Mathematical Development for the Minimum Cost of Elliptical Combined Footings

Abstract

1. Introduction

2. Methodology

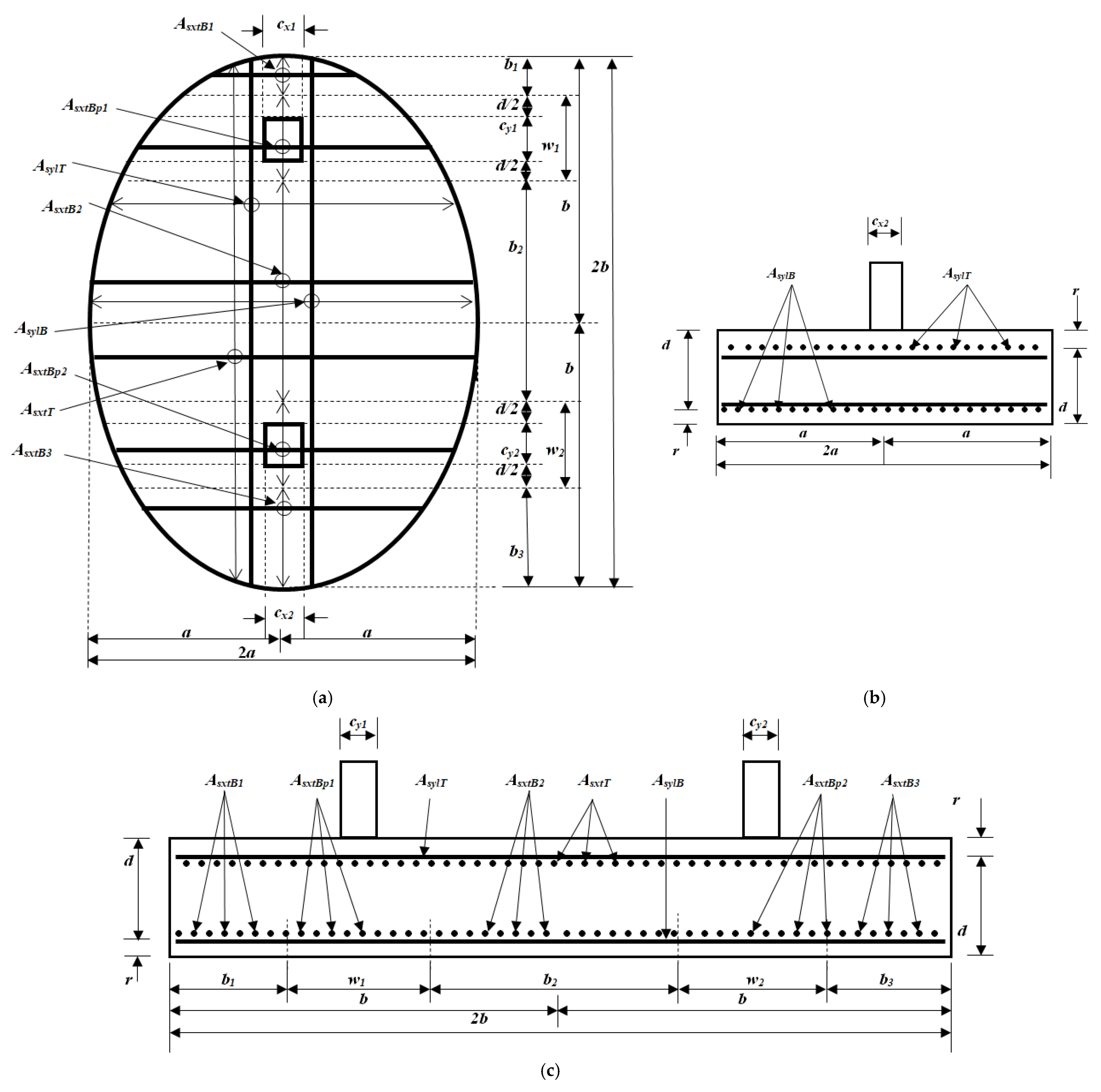

2.1. Minimum Surface of Elliptical Combined Footings

2.2. Minimum Cost of Elliptical Combined Footings

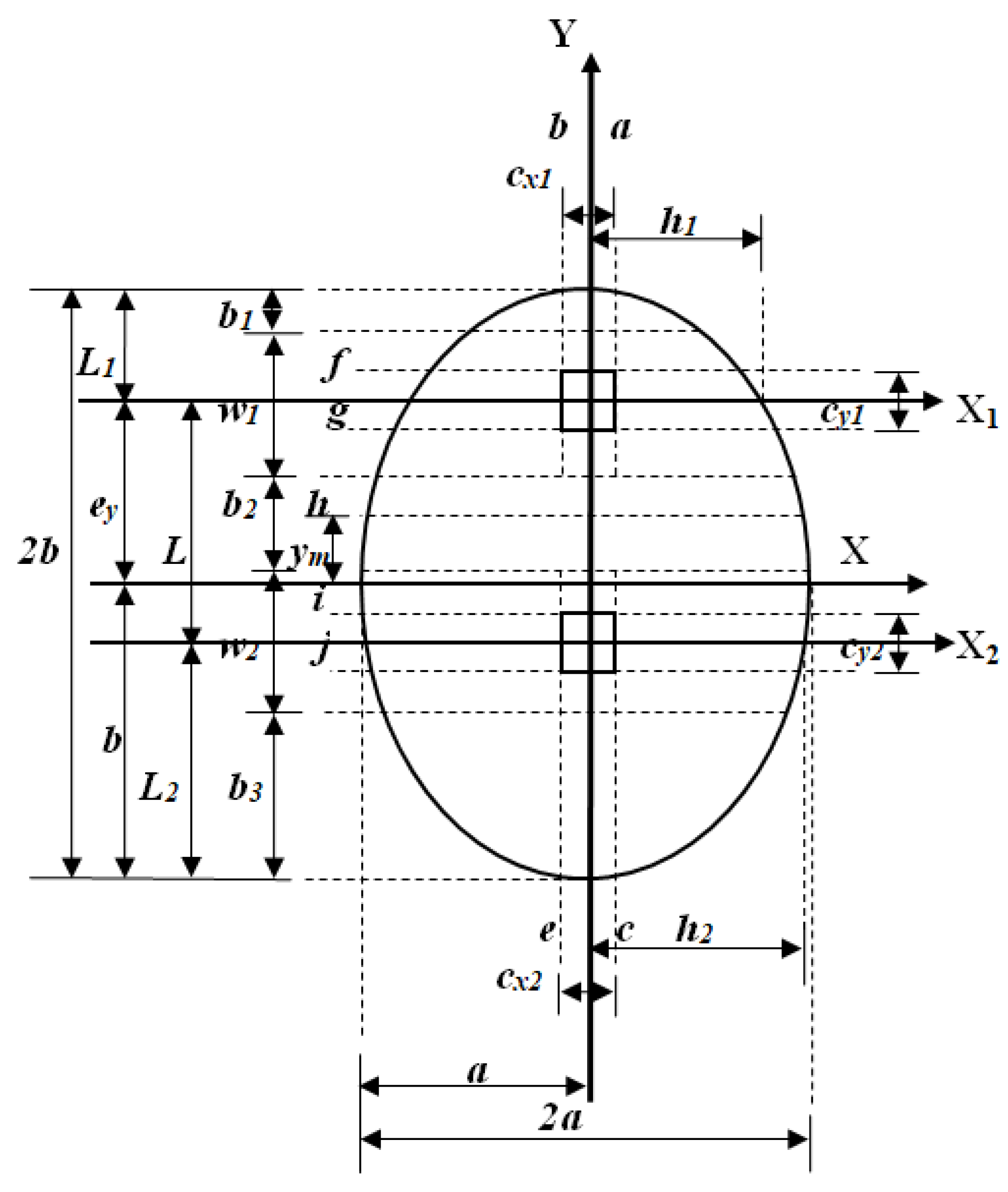

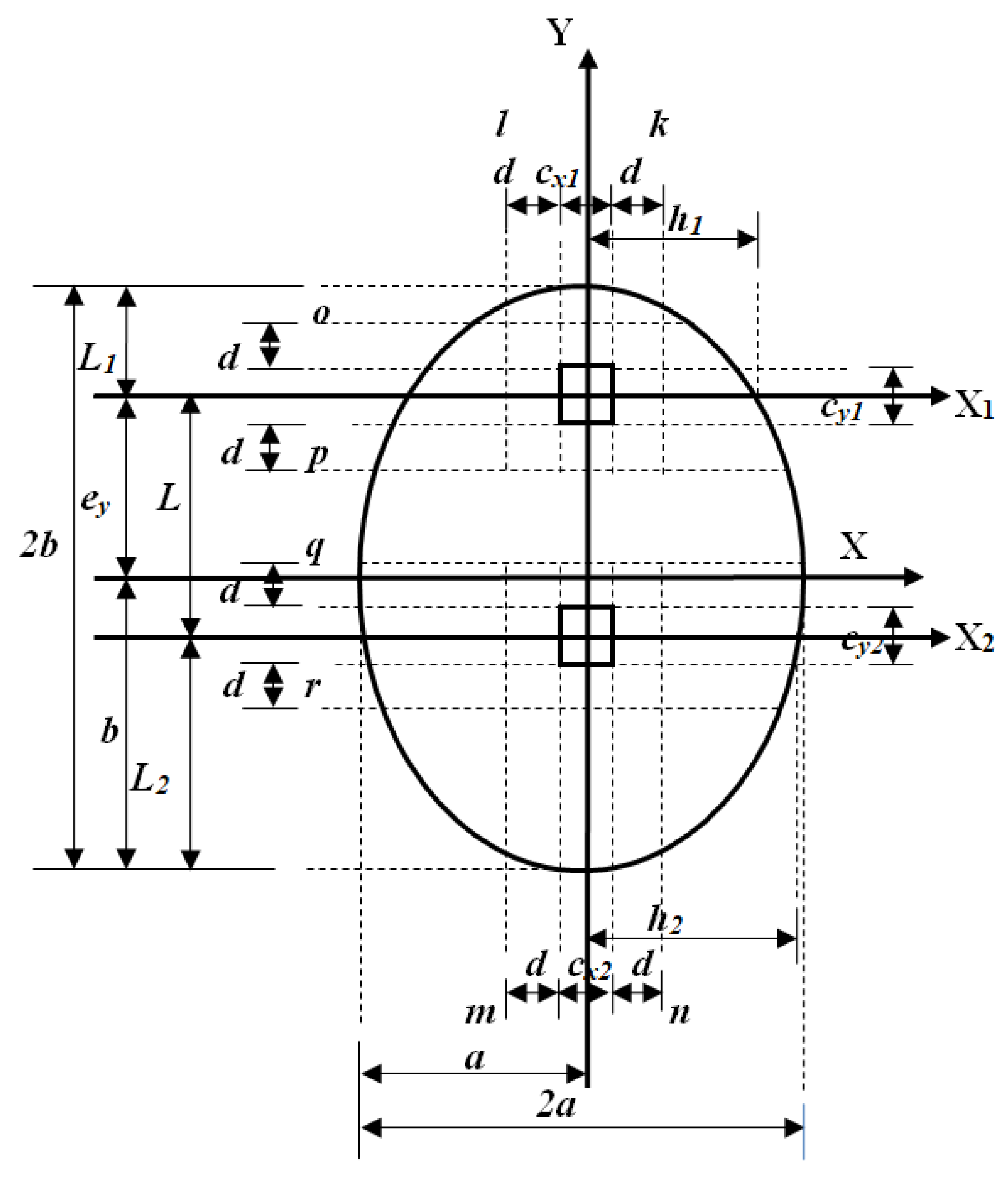

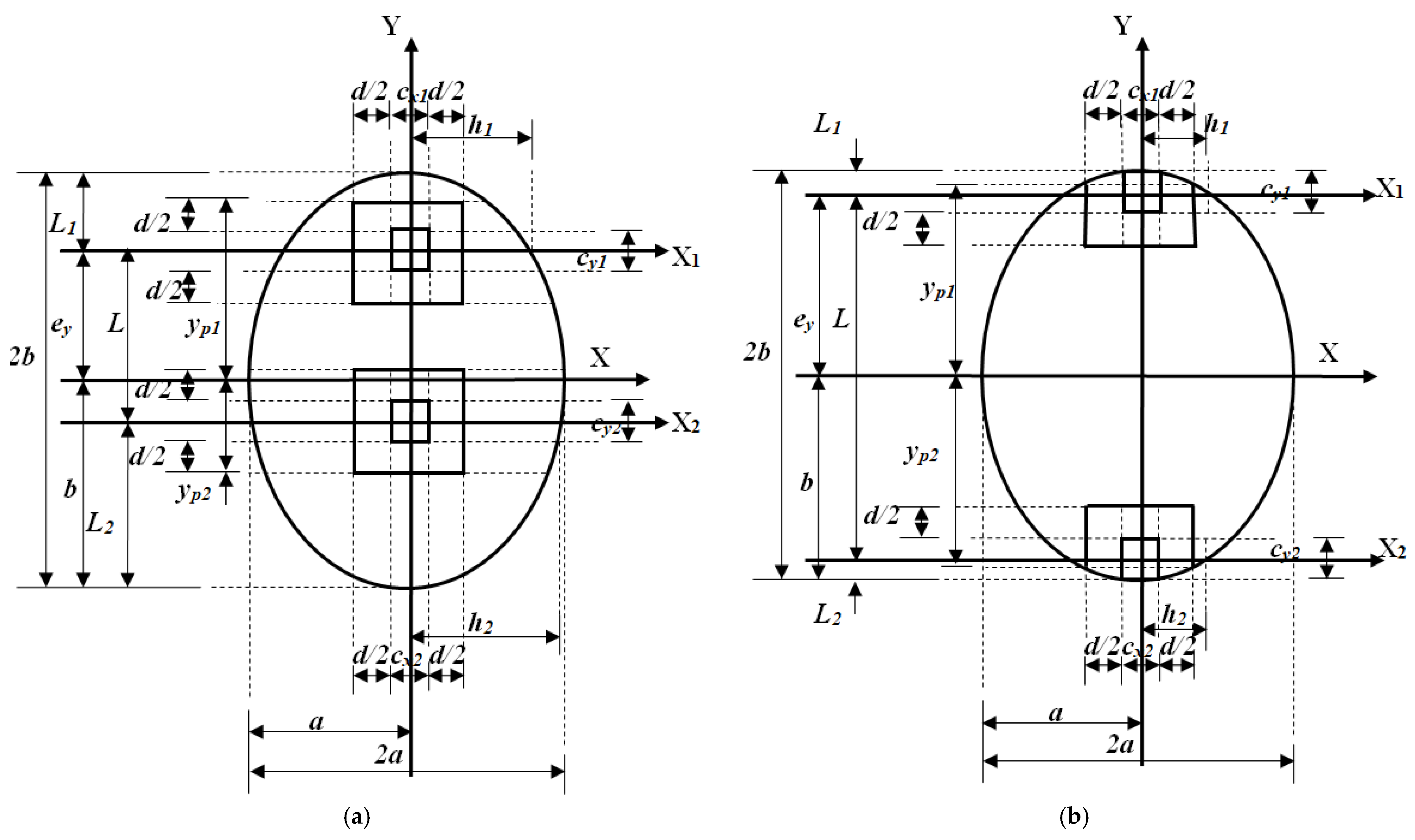

2.2.1. Moments

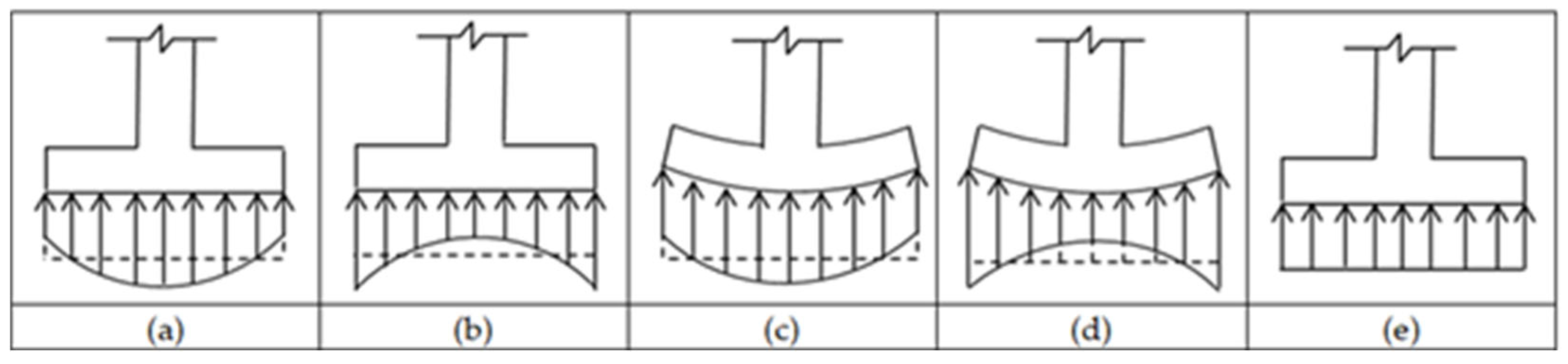

2.2.2. Unidirectional Shears

2.2.3. Punching Shears

2.2.4. Objective Function

2.2.5. Constraints

- The parameters known as L, cx1, cx2, cy1, cy2, P1, P2, Mx1, Mx2, My1, My2, and paabcs must be well defined, where paabcs = pabcs − γcdH − γsd(H − t).

- Show the objective function and evaluate the constraints for minimum area.

- Use MAPLE software to determine the minimum area, assuming all variables are non-negative except MxT, which can be negative.

- If the optimal solution is not obtained, narrow the decision variables and then determine the optimal solution again. Once the solution is reached, these variables are adjusted.

- Determine the factored moments, the factored bending shears, and the factored punching shears (the latter two are presented as a function of “d”).

- Show the objective function and evaluate the constraints for minimum cost.

- Use MAPLE software to determine the minimum cost, assuming all variables are non-negative.

- Step 4 is the same but for the minimum cost.

3. Numerical Studies

4. Results

- If the integral of Equation (20) is developed with limits from “h1” to “h1”, the moment at the free end at “h1” gives Mua = 0.

- If the integral of Equation (20) is developed with limits from “−h1” to “h1”, the moment at the free end at “−h1” gives Mua = − Muy1 − Pu1h1. This moment is equal to the moment acting on the footing but of opposite signs.

- If the integral of Equation (20) is developed with limits from “0” to “h1”, the moment at “0” gives Mua = − Muy1/2 − Pu1h1/4; now, if the integral of Equation (21) is developed with limits from “−h1” to “0”, the moment at “0” gives Mub = Muy1/2 + Pu1h1/4. Therefore, Mua and Mub are the same, but in the opposite signs. In this way, continuity is verified.

- If the integral of Equation (22) is developed with limits from “h2” to “h2”, the moment at the free end at “h2” gives Muc = 0.

- If the integral of Equation (22) is developed with limits from “−h2” to “h2”, the moment at the free end at “−h2” gives Muc = −Muy2 − Pu2h2. This moment is equal to the moment acting on the footing but of opposite signs.

- If the integral of Equation (22) is developed with limits from “0” to “h2”, the moment at “0” gives Muc = −Muy2/2 − Pu2h2/4; now, if the integral of Equation (23) is developed with limits from “−h2” to “0”, the moment at “0” gives Mue = Muy2/2 + Pu2h2/4. Therefore, Muc and Mue are the same but in the opposite signs. In this way, continuity is verified.

- If the integral of Equation (24) is developed with limits from “b” to “b”, the moment at the free end at “b” gives Muf = 0.

- If the integral of Equation (24) is developed with limits from “b − L1” to “b”, the moment at “b − L1”gives Muf; now, if the integral of Equation (25) is developed with limits from “b − L1” to “b”, the moment at “b − L1”gives Mug, and if Muf = Mug is performed, the following is given: Mux1.

- If the integral of Equation (27) is developed with limits from “b − L1 − L” to “b”, the moment at “b − L1 − L” gives Mui; now, if the integral of Equation (28) is developed with limits from “b − L1 − L” to “b”, the moment at “b − L1 − L” gives Muj, and if Mui = Muj is performed, the following is given: Mux2.

- If the integral of Equation (28) is developed with limits from “−b” to “b”, the moment at the free end at “−b” gives Muj = 0.

- If the integral of Equation (29) is developed with limits from “h1” to “h1”, the unidirectional shear at the free end at “h1” gives Vuk = 0.

- If the integral of Equation (29) is developed with limits from “−h1” to “h1”, the unidirectional shear at the free end at “−h1” gives Vuk = − Pu1. This unidirectional shear is equal to the unidirectional shear acting on the footing but of opposite signs.

- If the integral of Equation (29) is developed with limits from “0” to “h1”, the unidirectional shear at “0” gives Vuk = −3Muy1/4h1 − Pu1/2; now, if the integral of Equation (30) is developed with limits from “−h1” to “0”, the unidirectional shear at “0” gives Vul = 3Muy1/4h1 + Pu1/2. Therefore, Vuk and Vul are the same but in the opposite signs. In this way, continuity is verified.

- If the integral of Equation (31) is developed with limits from “h2” to “h2”, the unidirectional shear at the free end at “h2” gives Vum = 0.

- If the integral of Equation (31) is developed with limits from “−h2” to “h2”, the unidirectional shear at the free end at “−h2” gives Vum = −Pu2. This unidirectional shear is equal to the unidirectional shear acting on the footing but of opposite signs.

- If the integral of Equation (31) is developed with limits from “0” to “h2”, the unidirectional shear at “0” gives Vum = −3Muy2/4h2 − Pu2/2; now, if the integral of Equation (32) is developed with limits from “−h2” to “0”, the unidirectional shear at “0” gives Vun = 3Muy2/4h2 + Pu2/2. Therefore, Vum and Vun are the same but in the opposite signs. In this way continuity is verified.

- If the integral of Equation (33) is developed with limits from “b” to “b”, the unidirectional shear at the free end at “b” gives Vuo = 0.

- If the integral of Equation (33) is developed with limits from “b − L1” to “b”, the unidirectional shear at “b − L1” gives Vuo; now, if the integral of Equation (34) is developed with limits from “b − L1” to “b”, the unidirectional shear at “b − L1”gives Vup, and if Vuo = Vup is performed, the following is given: Pu1.

- If the integral of Equation (35) is developed with limits from “b − L1 − L” to “b”, the unidirectional shear at “b − L1 − L” gives Vuq, now, if the integral of Equation (36) is developed with limits from “b − L1 − L” to “b”, the unidirectional shear at “b − L1 − L” gives Vur, and if Vuq = Vur is performed, the following is given: Pu2.

- If the integral of Equation (36) is developed with limits from “−b” to “b”, the unidirectional shear at the free end at “−b” gives Vur = 0.

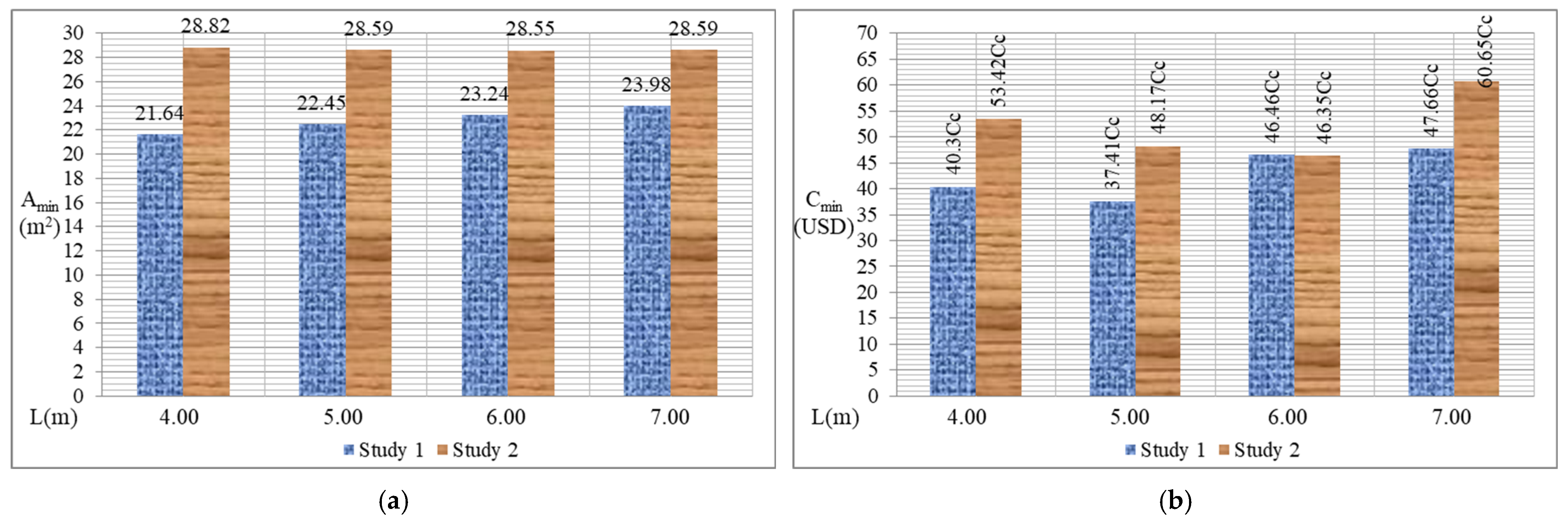

- The minimum area “Amin” is smaller for ECF compared to RCF, presenting a savings of 7.17% using the ECF.

- The minimum cost “Cmin” is lower for ECF compared to RCF, showing a savings of 23.95% using the ECF.

- The ECF and RCF are governed by unidirectional shears: For the unidirectional critical shear for RCF, it appears in section “k”, and for ECF, it appears in section “p”. This is because in section “k” for ECF h1 = 0.70 m, the critical section must appear at a distance “d” from the face of the column, and this distance is outside the footing. For this reason, “d” is smaller for ECF, and therefore, ECF is more economical than RCF.

- The minimum area “Amin” is smaller for ECF compared to RCF, presenting a savings of 1.67% using the ECF.

- The minimum cost “Cmin” is lower for ECF compared to RCF, showing a savings of 9.14% using the ECF.

- ECF and RCF are governed by unidirectional shears: For the unidirectional critical shear for RCF, it appears in section “k”, and for ECF, it appears in section “p”. This is because in section “k” for ECF h1 = 0.63 m, the critical section must appear at a distance “d” from the face of the column, and this distance is outside the footing. For this reason, “d” is smaller for ECF, and therefore, ECF is more economical than RCF.

5. Conclusions

- (1)

- There are no similar contributions on the subject of this article, as it is an innovative contribution in terms of its form.

- (2)

- The moments and unidirectional shears are verified by continuity and equilibrium (see results section).

- (3)

- This model for an ECF can be used for other construction codes since the moments, unidirectional shears, and punching shears acting on the foundation do not vary; the values that vary are the resistant effects.

- (4)

- When the spacing “L” between columns increases with free ends in the Y direction for these examples, the minimum area “Amin” increases (see Table 1).

- (5)

- When the spacing “L” between columns increases with free ends in the Y direction for these examples, the minimum cost “Cmin” tends to decrease to L = 5.00 m and then increases (see Table 2).

- (6)

- When the spacing “L” between columns increases with ends limited in the Y direction for these examples, the minimum area “Amin” tends to decrease to L = 6.00 m and then increases (see Table 3).

- (7)

- When the spacing “L” between columns increases with ends limited in the Y direction for these examples, the minimum cost “Cmin” tends to decrease to L = 6.00 m and then increases (see Table 4).

- (8)

- When the allowable bearing capacity of the ground “pabcs” increases with free ends in the Y direction for these examples, the minimum area “Amin” decreases (see Table 5).

- (9)

- When the allowable bearing capacity of the ground “pabcs” increases with free ends in the Y direction for these examples, the minimum cost “Cmin” decreases (see Table 6).

- (10)

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ps = pressure on the ground at any point below the footing in kN/m2 |

| P = unfactored load in kN |

| A = contact area with the ground under the footing in m2 |

| Mx = unfactored moment on the X axis in kN-m |

| My = unfactored moment on the Y axis in kN-m |

| Ix = moment of inertia on the X axis in m4 |

| Iy = moment of inertia on the Y axis in m4 |

| x = coordinate in the X direction of the foundation in m |

| y = coordinate in the Y direction of the foundation in m |

| P1 = load on column 1 in kN |

| P2 = load on column 2 in kN |

| R = resultant force in kN |

| Mx1 = moment on the X1 axis due to column 1 in kN-m |

| Mx2 = moment on the X2 axis due to column 2 in kN-m |

| MxT = resultant moment on the X axis in kN-m |

| My1 = moment on the Y1 axis due to column 1 in kN-m |

| My2 = moment on the Y2 axis due to column 2 in kN-m |

| MyT = resultant moment on the Y axis in kN-m |

| ey (eccentricity in the Y direction) = distance from the center of the footing to the center of column 1 in m |

| L = center-to-center distance of the columns in m |

| p1, p2, p3, and p4 = soil pressures on the extreme fibers of the X and Y axes in kN/m2 |

| pmax = maximum pressure with coordinates (xmax, ymax) in kN/m2 |

| pmin = minimum pressure with coordinates (xmin, ymin) in kN/m2 |

| a = distance of the X semi-axis of the ellipse in m |

| b = distance of the Y semi-axis of the ellipse in m |

| cmax = coordinates of the maximum pressure in m |

| cmin = coordinates of the minimum pressure in m |

| paabcs = available allowable bearing capacity of the ground to support all loads in kN/m2 |

| pabcs = allowable bearing capacity of the ground in kN/m2 |

| γcd = weight of the concrete in kN/m3 |

| γsd = weight of the earth fill in kN/m3 |

| H = depth of the footing in m |

| t = total thickness of the footing |

| Ru = factored resultant force in kN |

| MuxT = factored total moment on the X axis in kN-m |

| MuyT = factored total moment on the Y axis in kN-m |

| Amin = minimum area in m2 |

| pu = factored soil pressure in kN/m2 |

| pu1 = factored soil pressure due to column 1 in kN/m2 |

| Pu1 = factored load of column 1 in kN |

| Mux1 = factored moment on the X1 axis in kN-m |

| Muy1 = factored moment on the Y1 axis in kN-m |

| w1 = analysis width which is the side of the column 1 more a distance d/2 on each side of the column 1 in m |

| h1 = horizontal distance from the center of column 1 to the free end of the foundation in m. |

| pu2 = factored soil pressure due to column 2 in kN/m2 |

| Pu2 = factored load of column 2 in kN |

| Mux2 = factored moment on the X2 axis in kN-m |

| Muy2 = factored moment on the Y2 axis in kN-m |

| w2 = analysis width which is the side of the column 2 more a distance d/2 on each side of the column 2 in m |

| h2 = horizontal distance from the center of column 2 to the free end of the foundation in m. |

| Mua = factored moment on the a axis in kN-m |

| Mub = factored moment on the b axis in kN-m |

| Muc = factored moment on the c axis in kN-m |

| Mue = factored moment on the e axis in kN-m |

| cx1 = side of the column 1 in the X direction in m |

| cx2 = side of the column 2 in the X direction in m |

| Muf = factored moment on the f axis in kN-m |

| Mug = factored moment on the g axis in kN-m |

| Muh = maximum positive moment factored on the h axis in kN-m |

| Mui = factored moment on the i axis in kN-m |

| Muj = factored moment on the j axis in kN-m |

| ym = position of the maximum moment in m |

| cy1 = side of the column 1 in the Y direction in m |

| cy2 = side of the column 2 in the Y direction in m |

| d = effective depth of the footing in m |

| Vuk = factored unidirectional shear on the k axis in kN |

| Vul = factored unidirectional shear on the l axis in kN |

| Vum = factored unidirectional shear on the m axis in kN |

| Vun = factored unidirectional shear on the n axis in kN |

| Vuo = factored unidirectional shear on the o axis in kN |

| Vup = factored unidirectional shear on the p axis in kN |

| Vuq = factored unidirectional shear on the q axis in kN |

| Vur = factored unidirectional shear on the r axis in kN |

| Vup1 = factored punching shear in column 1 in kN |

| Vup2 = factored punching shear in column 2 in kN |

| Cmin = minimum cost in USD |

| Cc = cost of concrete in USD/m3 |

| Vc = volume of concrete in m3 |

| Cs = cost of steel in USD/kN |

| Vs = volume of steel in m3 |

| γs = steel density = 78 kN/m3 |

| AsxtB1 = steel by temperature in width b1 in m2 |

| AsxtB2 = steel by temperature in width b2 in m2 |

| AsxtB3 = steel by temperature in width b3 in m2 |

| AsxBp1 = steel in the X direction at the bottom of column 1 in m2 |

| Asxa = steel on the a-axis in the X direction in m2 |

| Asxb = steel on the b-axis in the X direction in m2 |

| ρ1 = percentage of reinforcing steel in the X direction at the bottom of column 1 |

| AsxBp2 = steel in the X direction at the bottom of column 2 in m2 |

| Asxc = steel on the c-axis in the X direction in m2 |

| Asxe = steel on the e-axis in the X direction in m2 |

| ρ2 = percentage of reinforcing steel in the X direction at the bottom of column 2 |

| AsxtT = steel in the X direction at the top in m2 |

| AsylB = steel in the Y direction at the bottom in m2 |

| Asyf = steel on the f-axis in the Y direction in m2 |

| Asyg = steel on the g-axis in the Y direction in m2 |

| Asyi = steel on the i-axis in the Y direction in m2 |

| Asyj = steel on the j-axis in the Y direction in m2 |

| ρyB = percentage of reinforcing steel in the Y direction at the bottom |

| AsylT = steel in the Y direction at the top in m2 |

| ρyT = percentage of reinforcing steel in the Y direction at the top of section h |

| nxtB1, nxtB2, nxtB3, nxBp1, nxBp2, nxtT, nylB, nylT = number of rods in each zone |

| ast = area of the rod used in the steel by temperature in m2 |

| asp1 = area of the rod used at the bottom of column 1 in m2 |

| asp2 = area of the rod used at the bottom of column 2 in m2 |

| aslB = area of the rod used at the bottom in the Y direction in m2 |

| aslT = area of the rod used at the top in the Y direction in m2 |

| Ast = area of steel per temperature in m2 |

| bw = analysis width in m |

| b1, b2, b3, bxf, bxg, bxi, bxj, bxh = analysis width in each zone in m |

| sxtB1, sxtB2, sxtB3, sxBp1, sxBp2, sxtT, sylB, sylT = separation of the rods in each zone in m |

| LxBp1 = total length of the rods in the X direction at the bottom of column 1 in m |

| LxBp2 = total length of the rods in the X direction at the bottom of column 2 in m |

| LxtB1 = total length of the rods in the X direction at the width b1 in m |

| LxtB2 = total length of the rods in the X direction at the width b2 in m |

| LxtB3 = total length of the rods in the X direction at the width b3 in m |

| LxtT = total length of the rods in the X direction at the top in m |

| LylB = total length of the rods in the Y direction at the bottom in m |

| LylT = total length of the rods in the Y direction at the top in m |

| r = concrete cover in m |

| fy = strength of the reinforcing steel in MPa |

| f’c = compressive strength of the concrete in MPa |

| Øf = bending strength reduction factor |

| Øv = shear strength reduction factor |

| bwsxo, bwsxp, bwsxq, and bwsxr = analysis width in each zone in m |

| βc = long side of column/short side of column |

| b0 = perimeter of the critical punching shear section in m |

| β1 = factor relating the depth of the equivalent rectangular compressive stress block to the depth of the neutral axis |

References

- Bowles, J.E. Foundation Analysis and Design; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Girgin, K. Simplified formulations for the determination of rotational spring constants in rigid spread footings resting on tensionless soil. J. Civ. Eng. Manag. 2017, 23, 464–474. [Google Scholar] [CrossRef]

- Basudhar, P.K.; Das, A.; Das, S.K.; Dey, A.; Deb, K.; De, S. Optimal cost design of rigid raft foundation. In Proceedings of the 10th East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-10), Bangkok, Thailand, 3–5 August 2006; pp. 39–44. [Google Scholar]

- Algin, H.M. Stresses from linearly distributed pressures over rectangular areas. Int. J. Numer. Anal. Methods Geomech. 2000, 24, 681–692. [Google Scholar] [CrossRef]

- Algin, H.M. Practical formula for dimensioning a rectangular footing. Eng. Struct. 2007, 29, 1128–1134. [Google Scholar] [CrossRef]

- Aydogdu, I. New Iterative method to Calculate Base Stress of Footings under Biaxial Bending. Int. J. Eng. Appl. Sci. 2016, 8, 40–48. [Google Scholar] [CrossRef]

- Highter, W.H.; Anders, J.C. Dimensioning Footings Subjected to Eccentric Loads. J. Geotech. Eng. 1985, 111, 659–665. [Google Scholar] [CrossRef]

- Vitone, D.M.A.; Valsangkar, A.J. Stresses from Loads over Rectangular Areas. J. Geotech. Eng. 1986, 112, 961–964. [Google Scholar] [CrossRef]

- Ozmen, G. Determination of Base Stresses in Rectangular Footings under Biaxial Bending. Tek. Dergi 2011, 22, 1519–1535. Available online: https://dergipark.org.tr/tr/download/article-file/136568 (accessed on 15 May 2025).

- Dagdeviren, U. Shear stresses below the rectangular foundations subjected to biaxial bending. Geomech. Eng. 2016, 10, 189–205. [Google Scholar] [CrossRef]

- Keskin, M.S.; Bildik, S.; Laman, M. Experimental and Numerical Studies of Vertical Stresses Beneath the Circular Footings on Sand. Appl. Sci. 2023, 13, 1635. [Google Scholar] [CrossRef]

- Shaaban, M.Q.; Al-kuaity, S.A.; Aliakbar, M.R.M. Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads. Open Eng. 2023, 13, 20220458. [Google Scholar] [CrossRef]

- Luevanos-Soto, I.; Luevanos-Rojas, A.; Moreno-Landeros, V.M.; Santiago-Hurtado, G. Minimum area for circular isolated footings with eccentric column taking into account that the surface in contact with the ground works partially in compression. Couple Syst. Mech. 2024, 13, 201–217. [Google Scholar] [CrossRef]

- Babu, T.S.; Ibrahim, S.K.N. Design of circular footings considering soil-structure interaction. In Proceedings of the International Conference on Smart Materials and Structures, ICSMS-2022, Andhra Pradesh, India, 15–16 February 2022. [Google Scholar] [CrossRef]

- Fazeli-Dehkordi, P.; Karim, U.F.A. Behaviour of circular footings confined by rigid base and geocell reinforcement. Arab. J. Geosci. 2020, 13, 1100. [Google Scholar] [CrossRef]

- Magade, S.B.; Ingle, R.K. Numerical method for analysis and design of isolated square footing under concentric loading. Int. J. Adv. Struct. Eng. 2019, 11, 9–20. [Google Scholar] [CrossRef]

- Galvis, F.A.; Smith-Pardo, P.J. Axial load biaxial moment interaction (PMM) diagrams for shallow foundations: Design aids, experimental verification, and examples. Eng. Struct. 2020, 213, 110582. [Google Scholar] [CrossRef]

- Rawat, S.; Mittal, R.K.; Muthukumar, G. Isolated Rectangular Footings under Biaxial Bending: A Critical Appraisal and Simplified Analysis Methodology. Pract. Period. Struct. Des. Const. 2020, 25, 04020011. [Google Scholar] [CrossRef]

- Al-Ansari, M.S.; Afzal, M.S. Structural analysis and design of irregular shaped footings subjected to eccentric loading. Eng. Rep. 2021, 3, e12283. [Google Scholar] [CrossRef]

- Luévanos-Rojas, A.; Moreno-Landeros, V.M.; Santiago-Hurtado, G.; Olguin-Coca, F.J.; López-León, L.D.; Baltazar-Zamora, M.A.; Diaz-Gurrola, E.R. Mathematical Modeling for the Optimal Cost Design of Circular Isolated Footings with Eccentric Column. Mathematics 2024, 12, 733. [Google Scholar] [CrossRef]

- Elhanash, M.; Elsherif, A.K.; Aref, A.; Nagy, N.M. New analytical method for optimum design of circular and elliptical footings. Adv. Comput. Des. 2025, 10, 151–167. [Google Scholar] [CrossRef]

- Diaz-Gurrola, E.R.; Luevanos-Rojas, A.; Santiago-Hurtado, G.; Moreno-Landeros, V.M.; Landa-Gomez, A.E. Mathematical Calculations for the Design of Elliptical Isolated Foundations with Optimal Cost. Mathematics 2025, 13, 1777. [Google Scholar] [CrossRef]

- Luevanos-Soto, I.; Luevanos-Rojas, A.; Moreno-Landeros, V.M.; Santiago-Hurtado, G. Minimum cost design for circular isolated footings with eccentric column taking into account that the surface in contact with the ground works partially in compression. Couple Syst. Mech. 2024, 13, 311–335. [Google Scholar] [CrossRef]

- Nigdeli, S.M.; Bekdaş, G. The investigation of optimization of eccentricity in reinforced concrete footings. In Proceedings of the 7th International Conference on Harmony Search, Soft Computing and Applications; Springer Nature Singapore: Singapore, 2022; pp. 207–215. [Google Scholar] [CrossRef]

- Naik, B.; Sandeep Nighojkar, S.; Pendharkar, D.U. Effectiveness of Skirt in Rectangular Combined Footing for Two Symmetric Columns. IOSR J. Mech. Civ. Eng. 2020, 17, 11–23. [Google Scholar]

- Ranpura, N.A.; Areakar, V.; Patel, V. Optimum Design of Combined Rectangular RCC Footing using GA. Int. J. Adv. Res. Sci. Commun. Technol. 2021, 7, 202–210. [Google Scholar] [CrossRef]

- Solorzano, G.; Plevris, V. Optimum design of RC footings with genetic algorithms according to ACI 318-19. Buildings 2020, 10, 110. [Google Scholar] [CrossRef]

- Al-Douri, E.M.F. Optimum design of trapezoidal combined footings. Tikrit J. Eng. Sci. 2007, 14, 85–115. [Google Scholar] [CrossRef]

- Moreno-Landeros, V.M.; Luévanos-Rojas, A.; Santiago-Hurtado, G.; López-León, L.D.; Olguin-Coca, F.J.; López-León, A.L.; Landa-Gómez, A.E. Optimal Cost Design of RC T-Shaped Combined Footings. Buildings 2024, 14, 3688. [Google Scholar] [CrossRef]

- Naik, B.; Sandeep Nighojkar, S.; Pendharkar, D.U. Design of Skirted Rectangular Combined Footing with Vertical Skirt All Around the Four Edges. Int. J. Creat. Res. Thoughts 2020, 8, 674–680. [Google Scholar]

- Aishwarya, K.M.; Balaji, N.C. Analysis and design of eccentrically loaded corner combined footing for rectangular columns. In Proceedings of the International Conference on Advances in Sustainable Construction Materials, Guntur, India, 18–19 March 2022. [Google Scholar] [CrossRef]

- Luévanos-Rojas, A.; Santiago-Hurtado, G.; Moreno-Landeros, V.M.; Olguin-Coca, F.J.; López-León, L.D.; Diaz-Gurrola, E.R. Mathematical Modeling of the Optimal Cost for the Design of Strap Combined Footings. Mathematics 2024, 12, 294. [Google Scholar] [CrossRef]

- Rizwan, M.; Alam, B.; Rehman, F.U.; Masud, N.; Shahzada, K.; Masud, T. Cost Optimization of Combined Footings Using Modified Complex Method of Box. Int. J. Adv. Struct. Geotech. Eng. 2012, 1, 24–28. [Google Scholar]

- Kashani, A.R.; Camp, C.V.; Akhani, M.; Ebrahimi, S. Optimum design of combined footings using swarm intelligence-based algorithms. Adv. Eng. Soft. 2022, 169, 103140. [Google Scholar] [CrossRef]

- Moayedi, H.; Hayati, S. Modelling and optimization of ultimate bearing capacity of strip footing near a slope by soft computing methods. Appl. Soft Comput. 2018, 14, 208–221. [Google Scholar] [CrossRef]

- Konapure, C.G.; Vivek, B. Analysis of Combined rectangular footing by Winkler’s Model and Finite Element Method. Int. J. Eng. Innov. Technol. 2013, 3, 128–132. Available online: https://www.ijeit.com/Vol%203/Issue%205/IJEIT1412201311_21.pdf (accessed on 16 May 2025).

- Ravi Kumar Reddy, C.; Satish Kumar, M.; Kondala Rao, M.; Gopika, N. Numerical Analysis of Rectangular Combined Footings Resting on Soil for Contact Pressure. Int. J. Civil Eng. Technol. 2018, 9, 1425–1431. Available online: https://iaeme.com/MasterAdmin/Journal_uploads/IJCIET/VOLUME_9_ISSUE_9/IJCIET_09_09_137.pdf (accessed on 3 June 2025).

- Waheed, J.; Azam, R.; Riaz, M.R.; Shakeel, M.; Mohamed, A.; Ali, E. Metaheuristic-Based Practical Tool for Optimal Design of Reinforced Concrete Isolated Footings: Development and Application for Parametric Investigation. Buildings 2022, 12, 471. [Google Scholar] [CrossRef]

- Nawaz, M.N.; Ali, A.S.; Jaffar, S.T.A.; Jafri, T.H.; Oh, T.-M.; Abdallah, M.; Karam, S.; Azab, M. Cost-Based Optimization of Isolated Footing in Cohesive Soils Using Generalized Reduced Gradient Method. Buildings 2022, 12, 1646. [Google Scholar] [CrossRef]

- Khajehzadeh, M.; Keawsawasvong, S.; Nehdi, M.L. Effective Hybrid Soft Computing Approach for Optimum Design of Shallow Foundations. Sustainability 2022, 14, 1847. [Google Scholar] [CrossRef]

- Luévanos-Rojas, A. A new model for the design of rectangular combined boundary footings with two restricted opposite sides. Rev. ALCONPAT 2016, 6, 173–189. [Google Scholar] [CrossRef]

- Velázquez-Santillán, F.; Luévanos-Rojas, A.; López-Chavarría, S.; Medina-Elizondo, M.; Sandoval-Rivas, R. Numerical experimentation for the optimal design for reinforced concrete rectangular combined footings. Adv. Compt. Des. 2018, 3, 49–69. [Google Scholar] [CrossRef]

- Das, B.M.; Sordo-Zabay, E.; Arrioja-Juárez, R. Principios de Ingeniería de Cimentaciones; Cengage Learning Latín América: Mexico City, Mexico, 2006. [Google Scholar]

- McCormac, J.C.; Brown, R.H. Design of Reinforced Concrete; John Wiley & Sons, Inc.: Mexico City, Mexico, 2014. [Google Scholar]

- ACI 318-19; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2019.

| Example | a (m) | b (m) | ey (m) | L (m) | L1 (m) | L2 (m) | h1 (m) | h2 (m) | R (kN) | MxT (kN-m) | MyT (kN-m) | pmax (kN/m2) | pmin (kN/m2) | Amin (m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.1 | 2.68 | 2.57 | 1.63 | 4.00 | 0.94 | 0.20 | 2.07 | 1.04 | 3700 | 47.15 | 700 | 219.33 | 122.66 | 21.64 |

| 1.2 | 2.29 | 3.12 | 2.08 | 5.00 | 1.04 | 0.20 | 1.71 | 0.81 | 3700 | 78.85 | 700 | 219.50 | 110.18 | 22.45 |

| 1.3 | 2.01 | 3.68 | 2.52 | 6.00 | 1.16 | 0.20 | 1.46 | 0.65 | 3700 | 120.15 | 700 | 219.43 | 99.01 | 23.24 |

| 1.4 | 1.80 | 4.24 | 2.97 | 7.00 | 1.28 | 0.20 | 1.28 | 0.56 | 3700 | 171.44 | 700 | 219.54 | 89.09 | 23.98 |

| Example | MuxT (kN-m) | MuyT (kN-m) | Ru (kN) | AsxBp1 (cm2) | AsxBp2 (cm2) | AsxtB1 (cm2) | AsxtB2 (cm2) | AsxtT (cm2) | AsylB (cm2) | AsylT (cm2) | d (m) | ρ1 | ρ2 | ρyT | ρyB | Cmin (USD) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.1 | −6.80 | 1004 | 5240 | 61.34 | 41.28 | 4.78 | 39.09 | 70.90 | 173.28 | 219.32 | 0.77 | 0.00686 | 0.00688 | 0.00601 | 0.00601 | 40.30Cc |

| 1.2 | 71.20 | 1004 | 5240 | 74.55 | 60.53 | 6.47 | 50.77 | 81.84 | 120.96 | 120.96 | 0.73 | 0.00906 | 0.01087 | 0.00413 | 0.00531 | 37.41Cc |

| 1.3 | 96.80 | 1004 | 5240 | 50.51 | 32.84 | 8.19 | 72.68 | 112.62 | 144.74 | 187.38 | 0.85 | 0.00475 | 0.00468 | 0.00629 | 0.00629 | 46.46Cc |

| 1.4 | 174.80 | 1004 | 5240 | 99.47 | 70.55 | 10.23 | 99.26 | 149.81 | 95.05 | 110.90 | 0.98 | 0.00734 | 0.00807 | 0.00362 | 0.00405 | 47.66Cc |

| Example | a (m) | b (m) | ey (m) | L (m) | L1 (m) | L2 (m) | h1 (m) | h2 (m) | R (kN) | MxT (kN-m) | MyT (kN-m) | pmax (kN/m2) | pmin (kN/m2) | Amin (m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.1 | 4.17 | 2.20 | 2.00 | 4.00 | 0.20 | 0.20 | 1.74 | 1.74 | 3700 | 1400 | 700 | 219.72 | 37.04 | 28.82 |

| 2.2 | 3.37 | 2.70 | 2.50 | 5.00 | 0.20 | 0.20 | 1.27 | 1.27 | 3700 | 1650 | 700 | 219.76 | 39.12 | 28.59 |

| 2.3 | 2.84 | 3.20 | 3.00 | 6.00 | 0.20 | 0.20 | 0.99 | 0.99 | 3700 | 1900 | 700 | 219.67 | 39.52 | 28.55 |

| 2.4 | 2.46 | 3.70 | 3.50 | 7.00 | 0.20 | 0.20 | 0.80 | 0.80 | 3700 | 2150 | 700 | 219.90 | 38.89 | 28.59 |

| Example | MuxT (kN-m) | MuyT (kN-m) | Ru (kN) | AsxBp1 (cm2) | AsxBp2 (cm2) | AsxtB2 (cm2) | AsxtT (cm2) | AsylB (cm2) | AsylT (cm2) | d (m) | ρ1 | ρ2 | ρyT | ρyB | Cmin (USD) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.1 | 1932 | 1004 | 5240 | 41.51 | 27.83 | 43.48 | 70.65 | 220.18 | 220.36 | 0.89 | 0.00550 | 0.00368 | 0.00359 | 0.00515 | 53.42Cc |

| 2.2 | 2272 | 1004 | 5240 | 33.51 | 21.63 | 54.39 | 77.17 | 177.94 | 177.94 | 0.79 | 0.00530 | 0.00342 | 0.00408 | 0.00635 | 48.17Cc |

| 2.3 | 2612 | 1004 | 5240 | 26.73 | 20.75 | 66.88 | 88.61 | 149.95 | 149.95 | 0.77 | 0.00443 | 0.00344 | 0.00424 | 0.00709 | 46.35Cc |

| 2.4 | 2952 | 1004 | 5240 | 57.69 | 112.50 | 88.29 | 113.70 | 189.91 | 233.56 | 0.85 | 0.00817 | 0.01594 | 0.00692 | 0.01000 | 60.65Cc |

| Example | paabcs (kN/m2) | a (m) | b (m) | ey (m) | L1 (m) | L2 (m) | h1 (m) | h2 (m) | R (kN) | MxT (kN-m) | MyT (kN-m) | pmax (kN/m2) | pmin (kN/m2) | Amin (m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.1 | 120.25 | 2.18 | 4.02 | 1.18 | 2.84 | 0.20 | 2.08 | 0.70 | 1900 | 243.28 | 750 | 119.76 | 18.26 | 27.53 |

| 3.2 | 170.25 | 1.74 | 3.95 | 1.25 | 2.71 | 0.20 | 1.65 | 0.55 | 1900 | 369.64 | 750 | 169.71 | 6.28 | 21.59 |

| 3.3 | 220.25 | 1.63 | 3.93 | 1.27 | 2.65 | 0.20 | 1.54 | 0.51 | 1900 | 419.19 | 750 | 188.29 | 0.53 | 20.12 |

| 3.4 | 270.25 | 1.63 | 3.93 | 1.27 | 2.65 | 0.20 | 1.54 | 0.51 | 1900 | 419.19 | 750 | 188.29 | 0.53 | 20.12 |

| Example | MuxT (kN-m) | MuyT (kN-m) | Ru (kN) | AsxBp1 (cm2) | AsxBp2 (cm2) | AsxtB1 (cm2) | AsxtB2 (cm2) | AsxtT (cm2) | AsylB (cm2) | AsylT (cm2) | d (m) | ρ1 | ρ2 | ρyT | ρyB | Cmin (USD) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.1 | 308.00 | 1020 | 2600 | 117.81 | 71.50 | 43.78 | 73.01 | 172.11 | 257.78 | 265.68 | 1.19 | 0.00623 | 0.00604 | 0.00529 | 0.00529 | 79.50Cc |

| 3.2 | 490.00 | 1020 | 2600 | 65.47 | 41.00 | 37.51 | 67.09 | 149.28 | 133.19 | 138.35 | 1.05 | 0.00430 | 0.00422 | 0.00392 | 0.00392 | 45.60Cc |

| 3.3 | 542.00 | 1020 | 2600 | 48.35 | 31.04 | 35.22 | 65.02 | 142.15 | 102.81 | 107.05 | 1.01 | 0.00343 | 0.00342 | 0.00338 | 0.00338 | 41.23Cc |

| 3.4 | 542.00 | 1020 | 2600 | 48.35 | 31.04 | 35.22 | 65.02 | 142.15 | 102.81 | 107.05 | 1.01 | 0.00343 | 0.00342 | 0.00338 | 0.00338 | 41.23Cc |

| Example | a (m) | b (m) | ey (m) | L (m) | L1 (m) | L2 (m) | h1 (m) | h2 (m) | R (kN) | MxT (kN-m) | MyT (kN-m) | pmax (kN/m2) | pmin (kN/m2) | Amin (m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.1 | 2.00 | 3.70 | 1.62 | 4.00 | 2.08 | 1.32 | 1.80 | 1.53 | 3700 | 0.98 | 700 | 219.40 | 98.93 | 23.25 |

| 2.20 | 3.28 | 1.62 | 4.00 | 1.66 | 0.90 | 1.91 | 1.51 | 3700 | 0.99 | 700 | 219.36 | 107.07 | 22.67 | |

| 2.40 | 2.94 | 1.62 | 4.00 | 1.32 | 0.56 | 2.00 | 1.41 | 3700 | 0.99 | 700 | 219.54 | 114.28 | 22.17 | |

| 2.60 | 2.66 | 1.62 | 4.00 | 1.04 | 0.28 | 2.06 | 1.16 | 3700 | 0.99 | 700 | 219.86 | 120.73 | 21.73 | |

| 2.68 | 2.57 | 1.63 | 4.00 | 0.94 | 0.20 | 2.07 | 1.04 | 3700 | 47.15 | 700 | 219.33 | 122.66 | 21.64 | |

| 2.80 | 2.50 | 1.70 | 4.00 | 0.80 | 0.20 | 2.05 | 1.10 | 3700 | 290.00 | 700 | 218.38 | 118.12 | 21.99 | |

| 3.00 | 2.43 | 1.77 | 4.00 | 0.66 | 0.20 | 2.06 | 1.19 | 3700 | 549.00 | 700 | 218.28 | 104.83 | 22.90 | |

| 3.20 | 2.38 | 1.82 | 4.00 | 0.56 | 0.20 | 2.06 | 1.28 | 3700 | 734.00 | 700 | 217.85 | 91.43 | 23.93 | |

| 3.40 | 2.34 | 1.86 | 4.00 | 0.48 | 0.20 | 2.06 | 1.38 | 3700 | 882.00 | 700 | 216.77 | 79.30 | 24.99 |

| Example | MuxT (kN-m) | MuyT (kN-m) | Ru (kN) | AsxBp1 (cm2) | AsxBp2 (cm2) | AsxtB1 (cm2) | AsxtB2 (cm2) | AsxtB3 (cm2) | AsxtT (cm2) | AsylB (cm2) | AsylT (cm2) | d (m) | ρ1 | ρ2 | ρyT | ρyB | Cmin (USD) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.1 | −59.20 | 1004 | 5240 | 70.27 | 70.27 | 22.94 | 43.62 | 10.68 | 119.41 | 207.79 | 225.48 | 0.90 | 0.00605 | 0.00605 | 0.00666 | 0.00666 | 55.30Cc |

| −59.20 | 1004 | 5240 | 86.67 | 72.69 | 16.53 | 44.30 | 3.98 | 108.32 | 226.91 | 234.58 | 0.92 | 0.00717 | 0.00602 | 0.00676 | 0.00676 | 54.42Cc | |

| −59.20 | 1004 | 5240 | 83.69 | 71.27 | 10.98 | 44.84 | 0 | 98.92 | 209.63 | 244.06 | 0.93 | 0.00671 | 0.00571 | 0.00595 | 0.00595 | 51.51Cc | |

| −59.20 | 1004 | 5240 | 45.81 | 44.80 | 6.25 | 45.12 | 0 | 90.37 | 137.28 | 146.50 | 0.94 | 0.00361 | 0.00333 | 0.00333 | 0.00384 | 41.31Cc | |

| −6.80 | 1004 | 5240 | 61.34 | 41.28 | 4.78 | 39.09 | 0 | 70.90 | 173.28 | 219.32 | 0.77 | 0.00686 | 0.00688 | 0.00601 | 0.00601 | 40.30Cc | |

| 360.00 | 1004 | 5240 | 73.29 | 46.02 | 2.15 | 45.23 | 0 | 85.26 | 170.31 | 230.55 | 0.95 | 0.00574 | 0.00556 | 0.00494 | 0.00494 | 46.14Cc | |

| 726.80 | 1004 | 5240 | 64.51 | 40.58 | 0 | 51.95 | 0 | 105.44 | 158.40 | 212.12 | 1.21 | 0.00333 | 0.00336 | 0.00337 | 0.00374 | 53.95Cc | |

| 988.80 | 1004 | 5240 | 170.72 | 131.56 | 0 | 46.21 | 0 | 83.94 | 291.50 | 475.23 | 0.98 | 0.01263 | 0.01509 | 0.00880 | 0.00879 | 70.68Cc | |

| 1198.40 | 1004 | 5240 | 170.63 | 131.56 | 0 | 46.21 | 0 | 82.54 | 277.89 | 501.04 | 0.98 | 0.01262 | 0.01509 | 0.00880 | 0.00879 | 73.00Cc |

| Footing | a (m) | b (m) | d (m) | L (m) | L1 (m) | L2 (m) | AsxBp1 (cm2) | AsxBp2 (cm2) | AsxtB2 (cm2) | AsxtT (cm2) | AsylB (cm2) | AsylT (cm2) | ρp1 | ρp2 | ρyB | ρyT | Amin (m2) | Cmin (USD) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ECF | 1.95 | 3.00 | 0.53 | 5.60 | 0.20 | 0.20 | 27.73 | 27.73 | 44.58 | 57.29 | 102.96 | 102.96 | 0.00786 | 0.00786 | 0.00998 | 0.00604 | 18.38 | 24.45Cc |

| RCF | 6.00 | 3.30 | 0.77 | 5.60 | 0.20 | 0.20 | 22.80 | 22.80 | 68.41 | 94.06 | 86.19 | 86.19 | 0.00333 | 0.00333 | 0.00333 | 0.00333 | 19.80 | 32.15Cc |

| Footing | a (m) | b (m) | d (m) | L (m) | L1 (m) | L2 (m) | AsxBp1 (cm2) | AsxBp2 (cm2) | AsxtB2 (cm2) | AsxtB3 (cm2) | AsxtT (cm2) | AsylB (cm2) | AsylT (cm2) | ρp1 | ρp2 | ρyB | ρyT | Amin (m2) | Cmin (USD) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ECF | 2.01 | 4.00 | 0.71 | 6.00 | 0.20 | 1.80 | 18.10 | 58.03 | 63.01 | 16.02 | 103.22 | 83.10 | 98.75 | 0.00333 | 0.00725 | 0.00333 | 0.00409 | 25.26 | 37.97Cc |

| RCF | 9.11 | 2.82 | 0.80 | 6.00 | 0.20 | 2.91 | 21.14 | 31.68 | 68.76 | 33.09 | 130.33 | 74.84 | 74.84 | 0.00333 | 0.00333 | 0.00333 | 0.00333 | 25.69 | 41.79Cc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santiago-Hurtado, G.; Luévanos-Rojas, A.; Moreno-Landeros, V.M.; Diaz-Gurrola, E.R.; Narayanasamy, R.; Cortés-Martínez, F.; López-León, L.D. Mathematical Development for the Minimum Cost of Elliptical Combined Footings. Buildings 2025, 15, 3633. https://doi.org/10.3390/buildings15193633

Santiago-Hurtado G, Luévanos-Rojas A, Moreno-Landeros VM, Diaz-Gurrola ER, Narayanasamy R, Cortés-Martínez F, López-León LD. Mathematical Development for the Minimum Cost of Elliptical Combined Footings. Buildings. 2025; 15(19):3633. https://doi.org/10.3390/buildings15193633

Chicago/Turabian StyleSantiago-Hurtado, Griselda, Arnulfo Luévanos-Rojas, Victor Manuel Moreno-Landeros, Eyran Roberto Diaz-Gurrola, Rajeswari Narayanasamy, Facundo Cortés-Martínez, and Luis Daimir López-León. 2025. "Mathematical Development for the Minimum Cost of Elliptical Combined Footings" Buildings 15, no. 19: 3633. https://doi.org/10.3390/buildings15193633

APA StyleSantiago-Hurtado, G., Luévanos-Rojas, A., Moreno-Landeros, V. M., Diaz-Gurrola, E. R., Narayanasamy, R., Cortés-Martínez, F., & López-León, L. D. (2025). Mathematical Development for the Minimum Cost of Elliptical Combined Footings. Buildings, 15(19), 3633. https://doi.org/10.3390/buildings15193633