Low-Carbon Climate-Resilient Retrofit Pilot: Construction Report

Abstract

1. Introduction

1.1. The Pilot

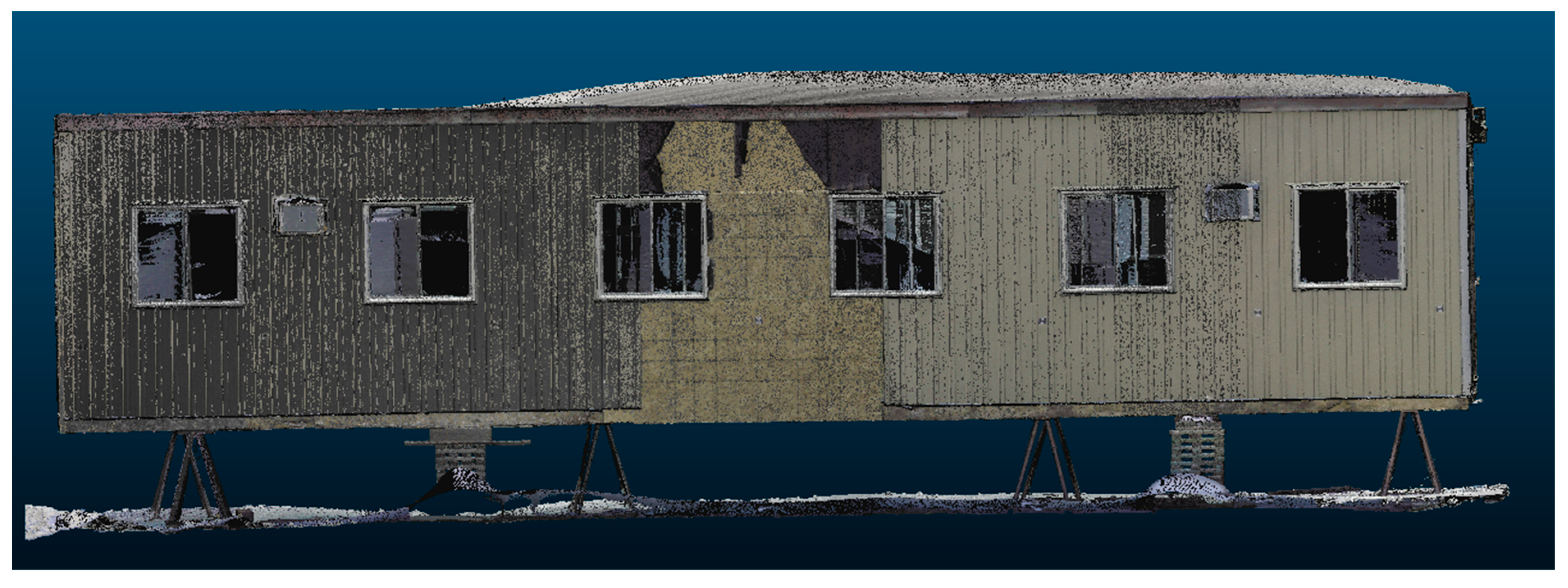

1.2. Original Structure

2. Materials and Methods

2.1. Design Stage

2.1.1. Building Capture and Model Creation

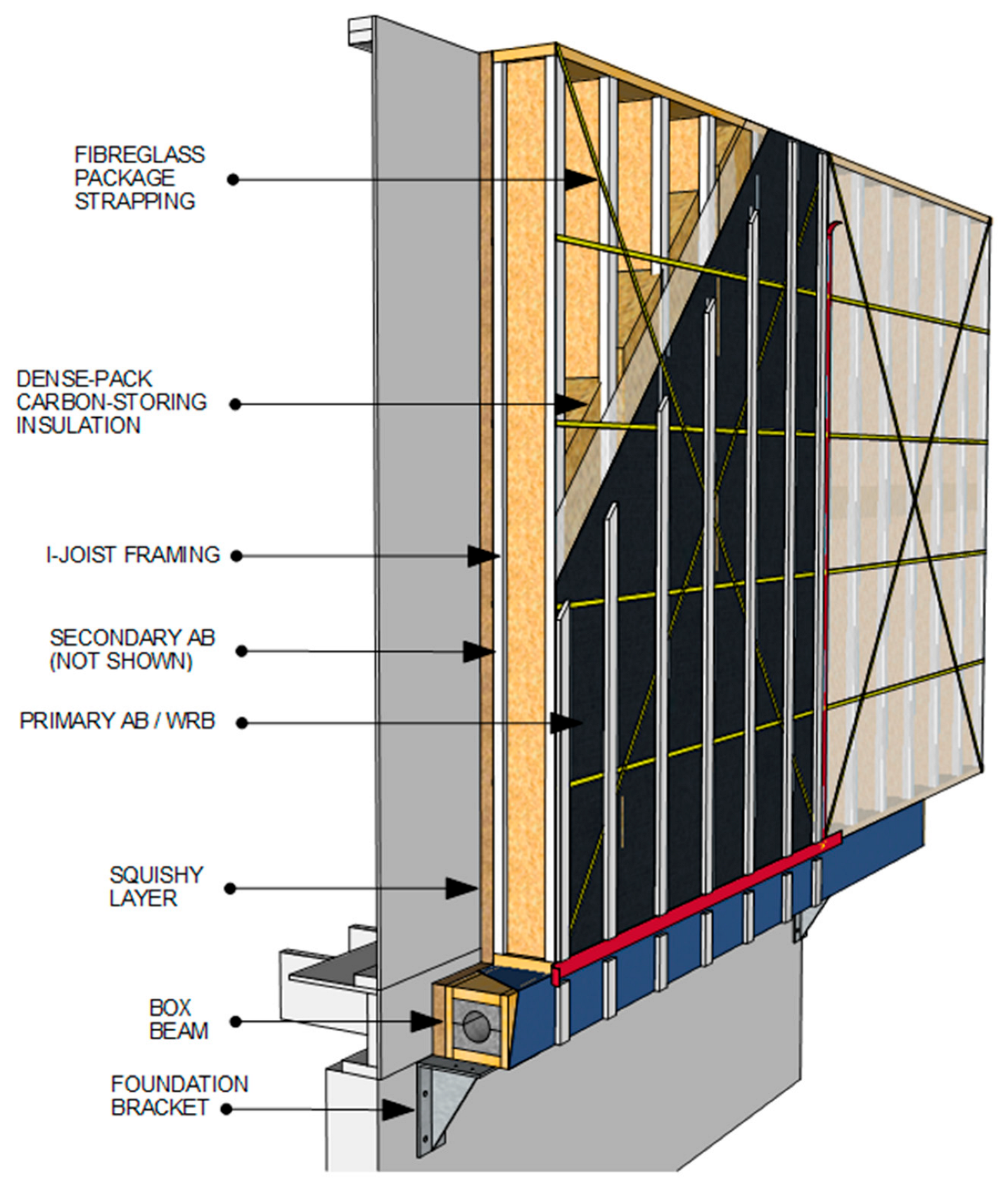

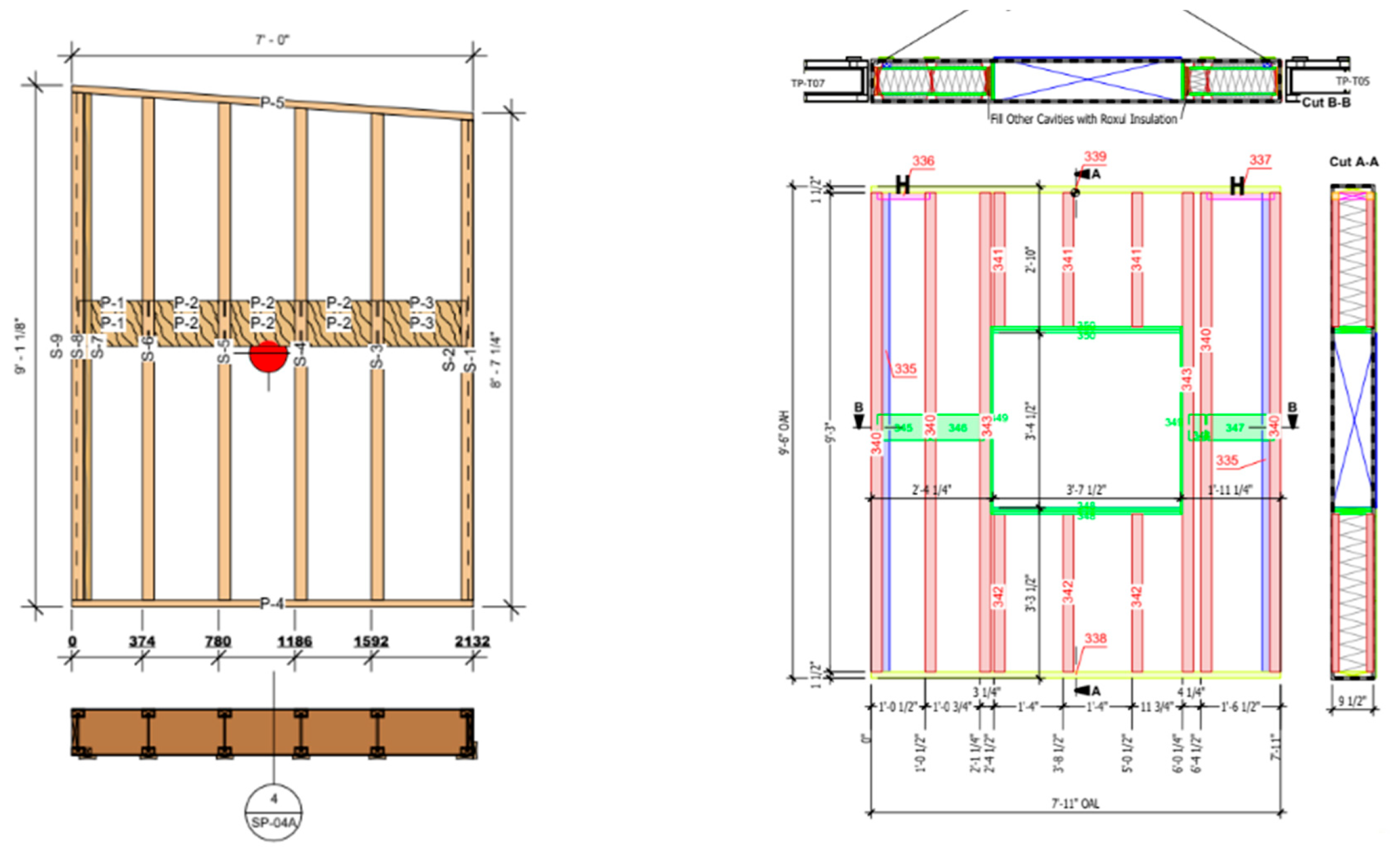

2.1.2. Panel Designs Developed

2.2. Fabricator Work

2.2.1. Shop Drawings Were Developed

2.2.2. Panel Fabrication

2.2.3. Panels Loaded and Shipped

2.3. Onsite Work

2.3.1. Building Preparation

2.3.2. Brackets and Box Beam Installed

2.3.3. Wall Panel Installation—Hemp Squishy Layer

2.3.4. Wall Panel Installation—Crane

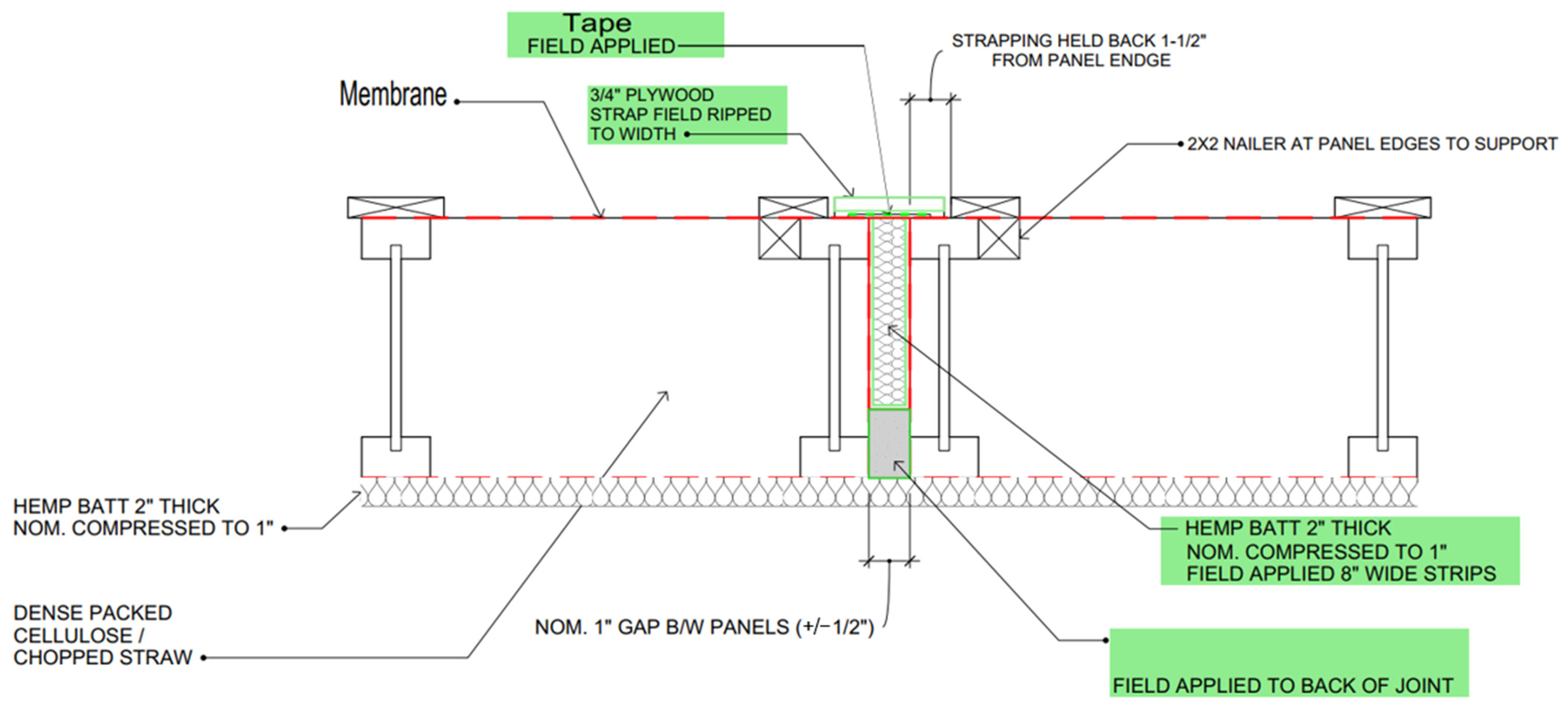

2.3.5. Panel Joints

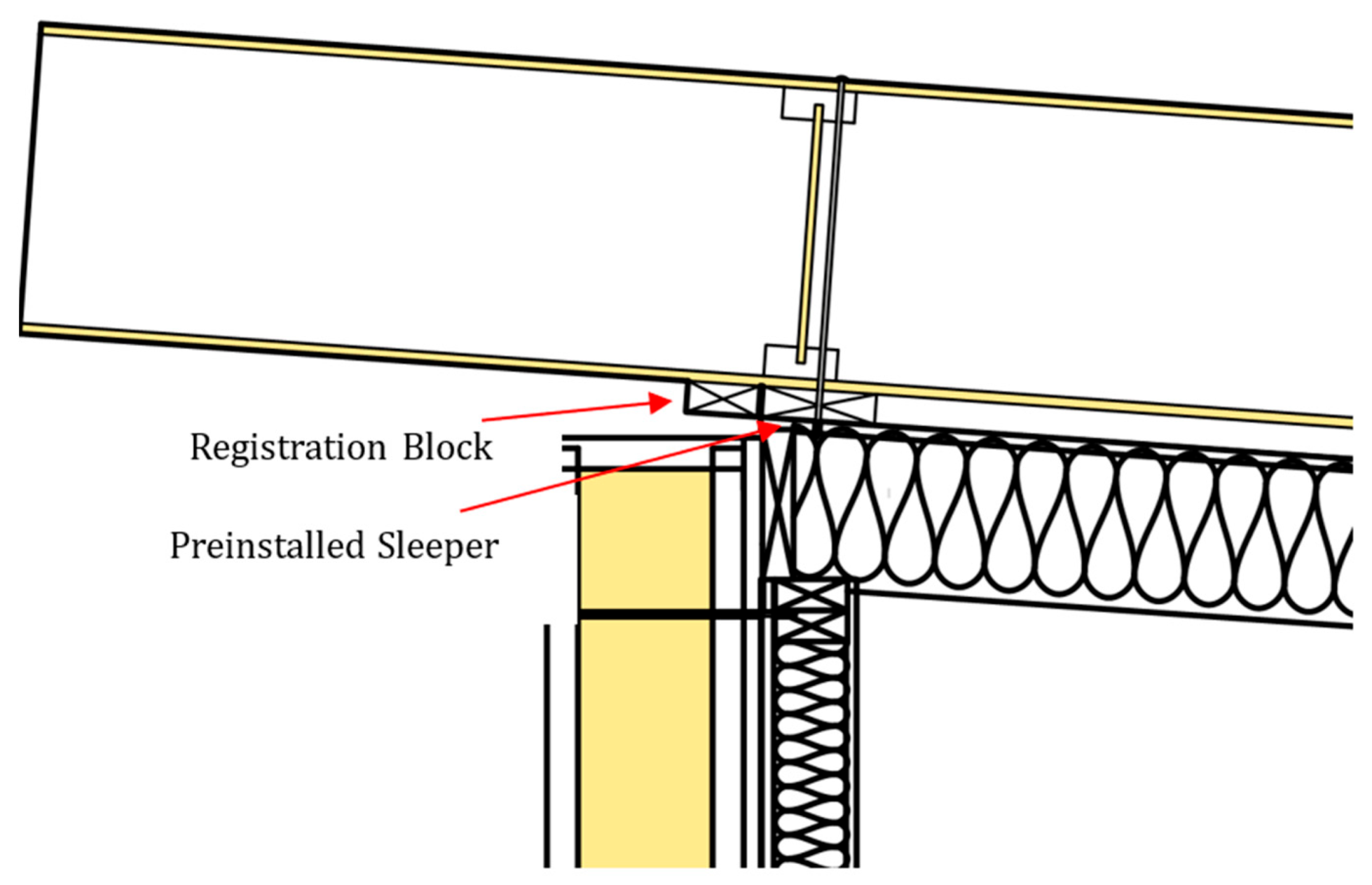

2.3.6. Roof Panel Installation

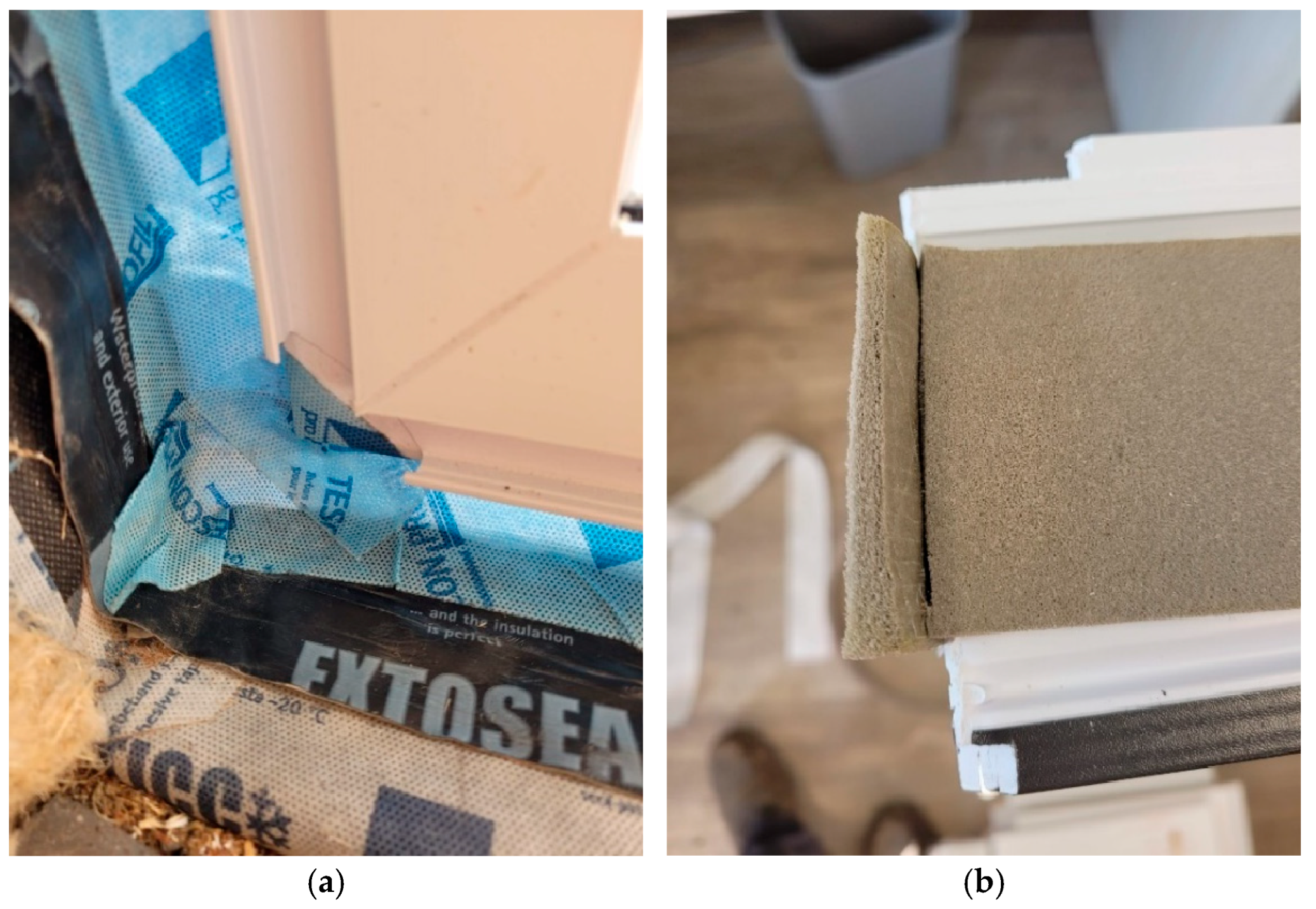

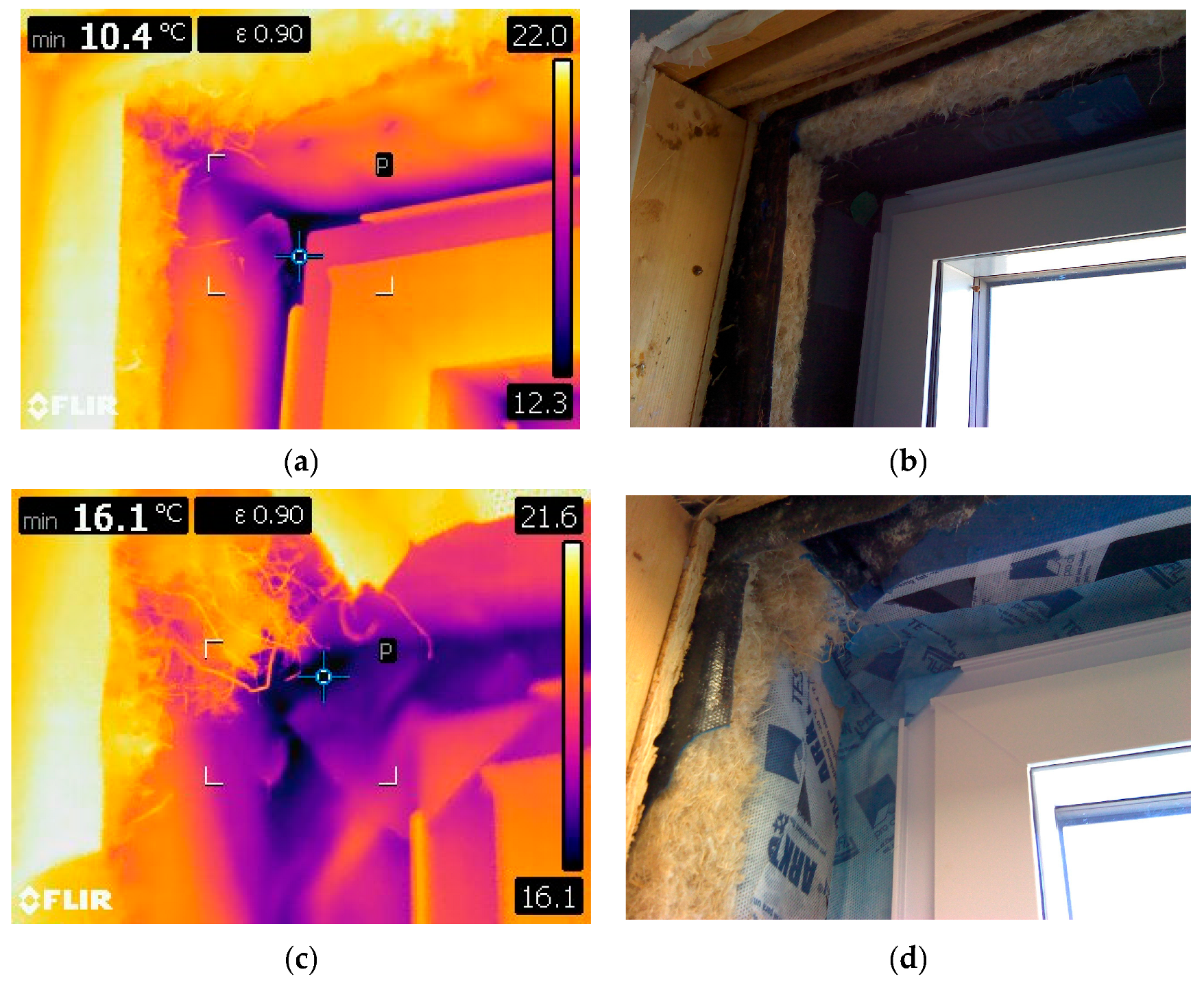

2.3.7. Window Installation

2.3.8. Penetrations

2.3.9. Interior and Exterior Finishing

2.3.10. Mechanical Installation

2.4. Modelling and Monitoring Methods

2.4.1. Thermal Performance Methodology

2.4.2. Embodied Carbon Methodology

2.4.3. Cost Analysis

2.4.4. Monitoring Plan

3. Results

3.1. Panel Design

3.2. Panel Construction

3.3. Installation

3.3.1. Box Beam

3.3.2. Squishy Layer

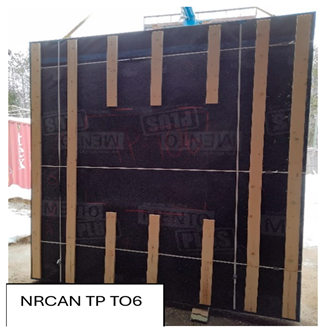

3.3.3. Panel Installation and Joints

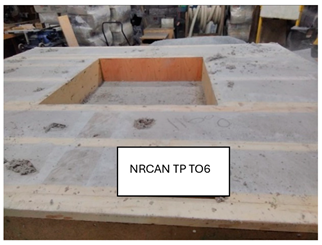

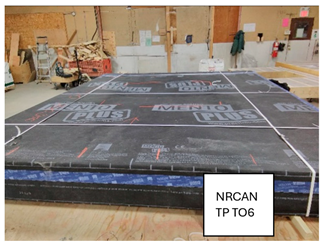

3.3.4. Roof Panels

3.3.5. Windows

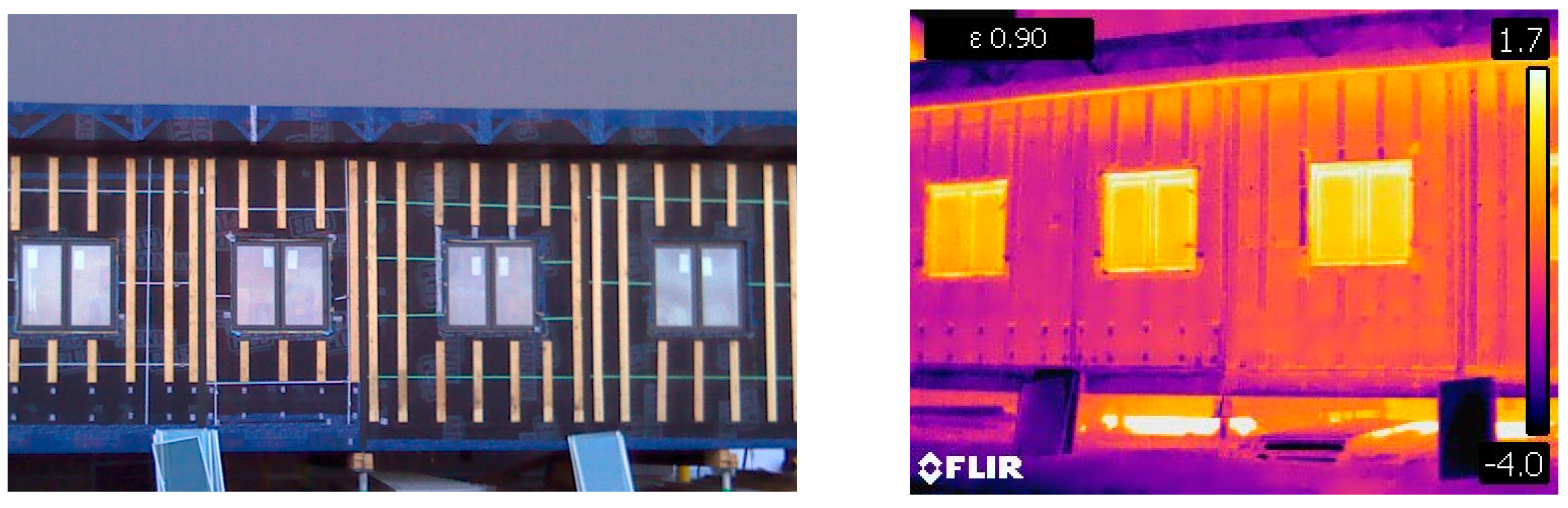

3.4. Thermal Performance

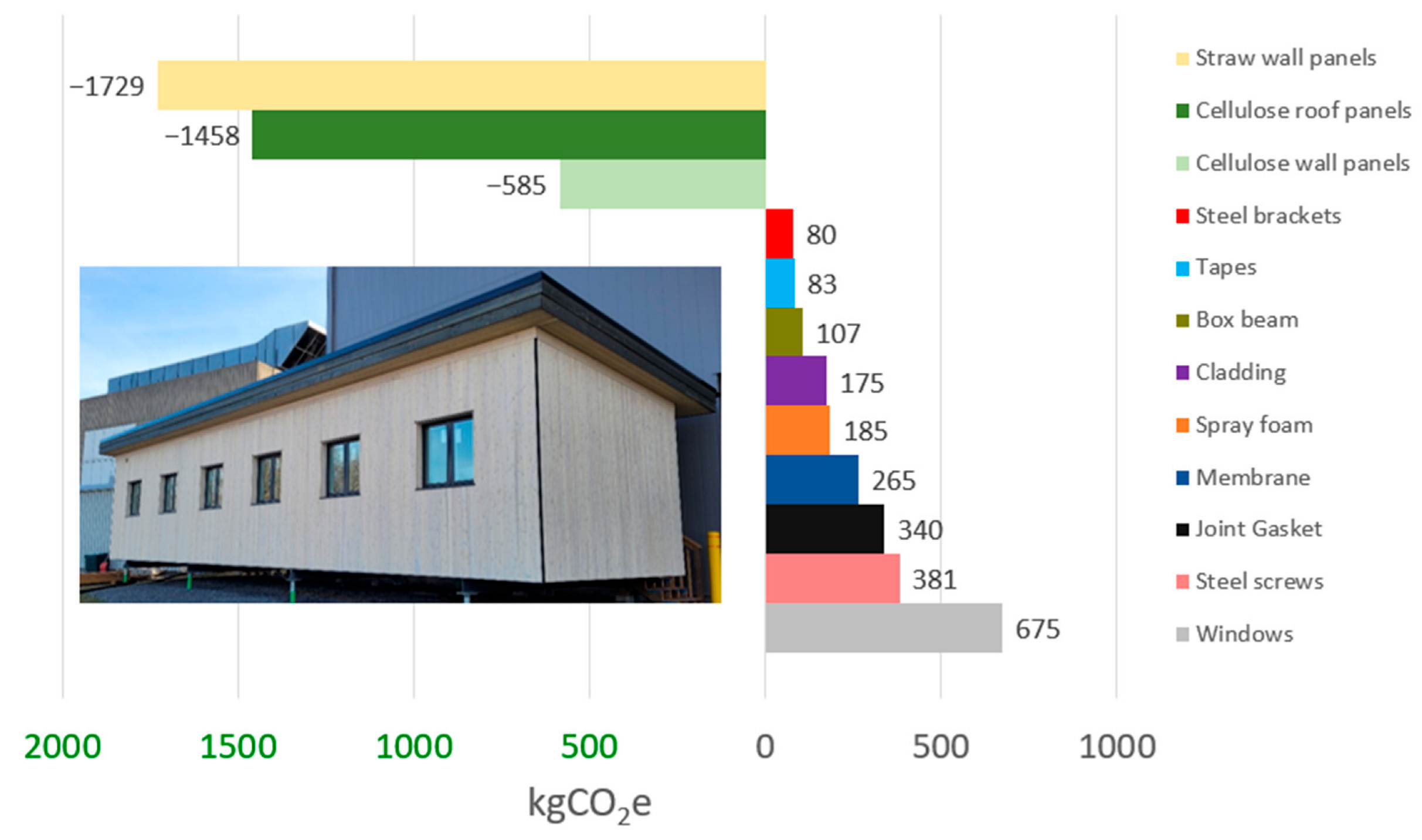

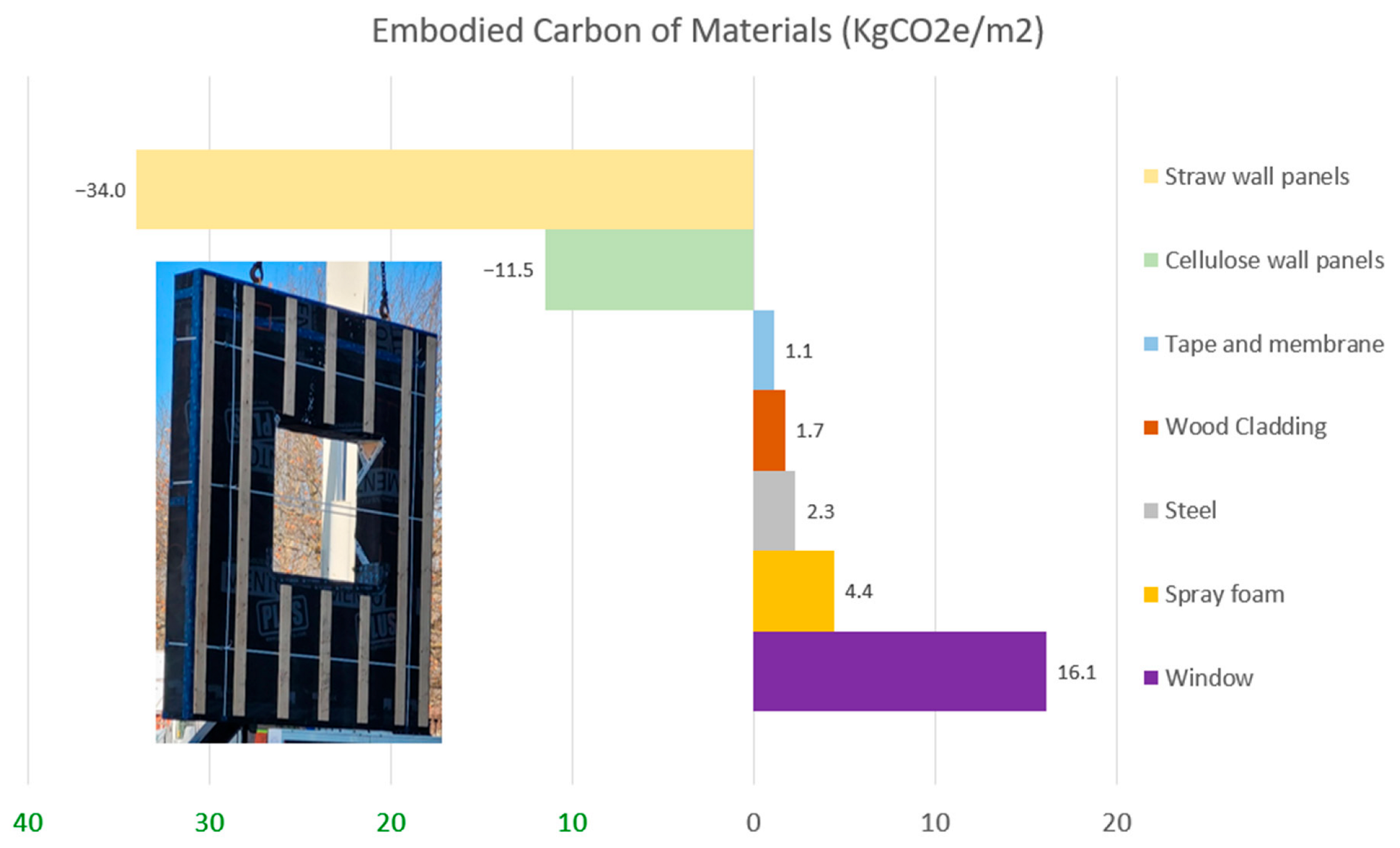

3.5. Embodied Carbon

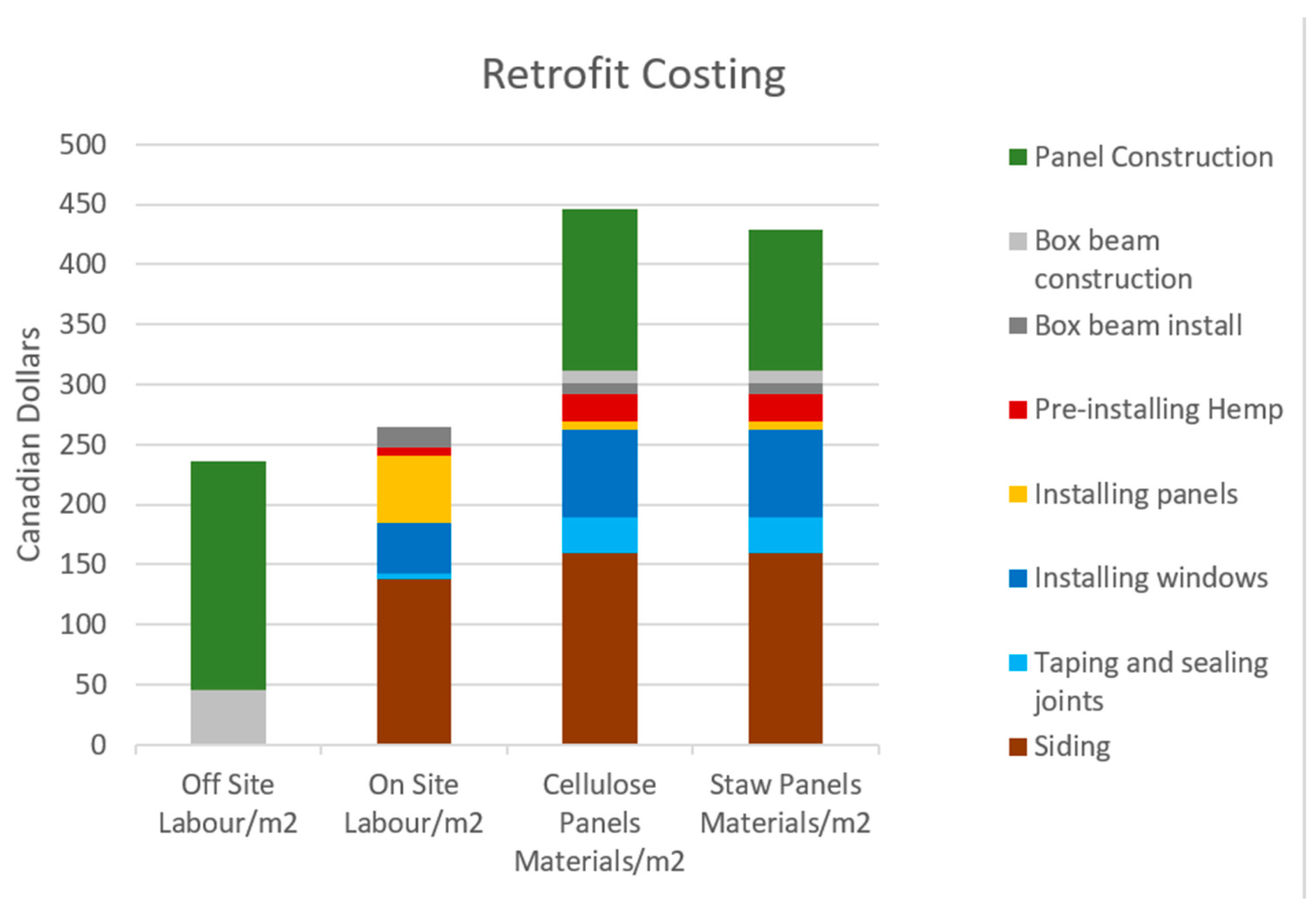

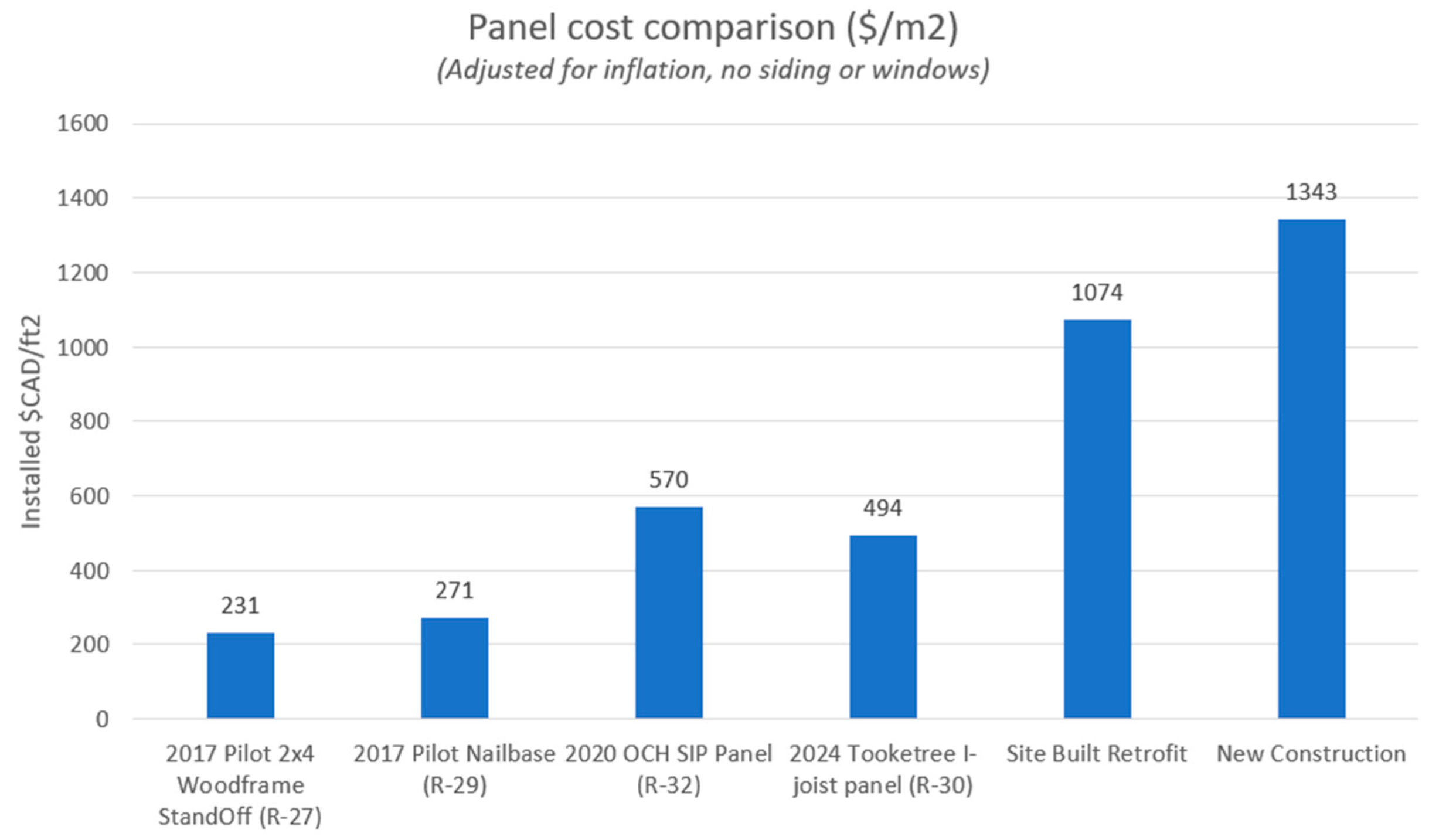

3.6. Costing

4. Conclusions

- The sheathing-less I-joist panel design was found to be viable for lowrise residential buildings. The panels arrived without significant racking, and the lack of sheathing had no major impact on the installation process. As the I-joists were expensive, the fabricators suggested using a double-stud wall design, which they could fabricate easily and more cost-effectively.

- Both fabricators mentioned that sheathing-less panels took more time to prepare, and that including sheathing should save time and money (even when accounting for the additional materials).

- The box beams were a success and simplified the panel installation. The contractors installing the panels found it much easier to install and prepare the box beams first, and then the panel installation and alignment process was more streamlined.

- A lower-density squishy layer is required to make panel installation easier. This could be accomplished by using a lower-density material or using a thicker hemp batt and planning for it to compress less.

- Flat roof panels with registration blocks can be installed quite quickly. The first panel takes the most time to install correctly, but once installed, the other panels can be quickly placed, adjusted, and installed.

- The thermal air tightness and thermal performance of the building were significantly improved post-retrofit. Thermal bridging was modelled, and Ψ-values of the linear thermal bridges and Χ-values of the point thermal bridges were calculated.

- A total of 1480 kgCO2e net carbon storage was achieved during retrofitting from the addition of the new envelope panels and box beams.

- The cost of labour and materials for the retrofitting process was outlined and compared to other retrofitting projects, onsite construction, and new construction.

- The prefabricated wall panels have been instrumented, as well as the interior of the building itself. The thermal and hygrothermal performance of the wall panels will be monitored. The interior conditions of the building will be monitored to study occupant comfort and climate resilience. At certain points during the winter and summer, the power will be shut off to determine the building’s ability to maintain safe living conditions during an extended power outage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Actions for a Zero Carbon Built Environment. Architecture 2030. 2023. Available online: https://architecture2030.org/why-the-building-sector/ (accessed on 7 July 2023).

- Wang, Y.; Ma, M.; Zhou, N.; Ma, Z. Paving the way to carbon neutrality: Evaluating the decarbonization of residential building electrification worldwide. Sustain. Cities Soc. 2025, 130, 106549. [Google Scholar] [CrossRef]

- Government of Canada. Canada’s 2030 Emissions Reduction Plan; Environment and Climate Change Canada: Gatineau, QC, Canada, 2022.

- Natural Resources Canada. National Energy Use Database (NEUD) Comprehensive Energy Use Database. 2019. Available online: https://oee.nrcan.gc.ca/corporate/statistics/neud/dpa/data_e/databases.cfm?attr=0 (accessed on 2 January 2024).

- HOME. Government of Canada. 2024. Available online: https://data-donnees.az.ec.gc.ca/data/substances/monitor/canada-s-greenhouse-gas-emissions-projections/Current-Projections-Actuelles/GHG-GES/detailed_GHG_emissions_GES_detaillees.csv (accessed on 7 July 2024).

- The Canada Green Buildings Strategy: Transforming Canada’s Buildings Sector for a Net-Zero and Resilient Future. Government of Canada, 8 July 2024. Available online: https://natural-resources.canada.ca/transparency/reporting-and-accountability/plans-and-performance-reports/departmental-strategies/the-canada-green-buildings-strategy-transforming-canadas-buildings-sector-for-net-zer/26065 (accessed on 20 July 2024).

- Residential Sector Canada Table 2: Secondary Energy Use and GHG Emissions by End-Use. Natural Resources Canada. 2024. Available online: https://oee.nrcan.gc.ca/corporate/statistics/neud/dpa/showTable.cfm?type=CP§or=res&juris=ca&year=2021&rn=2&page=0 (accessed on 22 July 2024).

- BERTIM Consortium. BERTIM—Innovative wood prefabrication for energy efficient renovations: Project results booklet. European Union Horizon 2020 Research and Innovation Programme. 2019. [Google Scholar]

- CanmetENERGY. Prefabricated Exterior Energy Retrofit (PEER) Project Guide; Natural Resources Canada: Ottawa, ON, Canada, 2023.

- TAF the Atmospheric Fund. The Case for Deep Retrofits; The Atmospheric Fund: Toronto, ON, Canada, 2020. [Google Scholar]

- Government of Canada Promotes in-Demand Skilled Trades as a First-Choice Career Path. Government of Canada, 3 January 2022. Available online: https://www.canada.ca/en/employment-social-development/news/2022/01/skills-trade.html (accessed on 2 August 2023).

- Affordable and Adaptable Public Buildings Through Energy Efficient Retrofitting. CORDIS EU Research Results. 2018. Available online: https://cordis.europa.eu/project/id/609060/reporting (accessed on 1 January 2023).

- New Easy to Install and Manufacture PRE-Fabricated Modules Supported by a BIM based Integrated Design ProceSS. CORDIS EU Research Results. 2020. Available online: https://cordis.europa.eu/article/id/413460-old-meets-new-sustainable-retrofit-of-buildings-through-prefabricated-panels (accessed on 1 January 2023).

- BuildForce Canada. Construction and Maintenance Looking Forward; BuildForce Canada: Ottawa, ON, Canada, 2022. [Google Scholar]

- Industrialised Energy Efficient Retrofitting of Resident Buildings in Cold Climates. CORDIS EU Research Results. 2022. Available online: https://cordis.europa.eu/project/id/260058 (accessed on 1 January 2023).

- Make Net Zero Energy Refurbishments for Houses a Mass Market Reality. CORDIS EU Research Results. 2021. Available online: https://cordis.europa.eu/project/id/696186/reporting (accessed on 1 January 2023).

- Multifunctional Energy Efficient Façade System for Building Retrofitting. CORDIS EU Research Results. 2017. Available online: https://cordis.europa.eu/project/id/285411/reporting (accessed on 1 January 2023).

- Energiesprong. What Is Energiesprong. Energiesprong. 2025. Available online: https://www.energiesprong.org/what-is-energiesprong (accessed on 18 September 2025).

- Building Energy Renovation Through Timber Prefabricated Modules. CORDIS EU Research Results. 2022. Available online: https://cordis.europa.eu/project/id/636984 (accessed on 1 January 2023).

- Holistic Energy-Efficient Retrofitting of Residential Buildings. CORDIS EU Research Results. 2015. Available online: https://cordis.europa.eu/article/id/159896-energyefficient-technology-demonstrated-in-13-old-buildings (accessed on 1 January 2023).

- National Research Council Canada. National Building Code of Canada: 2020; National Research Council of Canada: Ottawa, ON, Canada, 2022.

- Guide to Oversize/Overweight Vehicles and Loads. Ontario. 2022. Available online: https://www.ontario.ca/page/guide-oversizeoverweight-vehicles-and-loads#:~:text=width%20of%203.70%20m%20on,height%20maximum%20of%204.26%20m (accessed on 6 June 2024).

- Mott, H. The good, the bad, and the hygge: Designing for prefab from a manufacturer’s perspective. In Passive House Canada Prefab Symposium; Passive House Canada: Victoria, BC, Canada, 2022. [Google Scholar]

- Proclima. System Products. Proclima. Available online: https://proclima.com/products (accessed on 12 December 2024).

- Material Carbon Emissions Estimator (MCE2). Government of Canada, 11 July 2022. Available online: https://natural-resources.canada.ca/maps-tools-and-publications/tools/modelling-tools/material-carbon-emissions-estimator/24452 (accessed on 8 July 2023).

- BC Building Codes and Standards Branch. BC Codes 2024. 2024. Available online: https://www2.gov.bc.ca/gov/content/industry/construction-industry/building-codes-standards/bc-codes/2024-bc-codes (accessed on 5 September 2025).

- Jevons, R.; Carmichael, C.; Crossley, A.; Bone, A. Minimum indoor temperature threshold recommendations for English homes in winter—A systematic review. Public Health 2016, 136, 4–12. [Google Scholar] [CrossRef] [PubMed]

- Purdy, J.; Parekh, A. Building Envelope Thermal and Air Leakage Characteristics of Canadian Housing. In CCBST 2017; Vancouver, BC Building Envelope Council: Delta, BC, Canada, 2017. [Google Scholar]

- Passive House Requirements. Passive House. 2025. Available online: https://passiv.de/en/02_informations/02_passive-house-requirements/02_passive-house-requirements.htm (accessed on 20 September 2025).

- Statistics Canada. Building Construction Price Index. Statistics Canada. 2025. Available online: https://www150.statcan.gc.ca/n1/en/surveys/2317 (accessed on 7 January 2025).

| Step | Time (People-Hours) | Picture |

|---|---|---|

| Processing/ripping plates and RSO plywood and cutting members to length | 0.75 hr × 2ppl =1.5 ppl-hrs |  |

| Assembling frames and installing blocking | 5 hrs × 2 ppl =10 ppl-hrs |  |

| Installing insulating mesh on both panel faces | 0.75 hrs × 1 ppl =0.75 ppl-hrs |  |

| Blowing in insulation to required density | 0.75 hr × 1 ppl =0.75 ppl-hr |  |

| Installing AB/WRB to fully wrap the panel | 1.5 hrs × 1 ppl =1.5 ppl-hrs |  |

| Installing strapping on the panel’s exterior side | 0.5 hr × 1 ppl =0.5 ppl-hr |  |

| Installing industrial package strapping/final Q/A | 1 hr × 1 ppl =1 ppl-hr |  |

| TOTAL | 16 people-hours |

| Performance Metric | Baseline | Retrofit | % Improvement | |

|---|---|---|---|---|

| Air Change Rate (ACH@50Pa) | 7.20 | 0.26 | 96 | |

| Normalized Leakage Area @10Pa (cm2/m2) | 1.03 | 0.07 | 93 | |

| Thermal Resistance (R-Value [RSI]) | Walls | 13 [2.3] | 40 [7.0] | 308 |

| Roof | 20 [3.5] | 60 [10.6] | 300 | |

| Design Heat Loss (−25 °C) W | 3380 | 1610 | 52 | |

| Thermal Energy Demand Intensity (kWh/m2a) | 260 | 8.0 | 97 | |

| Clear Field | Thermal Resistance | Surface Area | % Area | % Heat Flow | ||

|---|---|---|---|---|---|---|

| Assembly | (m2·K/W) | (hr·ft2·°F/BTU) | (m2) | (ft2) | ||

| Floor | 5.4 | 30.9 | 50.4 | 542 | 22.7% | 29.8% |

| Cellulose Insulated Roof | 12.5 | 71.2 | 50.4 | 542 | 22.7% | 12.9% |

| Cellulose Insulated Walls | 8.2 | 46.5 | 55.7 | 600 | 23.7% | 22.8% |

| Straw Insulated Walls | 8.0 | 45.4 | 55.7 | 600 | 23.7% | 23.4% |

| Linear Thermal Bridges | Ψ-value | Total Length | % Area | % Heat flow | ||

| (W/m·K) | (BTU/hr·ft·°F) | (m) | (ft) | |||

| Window-to-wall interface | 0.038 | 0.0220 | 6.5625 | 21 | 2.8% | 2.7% |

| Vertical panel Joint | 0.004 | 0.0023 | 39.4 | 126 | 1.0% | 1.0% |

| Box Beam | 0.018 | 0.0104 | 42.5 | 136 | 4.5% | 4.4% |

| Point Thermal Bridges | Χ-value | Quantity | % Area | % Heat flow | ||

| (W/K) | (BTU/hr·°F) | |||||

| Foundation Bracket | 0.0063 | 0.011648448 | 8 | - | 2.7% | |

| Long Screws | 0.00022 | 0.000406771 | 28 | - | 0.3% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pope, H.; Carver, M.; Armstrong, J. Low-Carbon Climate-Resilient Retrofit Pilot: Construction Report. Buildings 2025, 15, 3666. https://doi.org/10.3390/buildings15203666

Pope H, Carver M, Armstrong J. Low-Carbon Climate-Resilient Retrofit Pilot: Construction Report. Buildings. 2025; 15(20):3666. https://doi.org/10.3390/buildings15203666

Chicago/Turabian StylePope, Hamish, Mark Carver, and Jeff Armstrong. 2025. "Low-Carbon Climate-Resilient Retrofit Pilot: Construction Report" Buildings 15, no. 20: 3666. https://doi.org/10.3390/buildings15203666

APA StylePope, H., Carver, M., & Armstrong, J. (2025). Low-Carbon Climate-Resilient Retrofit Pilot: Construction Report. Buildings, 15(20), 3666. https://doi.org/10.3390/buildings15203666