate hydrate (C–S–H) gel, unreacted MK, and BS. The increase in intensity in this region reflects enhanced pozzolanic reactions.

2. O–H stretching (~3640 cm−1): Attributed to Ca(OH)2 (portlandite), the intensity decreased with MK and BS additions, indicating their consumption during pozzolanic activity.

3. S–O stretching (~1100 cm−1): This suggests the formation of ettringite in early hydration stages.

4. Al–O vibrations (~600–700 cm−1): These are detected in MK and hydrated samples, indicative of the presence of aluminate phases [34].

The control sample exhibited higher portlandite content, while MK- and BS-containing mortars showed decreased Ca(OH)2 signals, consistent with active pozzolanic behavior. The 10MK5BS + Mf sample displayed the most intense C–S–H bands and the lowest O–H peak, confirming the beneficial role of additive synergy in enhancing hydration and microstructural development [34,35].

Sample 1 without BS and sample 2 with BS (28 days) were subjected to FTIR analysis. After 28 days, a decrease in the Ca(OH)2 band (3640 cm−1) is observed, as it reacts with silica sources (like MK and BS). The C-S-H peak will be more defined.

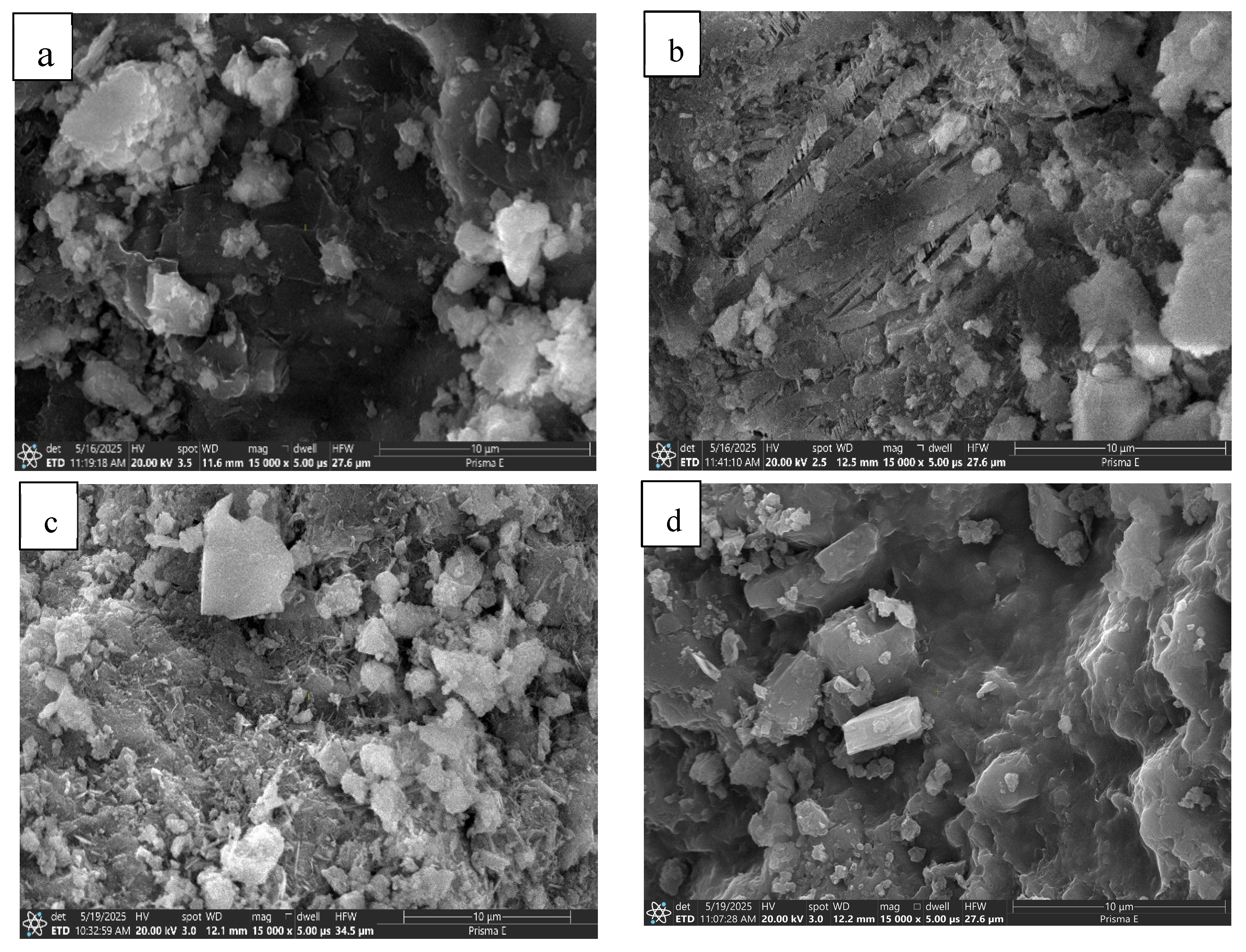

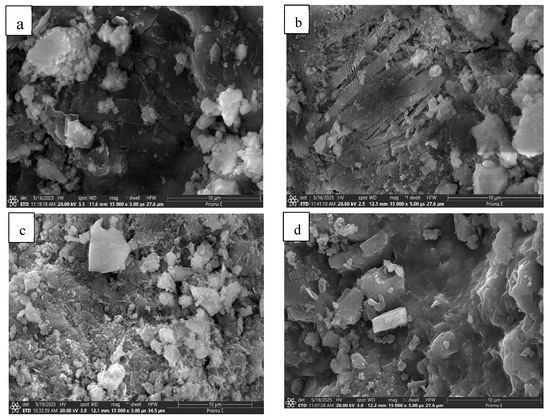

3.3. SEM Analysis of Mortars

SEM was employed to investigate the microstructural development of mortar samples incorporating MK, BS, and Mf superplasticizer (Figure 5). The matrix of the sample containing 10% MK (Figure 5a) appeared relatively porous, with irregularly shaped particles and limited gel-like hydration. Unreacted or partially reacted MK particles, voids, and a discontinuous matrix structure were evident.

Figure 5.

The SEM results of the (a) 10Mk, (b) 10MK + Mf, (c) 10MK5BS. and (d) 10MK5BS + MF specimens.

This suggests that although metakaolin participated in the pozzolanic reaction, the dispersion was suboptimal, likely reducing the efficiency of the microstructural densification. The addition of Mf (Figure 5b) improved particle dispersion, leading to a more compact and refined microstructure. Needle-like and plate-shaped crystalline formations, possibly ettringite or AFt Phases (the calcium aluminate ferrite trisubstituted phases found in hydrated (or hardened) cement paste in concrete are referred to as AFt Phases), were observed, indicating enhanced hydration activity. The matrix exhibited fewer voids and better particle packing than the plain MK sample, demonstrating the positive role of the superplasticizer in promoting uniform distribution and reaction kinetics [36,37].

SEM images were acquired at a magnification of 15,000×, corresponding to a horizontal field width (HFW) of 27.6 µm with a pixel dwell time of 5.00 µs.

The 10% MK + 5% BS (Figure 5c) sample revealed a denser and more homogenous matrix, with fine, gel-rich areas suggestive of an extensive pozzolanic reaction. The incorporation of BS nanoparticles accelerated the formation of calcium-silicate-hydrate (C–S–H) phases, contributing to matrix refinement [38]. However, occasional agglomerates were observed, indicating possible challenges in dispersing nanosilica without a dispersing agent. The 10% MK + 5% BS + Mf (Figure 5d) mortar containing both BS and Mf exhibited the most compact and uniform microstructure among all samples. The matrix was densely packed with a continuous gel phase and minimal porosity. The synergistic effect of MK and BS, combined with the improved particle dispersion facilitated by Mf, resulted in a highly homogeneous and refined microstructure. The absence of large unreacted particles and the rich development of hydration products suggest optimal pozzolanic activity and hydration progression [38,39]. The SEM results confirmed that the combined use of BS and Mf with MK (Figure 5d) significantly enhanced the microstructure of cement mortar. This combination leads to improved particle dispersion, increased formation of C–S–H gel, and reduced porosity, all of which are expected to positively influence the mechanical strength and durability. According to the SEM analysis results, there is an evident change from raw/partially reacted powders (Figure 5a,c) to more consolidated or hydrated structures (Figure 5b,d). Surface roughness, particle size distribution, and morphology differences could explain variations in mechanical properties (e.g., compressive strength, water absorption). Agglomeration and fine particle distribution play key roles in the pozzolanic reaction and microstructure densification [39].

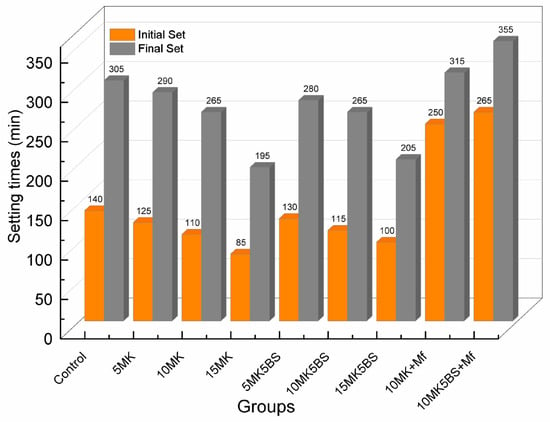

3.4. Influence of MK and BS as Partial Cement Replacements on Setting Times

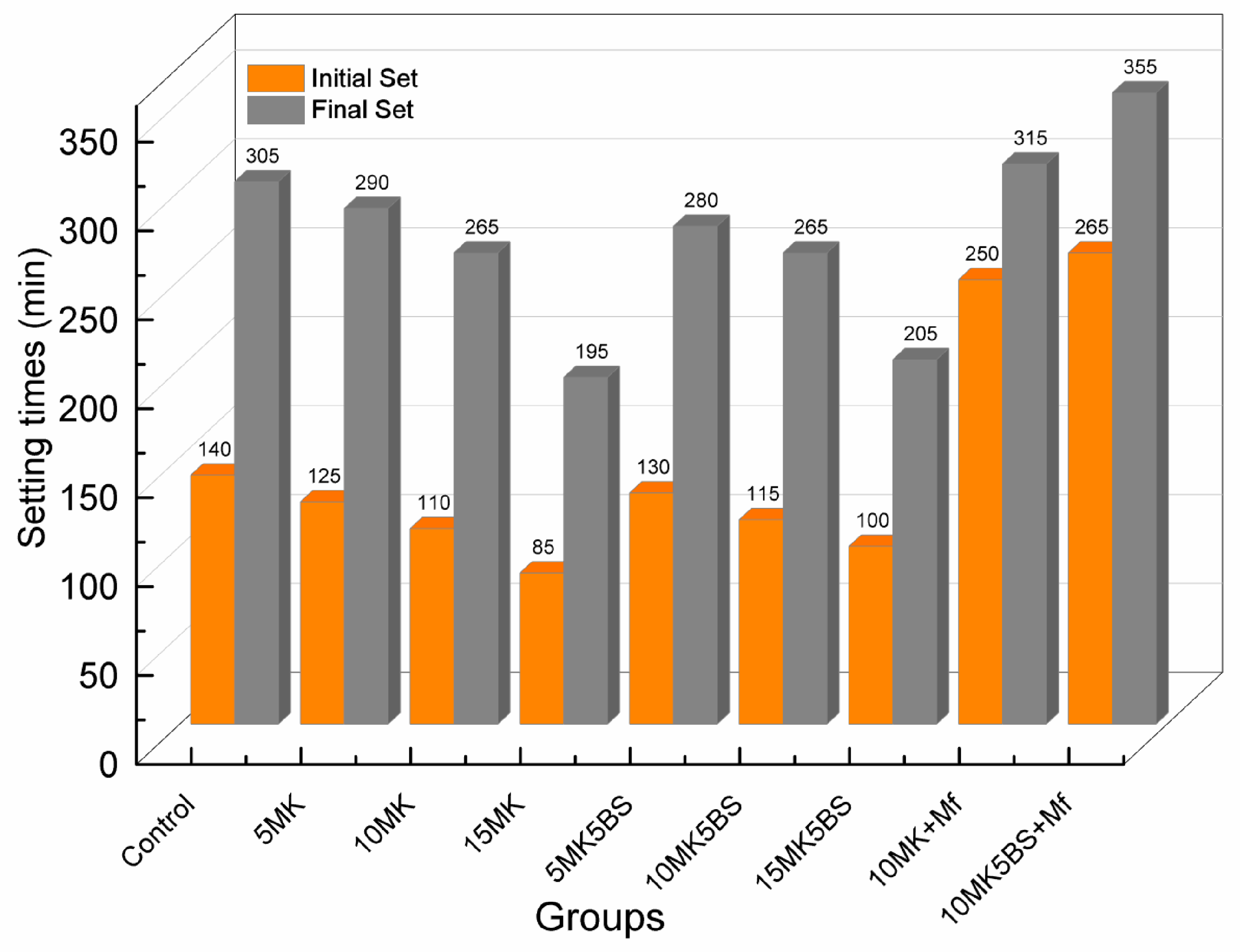

Figure 6 illustrates the initial and final setting times of the cement pastes incorporating varying amounts of MK, BS, and a polycarboxylate ether-based Mf. The inclusion of MK significantly accelerated the setting process compared to the control paste, which exhibited initial and final setting times of 140 and 305 min, respectively. With increasing MK content from 5 wt.% to 15 wt.%, both initial and final setting times decreased progressively, indicating enhanced pozzolanic reactivity and earlier formation of hydration products.

Figure 6.

Setting times of cement paste with partial replacement of MK and BS.

When 5 wt.% BS was introduced alongside MK, a slight extension in setting times was observed relative to mixes containing MK alone. This suggests that BS partially offsets the accelerating effect of MK, potentially because of its higher specific surface area and differing reactivity. In contrast, the presence of Mf led to a pronounced retardation of the setting behavior. Mixes containing 10 wt.% MK with Mf (10MK + Mf) and a ternary blend of 10 wt.% MK, 5 wt.% BS, and Mf (10MK5BS + Mf) exhibited initial setting times of 250 and 265 min, respectively. This delay is attributed to the dispersive action of the superplasticizer, which hinders particle agglomeration and slows the nucleation and growth of hydration products [40,41,42].

Metakaolin (Al2Si2O7) is a highly reactive aluminosilicate. Upon hydration, it consumes portlandite (Ca(OH)2) released from cement hydration to form additional C–A–S–H and C–A–H gels:

Al2Si2O7 + 3Ca(OH)2 + 5H2O → 3CaO⋅Al2O3⋅2SiO2⋅H2O

Biosilica, being primarily amorphous SiO2 with high surface area, reacts similarly to produce extra C–S–H:

SiO2 (amorphous) + Ca(OH)2 + H2O → C–S–H

When both are present, BS accelerates MK hydration by rapidly consuming Ca(OH)2, maintaining a high Ca2+ diffusion gradient. This favors simultaneous formation of C–S–H (from BS) and C–A–S–H (from MK), resulting in a refined pore structure and enhanced binding gel continuity.

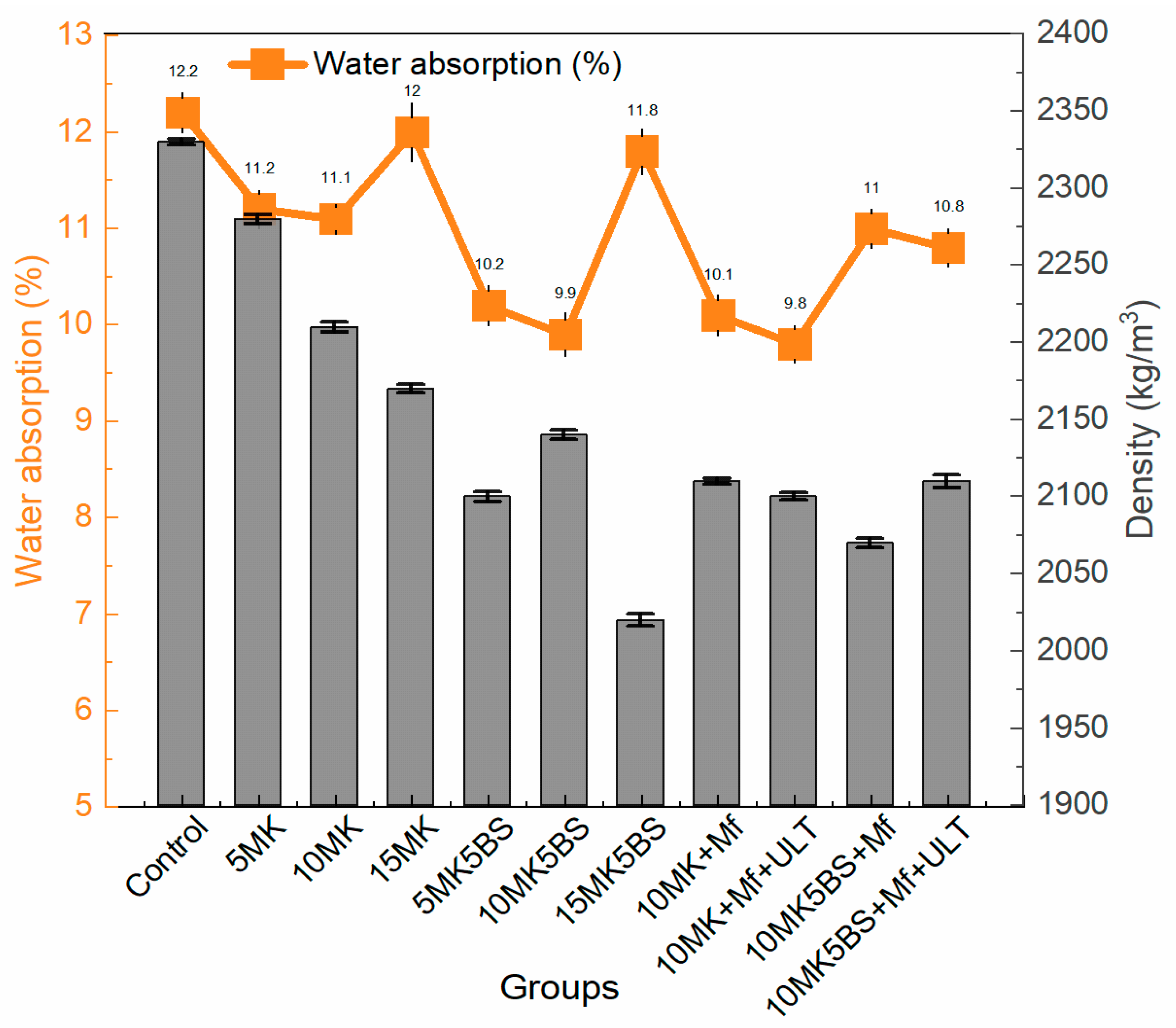

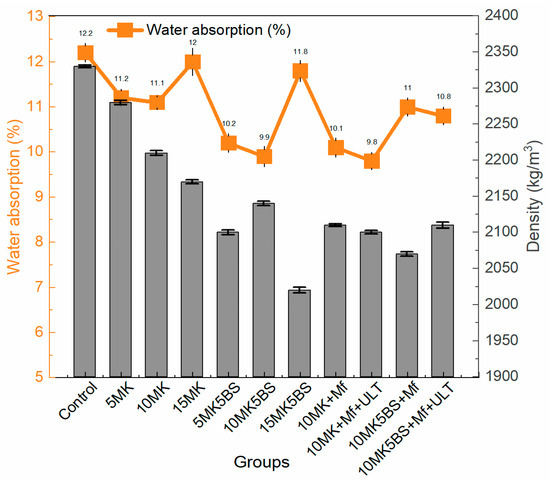

3.5. Water Absorption and Density

The partial substitution of cement with MK and BS in mortar formulations results in a reduction in water absorption and a slight decrease in overall density. Both MK and BS exhibit pozzolanic activity, contributing to the refinement of the pore structure, which in turn reduces capillary porosity and enhances the durability characteristics of the mortar. Despite their lower specific gravities—approximately 2500 kg/m2 for MK and 2300 kg/m2 for BS, compared to 3000 kg/m2 for ordinary Portland cement—the incorporation of these materials promotes a denser microstructure, thereby contributing to the observed improvements in performance [43,44,45].

The analysis of the density and water absorption test results, presented in Figure 7, was conducted on samples cured for 28 days. The control mix exhibited a density of 2330 kg/m3 and a water absorption value of 12.21%. Comparisons made by changing the mix design were carried out with reference to the parameters of the control sample and expressed as relative percentages. With a 5% MK replacement (5MK), density decreased by 2.1%, while water absorption decreased from 12.21 to 11.16%. For the 10MK mix, density was reduced by 5.2%, and water absorption decreased to 11.07%. In the case of the 15MK mixture, density decreased by 6.8% and water absorption increased to 12.01%. These reductions can be attributed to the lower specific gravity and finer particle size of MK (≈277 nm), which contribute to a less porous and more compact microstructure.

Figure 7.

Water absorption and density of mortars.

The incorporation of 5% BS into MK-blended mortars further enhanced performance. In the 5MK5BS mix, density was decreased by 9.8%, and water absorption to 10.21%. The 10MK5BS composition demonstrated notable enhancements, by an 8.9% reduction in density and a water absorption to 9.9%.

The 15MK5BS mix demonstrated a reduction of 13.3% in density compared to the control, with water absorption decreasing to 11.80%. These results confirm that the combined application of MK and BS enhances the pore structure and decreases water uptake, similar to the advantages noted with MK used alone. to the benefits observed with MK alone.

Further enhancements were observed with the incorporation of Mf and ultrasonic treatment. The densities in the 10MK + Mf and 10MK5BS + Mf compositions decreased by 10.4% and 10.9%, respectively, and water absorption decreased to 10.10% and 11.04%. When MK and Mf were dispersed by ultrasonic treatment, the density remained almost the same, and water absorption decreased to 9.8%. These findings suggest that the synergistic effects of pozzolanic admixtures, superplasticizer addition, and ultrasonic dispersion techniques significantly enhance the physical properties of cementitious mortars [10,46].

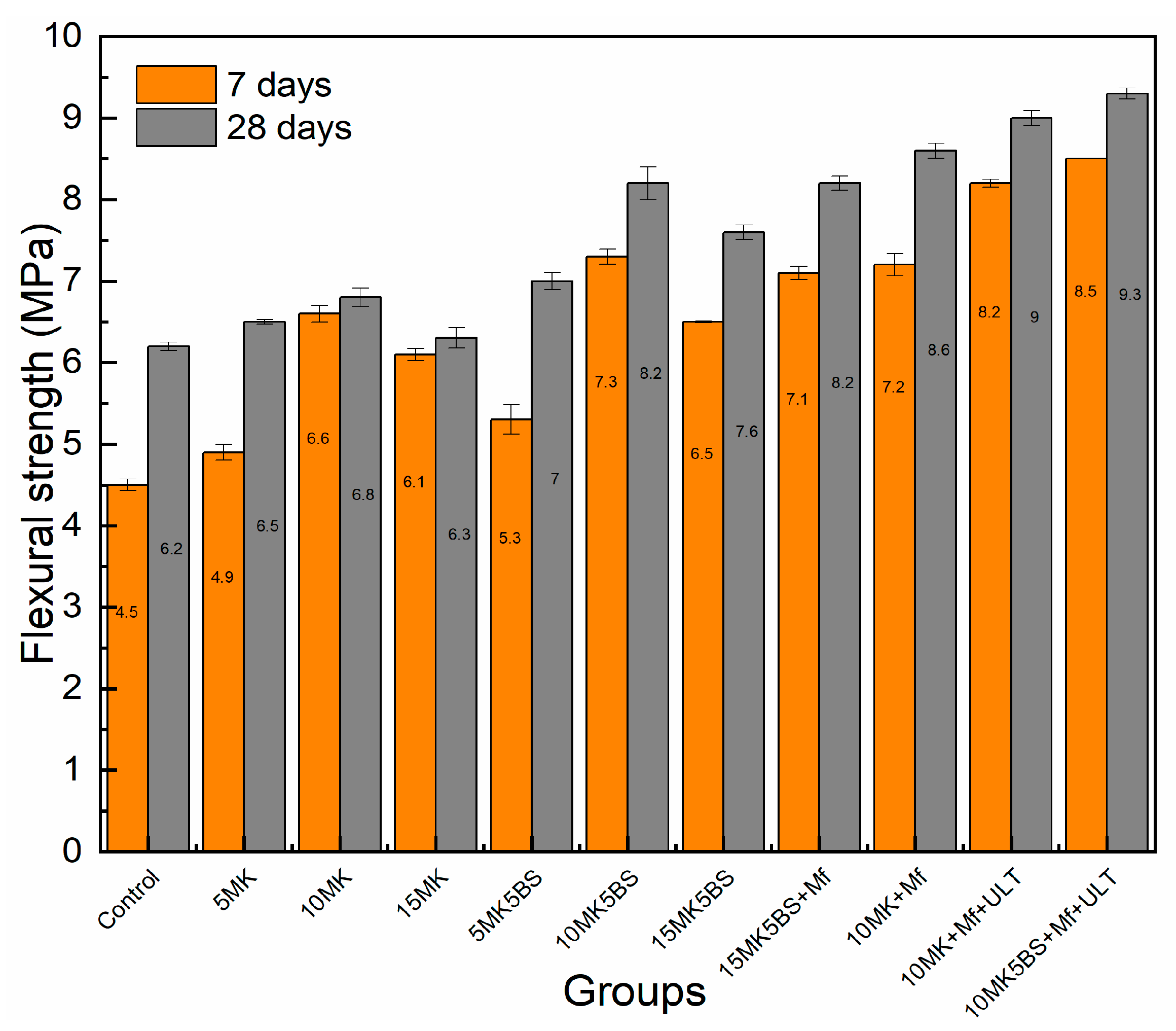

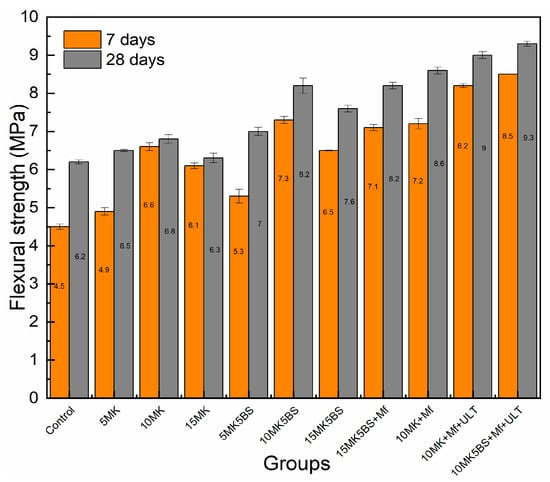

3.6. Flexural Strength

The evolution of the flexural strength at 7 and 28 days is shown in Figure 8. All modified mixtures exhibited higher flexural strengths than the control (4.49 MPa at 7 days and 6.21 MPa at 28 days). The incorporation of 10% MK significantly improved the early and late flexural strength values, whereas 15% MK showed slightly lower results, indicating an optimal replacement level of approximately 10%.

Figure 8.

Flexural strength of mortars modified with MK and BS.

The addition of 5% BS to the 10MK mix (10MK5BS) further enhanced the flexural strength, yielding values that were 10.1% and 21.7% higher at 7 and 28 days, respectively, compared to those of 10MK. The 10MK + Mf and 10MK5BS + Mf compositions also exhibited increased flexural strengths, with the latter increasing by 16.3% at 7 days and 10.0% at 28 days. When ultrasonic treatment was performed during the preparation of the mixtures, that is, 10Mk + Mf + ULT and 10Mk5Bio + Mf + ULT, the flexural strengths increased further, with the latter increasing by 17.8% and 8.5% at 7 and 28 days, respectively. The combined use of BS and Mf enhanced particle dispersion, interfacial bonding, and microstructural homogeneity, thereby improving the load transfer and crack resistance [43,47,48].

Flexural strength of all modified mortars exhibited a significant improvement compared to the control mix, ranging from 10.0% to 89.9% at 7 days and from 4.7% to 50.4% at 28 days. This enhancement can be attributed to the beneficial role of the modifying components in refining the microstructure, improving the matrix cohesion, and ensuring a more efficient stress distribution, which collectively contributed to the sustained mechanical performance over time.

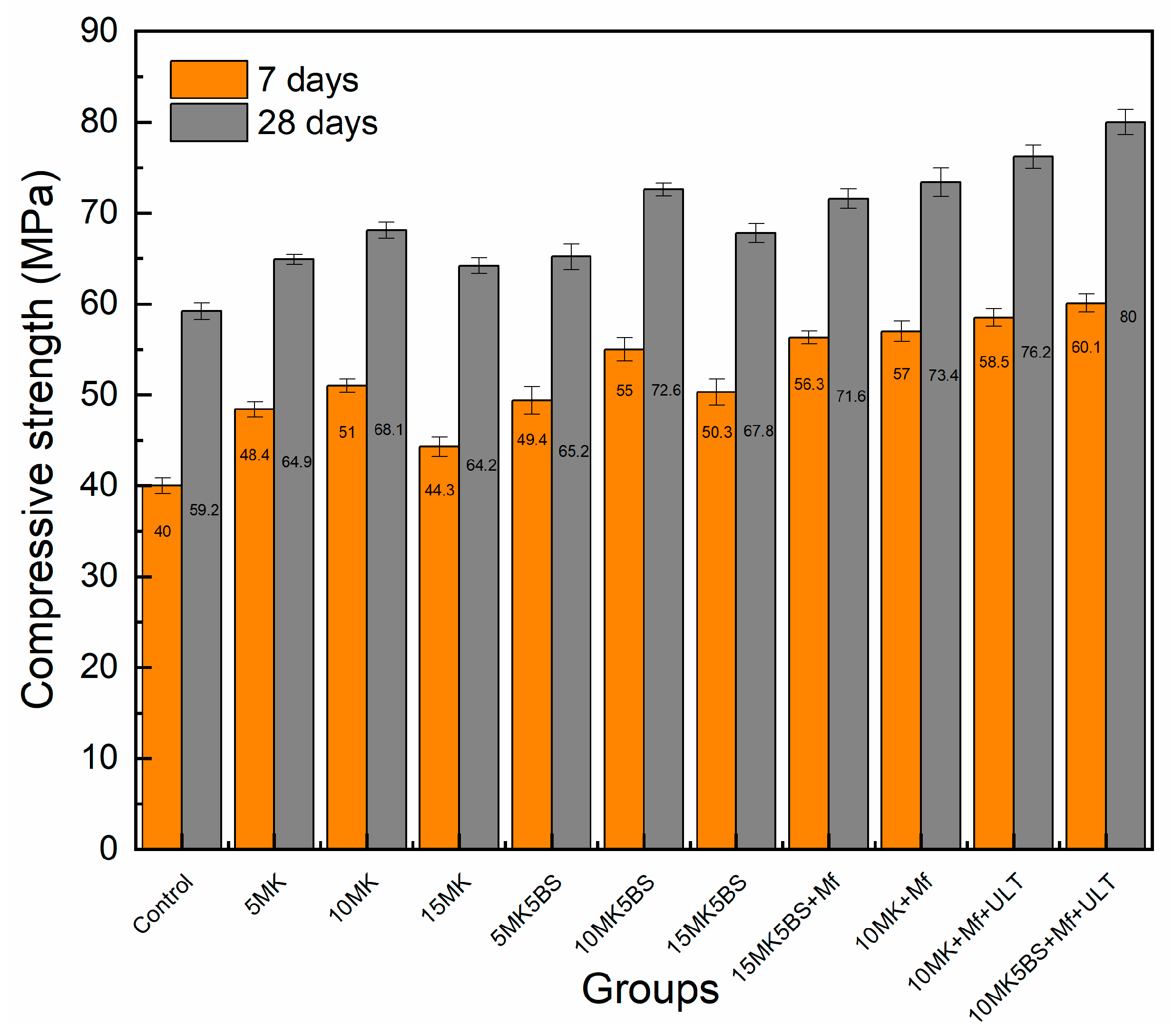

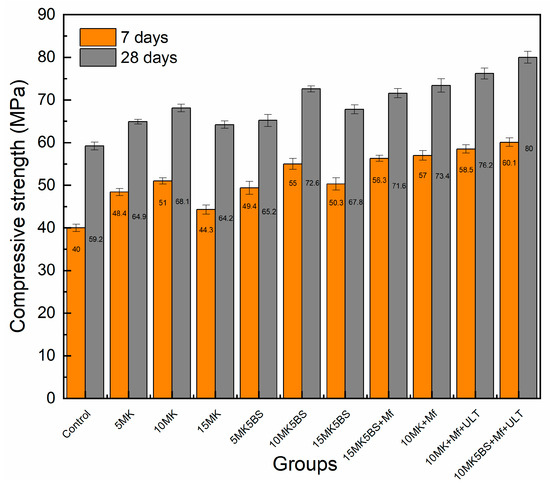

3.7. Compressive Strength

Figure 9 presents the compressive strengths of the mortars at 7 d and 28 d. The mortar control sample achieved 40.04 MPa at 7 days and 59.20 MPa at 28 days. The inclusion of 10% MK enhanced these values, representing increases of 27.39% and 15%, respectively. Further enhancement was observed with the 10MK5BS composition, which increased by 7.8% at 7 days and 6.7% at 28 days. This confirms the synergistic effect of MK and BS in strengthening the cement matrix through pozzolanic reactions and microfiller effects, respectively.

Figure 9.

Compressive strength of mortars modified with MK and BS.

The 10MK + Mf and 10MK5BS + Mf mixtures demonstrated even greater strength improvement. The 10MK5BS + Mf sample exhibited 4.1% and 6.3% increases in compressive strength at 7 and 28 days of curing, respectively, compared to the 10MK + Mf sample. These gains are attributed to the improved packing density and reduced porosity enabled by the Mf [49,50]. The highest compressive strength was recorded in the 10MK5BS + Mf + ULT mix, which increased by 2.6% and 5.1% (7 and 28 days) compared to the 10MK5BS + Mf. Ultrasonic treatment enhances particle dispersion, reduces agglomeration, and promotes the formation of denser hydration products, further improving mechanical performance [51].

Overall, the compressive strength of the mortars improved markedly with the incorporation of MK and BS, showing increases of 20.8% to 51.3% at 7 days and 9.7% to 35.2% at 28 days compared to the control sample. This improvement is mainly attributed to the pozzolanic reactivity of MK and the filler effect of BS, which promoted matrix densification, reduced porosity, and facilitated the formation of additional binding phases, thereby ensuring enhanced strength development at both early and later curing stages.

4. Conclusions

This study demonstrates the considerable potential of partially substituting cement with MK and BS to enhance the mechanical, physical, and microstructural properties of cement mortar while promoting sustainability in construction. The following results were obtained.

- The partial replacement of cement with MK significantly accelerated the mortar setting time from 12% to 64.7% owing to its high pozzolanic reactivity and fine particle size.

- Incorporating BS alongside MK slightly delayed setting compared to MK-only blends from 7.7% to 40%, owing to its high surface area and differing reactivity, which moderated hydration kinetics.

- The addition of polycarboxylate ether-based superplasticizer Mf considerably extended the setting times from 78.6% to 89.3% owing to improved dispersion and delayed nucleation of hydration products.

- The water absorption of the mortars decreased substantially from 12.21% to 9.8% with increasing MK and BS contents, indicating enhanced pore structure refinement and improvements in mortar density and microstructure. Density reductions of up to 15.3% were observed, reflecting the lower specific gravity of MK and BS.

- Flexural strength of all modified mortars exceeded that of the control mix: from 10.0% to 89.9% at 7 days, and from 4.7% to 50.4% at 28 days.

- The compressive strength improved markedly with MK and BS incorporation, from 20.8% to 51.3% at 7 days and from 9.7% to 35.2% at 28 days compared to the control sample.

- FTIR analysis confirmed enhanced pozzolanic activity, evidenced by intensified C–S–H bands and reduced portlandite (Ca(OH)2) peaks in the MK- and BS-containing mortars.

- The synergistic use of MK, BS, Mf, and ultrasonic dispersion is a promising strategy for producing durable, mechanically robust, and environmentally friendly cementitious composites.

Author Contributions

M.K.: Writing—review & editing, Methodology, Formal analysis, N.M.: Writing—review & editing, Methodology, Investigation, Software, A.A.: Investigation, Conceptualization, Data curation, Y.M.: Writing—review & editing, Validation, Investigation, D.L.: Writing—review and editing, Visualization, Supervision, M.B.: Writing—original draft, Project administration, Conceptualization, Funding acquisition, Supervision, Y.V.: Writing—review & editing, Visualization. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to acknowledge the financial support of the Higher Education and Science Committee of the Republic of Armenia (Project No. 21AG-1C008).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A review of low-carbon technologies and projects for the global cement industry. J. Environ. Sci. 2024, 136, 682–697. [Google Scholar] [CrossRef]

- Zhuang, W.; Li, S.; Yu, Q. The effect of supplementary cementitious material systems on dynamic compressive properties of ultra-high performance concrete paste. Constr. Build. Mater. 2022, 321, 126361. [Google Scholar] [CrossRef]

- Sabir, B.B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement-based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Ramli, M.; Matthews, J. Production of geopolymer mortar system containing high calcium biomass wood ash as a partial substitution to fly ash: An early age evaluation. Compos. Part B Eng. 2019, 174, 106941. [Google Scholar] [CrossRef]

- Ahmad, S.; Hakeem, I.; Maslehuddin, M. Development of an optimum mixture of ultra-highperformance concrete. Eur. J. Environ. Civ. Eng. 2016, 20, 1106–1126. [Google Scholar] [CrossRef]

- Commeh, M.; Thiedeitz, M.; Acheampong, B.; Ashley, N.N.K.; Gafah, G.; Tsitsi, J.M.; Acheampong, S.; Tsekpo, E.; Van Ess, R.N.; Barnor-Arthur, J.O. Utilization of rice husk waste as biochar and pozzolanic ashes in cementitious blends. Discov. Civ. Eng. 2025, 2, 23. [Google Scholar] [CrossRef]

- Li, J.; Jin, Q.; Zhang, W.; Li, C.; Monteiro, P. Microstructure and durability performance of sustainable cementitious composites containing high-volume regenerative biosilica. Resour. Conserv. Recycl. 2022, 178, 106038. [Google Scholar] [CrossRef]

- Muradyan, N.; Arzumanyan, A.; Kalantaryan, M.; Vardanyan, Y.; Yeranosyan, M.; Ulewicz, M.; Laroze, D.; Barseghyan, M. The Use of Biosilica to Increase the Compressive Strength of Cement Mortar: The Effect of the Mixing Method. Materials 2023, 16, 5516. [Google Scholar] [CrossRef]

- Gupta, S.; Krishnan, P.; Kashani, A.; Kua, H. Application of biochar from coconut and wood waste to reduce shrinkage and improve physical properties of silica fume-cement mortar. Constr. Build. Mater. 2020, 262, 120688. [Google Scholar] [CrossRef]

- Hou, P.; Kawashima, S.; Wang, K.-J.; Corr, D.; Qian, J.; Shah, S. Effects of colloidal nanosilica on rheological and mechanical properties of fly ash–cement mortar. Cem. Concr. Compos. 2013, 35, 12–22. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Yuan, H.; Shi, Y.; Xu, Z.; Lu, C.; Ni, Y.; Lan, X. Influence of nano-ZrO2 on the mechanical and thermal properties of high temperature cementitious thermal energy storage materials. Constr. Build. Mater. 2013, 48, 6–10. [Google Scholar] [CrossRef]

- Al-Jabri, K.; Shoukry, H. Influence of nano metakaolin on thermo-physical, mechanical and icrostructural properties of high-volume ferrochrome slag mortar. Constr. Build. Mater. 2018, 177, 210–221. [Google Scholar] [CrossRef]

- Pera, P. Metakaolin and Calcined Clays. Cement and Concrete Composites; Elsevier: Amsterdam, The Netherlands, 2001; pp. 441–520. Available online: https://www.sciencedirect.com/journal/cement-and-concrete-composites/vol/23/issue/6 (accessed on 31 December 2001).

- Zunino, F.; Scrivener, K. Reactivity of kaolinitic clays calcined in the 650 °C–1050 °C temperature range: Towards a robust assessment of overcalcination. Cem. Concr. Compos. 2024, 146, 105380. [Google Scholar] [CrossRef]

- Guo, H.; Huang, Z.; Pantongsuk, T.; Yu, T.; Zhang, B.; Luo, J.; Yuan, P. Utilisation of Biosilica as Active Silica Source for Metakaolin-Based Geopolymers. Minerals 2024, 14, 816. [Google Scholar] [CrossRef]

- EN 933-1:2012; Tests for Geometrical Properties of Aggregates. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 196-3-2002; Methods of Testing Cement. Part 3. Determination of Setting Time and Soundness. European Committee for Standardization: Brussels, Belgium, 2002. Available online: https://www.armstandard.am/en/standards/1 (accessed on 4 October 2025).

- EN 196-2-2002; Methods of Testing Cement. Part 2. Chemical Analysis of Cement. European Committee for Standardization: Brussels, Belgium, 2002. Available online: https://www.armstandard.am/en/standards/1 (accessed on 4 October 2025).

- EN 196-1-2002; Methods of Testing Cement. Part 1. Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2002. Available online: https://www.armstandard.am/en/standards/1 (accessed on 4 October 2025).

- Zegeye, A.; Yahaya, S.; Claire, F.; White, M. Refinement of industrial kaolin by microbial removal of iron-bearing impurities. Appl. Clay Sci. 2013, 86, 47–53. [Google Scholar] [CrossRef]

- Kadri, H.; Kenai, S.; Ezziane, K.; Siddique, R.; De Schutter, G. Influence of metakaolin and silica fume on the heat of hydration and compressive strength development of mortar. Appl. Clay Sci. 2011, 53, 704–708. [Google Scholar] [CrossRef]

- San, C.A.; Castello, R.; Luengo, M.M.; Vizvayno, C. Acid activation of mechanically and thermally modified kaolins. Mater. Res. Bull. 2009, 44, 2103–2111. [Google Scholar] [CrossRef]

- Fabbri, B.; Gualtieri, S.; Leonardi, C. Modifications induced by the thermal treatment of kaolin and determination of reactivity of metakaolin. Appl. Clay Sci. 2013, 73, 2–10. [Google Scholar] [CrossRef]

- Poon, C.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2005, 20, 858–865. [Google Scholar] [CrossRef]

- Nandiyanto, A.; Ragadhita, R.; Fiandini, M.; Ijost, I. Interpretation of Fourier Transform Infrared Spectra (FTIR): A Practical Approach in the Polymer/Plastic Thermal Decomposition. Indones. J. Sci. Technol. 2023, 8, 113–126. [Google Scholar] [CrossRef]

- Zhang, M.; Zang, Y.; Shan, L. Enhancing Volumetric Stability of Metakaolin-Based Geopolymer Composites with Organic Modifiers WER and SCA. Buildings 2024, 14, 586. [Google Scholar] [CrossRef]

- Wang, X.; Schroder, H.; Wiens, M.; Schloßmacher, U.; Muller, W. Chapter five-Biosilica: Molecular Biology, Biochemistry and Function in Demosponges as well as its Applied Aspects for Tissue Engineering1. Adv. Mar. Biol. 2012, 62, 231–271. [Google Scholar] [CrossRef]

- BS EN 772-11:2011; Testing Concrete. Method for Determination of Water Absorption. British Standards Institution: London, UK, 2011.

- EN 1015-2; Methods of Test for Mortar for Masonry. Bulk Sampling of Mortars and Preparation of Test Mortars. European Committee for Standardization: Brussels, Belgium, 1998.

- Giuseppe, M.; Maria Teresa, C.; Letterio, M.; Magazù, S. XRD, FTIR and RAMAN Characterizations of Metakaolin Geopolymers. Mod Concept Mater. Sci. 2024, 5, 620. [Google Scholar] [CrossRef]

- Zhong, C.; Zhang, L.; Mao, W.; Xing, S.; Chen, J.; Zhou, J. An investigation on mechanical properties and durability of metakaolin reinforced modified recycled concrete. Case Stud. Constr. Mater. 2024, 20, e02978. [Google Scholar] [CrossRef]

- Jo, B.-W.; Kim, C.-H.; Lim, J.-H. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Muthu, M.; Kumar, B.; Ukrainczyk, N.; Sadowski, L.; Koenders, E. Impact of Superplasticizers on the Performance of Low-Grade Limestone-Based Cement Mixes. Materials 2024, 17, 2500. [Google Scholar] [CrossRef]

- Chithiraputhiran, S.; Neithalath, N. Isothermal reaction kinetics and temperature dependence of alkali activation of slag, fly ash and their blends. Constr. Build. Mater. 2013, 45, 233–242. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, Y.; Sun, J.; Han, F. Effect of Ultrafine Metakaolin on the Properties of Mortar and Concrete. Crystals 2021, 11, 665. [Google Scholar] [CrossRef]

- Deveshan, L.; Oladimeji, B.; Awoyera, O.; Rondon, C.; Echeverría, A.; Kolawole, J. A Review of the Engineering Properties of Metakaolin Based Concrete: Towards Combatting Chloride Attack in Coastal/Marine Structures. Adv. Civ. Eng. 2020, 1, 8880974. [Google Scholar] [CrossRef]

- Zhang, M.H.; Islam, J. Use of nano-silica to reduce setting time and increase early strength of concretes with high volumes of fly ash or slag. Constr. Build. Mater. 2012, 29, 573–580. [Google Scholar] [CrossRef]

- Collepardi, M. Admixtures used to enhance placing characteristics of concrete. Cem. Concr. Compos. 2001, 23, 209–216. [Google Scholar] [CrossRef]

- Gameiro, A.; Santos, A.; Silva, P.; Faria, P.; Grilo, J.; Branco, T.; Veiga, R.; Velosa, A. Physical and chemical assessment of lime–metakaolin mortars: Influence of binder:aggregate ratio. Cem. Concr. Compos. 2014, 45, 264–271. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Tayeh, B.A. Metakaolin in ultra-high-performance concrete: A critical review of its effectiveness as a green and sustainable admixture. Case Stud. Constr. Mater. 2024, 21, e03967. [Google Scholar] [CrossRef]

- Badalyan, M.M.; Muradyan, N.G.; Shainova, R.S.; Arzumanyan, A.A.; Kalantaryan, M.A.; Sukiasyan, R.R.; Yeranosyan, M.; Laroze, D.; Vardanyan, Y.V.; Barseghyan, M.G. Effect of Silica Fume Concentration and Water–Cement Ratio on the Compressive Strength of Cement-Based Mortars. Buildings 2024, 14, 757. [Google Scholar] [CrossRef]

- Qian, X.; Li, M.; Wang, J.; Wang, L.; Chen, P.; Fang, Y.; Wang, X.; Yang, F. A bio-inspired, plant-derived admixture for metakaolin blended cement mortars. Constr. Build. Mater. 2022, 354, 129185. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Gao, S.; Zheng, Y. Improvement effects of nano-silica on bonding performance of polymer concrete for repairing damaged concrete. Constr. Build. Mater. 2023, 409, 133768. [Google Scholar] [CrossRef]

- Malumyan, S.; Muradyan, N. The Effect of Different Multi-Walled Carbon Nanotubes Aspect Ratio on the Compressive Strength of the Cement-Based Concrete. J. Adv. Eng. Res. 2025, 8, 62–68. [Google Scholar] [CrossRef]

- Arzumanyan, A.; Muradyan, N.; Arzumanyan, A.; Laroze, D.; Barseghyan, M. Non-Cement Building Materials from Volcanic Rock Extraction Waste. Buildings 2024, 14, 1555. [Google Scholar] [CrossRef]

- Nili, M.; Salehi, H. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef]

- Muradyan, N.; Gyulasaryan, H.; Arzumanyan, A.; Badalyan, M.; Kalantaryan, M.; Vardanyan, V.; Laroze, D.; Manukyan, A.; Barseghyan, M. The Effect of Multi-Walled Carbon Nanotubes on the Compressive Strength of Cement Mortars. Coatings 2022, 12, 1933. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).