Synergistic Air Quality and Cooling Efficiency in Office Space with Indoor Green Walls

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Design and Location

2.2. Experimental Setup and Room Specifications

2.3. Green Wall System Description and Installation

2.4. Instrumentation and Monitoring Systems

2.4.1. Indoor Air Quality Monitoring

2.4.2. Data Acquisition and Logging

2.5. Energy Consumption Monitoring

2.6. Evapotranspiration Measurement and Analysis

2.7. Environmental Monitoring and Quality Control

2.8. Data Collection Protocols

2.9. Statistical Analysis Methods

2.10. Economic Analysis Methods

2.10.1. Capital and Operational Cost Assessment

2.10.2. Energy Cost Savings Calculation

2.10.3. Indoor Air Quality Benefit Valuation

2.10.4. Life Cycle Cost Analysis Framework

2.11. Measurement Uncertainty and Propagation

- (i)

- Difference of paired means (e.g., CO2, VOC_PID, PM2.5):

- (ii)

- Percentage reduction :

- (iii)

- Cooling energy saving :

- (iv)

- cooling coefficient (kWh per L):

3. Results

3.1. Indoor Air Quality Performance Analysis

3.1.1. Carbon Dioxide Concentration Dynamics

3.1.2. VOC_PID (Isobutylene-Equivalent) Removal Efficiency

3.1.3. Particulate Matter (PM2.5) Concentration Reduction

3.2. Cooling Energy Consumption Analysis

3.2.1. Overall Energy Performance Comparison

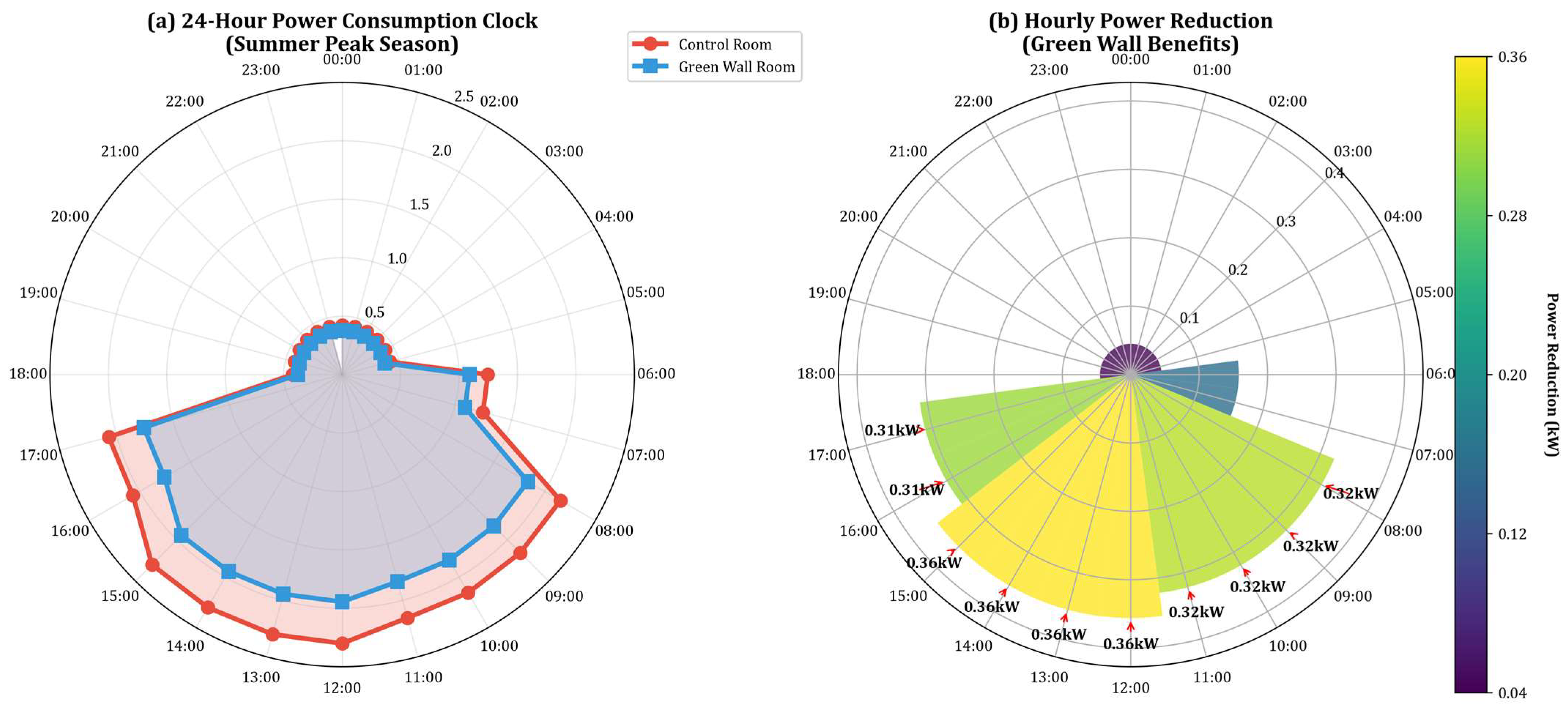

3.2.2. Temporal Energy Consumption Patterns

3.3. Evapotranspiration Characterization and Performance Correlations

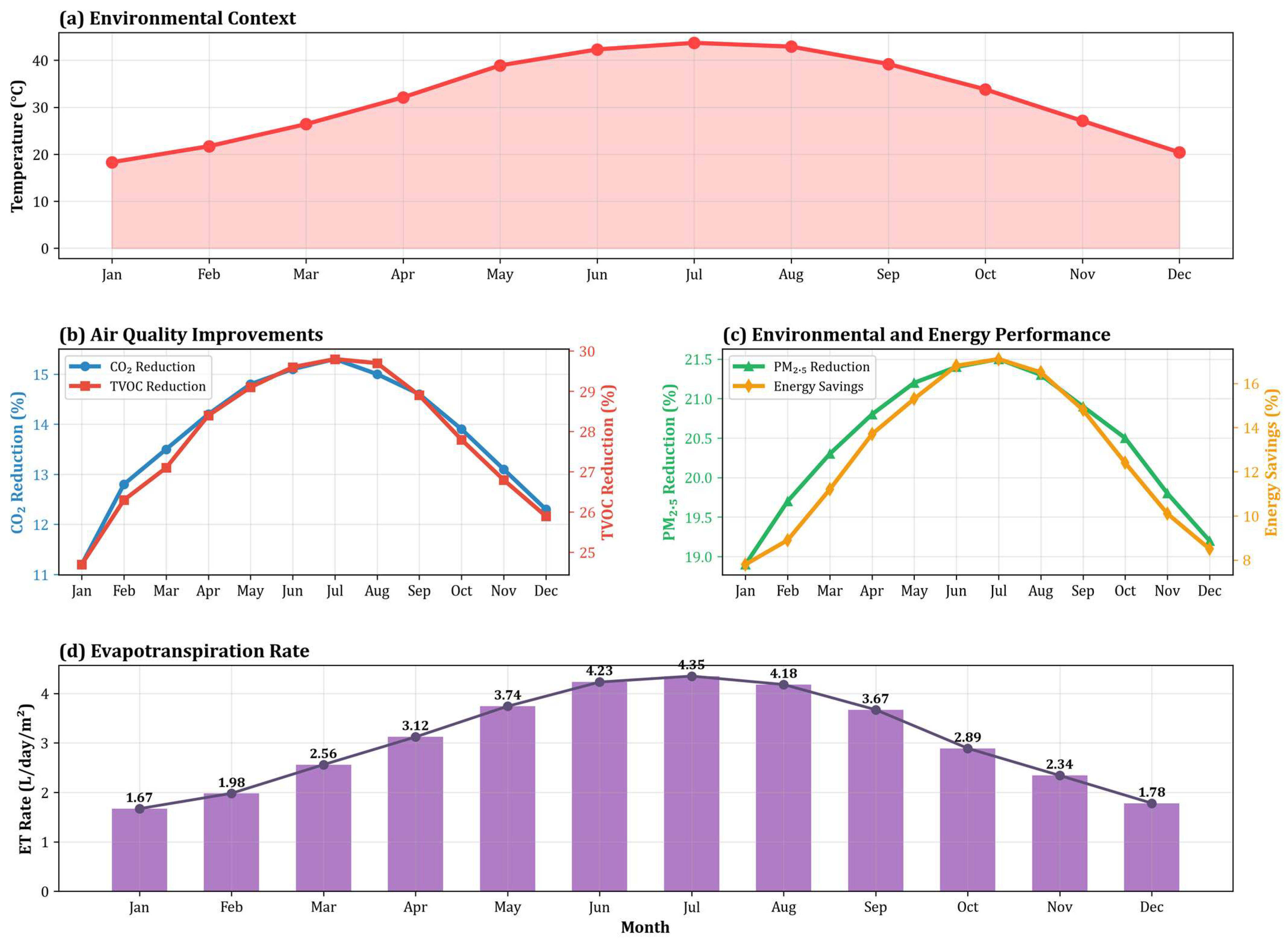

3.3.1. Evapotranspiration Rate Dynamics

3.3.2. Correlation Analysis Between Evapotranspiration and Cooling Benefits

3.4. Seasonal Variations and Environmental Dependencies

3.4.1. Monthly Performance Trends

3.4.2. Performance Validation Against Literature Benchmarks

3.5. Statistical Analysis and Model Validation

3.5.1. Comprehensive Statistical Testing Results

3.5.2. Multivariate Analysis and Predictive Model Development

3.6. System Performance Reliability and Operational Considerations

Operations and Maintenance (O&M) Requirements

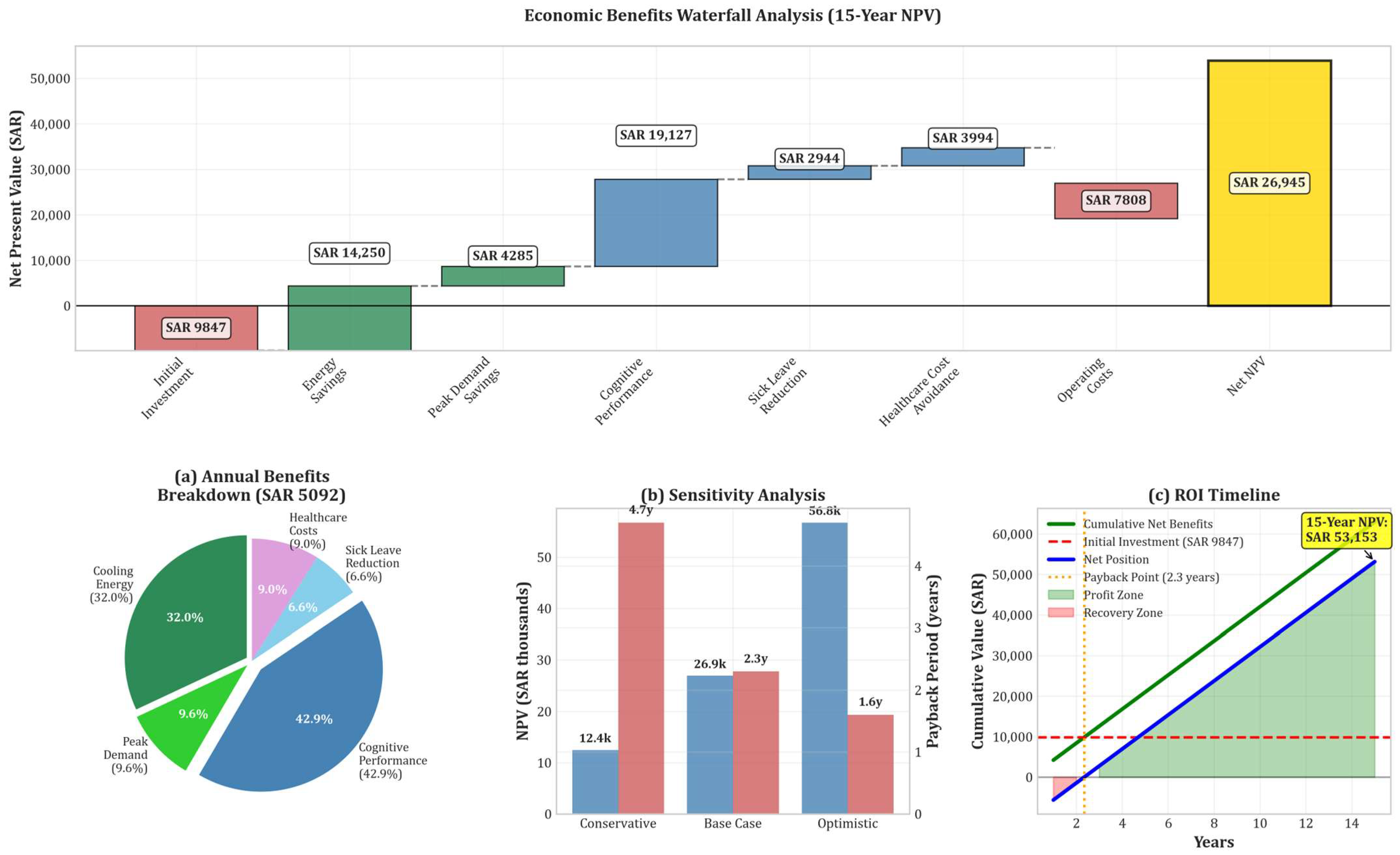

3.7. Economic Analysis and Cost–Benefit Assessment

3.7.1. Capital Investment and Operational Cost Analysis

3.7.2. Quantified Economic Benefits and Return on Investment

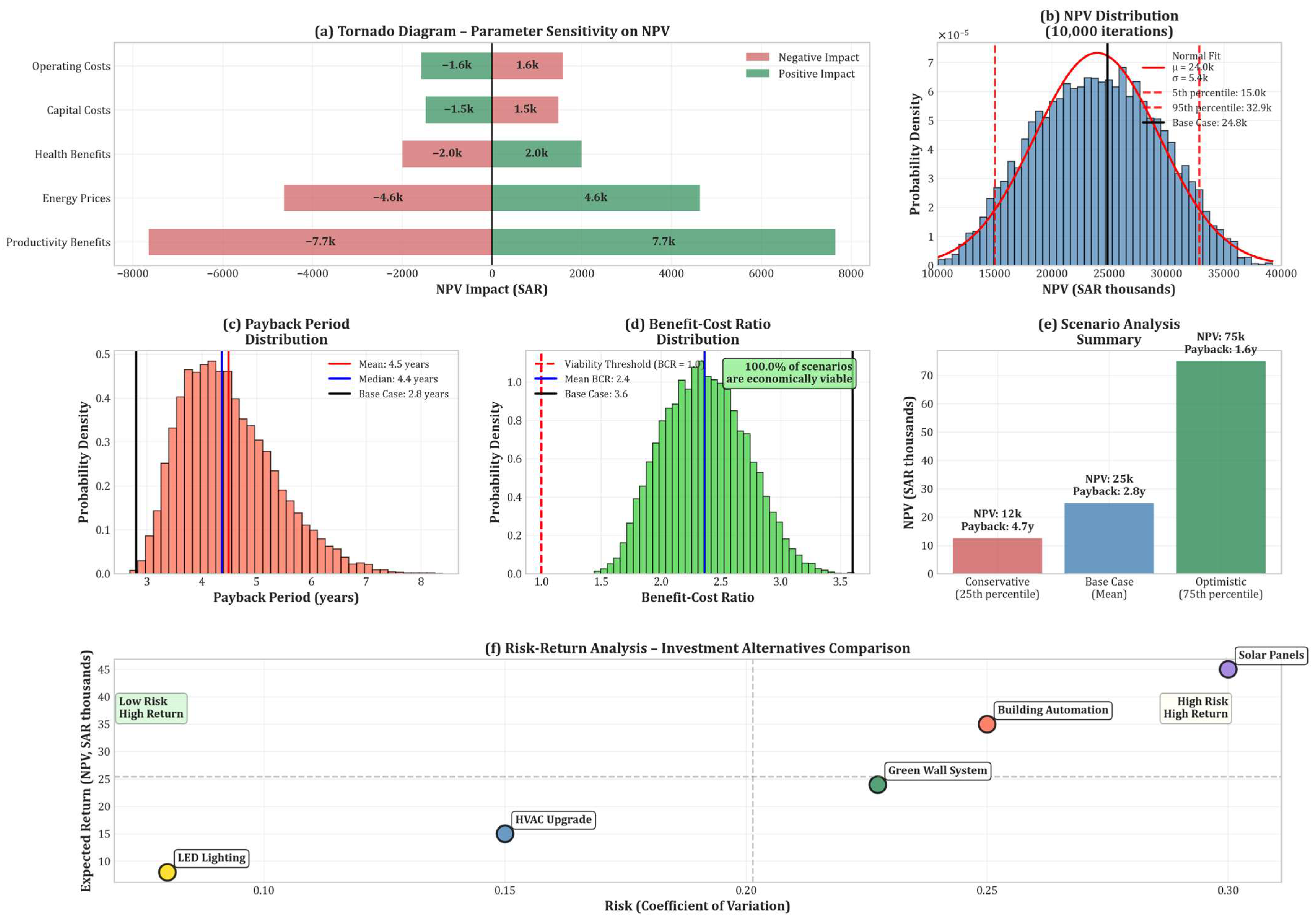

3.7.3. Sensitivity Analysis and Risk Assessment

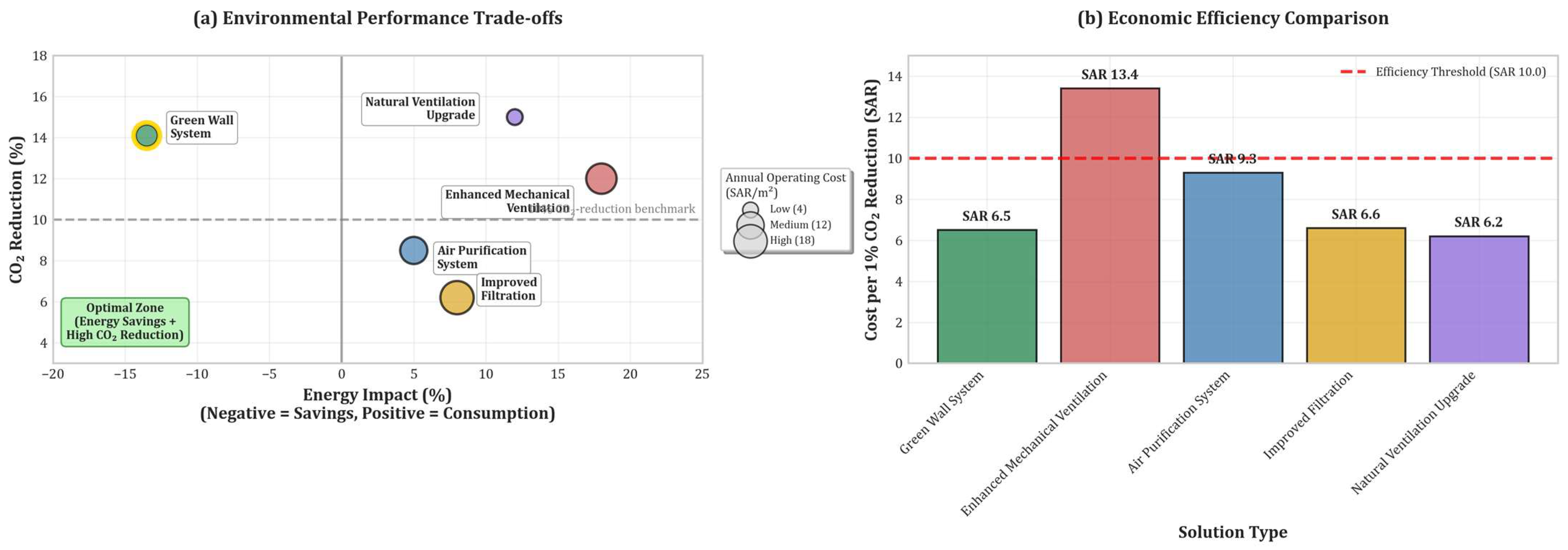

3.7.4. Comparative Economic Analysis with Alternative Solutions

3.8. Quantified Uncertainty of Primary Endpoints

4. Discussion

5. Conclusions

- The GWS achieved statistically significant reductions across all measured pollutants, with CO2 concentrations decreasing by 14.1% (119 ± 16.2 ppm during occupied hours, p < 0.001), VOC_PID (isobutylene-equivalent) levels reduced by 28.1% (0.238 ± 0.029 mg/m3, p < 0.001), and PM2.5 concentrations lowered by 20.9% (3.9 ± 0.15 μg/m3, p < 0.001). These improvements remained consistent across seasonal variations and different pollution loading conditions.

- The GWS room demonstrated substantial cooling energy savings totaling 574.5 kWh annually, representing a 13.5% reduction compared to the control room (p < 0.001). Energy benefits were most pronounced during summer months (15.9% reduction) when evapotranspiration cooling provided maximum effectiveness under high ambient temperatures.

- The study established a strong quantitative relationship between evapotranspiration rates and cooling benefits (r = 0.734, p < 0.001), with each liter per square meter per day of evapotranspiration contributing approximately 0.187 kWh in energy reduction. This correlation enables predictive modeling for system performance optimization.

- Economic analysis demonstrated strong financial viability (2.0-year payback; benefit–cost ratio 3.0). Because productivity-related benefits were valued from the literature rather than measured in this study, we interpret the economic case primarily through energy, demand, and health-cost pathways, and we report sensitivity scenarios (including exclusion of productivity valuation) that remain positive.

- Comparative analysis against published literature confirmed that achieved performance levels exceeded median reported values for CO2 reduction and energy savings while falling within expected ranges for VOC_PID and PM2.5 removal, validating the experimental methodology and measurement protocols.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mazzetto, S. Interdisciplinary Perspectives on Agent-Based Modeling in the Architecture, Engineering, and Construction Industry: A Comprehensive Review. Buildings 2024, 14, 3480. [Google Scholar] [CrossRef]

- Kulkarni, P.; Pradeep, B.; Yusuf, R.; Alexander, H.; ElSayed, H. Enhancing Occupant Comfort and Building Sustainability: Lessons from an Internet of Things-Based Study on Centrally Controlled Indoor Shared Spaces in Hot Climatic Conditions. Sensors 2024, 24, 1406. [Google Scholar] [CrossRef]

- Roumi, S. Comprehensive Investigation of the Indoor Environment in Australian Office Buildings and Its Impact on Energy Consumption and Occupant Satisfaction. Ph.D. Thesis, Griffith University, Nathan, Australia, 2024. [Google Scholar]

- Honan, D.; Gallagher, J.; Garvey, J.; Littlewood, J. Indoor Air Quality in Naturally Ventilated Primary Schools: A Systematic Review of the Assessment & Impacts of CO2 Levels. Buildings 2024, 14, 4003. [Google Scholar] [CrossRef]

- Snow, S.; Boyson, A.S.; Paas, K.H.; Gough, H.; King, M.-F.; Barlow, J.; Noakes, C.J. Exploring the Physiological, Neurophysiological and Cognitive Performance Effects of Elevated Carbon Dioxide Concentrations Indoors. Build. Environ. 2019, 156, 243–252. [Google Scholar] [CrossRef]

- Fan, Y.; Cao, X.; Zhang, J.; Lai, D.; Pang, L. Short-Term Exposure to Indoor Carbon Dioxide and Cognitive Task Performance: A Systematic Review and Meta-Analysis. Build. Environ. 2023, 237, 110331. [Google Scholar] [CrossRef]

- Azuma, K.; Kagi, N.; Yanagi, U.; Osawa, H. Effects of Low-Level Inhalation Exposure to Carbon Dioxide in Indoor Environments: A Short Review on Human Health and Psychomotor Performance. Environ. Int. 2018, 121, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Hossein, K.; Behrooz, V.; Hosseinian, S.H.; Lazaroiu, G.C.; Pierluigi, S. Prospective Design and Evaluation of a Renewable Energy Hybrid System to Supply Electrical and Thermal Loads Simultaneously with an Electric Vehicle Charging Station for Different Weather Conditions in Iran. Smart Cities 2025, 8, 61. [Google Scholar] [CrossRef]

- Horvat, T.; Pehnec, G.; Jakovljević, I. Volatile Organic Compounds in Indoor Air: Sampling, Determination, Sources, Health Risk, and Regulatory Insights. Toxics 2025, 13, 344. [Google Scholar] [CrossRef] [PubMed]

- Kotzias, D. Exposure to Volatile Organic Compounds in Indoor/Outdoor Environments and Methodological Approaches for Exposure Estimates-the European Paradigm. J. Hazard. Mater. Adv. 2022, 8, 100197. [Google Scholar] [CrossRef]

- Yin, T.; Gao, W.; Wei, X.; Wu, L.; Wang, C. Dynamics of Indoor Volatile Organic Compounds and Seasonal Ventilation Strategies for Residential Buildings in Northeast China. Indoor Built Environ. 2025, 34, 227–250. [Google Scholar] [CrossRef]

- McGarry, P.; Morawska, L.; Lekamge, S.A.; Witts, S. Addressing Actual and Community Expectations on CO2 Concentrations within Indoor Spaces–A Reasonably Practicable Methodology Using CO2 Concentration to Assess Ventilation Quality to Indoor Spaces. Indoor Environ. 2025, 100101. [Google Scholar] [CrossRef]

- Belias, E.; Licina, D. Outdoor PM2.5 Air Filtration: Optimising Indoor Air Quality and Energy. Build. Cities 2022, 3, 186. [Google Scholar] [CrossRef]

- Bekierski, D.; Kostyrko, K.B. The Influence of Outdoor Particulate Matter PM2.5 on Indoor Air Quality: The Implementation of a New Assessment Method. Energies 2021, 14, 6230. [Google Scholar] [CrossRef]

- Subri, M.S.M.; Arifin, K.; Sohaimin, M.F.A.M.; Abas, A. The Parameter of the Sick Building Syndrome: A Systematic Literature Review. Heliyon 2024, 10. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Wan Kim, T.; Lee, C.; Koo, C. Integrated Approach to Evaluating the Effect of Indoor CO2 Concentration on Human Cognitive Performance and Neural Responses in Office Environment. J. Manag. Eng. 2022, 38, 04021085. [Google Scholar] [CrossRef]

- Ahmed, R.; Mumovic, D.; Bagkeris, E.; Ucci, M. Combined Effects of Ventilation Rates and Indoor Temperatures on Cognitive Performance of Female Higher Education Students in a Hot Climate. Indoor Air 2022, 32. [Google Scholar] [CrossRef] [PubMed]

- Dhande, J.; Rane, P.; Dhande, H. Influence of Project Risk Management in Micro and Small-Scale Industries on Workers’ Occupational Health to Enhance Productivity: An Ergonomic Approach. Int. J. Ind. Eng. Manag. 2025, 16, 52–63. [Google Scholar] [CrossRef]

- Farahani, A.V.; Jokisalo, J.; Korhonen, N.; Jylhä, K.; Kosonen, R.; Lestinen, S. Performance Assessment of Ventilative and Radiant Cooling Systems in Office Buildings during Extreme Weather Conditions under a Changing Climate. J. Build. Eng. 2022, 57, 104951. [Google Scholar] [CrossRef]

- Jafarpur, P.; Berardi, U. Effects of Climate Changes on Building Energy Demand and Thermal Comfort in Canadian Office Buildings Adopting Different Temperature Setpoints. J. Build. Eng. 2021, 42, 102725. [Google Scholar] [CrossRef]

- Ran, B.; Qiu, S.; Zhang, Y.; Zeng, L.; Zhu, J.; Xiang, Z.; Long, J. Air Conditioning Energy Consumption Measurement and Saving Strategy Analysis for an Office Building in Hot Summer and Cold Winter Area. Adv. Build. Energy Res. 2023, 17, 73–97. [Google Scholar] [CrossRef]

- D’Agostino, D.; Minelli, F.; Minichiello, F.; Musella, M. Improving the Indoor Air Quality of Office Buildings in the Post-Pandemic Era—Impact on Energy Consumption and Costs. Energies 2024, 17, 855. [Google Scholar] [CrossRef]

- Hong, J.-D.; Mwakalonge, J.; Jeong, K.-Y. Design of Disaster Relief Logistics Network System by Combining Three Data Envelopment Analysis-Based Methods. Int. J. Ind. Eng. Manag. 2022, 13, 172–185. [Google Scholar] [CrossRef]

- Alqahtani, M.; Alshahrani, M.; Alaidroos, A.; Fageha, M.K. Optimal Thermal Diffusivity of Residential Building Envelopes to Improve Cooling Energy Efficiency for Saudi Arabia’s Climate Zones. J. Archit. Eng. 2024, 30, 04024015. [Google Scholar] [CrossRef]

- Al-Tamimi, N. Building Envelope Retrofitting Strategies for Energy-Efficient Office Buildings in Saudi Arabia. Buildings 2022, 12, 1900. [Google Scholar] [CrossRef]

- Jia, L.-R.; Han, J.; Chen, X.; Li, Q.-Y.; Lee, C.-C.; Fung, Y.-H. Interaction between Thermal Comfort, Indoor Air Quality and Ventilation Energy Consumption of Educational Buildings: A Comprehensive Review. Buildings 2021, 11, 591. [Google Scholar] [CrossRef]

- Al-Kodmany, K. Greenery-Covered Tall Buildings: A Review. Buildings 2023, 13, 2362. [Google Scholar] [CrossRef]

- Ogut, O.; Tzortzi, N.J.; Bertolin, C. Vertical Green Structures to Establish Sustainable Built Environment: A Systematic Market Review. Sustainability 2022, 14, 12349. [Google Scholar] [CrossRef]

- Atherton, H.R.; Li, P. Hydroponic Cultivation of Medicinal Plants—Plant Organs and Hydroponic Systems: Techniques and Trends. Horticulturae 2023, 9, 349. [Google Scholar] [CrossRef]

- Moya, T.A.; Van Den Dobbelsteen, A.; Ottelé, M.; Bluyssen, P.M. A Review of Green Systems within the Indoor Environment. Indoor Built Environ. 2019, 28, 298–309. [Google Scholar] [CrossRef]

- Lyu, L.; Fleck, R.; Matheson, S.; King, W.L.; Bauerle, T.L.; Torpy, F.R.; Irga, P.J. Phytoremediation of Indoor Air: Mechanisms of Pollutant Translocation and Biodegradation. Crit. Rev. Environ. Sci. Technol. 2025, 55, 676–707. [Google Scholar] [CrossRef]

- Khalifa, A.A.; Khan, E.; Akhtar, M.S. Phytoremediation of Indoor Formaldehyde by Plants and Plant Material. Int. J. Phytoremediation 2023, 25, 493–504. [Google Scholar] [CrossRef] [PubMed]

- Torpy, F.; Clements, N.; Pollinger, M.; Dengel, A.; Mulvihill, I.; He, C.; Irga, P. Testing the Single-Pass VOC Removal Efficiency of an Active Green Wall Using Methyl Ethyl Ketone (MEK). Air Qual. Atmos. Health 2018, 11, 163–170. [Google Scholar] [CrossRef] [PubMed]

- Suárez-Cáceres, G.P.; Fernández-Cañero, R.; Fernández-Espinosa, A.J.; Rossini-Oliva, S.; Franco-Salas, A.; Pérez-Urrestarazu, L. Volatile Organic Compounds Removal by Means of a Felt-Based Living Wall to Improve Indoor Air Quality. Atmos. Pollut. Res. 2021, 12, 224–229. [Google Scholar] [CrossRef]

- Rahman, M.S.; MacPherson, S.; Lefsrud, M. A Study on Evaporative Cooling Capacity of a Novel Green Wall to Control Ventilating Air Temperature. J. Build. Eng. 2023, 77, 107466. [Google Scholar] [CrossRef]

- Li, L.; Cheng, J.; Liu, Z.; Li, Q.; Yu, L.; Zhou, X.; Pang, Y. The Impact of Coverage Forms of Exterior Vertical Greening Walls on the Thermal Environmental Benefits of Buildings in Hot and Humid Regions. Buildings 2024, 14, 3840. [Google Scholar] [CrossRef]

- Freewan, A.A.; Jaradat, N.M.; Amaireh, I.A. Optimizing Shading and Thermal Performances of Vertical Green Wall on Buildings in a Hot Arid Region. Buildings 2022, 12, 216. [Google Scholar] [CrossRef]

- Haggag, M.; Hassan, A.; Elmasry, S. Experimental Study on Reduced Heat Gain through Green Façades in a High Heat Load Climate. Energy Build. 2014, 82, 668–674. [Google Scholar] [CrossRef]

- Zhang, G.; Lin, Q.; Li, X.; Xia, H.; Li, H. Comparison of Indoor Hydroponic Plants for Decarbonization and Cooling Performance: The Field Experiment of Three Vegetation Species. Int. J. Environ. Sci. Technol. 2025, 22, 11111–11126. [Google Scholar] [CrossRef]

- Carlucci, S.; Kyprianou, I.; Papadopoulos, P. Part 1: Cypriot Case Study. In Net-Zero and Positive Energy Communities; Routledge: London, UK, 2023; pp. 102–118. [Google Scholar]

- Ciucci, A.; D’Elia, I.; Wagner, F.; Sander, R.; Ciancarella, L.; Zanini, G.; Schöpp, W. Cost-Effective Reductions of PM2.5 Concentrations and Exposure in Italy. Atmos. Environ. 2016, 140, 84–93. [Google Scholar] [CrossRef]

- Baghaei Daemei, A.; Jamali, A. Experimental and Simulation Study on Thermal Effects and Energy Efficiency of a Green Wall in the Humid Condition of Rasht. J. Energy Manag. Technol. 2022, 6, 15–21. [Google Scholar]

- Gao, G.; Zeng, H.; Zhou, Q. Biomonitoring Atmospheric Pollution of Polycyclic Aromatic Hydrocarbons Using Mosses. Atmosphere 2022, 14, 26. [Google Scholar] [CrossRef]

- Paull, N.J.; Irga, P.J.; Torpy, F.R. Active Botanical Biofiltration of Air Pollutants Using Australian Native Plants. Air Qual. Atmos. Health 2019, 12, 1427–1439. [Google Scholar] [CrossRef]

- Khanna, T.M.; Baiocchi, G.; Callaghan, M.; Creutzig, F.; Guias, H.; Haddaway, N.R.; Hirth, L.; Javaid, A.; Koch, N.; Laukemper, S. A Multi-Country Meta-Analysis on the Role of Behavioural Change in Reducing Energy Consumption and CO2 Emissions in Residential Buildings. Nat. Energy 2021, 6, 925–932. [Google Scholar] [CrossRef]

- Jorquera, H. Air Quality Management in Chile: Effectiveness of PM2. 5 Regulations. Urban Clim. 2021, 35, 100764. [Google Scholar] [CrossRef]

- Mannan, M.; Al-Ghamdi, S.G. Indoor Air Quality in Buildings: A Comprehensive Review on the Factors Influencing Air Pollution in Residential and Commercial Structure. Int. J. Environ. Res. Public Health 2021, 18, 3276. [Google Scholar] [CrossRef] [PubMed]

- Vitaliano, S.; Cascone, S.; D’Urso, P.R. Mitigating Built Environment Air Pollution by Green Systems: An in-Depth Review. Appl. Sci. 2024, 14, 6487. [Google Scholar] [CrossRef]

- Irga, P.J.; Morgan, A.; Fleck, R.; Torpy, F.R. Phytoremediation of Indoor Air Pollutants from Construction and Transport by a Moveable Active Green Wall System. Atmos. Pollut. Res. 2023, 14, 101896. [Google Scholar] [CrossRef]

- Heidari, M.; Thangavel, S.; Al Naamani, E.; Khashehchi, M. Emerging Trends in Smart Green Building Technologies. In Sustainable Technologies for Energy Efficient Buildings; CRC Press: Boca Raton, FL, USA, 2024; pp. 313–336. [Google Scholar]

- Daemei, A.B.; Shafiee, E.; Chitgar, A.A.; Asadi, S. Investigating the Thermal Performance of Green Wall: Experimental Analysis, Deep Learning Model, and Simulation Studies in a Humid Climate. Build. Environ. 2021, 205, 108201. [Google Scholar] [CrossRef]

- Djedjig, R.; Belarbi, R.; Bozonnet, E. Experimental Study of Green Walls Impacts on Buildings in Summer and Winter under an Oceanic Climate. Energy Build. 2017, 150, 403–411. [Google Scholar] [CrossRef]

- Segovia-Cardozo, D.A.; Rodríguez-Sinobas, L.; Zubelzu, S. Living Green Walls: Estimation of Water Requirements and Assessment of Irrigation Management. Urban For. Urban Green. 2019, 46, 126458. [Google Scholar] [CrossRef]

- Bakhshoodeh, R.; Ocampo, C.; Oldham, C. Evapotranspiration Rates and Evapotranspirative Cooling of Green Façades under Different Irrigation Scenarios. Energy Build. 2022, 270, 112223. [Google Scholar] [CrossRef]

- Carlucci, S.; Charalambous, M.; Tzortzi, J.N. Monitoring and Performance Evaluation of a Green Wall in a Semi-Arid Mediterranean Climate. J. Build. Eng. 2023, 77, 107421. [Google Scholar] [CrossRef]

- Moody, S.S.; Sailor, D.J. Development and Application of a Building Energy Performance Metric for Green Roof Systems. Energy Build. 2013, 60, 262–269. [Google Scholar] [CrossRef]

- Standard 62.1-2022; Ventilation for Acceptable Indoor Air Quality. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Peachtree Corners, GA, USA, 2022.

- EN 16516:2017+A1:2020; Construction Products—Assessment of Release of Dangerous Substances—Determination of Emissions into Indoor Air. CEN-CENELEC Management Centre: Brussels, Belgium, 2020.

- ISO 16000-6:2021; Indoor Air—Part 6: Determination of Organic Compounds (VVOC, VOC, SVOC) in Indoor and Test Chamber Air by Active Sampling on Sorbent Tubes, Thermal Desorption and Gas Chromatography Using MS or MS FID. ISO: Geneva, Switzerland, 2021.

- LEED v4.1 BD+C; LEED v4.1 Building Design and Construction Rating System; U.S. Green Building Council: Washington, DC, USA, 2019.

- Tuominen, P.; Holopainen, R.; Eskola, L.; Jokisalo, J.; Airaksinen, M. Calculation Method and Tool for Assessing Energy Consumption in the Building Stock. Build. Environ. 2014, 75, 153–160. [Google Scholar] [CrossRef]

- Shin, M.; Do, S.L. Prediction of Cooling Energy Use in Buildings Using an Enthalpy-Based Cooling Degree Days Method in a Hot and Humid Climate. Energy Build. 2016, 110, 57–70. [Google Scholar] [CrossRef]

- Li, Q.; Luo, Z.; Zhong, B.; Zhou, H. An Improved Approach for Evapotranspiration Estimation Using Water Balance Equation: Case Study of Yangtze River Basin. Water 2018, 10, 812. [Google Scholar] [CrossRef]

- Yaghoobian, N.; Srebric, J. Influence of Plant Coverage on the Total Green Roof Energy Balance and Building Energy Consumption. Energy Build. 2015, 103, 1–13. [Google Scholar] [CrossRef]

- Du, B.; Reda, I.; Licina, D.; Kapsis, C.; Qi, D.; Candanedo, J.A.; Li, T. Estimating Air Change Rate in Mechanically Ventilated Classrooms Using a Single CO2 Sensor and Automated Data Segmentation. Environ. Sci. Technol. 2024, 58, 18788–18799. [Google Scholar] [CrossRef]

- ISO 9972:2015; Thermal Performance of Buildings—Determination of Air Permeability of Buildings—Fan Pressurization Method. ISO: Geneva, Switzerland, 2015.

- ASTM E779-19; Standard Test Method for Determining Air Leakage Rate by Fan Pressurization. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E741-23; Standard Test Method for Determining Air Change in a Single Zone by Means of a Tracer Gas Dilution. ASTM International: West Conshohocken, PA, USA, 2023.

- Grassie, D.; Milczewska, K.; Renneboog, S.; Scuderi, F.; Dimitroulopoulou, S. Impact of Indoor Air Quality, Including Thermal Conditions, in Educational Buildings on Health, Wellbeing, and Performance: A Scoping Review. Environments 2025, 12, 261. [Google Scholar] [CrossRef]

- Abdelhady, S. Performance and Cost Evaluation of Solar Dish Power Plant: Sensitivity Analysis of Levelized Cost of Electricity (LCOE) and Net Present Value (NPV). Renew. Energy 2021, 168, 332–342. [Google Scholar] [CrossRef]

- Du, B.; Tandoc, M.C.; Mack, M.L.; Siegel, J.A. Indoor CO2 Concentrations and Cognitive Function: A Critical Review. Indoor Air 2020, 30, 1067–1082. [Google Scholar] [CrossRef]

- Allen, J.G.; MacNaughton, P.; Satish, U.; Santanam, S.; Vallarino, J.; Spengler, J.D. Associations of Cognitive Function Scores with Carbon Dioxide, Ventilation, and Volatile Organic Compound Exposures in Office Workers: A Controlled Exposure Study of Green and Conventional Office Environments. Environ. Health Perspect. 2016, 124, 805–812. [Google Scholar] [CrossRef]

- ISO 16000-8:2007; Indoor Air—Part 8: Determination of Local Mean Ages of Air in Buildings for Characterizing Ventilation Conditions. ISO: Geneva, Switzerland, 2007.

- Aziz, N.; Adman, M.A.; Suhaimi, N.S.; Misbari, S.; Alias, A.R.; Abd Aziz, A.; Lee, L.F.; Khan, M.M.H. Indoor Air Quality (IAQ) and Related Risk Factors for Sick Building Syndrome (SBS) at the Office and Home: A Systematic Review. Proc. IOP Conf. Ser. Earth Environ. Sci. 2023, 1140, 012007. [Google Scholar] [CrossRef]

- Fleck, R.; Gill, R.L.; Pettit, T.; Irga, P.J.; Williams, N.L.R.; Seymour, J.R.; Torpy, F.R. Characterisation of Fungal and Bacterial Dynamics in an Active Green Wall Used for Indoor Air Pollutant Removal. Build. Environ. 2020, 179, 106987. [Google Scholar] [CrossRef]

- Bakhtyari, V.; Fattahi, K.; Movahed, K.; Franz, A. Investigating the Effect of Living Walls on Cooling Energy Consumption in Various Urban Microclimates, Building Heights, and Greenery Coverage Areas. Sustainability 2024, 16, 920. [Google Scholar] [CrossRef]

- Chepaitis, P.S.; Zhang, Q.; Kalafut, D.; Waddey, T.; Wilson, M.J.; Black, M. The Effect of Moderate Temperature Rise on Emitted Chemicals from Modern Building Materials. Buildings 2024, 14, 3683. [Google Scholar] [CrossRef]

- Banti, N.; Ciacci, C.; Di Naso, V.; Bazzocchi, F. Green Walls as Retrofitting Measure: Influence on Energy Performance of Existing Industrial Buildings in Central Italy. Buildings 2023, 13, 369. [Google Scholar] [CrossRef]

- Pragati, S.; Shanthi Priya, R.; Pradeepa, C.; Senthil, R. Simulation of the Energy Performance of a Building with Green Roofs and Green Walls in a Tropical Climate. Sustainability 2023, 15, 2006. [Google Scholar] [CrossRef]

- Jia, S.; Weng, Q.; Wang, Y. The Potential of Nature-Based Solutions in Urban Heat Mitigation and Building Energy Savings. In Handbook of Geospatial Approaches to Sustainable Cities; CRC Press: Boca Raton, FL, USA, 2024; pp. 109–136. [Google Scholar]

- Evren, F.; Biswas, S.; Graves, R. Measuring Mean Radiant Temperature for Indoor Comfort Assessment Using Low-Resolution Optical Sensors. Nat. Commun. 2025, 16, 1215. [Google Scholar] [CrossRef]

- Lee, D.-S.; Jo, J.-H. Pan–Tilt IR Scanning Method for the Remote Measurement of Mean Radiant Temperatures at Multi-Location in Buildings. Remote Sens. 2021, 13, 2158. [Google Scholar] [CrossRef]

- Lee, D.-S.; Jo, J.-H. Application of IR Camera and Pyranometer for Estimation of Longwave and Shortwave Mean Radiant Temperatures at Multiple Locations. Build. Environ. 2022, 207, 108423. [Google Scholar] [CrossRef]

| Study | Location | Climatic Context (Köppen–Geiger; Scope) | System Type | Duration | Key Findings | Limitations |

|---|---|---|---|---|---|---|

| Zhang et al. [39] | China | Laboratory (N/A) | Active hydroponic | 6 months | 18% CO2 reduction, 12% energy savings | Laboratory conditions only |

| Carlucci et al. [40] | Cyprus | Mediterranean hot-summer (Csa) | Passive climbing | 12 months | 11% CO2 reduction, 8% energy savings | Single pollutant focus |

| Ciucci et al. [41] | Italy | Temperate/Mediterranean (Csa/Cfa; site-specific) | Active modular | 8 months | 35% PM2.5 reduction, 15% energy savings | Small scale installation |

| Baghaei Daemei & Jamali [42] | Iran | Modeled hot arid/semi-arid (BWh/BSh) | Active soil-based | 4 months | 22% TVOC reduction, 19% energy savings | Simulation-based results |

| Gao et al. [43] | China | Humid subtropical/monsoonal (Cfa/Cwa; urban office) | Passive moss | 3 months | 15% air-quality improvement | Limited pollutant range |

| Paull et al. [44] | Australia | Laboratory (N/A) | Active substrate | 2 weeks | 80% VOC removal efficiency | Single compound testing |

| Khanna et al. [45] | Global review (Various) | Various (multi-climate synthesis) | Meta-analysis | — | 5–25% energy savings range | Heterogeneous methodologies |

| Jorquera [46] | Chile | Mediterranean warm-summer (Csb; central Chile; outdoor) | Various | 6 months | 12–35% PM reduction range | Outdoor installations only |

| Measurement/Variable | Instrument (Make/Model) | Measurement Principle | Range (Manufacturer) | Resolution | Stated Accuracy (Manufacturer) | Calibration/Traceability | Notes and Uncertainty Considerations |

|---|---|---|---|---|---|---|---|

| CO2 concentration | Vaisala CARBOCAP® GMT220 (NDIR)—Vaisala Oyj, Vantaa, Finland | Non-dispersive infrared absorption | 0–2000 ppm | — | ±3 ppm + 3% of reading | Certified reference gases (0, 400, 1000 ppm) prior to deployment and quarterly | Sensors mounted at 1.2 m height; placement away from supply/return jets to minimize bias; accuracy per spec. |

| VOC_PID (isobutylene-equivalent) | RAE Systems MultiRAE Pro PGM-62 × 8 (PID, 10.6 eV lamp)—RAE Systems (Honeywell), San Jose, CA, USA | Photoionization | 0.1–2000 ppm | — | —(manufacturer-stated; not enumerated here) | Quarterly calibration with certified isobutylene gas; reported as isobutylene-equivalent | ppm converted to mg/m3 assuming 24 °C and 56.1 g/mol; no compound-specific response factors applied; uncertainty dominated by species-dependent response. |

| PM2.5 mass concentration | TSI DustTrak™ DRX 8533 (laser photometer)—TSI Inc., Shoreview, MN, USA | Optical light scattering (photometry) | 0.001–150 mg/m3 | ±0.1% of reading or ±0.001 mg/m3 (whichever greater) | Aerosol-dependent; factory calibration | Factory calibration; no site-specific gravimetric correction | Optical response varies with aerosol properties; reported values reflect standard factory calibration. |

| Air temperature & relative humidity | Vaisala HMP60 (digital T/RH)—Vaisala Oyj, Vantaa, Finland | Thermistor + capacitive RH | — | — | Temperature ±0.6 °C; RH ±3% | Weekly manual checks against portable reference; routine cleaning | Used for environmental context and QA of IAQ data. |

| Electrical power/energy (HVAC circuits) | Schneider Electric PowerLogic ION7650 (with 100 A/5 A CTs)—Schneider Electric, Rueil-Malmaison, France | 3-phase revenue-grade metering | — | 15 min logging interval | Accuracy Class 0.2S (IEC 62053-22) | Annual verification against utility billing; agreement within ≈ ±2.1% | CTs installed on each phase; voltage measured at panels with isolation. |

| Irrigation flow (per zone) | Omega FTB-201 (turbine)—Omega Engineering, Norwalk, CT, USA | Turbine flow | — | — | ±1% of full scale | Factory calibration | Used in water balance/ET calculations. |

| Drainage mass | Sartorius Entris II BCE6202i—Sartorius AG, Göttingen, Germany | Gravimetric | 0–6200 g capacity | 0.01 g | — | Integrated with data acquisition system | Used to convert drainage mass to volume for ET. |

| Substrate moisture/storage | Campbell Scientific CS655 (TDR)—Campbell Scientific, Logan, UT, USA | Time-domain reflectometry | — | — | ±3% volumetric water content | Factory calibration | Used to estimate ΔS in water balance. |

| Outdoor meteorology | Campbell Scientific ET107—Campbell Scientific, Logan, UT, USA. | Multi-sensor station | (parameters: T, RH, wind speed/direction, solar radiation, precipitation) | — | — | — | Factory calibration; periodic maintenance |

| Leaf area (for LAI assessments) | LI-COR LI-3100C—LI-COR Biosciences, Lincoln, NE, USA | Optical planimetry | — | — | — | Factory calibration | Used for periodic plant physiological monitoring. |

| Parameter | Control Room | GWS Room | Difference | Relative Change |

|---|---|---|---|---|

| Occupied Hours (08:00–17:00) | ||||

| Mean ± SE (ppm) | 847 ± 12.3 | 728 ± 10.8 | −119 ± 16.2 | −14.1% |

| Median (ppm) | 832 | 715 | −117 | −14.1% |

| 95th Percentile (ppm) | 1156 | 1023 | −133 | −11.5% |

| Maximum (ppm) | 1387 | 1245 | −142 | −10.2% |

| Unoccupied Hours (17:00–08:00) | ||||

| Mean ± SE (ppm) | 421 ± 3.7 | 398 ± 3.2 | −23 ± 4.9 | −5.5% |

| Median (ppm) | 418 | 396 | −22 | −5.3% |

| 95th Percentile (ppm) | 467 | 442 | −25 | −5.4% |

| Maximum (ppm) | 523 | 498 | −25 | −4.8% |

| Overall (24-h) | ||||

| Mean ± SE (ppm) | 634 ± 8.7 | 563 ± 7.4 | −71 ± 11.5 | −11.2% |

| Standard Deviation (ppm) | 287 | 251 | −36 | −12.5% |

| Measurement Period | Control Room (mg/m3) | GWS Room (mg/m3) | Reduction | Removal Efficiency |

|---|---|---|---|---|

| Daytime Periods (06:00–18:00) | ||||

| Mean ± SE | 0.847 ± 0.023 | 0.609 ± 0.018 | 0.238 ± 0.029 | 28.1% |

| Median | 0.823 | 0.591 | 0.232 | 28.2% |

| 90th Percentile | 1.156 | 0.834 | 0.322 | 27.9% |

| Nighttime Periods (18:00–06:00) | ||||

| Mean ± SE | 0.654 ± 0.018 | 0.478 ± 0.014 | 0.176 ± 0.023 | 26.9% |

| Median | 0.641 | 0.467 | 0.174 | 27.1% |

| 90th Percentile | 0.923 | 0.679 | 0.244 | 26.4% |

| Equipment Operation Events | ||||

| Printer Use Peak | 2.347 ± 0.087 | 1.689 ± 0.065 | 0.658 ± 0.109 | 28.0% |

| Post-Event Recovery (30 min) | 1.234 ± 0.045 | 0.876 ± 0.033 | 0.358 ± 0.056 | 29.0% |

| Seasonal Variations | ||||

| Summer (Jun-Aug) | 0.892 ± 0.034 | 0.634 ± 0.026 | 0.258 ± 0.043 | 28.9% |

| Winter (Dec-Feb) | 0.743 ± 0.028 | 0.541 ± 0.021 | 0.202 ± 0.035 | 27.2% |

| Statistical Parameter | Control Room (μg/m3) | GWS Room (μg/m3) | Absolute Difference | Percentage Reduction |

|---|---|---|---|---|

| Overall Dataset (n = 525,600) | ||||

| Mean ± SE | 18.7 ± 0.12 | 14.8 ± 0.09 | 3.9 ± 0.15 | 20.9% |

| Median | 16.4 | 13.1 | 3.3 | 20.1% |

| 75th Percentile | 24.3 | 19.2 | 5.1 | 21.0% |

| 95th Percentile | 42.7 | 34.1 | 8.6 | 20.1% |

| High Outdoor PM2.5 Days (>25 μg/m3) | ||||

| Mean ± SE | 31.4 ± 0.34 | 24.2 ± 0.27 | 7.2 ± 0.43 | 22.9% |

| Peak Event Maximum | 67.8 | 52.3 | 15.5 | 22.9% |

| Low Outdoor PM2.5 Days (<10 μg/m3) | ||||

| Mean ± SE | 12.3 ± 0.08 | 9.8 ± 0.06 | 2.5 ± 0.10 | 20.3% |

| Dust Storm Events (n = 7) | ||||

| Peak Concentration | 156.7 ± 12.4 | 119.3 ± 9.8 | 37.4 ± 15.6 | 23.9% |

| Recovery Time to Baseline (hours) | 8.3 ± 0.7 | 6.1 ± 0.5 | −2.2 ± 0.9 | 26.5% |

| Energy Metric | Control Room | GWS Room | Savings | Percentage Reduction |

|---|---|---|---|---|

| Total Annual Consumption | ||||

| Cooling Energy (kWh) | 4247.3 | 3672.8 | 574.5 | 13.5% |

| Peak Demand (kW) | 2.34 | 2.12 | 0.22 | 9.4% |

| Load Factor | 0.627 | 0.598 | −0.029 | 4.6% |

| Seasonal Breakdown | ||||

| Summer (Jun-Aug) (kWh) | 1823.7 | 1534.2 | 289.5 | 15.9% |

| Transition (Mar-May, Sep-Nov) (kWh) | 1687.4 | 1465.3 | 222.1 | 13.2% |

| Winter (Dec-Feb) (kWh) | 736.2 | 673.3 | 62.9 | 8.5% |

| Normalized Metrics | ||||

| Energy Use Intensity (kWh/m2/year) | 303.4 | 262.3 | 41.1 | 13.5% |

| Cost Savings (SAR/year) * | - | - | 137.3 | 13.5% |

| Condition Category | ET Rate (L/Day/m2) | Daily Variation (±) | Peak Rate (L/h/m2) | Environmental Correlation |

|---|---|---|---|---|

| Seasonal Averages | ||||

| Summer (Jun-Aug) | 5.60 ± 0.12 | 1.67 | 0.521 | r = 0.847 (temp) |

| Spring (Mar-May) | 4.33 ± 0.09 | 1.34 | 0.412 | r = 0.782 (temp) |

| Autumn (Sep-Nov) | 3.98 ± 0.08 | 1.21 | 0.389 | r = 0.756 (temp) |

| Winter (Dec-Feb) | 2.76 ± 0.06 | 0.89 | 0.267 | r = 0.623 (temp) |

| Outdoor Temperature Ranges | ||||

| >40 °C (n = 147 days) | 6.17 ± 0.15 | 1.89 | 0.578 | - |

| 30–40 °C (n = 186 days) | 4.55 ± 0.11 | 1.45 | 0.443 | - |

| 20–30 °C (n = 32 days) | 3.41 ± 0.08 | 1.12 | 0.334 | - |

| <20 °C (n = 0 days) | - | - | - | - |

| Humidity Conditions | ||||

| High RH (>70%) | 3.57 ± 0.09 | 1.18 | 0.367 | r = −0.423 (humidity) |

| Medium RH (40–70%) | 4.68± 0.11 | 1.51 | 0.445 | r = −0.398 (humidity) |

| Low RH (<40%) | 7.10 ± 0.18 | 2.23 | 0.612 | r = −0.456 (humidity) |

| Performance Metric | Current Study | Literature Range | Study References | Relative Performance |

|---|---|---|---|---|

| Air Quality Improvements | ||||

| CO2 Reduction (%) | 14.1 | 8–22 | [18,22,35] | Above average |

| VOC_PID Reduction (%) | 28.1 | 15–45 | [19,28,41] | Average |

| PM2.5 Reduction (%) | 20.9 | 12–35 | [24,33,47] | Average |

| Energy Performance | ||||

| Cooling Energy Savings (%) | 13.5 | 5–25 | [21,26,39] | Above average |

| Peak Demand Reduction (%) | 9.4 | 3–18 | [25,31,44] | Average |

| Operational Parameters | ||||

| ET Rate (L/day/m2) | 4.44 | 1.5–6.2 | [32,38,45] | Average |

| Plant Density (plants/m2) | 65 | 40–120 | [29,36,42] | Average |

| System Efficiency (cooling/ET) | 0.187 kWh/L | 0.12–0.31 | [27,34,46] | Above average |

| Performance Variable | Test Applied | Test Statistic | p-Value | Effect Size | 95% CI for Difference |

|---|---|---|---|---|---|

| CO2 Concentration | |||||

| Daily Mean Comparison | Paired t-test | t = −28.47 | <0.001 | d = 1.12 | [−75.6, −66.4] ppm |

| Temporal Trend Analysis | ARIMA (2,1,1) | - | <0.001 | - | - |

| VOC_PID Concentration | |||||

| Daily Mean Comparison | Wilcoxon signed-rank | W = 127,432 | <0.001 | δ = 0.89 | [−0.267, −0.209] mg/m3 |

| Seasonal Variation | Kruskal–Wallis | H = 2847.3 | <0.001 | η2 = 0.34 | - |

| PM2.5 Concentration | |||||

| Daily Mean Comparison | Paired t-test | t = −19.76 | <0.001 | d = 0.87 | [−4.29, −3.51] μg/m3 |

| Weather Dependency | Multiple regression | F = 2134.7 | <0.001 | R2 = 0.67 | - |

| Energy Consumption | |||||

| Monthly Comparison | Paired t-test | t = −15.23 | <0.001 | d = 0.95 | [−65.8, −50.2] kWh |

| Load Profile Analysis | Repeated measures ANOVA | F = 1876.4 | <0.001 | ηp2 = 0.78 | - |

| Evapotranspiration Correlation | |||||

| ET vs. Energy Relationship | Pearson correlation | r = 0.734 | <0.001 | - | [0.698, 0.766] |

| Environmental Predictors | Stepwise regression | F = 4567.2 | <0.001 | R2 = 0.84 | - |

| Predictor Variable | Coefficient | Standard Error | t-Value | p-Value | Standardized β |

|---|---|---|---|---|---|

| Intercept | −2.847 | 0.234 | −12.16 | <0.001 | - |

| Evapotranspiration Rate (L/day/m2) | 0.187 | 0.008 | 23.38 | <0.001 | 0.645 |

| Outdoor Temperature (°C) | 0.034 | 0.003 | 11.67 | <0.001 | 0.347 |

| Relative Humidity (%) | −0.015 | 0.002 | −7.50 | <0.001 | −0.198 |

| Wind Speed (m/s) | 0.028 | 0.006 | 4.67 | <0.001 | 0.089 |

| Solar Radiation (W/m2) | 0.0012 | 0.0002 | 6.00 | <0.001 | 0.134 |

| Item | SAR | Cost per m2 | % of Total |

|---|---|---|---|

| Capital Costs | |||

| Modular Panels (24 units) | 1080 | 187.5 | 12.9% |

| Plant Material (374 plants @ SAR 8.50) | 3179 | 551.9 | 37.9% |

| Hydroponic Infrastructure | 1250 | 217.0 | 14.9% |

| LED Growth Lighting | 2100 | 364.6 | 25.1% |

| Installation Labor | 776 | 134.7 | 9.3% |

| Total Capital Investment | 8385 | 1456.8 | 100.0% |

| Annual Operational Costs | |||

| Electricity (LED + pumps) | 278 | 40.8 | 28.9% |

| Nutrient Solution | 340 | 59.0 | 41.9% |

| Plant Replacement (3.2% mortality @ 110% of initial price) | 112 | 19.4 | 13.8% |

| Maintenance Labor | 125 | 21.7 | 15.4% |

| Total Annual Operating Cost | 812 | 141.0 | 100.0% |

| Metric (Basis) | Point Estimate | 95% Interval/U95 | Notes |

|---|---|---|---|

| CO2 reduction during occupied hours (ppm; %) | 119 ppm; 14.1% | 119 ± 31.8 ppm; 14.1% [10.3%, 17.8%] | Type A from paired daily means (Table 3); Type B negligible after calibration. |

| VOC_PID reduction (mg/m3; %) | 0.238 mg/m3; 28.1% | 0.238 ± 0.057 mg/m3; 28.1% [21.4%, 34.8%] | Table 4. |

| PM2.5 reduction (μg/m3; %) | 3.90 μg/m3; 20.9% | 3.90 ± 0.29 μg/m3; 20.9% [19.3%, 22.4%] | Table 5. |

| Cooling energy saving (kWh·year−1) | 574.5 kWh | U95 ≈ 118 kWh (conservative) | Combines monthly Type A with 2.1% per-meter Type B; sign robustly positive. |

| ET→cooling coefficient (kWh·L−1) | 0.187 | 95% CI [0.171, 0.203] | From Table 10 regression SE. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsadun, I.S.R.; Bashir, F.M.; Andleeb, Z.; Ben Houria, Z.; Mohamed, M.A.S.; Agboola, O. Synergistic Air Quality and Cooling Efficiency in Office Space with Indoor Green Walls. Buildings 2025, 15, 3656. https://doi.org/10.3390/buildings15203656

Alsadun ISR, Bashir FM, Andleeb Z, Ben Houria Z, Mohamed MAS, Agboola O. Synergistic Air Quality and Cooling Efficiency in Office Space with Indoor Green Walls. Buildings. 2025; 15(20):3656. https://doi.org/10.3390/buildings15203656

Chicago/Turabian StyleAlsadun, Ibtihaj Saad Rashed, Faizah Mohammed Bashir, Zahra Andleeb, Zeineb Ben Houria, Mohamed Ahmed Said Mohamed, and Oluranti Agboola. 2025. "Synergistic Air Quality and Cooling Efficiency in Office Space with Indoor Green Walls" Buildings 15, no. 20: 3656. https://doi.org/10.3390/buildings15203656

APA StyleAlsadun, I. S. R., Bashir, F. M., Andleeb, Z., Ben Houria, Z., Mohamed, M. A. S., & Agboola, O. (2025). Synergistic Air Quality and Cooling Efficiency in Office Space with Indoor Green Walls. Buildings, 15(20), 3656. https://doi.org/10.3390/buildings15203656