Axial Compression and Uplift Performance of Continuous Helix Screw Piles

Abstract

1. Introduction

2. Pile Geometry and Material

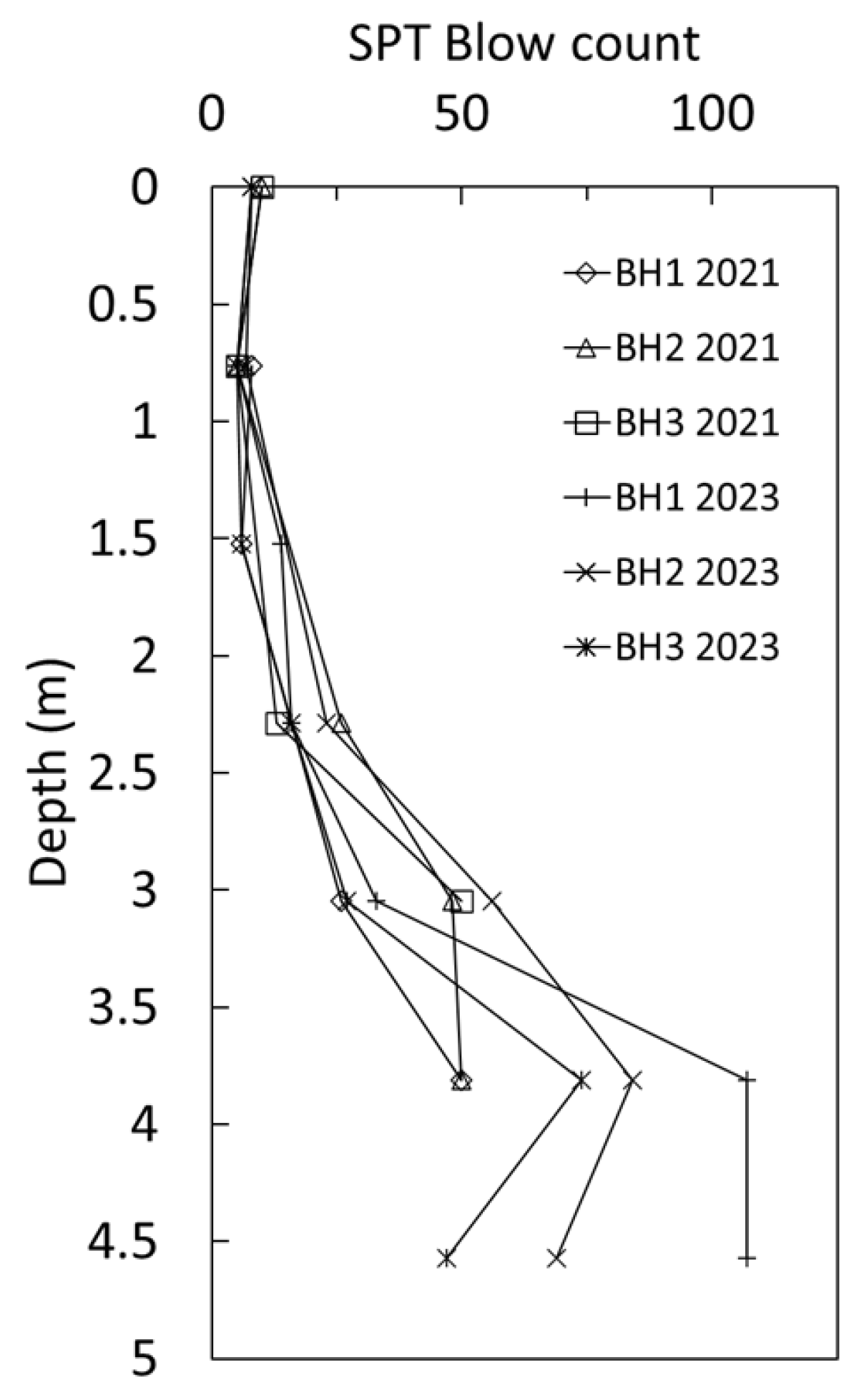

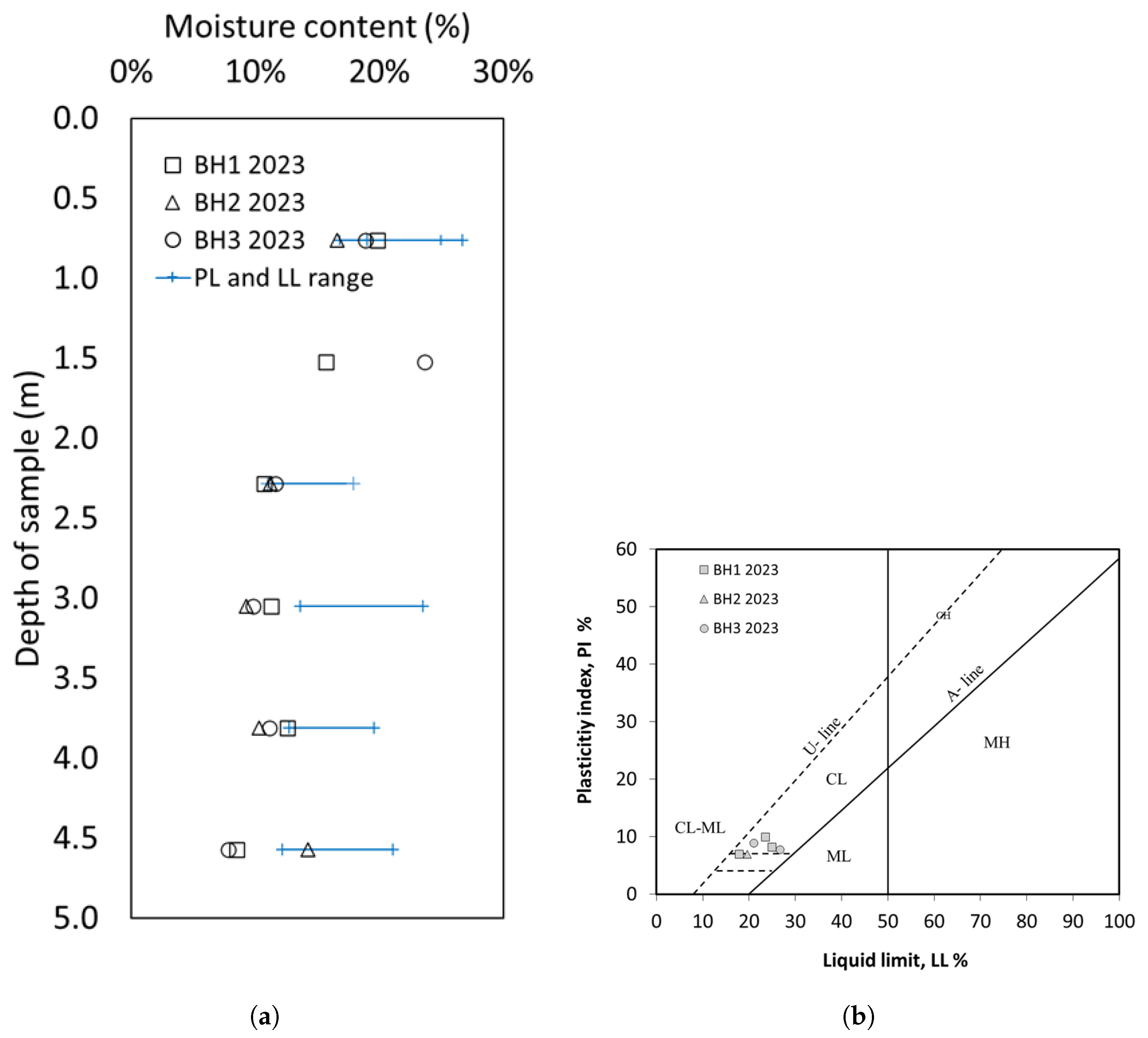

3. Site Investigation

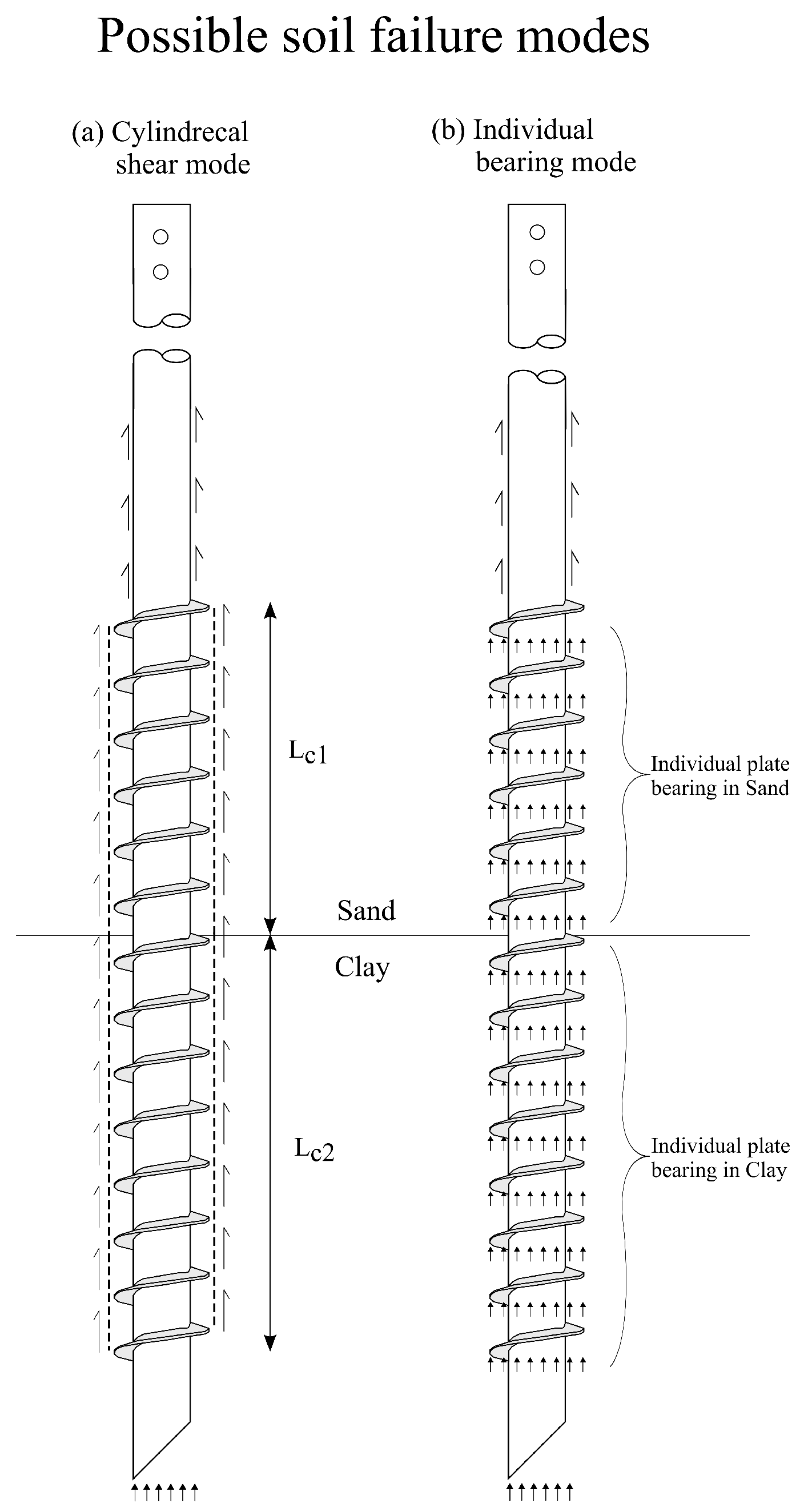

4. Estimated Pile Capacity

5. Experimental Program

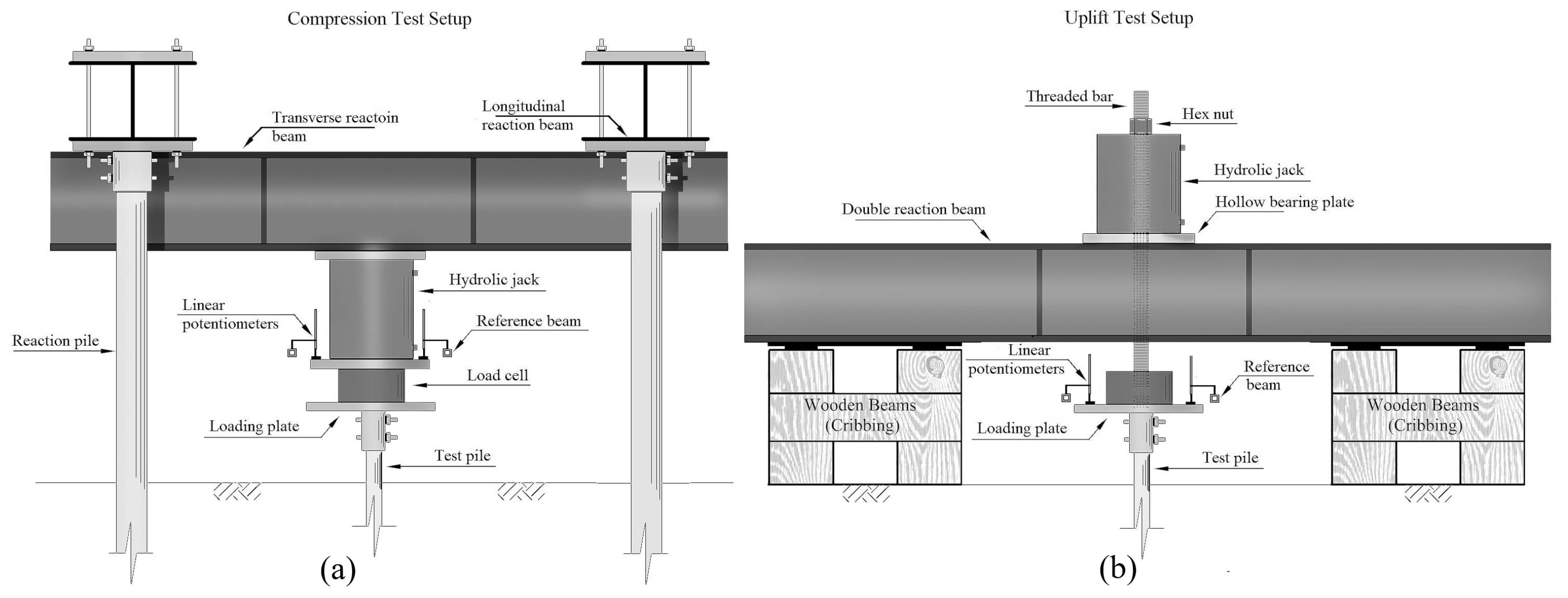

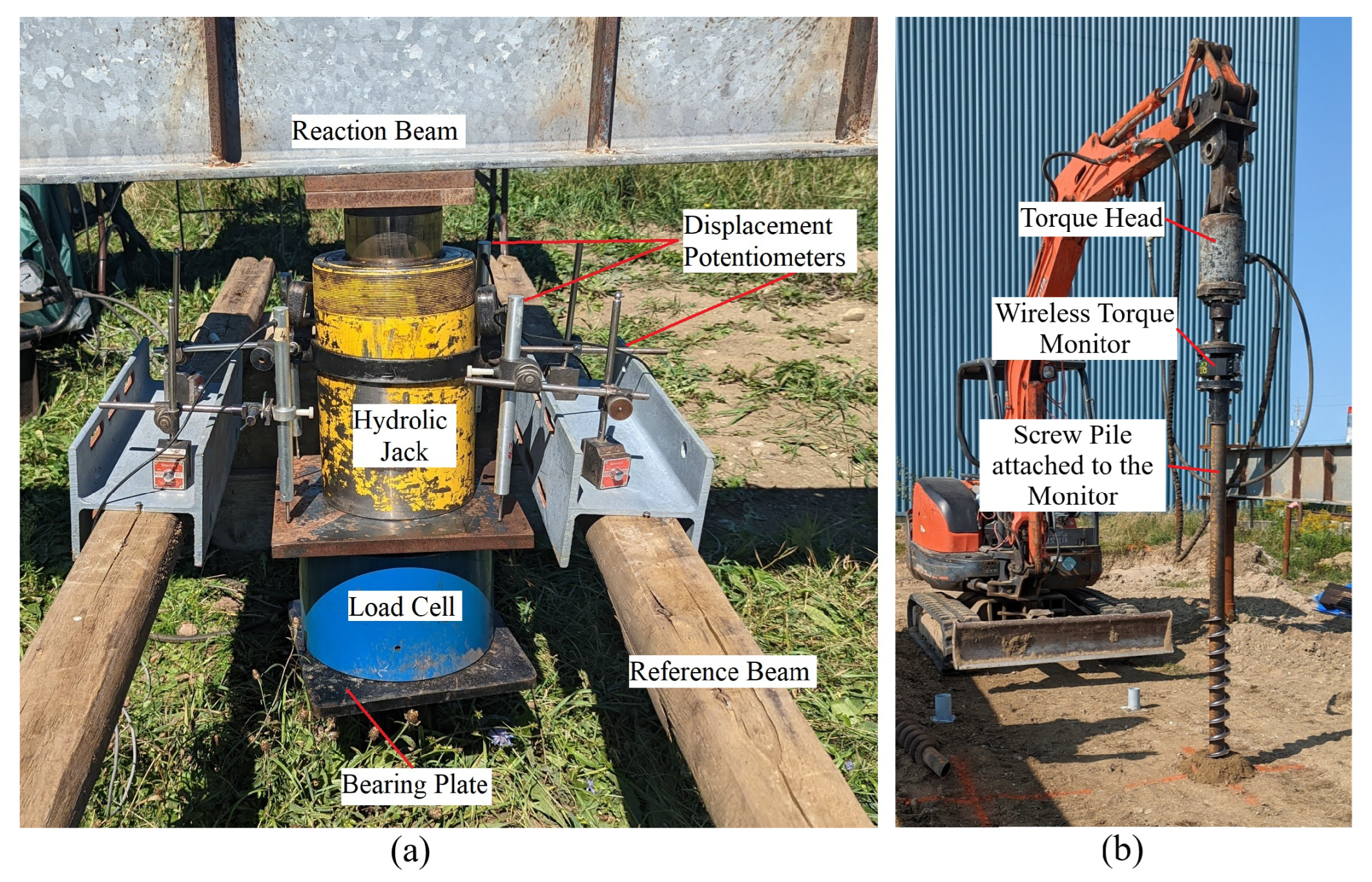

5.1. Test Setup and Procedure

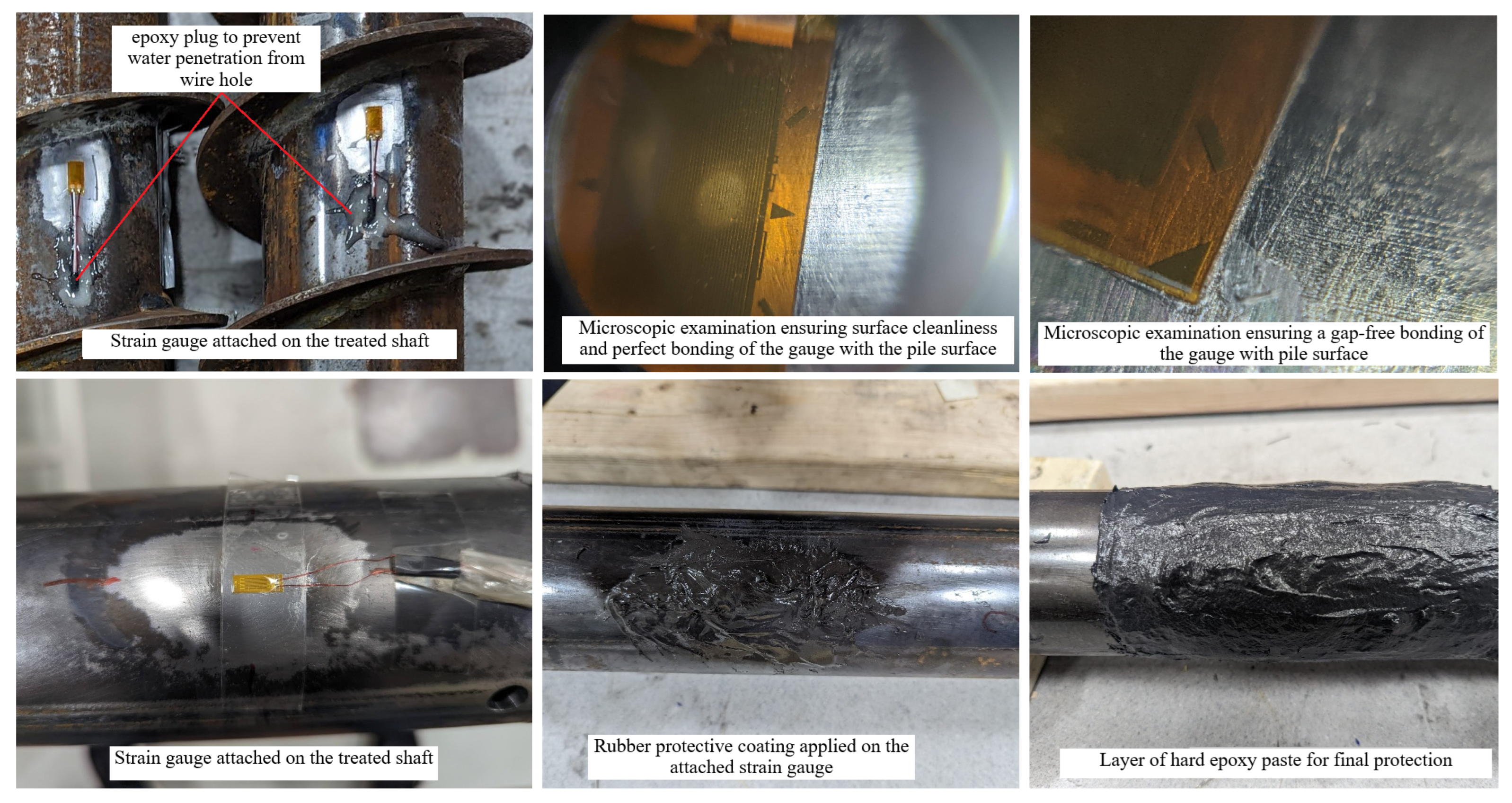

5.2. Instrumentation

6. Results and Discussion

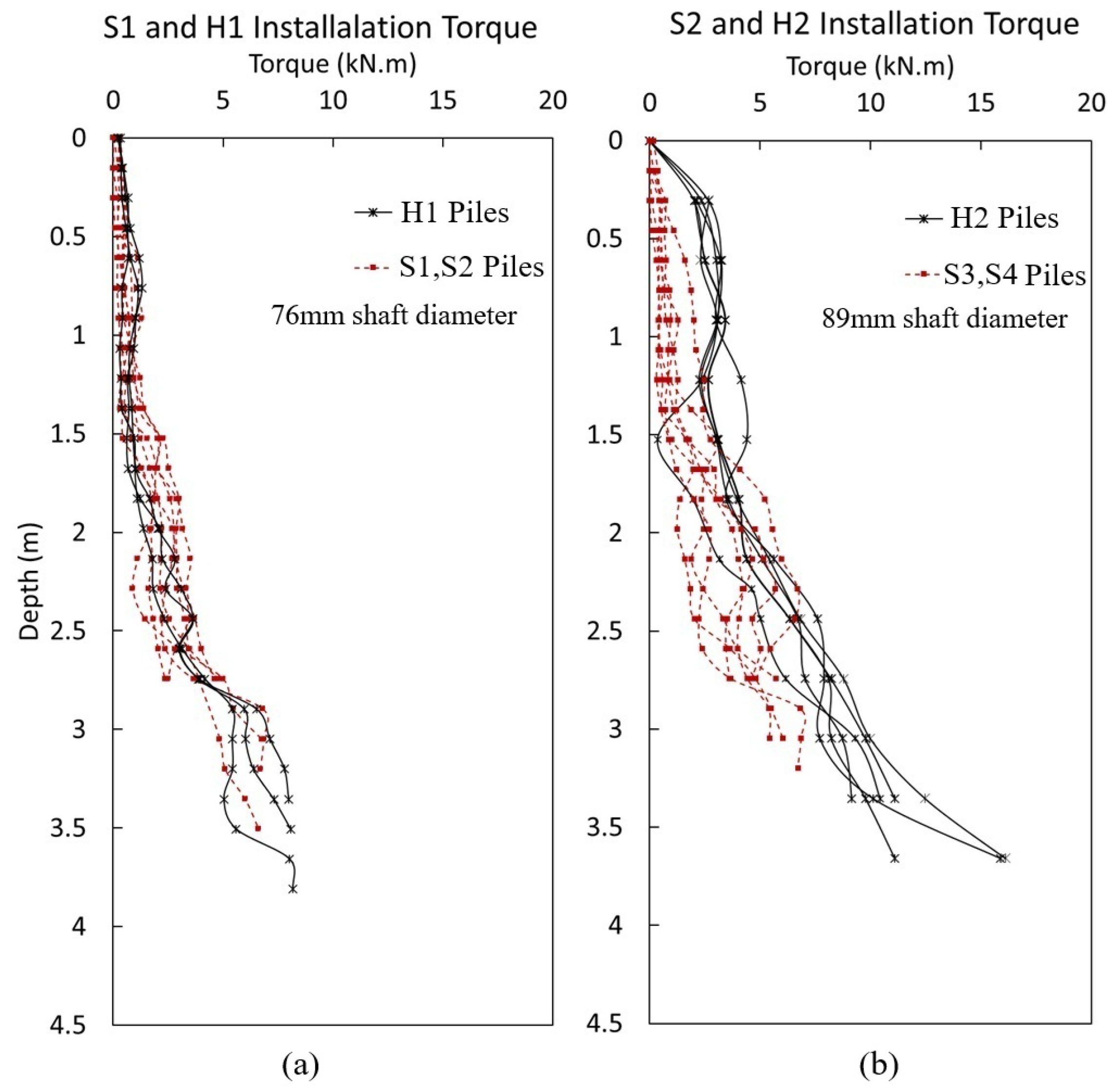

6.1. Installation Torque

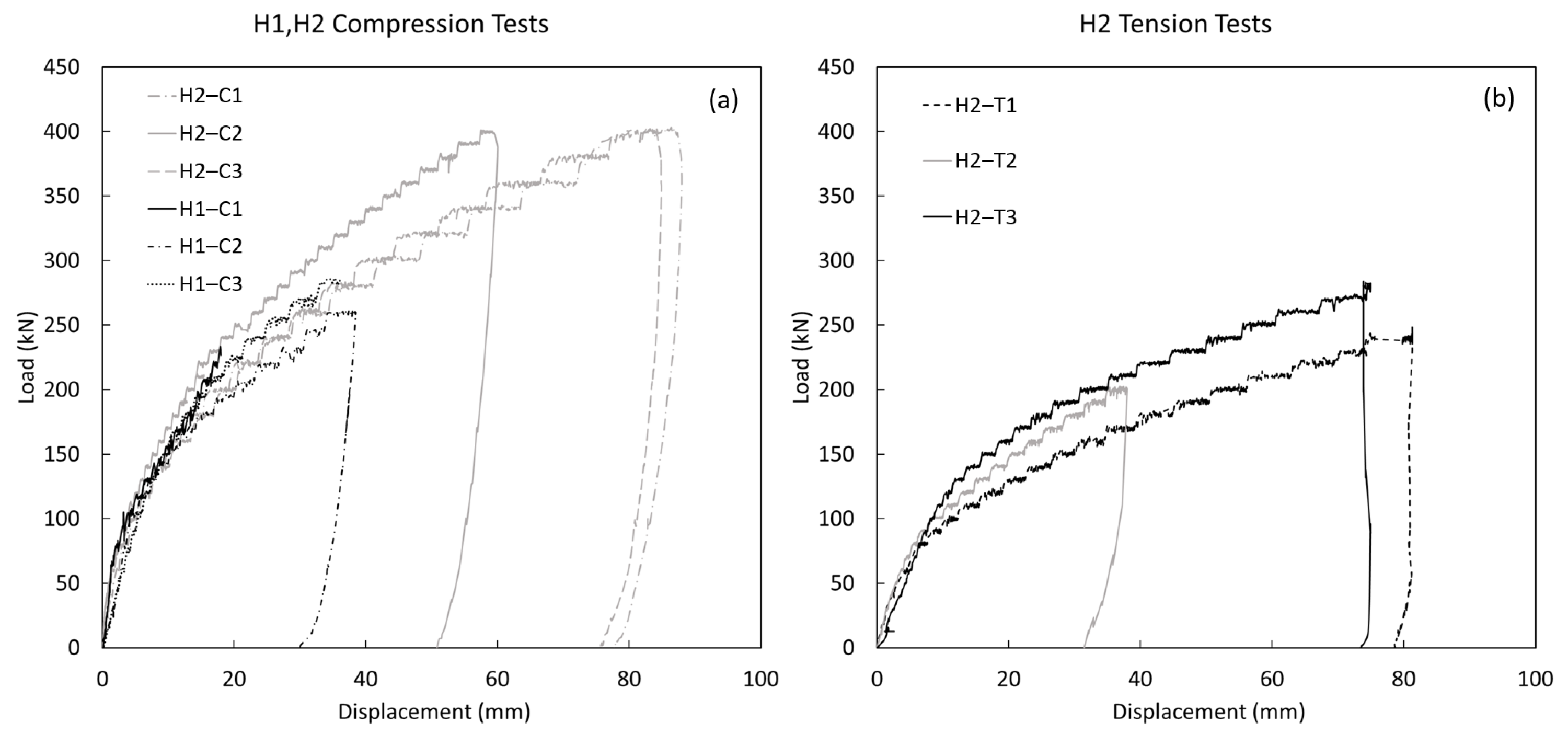

6.2. Pile Load Test

6.3. Capacity-Torque Correlation

6.4. Theoretical Capacity of Screw Piles

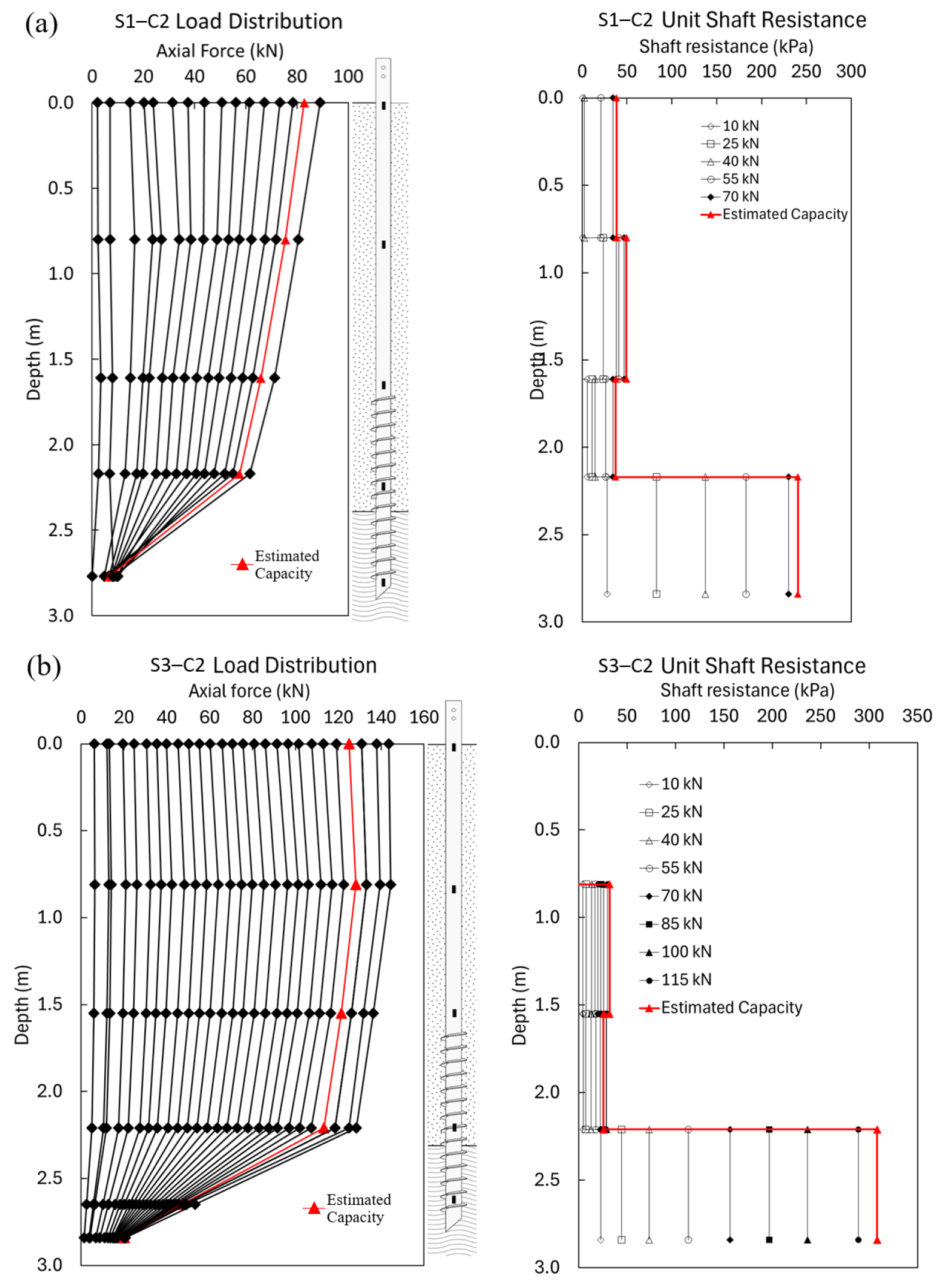

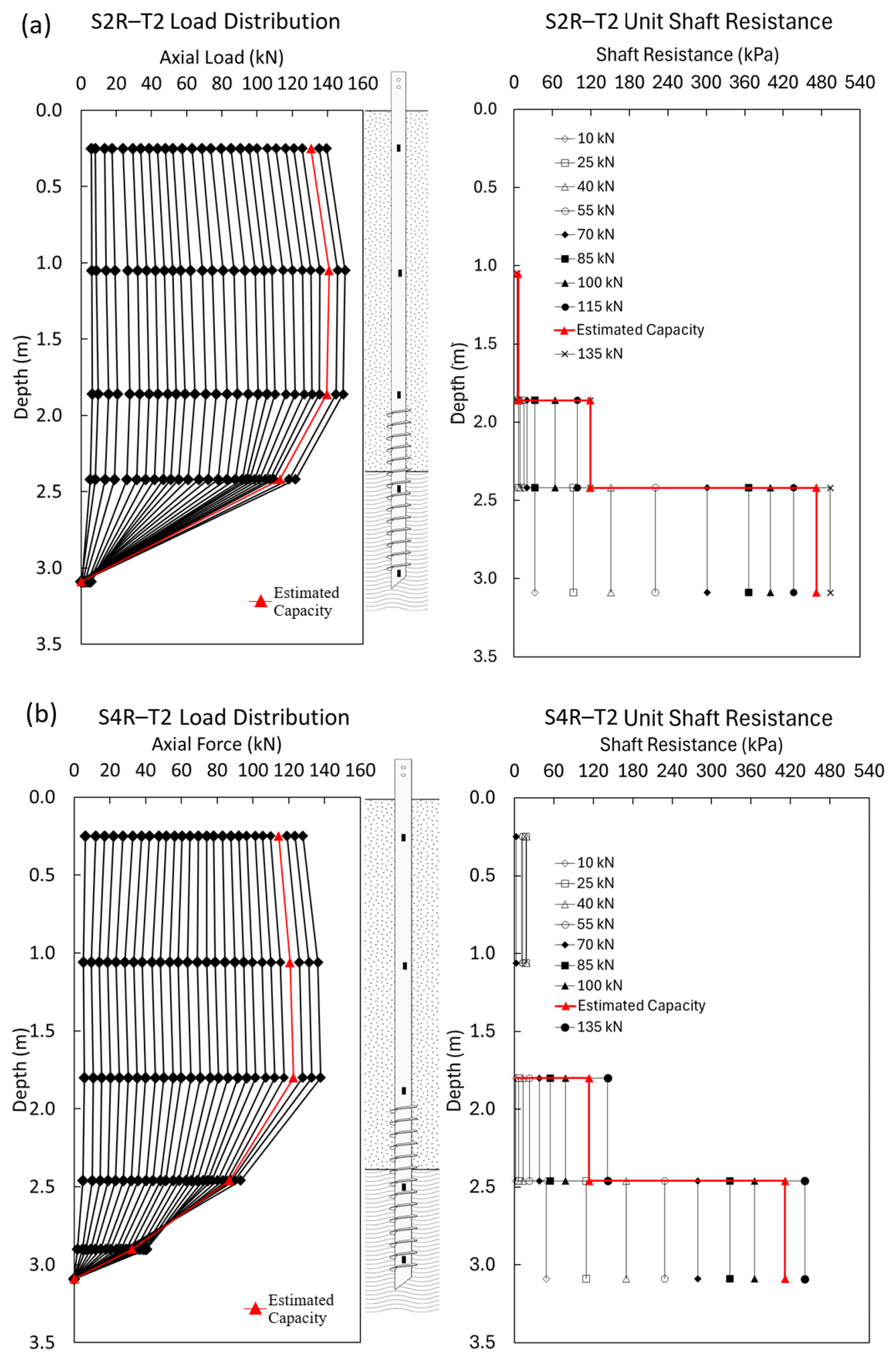

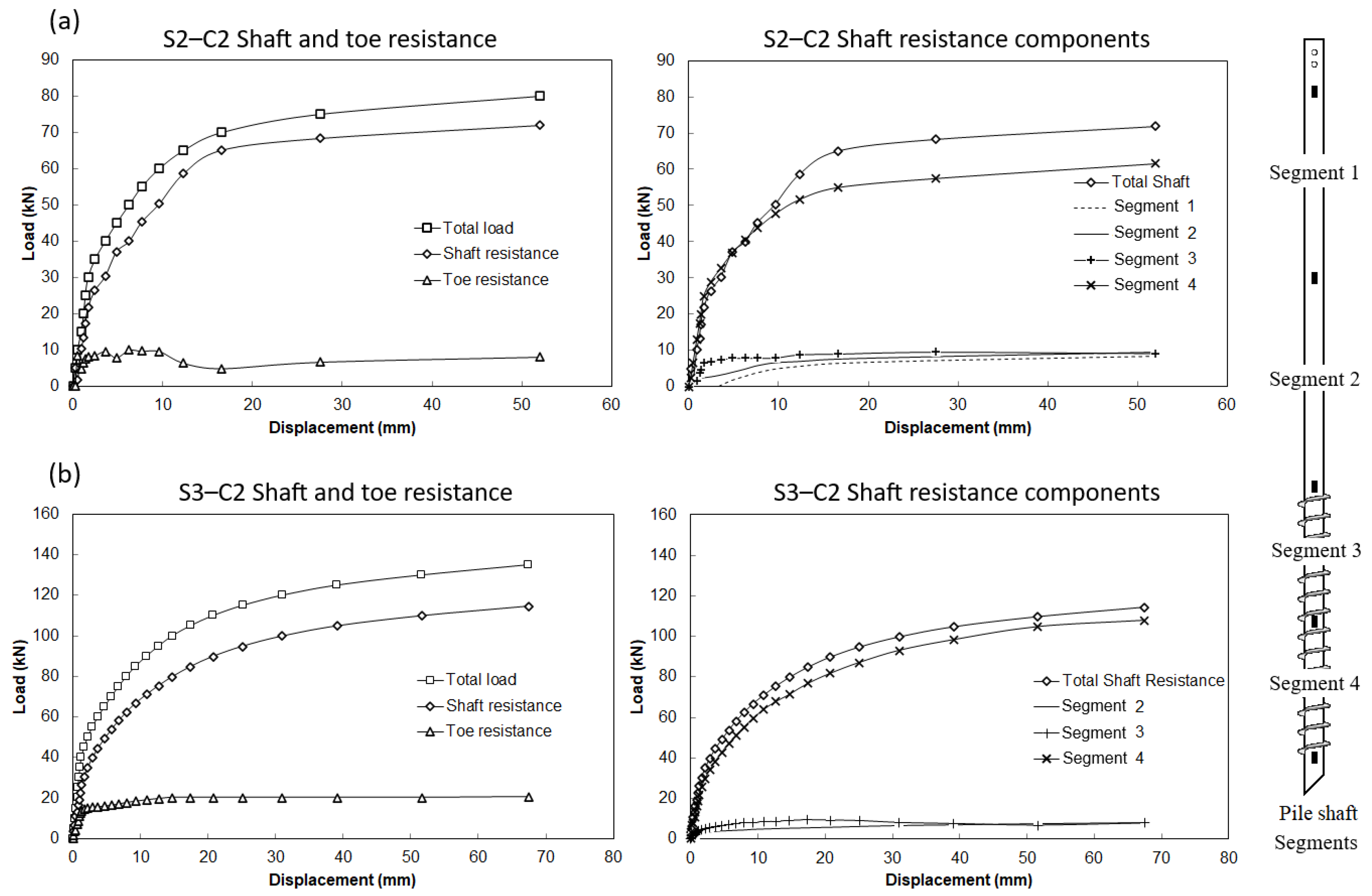

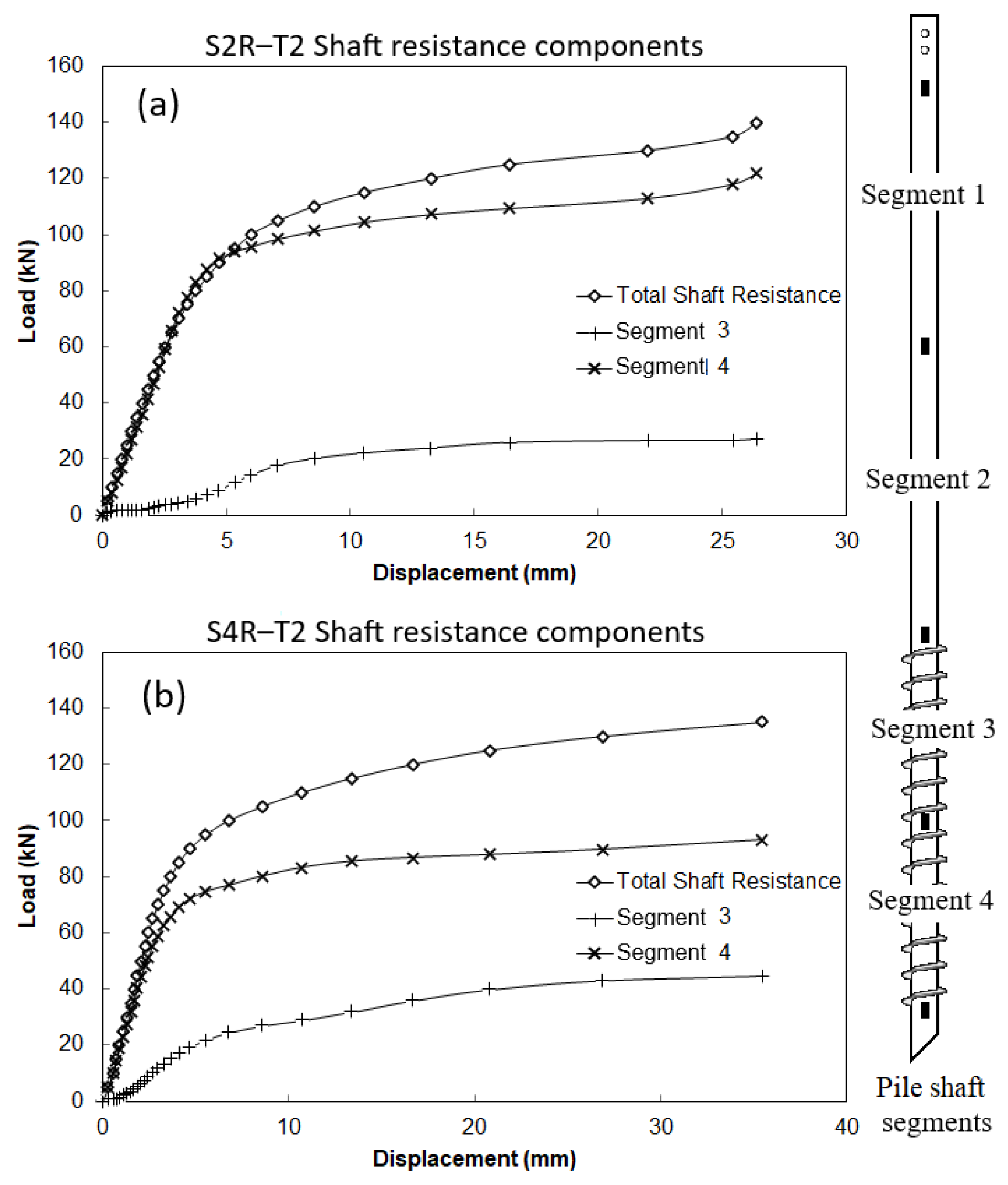

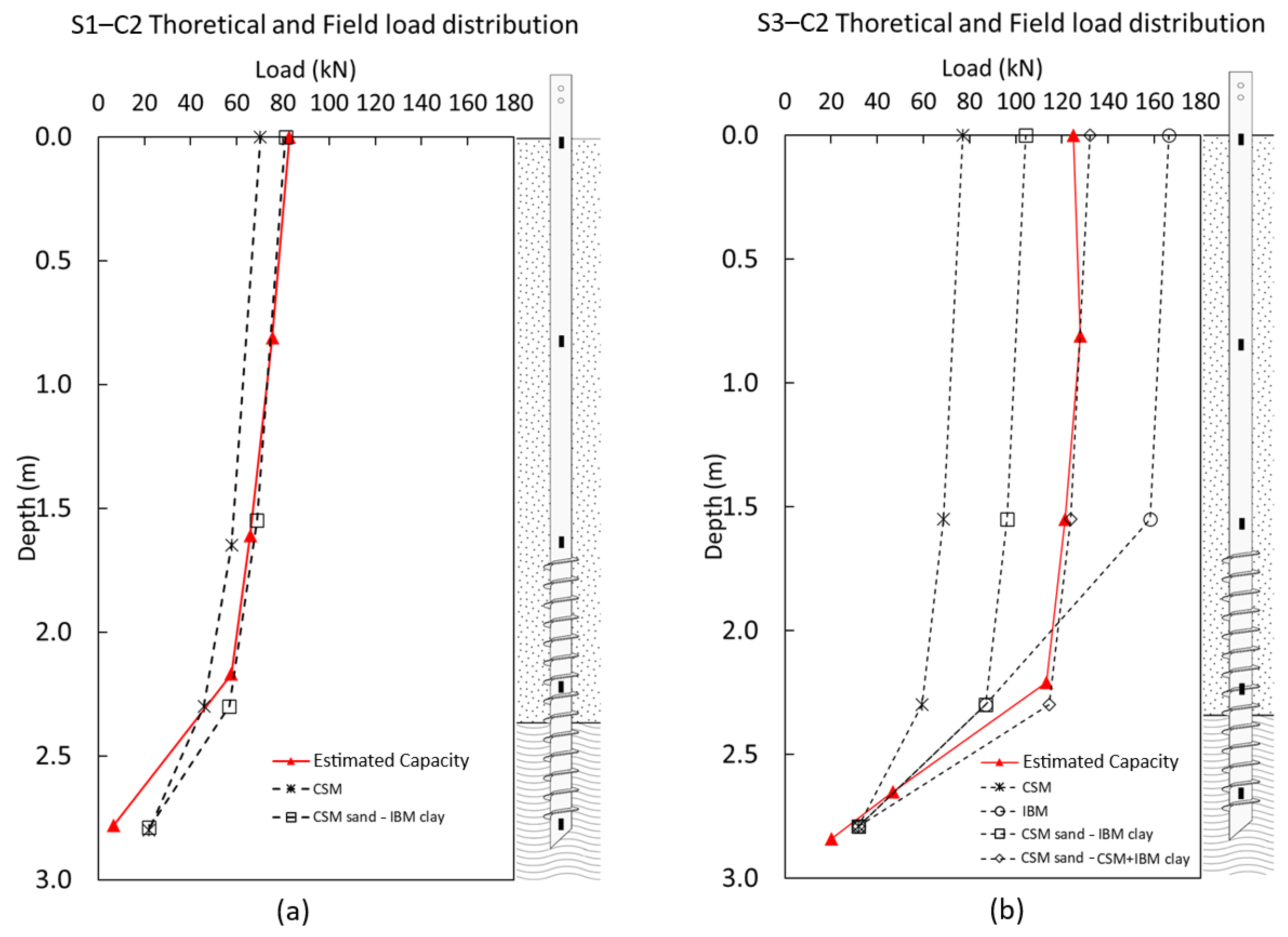

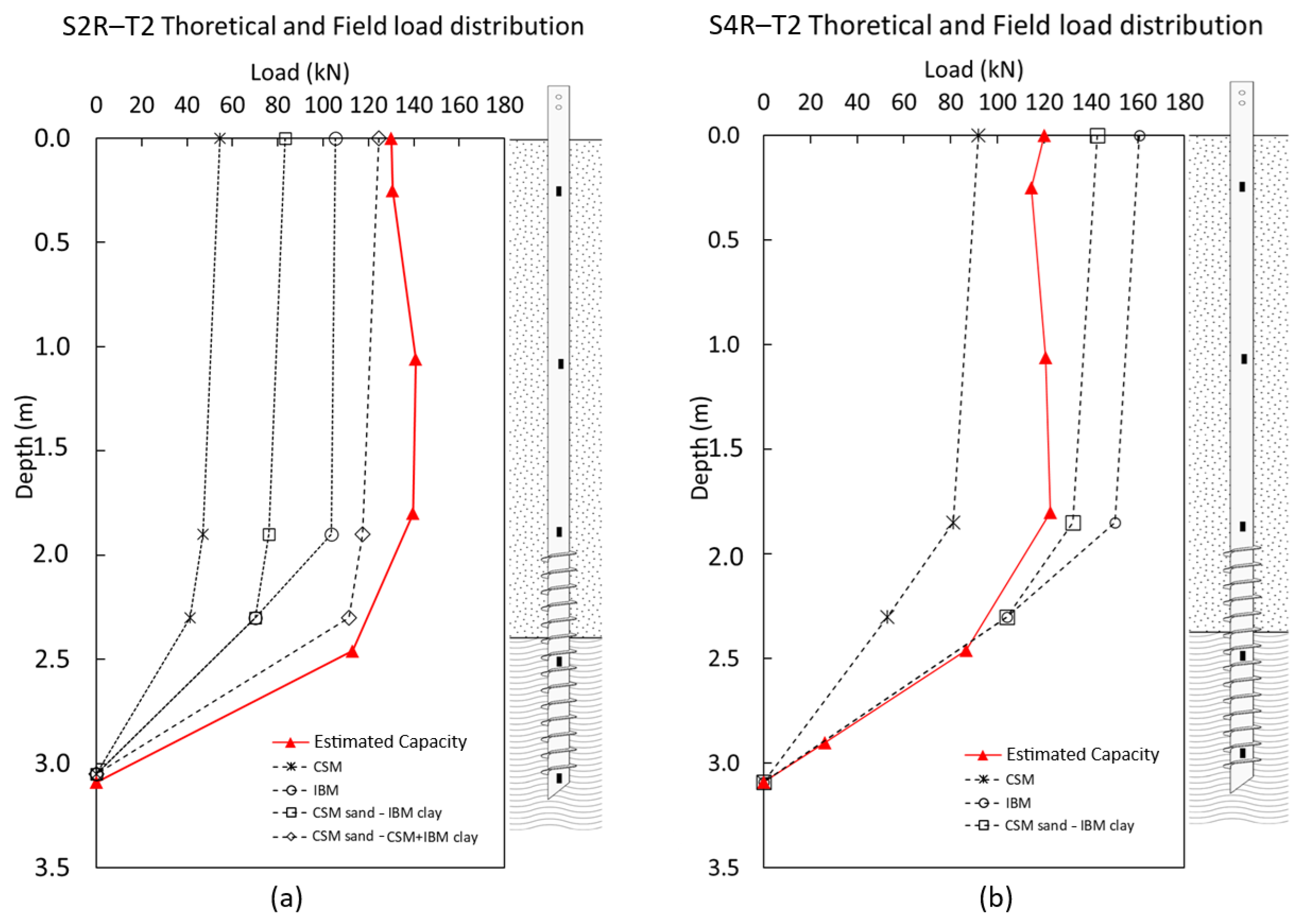

6.4.1. Load Distribution Along the Pile

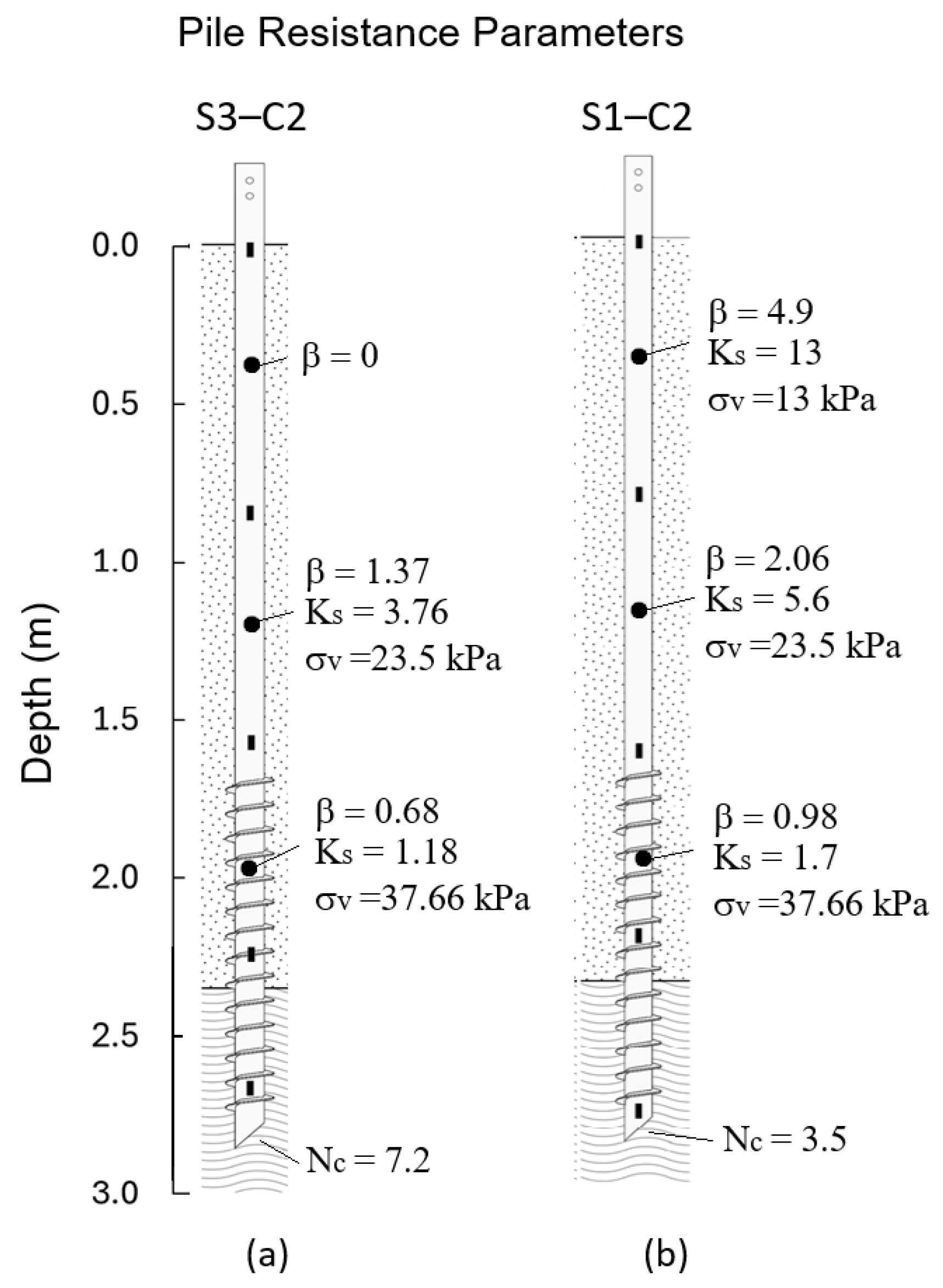

6.4.2. Back Calculation of Pile Resistance Parameters

7. Conclusions

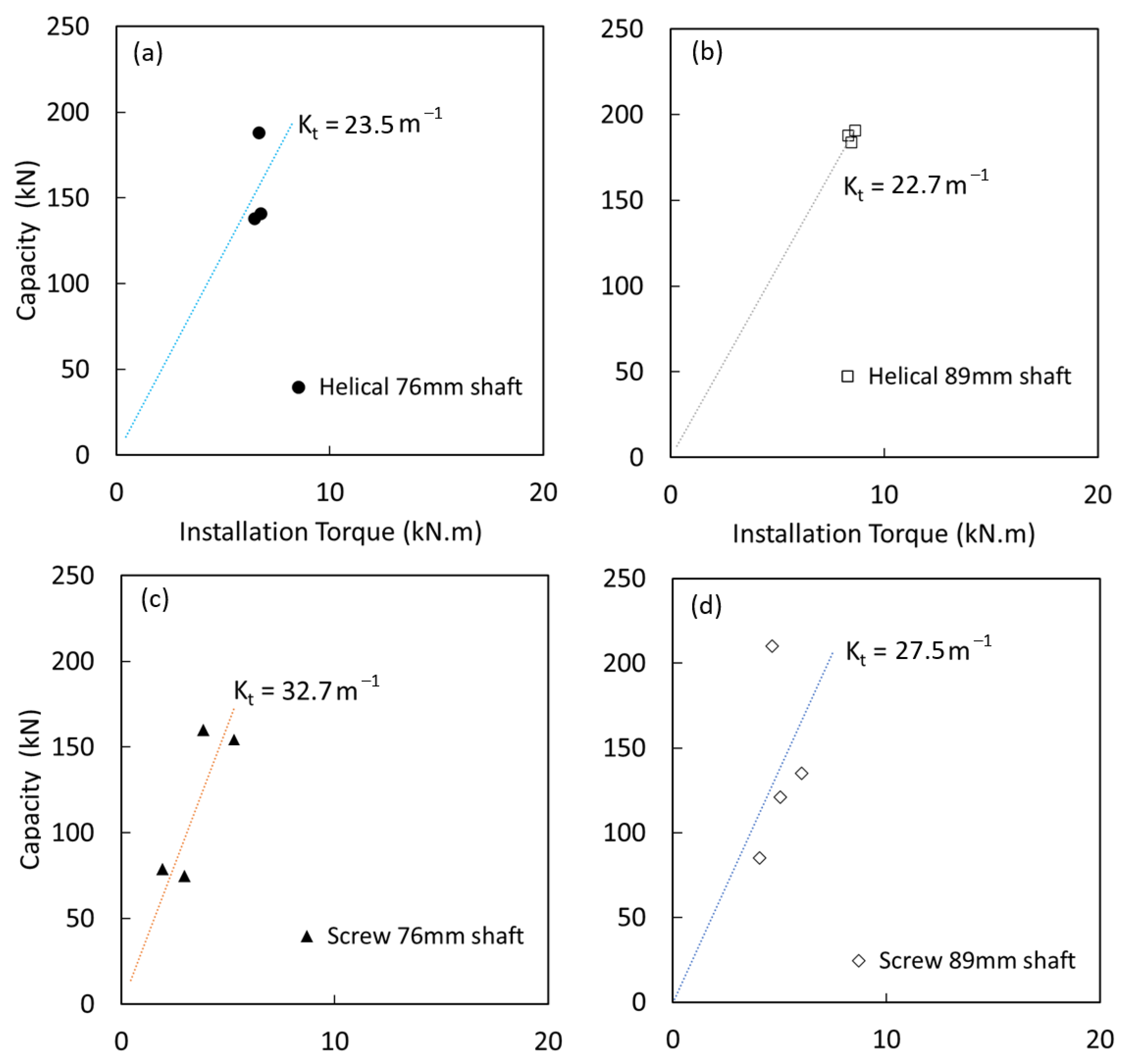

- The screw piles can offer significant axial capacity over torque ratio, especially in tension, as they required lower installation torque than helical piles. In compression, the torque factors () for screw piles were 32.7 and 27.5 for shaft diameters of 76 mm and 89 mm, respectively, compared to 23.5 and 22.7 for helical piles of the same diameters. In tension, values for screw piles were 35.35 (76 mm shaft) and 30.05 (89 mm shaft), whereas the helical pile with an 89 mm shaft exhibited a much lower of 10.56 .

- The capacity—torque correlation for screw piles was more consistent in both compression and tension compared to helical piles, which could be due to reduced soil disturbance caused by the smaller helix projection. For instance, for screw piles with a shaft diameter of 89 mm, was 27.5 in compression and 22.7 in tension, whereas for helical piles, decreased from 22.7 in compression to 10.56 in tension.

- The interpretation of strain gauge results indicated that screw piles behave predominantly as friction piles, with the majority of axial load resisted by the threaded shaft, particularly in the stiffer clay layer.

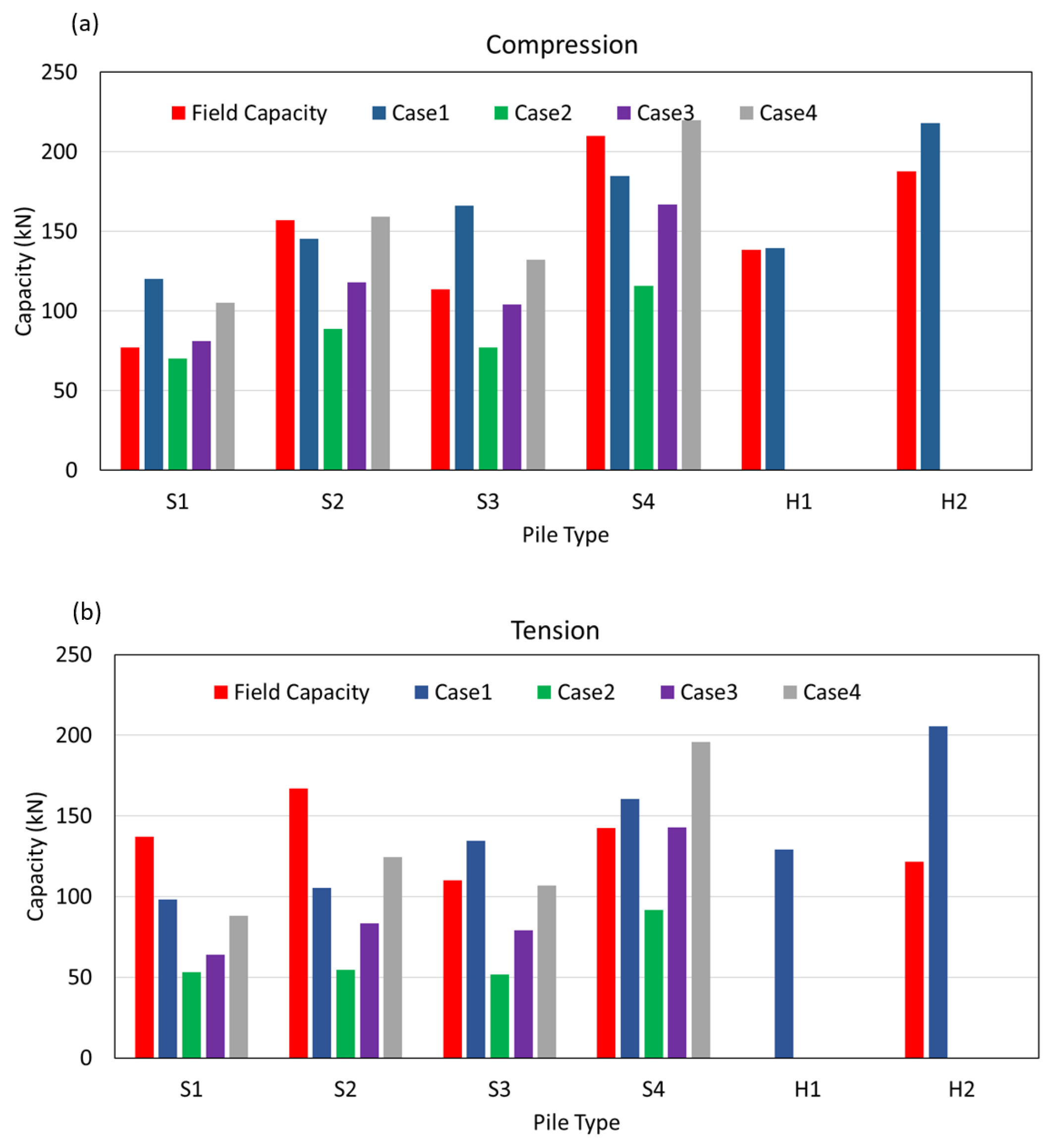

- For helical piles, the theoretical failure modes provided reliable estimates for compression capacity, using IBM method. For screw piles, the theoretical failure modes provided reliable estimates of compression capacity, using CSM for sand and IBM for clay for piles with a length of 2.8 m, and CSM for sand and IBM + CSM for clay for piles with a length of 3.0 m. However, tension capacity predictions showed high variability, likely due to soil disturbance, with no clear failure pattern linked to pile type or depth.

- The commonly used spacing ratio (S/D) to predict the mode of failure may not be utilized in screw piles directly, as the ratio does not consider the comparatively small difference between helix and shaft diameters in their design. Such a criterion, specifically developed for traditional helical piles, may not be an accurate reflection of failure mechanisms in screw piles.

- The contribution of the smooth shaft section to overall pile resistance was observed only in compression tests, where it accounted for 20% and 5.5% of the total load in piles S1 and S3, respectively. In tension, the smooth shaft provided no measurable resistance. These findings align with existing literature on helical piles and suggest that the smooth shaft contribution should not be considered in the design of screw piles [25,26].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lutenegger, A.J. Historical Development of Iron Screw-Pile Foundations: 1836–1900. Int. J. Hist. Eng. Technol. 2011, 81, 108–128. [Google Scholar] [CrossRef]

- Lutenegger, A.J. Screw piles and helical anchors—What we know and what we don’t know: An academic perspective—2019. In Proceedings of the 1st International Symosuym on Screw Piles for Energy Applications—University of Dundee, Dundee, UK, 27–28 May 2019; pp. 15–28. [Google Scholar]

- Mneina, A.; El Naggar, M.H. Capacity-torque correlation of continuous helix screw piles in cohesive soil. In Proceedings of the 77th Canadian Geotechnical Conference and the 16th Joint CGS/IAH-CNC Groundwater Conference, Montreal, QC, Canada, 15–18 September 2024. [Google Scholar]

- Guo, Z.; Deng, L. Field behaviour of screw micropiles subjected to axial loading in cohesive soils. Can. Geotech. J. 2018, 55, 34–44. [Google Scholar] [CrossRef]

- Khidri, M.; Deng, L. Field axial loading tests of screw micropiles in sand. Can. Geotech. J. 2022, 59, 458–472. [Google Scholar] [CrossRef]

- Sanzeni, A.; Danesi, E.G. Behaviour of screw micropiles subjected to axial tensile and compressive loading. Int. J. Geotech. Eng. 2022, 16, 450–461. [Google Scholar] [CrossRef]

- Chen, Y.; Deng, A.; Lu, F.; Sun, H. Failure mechanism and bearing capacity of vertically loaded pile with partially-screwed shaft: Experiment and simulations. Comput. Geotech. 2020, 118, 103337. [Google Scholar] [CrossRef]

- Elsherbiny, Z.H.; El Naggar, M.H. Axial compressive capacity of helical piles from field tests and numerical study. Can. Geotech. J. 2013, 50, 1191–1203. [Google Scholar] [CrossRef]

- Lutenegger, A.J. Cylindrical Shear or Plate Bearing?—Uplift Behavior of Multi-Helix Screw Anchors in Clay. In Contemporary Topics in Deep Foundations, Proceedings of the International Foundation Congress and Equipment Expo, Orlando, FL, USA, 15–19 March 2009; American Society of Civil Engineers: Reston, VA, USA, 2009; pp. 456–463. [Google Scholar] [CrossRef]

- Lanyi-Bennett, S.A.; Deng, L. Effects of inter-helix spacing and short-term soil setup on the behaviour of axially loaded helical piles in cohesive soil. Soils Found. 2019, 59, 337–350. [Google Scholar] [CrossRef]

- ASTM-D7928-17; Standard Test Method for Particle-Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM-D2487-00; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). Anual Book of ASTM. Committee D18.07 on Identification and Classification of Soils. ASTM International: West Conshohocken, PA, USA, 2000; Volume 4.

- Sivrikaya, O.; Toğrol, E. Determination of undrained strength of fine-grained soils by means of SPT and its application in Turkey. Eng. Geol. 2006, 86, 52–69. [Google Scholar] [CrossRef]

- Hoyt, R.; Clemence, S. Uplift capacity of helical anchors in soil. In Proceedings of the 12th International Conference on Soil Mechanics and Foundation Engineering, Rio de Janeiro, Brazil, 13–18 August 1989. [Google Scholar]

- Bowles, J.E.; Guo, Y. Foundation Analysis and Design; McGraw-Hill: New York, NY, USA, 1996; Volume 5. [Google Scholar]

- El Sharnouby, M.E.; El Naggar, M.H. Field investigation of axial monotonic and cyclic performance of reinforced helical pulldown micropiles. Can. Geotech. J. 2012, 49, 560–573. [Google Scholar] [CrossRef]

- Livneh, B.; El Naggar, M.H. Axial testing and numerical modeling of square shaft helical piles under compressive and tensile loading. Can. Geotech. J. 2008, 45, 1142–1155. [Google Scholar] [CrossRef]

- Society, C.G. Canadian Foundation Engineering Manual, 4th ed.; BiTech Publishers Ltd.: Richmond, BC, Canada, 2006. [Google Scholar]

- ASTM-D1143; Standard Test Methods for Deep Foundations Under Static Axial Compressive Load. Technical Report. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM-D3689; Standard Test Methods for Deep Foundations Under Static Axial Tensile Load. Technical Report. ASTM International: West Conshohocken, PA, USA, 2007.

- Mansour, M.A.; El Naggar, M.H. Optimization of grouting method and axial performance of pressure-grouted helical piles. Can. Geotech. J. 2022, 59, 702–714. [Google Scholar] [CrossRef]

- Perko, H.A. Helical Piles: A Practical Guide to Design and Installation; John Wiley & Sons: Hoboken, NJ, USA, 2009; p. 512. [Google Scholar]

- Hirany, A.; Kulhawy, F.H. Conduct and Interpretation of Load Tests on Drilled Shaft Foundations: Volume 1, Detailed Guidelines: Final Report; Technical Report, Electric Power Research Institute, Palo Alto, CA (USA); Cornell University, Ithaca, NY (USA); Geotechnical Engineering Group: Grand Junction, CO, USA, 1988. [Google Scholar]

- Lutenegger, A.J.; Tsuha, C.D.H. Evaluating Installation Disturbance from Helical Piles and Anchors Using Compression and Tension Tests. In Proceedings of the 15th American Conference on Soil Mechanics and Geotechnical Engineering (XV PCSMGE), Buenos Aires, Argentina, 15–19 November 2015; pp. 373–381. [Google Scholar]

- George, B.E.; Banerjee, S.; Gandhi, S.R. Numerical analysis of helical piles in cohesionless soil. Int. J. Geotech. Eng. 2020, 14, 361–375. [Google Scholar] [CrossRef]

- Nazir, R.; Chuan, H.S.; Niroumand, H.; Kassim, K.A. Performance of single vertical helical anchor embedded in dry sand. Measurement 2014, 49, 42–51. [Google Scholar] [CrossRef]

| Pile | Type | L1 (mm) | L2 (mm) | d (mm) | Dh (mm) | Pitch (mm) |

|---|---|---|---|---|---|---|

| S1 | Screw pile | 1650 | 1150 | 76 | 127 | 76 |

| S2 | Screw pile | 1900 | 1150 | 76 | 127 | 76 |

| S3 | Screw pile | 1550 | 1240 | 89 | 152 | 89 |

| S4 | Screw pile | 1850 | 1240 | 89 | 152 | 89 |

| H1 | Helical pile | 3650 | - | 76 | 254 | 76 |

| H2 | Helical pile | 3350 | - | 89 | 356 | 89 |

| Depth (m) | Soil Layer | SPT N | γ (kN/m3) | ϕ′ | Su (kPa) |

|---|---|---|---|---|---|

| 0–0.8 | Fill | 8 | 19.0 | - | - |

| 0.8–1.5 | Clayey Sand SC | 6 | 21.3 | 25–29 | - |

| 1.5–2.3 | Silty Sand SM, Sandy Lean Clay CL | 10 | 20.0 | 25–30 | - |

| 2.3–4.6 | Sandy Lean Clay CL, Sandy Silty Clay CL-ML | 18 to 100 | 23.5 | - | 88 to 270 |

| Pile | L1–L2 Capacity (kN) | Test Type | Pile Type | Depth (m) | Installation Torque (kN.m) | Kt (m−1) |

|---|---|---|---|---|---|---|

| H1–C1 | 138 | Compression | Helical | 3.6 | 6.5 | 21 |

| H1–C2 | 141 | Compression | Helical | 3.6 | 6.8 | 21 |

| H1–C3 | 188 | Compression | Helical | 3.6 | 6.7 | 28 |

| H2–C1 | 191 | Compression | Helical | 3.3 | 8.6 | 22 |

| H2–C2 | 188 | Compression | Helical | 3.3 | 8.3 | 23 |

| H2–C3 | 184 | Compression | Helical | 3.3 | 8.5 | 22 |

| S1–C1 | 79 | Compression | Screw | 2.8 | 1.9 | 41 |

| S1–C2 | 75 | Compression | Screw | 2.8 | 3.0 | 25 |

| S2–C1 | 160 | Compression | Screw | 3.0 | 3.8 | 42 |

| S2–C2 | 154 | Compression | Screw | 3.0 | 5.3 | 29 |

| S3–C1 | 85 | Compression | Screw | 2.8 | 4.1 | 21 |

| S3–C2 | 121 | Compression | Screw | 2.8 | 5.0 | 24 |

| S3–C3 | 135 | Compression | Screw | 2.8 | 6.0 | 22 |

| S4–C3 | 210 | Compression | Screw | 3.0 | 4.7 | 45 |

| H2–T1 | 115 | Tension | Helical | 3.3 | 9.7 | 12 |

| H2–T2 | 88 | Tension | Helical | 3.6 | 12.9 | 7 |

| H2–T3 | 162 | Tension | Helical | 3.6 | 11.2 | 14 |

| S1–T1 | 137 | Tension | Screw | 2.8 | 3.4 | 40 |

| S2–T1 | 179 | Tension | Screw | 3.0 | 5.4 | 33 |

| S2–T2 | 155 | Tension | Screw | 3.0 | 4.3 | 36 |

| S3–T1 | 110 | Tension | Screw | 2.8 | 3.5 | 32 |

| S4–T1 | 165 | Tension | Screw | 3.0 | 5.3 | 31 |

| S4–T2 | 120 | Tension | Screw | 3.0 | 4.4 | 27 |

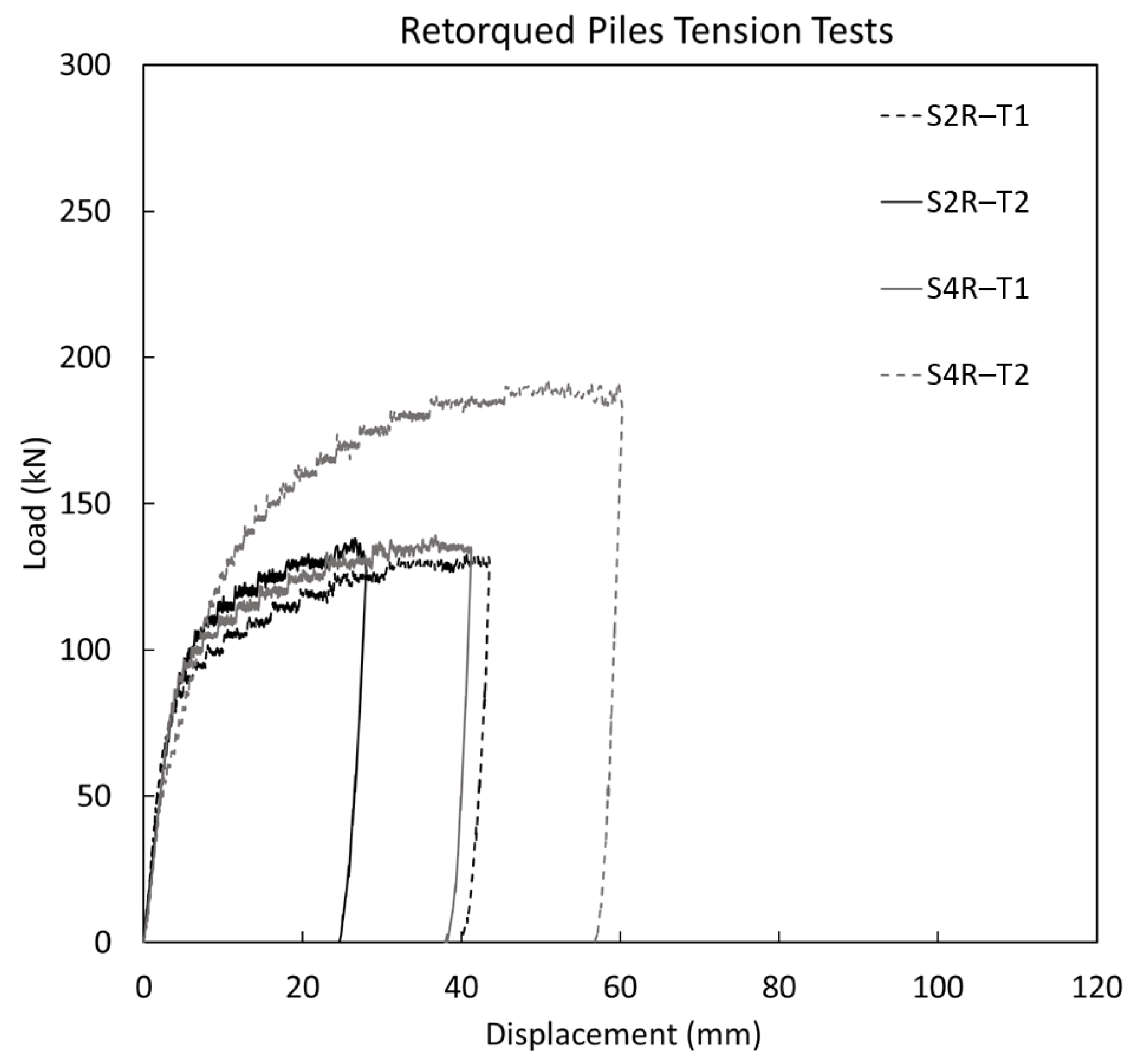

| S2R–T1 | 125 | Tension (Retorqued) | Screw | 3.0 | 3.5 | 35 |

| S2R–T2 | 130 | Tension (Retorqued) | Screw | 3.0 | 4.4 | 29 |

| S4R–T1 | 119 | Tension (Retorqued) | Screw | 3.0 | 6.0 | 20 |

| S4R–T2 | 125 | Tension (Retorqued) | Screw | 3.0 | 5.5 | 23 |

| Soil Layer/Failure Mode | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Sand (0–2.3 m) | IBM | CSM | CSM | CSM |

| Clay (>2.3 m) | IBM | CSM | IBM | IBM + CSM |

| CASE1 Error% | CASE2 Error% | CASE3 Error% | CASE4 Error% | |||||

|---|---|---|---|---|---|---|---|---|

| Pile Type | Comp. * | Ten. * | Comp. | Ten. | Comp. | Ten. | Comp. | Ten. |

| S1 | 56% | −28% | −9% | −61% | 5% | −53% | 36% | −36% |

| S2 | −7% | −37% | −43% | −67% | −25% | −50% | 1% | −25% |

| S3 | 46% | 22% | −32% | −53% | −8% | −28% | 16% | −3% |

| S4 | −12% | 13% | −45% | −36% | −21% | 0% | 5% | 37% |

| H1 | 1% | No data | - | - | - | - | - | - |

| H2 | 16% | 69% | - | - | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mneina, A.; El Naggar, M.H.; Drbe, O. Axial Compression and Uplift Performance of Continuous Helix Screw Piles. Buildings 2025, 15, 3620. https://doi.org/10.3390/buildings15193620

Mneina A, El Naggar MH, Drbe O. Axial Compression and Uplift Performance of Continuous Helix Screw Piles. Buildings. 2025; 15(19):3620. https://doi.org/10.3390/buildings15193620

Chicago/Turabian StyleMneina, Ahmed, Mohamed Hesham El Naggar, and Osama Drbe. 2025. "Axial Compression and Uplift Performance of Continuous Helix Screw Piles" Buildings 15, no. 19: 3620. https://doi.org/10.3390/buildings15193620

APA StyleMneina, A., El Naggar, M. H., & Drbe, O. (2025). Axial Compression and Uplift Performance of Continuous Helix Screw Piles. Buildings, 15(19), 3620. https://doi.org/10.3390/buildings15193620