Experimental Study on the Estimation of Structural Strength Correction for Concrete Using Ordinary Portland Cement

Abstract

1. Introduction

2. Materials and Methods

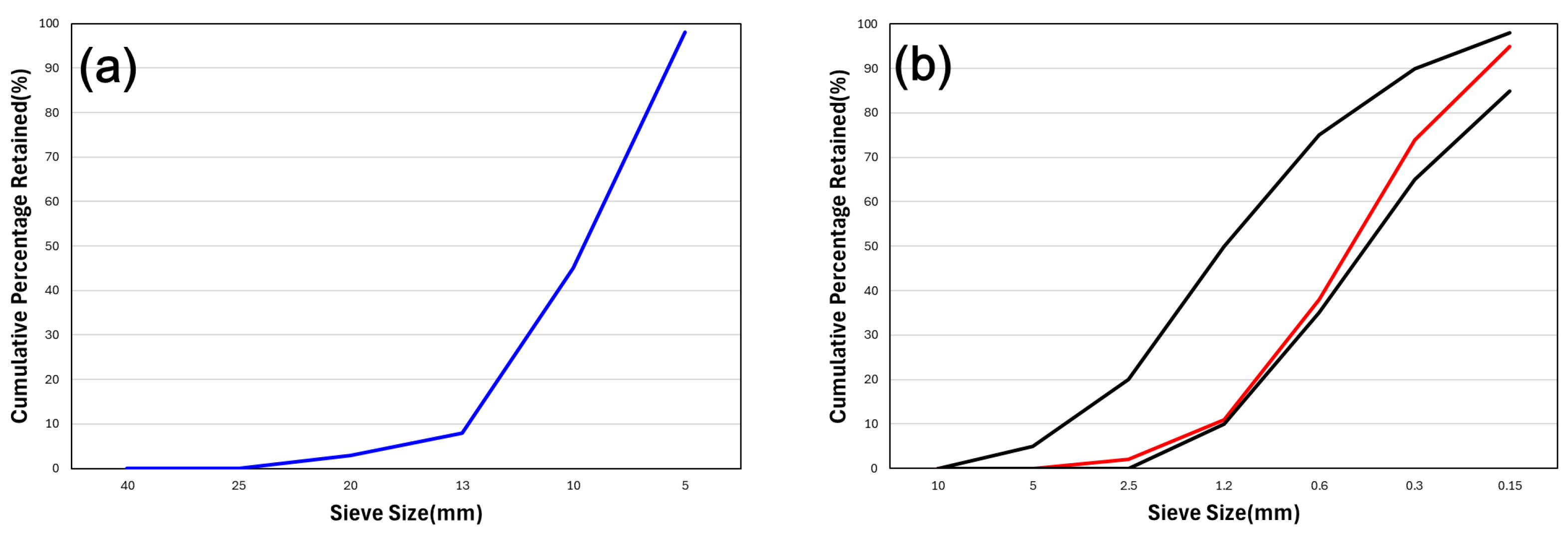

2.1. Materials

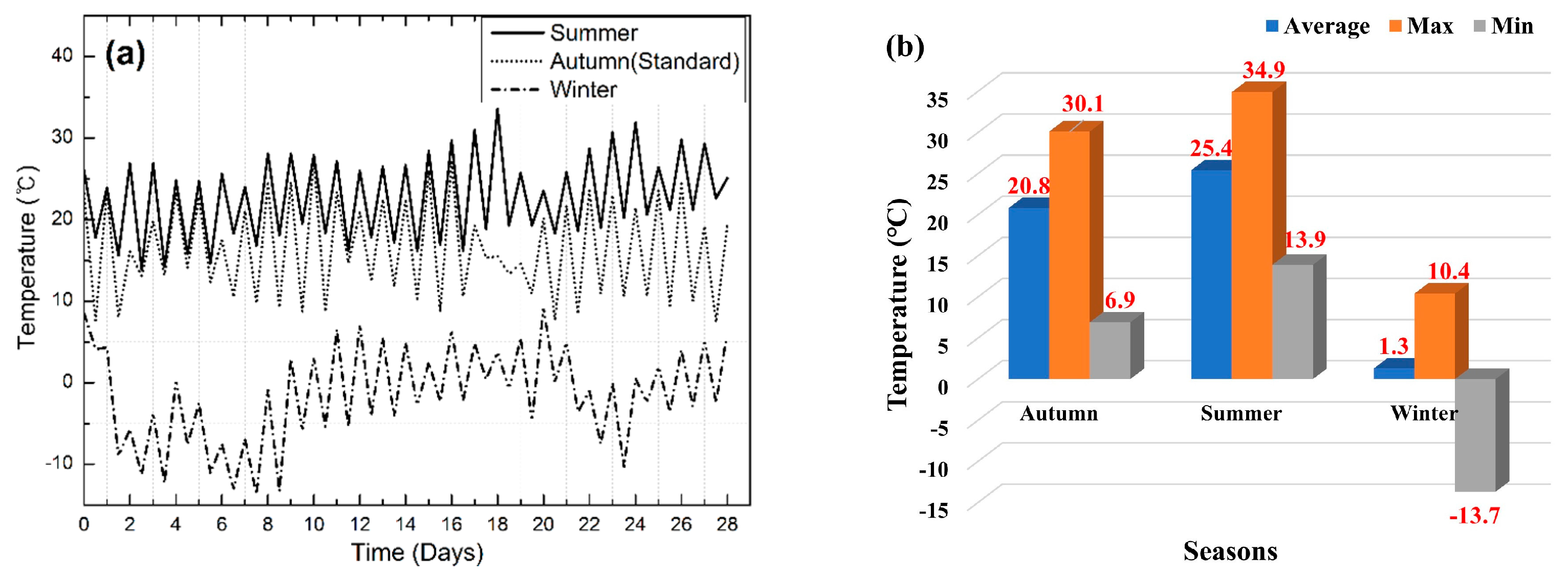

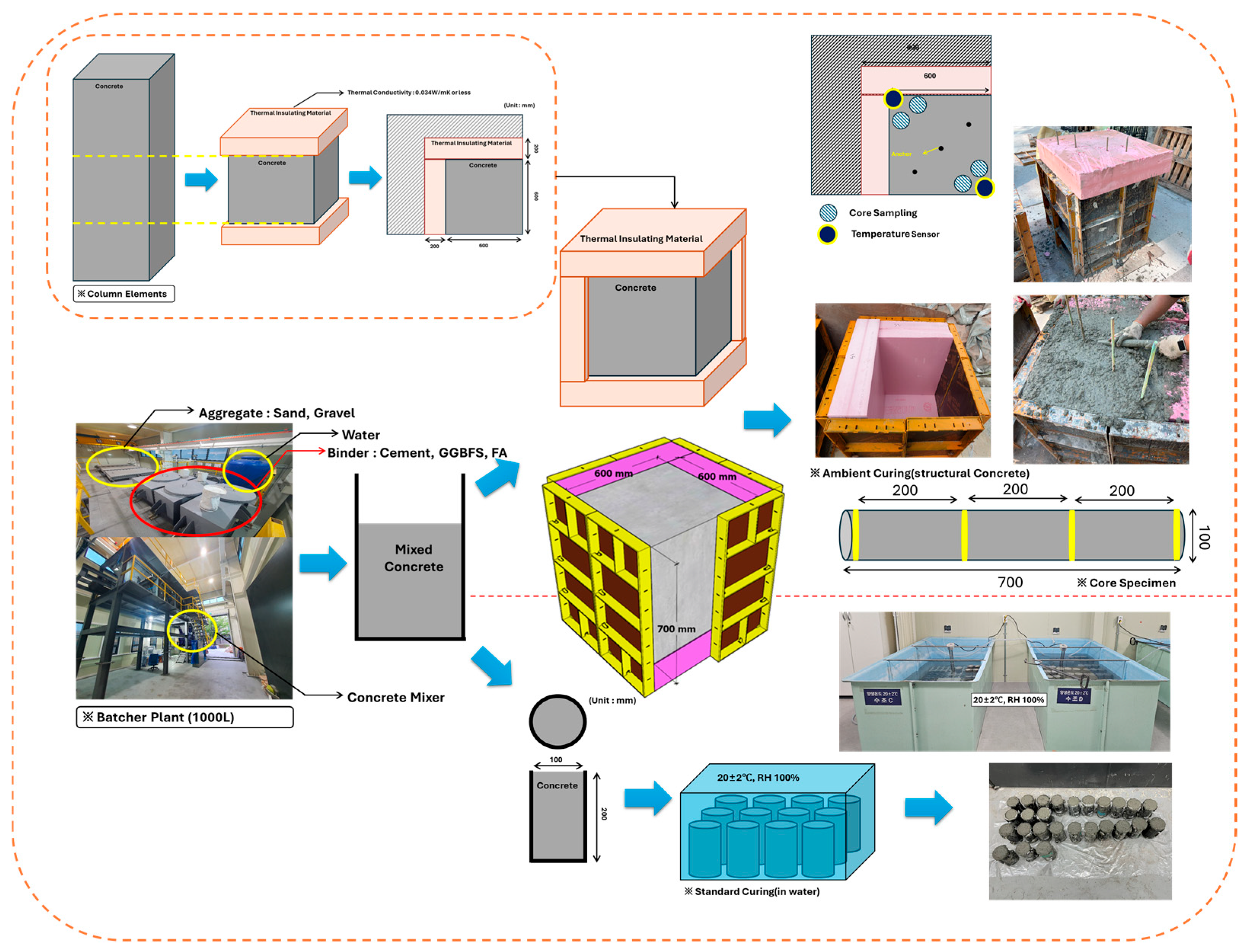

2.2. Method

2.2.1. Mixture Design and Ambient

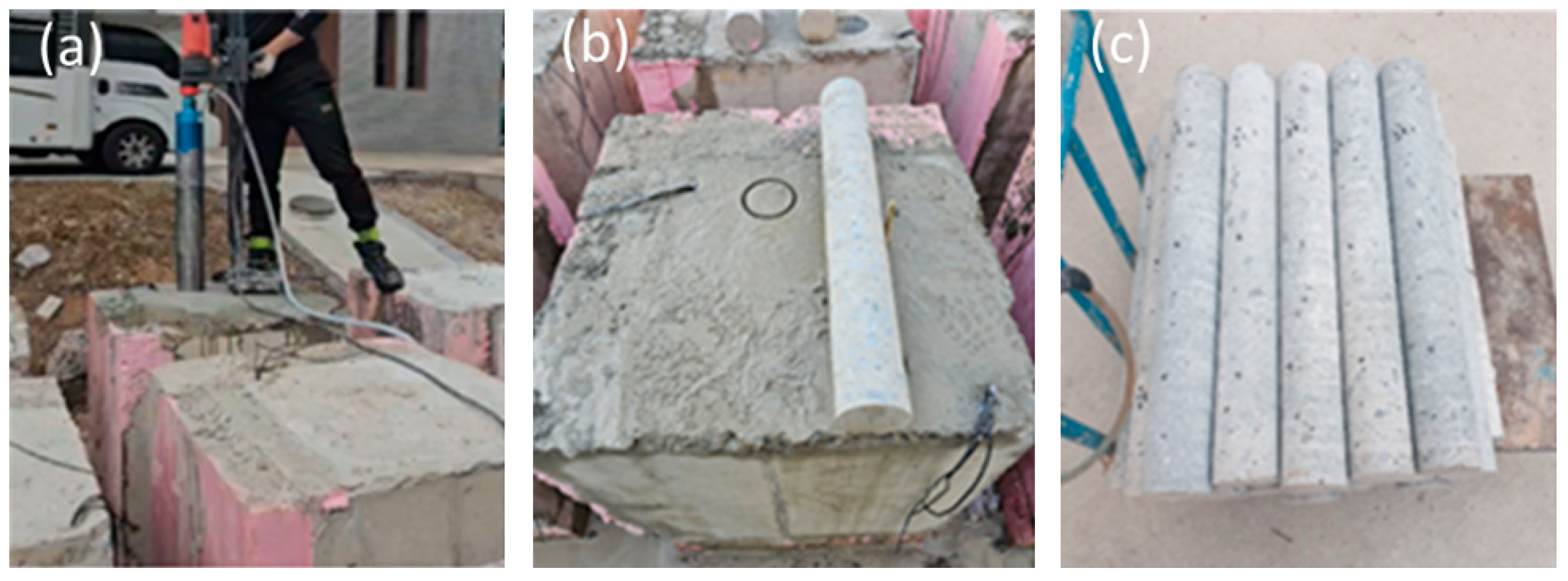

2.2.2. Experimental Procedure

3. Results and Discussions

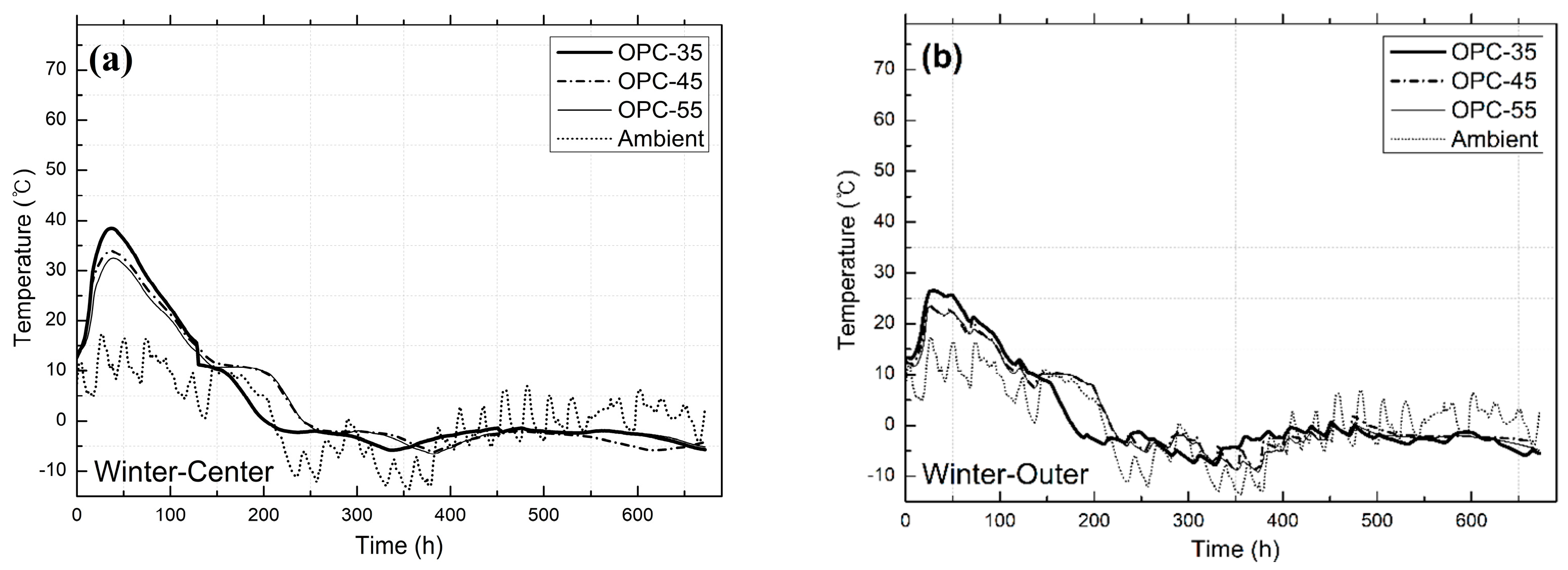

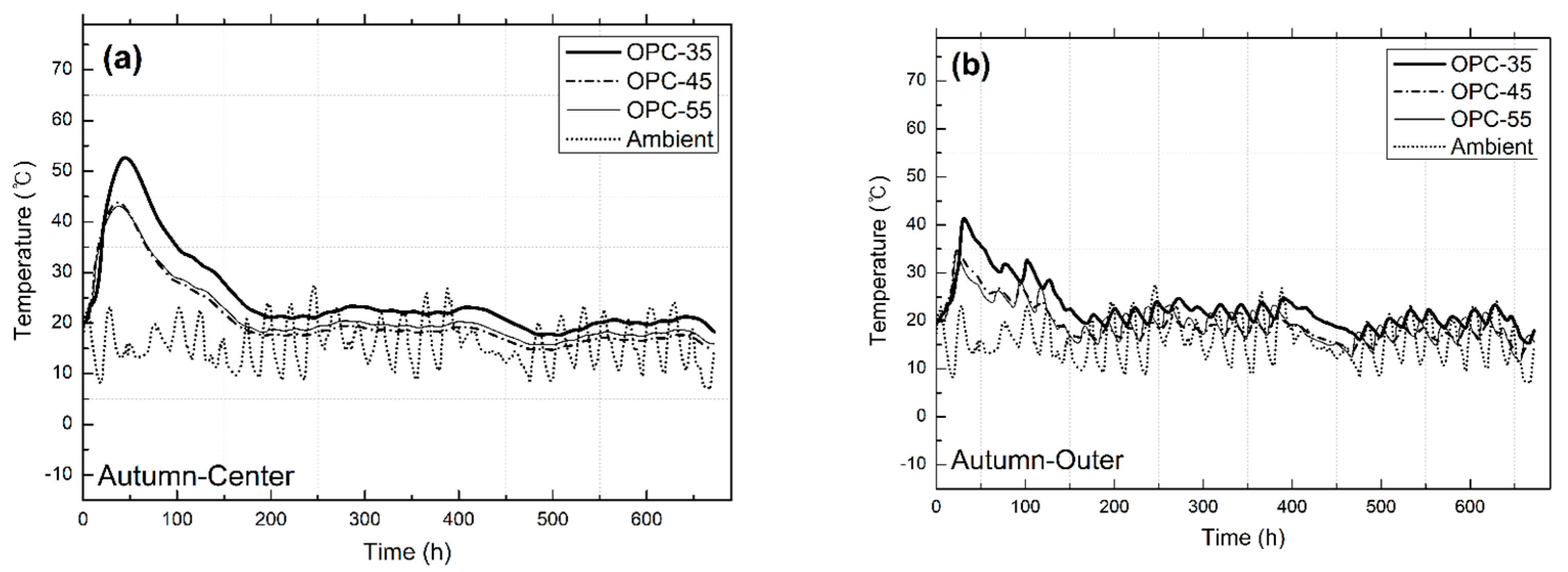

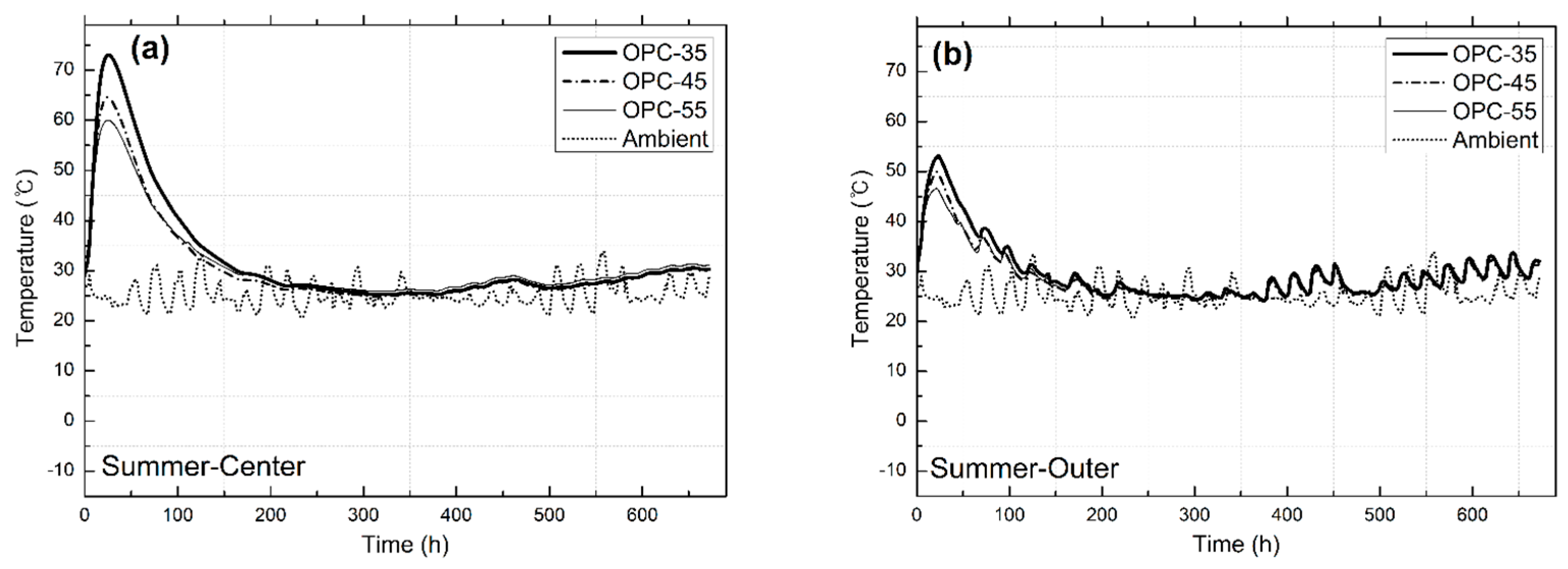

3.1. Heat of Hydration Under Different Seasonal Conditions

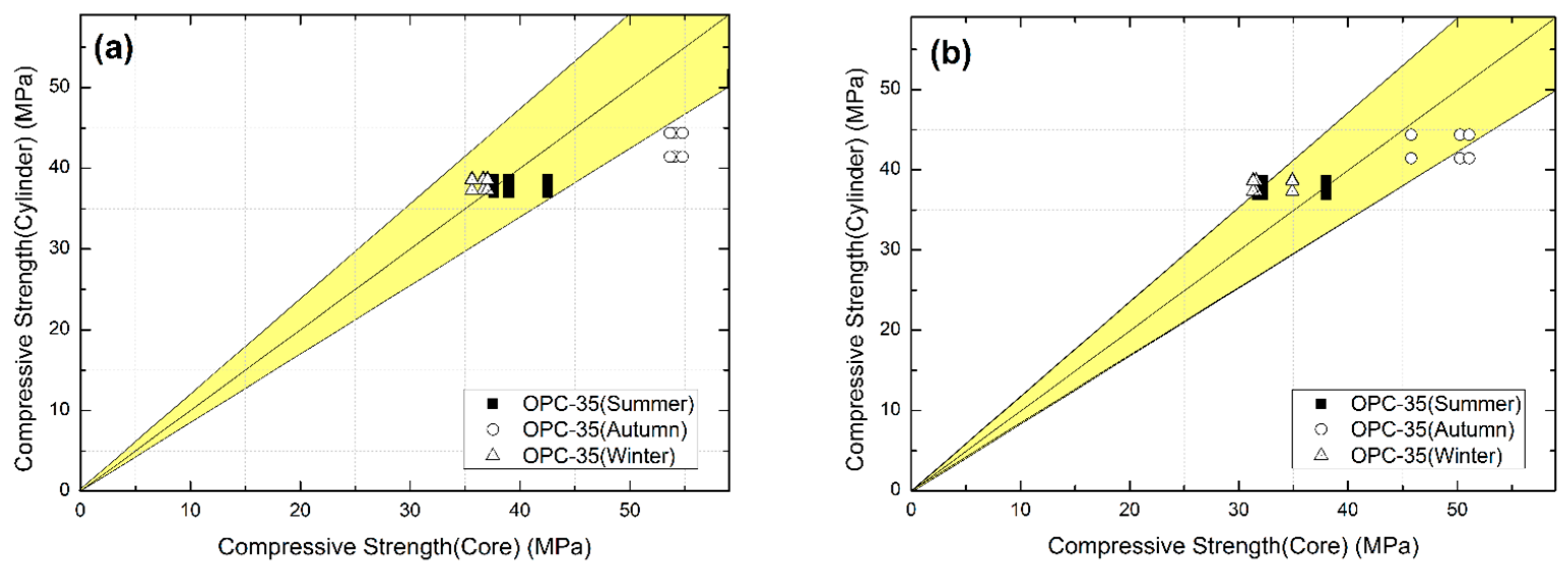

3.2. Compressive Strength

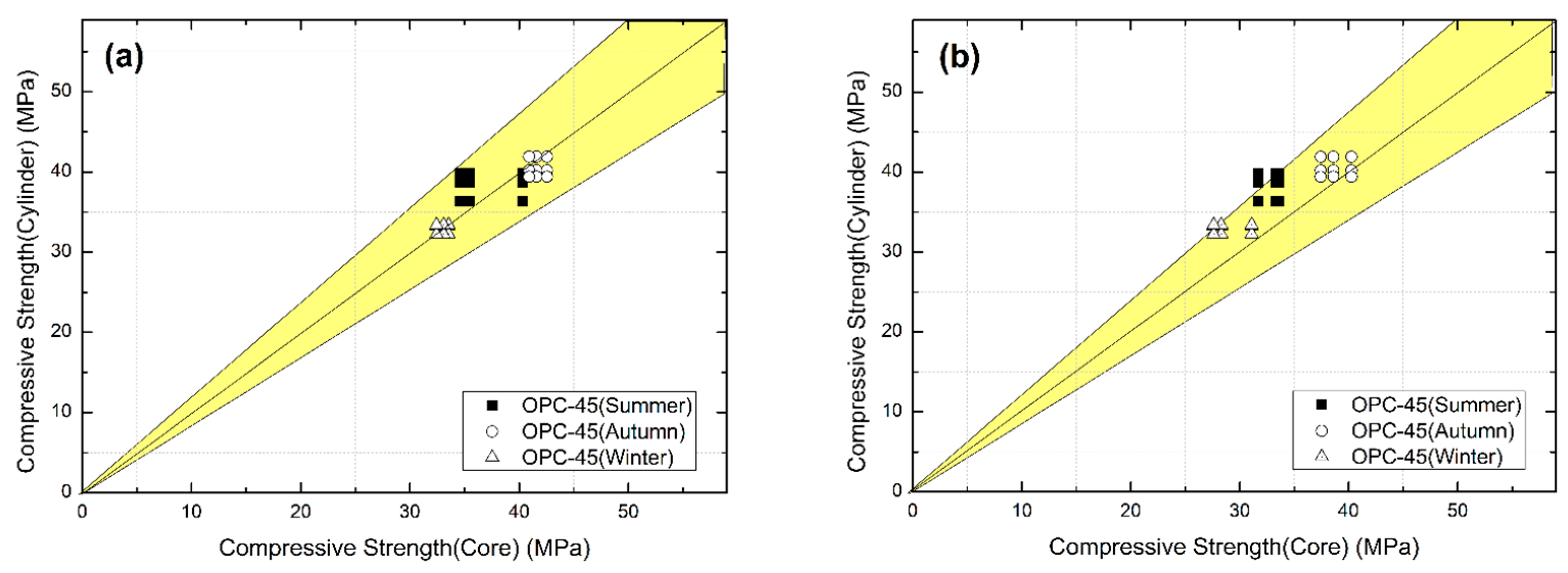

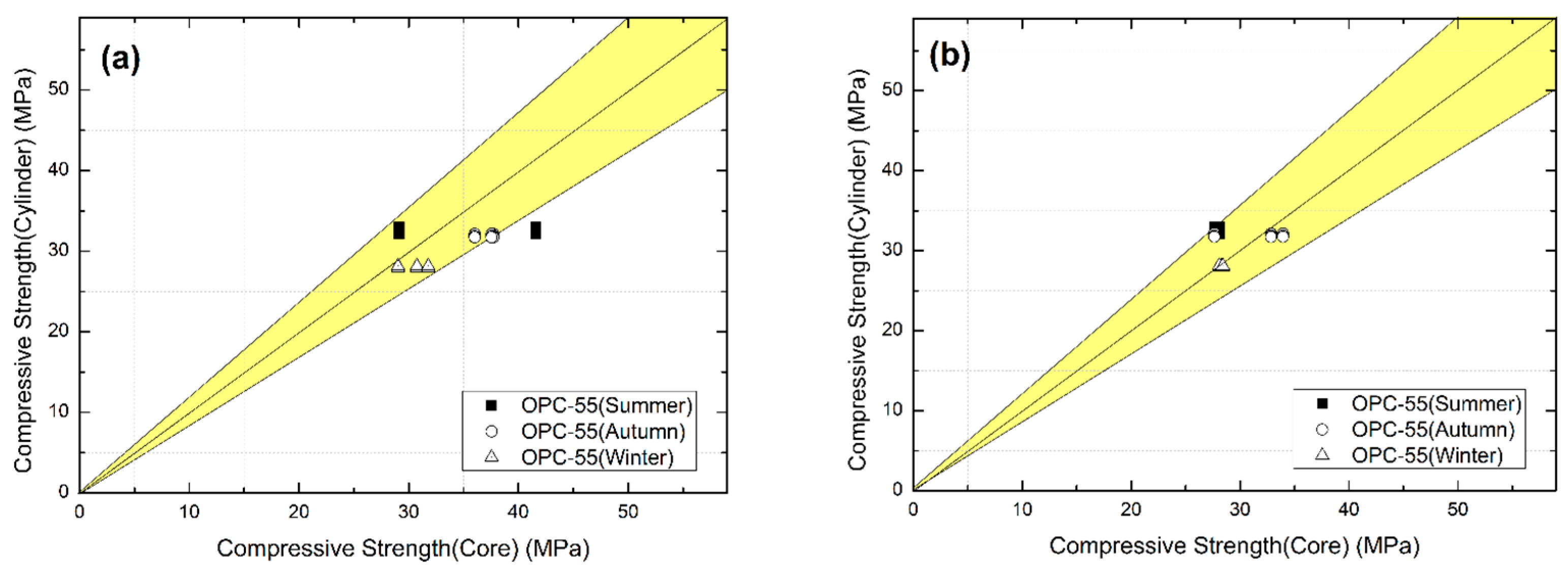

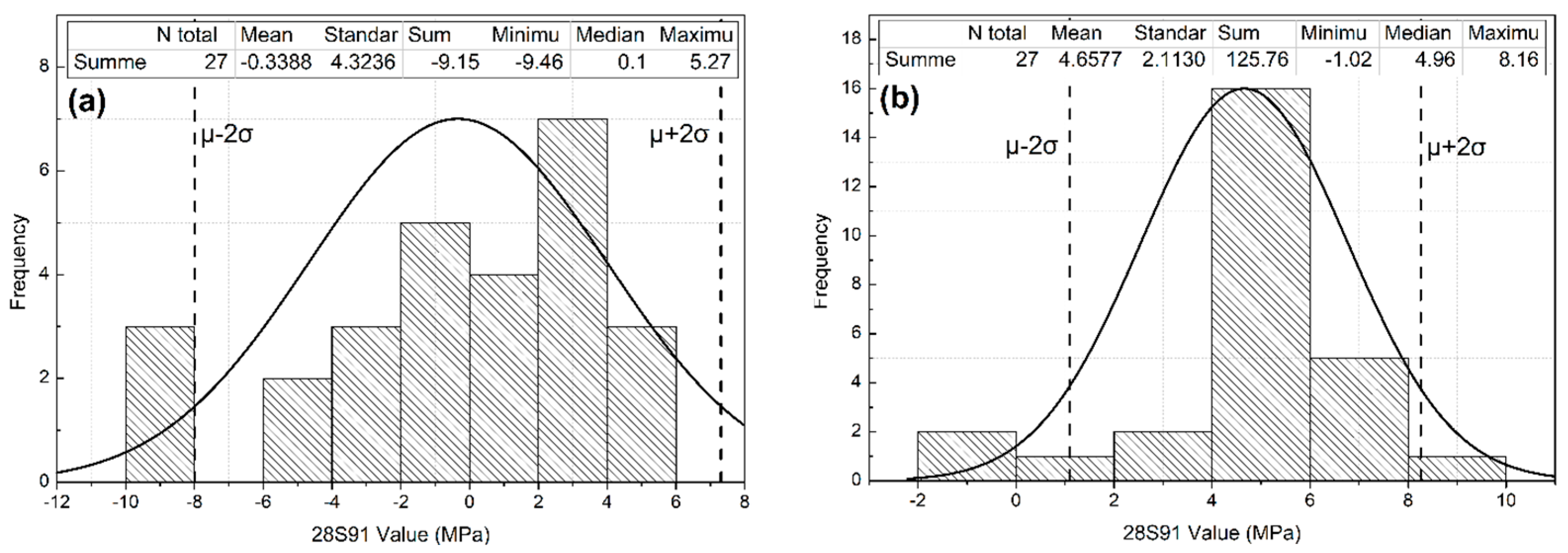

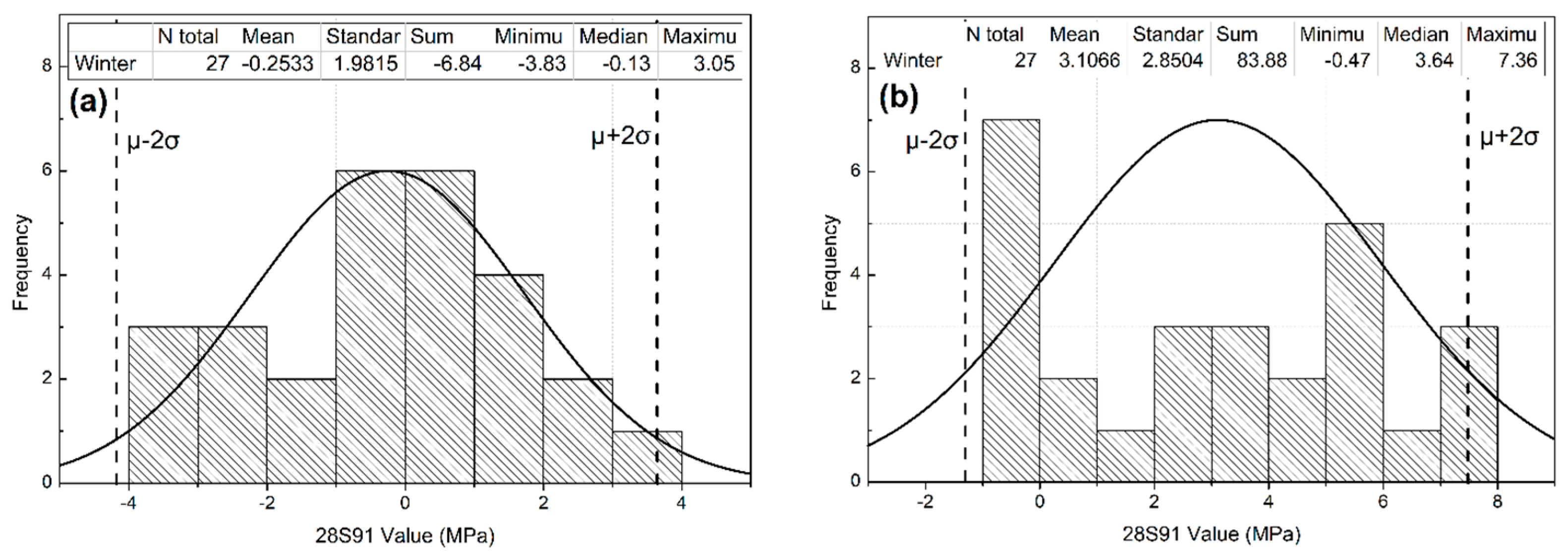

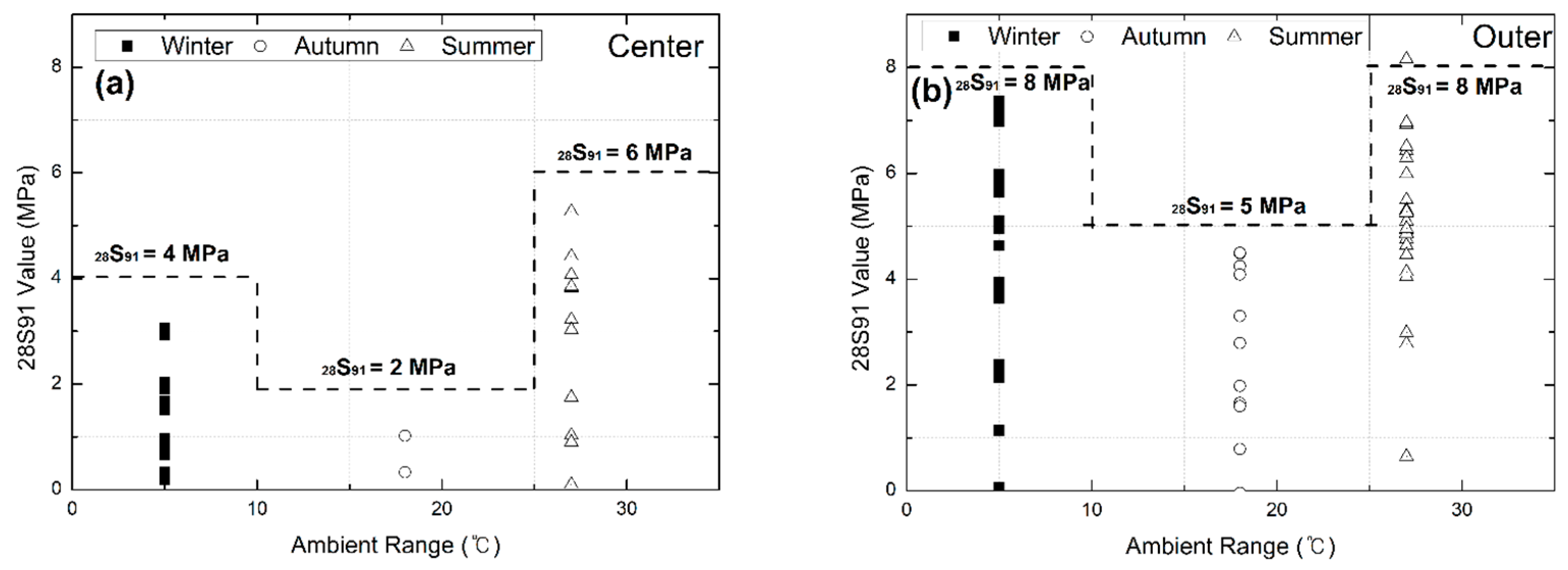

3.3. 28S91 Value of Core Specimen vs. Cylinder Specimen

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Atsbha, T.G.; Zhutovsky, S. The effect of external curing methods on the development of mechanical and durability-related properties of normal-strength concrete. Constr. Build. Mater. 2022, 324, 126706. [Google Scholar] [CrossRef]

- Cristofaro, M.T.; Nudo, R.; Tanganelli, M.; D’Ambrisi, A.; De Stefano, M.; Pucinotti, R. Issues concerning the assessment of concrete compressive strength in existing buildings: Application to a case study. Struct. Concr. 2018, 19, 795–805. [Google Scholar] [CrossRef]

- Hasuo, K.; Matsuda, T. 1123 The effect of core sampling on concrete strength test results (Testing and Inspection (1), Materials and Construction, 2012 Annual Conference (Tokai), Academic Lecture and Architectural Design Presentation). Mater. Constr. 2012, 245–246. [Google Scholar]

- Bartlett, F.M.; MacGregor, J.G. Statistical analysis of the compressive strength of concrete in structures. Mater. J. 1996, 93, 158–168. [Google Scholar]

- Price, W.F.; Hynes, J.P. In-situ strength testing of high strength concrete. Mag. Concr. Res. 1996, 48, 189–197. [Google Scholar] [CrossRef]

- Gavilan, S.; Da, S.; Filho, L.C.P. Variations of in situ concrete strength by European Standard and American Code. Struct. Concr. 2018, 19, 1185–1194. [Google Scholar] [CrossRef]

- Haavisto, J.; Husso, A.; Laaksonen, A. Compressive strength of core specimens drilled from concrete test cylinders. Struct. Concr. 2021, 22, E683–E695. [Google Scholar] [CrossRef]

- Che, Y.; Ban, S.L.; Cui, J.Y.; Chen, G.; Song, Y.P. Effect of specimen shape and size on compressive strength of concrete. Adv. Mater. Res. 2011, 163, 1375–1379. [Google Scholar] [CrossRef]

- Malhotra, H.L. The effect of temperature on the compressive strength of concrete. Mag. Concr. Res. 1956, 8, 85–94. [Google Scholar] [CrossRef]

- Canpolat, F.; Naik, T.R. Effect of curing conditions on strength and durability of high-performance concrete. Sci. Iran. 2017, 24, 576–583. [Google Scholar] [CrossRef]

- Roller, J.J.; Russell, H.G.; Bruce, R.N.; Hassett, B. Effect of curing temperatures on high strength concrete bridge girders. PCI J. 2003, 48, 72–79. [Google Scholar] [CrossRef]

- Kadri, E.H.; Duval, R.; Aggoun, S.; Kenal, S. Silica Fume Effect on Hydration Heat and Compressive Strength of High-Performance Concrete. ACI Mater. J. 2009, 106, 107. [Google Scholar] [CrossRef]

- Kim, T.; Rens, K.L. Concrete maturity method using variable temperature curing for normal-strength concrete mixes. II: Theoretical study. J. Mater. Civ. Eng. 2008, 20, 735–741. [Google Scholar] [CrossRef]

- Kim, J.K.; Moon, Y.H.; Eo, S.H. Compressive strength development of concrete with different curing time and temperature. Cem. Concr. Res. 1998, 28, 1761–1773. [Google Scholar] [CrossRef]

- Klieger, P. Effect of mixing and curing temperature on concrete strength. J. Proc. 1958, 54, 1063–1081. [Google Scholar]

- Schindler, A.K. Concrete Hydration, Temperature Development, and Setting at Early-Ages; The University of Texas at Austin: Austin, TX, USA, 2002. [Google Scholar]

- Schindler, A.K.; Folliard, K.J. Heat of hydration models for cementitious materials. ACI Mater. J. 2005, 102, 24. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.Y.; Lee, H.S. Heat of hydration models of cementitious materials. Adv. Cem. Res. 2012, 24, 77–90. [Google Scholar] [CrossRef]

- Escalante-Garcia, J.I.; Sharp, J.H. The effect of temperature on the early hydration of Portland cement and blended cements. Adv. Cem. Res. 2000, 12, 121–130. [Google Scholar] [CrossRef]

- Schindler, A.K. Effect of temperature on hydration of cementitious materials. Mater. J. 2004, 101, 72–81. [Google Scholar]

- Goto, S. Hydration of hydraulic materials–a discussion on heat liberation and strength development. Adv. Cem. Res. 2009, 21, 113–117. [Google Scholar] [CrossRef]

- Matsuda, T.; Kawakami, H.; Koide, T.; Noguchi, T. Development of Mechanical Properties of Ultra-High-Strength Concrete Subjected to Early Heat Curing. J. Adv. Concr. Technol. 2009, 7, 183–193. [Google Scholar] [CrossRef]

- Bentz, D.P.; Stutzman, P.E. Curing, hydration, and microstructure of cement paste. ACI Mater. J. 2006, 103, 348. [Google Scholar] [CrossRef]

- Khatib, J.M. Low temperature curing of metakaolin concrete. J. Mater. Civ. Eng. 2009, 21, 362–367. [Google Scholar] [CrossRef]

- Lopes, A.; Lopes, S.; Pinto, I. Influence of curing temperature on the strength of a metakaolin-based geopolymer. Materials 2023, 16, 7460. [Google Scholar] [CrossRef] [PubMed]

- Hossain, K.M.A. Influence of extreme curing conditions on compressive strength and pulse velocity of lightweight pumice concrete. Comput. Concr. 2014, 6, 437–450. [Google Scholar] [CrossRef]

- Oh, B.H.; Cha, S.W. Nonlinear analysis of temperature and moisture distributions in early-age concrete structures based on degree of hydration. Mater. J. 2003, 100, 361–370. [Google Scholar]

- Rastrup, E. Heat of hydration in concrete. Mag. Concr. Res. 1954, 6, 79–92. [Google Scholar] [CrossRef]

- Branco, F.A.; Mendes, P.; Mirambell, E. Heat of hydration effects in concrete structures. Mater. J. 1992, 89, 139–145. [Google Scholar]

- Pane, I.; Hansen, W. Concrete hydration and mechanical properties under nonisothermal conditions. Mater. J. 2002, 99, 534–542. [Google Scholar]

- ACI Committee, 3. 301-16 Specifications for Structural Concrete. 2016. Available online: https://www.concrete.org/Portals/0/Files/PDF/Previews/301_16_preview.pdf (accessed on 2 September 2025).

- Korea Concrete Institute. KCS 14 20 10 Normal Concrete. 2024. Available online: https://www.kcsc.re.kr/standardCode/viewer/KCS%2014%2020%2010:2024-12-30 (accessed on 2 September 2025).

- Architectural Institute of Japan. JASS 5 Standard Specifications for Building Construction and Commentary. In Reinforced Concrete Construction; Architectural Institute of Japan: Tokyo, Japan, 2005; Available online: https://item.rakuten.co.jp/guruguru2/9784818915558/?scid=af_pc_etc&sc2id=af_113_1_10002790&icm_tgid=1&icm_agid=60810&icm_mt=guruguru2%3A13423489%3A9784818915558&icm_acid=1372271&icm_kw=359158&icm_cid=30609 (accessed on 2 September 2025).

- Sedaghatdoost, A. Cold Weather Concrete: Current Practices and Innovative Mix Designs and Protection Methods. 2023. Available online: https://mspace.lib.umanitoba.ca/server/api/core/bitstreams/635f9f55-70c5-47c5-8c1a-d0ed3422ae09/content (accessed on 2 September 2025).

- Krylov, B.A. Cold Weather Concreting; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Kay, E.A. Hot and cold weather concreting. In Advanced Concrete Technology, Concrete Properties; Newman, J., Choo, B.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- ACI Committee, 3. 306R-16 Guide to cold Weather Concreting. 2016. Available online: https://www.studocu.com/en-us/document/louisiana-state-university-at-eunice/consruction-material-and-methods/aci-306r-16-guide-to-cold-weather-concreting/96557663 (accessed on 2 September 2025).

- Fukudome, K.; Saito, J. Curing planning method based on cement hydration analysis. J. Concr. Eng. 2021, 32, 35–47. [Google Scholar] [CrossRef]

- Masuda, Y.; Abe, M. Architectural Institute of Japan, Revised JASS 5-2009. Concr. Eng. 2009, 47, 63–610. [Google Scholar]

- KS F 2403; Standard Test Method for Making Concrete Specimens. Korea Standard Institute: Daejeon, Republic of Korea, 2019.

- Wang, X.Y. Modeling of hydration, compressive strength, and carbonation of portland-limestone cement (PLC) concrete. Materials 2017, 10, 115. [Google Scholar] [CrossRef]

- Park, K.B.; Jee, N.Y.; Yoon, I.S.; Lee, H.S. Prediction of temperature distribution in high-strength concrete using hydration model. ACI Mater. J. 2008, 105, 180. [Google Scholar] [CrossRef]

- Ng, I.Y.T.; Ng, P.L.; Kwan, A.K.H. Effect of Cement and Water Contents on Adiabatic Temperature Rise of Concrete. ACI Mater. J. 2009, 106, 42. [Google Scholar] [CrossRef] [PubMed]

- Mitarai, Y.; Ohike, T.; Moriya, M.; Ogata, T.; Koyama, T. Long-term Study on Properties of High-strength Mass Concrete in PCCV (Prestressed Concrete Containment Vessel) (Monitoring Test Results and Durability of Concrete over 22 Years). 2007. Available online: https://repository.lib.ncsu.edu/server/api/core/bitstreams/acfa84c0-a88d-4d8d-be34-08e88618c71b/content (accessed on 2 September 2025).

- Awasthy, N.; Schlangen, E.; Hordijk, D.; Šavija, B.; Luković, M. The role of eigen-stresses on apparent strength and stiffness of normal, high strength, and ultra-high performance fibre reinforced concrete. Dev. Built Environ. 2023, 16, 100277. [Google Scholar] [CrossRef]

- Szypula, A.; Grossman, J.S. Cylinder vs. core strength. Concr. Int. 1990, 12, 55–61. [Google Scholar]

- Akca, A.H.; Özyurt, N. Effects of re-curing on residual mechanical properties of concrete after high temperature exposure. Constr. Build. Mater. 2018, 159, 540–552. [Google Scholar] [CrossRef]

- Shahraki, M.; Hua, N.; Elhami-Khorasani, N.; Tessari, A.; Garlock, M. Residual compressive strength of concrete after exposure to high temperatures: A review and probabilistic models. Fire Saf. J. 2023, 135, 103698. [Google Scholar] [CrossRef]

- Rawan, R.; Hassan, G.; Jamal, K.; Adel, E. Effect of hot weather concreting on the mechanical and durability properties of concrete—A review. BAU J.-Sci. Technol. 2022, 4, 4. [Google Scholar]

- Ishee, C.; Surana, S. Hot weather concreting. In Developments in the Formulation and Reinforcement of Concrete; Woodhead Publishing: Sutton, UK, 2019; pp. 131–150. [Google Scholar]

- Shumuye, E.D.; Zhao, J.; Wang, Z. Effect of the curing condition and high-temperature exposure on ground-granulated blast-furnace slag cement concrete. Int. J. Concr. Struct. Mater. 2021, 15, 15. [Google Scholar] [CrossRef]

- Kovler, K.; Schamban, I.; Igarashi, S.I.; Bentur, A. Influence of mixture proportions and curing conditions on compressive strength of high-performance concrete. Mater. J. 2000, 97, 21–26. [Google Scholar]

- Lee, J.; Lee, T. Influences of chemical composition and fineness on the development of concrete strength by curing conditions. Materials 2019, 12, 4061. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Chang, J.; Xie, S.; Zhao, Y. Effect of the Thermal Insulation Cover Curing on Temperature Rise and Early-Age Strength of Concrete. Materials 2022, 15, 2781. [Google Scholar] [CrossRef]

- Lee, G.C.; Han, M.C.; Baek, D.H.; Koh, K.T. Effect of heat curing methods on the temperature history and strength development of slab concrete for nuclear power plant structures in cold climates. Nucl. Eng. Technol. 2012, 44, 523–534. [Google Scholar] [CrossRef]

- Bartlett, F.M.P. Assessment of Concrete Strength in Existing Structures; National Library of Canada: Ottawa, ON, Canada, 1994. [Google Scholar]

- Otsuka, S.; Nakata, Y.; Oki, S. Effects of sampling depth for distribution of compressive strength and strength development of core specimens in full-scale model of high-strength concrete column using various cements. J. Archit. Build. Sci. 2011, 76, 8. [Google Scholar] [CrossRef]

- Hasuo, K.; Matsu, T. Report: Effect of core sampling on the results of concrete strength tests. Proc. Jpn. Concr. Inst. 2013, 35, 6. [Google Scholar]

- Ishiyoshi, Y. Report: Experimental study on concrete mix design using large amounts of fly ash. Proc. Jpn. Concr. Inst. 2015, 37, 6. [Google Scholar]

- Zhai, Y. Experimental study on the size effect on the probability distribution of concrete compressive strength. Adv. Civ. Eng. 2022, 2022, 7568279. [Google Scholar] [CrossRef]

- Yue, Q.; Wang, W.; Zhang, X. Probabilistic analysis and time variation model of concrete compressive strength in existing buildings. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2023, 9, 04023026. [Google Scholar] [CrossRef]

- Shimizu, Y.; Hirosawa, M.; Zhou, J. Statistical analysis of concrete strength in existing reinforced concrete buildings in Japan. In Proceedings of the 12th World Conference on Earthquake Engineering, Auckland, New Zealand, 30 January–4 February 2000. [Google Scholar]

- Aichouni, M.; Messaoudene, N.A.; Touahmia, M.; Al-Ghonamy, A. Statistical analysis of concrete strength variability for quality assessment: Case study of a Saudi construction project. Int. J. Adv. Appl. Sci. 2017, 4, 101–109. [Google Scholar] [CrossRef]

- Vu, C.C.; Ho, N.K. A comparative study on the probability distribution model for the compressive strength of concrete with consideration of the size effect. J. Eng. Res. 2025, 13, 1403–1413. [Google Scholar] [CrossRef]

- Shen, Z.; Deifalla, A.F.; Kamiński, P.; Dyczko, A. Compressive strength evaluation of ultra-high-strength concrete by machine learning. Materials 2022, 15, 3523. [Google Scholar] [CrossRef]

- Rai, B.; Singh, N.K. Statistical and experimental study to evaluate the variability and reliability of impact strength of steel-polypropylene hybrid fiber reinforced concrete. J. Build. Eng. 2021, 44, 102937. [Google Scholar] [CrossRef]

- Silvestri, S.; Gasparini, G.; Trombetti, T.; Ceccoli, C. Statistical analysis towards the identification of accurate probability distribution models for the compressive strength of concrete. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Momeni, K.; Madandoust, R.; Ranjbar, M.M. Evaluating the application of reinforcement correction factor for concrete core testing. J. Rehabil. Civ. Eng. 2019, 7, 166–182. [Google Scholar]

- Qasrawi, H. Effect of the position of core on the strength of concrete of columns in existing structures. J. Build. Eng. 2019, 25, 100812. [Google Scholar] [CrossRef]

| Country | Mixture Design Formula | References |

|---|---|---|

| United States of America |

| ACI 301 [31] |

| Republic of Korea | KCS 14 20 10 [32] | |

| Japan | mSn (MPa) | JASS 5 [33] |

| Component | Content (%) |

|---|---|

| Na2O | 0.2 |

| MgO | 1.5 |

| Al2O3 | 4.8 |

| SiO2 | 18.6 |

| SO3 | 3.5 |

| K2O | 1.3 |

| CaO | 65.4 |

| Fe2O3 | 3.9 |

| Others | 0.9 |

| Type | Max Size (mm) | Density (g/cm3) | Absorption (%) | F.M. |

|---|---|---|---|---|

| Fine | Under 3 | 2.59 | 1.50 | 2.47 |

| Coarse | 25 | 2.62 | 2.02 | 7.27 |

| Curing Season | Specimen ID | Cement (Kg/m3) | Water (Kg/m3) | W/B (%) | Sand (Kg/m3) | Gravel (Kg/m3) | S/a (%) |

|---|---|---|---|---|---|---|---|

| Autumn (Standard) | OPC 35 | 360 | 126 | 35 | 964 | 933 | 51 |

| OPC 45 | 360 | 162 | 45 | 916 | 887 | ||

| OPC 55 | 330 | 181.5 | 55 | 903 | 874 | ||

| Summer | OPC 35 | 360 | 126 | 35 | 964 | 933 | |

| OPC 45 | 360 | 162 | 45 | 916 | 887 | ||

| OPC 55 | 330 | 181.5 | 55 | 903 | 874 | ||

| Winter | OPC 35 | 380 | 133 | 35 | 946 | 916 | |

| OPC 45 | 380 | 171 | 45 | 896 | 868 | ||

| OPC 55 | 360 | 181.5 | 55 | 903 | 874 |

| W/B of Specimen | 28—Day Mold Cylinder Strength (MPa) | 91—Day In Situ Core Specimen Strength (MPa) | ||||

|---|---|---|---|---|---|---|

| Summer | Autumn | Winter | Summer | Autumn | Winter | |

| 0.35 | 37.7 | 42.4 | 38.2 | 36.9 | 51.6 | 34.5 |

| 0.45 | 38.3 | 40.5 | 33.0 | 34.9 | 40.2 | 31.0 |

| 0.55 | 32.7 | 32.0 | 28.1 | 30.7 | 34.3 | 29.4 |

| Type | Summer Season | Autumn Season | Winter Season |

|---|---|---|---|

| Compressive Strength difference | −9.5~8.2 MPa | −13.4~4.5 MPa | −3.8~7.4 MPa |

| Normal distribution of Center 28S91 Value (μ + 2σ) | 0~8 MPa | 0~3 MPa | 0~3 MPa |

| Normal distribution of Outer 28S91 Value (μ + 2σ) | 0~8 MPa | 0~7 MPa | 0~8 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, M.-G.; Lee, H.-S. Experimental Study on the Estimation of Structural Strength Correction for Concrete Using Ordinary Portland Cement. Buildings 2025, 15, 3642. https://doi.org/10.3390/buildings15203642

Jeong M-G, Lee H-S. Experimental Study on the Estimation of Structural Strength Correction for Concrete Using Ordinary Portland Cement. Buildings. 2025; 15(20):3642. https://doi.org/10.3390/buildings15203642

Chicago/Turabian StyleJeong, Min-Gu, and Han-Seung Lee. 2025. "Experimental Study on the Estimation of Structural Strength Correction for Concrete Using Ordinary Portland Cement" Buildings 15, no. 20: 3642. https://doi.org/10.3390/buildings15203642

APA StyleJeong, M.-G., & Lee, H.-S. (2025). Experimental Study on the Estimation of Structural Strength Correction for Concrete Using Ordinary Portland Cement. Buildings, 15(20), 3642. https://doi.org/10.3390/buildings15203642