A Hybrid Optimization Method for Rebar Cutting in Structural Reinforcement

Abstract

1. Introduction

2. Rebar Cutting Optimization Methods

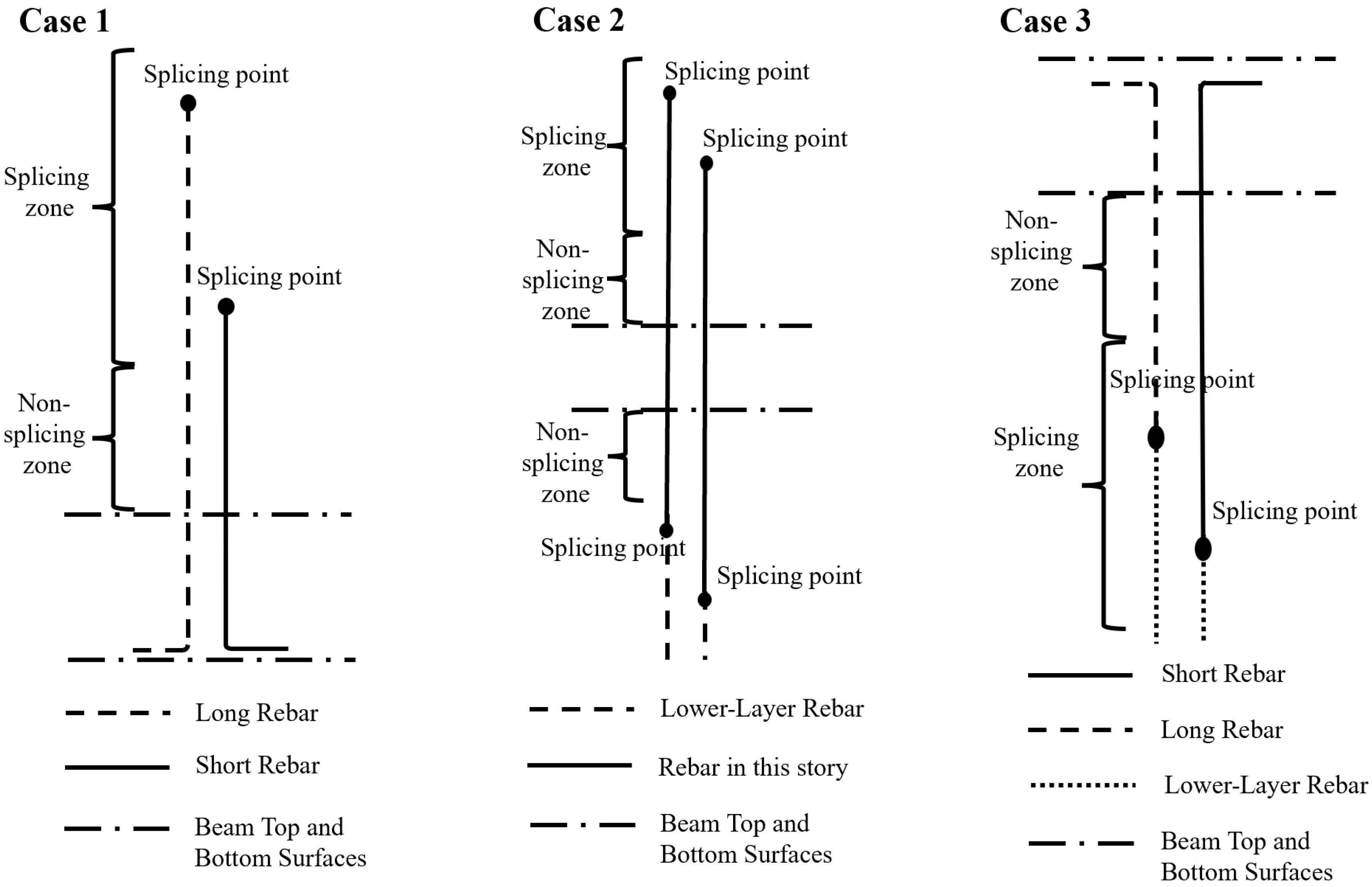

2.1. Optimization of Rebar Splice Points

2.2. Hybrid Optimization Method for Rebar Cutting

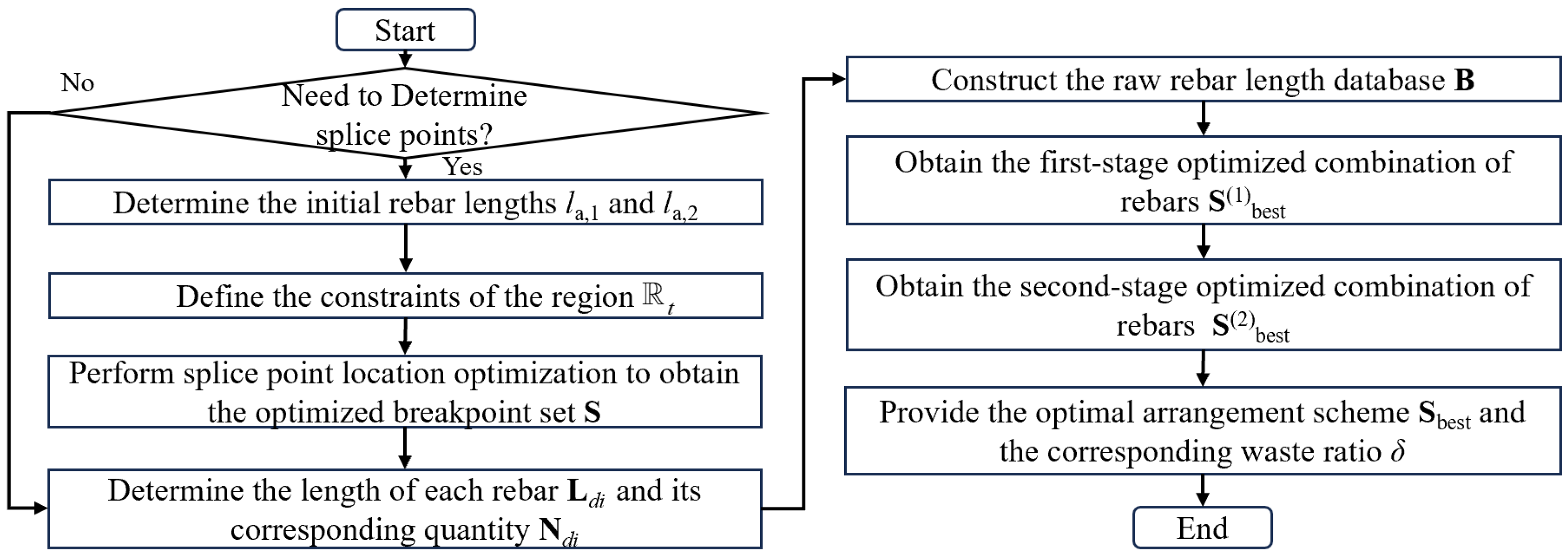

2.3. Framework of the Rebar Cutting Optimization Method

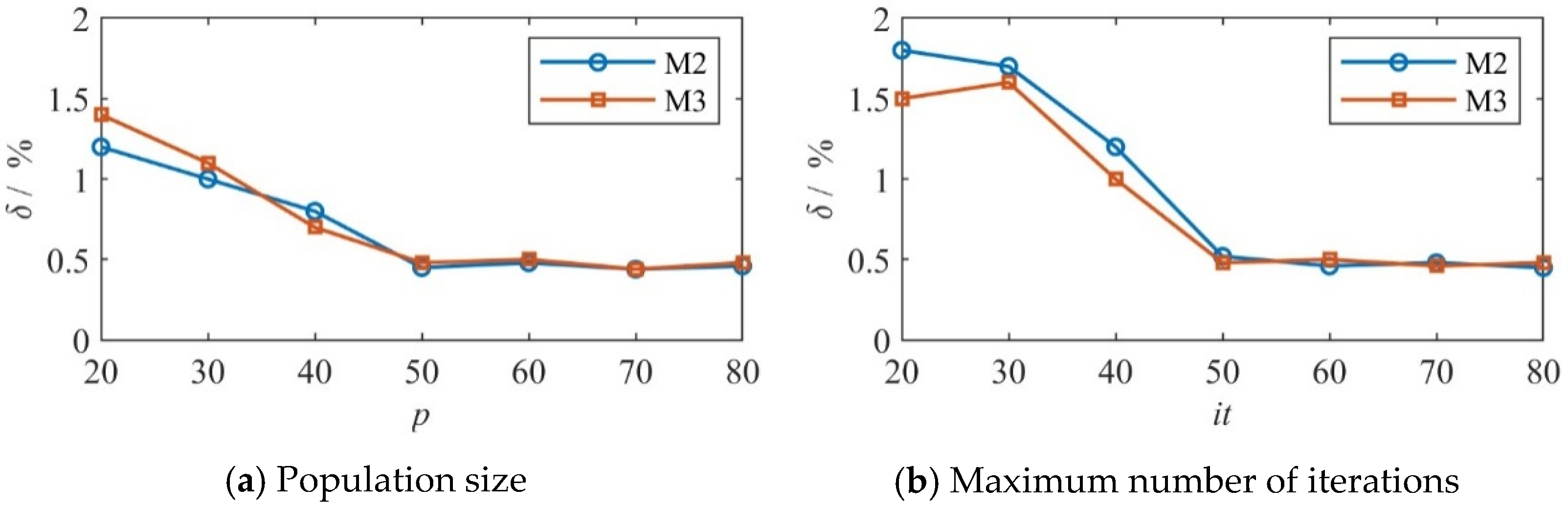

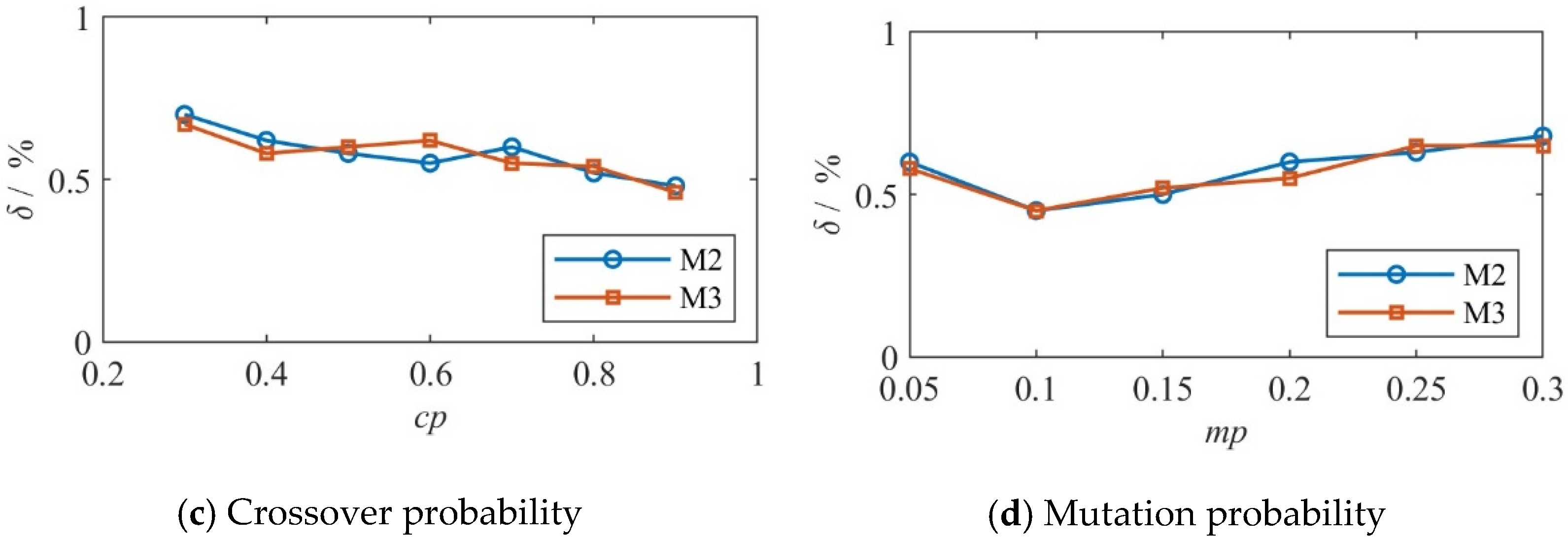

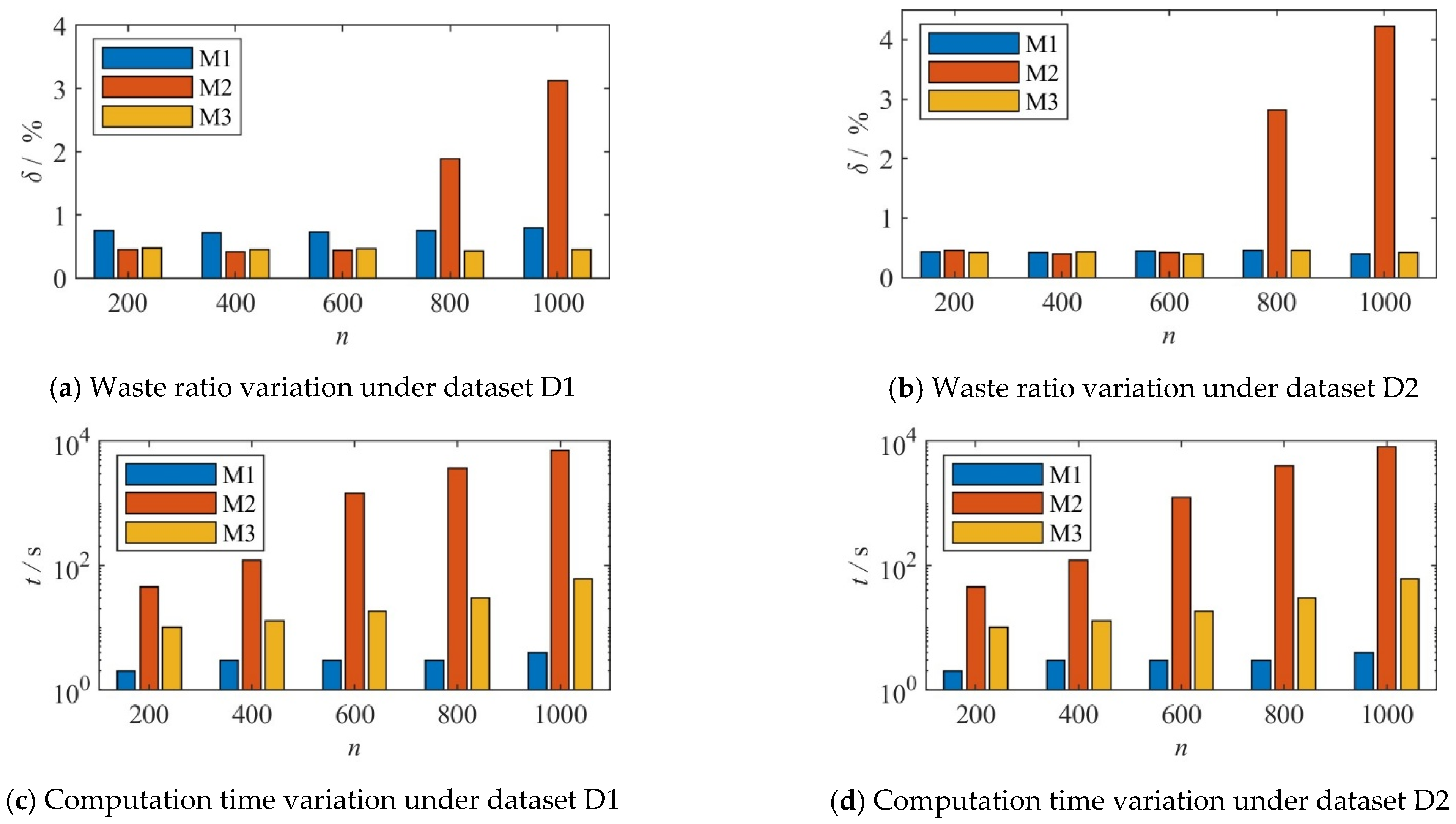

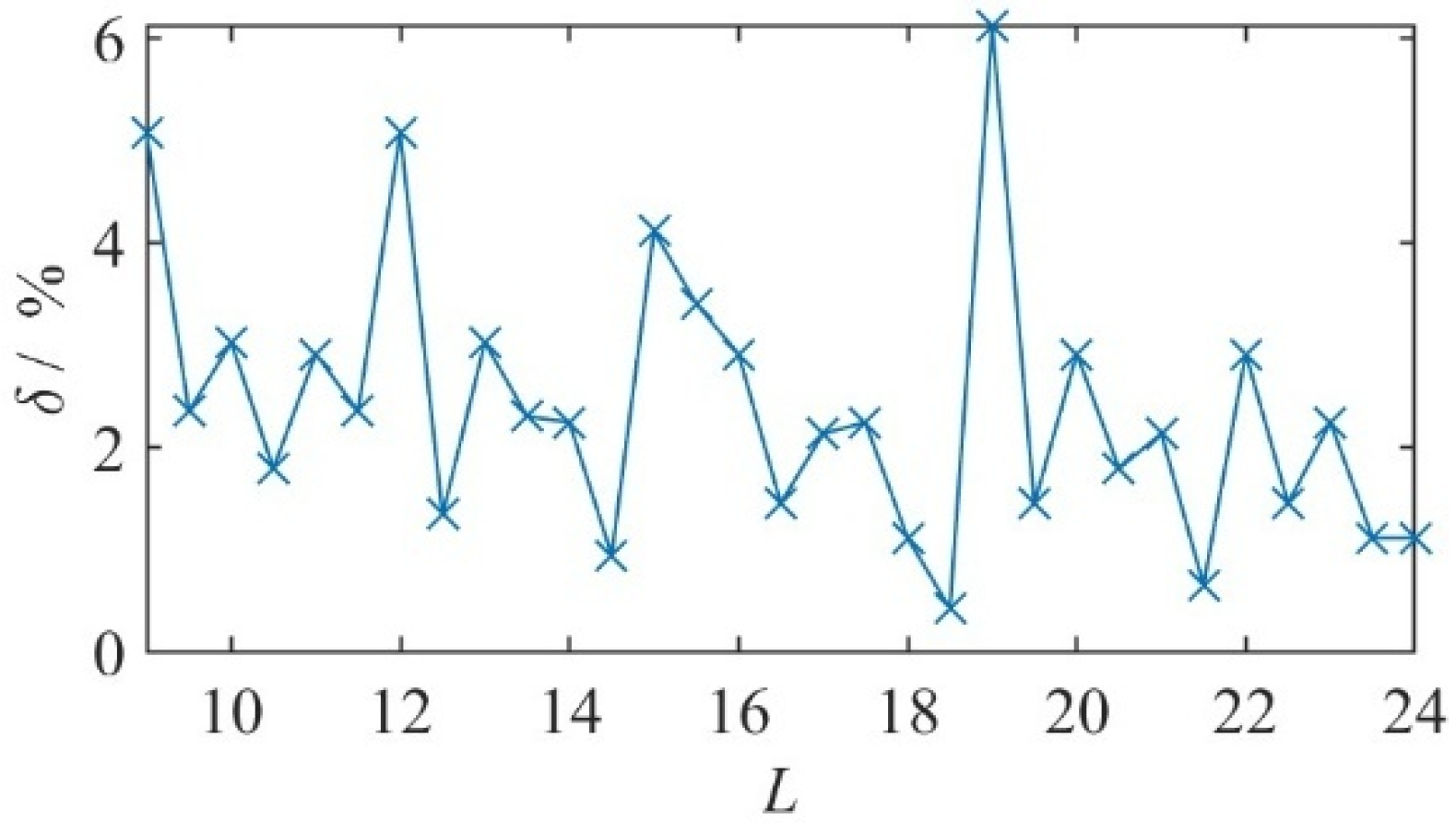

3. Numerical Example: Performance Analysis of the Algorithm

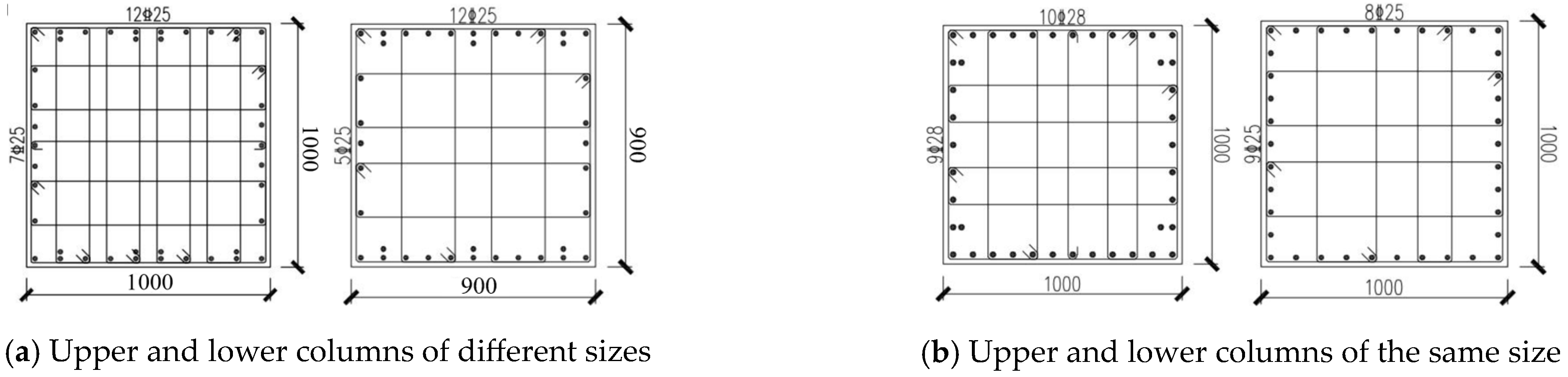

4. Engineering Example 1: Cutting Optimization of Column Reinforcement

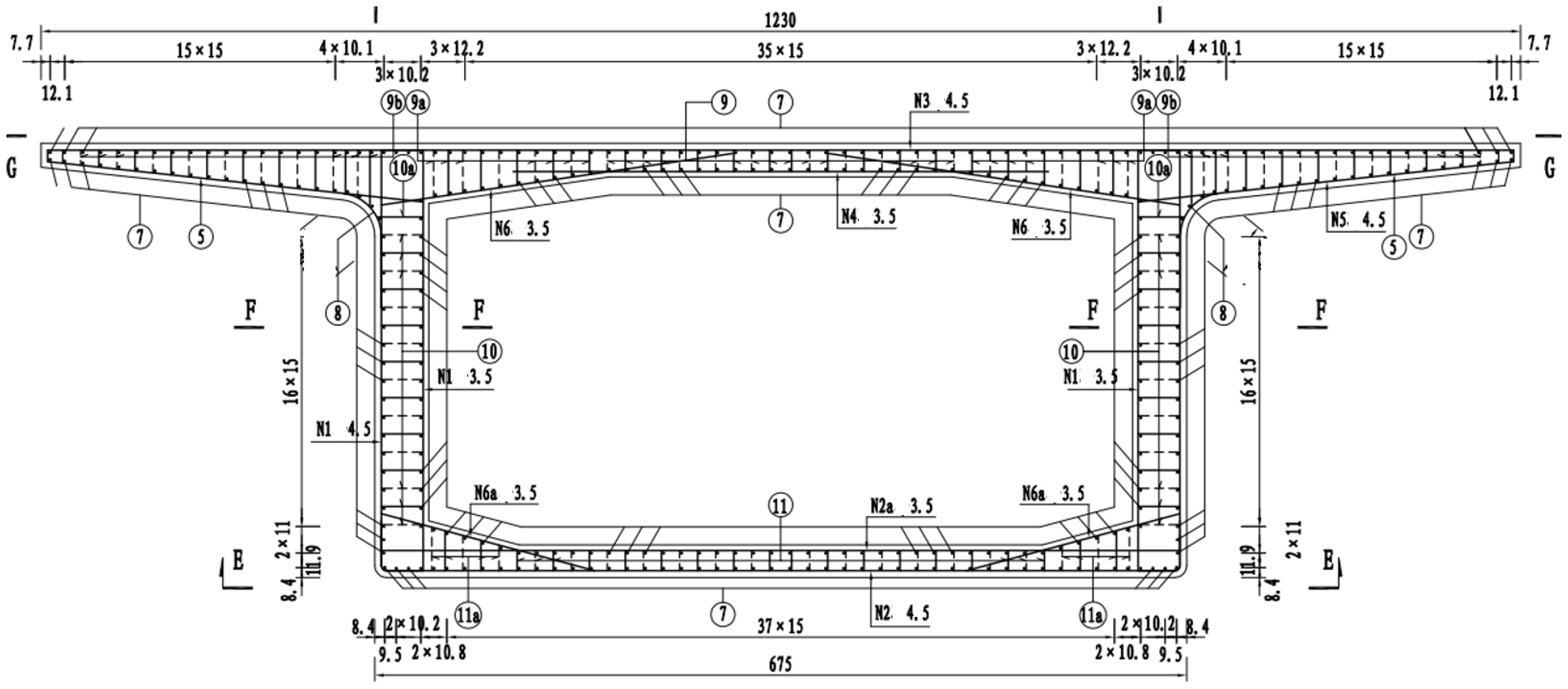

5. Engineering Example 2: Cutting Optimization of Beam Reinforcement

6. Conclusions

- A Markov-based cutting-point determination method for long rebars is proposed. The splicing process of long rebars during construction is modeled as a state-transition path, and the optimal cutting-point path is determined by a state-transition optimization function under the constraint of code-specified splice zones.

- For large-scale combinations of rebars with varying lengths, a hybrid cutting optimization method is developed, integrating local sequential arrangement with global combinatorial arrangement. In the first stage, the local sequential method rapidly identifies rebars suitable for efficient combinations. In the second stage, the remaining rebars that are difficult to optimize are further processed using global combinatorial arrangement, thereby improving the overall solution quality while maintaining computational efficiency.

- Numerical examples demonstrate that the proposed hybrid optimization algorithm exhibits excellent capability in controlling waste ratios under various length distributions and large-scale datasets, while significantly outperforming the pure global combinatorial arrangement method in terms of optimization time.

- Engineering Case 1 shows that the proposed method can reduce the waste ratio of longitudinal column rebar cutting to below 1% at each story, achieving rapid and precise optimization of thousands of rebars. Engineering Case 2 further demonstrates that the algorithm can flexibly integrate custom raw rebar lengths to adjust cutting schemes, achieving significant material savings in the standard segment of a precast bridge.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z.; Jia, L.; Lv, J.; Huang, J. Minimization of rebar cutting waste using BIM and cutting pattern-oriented multiobjective optimization. J. Constr. Eng. Manag. 2024, 150, 15104. [Google Scholar] [CrossRef]

- Widjaja, D.D.; Rachmawati, T.S.N.; Kim, S. A BIM-based intelligent approach to rebar layout optimization for reinforced concrete columns. J. Build. Eng. 2025, 99, 111604. [Google Scholar] [CrossRef]

- Ren, K.; Jia, L.; Huang, J.; Wu, M. Research on cutting stock optimization of rebar engineering based on building information modeling and an improved particle swarm optimization algorithm. Dev. Built Environ. 2023, 13, 100121. [Google Scholar] [CrossRef]

- Rozvany, G.I.N. A critical review of established methods of structural topology optimization. Struct. Multidiscip. Optim. 2009, 37, 217–237. [Google Scholar] [CrossRef]

- Rajeev, S.; Krishnamoorthy, C.S. Discrete optimization of structures using genetic algorithms. J. Struct. Eng. ASCE 1992, 118, 1233–1250. [Google Scholar] [CrossRef]

- Camp, C.V.; Pezeshk, S.; Hansson, H. Flexural design of reinforced concrete frames using a genetic algorithm. J. Struct. Eng. ASCE 2003, 129, 105–115. [Google Scholar] [CrossRef]

- Doğan, E.; Saka, M.P. Optimum design of unbraced steel frames to LRFD-AISC using particle swarm optimization. Adv. Eng. Softw. 2012, 46, 27–34. [Google Scholar] [CrossRef]

- Chen, A.; Trivedi, K.S. Optimization for condition-based maintenance: A semi-Markov decision process approach. Reliab. Eng. Syst. Saf. 2005, 90, 25–29. [Google Scholar] [CrossRef]

- Guo, C.; Ramadan, H.; Hovakimyan, N. A predictive Markov decision process for optimizing condition-based maintenance policies. Reliab. Eng. Syst. Saf. 2022, 226, 108683. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, T.; Liu, Z.; Li, G.; Jiang, J. Seismic behavior of steel-reinforced concrete cross-shaped columns after exposure to high temperatures. Eng. Struct. 2021, 230, 111723. [Google Scholar] [CrossRef]

- Pan, R.; Liao, P.; Zou, J.; Zhou, X.; Li, C. Experimental investigation on bond performance of helically ribbed GFRP rebar embedded in Ultra-high performance concrete. Constr. Build. Mater. 2022, 357, 129295. [Google Scholar] [CrossRef]

- Widjaja, D.D.; Kim, S. Reducing rebar cutting waste and rebar usage of beams: A two-stage optimization algorithm. Buildings 2023, 13, 2279. [Google Scholar] [CrossRef]

- Uzer, M.S. New hybrid approaches based on swarm-based metaheuristic algorithms and applications to optimization problems. Appl. Sci. 2025, 15, 1355. [Google Scholar] [CrossRef]

- Widjaja, D.D.; Kim, S. Intelligent rebar optimization framework for urban transit infrastructure: A case study of a diaphragm wall in a Singapore Mass Rapid Transit station. Smart Cities 2025, 8, 130. [Google Scholar] [CrossRef]

- Fu, X.; Ji, K.; Zhang, Y.; Xie, Q.; Huang, J. Intelligent optimization method for rebar cutting in pump station based on an improved genetic algorithm with BIM. Buildings 2025, 15, 1790. [Google Scholar] [CrossRef]

- Widjaja, D.D.; Kim, S.; Kim, D.J. Optimizing rebar consumption and cutting waste in column reinforcement: Integrated mechanical couplers and a special-length-priority minimization algorithm. Buildings 2024, 14, 287. [Google Scholar] [CrossRef]

- JGJ 107-2016; Technical Specification for Mechanical Splicing of Steel Reinforcing Bars. Architecture & Building Press: Beijing, China, 2016.

- GB 50010-2010; Code for Design of Concrete Structures. Architecture & Building Press: Beijing, China, 2016.

- GB 50011-2010; Code for Seismic Design of Buildings. Architecture & Building Press: Beijing, China, 2024.

| Symbol | Type | Description |

|---|---|---|

| t | index | the splicing step |

| St | state variable | the splicing state at step t |

| at | decision variable | the action taken at the t-th splicing step |

| R(St,at,St+1) | reward function | the benefit or penalty associated with the state transition |

| ALB,t | parameter | the lower bound of the permissible interval for the t-th splicing |

| AUB,t | parameter | the upper bound of the permissible interval for the t-th splicing |

| dt | parameter | the minimum spacing between adjacent splicing points |

| Symbol | Type | Description |

|---|---|---|

| Rj | parameter | the waste length of the j-th raw rebar. |

| Bj | parameter | the length of the j-th raw rebar |

| k | parameter | the number of rebars cut from the j-th raw rebar |

| S(2) | decision variable | the cutting scheme in the second stage |

| f(S(2)) | function | the fitness function of the second-stage optimization |

| α | parameter | the penalty coefficient |

| S(2)best | result | the optimal cutting scheme obtained in the second-stage optimization |

| S(1)best | result | the cutting scheme obtained in the first-stage greedy optimization |

| Sbest | result | the overall optimal cutting scheme, combining both the first and second stages |

| Number of Stories | 1 | 2–4 | 5–7 | |

|---|---|---|---|---|

| Floor Information | ||||

| Story height/m | 5.95 | 7.80 | 7.00 | |

| Maximum beam depth/m | 1.10 | 1.10 | 1.10 | |

| Upper limit of splicing zone/m | 3.85 | 5.58 | 4.92 | |

| Lower limit of splicing zone/m | 1.00 | 1.12 | 0.98 | |

| Number of Stories | Breakpoint 1/m | Height Difference from Floor Base/m | Breakpoint 2/m | Height Difference from Floor Base/m |

|---|---|---|---|---|

| 1 | 2 | 2.00 | 1 | 1.00 |

| 2 | 11 | 5.05 | 10 | 4.05 |

| 3 | 15 | 1.25 | 16 | 2.25 |

| 4 | 24 | 2.45 | 25 | 3.45 |

| 5 | 33 | 3.65 | 34 | 4.65 |

| 6 | 37.5 | 1.15 | 38.5 | 2.15 |

| 7 | 46.5 | 3.15 | 47.5 | 4.15 |

| Number of Stories | 22 mm | 25 mm | 28 mm | 32 mm |

|---|---|---|---|---|

| 1 | 0.30 | 0.77 | 0.42 | 0.55 |

| 2 | 0.56 | 0.67 | 0.44 | 0.61 |

| 3 | 1.10 | 0.68 | 0.46 | 0.59 |

| 4 | 0.72 | 0.84 | 0.77 | 0.62 |

| 5 | 0.44 | 0.80 | 0.69 | 0.23 |

| 6 | 0.69 | 0.50 | 0.52 | 0.33 |

| 7 | 0.90 | 0.62 | 0.66 | 0.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Chen, X.; Lv, F. A Hybrid Optimization Method for Rebar Cutting in Structural Reinforcement. Buildings 2025, 15, 3693. https://doi.org/10.3390/buildings15203693

Zhang J, Chen X, Lv F. A Hybrid Optimization Method for Rebar Cutting in Structural Reinforcement. Buildings. 2025; 15(20):3693. https://doi.org/10.3390/buildings15203693

Chicago/Turabian StyleZhang, Jindong, Xiaoming Chen, and Fanghong Lv. 2025. "A Hybrid Optimization Method for Rebar Cutting in Structural Reinforcement" Buildings 15, no. 20: 3693. https://doi.org/10.3390/buildings15203693

APA StyleZhang, J., Chen, X., & Lv, F. (2025). A Hybrid Optimization Method for Rebar Cutting in Structural Reinforcement. Buildings, 15(20), 3693. https://doi.org/10.3390/buildings15203693