A Novel Prediction Model for Estimating Ground Settlement Above the Existing Tunnel Caused by Undercrossing

Abstract

1. Introduction

2. Theoretical Basis and Preliminary Model Construction

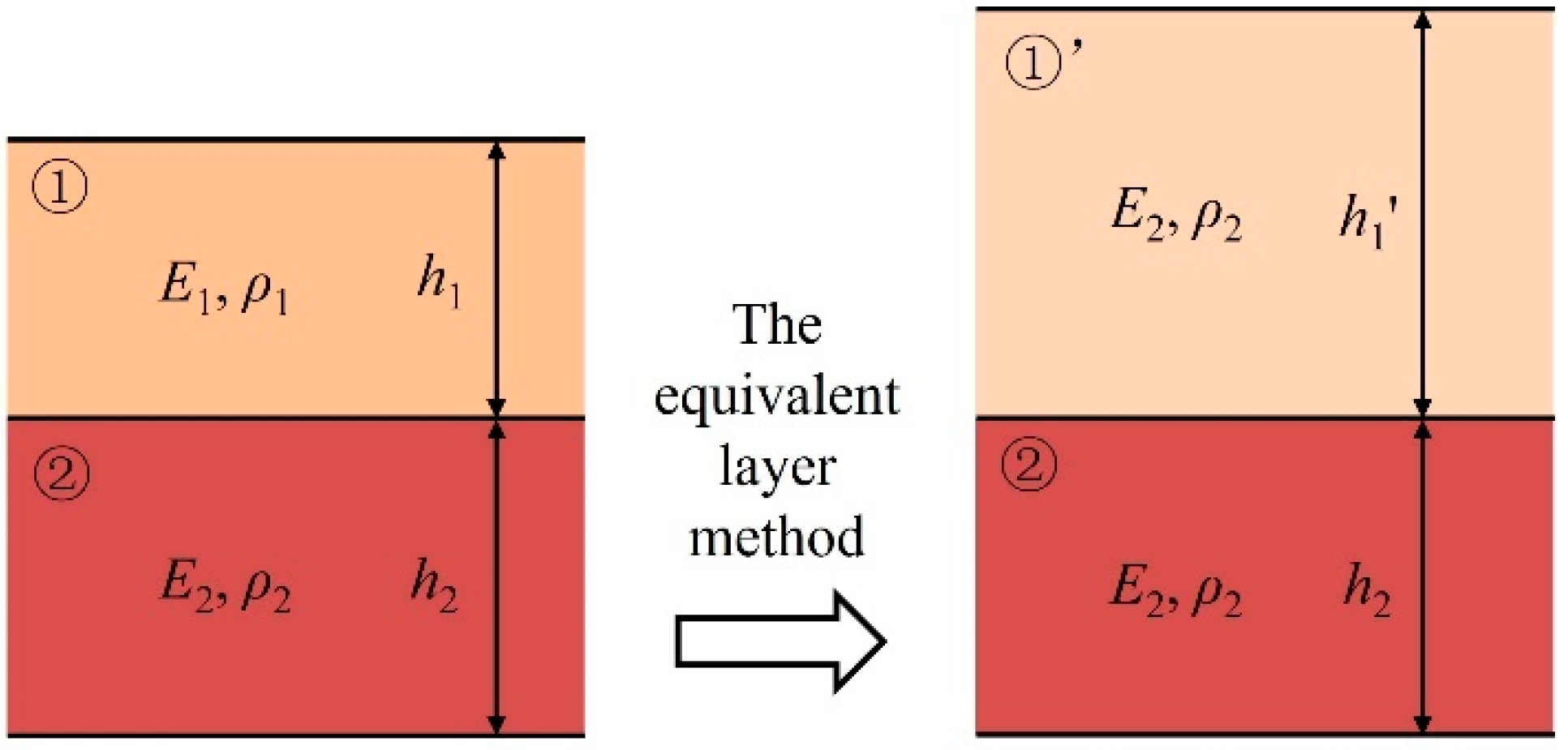

2.1. The Equivalent Layer Method

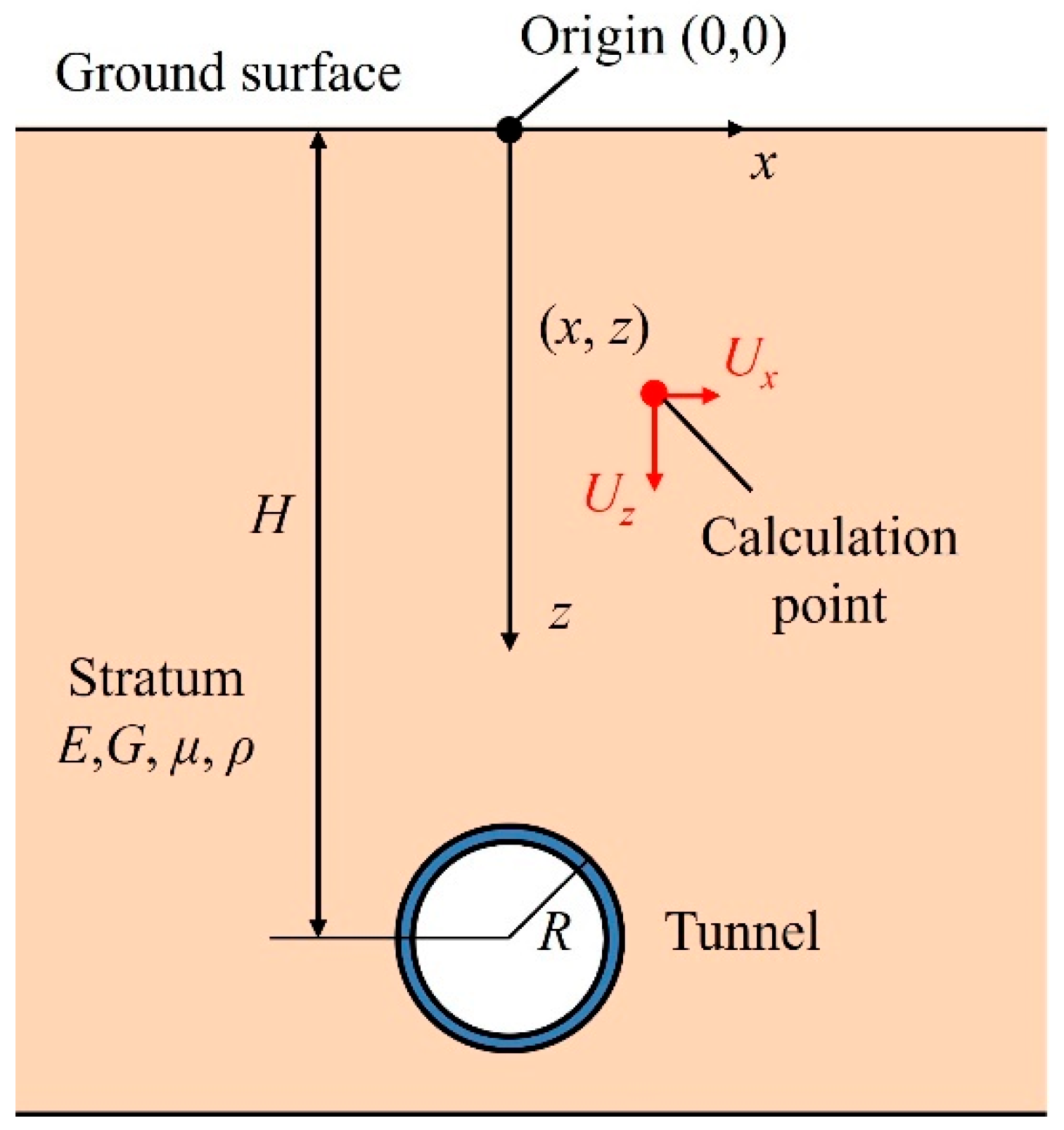

2.2. The Mirror Method

2.3. Preliminary Construction of the Ground Settlement Prediction Model

- Convert existing tunnels into equivalent strata;

- Homogenize multi-layer strata, including strata derived from existing tunnels through the equivalent layer method;

- Calculate the settlement of the existing tunnel layer caused by the excavation of new tunnels in homogenized strata using the mirror method.

3. Verification

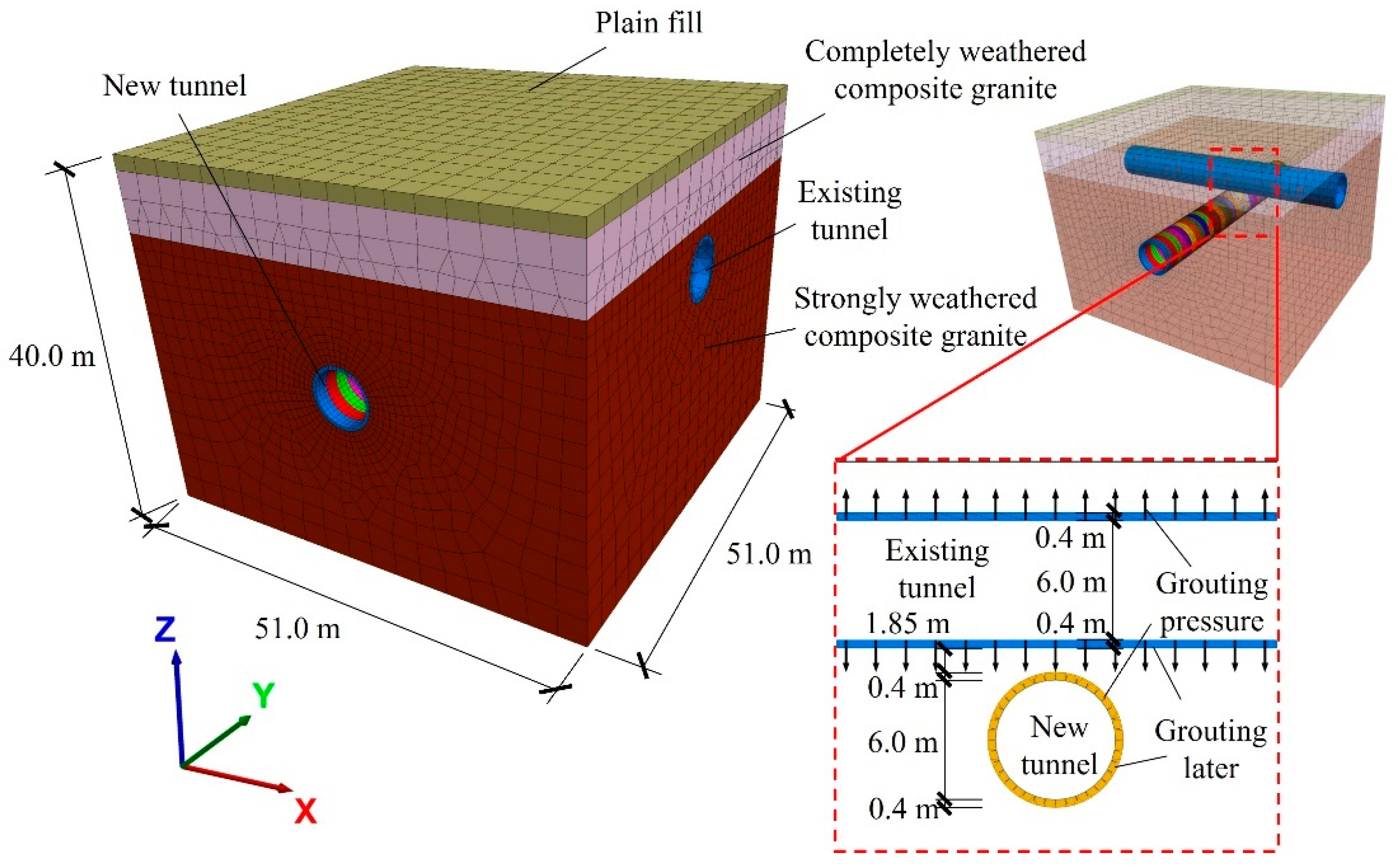

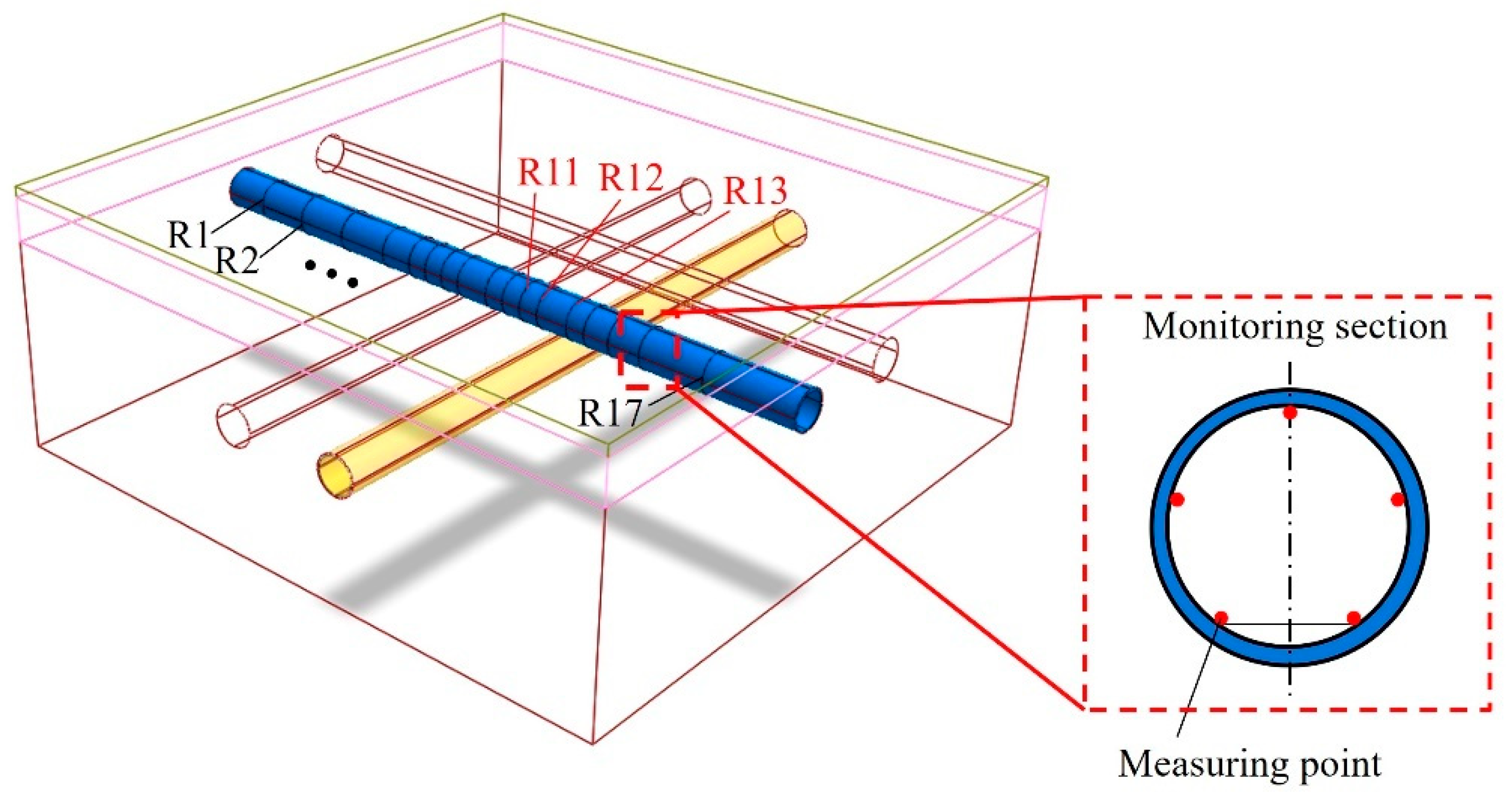

3.1. Numerical Simulation

- Initialize the ground stress equilibrium and reset the initial displacement;

- Excavate the existing tunnel at one time, install the lining segments, define the grouting layers, and simultaneously apply grouting pressure; calculate and reset the displacement;

- Excavate the new tunnel in stages, install the lining segments in each step, define the grouting layers, and apply grouting pressure until completion;

- Extract the ground settlement directly above the existing tunnel.

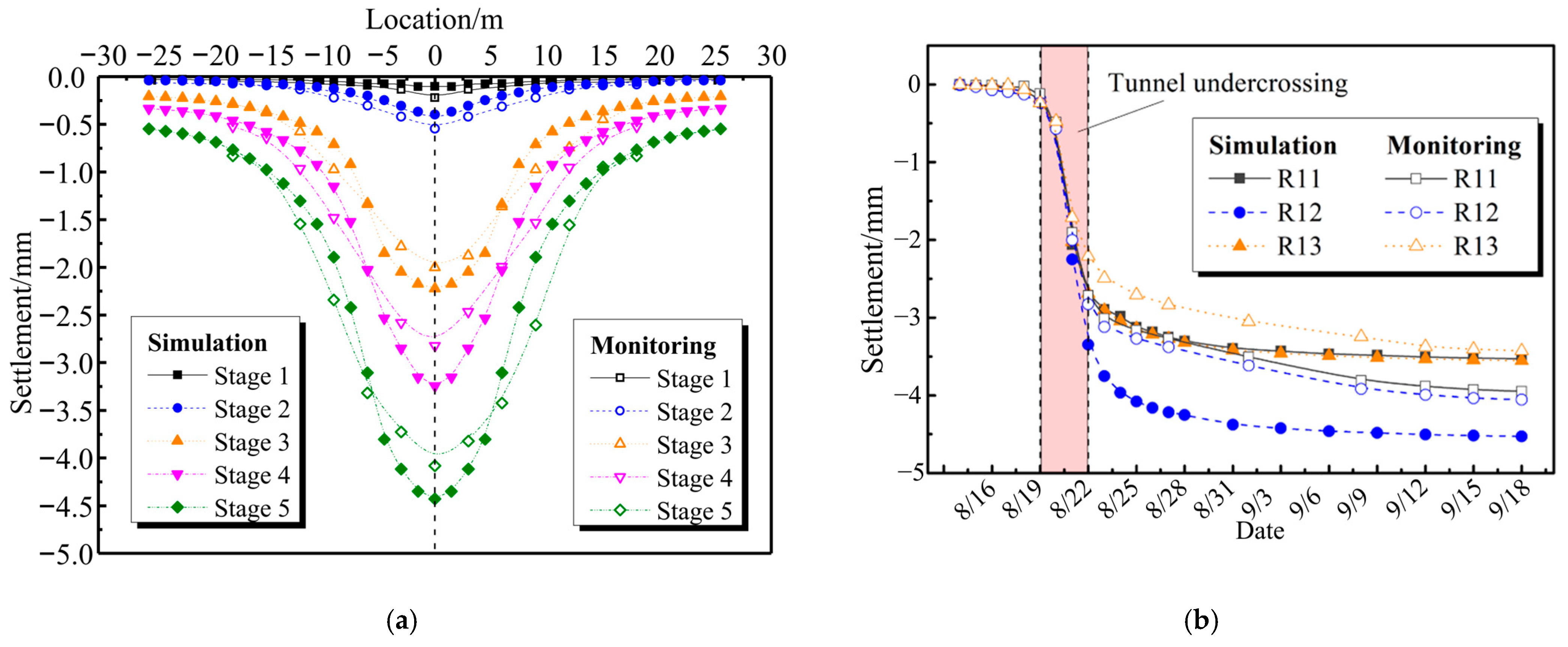

3.2. Verification of the Simulation

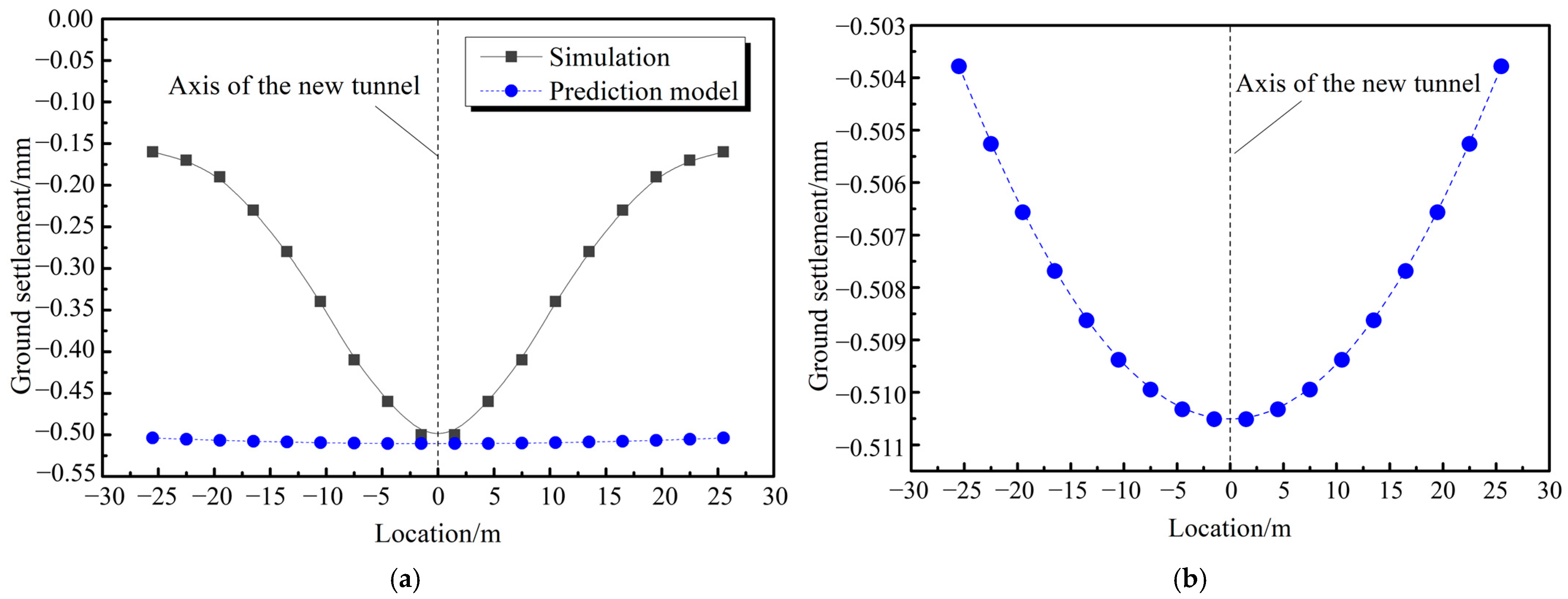

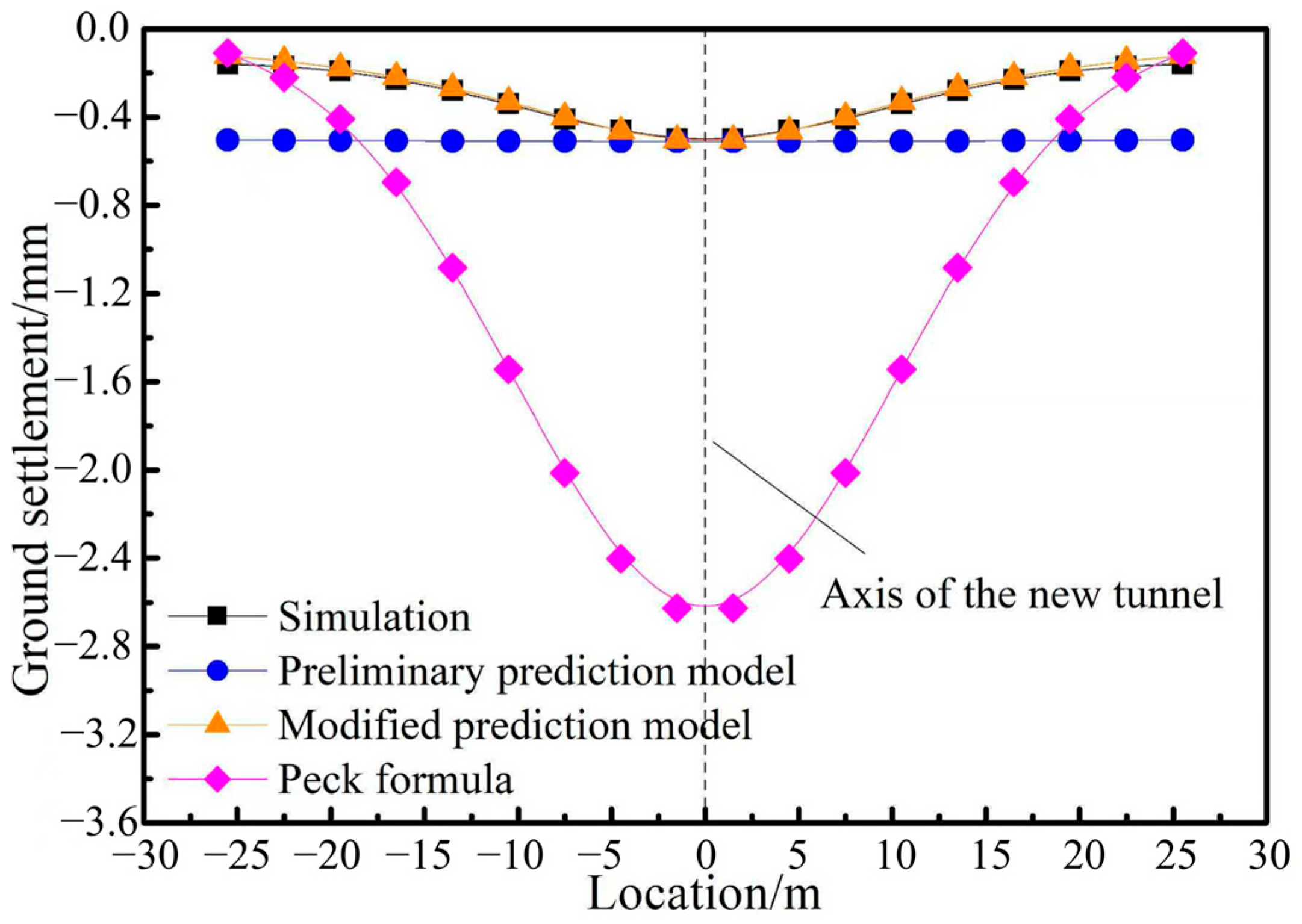

3.3. Verification of the Prediction Model

4. Modification of the Prediction Model

5. Parameter Analysis and Adaptability Study

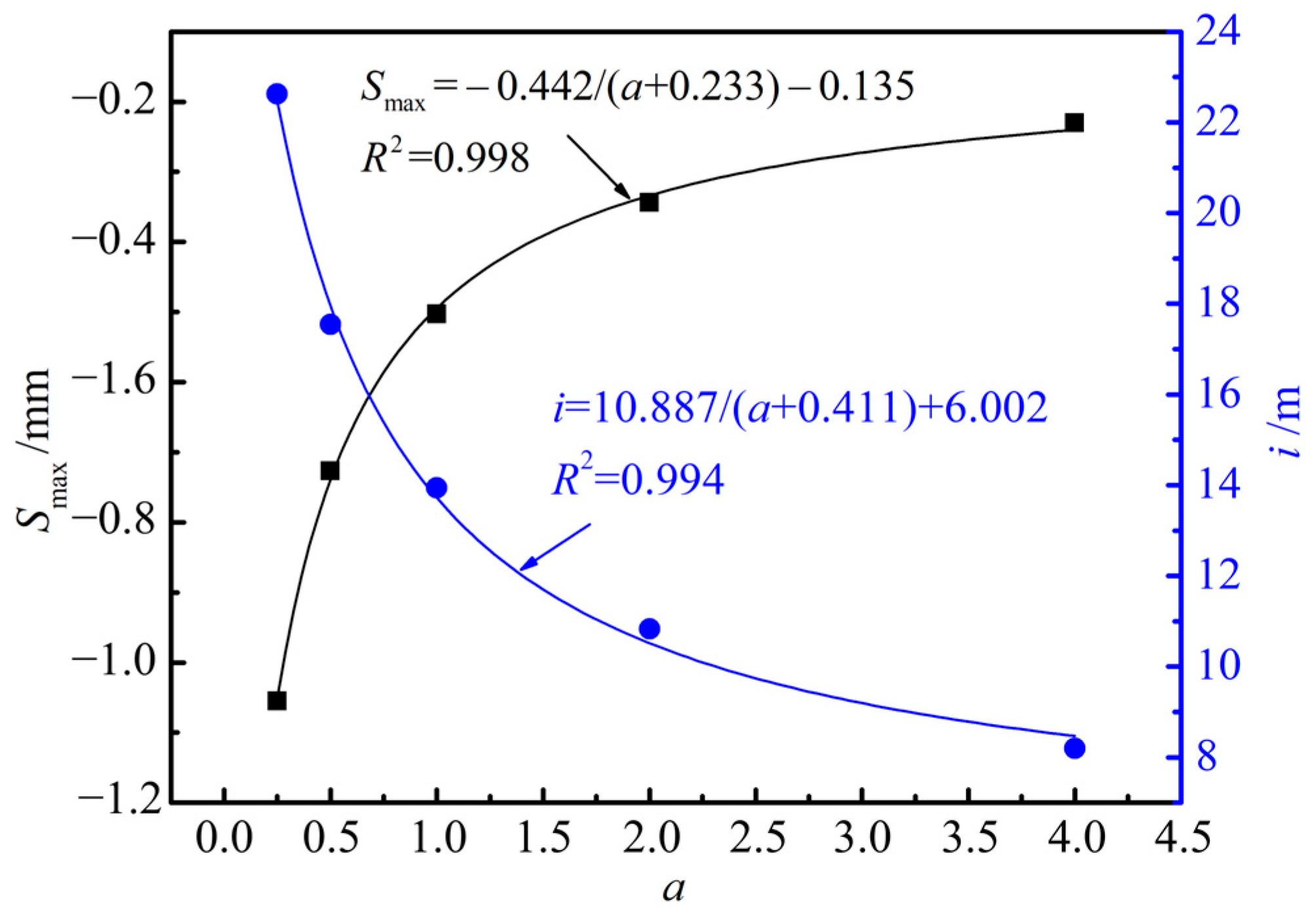

5.1. Elastic Modulus of the Strata

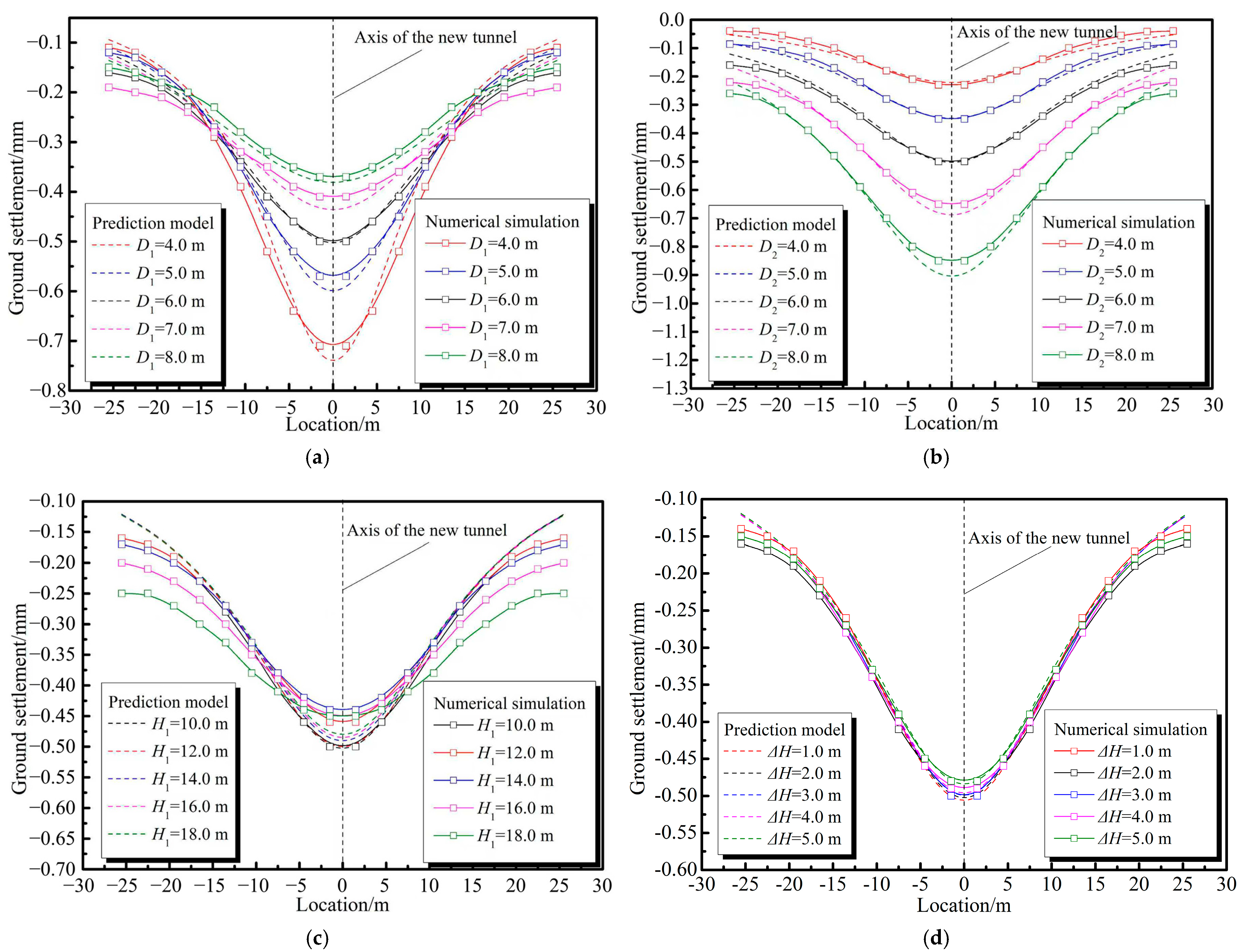

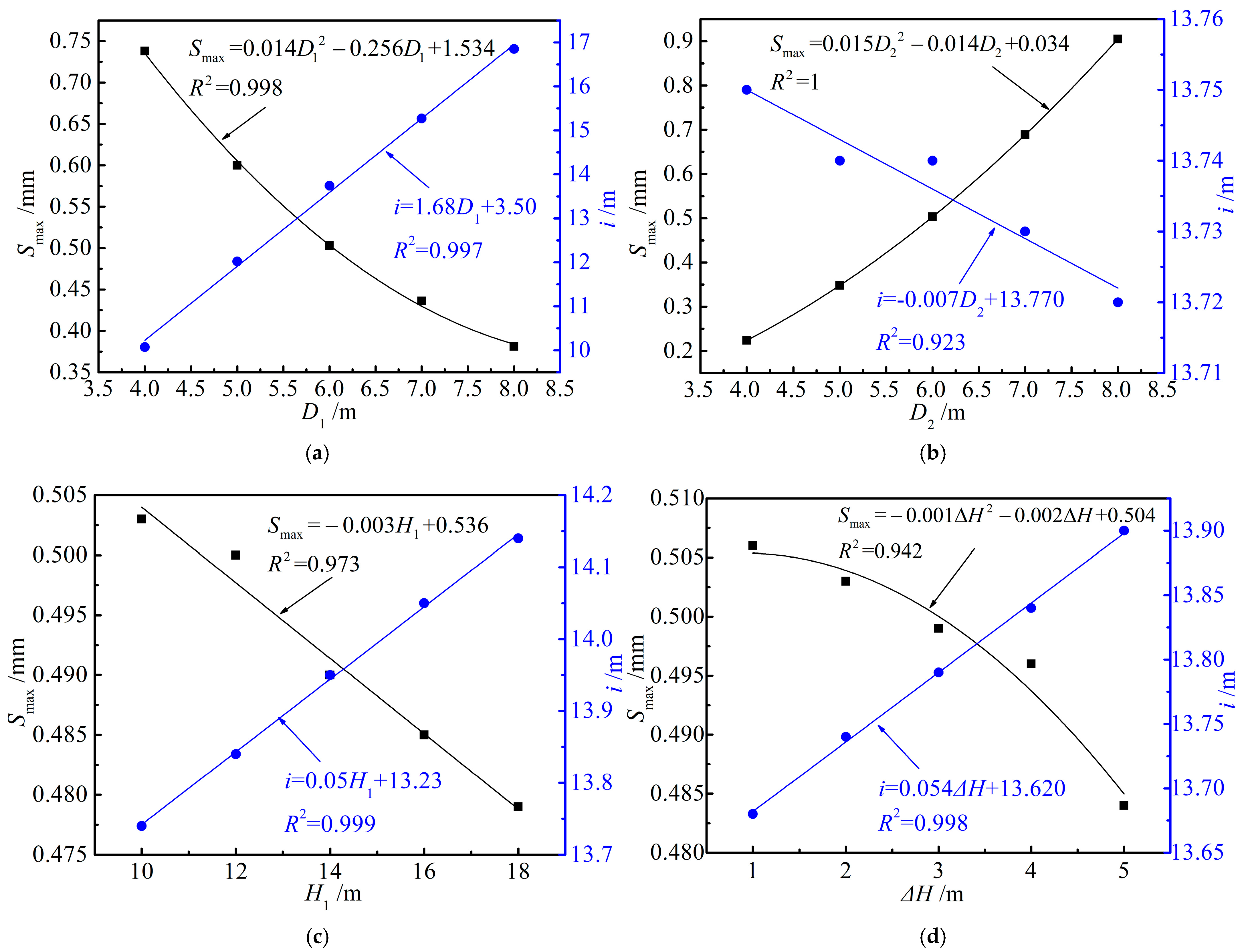

5.2. Dimensions and Spatial Layout of the Tunnels

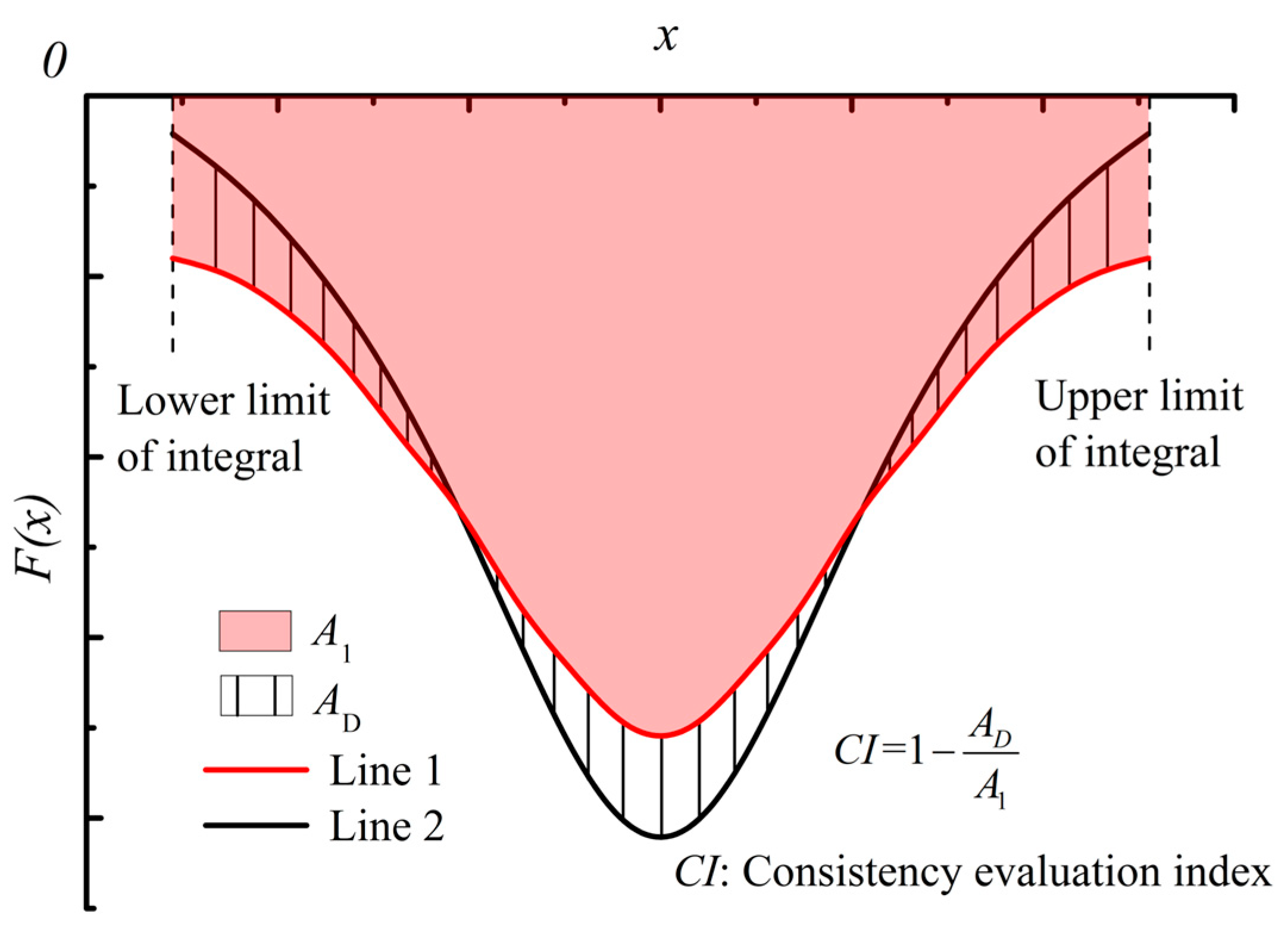

5.3. Adaptability of the Prediction Model

6. Engineering Case Verification

6.1. Engineering Background

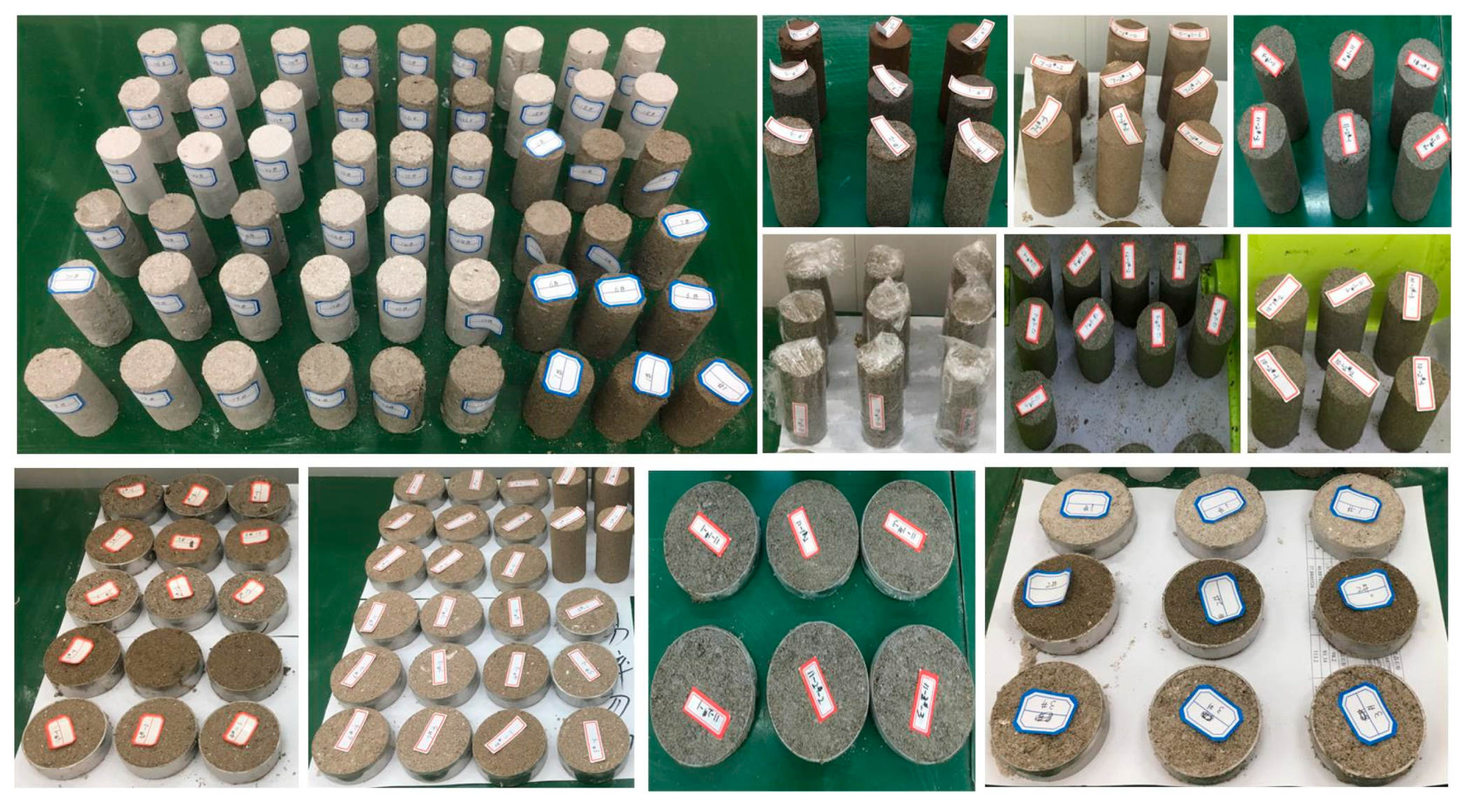

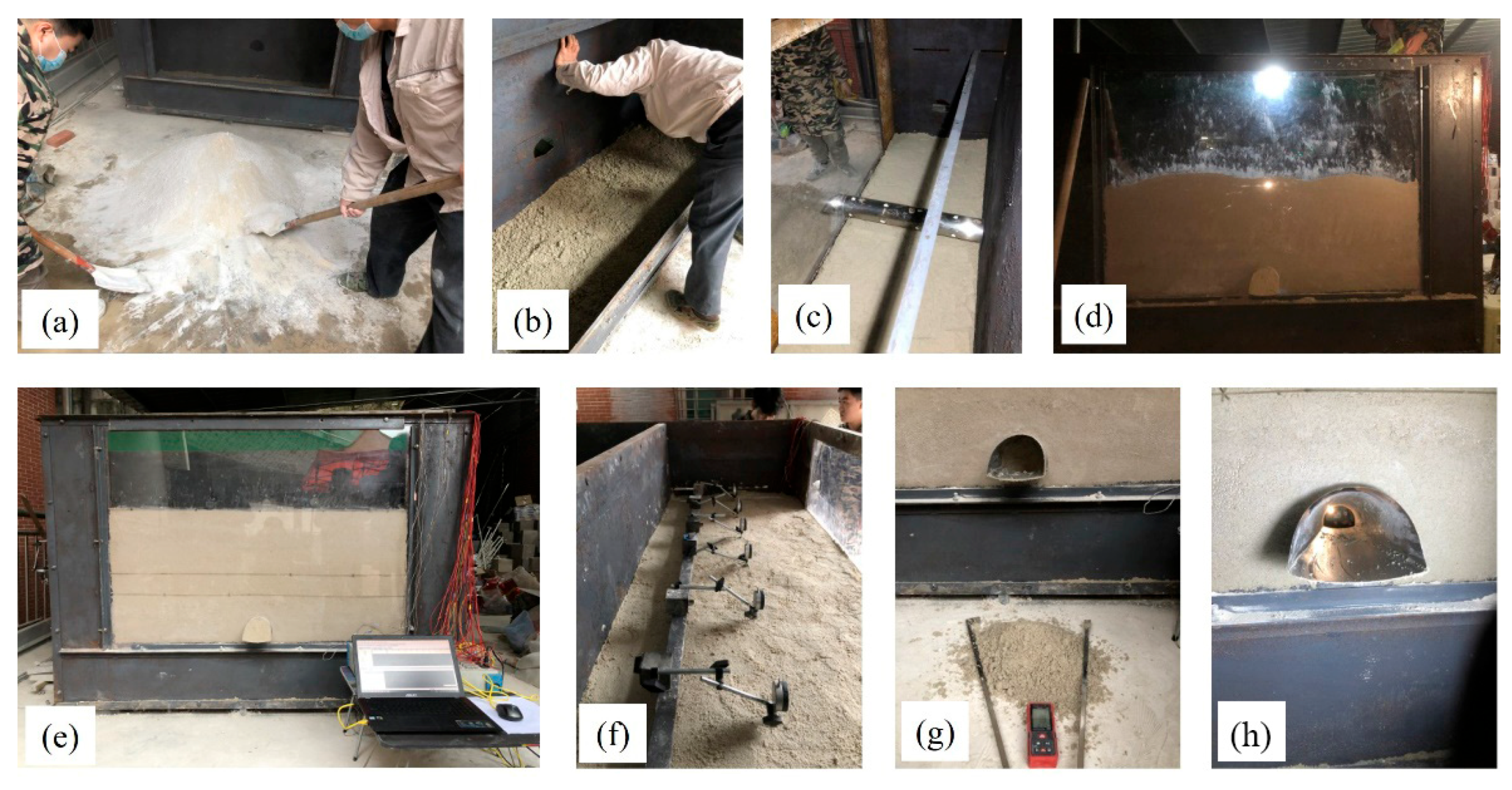

6.2. Model Test Process

6.3. Results and Verification

7. Discussion

7.1. Applicability of the Double-Track Tunnel Undercrossing Problems

7.2. Applicability in Non-Vertical Undercrossing Problems

8. Conclusions

- In cases where a new tunnel undercrosses an existing tunnel, the significant stiffness of the existing tunnel interacts with the foundation settlement, resulting in a flatter settlement curve and a reduction in the maximum settlement value directly above it. The classic Peck formula does not account for the presence of existing tunnels when calculating foundation settlement, leading to significant errors in the results.

- Based on the equivalent layer method and the mirror method, the preliminary proposed ground settlement prediction model has the advantages of simple formulas, clear parameters, and high computational efficiency. Compared to the Peck formula, this model considers the influence of existing tunnels on ground settlement; however, it overestimates the stiffness difference between the tunnel and the surrounding strata, as well as the overall deformation capacity of the tunnel lining.

- The modified prediction model retains the advantages of the original model while introducing a correction coefficient A to optimize the calculation results, thereby enabling a more reasonable assessment of the impact of existing tunnels on ground settlement. Compared with the Peck formula and the preliminary prediction model, this model has significantly improved prediction accuracy.

- The elastic modulus of the strata has a minor influence on the shape of the ground settlement curve but a significant impact on the magnitude of settlement. Softer strata result in greater settlement at all locations. The diameter of existing tunnels primarily affects settlement within approximately 15 m of the new tunnel axis, with settlement values decreasing gradually as the diameter increases. Conversely, the diameter of the new tunnel determines the overall shape of the settlement curve; the larger the tunnel diameter, the more pronounced the settlement amplitude will be. The burial depth of existing tunnels and the spacing between tunnels have negligible effects on settlement. Consistency assessments confirm that the prediction model exhibits strong adaptability under various conditions (CI > 0.9).

- When the new tunnel is directly located below the existing tunnel, ground settlement begins to occur, with a maximum settlement of 0.17 mm. After the new tunnel passes the existing tunnel, ground settlement continues to increase within approximately 50 m on either side of the new tunnel axis, eventually reaching approximately 0.765 mm. The consistency evaluation results indicate that the prediction model demonstrates good application effectiveness in actual engineering projects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, K.; Zhang, L.; Li, S.; Huang, Y.P.; Ding, X.; Hao, J.N.; Huang, S.Q.; Li, X.J.; Lu, F.; Zhang, H.W. Urban Rail Transit in China: Progress Report and Analysis (2015–2023). Urban Rail Transit 2025, 11, 1–27. [Google Scholar] [CrossRef]

- Ding, Z.; Zhang, M.B.; Zhang, X.; Wei, X.J. Theoretical analysis on the deformation of existing tunnel caused by under-crossing of large-diameter slurry shield considering construction factors. Tunn. Undergr. Space Technol. 2023, 133, 104913. [Google Scholar] [CrossRef]

- Zhou, Z.; Zheng, Y.D.; Hu, J.F.; Yang, H.; Gong, C.J. Deformation analysis of shield undercrossing and vertical paralleling excavation with existing tunnel in composite stratum. J. Cent. South. Univ. 2023, 30, 2238–2246. [Google Scholar] [CrossRef]

- Yang, Z.P.; Cheng, Z.K.; Wu, D. Deep learning driven prediction and comparative study of surrounding rock deformation in high speed railway tunnels. Sci. Rep. 2025, 15, 24104. [Google Scholar] [CrossRef]

- Zhang, J.C.; Yu, J.C.; Li, C.J.; Liu, Y.Z.; Tian, L.G.; He, Y.L.; Zhang, Q. Deformation and reinforcement of the existing tunnel affected by new shield tunnel construction with small clearance. Buildings 2025, 15, 265. [Google Scholar] [CrossRef]

- Lai, H.P.; Zheng, H.W.; Chen, R.; Kang, Z.; Liu, Y. Settlement behaviors of existing tunnel caused by obliquely under-crossing shield tunneling in close proximity with small intersection angle. Tunn. Undergr. Space Technol. 2020, 97, 103258. [Google Scholar] [CrossRef]

- Fang, Q.; Zhang, D.L.; Li, Q.Q.; Wong, L.N.Y. Effects of twin tunnels construction beneath existing shield-driven twin tunnels. Tunn. Undergr. Space Technol. 2015, 45, 128–137. [Google Scholar] [CrossRef]

- Feng, Z.B.; Wang, J.Y.; Liu, W.; Li, T.J.; Wu, X.G.; Zhao, P.X. Data-driven deformation prediction and control for existing tunnels below shield tunneling. Eng. Appl. Artif. Intel. 2024, 137, 109379. [Google Scholar] [CrossRef]

- Dong, M.; Guan, M.Z.; Wang, K.H.; Wu, Y.Y.; Fu, Y.H. Machine learning-based measurement and prediction of ground settlement induced by shield tunneling undercrossing existing tunnels in composite strata. Sensors 2025, 25, 1600. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xue, J.F.; Ye, J.Z.; Qian, J.G. A simplified two-stage method to estimate the settlement and bending moment of upper tunnel considering the interaction of undercrossing twin tunnels. Transp. Geotech. 2021, 29, 100558. [Google Scholar] [CrossRef]

- Li, Y.F.; Huang, C.F.; Lu, H.J.; Mou, C. Deformation prediction model of existing tunnel structures with equivalent layered method–Peck coupled under multiple factors. Mathematics 2024, 12, 1479. [Google Scholar] [CrossRef]

- Yao, J.Q.; Nie, J.J.; Li, C.F. Research on prediction of surrounding rock deformation and optimization of construction parameters of high ground stress tunnel based on WOA-LSTM. Sci. Rep. 2024, 14, 27396. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.Q.; Thewes, M.; Zhang, D.M.; Huang, H.W.; Lin, W. Deformational behaviors of existing three-line tunnels induced by under-crossing of three-line mechanized tunnels: A case study. Can. Geotech. J. 2025, 62, 23. [Google Scholar] [CrossRef]

- Ahmed, N.Z.; El-Shourbagy, M.; Akl, A.; Metwally, K. Field monitoring and numerical analysis of ground deformation induced by tunnelling beneath an existing tunnel. Cogent. Eng. 2021, 8, 1861731. [Google Scholar] [CrossRef]

- Liu, S.G.; Wang, Y.H.; Zhou, H.; Sun, C.Z.; Lin, D.F. Model test on approaching the construction of multi-line overlapping shield tunnels for up- and down-crossing. Processes 2022, 10, 500. [Google Scholar] [CrossRef]

- Cai, Q.P.; Elbaz, K.; Guo, X.Y.; Ding, X.M. Physics-informed deep learning and analytical patterns for predicting deformations of existing tunnels induced by new tunnelling. Comput. Geotech. 2025, 187, 107451. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, Y.; Liu, Z.Z.; Miao, L.W. Theoretical prediction model for deformations caused by construction of new tunnels undercrossing existing tunnels based on the equivalent layered method. Comput. Geotech. 2020, 123, 103565. [Google Scholar] [CrossRef]

- Liu, X.R.; Wang, L.F.; Zhou, X.H.; Wang, J.M.; Zhong, Z.L.; Liu, P.; Xiong, F.; He, C.M. E-M calculation model and its application of calculating deformation in a new tunnel orthogonally undercrossing an existing tunnel. Tunn. Undergr. Space Technol. 2022, 123, 104418. [Google Scholar] [CrossRef]

- Hiroyoshi, H. Settlements and stresses of multi-layered grounds and improved grounds by equivalent elastic method. Int. J. Numer. Anal. Met. 2008, 32, 523–557. [Google Scholar] [CrossRef]

- Bao, L.L.; Wei, F. Impact mechanism of shallow buried soft rock tunnel excavation on existing highways and pipe-shed reinforcement effect. Sci. Rep. 2024, 14, 3401. [Google Scholar] [CrossRef]

- Verruijt, A.; Booker, J.R. Ground settlements due to deformation of a tunnel in an elastic half plane. Geotechnique 1996, 46, 753–756. [Google Scholar] [CrossRef]

- González, C.; Sagaseta, C. Patterns of soil deformations around tunnels. Application to the extension of Madrid Metro. Comput. Geotech. 2001, 28, 445–468. [Google Scholar] [CrossRef]

- Park, K.H. Analytical solution for tunnelling-induced ground movement in clays. Tunn. Undergr. Space Technol. 2005, 20, 249–261. [Google Scholar] [CrossRef]

- Tan, X.R.; Zhang, H.; Zhang, G.; Zhu, Y.M. An improved method for predicting the greenfield stratum movements caused by shield tunnel construction. Appl. Sci. 2019, 9, 4522. [Google Scholar] [CrossRef]

- Li, Y.; Bian, X.W.; Peng, H.; Zhu, B.Q.; Zhou, Y.L. Additional stress of soil and surface settlement during tunnel shield construction. Buildings 2023, 13, 1437. [Google Scholar] [CrossRef]

- Chen, X.J.; Zhang, J.Z.; Hu, Y.; Wang, W.; Liu, Y. Random large-deformation modelling on face stability considering dynamic excavation process during tunnelling through spatially variable soils. Can. Geotech. J. 2025, 62, 280. [Google Scholar] [CrossRef]

- Liang, J.B. Study on the Effect of Construction of Undercrossing Shield Tunnel on the Existing Shield Tunnel. Master’s Thesis, Guangzhou University, Guangzhou, China, 2016. [Google Scholar]

- Itasca Consulting Group, Inc. FLAC3D: Fast Lagrangian Analysis of Continua in 3 Dimensions, version 5.0; Itasca Consulting Group, Inc.: Minneapolis, MN, USA, 2012. [Google Scholar]

- MIDAS Information Technology Co., Ltd. Midas-GTS NX: Geotechnical Analysis System, version 2021; MIDAS Information Technology Co., Ltd.: Seongnam-si, Republic of Korea, 2021. [Google Scholar]

- Guo, H.P.; Yuan, D.J.; Jin, D.L.; Ma, Q.L.; Zhao, H.Y. Theoretical analysis and numerical simulations for the safe clear distance of a shallow-buried twin-shield tunnel with small spacing. KSCE J. Civ. Eng. 2024, 28, 5277–5289. [Google Scholar] [CrossRef]

- Nong, X.Z.; Bai, W.F.; Yi, S.X.; Lu, Z.Z.; Lu, Y. Numerical simulation for risk assessment of tunnel construction through fault fracture zones. Buildings 2024, 14, 3161. [Google Scholar] [CrossRef]

- Dun, H.D.; Chen, S.; Liu, H.T.; Chen, C.; Zhang, Y.S.; Yuan, Y. Numerical simulation analysis of the stability of the construction face of a super long tunnel under conditions of precipitation and abundant water. Front. Mater. 2024, 11, 1461308. [Google Scholar] [CrossRef]

- Lin, X.T.; Chen, R.P.; Wu, H.N.; Chen, H.Z. Deformation behaviors of existing tunnels caused by shield tunneling undercrossing with oblique angle. Tunn. Undergr. Space Technol. 2019, 89, 78–90. [Google Scholar] [CrossRef]

- Peck, R.B. Deep excavation and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, Mexico, 25–29 August 1969. [Google Scholar]

- Gao, Y.X.; Liu, Y.W.; Tang, P.J.; Mi, C.Q. Modification of Peck formula to predict surface settlement of tunnel construction in water-rich sandy cobble strata based on visual analysis of grouting parameters. Sustainability 2022, 14, 14545. [Google Scholar] [CrossRef]

- Liu, Y.N.; Li, Y.F.; Chen, G.J.; Li, Y.H.; Li, J.L.; Jin, J.X. Theoretical analysis of surface settlement during parallel excavation of twin tunnels based on modified Peck formula. Buildings 2025, 15, 1143. [Google Scholar] [CrossRef]

- O’Reilly, M.P.; New, B.M. Settlement above tunnels in the United Kingdom-their magnitude and prediction. In Proceedings of the Tunnelling Conference, Brighton, UK, 7–11 June 1982. [Google Scholar]

- Wu, C.S.; Zhu, Z.D. Statistical analysis of ground loss ratio caused by different tunnel construction methods in China. J. Zhejiang Univ. (Eng. Sci.) 2019, 53, 19–30. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, X.H.; Liu, X.R.; Lojain, S.; Xu, Q.; Ren, L.J. Study on construction mechanical characteristics and pinch rocks reinforcement schemes of honeycomb tunnel clusters in Mountainous City. Tunn. Undergr. Space Technol. 2025, 158, 106397. [Google Scholar] [CrossRef]

- Liu, X.R.; Suliman, L.; Zhou, X.H.; Wang, J.W.; Wang, L.F.; Abd Elmageed, A. Settlement characteristic due to excavate parallel tunnels in a fill-rock slope: Model test and numerical analysis. Rock Mech. Rock Eng. 2022, 55, 7125–7143. [Google Scholar] [CrossRef]

| Layer | Soil | Density | Elastic Modulus | Friction Angle | Cohesion | Poisson’s Ratio | Strength of Extension | Thickness |

|---|---|---|---|---|---|---|---|---|

| ρ/(kg/m3) | E/MPa | φ/° | c/kPa | μ/− | T/MPa | h/m | ||

| ① | Plain fill | 1880 | 6.0 | 10.0 | 15.0 | 0.38 | 0.0 | 1.6 |

| ② | Completely weathered composite granite | 1890 | 27.0 | 21.0 | 28.0 | 0.28 | 8.0 | 6.5 |

| ③ | Strongly weathered composite granite | 1940 | 30.0 | 26.7 | 40.0 | 0.25 | 10.0 | - |

| Materials | Thickness | Density | Elastic Modulus | Poisson’s Ratio |

|---|---|---|---|---|

| t/m | ρ/(kg/m3) | E/MPa | μ/− | |

| Lining segments | 0.3 | 2500 | 34,500 | 0.25 |

| Grouting layer | 0.4 | 2300 | 1000 | 0.25 |

| Group Number | The Diameter of the Existing Tunnel | The Diameter of the New Tunnel | The Depth of the Existing Tunnel | The Spacing Between Two Tunnels |

|---|---|---|---|---|

| D1/m | D2/m | H1/m | ΔH/m | |

| 1 | 6 | 6 | 10 | 2 |

| 2, 3, 4, 5 | 4, 5, 7, 8 | 6 | 10 | 2 |

| 6, 7, 8, 9 | 6 | 4, 5, 7, 8 | 10 | 2 |

| 10, 11, 12, 13 | 6 | 6 | 12, 14, 16, 18 | 2 |

| 14, 15, 16, 17 | 6 | 6 | 10 | 1, 3, 4, 5 |

| a | 0.25 | 0.5 | 1 | 2 | 4 | Average |

| CI | 0.873 | 0.928 | 0.959 | 0.939 | 0.768 | 0.895 |

| D1/m | 4 | 5 | 6 | 7 | 8 | Average |

| CI | 0.931 | 0.971 | 0.959 | 0.923 | 0.954 | 0.948 |

| D2/m | 4 | 5 | 6 | 7 | 8 | Average |

| CI | 0.895 | 0.960 | 0.959 | 0.956 | 0.967 | 0.947 |

| H1/m | 10 | 12 | 14 | 16 | 18 | Average |

| CI | 0.959 | 0.940 | 0.920 | 0.885 | 0.825 | 0.906 |

| ΔH/m | 1 | 2 | 3 | 4 | 5 | Average |

| CI | 0.980 | 0.959 | 0.978 | 0.972 | 0.976 | 0.973 |

| Unit Weight γ/kN/m3 | Elastic Modulus E/GPa | Poisson’s Ratio μ/− | Cohesion c/MPa | Friction Angle φ/° | |

|---|---|---|---|---|---|

| Prototype materials | 24.60 | 0.3 | 0.33 | 0.13 | 31–33 |

| Similar materials | 19.40 | 0.0028 | 0.31 | 0.0011 | 26.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Liu, X.; Zhou, X.; Yu, W. A Novel Prediction Model for Estimating Ground Settlement Above the Existing Tunnel Caused by Undercrossing. Buildings 2025, 15, 3708. https://doi.org/10.3390/buildings15203708

Wang L, Liu X, Zhou X, Yu W. A Novel Prediction Model for Estimating Ground Settlement Above the Existing Tunnel Caused by Undercrossing. Buildings. 2025; 15(20):3708. https://doi.org/10.3390/buildings15203708

Chicago/Turabian StyleWang, Linfeng, Xinrong Liu, Xiaohan Zhou, and Wenbing Yu. 2025. "A Novel Prediction Model for Estimating Ground Settlement Above the Existing Tunnel Caused by Undercrossing" Buildings 15, no. 20: 3708. https://doi.org/10.3390/buildings15203708

APA StyleWang, L., Liu, X., Zhou, X., & Yu, W. (2025). A Novel Prediction Model for Estimating Ground Settlement Above the Existing Tunnel Caused by Undercrossing. Buildings, 15(20), 3708. https://doi.org/10.3390/buildings15203708