Comprehensive Rehabilitation of the Punta del Este Shopping Center After Fire Damage

Abstract

1. Introduction

2. Preliminary Inspection and Testing

2.1. Preliminary Works and Visual Inspection

2.2. Testing and Evaluations

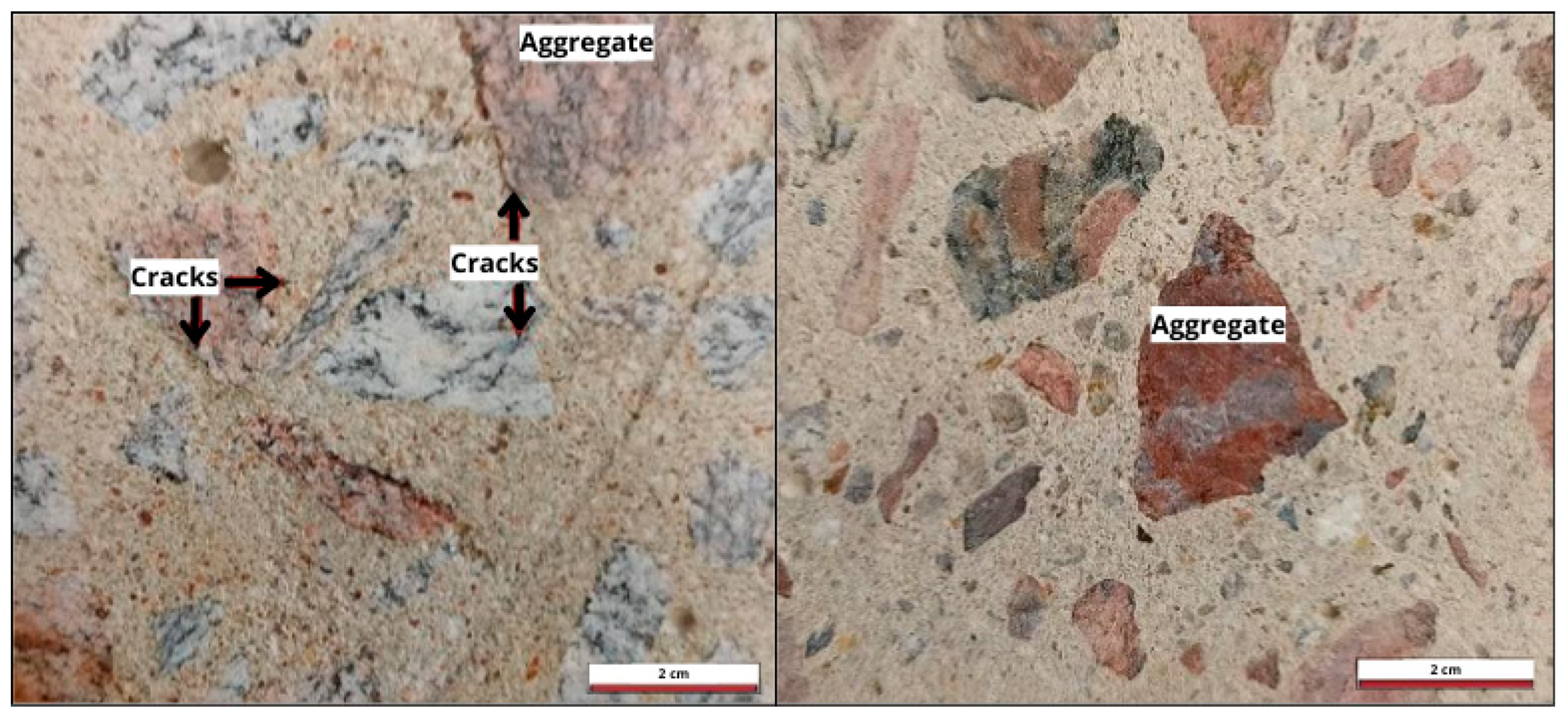

2.2.1. Macro- and Microstructural Analysis of Concrete Samples

2.2.2. Mechanical Testing of Concrete and Steel Samples from the Structure

- Extremely low results in an area with values of 9 MPa for compressive strength and 3.4 GPa for the modulus of elasticity.

- The impossibility of ensuring that a single element, such as a column, had not been affected differently along its height, with some areas potentially having lower strength than others.

- The literature has reported compressive strength losses in conventional concrete exposed to high temperatures of approximately 20% at 400 °C, 50% at 600 °C, and up to 80% or more at 800 °C, as well as significant variability in results. Similarly, the literature has reported modulus of elasticity losses ranging from 50% at 400 °C to up to 80% at temperatures exceeding 600 °C [25,26,27].

3. Recovery Project

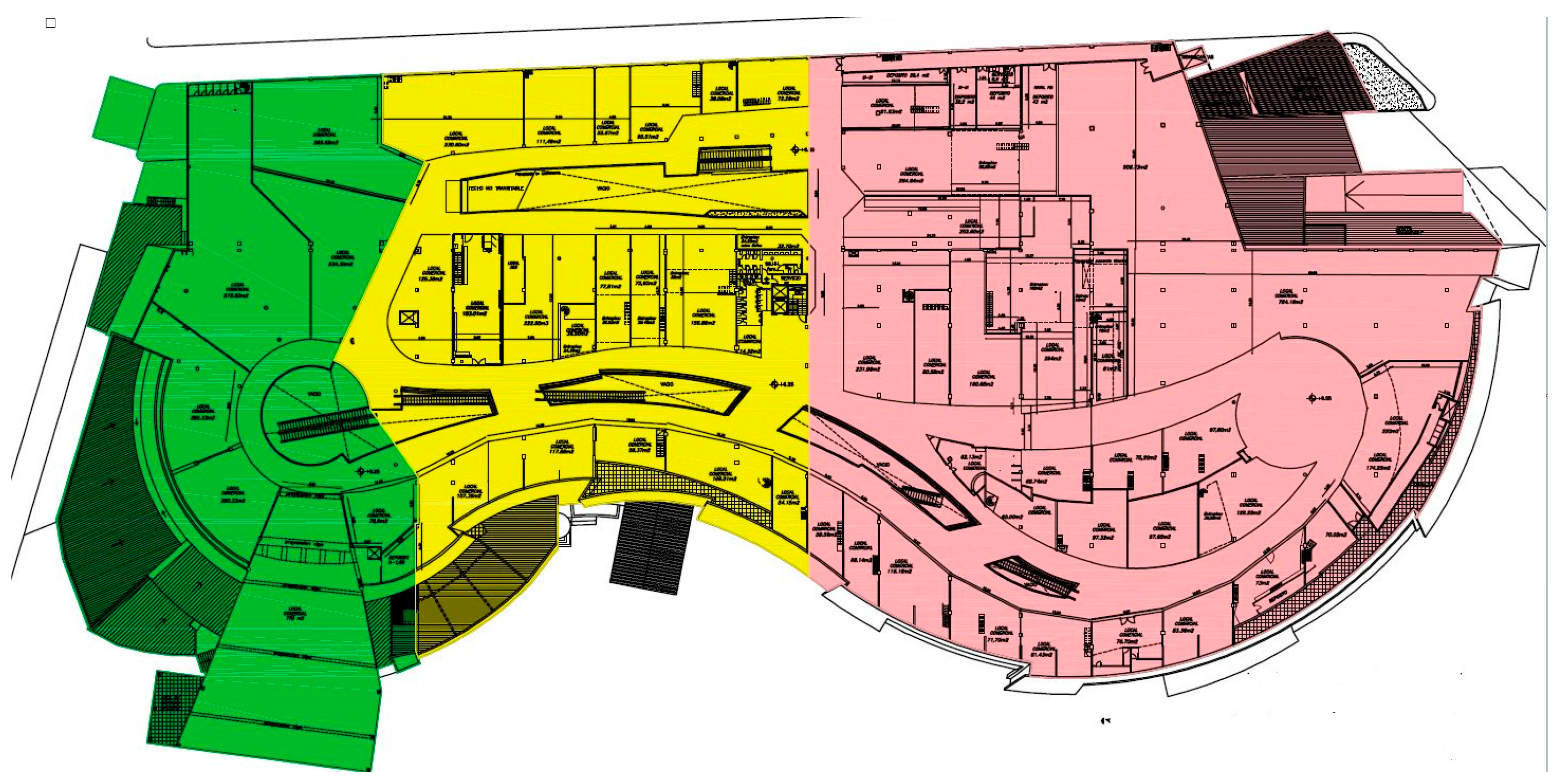

3.1. Red Zone

3.1.1. Basement (SS)

- Complete demolition.

- Reinforcing beams and columns through “jacketed reinforcements” and reconstructing slabs according to the degree of deterioration observed in each one, either reinforcing them or demolishing them.

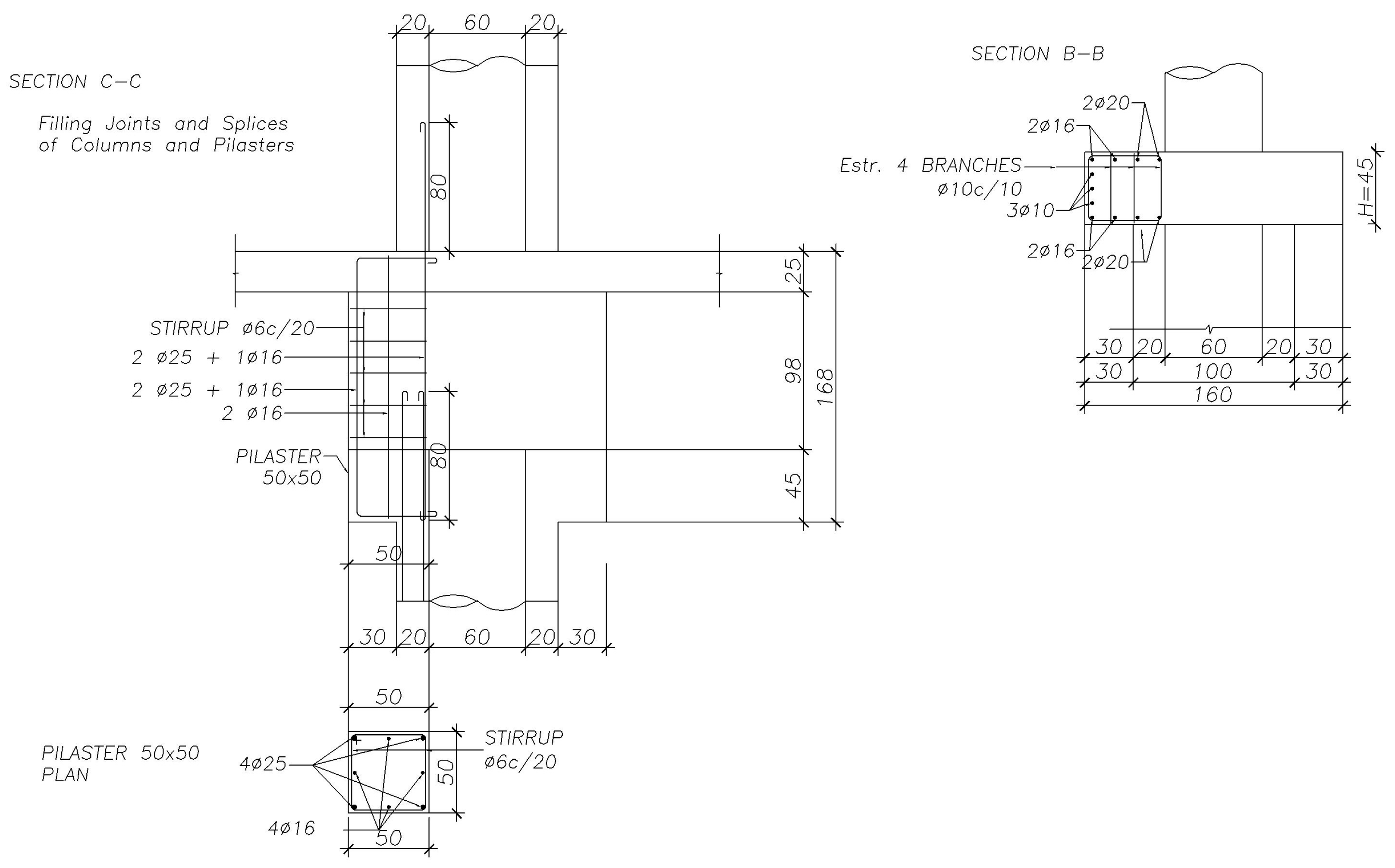

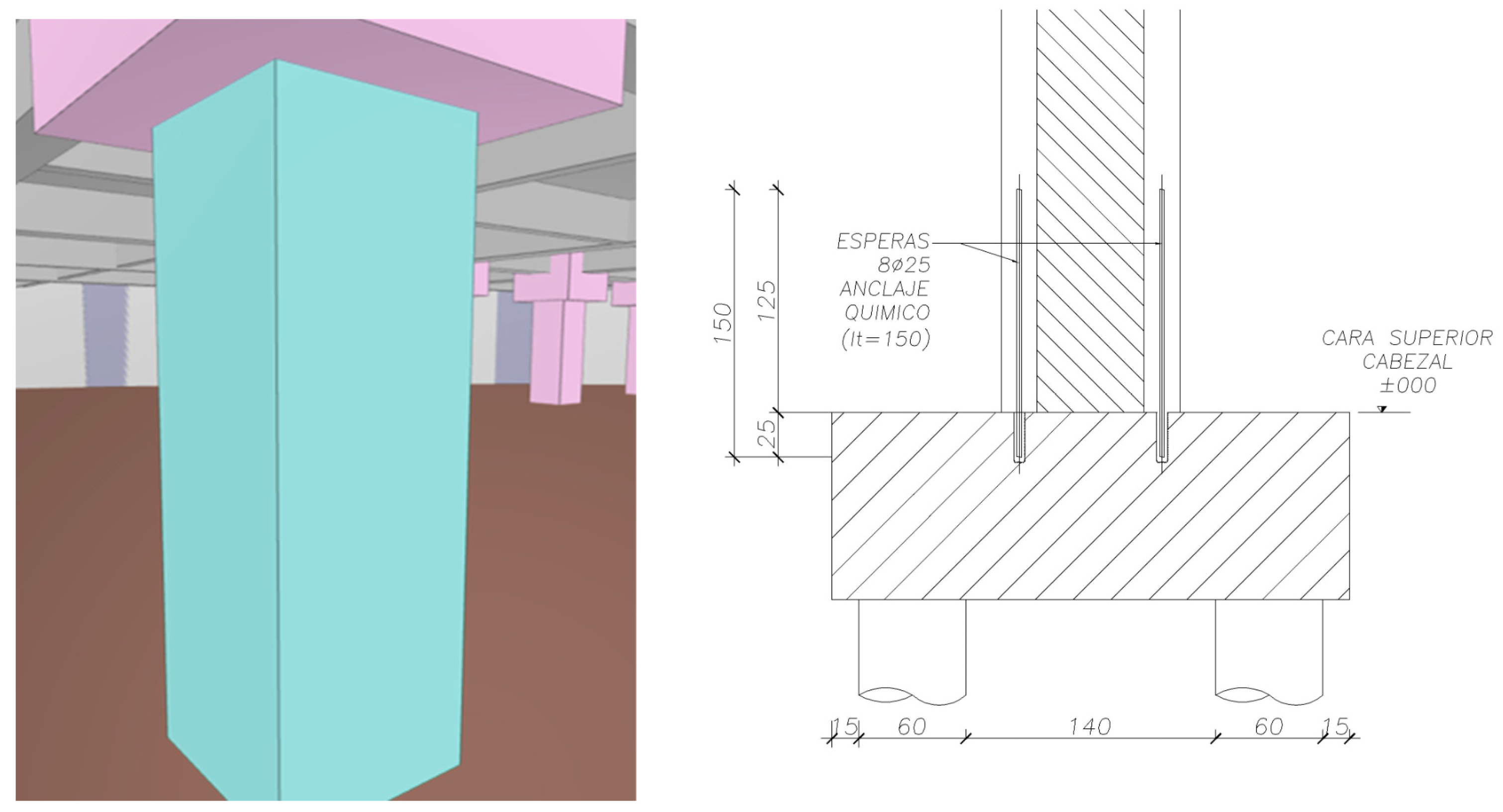

- Jacketed reinforcements for all circular columns (60 cm diameter): these were transformed into square sections with 100 cm sides. Prior to this, the foundation caps were uncovered, and eight φ25 rebars were inserted with chemical anchorage penetrating the jacketed reinforcements, as shown in Figure 7. For the jackets, C40 self-compacting concrete was used (strength according to UNIT 972 [33]) to avoid filling difficulties. These “jackets” effectively function as the new columns, since the cracking observed in the existing columns rendered their contribution to structural resistance negligible. The foundations were verified as described later

- Elimination of beams as structural elements.

3.1.2. Ground Floor (PB)

3.1.3. Upper Floor (PA)

3.1.4. Foundation Verification

- The existing overloads (masonry and technical walkways) were reduced as much as possible. The original structure was designed for a dead load of 300 kg/m2 plus the self-weight of the concrete. The masonry, consistent with the standard at the time when the building was constructed, was built with solid blocks. The damage it sustained during the fire and the new area distribution resulting from the building’s functional adaptation required its replacement. In this regard, it was replaced with dry masonry, which is significantly lighter.

- The upper floor had a subfloor with variable thickness that was always greater than 25 cm. This was removed, which also solved the level discrepancies caused by the new slab.

- All technical walkways made of concrete were replaced with metal walkways.

- Since it was necessary to uncover the pile caps to insert the φ 25 bars and support the casing, it was possible to inspect all of them. None showed any damage; they were located approximately 1.50 m below the floor slab and performed perfectly when drilled to embed the anchor bars.

- Integrity tests were conducted on a sample of piles, yielding satisfactory results and providing information about their length.

- Once the length was determined, standard penetration tests (SPTs) were carried out on the soil to establish the bearing capacity of the piles. After penetrating a three-meter-thick sand layer, hard-consistency clay was encountered. The SPT results for the clay showed a gradual increase in resistance, from 45 blows to 100 blows along the length of the piles. This evaluation allowed us to calculate a load-bearing capacity of 120 tons per pile, which was found to be adequate for the project’s requirements.

3.2. Remaining Areas of the Building

- New foundations constructed on piles, with composite columns consisting of a steel tubular section filled with reinforced concrete. This design allowed 75% of the design load (increased by the appropriate safety factors) to be supported by the reinforced concrete core.

- Steel beams bolted to the columns and interconnected, combined with steel deck slabs, which simplified the assembly process and eliminated the need for traditional formwork.

3.3. Area Adjacent to the Supermarket Entrance (Practically Collapsed)

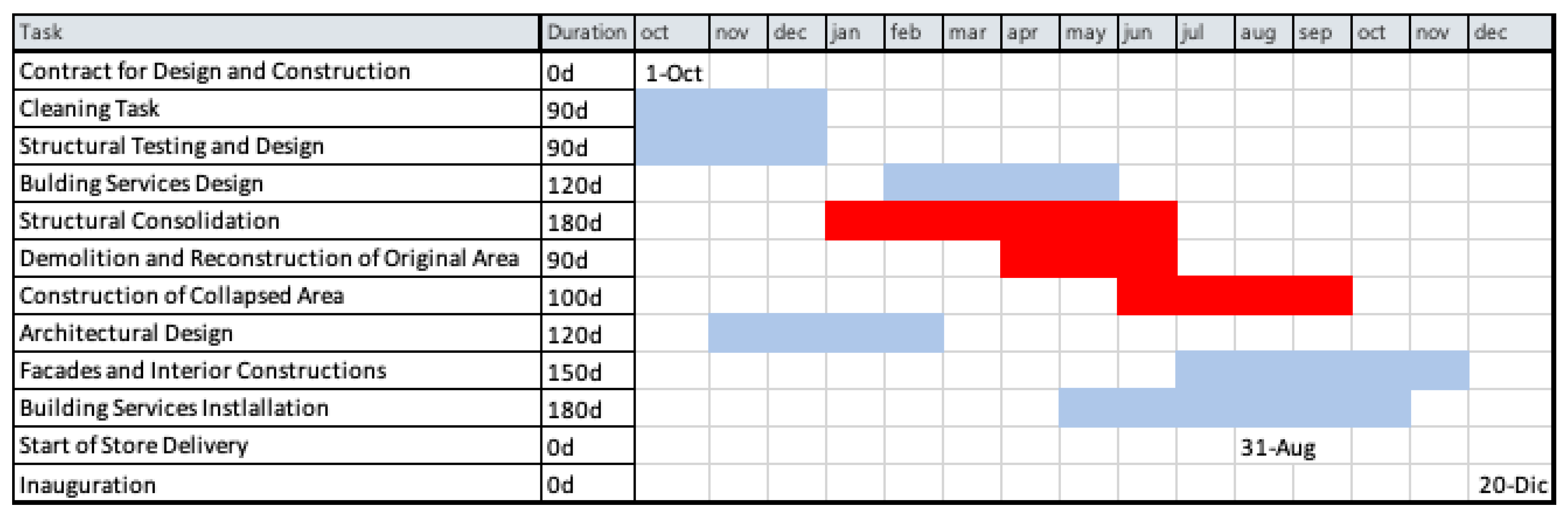

4. Work Schedule

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pereyra, M.N.; Leez, Á.; Bonjour, H.; Vila, P. Comprehensive Rehabilitation of the Punta del Este Shopping Center After Fire Damage. In Proceedings of the 10th Euro-American Congress REHABEND 2024, Construction Pathology, Rehabilitation Technology and Heritage Management, Gijón, Spain, 7–10 May 2024; University of Cantabria: Santander, Spain, 2024. [Google Scholar]

- Aseem, A.; Baloch, W.L.; Khushnood, R.A.; Mushtaq, A. Structural health assessment of fire damaged building using non-destructive testing and micro-graphical forensic analysis: A case study. Case Stud. Constr. Mater. 2019, 11, e00258. [Google Scholar] [CrossRef]

- Folic, R.; Radonjanin, V.; Malesev, M. The assessment of the structure of Novi sad Open University damaged in a fire. Constr. Build. Mater. 2002, 16, 427–440. [Google Scholar] [CrossRef]

- Ha, T.; Ko, J.; Lee, S.; Kim, S.; Jung, J.; Kim, D.-J. A case study on the rehabilitation of a fire-damaged structure. Appl. Sci. 2016, 6, 126. [Google Scholar] [CrossRef]

- Knyziak, P.; Kowalski, R.; Krentowski, J.R. Fire damage of RC slab structure of a shopping center. Eng. Fail. Anal. 2019, 97, 53–60. [Google Scholar] [CrossRef]

- Wijaya, G. Comprehensive condition assessment program on the fire damaged structure—A project case in Singapore. MATEC Web Conf. 2018, 195, 2034. [Google Scholar] [CrossRef]

- Dilek, U. Assessment of fire damage to a reinforced concrete structure during construction. J. Perform. Constr. Facil. 2007, 21, 257–263. [Google Scholar] [CrossRef]

- Jovanović, B.; Caspeele, R.; Lombaert, G.; Reynders, E.; Van Coile, R. State-of-the-art review on the post-fire assessment of concrete structures. Struct. Concr. 2023, 24, 5370–5387. [Google Scholar] [CrossRef]

- Srinivasan, P.; Cinitha, A.; Mohan, V.; Iyer, N.R. Evaluation of fire-damaged concrete structures with a case study. In National Conference on Fire Research and Engineering; IIT Roorkee: Uttarakhand, India, 1–2 March 2014; p. 29. [Google Scholar]

- Gosain, N.K.; Drexler, R.F.; Choudhuri, D. Evaluation and repair of fire-damaged buildings. Struct. Eng. Mag. 2008, 30, 1–11. [Google Scholar]

- Stochino, F.; Mistretta, F.; Meloni, P.; Carcangiu, G. Integrated approach for post-fire reinforced concrete structures assessment. Period. Polytech. Civ. Eng. 2017, 61, 677–699. [Google Scholar] [CrossRef]

- Ali Musmar, M. A case study on fire damage assessment of a two-story building with precast pretensioned hollow core slabs. J. King Saud. Univ.—Eng. Sci. 2020, 32, 501–509. [Google Scholar] [CrossRef]

- Canisius, T.D.G.; Baker, J.; Diamantidis, D.; Ellingwood, B.; Faber, M.; Markova, M.H.J.; Maitra, A.; Narasimhan, H.; Sørensen, J.D.; Vogel, T.; et al. Structural Robustness Design for Practising Engineers. In Report of the European Network COST Action: TU0601 “Robustness of Structures”; Gerard Canisius, T.D., Ed.; Prepared by the JCSS-COST Task Group on Robustness of Structures; European Cooperation in Science and Technology: Brussels, Belgium, 2011. [Google Scholar]

- FIB. Fire Design of Concrete Structures-Materials, Structures and Modeling. FIB Bulletin, Volume 38; Fédération International du Béton: Lausanne, Switzerland, 2007. [Google Scholar]

- Helene, P.; Britez, C.; Carvalho, M. Fire impacts on concrete structures. A brief review. Rev. Alconpat 2019, 10, 1–21. [Google Scholar] [CrossRef]

- Khoury, G.A. Effect of fire on concrete and concrete structures. Prog. Struct. Eng. Mater. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Onundi, L.O.; Oumarou, M.B.; Alkali, A.M. Effects of fire on the strength of reinforced concrete structural members. Am. J. Civ. Eng. Archit. 2019, 7, 1–12. [Google Scholar] [CrossRef]

- Short, N.R.; Purkiss, J.A.; Guise, S.E. Assessment of fire damaged concrete using colour image analysis. Constr. Build. Mater. 2001, 15, 9–15. [Google Scholar] [CrossRef]

- Awoyera, P.; Akinwumi, I.; Ede, A.; Olofinnade, M. Forensic investigation of fire-affected reinforced concrete buildings. IOSR J. Mech. Civ. Eng. 2014, 11, 17–23. [Google Scholar] [CrossRef]

- Colombo, M.; Felicetti, R. New NDT techniques for the assessment of fire-damaged concrete structures. Fire Saf. J. 2007, 42, 461–472. [Google Scholar] [CrossRef]

- UNIT-ISO 1920-6:2019; Instituto Uruguayo de Normas Técnicas. Ensayos de Hormigón—Parte 6: Muestreo, Preparación y Ensayo de Testigos de Hormigón. UNIT: Montevideo, Uruguay, 2019; 13p.

- UNIT-ISO 1920-7:2004; Instituto Uruguayo de Normas Técnicas. Ensayos de Hormigón—Parte 7: Ensayos no Destructivos Sobre Hormigón Endurecido. UNIT: Montevideo, Uruguay, 2014; 40p.

- UNIT-ISO 1920-10:2010; Instituto Uruguayo de Normas Técnicas. Ensayos de Hormigón—Parte 10: Determinación del Módulo de Elasticidad Estático en Compresión. UNIT: Montevideo, Uruguay, 2010; 13p.

- UNE-EN ISO 6892-1:2020; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature (ISO 6892-1:2019). ISO: Geneva, Switzerland, 2020.

- Kodur, V. Properties of Concrete al Elevated Temperatures. Int. Sch. Res. Not. 2014, 2014, 468510. [Google Scholar] [CrossRef]

- Fernández Cánovas, M. Patología y Terapeútica del Hormigón Armado, 3rd ed.; Colegio de Ingenieros de Caminos, Canales y Puertos, Servicio de Publicaciones: Madrid, Spain, 1994; ISBN 84-7493-1994. [Google Scholar]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Xargay, H.; Ripani, M.; Sambataro, L.; Folino, P. Degradación del Hormigón Frente a Altas Temperaturas. 24 Jornadas Argentinas de Ingeniería Estructural. Buenos Aires, Argentina. Available online: https://jornadasaie.org.ar/jornadas-aie-anteriores/2016-24JAIE-BuenosAires/contenidos/trabajos/071.pdf (accessed on 26 December 2024).

- EN 1992-1-2:2004; Eurocode 2: Design of Concrete Structures—Part 1–2: General Rules. Structural Fire Design. The European Union: Brussels, Belgum, 2004.

- Pereira, R.G.S.; Pires, T.A.C.; Duarte, D.; Silva, J.J.R. Evaluación de la resistencia mecánica de vigas en hormigón armado después del incendio. Rev. Alconpat 2019, 9, 93–105. [Google Scholar] [CrossRef]

- Guo, Z.; Shi, X. Experiment and Calculation of Reinforced Concrete at Elevated Temperatures; eBook; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 9780123869630. 336p. [Google Scholar]

- Maraveas, C.; Fasoulakis, Z.; Tsavdaridis, K.D. Post-fire assessment and resinstatement of stell structures. J. Struct. Fire Eng. 2017, 8, 181–201. [Google Scholar] [CrossRef]

- UNIT 972:1997; Instituto Uruguayo de Normas Técnicas. Hormigón. Clasificación por la Resistencia Característica. UNIT: Montevideo, Uruguay, 1997; 4p.

| Id. | σ (MPa) | E (GPa) | RH Index | Obs. |

|---|---|---|---|---|

| V1 | 16.5 | 4.9 | 33 | - |

| V2 | - | - | - | Discarded due to excessive cracking, disassembled during extraction |

| V3 | 14.4 | - | 43 | Longitudinal crack |

| V4 | 17.8 | 7.0 | 42 | Longitudinal crack |

| V5 | 40.9 | 22.1 | 57 | |

| V6 | 32.8 | - | 56 | |

| V7 | 19.6 | - | 50 | |

| V8 | 25.9 | - | 43 | Irregular surface due to extraction |

| V9 | 21.1 | - | 44 | |

| V10 | 9.2 | - | 30 | Longitudinal non-through cracks |

| V11 | 10.9 | 3.5 | 31 | Longitudinal non-through cracks |

| V12 | 18.3 | - | 51 | Tested with 2 ø 10, perpendicular to the axis |

| V13 | 25.5 | - | 34 | |

| V14 | 20.5 | - | 40 | Longitudinal through crack |

| V15 | 21.4 | - | 35 | Longitudinal non-through cracks |

| V16 | 25.3 | - | 34 | Longitudinal non-through cracks |

| V17 | 20.1 | - | 38 | Longitudinal non-through cracks |

| V18 | 10.6 | - | 32 | Longitudinal through crack |

| V19 | 31.6 | 15.2 | - | Longitudinal non-through cracks |

| V20 | 25.6 | - | - | Longitudinal through crack |

| V21 | 26.4 | - | - | Longitudinal through crack |

| V22 | 26.4 | - | - | Longitudinal through crack |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leez, Á.; Pereyra, M.N.; Vila, P. Comprehensive Rehabilitation of the Punta del Este Shopping Center After Fire Damage. Buildings 2025, 15, 161. https://doi.org/10.3390/buildings15020161

Leez Á, Pereyra MN, Vila P. Comprehensive Rehabilitation of the Punta del Este Shopping Center After Fire Damage. Buildings. 2025; 15(2):161. https://doi.org/10.3390/buildings15020161

Chicago/Turabian StyleLeez, Álvaro, María Noel Pereyra, and Patricia Vila. 2025. "Comprehensive Rehabilitation of the Punta del Este Shopping Center After Fire Damage" Buildings 15, no. 2: 161. https://doi.org/10.3390/buildings15020161

APA StyleLeez, Á., Pereyra, M. N., & Vila, P. (2025). Comprehensive Rehabilitation of the Punta del Este Shopping Center After Fire Damage. Buildings, 15(2), 161. https://doi.org/10.3390/buildings15020161