Experimental Study on the Out-of-Plane Seismic Performance of Shear Walls with Bolted Connections in Nuclear Power Plants

Abstract

1. Introduction

- (1)

- Precast concrete structural systems offer advantages such as simplified construction procedures, reduced demand on on-site formworks, and improved assembly efficiency. Despite these benefits, the development and application of precast NPPs has not been conducted, and relevant experimental and numerical studies remain limited.

- (2)

- Bolted connections, as a representative dry connection technique, can offer strong potential for application in NPPs. Existing studies have confirmed that bolted connections can provide in-plane seismic performance comparable to that of CIP shear walls. However, due to the orthogonal layout of walls and the inherently high lateral stiffness associated with the large thickness of shear walls in NPPs, significant out-of-plane seismic demands are inevitably introduced. And the out-of-plane seismic behavior of PCSWs with bolted connections has received limited attention, and to date, no experimental investigations have been reported in this regard.

- (3)

- Current domestic and international design codes provide analytical procedures for evaluating the out-of-plane capacity of CIP shear walls and steel–concrete composite shear walls in nuclear structures. However, no dedicated design methods exist for assessing the out-of-plane seismic behavior of bolted connection PCSWs in NPPs.

2. Experimental Program

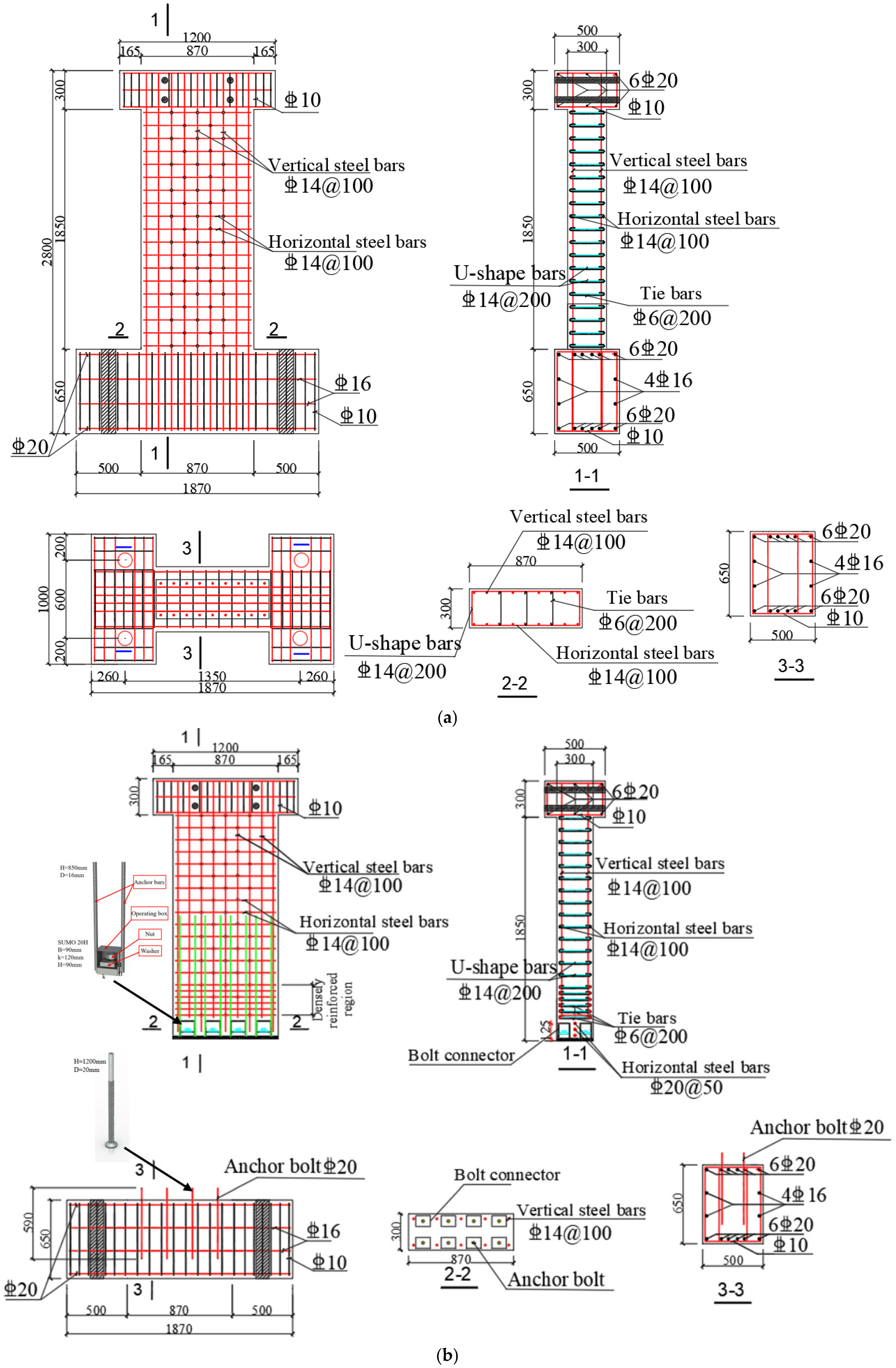

2.1. Test Specimens

2.2. Material Properties

2.3. Cast of Specimens

- (1)

- Strain gauges were first attached to the reinforcement. Subsequently, the reinforcement cages for both the wall panel and the base were tied and placed into the steel formwork. The bolt connectors were fixed to the formwork, after which the forms were assembled and the connector hand holes were sealed to prevent mortar ingress during concrete casting.

- (2)

- Concrete was poured into the formwork. Once the required strength was achieved, the forms for both the wall panel and the base were removed, preparing the components for subsequent assembly.

- (3)

- The precast wall panel was then lifted by a crane and positioned above the base.

- (4)

- Using temporary supports, the wall panel was aligned vertically, and the bolts were tightened with a torque wrench to 150 N·m. The joint between the wall panel and base was sealed with formwork, followed by injection of high-strength grout using a grouting pump.

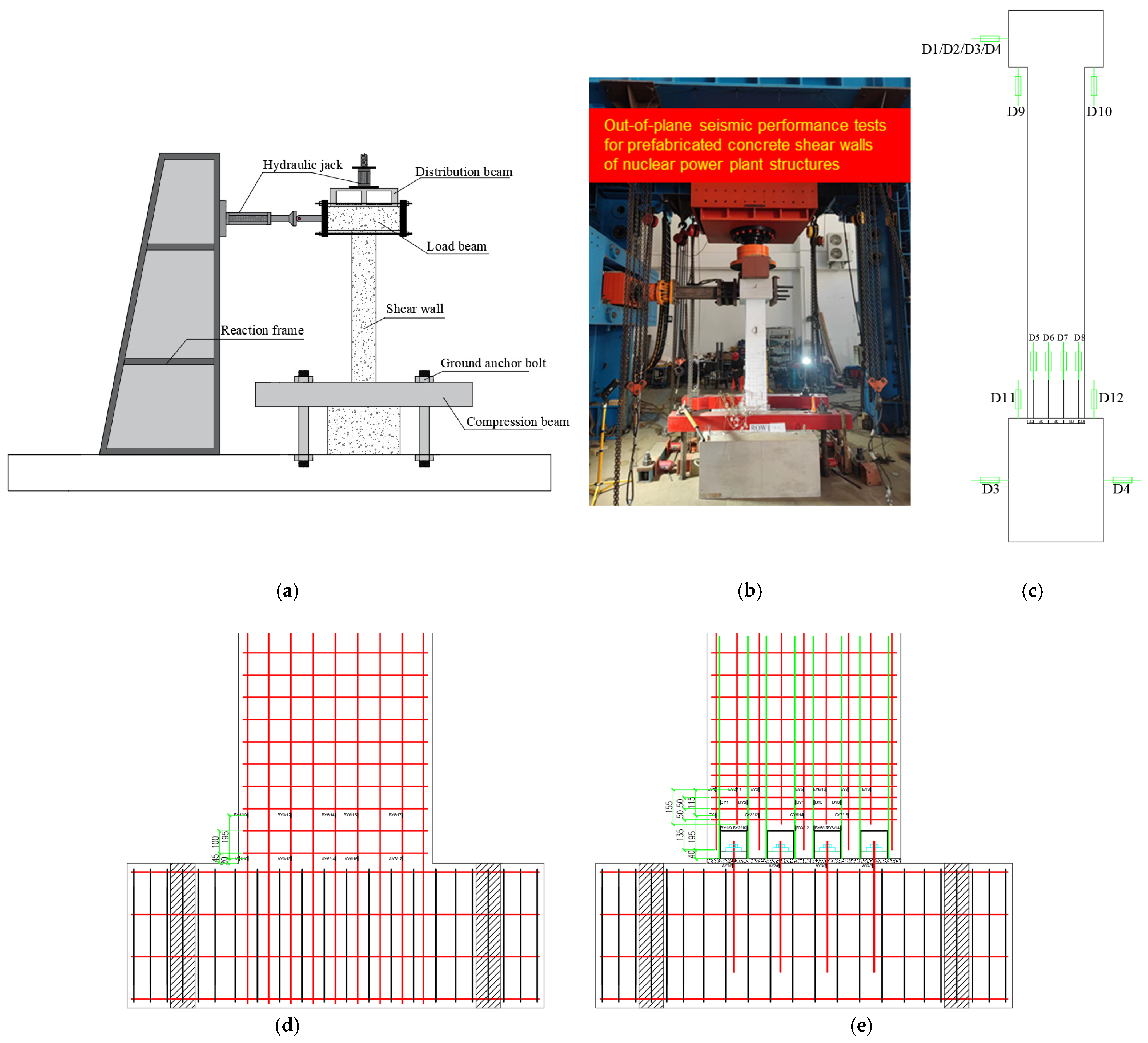

2.4. Loading Protocol and Experimental Program

3. Results and Discussion

3.1. Global Response and Failure Mode

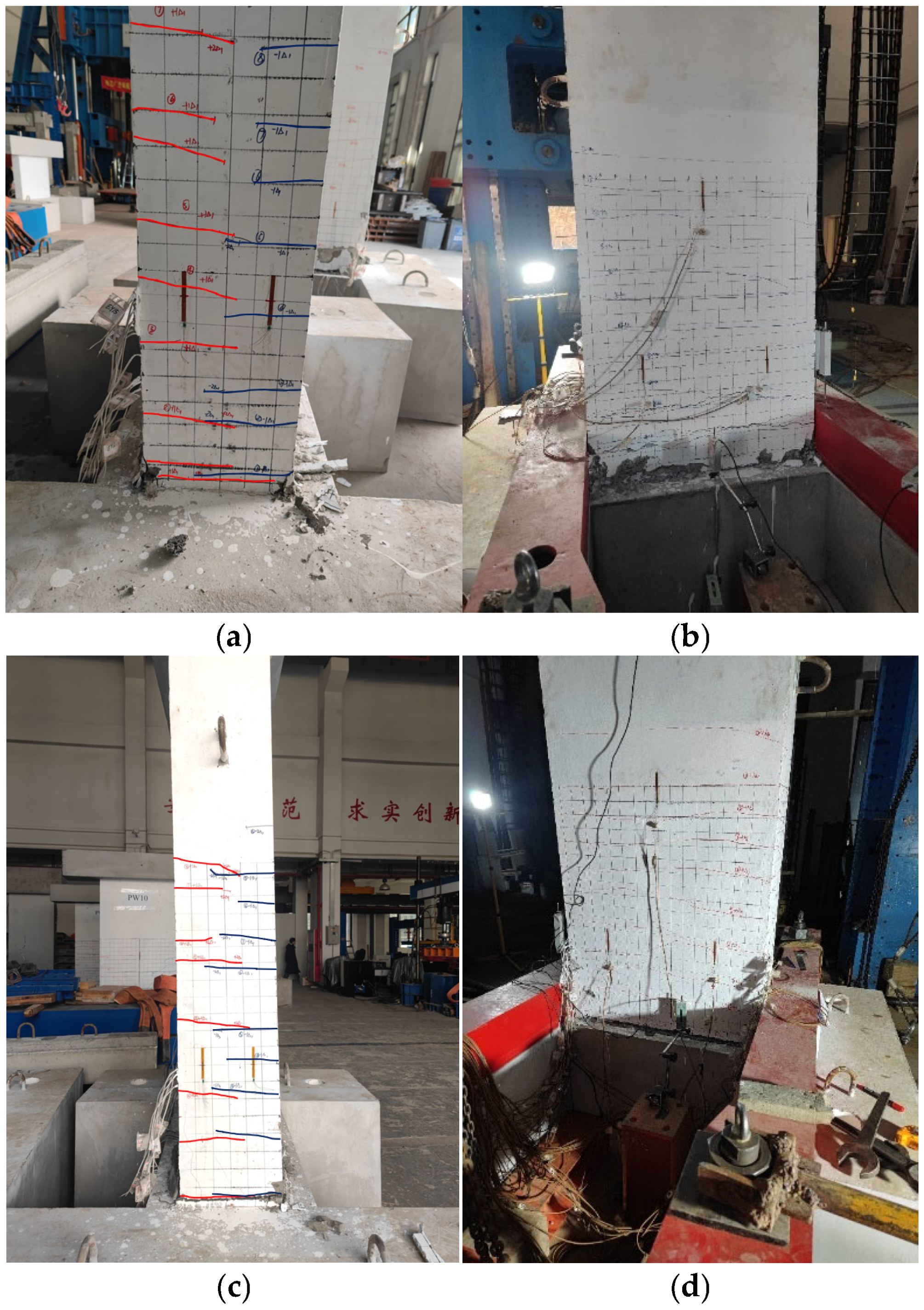

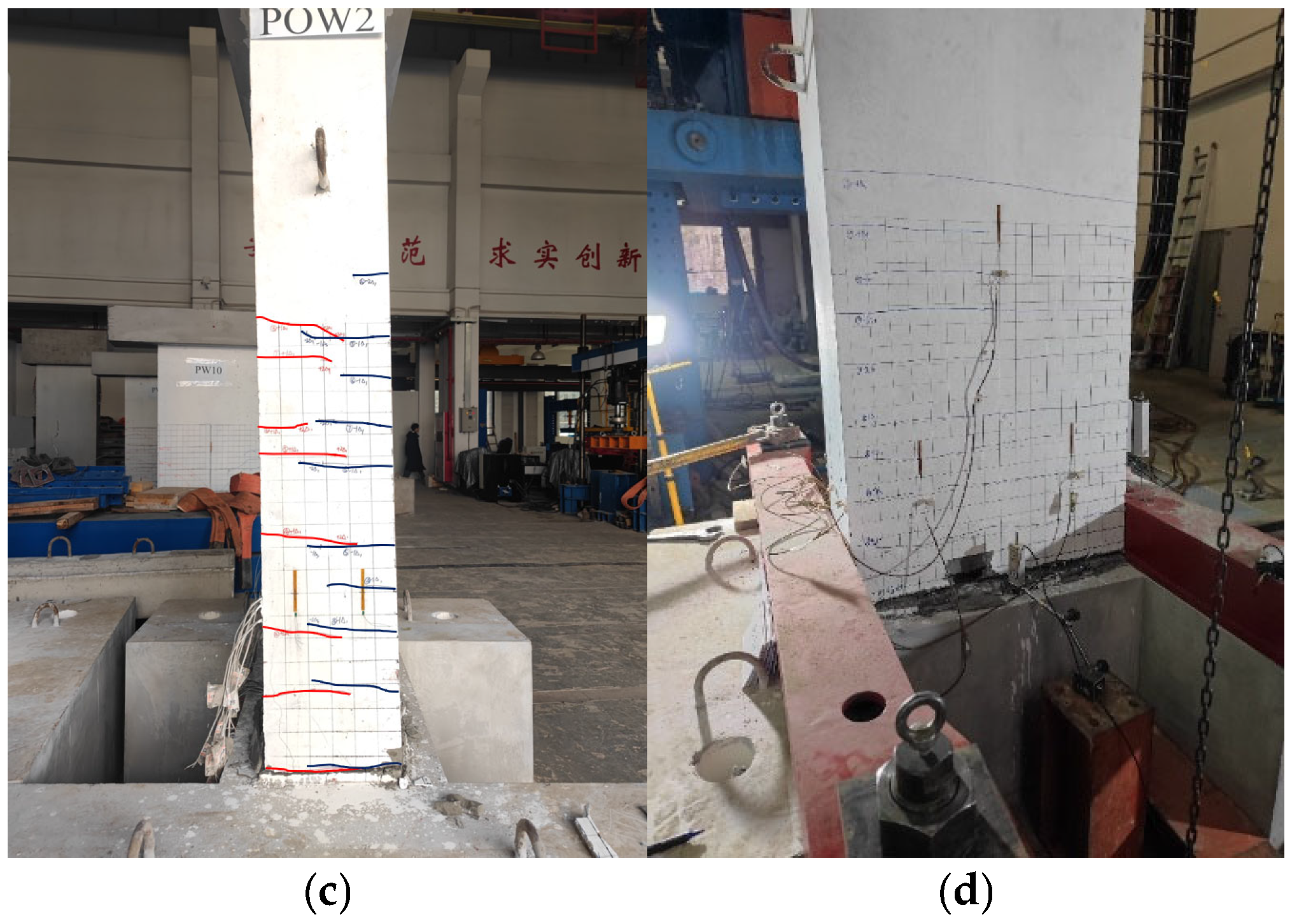

- (1)

- Cracking stage: For the first group (axial compression ratio = 0.2), the cracking loads of ROW1 and POW1 were 25 kN and 65 kN, respectively. For the second group without axial compression, the cracking loads of ROW2 and POW2 were 15 kN and 35 kN, respectively. In the CIP specimens, the first cracks appeared at the interface between the wall and the ground beam, while in the precast specimens, they occurred at the interface between the bedding mortar layer and the upper wall. The cracking load increased with axial compression.

- (2)

- Yield stage: As the horizontal displacement increased, existing cracks propagated, vertical splitting cracks developed at the wall corners, and more horizontal flexural cracks formed and extended through the wall thickness. At a drift ratio of 1%, the connector bolts in POW1 and POW2 exceeded 2000 με, indicating yielding, while the longitudinal reinforcement in ROW1 and ROW2 reached strains of 2200–2600 με, also indicating yielding. With further drift, additional reinforcement yielded in tension, and concrete spalling initiated at the wall base.

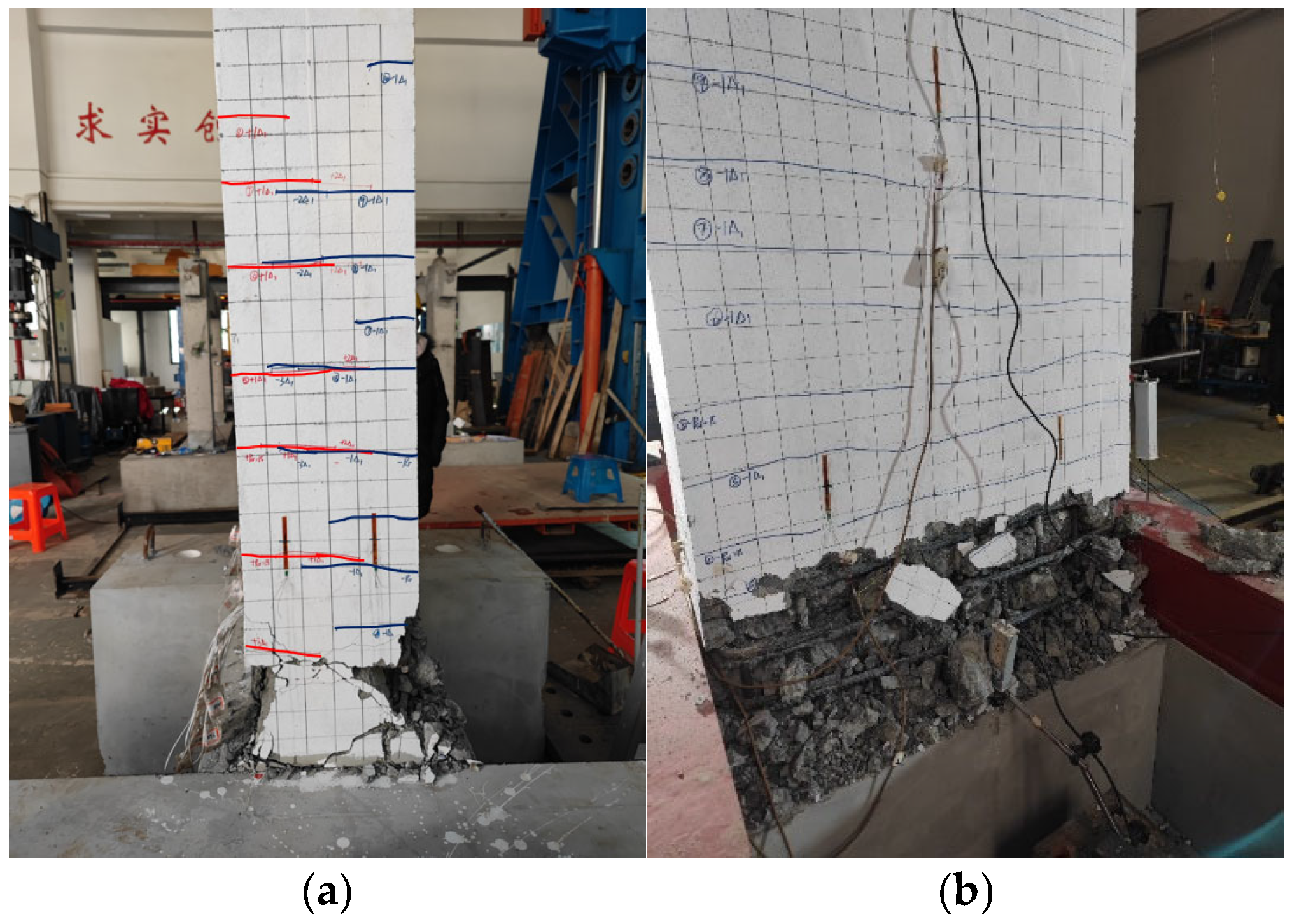

- (3)

- Peak stage: When the drift ratio reached 2–6%, all specimens attained their maximum lateral capacity. For ROW1, the peak load was 147.5 kN at a crack height of 1300 mm, followed by the formation of two wide cracks at heights of 150 mm and 250 mm, and crushing of concrete below 100 mm. ROW2 reached its peak load of 90.8 kN at a drift ratio of 6%, with cracks extending up to 1200 mm, three wide cracks forming at 50 mm, 150 mm, and 250 mm, and crushing below 300 mm. For POW1 and POW2, peak loads of 138.9 kN and 85.4 kN were reached at a drift ratio of 2%, with cracks distributed up to heights of 1600 mm and 1300 mm, respectively.

- (4)

- Failure stage: Beyond the peak load, the lateral capacity began to decline. Severe spalling occurred on both sides of the wall base. In the first group, the reinforcement and bolts yielded in tension but did not fracture; in the second group, some reinforcement and bolts fractured. Failure was defined when the lateral load dropped to 85% of the peak value.

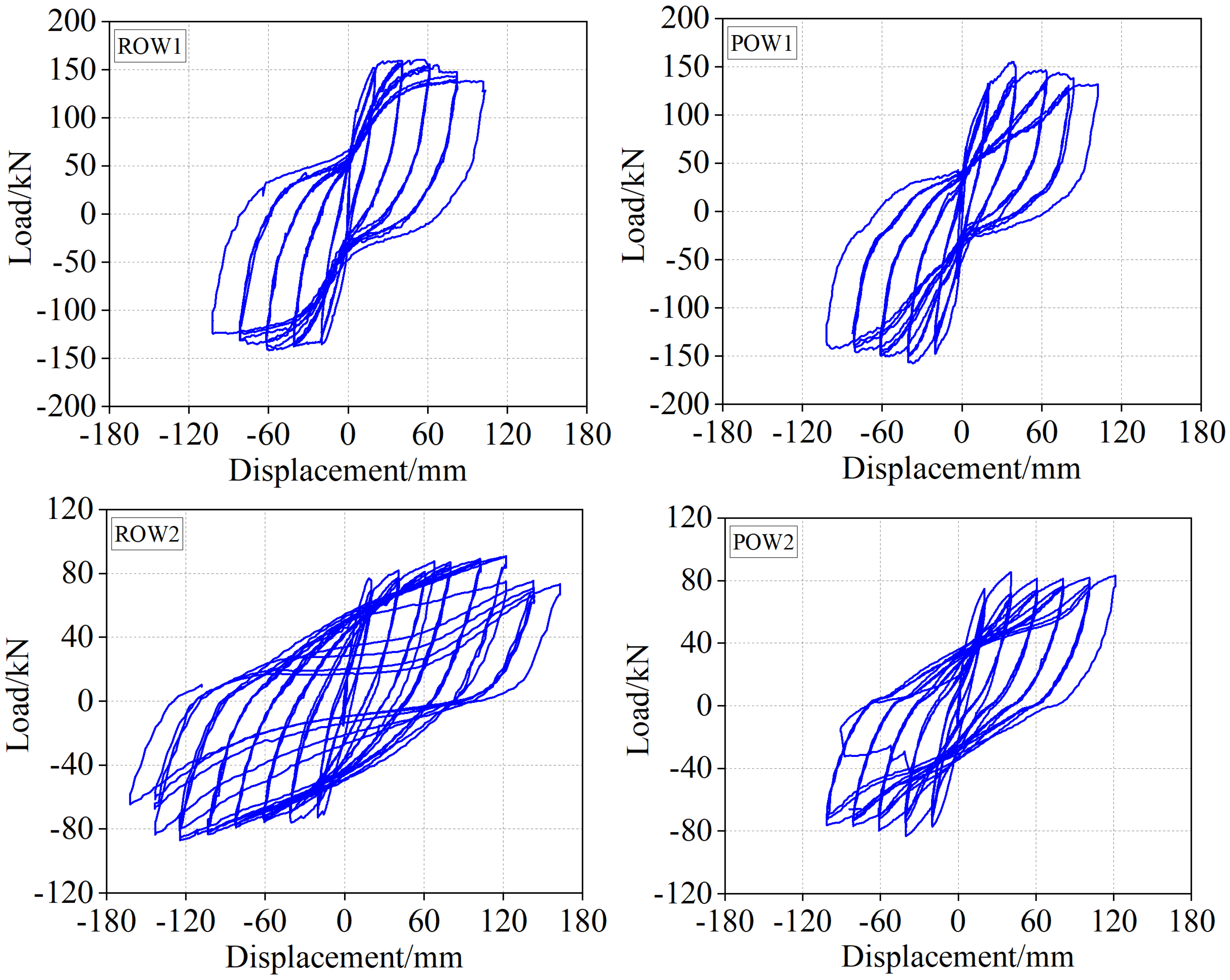

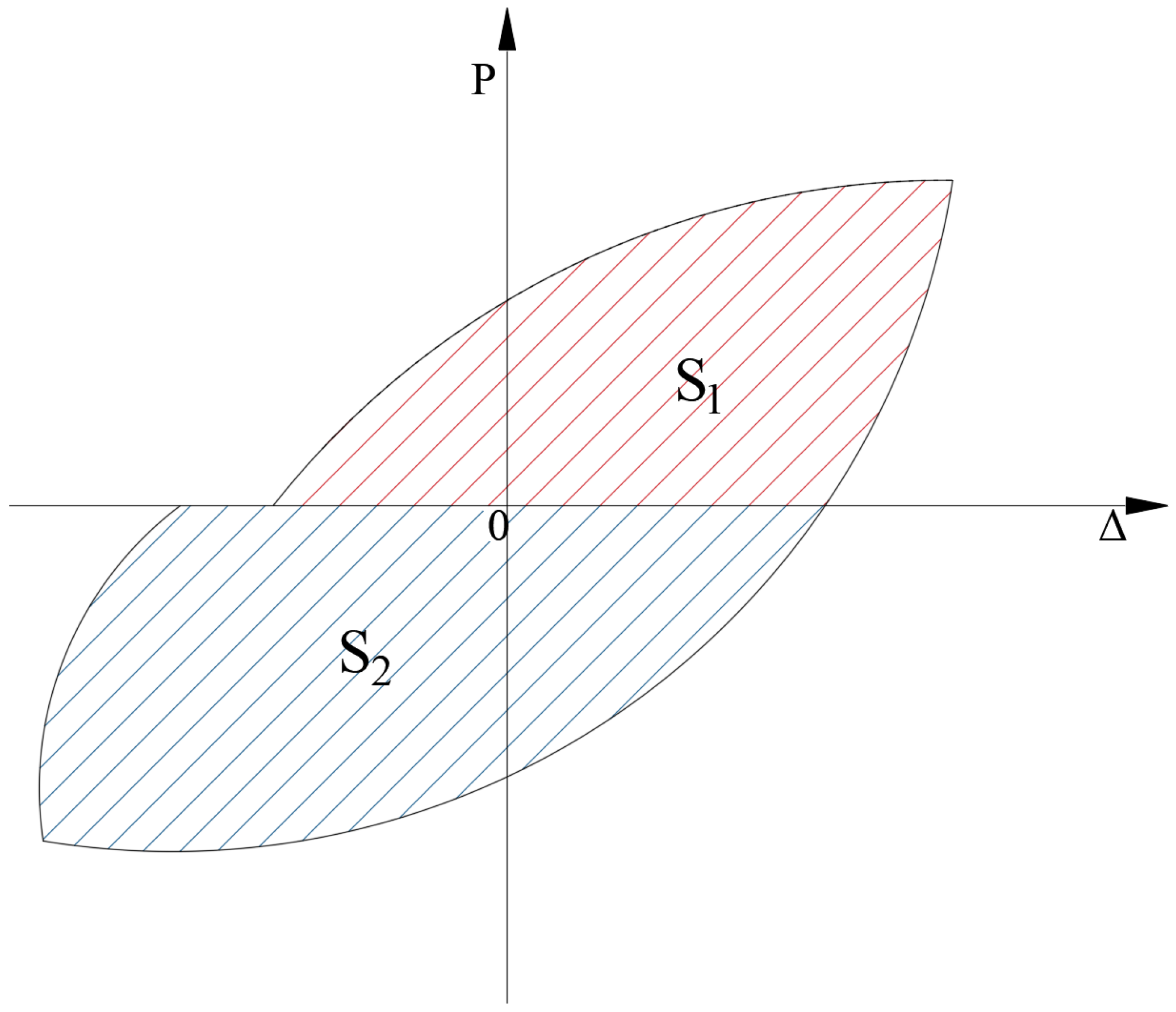

3.2. Hysteresis Loops

3.3. Envelop Curves

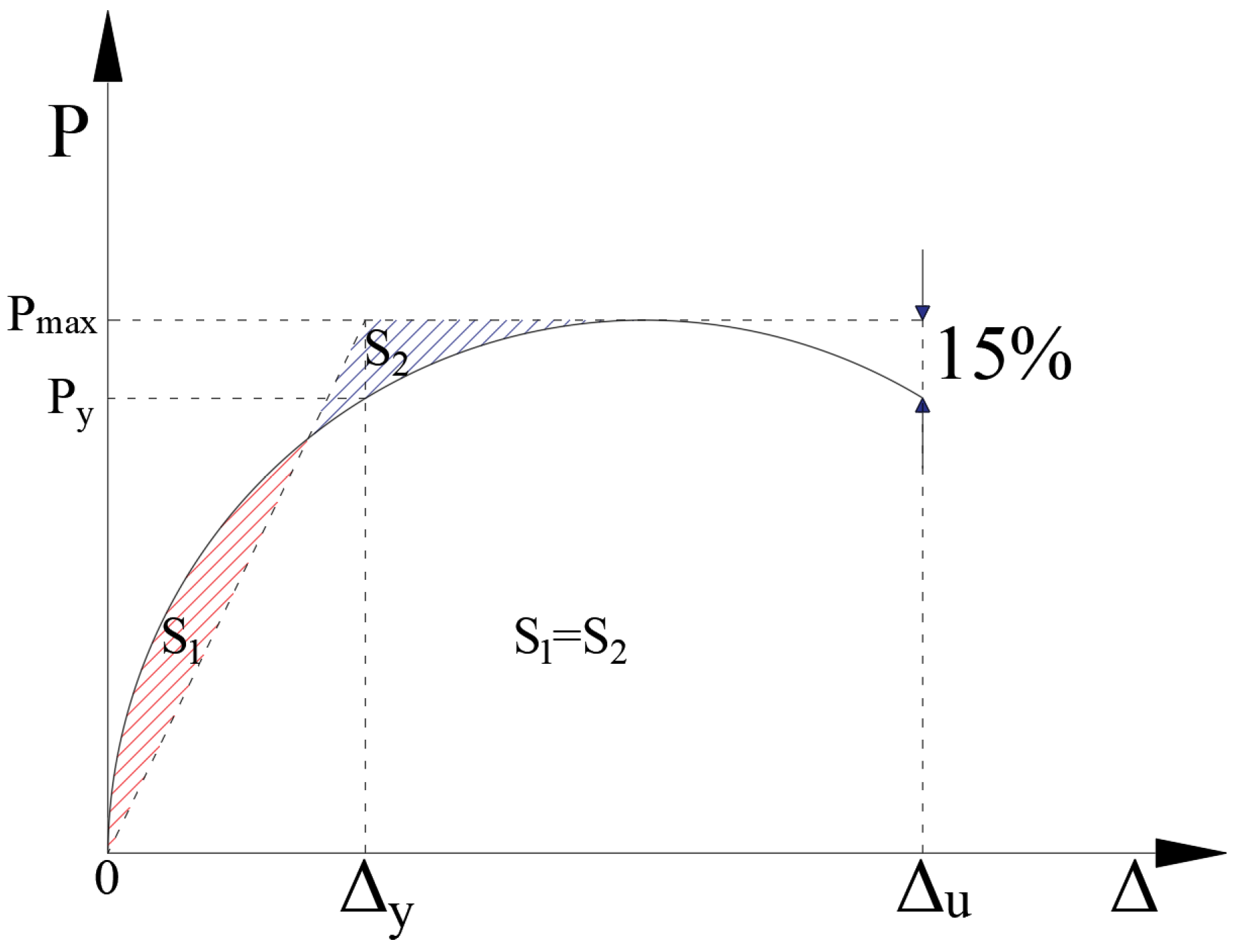

3.4. Displacement Ductility

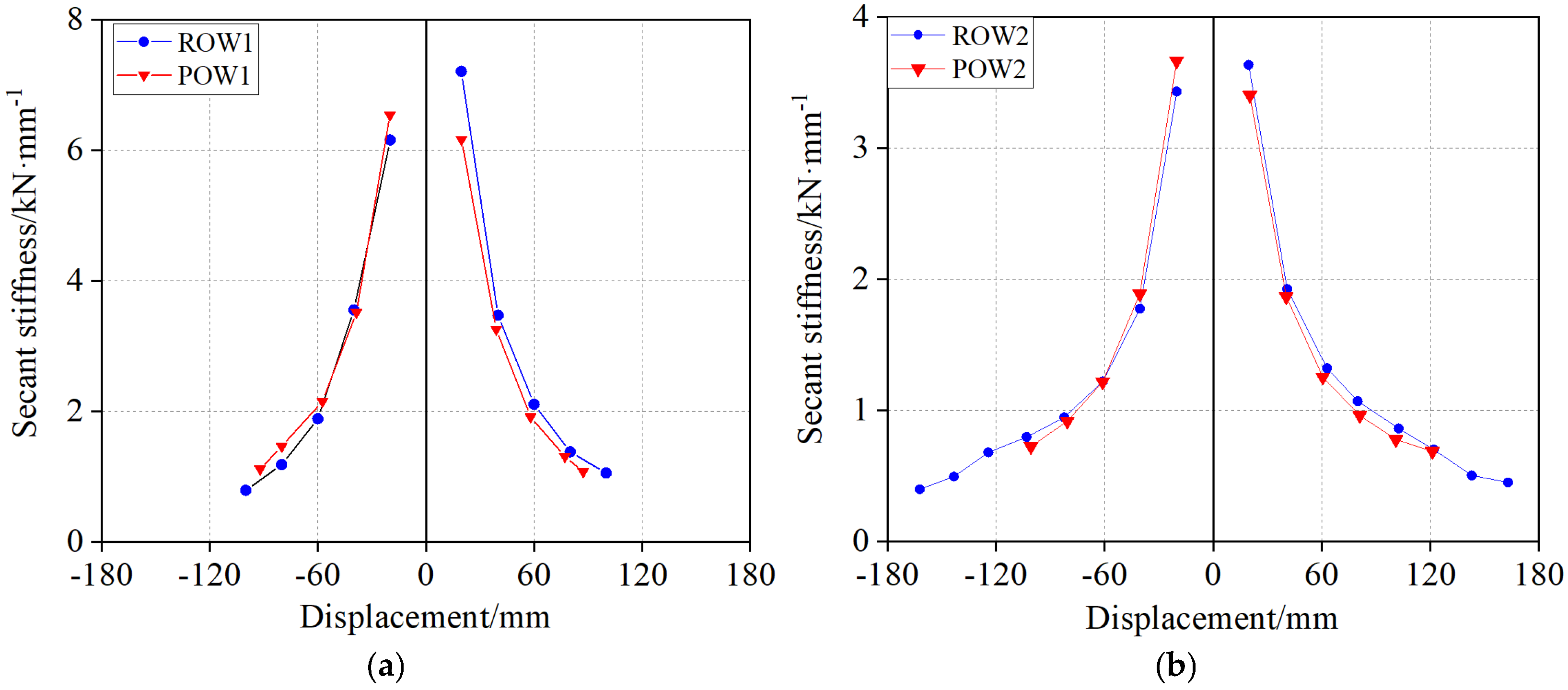

3.5. Stiffness Degradation

3.6. Energy Dissipation

4. Performance Evaluation

5. Conclusions

- (1)

- All shear wall specimens failed in a flexure-dominated mode, characterized by concrete crushing and spalling at the wall base, as well as yielding or even fracturing the boundary reinforcement/bolts. The primary difference was that damage in the precast specimens was concentrated in the bedding mortar layer, whereas in the CIP specimens, the damage height ranged from 100 mm to 300 mm above the base.

- (2)

- Precast and CIP specimens showed similar hysteretic patterns. Due to differences in longitudinal reinforcement and bolt locations relative to the central axis, and variations in wall damage, the hysteresis loops of precast specimens were slightly less full. Specimens under axial compression exhibited fewer hysteresis loops and more pronounced pinching compared with specimens without axial compression.

- (3)

- The skeleton curves of precast and CIP specimens followed consistent trends. Peak displacements varied slightly due to structural detailing and axial compression effects, and peak load differences were within 5%, satisfying the principle of equivalent load-bearing capacity. This confirms the reliability of the bolted connection system and indicates that design approaches for CIP walls can be directly applied to the precast system.

- (4)

- Regardless of axial compression, precast specimens showed slightly lower deformation capacity than CIP counterparts, but all met international code requirements. The ductility parameters of the PCSWs complied with European code provisions for medium- and high-ductility classes under the tested axial compression conditions. Additionally, the precast specimens exhibited smaller residual deformations compared with CIP walls.

- (5)

- Stiffness degradation curves were generally similar for both precast and CIP specimens. In later loading stages, precast specimens displayed slower stiffness degradation due to damage concentration in the bedding mortar layer. At a 2% drift ratio, the cumulative energy dissipation of PCSWs reached 80% of that of CIP walls. To further improve the energy dissipation performance of bolted connection shear walls, future research may consider increasing the horizontal reinforcement ratio in the connection zone to enhance confinement or incorporating high-ductility cementitious materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ACI 349-06; Code Requirements for Nuclear Safety-Related Concrete Structures and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2006.

- AISC N690s1; Specification for Safety-Related Steel Structures for Nuclear Facilities Including Supplement No. 1. American Institute of Steel Construction: Chicago, IL, USA, 2015.

- Parsi, S.S.; Mertz, G.; Whittaker, A.S. Evaluation of design equations for out-of-plane shear strength of deep concrete sections in nuclear power plant buildings. Nucl. Eng. Des. 2022, 386, 111545. [Google Scholar] [CrossRef]

- Hu, X.; Xue, W.; Lv, Y. Seismic Behavior of a New Type of Precast Concrete Shear Wall Using UHPC Connections at Boundary Elements. Eng. Struct. 2024, 302, 117468. [Google Scholar] [CrossRef]

- Xue, W.; Lei, J.; Zhang, B.; Huang, Q. Hysteretic Behavior of Full-Scale Precast U-Shaped Composite Beam–Column Connections with Large-Diameter Reinforcements under High Axial Compression. Buildings 2024, 14, 317. [Google Scholar] [CrossRef]

- Xue, W.; Zhang, B.; Liao, X. Cyclic Loading Response of Precast Concrete Frame with Composite Beams Prestressed by Partially Bonded Draped Tendons under High Axial Compression. Eng. Struct. 2025, 334, 120229. [Google Scholar] [CrossRef]

- Singhal, S.; Chourasia, A.; Chellappa, S.; Parashar, J. Precast Reinforced Concrete Shear Walls: State-of-the-Art Review. Struct. Concr. 2019, 20, 886–898. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Chougan, M.; Albar, A.; Skibicki, S.; Federowicz, K.; Hoffman, M.; Ghaffar, S.H. Recycled brick aggregates in one-part alkali-activated materials: Impact on 3D printing performance and material properties. Dev. Built Environ. 2023, 16, 100248. [Google Scholar] [CrossRef]

- Liu, F.; Liu, A.; Wang, L.; Zhang, Q. Accurate Modeling and Wave Propagation Analysis of Cracked Slender Structural Members by the Spectral Element Method. Struct. Control Health Monit. 2023, 2023, 5569434. [Google Scholar] [CrossRef]

- Precast/Prestressed Concrete Institute (PCI). PCI Design Handbook, 8th ed.; Precast/Prestressed Concrete Institute: Chicago, IL, USA, 2017. [Google Scholar]

- Gong, Y.; Chu, Y.; Liu, Y.; Wang, Z. Experimental and Numerical Study on Mechanical Properties of PC Shear Wall Bolted Connection Joints. Adv. Struct. Eng. 2025, 28, 227–245. [Google Scholar] [CrossRef]

- Xue, W.; Bai, H.; Dai, L.; Xu, J. Seismic Behavior of Precast Concrete Beam–Column Connections with Bolt Connectors in Columns. Struct. Concr. 2021, 22, 1297–1314. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Yu, D. Experimental and Numerical Studies on the Seismic Performance of New Assembled Concrete Frame Beam–Column Joints. Buildings 2023, 13, 329. [Google Scholar] [CrossRef]

- Soudki, K.A.; Rizkalla, S.H.; LeBlanc, B. Horizontal Connections for Precast Concrete Shear Walls Subjected to Cyclic Deformations. Part 1: Mild Steel Connections. PCI J. 1995, 40, 78–96. [Google Scholar] [CrossRef]

- Han, Q.; Wang, D.; Zhang, Y.; Zhang, J.; Liu, F. Experimental Investigation and Simplified Stiffness Degradation Model of Precast Concrete Shear Wall with Steel Connectors. Eng. Struct. 2020, 220, 110943. [Google Scholar] [CrossRef]

- Liu, H.; Guo, R.; Wang, Z.; Zhang, L.; Li, M. Experimental Study on Seismic Performance of Precast Concrete Shearing Walls Connected by High-Strength Bolts. J. Build. Eng. 2025, 101, 111817. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, T.; Kong, Z.; Wang, S.; Cheng, R.; Zhou, Y.; Zhang, Y. Effects of Semi-Rigid Behavior on the Seismic Performance of the Precast Shear Wall with a Box-Shaped Connection Joint. Steel Compos. Struct. 2025, 56, 67–82. [Google Scholar]

- Xue, W.; He, L.; Liu, Y.; Dai, L.; Zhang, B. Cyclic Response of Precast Concrete Shear Walls with Bolt-Sleeve Hybrid Connections. J. Build. Eng. 2025, 101, 111846. [Google Scholar] [CrossRef]

- Xue, W.; Chen, S.; Hu, X.; Zhang, B.; Dai, L. Full-Scale Cyclic Test on Hybrid Connection Precast Shear Wall under High Axial Compression Ratio. Structures 2025, 77, 109150. [Google Scholar] [CrossRef]

- Guo, W.; Zhai, Z.; Cui, Y.; Zhang, M.; Zhang, J. Seismic Performance Assessment of Low-Rise Precast Wall Panel Structure with Bolt Connections. Eng. Struct. 2019, 181, 562–578. [Google Scholar] [CrossRef]

- Bhardwaj, S.R.; Varma, A.H.; Wazalwar, P. Axial Force–Biaxial Moment–Vector Shear (PMV) Interaction for Steel-Plate Composite (SC) Wall Piers. Nucl. Eng. Des. 2019, 349, 162–173. [Google Scholar] [CrossRef]

- Varma, A.H.; Malushte, S.R.; Sener, K.C.; Lai, B. Steel-Plate Composite (SC) Walls for Safety Related Nuclear Facilities: Design for In-Plane Forces and Out-of-Plane Moments. Nucl. Eng. Des. 2014, 269, 240–249. [Google Scholar] [CrossRef]

- Niroomandi, A.; Pampanin, S.; Dhakal, R.P.; Ashtiani, M.S.; Torre, C.D.L. Out-of-Plane Shear–Axial Failure in Slender Rectangular Reinforced Concrete Walls. Earthq. Eng. Struct. Dyn. 2022, 51, 2426–2448. [Google Scholar] [CrossRef]

- Cheng, Y.; He, H.; Sun, H.; Cheng, S. Experimental Study and Mechanism Analysis of Out-of-Plane Seismic Performance of Reinforced Concrete Shear Walls. J. Build. Eng. 2023, 80, 108058. [Google Scholar] [CrossRef]

- Xue, W.-C.; Li, Y.; Cai, L.; Hu, X. In-Plane and Out-of-Plane Mechanical Behavior of Double-Faced Superposed Concrete Shear Walls. Eng. Mech. 2018, 35, 47–53. (In Chinese) [Google Scholar]

- Xue, W.; Huang, Q.; Xu, Z.; Liu, Y.; Dai, L. Out-of-Plane Response of Precast Concrete Shear Walls Connected via Grouted Sleeves. Struct. Concr. 2024, 25, 3570–3582. [Google Scholar] [CrossRef]

- Li, X.; Li, X. Out-of-Plane Flexural Capacity of Double Steel Plates and Concrete Infill Composite Shear Walls for Nuclear Power Engineering. J. Harbin Eng. Univ. 2017, 38, 1238–1246. [Google Scholar]

- Peikko Group. SUMO Wall Shoe for Bolted Wall Connections. Peikko Technical Manual. 2014. Available online: https://www.peikko.com/products/product/sumo-wall-shoe/ (accessed on 20 August 2025).

- DGJ 08-2154-2022; Code for Design of Monolithic Precast Concrete Public Buildings. Tongji Press: Shanghai, China, 2022.

- GB/T 51231-2016; Technical Code for Assembled Buildings with Concrete Structure. China Architecture & Building Press: Beijing, China, 2016.

- JGJ 1-2014; Technical Specification for Precast Concrete Structures. China Architecture & Building Press: Beijing, China, 2014.

- GB/T 50152-2012; Standard for Test Method of Concrete Structures. China Architecture & Building Press: Beijing, China, 2012.

- Teng, M.-R.; Feng, P.; Lin, H.-W.; Qu, Z. Seismic performance assessment based on hysteresis curves: Index definition, algorithm optimization and automatic identification. Eng. Mech. 2025, 42, 89–101. [Google Scholar]

- ACI 318-19; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Park, R. Evaluation of ductility of structures and structural assemblages from laboratory testing. Bull. N. Z. Soc. Earthq. Eng. 1989, 22, 155–166. [Google Scholar] [CrossRef]

- EN 1998-1:2004; Eurocode 8: Design of Structures for Earthquake Resistance—Part 1: General Rules, Seismic Actions and Rules for Buildings. CEN: Brussels, Belgium, 2004.

- GB50011-2010; Code for Seismic Design of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- JASS 10; Precast Concrete Engineering. AIJ: Tokyo, Japan, 2003. (In Japanese)

- National Earthquake Hazards Reduction Program (NEHRP). Recommended Seismic Provisions for New Buildings and Other Structures; Building Seismic Safety Council: Washington, DC, USA, 2020. [Google Scholar]

| Specimens № | Specimen Type | Axial Compression Ratio | Vertical Reinforcement Connection Method |

|---|---|---|---|

| ROW1 | CIP | 0.2 | — |

| POW1 | Precast | 0.2 | Bolt |

| ROW2 | CIP | 0 | — |

| POW2 | Precast | 0 | Bolt |

| Specimens | Cube Strength fcu (MPa) | Prism Strength fc (MPa) | tensile Strength ft (MPa) | Elastic Modulus Ec (×104 MPa) |

|---|---|---|---|---|

| ROW1 | 44.3 | 32.4 | 3.5 | 3.01 |

| POW1 | 41.2 | 29.8 | 3.2 | 2.96 |

| ROW2 | 48.8 | 34.1 | 3.7 | 3.29 |

| POW2 | 47.5 | 35.1 | 3.6 | 3.26 |

| Specimens | Cube Strength fcu (MPa) | Flexural Strength ff (MPa) | Elastic Modulus Ec (×104 MPa) |

|---|---|---|---|

| ROW1 | — | — | — |

| POW1 | 83.7 | 10.16 | 4.15 |

| ROW2 | — | — | — |

| POW2 | 82.5 | 9.62 | 3.88 |

| Diameter (mm) | Yield Strength fy (N/mm2) | Maximum Strength fu (N/mm2) | Elastic Modulus Ec (×105 MPa) | Elongation (%) |

|---|---|---|---|---|

| Φ20 (screw) | 520 | 662 | 2.02 | 25 |

| Φ14 | 425 | 588 | 2.07 | 24 |

| Φ6 | 418 | 556 | 2.05 | 21 |

| Specimen | Py (kN) | Δy (mm) | Pmax (kN) | Δmax (mm) | Pu (kN) | Δu (mm) | Δu/Δy | Avg | Δu/H | Avg | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ROW1 | P | 125.7 | 24.66 | 138.9 | 37.56 | 118.1 | 61.16 | 2.48 | 2.68 | 1/32 | 1/33 |

| N | 139.4 | 20.77 | 142 | 36.77 | 120.7 | 59.94 | 2.88 | 1/33 | |||

| POW1 | P | 144.1 | 19.72 | 147.5 | 25.99 | 125.4 | 56.87 | 2.88 | 2.96 | 1/35 | 1/34 |

| N | 124.9 | 20.23 | 126.9 | 21.58 | 107.9 | 61.89 | 3.05 | 1/32 | |||

| ROW2 | P | 77.37 | 25.28 | 85.4 | 40.62 | 83.2 | 121.18 | 4.79 | 4.54 | 1/17 | 1/18 |

| N | 78.09 | 23.00 | 83.3 | 40.32 | 76.2 | 100.82 | 4.28 | 1/20 | |||

| POW2 | P | 80.12 | 33.29 | 90.8 | 122 | 77.18 | 140.4 | 4.22 | 3.89 | 1/14 | 1/14 |

| N | 75.87 | 42.97 | 87.0 | 124.4 | 73.95 | 152.7 | 3.56 | 1/13 | |||

| n = 0.2 | n = 0 | Acceptance Criteria | ||||

|---|---|---|---|---|---|---|

| POW1 | ROW1 | POW2 | ROW2 | |||

| 1.125 | 1.045 | 1.030 | 1.035 | 0.90–1.20 | ||

| 0.354 | 0.488 | 0.261 | 0.272 | ≥0.125 | ||

| Pos. | 0.116 | 0.193 | 0.120 | 0.110 | ≥0.1 | |

| Neg. | 0.313 | 0.184 | 0.118 | 0.076 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; He, L.; Yang, H.; Xue, W. Experimental Study on the Out-of-Plane Seismic Performance of Shear Walls with Bolted Connections in Nuclear Power Plants. Buildings 2025, 15, 3787. https://doi.org/10.3390/buildings15203787

Jiang J, He L, Yang H, Xue W. Experimental Study on the Out-of-Plane Seismic Performance of Shear Walls with Bolted Connections in Nuclear Power Plants. Buildings. 2025; 15(20):3787. https://doi.org/10.3390/buildings15203787

Chicago/Turabian StyleJiang, Jiafei, Lei He, Han Yang, and Weichen Xue. 2025. "Experimental Study on the Out-of-Plane Seismic Performance of Shear Walls with Bolted Connections in Nuclear Power Plants" Buildings 15, no. 20: 3787. https://doi.org/10.3390/buildings15203787

APA StyleJiang, J., He, L., Yang, H., & Xue, W. (2025). Experimental Study on the Out-of-Plane Seismic Performance of Shear Walls with Bolted Connections in Nuclear Power Plants. Buildings, 15(20), 3787. https://doi.org/10.3390/buildings15203787