Research on the Leakage Effect of Shield Tunnels in Water-Rich Silty Clay Strata Based on On-Site Investigation and Numerical Simulation

Abstract

1. Introduction

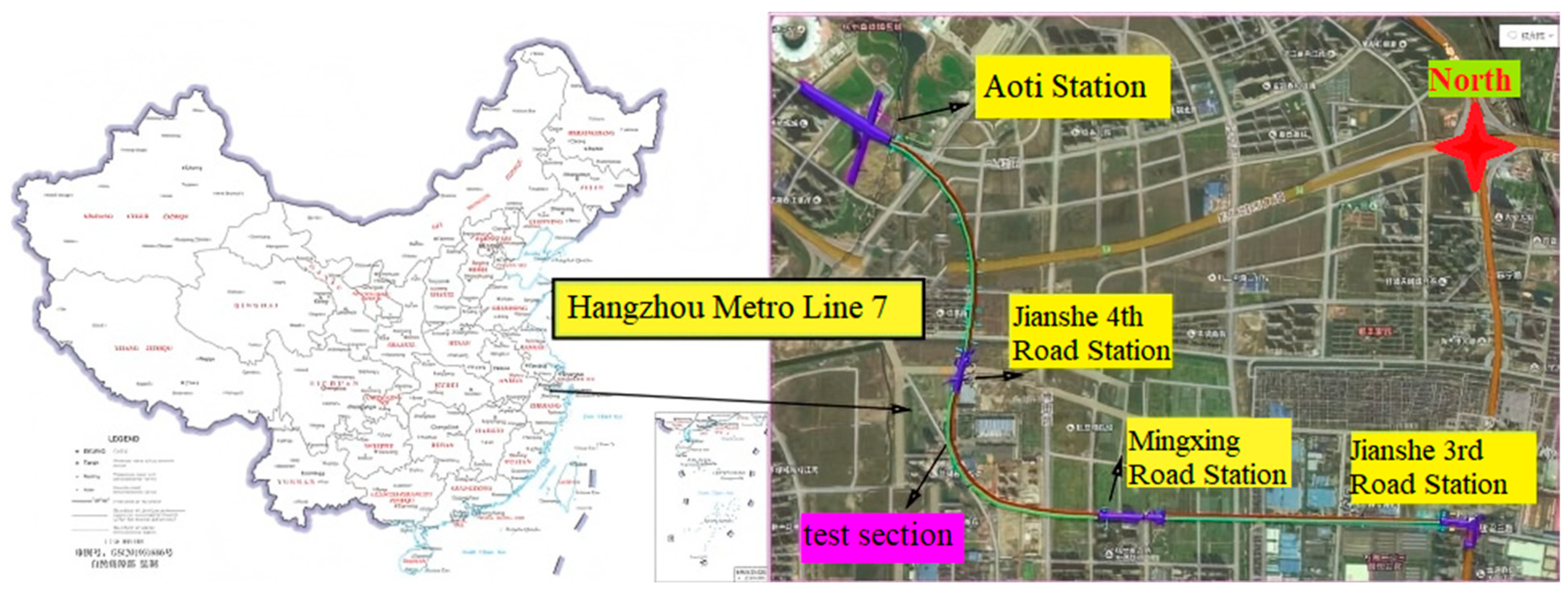

2. Overview of the Test Site

3. On-Site Investigation and Analysis of Segment Damage and Leakage

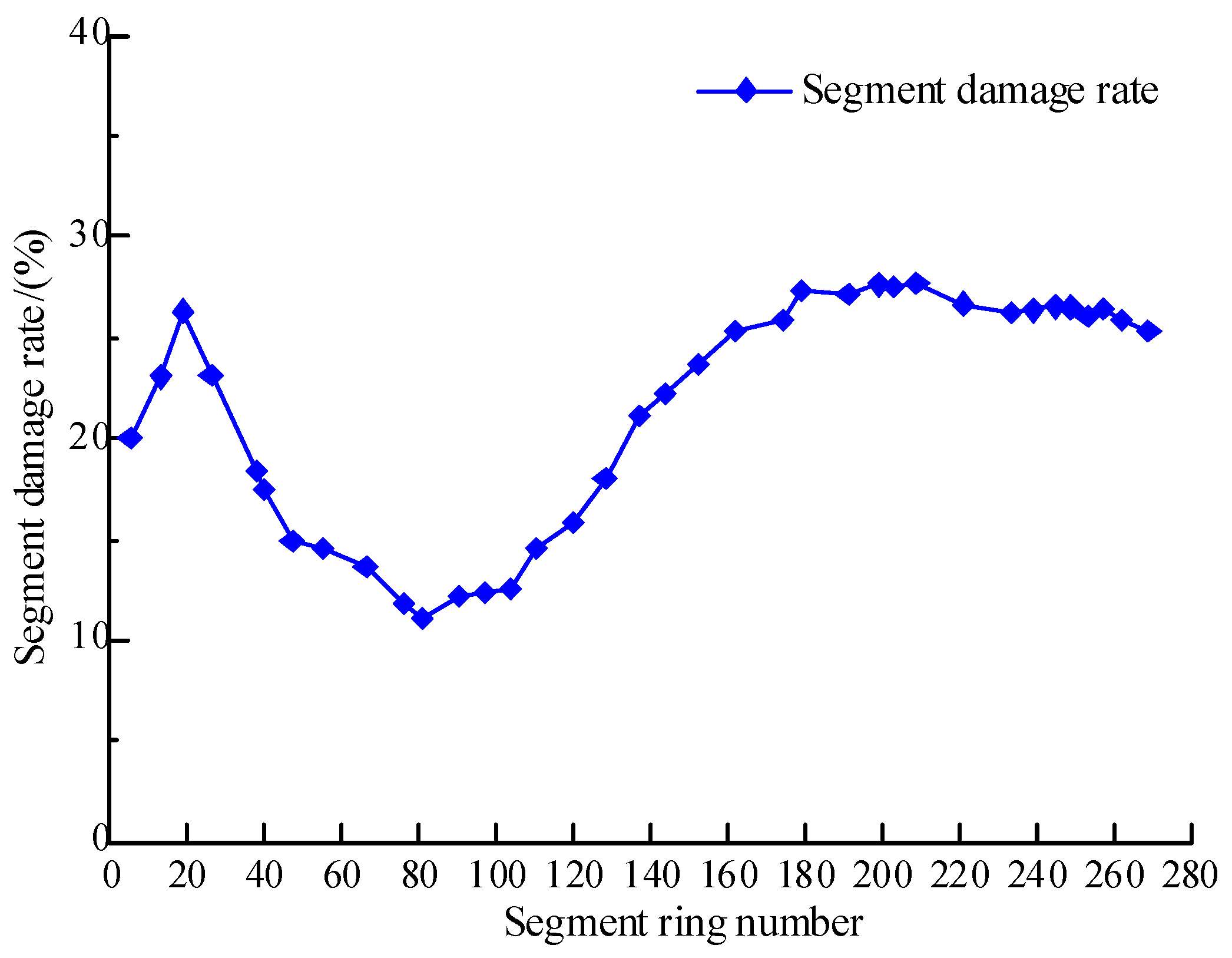

3.1. Analysis of Segment Damage

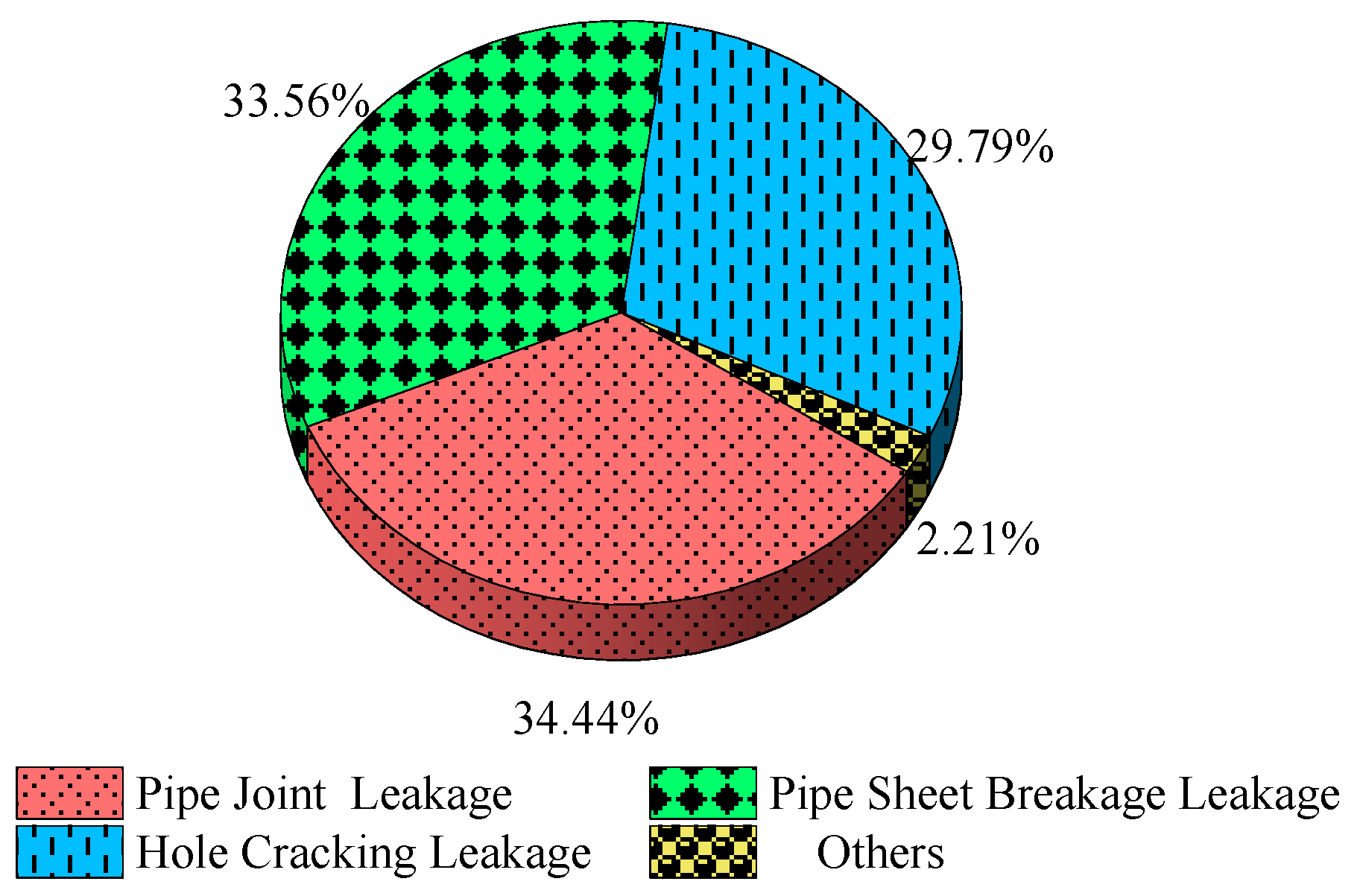

3.2. Analysis of Segment Leakage

4. Finite Element Simulation of Leakage Effect in Shield Tunnels

4.1. Tunnel Seepage Field Simulation

- (1)

- The first type of boundary condition (Dirichlet boundary): Specifies the water head value on the boundary;

- (2)

- The second type of boundary condition (Neumann boundary): Specifies the seepage rate or flow rate per unit area on the boundary;

- (3)

- The third type of boundary condition (natural boundary): It refers to the situation where there is neither water pressure nor seepage in the normal direction of the boundary (i.e., adiabatic or impermeable boundary).

4.2. Selection of Soil Parameters and Constitutive Models

4.3. Modeling of Lining Structure and Simplification of Stiffness

- (1)

- Overall stiffness reduction method: Previous studies have demonstrated that the global stiffness of shield tunnels with staggered joint assembly is typically 70–80% of the designed stiffness because of the discontinuous circumferential connections between segmental rings. Kavvadas et al. [27] established three-dimensional finite element models of segmental linings with various joint configurations and found that the effective stiffness of staggered-joint linings approaches about 70–80% of the design stiffness. Similarly, Zhang et al. [28] conducted full-scale tests and iterative analyses of quasi-rectangular shield tunnels, further confirming this stiffness range. Referring to these studies and the design data of the present section, the reduced overall elastic modulus was set to 26.80 GPa, corresponding to approximately 75% of the design stiffness.

- (2)

- Joint stiffness weakening method: Experimental and numerical investigations have indicated that the stiffness of circumferential joints is substantially lower than that of the segment bodies, typically one to two orders of magnitude smaller. Liu et al. [29] analyzed leakage-induced deformation in shield tunnels and found that insufficient joint stiffness can cause ring dislocation, while Kou et al. [26] confirmed through simulation that joint bending stiffness under ultra-high water pressure conditions is 1–2 orders of magnitude below that of the segments. Based on these findings, a 6 mm-wide joint zone was introduced into the continuous lining model, and its elastic modulus was appropriately weakened to maintain the overall stiffness at about 0.75 of the design value. In the model, the elastic modulus of the segment body is set to 31.50 GPa, and that of the joint area is set to 0.5 GPa.

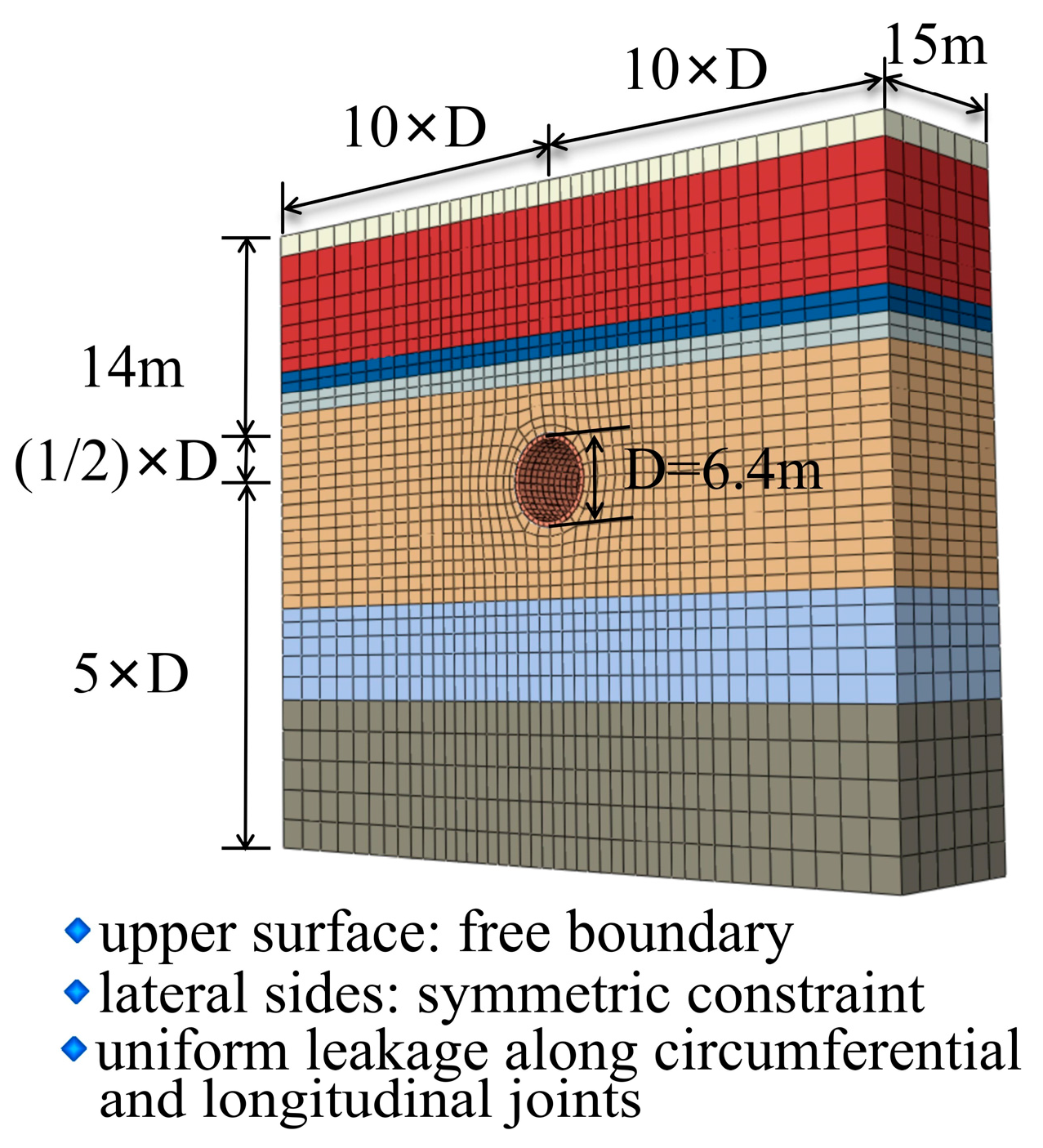

4.4. Model Establishment

4.5. Simulation of Water Leakage Process in Shield Tunnels

- (1)

- Eliminate the influence of construction disturbances: The excavation of shield tunnels can cause stratum disturbances and stress redistribution, leading to initial settlement and deformation of the soil around the tunnel. To eliminate the interference of this factor, this paper first extracts the initial stress field of the soil caused by shield excavation and introduces it as the initial stress condition for seepage and leakage analysis into the finite element model, so that the node stress reaches a static equilibrium state, thereby eliminating the influence of the shield construction process on the seepage and leakage simulation results.

- (2)

- Numerical simulation of seepage and leakage defect: In the simulation of seepage and leakage conditions, the drainage boundary conditions at the leakage location of the shield lining structure are first activated, and the seepage duration is set. Regarding the selection of seepage stabilization time, Liu et al. [40] set the seepage duration as 10,000 days in their study. Zheng et al. [33,34] conducted the analysis over 200 days. Wang et al. [19,35] pointed out that the seepage stability time of different strata varies significantly, mainly constrained by the soil permeability coefficient. Based on the geological investigation data of this project and the test results of the basic physical and mechanical properties of the water-rich silty clay, the seepage duration in the finite element model was set to 3650 days. This value was determined considering the permeability and consolidation characteristics of the stratum, which are consistent with the findings of Mei et al. [30] and Cui et al. [43] in similar geological environments. Moreover, the rationality of this parameter has been further verified through the comparative analysis between the simulated and measured soil settlement presented in Section 4.7.

4.6. Numerical Simulation Working Condition Settings

- (1)

- Working Condition 1: Simulation of leakage at the joint of the segment

- (2)

- Working Condition 2: Simulation of local leakage in the segment

4.7. Correctness Verification of the Model

- (1)

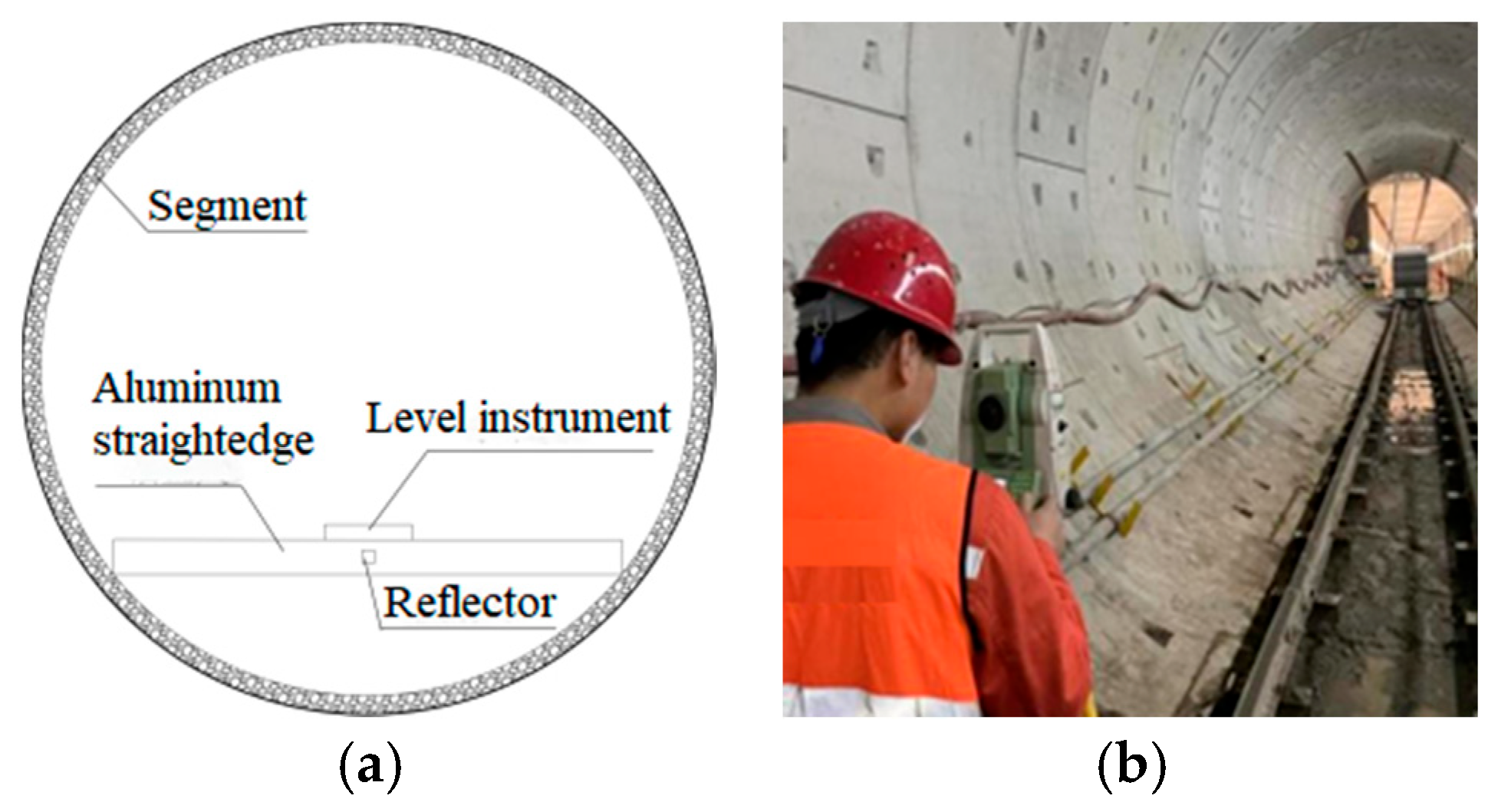

- On-site monitoring plan for shield tunnels

- (2)

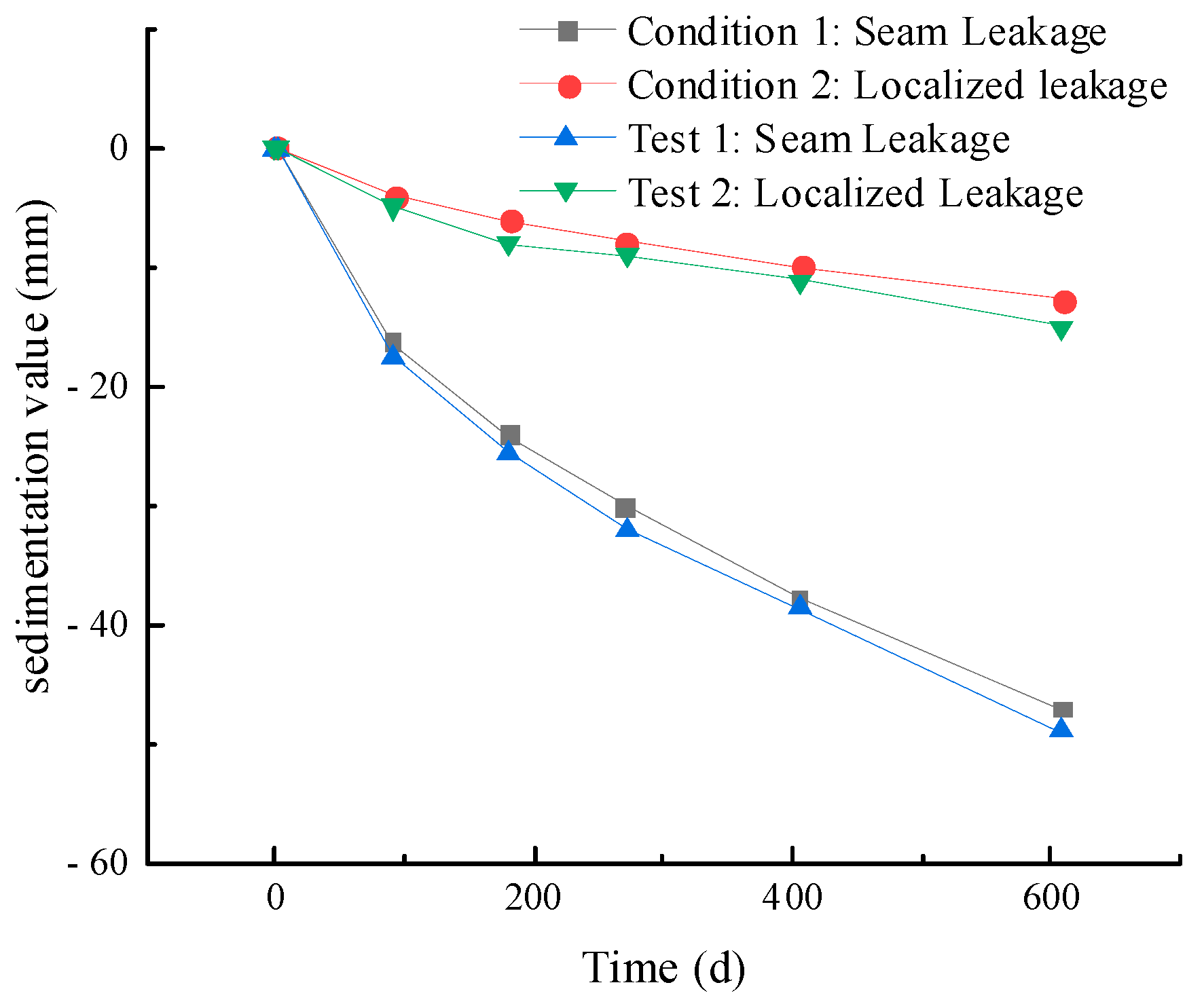

- Comparative analysis of monitoring data for shield tunnels

5. Analysis of Numerical Results

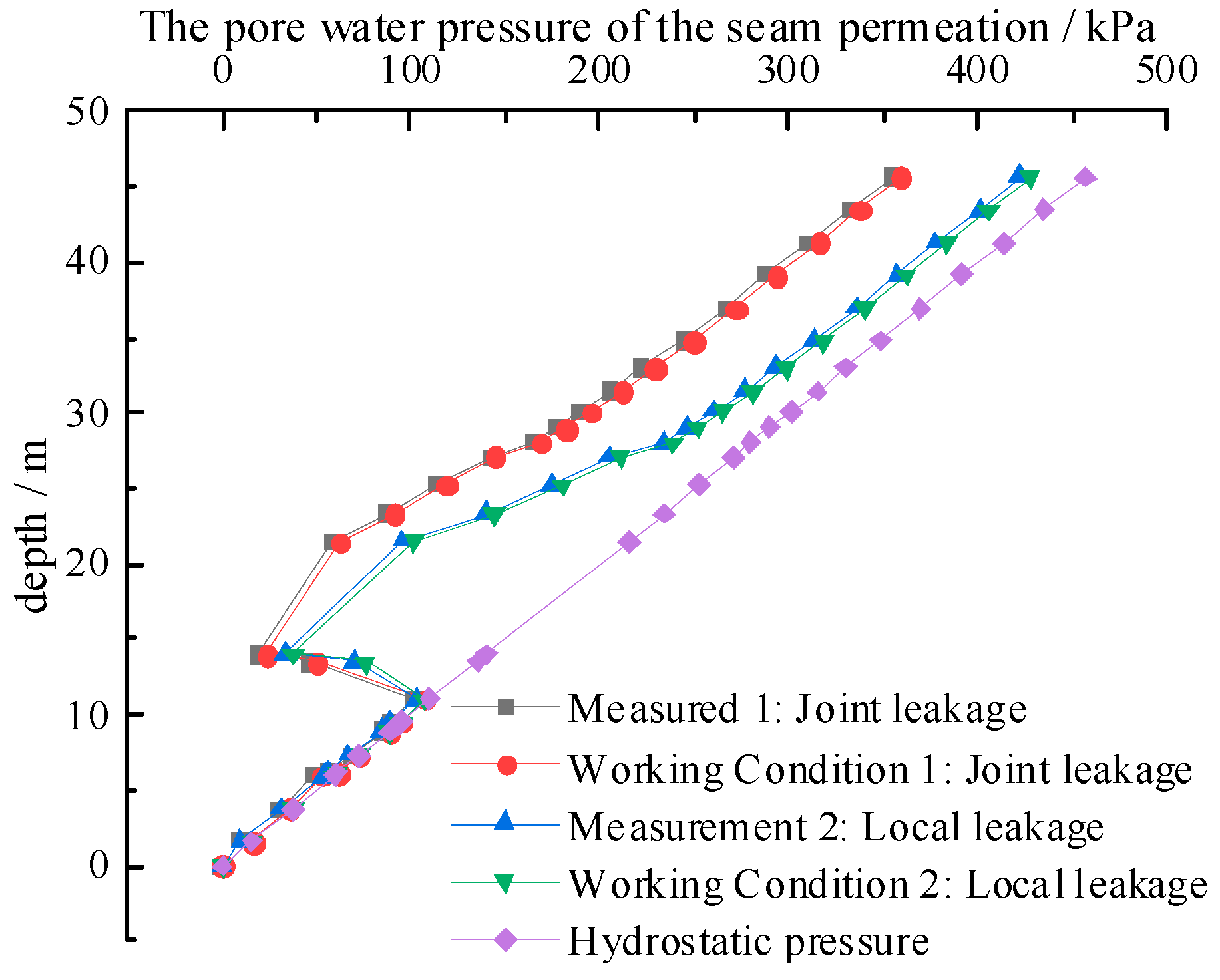

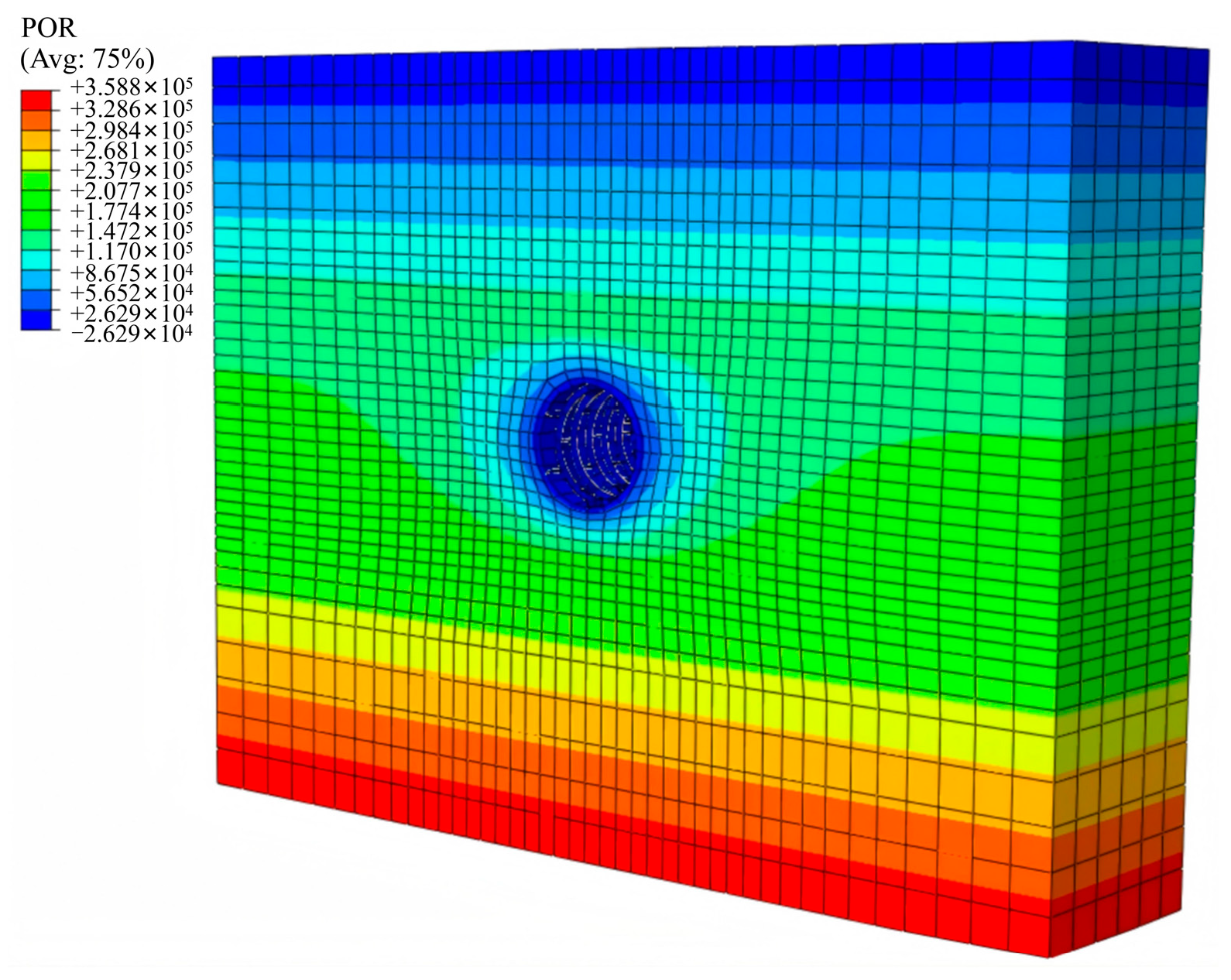

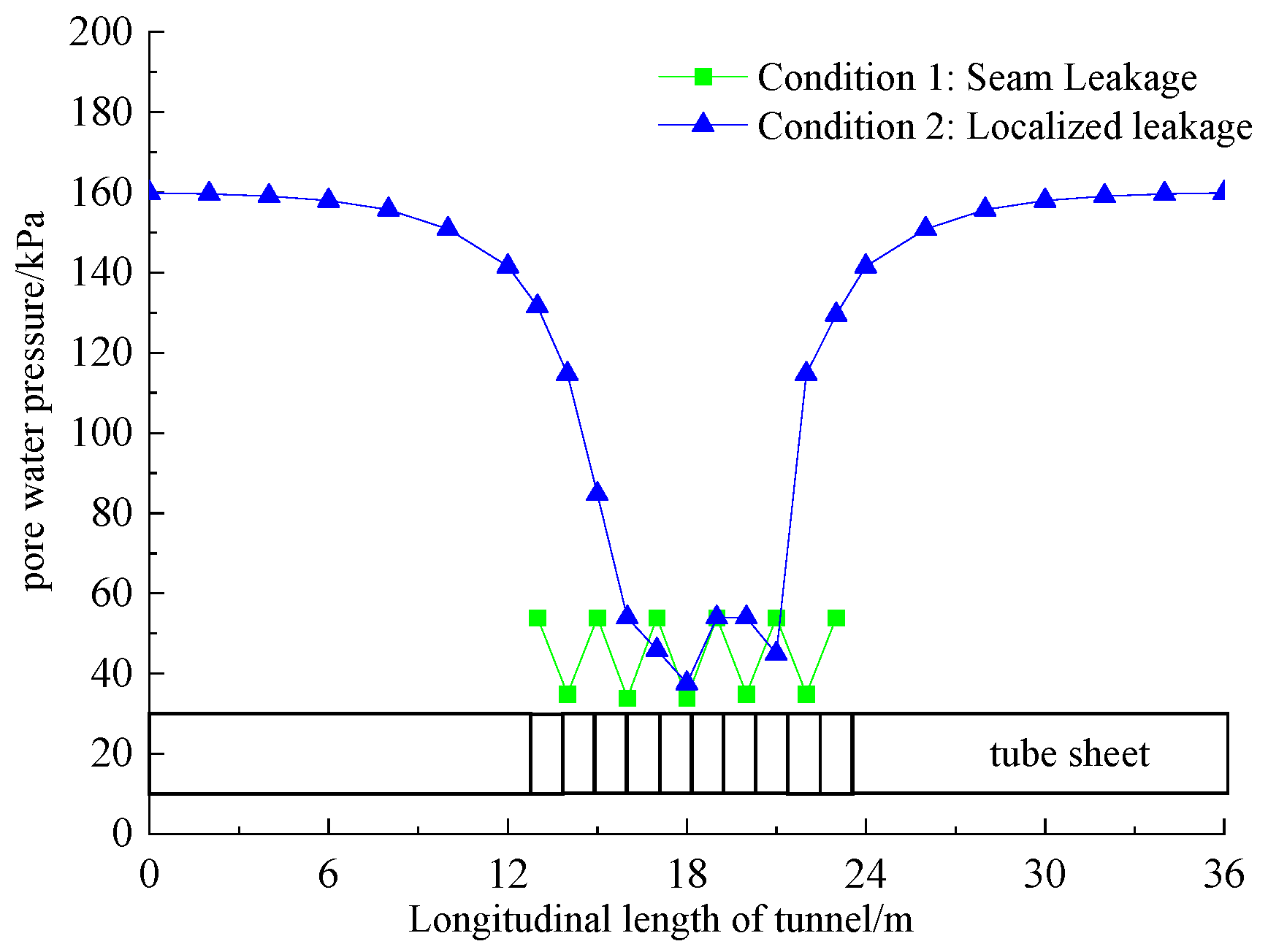

5.1. The Influence of Different Seepage and Leakage Conditions on the Pore Water Pressure of the Surrounding Soil

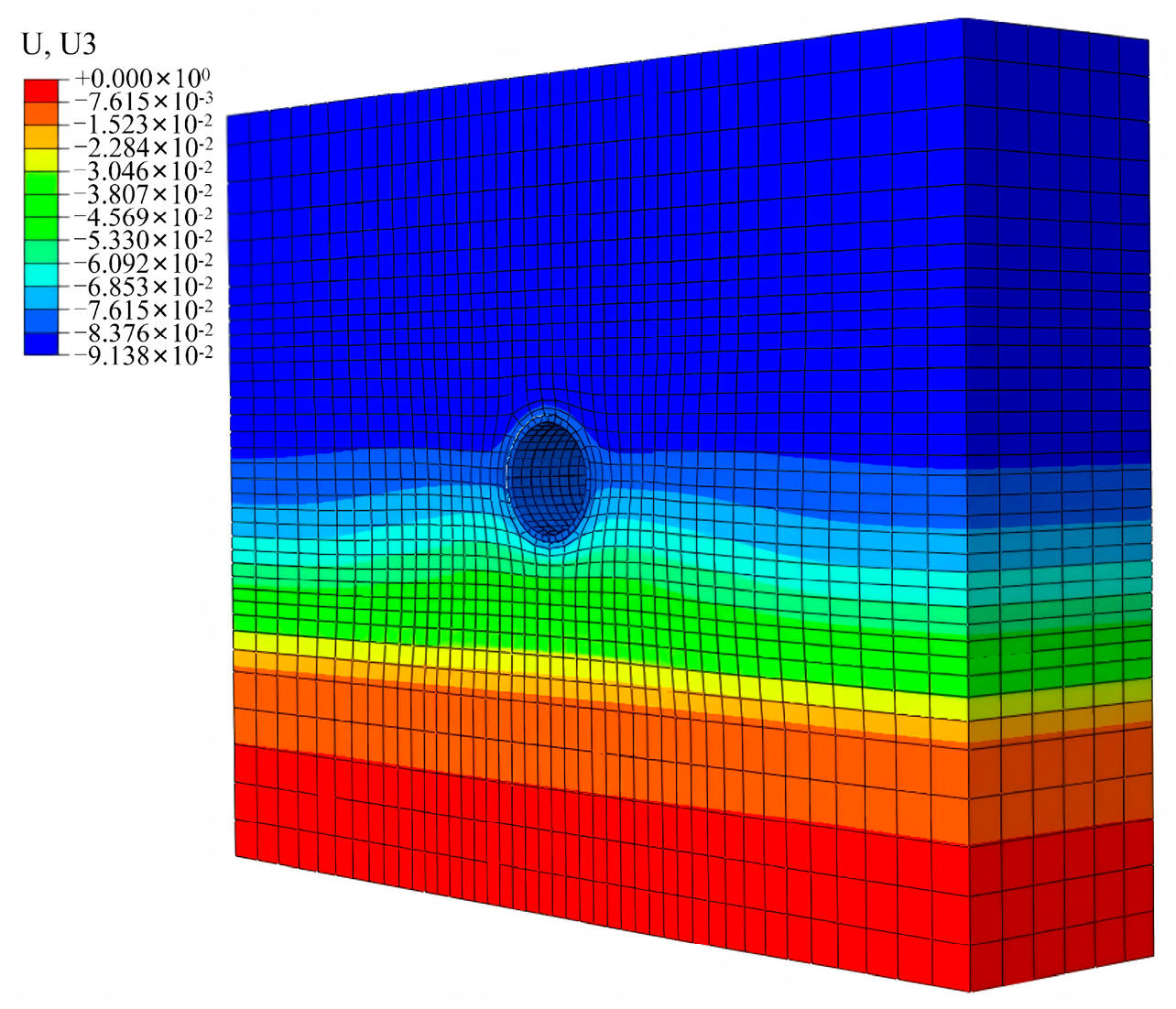

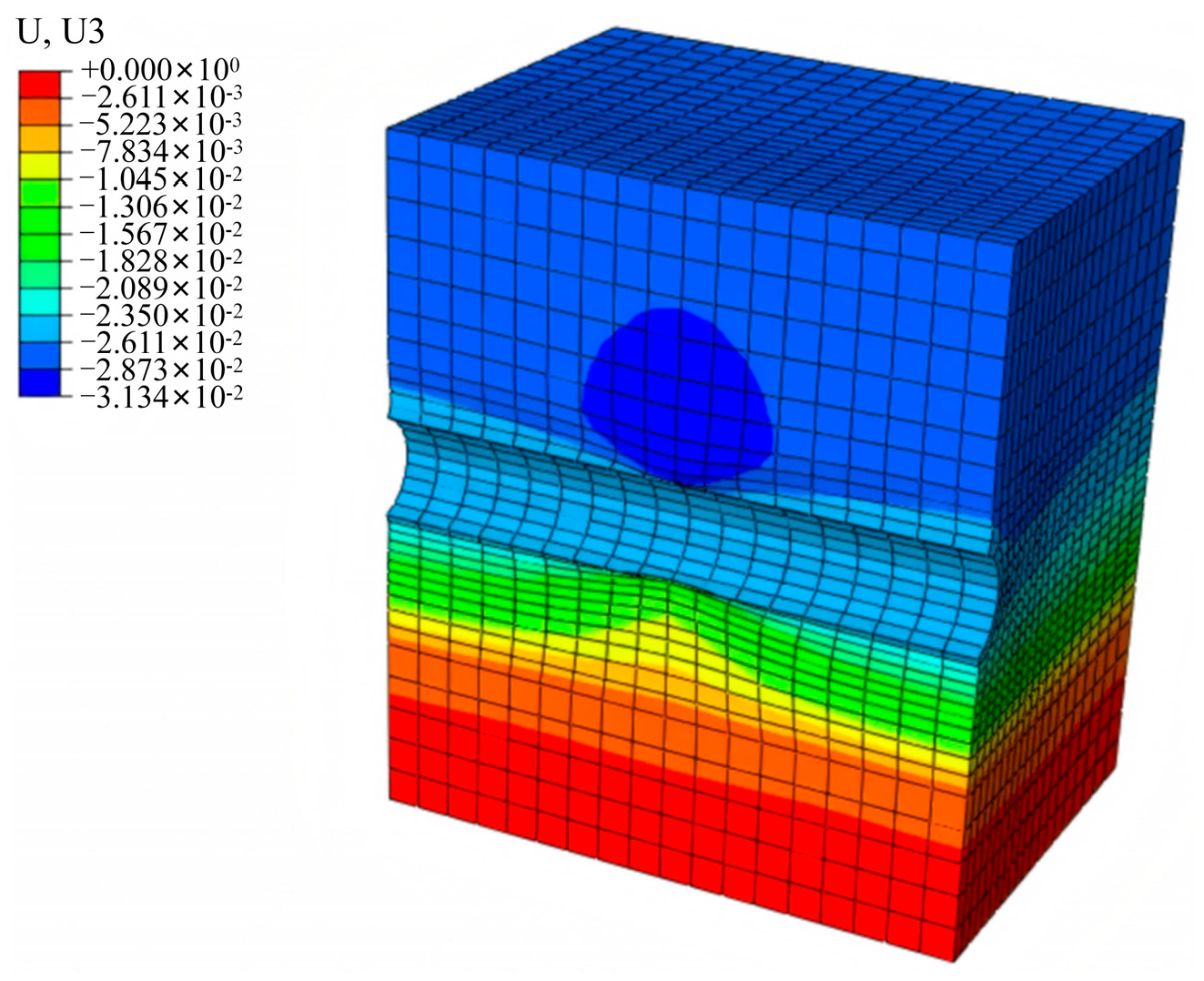

5.2. The Influence of Different Seepage Conditions on the Settlement of Soil Around the Tunnel

- (1)

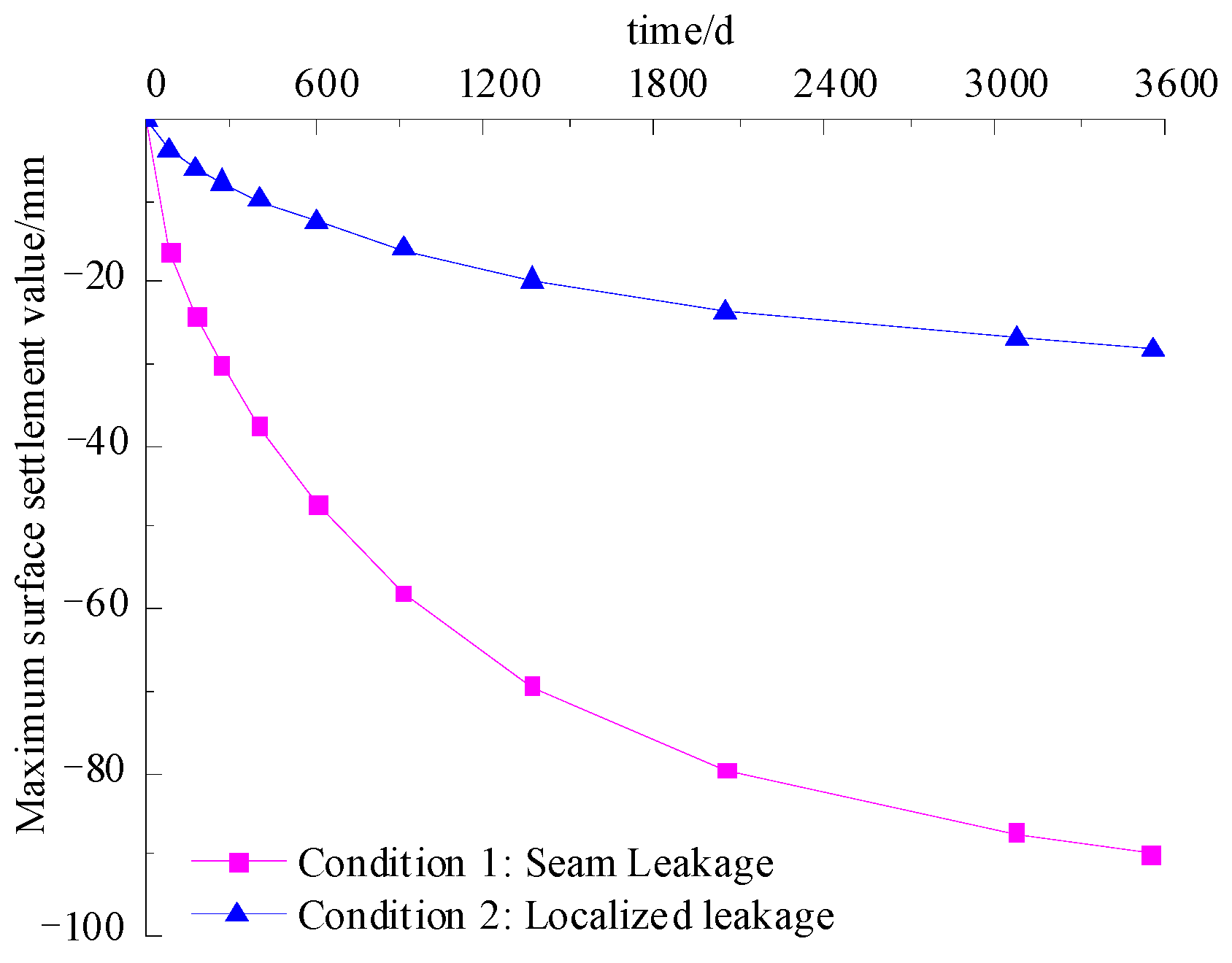

- The evolution law of maximum surface subsidence over time

- (2)

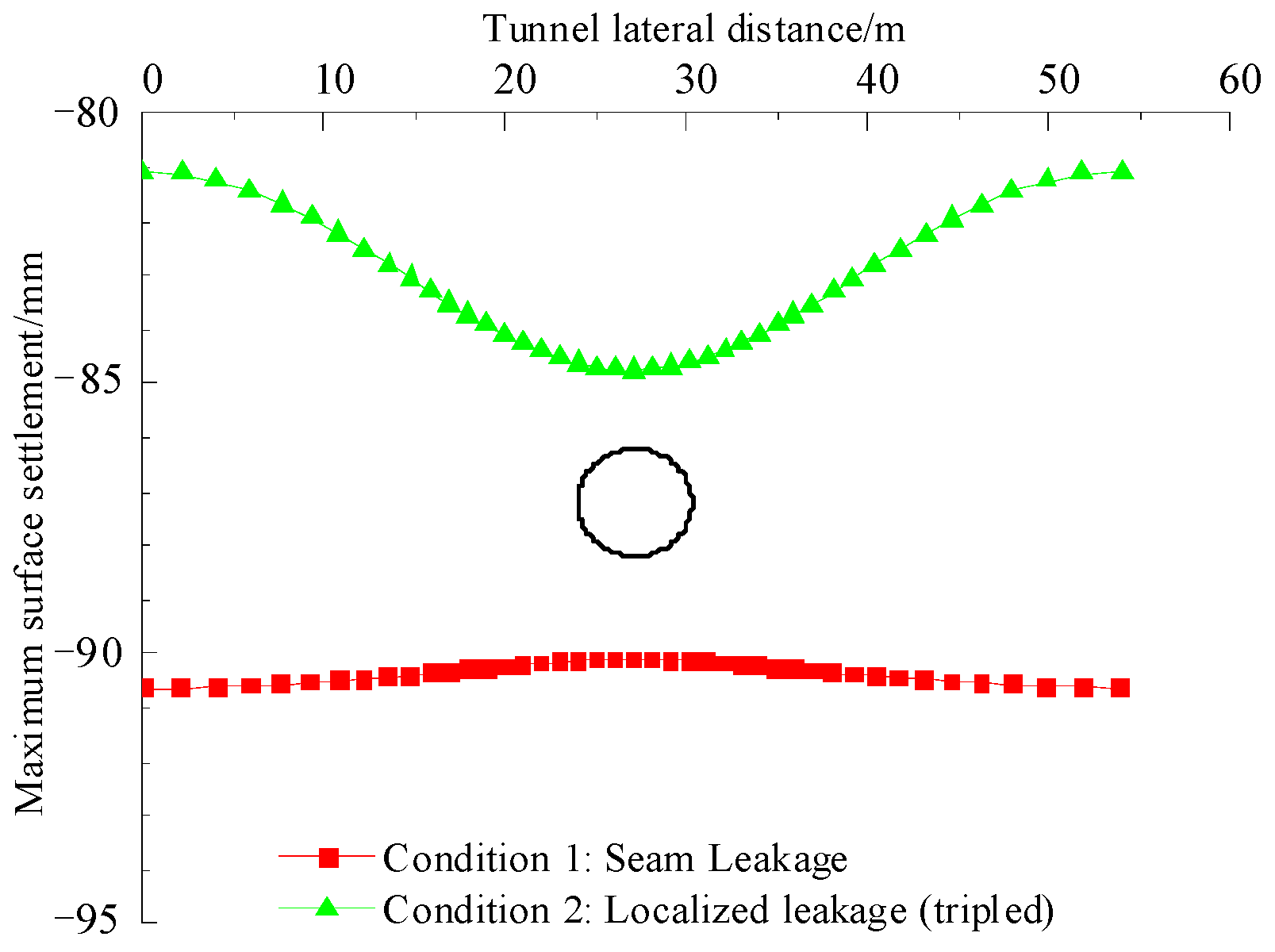

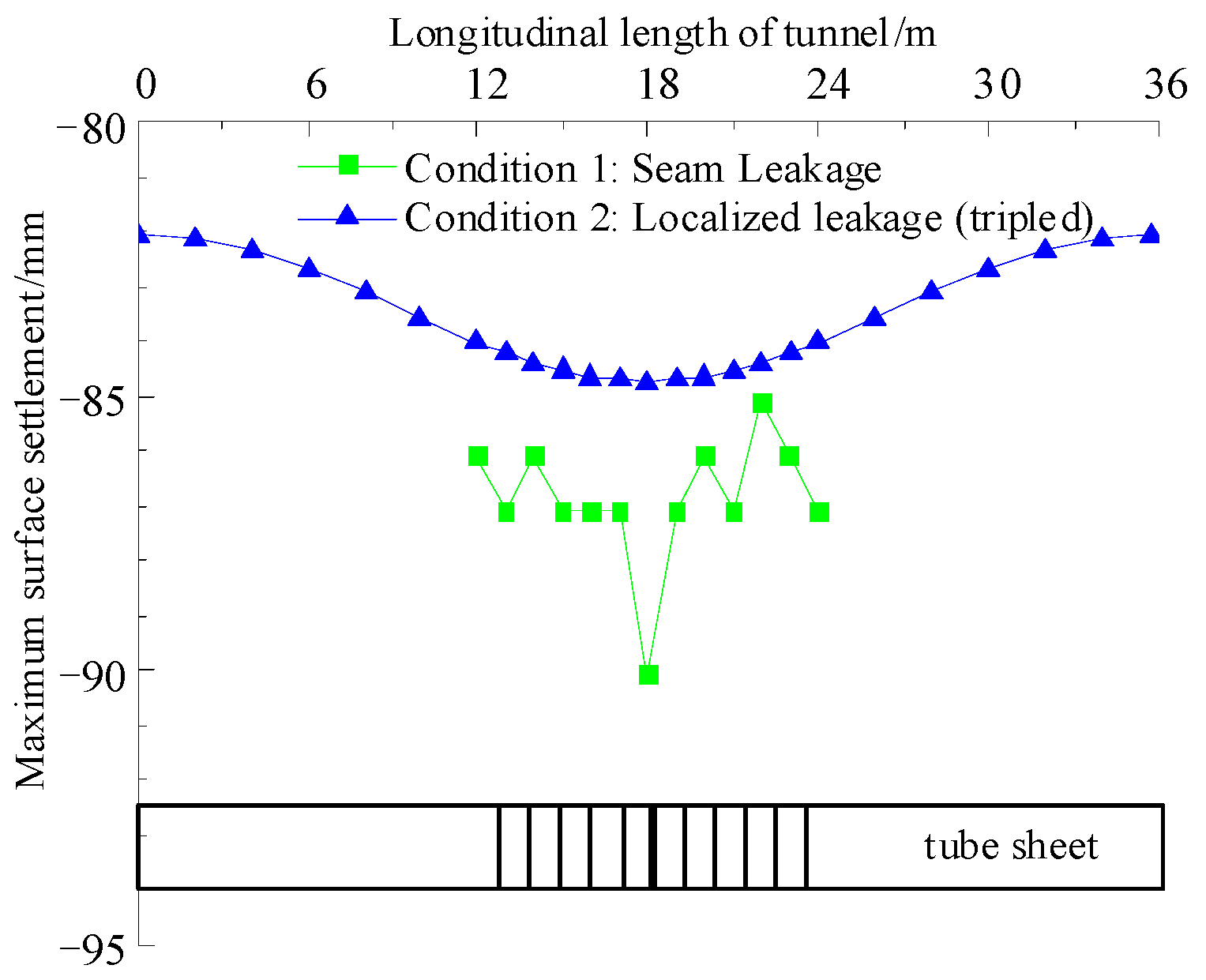

- Spatial distribution characteristics of the maximum surface settlement value

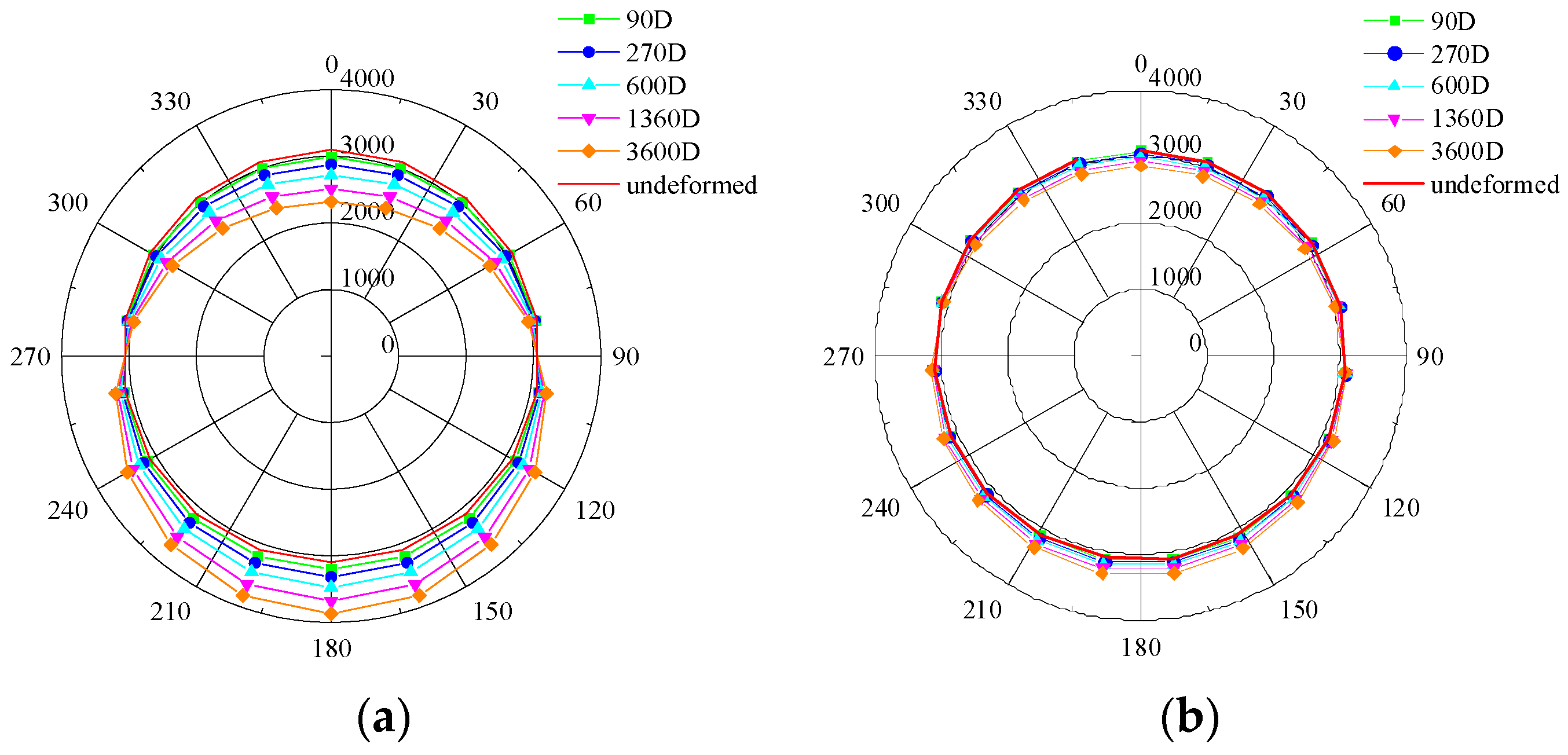

5.3. The Influence of Different Seepage and Leakage Conditions on the Deformation of Tunnel Lining Structures

- (1)

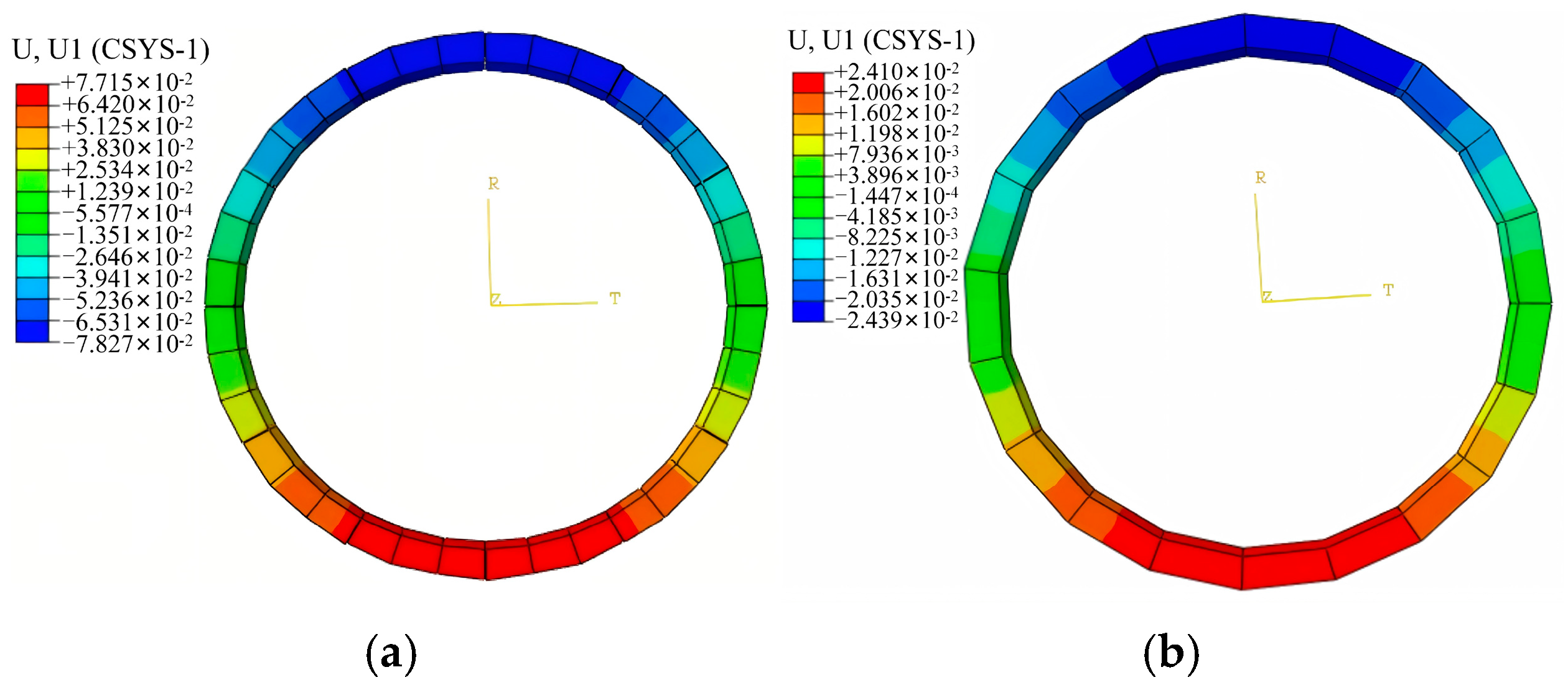

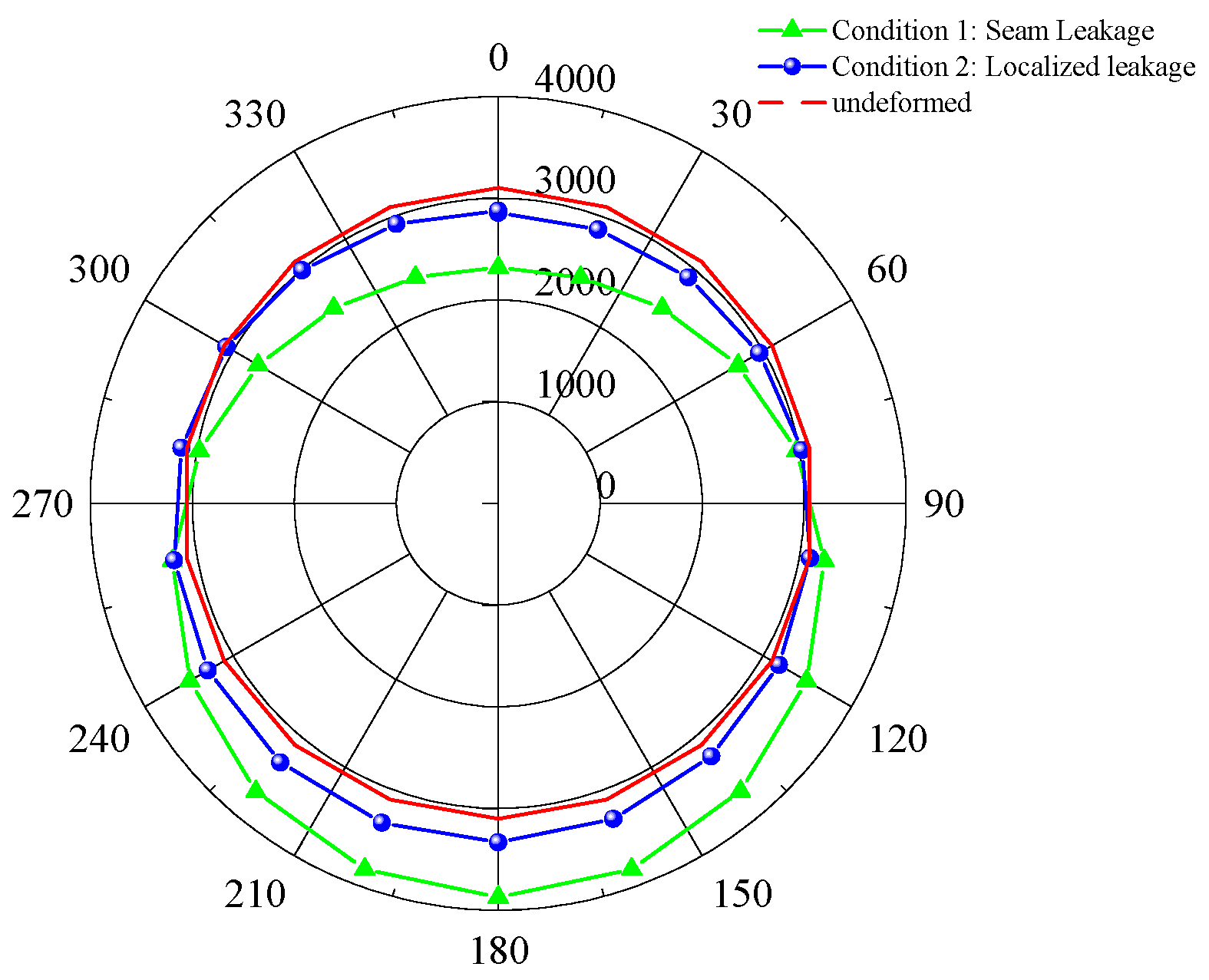

- Comparison of tunnel displacement and deformation values under different seepage and leakage conditions

- (2)

- The variation law of tunnel displacement and deformation with time under different seepage and leakage conditions

6. Conclusions

- (1)

- Leakage at segment joints and local segment leakage both lead to a significant decrease in pore water pressure in the surrounding soil, with the effect weakening as the distance from the leakage source increases. The influence of joint leakage is more pronounced than local leakage, highlighting the dominant role of segment joints in tunnel hydraulic response.

- (2)

- Surface settlement exhibits a “fast initial and then slow” development trend. Joint leakage results in a higher maximum settlement (91 mm), exceeding regulatory control standards, whereas local leakage leads to smaller settlement (32 mm), with a localized “groove-shaped” distribution above the leakage point. This indicates that seepage softening and local stress redistribution are key mechanisms controlling surface settlement.

- (3)

- Vertical deformation of the lining structure is greater than horizontal deformation, and both forms of leakage induce downward displacement trends toward deeper strata. The maximum lining displacements caused by joint leakage and local leakage are 78.26 mm and 24.38 mm, respectively, both exceeding design control standards. Segment misalignment under local leakage suggests adverse effects on structural continuity, emphasizing the importance of prompt monitoring and reinforcement.

- (4)

- The results indicate that segment joints should be prioritized for monitoring and emergency repair, while localized leakage areas also require timely inspection and remedial measures. The findings provide a theoretical reference for tunnel maintenance, emergency response prioritization, and design optimization beyond existing code requirements.

- (5)

- This study is based on a simplified 3D model and assumes uniform leakage at joints and segments. Results are primarily applicable to water-rich silty clay strata and may differ under other geological conditions. Future research should explore different soil types, long-term monitoring strategies, coupled seepage–structure interactions, and probabilistic approaches to improve tunnel safety assessment and maintenance planning.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, J.; Huang, X.; Jin, G.; Zhang, Z. Seepage characteristics and mechanical response of shield tunnels under localized leakage and exosmosis. Rock Soil Mech. 2023, 44, 1179–1189. [Google Scholar]

- Chen, F.; Sun, J.; Xiong, H.; Yin, Z.; Chen, X. Numerical implication of water–soil leakage induced by longitudinal tunnel segment dislocation opening in saturated strata. J. Rock Mech. Geotech. Eng. 2025; in press. [Google Scholar]

- Zhao, R.; Li, L.; Chen, X.; Zhang, S. Mechanical Response of Pipeline Leakage to Existing Tunnel Structures: Insights from Numerical Modeling. Buildings 2025, 15, 1771. [Google Scholar] [CrossRef]

- Macchiarulo, V.; Milillo, P.; DeJong, M.; Gonzalez Marti, J.; Sánchez, J.; Giardina, G. Integrated InSAR monitoring and structural assessment of tunnelling-induced building deformations. Struct. Control Health Monit. 2021, 28, e2781. [Google Scholar] [CrossRef]

- Afshani, A.; Li, W.; Oka, S.; Itoh, Y.; Akagi, H. Study of the long-term behavior of segmented tunnels in cohesive soil based on the circumferential joint opening. Tunn. Undergr. Space Technol. 2022, 120, 104210. [Google Scholar] [CrossRef]

- Banerjee, S.; Sikdar, P. Land Subsidence due to leakage of aquitard-aquifer pore water in an under-construction tunnel of East-West Metro Railway Project, Kolkata. J. Geol. Soc. India 2020, 96, 467–474. [Google Scholar] [CrossRef]

- Wang, L.; Niu, X.; Zhao, Y.; Li, W.; Song, W.; Zhang, C. Study on the mechanism and rapid treatment method of leakage disease at the junction between the shaft and shield tunnel. Eng. Fail. Anal. 2023, 154, 107639. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Y.; Niu, X. Research on the Application of Backwall Grouting in Leakage Treatment of Operating Tunnels. E3S Web Conf. 2023, 439, 02011. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, H.; Wan, L.; Zhang, C.; Shao, X.; Lin, Z.; Song, J. Causes of tunnel diseases in a karst stratum and remediation measures: A case study. Front. Earth Sci. 2022, 10, 882058. [Google Scholar] [CrossRef]

- Lin, C.; Wang, X.; Li, Y.; Zhang, F.; Xu, Z.; Du, Y. Forward modelling and GPR imaging in leakage detection and grouting evaluation in tunnel lining. KSCE J. Civ. Eng. 2020, 24, 278–294. [Google Scholar] [CrossRef]

- Jiang, J.; Shen, Y.; Wang, J.; Zang, Y.; Wu, W.; Wang, J.; Zang, Y.; Wu, W.; Wang, J.; Li, J.; et al. Boosted bagging: A hybrid ensemble deep learning framework for point cloud semantic segmentation of shield tunnel leakage. Tunn. Undergr. Space Technol. 2025, 164, 106842. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, K.; Sun, L.; Gao, J.; Guo, Z.; Chen, X. WLAN: Water Leakage-Aware Network for water leakage identification in metro tunnels. Neural Comput. Appl. 2025, 37, 22179–22189. [Google Scholar] [CrossRef]

- Wang, W.; Xu, X.; Yang, H. Intelligent detection of tunnel leakage based on improved mask R-CNN. Symmetry 2024, 16, 709. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.; Yin, Z. Numerical analysis of the impact of internal erosion on underground structures: Application to tunnel leakage. Rock Soil Mech. 2022, 43, 8. [Google Scholar]

- Park, D. Numerical investigation on the effect of water leakage on the ground surface settlement and tunnel stability. Tunn. Undergr. Space Technol. 2024, 146, 105656. [Google Scholar] [CrossRef]

- Shi, X.; Zheng, L.; Rong, C.; Cheng, H.; Cai, H.; Li, T. Study on the rules of ground settlement and pipeline deformation considering the combined effects of pipeline damage leakage and shield tunneling construction. Transp. Geotech. 2024, 49, 101367. [Google Scholar] [CrossRef]

- Mu, W.; Li, L.; Chen, D.; Wang, S.; Xiao, F. Long-term deformation and control structure of rheological tunnels based on numerical simulation and on-site monitoring. Eng. Fail. Anal. 2020, 118, 104928. [Google Scholar] [CrossRef]

- Gong, C.; Cheng, M.; Ge, Y.; Song, J.; Zhou, Z. Leakage mechanisms of an operational underwater shield tunnel and countermeasures: A case study. Tunn. Undergr. Space Technol. 2024, 152, 105892. [Google Scholar] [CrossRef]

- Zhang, Z.; Mao, M.; Pan, Y.; Zhang, M.; Ma, S.; Cheng, Z.; Wu, Z. Experimental study for joint leakage process of tunnel lining and particle flow numerical simulation. Eng. Fail. Anal. 2022, 138, 106348. [Google Scholar] [CrossRef]

- Chen, S.; Yang, Z.; Liu, S.; Li, L.; Zheng, Y.; Yuan, Y. Numerical simulation and analysis of crack disease in tunnel lining structure. Front. Mater. 2022, 9, 1007855. [Google Scholar] [CrossRef]

- Martínez, R.; Schroeder, F.; Potts, D. Numerical study of long-term settlement following twin tunnel construction. Obras Proy. 2015, 17, 23–29. [Google Scholar] [CrossRef]

- Lu, X.; Wang, H.; Huang, M. Upper bound solution for the face stability of shield tunnel below the water table. Math. Probl. Eng. 2014, 2014, 727964. [Google Scholar] [CrossRef]

- Miranda, P.; Vargas Jr, E.A.; Moraes, A. Evaluation of the Modified Cam Clay model in basin and petroleum system modeling (BPSM) loading conditions. Mar. Pet. Geol. 2020, 112, 104112. [Google Scholar] [CrossRef]

- Wang, F.; Shao, J.; Li, W.; Wang, L.; Wang, Y.; Liu, H. Numerical simulation study on lining damage of shield tunnel under train load. Sustainability 2022, 14, 14018. [Google Scholar] [CrossRef]

- Shi, L.; Wang, D.; Zhang, Y.; Han, F.; Lyu, Q. An analytical solution for internal forces of shallow circular low-to-vacuum tunnel linings in soft soils. Sci. Rep. 2024, 14, 31436. [Google Scholar] [CrossRef] [PubMed]

- Kou, L.; Xiong, Z.; Cui, H.; Zhao, J. Study on mechanical characteristics of segmental joints of a large-diameter shield tunnel under ultrahigh water pressure. Sensors 2021, 21, 8392. [Google Scholar] [CrossRef]

- Kavvadas, M.; Litsas, D.; Vazaios, I.; Fortsakis, P. Development of a 3D finite element model for shield EPB tunnelling. Tunn. Undergr. Space Technol. 2017, 65, 22–34. [Google Scholar] [CrossRef]

- Zhang, W.; De Corte, W.; Liu, X.; Taerwe, L. Influence of rotational stiffness modeling on the joint behavior of quasi-rectangular shield tunnel linings. Appl. Sci. 2020, 10, 8396. [Google Scholar] [CrossRef]

- Liu, D.; Wang, F.; Hu, Q.; Huang, H.; Zuo, J.; Tian, C.; Zhang, D. Structural responses and treatments of shield tunnel due to leakage: A case study. Tunn. Undergr. Space Technol. 2020, 103, 103471. [Google Scholar] [CrossRef]

- Mei, Y.; Luo, Z.; Jiang, H.; Gong, H.; Hou, Y.; Wang, X. Study on the floating law of metro segments in water-rich sandy silt and silty clay strata. KSCE J. Civ. Eng. 2022, 26, 2979–2991. [Google Scholar] [CrossRef]

- Yu, J.; Sun, M.; He, S.; Huang, X.; Wu, X.; Liu, L. Accumulative deformation characteristics and microstructure of saturated soft clay under cross-river subway loading. Materials 2021, 14, 537. [Google Scholar] [CrossRef]

- Li, Y.; Mu, L.; Cao, J. Impact of Seepage on the Underground Water Level in a Complex Soil-Water-Structure System. Adv. Civ. Eng. 2022, 2022, 7034778. [Google Scholar] [CrossRef]

- Zheng, G.; Lei, Y.; Cui, T.; Cheng, X.; Diao, Y.; Zhang, T.; Sun, J. Experimental research on the transverse effective bending rigidity of shield tunnels. Adv. Civ. Eng. 2019, 2019, 2174562. [Google Scholar] [CrossRef]

- Zheng, G.; Sun, J.; Zhang, T.; Zhang, X.; Li, X.; Cheng, H.; Diao, Y. Numerical study on the impact of local failure on adjacent structures in a shield tunnel. Acta Geotech. 2023, 18, 2155–2168. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, C.; Ma, S.; Zhang, J.; Zhu, Q. Study of the mechanical behaviour and damage characteristics of three new types of joints for fabricated rectangular tunnels using a numerical approach. Tunn. Undergr. Space Technol. 2021, 118, 104184. [Google Scholar] [CrossRef]

- Lan, X.; Zhang, X.; Yin, Z.; Li, X.; Yang, T. Mitigation of karst tunnel water inrush during operation in seasonal variation zone: Case study in Nanshibi Tunnel. J. Perform. Constr. Facil. 2021, 35, 04021010. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, X.; Wang, L.; Yue, C.; Chen, X.; Luo, Z.; Fu, L. Study on the Mechanism of Water and Sand Leakage in a Foundation Pit Retaining Structure Based on the Computational Fluid Dynamics–Discrete Element Method. Buildings 2024, 14, 724. [Google Scholar] [CrossRef]

- Gong, C.; Ding, W. A computational framework to predict the water-leakage pressure of segmental joints in underwater shield tunnels using an advanced finite element method. Int. J. Numer. Anal. Methods Geomech. 2018, 42, 1957–1975. [Google Scholar] [CrossRef]

- Li, S.; Liu, H.; Li, L.; Zhang, Q.; Wang, K.; Wang, K. Large scale three-dimensional seepage analysis model test and numerical simulation research on undersea tunnel. Appl. Ocean Res. 2016, 59, 510–520. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Liu, X.; Han, J. Study on leakage assessment and stability analysis of water level changes in tunnels near reservoirs. Water 2024, 16, 2378. [Google Scholar] [CrossRef]

- Huang, L.; Ma, J.; Lei, M.; Liu, L.; Lin, Y.; Zhang, Z. Soil-water inrush induced shield tunnel lining damage and its stabilization: A case study. Tunn. Undergr. Space Technol. 2020, 97, 103290. [Google Scholar] [CrossRef]

- Xu, S.; Ma, E.; Lai, J.; Yang, Y.; Liu, H.; Yang, C.; Hu, Q. Diseases failures characteristics and countermeasures of expressway tunnel of water-rich strata: A case study. Eng. Fail. Anal. 2022, 134, 106056. [Google Scholar] [CrossRef]

- Cui, X.; Li, P.; Wang, C.; Ge, Z.; Li, S.; Di, Q. Effect of seepage flow on face stability for a tunnel in water-rich silty clay overlying sandy cobble strata. Tunn. Undergr. Space Technol. 2025, 161, 106539. [Google Scholar] [CrossRef]

- Zhang, D.; Ma, L.; Zhang, J.; Hicher, P.; Juang, C. Ground and tunnel responses induced by partial leakage in saturated clay with anisotropic permeability. Eng. Geol. 2015, 189, 104–115. [Google Scholar] [CrossRef]

- Huang, Z.; Cheng, Y.; Zhang, D.; Yan, D.; Shen, Y. Seismic fragility and resilience assessment of shallowly buried large-section underground civil defense structure in soft soils: Framework and application. Tunn. Undergr. Space Technol. 2024, 146, 105640. [Google Scholar] [CrossRef]

- Shin, J.; Addenbrooke, T.; Potts, D. A numerical study of the effect of groundwater movement on long-term tunnel behaviour. Geotechnique 2002, 52, 391–403. [Google Scholar] [CrossRef]

- Wang, X.; Wang, B.; Yuan, Y.; Yang, T.; Dong, G.; Shi, C. Study on the Effect of EICP Combined with Nano-SiO2 and Soil Stabilizer on Improving Loess Surface Strength. Buildings 2025, 15, 1998. [Google Scholar] [CrossRef]

- Wang, X.; Chen, C. Vibration Table Test of Prefabricated L-Shaped Column Concrete Structure. Buildings 2025, 15, 2329. [Google Scholar] [CrossRef]

- Shijie, Z.; Guyi, Z.; Deming, L.; Shuyi, W.; Chao, W. The crucial techniques of water leakage treatment in operating highway tunnel. IOP Conf. Ser. Earth Environ. Sci. 2020, 525, 012160. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, J.; Huang, Z.; Yang, G.; Jiang, Y.; Jia, K. Waterproof performance of tunnel segmental joints under different deformation conditions. Tunn. Undergr. Space Technol. 2022, 123, 104437. [Google Scholar] [CrossRef]

| Serial Number | Leakage Location | |||

|---|---|---|---|---|

| Leakage Occurs at the Joint of the Segment | The Segment Is Damaged and Leaking | The Hole Cracked and Leaked | Others | |

| Left line | 141 | 157 | 143 | 9 |

| Right line | 170 | 146 | 126 | 11 |

| Total | 311 | 303 | 269 | 20 |

| Stratum Name | Elastic Modulus (E/MPa) | Poisson’s Ratio (μ) | Cohesion (c/kPa) | Internal Friction Angle (ψ/(°)) | Heavy γ (kN/m3) |

|---|---|---|---|---|---|

| Soft clay B1 | 10 | 0.42 | 8.00 | 8.00 | 17.00 |

| Miscellaneous fill soil B2 | 15 | 0.22 | 12.50 | 12.00 | 19.00 |

| Muddy clay B3 | 20 | 0.35 | 24.20 | 20.40 | 19.80 |

| Silty clay B4 | 25 | 0.35 | 32.70 | 19.00 | 20.80 |

| medium sand B5 | 30 | 0.30 | 3.00 | 34.00 | 19.47 |

| Sandy soil B6 | 35 | 0.32 | 3.00 | 35.00 | 20.00 |

| Aspect | Assumption | Limitation/Applicability |

|---|---|---|

| Soil behavior | The soil follows the Mohr–Coulomb elastic–plastic model. | Time-dependent and creep effects are not considered. |

| Groundwater conditions | Steady-state seepage field is assumed before leakage initiation. | Transient flow effects during early leakage are simplified. |

| Leakage representation | Leakage is modeled as local permeability enhancement at segment joints. | Real crack networks are simplified to uniform leakage zones. |

| Boundary conditions | The lateral boundaries are fixed horizontally, and the bottom boundary vertically. | Possible boundary influence near model edges is neglected. |

| Material parameters | Material properties are homogeneous within each soil layer. | Soil variability and anisotropy are not fully captured. |

| Interface behavior | Segment–soil contact is simulated with a friction coefficient of 0.4. | Micro-scale roughness and local detachment are simplified. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, X.; Mei, Y.; Han, F.; Tang, J. Research on the Leakage Effect of Shield Tunnels in Water-Rich Silty Clay Strata Based on On-Site Investigation and Numerical Simulation. Buildings 2025, 15, 3867. https://doi.org/10.3390/buildings15213867

Tian X, Mei Y, Han F, Tang J. Research on the Leakage Effect of Shield Tunnels in Water-Rich Silty Clay Strata Based on On-Site Investigation and Numerical Simulation. Buildings. 2025; 15(21):3867. https://doi.org/10.3390/buildings15213867

Chicago/Turabian StyleTian, Xinyu, Yuan Mei, Fangzhi Han, and Jinhua Tang. 2025. "Research on the Leakage Effect of Shield Tunnels in Water-Rich Silty Clay Strata Based on On-Site Investigation and Numerical Simulation" Buildings 15, no. 21: 3867. https://doi.org/10.3390/buildings15213867

APA StyleTian, X., Mei, Y., Han, F., & Tang, J. (2025). Research on the Leakage Effect of Shield Tunnels in Water-Rich Silty Clay Strata Based on On-Site Investigation and Numerical Simulation. Buildings, 15(21), 3867. https://doi.org/10.3390/buildings15213867