Mechanical Performance and Shrinkage Behavior of Ultrahigh-Performance Concrete with Ferronickel Slag Under Various Curing Conditions

Abstract

1. Introduction

2. Materials and Methods

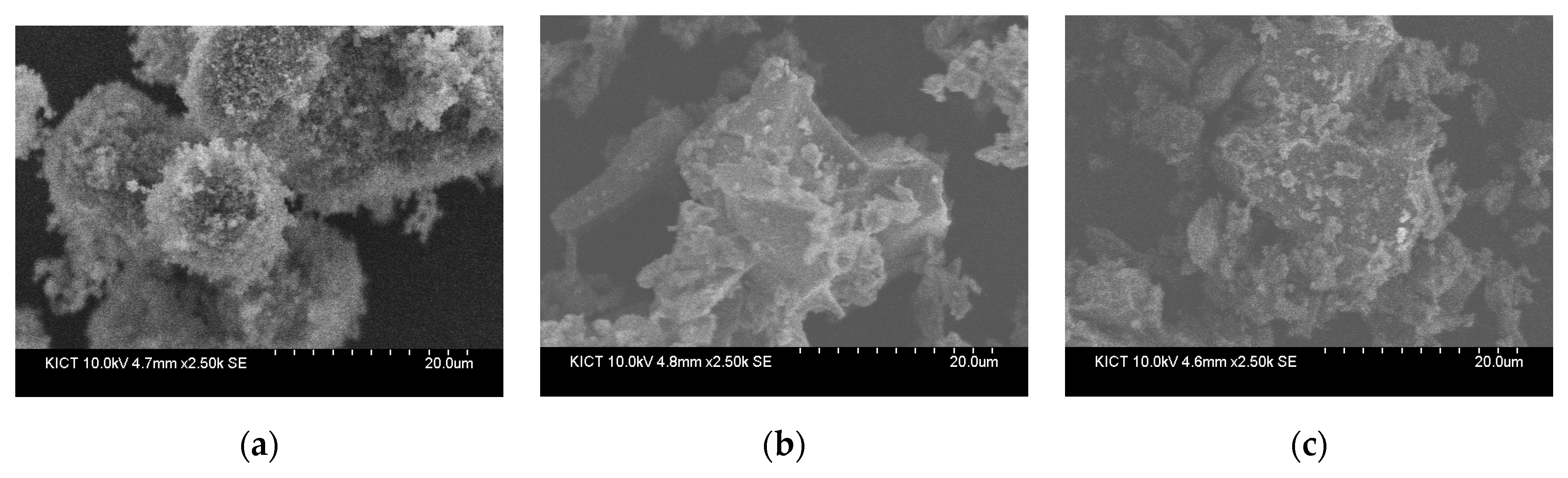

2.1. Characteristics of Binders Used

2.2. UHPC Mixture Compositions

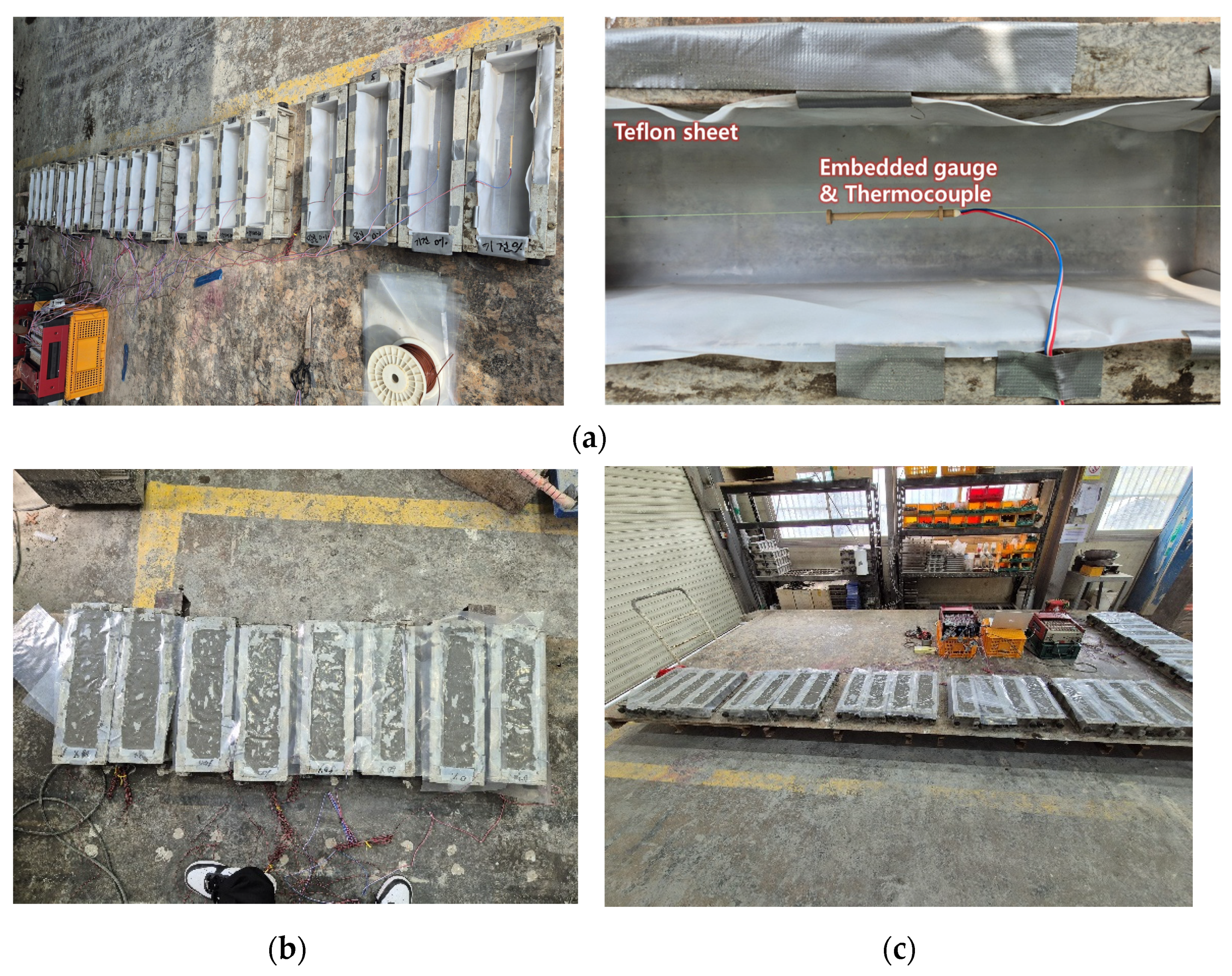

2.3. Specimen Preparation

2.4. Test Methods

2.4.1. Compressive and Tensile Strength Evaluation Method

2.4.2. Shrinkage Evaluation Method

3. Performance Evaluation of UHPCs Subjected to Different Curing Conditions

3.1. Short-Term Performance Evaluation of UHPCs Subjected to Steam Curing

3.2. Long-Term Mechanical Performance Evaluation of UHPCs Subjected to Constant-Temperature and Constant-Humidity Curing

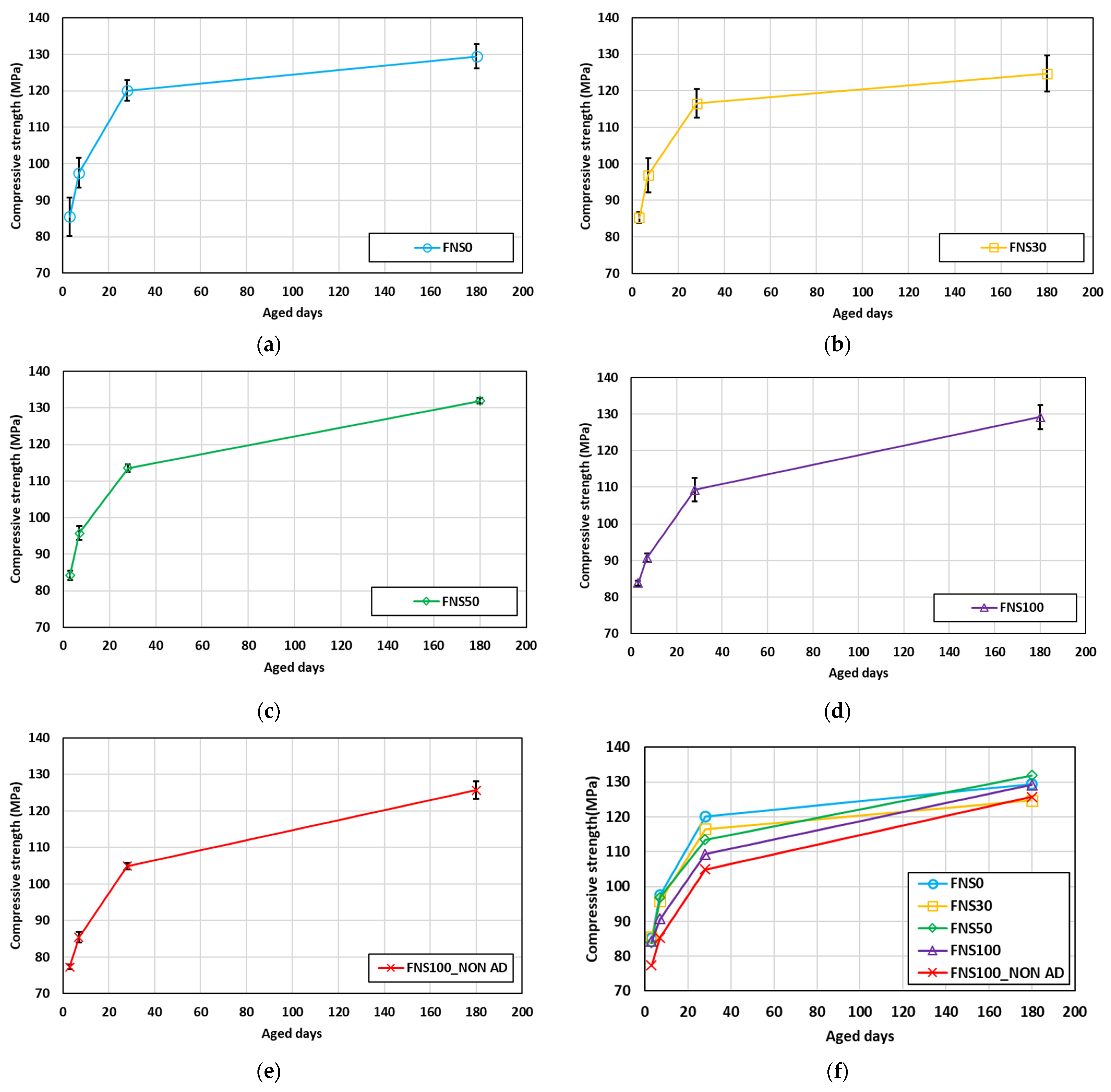

3.2.1. Compressive Strength

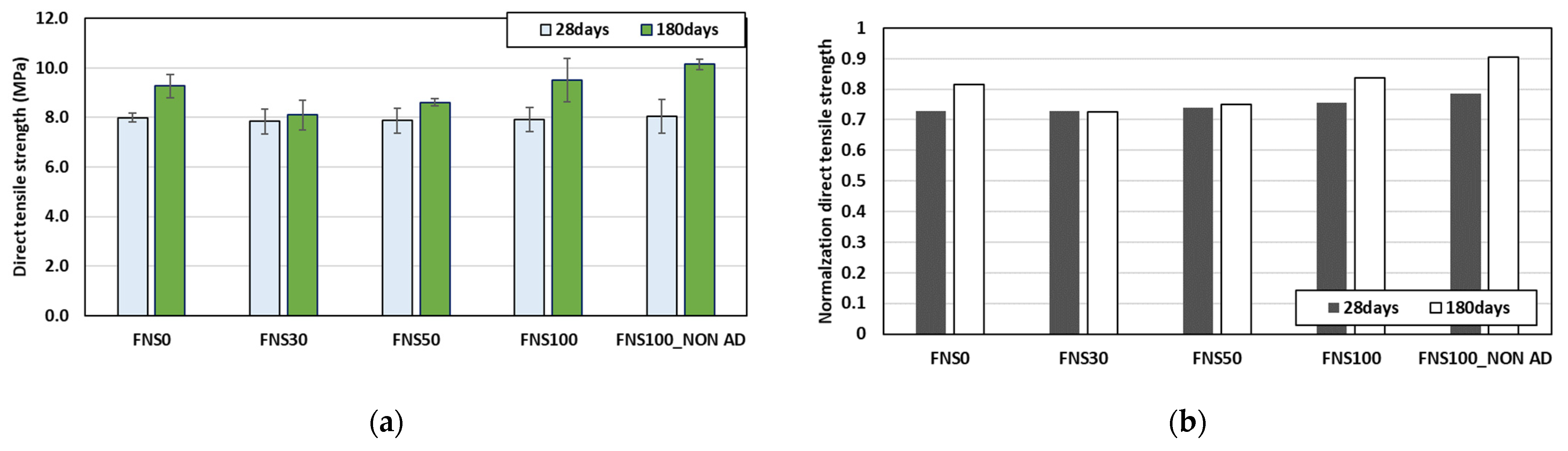

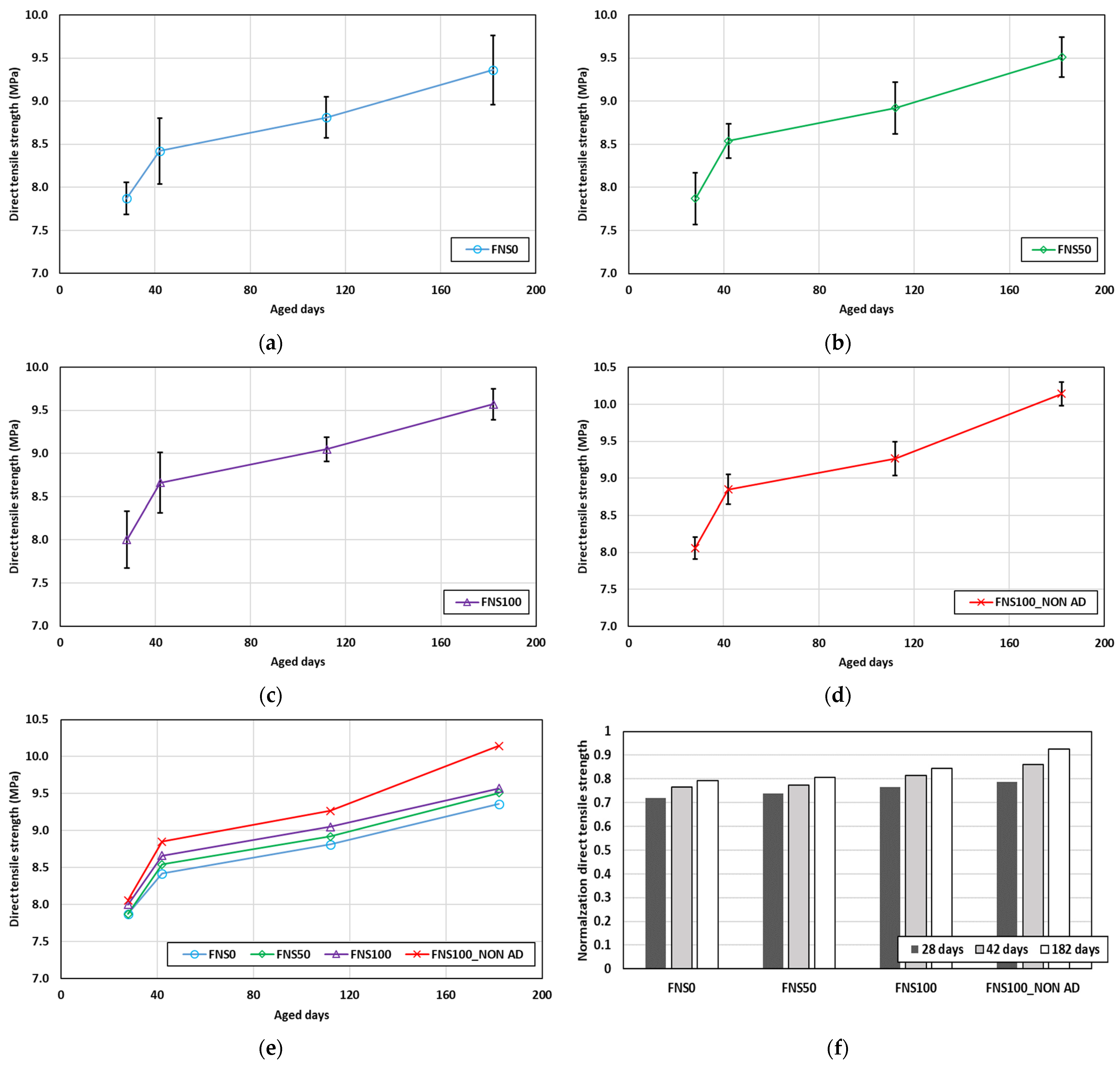

3.2.2. Tensile Strength

3.3. Long-Term Mechanical Performance Evaluation of UHPCs Subjected to Dry–Wet Cyclic Conditions After Curing

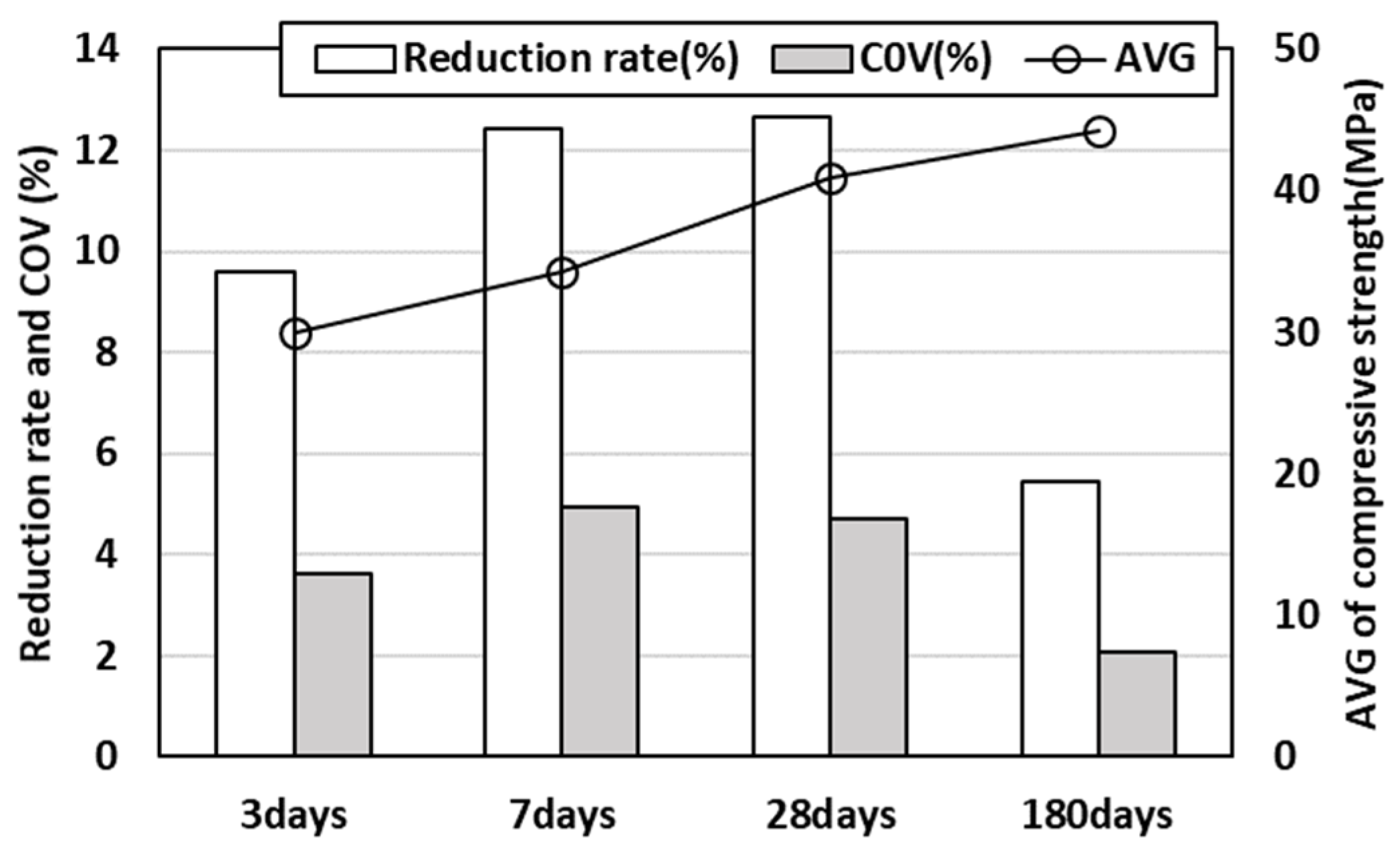

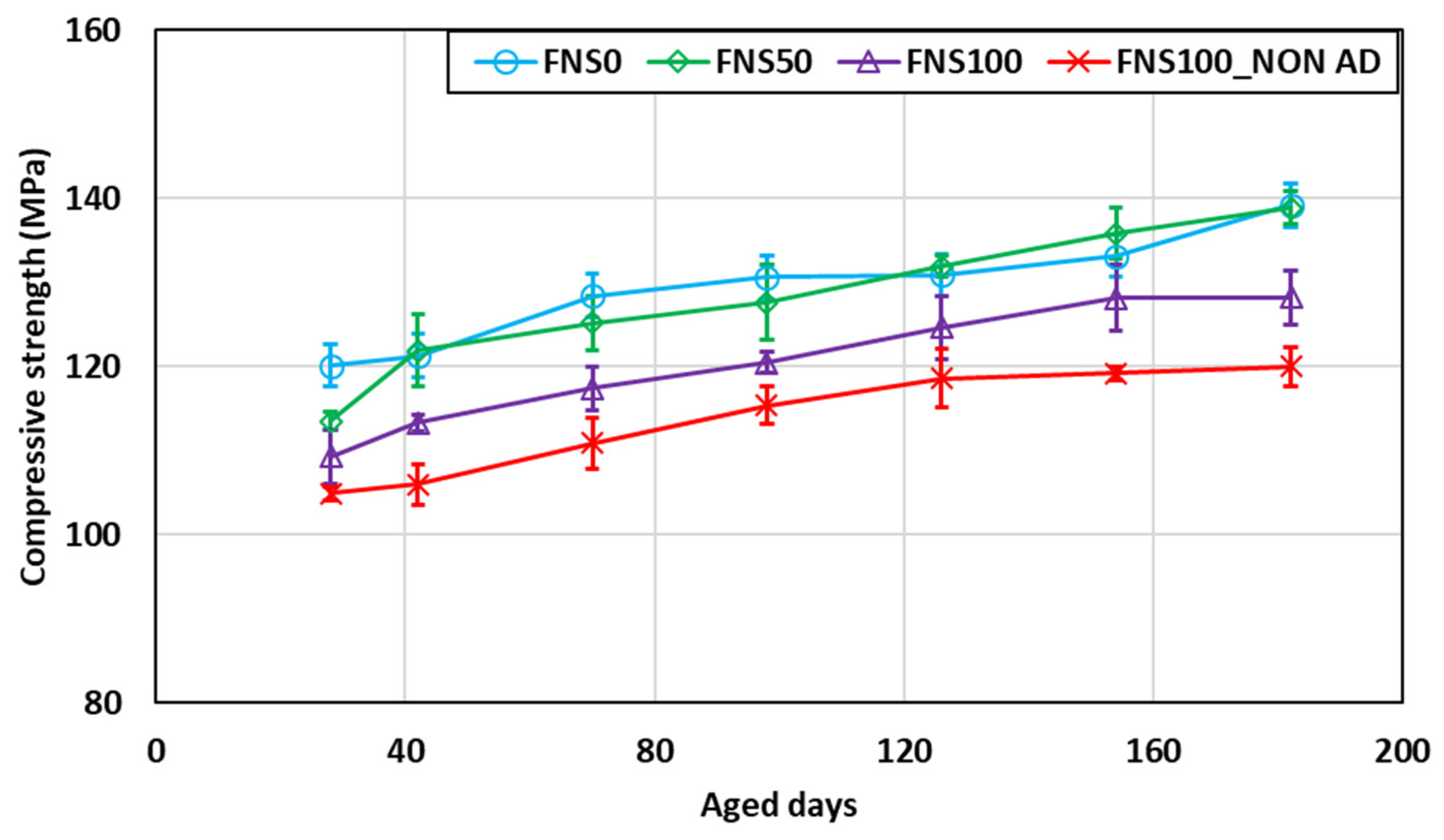

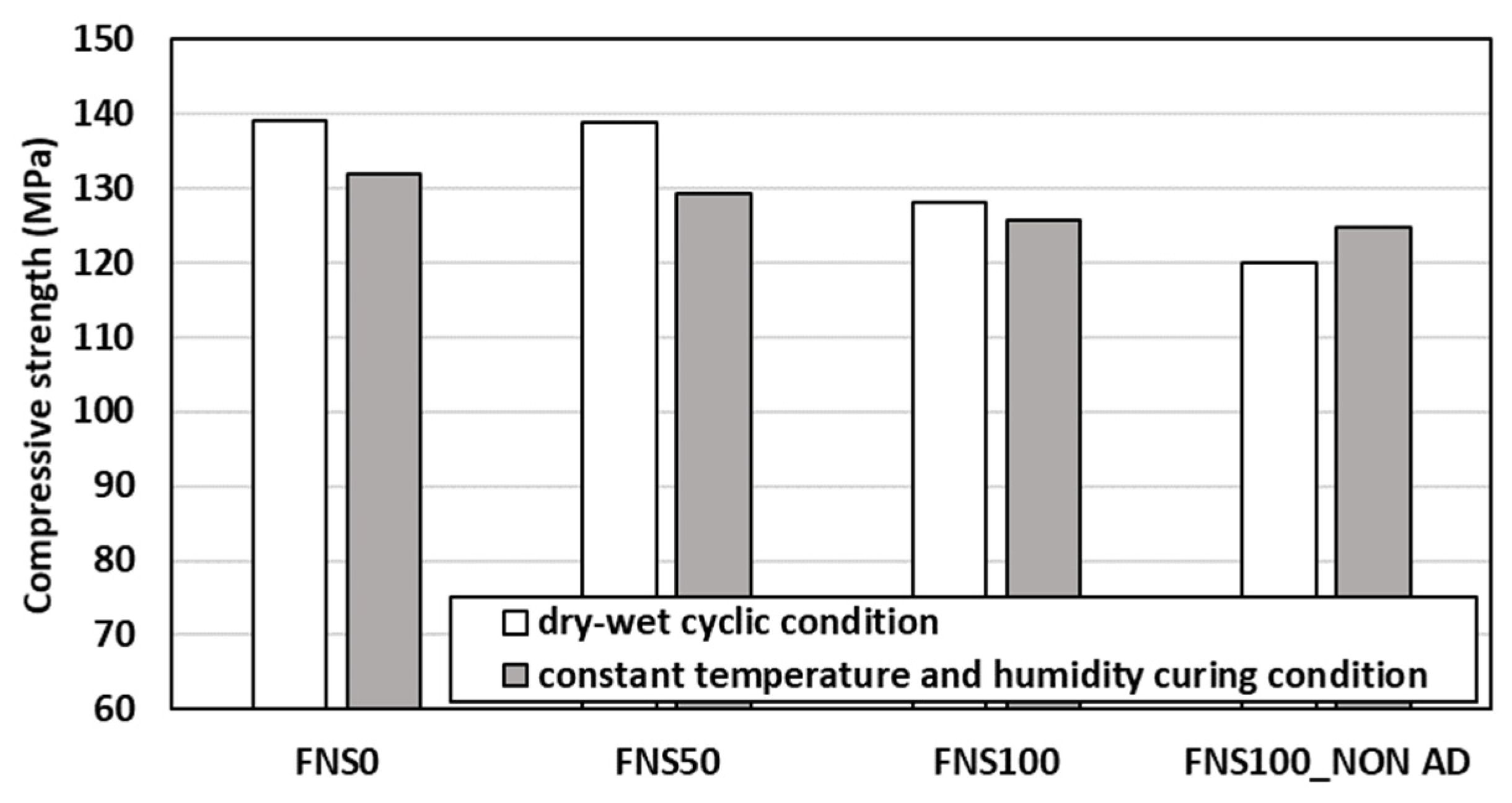

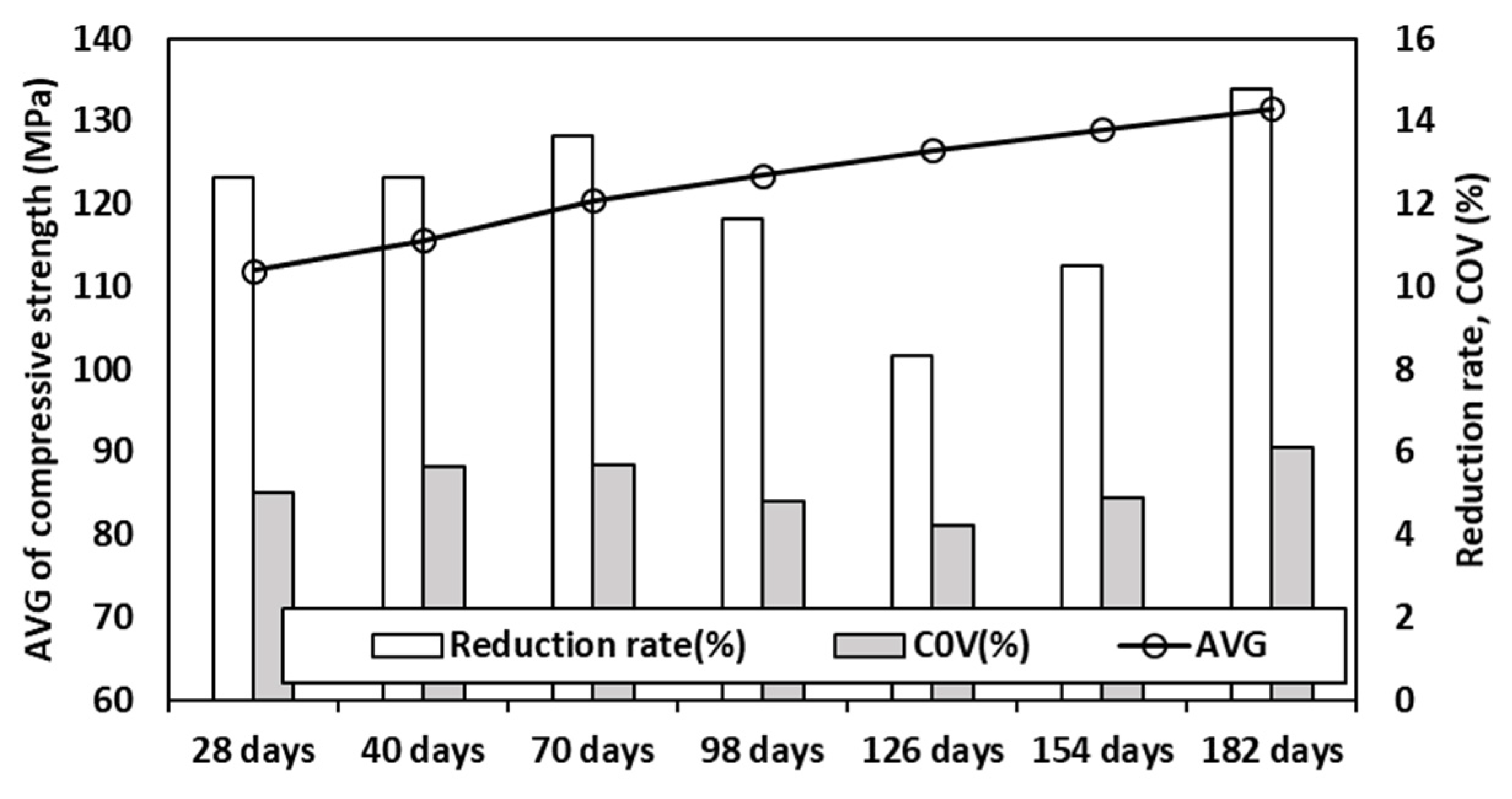

3.3.1. Compressive Strength

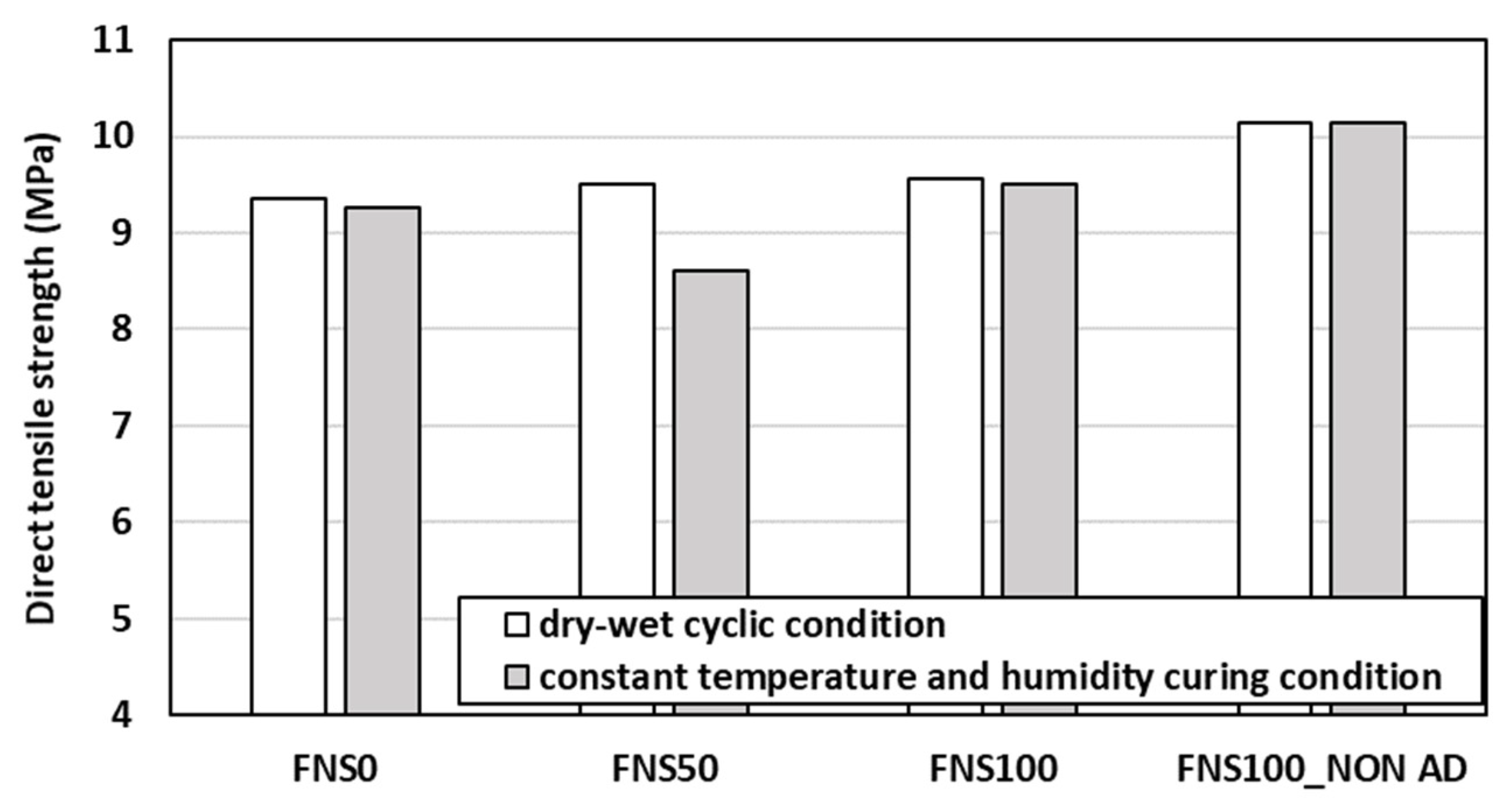

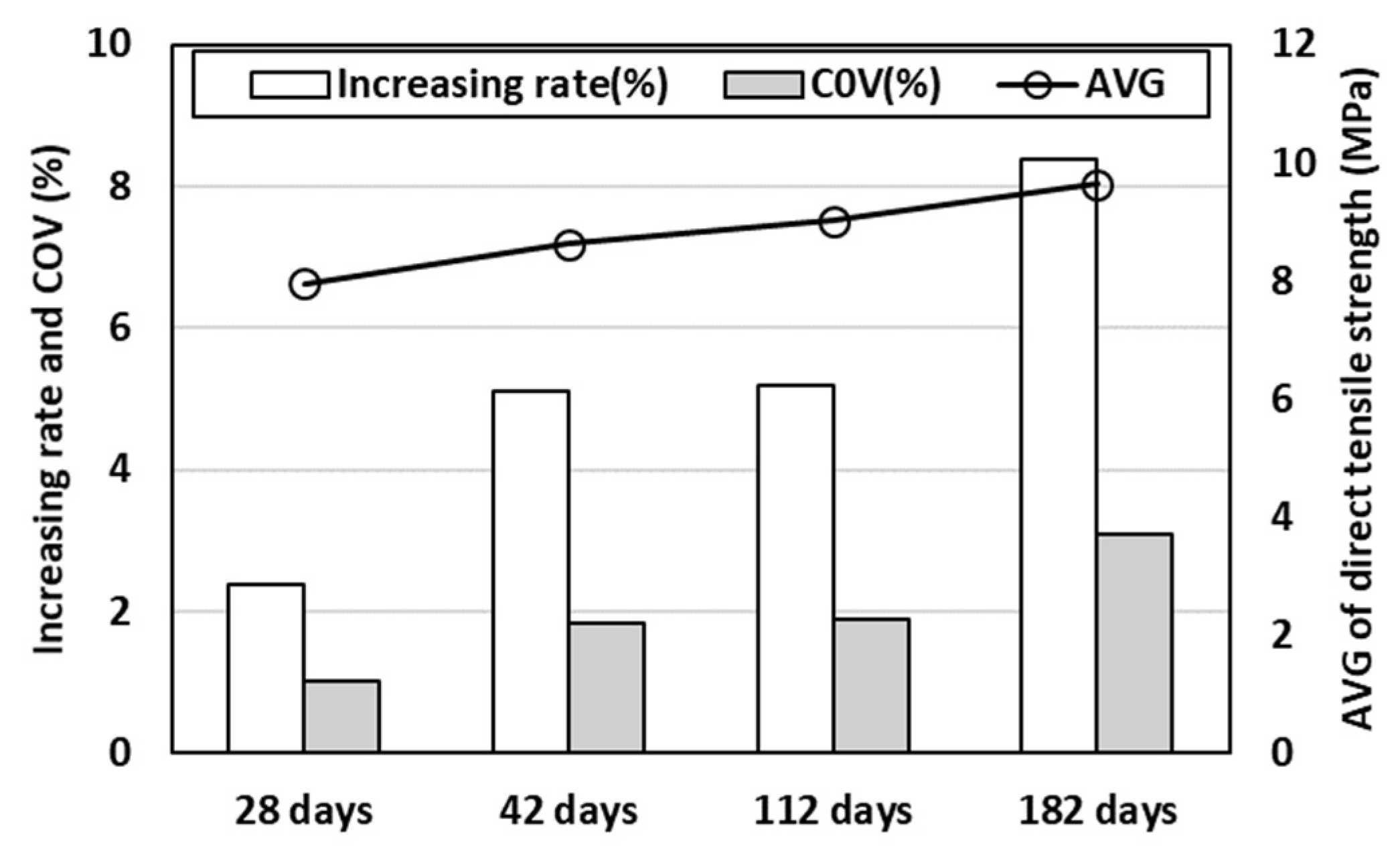

3.3.2. Tensile Strength

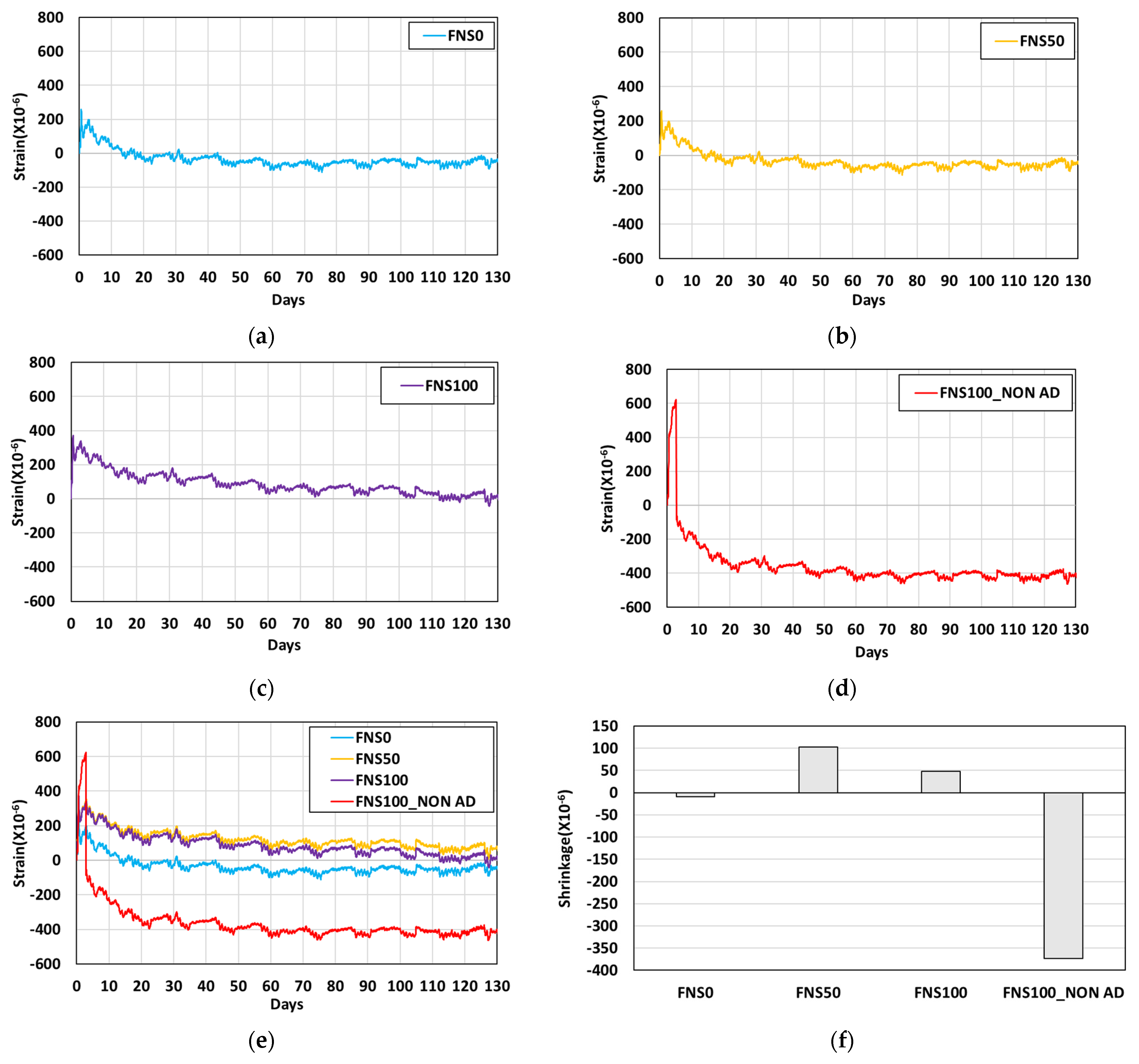

4. Expansion Evaluation of UHPCs Subjected to Different Curing Methods

4.1. Constant-Temperature and Constant-Humidity Condition

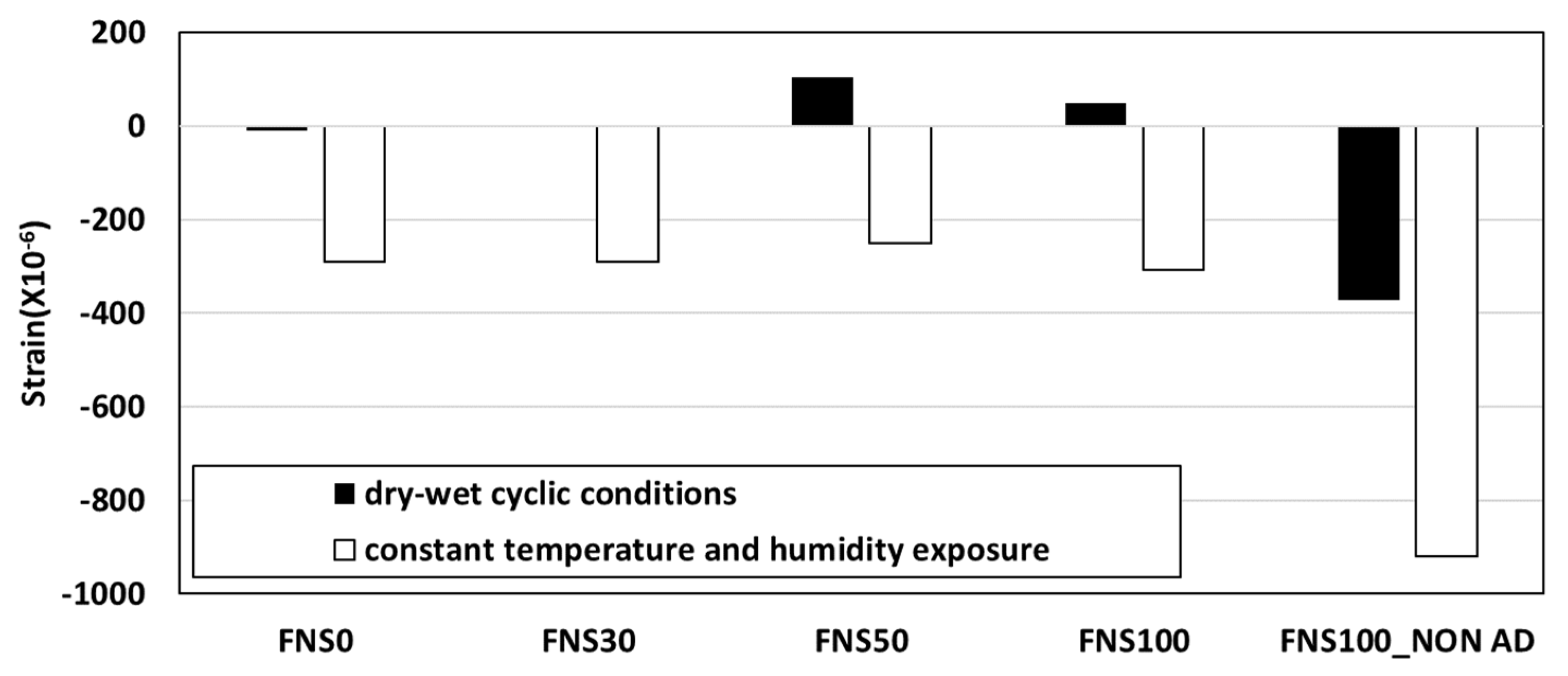

4.2. Dry–Wet Cyclic Condition

5. Conclusions

- 1.

- As a result of compressive and direct tensile strength evaluations of specimens subjected to 48-h steam curing, it was determined that FNS100 (100% GGBFS replacement with FNS) had compressive and direct tensile strengths equivalent to those of FNS0. Furthermore, FNS100 exhibited a 14.7% increase in flow compared to FNS0, indicating improved workability.

- 2.

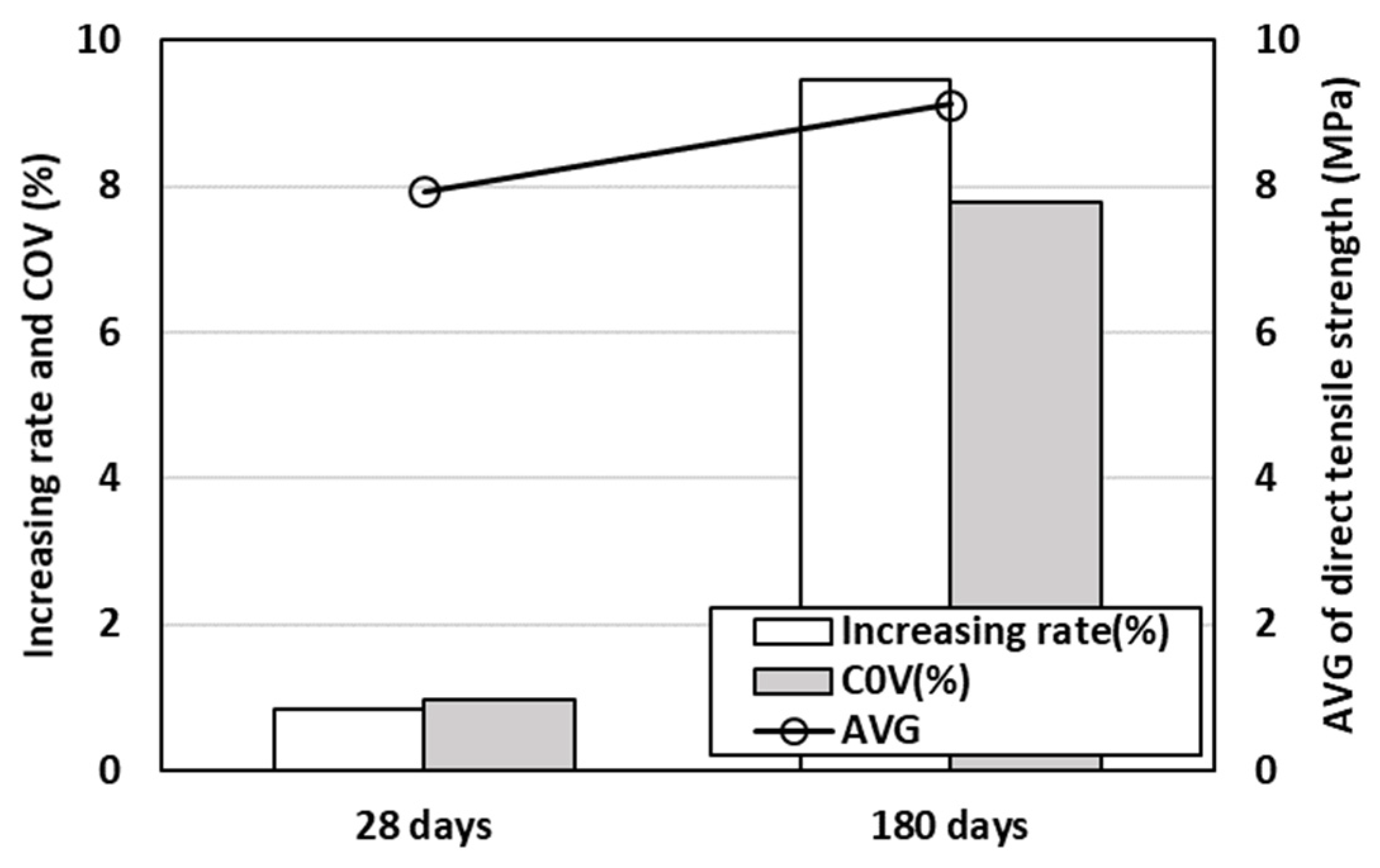

- Mechanical property evaluations under constant-temperature and constant-humidity curing revealed a slight decrease in compressive strength during the initial curing period with higher FNS replacement rates. However, by 180 days, all mixes satisfied the design strength criteria, and strength variability with FNS replacement decreased. Direct tensile strength showed minimal variation (COV < 1%) at 28 days but significantly increased to 6.2% by 180 days. This increase was primarily due to a significant tensile strength gain in FNS100_NON AD, which lacked expansion or shrinkage-reducing agents.

- 3.

- For specimens subjected to dry–wet cyclic curing, compressive strength evaluations showed a maximum reduction of 14.8% due to FNS incorporation. However, excluding FNS100_NON AD, all UHPC formulations met the design strength criteria after 98 days. Conversely, increased FNS replacement rates resulted in minimal differences in direct tensile strength. Notably, among specimens under constant-temperature and constant-humidity curing, FNS100_NON AD exhibited the highest strength levels.

- 4.

- Long-term shrinkage analysis showed minimal changes in drying and autogenous shrinkage with respect to FNS replacement, likely due to FNS’s stable Mg2SiO4 form. At 90 days, excluding FNS100_NON AD (which exhibited 3.8 times FNS0’s shrinkage, or −957), other UHPC mixes had similar total shrinkage values ranging from −259 to −307.6. Under dry–wet cyclic conditions, specimens experienced consistent volume expansion and contraction patterns, converging to a stable level. No expansion was observed from FNS incorporation as a UHPC binder, confirming that shrinkage can be effectively controlled by expansion and shrinkage-reducing agents.

- 5.

- The results of this study demonstrated that the full (100%) replacement of GGBFS with FNS powder did not compromise the overall performance of UHPC. The FNS100 mix met the design strength criteria and exhibited favorable long-term mechanical properties under various curing conditions. This finding suggested that a 100% FNS replacement can be considered an optimal and practical mix design for achieving both high performance and environmental benefits. However, this study was limited to a single type of FNS powder and a fixed binder formulation, without considering variability in FNS composition or particle fineness. Future research should explore the influence of different FNS sources, optimize admixture dosages for shrinkage mitigation, and evaluate long-term durability performance—such as chloride resistance and freeze–thaw behavior—in various environmental exposures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| COV | Coefficient of variation |

| CSA | Calcium sulfoaluminate |

| FA | Fly ash |

| FNS | Ferronickel slag |

| FRP | Fiber-reinforced polymer |

| GGBFS | Ground granulated blast-furnace slag |

| HPC | High-performance concrete |

| OPC | Ordinary Portland cement |

| RH | Relative humidity |

| SEM | Scanning electron microscopy |

| SF | Silica fume |

| UHPC | Ultrahigh-performance concrete |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence |

References

- KCI (Korea Concrete Institute). Advanced Concrete Engineering; Kimoondang: Seoul, Republic of Korea, 2024. [Google Scholar]

- Huang, H.; Zou, L.; Liu, J.; Xie, X. Shrinkage Control and Durability of UHPC Using Mineral Admixtures and Internal Curing Materials. Buildings 2024, 15, 565. [Google Scholar]

- Jung, S.H.; Ryu, H.S.; Karthick, S.; Kwon, S.J. Time and crack effect on chloride diffusion for concrete with fly ash. Int. J. Concr. Struct. Mater. 2018, 12, 14. [Google Scholar] [CrossRef]

- Song, H.W.; Cho, H.J.; Park, S.S.; Byun, K.J.; Maekawa, K. Early-age cracking resistance evaluation of concrete structure. Concr. Sci. Eng. 2001, 3, 62–72. [Google Scholar]

- Yang, K.H.; Mun, J.H.; Yoon, Y.S. Effects of loading conditions and cold joint on service life against chloride ingress. Comput. Concr. 2018, 22, 319–326. [Google Scholar]

- Koh, T.-H.; Kim, M.-K.; Yang, K.-H.; Yoon, Y.-S.; Kwon, S.-J. Service life evaluation of RC T-girder under carbonation considering cold joint and loading effects. Constr. Build. Mater. 2019, 226, 106–116. [Google Scholar] [CrossRef]

- Gérard, B.; Marchand, J. Influence of cracking on the diffusion properties of cement-based materials: Part I: Influence of continuous cracks on the steady-state regime. Cem. Concr. Res. 2000, 30, 37–43. [Google Scholar] [CrossRef]

- Yoon, Y.S.; Kwon, S.J.; Kim, K.C.; Kim, Y.; Koh, K.T.; Choi, W.Y.; Lim, K.M. Evaluation of durability performance for chloride ingress considering long-term aged GGBFS and FA concrete and analysis of the relationship between concrete mixture characteristic and passed charge using machine learning algorithm. Materials 2023, 16, 7459. [Google Scholar] [CrossRef]

- Muthulingam, S.; Rao, B.N. Chloride binding and time-dependent surface chloride content models for fly ash. Front. Struct. Civ. Eng. 2016, 10, 112–120. [Google Scholar] [CrossRef]

- Guo, K.; Dong, H.; Zhang, J.; Zhang, L.; Li, Z. Experimental Study of Alkali-Activated Cementitious Materials Using Thermally Activated Red Mud: Effect of the Si/Al Ratio on Fresh and Mechanical Properties. Buildings 2025, 15, 565. [Google Scholar] [CrossRef]

- Kim, H.J.; Yoon, Y.S.; Yang, K.H.; Kwon, S.J. Durability and purification performance of concrete impregnated with silicate and sprayed with photocatalytic TiO2. Constr. Build. Mater. 2019, 199, 106–114. [Google Scholar] [CrossRef]

- Oh, K.S.; Park, K.T.; Kwon, S.J. Evaluation of anti-corrosion performance of FRP hybrid bar with notch in GGBFS concrete. J. Korea Inst. Struct. Maint. Insp. 2016, 20, 51–58. [Google Scholar] [CrossRef]

- Silva, M.L.D.; Prado, L.P.; Félix, E.F.; Sousa, A.M.D.D.; Aquino, D.P. The influence of materials on the mechanical properties of ultra-high-performance concrete (UHPC): A literature review. Materials 2024, 17, 1801. [Google Scholar] [CrossRef]

- Kravanja, G.; Mumtaz, A.R.; Kravanja, S. A comprehensive review of the advances, manufacturing, properties, innovations, environmental impact and applications of ultra-high-performance concrete (UHPC). Buildings 2024, 14, 382. [Google Scholar] [CrossRef]

- Graybeal, A.G. Material Property Characterization of Ultra-High Performance Concrete; Technical Report (FHWA-HRT-06-103); Federal Highway Administration: McLean, VA, USA, 2006. [Google Scholar]

- Abbas, S.M.L.N.; Nehdi, M.L.; Saleem, M.A. Ultra-high performance concrete: Mechanical performance, durability, sustainability and implementation challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- KCI. The Structural Design Guidelines of Fiber Reinforced SUPER Concrete; Korea Concrete Institute: Seoul, Republic of Korea, 2019. [Google Scholar]

- Yang, Y.; Chen, B.; Chen, Y.; Zhou, H.; Liu, F.; Xie, X.; Chen, J.; Guo, W.; Wang, H. Performances of concrete columns with modular UHPC permanent formworks under axial load. Int. J. Concr. Struct. Mater. 2023, 17, 38. [Google Scholar] [CrossRef]

- He, Q.F.; Zou, J.M.; Zhang, C.F.; Zhong, Y.; Li, J.S.; Yi, W.J. Experimental study on the seismic performance of two-storey UHPC modular building structure. J. Build. Eng. 2024, 97, 110966. [Google Scholar] [CrossRef]

- Kim, K.C.; Yoon, Y.S.; Ryu, G.S.; Koh, K.T.; Lim, K.M. Performance evaluation of architectural modular member with ultra-high-performance fiber-reinforced concrete for application. Appl. Sci. 2024, 14, 2269. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G. Examining the “time-zero” of autogenous shrinkage in high/ultra-high performance cement pastes. Cem. Concr. Res. 2017, 97, 107–114. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; He, Y.; Rao, M.; Fu, Z.; Wang, F.; Hu, S. Experimental investigation on the autogenous shrinkage of steam cured ultra-high performance concrete. Constr. Build. Mater. 2018, 162, 512–522. [Google Scholar] [CrossRef]

- Kim, S.W.; Choi, S.; Lee, K.M.; Park, J.J. Autogeneous shrinkage characteristics of ultra high performance concrete. J. Korea Concr. Inst. 2011, 23, 295–301. [Google Scholar] [CrossRef][Green Version]

- Shen, P.; Lu, L.; He, Y.; Wang, F.; Lu, J.; Zheng, H.; Hu, S. Investigation on expansion effect of the expansive agents in ultra-high performance concrete. Cem. Concr. Compos. 2020, 105, 103425. [Google Scholar] [CrossRef]

- Folliard, K.J.; Berke, N.S. Properties of high-performance concrete containing shrinkage-reducing admixture. Cem. Concr. Res. 1997, 27, 1357–1364. [Google Scholar] [CrossRef]

- Yang, Y.; Sato, R.; Kawai, K. Autogenous shrinkage of high-strength concrete containing silica fume under drying at early ages. Cem. Concr. Res. 2005, 35, 449–456. [Google Scholar] [CrossRef]

- Zhang, W.; Zakaria, M.; Hama, Y. Influence of aggregate materials characteristics on the drying shrinkage properties of mortar and concrete. Constr. Build. Mater. 2013, 49, 500–510. [Google Scholar] [CrossRef]

- Coelho, L.M.; Guimarães, A.C.R.; Alves Moreira, C.R.C.L.; dos Santos, G.P.P.; Monteiro, S.N.; da Silveira, P.H.P.M. Feasibility of using ferronickel slag as a sustainable alternative aggregate in hot mix asphalt. Sustainability 2024, 16, 8642. [Google Scholar] [CrossRef]

- Kurniati, E.O.; Pederson, F.; Kim, H.J. Application of steel slags, ferronickel slags, and copper mining waste as construction materials: A review. Resour. Conserv. Recycl. 2023, 198, 107175. [Google Scholar] [CrossRef]

- Petrounias, P.; Rogkala, A.; Giannakopoulou, P.P.; Christogerou, A.; Lampropoulou, P.; Liogris, S.; Koutsovitis, P.; Koukouzas, N. Utilization of industrial ferronickel slags as recycled concrete aggregates. Appl. Sci. 2022, 12, 2231. [Google Scholar] [CrossRef]

- Cho, W.J.; Kim, M.J.; Kim, J.S. Study on the pore structure characteristics of ferronickel-slag-mixed ternary-blended cement. Materials 2020, 13, 4863. [Google Scholar] [CrossRef]

- Tang, Z.; Peng, H.; Mei, P.; Huang, F.; Yi, S.; Feng, F. Performance Analysis of Ferronickel Slag-Ordinary Portland Cement Pervious Concrete. Materials 2024, 17, 1628. [Google Scholar] [CrossRef]

- Cui, Y.; Li, Y.; Wang, Q. Engineering performance and expansion mechanism of MgO expansion agent in ultra-high performance concrete(UHPC). J. Build. Eng. 2023, 68, 10607. [Google Scholar] [CrossRef]

- Ali, A.M.; AI-Mowali, A.H. Ceramic expansion by water Layers on magnesium oxide: AB InitioStudy. Am. J. Mater. Sci. Eng. 2013, 1, 50–53. [Google Scholar]

- Huang, Y.; Wang, Q.; Shi, M. Characteristics and reactivity of ferronickel slag powder. Constr. Build. Mater. 2017, 156, 773–789. [Google Scholar] [CrossRef]

- Rahman, M.A.; Sarker, P.K.; Shaikh, F.U.A.; Saha, A.K. Soundness and compressive strength of Portland cement blended with ground granulated ferronickel slag. Constr. Build. Mater. 2017, 140, 194–202. [Google Scholar] [CrossRef]

- Kang, S.H.; Hong, S.G. Performance of Fresh and Hardened Ultra High Performance Concrete without Heat Treatment. J. Korea Concr. Inst. 2014, 26, 23–34. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-high-performance concrete (UHPC): A state-of-the-art review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef]

- Rangel, C.S.; Amario, M.; Pepe, M.; Martinelli, E.; Toledo Filho, R.D. Influence of wetting and drying cycles on physical and mechanical behavior of recycled aggregate concrete. Materials 2020, 13, 5675. [Google Scholar] [CrossRef]

- Hu, J.; Meng, Z.; Gao, T.; Dong, S.; Ni, P.; Li, Z.; Yang, W.; Wang, K. Optimization of Proportions of Alkali-Activated Slag–Fly Ash-Based Cemented Tailings Backfill and Its Strength Characteristics and Microstructure under Combined Action of Dry–Wet and Freeze–Thaw Cycles. Materials 2024, 17, 4945. [Google Scholar] [CrossRef]

| Item Type | Density (g/cm3) | Surface Area (cm2/g) | Chemical Property (%) | |||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | |||

| OPC | 3.15 | 3512 | 21.0 | 4.29 | 3.35 | 62.10 | 2.27 | 2.35 |

| SF | 2.10 | 200,000 | 95.10 | 0.25 | 0.10 | 0.42 | 0.85 | 0.30 |

| GGBFS | 2.90 | 4500 | 32.58 | 13.75 | 0.46 | 45.19 | 3.26 | 2.52 |

| FNS | 2.90 | 4600 | 51.74 | 2.53 | 11.47 | 1.00 | 31.08 | 0.10 |

| UHPC Mix No. | Weight Ratio (%) by Unit Weight (kg/m3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OPC | SF | Filler | GGBFS | FNS | Water | Silica sand | Steel Fiber | Super Plasticizer | Shrinkage Reducing Agent | Expansion Agent | |

| FNS0 | 32.31 | 2.42 | 9.70 | 5.65 | 0 | 8.45 | 35.54 | 3.25 | 0.74 | 0.32 | 1.61 |

| FNS30 | 3.95 | 1.70 | |||||||||

| FNS50 | 1.70 | 3.95 | |||||||||

| FNS100 | 0 | 5.65 | |||||||||

| FNS100_NON AD | 0 | 0 | |||||||||

| Density | Tensile Strength | Diameter | Length | Aspect Ratio |

|---|---|---|---|---|

| 7.5 g/cm3 | 2500 MPa | 0.2 mm | 19 mm | 0.65 |

| Evaluation Item | UHPC Mixes | Curing Condition | Evaluation Days and Curing Conditions |

|---|---|---|---|

| Compressive Strength | FNS0, FNS30, FNS50, FNS100, FNS100-NON_AD | Constant temperature and humidity | 3, 7, 28, and 180 days 23 ± 2 °C, RH 50 ± 5% |

| FNS0, FNS50, FNS100, FNS100-NON_AD | Dry/wet | 28, 42, 70, 98, 126, 154, and 182 days Pouring: 28 days; 23 ± 2 °C, RH 50 ± 5% 28–182 days: Immersion in water and exposure to air (23 ± 2 °C, RH 50 ± 5%), applied alternately at 7-day intervals | |

| FNS0, FNS100 | Steam curing | 90 ± 2 °C, 48 h | |

| Tensile strength | FNS0, FNS30, FNS50, FNS100, FNS100-NON_AD | Constant temperature and humidity | 28 and 180 days 23 ± 2 °C, RH 50 ± 5% |

| FNS0, FNS50, FNS100, FNS100-NON_AD | Dry/wet | 28, 42, 112, and 182 days Pouring: 28 days; 23 ± 2 °C, RH 50 ± 5% 28–182 days: Immersion in water and exposure to air (23 ± 2 °C, RH 50 ± 5%), applied alternately at 7-day intervals | |

| FNS0, FNS100 | Steam curing | 90 ± 2 °C, 48 h | |

| Shrinkage | FNS0, FNS30, FNS50, FNS100, FNS100-NON_AD | Constant temperature and humidity | Pouring: 90 days; 23 ± 2 °C, RH 50 ± 5% * |

| FNS0, FNS50, FNS100, FNS100-NON_AD | Dry/wet | Pouring: 28 days; 23 ± 2 °C and RH 50 ± 5% 28–130 days: Immersion in water and exposure to air (23 ± 2 °C, RH 50 ± 5%), applied alternately at 7-day intervals |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, Y.-S.; An, G.-H.; Koh, K.-T.; Ryu, G.-S. Mechanical Performance and Shrinkage Behavior of Ultrahigh-Performance Concrete with Ferronickel Slag Under Various Curing Conditions. Buildings 2025, 15, 3670. https://doi.org/10.3390/buildings15203670

Yoon Y-S, An G-H, Koh K-T, Ryu G-S. Mechanical Performance and Shrinkage Behavior of Ultrahigh-Performance Concrete with Ferronickel Slag Under Various Curing Conditions. Buildings. 2025; 15(20):3670. https://doi.org/10.3390/buildings15203670

Chicago/Turabian StyleYoon, Yong-Sik, Gi-Hong An, Kyung-Taek Koh, and Gum-Sung Ryu. 2025. "Mechanical Performance and Shrinkage Behavior of Ultrahigh-Performance Concrete with Ferronickel Slag Under Various Curing Conditions" Buildings 15, no. 20: 3670. https://doi.org/10.3390/buildings15203670

APA StyleYoon, Y.-S., An, G.-H., Koh, K.-T., & Ryu, G.-S. (2025). Mechanical Performance and Shrinkage Behavior of Ultrahigh-Performance Concrete with Ferronickel Slag Under Various Curing Conditions. Buildings, 15(20), 3670. https://doi.org/10.3390/buildings15203670