Structural Design Method for Narrow Coal Pillars in Gateway Protection: Framework and Field Case Study

Abstract

1. Introduction

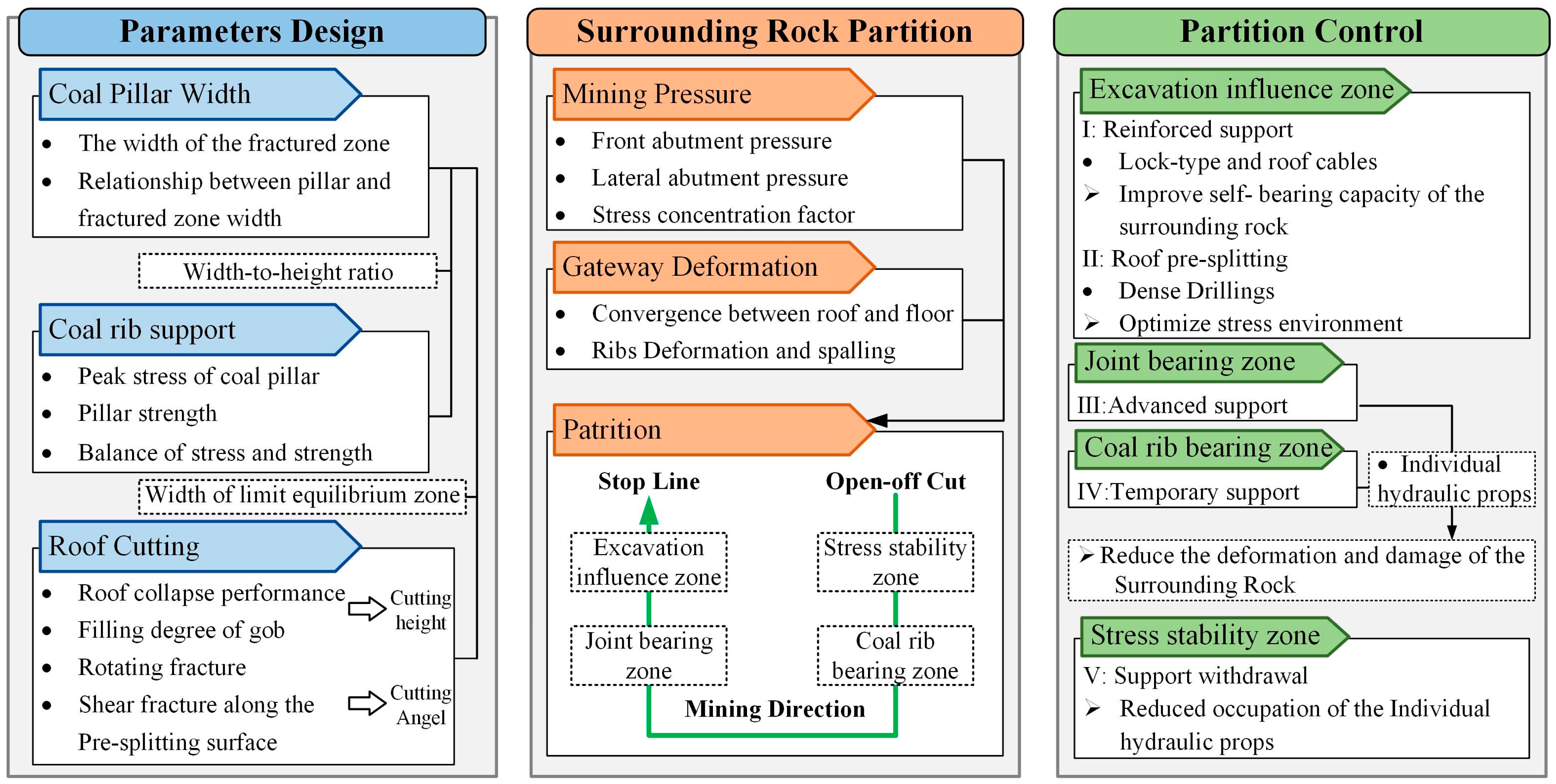

2. Design Methodology

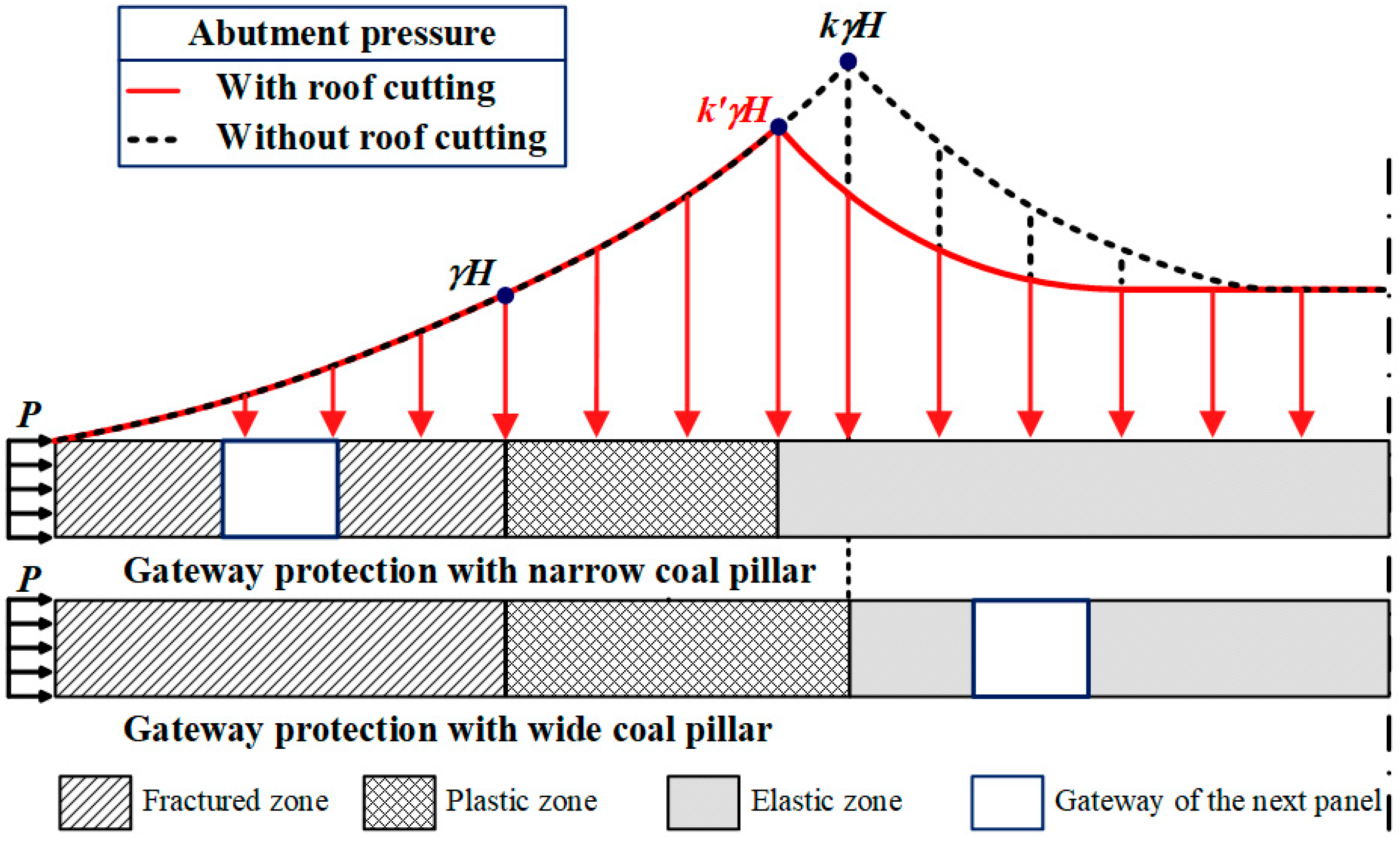

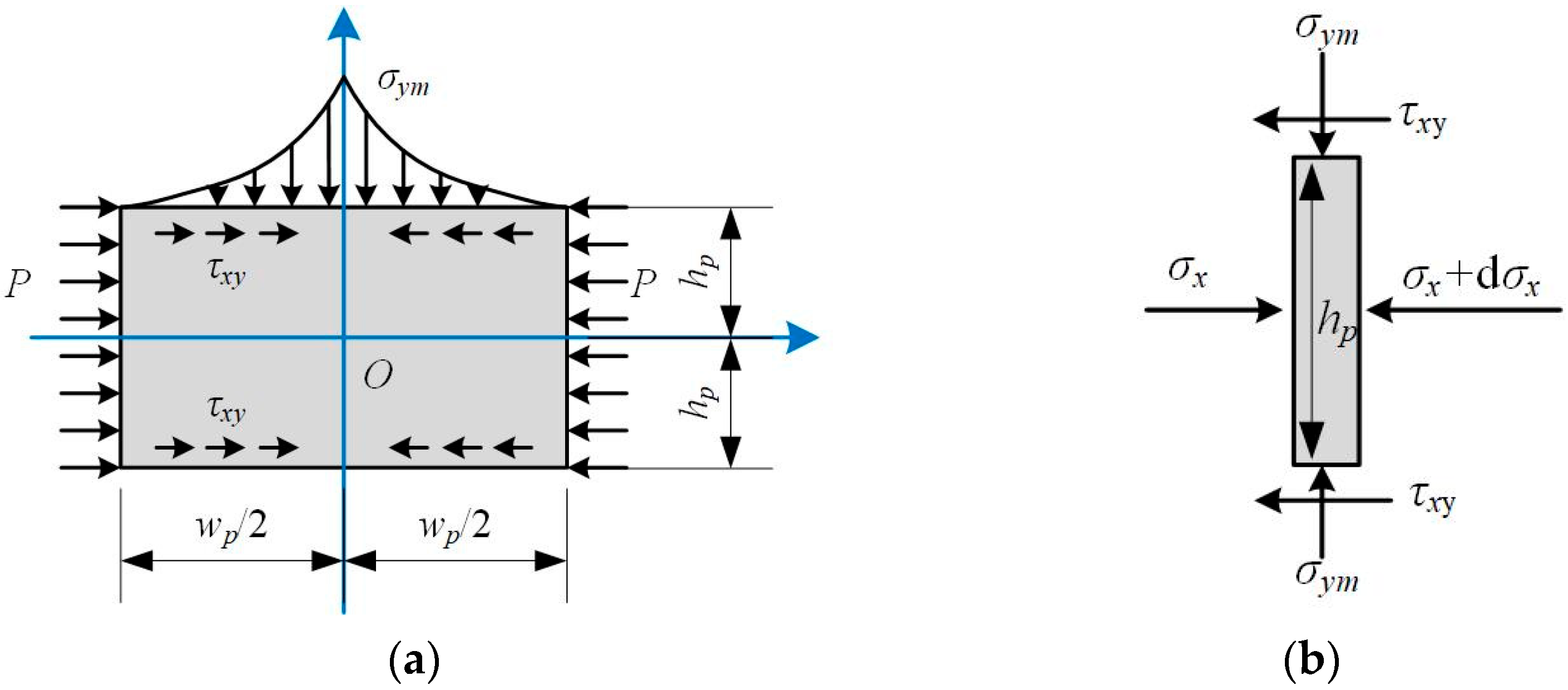

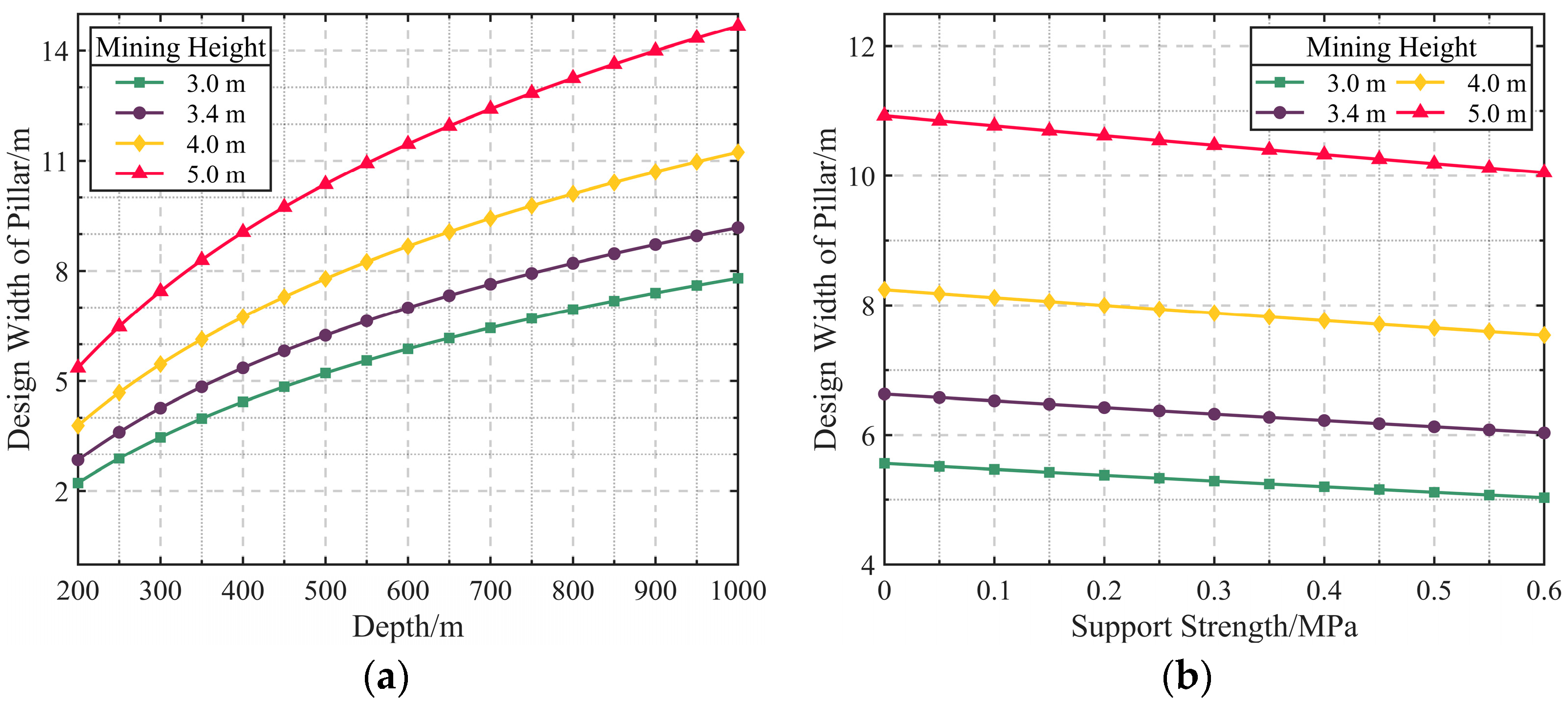

2.1. Determine the Extent of the Stress Reduction Zone and Optimize the Width of the Pillar

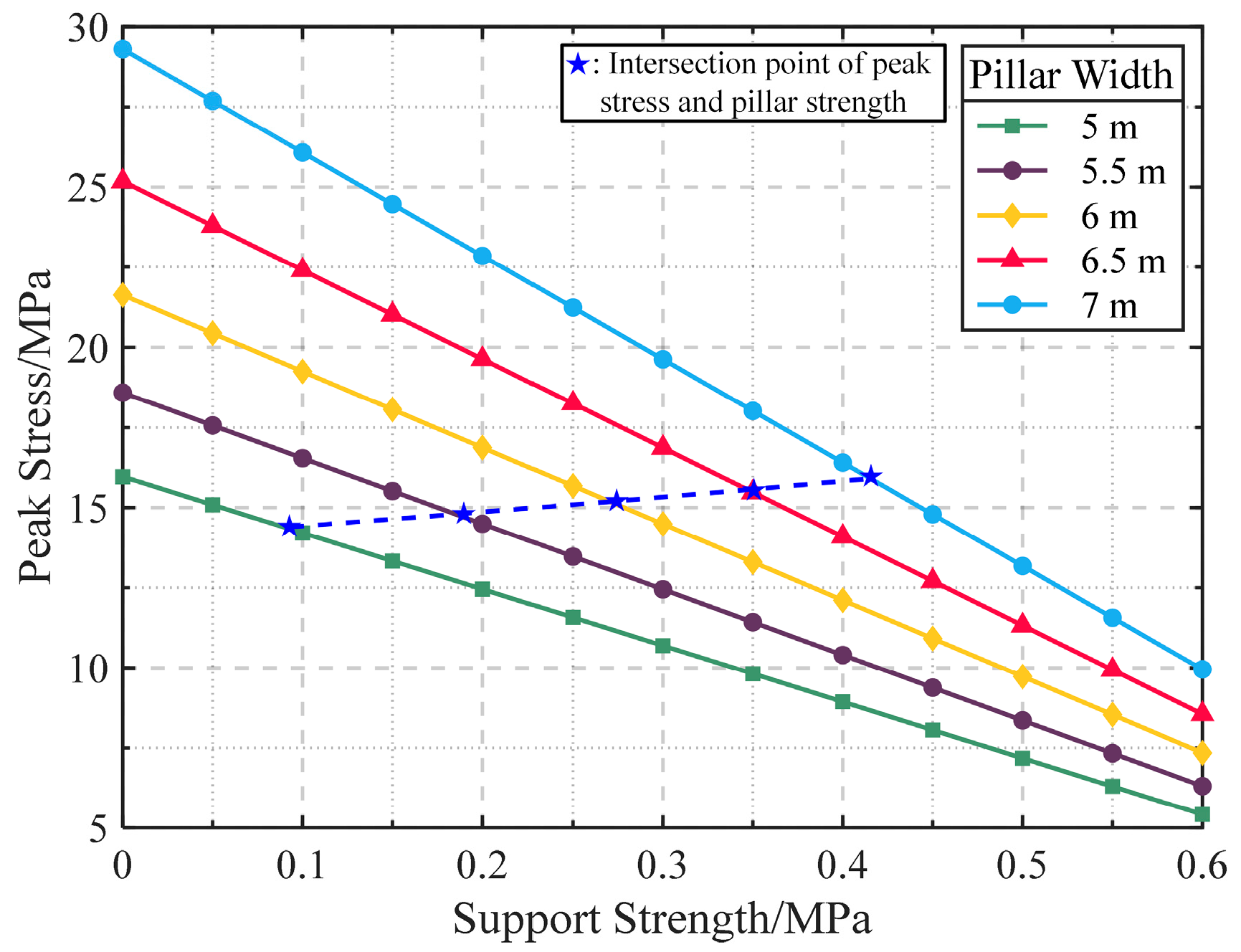

2.2. Enhance the Strength of the Narrow Pillar Through Increasing Support Strength

2.3. Implement Roof Cutting to Optimize the Stress Environment of the Gateway

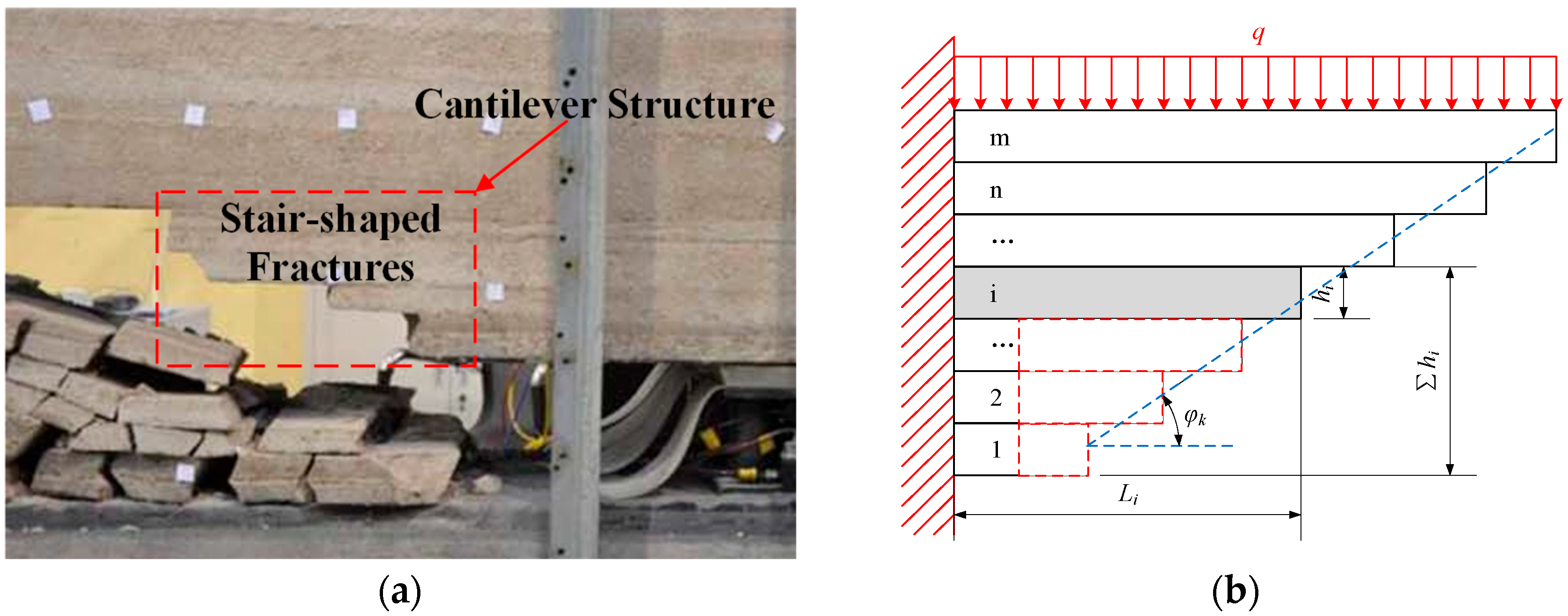

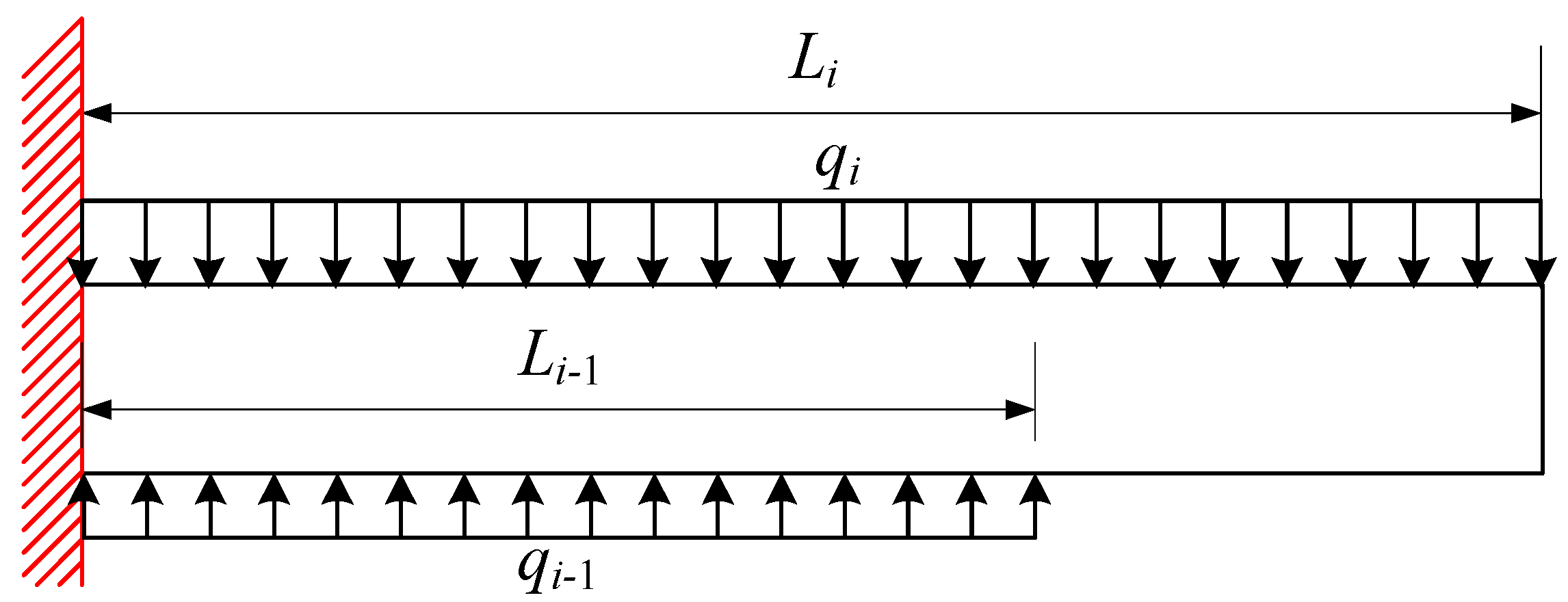

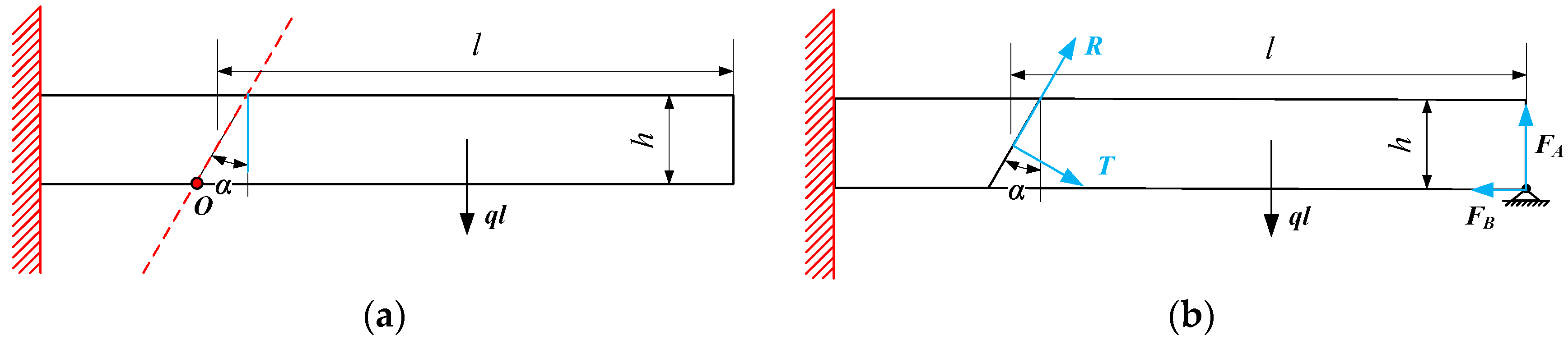

2.3.1. Design of Roof Pre-Splitting Height

2.3.2. Design of Pre-Splitting Cutting Angle

3. Case Study

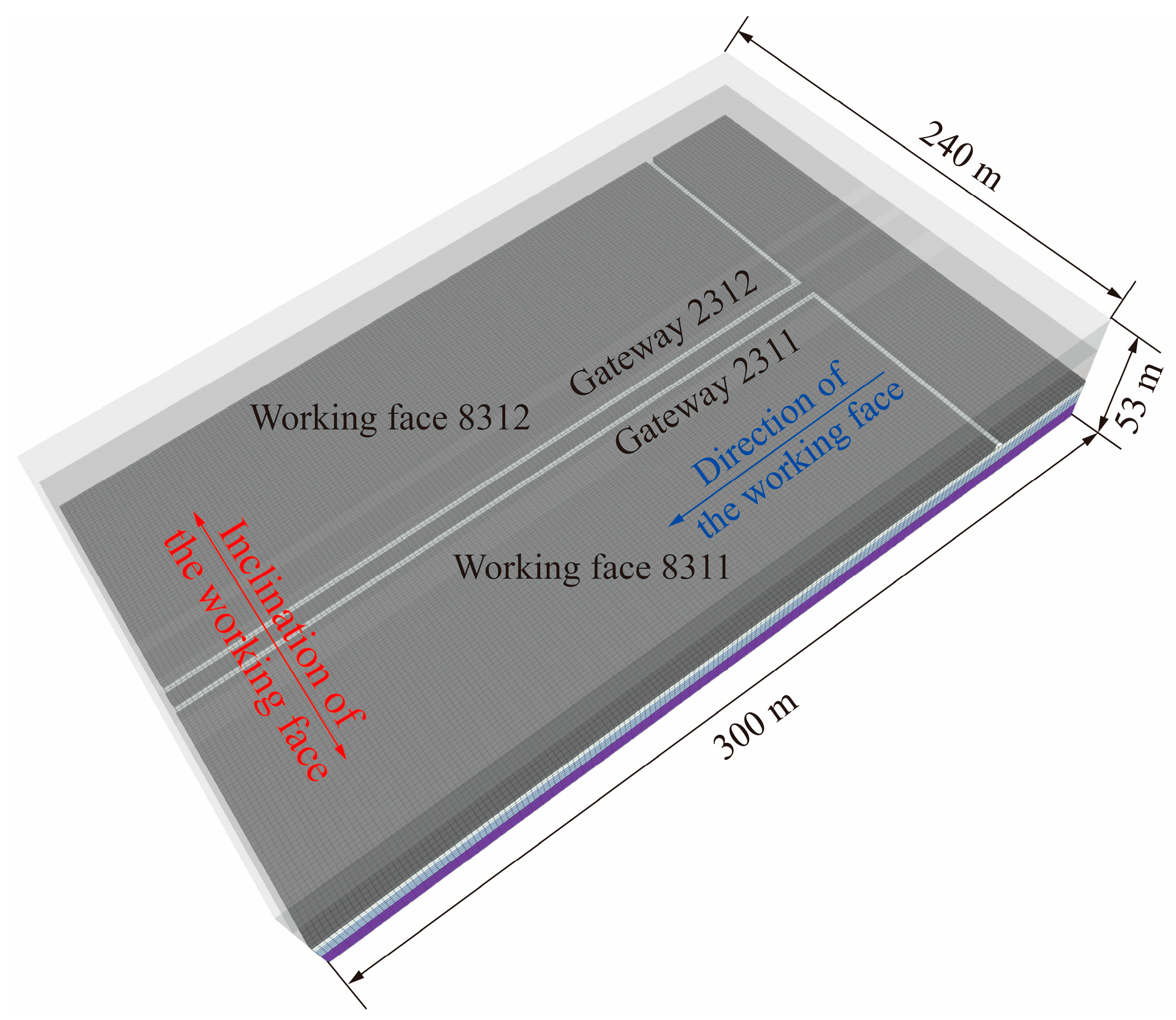

3.1. Geological and Geotechnical Overview

3.2. Design Parameters

3.3. Mechanism of Mining Pressure Manifestation

- (1)

- Excavation influence zone (outside the range of 50 m ahead of panel 8311). This area is less affected by the front abutment pressure but, due to gateway excavation, the surface of the coal body transitions from a three-dimensional stress state to a two-dimensional stress state, and its strength decreased. Therefore, the surface of the coal body of gateway 2312 was damaged, with a vertical stress of less than 6 MPa and only half of the virgin stress, while the internal vertical stress of the coal pillar reached 19.8 MPa, with a concentration coefficient of 1.56.

- (2)

- Joint-bearing zone (within 50 m head of panel 8311). Due to the influence of abutment pressure, the stress in the surrounding rock of gateway 2312 significantly increased. The narrow coal pillar began to fail under the action of front abutment pressure, but the overall coal pillar was still in an elastic state, and the peak stress was located inside the coal pillar. At this time, the overlying strata load was still jointly carried by the coal pillar and coal rib.

- (3)

- Coal-rib-bearing zone (within a lag range of 50 m behind panel 8311). The narrow coal pillar entered a plastic state under the abutment pressure, and the bearing capacity was greatly reduced. The peak stress of the surrounding rock was transferred from the inside of the coal pillar to the entity coal and gradually moved towards the depth of the entity coal. ML 1 to 4 reached peak values of 27.8 MPa, 29.2 MPa, 37.4 MPa, and 27.1 MPa at 137.5 m, 105 m, 60 m, and 60 m, respectively. At this time, the overlying strata load was mainly carried by the coal rib. In addition, the analysis showed that the impact range of front abutment pressure (LF), the severe impact range of side abutment pressure (LL′), and the impact range of side abutment pressure (LL) were 50 m, 25 m, and 75 m, respectively.

- (4)

- Stress stability zone (outside the range of 50 m behind panel 8311). The surrounding rock stress caused by the mining of the working face became redistributed, and the gangue in the gob and the coal wall in working face 8312 became the main load-bearing structure. The surrounding rock of the gateway was relatively stable. At this point, the peak stress inside the coal pillar was about 10 MPa, which still has a certain bearing capacity.

3.4. Technical Process Based on Theoretical Parameters

- (1)

- In the excavation influence zone, the lock-type cables and the roof cables were respectively used to reinforce the support of the narrow coal pillar and the roof of the gateway in working face 8312. The surrounding rock of both gateways in this area was in a stable state with relatively little deformation. Timely reinforcement and support can more effectively exert the effect of bolts and cables. In order to prevent severe fragmentation of the pillar after the influence of a single mining operation, using only conventional bolt or cable support was insufficient to meet the reinforcement requirements. Therefore, it is necessary to use high-strength 1 × 19 cables with 21.8 mm in diameter and 6600 mm in length, combined with Q335 bolts with 22 mm in diameter and 2000 mm in length, to reinforce the narrow pillar. According to the calculation results of a reasonable coal pillar support strength of 0.3MPa, the designed spacing and row spacing of lock-type cables for the narrow pillar were 1600 mm and 2400 mm, respectively. Both spacing and row spacing of the bolts of two ribs were designed to be 1000 mm. The roof was reinforced with Φ21.8 mm × 9300 mm 1 × 19 steel strand cables, with one cable per row and a row spacing of 2.4 m, as shown in Figure 14c.

- (2)

- For the excavation influence zone, outside the range of front abutment pressure in working face 8311, directional pre-splitting of the roof by dense drilling was implemented in gateway 2311 (with a height of 8 m and a pre-splitting angle of 0°). Along the advancing direction of panel 8311, dense drilling holes were constructed 0.5 m from the narrow pillar with a hole diameter of 30 mm and spacing of 250 mm, giving a hole-to-spacing ratio of 8.33. The drilling angle was 0° ± 5° along the plumb line direction, and the height was 9.0 m. The roof pre-splitting through dense drilling helped to further develop and fully connect the pre-splitting surface under mining stress, further promoting the timely collapse of the cantilever structure and reducing the stress of the surrounding rock in the gateway of working face 8312.

- (3)

- Individual hydraulic props were used (one per row, with a row spacing of 0.5 m, working resistance of 300 kN, maximum height of 4 m) to provide advanced support in the joint-bearing zone of panel 8311 and, at the same time, individual hydraulic props were used for temporary support in both the joint-bearing zone and coal-rib-bearing zone of the gateway in panel 8312. The stress transfer process within the joint-bearing zone and coal-rib-bearing zone continued, and the combination of active and passive support was used to enhance the strength of surrounding rock support, which helps maintain gateway stability.

- (4)

- After the gateway entered the stress stability zone, the cantilever structure collapsed and filled the gob, which could bear the load on the overlying strata. The bearing performance of the surrounding rock formed a new balance with the stress. As the working face advanced, the passive support equipment could be gradually withdrawn to reduce its occupancy.

- (1)

- To ensure the normal service of gateway 2312 under the influence of repeated mining, it is necessary to reinforce the support in a timely manner after its excavation, which needs to be completed within a range of 50 m ahead of panel 8311.

- (2)

- The roof pre-splitting operation should be completed within a range of 50 m ahead of panel 8311 but should lag the support reinforcement.

- (3)

- To avoid the impact of mining on working face 8311, which may cause the two gateways to be subjected to front abutment pressure and affect normal use, the advanced support area is set up within a range of 30–50 m ahead of the longwall face, and passive support is used to temporarily support gateway 2312 within a range of 50 m behind panel 8311.

- (4)

- After the side abutment pressure of the 8311 gob stabilizes, the individual hydraulic props are retreated and moved forward.

4. Results

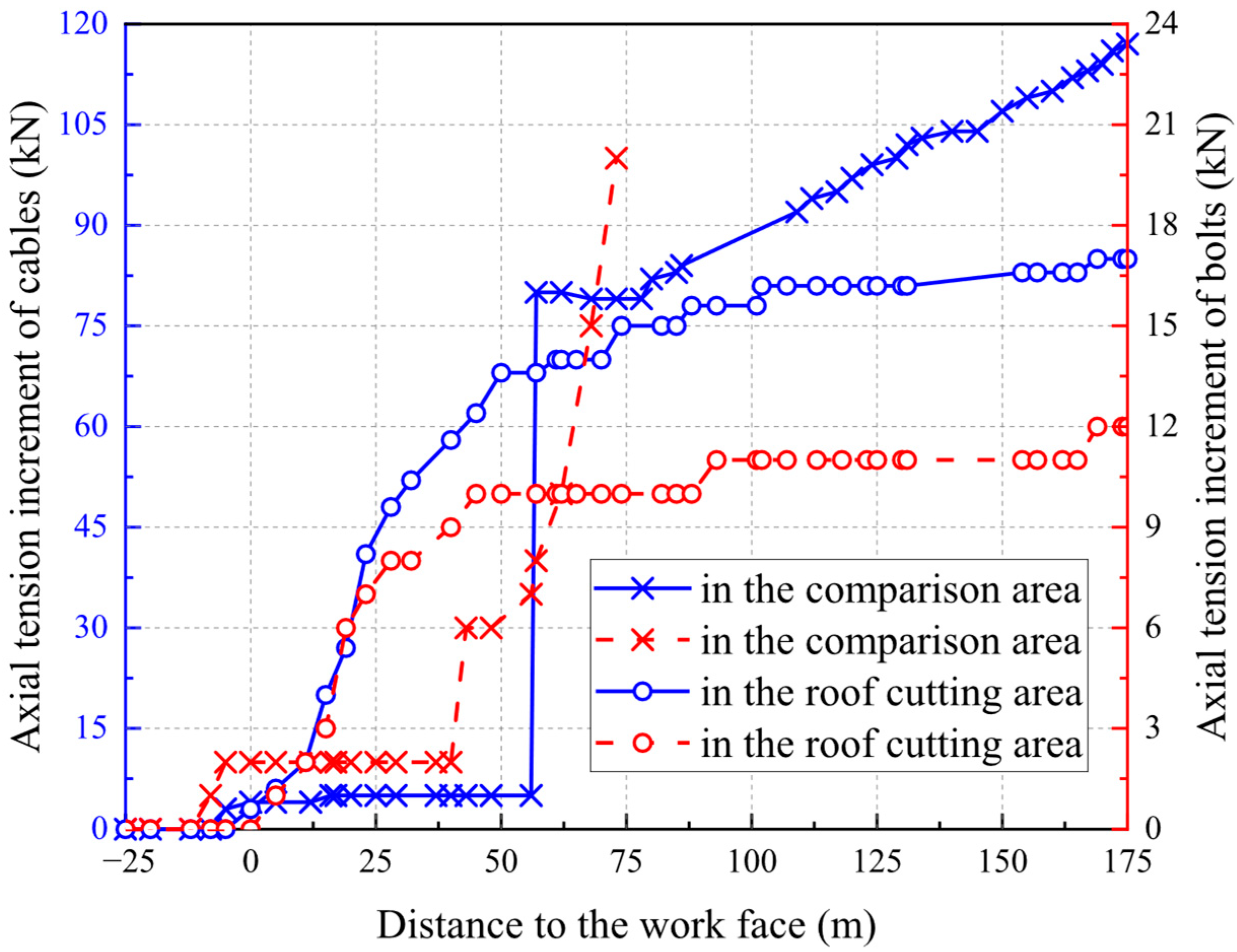

4.1. Force Monitoring of Bolts and Cables

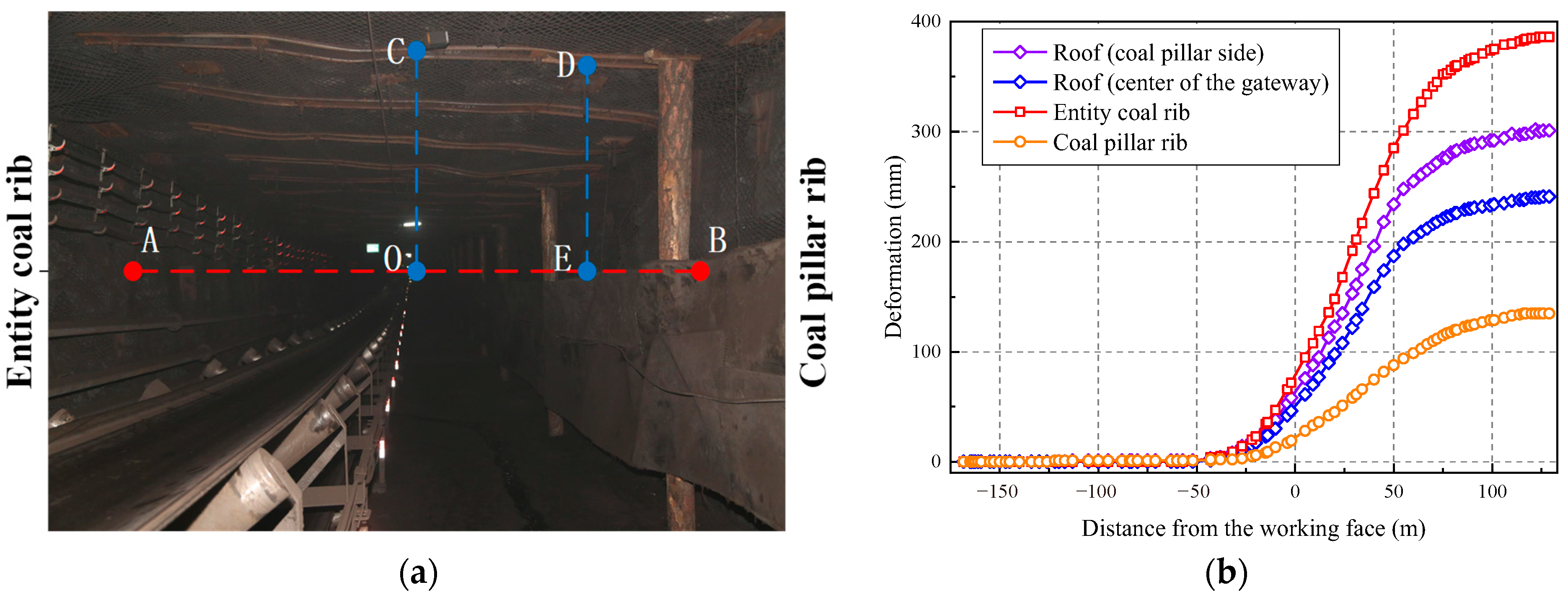

4.2. Gateway Deformation Monitoring

5. Discussion and Conclusions

5.1. Discussion

5.2. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nacke, L.; Vinichenko, V.; Cherp, A.; Jakhmola, A.; Jewell, J. Compensating Affected Parties Necessary for Rapid Coal Phase-out but Expensive If Extended to Major Emitters. Nat. Commun. 2024, 15, 3742. [Google Scholar] [CrossRef] [PubMed]

- Lin, B.; Shi, F. Coal Price, Economic Growth and Electricity Consumption in China under the Background of Energy Transition. Energy Policy 2024, 195, 114400. [Google Scholar] [CrossRef]

- Zhang, G.; Zang, C.; Chen, M.; Tao, G.; Li, Y.; Weng, H. Ground Response of Entries Driven Adjacent to a Retreating Longwall Panel. Int. J. Rock Mech. Min. Sci. 2021, 138, 104630. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, F.; Liang, N.; Wang, W. Reasonable Segment Pillar Width and Its Control Technology for Fully Mechanized Top-Coal Caving Face with High Stress. J. Min. Saf. Eng. 2018, 35, 19–26. [Google Scholar] [CrossRef]

- Zhao, S.; Zuo, J.; Liu, L.; Wu, K. Study on the Retention of Large Mining Height and Small Coal Pillar under Thick and Hard Roof of Bayangaole Coal. Adv. Civ. Eng. 2021, 2021, 8837189. [Google Scholar] [CrossRef]

- Yang, R.; Zhu, Y.; Li, Y.; Li, W.; Lin, H. Coal Pillar Size Design and Surrounding Rock Control Techniques in Deep Longwall Entry. Arab. J. Geosci. 2020, 13, 453. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, C.; Cheng, G.; Von Lau, E. Towards Carbon Neutrality: A Comprehensive Study on the Utilization and Resource Recovery of Coal-Based Solid Wastes. Int. J. Coal Sci. Technol. 2025, 12, 34. [Google Scholar] [CrossRef]

- Ren, S.-H.; Jiao, X.-M.; Zheng, D.-Z.; Zhang, Y.-N.; Xie, H.-P.; Guo, Z.-Q. Demand and Fluctuation Range of China’s Coal Production under the Dual Carbon Target. Energy Rep. 2024, 11, 3267–3282. [Google Scholar] [CrossRef]

- Guo, W.B.; Hu, Y.H.; Hu, C.Q.; Li, L.X.; Wu, D.T.; Ge, Z.B. System and engineering practice of coal mining technology under buildings, water bodies and railways in China. Coal Sci. Technol. 2025, 53, 19–38. [Google Scholar] [CrossRef]

- Li, H.; Cao, J.; Tang, C.; Guo, G.; Chen, Y.; Zha, J.; Huang, W.; Yuan, Y.; Huang, J. Methods for Enhancing Resource Recovery Efficiency in Underground Coal Gasification to Promote Its Large-Scale Utilization. Geomech. Energy Environ. 2025, 41, 100651. [Google Scholar] [CrossRef]

- Li, X. Study on Stability of Big and Small Structure of Roadway Driving Along Next Goaf for Fully Mechanized Face. Ph.D. Thesis, China University of Mining &Technology, Xuzhou, China, 2000. [Google Scholar]

- Zhang, Z.; Deng, M.; Bai, J.; Yan, S.; Yu, X. Stability Control of Gob-Side Entry Retained under the Gob with Close Distance Coal Seams. Int. J. Min. Sci. Technol. 2021, 31, 321–332. [Google Scholar] [CrossRef]

- Hou, C.; Li, X. Stability Principle of Big and Small Structures of Rock Surrounding Roadway Driven along Goaf in Fully Mechanized Top Coal Caving Face. J. China Coal Soc. 2001, 26, 1–7. [Google Scholar]

- Li, X.; Zhao, Y.; He, W.; Li, L.; He, F. Study on Coal Pillar Width and Surrounding Rock Control of Gob-Side Entry in Extra-Thick Coal Seam. Geotech. Geol. Eng. 2020, 38, 6855–6868. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, J.; Wang, W.; Zhang, R. Research on Coal Pillar Width and Support Design of Gob-Side Entry. Geotech. Geol. Eng. 2023, 41, 847–860. [Google Scholar] [CrossRef]

- He, W.; He, F.; Zhao, Y. Field and Simulation Study of the Rational Coal Pillar Width in Extra-Thick Coal Seams. Energy Sci. Eng. 2020, 8, 627–646. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, P.; Chen, L.; Hao, Z.; Sainoki, A.; Mitri, H.S.; Wang, Q. Numerical Approach for Goaf-Side Entry Layout and Yield Pillar Design in Fractured Ground Conditions. Rock Mech. Rock Eng. 2017, 50, 3049–3071. [Google Scholar] [CrossRef]

- Mark, C.; Gauna, M. Pillar Design and Coal Burst Experience in Utah Book Cliffs Longwall Operations. Int. J. Min. Sci. Technol. 2021, 31, 33–41. [Google Scholar] [CrossRef]

- Escobar, S. Implementing the Empirical Stone Mine Pillar Strength Equation into the Boundary Element Method Software LaModel. Master’s Thesis, West Virginia University Libraries, Keyser, WV, USA, 2021. [Google Scholar]

- Tuncay, D.; Tulu, I.B.; Klemetti, T. Investigating Different Methods Used for Approximating Pillar Loads in Longwall Coal Mines. Int. J. Min. Sci. Technol. 2021, 31, 23–32. [Google Scholar] [CrossRef]

- Klemetti, T.M.; Van Dyke, M.A.; Evanek, N.; Compton, C.C.; Tulu, I.B. Insights into the Relationships Among the Roof, Rib, Floor, and Pillars of Underground Coal Mines. Min. Metall. Explor. 2021, 38, 531–538. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, C.; Tang, S.; Dou, L.; Cao, J. Rock Burst Mechanism Analysis in an Advanced Segment of Gob-Side Entry under Different Dip Angles of the Seam and Prevention Technology. Int. J. Min. Sci. Technol. 2018, 28, 891–899. [Google Scholar] [CrossRef]

- Ma, X.; He, M.; Li, Z.; Liu, Y.; Yu, G.; Du, H. Key Parameters of Gob-Side Entry Retaining Automatically Formed by Roof Cutting and Blasting in Compound Roof Condition. J. China Univ. Min. Technol. 2019, 48, 474–483. [Google Scholar] [CrossRef]

- Zhang, N.; Han, C.; Kan, J.; Zheng, X. Theory and Practice of Surrounding Rock Control for Pillarless Gob-Side Entry Retaining. J. China Coal Soc. 2014, 39, 1635–1641. [Google Scholar] [CrossRef]

- Han, C.; Zhang, N.; Li, B.; Si, G.; Zheng, X. Pressure Relief and Structure Stability Mechanism of Hard Roof for Gob-Side Entry Retaining. J. Cent. South Univ. 2015, 22, 4445–4455. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, F.; Wang, H.; Yuan, G.; Guo, Z.; Yang, J. Determination of Key Parameters of Gob-Side Entry Retaining by Cutting Roof and Its Application to a Deep Mine. Rock Soil Mech. 2019, 40, 332–342+350. [Google Scholar] [CrossRef]

- Fan, D.; Liu, X.; Tan, Y.; Song, S.; Gu, Q.; Yan, L.; Xu, Q. Roof Cutting Parameters Design for Gob-Side Entry in Deep Coal Mine: A Case Study. Energies 2019, 12, 2032. [Google Scholar] [CrossRef]

- Zhang, X.; Pak, R.Y.S.; Yang, J.; Lei, L.; Niu, H.; Niu, Y.; Zhao, C.; Gao, H.; He, M. Mechanistic Formulation and Validation of Cutting Seam by Energy-Focusing Blast for Pressure Relief of Deep Roadway. Eng. Fail. Anal. 2023, 150, 107378. [Google Scholar] [CrossRef]

- Zhang, X.; Pak, R.Y.S.; Gao, Y.; Liu, C.; Zhang, C.; Yang, J.; He, M. Field Experiment on Directional Roof Presplitting for Pressure Relief of Retained Roadways. Int. J. Rock Mech. Min. Sci. 2020, 134, 104436. [Google Scholar] [CrossRef]

- Kang, H.; Jiang, P.; Wu, Y.; Gao, F. A Combined “Ground Support-Rock Modification-Destressing” Strategy for 1000-m Deep Roadways in Extreme Squeezing Ground Condition. Int. J. Rock Mech. Min. Sci. 2021, 142, 104746. [Google Scholar] [CrossRef]

- Kuang, T.; Tai, Y.; Huo, B.; Xia, B.; Zhang, Y.; Xia, H. A Protective Seam Mining Method by Cutting Roof with Chainsaw Arm Machine. J. Geophys. Eng. 2020, 17, 730–741. [Google Scholar] [CrossRef]

- Duan, H.; Zhao, L. Gob-Side Entry Driving with Small-Coal-Pillar for Carboniferous Extra Thick Coal Seam under Jurassic Coal Pillar. Arab. J. Geosci. 2022, 15, 935. [Google Scholar] [CrossRef]

- Zhai, W.; He, F.; Song, J.; Wu, Y.; Xu, X.; Wang, D.; Zhang, J.; Li, L. Strong Strata Behavior Mechanism and Roof Cutting Control of Small Pillar Gob-Side Roadway in Extra-Thick Coal Seam. Bull. Eng. Geol. Environ. 2024, 83, 77. [Google Scholar] [CrossRef]

- Liu, X.; He, M.; Wang, J.; Ma, Z. Research on Non-Pillar Coal Mining for Thick and Hard Conglomerate Roof. Energies 2021, 14, 299. [Google Scholar] [CrossRef]

- Ünlü, T.; Reddish, D.J. Multiple Entry Pillar Stability Assessment Using the Limit Equilibrium Method. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1994, 31, 429–438. [Google Scholar] [CrossRef]

- Hou, C.; Ma, N. Stress in In-Seam Roadway Sides and Limit Equilibrium Zone. J. China Coal Soc. 1989, 4, 21–29. [Google Scholar]

- Zhang, G.; Liang, S.; Tan, Y.; Xie, F.; Chen, S.; Jia, H. Numerical Modeling for Longwall Pillar Design: A Case Study from a Typical Longwall Panel in China. J. Geophys. Eng. 2018, 15, 121–134. [Google Scholar] [CrossRef]

- Zhang, G.; He, F.; Jia, H.; Lai, Y. Analysis of Gateroad Stability in Relation to Yield Pillar Size: A Case Study. Rock Mech. Rock Eng. 2017, 50, 1263–1278. [Google Scholar] [CrossRef]

- Feng, G.; Wang, P.; Chugh, Y.P. Stability of Gate Roads Next to an Irregular Yield Pillar: A Case Study. Rock Mech. Rock Eng. 2019, 52, 2741–2760. [Google Scholar] [CrossRef]

- Wang, X.; Bai, J.; Wang, R.; Sheng, W. Bearing Characteristics of Coal Pillars Based on Modified Limit Equilibrium Theory. Int. J. Min. Sci. Technol. 2015, 25, 943–947. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, R.; Wang, B. Analysis on Limit Equilibrium Zone of Coal Pillar in Mining Roadway Based on Mechanical Model of Elastic Foundation Beam. J. Eng. Mech. 2016, 142, 04016009. [Google Scholar] [CrossRef]

- Huang, B.; Liu, J.; Zhang, Q. The Reasonable Breaking Location of Overhanging Hard Roof for Directional Hydraulic Fracturing to Control Strong Strata Behaviors of Gob-Side Entry. Int. J. Rock Mech. Min. Sci. 2018, 103, 1–11. [Google Scholar] [CrossRef]

- Shi, L.; Wang, Y.; Qiu, M.; Han, L.; Zhao, Y. Research on the Required Width of a Fault Waterproof Coal Pillar Based on Underground Pressure Control Theory. Arab. J. Geosci. 2019, 12, 480. [Google Scholar] [CrossRef]

- Yao, Q.; Wang, X.; Xia, Z.; Li, L.; Zhu, L.; Li, X. Key Technology and Application of Active Forepoling for Longwall Coal Mining in Coal Mine. J. Min. Saf. Eng. 2020, 37, 289–297. [Google Scholar] [CrossRef]

- Rezaei, M.; Hossaini, M.F.; Majdi, A. Determination of Longwall Mining-Induced Stress Using the Strain Energy Method. Rock Mech. Rock Eng. 2015, 48, 2421–2433. [Google Scholar] [CrossRef]

- Shan, R.; Kong, X.; Yan, F.; Meng, C. Research on Sidewall and Corner Strengthened Support for Coal Roadway by Modeling Experiments. Chin. J. Rock Mech. Eng. 2015, 34, 2336–2345. [Google Scholar] [CrossRef]

- Shan, R.; Kong, X.; Wei, Z.; Li, M.; Yang, S.; Tian, L. Theory and Application of Strong Support for Coal Roadway Sidewall. Chin. J. Rock Mech. Eng. 2013, 32, 1304–1314. [Google Scholar]

- Ma, N.; Hou, C. The Underground Pressure of Sectional Roadways and Its Control; Coal Industry Publishing House: Beijing, China, 1995; ISBN 978-7-5020-1192-5. [Google Scholar]

- Esterhuizen, G.S.; Dolinar, D.R.; Ellenberger, J.L. Pillar Strength in Underground Stone Mines in the United States. Int. J. Rock Mech. Min. Sci. 2011, 48, 42–50. [Google Scholar] [CrossRef]

- Ma, X.; He, M.; Li, X.; Wang, E.; Hu, C.; Gao, R. Deformation Mechanism and Control Measures of Overlying Strata with Gob-Side Entry Retaining Formed by Roof Cutting and Pressure Releasing. J. China Univ. Min. Technol. 2019, 48, 236–246+277. [Google Scholar] [CrossRef]

- Bai, Q.; Tu, S.; Wang, F.; Zhang, C. Field and Numerical Investigations of Gateroad System Failure Induced by Hard Roofs in a Longwall Top Coal Caving Face. Int. J. Coal Geol. 2017, 173, 176–199. [Google Scholar] [CrossRef]

- Li, X.; Ju, M.; Yao, Q.; Zhou, J.; Chong, Z. Numerical Investigation of the Effect of the Location of Critical Rock Block Fracture on Crack Evolution in a Gob-Side Filling Wall. Rock Mech. Rock Eng. 2016, 49, 1041–1058. [Google Scholar] [CrossRef]

- Shi, J.; Ma, N.; Bai, Z. Analysis on Roof Broken Location of Gateway Retained along Goaf and Technology of Roof Support. Coal Sci. Technol. 2013, 41, 35–37+42. [Google Scholar] [CrossRef]

- Xia, Z.; Yao, Q.; Meng, G.; Xu, Q.; Tang, C.; Zhu, L.; Wang, W.; Shen, Q. Numerical Study of Stability of Mining Roadways with 6.0-m Section Coal Pillars under Influence of Repeated Mining. Int. J. Rock Mech. Min. Sci. 2021, 138, 104641. [Google Scholar] [CrossRef]

- Kang, H.; Lou, J.; Gao, F.; Yang, J.; Li, J. A Physical and Numerical Investigation of Sudden Massive Roof Collapse during Longwall Coal Retreat Mining. Int. J. Coal Geol. 2018, 188, 25–36. [Google Scholar] [CrossRef]

- Li, J.; Liu, C.; Guo, X.; Wu, X. Instability Motion Characteristics of Overburden Rock and the Distribution Pattern of Fissures in Shallow Thick Seam Mining. Sci. Rep. 2022, 12, 6184. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, P.; Cui, S.; Fan, M.; Qiu, Y. Mechanism and Surrounding Rock Control of Roadway Driving along Gob in Shallow-Buried, Large Mining Height and Small Coal Pillars by Roof Cutting. J. China Coal Soc. 2021, 46, 2254–2267. [Google Scholar] [CrossRef]

- Zhao, T.; Liu, C.; Yetilmezsoy, K.; Zhang, B.; Zhang, S. Fractural Structure of Thick Hard Roof Stratum Using Long Beam Theory and Numerical Modeling. Environ. Earth Sci. 2017, 76, 751. [Google Scholar] [CrossRef]

- Kang, H.; Wang, Q.; Wang, B.; Jiang, P.; Gao, F.; Zhang, X.; Song, D.; Yang, J. Mechanism and Technology of Partitioned Parallel Anchoring in Rapid Heading Faces with Moderately Stable Surrounding Rock. Tunn. Undergr. Space Technol. 2025, 157, 106368. [Google Scholar] [CrossRef]

- Ile, D.; Malan, D.F. A Study of Backfill Confinement to Reinforce Pillars in Bord-and-Pillar Layouts. J. S. Afr. Inst. Min. Metall. 2023, 123, 223–233. [Google Scholar] [CrossRef]

- Sonu; Chawla, S.; Jaiswal, A. An Experimental Study on Effect of Limited Boundness (LB) on Peak and Residual Strength of Intact Rock. Min. Metall. Explor. 2024, 41, 985–995. [Google Scholar] [CrossRef]

- Kostecki, T.; Spearing, A.J.S. Influence of Backfill on Coal Pillar Strength and Floor Bearing Capacity in Weak Floor Conditions in the Illinois Basin. Int. J. Rock Mech. Min. Sci. 2015, 76, 55–67. [Google Scholar] [CrossRef]

- Mo, S.; Canbulat, I.; Zhang, C.; Oh, J.; Shen, B.; Hagan, P. Numerical Investigation into the Effect of Backfilling on Coal Pillar Strength in Highwall Mining. Int. J. Min. Sci. Technol. 2018, 28, 281–286. [Google Scholar] [CrossRef]

- Wang, Y.; He, M.; Zhang, J.; Wang, Q.; Yang, J.; Hou, S. Roof Control Mechanism and Design Methods of Gob-Side Entry Retained by N00 Coal Mining Method. Rock Mech. Rock Eng. 2024, 57, 621–638. [Google Scholar] [CrossRef]

- Gai, Q.; He, M.; Gao, Y.; Fei, Y. Research on Floor Failure Characteristics of Dip Direction in Non-Pillar Mining with Automatically Formed Roadway above Confined Water. Eng. Geol. 2025, 344, 107844. [Google Scholar] [CrossRef]

- Gai, Q.; He, M.; Gao, Y.; Li, S. Mechanism of Floor Damage Reduction in Non-Pillar Mining with Automatically Formed Roadway: A Model Test Study. Rock Mech. Rock Eng. 2025, 58, 9573–9600. [Google Scholar] [CrossRef]

| Lithological | Density/kg·m−3 | Elastic Modulus/GPa | Poisson’s Ratio | Cohesion/MPa | Internal Friction Angle/° | Tensile Strength/MPa |

|---|---|---|---|---|---|---|

| mudstone | 2450 | 7.36 | 0.24 | 1.60 | 30 | 1.6 |

| medium-grained sandstone | 2450 | 25.37 | 0.20 | 7.26 | 43 | 6.1 |

| fine-grained sandstone | 2510 | 25.31 | 0.20 | 7.26 | 43 | 6.1 |

| siltstone | 2500 | 16.43 | 0.26 | 4.50 | 43 | 5.9 |

| fine-grained sandstone | 2510 | 25.31 | 0.20 | 7.26 | 43 | 6.1 |

| coal | 1500 | 2.00 | 0.32 | 1.44 | 36 | 0.4 |

| mudstone | 2450 | 7.36 | 0.24 | 1.60 | 30 | 1.6 |

| sandy mudstone | 2300 | 9.82 | 0.32 | 3.80 | 40 | 4.4 |

| Plastic shear strain | 0 | 0.05 | 0.1 | 1 |

| Cohesion/MPa | 3.20 | 1.60 | 1.07 | 1.07 |

| Internal friction angle/° | 25.0 | 20.0 | 17.0 | 17.0 |

| Density/(kg·m−3) | Elastic Modulus/GPa | Poisson’s Ratio | Cohesion/MPa | Internal Friction Angle/° | |||||

|---|---|---|---|---|---|---|---|---|---|

| 1900 | 11.6 | 9.3 | 20 | 4 | |||||

| Strain | 0 | 0.01 | 0.02 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 |

| Stress/MPa | 0 | 1.18 | 2.5 | 3.98 | 5.67 | 7.59 | 9.81 | 12.39 | 15.45 |

| Strain | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.14 | 0.15 | 0.16 | 0.17 |

| Stress/MPa | 19.12 | 23.61 | 29.21 | 36.42 | 46.03 | 59.49 | 79.67 | 113.31 | 180.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xia, Z.; Yao, Q.; Xu, Q.; Zheng, C.; Hu, H.; Li, H. Structural Design Method for Narrow Coal Pillars in Gateway Protection: Framework and Field Case Study. Buildings 2025, 15, 3682. https://doi.org/10.3390/buildings15203682

Li Y, Xia Z, Yao Q, Xu Q, Zheng C, Hu H, Li H. Structural Design Method for Narrow Coal Pillars in Gateway Protection: Framework and Field Case Study. Buildings. 2025; 15(20):3682. https://doi.org/10.3390/buildings15203682

Chicago/Turabian StyleLi, Yinghu, Ze Xia, Qiangling Yao, Qiang Xu, Chuangkai Zheng, Haodong Hu, and Haitao Li. 2025. "Structural Design Method for Narrow Coal Pillars in Gateway Protection: Framework and Field Case Study" Buildings 15, no. 20: 3682. https://doi.org/10.3390/buildings15203682

APA StyleLi, Y., Xia, Z., Yao, Q., Xu, Q., Zheng, C., Hu, H., & Li, H. (2025). Structural Design Method for Narrow Coal Pillars in Gateway Protection: Framework and Field Case Study. Buildings, 15(20), 3682. https://doi.org/10.3390/buildings15203682