Enhancing Tunnel Fault-Resistance with Combined Seismic Joints and Steel–Polypropylene Fiber Concrete Linings

Abstract

1. Introduction

2. Model Establishment and Calculation Settings

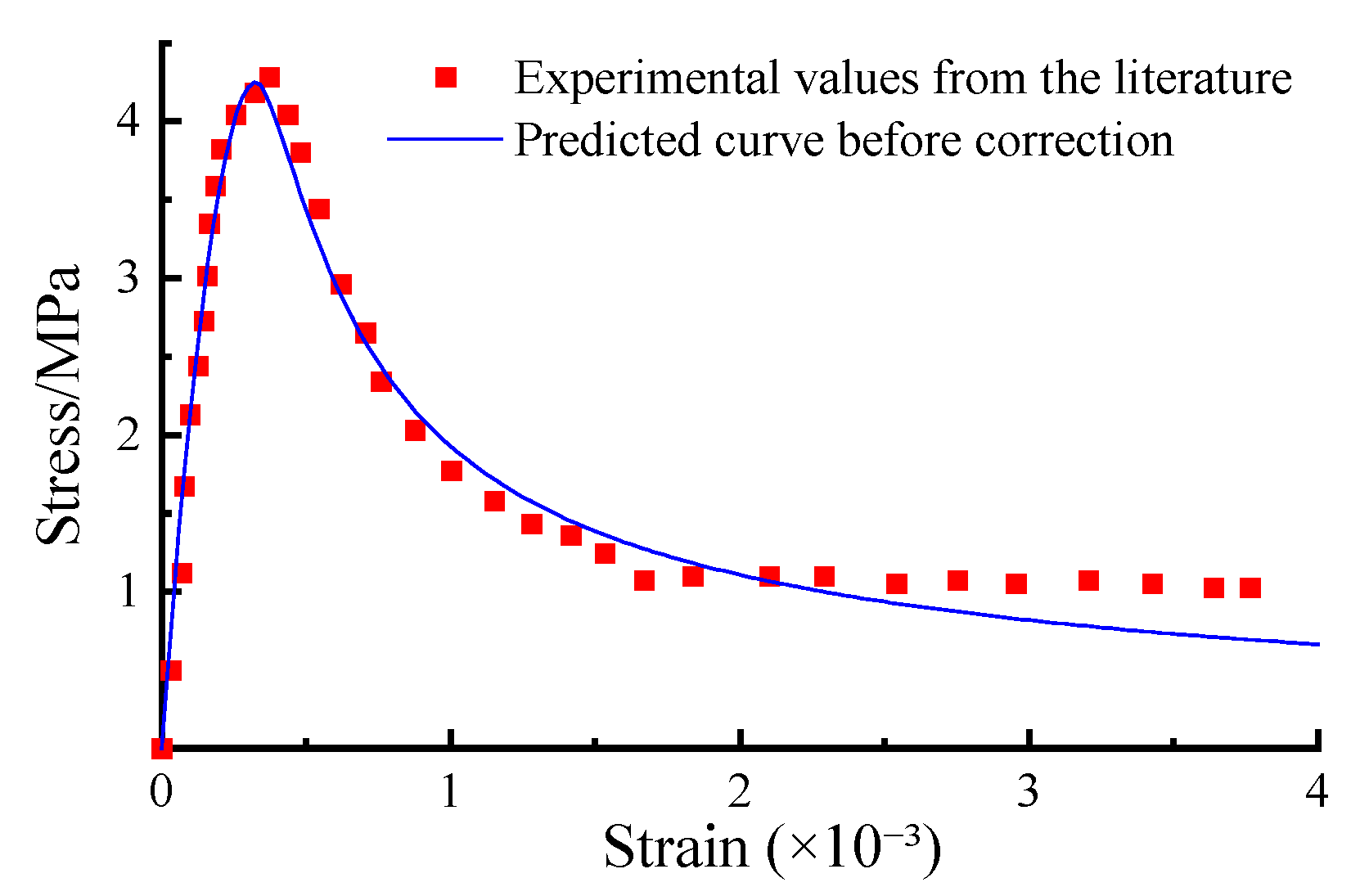

2.1. Determination of the Material Constitutive Model for Steel–Polypropylene Fiber Concrete Linings

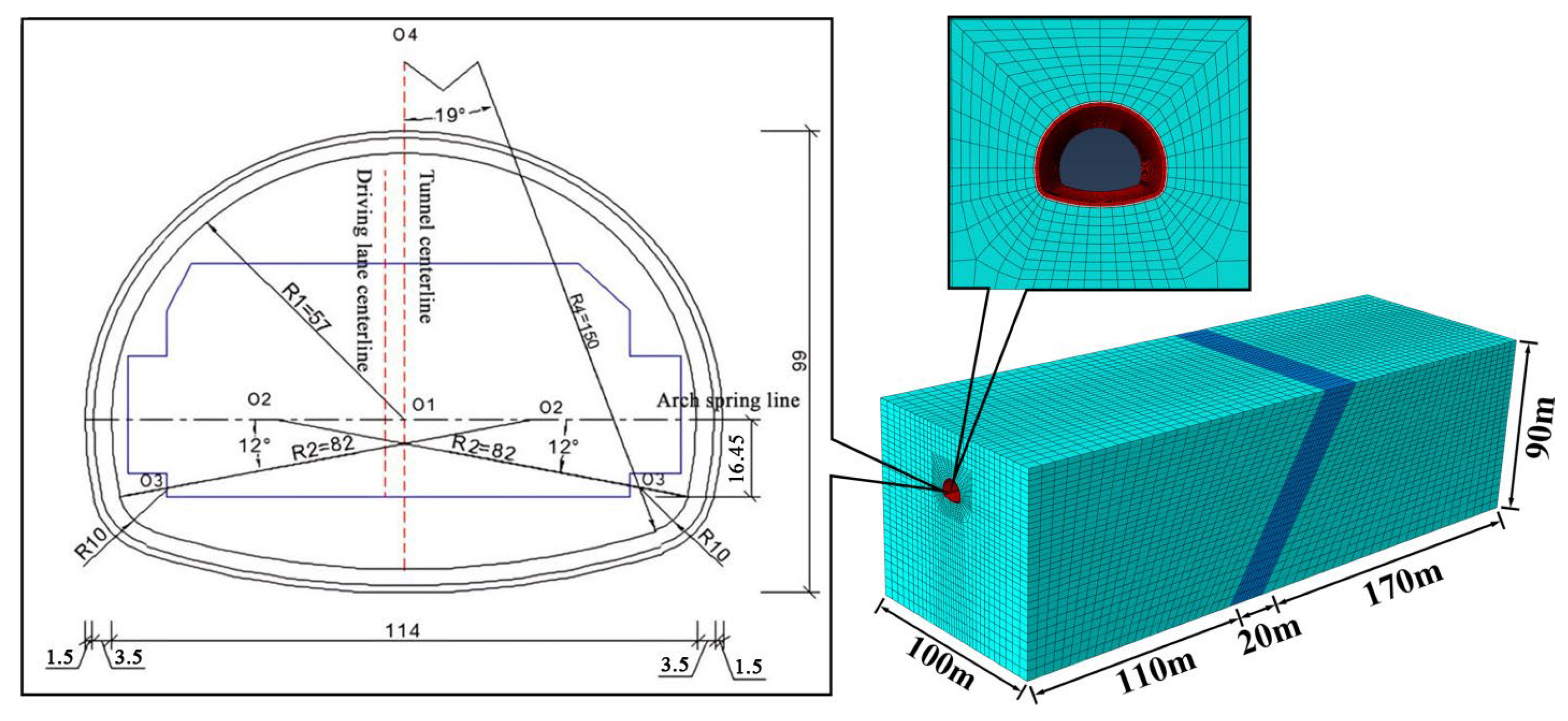

2.2. Model Establishment

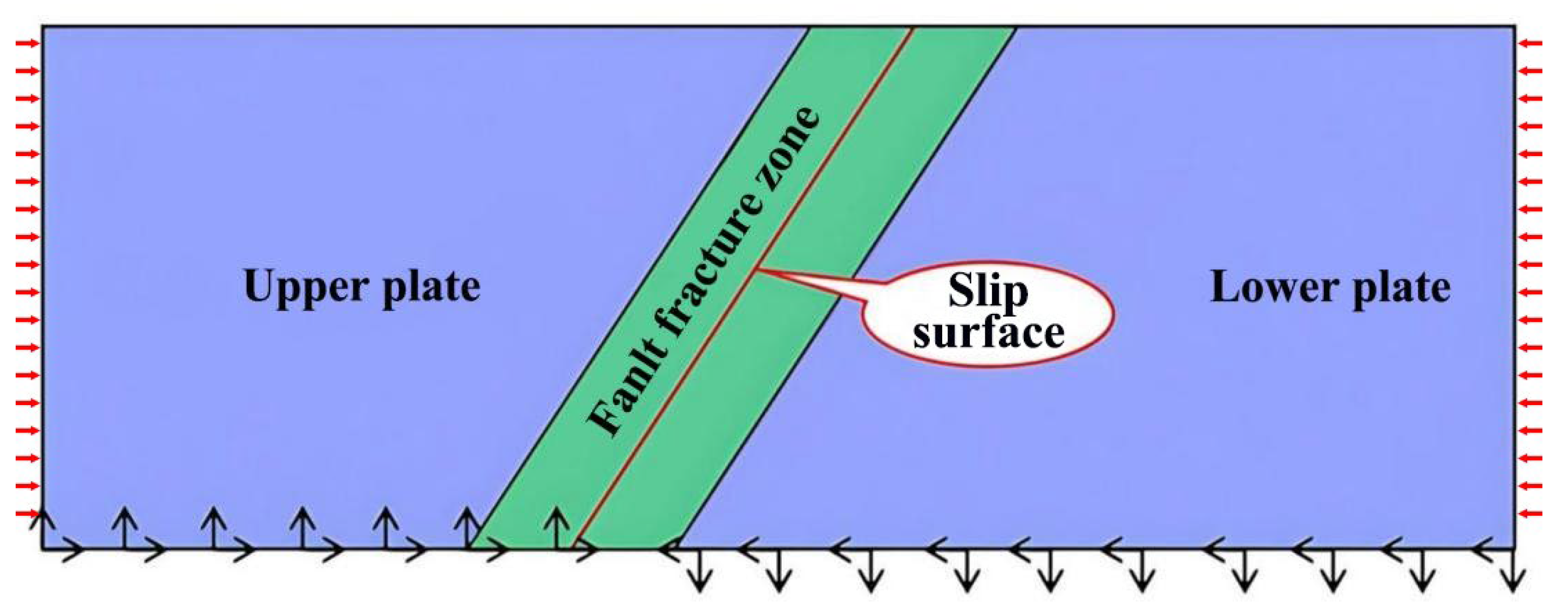

2.3. Fault Movement Simulation

- Initial Geostress Equilibrium:

- 2.

- Tunnel Excavation:

- 3.

- Fault Dislocation:

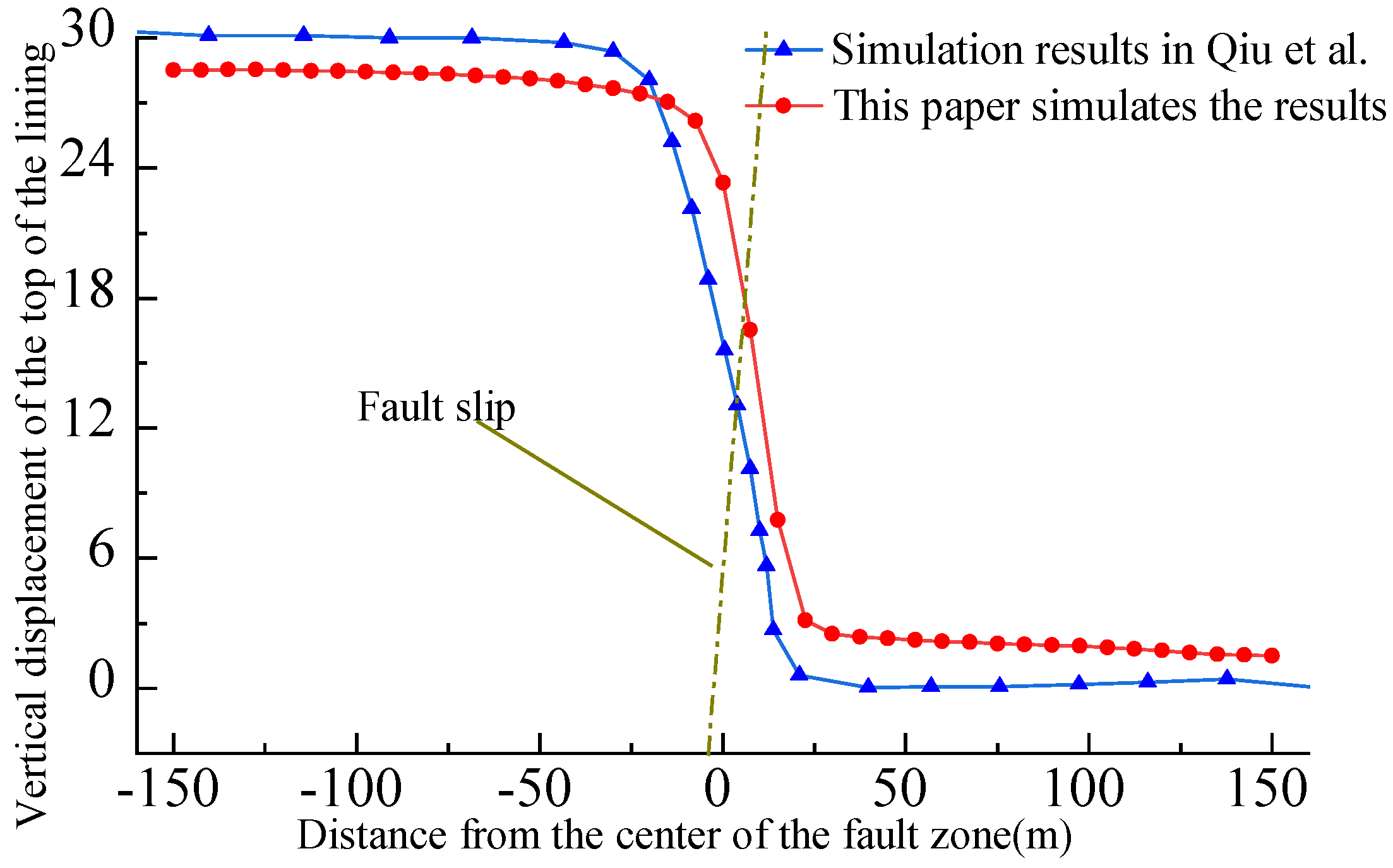

2.4. Model Validation

2.5. Layout of Combined Seismic Joints

3. Analysis of Seismic Performance of Combined Seismic Joints and Steel–Polypropylene Fiber Lining in the Tunnel

3.1. Longitudinal Strain Analysis

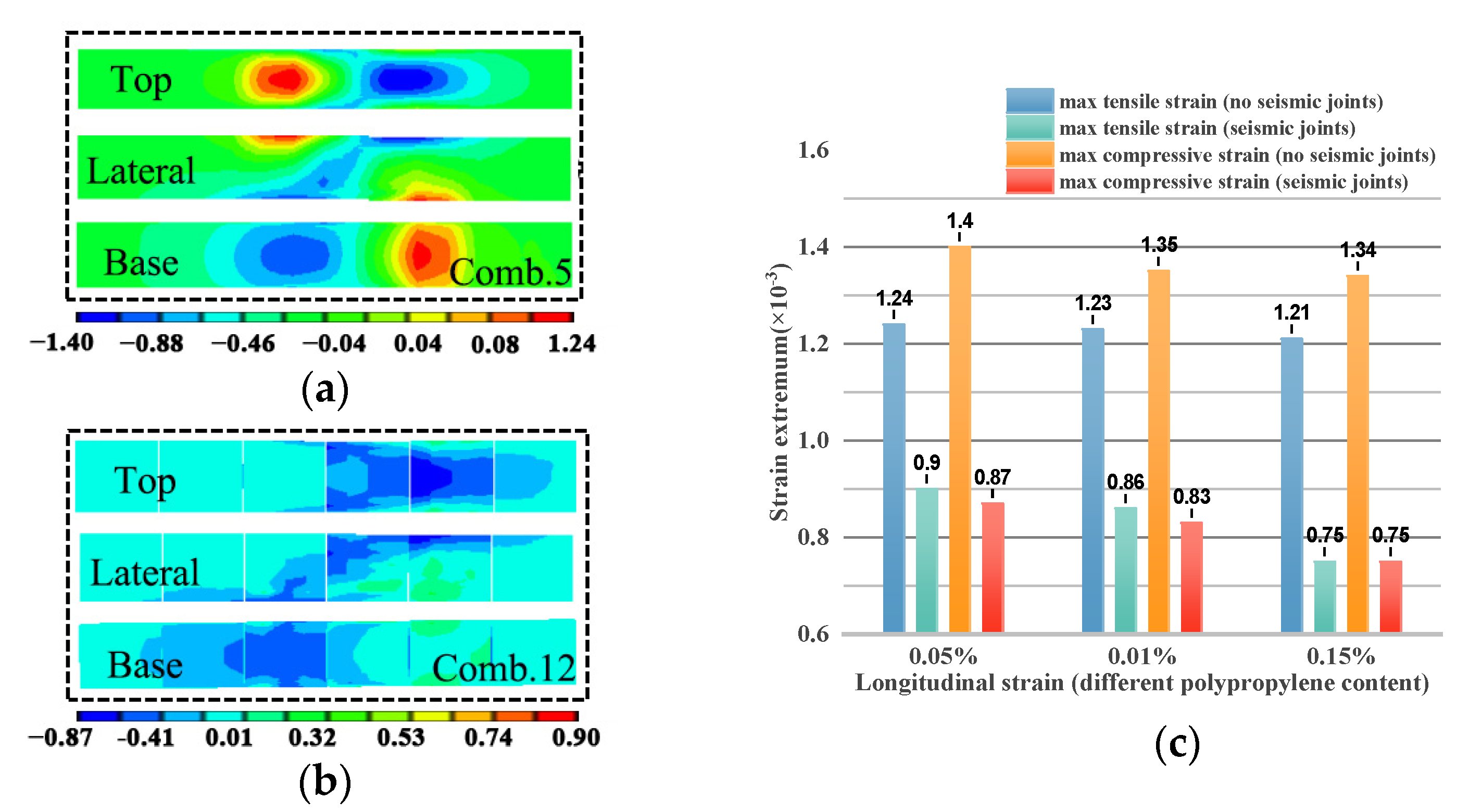

3.1.1. Effect of Different Polypropylene Fiber Content

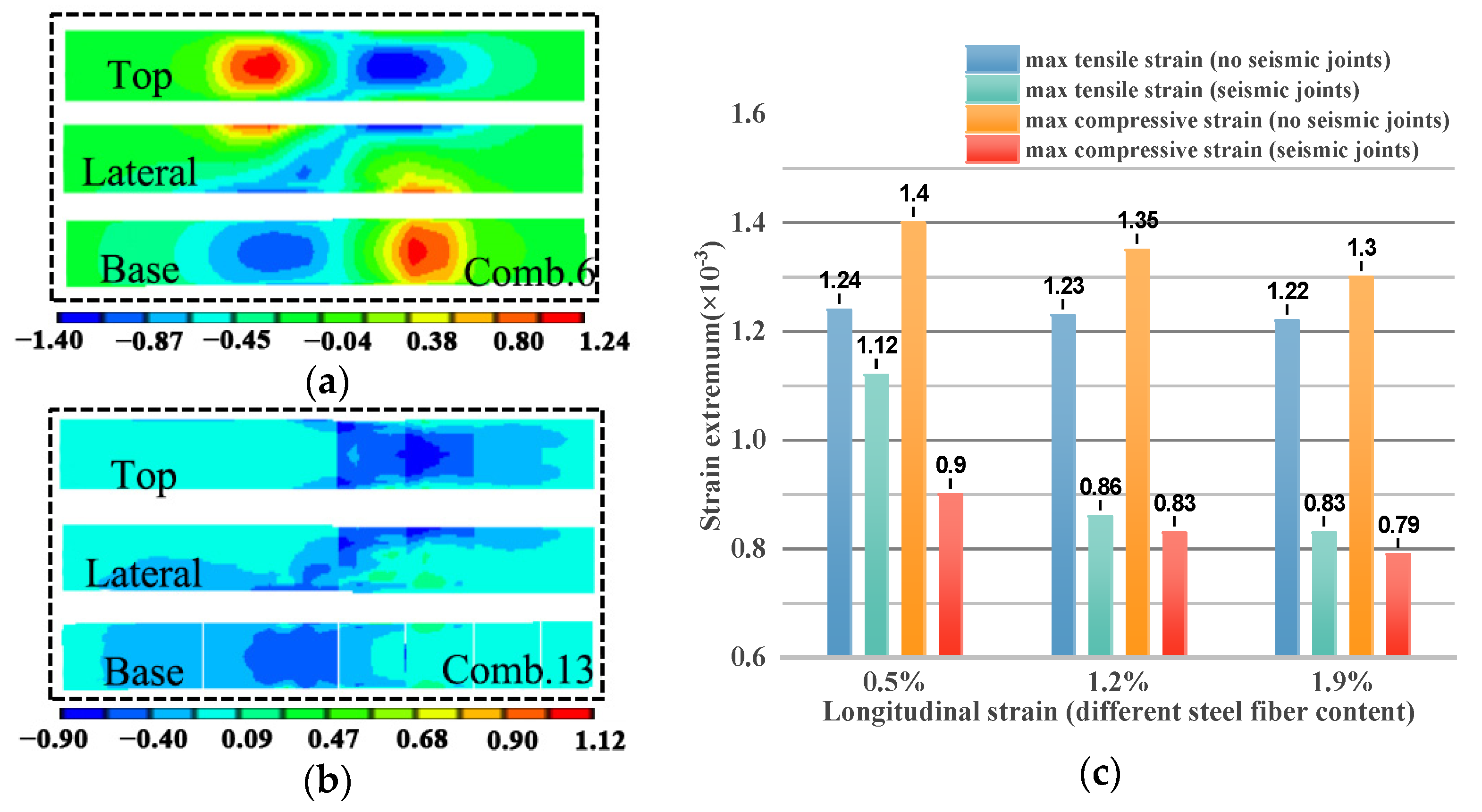

3.1.2. Different Steel Fiber Contents

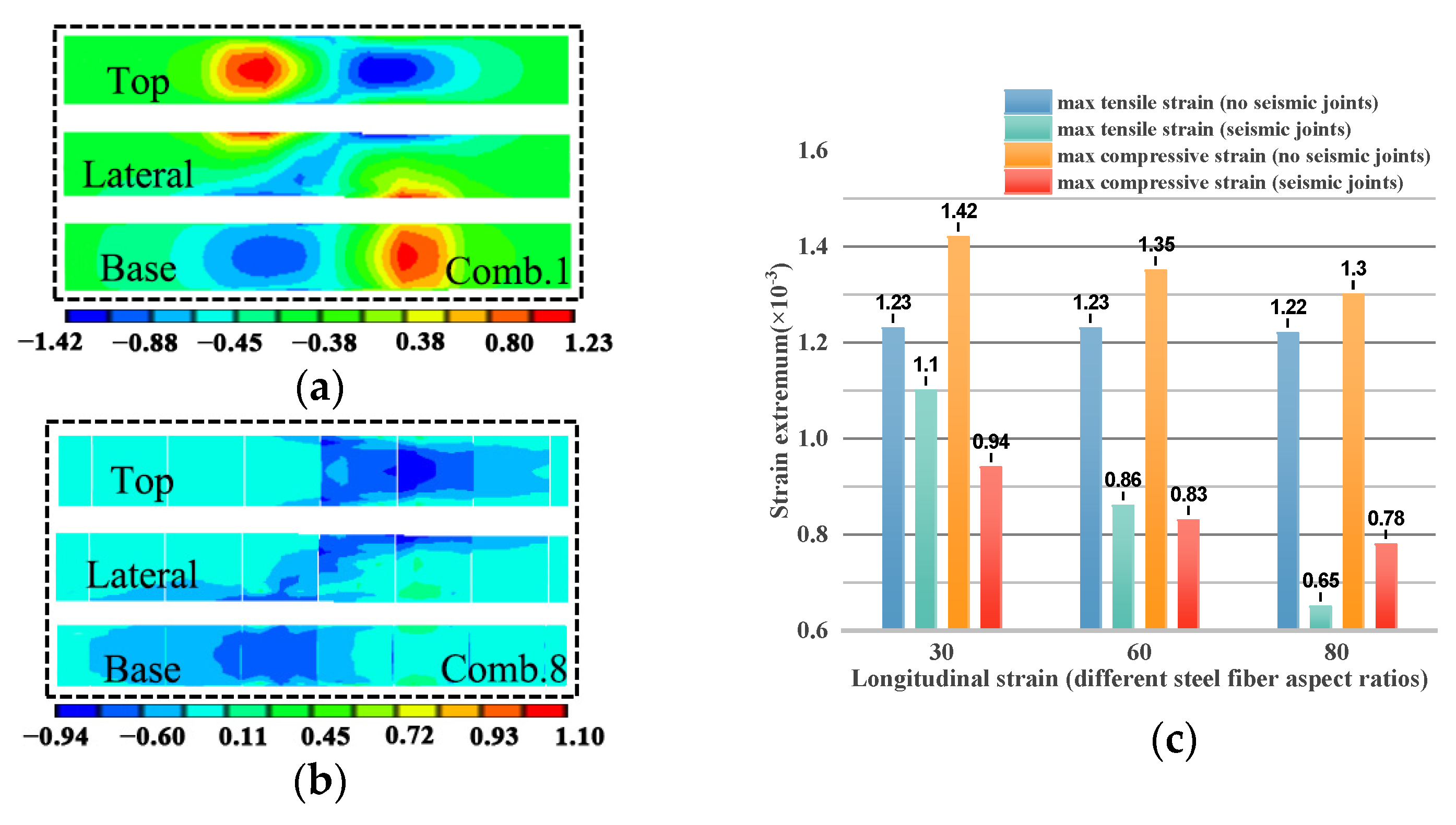

3.1.3. Different Steel Fiber Aspect Ratios

3.2. Plastic Strain Analysis

3.2.1. Different Polypropylene Fiber Contents

3.2.2. Different Steel Fiber Contents

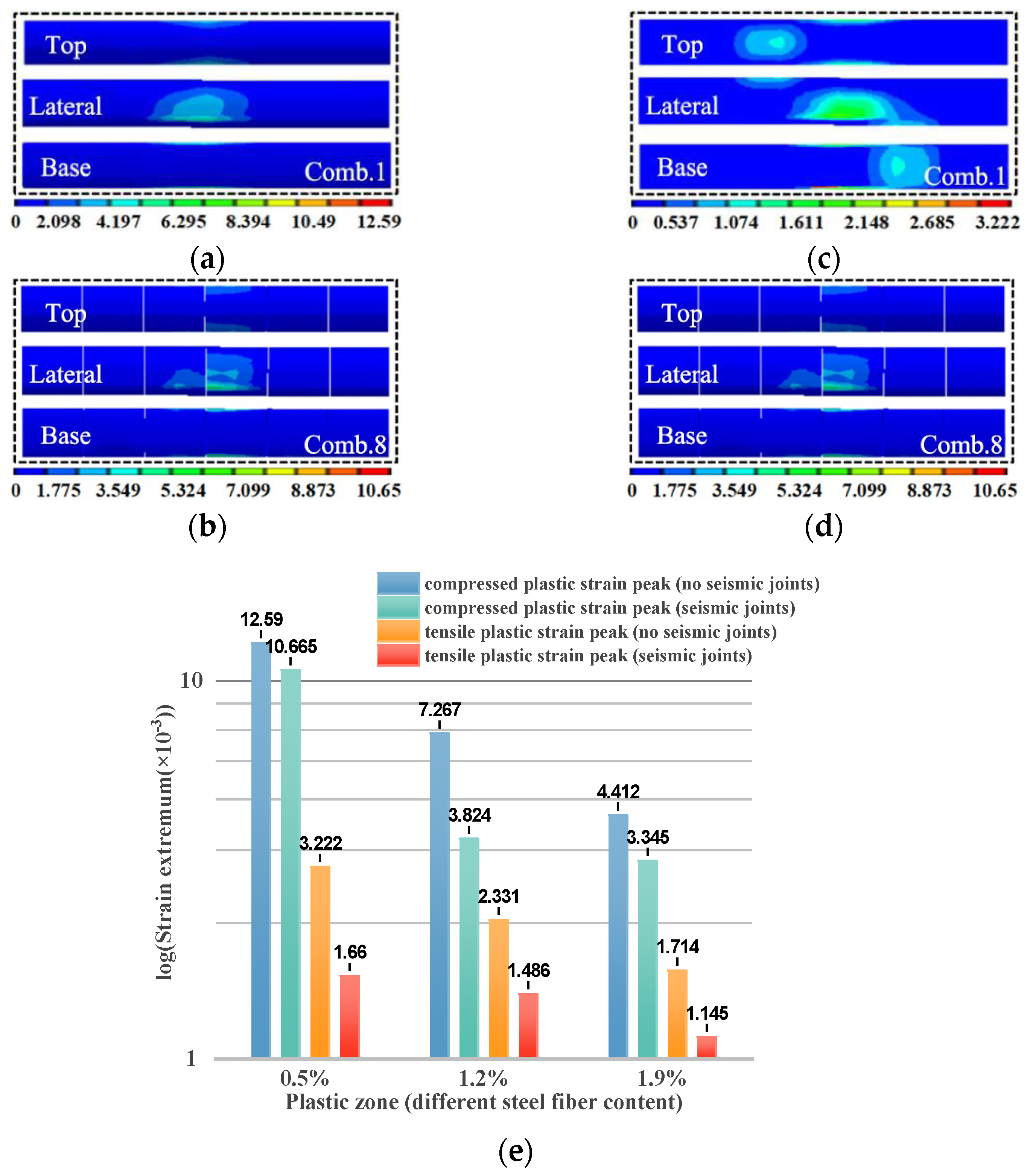

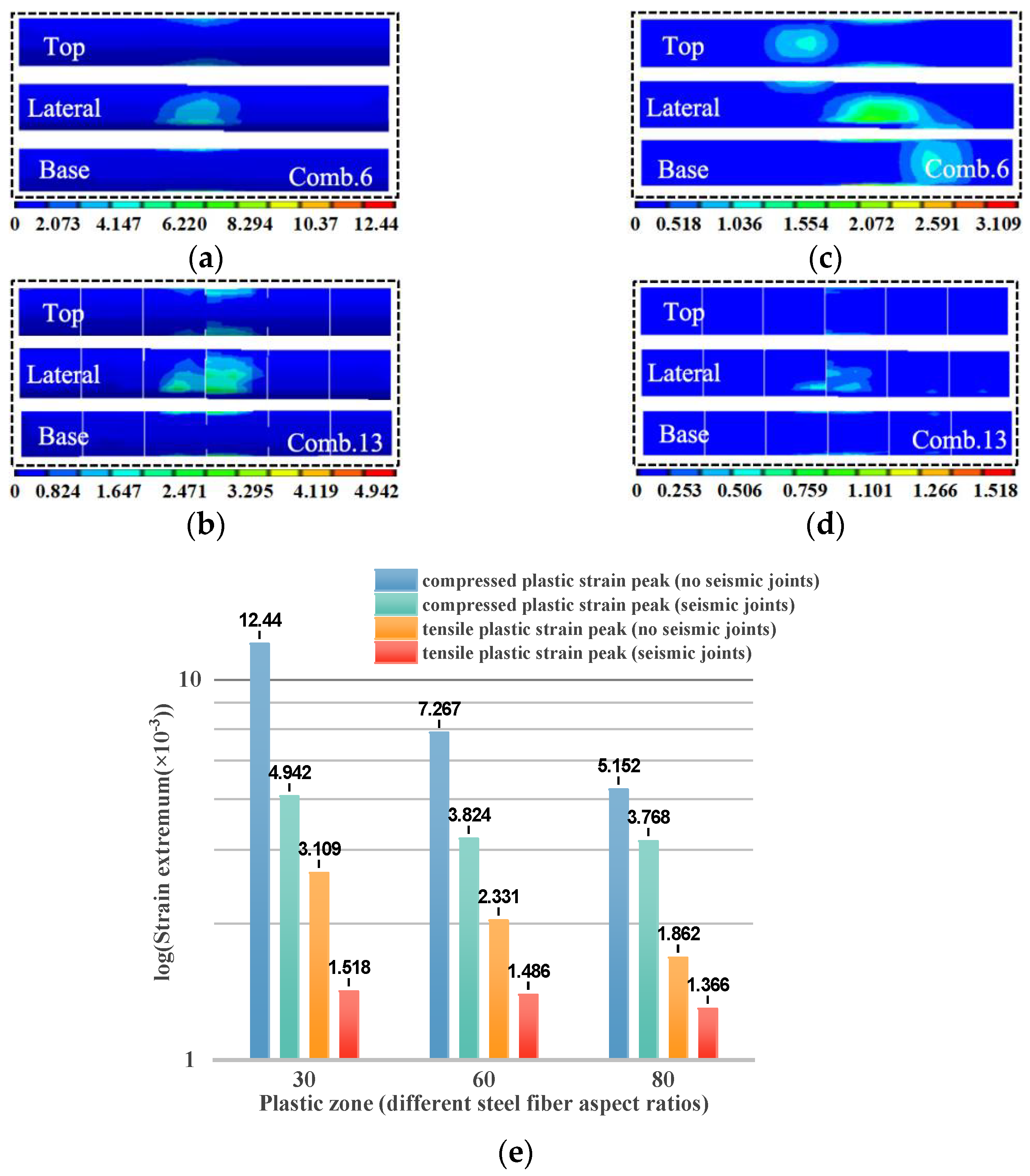

3.2.3. Different Steel Fiber Length-to-Diameter Ratios

3.3. Tensile and Compressive Damage Analysis

3.3.1. Different Polypropylene Fiber Contents

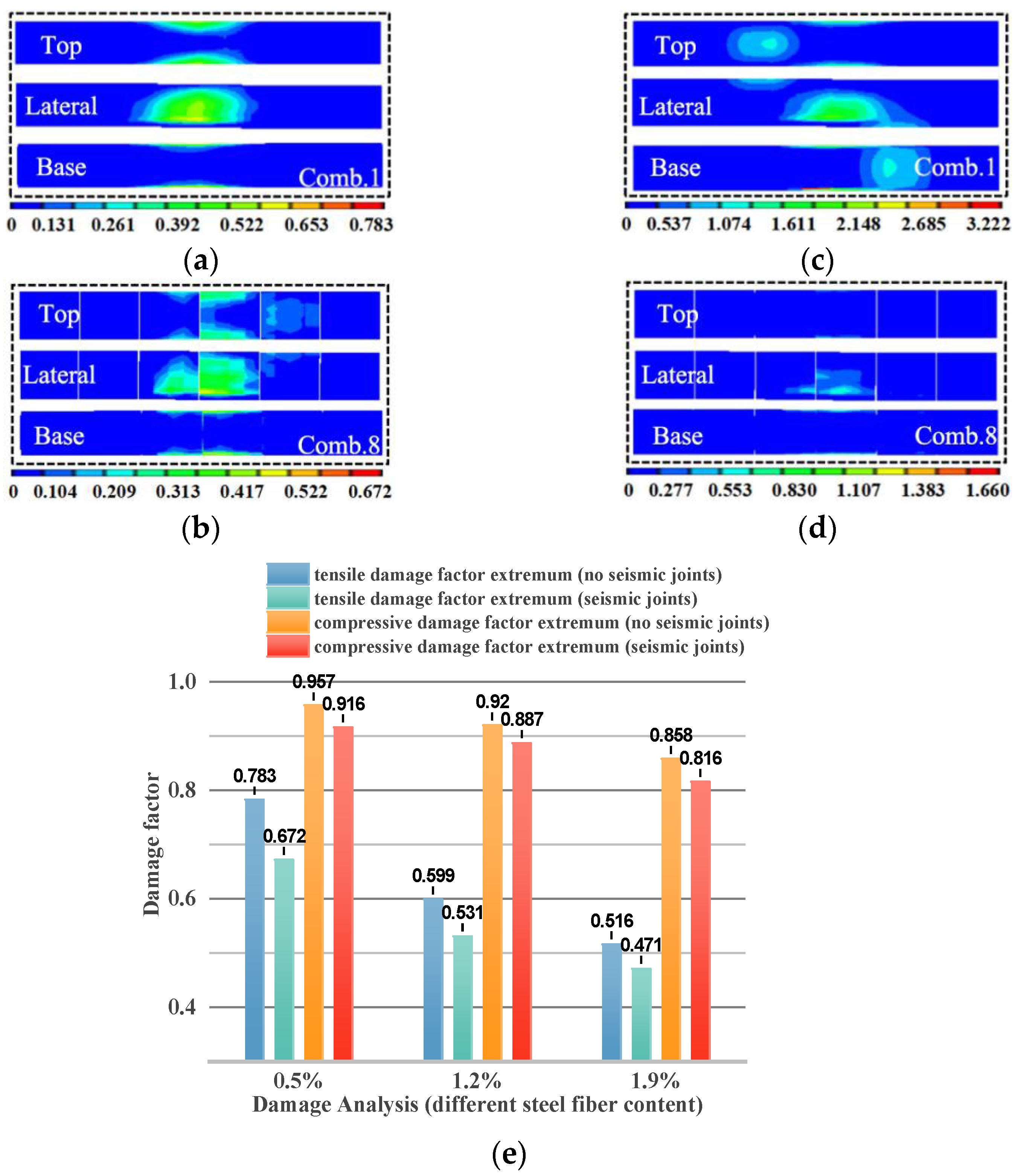

3.3.2. Different Steel Fiber Contents

3.3.3. Different Steel Fiber Length-to-Diameter Ratios

4. Results

4.1. Strain Distribution in Tunnel Linings

- (1)

- Influence of polypropylene fiber content (ρpf): With the steel fiber content and aspect ratio fixed at 1.2% and 60, respectively, increasing ρpf from 0.05% to 0.15% resulted in maximum reductions in compressive strain of 37.8–40.3% and tensile strain of 27.4–38.1%.Statistical Analysis: Variations exceeding 10% in compressive and tensile strains were considered practically significant, confirming the robustness of the observed trends.

- (2)

- Influence of steel fiber content (ρsf): With ρpf = 0.1% and aspect ratio 60, increasing ρsf from 0.5% to 1.9% reduced compressive strain by 9.7–39.2% and tensile strain by 35.7–39.2%.Statistical Analysis: One-way ANOVA showed that the reductions in both compressive and tensile strains were statistically significant (p < 0.05).

- (3)

- Influence of steel fiber aspect ratio (lsf/dsf): With ρsf = 0.5% and ρpf = 0.1%, increasing the aspect ratio from 30 to 80 reduced tensile strain by 10.6–46.7% and compressive strain by 33.8–40.1%.Statistical Analysis: Variations exceeding 10% in tensile and compressive strain were considered significant, further validating the findings.

4.2. Plastic Zone Characteristics

- (1)

- Increasing ρpf from 0.05% to 0.15% lowered peak compressive plastic strain by 42.2–50.8% and tensile plastic strain by 30.7–40.8%.Statistical Analysis: Variations greater than 10% were considered statistically significant, confirming the effectiveness of fiber reinforcement.

- (2)

- Increasing ρsf from 0.5% to 1.9% lowered peak compressive plastic strain by 15.4–47.4% and tensile plastic strain by 33.2–48.5%.Statistical Analysis: The reductions in plastic strain were statistically significant (p < 0.05), confirming the strong effect of steel fibers.

- (3)

- Increasing lsf/dsf from 30 to 80 lowered peak compressive plastic strain by 26.9–60.3% and tensile plastic strain by 26.6–51.1%.Statistical Analysis: This reduction was found to be statistically significant (p < 0.05).

4.3. Tensile and Compressive Damage

- (1)

- Increasing ρpf to 0.15% decreased the compressive damage factor by up to 13.6% and the tensile damage factor by up to 3.7%.Statistical Analysis: The reduction in compressive damage was statistically significant (p < 0.05).

- (2)

- Increasing ρsf to 1.9% decreased compressive damage by 8.7–14.2% and tensile damage by 3.6–4.9%.Statistical Analysis: The reductions in damage were statistically significant (p < 0.05), particularly at higher ρsf.

- (3)

- Increasing lsf/dsf to 80 decreased compressive damage by 3.4–17.3% and tensile damage by 1.9–3.5%.Statistical Analysis: The reduction in both tensile and compressive damage was statistically significant (p < 0.05).

5. Discussion

- (1)

- Fibers increase matrix toughness and bridge cracks, delaying both tensile and compressive failure;

- (2)

- Seismic joints redistribute stress concentrations and provide additional deformation capacity.

Limitations

6. Conclusions

- (1)

- Strain suppression: The integrated design reduced longitudinal tensile and compressive strains by up to 40.1% and 46.7%, respectively, compared with fiber reinforcement alone.

- (2)

- Plastic zone optimization: Peak compressive plastic strain decreased by as much as 60.3%, producing a more uniform strain distribution and improved deformation capacity.

- (3)

- Damage mitigation: Tensile and compressive damage factors decreased by up to 4.9% and 17.3%, respectively, with a more pronounced effect on compressive damage.

- (4)

- Optimal parameters: The best fault-resistance performance was achieved at 1.90% steel fiber content, an aspect ratio of 60, and 0.15% polypropylene fiber content.

- (5)

- Engineering implication: The combined use of seismic joints and SPF concrete linings provides a flexible and durable solution for tunnels crossing fault-fracture zones, ensuring long-term structural stability and service life.

- (6)

- Practical applicability and broader implementation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, X.; Feng, L.; Wang, C.; Chen, Z.; Han, L. Shaking table tests of the seismic response of a utility tunnel with a joint connection. Soil Dyn. Earthq. Eng. 2020, 133, 106133. [Google Scholar] [CrossRef]

- Tsinidis, G.; Rovithis, E.; Pitilakis, K.; Chazelas, J.L. Seismic response of box-type tunnels in soft soil: Experimental and numerical investigation. Tunn. Undergr. Space Technol. 2016, 59, 199–214. [Google Scholar] [CrossRef]

- Yao, C.; Duan, J.; Liu, Y.; He, C.; Liu, Y.; Yang, W.; Yan, Q.; Luo, W. Tunnels crossing active faults: A review of case histories and modeling methods. Tunn. Undergr. Space Technol. 2025, 157, 107086. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Xiao, H.; Zhou, H.; Chi, F. Deformation and failure characteristics of a deeply buried tunnel subjected to creep slip fault movement: Based on the engineering conditions of Yunnan Water Intake Project. Bull. Eng. Geol. Environ. 2022, 81, 322. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Yin, C.; Wei, R.; Zhang, H. Experimental study on forced response characteristics and anti-dislocation performance of articulated tunnel structure under dislocation action of normal fault. Structures 2023, 48, 867–881. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, E.D.; Liu, Z.; Gao, L. Damage analysis of urban metro tunnel under strike-slip fault. Rock Soil Mech. 2014, 35 (Suppl. S2), 467–473. (In Chinese) [Google Scholar]

- Hu, H.; Liu, Y.; Lan, Y.; Zhang, H.; Qiu, W. Study on Failure Characteristics and Treatment of Tunnel Lining Crossing Active Faults. Transp. Res. Rec. 2025, 2679, 03611981251337673. [Google Scholar] [CrossRef]

- Mei, X.; Xu, W.; Zhang, L.; Li, Y. The response characteristics of fault-crossing tunnel under combined fault slip and seismic loading. Soil Dyn. Earthq. Eng. 2025, 198, 109653. [Google Scholar] [CrossRef]

- Zhao, F.; Liang, B.; Zhao, N.; Jiang, B. Shaking table testing and numerical study on aseismic measures of twin-tube tunnel crossing fault zone with extra-large section. Appl. Sci. 2024, 14, 2391. [Google Scholar] [CrossRef]

- Cui, G.Y.; Song, B.H.; Wang, D.Y. Seismic model test research on the combination of rigidity with flexibility of tunnel portal in high intensity seismic areas. Geomatics Nat. Hazards Risk 2021, 12, 1195–1211. [Google Scholar] [CrossRef]

- Cheng, Z.; Su, Y.; Xu, C. Seismic Response of Mountain Tunnels by Comprehensive Analysis Methods and Feasible Aseismic Measures. Highlights Sci. Eng. Technol. 2022, 28, 31–44. [Google Scholar] [CrossRef]

- Anastasopoulos, I.; Gerolymos, N.; Drosos, V.; Georgarakos, T.; Kourkoulis, R.; Gazetas, G. Behaviour of deep immersed tunnel under combined normal fault rupture deformation and subsequent seismic shaking. Bull. Earthq. Eng. 2008, 6, 213–239. [Google Scholar] [CrossRef]

- Soe, K.T.; Zhang, Y.X.; Zhang, L.C. Material properties of a new hybrid fibre-reinforced engineered cementitious composite. Constr. Build. Mater. 2013, 43, 399–407. [Google Scholar] [CrossRef]

- Qian, C.X.; Stroeven, P. Development of hybrid polypropylene–steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.; Salehi, A.M.; Mehraein, M.; Asadollahfardi, G. The effects of steel, polypropylene, and high-performance macro polypropylene fibers on mechanical properties and durability of high-strength concrete. Constr. Build. Mater. 2023, 386, 131589. [Google Scholar] [CrossRef]

- Chi, Y.; Xu, L.; Yu, H.S. Constitutive modeling of steel–polypropylene hybrid fiber reinforced concrete using a non-associated plasticity and its numerical implementation. Compos. Struct. 2014, 111, 497–509. [Google Scholar] [CrossRef]

- Kotoky, N.; Dutta, A.; Deb, S.K. Mechanical properties of hybrid fiber reinforced concrete with steel and polypropylene fibers. Indian Concr. J. 2020, 94, 29–37. [Google Scholar]

- Wang, L.; Cui, G.; Zhang, C.; Zhao, Y.; Ma, J.; Min, B. Failure characteristics and seismic behavior of steel-basalt hybrid fiber reinforced concrete lining for the tunnel in strong earthquake areas. Eng. Fail. Anal. 2024, 162, 108357. [Google Scholar] [CrossRef]

- Sun, F.B.; Zhao, B.M.; Yang, Q.Y. Calculation formula and test verification for quantitative setting of combined seismic joint for tunnel through active fault. Chin. Railw. Sci. 2018, 39, 61–70. (In Chinese) [Google Scholar]

- Shen, Y.S.; Wang, Z.Z.; Yu, J.; Zhang, X.; Gao, B. Shaking table test on flexible joints of mountain tunnels passing through normal fault. Tunn. Undergr. Space Technol. 2020, 98, 103299. [Google Scholar] [CrossRef]

- Li, J.; Luo, J.; Chen, L.; Fan, X.; Zhu, Y.; Wang, X.; Guo, J. Research on mechanical properties of steel–polypropylene fiber concrete and application of beam structure. Front. Mater. 2024, 11, 1440466. [Google Scholar] [CrossRef]

- Zhou, M.; He, X.; Wang, H.; Wu, C.; He, J.; Wei, B. Mechanical properties and microstructure of ITZs in steel and polypropylene hybrid fiber-reinforced concrete. Constr. Build. Mater. 2024, 415, 135119. [Google Scholar] [CrossRef]

- Wang, S.; Xu, L.; Li, B.; Liu, S.; Chi, Y. Mechanical behavior and stress–strain model of steel-polypropylene hybrid fiber reinforced ultra-high performance concrete under triaxial compression. Constr. Build. Mater. 2024, 450, 138595. [Google Scholar] [CrossRef]

- Yang, M.; Huang, C.K. Study on stress–strain curve of high-strength steel fiber reinforced concrete under uniaxial tension. Chin. Civ. Eng. J. 2006, 39, 55–61. (In Chinese) [Google Scholar]

- Shi, X.; Park, P.; Rew, Y.; Huang, K.; Sim, C. Constitutive behaviors of steel fiber reinforced concrete under uniaxial compression and tension. Constr. Build. Mater. 2020, 233, 117316. [Google Scholar] [CrossRef]

- Cui, G.; Ma, J. Structure strengthening method for enhancing seismic behavior of soft tunnel portal section. Math. Probl. Eng. 2021, 2021, 6624963. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Y.; Ding, Q.; Zhang, C. Influence of hybrid fibers on the mechanical and impermeability properties of high-performance concrete. Concr. Cem. Prod. 2004, 1, 38–40. (In Chinese) [Google Scholar]

- Huang, C. Introduction to Technical Specification for Fiber-Reinforced Concrete Structures (CECS38:2004). Eng. Constr. Stand. 2005, 5, 5. (In Chinese) [Google Scholar]

- Xu, L.; Mei, G.; Huang, L.; Lu, W. Study on uniaxial tensile stress–strain relationship of steel–polypropylene hybrid fiber reinforced concrete. China Civ. Eng. J. 2014, 47, 35–45. (In Chinese) [Google Scholar]

- Najar, J. A theory of concrete damage. Int. J. Solids Struct. 1987, 23, 451–469. [Google Scholar]

- Lei, Z. A modified constitutive model for concrete. J. Struct. Eng. 1996, 122, 1126–1134. [Google Scholar]

- Wang, Z.Q. Energy damage theory for fiber-reinforced concrete. Cem. Concr. Compos. 2004, 26, 397–402. [Google Scholar]

- Jasim, B.W.; Al-Gasham, T.S. Hybrid fiber reinforced concrete–A review of recent progress. Case Stud. Constr. Mater. 2022, 17, e01341. [Google Scholar] [CrossRef]

- Reddy, K.C.; Gudur, C.; Subramaniam, K.V.L. Study on the influences of silica and sodium in the alkali-activation of ground granulated blast furnace slag. Constr. Build. Mater. 2020, 257, 119514. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, W.; Zhang, Y.; Wang, C. Arresting Properties of Polypropylene Fiber-Reinforced Foamed Concrete Under Wet-Dry Cycles. Constr. Build. Mater. 2024, 427, 136233. [Google Scholar] [CrossRef]

- Dhanalakshmi, A.; Shahul Hameed, M.A.; Jeyaseela, J.; Karthika, S. Study on the Performance Behaviour of Fibre Reinforced Foam Concrete. Mater. Sci. Forum 2024, 1120, 127–136. [Google Scholar] [CrossRef]

- Tao, Z.; Mao, Y.; Sun, J.; Zhang, X.; Huo, S.; He, M. Research on Energy-Absorption Active Control Method for Large Deformation of Tunnel Surrounding Rock through Multi-Fault Fracture Zone. Can. Geotech. J. 2024, 61, 1977–1995. [Google Scholar] [CrossRef]

- Qiu, Z.W.; Yu, Y.; Du, Y.; Zhou, Z.H. Numerical Simulation of the Impact of Reverse Fault Displacement on Tunnel Engineering. J. Seismol. Res. 2021, 43, 237–244. (In Chinese) [Google Scholar]

| Working Conditions | Steel Fiber | Polypropylene Fiber | Seismic Joint Setting | ||

|---|---|---|---|---|---|

| Dosage | Aspect Ratio | Dosage | Aspect Ratio | ||

| 1 | 0.50% | 60 | 0.10% | 396 | No |

| 2 | 1.90% | 60 | 0.10% | 396 | No |

| 3 | 1.20% | 60 | 0.10% | 396 | No |

| 4 | 1.20% | 60 | 0.15% | 396 | No |

| 5 | 1.20% | 60 | 0.05% | 396 | No |

| 6 | 1.20% | 30 | 0.10% | 396 | No |

| 7 | 1.20% | 80 | 0.10% | 396 | No |

| 8 | 0.50% | 60 | 0.10% | 396 | Yes |

| 9 | 1.90% | 60 | 0.10% | 396 | Yes |

| 10 | 1.20% | 60 | 0.10% | 396 | Yes |

| 11 | 1.20% | 60 | 0.15% | 396 | Yes |

| 12 | 1.20% | 60 | 0.05% | 396 | Yes |

| 13 | 1.20% | 30 | 0.10% | 396 | Yes |

| 14 | 1.20% | 80 | 0.10% | 396 | Yes |

| Parameter | Grade IV Surrounding Rock | Fault Fracture Zone | Primary Support (C25) | Secondary Lining (C30) |

|---|---|---|---|---|

| Density (kg/m3) | 2200 | 2000 | 2400 | 2500 |

| Elastic Modulus (GPa) | 7 | 5 | 27.5 | 29 |

| Poisson’s Ratio | 0.3 | 0.3 | 0.2 | 0.25 |

| Cohesion (MPa) | 0.5 | 0.25 | 12.5 | / |

| Friction Angle (°) | 35 | 25 | 51 | / |

| Stress (MPa) | Concrete Inelastic Strain () | Damage Factor () |

|---|---|---|

| 12.89 | 0.00000 | 0.0000 |

| 17.27 | 0.00005 | 0.0057 |

| 21.40 | 0.00014 | 0.0399 |

| 24.77 | 0.00026 | 0.0843 |

| 27.45 | 0.00041 | 0.1276 |

| Stress (MPa) | Concrete Inelastic Strain () | Damage Factor () |

|---|---|---|

| 3.93 | 0.00000 | 0.0000 |

| 3.66 | 0.00020 | 0.2950 |

| 3.26 | 0.00028 | 0.3741 |

| 2.89 | 0.00036 | 0.4474 |

| 2.59 | 0.00044 | 0.5118 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yin, Z.; Wang, R.; Ding, B.; Wang, Z. Enhancing Tunnel Fault-Resistance with Combined Seismic Joints and Steel–Polypropylene Fiber Concrete Linings. Buildings 2025, 15, 3819. https://doi.org/10.3390/buildings15213819

Wang Y, Yin Z, Wang R, Ding B, Wang Z. Enhancing Tunnel Fault-Resistance with Combined Seismic Joints and Steel–Polypropylene Fiber Concrete Linings. Buildings. 2025; 15(21):3819. https://doi.org/10.3390/buildings15213819

Chicago/Turabian StyleWang, You, Zixi Yin, Rui Wang, Bosong Ding, and Ziwei Wang. 2025. "Enhancing Tunnel Fault-Resistance with Combined Seismic Joints and Steel–Polypropylene Fiber Concrete Linings" Buildings 15, no. 21: 3819. https://doi.org/10.3390/buildings15213819

APA StyleWang, Y., Yin, Z., Wang, R., Ding, B., & Wang, Z. (2025). Enhancing Tunnel Fault-Resistance with Combined Seismic Joints and Steel–Polypropylene Fiber Concrete Linings. Buildings, 15(21), 3819. https://doi.org/10.3390/buildings15213819