Utilization of Desulfurization Gypsum in Alkali-Activated Mortar: Performance Enhancement and Microstructural Evolution

Abstract

1. Introduction

2. Experimental Program

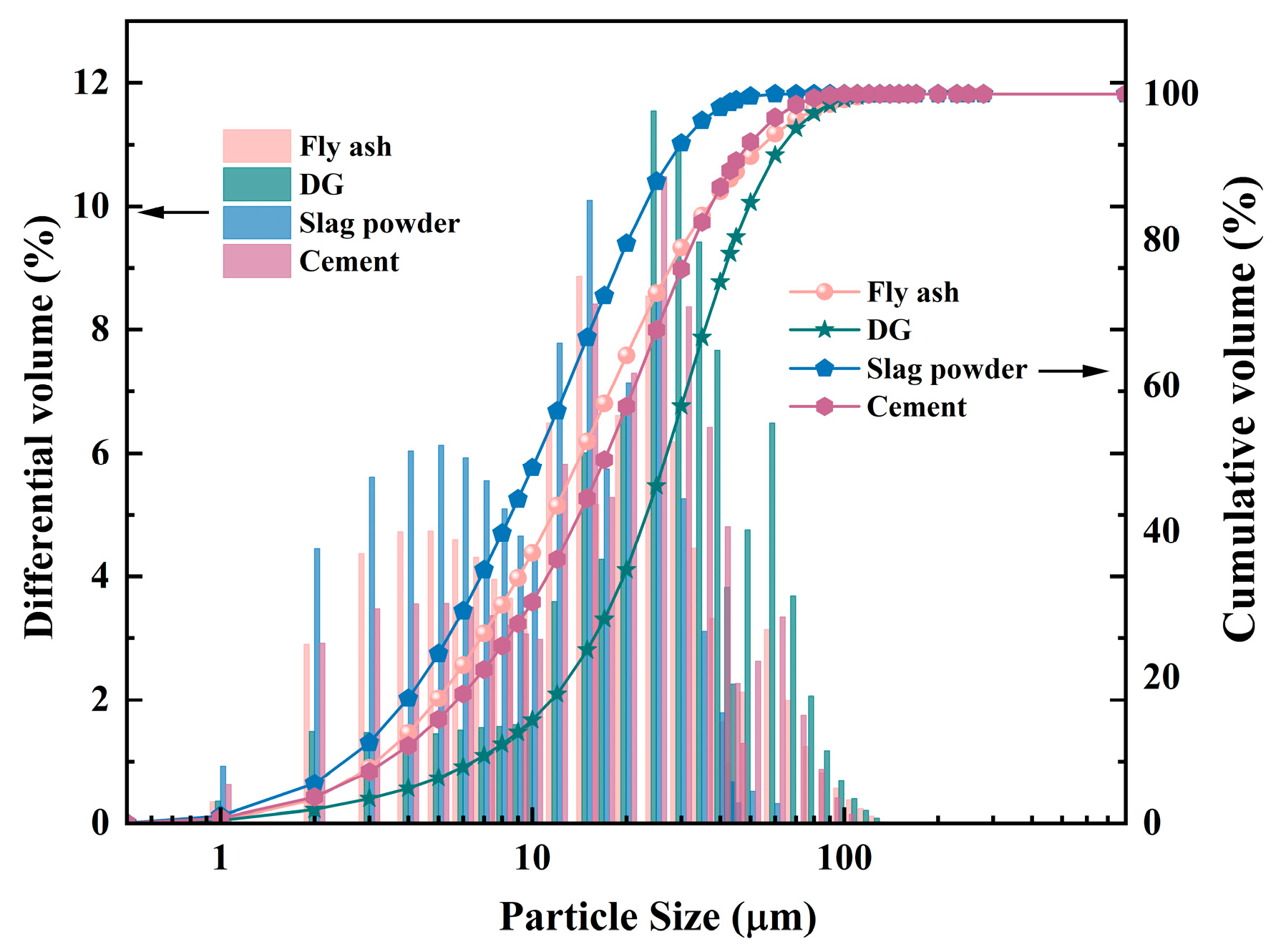

2.1. Raw Materials

2.2. Mix Proportion

2.3. Testing Method

2.3.1. Workability

2.3.2. Mechanical Property

2.3.3. Shrinkage Performance and Corrosion Resistance

2.3.4. Microstructure

3. Results and Discussion

3.1. Workability

3.1.1. Fluidity

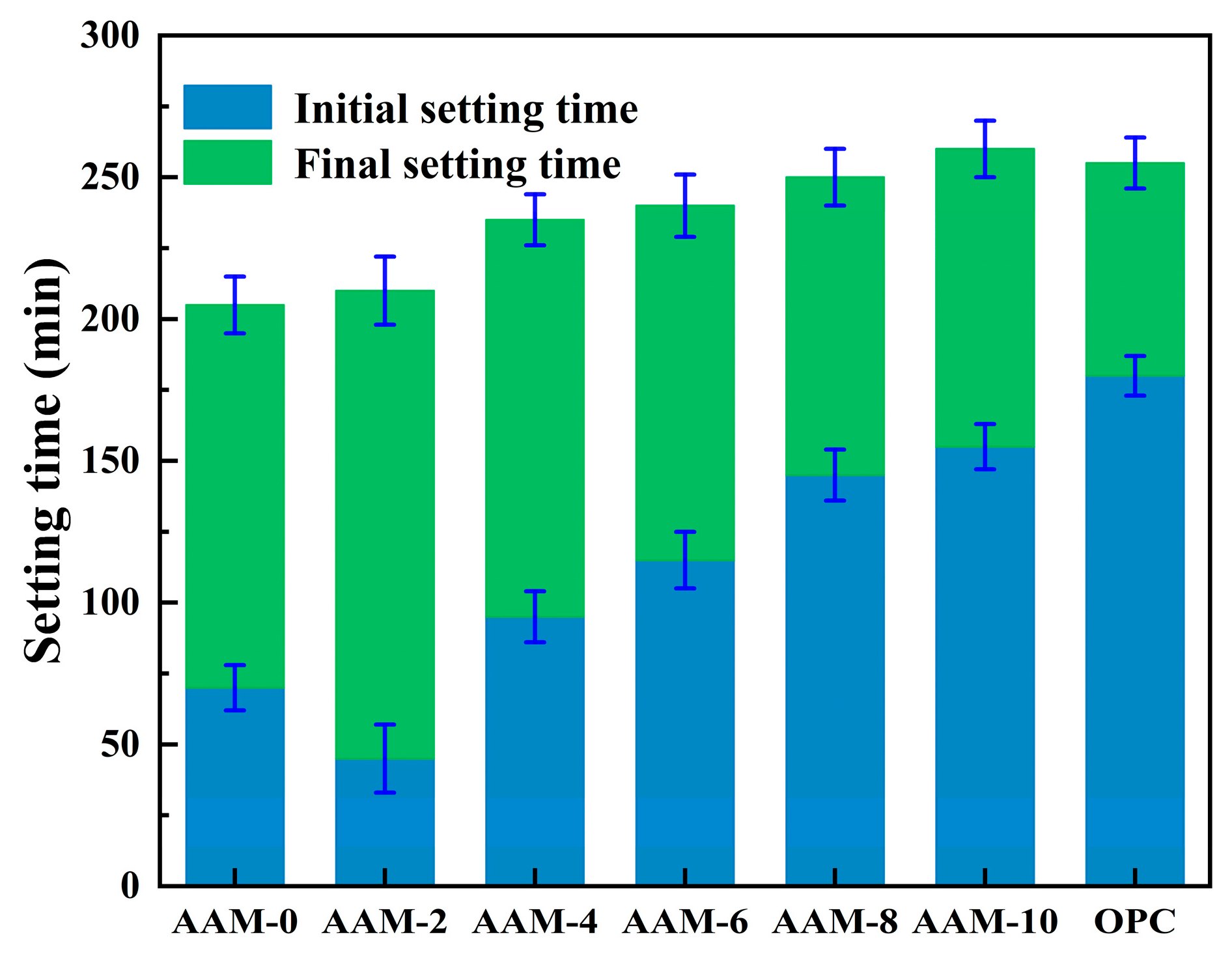

3.1.2. Setting Time

3.2. Mechanical Property

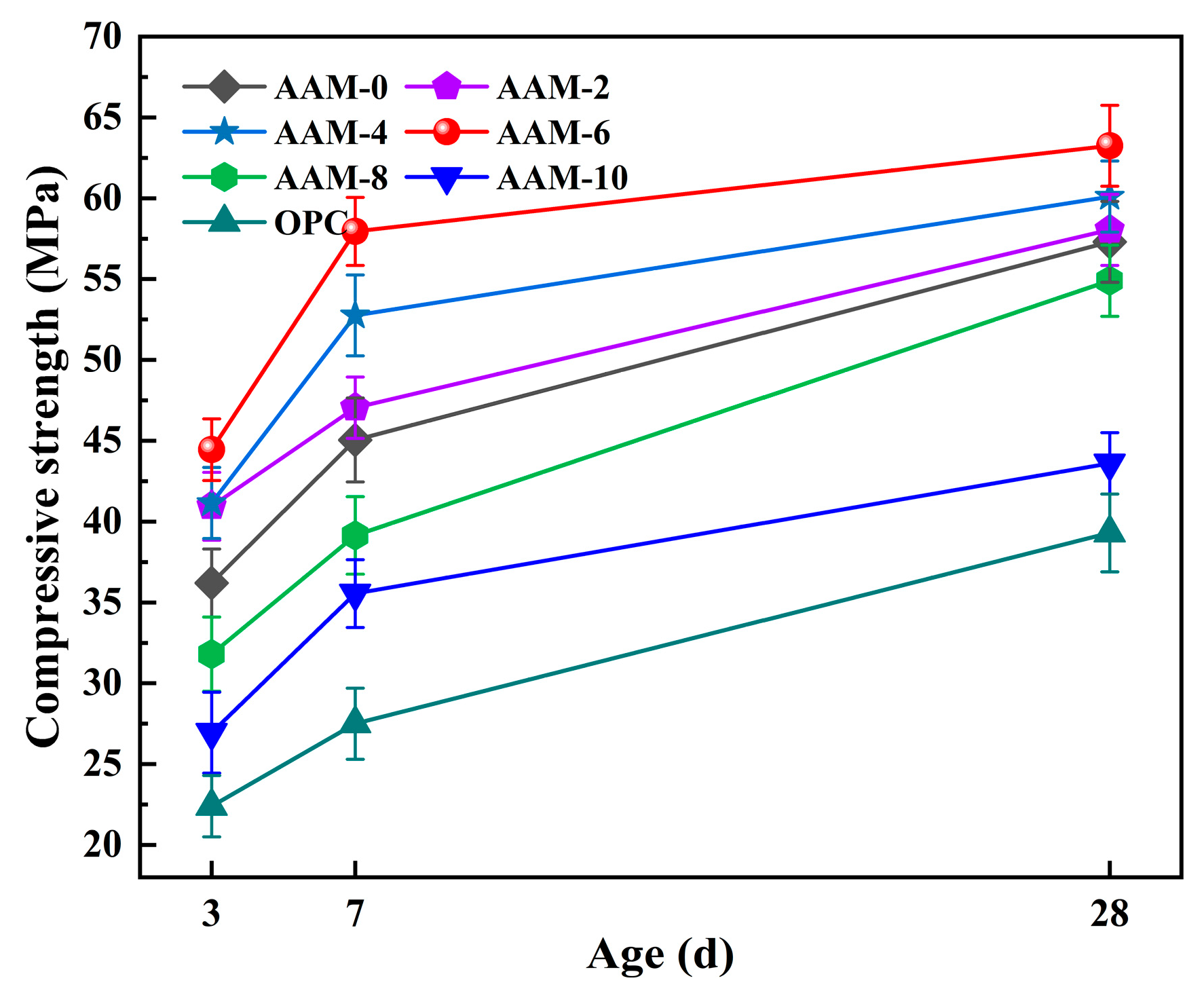

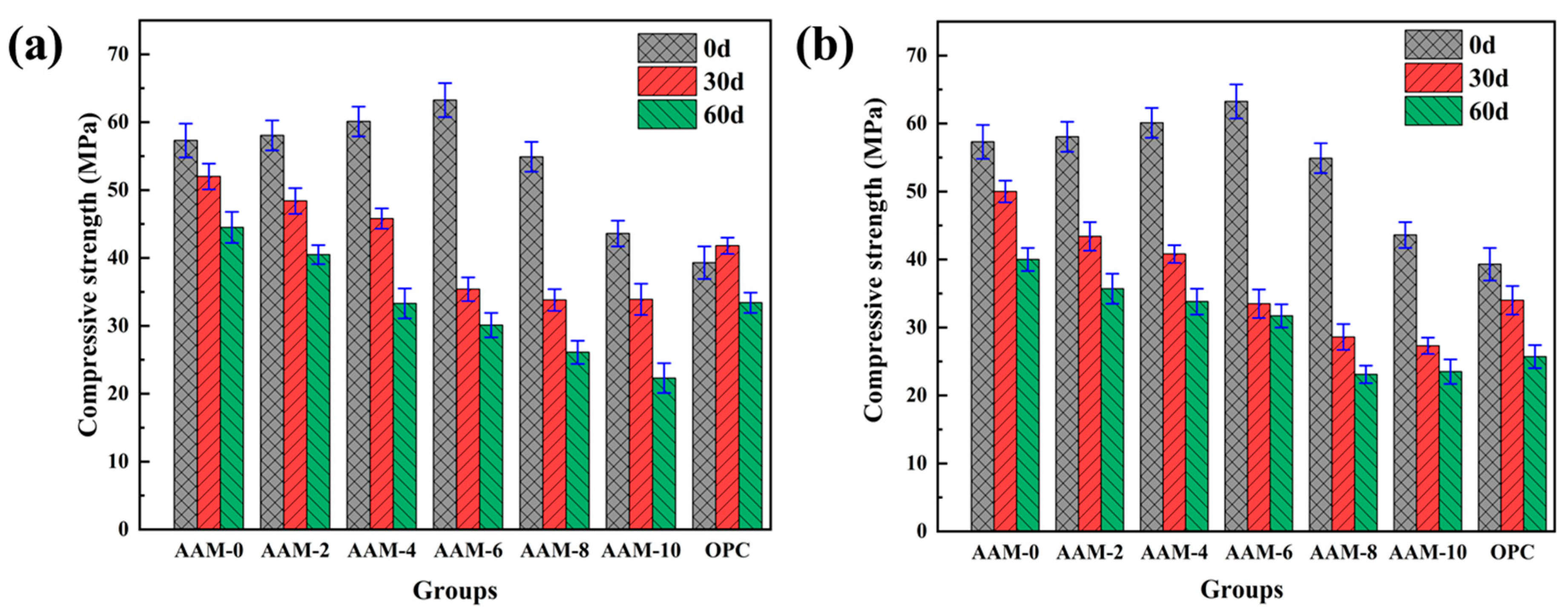

3.2.1. Compressive Strength

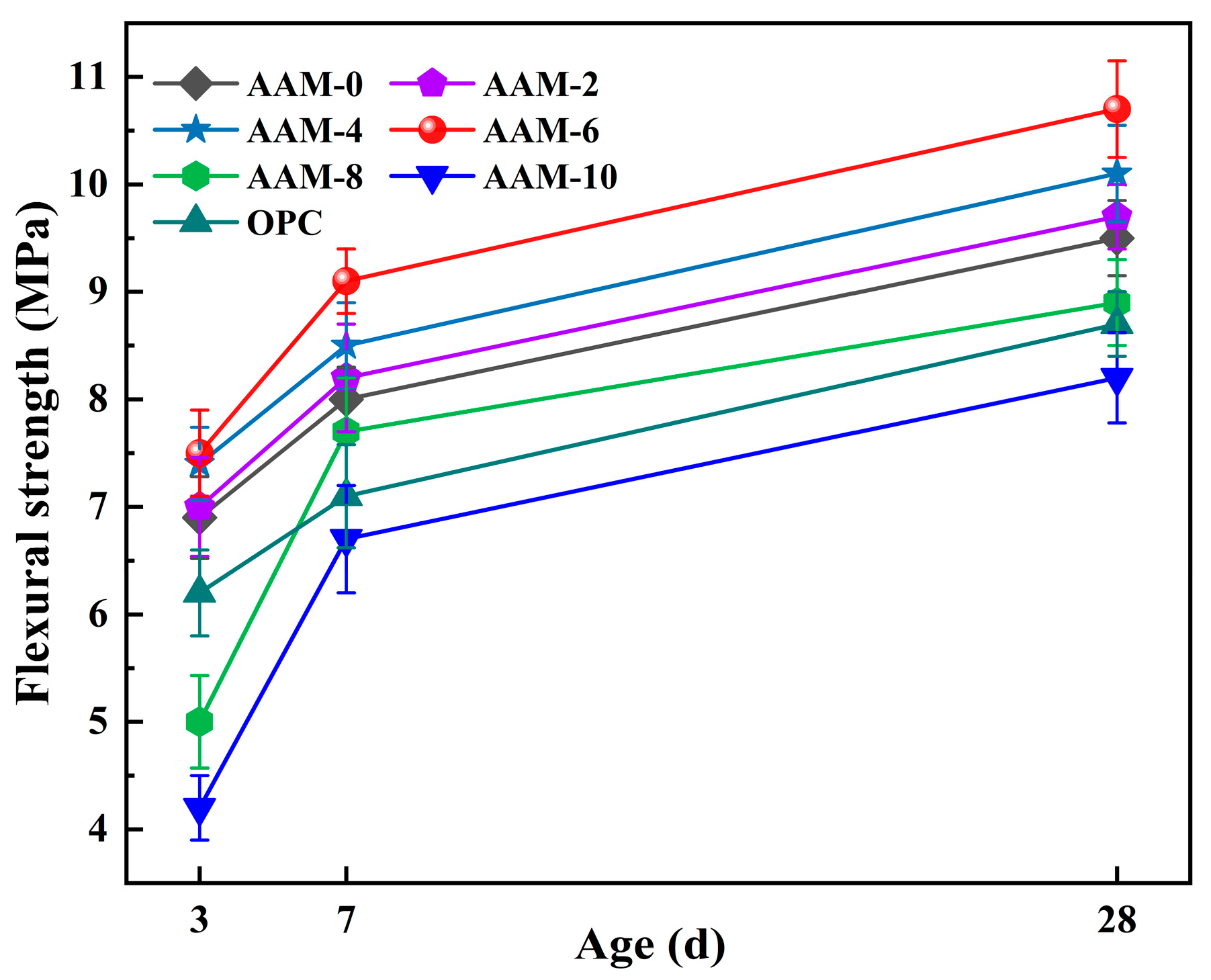

3.2.2. Flexural Strength

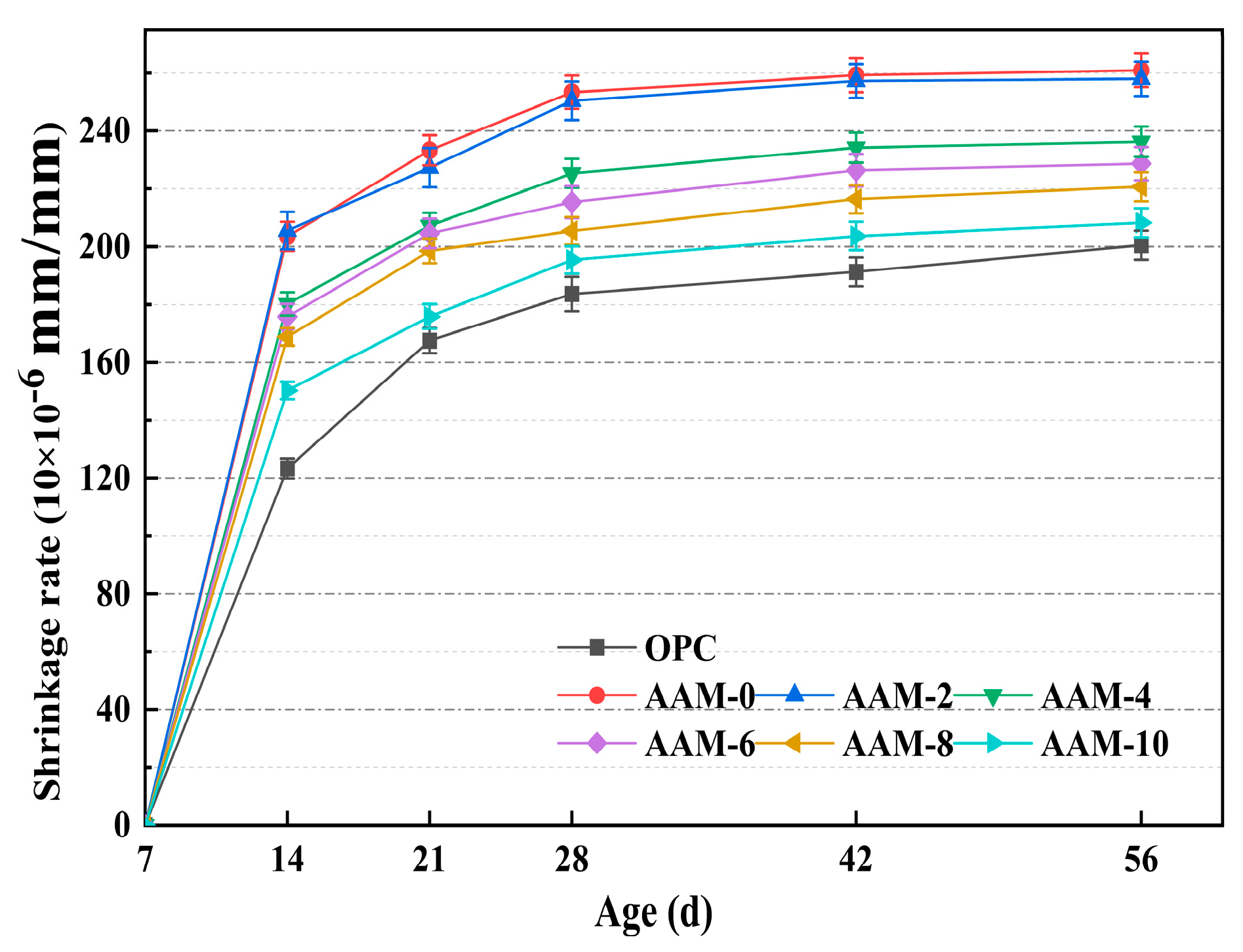

3.3. Drying Shrinkage

3.4. Water Erosion Resistance and Sulfate Resistance

3.5. Microstructure

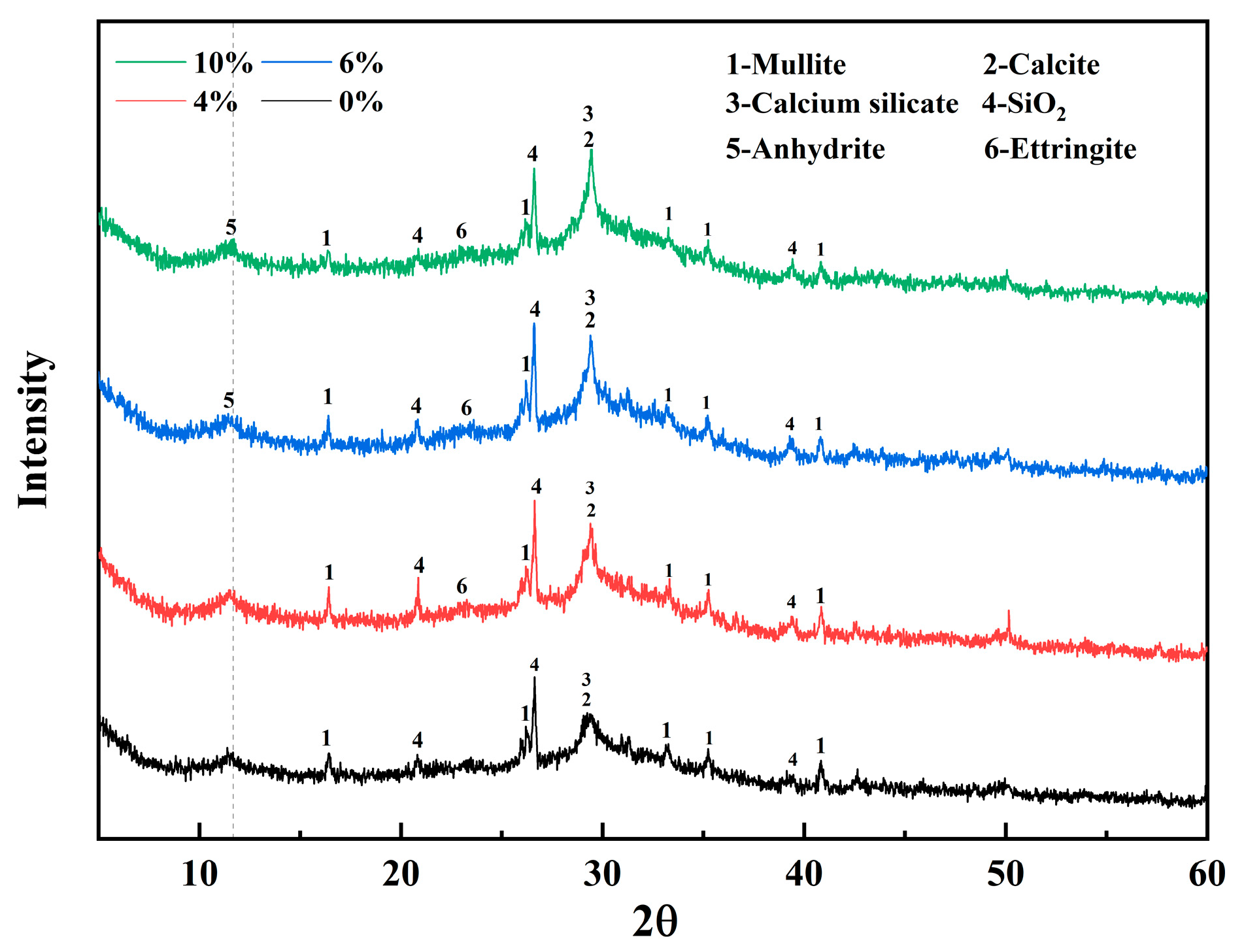

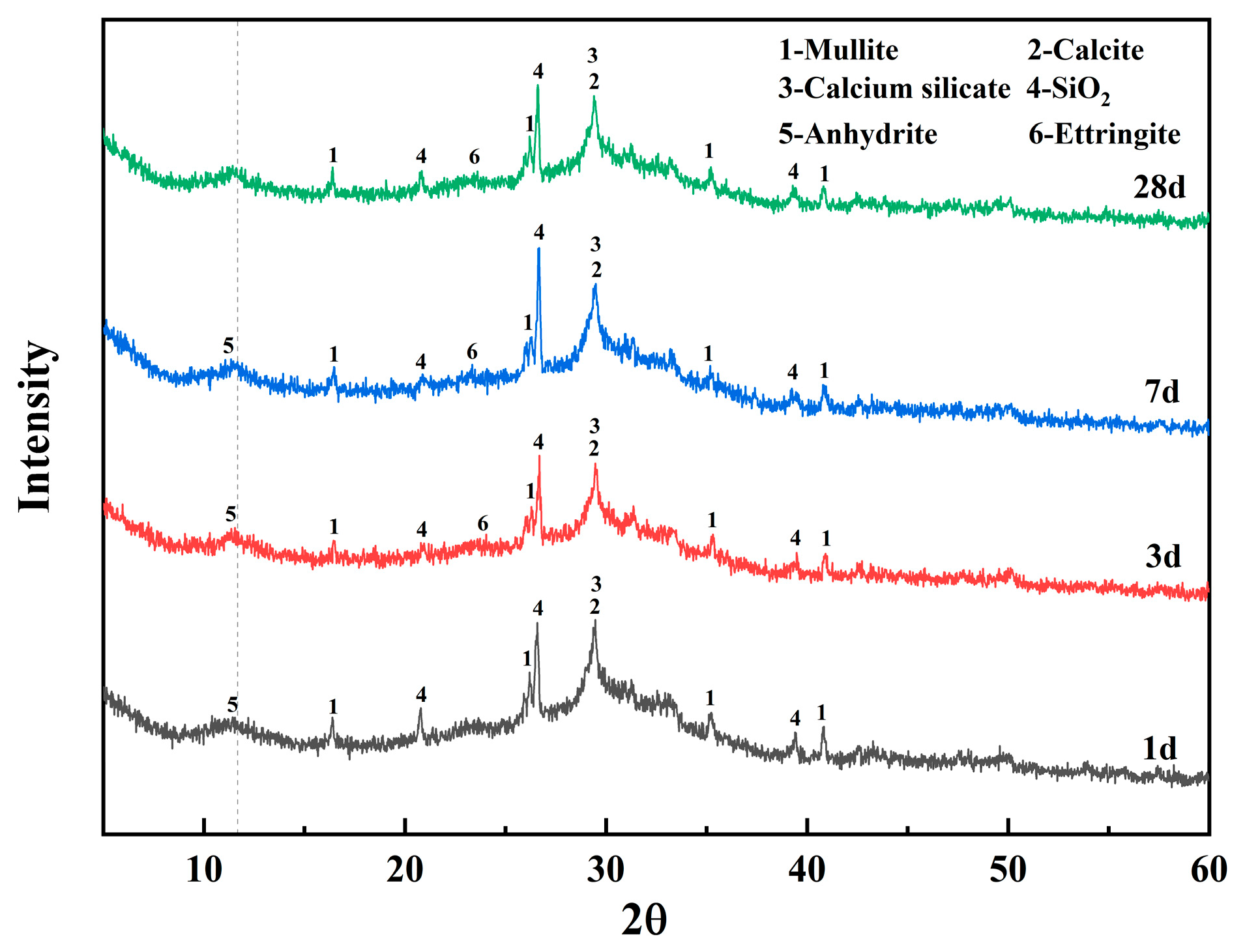

3.5.1. XRD

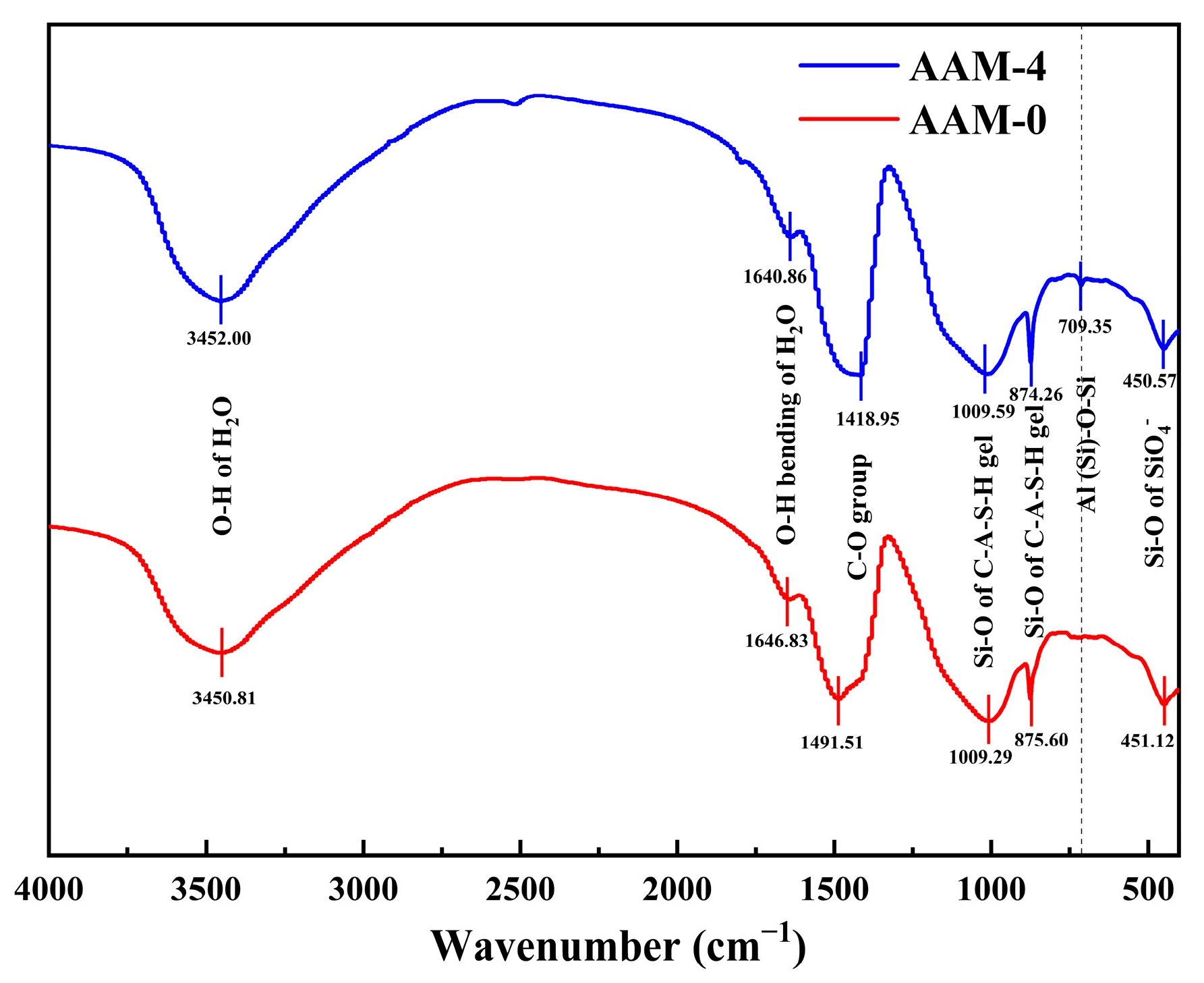

3.5.2. FTIR

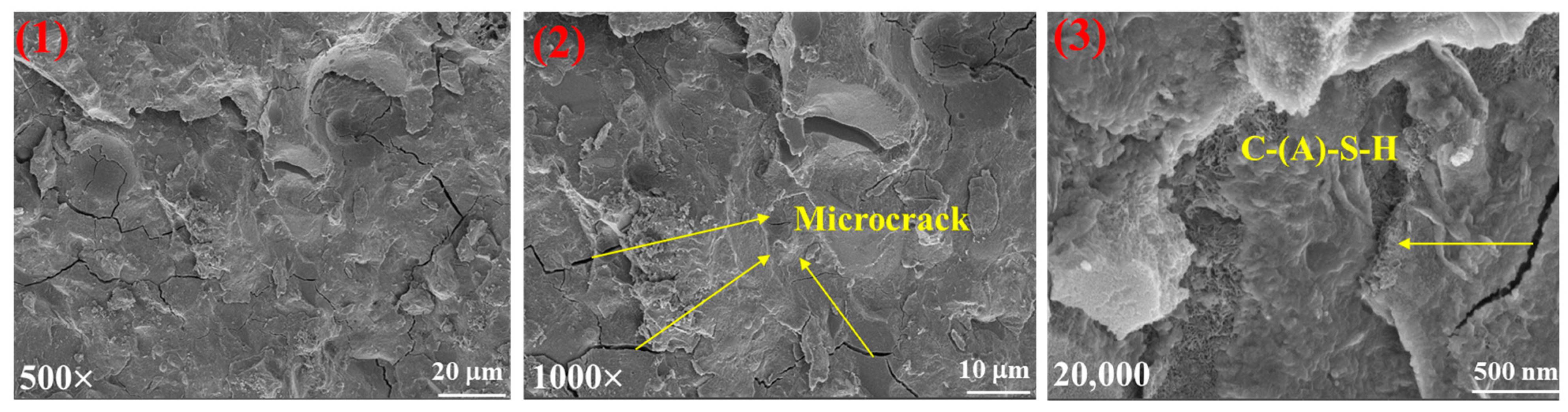

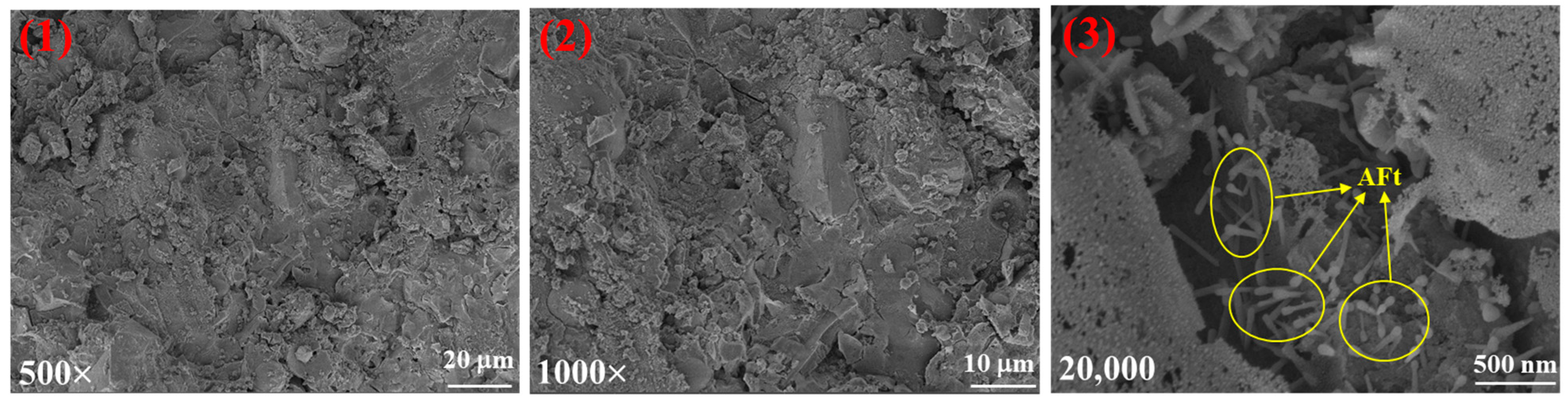

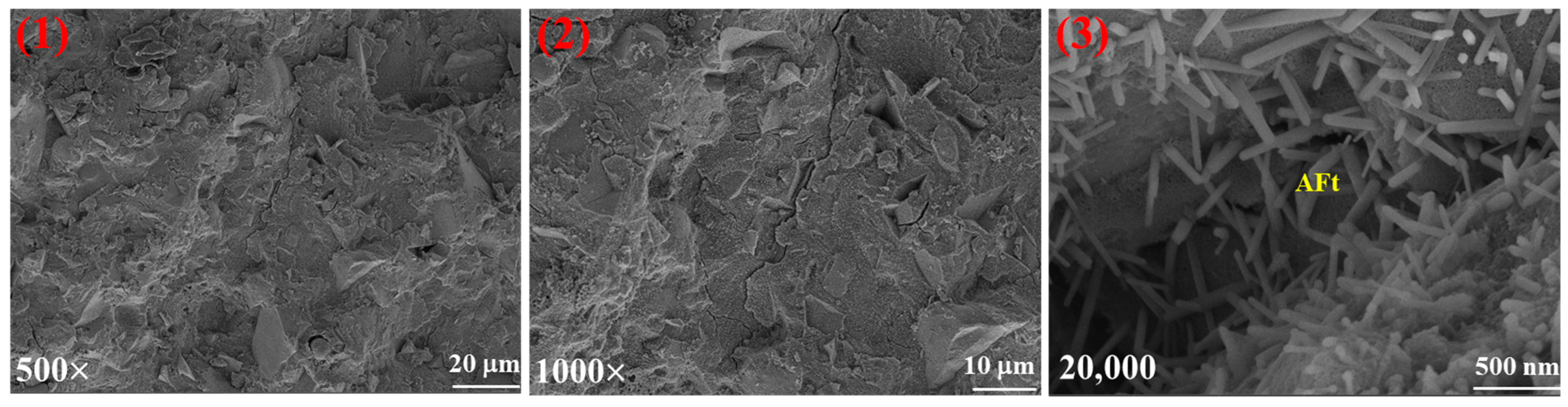

3.5.3. SEM

4. Conclusions

- (1)

- The fluidity of the AAM gradually decreased with increasing DG content, while the setting time showed the opposite change rule. When the DG content was 10%, the fluidity of AAM reached 126 mm, and its setting time was equivalent to that of OPC.

- (2)

- DG can effectively improve the shrinkage performance of AAM, while reducing its resistance to water erosion and sulfate erosion. With a DG content of 10%, the 56-d drying shrinkage of AAM was reduced by 20.2%.

- (3)

- The mechanical properties first increased and then decreased with increasing DG content. When the DG content was 6%, the 28-day compressive strength of AAM reached 63.25 MPa and the flexural strength was 10.7 MPa. After 60 days of water corrosion and sulfate corrosion, the compressive strength of AAM-6 was significantly better than that of OPC under the same conditions.

- (4)

- Microscopic analysis shows that DG contributes to the formation of needle-like AFt crystals in alkali-activated systems. AFt grew continuously during the curing process, filling the voids of the hydration product and forming a dense microstructure, which improved the mechanical and contractile properties of the material.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hou, Z.; Xiong, Y.; Luo, J.; Fang, Y.; Haris, M.; Chen, Q.; Yue, Y. International experience of carbon neutrality and prospects of key technologies: Lessons for China. Pet. Sci. 2023, 20, 893–909. [Google Scholar] [CrossRef]

- Supriya, R.; Chaudhury, U.; Sharma, P.; Thapliyal, L. Singh, Low-CO2 emission strategies to achieve net zero target in cement sector. J. Clean. Prod. 2023, 417, 137466. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Wang, S.; Feng, X. Comparative study on the effect of agricultural waste biochar on the properties of cement mortar. Ind. Crops Prod. 2025, 227, 120854. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, B.; Fan, C. Research progress on two-dimensional carbon nanomaterials modified alkali-activated cementitious materials: A review. J. Build. Eng. 2024, 92, 109690. [Google Scholar] [CrossRef]

- Zhong, M.; Meng, J.; Ning, B.; Na, F.; Cui, T.; Shi, X.; Cui, T. Preparation and alkali excitation mechanism of coal gangue-iron ore tailings non-sintering ceramsite. Constr. Build. Mater. 2024, 426, 136209. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Wang, S.; Xia, X.; Feng, X. Eco-friendly utilization of plant-derived biochar as partial replacement of sand in alkali-activated mortar. Constr. Build. Mater. 2025, 495, 143723. [Google Scholar] [CrossRef]

- Li, B.; Wu, J.; Song, N.; Zheng, Y.; Lu, Y.; Chi, Y. Time-dependent drying shrinkage model for alkali-activated slag/fly ash-based concrete modified with multi-walled carbon nanotubes. J. Build. Eng. 2025, 111, 113082. [Google Scholar] [CrossRef]

- Nassar, A.; Sivanandam, S.; Saran, D.; Sundar, S.B.S.; Kathirvel, P.; Murali, G.; Dixit, S. Durability assessment of sustainable one-part alkali activated concrete produced from agricultural and industrial waste activators under aggressive environmental conditions. Constr. Build. Mater. 2025, 486, 141823. [Google Scholar] [CrossRef]

- Xi, X.; Zheng, Y.; Zhuo, J.; Zhang, P.; Golewski, G.L.; Du, C. Influence of water glass modulus and alkali content on the properties of alkali-activated thermally activated recycled cement. Constr. Build. Mater. 2024, 452, 138867. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, Z.; Sun, X.; Zhu, X. Utilization of surface-modified fly ash cenosphere waste as an internal curing material to intensify concrete performance. J. Clean. Prod. 2022, 358, 132042. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Dalvand, A.; Firouz, R.M.; Illikainen, M. Drying shrinkage in alkali-activated binders-a critical review. Constr. Build. Mater. 2018, 190, 533–550. [Google Scholar] [CrossRef]

- Deng, J.; Zhu, X.; Xiong, D.; Li, Q.; Yang, C.; Yang, K.; Basheer, M. Mitigation of autogenous shrinkage of alkali-activated slag mortar by stearate salts. Constr. Build. Mater. 2023, 384, 131383. [Google Scholar] [CrossRef]

- Tran, N.P.; Nguyen, T.N.; Ngo, T.D. The role of organic polymer modifiers in cementitious systems towards durable and resilient infrastructures: A systematic review. Constr. Build. Mater. 2022, 360, 129562. [Google Scholar] [CrossRef]

- Ma, H.; Fu, C.; Huang, K.; Dai, E.; Zhang, S.; Fang, Y.; Feng, J. Study on the characteristics of alkali-activated fly ash-slag improved by cenosphere: Hydration and drying shrinkage. Constr. Build. Mater. 2023, 372, 130822. [Google Scholar] [CrossRef]

- Liu, J.; Hu, L.; Tang, L.; Zhang, E.Q.; Ren, J. Shrinkage behaviour, early hydration and hardened properties of sodium silicate activated slag incorporated with gypsum and cement. Constr. Build. Mater. 2020, 248, 118687. [Google Scholar] [CrossRef]

- Shen, J.; Li, Y.; Lin, H.; Li, Y.; Ye, J.; Zhang, W. New insights on the action mechanisms of anhydrite on autogenous shrinkage and mechanical properties of clinkerless Ultra-high performance concrete. Constr. Build. Mater. 2025, 486, 141949. [Google Scholar] [CrossRef]

- Liu, P.; Gu, Y.; Zhong, J.; Kuang, J.; Huang, X.; Jin, F.; Zhao, M.; Mo, L. Carbonated steel slag powder in cement: Retardation mechanism and triethanolamine-enhanced hydration strategy. Constr. Build. Mater. 2025, 492, 142881. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, X.; Cai, Z.; Liu, R.; Zhu, P.; Yan, X.; Yu, J.; He, J. Synergistic mechanism of the performance and recyclability of recycled fine aggregate concrete under chloride salt dry-wet cycles by composite mineral admixtures. Constr. Build. Mater. 2025, 491, 142683. [Google Scholar] [CrossRef]

- An, Q.; Pan, H.; Zhao, Q.; Du, S.; Wang, D. Strength development and microstructure of recycled gypsum-soda residue-GGBS based geopolymer. Constr. Build. Mater. 2022, 331, 127312. [Google Scholar] [CrossRef]

- Zhao, Y.; Yao, J.; Zhang, S.; Wang, X.; Huang, X.; Ni, W. Properties and hydration mechanism of eco-friendly binder from circulating fluidized bed bottom ash, carbide slag, and desulfurization gypsum. Constr. Build. Mater. 2024, 457, 139411. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Injorhor, B.; Phoo-ngernkham, T.; Damrongwiriyanupap, N.; Li, L.Y.; Sukontasukkul, P.; Chindaprasirt, P. Drying shrinkage, strength and microstructure of alkali-activated high-calcium fly ash using DSG-gypsum and dolomite as expansive additive. Cem. Concr. Compos. 2020, 114, 103760. [Google Scholar]

- Li, Y.; Liu, X.; Li, Z.; Ren, Y.; Wang, Y.; Zhang, W. Preparation, characterization and application of red mud, fly ash and desulfurized gypsum based eco-friendly road base materials. J. Clean. Prod. 2021, 284, 124777. [Google Scholar] [CrossRef]

- Duan, D.; Liao, H.; Wei, F.; Wang, J.; Wu, J.; Cheng, F. Solid waste-based dry-mix mortar using fly ash, carbide slag, and flue gas desulfurization gypsum. J. Mater. Res. Technol. 2022, 21, 3636–3649. [Google Scholar]

- Ying, J.; Yang, Z.; Xie, Z.; Tian, Z.; Liang, L. Enhancing cement-based grouting materials with water-based three-dimensional porous graphene nanofluid: Effects on pore structure, hydration products, and multi-scale mechanical properties. Constr. Build. Mater. 2025, 493, 143189. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.; Liu, C.; Wang, L.; Chen, M.; Yue, G. Study of mix design and performance of alkali-activated concrete with recycled concrete aggregate. Constr. Build. Mater. 2023, 400, 132882. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Wang, S.; Feng, X. Study on improving the properties of alkali-activated materials by using corncob ash. ACS Omega 2025, 10, 16291–16299. [Google Scholar] [CrossRef]

- GB/T 2419-2024; Method for Determining the Flowability of Cement Mortar. Cement New Materials Institute, China National Building Materials Academy: Beijing, China, 2024.

- GB/T 1346-2024; Test Methods for Water Requirement of Standard Consistency, Setting Time and Soundness of the Portland Cement. National Technical Committee for Cement Standardization: Beijing, China, 2024.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). General Administration for National Market Supervision: Beijing, China, 2021.

- JGJ/T70-2009; Standard for Test Method of Performance on Building Mortar. Shanxi Academy of Building Research: Shanxi, China, 2009.

- ASTM C267-01; Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes. Annual Book of ASTM Standard: Philadelphia, PA, USA, 2012.

- Wang, W.; Li, L.; Ren, Z.; Yang, J.; Kong, T. Filling mechanism of coal gasification fly ash in lightweight gypsum blocks with a high water-to-gypsum ratio. Constr. Build. Mater. 2025, 460, 139828. [Google Scholar] [CrossRef]

- Luo, T.; Ma, Y.; Xie, H.; Li, F.; Li, Z.; Fu, J. Piezoresistivity of carbon fiber-reinforced alkali-activated materials: Effect of fly ash microspheres and quartz sands. Constr. Build. Mater. 2024, 425, 136125. [Google Scholar] [CrossRef]

- Nanda, B.; Mishra, J.; Patro, S.K. Synthesis of rice husk ash based alkaline activators for geopolymer binder systems: A review. J. Build. Eng. 2024, 91, 109694. [Google Scholar] [CrossRef]

- Parhizkar, A.; Nazarpour, A.; Khayat, N. Investigation of geotechnical and microstructure characteristics of gypsum soil using ground granulated blast-furnace slag (GGBS), fly ash, and lime. Constr. Build. Mater. 2024, 418, 135358. [Google Scholar] [CrossRef]

- Hu, Y.; Ren, X.; Ye, J.; Luan, Z.; Xiao, Y.; Zhang, W. Performance of a steel slag-based supplementary cementitious material via the synergistic modification of binary fly ash and gypsum system. Constr. Build. Mater. 2023, 405, 133186. [Google Scholar] [CrossRef]

- Mareya, M.; Tchadjie, L.; Sithole, T. Turning fly ash and waste gypsum into a resource for backfilling applications. Case Stud. Constr. Mater. 2024, 20, e02703. [Google Scholar] [CrossRef]

- Luan, Y.; Wang, J.; Ma, T.; Wang, S.; Li, C. Modification mechanism of flue gas desulfurization gypsum on fly ash and ground granulated blast-furnace slag alkali-activated materials: Promoting green cementitious material. Constr. Build. Mater. 2023, 396, 132400. [Google Scholar] [CrossRef]

- Fan, K.; Cui, S.; Yao, Y. Fire resistance performance of clinker-free cementitious materials produced from phosphorus slag, calcium carbide slag, desulfurization gypsum, and metakaolin. Constr. Build. Mater. 2025, 467, 140400. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, X.; Guo, W. Effect of alkaline activator on SIOT-GGBS-MK based alkali-activated mortar. Constr. Build. Mater. 2025, 467, 140322. [Google Scholar] [CrossRef]

- Ma, Y.; Chu, H.; Rong, H.; Ba, M. Influence of sodium silicate on the properties of ground granulated blast furnace slag-desulfurized gypsum (GGBS-DG) based composite cementitious materials and LCA evaluation. Sustain. Chem. Pharm. 2025, 46, 102066. [Google Scholar] [CrossRef]

- Shi, P.; Falliano, D.; Vecchio, F.; Marano, G.C. Investigation on the compressive strength and durability properties of alkali-activated slag mortar: Effect of superabsorbent polymer dosage and water content. Dev. Built Environ. 2024, 17, 100322. [Google Scholar] [CrossRef]

- Lv, F.; Wang, L.; An, H.; Chen, S.; Shu, J.; Kong, D. Effects of hybrid fibers on properties of desulfurized gypsum-based composite cementitious materials. Constr. Build. Mater. 2023, 392, 131840. [Google Scholar] [CrossRef]

- Xue, L.; Ni, Z.; Zhou, Z.; Zhang, Z.; Xiong, H.; Wang, H.; Zhuge, X.; Liu, H. Effects of desulfurized gypsum on shrinkage behavior of alkali-activated slag (AAS) and hybrid alkali-activated cement (HAC). Case Stud. Constr. Mater. 2025, 22, e04320. [Google Scholar]

- Yang, J.; Meng, T.; Han, J.; Qiao, Y.; Chen, X.; Wang, Q.; Zhang, T. Mechanical properties and microstructure of circulating fluidized bed fly ash-based hybrid alkali-activated cement. Constr. Build. Mater. 2025, 486, 142006. [Google Scholar]

- Feng, C.; Wang, Y.; Wang, L.; Zhao, X.; Zhang, W.; Zhu, J.; Du, M. Improving the water resistance of gypsum-based building materials with slag activated by calcium oxide. J. CO2 Util. 2024, 90, 102996. [Google Scholar] [CrossRef]

- Wang, X.; Li, F.; Gao, F.; Wang, Y.; Li, M.; Wang, J.; Guo, X.; Nikolayevich, K.S.; Nikolaevich, L.S. Characteristics of alkali-activated slag mortar under combined freeze-thaw cycles and sulfate exposure: Microstructural and mechanical insights. Constr. Build. Mater. 2025, 493, 143087. [Google Scholar] [CrossRef]

- Lou, Y.; Ma, S.; Wang, Y.; Wu, W.; Wang, X. Effect of multi-factors on the performance of one-part geopolymer mortar against magnesium sulfate erosion. Adv. Cem. Res. 2025, 37, 199–213. [Google Scholar] [CrossRef]

- Shu, T.; Xu, J.; Guo, P.; Tian, Y.; Liu, D. Experimental study on durability and performance evaluation of alkali activated metakaolin slag concrete under sulphate dry-wet cycle. Case Stud. Constr. Mater. 2025, 23, e05310. [Google Scholar] [CrossRef]

- Ponomar, V.; Kamali, S.; Luukkonen, T.; Hajimohammadi, A.; Kilpimaa, K. The effect of gypsum on reaction kinetics and microstructure of alkali-activated CaO-FeOx-SiO2 slag. Cem. Concr. Compos. 2025, 160, 106033. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Zhang, W.; Li, Z.; Zhang, Y.; Li, Y.; Ren, Y. Effects of Si/Al ratio on the efflorescence and properties of fly ash based geopolymer. J. Clean. Prod. 2020, 244, 118852. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, Y.; Liu, T.; Wan, Q.; Zheng, D. Effect of high alumina-based solid waste on efflorescence behavior of alkali-activated steel slag. Constr. Build. Mater. 2022, 349, 128804. [Google Scholar]

- Pradhan, S.S.; Mishra, U.; Biswal, B.K. Mechanical and microstructural study of slag based alkali activated concrete incorporating RHA. Constr. Build. Mater. 2023, 400, 132685. [Google Scholar] [CrossRef]

- Yang, M.; Zheng, Y.; Li, X.; Yang, X.; Rao, F.; Zhong, L. Durability of alkali-activated materials with different C-S-H and N-AS-H gels in acid and alkaline environment. J. Mater. Res. Technol. 2022, 16, 619–630. [Google Scholar]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Others | |

|---|---|---|---|---|---|---|---|

| Cement | 52.78 | 21.23 | 9.8 | 5.72 | 3.24 | 3.98 | 3.25 |

| Slag powder | 38.83 | 28.85 | 18.56 | 0.31 | 7.43 | - | 6.02 |

| Fly ash | 3.9 | 46.5 | 26.23 | 3.54 | 0.95 | - | 18.88 |

| DG | 38.10 | 7.67 | 1.78 | 1.46 | 0.7 | 41.14 | 9.15 |

| Cementitious Materials | Water Glass | NaOH | Sand | Water-Binder Ratio | ||||

|---|---|---|---|---|---|---|---|---|

| Cement | Slag Powder | FA | DG | |||||

| AAM-0 | 0 | 308 | 132.0 | 0 | 54.71 | 13.85 | 745 | 0.42 |

| AAM-2 | 0 | 308 | 123.2 | 8.8 | 54.71 | 13.85 | 745 | 0.42 |

| AAM-4 | 0 | 308 | 114.4 | 17.6 | 54.71 | 13.85 | 745 | 0.42 |

| AAM-6 | 0 | 308 | 105.6 | 26.4 | 54.71 | 13.85 | 745 | 0.42 |

| AAM-8 | 0 | 308 | 96.8 | 35.2 | 54.71 | 13.85 | 745 | 0.42 |

| AAM-10 | 0 | 308 | 88.0 | 44.0 | 54.71 | 13.85 | 745 | 0.42 |

| OPC | 440 | 0 | 0 | 0 | 0 | 0 | 745 | 0.42 |

| Mixes | Mass Change in AAM with DG After Immersion Test (%) | |||

|---|---|---|---|---|

| 30 Days | 60 Days | |||

| H2O | MgSO4 | H2O | MgSO4 | |

| AAM-0 | 1.3 | 1.2 | 2.0 | 2.0 |

| AAM-2 | 1.6 | 1.6 | 2.1 | 2.7 |

| AAM-4 | 1.4 | 3.2 | 2.3 | 3.7 |

| AAM-6 | 1.3 | 2.8 | 2.5 | 4.2 |

| AAM-8 | 1.0 | 3.0 | 2.2 | 4.3 |

| AAM-10 | 1.6 | 3.0 | 2.8 | 4.4 |

| OPC | 2.7 | 2.2 | 3.6 | 3.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Wang, X.; Yu, W.; Zhao, Y.; Li, Z. Utilization of Desulfurization Gypsum in Alkali-Activated Mortar: Performance Enhancement and Microstructural Evolution. Buildings 2025, 15, 3628. https://doi.org/10.3390/buildings15193628

Zhou X, Wang X, Yu W, Zhao Y, Li Z. Utilization of Desulfurization Gypsum in Alkali-Activated Mortar: Performance Enhancement and Microstructural Evolution. Buildings. 2025; 15(19):3628. https://doi.org/10.3390/buildings15193628

Chicago/Turabian StyleZhou, Xiaolong, Xinyan Wang, Wenjing Yu, Yuhui Zhao, and Zhonghao Li. 2025. "Utilization of Desulfurization Gypsum in Alkali-Activated Mortar: Performance Enhancement and Microstructural Evolution" Buildings 15, no. 19: 3628. https://doi.org/10.3390/buildings15193628

APA StyleZhou, X., Wang, X., Yu, W., Zhao, Y., & Li, Z. (2025). Utilization of Desulfurization Gypsum in Alkali-Activated Mortar: Performance Enhancement and Microstructural Evolution. Buildings, 15(19), 3628. https://doi.org/10.3390/buildings15193628