Measurement of Dynamic Response and Analysis of Characteristics of Heavy-Haul Railway Tunnel Bottom Structure Under Train Loading

Abstract

1. Introduction

2. Field Measurement

2.1. Survey Point Engineering Overview

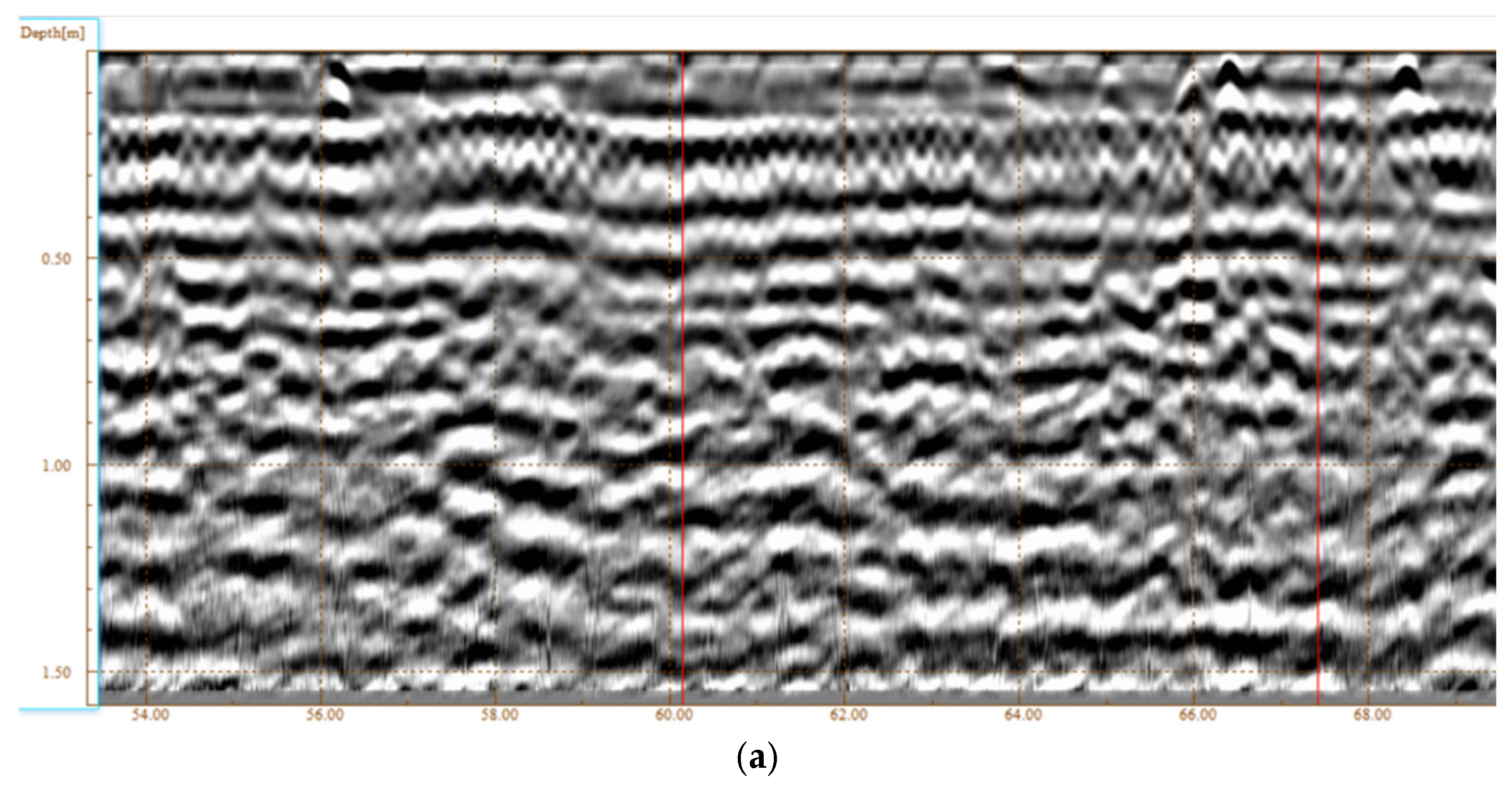

2.2. On Site Disease Detection

2.3. Dynamic Testing Content

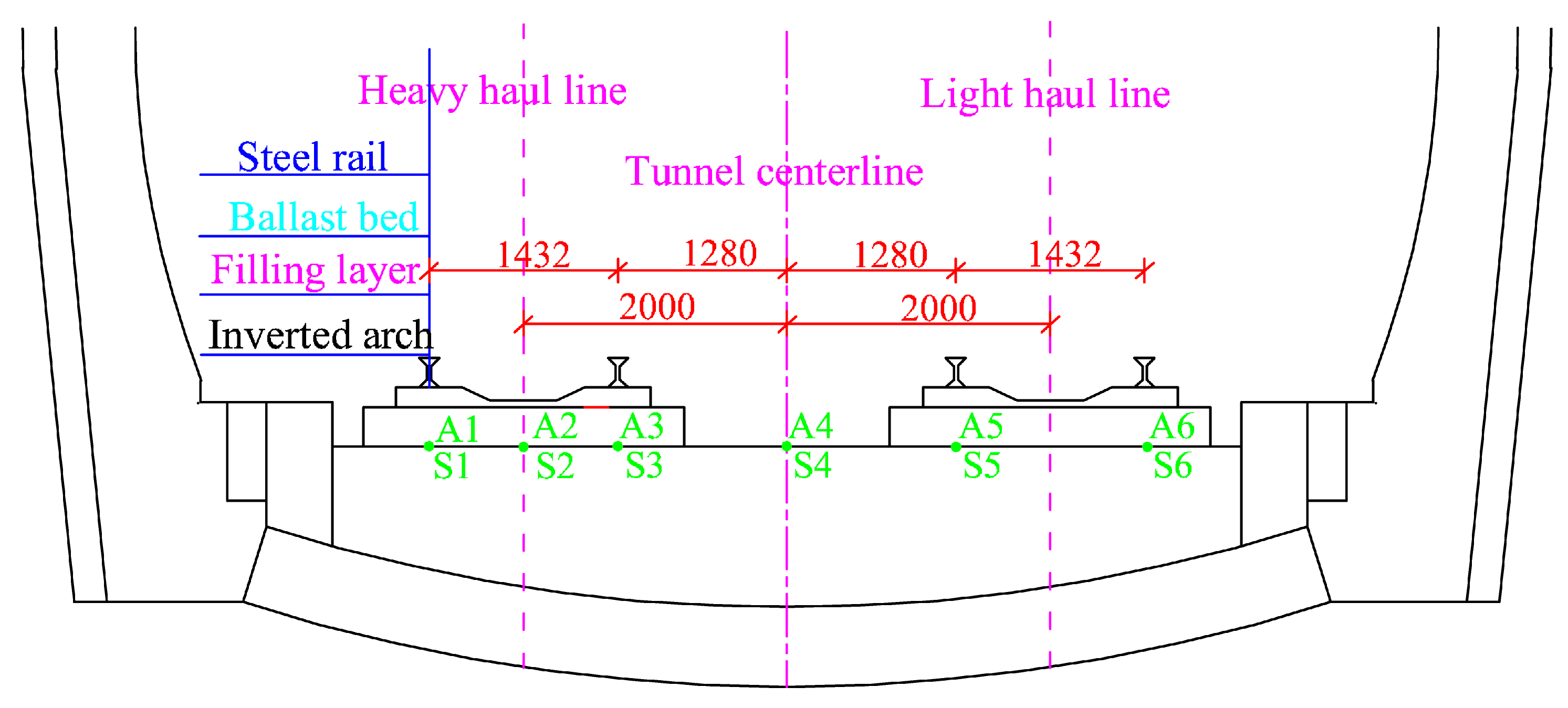

2.4. Sensor Layout and Installation

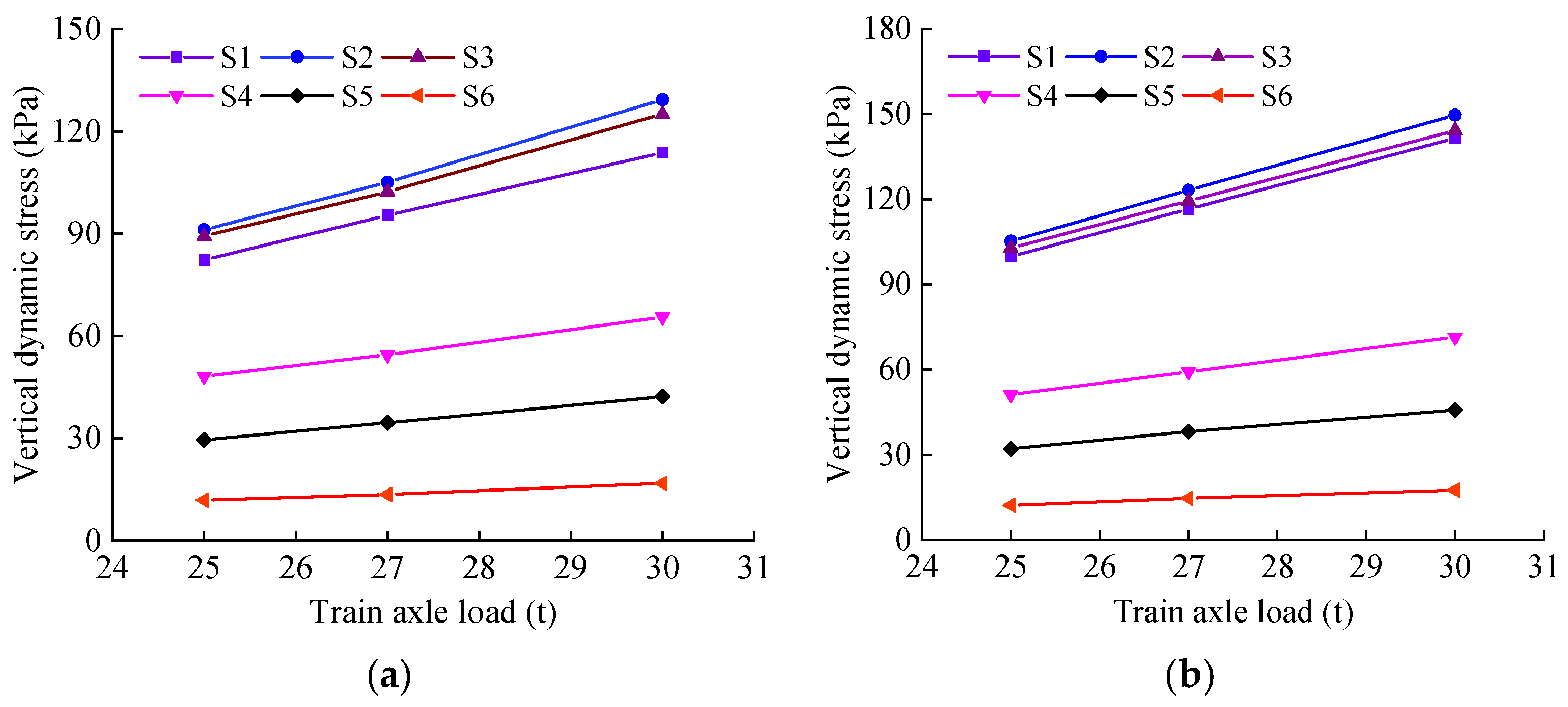

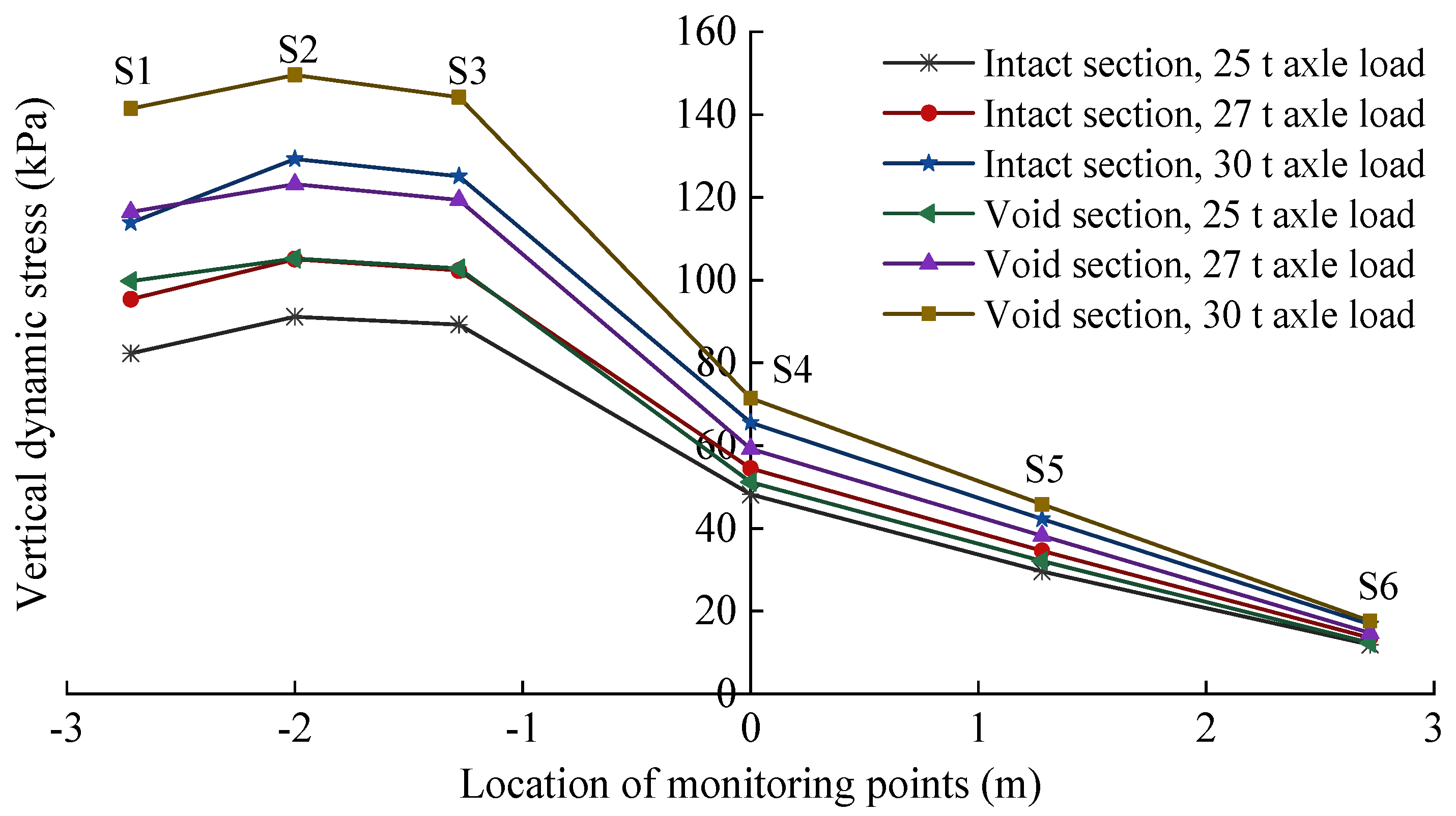

3. Analysis of Dynamic Stress Test Results

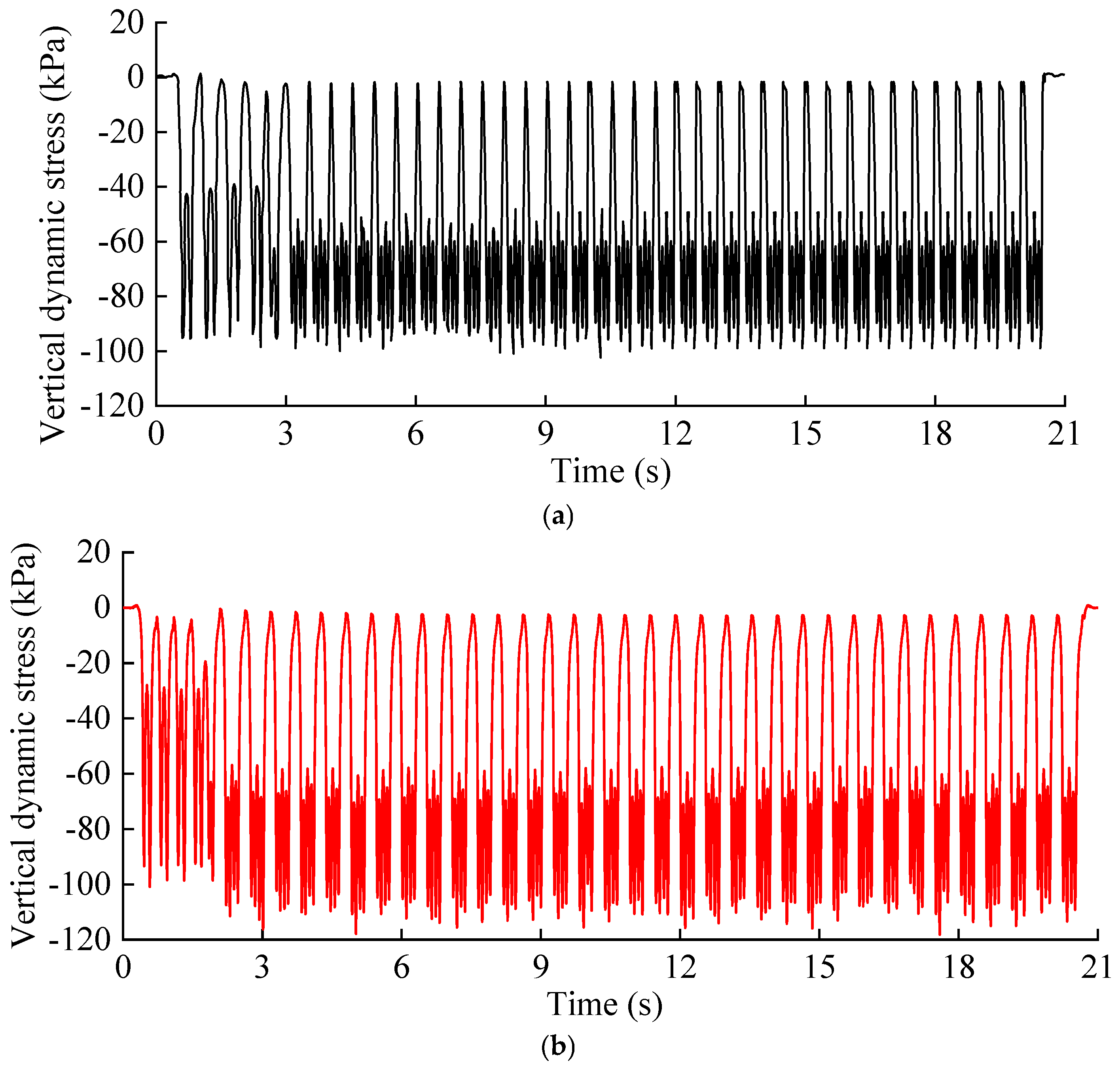

3.1. Time-Domain Dynamic Stress Response Characteristics

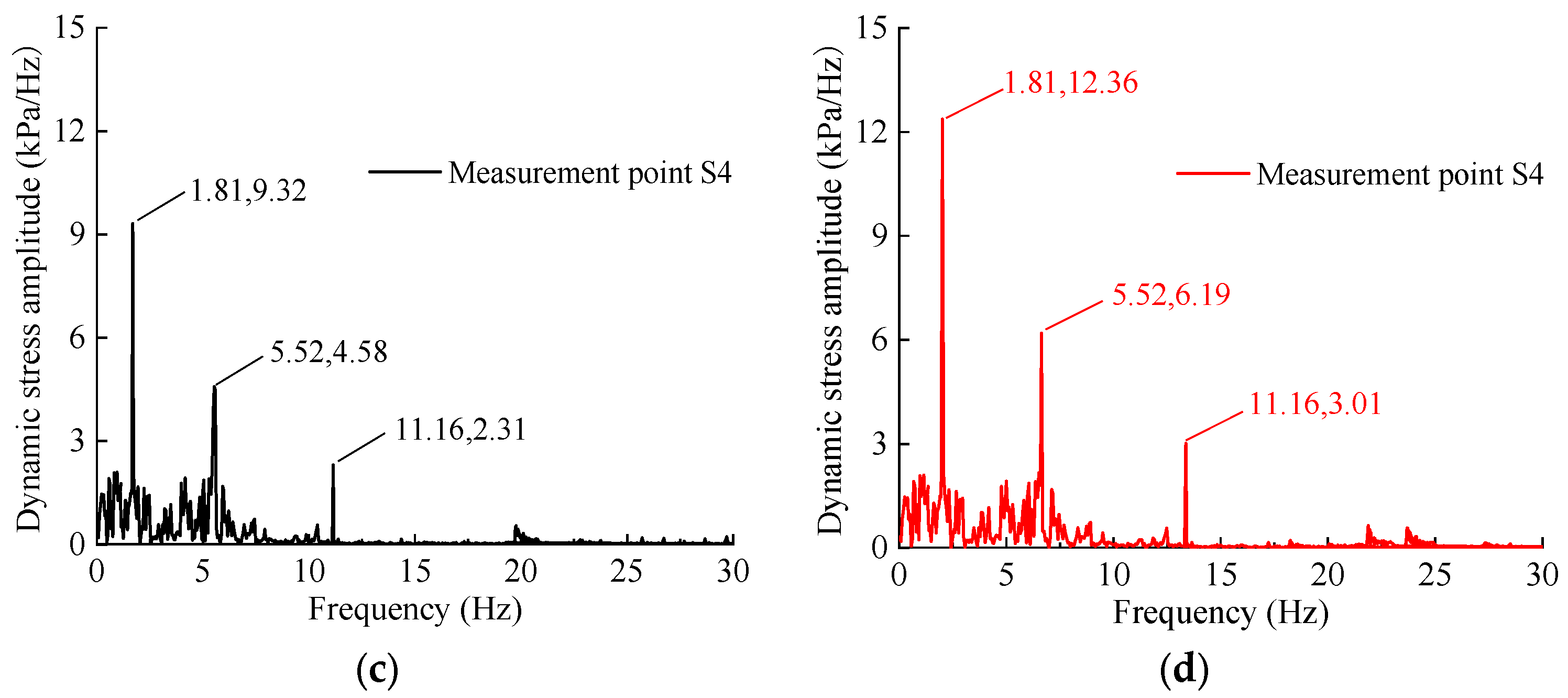

3.2. Frequency-Domain Dynamic Stress Response Characteristics

- (1)

- Frequency of Adjacent Vehicle Pairs: This frequency arises from the combined action of the rear bogie of a leading car and the front bogie of a following car, with a unit spacing of 12.0 m [4]:

- (2)

- Frequency of Adjacent Wheelsets within a Bogie: This is determined by the 1.83 m wheelset spacing within a single bogie:

- (3)

- Frequency of Inter-Car Bogie Pairs: This corresponds to the interaction between the rear bogie of a leading car and the front bogie of the following car, with a center-to-center distance of 3.8 m:

- (4)

- Frequency of Intra-Car Bogie Spacing: This is based on the distance between the centers of the two bogies within the same carriage, which is 8.2 m:

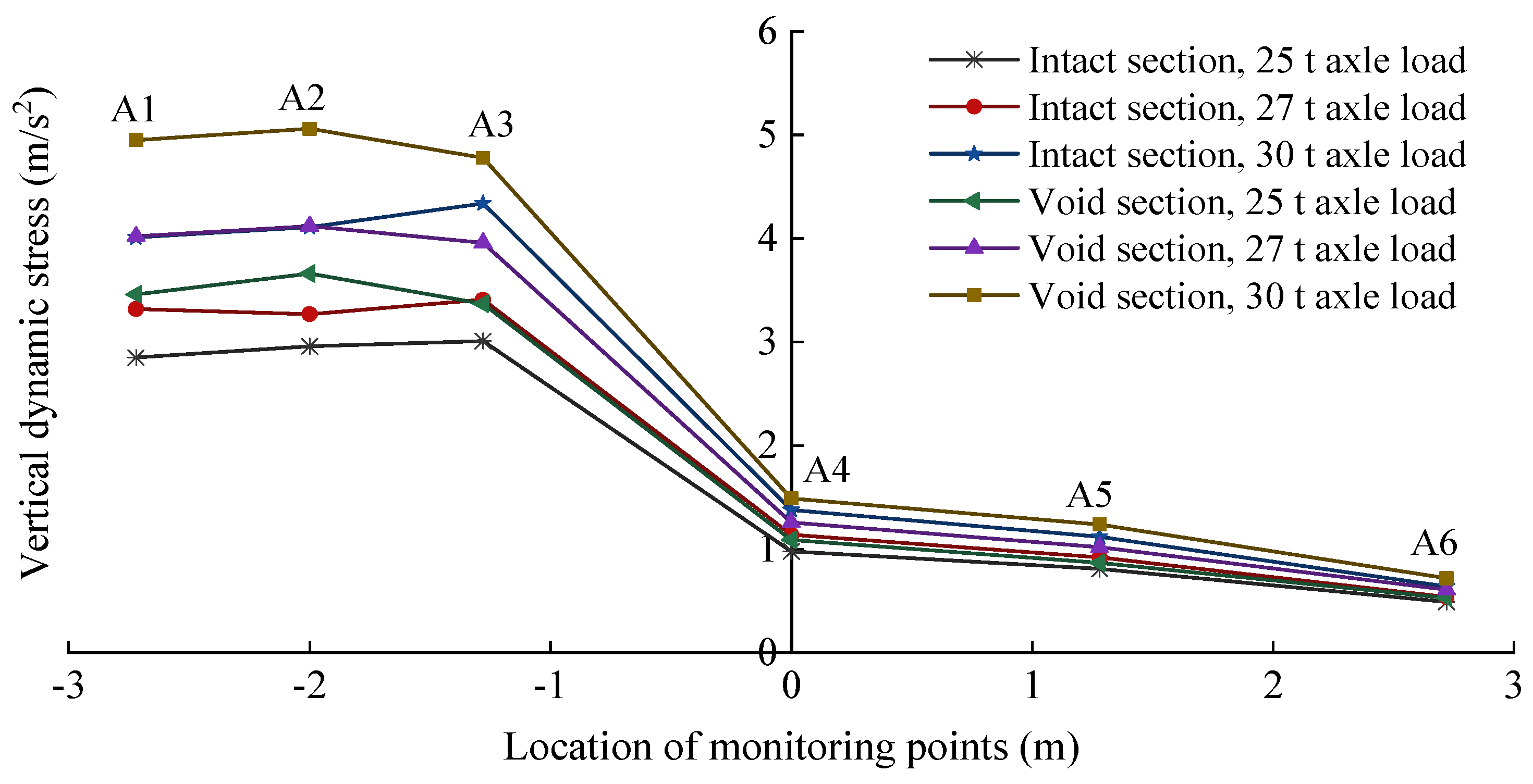

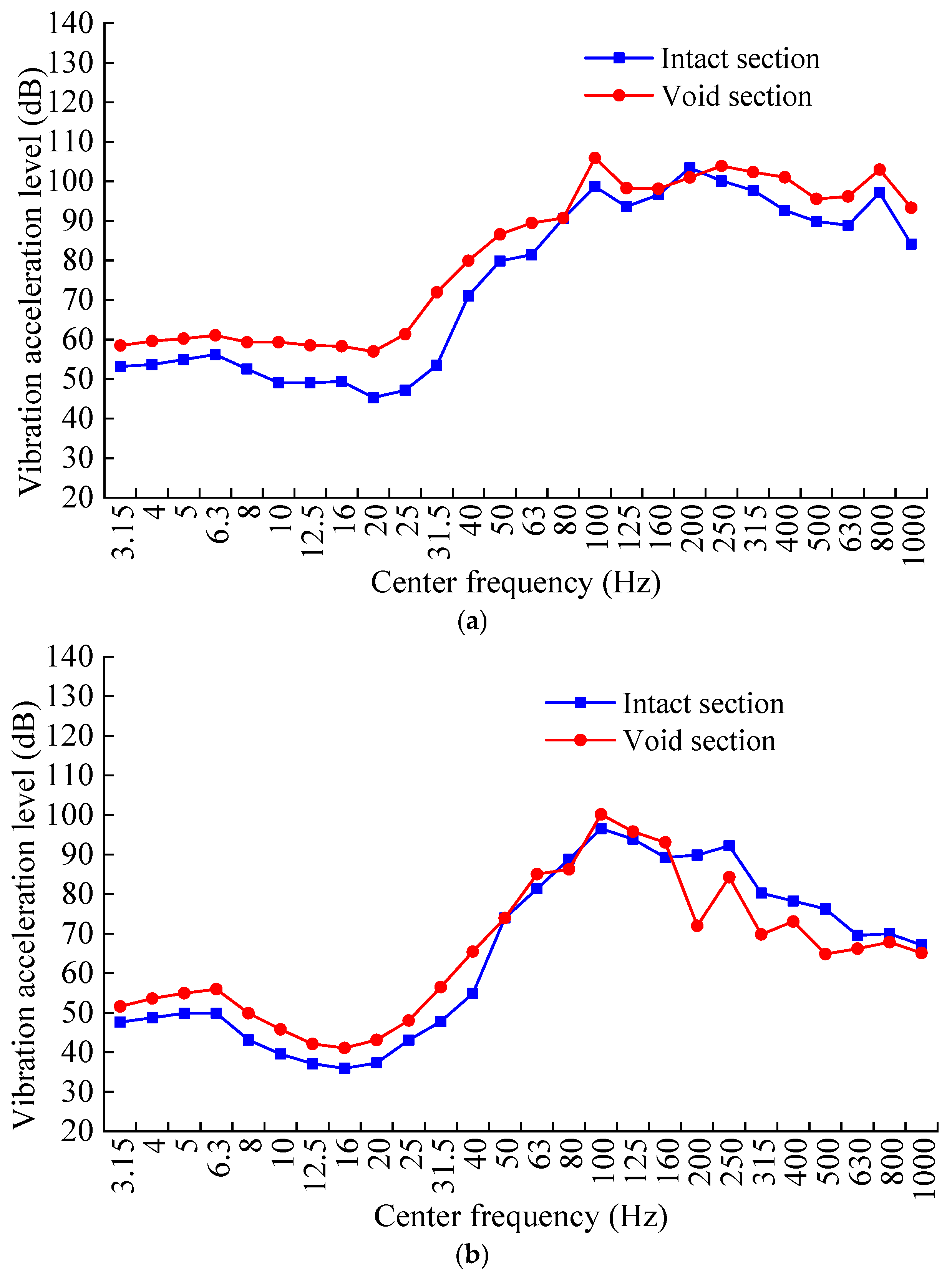

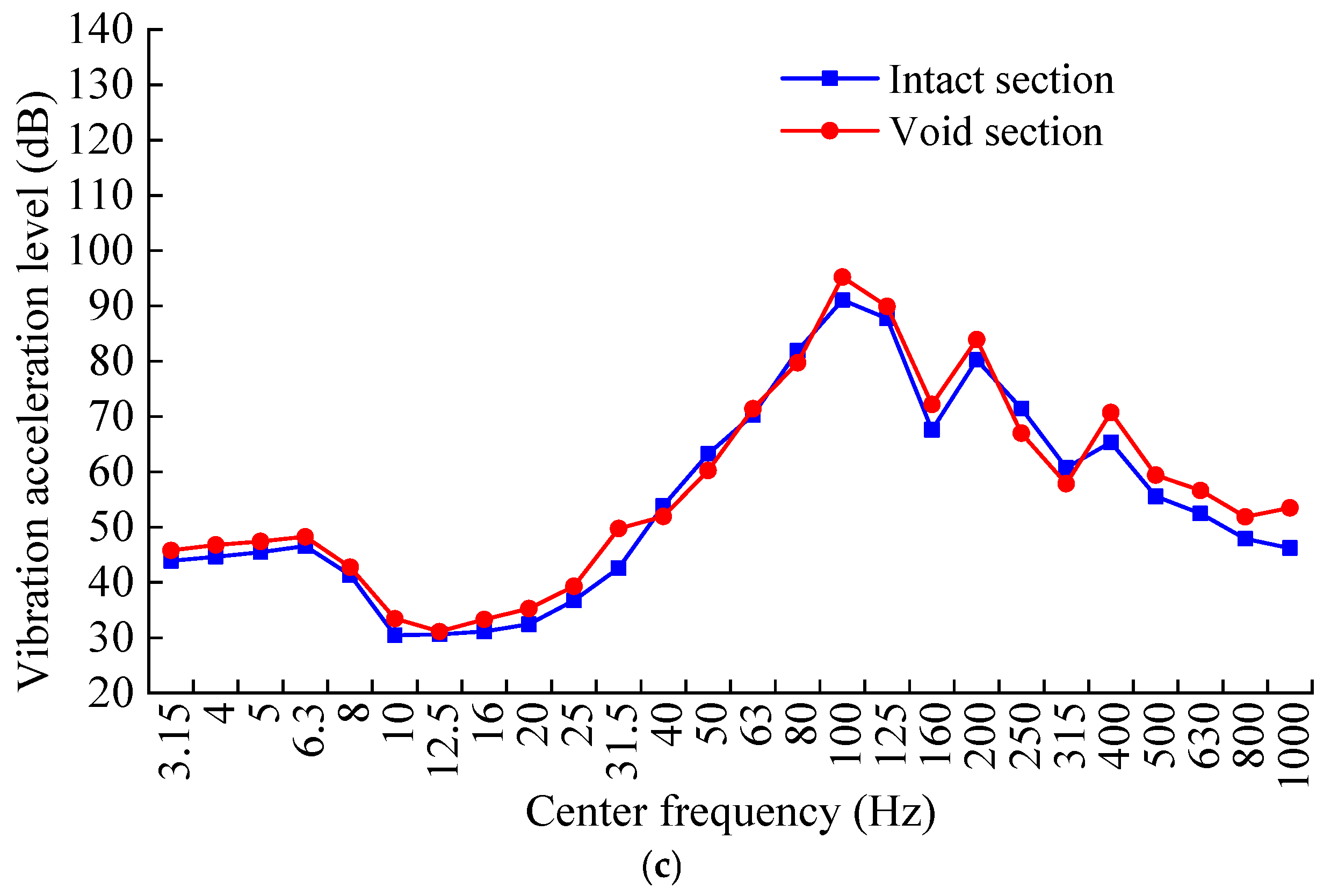

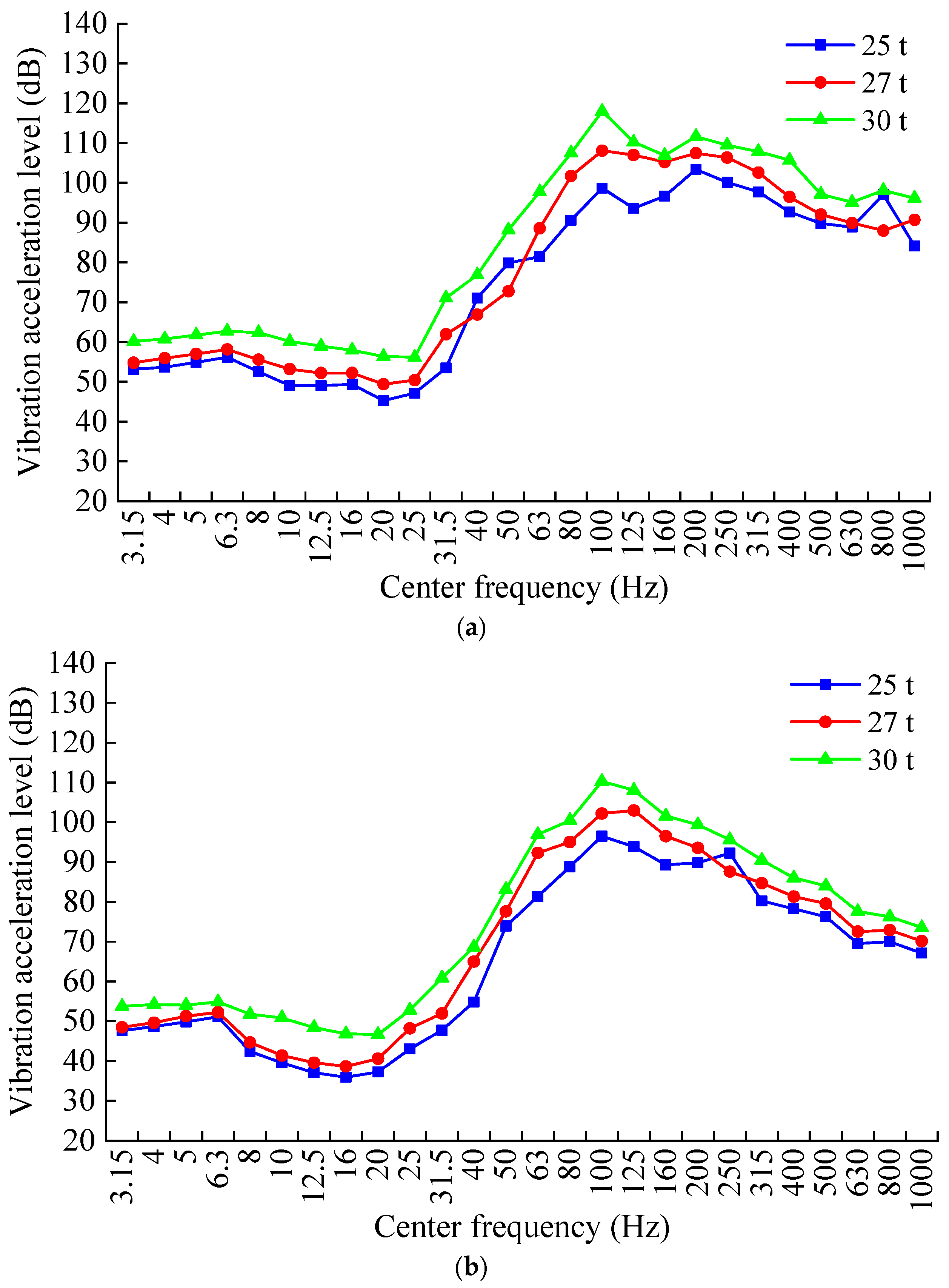

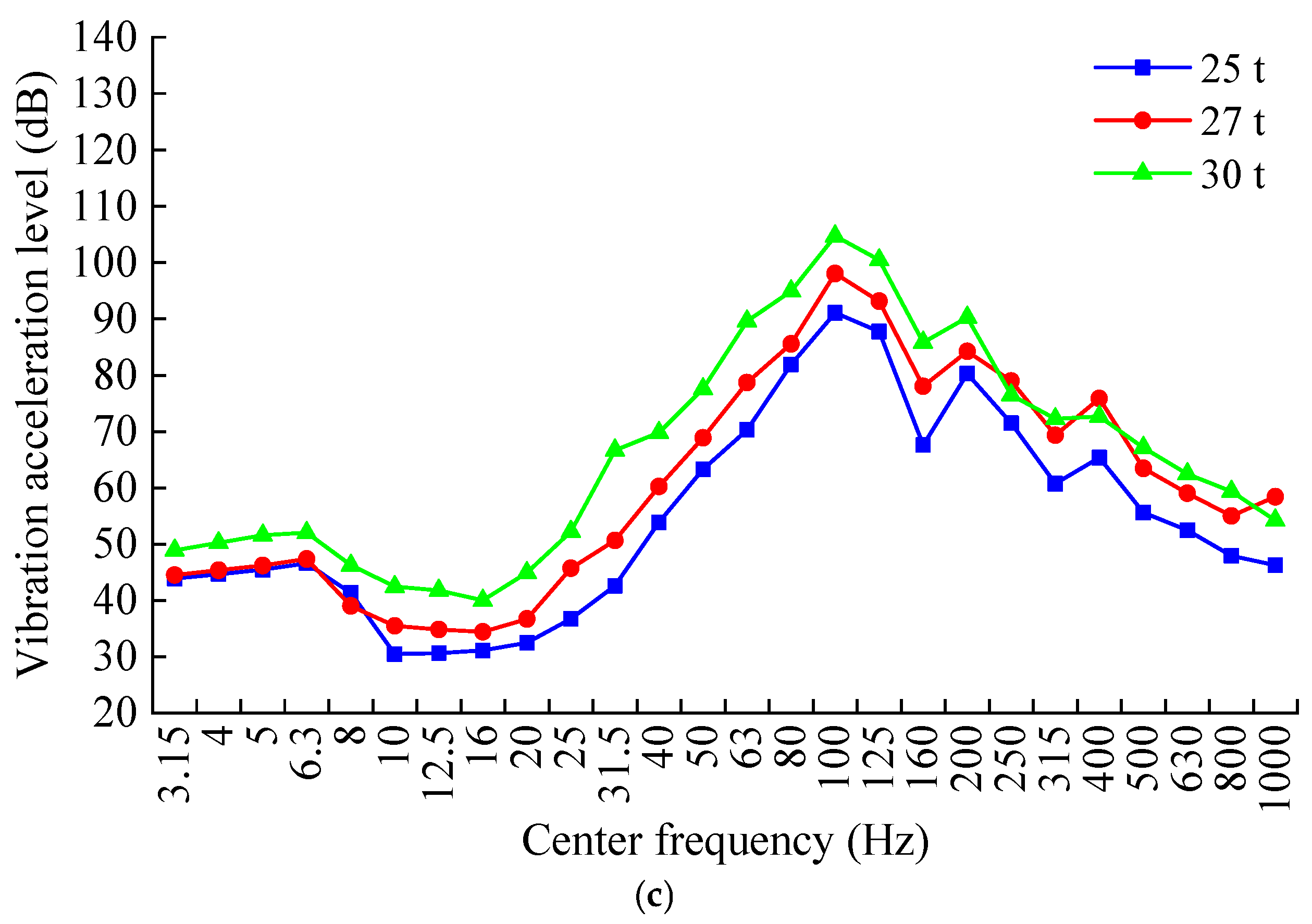

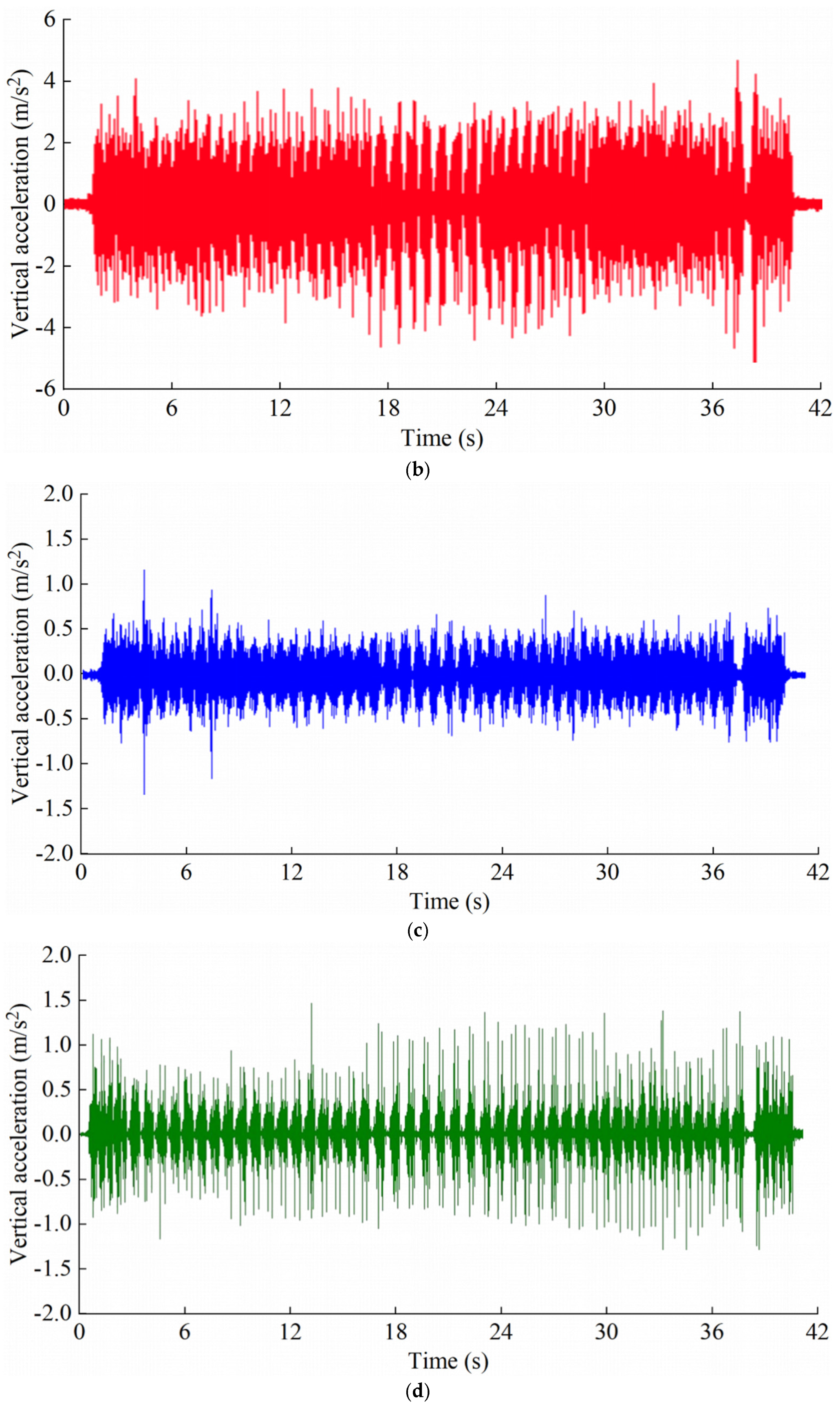

4. Analysis of Vibration Acceleration Results

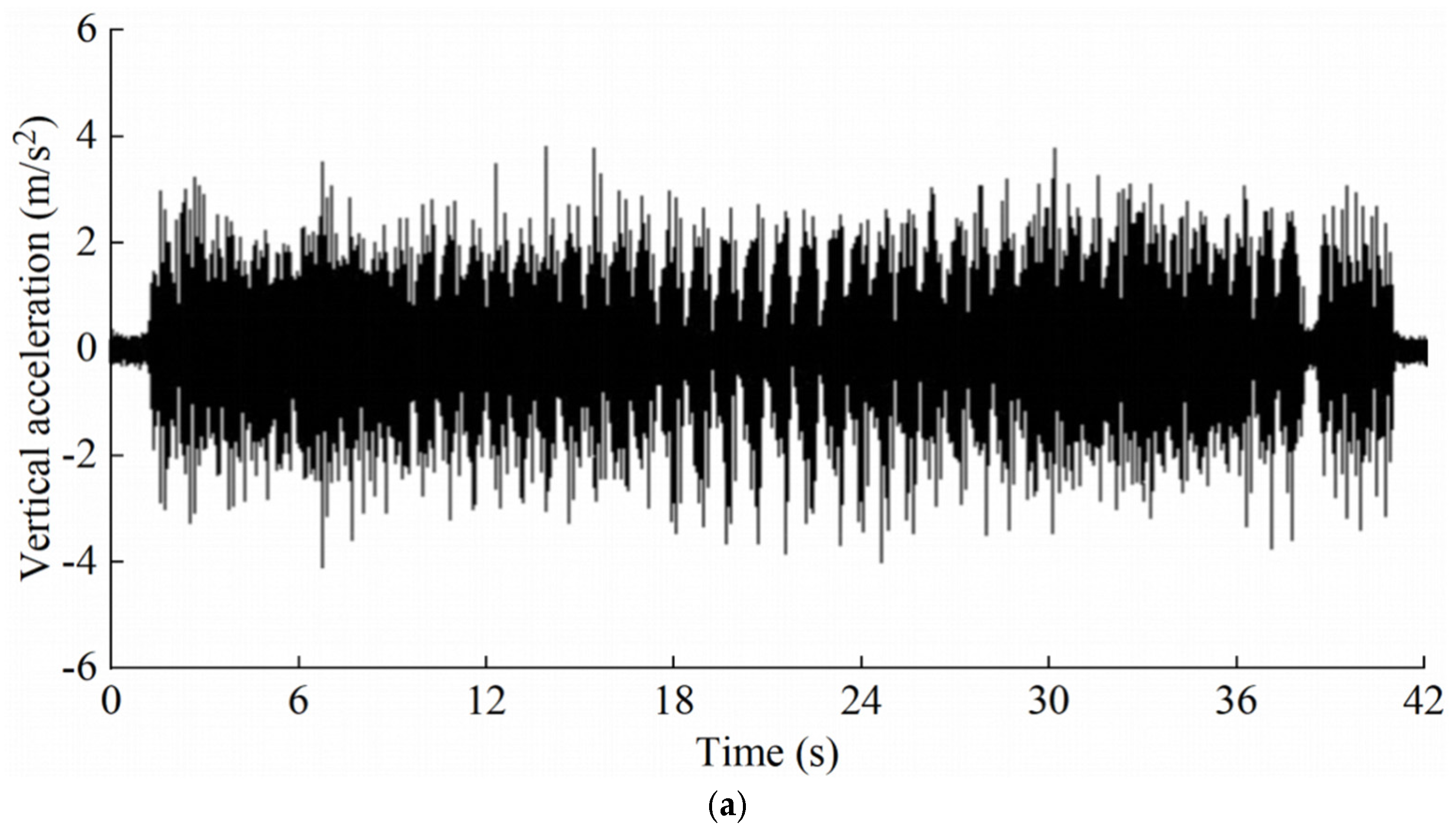

4.1. Time-Domain Vibration Acceleration Response Characteristics

4.2. Frequency-Domain Vibration Acceleration Response Characteristics

| Monitoring Point | 3.15 Hz | 5 Hz | 8 Hz | 12.5 Hz | 20 Hz | 31.5 Hz | 50 Hz | 100 Hz | 200 Hz | 315 Hz | 500 Hz | 800 Hz | 1000 Hz |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A2 | 53.2 | 55.0 | 52.5 | 49.1 | 45.3 | 53.5 | 79.9 | 98.7 | 93.6 | 103.4 | 89.8 | 97.1 | 84.1 |

| A4 | 47.6 | 49.8 | 43.1 | 37.1 | 37.3 | 47.8 | 73.9 | 96.5 | 89.8 | 80.2 | 76.2 | 70.0 | 67.1 |

| A6 | 43.9 | 45.5 | 41.3 | 30.6 | 32.4 | 42.3 | 63.2 | 91.1 | 80.3 | 60.7 | 55.6 | 47.9 | 46.2 |

| Monitoring Point | 3.15 Hz | 5 Hz | 8 Hz | 12.5 Hz | 20 Hz | 31.5 Hz | 50 Hz | 100 Hz | 200 Hz | 315 Hz | 500 Hz | 800 Hz | 1000 Hz |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A2 | 58.5 | 60.3 | 59.3 | 58.5 | 57.0 | 72.0 | 86.6 | 106.0 | 98.3 | 101.0 | 95.5 | 102.9 | 93.3 |

| A4 | 51.6 | 54.9 | 49.9 | 42.1 | 43.1 | 56.5 | 73.9 | 100.1 | 71.9 | 69.8 | 64.8 | 67.8 | 65.1 |

| A6 | 45.8 | 47.4 | 42.8 | 31.1 | 35.3 | 49.7 | 60.2 | 95.2 | 83.9 | 57.9 | 59.4 | 51.8 | 53.5 |

5. Conclusions

- (1)

- The vertical dynamic stress of the tunnel bottom structure is compressive stress. The maximum compressive stress is observed directly beneath the heavy-load line at the surface of the infill layer, from which it propagates laterally in both directions. Both an increase in train axle load and the occurrence of base detachment contribute to a corresponding increase in the power response.

- (2)

- The load transmitted from heavy-duty trains to the base structure constitutes a low-frequency dynamic effect, with its primary energy distribution confined to the 0–20 Hz band. It was determined that while variations in axle load directly influence the magnitude of the dynamic stress, they have no discernible effect on its principal frequency components. The overall dynamic response is predominantly characterized by the coupled influence of adjacent bogies from successive rail carriages.

- (3)

- A marked escalation in the acceleration response of the tunnel bottom structure was observed in conjunction with increasing axle loads. Specifically, an increase in axle load from 25 t to 27 t precipitated a rise in peak acceleration ranging from 10.2% to 17.5%. A further increase from 27 t to 30 t induced a significantly greater escalation, with peak acceleration growth rates between 18.0% and 27.3%.

- (4)

- The one-third octave band analysis indicates that the most pronounced difference in center frequency vibration acceleration levels is manifest at 31.5 Hz. Moreover, the dynamic response attributable to the void defect attenuates with increasing distance between the measurement point and the vibration source.

- (5)

- The 31.5 Hz frequency serves as a key indicator for track structure void defects. This allows for the creation of portable or online monitoring systems that target this specific frequency. When the vibration acceleration level exceeds a statistically determined threshold, the system can issue an alert for the rapid and accurate localization of these defects.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, C.; Gong, Z.b.; Sha, M.; Wu, B.; Zeng, J.J.; Zhu, R.N. Dynamic response of heavy haul railway tunnel’s bottom structures with base cavity in hard rock environment. J. Railw. Sci. Eng. 2023, 20, 4667–4677. [Google Scholar] [CrossRef]

- Xiao, P.; Peng, L.M.; Li, R.; Wang, H.L.; Lei, M.F. Research on vehicle-rail-tunnel coupling model and influence factors of dynamic response of bottom structure of heavy-haul railway tunnel. J. Railw. Sci. Eng. 2022, 19, 3737–3745. [Google Scholar] [CrossRef]

- Wang, F.; Liu, C.; Peng, L.M.; Lei, M.F.; Shi, C.H. Experimental study on fatigue performances of heavy haul railway tunnel’s pavement structure with base cavity. J. Railw. Sci. Eng. 2021, 18, 2688–2693. [Google Scholar] [CrossRef]

- Nie, R.S.; Mei, H.H.; Leng, W.M.; Zhao, C.Y.; Li, Y.F.; Tu, R.P. Experimental research on dynamic response characteristics of transition subgrade induced by heavy-haul trains. China Civ. Eng. J. 2019, 52, 101–115. [Google Scholar] [CrossRef]

- Li, P.; Ling, X.; Zhang, F.; Li, Y.; Zhao, Y. Field testing and analysis of embankment vibrations induced by heavy haul trains. Shock Vib. 2017, 2017, 7410836. [Google Scholar] [CrossRef]

- Guo, F.Q.; Wang, P.J.; Yang, Q.; Yu, Z.W.; Leng, M.W.; Chen, C. Experimental research on characteristics of vertical dynamic load on bridge pier and pile foundation under heavy-haul railway train. China Civ. Eng. J. 2019, 52, 101–115. [Google Scholar] [CrossRef]

- Chen, T.; Ma, W.; Wu, Z.J.; Mu, Y.H. Characteristics of dynamic response of the active layer beneath embankment in permafrost regions along the Qinghai–Tibet Railroad. Cold Reg. Sci. Technol. 2014, 98, 1–7. [Google Scholar] [CrossRef]

- Mei, H.H.; Leng, W.M.; Nie, R.S.; Tu, R.P.; Li, Y.F.; Dong, J.L. Experimental research on the dynamic response characteristics of the transition subgrade induced by heavy-haul train passage. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit. 2019, 233, 974–987. [Google Scholar] [CrossRef]

- Ribeiro, C.A.; Rui, C.; Delgado, R. Experimental assessment of the dynamic behaviour of the train-track system at a culvert transition zone. Eng. Struct. 2017, 138, 215–228. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.Q.; Cai, R.Y.; Hua, Y.; Wang, L.; Gu, D.M. Refined model analysis of basement rock degradation mechanism of heavy-haul railway tunnel. Undergr. Space. 2021, 6, 342–352. [Google Scholar] [CrossRef]

- Wang, D.K.; Luo, J.J.; Li, F.L.; Wang, L.; Su, J. Research on dynamic response and fatigue life of tunnel bottom structure under coupled action of train load and groundwater. Soil Dyn. Earthq. Eng. 2022, 161, 107405. [Google Scholar] [CrossRef]

- Wang, D.K.; Luo, J.J.; Wang, G.Q.; Li, F.L.; Su, J. Dynamic response of the tunnel bottom structure considering groundwater influence under heavy-haul train loading. Structures 2022, 46, 1469–1479. [Google Scholar] [CrossRef]

- Wang, D.K.; Luo, J.J.; Wang, G.Q.; Li, F.L.; Hou, Y.J. Dynamic response of heavy-duty railway tunnel under the condition of water-rich surrounding rock void of the tunnel bottom. J. Harbin Inst. Technol. 2023, 55, 33–42. [Google Scholar] [CrossRef]

- Mandal, S.K.; Singh, M.M. Evaluating extent and causes of overbreak in tunnels. Tunn. Undergr. Spa. Tech. 2009, 24, 22–36. [Google Scholar] [CrossRef]

- Jeon, S.; Kim, J.; Seo, Y.; Hong, C. Effect of a fault and weak plane on the stability of a tunnel in rock—A scaled model test and numerical analysis. Inter. J. Roc. Mech. Min. Sci. 2004, 41, 486. [Google Scholar] [CrossRef]

- Nejati, H.R.; Ahmadi, M.; Hashemolhosseini, H. Numerical analysis of ground surface vibration induced by underground train movement. Tunn. Undergr. Spa. Tech. 2012, 29, 1–9. [Google Scholar] [CrossRef]

- Takemiya, H.; Bian, X. Substructure simulation of inhomogeneous track and layered ground dynamic interaction under train passage. J. Eng. Mech. 2005, 131, 699–711. [Google Scholar] [CrossRef]

- Andersen, L.; Jones, C.J.C. Coupled boundary and finite element analysis of vibration from railway tunnels—A comparison of two-and three-dimensional models. J. Sou. Vib. 2006, 293, 611–625. [Google Scholar] [CrossRef]

- Auersch, L. Dynamic stiffness of foundations on inhomogeneous soils for a realistic prediction of vertical building resonance. J. Geotech. Geoenv. 2008, 134, 328–340. [Google Scholar] [CrossRef]

- Indraratna, B.; Singh, M.; Nguyen, T.T.; Leroueil, S.; Abeywickrama, A.; Kelly, R.; Neville, T. Laboratory study on subgrade fluidization under undrained cyclic triaxial loading. Can. Geotech. J. 2020, 57, 1767–1779. [Google Scholar] [CrossRef]

- Du, M.Q.; Zhang, D.L.; Fang, Q.; Zhang, S.L.; Xiong, L.J. Dynamic response analysis of railway tunnel invert and its filling layer. China Railw. Sci. 2016, 37, 38–45. [Google Scholar]

- Du, M.Q.; Zhang, D.L.; Zhang, S.L.; Fang, Q. Field test and analysis of mechanical characteristics of tunnel invert structure for high-speed railway. China Railw. Sci. 2017, 38, 53–61. [Google Scholar] [CrossRef]

- Ma, W.B.; Chai, J.F.; Han, Z.L.; Ma, Z.G.; Guo, X.X.; Zou, W.H.; An, Z.L.; Li, T.F.; Niu, Y.B. Research on design parameters and fatigue life of tunnel bottom structure of single-track ballasted heavy-haul railway tunnel with 40-Ton axle load. Math. Probl. Eng. 2020, 2020, 3181480. [Google Scholar] [CrossRef]

- Ma, W.B.; Chai, J.F.; Zhu, Z.F.; Han, Z.L.; Ma, C.F.; Li, Y.J.; Zhu, X.Y.; Liu, Z.Y.; Niu, Y.B.; Ma, Z.G.; et al. Research on vibration law of railway tunnel substructure under different axle loads and health conditions. Shock Vib. 2021, 2021, 9954098. [Google Scholar] [CrossRef]

- Zou, W.H.; Zhang, M.; Liu, Y.Q.; Ma, W.B. Stress distribution and dynamic response of base structure for heavy haul railway tunnel under 30 t axle load. China Railw. Sci. 2016, 37, 50–57. [Google Scholar] [CrossRef]

- Wang, D.K.; Luo, J.J.; Li, F.L.; Wang, G.Q.; Wang, L.; Su, J.; Yin, K.Y. Dynamic response and service life of tunnel bottom structure considering hydro-mechanical coupling effect under the condition of bedrock softening. Materials 2022, 15, 6496. [Google Scholar] [CrossRef]

- Wang, H.L.; Dong, J.; Wu, Z.H.; Wang, Z.G. Impact of undercrossing tunnel on safety and stability of existing heavy-duty railway tunnel. J. China Railw. Soc. 2020, 42, 102–111. [Google Scholar] [CrossRef]

- Connolly, D.P.; Kouroussis, G.; Laghrouche, O.; Ho, C.L.; Forde, M.C. Benchmarking railway Vibrations-Track, vehicle, ground and building effects. Constr. Build. Mater. 2015, 92, 64–81. [Google Scholar] [CrossRef]

- Zou, W.H. Research on Dynamic Response Characteristics and Evaluation System of Heavy Haul Railway Tunnel Base Structure. Ph.D. Thesis, China Academy of Railway Sciences, Beijing, China, 2016. [Google Scholar]

- GB/T 50218-2014; Standard for Engineering Classification of Rock Masses. Ministry of Housing and Urban–Rural Development of the People’s Republic of China: Beijing, China, 2014.

- Bian, X.C.; Jiang, H.G.; Chang, C.; Hu, J.; Chen, Y.M. Track and ground vibrations generated by high-speed train running on ballastless railway with excitation of vertical track irregularities. Soil Dyn. Earthq. Eng. 2015, 76, 29–43. [Google Scholar] [CrossRef]

| Monitoring Point | 25 t Axle Load | Growth Rate | 27 t Axle Load | Growth Rate | 30 t Axle Load |

|---|---|---|---|---|---|

| A1 | 2.85 | 16.5% | 3.32 | 20.8% | 4.01 |

| A2 | 2.96 | 10.5% | 3.27 | 25.7% | 4.11 |

| A3 | 3.01 | 13.3% | 3.41 | 27.3% | 4.34 |

| A4 | 0.98 | 16.3% | 1.14 | 21.1% | 1.38 |

| A5 | 0.81 | 13.6% | 0.92 | 21.7% | 1.12 |

| A6 | 0.49 | 10.2% | 0.54 | 18.5% | 0.64 |

| Monitoring Point | 25 t Axle Load | Growth Rate | 27 t Axle Load | Growth Rate | 30 t Axle Load |

|---|---|---|---|---|---|

| A1 | 3.46 | 16.2% | 4.02 | 23.1% | 4.95 |

| A2 | 3.66 | 12.6% | 4.12 | 22.8% | 5.06 |

| A3 | 3.37 | 17.5% | 3.96 | 20.7% | 4.78 |

| A4 | 1.09 | 15.6% | 1.26 | 18.3% | 1.49 |

| A5 | 0.87 | 17.2% | 1.02 | 21.6% | 1.24 |

| A6 | 0.53 | 15.1% | 0.61 | 18.0% | 0.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Su, J.; Luo, F.; Wang, Z.; Fan, J.; Luo, J.; Wang, G. Measurement of Dynamic Response and Analysis of Characteristics of Heavy-Haul Railway Tunnel Bottom Structure Under Train Loading. Buildings 2025, 15, 3880. https://doi.org/10.3390/buildings15213880

Wang D, Su J, Luo F, Wang Z, Fan J, Luo J, Wang G. Measurement of Dynamic Response and Analysis of Characteristics of Heavy-Haul Railway Tunnel Bottom Structure Under Train Loading. Buildings. 2025; 15(21):3880. https://doi.org/10.3390/buildings15213880

Chicago/Turabian StyleWang, Dengke, Jie Su, Furong Luo, Zhe Wang, Jiansheng Fan, Jianjun Luo, and Guanqing Wang. 2025. "Measurement of Dynamic Response and Analysis of Characteristics of Heavy-Haul Railway Tunnel Bottom Structure Under Train Loading" Buildings 15, no. 21: 3880. https://doi.org/10.3390/buildings15213880

APA StyleWang, D., Su, J., Luo, F., Wang, Z., Fan, J., Luo, J., & Wang, G. (2025). Measurement of Dynamic Response and Analysis of Characteristics of Heavy-Haul Railway Tunnel Bottom Structure Under Train Loading. Buildings, 15(21), 3880. https://doi.org/10.3390/buildings15213880