Abstract

Waste tyre rubber (TR) from end-of-life tyres poses a major environmental challenge. Therefore, recycling this waste into useful applications contributes to sustainable waste management strategies and supports a circular economy. Rubber possesses properties that can enhance the flexibility and ductility of pavements, making it a feasible material for use in road infrastructure. This study investigates the mechanical and fatigue performance of recycled concrete aggregates (RCA) mixed with waste TR. RCA was partially replaced at three different levels: 5%, 10% and 15% by weight. To mitigate the loss in mechanical strength associated with rubber inclusion, the TR + RCA mixes were stabilised through geopolymerisation using slag as a precursor. The unconfined compressive strength (UCS) increased with higher binder content. For instance, the mix containing 15% TR and stabilised with 5% slag geopolymer achieved a UCS of only 0.7 MPa, whereas increasing the binder content to 15% raised the UCS to 2.2 MPa. Similarly, resilient modulus improved with increasing slag content. Results from the four-point bending fatigue test showed that replacing RCA with rubber particles enhanced the fatigue performance of the mixes. The initial fatigue modulus of 100% RCA mix stabilised with 15% binder was 13,690 MPa, which reduced to 9740 MPa when 10% TR was introduced. In contrast, the number of cycles to reach half the initial modulus increased by four times when the TR content was raised from 0% to 15%. Microstructural observations of the slag-stabilised TR + RCA mixes showed improved microstructure due to geopolymerisation. Only insignificant traces of arsenic (<0.0008 mg/L) and barium (<0.000208 mg/L) were present in the TR + RCA mixes, while all other concerning heavy metals, including mercury and lead, were not detected in the leaching test. This indicates that there is no potential risk of soil or groundwater contamination, confirming the environmental safety of using slag geopolymer-stabilised TR + RCA mixes in subbase applications.

1. Introduction

Population growth and increased demand for new services and infrastructure have created immense pressure on existing natural resources and amplified the generation of solid waste. According to the Australian National Waste Report 2022, 75.8 million tonnes of core waste, which includes municipal, industrial, and demolition waste, were generated in Australia annually [1]. The recovery rate of construction and demolition waste in Australia is 63%, which is less than the target recovery of 80% set by state authorities [1,2]. These solid wastes end up in landfills, creating air, water, and soil pollution. An innovative approach to incorporating solid waste streams in pavement infrastructure provides a sustainable solution and encourages a circular economy [3,4].

Flexible pavements are widely used all around the world in the construction of roads. Flexible pavements spread the load uniformly through a series of layers, namely, base, subbase, and subgrade. These layers are continuously subjected to cyclic loads due to the movement of traffic and can be detrimental to their material performance with cracking, eventually leading to fatigue failure. In addition, cemented pavement base and subbase layers are subjected to shrinkage cracks which reduce the service life of pavements. In conventional concretes, different fibres are often used to improve the mechanical properties, especially flexural behaviour, fatigue resistance, and shrinkage [5]. Similarly, researchers have attempted to add rubber particles which improve the flexibility and fatigue life in subbase applications.

The addition of tyre crumb can reduce the aggregate impact value (AIV), Los Angeles abrasion value (LAAV), and improve California bearing ratio (CBR), which are beneficial for subbase applications [6,7]. On the other hand, the addition of rubber particles could reduce the overall mechanical strength of the mixes [8]. For example, a 5% replacement of recycled concrete aggregate (RCA) stabilised using slag with waste rubber resulted in a 50% decrease in unconfined compressive strength (UCS) at 7 days [8]. To address this loss of UCS, several studies suggest improving the bonding between rubber and aggregate composites with the geopolymerisation technique [9,10]. In geopolymerisation, aluminosilicate materials, such as fly ash and slag, are combined with strong alkaline solutions, such as sodium hydroxide, to obtain a binder [11]. These binders are more environmentally friendly, especially considering their embodied carbon and energy compared to traditional ordinary Portland cement (OPC) [11,12].

To mitigate the strength loss of RCA when added to waste plastic (PET), geopolymer stabilisation has shown significant improvements in the strength and stiffness of the pavement base and subbase materials [13]. This technique thus provides a viable alternative to incorporate solid wastes in pavement without compromising strength requirements. Further, several studies used geopolymerisation as a technique to improve flexural characteristics. For example, studies conducted on rubberised concrete composites with fly ash-based geopolymer showed improvements in flexural strength and durability when compared with cement rubberised concrete composites [14]. Similarly, improvements in flexural fatigue behaviour for pavement base layers were noted for reclaimed asphalt pavement (RAP) aggregates and virgin aggregate mixes stabilised with geopolymerised fly ash [15].

The majority of the existing literature on waste tyre rubber (TR) has focused primarily on its incorporation into concrete and asphalt mixtures. However, there is a significant gap regarding the use of TR in pavement subbase applications, particularly when combined with RCA. Moreover, no studies to date have explored the effectiveness of slag-based geopolymer stabilisation of TR + RCA mixes in subbase applications. Traditional stabilisation methods often rely on OPC, which has a considerable environmental footprint. The main objective of this study is to address these gaps by investigating the potential of slag-based geopolymerisation to enhance the performance of TR and RCA mixtures for use in the pavement subbase layer. This research will contribute to promoting recycling of waste, specifically providing a sustainable solution to the challenges associated with discarding waste TR and construction and demolition waste.

2. Materials and Methods

2.1. Materials

RCA, TR, and slag were provided by Alex Fraser Group, Laverton, Victoria, Australia; TyreCycle, Somerton, Australia; and Independent Cement & Lime Pty Limited, Port Melbourne, Australia, respectively. X-ray fluorescence (XRF) analysis was carried out to determine the chemical composition of RCA and slag. XRF analysis could not be performed on TR samples due to the involvement of ignition at high temperatures in the testing procedure. The chemical compositions of RCA and slag are summarised in Table 1. Detailed characterisation and properties of RCA, TR, and slag are available in a previous study by Juveria et al. [8].

Table 1.

Chemical composition of slag and RCA as a percentage of weight.

Generally, an activator solution containing sodium hydroxide (NaOH) and sodium silicate (Na2SiO3) with a silicate modulus (Ms) of 1 can be considered as effective when producing slag-based geopolymer [16]. To prepare the activator solution, Na2SiO3 with Ms = 2, which contains 29.4 weight% SiO2, 14.7 weight% Na2O, and 55.9 weight% H2O, was used. A NaOH 10M solution was prepared by using NaOH crystals of 97% purity. The two solutions were then mixed with a Na2SiO3:NaOH = 70:30 weight ratio to obtain the final activator solution with Ms = 1.

2.2. Mix Proportions

RCA was replaced with TR with 5%, 10%, and 15% replacement percentages by weight. To this parent mix, slag was added with 5%, 10%, and 15% by weight of the RCA + TR mix. Here, slag acts as the precursor material in the geopolymer binder. Previous studies showed that increasing slag content results in the increase of unconfined compressive strength (UCS); however, it reduced repeated load triaxial stress (RLT) after an optimum of 15% [8]. Hence, in this study, slag addition was limited to a range of 5% to 15%.

2.3. Experimental Programme

A summary of the experiments conducted in this study is given in Table 2.

Table 2.

Summary of laboratory tests conducted in the present study.

2.3.1. Compaction

Maximum dry density (MDD) and optimum moisture content (OMC) of the slag-stabilised RCA + TR mixes were determined by the modified Proctor compaction test as per AS 1289.5.2.1 standards [17]. First, all the dry ingredients were oven-dried to remove any moisture trapped in the material and brought to room temperature. Activator was added to the mix with a liquid-to-precursor ratio of 0.4. Then suitable amounts of the water were added to the mix, and the compaction was performed after mixing the components thoroughly. A mixture from each slag stabilised TR + RCA was evaluated to determine the corresponding OMC and MDD.

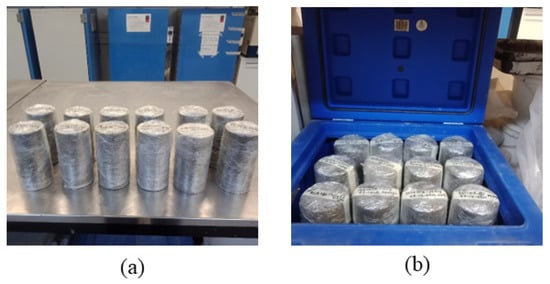

2.3.2. Unconfined Compression Strength (UCS)

UCS samples were prepared based on the OMC and MDD values obtained from the compaction test. UCS specimens were compacted similarly to the modified compaction test method. As per ASTM D5102 [18], samples were wrapped with thin plastic film and stored for a curing time of 7 days in a plastic, airtight, moisture-proof container at a temperature of 23 ± 2 °C to prevent moisture loss and carbonation (Figure 1). The mixes were tested after 7 days to determine the percentage of slag needed to achieve the target UCS values as per the specifications of the Texas Department of Transportation [22]. Sample ends were ground to obtain a smooth and horizontal surface to avoid eccentric and inclined loading.

Figure 1.

Specimens for the UCS study: (a) after compaction; (b) curing of the specimens in a humidity chamber for 7 days.

2.3.3. Repeated Load Triaxial Test (RLT)

To understand the influence of traffic loading conditions on two combined wastes, the RLT test was performed on a sample from each mix to determine the resilient modulus (Mr) for slag geopolymer-stabilised TR + RCA mixes. The RLT tests were conducted under different cyclic axial stresses and confining stresses in 15 different sequences of loading to simulate the material response to traffic loading under existing physical conditions.

2.4. Flexural Characteristics

Flexural characteristics of the mixes were determined based on flexural strength, flexural modulus, and flexural fatigue. All tests were conducted in accordance with the Austroads test method AGPT/T600: flexural beam test method for cemented materials [21]. Beam test specimens of length 400 mm and square cross-section 100 mm × 100 mm were prepared. Samples were covered with a wet cloth and stored in a curing chamber. After 4 days, samples were demoulded and stored in the curing chamber for 28 days.

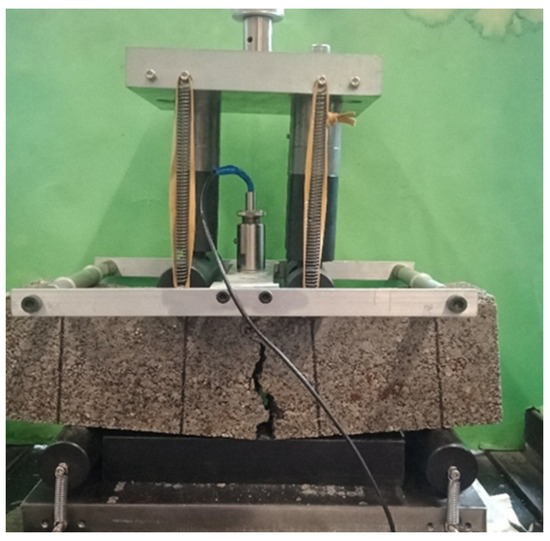

2.4.1. Flexural Strength Test

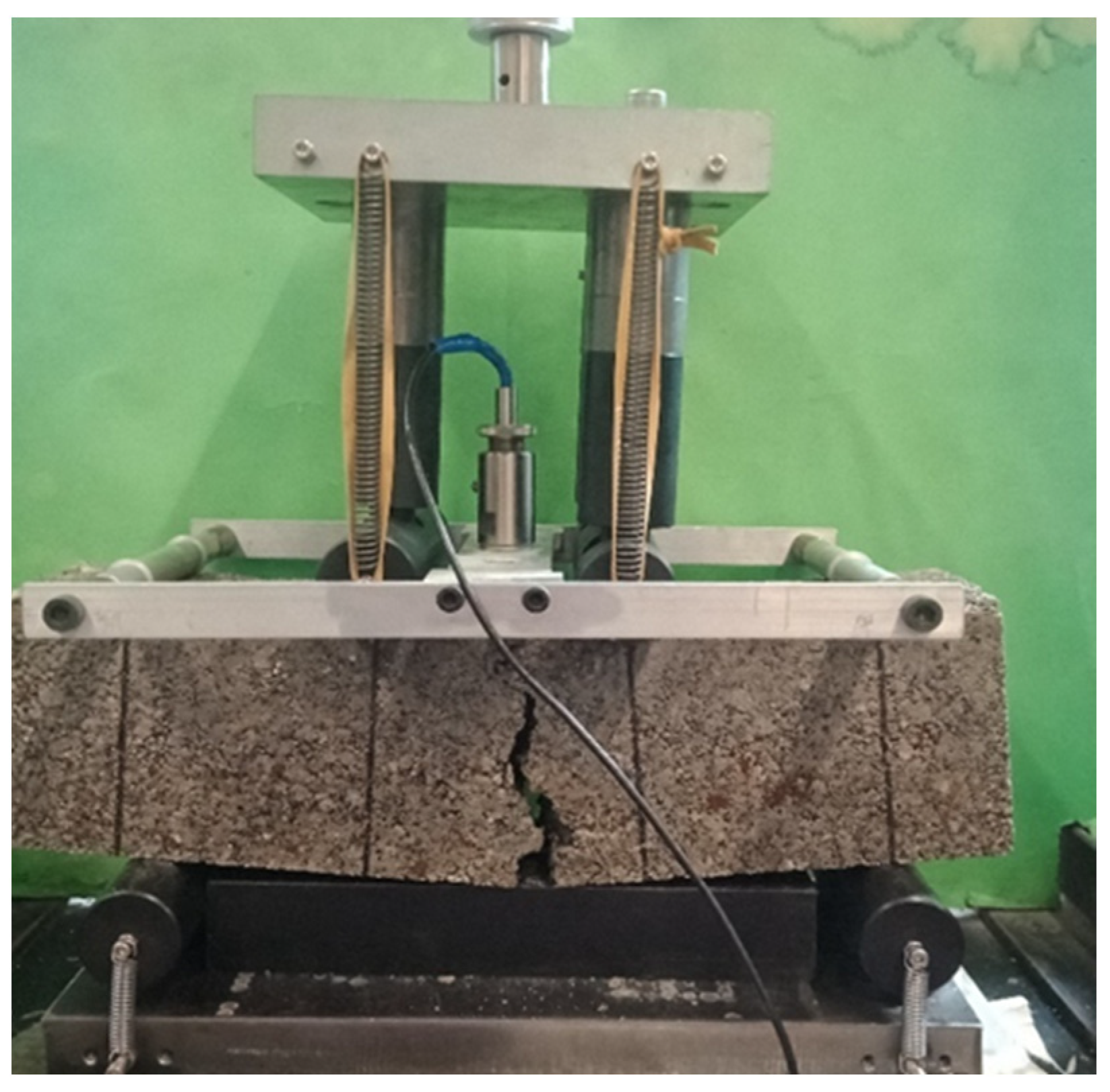

A four-point bending arrangement with a 300 mm distance between supporting rollers and a 100 mm distance between loading rollers was used, as shown in Figure 2. To ensure the contact between loading rollers and the specimen, a seating load of 50 N was applied before the loading. To determine the flexural strength, the load was applied at a rate of 3.3 kN/min until the specimen failed. Flexural strength was then calculated using Equation (1).

where ffs is the flexural strength in MPa, P is the peak load applied before the beam ruptures in kN, a is the distance between the loading roller and the supporting roller in mm (i.e., 100 mm for this test setup), b is the mean beam width in mm, and h is the mean beam height in mm.

Figure 2.

Four-point bending test setup to determine the flexural characteristics.

2.4.2. Flexural Modulus Test

To determine the flexural modulus, repeated haversine loading with a frequency of 4 Hz was applied for 100 cycles. Here, the maximum load of the haversine pulse was determined by the flexural strength test, where the peak load was set as 40% of the ultimate breaking load such that the specimen remains within the elastic range.

where P is the peak force in kN, Ls is the distance between supporting rollers in mm, b is the mean beam width in mm, h is the mean beam height in mm, a is the distance between the loading roller and the supporting roller in mm, and Δ is the resilient deflection at the centre of the beam in mm.

The flexural modulus can be adjusted to a standard applied strain of 50 µε using Equation (3):

where E50 is the flexural modulus at a standard bending strain of 50 µε in MPa, Ef is the flexural modulus obtained by Equation (2) in MPa, and εt is the tensile strain in macrostrain calculated by Equation (4).

where h is the mean beam height in mm, Δ is the resilient deflection at the centre of the beam in mm, Ls is the distance between supporting rollers in mm, and a is the distance between the loading roller and the supporting roller in mm.

The average flexural modulus can be obtained as the mean of the flexural modulus at a standard strain of 50 µε between cycle 50 and cycle 100.

2.4.3. Flexural Fatigue Test

Fatigue behaviour of the stabilised samples was conducted to understand how TR functions in improving the fatigue life under the influence of bending loads. As instructed in the AGPT/T600 test method [21], the same beams used to determine the flexural modulus were used to perform the fatigue test. A haversine loading pulse with a frequency of 4 Hz and with a peak load of 60% of the flexural strength was applied to the specimens. A rest period of 0.25 s was kept between each loading pulse as per the followed testing guidelines. Flexural fatigue modulus for each loading cycle was calculated using Equation (2). Initial flexural modulus was obtained as the mean of the flexural moduli resulting from 10 to 50 pulses. The specimens were loaded until they reached half of the initial flexural modulus. Only the variability of the fatigue life among different mixes was investigated using single sample for each stress level.2.4.4. Leaching Test

It is crucial to investigate the environmental impacts of using slag geopolymer-stabilised TR + RCA mixes as new pavement material. The possible existence of any heavy metals was investigated by the Australian Standard Leachate Procedure (ASLP) and Toxic Chemical and Leachate Procedures (TCLP) as per AS 4439.3 [23]. Acetate (i.e., acidic fluid with a pH of 4.7), tetraborate (i.e., an alkaline fluid of pH 9.2), and deionised water (i.e., neutral pH) were used as leachates during the tests. The results of total contaminants and heavy metal leachate were compared against the upper limits for solid inert wastes and drinking water standards as per Environmental Protection Authority Victoria (EPA Victoria) [24], Environmental Protection Agency, United States (EPA USA) [25] and European Union (EU) drinking water standards [26] and recycled aggregates [27].

3. Results and Discussion

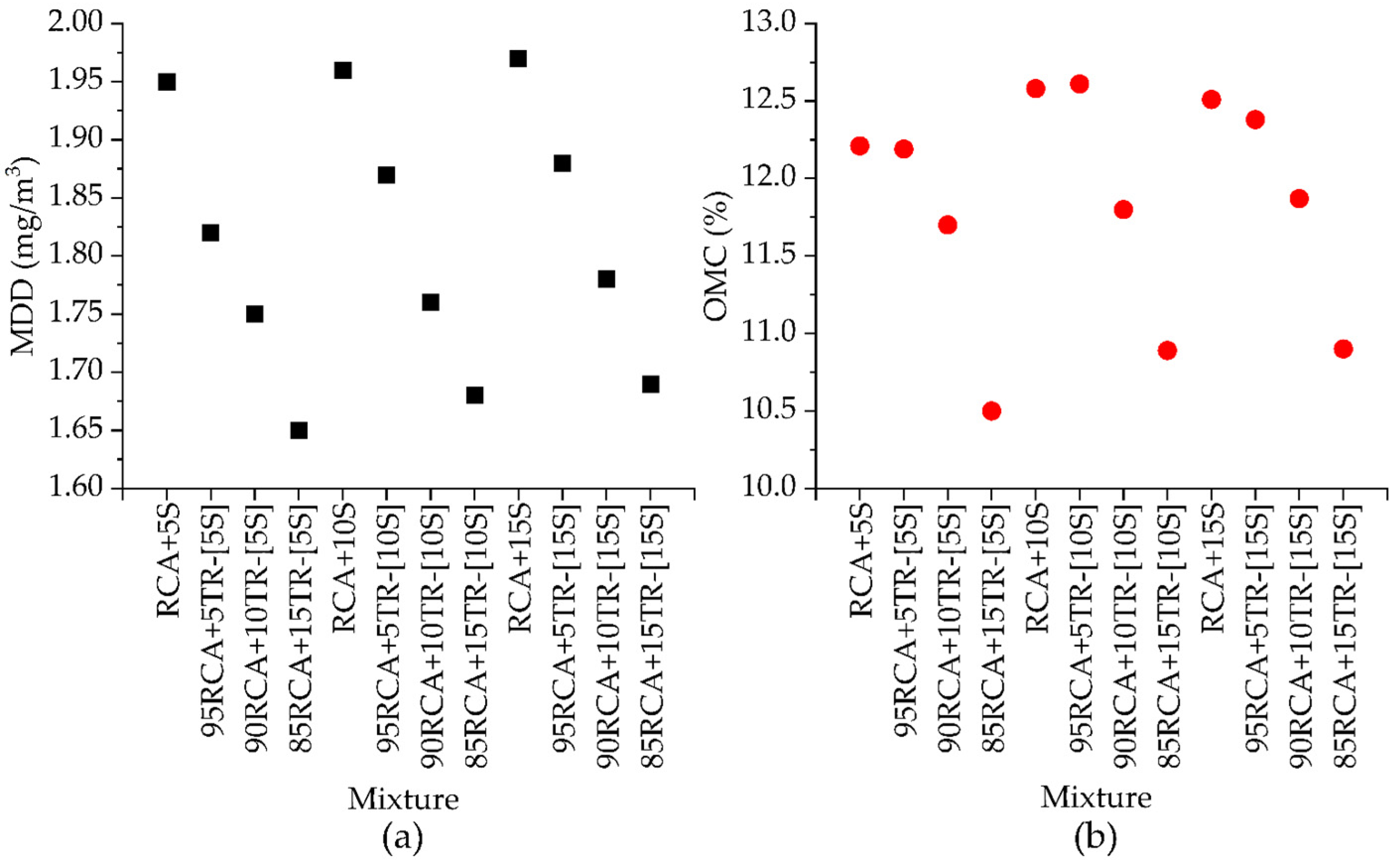

3.1. Compaction Characteristics

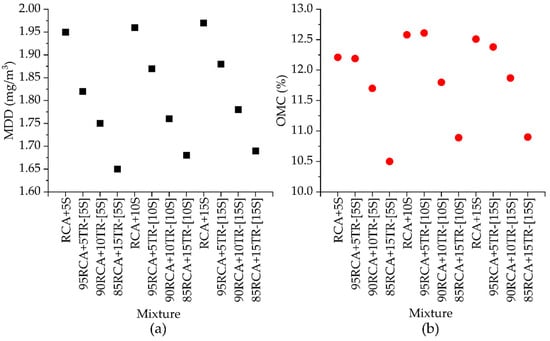

MDD and OMC for the mixtures were obtained to understand the compaction characteristics of different RCA + TR mixes stabilised with slag (Figure 3). It can be seen that a notable drop in compaction characteristics of stabilised TR + RCA mixes can be observed when compared with a control mix with only RCA + slag. This is primarily due to the low water absorption and low specific gravity of TR when compared with RCA [28,29]. The maximum reduction in OMC and MDD was attributed to mixes with 15% TR at all precursor contents. This is because TR particles with low specific gravity dominate the soil matrix, which decreases the overall unit weight of the stabilised mixes [30]. Additionally, due to the smooth surface and elastic nature of TR, there could be a loss in compaction effort, thereby reducing its compactness. The loss of fines during TR replacement may contribute to a decrease in the MDD of stabilised TR + RCA mixes. With the increase in precursor, the small-sized slag particles fill in the void spaces and increase the density of stabilised mixes. Therefore, an overall increase in MDD is noted after stabilisation [31,32]. Moreover, the density improvement could also be supported by the geopolymerisation process, where the dissolution of alumina silicate sources reorganises and produces a gel-like structure.

Figure 3.

(a) Maximum dry density (MDD) and (b) Optimum moisture cintent (OMC) of different RCA + TR + slag mixes.

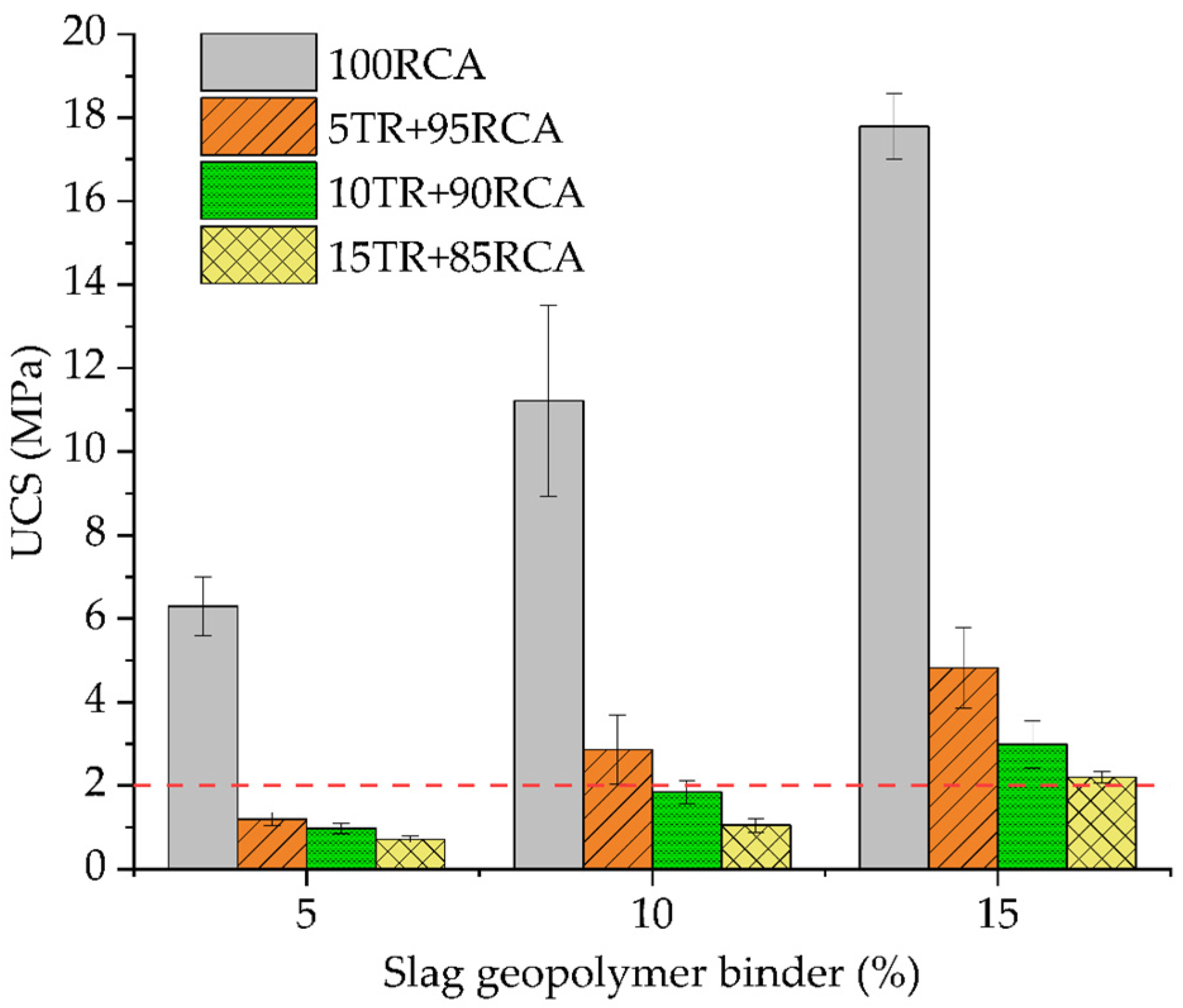

3.2. Unconfined Compressive Strength

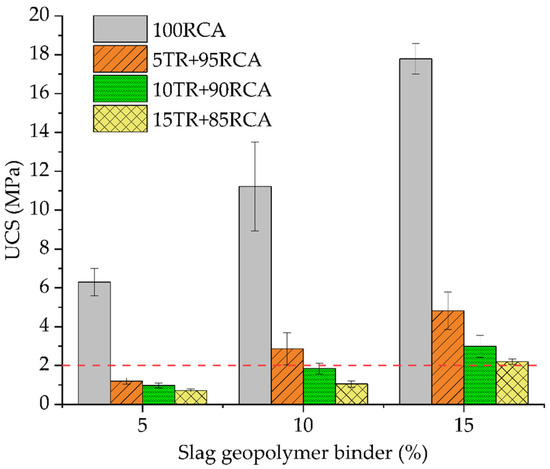

Considering the OMC and MDD values obtained for each formulation, samples were prepared to test the mechanical behaviour of different TR + RCA mixes with slag. Figure 4 shows the UCS values reported for different RCA + TR mixes stabilised with slag. With the increase in slag content, there is an overall increase in UCS for all the activated TR + RCA mixes. In particular, the control blends show a significant increase in compressive strength under the influence of slag in comparison with unbound RCA (i.e., UCS of 137 kPa [8]). This could be attributed to an increase in large amounts of freely available CaO present in slag, which aids the geopolymerisation process. CaO reacts faster when compared to Si and Al in the alkaline environment; hence, mixes with slag show high early strength characteristics [31,33].

Figure 4.

UCS values of TR + RCA mixes stabilised with slag. (Error bars indicates mean ± on standard deviation (SD)).

As shown in Figure 4, the highest recorded UCS for the control sample was observed for 15% slag (i.e., 17.8 MPa), and the lowest for the control mix was recorded for 5% slag (i.e., 6.3 MPa). The geopolymerisation process hardens the microstructure due to the dissolution and reorganisation of aluminate and silicate phases, followed by condensation and gelation [34]. The leaching process of amorphous aluminium silicates in slag when reacted with NaOH also helps in the formation of geopolymer compounds [35]. The OH- ions from NaOH react with silica and alumina in the presence of water molecules to give rise to C-S-H and C-A-H gel composites [36]. The solid precursors and aggregates are rich in alumina and silica, as shown in XRF studies. As reported in the previous studies by Juveria et al. [8], in RCA, crystalline silica is dominant, which was visible by the sharp peaks that appear in XRD. Hence, the predominant contribution to the geopolymerisation process is by slag.

Although an increase of slag increased the UCS of the mixture, within each formulation, the addition of TR decreased the UCS. This can be attributed to the increase in soft-surfaced TR particles contributing to creating large voids and poor bonding in the hardened mix. Moreover, the low specific gravity of the TR decreases the density of the mixtures, which could reduce the compactness and in turn reduce the capacity to resist the axial forces applied during compression [37]. Nevertheless, geopolymer stabilisation of TR + RCA mixes reduced this loss of compressive strength. Improvement in strength is mainly achieved due to the voids being filled up by the amorphous to semi-crystalline structures such as N-A-S-H, C-S-H, and C-A-S-H gel products and from the geopolymerisation of slag [38].

As shown in Table 3, all TR + RCA mixes stabilised with 15% slag reach more than 2 MPa in 7 days, satisfying the requirement to use as a pavement subbase material [22]. In contrast, all TR + RCA mixes with 5% slag, 0TR + 90RCA and 15TR + 85RCA stabilised with 10% slag do not meet the minimum UCS requirement as a pavement material (i.e., UCS values are less than 2 MPa). The compressive strength of stabilised TR + RCA mixes varies significantly with TR composition. Hence, an optimal TR + RCA content should be maintained to achieve a satisfactory UCS value.

Table 3.

Comparison of UCS values with standard specifications for construction and maintenance of highways, streets, and bridges (TxDOT) [19].

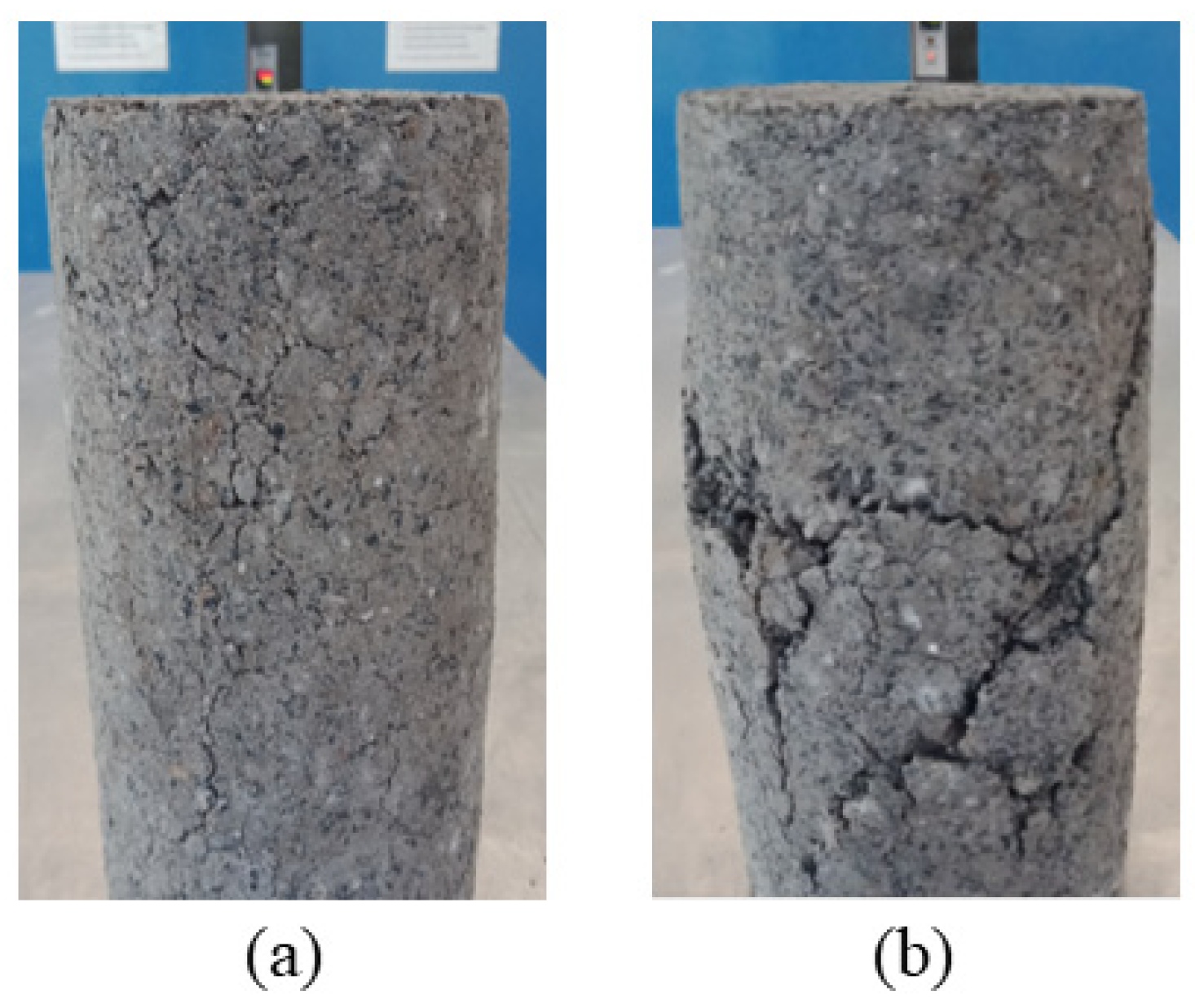

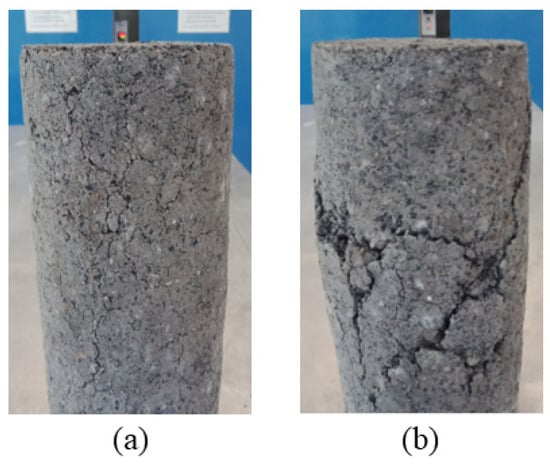

Failure Pattern of Slag-Stabilised TR + RCA Under Compression

Cemented pavement materials are easily susceptible to cracks due to the constant movement of traffic. Previous studies show that the addition of TR can delay crack propagation [39,40]. The failure pattern of mixes stabilised with 15% slag geopolymer-stabilised TR + RCA mixes is shown in Figure 5. The mixes with low TR contents (Figure 5a, 5TR + 95RCA) failed with few cracks, while the mixes with high volumes of TR (Figure 5b, 15TR + 85RCA) will bulge and fail by developing multiple cracks. This can be attributed to the TR particles acting as springs, leading to a delay in crack propagation by increasing the maximum strain failure [41].

Figure 5.

Failure pattern of 15% slag geopolymer-stabilised TR + RCA mixes (a) 5TR +95RCA and (b) 15TR + 85RCA.

It can also be seen that the crack propagation in mixes with 15TR + 95RCA produced many small cracking branches. These small cracks consumed energy and improved the ductile behaviour of the mixes [39]. Although increased TR replacements reduced the stiffness, it showed an improvement in the energy absorption of the mixes. Therefore, TR replacements in the mixes could be an effective approach to improve the ductility and limit the growth of cracks. If an optimum amount of TR and slag is maintained, TR particles can facilitate an increase in ductility, and, at the same time, the loss in stiffness could be regained by adding slag composites. Therefore, the slag geopolymer-stabilised TR + RCA mixes could be advantageous in improving the overall performance of the pavements by improving the long-term service life of pavements.

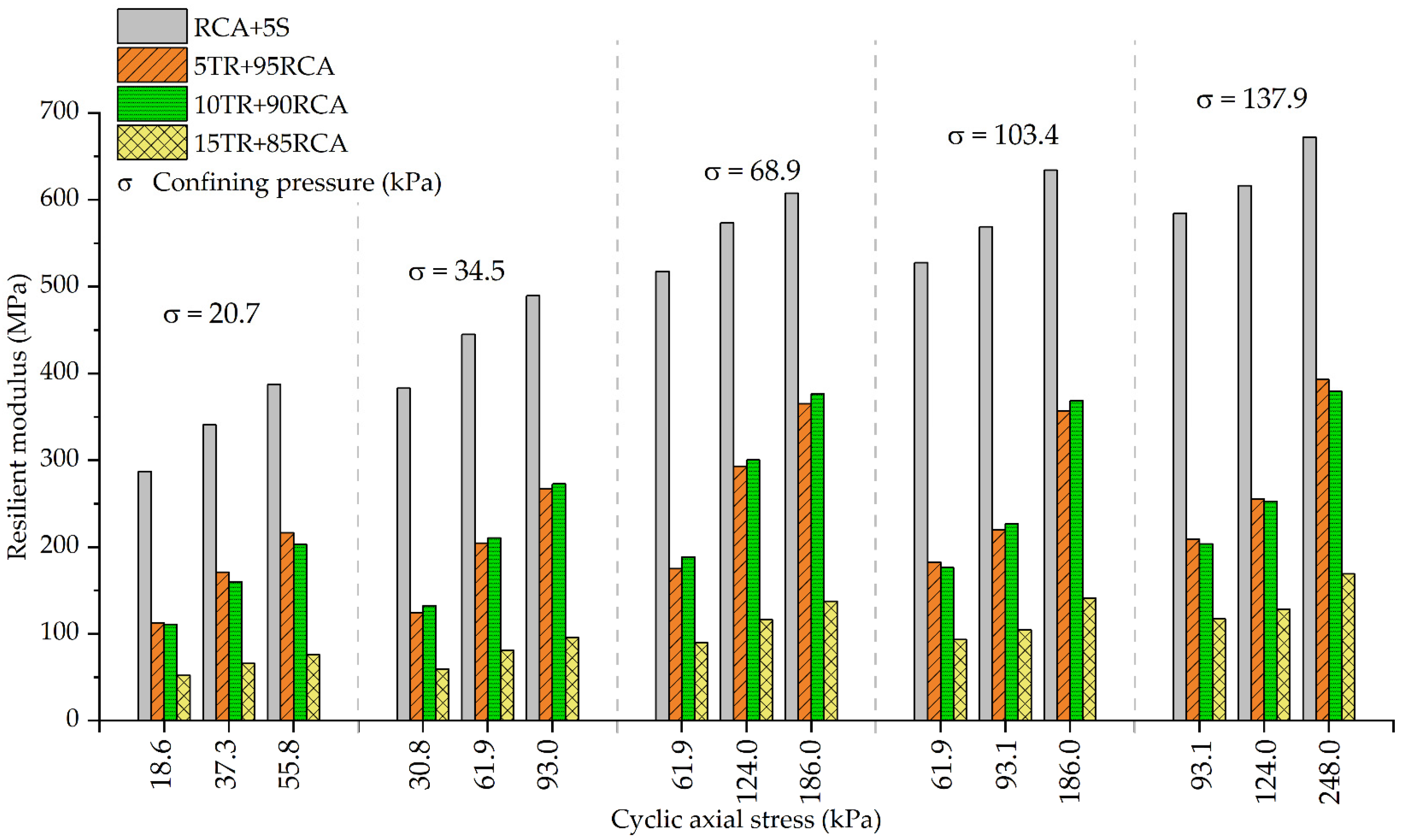

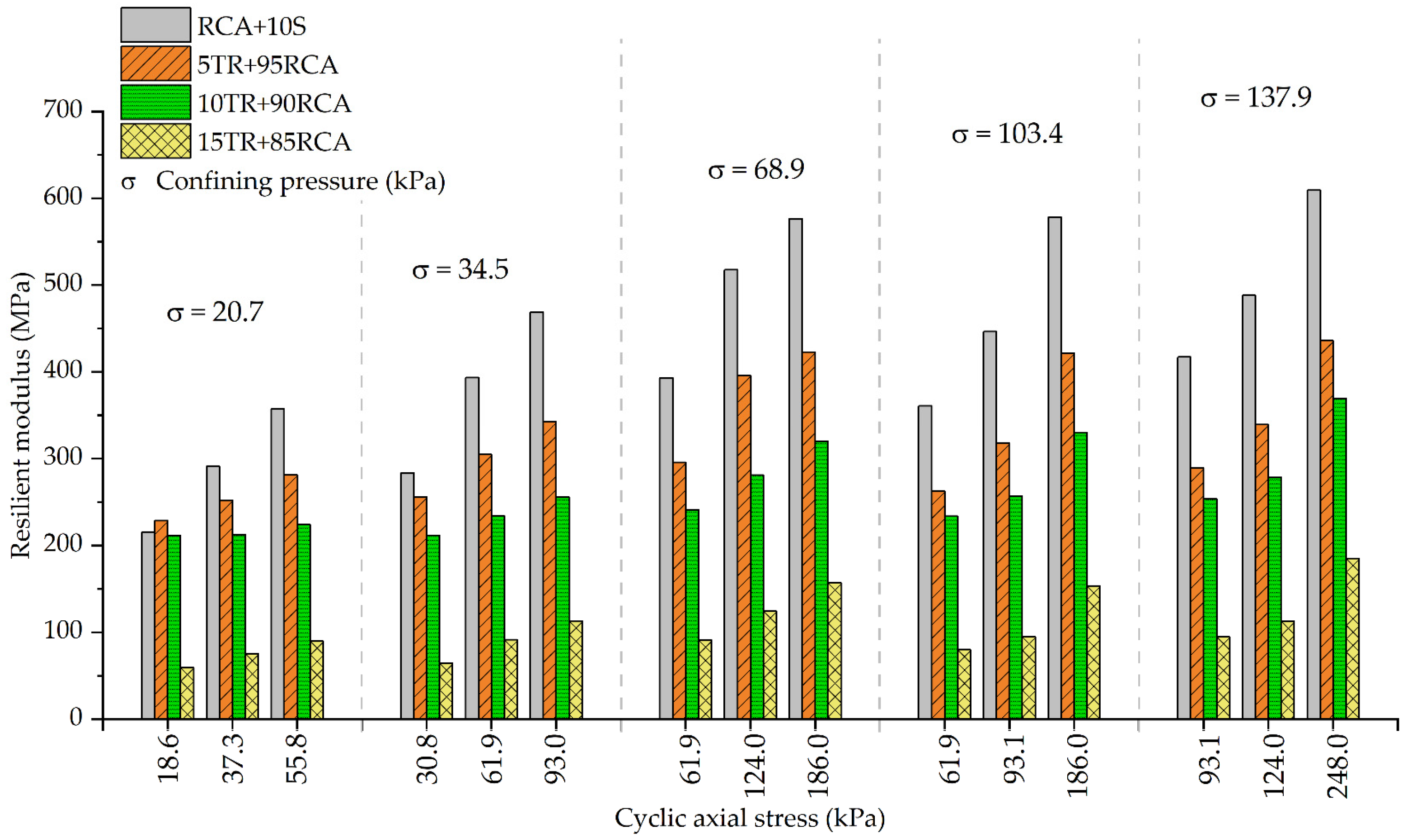

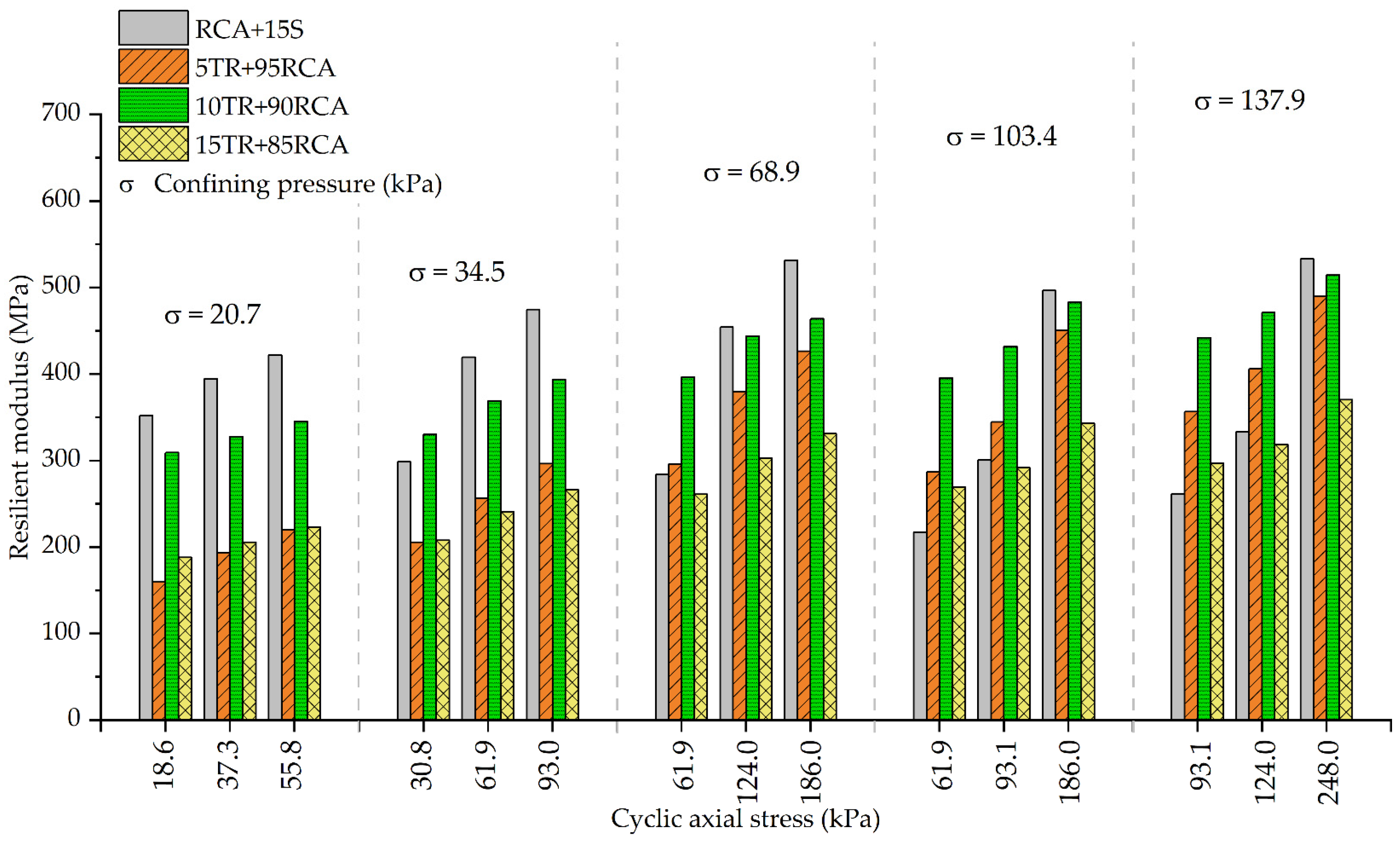

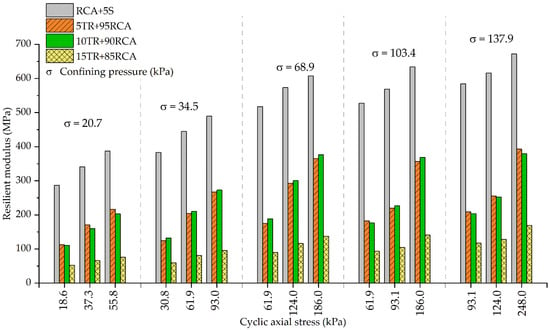

3.3. Evaluation of Resilient Modulus

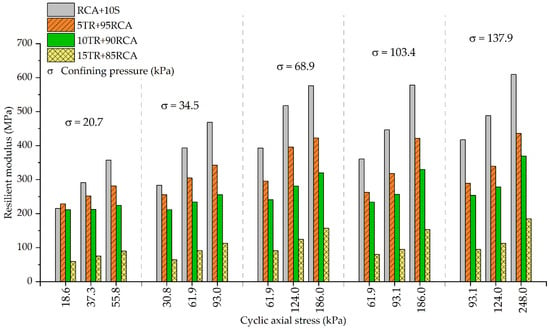

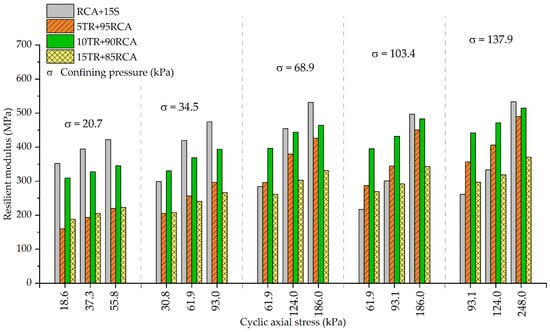

To understand the influence of traffic loading conditions on slag geopolymer-stabilised TR + RCA mixes, the repeated load triaxial test (RLT) was performed under different sets of cyclic axial and confining stresses. The variation of the resilient modulus (Mr) of the slag geopolymer-stabilised TR + RCA blends is illustrated in Figure 6, Figure 7 and Figure 8.

Figure 6.

Resilient modulus for slag geopolymer-stabilised TR + RCA mixes with 5% slag.

Figure 7.

Resilient modulus for slag geopolymer-stabilised TR + RCA mixes with 10% slag.

Figure 8.

Resilient modulus for slag geopolymer-stabilised TR + RCA mixes with 15% slag.

All slag geopolymer-stabilised TR + RCA mixes had higher stiffness when compared with unbound TR + RCA mixes due to the geopolymerisation phenomenon. For example, 5TR + 95RCA mixes with 5% slag have Mr in the range of 110 MPa to 379.3 MPa. However, unbound 5TR + 95RCA mixes had an Mr in the range of 18.5 MPa to 121.3 MPa [8]. This increment in Mr can be attributed to the densification of slag geopolymer-stabilised TR + RCA mixes compared to the unbound material. Similarly, increments in Mr can be noted in cement-stabilised soils [32]. Therefore, increased volumes of waste tyres can be employed in pavement base and subbase layers by using slag geopolymers.

All slag geopolymer-stabilised TR + RCA mixes show an increase in Mr with the increase in cyclic axial stress under constant confining pressure. This is attributed to the stress-hardening phenomenon [42]. In contrast, a decreasing trend in Mr is observed for the increase in TR at each stress level. This is because the soft surface and low specific gravity of TR cannot sustain the repeated loading. Therefore, 15% TR blends displayed lower Mr values than the control mixes among all slag geopolymer-stabilised TR + RCA mixes. The same trend was previously observed in UCS studies.

15TR + 85RCA mixes showed satisfactory Mr of 188.2 MPa to 370.2 MPa when stabilised with 15% slag. Nevertheless, all TR + RCA mixes, except 15TR + 85RCA + 5S and 15TR + 85RCA + 10S, were found to meet the minimum Mr requirement of 80 MPa for pavement bases, as specified by AASHTO guidelines [43].

Estimation of the Resilient Modulus

The determination of Mr for pavement materials from repeated load triaxial studies is a complicated and time-consuming procedure. Hence, a prediction model to estimate the Mr could be the best possible approach.

The Mr is highly influenced by changes in stress conditions. Therefore, numerical models based on the stress states have been proposed by researchers to predict the Mr [44]. These models have been found to be reliable and applicable for pavement base, subbase, and subgrade improvement materials [45]. The correlations encourage geotechnical engineers to model the predictive behaviour of Mr for slag geopolymer-stabilised TR + RCA mixes to be used in the pavement design and analysis.

The bulk stress model is one numerical model to predict Mr for pavement materials [46]. It demonstrates that Mr increases with an increase in confining pressure and is not affected by the magnitude of deviator stress (i.e., applied stress). The bulk stress model is generally recommended for pavement base and subbase layers [47] and is represented by Equations (5) and (6).

where Mr = resilient modulus; = bulk stress = for triaxial stress conditions; and k1 and k2 are regression constants.

The prediction of the Mr by the bulk stress model has few limitations since it does not account for shear strains. Moreover, the bulk stress model does not predict the volumetric strain and dilative behaviour of granular soils, which in turn cannot consider the effect of confining stresses and deviator stresses [48]. In contrast, the octahedral stress model was suggested by Puppala et al. [48] and is given in Equation (7) and can be expressed in Equation (8). Therefore, in this study octahedral stress models were used to predict the resilient modulus for slag geopolymer-stabilised TR + RCA mixes.

in which = atmospheric pressure; = confining pressure; = deviatoric stress; and = model constants.

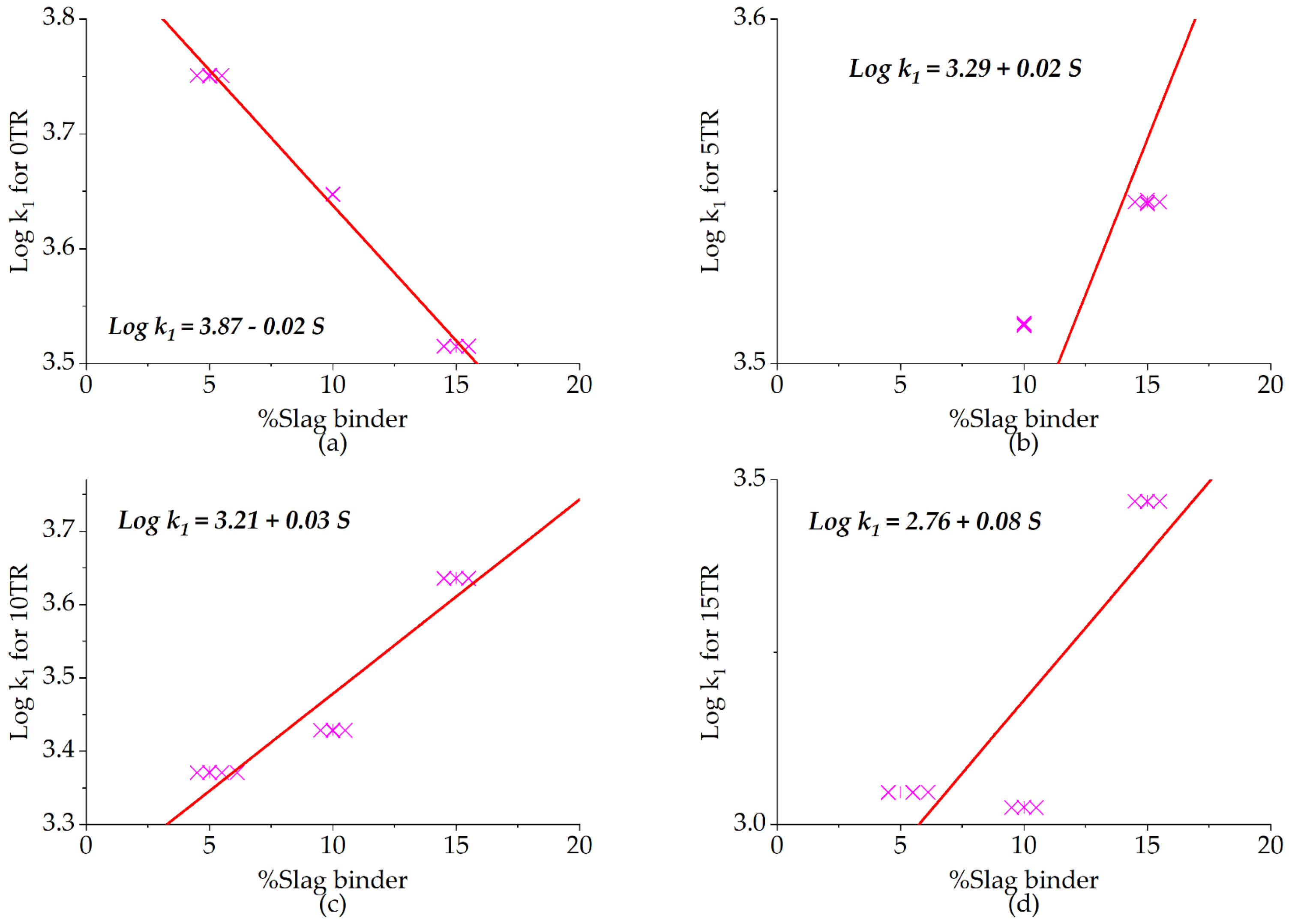

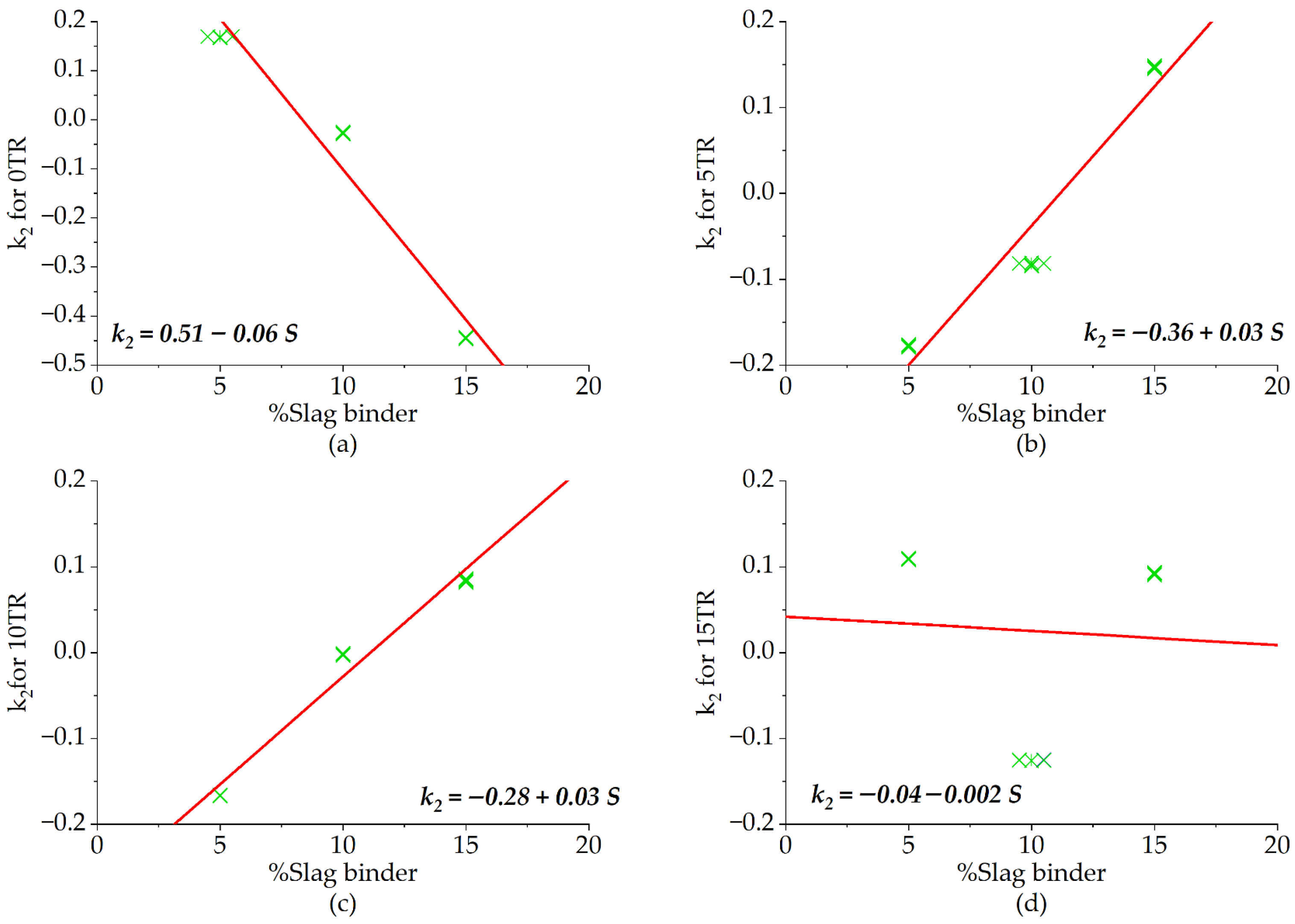

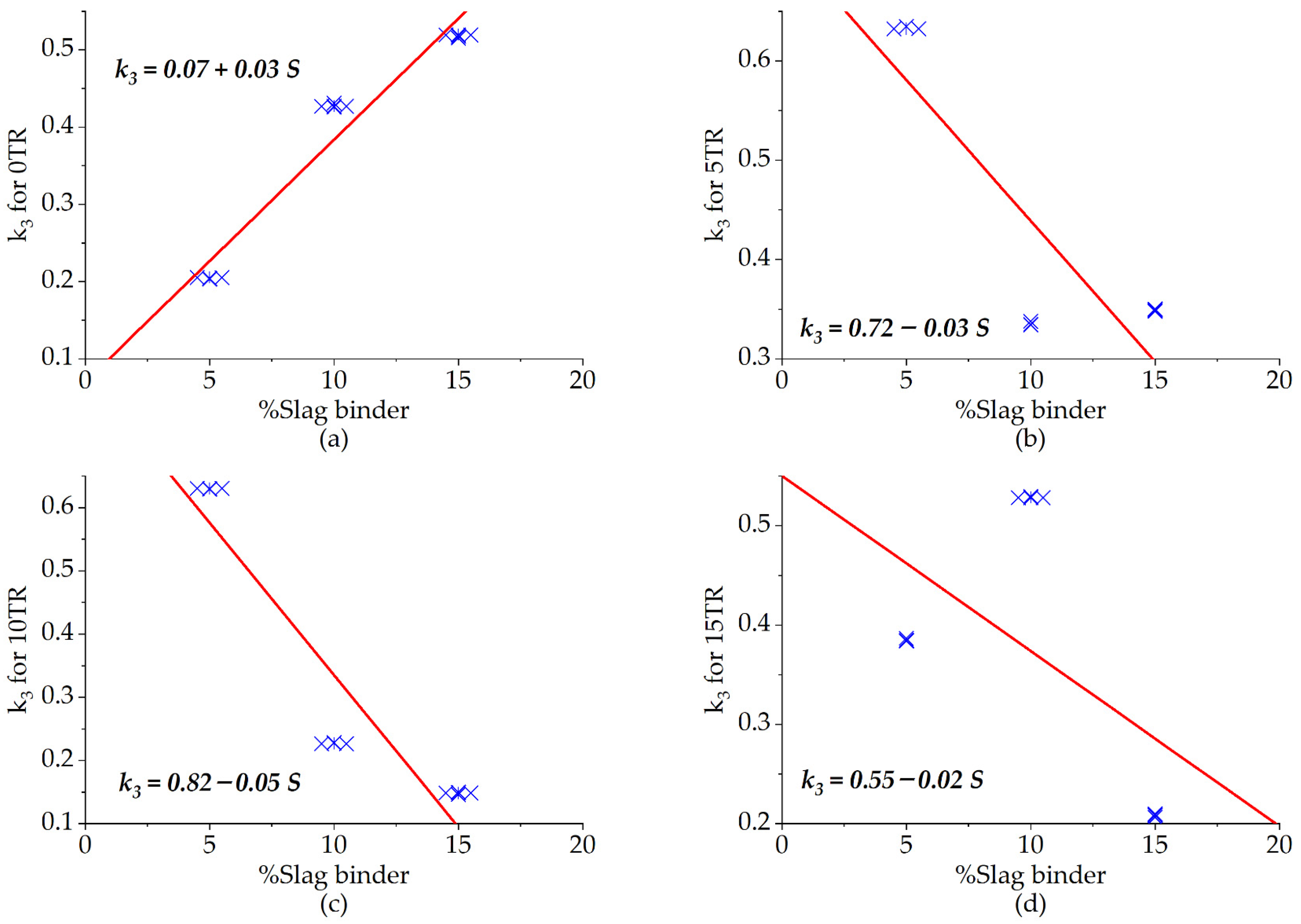

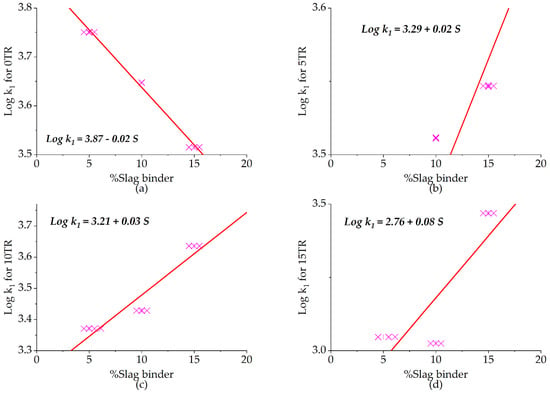

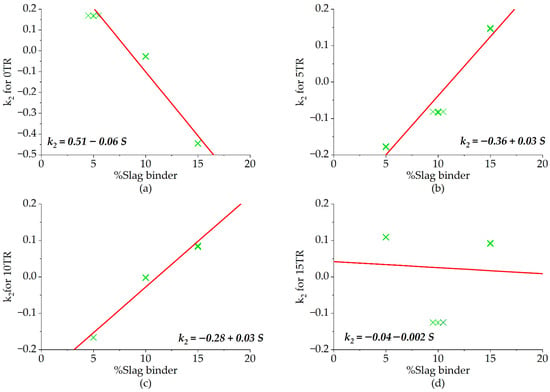

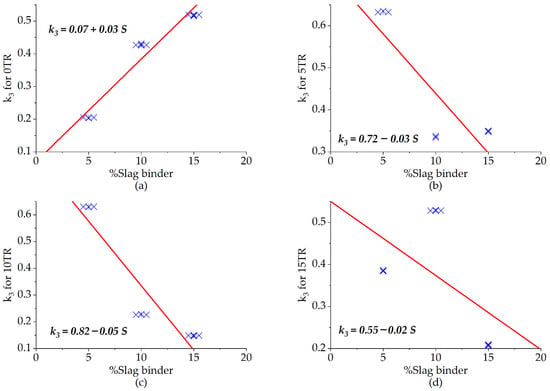

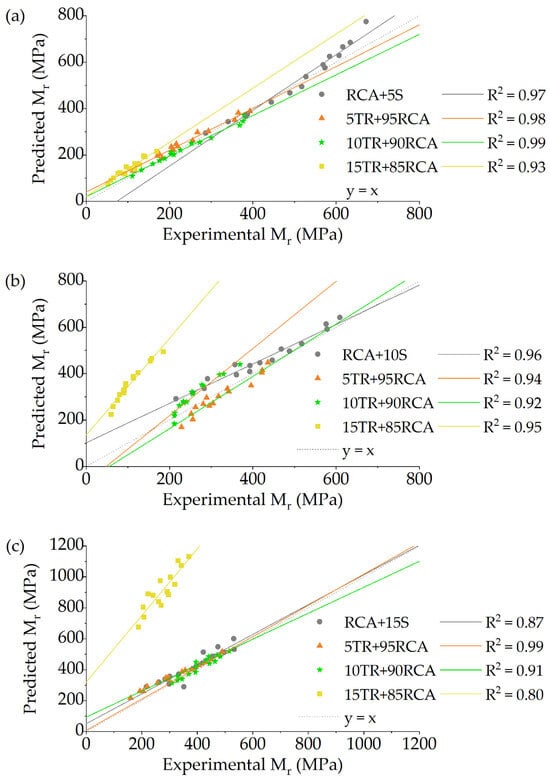

The octahedral stress model was used to predict the Mr of TR+RCA mixes, considering its higher accuracy compared to the bulk stress model. Figure 9, Figure 10 and Figure 11 show the trends identified for model parameters k1, k2, and k3, respectively, based on the experimental data from this work. These constants were obtained through multiple linear regression analysis considering the TR content and slag content. The relationship for each model constant was derived as a function of slag geopolymer content for each TR composition.

Figure 9.

Relationship between model constant k1 and slag content at different TR compositions. (a) 0% TR; (b) 5% TR; (c) 10% TR and (d) 15TR. Overlapped points are plotted with an offset, and the centre point is indicated with a bar (|).

Figure 10.

Relationship between model constant k2 and slag content at different TR compositions. (a) 0% TR; (b) 5% TR; (c) 10% TR and (d) 15TR. Overlapped points are plotted with an offset, and the centre point is indicated with a bar (|).

Figure 11.

Relationship between model constant k3 and slag content at different TR compositions. (a) 0% TR; (b) 5% TR; (c) 10% TR and (d) 15TR. Overlapped points are plotted with an offset, and the centre point is indicated with a bar (|).

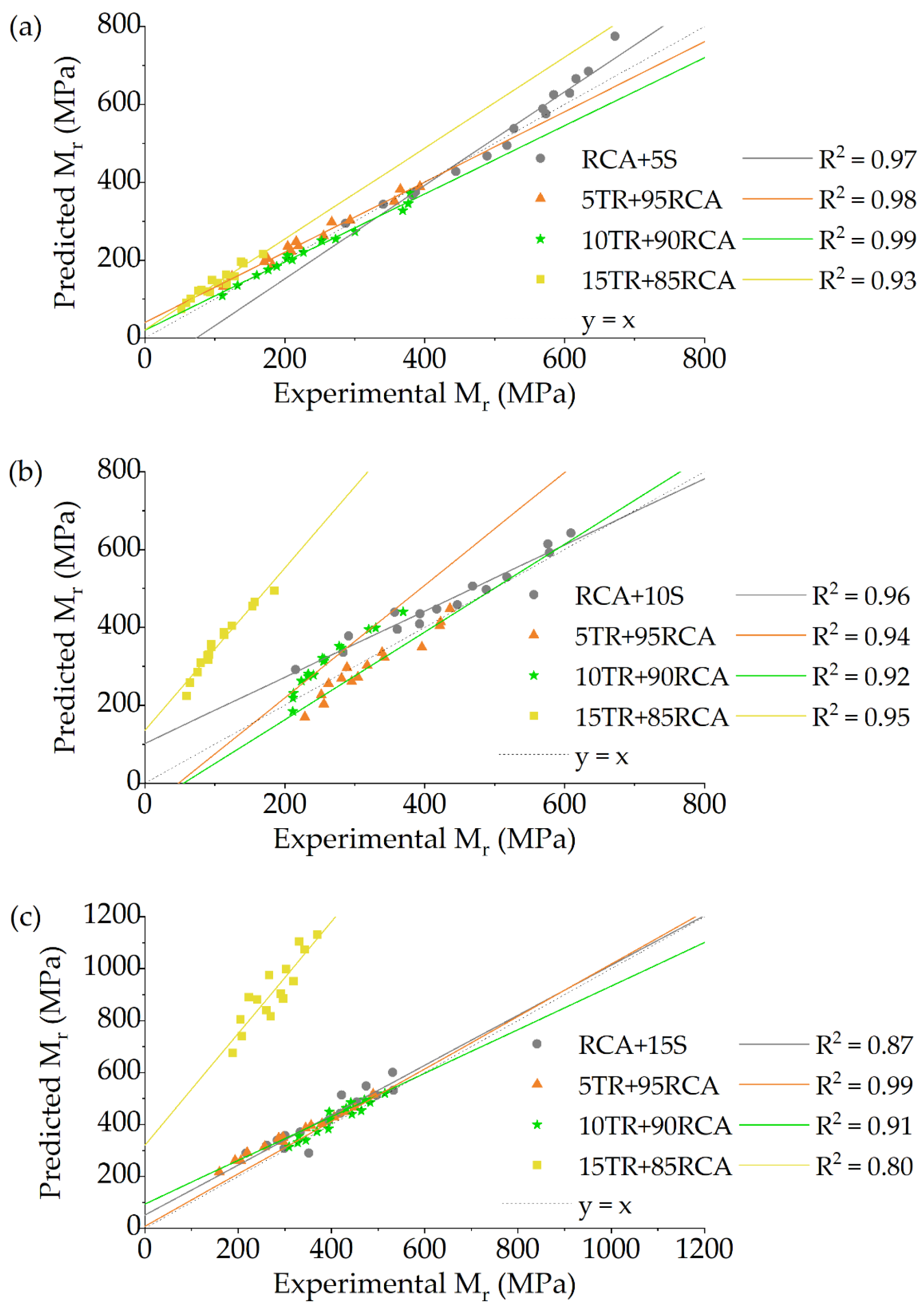

In general, all the model constants showed a linear trend with the varying slag content. The trend in all model constants for mixes with TR was always opposite to the trend in mixes without TR. Based on the above-identified trends, the Mr of different mixes were estimated. As shown in Figure 12, the octahedral stress model shows an excellent fit with experimental test data for mixes with TR content less than 10%. Table 4 shows the root mean square error (RMSE) obtained for the predicted and experimental values reported for all cases. Considering both the R2 value and the RMSE, it can be seen that this model can be effectively used for TR replacements of less than 10% and slag stabilisation with less than 15%. Further studies incorporating more experimental data and machine learning techniques are recommended to refine the model for mixes with higher TR content.

Figure 12.

Predicted and experimental Mr for slag geopolymer-stabilised TR + RCA mixes with (a) 5% slag, (b) 10% slag, and (c) 15% slag.

Table 4.

RMSE for predicted and experimental Mr values for different TR replacement levels and slag contents.

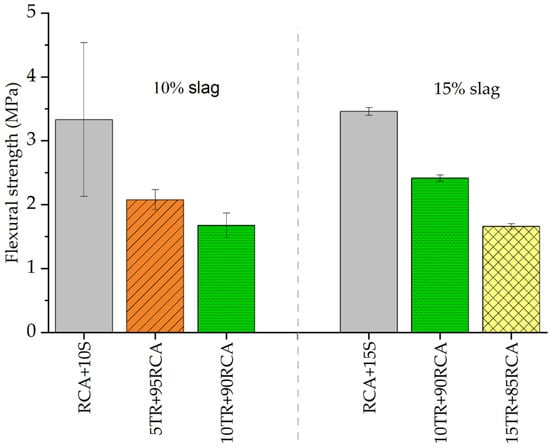

3.4. Flexural Performance

To understand the flexural performance of TR + RCA mixes stabilised with slag geopolymer, flexural strength, flexural modulus and flexural fatigue tests were conducted for the mixes with satisfactory UCS performance, namely, RCA only, 5TR + 95RCA, and 10TR + 90RCA stabilised with 10% slag geopolymer and RCA, 10TR + 90RCA, and 15TR + 85RCA stabilised with 15% slag geopolymer.

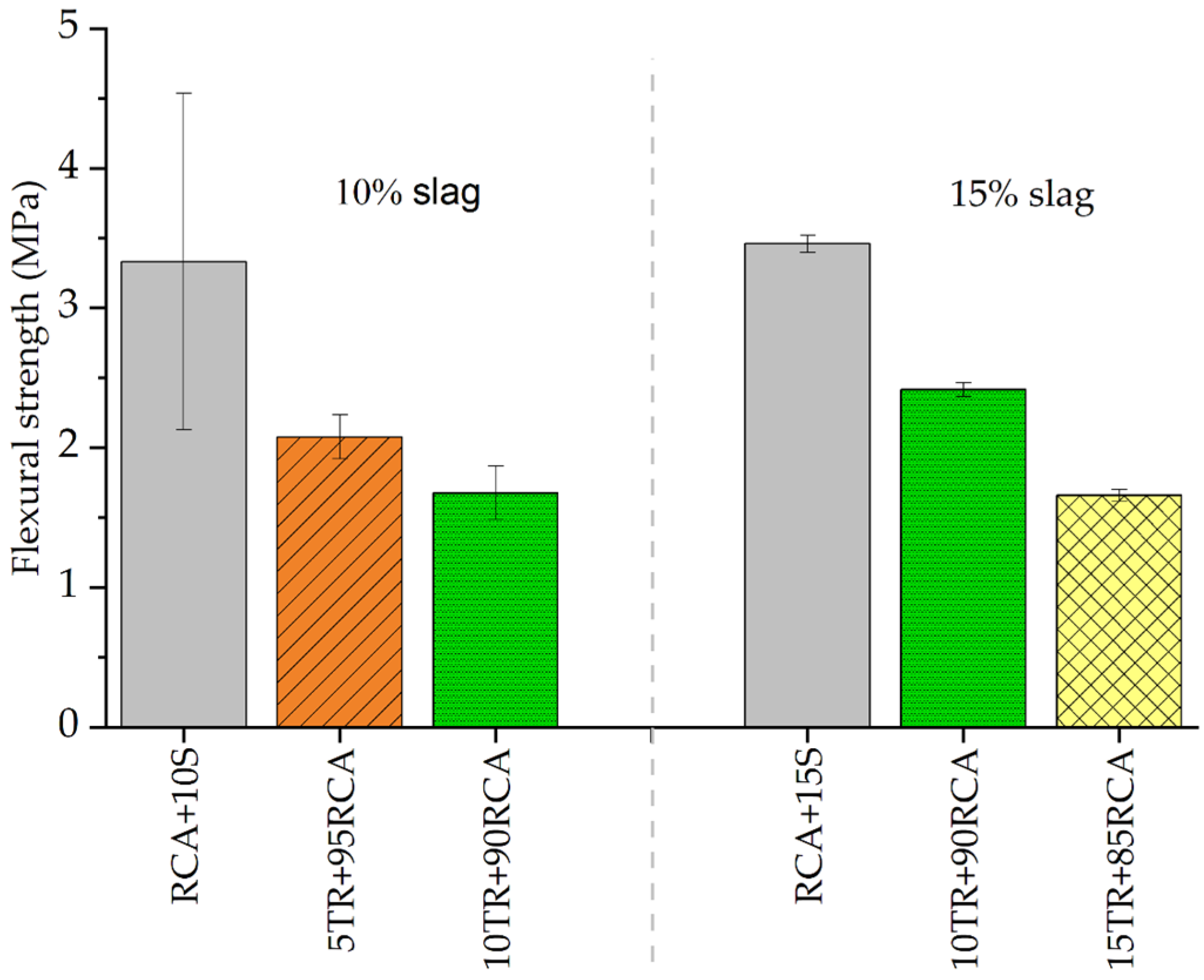

3.4.1. Flexural Strength

Flexural strength of these mixes is shown in Figure 13. The average flexural strengths for the control mixes are 3.3 MPa and 3.5 MPa for 10% and 15% slag, respectively. The increase in flexural strength is noted with an increase in precursor content. This is attributed to the increased formations of C-A-S-H gel precipitates after geopolymerisation of slag, which strengthens the stabilised matrix [10].

Figure 13.

Flexural strength of slag geopolymer-stabilised TR + RCA mixes.

However, a decrease in flexural strength was observed in mixes with an increase in TR content when compared with control mixes. Previous studies suggest that the high contrast between the modulus of elasticity of TR and RCA can lead to the decrease in the flexural strength [9,10]. Also, it was observed that the reduction in flexural strength is less than the reduction of UCS. This can be attributed to the delay of the onset crack due to the addition of TR [49].

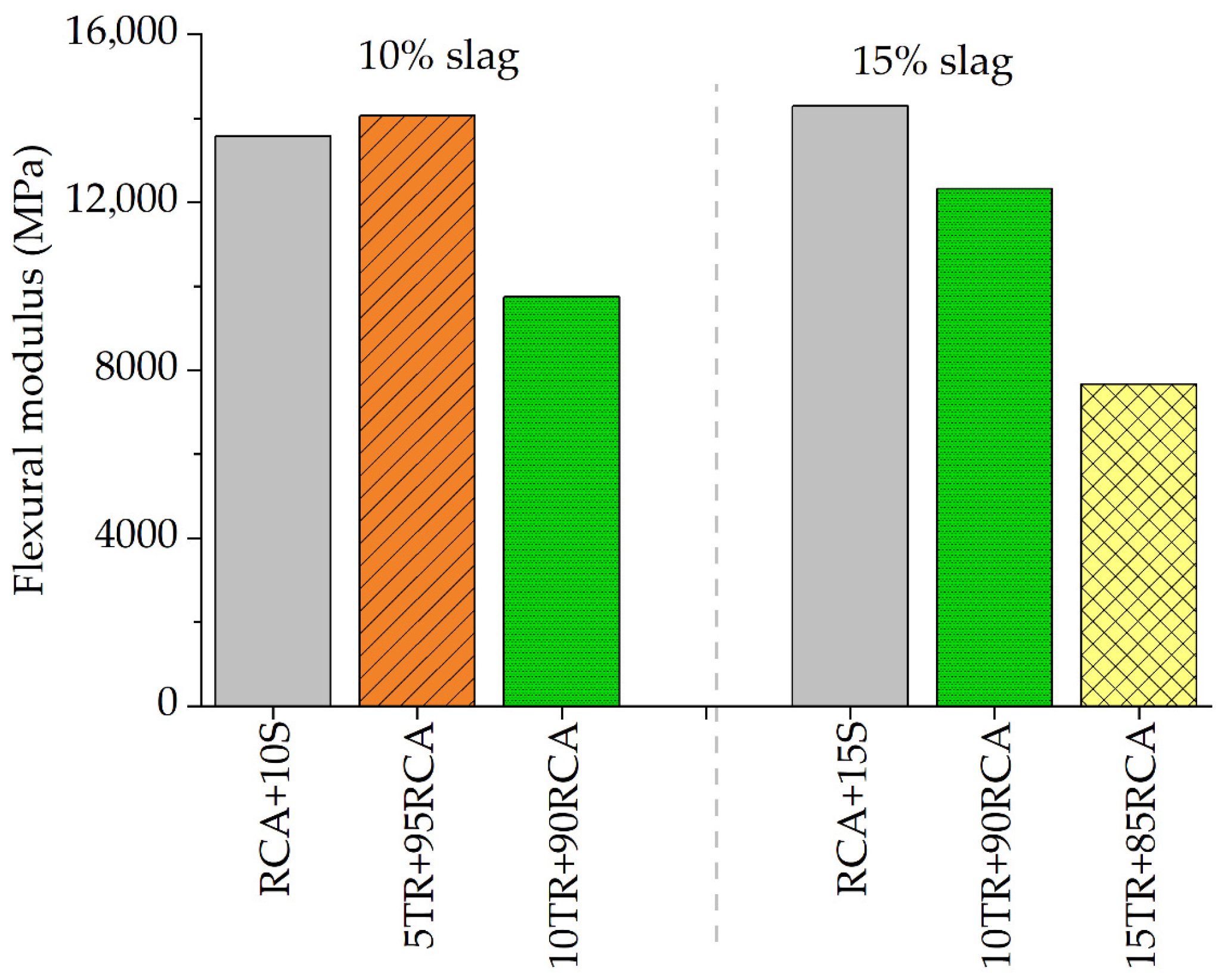

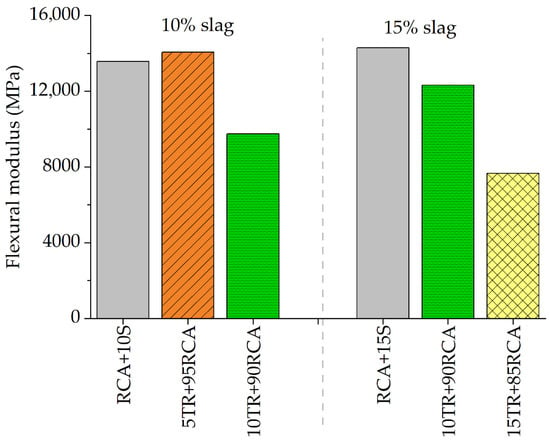

3.4.2. Flexural Modulus

The control sample RCA + 15S showed the highest flexural modulus, followed by mixes of 10TR + 90RCA + 15S and 5TR + 95RCA + 10S, as shown in Figure 14. It can be seen that flexural modulus increases with an increase in precursor content and decreases with an increase in TR content. In other words, the addition of TR reduced the stiffness of the stabilised mixes, while slag contributed to increasing the stiffness, making the material less prone to bending.

Figure 14.

Flexural modulus of slag geopolymer-stabilised TR + RCA mixes at a standard strain of 50 µε, with a peak load of 40% of the maximum flexural strength.

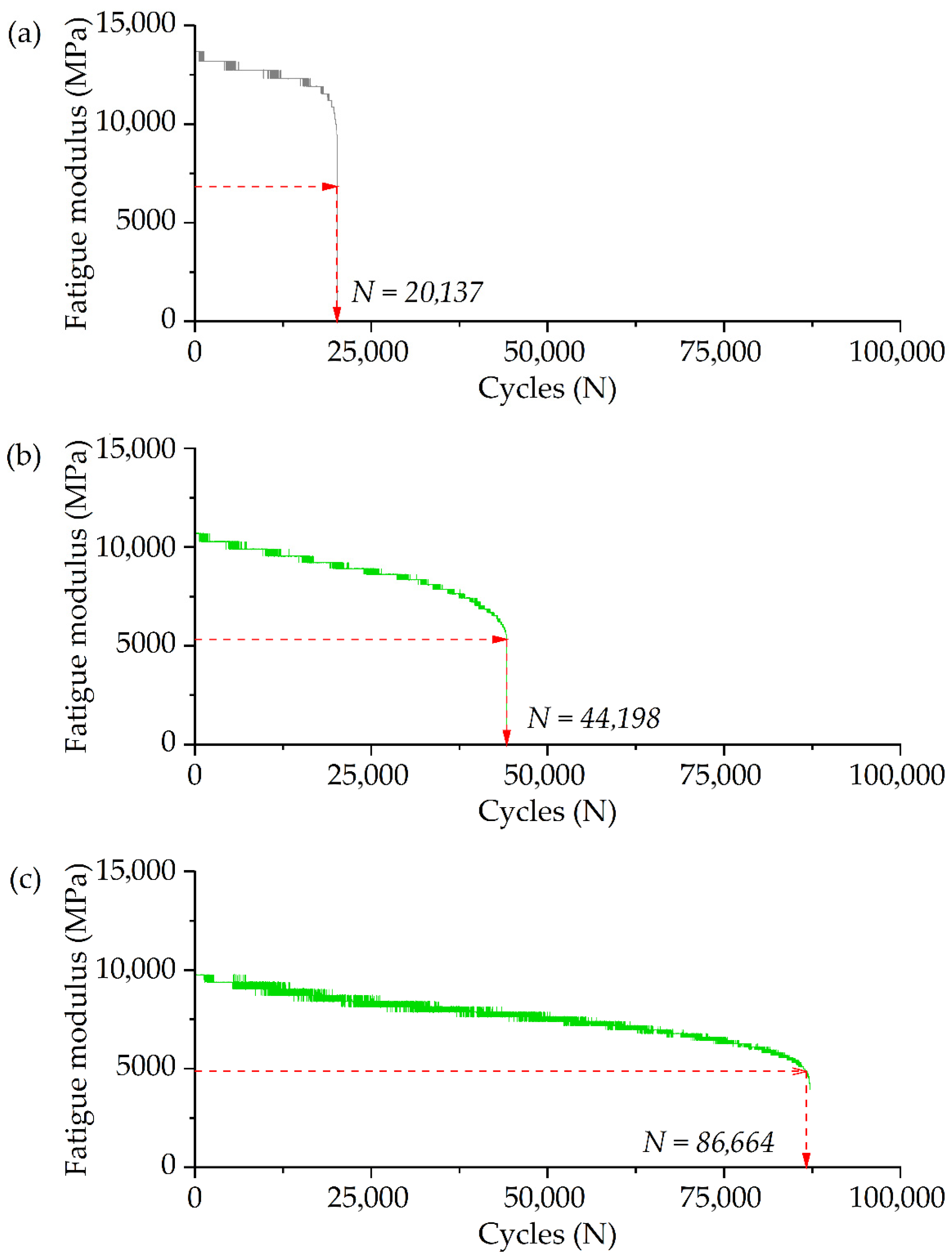

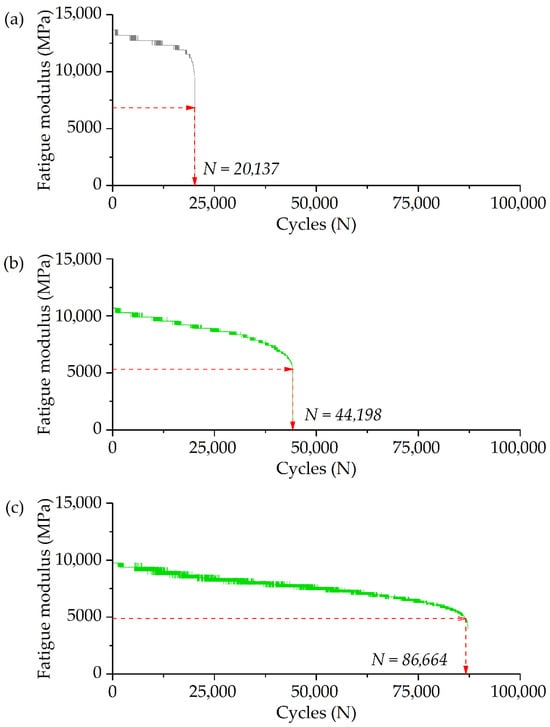

3.4.3. Flexural Fatigue

Fatigue cracking is a commonly observed phenomenon in cemented pavement layers due to repeated loading from the movement of traffic. If the tensile stresses exceed the capacity of the pavement layer, then the tensile strain increases, leading to cracks decreasing the service life of pavements. Hence, it is imperative to understand the premature fatigue cracking phenomenon for the design of cemented pavement layers [50]. Considering the overall behaviour, only RCA with 15% slag, 5TR + 95RCA stabilised with 10% slag, and 10TR + 90RCA stabilised with 15% slag were selected to investigate the fatigue performance. Here, a peak load of 60% of the ultimate failure load was applied.

Table 5 shows the initial flexural fatigue modulus of the mixtures and the corresponding number of cycles required to reduce it by half. The control sample (i.e., RCA only) with 15% slag recorded the highest initial flexural fatigue modulus. Since the ultimate flexural strength of control mixes was higher, the mixes recorded higher initial flexural modulus than the TR + RA mixes. However, the modulus degradation of the RCA mix was quicker when compared with the other two mixes with TR, as shown in Figure 15.

Table 5.

Initial flexural modulus and the number of cycles to reach half of the initial modulus under fatigue loading.

Figure 15.

Flexural fatigue performance of slag geopolymer-stabilised TR + RCA mixes. (a) RCA with 15% slag, (b) 5TR + 95RCA with 10% slag, and (c) 10TR + 90RCA with 15% slag. Red arrows indicate the cycles to reach half of the initial modulus.

The initial fatigue modulus of 13,690 MPa was noted for the control specimen, and it reached half of the initial modulus with 20,137 cycles. Generally, purely cemented material beams tend to fail just after reaching half the initial modulus [51]. On the contrary, the slag geopolymer-stabilised mixes with 5% TR and 10% TR showed lower initial moduli of 10,650 MPa and 9740 MPa, respectively. Although the modulus was less than the control mix, the number of cycles to reach half of it was significantly higher for the mixes with TR. For instance, mixe with 5TR + 95RCA reached half of their initial moduli with 44,198 cycles, and 10TR + 90RCA took 86,664 cycles. This suggests that inclusion of waste tyre rubber in the slag geopolymer-stabilised RCA mixes, even with lower initial stiffness, can enhance the resistance to fatigue loading. According to the study by Badiger, et al. [52], the addition of TR to RCA can increase fatigue life by up to 82% and rutting life by up to 61%. Similarly, TR was found to be effective in improving the fracture toughness and energy absorption of traditional concrete when used as a replacement for aggregates [53,54]. At a stress level of 0.85, concrete with 10% TR can withstand 24.5 times more fatigue cycles than concrete without any TR [55].

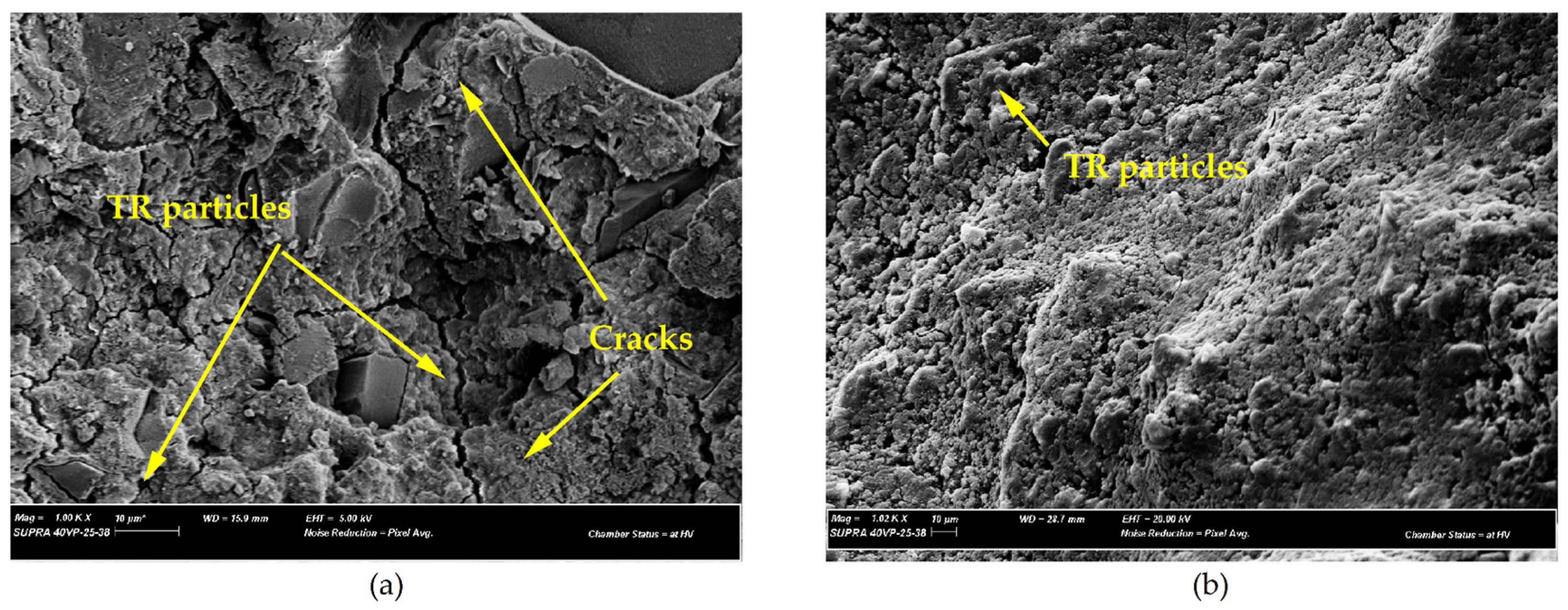

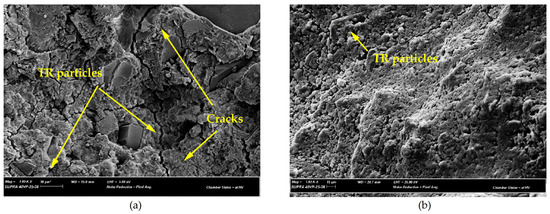

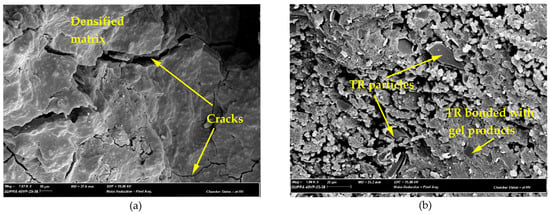

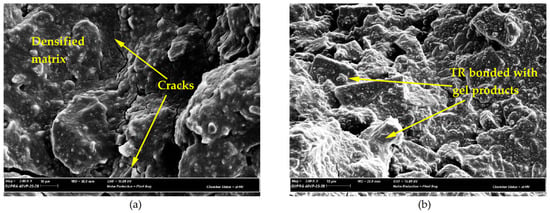

3.5. Microstructure of Slag Geopolymer-Stabilised TR + RCA Mixes

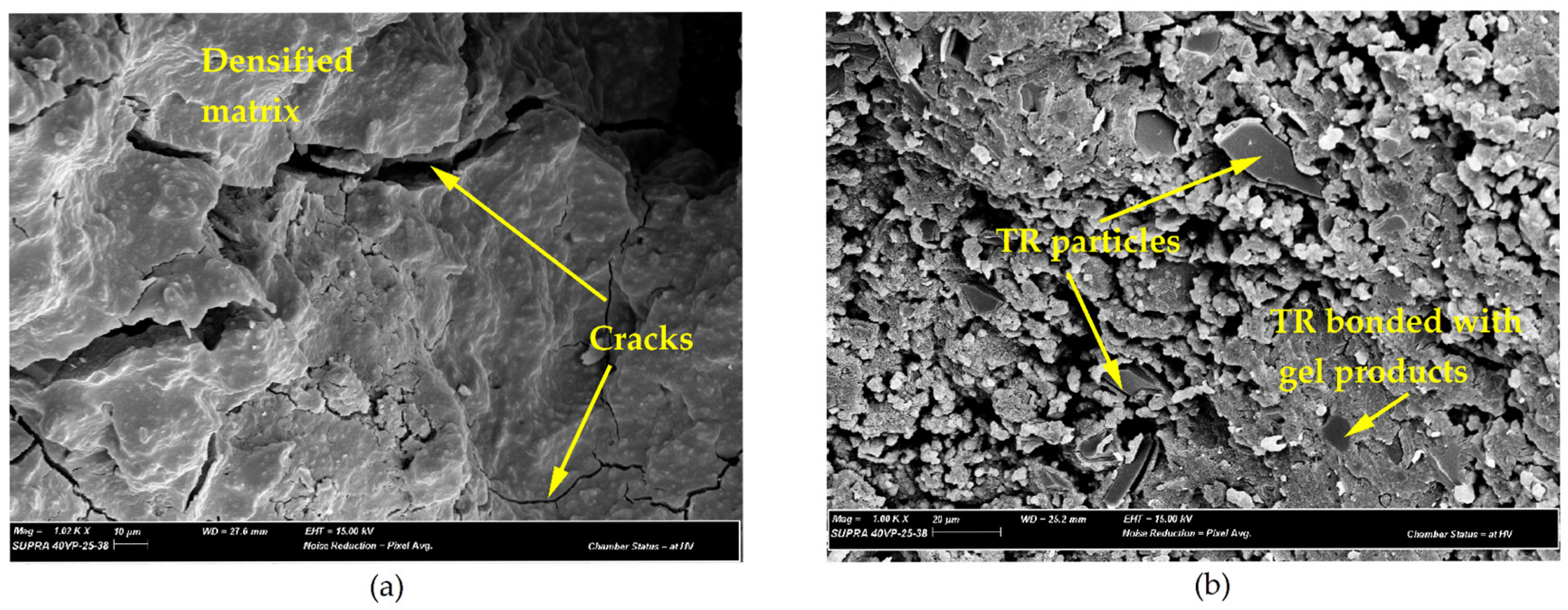

The microstructure of the stabilised TR + RCA mixes had significant differences based on the slag content. TR + RCA mix stabilised with 5% slag after seven days of curing at 21 °C is illustrated in Figure 16. The microstructure exhibits cracks, poor bonding and a rough-textured surface. An increase in slag geopolymer content resulted in a denser and more compacted microstructure (Figure 17).

Figure 16.

Microstructure of TR + RCA stabilised with 5% slag geopolymer. (a) 10TR + 90RCA (Magnification = 1k, EHT = 5.00 kV, WD = 15.9 mm and Chamber status = at HV) and (b) 15TR + 90RCA (Magnification = 1k, EHT = 20.00 kV, WD = 28.7 mm and Chamber status = at HV).

Figure 17.

Microstructure of TR + RCA stabilised with 10% slag geopolymer. (a) 10TR + 90RCA (Magnification = 1k, EHT = 15.00 kV, WD = 27.6 mm and Chamber status = at HV) and (b) 15TR + 90RCA (Magnification = 1k, EHT = 15.0 0kV, WD = 25.2 mm and Chamber status = at HV).

At low precursor contents, due to the insufficient formation of geopolymer gels, the bonding among the different constituents in the matrix is weak. At higher slag geopolymer additions, the reaction products improve bonding and result in a smoother, denser, and homogeneous microstructure. When high amounts of TR were added to the TR + RCA mixes with lower slag (i.e., 5%), cracks propagated at the interface of TR and RCA. The impact of a weak microstructure was evident in the low UCS values, with strengths less than 1 MPa recorded for mixes containing 10% TR stabilised with 5% slag.

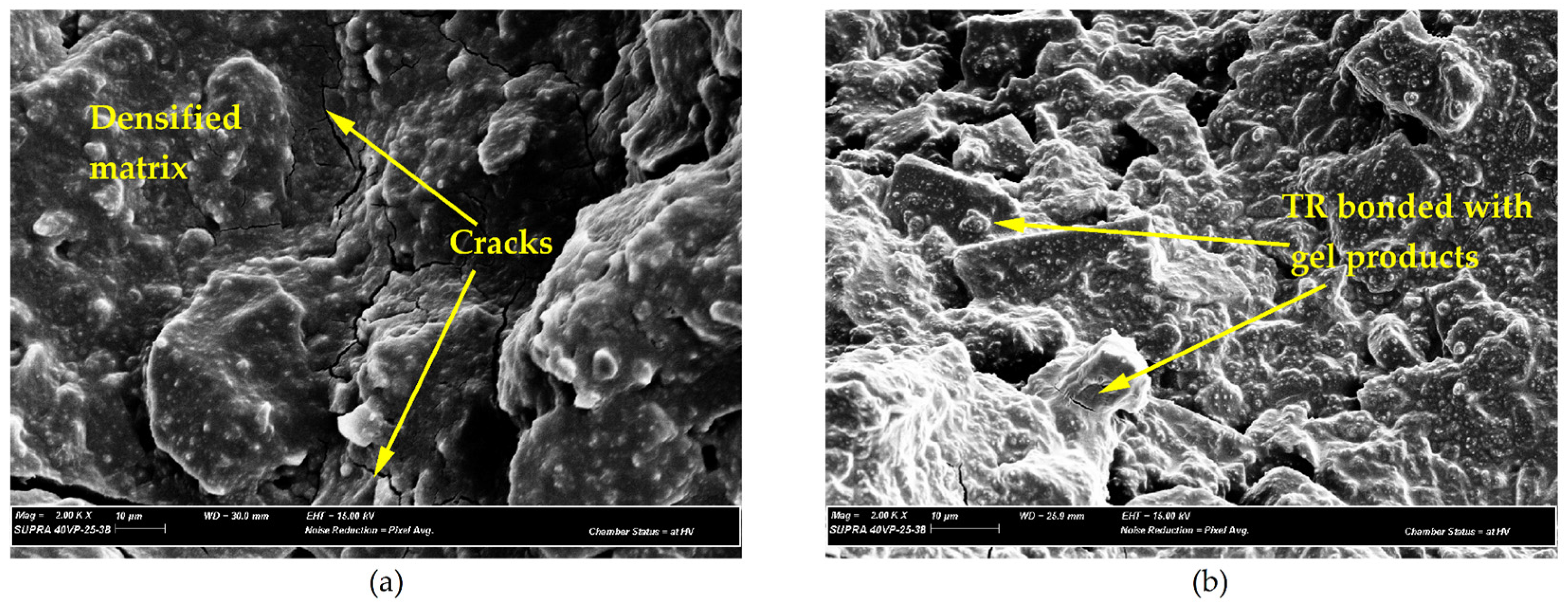

In the same mix, increasing binder content to 10% and 15% resulted in 88% and 205% improvements in the compressive strength, respectively. With 15% binder, the mix was able to exceed the minimum UCS requirement of 2 MPa. This improvement is further verified by the microstructure of TR + RCA stabilised with 15% slag (Figure 18). The microstructure appeared to be compact, smooth, and exhibited reduced surface roughness. The formation of the slag-based geopolymer resulted in well bonding between TR particles and RCA.

Figure 18.

Microstructure of TR + RCA stabilised with 15% slag geopolymer. (a) 10TR + 90RCA (Magnification = 2k, EHT = 15.00 kV, WD = 30.0 mm and Chamber status = at HV) and (b) 15TR + 90RCA (Magnification = 2k, EHT = 15.00 kV, WD = 25.9 mm and Chamber status = at HV).

3.6. Leaching Characteristics

When integrating different waste materials into pavement construction, it is crucial to assess the leaching potential. This is necessary to identify and mitigate the risk of contaminating soil, both groundwater and surface water, with any harmful compounds present in these waste materials. Although there are few studies available incorporating waste TR as a pavement material, the leaching characteristics of these composites are not well documented. Therefore, the possible existence of any heavy metal leachates and total contaminants in TR + RCA mixes was investigated.

Leachate concentrations and total contaminants (TC) present in slag geopolymer-stabilised TR + RCA mixes are shown in Table 6 and Table 7, respectively. It was found that all hazardous leachates and TC present in the slag geopolymer-stabilised TR + RCA mixes fall below the limits of ASLP [23] and TC values, as per EPA Victoria [24]. In addition, all the contaminants present in slag geopolymer-stabilised mixes fall below the minimum limits of drinking water standards [25]. Taken together, these findings suggest the feasibility of using slag geopolymer-stabilised TR + RCA composites in pavements, as they show no traces of heavy metals or toxic leachates that could pollute the soil and underground water. However, further studies are recommended to investigate the long-term leaching characteristics of RCA + TR mixes.

Table 6.

ASLP test results for slag geopolymer-stabilised TR + RCA mixes.

Table 7.

Total contaminant results for slag geopolymer-stabilised TR + RCA mixes.

4. Conclusions

The present study investigated the suitability of slag geopolymer-stabilised tyre rubber (TR) and recycled concrete aggregate (RCA) mixes as an alternative to virgin quarried materials in pavement subbases. The key outcomes are as follows:

- The decrease in compaction characteristics of unbound TR + RCA mixes was compensated by the addition of slag geopolymer, which increased the overall density of the mix despite the inclusion of TR.

- Unconfined compressive strength (UCS) results and microstructural studies suggest that the performance of slag geopolymer-stabilised TR + RCA mixes is primarily influenced by improved binding due to the formation of geopolymer gel products, resulting in enhanced compressive strength. All mixes with 15% slag satisfied the minimum subbase UCS requirement of 2 MPa.

- The resilient modulus values of all TR + RCA mixes stabilised with 15% slag geopolymer satisfied the minimum required range of 80 MPa to 330 MPa for pavement bases as specified in AASHTO T-307. The predicted results from the octahedral stress model showed excellent correlations with the experimental test results.

- The highest flexural strength was recorded for control mixes with 15% slag. A consistent decrease in flexural strength was observed with increasing TR content. However, the reduction in flexural strength was less pronounced compared to compressive strength, as the TR particles help delay the onset of cracks.

- The addition of TR decreased the flexural modulus of the material; however, it significantly improved the fatigue life of the material.

- No potential risk of soil and water contamination was detected when using slag geopolymer-stabilised TR + RCA.

The current study was limited to laboratory-based testing under controlled environmental conditions. However, for the successful application of these recycled materials in the pavement industry, a comprehensive understanding of their long-term behaviour, considering both durability and serviceability, is essential. Therefore, it is recommended that future research investigate durability properties, such as freeze-thaw resistance, long-term leachate characteristics, and a comprehensive analysis of the fatigue behaviour of slag geopolymer-stabilised TR + RCA composites. Additionally, field trials should be conducted, along with assessment of cost-effectiveness and the feasibility of establishing a supply chain for sourcing and processing waste TR.

Author Contributions

F.J.: methodology, data curation, investigation, conceptualisation, and writing—original draft. P.R.: supervision, formal analysis, conceptualisation, investigation, methodology, and writing—review and editing. J.M.: methodology, formal analysis, investigation, conceptualisation, and writing—review and editing. J.S.: supervision, conceptualisation, investigation, methodology, and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by ARC Discovery Grant DP210100020.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request for research purposes.

Acknowledgments

The support received from ARC Discovery Grant DP210100020 and the Swinburne University of Technology is gratefully acknowledged. The contents of the publications are from the Ph.D. thesis titled “Experimental investigation of waste tyre rubber and recycled concrete aggregate as a pavement material” by Fatima Juveria, Swinburne University of Technology.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AS | Australian standards |

| AIV | Aggregate impact value |

| CBR | California bearing ratio |

| LAAV | Los Angeles abrasion value |

| MDD | Maximum dry density |

| OMC | Optimum moisture content |

| OPC | Ordinary Portland cement |

| RAP | Reclaimed asphalt pavement |

| RCA | Recycled concrete aggregates |

| RLT | Repeated load triaxial |

| TR | Tyre rubber |

| UCS | Unconfined compression strength |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence |

References

- Pickin, J.; Wardle, C.; O’Farrell, K.; Stovell, L.; Nyunt, P.; Guazzo, S.; Lin, Y.; Caggiati-Shortell, G.; Chakma, P.; Edwards, C.; et al. National Waste Report; The Department of Climate Change, Energy, the Environment and Water: Parramatta, NSW, Australia; Blue Environment Pty Ltd.: Docklands, VIC, Australia, 2022. [Google Scholar]

- Pickin, J.; Wardle, C.; O’Farrell, K.; Nyunt, P.; Donovan, S. National Waste Report 2020; Department of Agriculture, Water and the Environment: Canberra, ACT, Australia, 2020. [Google Scholar]

- Velvizhi, G.; Shanthakumar, S.; Das, B.; Pugazhendhi, A.; Priya, T.S.; Ashok, B.; Nanthagopal, K.; Vignesh, R.; Karthick, C. Biodegradable and non-biodegradable fraction of municipal solid waste for multifaceted applications through a closed loop integrated refinery platform: Paving a path towards circular economy. Sci. Total Environ. 2020, 731, 138049. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Bui Van, D.; Ubachukwu, O.; Ezugwu, C.; Salahudeen, B.; Nguyen Van, M.; Ikeagwuani, C.; Amhadi, T.; Sosa, F.; Wu, W. Recycling and reuse of solid wastes; a hub for ecofriendly, ecoefficient and sustainable soil, concrete, wastewater and pavement reengineering. Int. J. Low-Carbon Technol. 2019, 14, 440–451. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Zhu, L. Property assessment of high-performance concrete containing three types of fibers. Int. J. Concr. Struct. Mater. 2021, 15, 39. [Google Scholar] [CrossRef]

- Anburuvel, A.; Priyadarshana, H.; Kulathunga, R. Assessment of mechanical characteristics of crushed rock substituted with tyre crumb for the application of road base or subbase layers of road pavement. Int. J. Pavement Res. Technol. 2025, 18, 843–857. [Google Scholar] [CrossRef]

- Ahmed, A.; Shah, S.K.H.; Ahmad, N.; Ali, U.; Malik, A.A.; Iqbal, M.J. Feasibility of utilizing recycled concrete aggregate blended with waste tire rubber and drywall waste as pavement subbase material. J. Mater. Cycles Waste Manag. 2024, 26, 2278–2293. [Google Scholar] [CrossRef]

- Juveria, F.; Rajeev, P.; Jegatheesan, P.; Sanjayan, J. Impact of stabilisation on mechanical properties of recycled concrete aggregate mixed with waste tyre rubber as a pavement material. Case Stud. Constr. Mater. 2023, 18, e02001. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Feky, M.; Kohail, M.; Nasr, E.-S.A. Performance of geopolymer concrete containing recycled rubber. Constr. Build. Mater. 2019, 207, 136–144. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.M.; Aslani, F.; Alabduljabbar, H. Properties and utilizations of waste tire rubber in concrete: A review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Migunthanna, J.; Rajeev, P.; Sanjayan, J. Waste Clay Bricks as a Geopolymer Binder for Pavement Construction. Sustainability 2022, 14, 6456. [Google Scholar] [CrossRef]

- Migunthanna, J.; Manjunatha, N.T.; Shatagar, V.G.; Raghu, D.H.; Zinzala, R.S.; Rajeev, P.; Sanjayan, J. Simplified life cycle analysis for rigid pavements constructed using waste materials as binders in concrete. Int. J. Stud. Proj. Report. 2022, 1, 143–165. [Google Scholar] [CrossRef]

- Arulrajah, A.; Perera, S.; Wong, Y.C.; Maghool, F.; Horpibulsuk, S. Stabilization of PET plastic-demolition waste blends using fly ash and slag-based geopolymers in light traffic road bases/subbases. Constr. Build. Mater. 2021, 284, 122809. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of rubberized geopolymer concrete: Strength and durability studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Jallu, M.; Arulrajah, A.; Saride, S.; Evans, R. Flexural fatigue behavior of fly ash geopolymer stabilized-geogrid reinforced RAP bases. Constr. Build. Mater. 2020, 254, 119263. [Google Scholar] [CrossRef]

- Mohamed, O.A. Effects of the curing regime, acid exposure, alkaline activator dosage, and precursor content on the strength development of mortar with alkali-activated slag and fly ash binder: A critical review. Polymers 2023, 15, 1248. [Google Scholar] [CrossRef]

- AS 1289.5.2.1; Methods of Testing Soils for Engineering Purposes Soil Compaction and Density Tests—Determination of the Dry Density/Moisture Content Relation of a Soil Using Modified Compactive Effort. Australian Standards: Sydney, NSW, Australia, 2017.

- ASTM D5102; Standard Test Method for Unconfined Compressive Strength of Compacted Soil-Lime Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2024.

- AASHTO T-307; Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2021.

- AS 1012.11; 2014 Methods of Testing Concrete, Methods 11: Determination of the Modulus of Rupture. Australian Standards: Sydney, NSW, Australia, 2014.

- Austroads. Austroads Test Method AGPT/T600: Flexural Beam Test Methods for Cemented Materials; Austroads: Sydney, NSW, Australia, 2018.

- TxDOT. Standard Specifications for Construction and Maintenance of Highways, Streets, and Bridges: Adopted by the Texas Department of Transportation, November 1, 2014; Texas Department of Transportation: Austin, TX, USA, 2014.

- AS 4439.3; Wastes, Sediments and Contaminated Soils-Part 3: Preparation of Bottle Leaching Procedure. Australian Standard: Sydney, NSW, Australia, 2019.

- EPA Victoria. Industrial Waste Resource Guidelines: Solid Industrial Waste Hazard Categorisation and Management; Environmental Protection Agency, Victoria: Carlton, VIC, Australia, 2009. [Google Scholar]

- EPA. National Primary Drinking Water Regulations. Drinking Water Contaminants. Available online: https://www.epa.gov/ground-water-and-drinking-water/national-primary-drinking-water-regulations (accessed on 20 July 2025).

- European Union. Directive (EU) 2020/2184 of the European Parliament and of the Council on the Quality of Water Intended for Human Consumption; European Union: Brussels, Belgium, 2020. [Google Scholar]

- National End-of-Waste Decision EoW-N001/2023 of 12th September 2023. Establishing Criteria Determining When Recycled Aggregate Ceases to Be Waste Under Regulation 28 of the European Union (Waste Directive) Regulations 2011–2020. Available online: https://www.epa.ie/publications/licensing--permitting/waste/Final-Decision---National-End-of-Waste-Criteria-N001-2023.pdf (accessed on 20 October 2025).

- Cabalar, A.F.; Karabash, Z.; Mustafa, W.S. Stabilising a clay using tyre buffings and lime. Road Mater. Pavement Des. 2014, 15, 872–891. [Google Scholar] [CrossRef]

- Yadav, J.; Tiwari, S. Evaluation of the strength characteristics of cement-stabilized clay–crumb rubber mixtures for its sustainable use in geotechnical applications. Environ. Dev. Sustain. 2018, 20, 1961–1985. [Google Scholar] [CrossRef]

- Yadav, J.; Tiwari, S. A study on the potential utilization of crumb rubber in cement treated soft clay. J. Build. Eng. 2017, 9, 177–191. [Google Scholar] [CrossRef]

- Abdila, S.R.; Abdullah, M.M.A.B.; Ahmad, R.; Rahim, S.Z.A.; Rychta, M.; Wnuk, I.; Nabiałek, M.; Muskalski, K.; Tahir, M.F.M.; Syafwandi; et al. Evaluation on the mechanical properties of ground granulated blast slag (GGBS) and fly ash stabilized soil via geopolymer process. Materials 2021, 14, 2833. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K.; Wasil, M.; Dobrzycki, P. Resilient response of cement-treated coarse post-glacial soil to cyclic load. Materials 2021, 14, 6495. [Google Scholar] [CrossRef]

- Arulrajah, A.; Maghool, F.; Yaghoubi, M.; Phetchuay, C.; Horpibulsuk, S. Temperature and Duration Impact on the Strength Development of Geopolymerized Granulated Blast Furnace Slag for Usage as a Construction Material. J. Mater. Civ. Eng. 2021, 33, 04020474. [Google Scholar] [CrossRef]

- Migunthanna, J.; Rajeev, P.; Sanjayan, J. Waste Clay Brick as a Part Binder for Pavement Grade Geopolymer Concrete. Int. J. Pavement Res. Technol. 2023, 17, 1450–1467. [Google Scholar] [CrossRef]

- Samantasinghar, S.; Singh, S.P. Strength and durability of granular soil stabilized with FA-GGBS geopolymer. J. Mater. Civ. Eng. 2021, 33, 06021003. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Chen, B. Strength evolutions of varying water content-dredged sludge stabilized with alkali-activated ground granulated blast-furnace slag. Constr. Build. Mater. 2021, 275, 122111. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Perera, S.T.A.M.; Zhou, A.; Roychand, R.; Ren, G. Large-scale direct shear testing of waste crushed rock reinforced with waste rubber as pavement base/subbase materials. Transp. Geotech. 2021, 28, 100546. [Google Scholar]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A state-of-the-art review of polymers used in soil stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Characterization of rubberized cement bound aggregate mixtures using indirect tensile testing and fractal analysis. Constr. Build. Mater. 2016, 105, 94–102. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, Q.; Chen, X.; Ni, F. Meso-cracking characteristics of rubberized cement-stabilized aggregate by discrete element method. J. Clean. Prod. 2021, 316, 128374. [Google Scholar] [CrossRef]

- Liu, F.; Meng, L.-Y.; Ning, G.-F.; Li, L.-J. Fatigue performance of rubber-modified recycled aggregate concrete (RRAC) for pavement. Constr. Build. Mater. 2015, 95, 207–217. [Google Scholar] [CrossRef]

- Puppala, A.J.; Mohammad, L.N.; Allen, A. Engineering behavior of lime-treated Louisiana subgrade soil. Transp. Res. Rec. 1996, 1546, 24–31. [Google Scholar] [CrossRef]

- AASHTO. American Association of State Highway and Transportation Officials, Guide for Design of Pavement Structures; AASHTO: Washington, DC, USA, 1993. [Google Scholar]

- Khasawneh, M.A.; Al-jamal, N.F. Modeling resilient modulus of fine-grained materials using different statistical techniques. Transp. Geotech. 2019, 21, 100263. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, F.; Zhang, Y. Use of building-related construction and demolition wastes in highway embankment: Laboratory and field evaluations. J. Clean. Prod. 2019, 230, 1051–1060. [Google Scholar] [CrossRef]

- Hicks, R.G. Factors Influencing the Resilient Properties of Granular Materials; University of California: Berkeley, CA, USA, 1970. [Google Scholar]

- Mohammadinia, A.; Arulrajah, A.; Sanjayan, J.; Disfani, M.M.; Bo, M.W.; Darmawan, S. Laboratory evaluation of the use of cement-treated construction and demolition materials in pavement base and subbase applications. J. Mater. Civ. Eng. 2015, 27, 04014186. [Google Scholar] [CrossRef]

- Puppala, A.J.; Hoyos, L.R.; Potturi, A.K. Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J. Mater. Civ. Eng. 2011, 23, 990–998. [Google Scholar] [CrossRef]

- Fakhri, M. The effect of waste rubber particles and silica fume on the mechanical properties of roller compacted concrete pavement. J. Clean. Prod. 2016, 129, 521–530. [Google Scholar] [CrossRef]

- Gnanendran, C.; Paul, D.K. Fatigue characterization of lightly cementitiously stabilized granular base materials using flexural testing. J. Mater. Civ. Eng. 2016, 28, 04016086. [Google Scholar] [CrossRef]

- González, A.; Jameson, G.; de Carteret, R.; Yeo, R. Laboratory fatigue life of cemented materials in Australia. Road Mater. Pavement Des. 2013, 14, 518–536. [Google Scholar] [CrossRef]

- Badiger, M.; Mamatha, K.; Dinesh, S. Mechanical Evaluation of Granular Sub-base Reinforced with Recycled Tyres: A Way Towards Sustainability. Geotech. Geol. Eng. 2025, 43, 189. [Google Scholar] [CrossRef]

- Karimi, H.R.; Aliha, M.; Ebneabbasi, P.; Salehi, S.; Khedri, E.; Haghighatpour, P.J. Mode I and mode II fracture toughness and fracture energy of cement concrete containing different percentages of coarse and fine recycled tire rubber granules. Theor. Appl. Fract. Mech. 2023, 123, 103722. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, W.; Li, L.; Feng, W.; Ning, G. Mechanical and fatigue performance of rubber concrete. Constr. Build. Mater. 2013, 47, 711–719. [Google Scholar] [CrossRef]

- Liu, M.; Lu, J.; Jiang, W.; Ming, P. Study on fatigue damage and fatigue crack propagation of rubber concrete. J. Build. Eng. 2023, 65, 105718. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).