3.3.2. Spatial Characteristics of Traditional Hani Dwellings in the Samaba Terraces Area

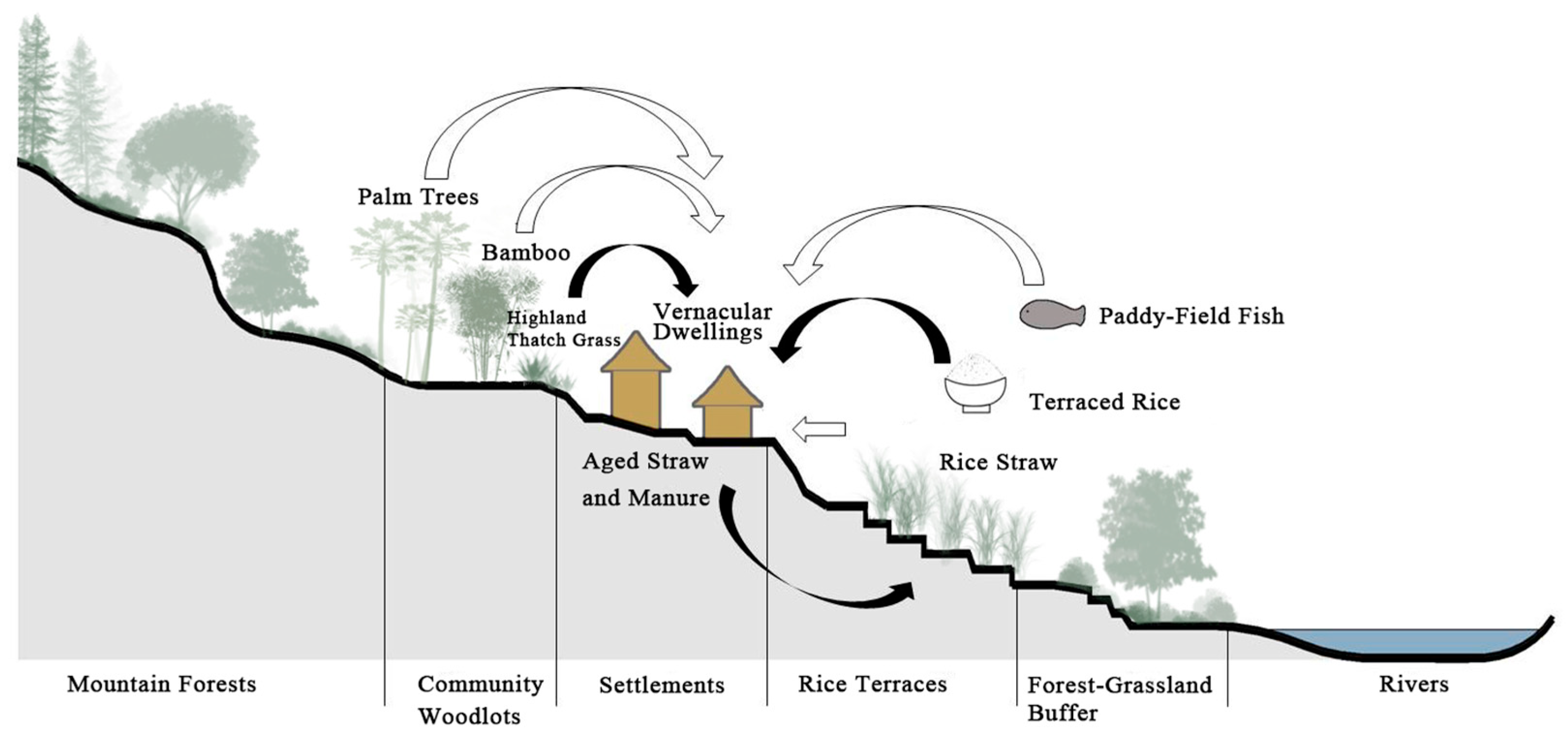

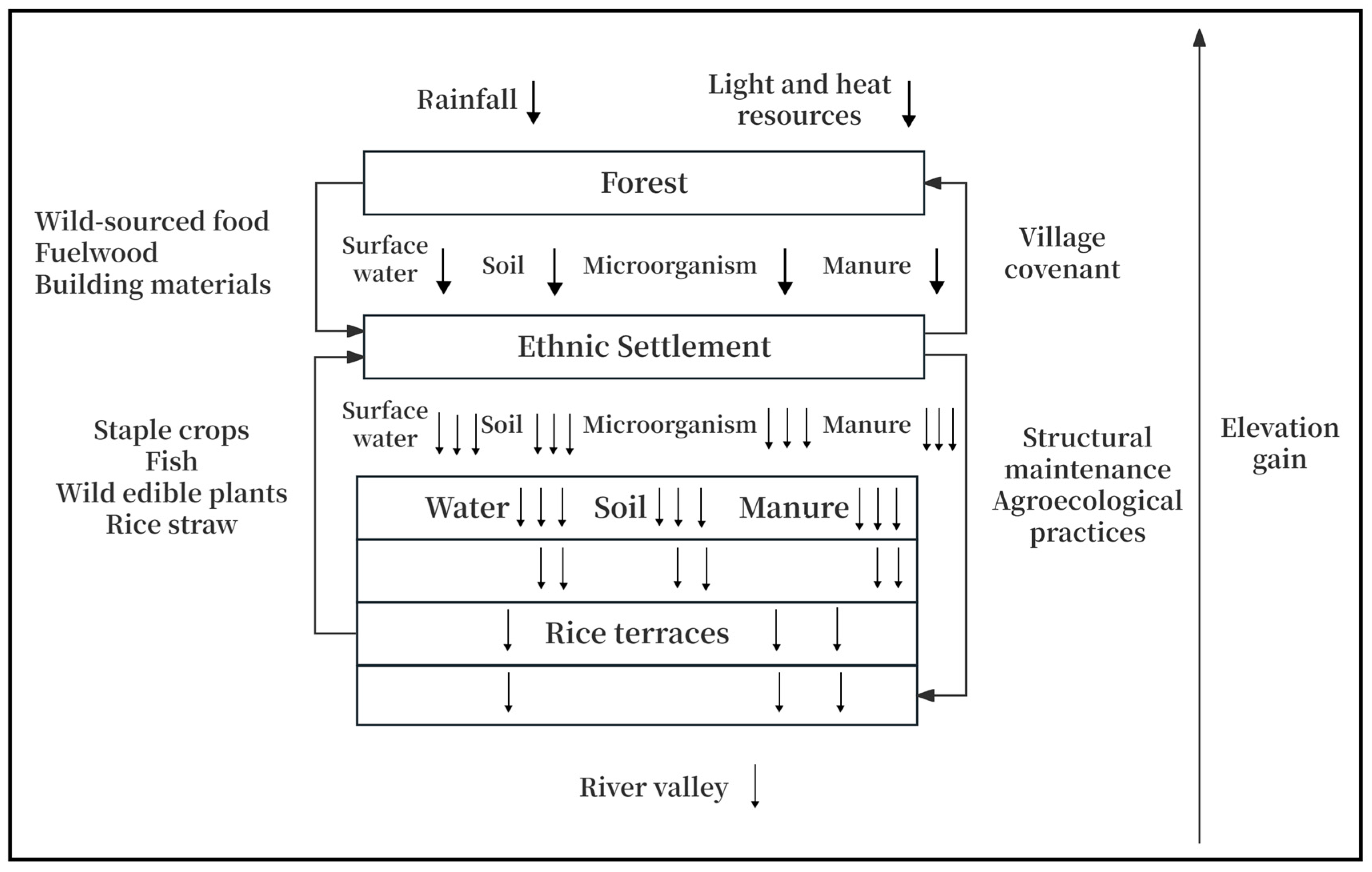

Traditional Hani dwellings in the Samaba Terraces region exhibit a vertically stratified spatial organization corresponding to local production and lifestyle, comprising three distinct tiers from base to summit (

Figure 7 and

Figure 8).

The ground-level utility space forms an elevated substructure dedicated to production activities, housing grain storage and processing areas, agricultural tool repositories, and livestock pens with adjacent fodder preparation zones. Directly above this, the primary living level serves as the core domestic domain, integrating communal spaces for ancestral worship, dining, and social gatherings with private bedroom quarters.

Crowning the structure, the rooftop multipurpose platform functions as a hybrid operational zone for crop drying, grain storage, household crafts, and domestic chores. Meanwhile, the veranda (lángshà) extending from the main building emerges as an architecturally fluid transitional space—termed a “gray zone”—that dynamically accommodates supplementary activities ranging from daily meals and handicraft production to social interaction and auxiliary household tasks.

The configuration of these functional spaces is profoundly dictated by topographical conditions. In areas with steep terrain gradients, where buildable land is severely constrained, residents systematically employ vertical stratification to maximize spatial efficiency—a practice vividly demonstrated during fieldwork in Longshi Village. One Hani homeowner recounted with palpable pride:

“Take a close look—how many stories does my house appear to have? You might count two, but in truth, it rises through four distinct levels …”

His description reveals the sophisticated layering within the main structure: the ground tier shelters livestock; the second level accommodates daily living and sleeping quarters; while the rooftop complex (incorporating an intermediate loft) serves dual purposes for grain storage and animal fodder preservation. This case exemplifies how vertical functional zoning has evolved into an ingrained architectural paradigm among communities navigating extreme mountainous constraints—transforming spatial limitations into multidimensional ingenuity.

Architecturally, the traditional Hani dwellings in the Samaba area represent a courtyard-style flat-roofed adobe complex. The load-bearing exterior walls of the principal wing are constructed of rammed earth, with partition walls filled by adobe bricks. Internally, its rammed-earth flooring is supported by timber framing.

The secondary wing features rammed-earth exterior walls facing outward, while its courtyard-facing wall employs wooden plank partitions. Similarly, the rammed-earth flooring within this wing is supported by timber framing.

3.3.3. Planar Layout of Traditional Hani Dwellings in the Samaba Terraces Area

Field investigations reveal three primary planar configurations for traditional Hani dwellings in this region: independent-type, L-shaped, and courtyard-type layouts.

Independent-type: Characterized by a compact rectangular footprint, this independent-type configuration typically manifests as a three-bay, two-story structure. The ground tier serves exclusively for livestock husbandry, such as cattle, sheep and pigs, while the elevated living quarters—situated approximately 1.2 m above the courtyard level—organize domestic spaces with ritual precision: the central bay houses the ancestral hall and communal space, flanked by a left-bay kitchen featuring an integral hearth and a right-bay bedroom.

Crowning the structure, the double-pitched tiled roof shelters a two-level attic complex. The primary loft stores staple crops like paddy rice, corn, and potatoes, while beneath it lies a fireproofed rammed-earth sub-loft dedicated to hay storage. Strategically placed apertures on both gable walls facilitate ventilation and enable external access for cattle feeding—exemplifying pragmatic resource management.

A defining architectural element is the 2-m-deep veranda lángshà), functioning as a semi-sheltered transition zone that dynamically extends cooking, craftwork, and social activities into the courtyard domain (

Figure 9).

L-Shaped Dwelling: This configuration integrates a three-bay, two-story principal wing with an adjoining secondary wing, maintaining functional parallels to the independent-type dwelling in its main structure. The secondary wing rises two stories, its floor level elevated 0.1–0.2 m above the inner courtyard. The ground tier stands as an approximately 2-m-high stilted space for agricultural tool and miscellaneous storage.

Access to the secondary wing’s upper level is gained via a 0.9-m-high transition from the principal wing’s second-story veranda, functioning either as junior family bedrooms or auxiliary storage. This L-shaped morphology represents an adaptive expansion—likely responding to household growth or spatial demands—where the secondary wing extends laterally from the principal structure.

Crucially, the two wings connect exclusively through the veranda space fronting the principal wing, while domestic activities unfold within the open courtyard. This arrangement sustains the dwelling’s outward-oriented character, maintaining visual and functional engagement with the surrounding landscape (

Figure 10).

Courtyard-type: As the most prevalent traditional dwelling in the region, this tripartite courtyard configuration represents the architectural crystallization of earlier independent and L-shaped forms. Compact in plan and enclosed by minimally fenestrated earthen walls, its core centers on the principal wing a 9–11 m wide, four-tiered structure comprising a ground-level livestock space, two main stories mirroring the independent-type layout, and a fireproofed loft cap.

Flanking this are two secondary wings, each spanning 6–7 m in width and 2.4–3 m in depth, featuring two-story flat-roofed construction. Their elevated ground tiers serve as stilted storage for tools or animal pens, while upper levels accommodate bedrooms and granaries. Vertical circulation hinges on a single-flight timber staircase ascending through a 0.8 m kitchen-floor access opening adjacent to the central bay. The roof complex is punctuated by a 0.6 × 1.4 m courtyard-facing aperture, leading to a 0.5 m-high transition onto the unified earthen rooftops of the veranda and secondary wings—strategically leveraged for highland crop drying.

Exemplified by Chen Zhouwang’s residence in Longshi Village, this typology manifests sophisticated topographic adaptation: the kula aligns parallel to contour lines in west-east orientation facing terraces, enclosing an eastern courtyard. Entry occurs through the southern secondary wing’s stilted space into the central courtyard framed by all three wings. Functionally integrating livestock, human habitation, and agricultural processing through tiered spatial logic, this layout epitomizes Hani vernacular intelligence in reconciling familial needs with mountainous constraints (

Figure 11 and

Figure 12).

3.3.4. Construction Techniques

Xu Jun and Zhou Ling’s seminal study Research on the Construction System and Renewal Design of Yuanyang Hani Traditional Dwellings posits that the most defining characteristic of Hani vernacular architecture lies in its authentic material expression—where each substance reveals its intrinsic properties through uncompromised structural honesty [

9]. This mastery of indigenous materials stems from generations of profound sensory engagement with local resources. Field investigations confirm near-identical material selection principles between Hani communities in Samaba Terraces and those in Yuanyang, demonstrating cross-regional cultural continuity.

The strategic deployment of locally sourced materials manifests a dual wisdom: it embodies intuitive ecological pragmatism while exemplifying context-responsive construction. This approach rigorously adheres to the maxim of site-specific sourcing and on-site procurement—transforming immediate environmental offerings into architectural solutions. As cataloged in

Table 1, traditional Hani dwellings in Samaba employ eight fundamental materials: rammed earth for load-bearing walls, fieldstone for foundations, adobe bricks for partitions, timber for structural framing, bamboo for auxiliary elements, rice straw for binding, highland thatch grass for roofing, and small blue-grey tiles for weather protection (

Table 1).

- (1)

Timber Framing Systems

Field investigations indicate that Hani communities in the Samaba Terraces sustainably manage community woodlots between villages and forests—primarily cultivating fast-maturing palm and bamboo species that reach harvest readiness within 10–15 years. These dedicated plantations supply over 80% of construction timber, effectively eliminating old-growth deforestation through customary conservation practices that critically safeguard local ecosystems.

Architecturally, while spatial layouts reflect Han Chinese courtyard influences, construction techniques remain fundamentally rooted in indigenous traditions. This duality manifests most distinctly in the principal wing’s two divergent timber framing approaches:

The hybrid structural system (

Figure 13 and

Figure 14) preserves the traditional flat-roofed adobe house’s dense-beam framework across its ground and living levels. Above this base, a pitched roof structure sits directly atop the third-level earthen surface, creating a triangular interstitial attic. Crucially independent from the lower floors, this superimposed roof employs 80–90 mm support columns bearing horizontal beams with central 40–50 mm king posts—all interconnected through mortise-and-tenon joints to support ridge purlins and tiled roofing. Though structurally decoupled, this configuration adequately handles lightweight tile loads.

Conversely, the integrated structural system (

Figure 14 and

Figure 15) embodies holistic engineering: full-height vertical members and horizontal beams unite across three stories via mortise-and-tenon joinery, with rammed-earth walls providing supplementary rather than primary support. This continuous framework prioritizes structural coherence from foundation to roof.

Notably, secondary wings invariably adhere to the traditional grid-beam framework—an economical solution where closely spaced timber members efficiently distribute earthen roof loads through expedient, material-conserving assembly.

While rammed earth and adobe brick construction remains widespread across rural Yunnan’s traditional dwellings, extant Hani structures in the Samaba Terraces reveal the near-total disappearance of rammed earth techniques, with pre-1990 residences universally employing adobe brick walls for exterior envelopes. This transition reflects profound anthropogenic landscape adaptation: after millennia of terrace farming, local soils have transformed into agronomically optimized but constructionally inadequate silty-sandy earth devoid of clay cohesion.

To fabricate adobe bricks, Hani artisans source clay-rich soil from nearby mountains—transporting it to village workshops where raw material undergoes meticulous processing: pulverization and compaction precede fine sifting to eliminate impurities, followed by integration of chopped rice husks and straw for fibrous reinforcement. The homogenized mixture is molded within standardized 300 × 150 × 100 mm wooden frames into wet adobe blocks, which harden over 3–5 days of sun-drying into load-bearing masonry units.

These dimensionally precise bricks are subsequently laid in running bond patterns using clay mortar, forming structural walls whose integrity derives from three synergistic factors: the engineered granular composition of the bricks themselves, the interlacing bond geometry, and gradual moisture equilibration during curing—collectively embodying a vernacular material ethos where agricultural byproducts become architectural substance.

The fabricated adobe bricks are laid directly atop stone foundations using the stretcher-and-header bond—a technique alternating longitudinal and transverse units with untreated mortar joints that ensures operational simplicity, interlocked stability, and structural integrity for load-bearing walls (

Figure 16). Courtyard enclosures under approximately 2.5 m height employ simplified bonding patterns, exempt from the full-header bond technique due to minimal slenderness ratio concerns.

Standard adobe walls measure roughly 450 mm thick, their upper sections—300–500 mm below the eaves—coated in lime plaster to protect against rain erosion at this critical interface. Driven by thermal insulation and wind resistance demands, solid wall surfaces prevail. When roof-level ventilation or access openings become necessary, builders selectively extract bricks to install timber lintels or construct corbelled arches through radial adobe placement.

- (ii)

Hybrid Brick-Earth Walls

These structurally integrated walls—combining fired bricks and adobe blocks—are extensively employed across Hani villages in the region, representing a sophisticated synthesis of material pragmatism and cultural adaptation. Primary types of Hybrid Brick-Earth Walls:

This technique—architecturally termed “Gold-Wrapped-Jade” (Jīn bāo yù)—strategically layers an external cladding of fired bricks (100–120 mm thick, symbolizing “gold”) over an internal 450 mm adobe core (representing “jade”). Constructed through flat-stretcher bricklaying with integrated header courses, the method achieves structural synergy by penetrating header bricks deep into the earthen mass, creating cross-bonded reinforcement that substantially enhances the wall’s tectonic cohesion (

Figure 17).

This localized approach concentrates fired bricks at critical architectural zones: corners receive brick armoring for impact and rain protection, while primary elevations—particularly ceremonial facades and entrances—feature full-brick surfacing as socioeconomic statements among affluent households. Secondary surfaces retain traditional adobe construction, creating a material dialectic where brick deployment negotiates between environmental pragmatism and social expression (

Figure 17).

In traditional Hani dwellings, the courtyard-facing walls of secondary wings consistently utilize timber planks instead of adobe—a strategic adaptation to their stilted ground levels housing livestock or storage. This lightweight solution, ingeniously employed by Hani builders, involves erecting timber frames with plank-clad upper stories that enclose space without impeding functional access below. Two distinct techniques prevail:

One method crafts planks into horizontally stacked layers nailed directly to the timber frame, reminiscent of log-cabin construction. These tightly fitted but non-sealed planks inherently limit fenestration due to interstitial gaps.

Another approach integrates an additional horizontal timber beam within the frame to create a uniform grid, into which vertical window frames are installed. Planks are then embedded between these mullions, achieving both enclosure and controlled ventilation (

Figure 18).

- (3)

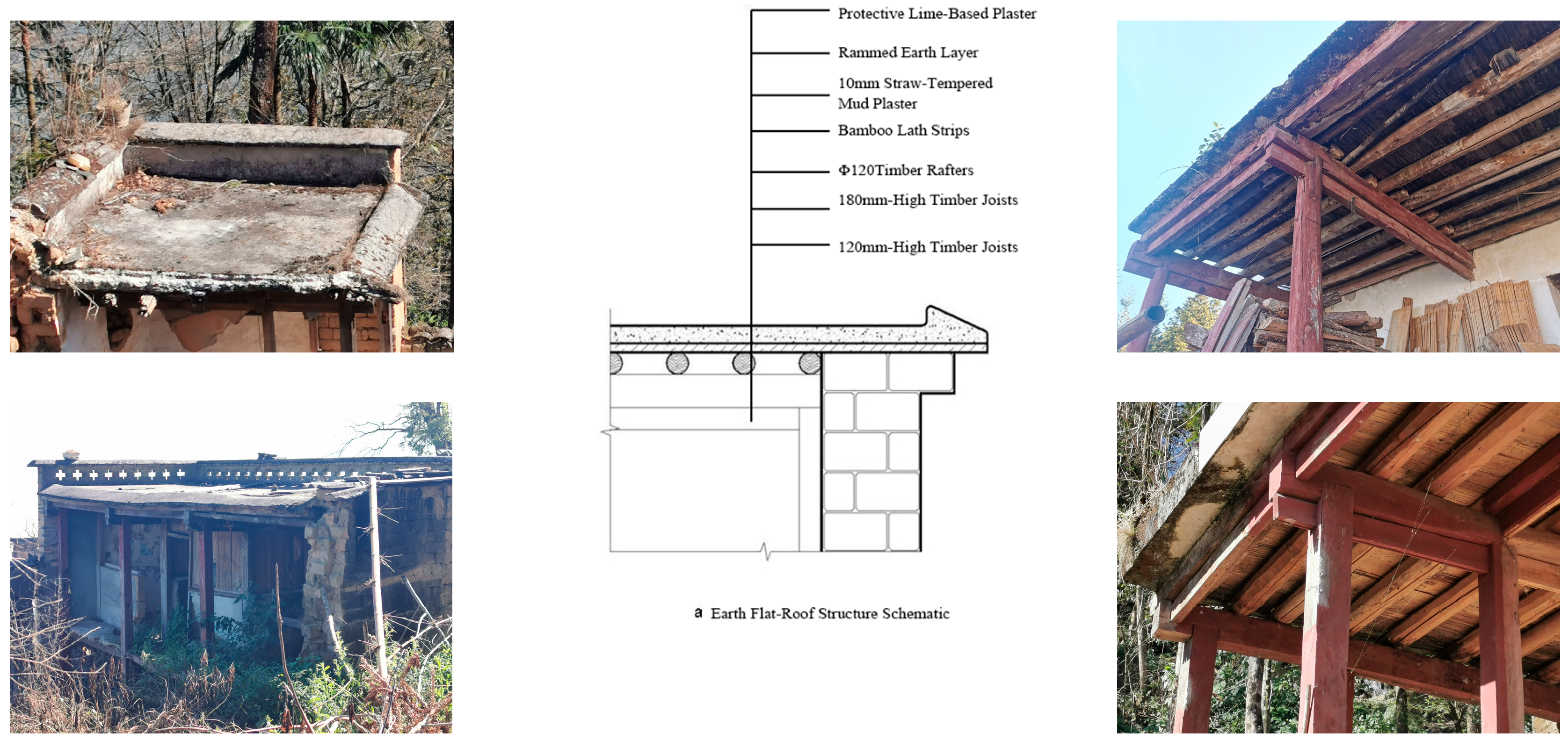

Flooring and Roofing Systems

Traditional Hani dwellings employ a closely-spaced rafter system which intervals 200–250 mm for interior flooring, where untreated timber or bamboo rafters—substituted during material scarcity—support layered bamboo strips, wood lathing, or woven mats. This substrate receives straw-tempered mud plaster compacted into rammed-earth flooring, with stairwell openings bordered by adobe curbs (

Figure 19). Affluent households occasionally install plank flooring directly over rafters, while exterior surfaces range from compacted earth to stone-paved courtyards in prosperous homes.

The principal wing features a double-sloped flush-gabled roof with minimally processed logs or bamboo as rafters nailed to purlins with 200 mm spacing, topped directly by blue-grey tiles. Distinctive eaves integrate four-tiered brick corbeling to adjust rafter angles, an upturned ridge contrasting level front eaves, and fireproof gables with triple-brick-and-tile corbeling—all subtly contoured by adobe adjustments that yield natural curved profiles.

Secondary wings and verandas utilize flat earthen roofs: timber beams support cross-battens overlaid with brushwood or bamboo mats, followed by stratified rammed earth mixed with straw/gravel, culminating in a waterproof lime-clay surface tamped smooth (

Figure 20).

Based on the integration of materials, structure, and construction techniques, a detailed analysis has been conducted on the building techniques of the wooden framework, walls, roof, and other components of the traditional courtyard dwellings of the Hani people in the Samaba terraced fields area. It can be observed that the locally sourced materials and construction methods used in these dwellings are adapted to the corresponding regional climate conditions. For example, raw earth materials can be locally sourced and have good thermal stability, making them suitable for the high-altitude climate with significant day-night temperature variations. However, raw earth materials have poor water resistance and must be used in combination with stone foundations and roof overhangs. Thickly layered thatched roofs provide insulation and help quickly drain rainwater, but due to their relatively short durability cycle, they require regular replacement. Wood is lightweight and strong, can be locally sourced, and is easy to work with, but it is not water-resistant, is prone to decay, and must be used with stone column bases.

In summary, each of these materials has obvious shortcomings in terms of individual durability, yet their overall durability is remarkably high. The secret lies in the combination of materials: instead of pursuing an “all-round” capability for each material, the structural design positions each material where it can best utilize its advantages and be most protected. By leveraging the different durability cycles of materials, a replaceable and maintainable cyclic system is created, extending the overall lifespan of the building. Roof overhangs and elevated ground floors are adaptive strategies to cope with the local high-humidity climate. This is undoubtedly a sustainable form of housing in terms of material acquisition, construction, and other aspects.

It is worth noting that through four detailed on-site investigations (which included both slack farming seasons, such as canal maintenance and plowing, and busy farming seasons, such as transplanting and harvesting), we observed an isomorphic relationship between the construction of traditional Hani settlements and dwellings and the material-energy cycle system of terrace farming activities: building materials are sourced from forests and terraces, such as rice straw for roofing from the terraces; the collaborative methods of house construction are similar to the multi-scale collaboration methods of terrace agricultural production. For example, terrace production collaboration occurs at multiple scales—among households, within villages, and between villages—while traditional Hani dwellings, being small in scale, require collective collaboration during the initial construction phase, with later maintenance requiring only minimal labor costs.