Performance Assessment of a Landfill Expansion Stabilized with Reinforced Fill Structure Using Numerical Analysis

Abstract

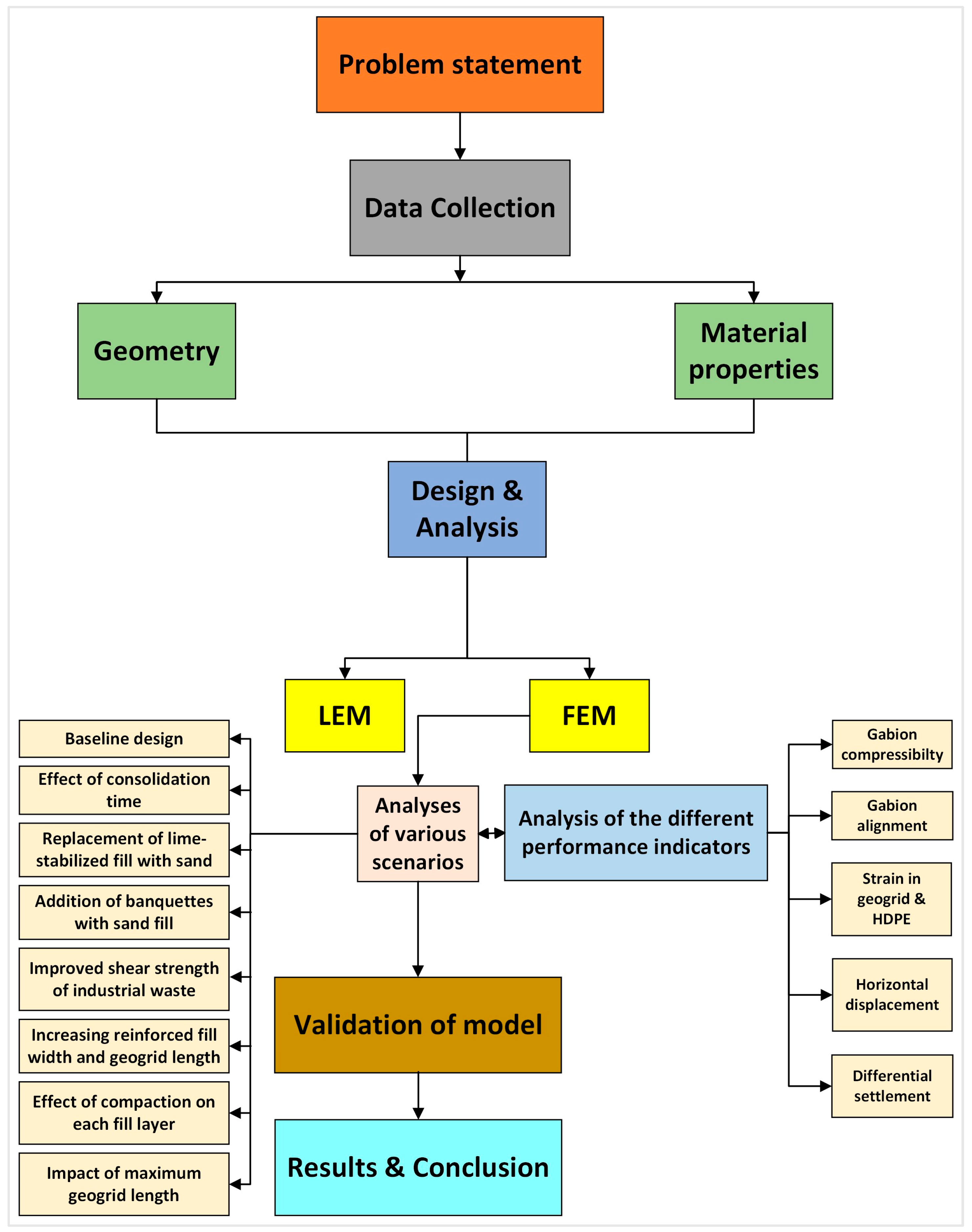

1. Introduction

- Consolidation rate (3 m/year vs. 5 m/year)

- Layer-by-layer compaction

- Addition of banquettes

- Fill material type

- Variation in the industrial waste properties

- RFS width and geogrid length changes

- Reinforced Walls and Abutments

- Reinforced Slopes

- Basal Reinforcement for Embankments

- Veneer Reinforcement on Landfill Slopes

2. Materials and Methods

2.1. Numerical Analysis

2.2. Limit Equilibrium Method

2.3. Finite Element Method

2.4. Soil Properties

- = Tangent stiffness modulus for primary (first-time) loading in a triaxial test.

- Reference secant modulus at reference pressure pref

- = Stiffness modulus for unloading/reloading

- = Reference unloading-reloading modulus at reference pressure pref

- = Minor principal effective stress (confining pressure in triaxial tests).

- c′ = Effective cohesion of the soil.

- Φ′ = Effective angle of internal friction.

- m = Power exponent that controls how strongly stiffness depends on pressure

- pref = Reference pressure

2.5. Geogrid Modeling in PLAXIS

- Np: Maximum axial tensile force (also referred to as allowable tensile strength).

- EA: Axial stiffness.

- Reinforcement should not exceed its ultimate limit state during the design life of the structure, i.e., the reinforcement should not rupture.

- Reinforcement should not exceed its serviceability limit state during the design life of the structure, i.e., creep in the reinforcement should remain within prescribed limits.

- is the design strength

- fm is the material safety factor

- RFID is the reduction factor for installation damage

- RFW is the reduction factor for weathering

- RFCH is the reduction factor for chemical/environmental effects

- fs is the factor of safety for the extrapolation of data

- is the design strength

- fm is the material safety factor

- RFID is the reduction factor for installation damage

- RFW is the reduction factor for weathering

- RFCH is the reduction factor for chemical/environmental effects

- fs is the factor of safety for the extrapolation of data

2.6. Gabions & Wiremesh Properties

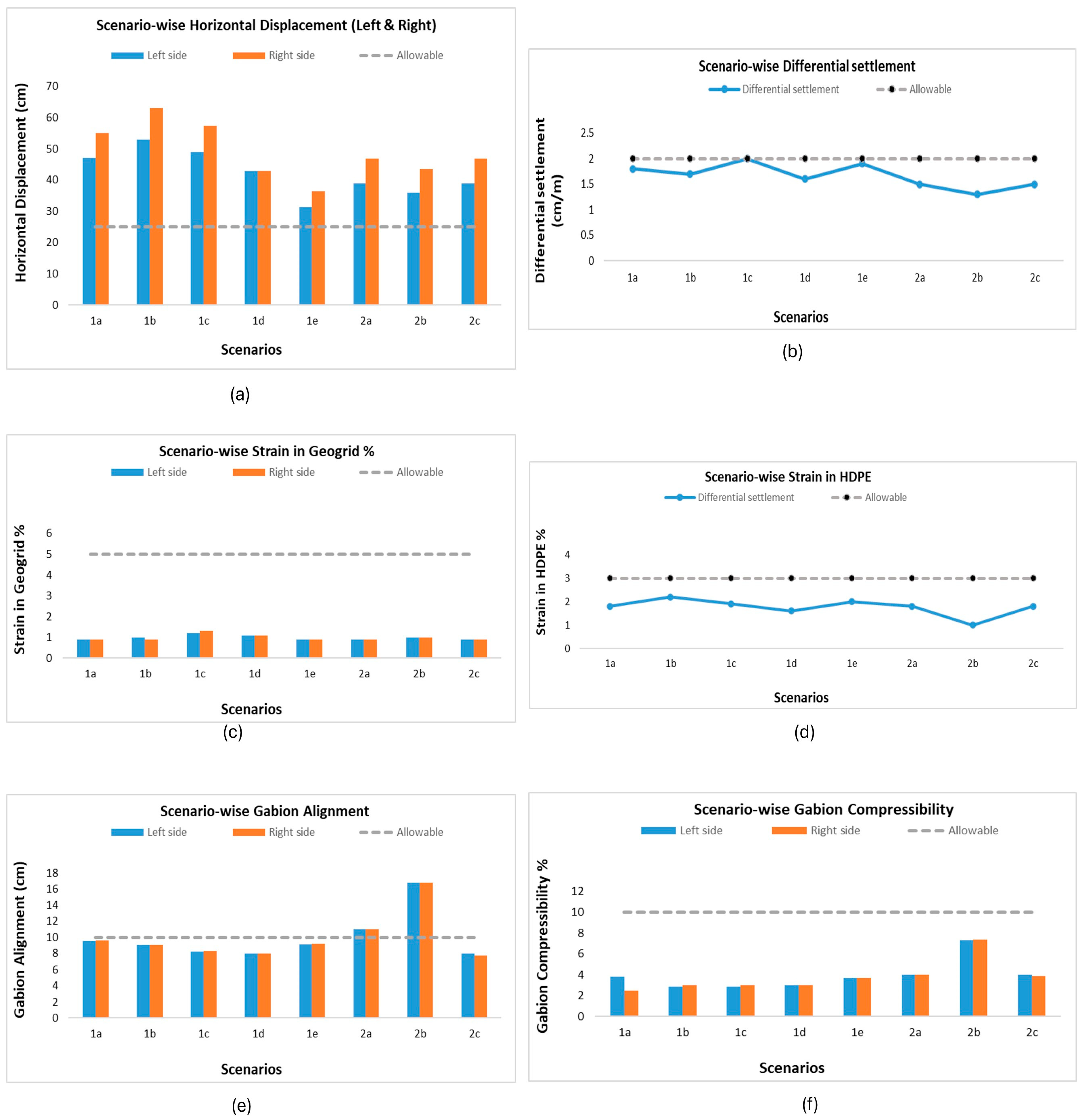

2.7. Performance Parameters

- Horizontal displacement: the lateral outward movement of the RFS, used to evaluate serviceability and global stability. Particular attention was given to the displacement at the toe of the reinforced zone, as this location typically governs overall slope deformation and serviceability. In Plaxis, this parameter was obtained from the numerical output using Equation (8).

- Differential settlement: the variation in vertical settlement across the structure, expressed in cm/m. The analysis focused on the settlement occurring directly beneath the RFS, since excessive differential settlement in this zone can affect reinforcement performance and facing stability. Also, this parameter was obtained from the numerical output using Equation (9).

- Geogrid strain: the tensile strain developed within the geogrid layers, representing the mobilization of reinforcement capacity relative to allowable strain limits and can be found using Equation (10).

- Geomembrane strain: the tensile strain in the HDPE geomembrane lining, assessed to ensure deformation remains within tolerable limits for durability and environmental protection and can be found using Equation (11).

- Gabions alignment: refers to the outward displacement of the gabion facing units relative to their original vertical alignment. It was used as a serviceability indicator to assess potential bulging or misalignment of the facing system under landfill loading. The values were obtained directly from the numerical output by measuring the horizontal displacement at the outer face of the gabion elements at the crest relative to the base. The difference in displacements between the top and bottom of the facing provides the total misalignment, as per Equation (12).

- Gabions compressibility: the relative deformation of the gabion units under loading, expressed as a percentage, indicating the ability of the facing system to accommodate stresses without compromising integrity. This parameter was obtained from the numerical output using Equation (13).

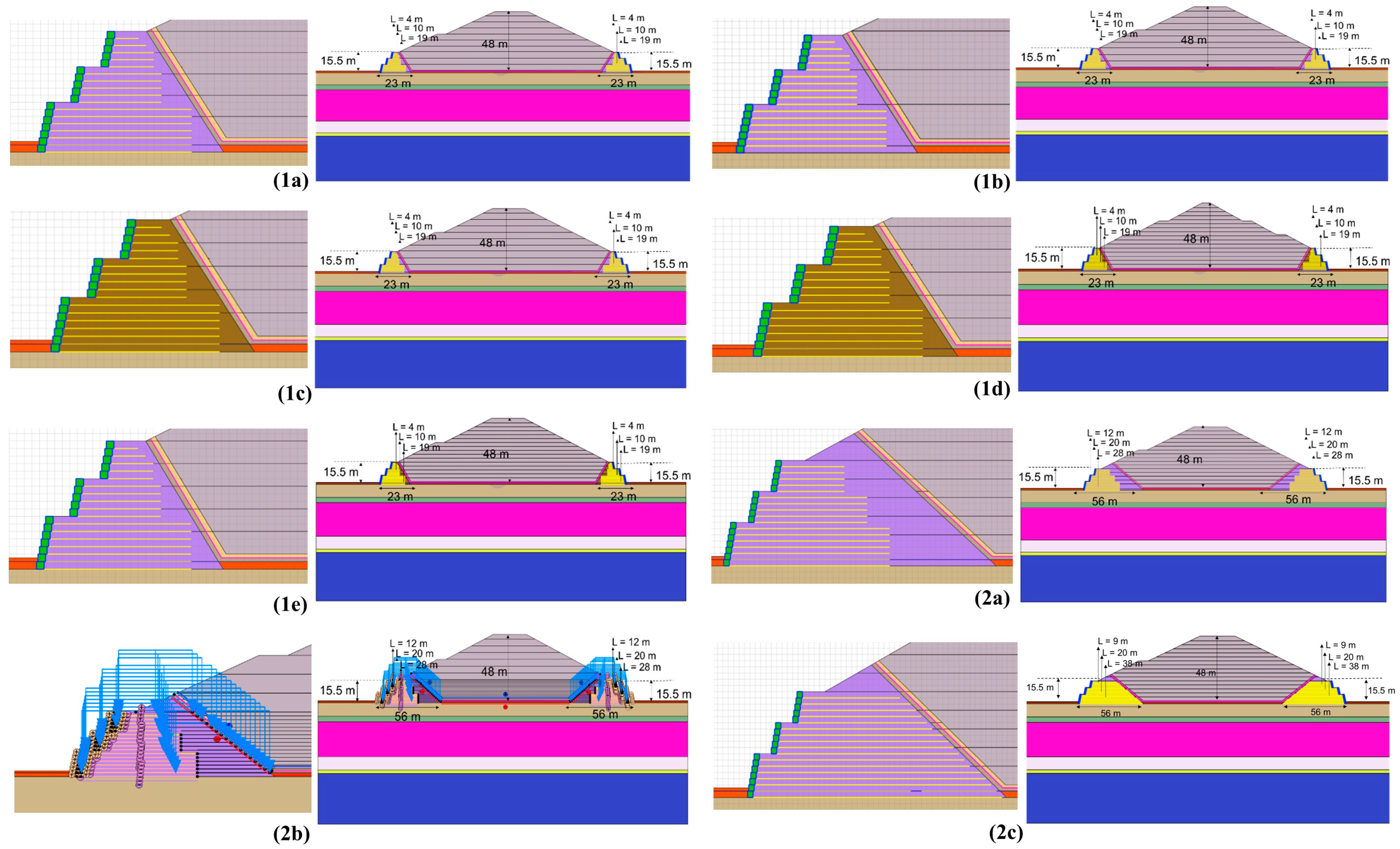

2.8. Details of Different Scenarios

- 1a. Baseline design with local fill stabilized with lime

- 1b. Effect of Consolidation time

- 1c. Effect of different fill material on landfill stability

- 1d. Influence of Banquettes on Landfill Stability

- 1e. Influence of the variation in industrial waste properties

- 2a. Impact of increasing RFS width

- 2b. Influence of Compaction

- 2c. Impact of Maximum Geogrid Length on Landfill Stability

3. Interface Coefficient

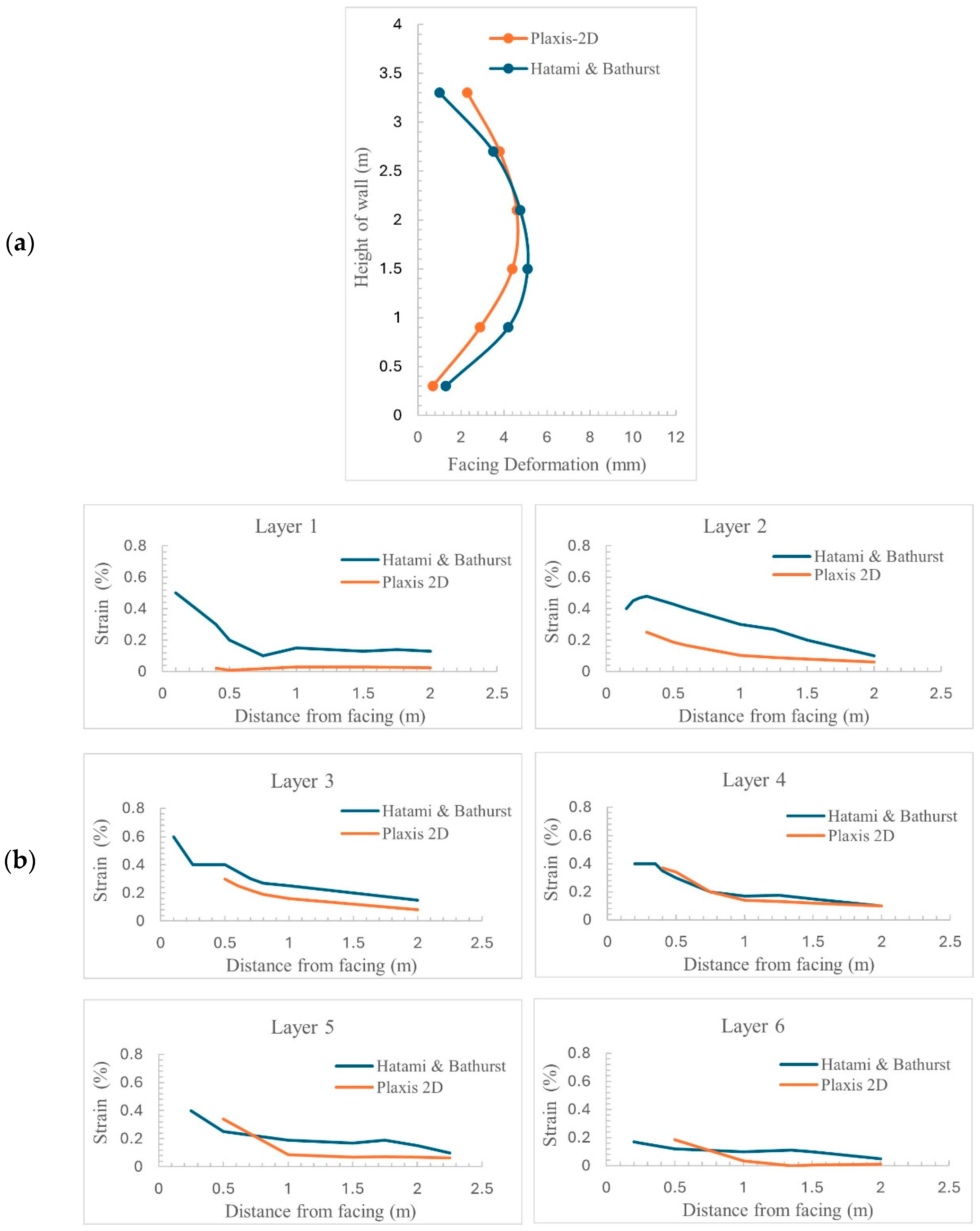

4. Validation of Model

5. Results

Comparison of Different Scenarios

- 1a. Baseline Design with local fill stabilized with lime

- 1b. Effect of change in Consolidation time (scenario 1a vs. 1b)

- 1c. Effect of different fill material on landfill stability (scenario 1a vs. 1c)

- 1d. Influence of Banquettes on Landfill Stability (scenario 1c vs. 1d)

- 1e. Influence of the variation in the industrial waste properties (scenario 1a vs. 1e)

- 2a. Impact of increasing RFS width (scenario 1a vs. 2a)

- 2b. Influence of Compaction (scenario 2a vs. 2b)

- 2c. Impact of Maximum Geogrid Length on Landfill Stability (scenario 2a vs. 2c)

6. Conclusions

- The baseline configuration (scenario 1a), using lime-stabilized local fill, demonstrated acceptable performance in terms of differential settlement and reinforcement strain. However, horizontal displacements significantly exceeded the allowable limit, raising serviceability concerns. This highlighted the need for design enhancements to manage lateral movements under heavy loading conditions.

- Increasing the consolidation rate (scenario 1b) resulted in greater horizontal displacements and geomembrane strain, indicating that faster consolidation accelerates lateral soil movement due to insufficient time for stress redistribution.

- The substitution of lime-stabilized fill with sand (scenario 1c) led to increased displacements and strain levels due to the sand’s lower cohesion and stiffness.

- Incorporating banquettes (scenario 1d) proved highly effective in reducing lateral displacement and enhancing overall slope stability.

- The enhancement of industrial waste properties (scenario 1e) substantially improved lateral stability by reducing horizontal displacements. While this led to a modest rise in geomembrane strain, it did not significantly affect geogrid performance, making it a favorable approach for improving global stability.

- From a geometric perspective, increasing the width of the reinforced fill system and the length of the geogrid (scenario 2a) improved deformation control, suggesting that geometry plays a critical role in managing global stability. Wider reinforced zones and longer geogrid embedment allow stresses to be distributed more efficiently, reduce the tendency for outward bulging, and improve the overall stiffness of the soil–reinforcement composite.

- Improving the degree of compaction of the fill material (scenario 2b) proved effective in reducing horizontal displacements and vertical settlements, thereby enhancing the overall stability of the reinforced fill system. However, higher compaction also increased the tensile demand on the geogrid and the stiffness of the fill, which in turn transferred greater lateral pressures to the gabion facing. This resulted in higher compressibility and greater alignment demands on the facing units.

- Lastly, maximizing geogrid length (scenario 2c) resulted in only marginal improvements in terms of overall landfill stability and deformation control. The additional reinforcement length did not significantly reduce displacements or strains within the reinforced soil mass, suggesting that after a certain point, adding more geogrid length does not bring much extra benefit to the overall stability. However, the longer reinforcement layers contributed positively to the facing system by improving alignment, reducing outward bulging, and distributing loads more evenly across the gabions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Keskin, M.S.; Kezer, S. Stability of MSW Landfill Slopes Reinforced with Geogrids. Appl. Sci. 2022, 12, 11866. [Google Scholar] [CrossRef]

- Zhou, X.; Jiang, H.; Zhou, M.; Hu, Y. Case Study: Extension of MSW landfill with reinforced earth berm. Waste Manag. 2023, 164, 37–46. [Google Scholar] [CrossRef]

- Zornberg, J.G.; Kavazanjian, E. Prediction of the performance of a geogrid-reinforced ssslope founded on solid waste. Soils Found. 2001, 41, 1–16. [Google Scholar] [CrossRef]

- Lounis, Z.; McAllister, T.P. Risk-based decision making for sustainable and resilient infrastructure systems. J. Struct. Eng. 2016, 142, F4016005. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Naftchali, F.M. Geosynthetic reinforcement stiffness for analytical and numerical modelling of reinforced soilstructures. Geotext. Geomembr. 2021, 49, 921–940. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, H.; Gu, P.; Hu, W. Application of FBG Sensing Technology in Stability Analysis of Geogrid-Reinforced Slope. Sensors 2017, 17, 597. [Google Scholar] [CrossRef] [PubMed]

- Leshchinsky, D.; Imamoglu, B.; Meehan, C.L. Exhumed Geogrid-Reinforced Retaining Wall. J. Geotech. Geoenviron. Eng. 2010, 136, 1311–1323. [Google Scholar] [CrossRef]

- Chen, R.P.; Wang, Y.W.; Ye, X.W.; Bian, X.C.; Dong, X.P. Tensile force of geogrids embedded in pile-supported reinforced embankment: A full-scale experimental study. Geotext. Geomembr. 2016, 44, 157–169. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Dessouky, S.H.; Kwon, J.; Tutumluer, E. Geogrid-reinforced low-volume flexible pavements: Pavement response and geogrid optimal location. J. Transp. Eng. 2012, 138, 1083–1090. [Google Scholar] [CrossRef]

- Abdesssemed, M.; Kenai, S.; Bali, A. Experimental and numerical analysis of the behavior of an airport pavement reinforced by geogrids. Constr. Build. Mater. 2015, 94, 547–554. [Google Scholar] [CrossRef]

- Cardile, G.; Pisano, M. Advances in soil reinforcement with geosynthetics: From laboratory tests to design practice. Riv. Ital. Geotech. 2020, 54, 52–82. [Google Scholar] [CrossRef]

- Miyata, Y. Geosynthetic MSE walls research and practice: Past, present, and future (2023 IGS Bathurst Lecture). Geosynth. Int. 2024, 32, 62–81. [Google Scholar] [CrossRef]

- prEN-1997-3:2022; Eurocode 7 Geotechnical Design-Part 3 Geotechnical Structures. British Standards Institution (BSI): London, UK, 2022; pp. 1–293.

- Koerner, R.M. Designing with Geosynthetics; Xlibris Corporation: Bloomington, IN, USA, 2012; Volume 1. [Google Scholar]

- Zornberg, J.G.; Christopher, B.R. Chapter 37—Geosynthetics. In The Handbook of Groundwater Engineering, 2nd ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2007; pp. 1–36. [Google Scholar]

- Tatsuoka, F.; Uchimura, T.; Tateyama, M.; Koseki, J. Geosynthetic-reinforced soil retaining walls as important permanent structures 1996–1997 mercer lecture. Geosynth. Int. 1997, 4, 81–136. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Allen, T.M.; Walters, D.L. Short-term strain and deformation behavior of geosynthetic walls at working stress conditions. Geosynth. Int. 2002, 9, 451–482. [Google Scholar] [CrossRef]

- Jones, C. Geoguide 6: Guide to Reinforced Fill Structures and Slope Design; Geotechnical Engineering Office: Hong Kong, China, 2002. [Google Scholar]

- Berg, R.R.; Christopher, B.R.; Samtani, N.C. Design and Construction of Mechanically Stabilized Earth Walls and Reinforced Soil Slopes—Volume I; Federal High Way Administration (FHWA): Washington, DC, USA, 2009. [Google Scholar]

- Majumder, M.; Venkatraman, S.; Bheda, M.; Patil, M. Numerical Studies on the Performance of Geosynthetic Reinforced Soil Walls Filled with Marginal Soil. Indian Geotech. J. 2023, 53, 805–826. [Google Scholar] [CrossRef]

- Korulla, M.; Padmaja, G.; Beena, K.S. Numerical Modelling of Reinforced Soil Structures Through Live Projects. Indian Geotech. J. 2022, 52, 1171–1181. [Google Scholar] [CrossRef]

- Cai, F. Finite element modeling of mechanical behavior of geogrid reinforced soil retaining walls. Proc. Indian Natl. Sci. Acad. 2025, 91, 484–497. [Google Scholar] [CrossRef]

- Jiang, Y.; Han, J.; Zornberg, J.; Parsons, R.L.; Leshchinsky, D.; Tanyu, B. Numerical analysis of field geosynthetic-reinforced retaining walls with secondary reinforcement. Geotechnique 2019, 69, 122–132. [Google Scholar] [CrossRef]

- Damians, I.P.; Bathurst, R.J.; Olivella, S.; Lloret, A.; Josa, A. 3D modelling of strip reinforced MSE walls. Acta Geotech. 2021, 16, 711–730. [Google Scholar] [CrossRef]

- Jiang, H.; Zhou, X.; Xiao, Z. Stability of Extended Earth Berm for High Landfill. Appl. Sci. 2020, 10, 6281. [Google Scholar] [CrossRef]

- Koerner, R.M.; Soong, T.Y. Leachate in landfills: The stability issues. Geotext. Geomembr. 2000, 18, 293–309. [Google Scholar] [CrossRef]

- Scotland, I.; Dixon, N.; Frost, M.; Wackrow, R.; Fowmes, G.J.; Horgan, G. Measuring deformation performance of geogrid reinforced structures using a terrestrial laser scanner. In Proceedings of the 10th International Conference of Geosynthetics, Berlin, Germany, 21–25 September 2014. [Google Scholar]

- Helwany, S.M.B.; Reardon, G.; Wu, J.T.H. Effects of backfill on the performance of GRS retaining walls. Geotext. Geomembr. 1999, 17, 1–16. [Google Scholar] [CrossRef]

- Mirmoradi, S.H.; Ehrlich, M. Numerical Simulation of Compaction-Induced Stress for the Analysis of RS Walls under Working Conditions. Geotext. Geomembr. 2018, 46, 354–365. [Google Scholar] [CrossRef]

- Mirmoradi, S.H.; Ehrlich, M. Modeling of the compaction-induced stress on reinforced soil walls. Geotext. Geomembr. 2015, 43, 82–88. [Google Scholar] [CrossRef]

- Ehrlich, M.; Mirmoradi, S.H.; Saramago, R.P. Evaluation of the effect of compaction on the behavior of geosynthetic-reinforced soil walls. Geotext. Geomembr. 2012, 34, 108–115. [Google Scholar] [CrossRef]

- Ambauen, S.; Leshchinsky, B.; Xie, Y.; Rayamajhi, D. Service-state behavior of reinforced soil walls supporting spread footings: A parametric study using finite-element analysis. Geosynth. Int. 2016, 23, 156–170. [Google Scholar] [CrossRef]

- Khan, A.R.; Di Emidio, G. Reinforced Fill Structure with Alternative Fill Materials: An Application of Geogrid Creep Strain Analysis Using Numerical Modeling. Materials 2025, 18, 1346. [Google Scholar] [CrossRef]

- Khan, A.R.; Di Emidio, G. Numerical analysis using FEM on the behavior of reinforced fill structure having geogrid and steel wire mesh as a reinforcing element. In Geosynthetics: Leading the Way to a Resilient Planet; CRC Press: Rome, Italy, 2023; pp. 991–996. [Google Scholar] [CrossRef]

- BS 8006-1:2010+A1:2016; Code of Practice for Strengthened/Reinforced Soils and Other Fills. BSI Standards Publication: London, UK, 2016.

- Lelli, M.; Laneri, R.; Rimoldi, P. Innovative reinforced soil structures for high walls and slopes combining polymeric and metallic reinforcements. Procedia Eng. 2015, 125, 397–405. [Google Scholar] [CrossRef]

- Maccaferri. FAQ on PLAXIS FEM. Available online: https://www.maccaferri.com/faq-on-plaxis-fem/ (accessed on 1 October 2023).

- BS EN 14475:2006; Execution of Special Geotechnical Works—Reinforced Fill. BSI Standards Publication: London, UK, 2004.

- Rowe, R.K.; Yu, Y. Magnitude and significance of tensile strains in geomembrane landfill liners. Geotext. Geomembr. 2019, 47, 439–458. [Google Scholar] [CrossRef]

- Hatami, K.; Bathurst, R.J. Parametric analysis of reinforced soil walls with different backfill material properties. In Proceedings of the NAGS’ Conference, Las Vegas, NV, USA, 1–3 December 2006; pp. 1–15. [Google Scholar]

| Factor of safety against Sliding | 1.09 > 1 |

| Factor of safety against Overturning | 5.14 > 1 |

| Factor of safety against Bearing | 1.96 > 1 |

| ϒdry kN/m3 | ϒwet kN/m3 | Model | c’ref kPa | ϕ’ [°] | |

|---|---|---|---|---|---|

| Fill (lime stabilized) | 18 | 19 | HS | 20 | 40 |

| Fill (sand) | 18 | 19 | HS | 2 | 35 |

| Waste (industrial) | 17.4 | 20 | HS | 20 | 30 |

| Clay 1 | 17 | 19 | HS | 8 | 22 |

| Sand 1 | 18 | 20 | HS | 3 | 27 |

| Sand 2 | 20 | 20 | HS | 2 | 35 |

| Clay 2 | 19 | 19 | HS | 15 | 20 |

| Sand 3 | 16 | 18 | HS | 2 | 30 |

| Sand 4 | 18 | 18 | HS | 2 | 27 |

| Clay 3 | 17 | 19 | HS | 8 | 20 |

| Property | Units | Geogrid |

|---|---|---|

| (a) | ||

| Axial Stiffness | kN/m2 | 3160 |

| Axial force | kN/m2 | 158 |

| Material type | --- | Elastoplastic |

| (b) | ||

| Axial Stiffness | kN/m2 | 1992 |

| Axial force | kN/m2 | 99.6 |

| Material type | --- | Elastoplastic |

| Property | Units | Gabion |

|---|---|---|

| Unit weight | kN/m3 | 18 |

| Angle of internal friction | Degree | 40 |

| Cohesion | kPa | 27 |

| Poisson’s ratio | - | 0.3 |

| Elastic modulus | MPa | 40 |

| Material model | - | Mohr-Coulomb |

| Properties | Symbol | Units | Value |

|---|---|---|---|

| Axial stiffness | EA | kN/m | 62,832 |

| Flexural Rigidity | EI | kNm2/m | 0.251 |

| Weight | W | kN/m/m | 0.023 |

| Poisson’s ratio | V | - | 0.3 |

| Maximum bending moment | Mp | kN/m/m | 0.23 |

| Maximum axial force | Np | kN/m | 135 |

| Cohesion | C | kPa | 27 |

| Parameter | Limit Value | Reference |

|---|---|---|

| Horizontal displacement (ux) | 25 cm | Decided by the stakeholders |

| Differential settlement (δD) | 2% | BS EN 14475:2006 [38] |

| Geogrid strain | 5% | BS 8006 [35] |

| Geomembrane strain | 3% | Rowe & Yu, 2019 [39] |

| Gabion compressibility | 5% | BS EN 14475:2006 [38] |

| Gabion alignment | ±100 mm | BS EN 14475:2006 [38] |

| Soil | tan δ/tan φ (Wire Mesh) | tan δ/tan φ (Geogrid) |

|---|---|---|

| Clay | 0.3 | 0.4 |

| Silt | 0.4 | 0.7 |

| Sand | 0.65 | 0.9 |

| Gravel | 0.9 | 0.9 |

| Property | Symbol | Value |

|---|---|---|

| Density | Ρ | 1680 kg/m3 |

| Angle of internal friction | Ø | 44° |

| Dilation angle | Ψ | 11° |

| Cohesion | C | 1 kPa |

| Poisson’s ratio | v | 0.3 |

| Young’s modulus | E | 48 MPa |

| Property | Symbol | Value |

|---|---|---|

| Young’s modulus | E | 20 MPa |

| Poisson’s ratio | v | 0.2 |

| Density | ρ | 2500 kg/m3 |

| Property | Symbol | Value |

|---|---|---|

| Axial stiffness | EA | 119 kN/m |

| Young’s modulus | E | 37.8 MPa |

| Poisson’s ratio | v | 0.5 |

| Scenario | Consolidation Time | Properties of Industrial Waste C (kPa), Ø (°) | Properties of Fill Cohesion (kPa), Friction Angle (°) | Horizontal Displacement | Differential Settlement cm/m | Strain in HDPE % | Strain in Geogrid | Gabion Alignment | Gabion Compressibility | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (Left) cm | (Right) cm | Left % | Right % | (Left) cm | (Right) cm | Left % | Right % | |||||||

| 1a. | 3 m/year | C = 20, Ø = 30 | Local fill stabilized with lime | C = 20, Ø = 40 E = 30 × 103 kPa | 47 | 55 | 1.8 | 1.8 | 0.9 | 0.9 | 9.5 | 9.6 | 3.8 | 2.5 |

| 1b. | 5 m/year | C = 20, Ø = 30 | Local fill stabilized with lime | C = 20, Ø = 40 E = 30 × 103 kPa | 53 | 63 | 1.7 | 2.2 | 1 | 0.9 | 9 | 9 | 2.9 | 3 |

| 1c. | 3 m/year | C = 20, Ø = 30 | Sand | C = 2, Ø = 35 E = 30 × 103 kPa | 49 | 57.4 | 2 | 1.9 | 1.2 | 1.3 | 8.2 | 8.3 | 2.9 | 3 |

| 1d. | 3 m/year | C = 20, Ø = 30 | sand | C = 2, Ø = 35 E = 30 × 103 kPa | 43 | 43 | 1.6 | 1.6 | 1.1 | 1.1 | 8 | 8 | 3 | 3 |

| 1e. | 3 m/year | C = 30, Ø = 40 | Local fill stabilized with lime | C = 20, Ø = 40 E = 30 × 103 kPa | 31.5 | 36.5 | 1.9 | 2. | 0.9 | 0.9 | 9.1 | 9.2 | 3.7 | 3.7 |

| 2a. | 3 m/year | C = 20, Ø = 30 | Local fill stabilized with lime | C = 20, Ø = 40 E = 30 × 103 kPa | 39 | 46.8 | 1.5 | 1.8 | 0.9 | 0.9 | 11 | 11 | 4 | 4 |

| 2b. | 3 m/year | C = 20, Ø = 30 | Local fill stabilized with lime | C = 20, Ø = 40 E = 30 × 103 kPa | 36 | 43.5 | 1.3 | 1 | 1 | 1 | 16.8 | 16.8 | 7.3 | 7.4 |

| 2c. | 3 m/year | C = 20, Ø = 30 | Local fill stabilized with lime | C = 20, Ø = 40 E = 30 × 103 kPa | 39 | 46.8 | 1.5 | 1.8 | 0.9 | 0.9 | 8 | 7.7 | 4 | 3.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.R.; Emidio, G.D. Performance Assessment of a Landfill Expansion Stabilized with Reinforced Fill Structure Using Numerical Analysis. Buildings 2025, 15, 3853. https://doi.org/10.3390/buildings15213853

Khan AR, Emidio GD. Performance Assessment of a Landfill Expansion Stabilized with Reinforced Fill Structure Using Numerical Analysis. Buildings. 2025; 15(21):3853. https://doi.org/10.3390/buildings15213853

Chicago/Turabian StyleKhan, Ahsan Rehman, and Gemmina Di Emidio. 2025. "Performance Assessment of a Landfill Expansion Stabilized with Reinforced Fill Structure Using Numerical Analysis" Buildings 15, no. 21: 3853. https://doi.org/10.3390/buildings15213853

APA StyleKhan, A. R., & Emidio, G. D. (2025). Performance Assessment of a Landfill Expansion Stabilized with Reinforced Fill Structure Using Numerical Analysis. Buildings, 15(21), 3853. https://doi.org/10.3390/buildings15213853