Investigation of Waste Steel Fiber Usage Rate and Length Change on Some Fresh State Properties of 3D Printable Concrete Mixtures

Abstract

1. Introduction

2. Materials and Methods

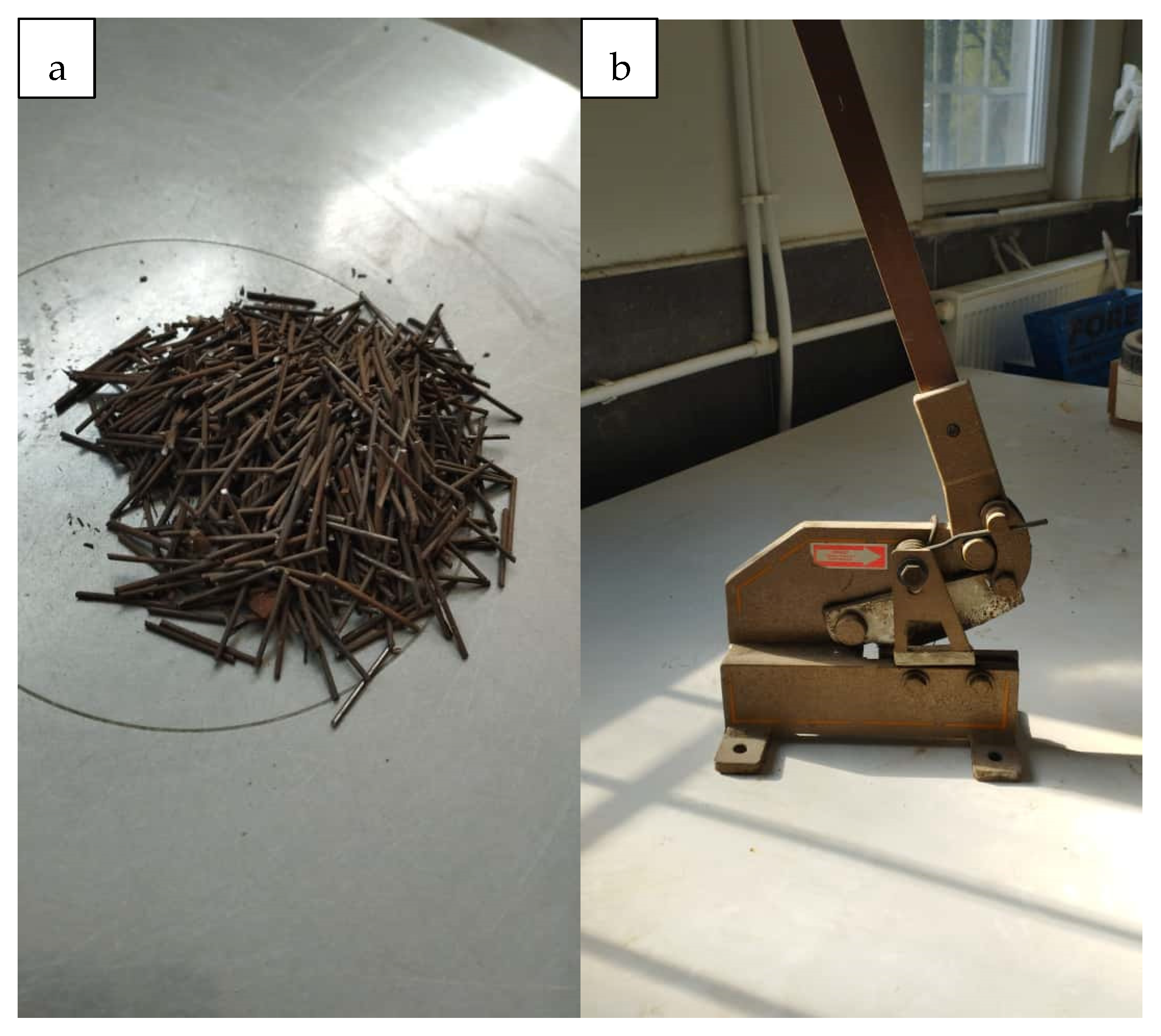

2.1. Materials

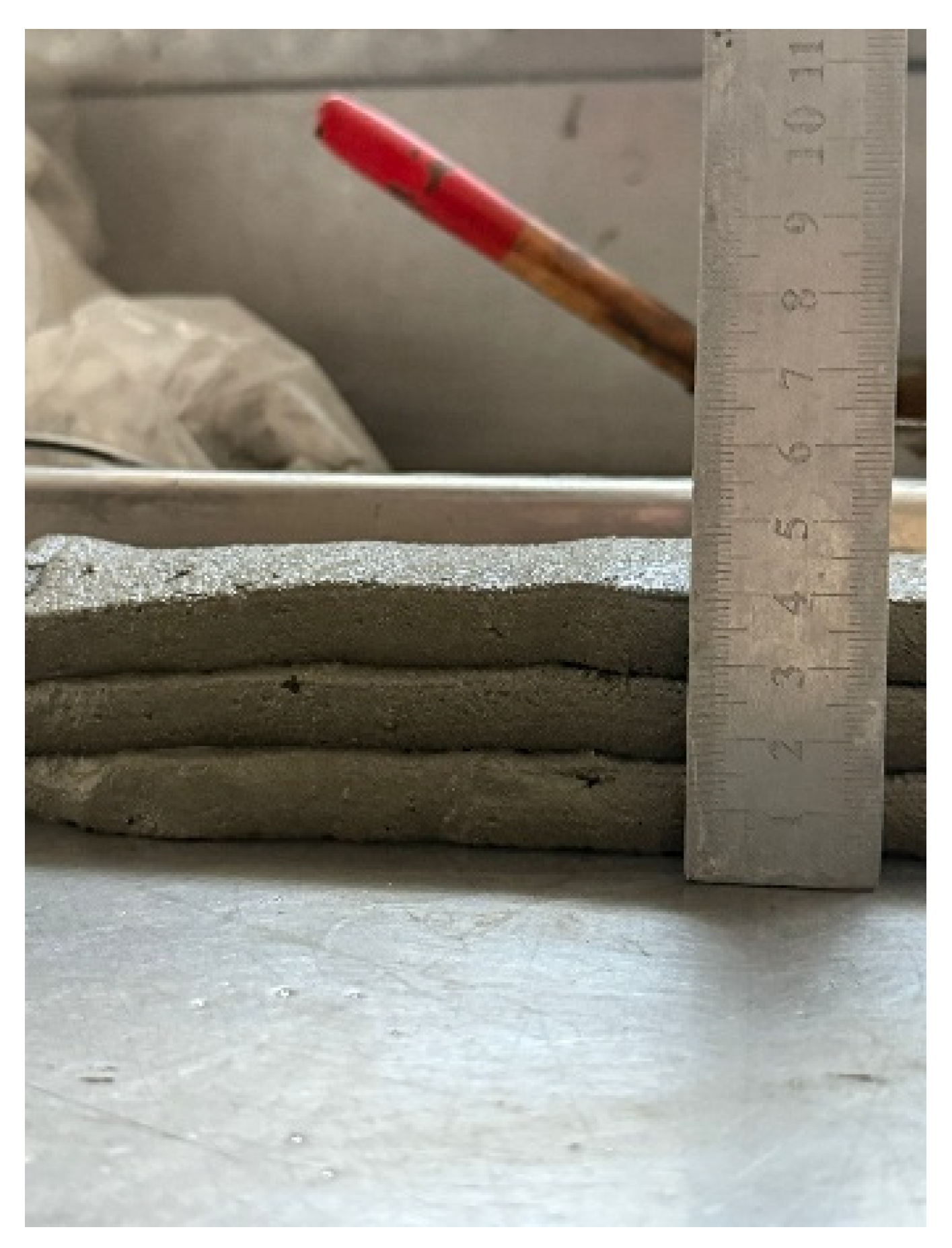

2.2. Preparation of Mixtures and Method

2.2.1. Rheological Measurements

2.2.2. Thixotropic Measurements

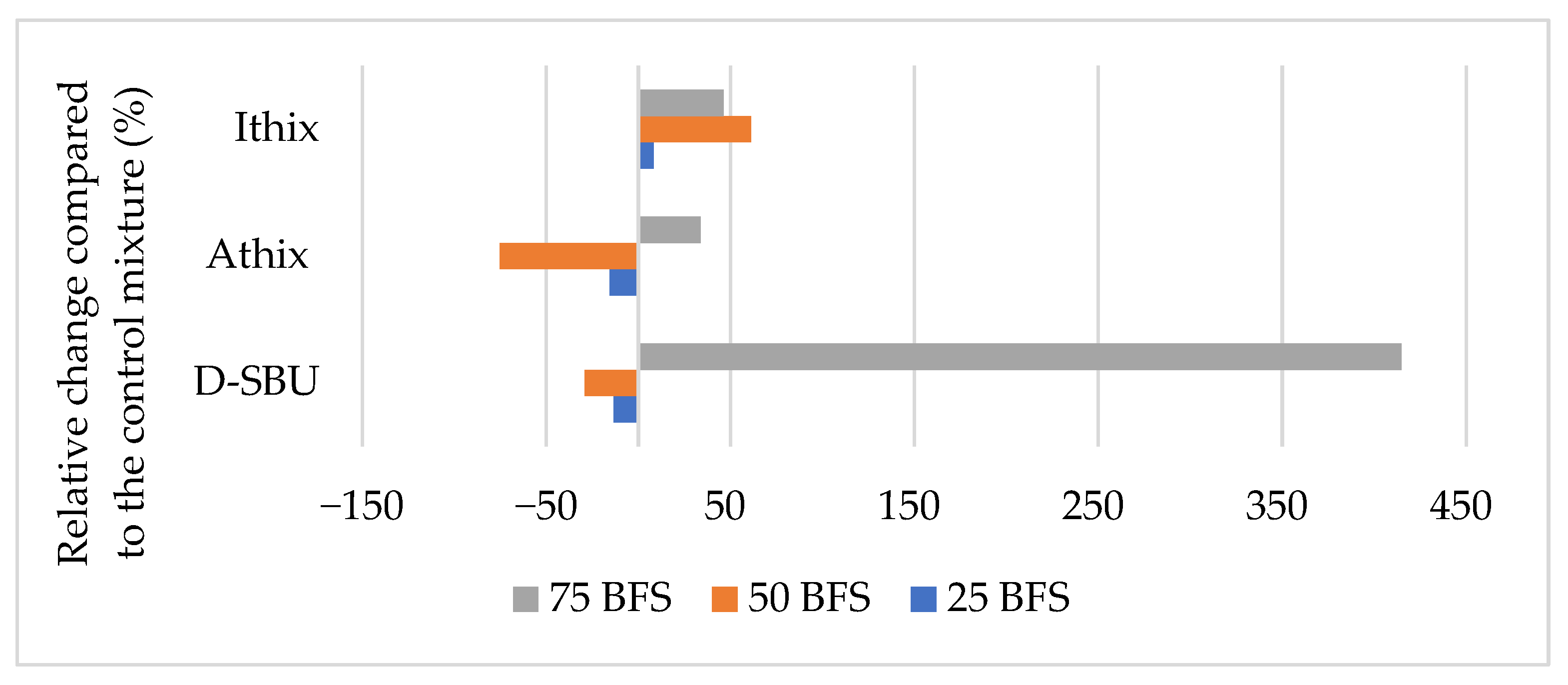

- Dynamic Structural Build-up (D-SBU): This approach, proposed by Zhang et al. [42], was calculated using data obtained from dynamic measurements Equation (2). This method represents the structural state of the material after the dynamic shear history.Here, τ3.p represents the dynamic yield stress (Pa) obtained from the 3rd period (descent curve) and τ2.p from the 2nd period (ascent curve).

- Structural Build-Up Development (Athix): Calculated with data obtained from static measurements to characterize the rate of structural strength increase observed during a given rest period Equation (3).Here, Athix represents the structural build-up development (Pa/s), τ(s,f) represents the static yield stress value (Pa) obtained from the 7th period, τ(s,i) represents the static yield stress value (Pa) obtained from the 5th period, and td represents the waiting time (s).

- Thixotropic Index (Ithix): The method proposed by Qian and Kawashima [43] was used to characterize the time-dependent behavior of shear stress under a constant deformation rate Equation (4). This index represents the ratio of the maximum shear stress required to initiate flow to the shear stress in steady-state flow.Here, Ithix represents the thixotropic index, τi represents the shear stress (Pa) required to initiate flow, and τe represents the steady-state flow shear stress (Pa).

2.2.3. Carbon Emission Assessment

3. Results and Discussion

3.1. Mixing Ratios

3.2. Rheological Properties and Thixotropic Behavior of 3DPC Mixtures

3.2.1. Rheological Properties

3.2.2. Thixotropic Behavior

3.3. Carbon Emissions Assessment

4. Conclusions

- 25% and 50% BFS replacement led to substantial reductions in dynamic yield stress and viscosity relative to the control mix—by 50%/23% and 69%/52%, respectively.

- The effect of waste steel fibers on rheology exhibited a complex interaction with fiber length and BFS content. In mixtures with low BFS contents, short fibers (5 mm) increased rheological resistance as fiber dosage rose, whereas in the presence of longer fibers (10–15 mm) and higher BFS contents, this effect diminished or reversed.

- Thixotropic behavior followed trends similar to rheology. While 25% and 50% BFS reduced structural build-up (D-SBU and Athix), 75% BFS together with silica fume markedly improved it. The high specific surface area of silica fume is considered to enhance cohesion and structural build-up, underpinning this positive effect.

- BFS replacement noticeably reduced water-reducing admixture demand. Owing to increased flowability up to 50% BFS, the admixture dosage decreased, and the 50% BFS mixture achieved optimal properties without any admixture. At 75% BFS, silica fume addition was required to maintain workability. Waste steel fibers did not change the admixture demand needed to satisfy printability criteria.

- BFS replacement demonstrated exceptional potential for environmental sustainability. 25%, 50%, and 75% BFS provided carbon-emission reductions of 23%, 47%, and 71%, respectively. The lowest footprint in the study (179 kgCO2/m3) was obtained for the fiber-free mixture with 75% BFS. Although waste steel fibers offer mechanical benefits, their relatively high embodied carbon led to emission increases between 6% and 43% as fiber dosage rose.

- In this study, the effects of using 0, 25, 50 and 75% BFS by volume and different lengths (5, 10 and 15 mm) of waste steel fibers on the performance of 3DPC mixtures were investigated. The findings of this study depend on the material properties and application method used.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Tittelboom, K.; Mohan, M.K.; Šavija, B.; Keita, E.; Ma, G.; Du, H.; Kruger, J.; Caneda-Martinez, L.; Wang, L.; Bekaert, M.; et al. On the micro-and meso-structure and durability of 3D printed concrete elements. Cem. Concr. Res. 2024, 185, 107649. [Google Scholar] [CrossRef]

- Tu, H.; Wei, Z.; Bahrami, A.; Kahla, N.B.; Ahmad, A.; Özkılıç, Y.O. Recent advancements and future trends in 3D concrete printing using waste materials. Dev. Built Environ. 2023, 16, 100187. [Google Scholar] [CrossRef]

- Ahmed, G.H. A review of “3D concrete printing”: Materials and process characterization, economic considerations and environmental sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Heywood, K.; Nicholas, P. Sustainability and 3D concrete printing: Identifying a need for a more holistic approach to assessing environmental impacts. Archit. Intell. 2023, 2, 12. [Google Scholar] [CrossRef]

- Singh, N.; Puttappa, S.; Ashwath, R.; Ali, H. Sustainable non-conventional concrete 3D printing—A review. Sustainability 2023, 15, 10121. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.-H. 3D concrete printing: A systematic review of rheology, mix designs, mechanical, microstructural, and durability characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef]

- Si, W.; Khan, M.; McNally, C. A Comprehensive Review of Rheological Dynamics and Process Parameters in 3D Concrete Printing. J. Compos. Sci. 2025, 9, 299. [Google Scholar] [CrossRef]

- Zhi, P.; Wu, Y.C.; Yang, Q.; Kong, X.; Xiao, J. Effect of spiral blade geometry on 3D-printed concrete rheological properties and extrudability using discrete element modeling. Autom. Constr. 2022, 137, 104199. [Google Scholar] [CrossRef]

- Chang, Z.; Chen, Y.; Schlangen, E.; Šavija, B. A review of methods on buildability quantification of extrusion-based 3D concrete printing: From analytical modelling to numerical simulation. Dev. Built Environ. 2023, 16, 100241. [Google Scholar] [CrossRef]

- Mishra, S.K.; Perera, B.J.C.; Kumar, N. A review on 3D concrete printing processes, materials, and lifecycle considerations. Constr. Build. Mater. 2025, 356, 129001. [Google Scholar]

- Gao, H.; Jin, L.; Chen, Y.; Chen, Q.; Liu, X.; Yu, Q. Rheological behavior of 3D printed concrete: Influential factors and printability prediction scheme. J. Build. Eng. 2024, 91, 109626. [Google Scholar] [CrossRef]

- Panda, B.; Noor Mohamed, N.A.; Paul, S.C.; Bhagath Singh, G.V.P.; Tan, M.J.; Šavija, B. The effect of material fresh properties and process parameters on buildability and interlayer adhesion of 3D printed concrete. Materials 2019, 12, 2149. [Google Scholar] [CrossRef]

- Rahman, M.; Rawat, S.; Yang, R.C.; Mahil, A.; Zhang, Y.X. A comprehensive review on fresh and rheological properties of 3D printable cementitious composites. J. Build. Eng. 2024, 91, 109719. [Google Scholar] [CrossRef]

- Girskas, G.; Kligys, M. 3D Concrete Printing Review: Equipment, Materials, Mix Design, and Properties. Buildings 2025, 15, 2049. [Google Scholar] [CrossRef]

- Yuan, Y.; Sheng, R.; Yao, X.; Pichler, B.; Mang, H.A.; Zhang, J.L. A three-step development strategy for 3D printable concrete containing coarse aggregates. Case Stud. Constr. Mater. 2025, 22, e04540. [Google Scholar] [CrossRef]

- Murali, G.; Wong, L.S. Waste-driven construction: A state-of-the-art review on the integration of waste in 3D printed concrete in recent researches for sustainable development. J. Build. Eng. 2024, 98, 111268. [Google Scholar] [CrossRef]

- Kaya, Y.; Kobya, V.; Mardani, A.; Mardani, N.; Beytekin, H.E. Effect of grinding conditions on clinker grinding efficiency: Ball size, mill rotation speed, and feed rate. Buildings 2024, 14, 2356. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef] [PubMed]

- Bayqra, S.H.; Mardani-Aghabaglou, A.; Ramyar, K. Physical and mechanical properties of high volume fly ash roller compacted concrete pavement (A laboratory and case study). Constr. Build. Mater. 2022, 314, 125664. [Google Scholar] [CrossRef]

- Yiğit, B.; Salihoğlu, G.; Mardani-Aghabaglou, A.; Salihoğlu, N.K.; Özen, S. Recycling of sewage sludge incineration ashes as construction material. J. Fac. Eng. Archit. Gazi Univ. 2020, 35, 1647–1664. [Google Scholar]

- Şahin, H.G.; Mardani, A. Mechanical properties, durability performance and interlayer adhesion of 3DPC mixtures: A state-of-the-art review. Struct. Concr. 2023, 24, 5481–5505. [Google Scholar] [CrossRef]

- Ulubeyli, G.C.; Artir, R. Properties of hardened concrete produced by waste marble powder. Procedia-Soc. Behav. Sci. 2015, 195, 2181–2190. [Google Scholar] [CrossRef]

- Tsai, C.J.; Huang, R.; Lin, W.T.; Wang, H.N. Mechanical and cementitious characteristics of ground granulated blast furnace slag and basic oxygen furnace slag blended mortar. Mater. Des. 2014, 60, 267–273. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. Performance of sustainable concretes containing very high volume Class-F fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2017, 162, 1407–1417. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, D.; Li, H.; Sun, X.; Zhao, K.; Wang, Y. Effect of FA and GGBFS on compressive strength, rheology, and printing properties of cement-based 3D printing material. Constr. Build. Mater. 2022, 339, 127685. [Google Scholar] [CrossRef]

- Yu, Q.; Zhu, B.; Li, X.; Meng, L.; Cai, J.; Zhang, Y.; Pan, J. Investigation of the rheological and mechanical properties of 3D printed eco-friendly concrete with steel slag. J. Build. Eng. 2023, 72, 106621. [Google Scholar] [CrossRef]

- Bayat, H.; Kashani, A. Analysis of rheological properties and printability of a 3D-printing mortar containing silica fume, hydrated lime, and blast furnace slag. Mater. Today Commun. 2023, 37, 107128. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Material properties of 3D printable high-volume slag cement. In Proceedings of the First International Conference on 3D Construction Printing (3DcP) in Conjunction with the 6th International Conference on Innovative Production and Construction (IPC 2018), Melbourne, Australia, 26–28 November 2018; pp. 26–28. [Google Scholar]

- Arularasi, V.; Thamilselvi, P.; Avudaiappan, S.; Saavedra Flores, E.I.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M. Rheological behavior and strength characteristics of cement paste and mortar with fly ash and GGBS admixtures. Sustainability 2021, 13, 9600. [Google Scholar] [CrossRef]

- Zheng, Z.; Feldman, D. Synthetic fibre-reinforced concrete. Prog. Polym. Sci. 1995, 20, 185–210. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical properties of steel fibre-reinforced concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Le, T.T.; Lampropoulos, A.P. Flexural performance of fibre reinforced concrete made with steel and synthetic fibres. Constr. Build. Mater. 2012, 36, 704–710. [Google Scholar] [CrossRef]

- Arunothayan, A.R.; Nematollahi, B.; Khayat, K.; Ramesh, A.; Sanjayan, J.G. Rheological Characterization of Ultra-High Performance Concrete for 3D Printing. Cem. Concr. Compos. 2023, 136, 104854. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. The effect of fibres in the rheology of self-compacting concrete. Constr. Build. Mater. 2019, 219, 144–153. [Google Scholar] [CrossRef]

- Şahin, H.G.; Akarsu Özenç, A.; Saka Dinç, Z.; Mardani, A.; Eren, S. Investigation of fresh and hardened properties of 3D printable concrete containing ozone-modified carbon fiber. J. Sustain. Cem.-Based Mater. 2025, 14, 534–548. [Google Scholar] [CrossRef]

- Şahin, H.G.; Akgümüş, F.E.; Mardani, A. Mechanical and rheological properties of fiber-reinforced 3D printable concrete; in terms of fiber content and aspect ratio. Struct. Concr. 2024, 26, 1597–1612. [Google Scholar] [CrossRef]

- Şahin, H.G.; Mardani, A.; Beytekin, H.E. Effect of silica fume utilization on structural build-up, mechanical and dimensional stability performance of fiber-reinforced 3D printable concrete. Polymers 2024, 16, 556. [Google Scholar] [CrossRef] [PubMed]

- Şahin, H.G.; Mardani, A.; Mardani, N. Performance requirements and optimum mix proportion of high-volume fly ash 3D printable concrete. Buildings 2024, 14, 2069. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A. Investigation of Cement-Superplasticizer Admixture Compatibility. Ph.D. Thesis, Ege University, İzmir, Turkey, 2016. [Google Scholar]

- Yao, H.; Xie, Z.; Li, Z.; Huang, C.; Yuan, Q.; Zheng, X. The relationship between the rheological behavior and interlayer bonding properties of 3D printing cementitious materials with the addition of attapulgite. Constr. Build. Mater. 2022, 316, 125809. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Z.; Zhu, Y.; Zhang, J.; Ren, Q.; Huang, T. Effects of redispersible polymer powders on the structural build-up of 3D printing cement paste with and without hydroxypropyl methylcellulose. Constr. Build. Mater. 2021, 267, 120551. [Google Scholar] [CrossRef]

- Qian, Y.; Kawashima, S. Distinguishing dynamic and static yield stress of fresh cement mortars through thixotropy. Cem. Concr. Compos. 2018, 86, 288–296. [Google Scholar] [CrossRef]

- Thilakarathna, P.S.M.; Seo, S.; Baduge, K.K.; Lee, H.; Mendis, P.; Foliente, G. Embodied carbon analysis and benchmarking emissions of high and ultra-high strength concrete using machine learning algorithms. J. Clean. Prod. 2020, 262, 121281. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, D.; Ftwi, E.; Ellis, B.R.; Li, V.C. Development of sustainable low carbon Engineered Cementitious Composites with waste polyethylene fiber, sisal fiber and carbonation curing. Resour. Conserv. Recycl. 2023, 197, 107096. [Google Scholar] [CrossRef]

- Mohanty, I.; Saha, P.; Patra, S.R.; Jha, S.K. Waste to valuable resource: Application of copper slag and steel slag in concrete with reduced carbon dioxide emissions. Innov. Infrastruct. Solut. 2023, 8, 122. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Inventory of Carbon Energy: ICE; Sustainable Energy Research Team, Department of Mechanical Engineering, University of Bath: Bath, UK, 2008; Volume 5. [Google Scholar]

- Kuruşcu, A.O.; Girgin, Z.C. Efficiency of structural materials in sustainable design. J. Civ. Eng. Archit. 2014, 8, 1260–1265. [Google Scholar]

- Yang, K.H.; Song, J.K.; Song, K.I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 2013, 39, 265–272. [Google Scholar] [CrossRef]

- Gan, V.J.; Cheng, J.C.; Lo, I.M. A comprehensive approach to mitigation of embodied carbon in reinforced concrete buildings. J. Clean. Prod. 2019, 229, 582–597. [Google Scholar] [CrossRef]

- Asare, G.O.; Barnett, S.; Awinda, K.; Martinson, B. Life cycle assessment of steel fibre-reinforced concrete beams. Cogent Eng. 2024, 11, 2374942. [Google Scholar] [CrossRef]

- Flower, D.J.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Jia, Z.; Zhou, M.; Chen, Y.; Wang, W.; Ma, L.; Chen, Y.; Liu, C.; Zhang, Y. Effect of steel fiber shape and content on printability, microstructure and mechanical properties of 3D printable high strength cementitious materials. Case Stud. Constr. Mater. 2024, 20, e03080. [Google Scholar] [CrossRef]

- Pham, L.; Tran, P.; Sanjayan, J. Steel fibres reinforced 3D printed concrete: Influence of fibre sizes on mechanical performance. Constr. Build. Mater. 2020, 250, 118785. [Google Scholar] [CrossRef]

- Singh, A.; Liu, Q.; Xiao, J.; Lyu, Q. Mechanical and macrostructural properties of 3D printed concrete dosed with steel fibers under different loading direction. Constr. Build. Mater. 2022, 323, 126616. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.İ. Utilization and efficiency of ground granulated blast furnace slag on concrete properties–A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Park, C.K.; Noh, M.H.; Park, T.H. Rheological properties of cementitious materials containing mineral admixtures. Cem. Concr. Res. 2005, 35, 842–849. [Google Scholar] [CrossRef]

- He, T.; Li, Z.; Zhao, S.; Zhao, X.; Qu, X. Study on the particle morphology, powder characteristics and hydration activity of blast furnace slag prepared by different grinding methods. Constr. Build. Mater. 2021, 270, 121445. [Google Scholar] [CrossRef]

- Johari, M.M.; Brooks, J.J.; Kabir, S.; Rivard, P. Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr. Build. Mater. 2011, 25, 2639–2648. [Google Scholar] [CrossRef]

- ACI. Slag Cement in Concrete and Mortar; 233 R03; ACI: Detroit, MI, USA, 2000. [Google Scholar]

- De Belie, N.; Soutsos, M.; Gruyaert, E. Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials; Springer: Cham, Switzerland, 2018; Volume 25. [Google Scholar]

- Salleh, N.; Jamalulail, N.S.; Hamid, N.A.A.; Jamellodin, Z.; Majid, M.A.; Suliman, N.H. New technology in 3D concrete printing by using ground granulated blast-furnace slag: A review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1200, 12007. [Google Scholar] [CrossRef]

- Doğruyol, M.; Ayhan, E.; Karaşin, A. Effect of waste steel fiber use on concrete behavior at high temperature. Case Stud. Constr. Mater. 2024, 20, e03051. [Google Scholar] [CrossRef]

- Mohammad, S.A.; Krishna, T.N.C.; Saketh, T.; Ganesh, C.Y.; Sathyan, D. Fresh and hardened state properties of waste tire fiber and steel fiber reinforced concrete. Mater. Today Proc. 2023, 80, 443–448. [Google Scholar] [CrossRef]

- Figueiredo, A.D.D.; Ceccato, M.R. Workability analysis of steel fiber reinforced concrete using slump and Ve-Be test. Mater. Res. 2015, 18, 1284–1290. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; Taha, M.R. Flow characteristics and acceptance criteria of fiber-reinforced self-compacted concrete (FR-SCC). Constr. Build. Mater. 2012, 27, 585–596. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Micelli, F.; Colonna, D.; Aiello, M.A. Concrete reinforced with recycled steel fibers from end of life tires: Mix-design and application. Key Eng. Mater. 2016, 711, 224–231. [Google Scholar]

- Wang, W.; Shen, A.; Lyu, Z.; He, Z.; Nguyen, K.T. Fresh and rheological characteristics of fiber reinforced concrete—A review. Constr. Build. Mater. 2021, 296, 123734. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Q.; Lombois-Burger, H.; Jia, Z.; Zhang, Z.; Niu, G.; Zhang, Y. Pore structure, internal relative humidity, and fiber orientation of 3D printed concrete with polypropylene fiber and their relation with shrinkage. J. Build. Eng. 2022, 61, 105250. [Google Scholar] [CrossRef]

- Gueciouer, D.; Youcef, G.; Tarek, N. Rheological and mechanical optimization of a steel fiber reinforced self-compacting concrete using the design of experiments method. Eur. J. Environ. Civ. Eng. 2022, 26, 1097–1117. [Google Scholar] [CrossRef]

- Grist, E.R.; Paine, K.A.; Heath, A.; Norman, J.; Pinder, H. Compressive strength development of binary and ternary lime–pozzolan mortars. Mater. Des. 2013, 52, 514–523. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete—A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Srinivas, D.; Dey, D.; Panda, B.; Sitharam, T.G. Printability, Thermal and Compressive Strength Properties of Cementitious Materials: A Comparative Study with Silica Fume and Limestone. Materials 2022, 15, 8607. [Google Scholar] [CrossRef]

- Inozemtcev, A.; Korolev, E.; Qui, D.T. Study of mineral additives for cement materials for 3D-printing in construction. IOP Conf. Ser. Mater. Sci. Eng. 2018, 365, 32009. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Xie, Y.; Zhang, Z.; Banthia, N. Unraveling pore structure alternations in 3D-printed geopolymer concrete and corresponding impacts on macro-properties. Addit. Manuf. 2022, 59, 103137. [Google Scholar] [CrossRef]

- Geng, Z.; She, W.; Zuo, W.; Lyu, K.; Pan, H.; Zhang, Y.; Miao, C. Layer-interface properties in 3D printed concrete: Dual hierarchical structure and micromechanical characterization. Cem. Concr. Res. 2020, 138, 106220. [Google Scholar] [CrossRef]

- Kaya, Y.; Kobya, V.; Kaya, Y.; Mardani, A.; Ramyar, K. Synthesis, characterization, and efficiency evaluation of next-generation grinding aids modified with organic acids. Constr. Build. Mater. 2025, 493, 143278. [Google Scholar] [CrossRef]

- Munro, D.; Di Benedetto, G.; Graham, M.; Jans-Singh, M.; Turpin, M.; Kanavaris, F. The assessment of the embodied carbon of resource-constrained materials including ground granulated blast-furnace slag (GGBS) and ferrous scrap. Structures 2025, 78, 109175. [Google Scholar] [CrossRef]

- Wang, Y.S.; Cho, H.K.; Wang, X.Y. Mixture optimization of sustainable concrete with silica fume considering CO2 emissions and cost. Buildings 2022, 12, 1580. [Google Scholar] [CrossRef]

- Roshan, N.; Ghalehnovi, M.; Pakzad, S.S. Recycled steel fiber for fiber reinforced concrete production: Fresh and hardened properties, cost, and ecological assessments. J. Build. Pathol. Rehabil. 2023, 8, 24. [Google Scholar] [CrossRef]

| Oxides (%) | Cement | Blast Furnace Slag | |

|---|---|---|---|

| SiO2 | 18 | 35.5 | |

| Al2O3 | 4.75 | 12.4 | |

| Fe2O3 | 3.58 | 1.5 | |

| CaO | 63 | 38.9 | |

| MgO | 1.4 | 5.05 | |

| Na2O + 0.658 K2O | 0.7 | 1.07 | |

| SO3 | 3.11 | 1.67 | |

| Specific gravity | 3.06 | 2.5 | |

| Specific Surface Area (cm2/g) | 3441 | 4950 | |

| Compressive Strength (MPa) | 7-day | 42.8 | - |

| 28-day | 51.8 | - | |

| Pozzolanic Activity Index (%) | 28-day | - | 80 |

| 90-day | - | 90 | |

| Setting Time (min) | İnital | 170 | - |

| Final | 240 | - | |

| Admixture | Density (g/cm3) | Solid Content (%) | pH | Chlorine Content (%) | Alkaline Content, Na2O (%) |

|---|---|---|---|---|---|

| Polycarboxylate-ether based high range water reducing | 1.060 | 32 | 2–5 | <0.1 | <10 |

| Fiber Type | Fiber Length (mm) | Tensile Capacity (MPa) | Modulus of Elasticity (MPa) | Specific Gravity |

|---|---|---|---|---|

| Steel | 5, 10, 15 | 1500 | 200,000 | 7.8 |

| Mixing Component | Embodied Carbon (kgCO2/kg) | |

|---|---|---|

| Minimum Value | Maximum Value | |

| Cement | 0.804 [44] | 0.94 [45] |

| BFS | 0.00 [46] | 0.07 [47] |

| Silica Fume | 0.014 [48] | 0.024 [49] |

| Fine Aggregate | 0.0026 [49] | 0.017 [44] |

| Water | 0 [47] | 0.001 [50] |

| Steel Fiber | 0.43 [47] | 1.59 [51] |

| Water Reducing Admixture | 0.0000052 [52] | 2.388 [44] |

| Mixture Name | Mixture No | Cement (kg/m3) | BFS (kg/m3) | Aggregate | Water Reducing Admixture (kg/m3) | Fiber Length (cm) | Fiber Usage Amount (kg/m3) | Silica Fume (kg/m3) | w/b | Extrudability | Buildability | Shape Stability | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dmax (mm) | Specific Gravity | Dosage (kg/m3) | ||||||||||||

| K | 1 | 700 | 0 | 2 | 2540 | 1216.1 | 5 | 0 | 0 | 0 | 1.74 | * 0 | 0 | 0 |

| 2 | 700 | 0 | 2 | 2540 | 1209 | 3 | 0 | 0 | 0 | 1.73 | ** 1 | 1 | 0 | |

| 3 | 700 | 0 | 2 | 2540 | 1211.3 | 2 | 0 | 0 | 0 | 1.73 | 1 | 1 | 1 | |

| K-0.5-0.5 | 4 | 700 | 0 | 2 | 2540 | 1198.6 | 2 | 0.5 | 39 | 0 | 1.71 | 1 | 1 | 1 |

| K-1-0.5 | 5 | 700 | 0 | 2 | 2540 | 1185.8 | 2 | 0.5 | 78 | 0 | 1.69 | 1 | 1 | 1 |

| K-0.5-1 | 6 | 700 | 0 | 2 | 2540 | 1198.6 | 2 | 1 | 39 | 0 | 1.71 | 1 | 1 | 1 |

| K-1-1 | 7 | 700 | 0 | 2 | 2540 | 1185.8 | 2 | 1 | 78 | 0 | 1.69 | 1 | 1 | 1 |

| K-0.5-1.5 | 8 | 700 | 0 | 2 | 2540 | 1198.6 | 2 | 1.5 | 39 | 0 | 1.71 | 1 | 1 | 1 |

| K-1-1.5 | 9 | 700 | 0 | 2 | 2540 | 1185.8 | 2 | 1.5 | 78 | 0 | 1.69 | 1 | 1 | 1 |

| 25 | 10 | 525 | 143 | 2 | 2540 | 1211.3 | 2 | 0 | 0 | 0 | 1.81 | 1 | 0 | 0 |

| 11 | 525 | 143 | 2 | 2540 | 1211.8 | 1.8 | 0 | 0 | 0 | 1.81 | 1 | 0 | 0 | |

| 12 | 525 | 143 | 2 | 2540 | 1212 | 1.65 | 0 | 0 | 0 | 1.81 | 1 | 1 | 0 | |

| 13 | 525 | 143 | 2 | 2540 | 1212.5 | 1.5 | 0 | 0 | 0 | 1.82 | 1 | 1 | 1 | |

| 25-0.5-0.5 | 14 | 525 | 143 | 2 | 2540 | 1199.8 | 1.5 | 0.5 | 39 | 0 | 1.80 | 1 | 1 | 1 |

| 25-1-0.5 | 15 | 525 | 143 | 2 | 2540 | 1187 | 1.5 | 0.5 | 78 | 0 | 1.78 | 1 | 1 | 1 |

| 25-0.5-1 | 16 | 525 | 143 | 2 | 2540 | 1199.8 | 1.5 | 1 | 39 | 0 | 1.80 | 1 | 1 | 1 |

| 25-1-1 | 17 | 525 | 143 | 2 | 2540 | 1187 | 1.5 | 1 | 78 | 0 | 1.78 | 1 | 1 | 1 |

| 25-0.5-1.5 | 18 | 525 | 143 | 2 | 2540 | 1199.8 | 1.5 | 1.5 | 39 | 0 | 1.80 | 1 | 1 | 1 |

| 25-1-1.5 | 19 | 525 | 143 | 2 | 2540 | 1187 | 1.5 | 1.5 | 78 | 0 | 1.78 | 1 | 1 | 1 |

| 50 | 20 | 350 | 285.9 | 2 | 2540 | 1212.5 | 1.5 | 0 | 0 | 0 | 1.91 | 1 | 0 | 0 |

| 21 | 350 | 285.9 | 2 | 2540 | 1213.8 | 1 | 0 | 0 | 0 | 1.91 | 1 | 1 | 0 | |

| 22 | 350 | 285.9 | 2 | 2540 | 1215 | 0.5 | 0 | 0 | 0 | 1.91 | 1 | 1 | 0 | |

| 23 | 350 | 285.9 | 2 | 2540 | 1216.1 | 0 | 0 | 0 | 0 | 1.91 | 1 | 1 | 1 | |

| 50-0.5-0.5 | 24 | 350 | 285.9 | 2 | 2540 | 1203.4 | 0 | 0.5 | 39 | 0 | 1.89 | 1 | 1 | 1 |

| 50-1-0.5 | 25 | 350 | 285.9 | 2 | 2540 | 1190.6 | 0 | 0.5 | 78 | 0 | 1.87 | 1 | 1 | 1 |

| 50-0.5-1 | 26 | 350 | 285.9 | 2 | 2540 | 1203.4 | 0 | 1 | 39 | 0 | 1.89 | 1 | 1 | 1 |

| 50-1-1 | 27 | 350 | 285.9 | 2 | 2540 | 1190.6 | 0 | 1 | 78 | 0 | 1.87 | 1 | 1 | 1 |

| 50-0.5-1.5 | 28 | 350 | 285.9 | 2 | 2540 | 1203.4 | 0 | 1.5 | 39 | 0 | 1.89 | 1 | 1 | 1 |

| 50-1-1.5 | 29 | 350 | 285.9 | 2 | 2540 | 1190.6 | 0 | 1.5 | 78 | 0 | 1.87 | 1 | 1 | 1 |

| 75 | 30 | 175.2 | 429.4 | 2 | 2540 | 1215.5 | 0 | 0 | 0 | 0 | 2.01 | 1 | 0 | 0 |

| 31 | 175.2 | 377.9 | 2 | 2540 | 1215.5 | 0 | 0 | 0 | 43.3 | 2.04 | 0 | 0 | 0 | |

| 32 | 175.2 | 412.2 | 2 | 2540 | 1215.5 | 0 | 0 | 0 | 14.4 | 2.02 | 1 | 1 | 0 | |

| 33 | 175.2 | 395 | 2 | 2540 | 1215.5 | 0 | 0 | 0 | 28.9 | 2.03 | 1 | 1 | 1 | |

| 75-0.5-0.5 | 34 | 175.2 | 395 | 2 | 2540 | 1202.8 | 0 | 0.5 | 39 | 28.9 | 2.01 | 1 | 1 | 1 |

| 75-1-0.5 | 35 | 175.2 | 395 | 2 | 2540 | 1190 | 0 | 0.5 | 78 | 28.9 | 1.99 | 1 | 1 | 1 |

| 75-0.5-1 | 36 | 175.2 | 395 | 2 | 2540 | 1202.8 | 0 | 1 | 39 | 28.9 | 2.01 | 1 | 1 | 1 |

| 75-1-1 | 37 | 175.2 | 395 | 2 | 2540 | 1190 | 0 | 1 | 78 | 28.9 | 1.99 | 1 | 1 | 1 |

| 75-0.5-1.5 | 38 | 175.2 | 395 | 2 | 2540 | 1202.8 | 0 | 1.5 | 39 | 28.9 | 2.01 | 1 | 1 | 1 |

| 75-1-1.5 | 39 | 175.2 | 395 | 2 | 2540 | 1190 | 0 | 1.5 | 78 | 28.9 | 1.99 | 1 | 1 | 1 |

| Mixture | Dynamic Yield Stress (Pa) | Viscosity (Pa·s) |

|---|---|---|

| K | 130.52 | 13.47 |

| 25 | 64.5 | 10.3 |

| 50 | 39.57 | 6.43 |

| 75 | 108.59 | 6.89 |

| K-0.5-0.5 | 201.81 | 19.03 |

| K-1-0.5 | 245.75 | 19.53 |

| 25-0.5-0.5 | 86.69 | 14.8 |

| 25-1-0.5 | 77.43 | 13.81 |

| 50-0.5-0.5 | 118.54 | 14.07 |

| 50-1-0.5 | 113.56 | 13.27 |

| 75-0.5-0.5 | 154.24 | 13.59 |

| 75-1-0.5 | 85.2 | 8.16 |

| K-0.5-1 | 88.47 | 14.53 |

| K-1-1 | 84.45 | 11.24 |

| 25-0.5-1 | 70.43 | 11.69 |

| 25-1-1 | 124.09 | 14.78 |

| 50-0.5-1 | 123.12 | 15.05 |

| 50-1-1 | 62.04 | 11.72 |

| 75-0.5-1 | 88.04 | 11.85 |

| 75-1-1 | 200.35 | 13.93 |

| K-0.5-1.5 | 155.17 | 15.93 |

| K-1-1.5 | 104.63 | 15.61 |

| 25-0.5-1.5 | 55.27 | 7.42 |

| 25-1-1.5 | 56.2 | 10.5 |

| 50-0.5-1.5 | 67.75 | 8.17 |

| 50-1-1.5 | 65.05 | 7.69 |

| 75-0.5-1.5 | 97.76 | 8.13 |

| 75-1-1.5 | 99.88 | 12.31 |

| Mixture | D-SBU | Athix (Pa/s) | Ithix |

|---|---|---|---|

| K | 0.82 | 0.89 | 1.21 |

| 25 | 0.71 | 0.75 | 1.31 |

| 50 | 0.58 | 0.22 | 1.95 |

| 75 | 2.52 | 1.04 | 1.49 |

| K-0.5-0.5 | 1.17 | 1.03 | 1.4 |

| K-1-0.5 | 1.3 | 4.78 | 1.23 |

| 25-0.5-0.5 | 0.82 | 3.56 | 1.25 |

| 25-1-0.5 | 0.69 | 2.36 | 1.47 |

| 50-0.5-0.5 | 0.57 | 3.09 | 1.34 |

| 50-1-0.5 | 0.45 | 1.94 | 1.34 |

| 75-0.5-0.5 | 0.98 | 3.19 | 1.44 |

| 75-1-0.5 | 1.3 | 0.72 | 1.45 |

| K-0.5-1 | 0.97 | 2.59 | 1.2 |

| K-1-1 | 0.88 | 1.03 | 1.47 |

| 25-0.5-1 | 0.64 | 0.131 | 1.19 |

| 25-1-1 | 0.76 | 4.38 | 1.35 |

| 50-0.5-1 | 0.68 | 0.08 | 1.3 |

| 50-1-1 | 0.22 | 1.3 | 1.3 |

| 75-0.5-1 | 0.91 | 5.58 | 1.8 |

| 75-1-1 | 1.5 | −0.09 | 1.37 |

| K-0.5-1.5 | 0.83 | 3.77 | 1.3 |

| K-1-1.5 | 0.98 | 9.32 | 1.67 |

| 25-0.5-1.5 | 1.02 | 1.09 | 1.42 |

| 25-1-1.5 | 0.52 | 2.4 | 1.41 |

| 50-0.5-1.5 | 1.08 | 2.04 | 1.59 |

| 50-1-1.5 | 0.99 | 3.71 | 2.05 |

| 75-0.5-1.5 | 1.1 | −2.53 | 1.41 |

| 75-1-1.5 | 1.16 | 5.76 | 1.4 |

| Mixture | Standard Deviation | Coefficient of Variation (%) |

|---|---|---|

| K | 83.2 | 13.3 |

| 25 | 72.6 | 15.2 |

| 50 | 60.4 | 18.4 |

| 75 | 49.1 | 27.4 |

| K-0.5-0.5 | 115.1 | 17.3 |

| K-1-0.5 | 146.9 | 20.9 |

| 25-0.5-0.5 | 104.5 | 20.3 |

| 25-1-0.5 | 136.4 | 24.6 |

| 50-0.5-0.5 | 92.2 | 25.2 |

| 50-1-0.5 | 124.1 | 30.6 |

| 75-0.5-0.5 | 81.0 | 37.1 |

| 75-1-0.5 | 112.9 | 43.8 |

| K-0.5-1 | 115.1 | 17.3 |

| K-1-1 | 146.9 | 20.9 |

| 25-0.5-1 | 104.5 | 20.3 |

| 25-1-1 | 136.4 | 24.6 |

| 50-0.5-1 | 92.2 | 25.2 |

| 50-1-1 | 124.1 | 30.6 |

| 75-0.5-1 | 81.0 | 37.1 |

| 75-1-1 | 112.9 | 43.8 |

| K-0.5-1.5 | 115.1 | 17.3 |

| K-1-1.5 | 146.9 | 20.9 |

| 25-0.5-1.5 | 104.5 | 20.3 |

| 25-1-1.5 | 136.4 | 24.6 |

| 50-0.5-1.5 | 92.2 | 25.2 |

| 50-1-1.5 | 124.1 | 30.6 |

| 75-0.5-1.5 | 81.0 | 37.1 |

| 75-1-1.5 | 112.9 | 43.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akgümüş, F.E.; Şahin, H.G.; Mardani, A. Investigation of Waste Steel Fiber Usage Rate and Length Change on Some Fresh State Properties of 3D Printable Concrete Mixtures. Buildings 2025, 15, 3731. https://doi.org/10.3390/buildings15203731

Akgümüş FE, Şahin HG, Mardani A. Investigation of Waste Steel Fiber Usage Rate and Length Change on Some Fresh State Properties of 3D Printable Concrete Mixtures. Buildings. 2025; 15(20):3731. https://doi.org/10.3390/buildings15203731

Chicago/Turabian StyleAkgümüş, Fatih Eren, Hatice Gizem Şahin, and Ali Mardani. 2025. "Investigation of Waste Steel Fiber Usage Rate and Length Change on Some Fresh State Properties of 3D Printable Concrete Mixtures" Buildings 15, no. 20: 3731. https://doi.org/10.3390/buildings15203731

APA StyleAkgümüş, F. E., Şahin, H. G., & Mardani, A. (2025). Investigation of Waste Steel Fiber Usage Rate and Length Change on Some Fresh State Properties of 3D Printable Concrete Mixtures. Buildings, 15(20), 3731. https://doi.org/10.3390/buildings15203731