Sound Absorption and Thermal Insulation by Polyurethane Foams Reinforced with Bio-Based Lignocellulosic Fillers: Data and Modeling

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemical Treatment of Sawdust

2.3. Sample Preparation and Fabrication of RFPUFs

2.4. Measurement of Physical Properties

2.4.1. Thickness

2.4.2. Areal Density

2.4.3. Bulk Density

2.4.4. Porosity

2.4.5. Airflow Resistivity (AFR)

2.4.6. Morphological Analysis

2.4.7. Thermal Conductivity Analysis (Keff)

2.4.8. Tensile Properties

2.5. Normal Sound Absorption Coefficient (SAC)

2.6. Prediction of Acoustical Characteristics

2.6.1. Johnson-Champoux-Allard-Lafarge Model (JCAL)

2.6.2. The Simplified JCAL Model

2.6.3. Non Uniform Cylindrical Pores with a Log-Normal Radius Distribution (NUPSD)

3. Results and Discussion

3.1. Thermal, Tensile and Morphological Properties of Optimized Sample

3.1.1. Thermal Properties

3.1.2. Tensile Properties

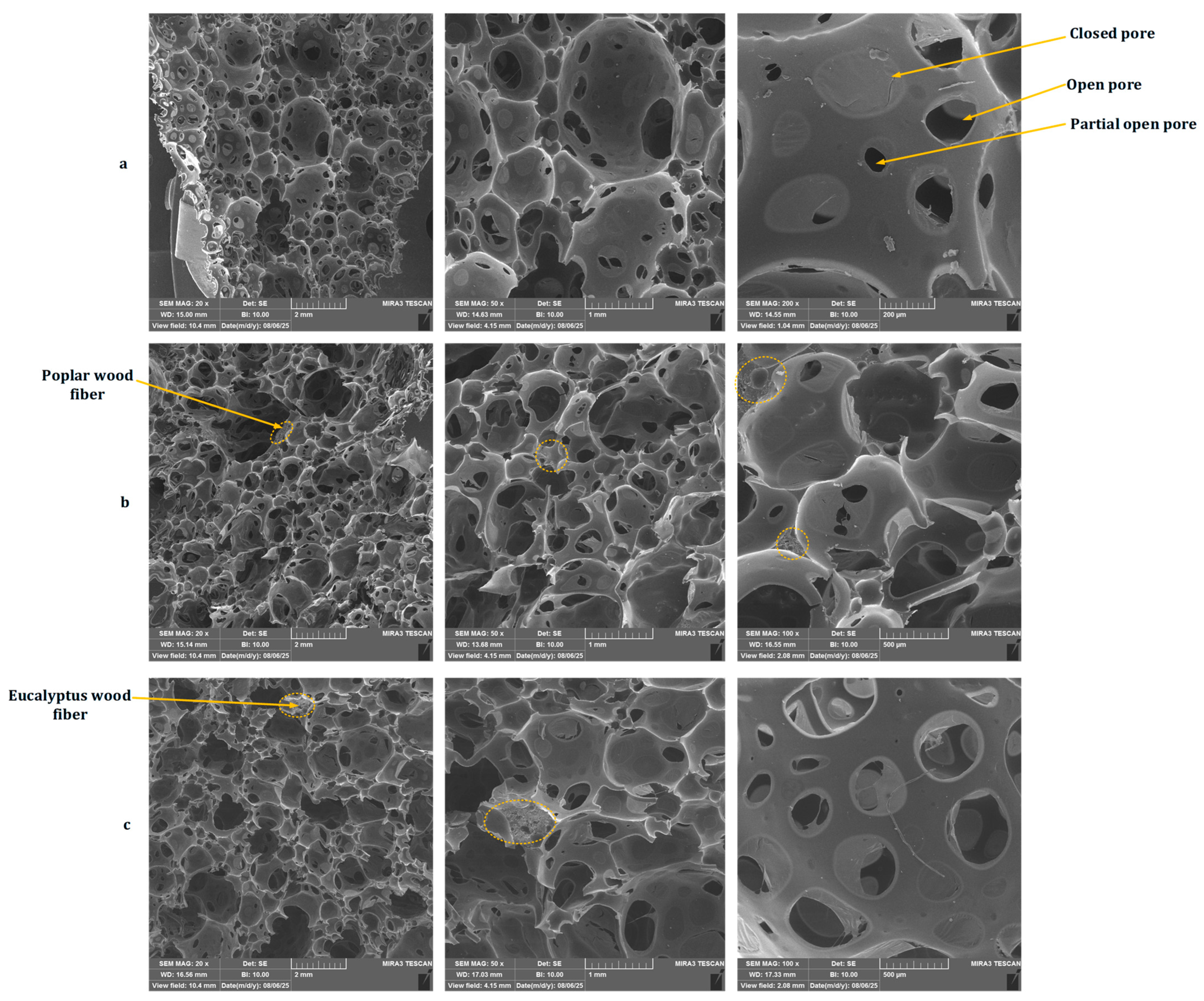

3.1.3. Morphological Properties

3.2. Sound Absorption Properties

3.2.1. Acoustical Performance Metrics, Flow Resistivity and Mesh Size

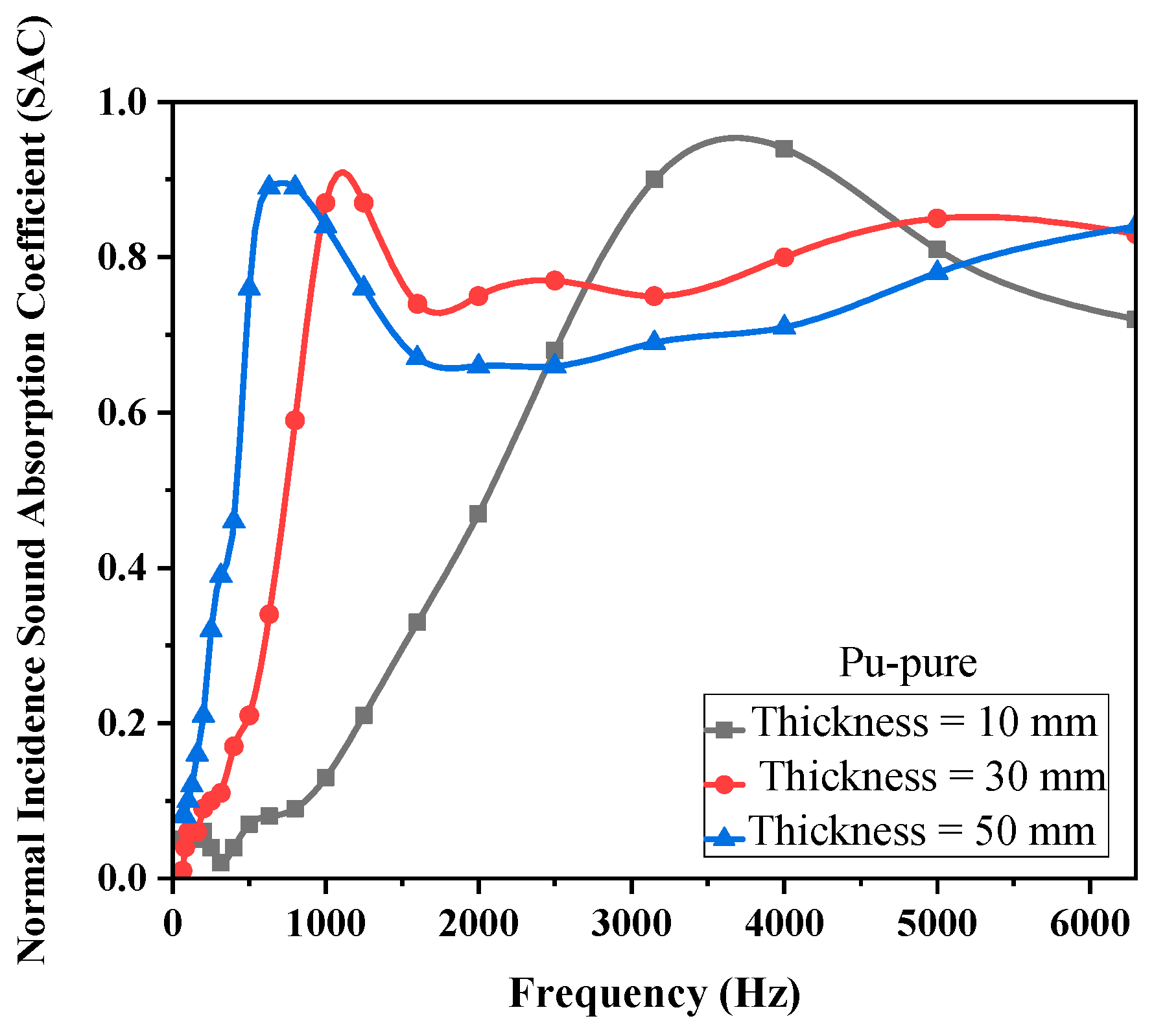

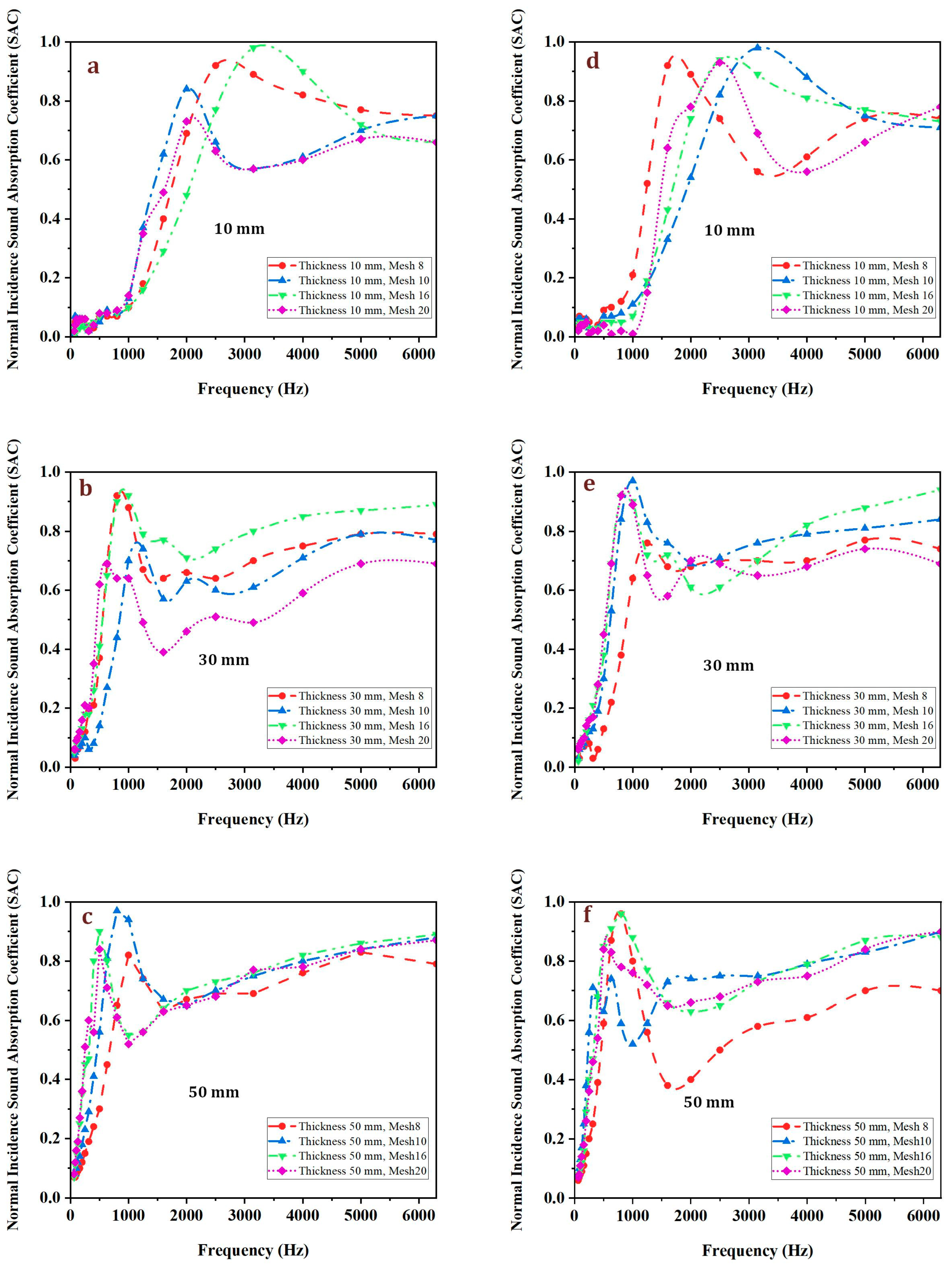

3.2.2. The Impact of Thickness, Flow Resistivity and Mesh Size on Normal Incidence SAC

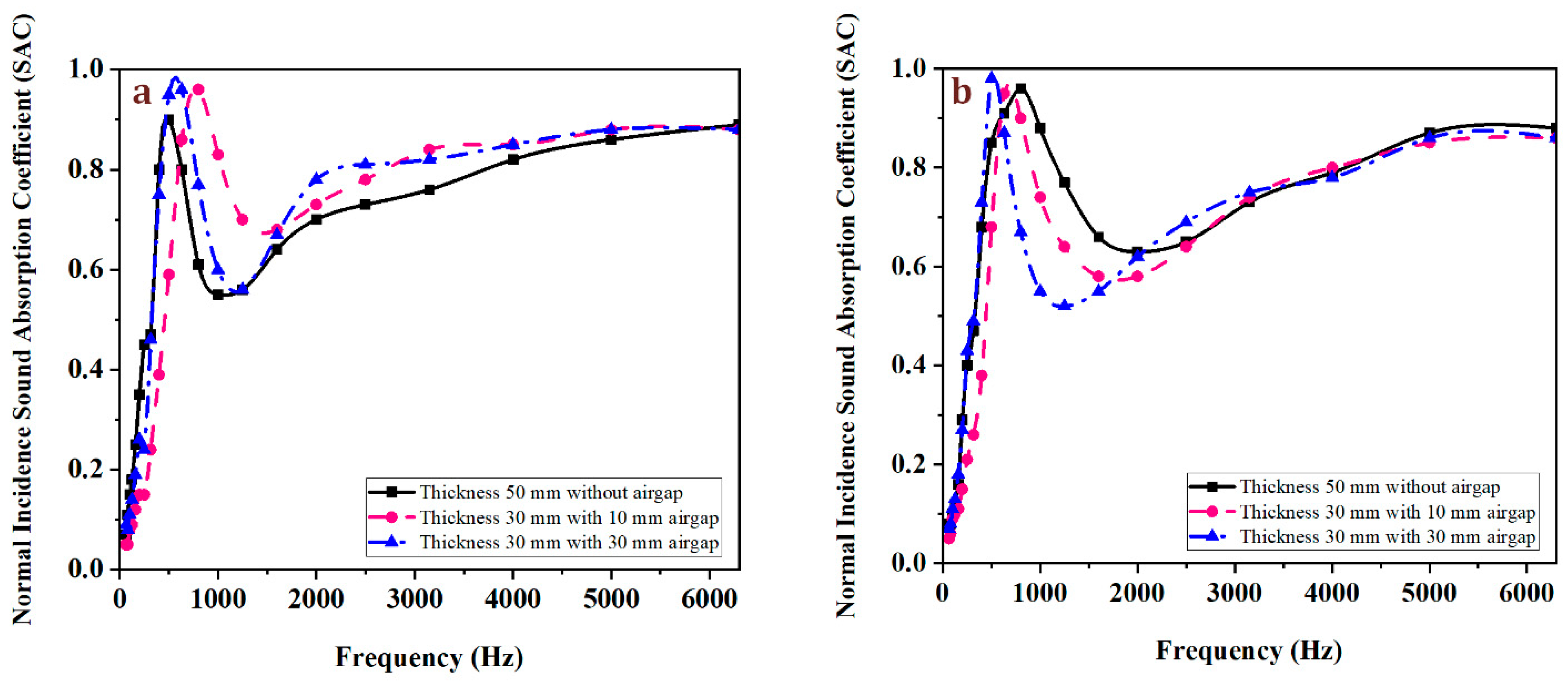

3.2.3. The Effect of Airgaps on Normal Incidence SAC

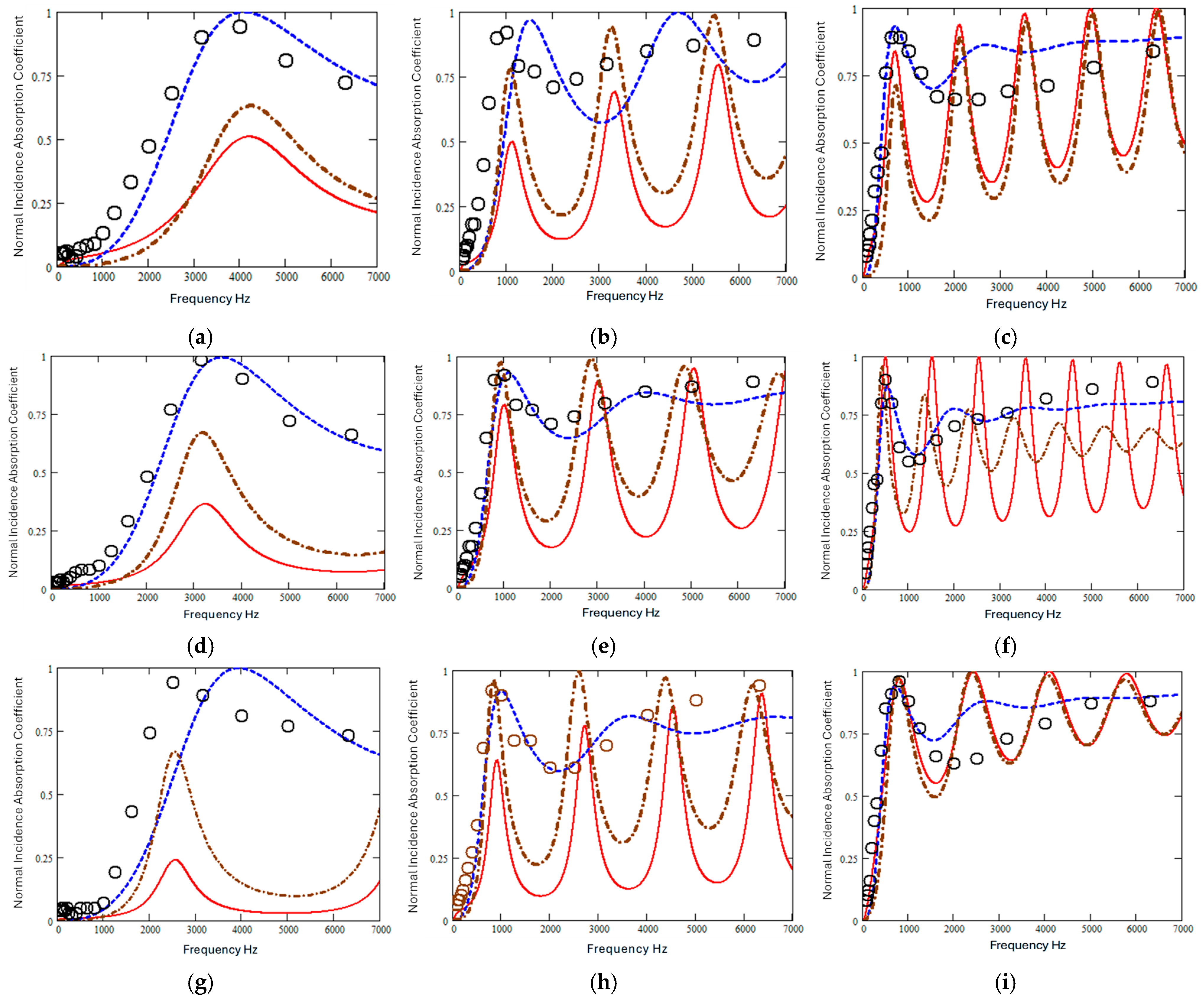

3.3. Modeling Results

3.4. The Impact of Combining Different Ratios of Eucalyptus and Poplar Sawdust

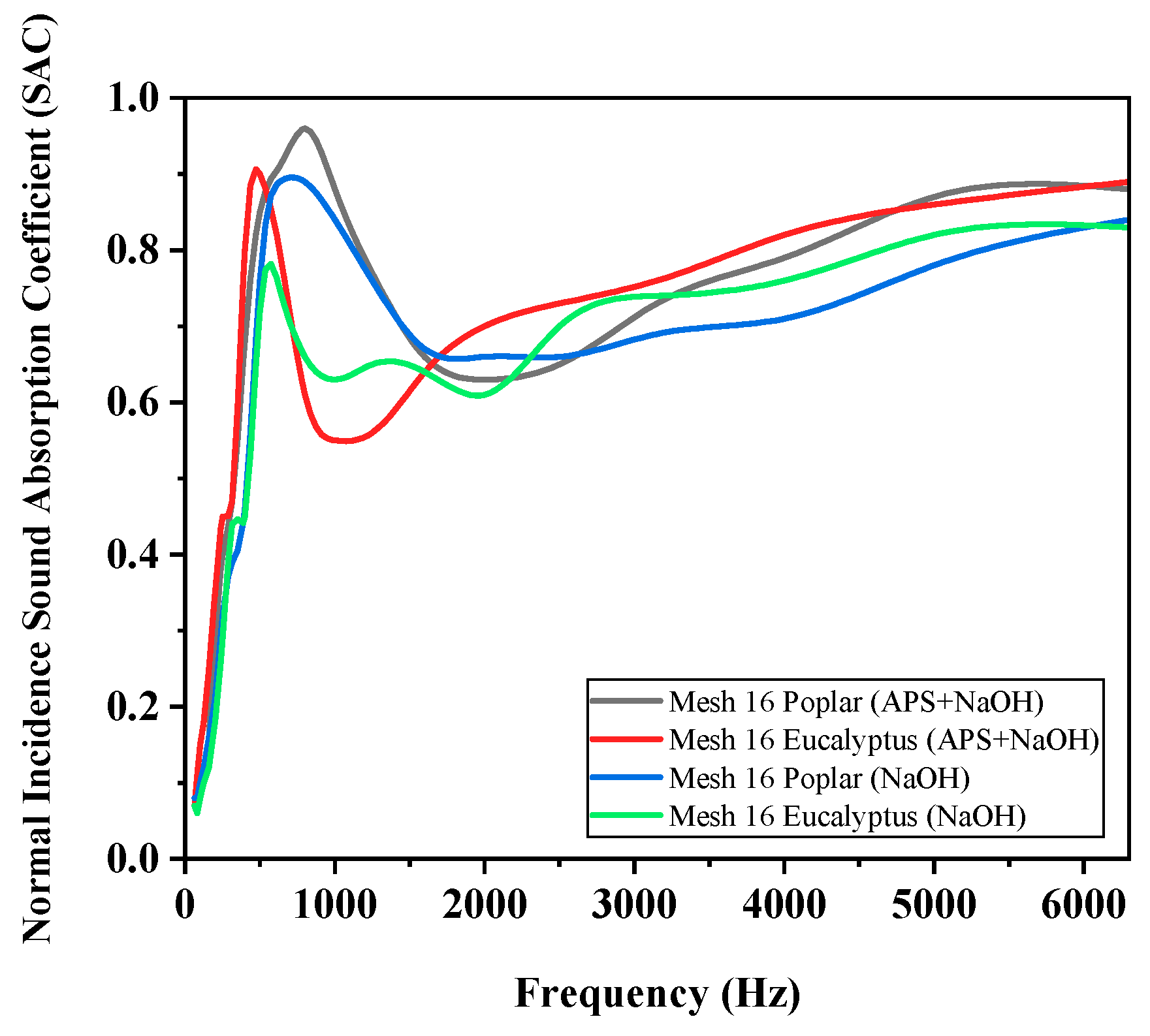

3.5. Comparison of Chemical Treatment Effects

4. Conclusions

- The sawdust-reinforced PU samples (Mesh 16) achieved NRC values exceeding 0.65, matching or surpassing the performance of commercially available acoustic foams. Also, the SAA values for samples (12, 15, 18, and 24) are higher than those of PU foam. For example, the SAA of the composite made of PU and poplar sawdust (sample 18) was calculated to be 0.68, which represents an increase of 9.68% over the calculated value of 0.62 for the PU foam

- Increasing sample thickness from 10 mm to 50 mm enhances the sound absorption coefficient (SAC) in the low- and mid-frequency ranges and shifts the first peak in the absorption spectra to lower frequencies.

- Increasing the mesh size (i.e., decreasing particle size) significantly enhances the normal incidence SAC across a broad frequency range, while also shifting the absorption peak to lower frequencies. Finer particles lead to increased airflow resistivity (σ), thereby improving acoustic efficiency. Samples with finer mesh sizes offer improved performance in the mid-frequency range of 500 to 2000 Hz, which is crucial for speech and common indoor noise sources.

- Introducing an air gap behind the sample enhances absorption at lower frequencies. This can produce absorption coefficient spectra comparable to those achieved with thicker materials, potentially reducing manufacturing costs.

- The effective thermal conductivity (Keff) values for the mesh 16 samples were measured at 0.044 W/mK, indicating a useful insulation performance.

- The mesh 16 samples demonstrated suitable tensile strengths of 0.06330 MPa for eucalyptus-reinforced foam and 0.06105 MPa for poplar-reinforced foam, respectively. Overall, the addition of Mesh 16 sawdust fibers offers the best balance between thermal insulation, acoustic properties, and structural integrity.

- The poplar composite treated with APS + NaOH exhibited the best broadband absorption, maintaining SAC values of approximately 0.9 or higher across a broad frequency spectrum. The eucalyptus composite treated with APS + NaOH also showed significant enhancements. NaOH-treated poplar composites exhibited high SAC values in the 500–2000 Hz range, which is crucial for controlling speech and everyday environmental noise.

- The JCAL model fits the data for both PU foam and PU foam and sawdust mixtures well, albeit some of the fitted parameter values are questionable. The NUPSD model predictions based on measured porosity, flow resistivity and the frequency of the first quarter wavelength resonance in the absorption spectra for hard-backed samples are relatively poor, but the NUPSD model predicts significantly higher values of tortuosity than result from fitting the JCAL model.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohamed, A.-M.O.; Paleologos, E.K.; Howari, F.M. Noise pollution and its impact on human health and the environment. In Pollution Assessment for Sustainable Practices in Applied Sciences and Engineering; Elsevier: Amsterdam, The Netherlands, 2021; pp. 975–1026. [Google Scholar]

- He, M.; Perrot, C.; Guilleminot, J.; Leroy, P.; Jacqus, G. Multiscale prediction of acoustic properties for glass wools: Computational study and experimental validation. J. Acoust. Soc. Am. 2018, 143, 3283–3299. [Google Scholar] [CrossRef]

- Morales, J.J.P.; Resuello, J.L.S.; Camacho, M.; Estorico, G.C. Noise Pollution in Urban Transport: A Systematic Review of Health Impacts from Buses, Trains, and Motorcycles. Int. J. Innov. Sci. Res. Technol. 2025, 10, 564–576. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound absorption properties of natural fibers: A review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Arenas, J.P.; del Rey, R.; Alba, J.; Oltra, R. Sound-absorption properties of materials made of esparto grass fibers. Sustainability 2020, 12, 5533. [Google Scholar] [CrossRef]

- Mylsamy, B.; Shanmugam, S.K.M.; Aruchamy, K.; Palanisamy, S.; Nagarajan, R.; Ayrilmis, N. A review on natural fiber composites: Polymer matrices, fiber surface treatments, fabrication methods, properties, and applications. Polym. Eng. Sci. 2024, 64, 2345–2373. [Google Scholar] [CrossRef]

- Haghighat, M.; Samaei, S.E.; Amininasab, S.; Faridan, M.; Mehrzad, S.; Sheikhmozafari, M.J.; Taban, E. The Impact of Fiber Size on the Sound Absorption Behavior of Composites Made from Sugarcane Bagasse Wastes Fibers. J. Nat. Fibers 2023, 20, 2175760. [Google Scholar] [CrossRef]

- SheikhMozafari, M.J.; Taban, E.; Soltani, P.; Faridan, M.; Khavanin, A. Sound absorption and thermal insulation performance of sustainable fruit stone panels. Appl. Acoust. 2024, 217, 109836. [Google Scholar] [CrossRef]

- Olcay, H.; Kocak, E.D. Rice plant waste reinforced polyurethane composites for use as the acoustic absorption material. Appl. Acoust. 2021, 173, 107733. [Google Scholar] [CrossRef]

- Mohammadi, M.; Ishak, M.R.; Sultan, M.T.H. Exploring chemical and physical advancements in surface modification techniques of natural fiber reinforced composite: A comprehensive review. J. Nat. Fibers 2024, 21, 2408633. [Google Scholar] [CrossRef]

- Kino, N.; Nakano, G.; Suzuki, Y. Non-acoustical and acoustical properties of reticulated and partially reticulated polyurethane foams. Appl. Acoust. 2012, 73, 95–108. [Google Scholar] [CrossRef]

- Yeşilyurt, A.; Parın, F.N.; Uysal, N. Mechanical, Thermal, and Sound Properties of Bamboo-Powder-Filled Polyurethane Composites. ChemistrySelect 2024, 9, e202401976. [Google Scholar] [CrossRef]

- MB, S.; GC, M.K.; Pitchaimani, J. Acoustic characterization of natural areca catechu fiber-reinforced flexible polyurethane foam composites. J. Appl. Polym. Sci. 2024, 141, e54866. [Google Scholar]

- Roseli, A.I.; Mat Hassan, N.N.; Abdul Mutalib Leman, A.M.L.; Abdul Latif, N.; Yulfian Aminanda, Y.A.; Djoko Setyanto, D.S.; Yuyun Tajunnusa, Y.T.; Yonrapach Areerob, Y.A.; Methawee Nukunudompanich, M.N. The Physical and Sound Absorption Property of Lightweight Rigid Polyurethane Composite Reinforced Bamboo Fiber for Roof Applications. J. Adv. Res. Appl. Sci. Eng. Technol. 2023, 31, 268–280. [Google Scholar] [CrossRef]

- Samaei, S.E.; Berardi, U.; Mahabadi, H.A.; Soltani, P.; Taban, E. Optimization and modeling of the sound absorption behavior of polyurethane composite foams reinforced with kenaf fiber. Appl. Acoust. 2023, 202, 109176. [Google Scholar] [CrossRef]

- Kocak, E.D.; Olcay, H.; Yildiz, Z. Mechanical and acoustic properties of alkali treated agricultural waste reinforced sustainable polyurethane composites. J. Reinf. Plast. Compos. 2023, 42, 1191–1203. [Google Scholar] [CrossRef]

- Tiuc, A.-E.; Borlea, S.I.; Nemeș, O.; Vermeșan, H.; Vasile, O.; Popa, F.; Pințoi, R. New composite materials made from rigid/flexible polyurethane foams with fir sawdust: Acoustic and thermal behavior. Polymers 2022, 14, 3643. [Google Scholar] [CrossRef] [PubMed]

- Udokpoh, U.; Nnaji, C. Reuse of sawdust in developing countries in the light of sustainable development goals. Recent Prog. Mater. 2023, 5, 1–33. [Google Scholar] [CrossRef]

- Singh, B.K.; Tomar, A. Growth and Biomass Models for Three Fast-growing Tree Species under High-density Plantation. Int. J. Environ. Clim. Change 2024, 14, 562–570. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, J.; Zhang, L.; Zhan, P.; Liu, N.; Wu, Z. Preparation of nanocellulose from steam exploded poplar wood by enzymolysis assisted sonication. Mater. Res. Express 2020, 7, 035010. [Google Scholar] [CrossRef]

- Sannigrahi, P.; Ragauskas, A.J.; Tuskan, G.A. Poplar as a feedstock for biofuels: A review of compositional characteristics. Biofuels Bioprod. Biorefining 2010, 4, 209–226. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, K.; Xiao, L.-P.; Sun, R.-C.; Song, G. Total utilization of lignin and carbohydrates in Eucalyptus grandis: An integrated biorefinery strategy towards phenolics, levulinic acid, and furfural. Biotechnol. Biofuels 2020, 13, 2. [Google Scholar] [CrossRef]

- Masruri, B.; Khavanin, A.; Taban, E.; Amininasab, S. Enhancing the acoustic performance of eucalyptus and poplar wood via ammonium persulfate treatment: Structural and functional insights. Appl. Acoust. 2025, 240, 110983. [Google Scholar] [CrossRef]

- Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM D1037-12(2020); ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D3776/D3776M-20(2025); Standard Test Methods for Mass per Unit Area (Weight) of Fabric. ASTM International: West Conshohocken, PA, USA, 2025.

- SRPS, E. 9053-1; Acoustics—Determination of Airflow Resistance—Part 1: Static Airflow Method. Institute for Standardization of Serbia: Belgrade, Serbia, 2019.

- ASTM C177-19; Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus. ASTM: West Conshohocken, PA, USA, 2019.

- Zhu, J. Impact of Size Distribution of Cell Model on the Effective Thermal Conductivity of Saturated Porous Media. Int. J. Thermophys. 2020, 41, 34. [Google Scholar] [CrossRef]

- Rezgar, H.; Taher, A.; Ali, D.; Richard, E.L. Thermal Conductivity of Low Density Polyethylene Foams Part I: Comprehensive Study of Theoretical Models. J. Therm. Sci. 2019, 28, 745–754. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Doniavi, A.; Lee, R.E. Multi-objective optimization of heat transfer mechanisms of microcellular polymeric foams from thermal-insulation point of view. Therm. Sci. Eng. Prog. 2019, 9, 21–29. [Google Scholar] [CrossRef]

- König, J.; Lopez-Gil, A.; Cimavilla-Roman, P.; Rodriguez-Perez, M.A.; Petersen, R.R.; Østergaard, M.B.; Iversen, N.; Yue, Y.; Spreitzer, M. Synthesis and properties of open-and closed-porous foamed glass with a low density. Constr. Build. Mater. 2020, 247, 118574. [Google Scholar] [CrossRef]

- Soloveva, O.V.; Solovev, S.A.; Vankov, Y.V.; Shakurova, R.Z. Experimental studies of the effective thermal conductivity of polyurethane foams with different morphologies. Processes 2022, 10, 2257. [Google Scholar] [CrossRef]

- ASTM D3574-17; Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams. ASTM: West Conshohocken, PA, USA, 2017.

- ISO 10534-2; Acoustics—Determination of acoustic properties in impedance tubes Part 2: Two-Microphone Technique for Normal Sound Absorption Coefficient and Normal Surface Impedance. ISO: Geneva, Switzerland, 2023.

- ASTM C423; Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method. ASTM: West Conshohocken, PA, USA, 2023.

- Horoshenkov, K.V.; Swift, M.J. The acoustic properties of granular materials with pore size distribution close to log-normal. J. Acoust. Soc. Am. 2001, 110, 2371–2378. [Google Scholar] [CrossRef]

- Allard, J.F.; Champoux, Y. New empirical equations for sound propagation in rigid frame fibrous materials. J. Acoust. Soc. Am. 1992, 91, 3346–3353. [Google Scholar] [CrossRef]

- Yang, T.; Eser, M.; Xiong, X.; Groby, J.-P.; Schmid, J.M.; Maeder, M.; Chang, Y.-H.; Marburg, S. Experiment-driven simplification of Johnson-Champoux-Allard-Lafarge model for fibrous materials. J. Acoust. Soc. Am. 2025, 157, 3497–3507. [Google Scholar] [CrossRef]

- Horoshenkov, K.V.; Hurrell, A.; Groby, J.-P. A three-parameter analytical model for the acoustical properties of porous media. J. Acoust. Soc. Am. 2019, 145, 2512–2517. [Google Scholar] [CrossRef]

- Saati, F.; Hoppe, K.-A.; Marburg, S.; Horoshenkov, K.V. The accuracy of some models to predict the acoustical properties of granular media. Appl. Acoust. 2022, 185, 108358. [Google Scholar] [CrossRef]

- Tran, V.H.; Kim, J.-D.; Kim, J.-H.; Kim, S.-K.; Lee, J.-M. Influence of cellulose nanocrystal on the cryogenic mechanical behavior and thermal conductivity of polyurethane composite. J. Polym. Environ. 2020, 28, 1169–1179. [Google Scholar] [CrossRef]

- Wang, D.; Peng, H.; Yu, B.; Zhou, K.; Pan, H.; Zhang, L.; Li, M.; Liu, M.; Tian, A.; Fu, S. Biomimetic structural cellulose nanofiber aerogels with exceptional mechanical, flame-retardant and thermal-insulating properties. Chem. Eng. J. 2020, 389, 124449. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Fathi, S.; Azdast, T.; Rostami, M. Theoretical Investigation and Optimization of Radiation Thermal Conduction of Thermal-Insulation Polyolefin Foams. Iran. J. Mater. Sci. Eng. 2020, 17, 58–65. [Google Scholar]

- Moghaddam, S.T.; Naimi-Jamal, M.R. Reinforced magnetic polyurethane rigid (PUR) foam nanocomposites and investigation of thermal, mechanical, and sound absorption properties. J. Thermoplast. Compos. Mater. 2019, 32, 1224–1241. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, Y. The acoustic property study of polyurethane foam with addition of bamboo leaves particles. Polym. Compos. 2018, 39, 1370–1381. [Google Scholar] [CrossRef]

- Abdou, A.; Budaiwi, I. The variation of thermal conductivity of fibrous insulation materials under different levels of moisture content. Constr. Build. Mater. 2013, 43, 533–544. [Google Scholar] [CrossRef]

- Olcay, H.; Kocak, E.D. The mechanical, thermal and sound absorption properties of flexible polyurethane foam composites reinforced with artichoke stem waste fibers. J. Ind. Text. 2022, 51, 8738S–8763S. [Google Scholar] [CrossRef]

- Hýsek, Š.; Neuberger, P.; Sikora, A.; Schönfelder, O.; Ditommaso, G. Waste utilization: Insulation panel from recycled polyurethane particles and wheat husks. Materials 2019, 12, 3075. [Google Scholar] [CrossRef]

- Shao, H.; Zhang, Q.; Liu, H.; Guo, W.; Jiang, Y.; Chen, L.; He, L.; Qi, J.; Xiao, H.; Chen, Y. Renewable natural resources reinforced polyurethane foam for use of lightweight thermal insulation. Mater. Res. Express 2020, 7, 055302. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. The impact of hemp shives impregnated with selected plant oils on mechanical, thermal, and insulating properties of polyurethane composite foams. Materials 2020, 13, 4709. [Google Scholar] [CrossRef]

- Datta, J.; Kopczyńska, P. Effect of kenaf fibre modification on morphology and mechanical properties of thermoplastic polyurethane materials. Ind. Crops Prod. 2015, 74, 566–576. [Google Scholar] [CrossRef]

- Tomin, M.; Kmetty, A. Evaluating the cell structure-impact damping relation of cross-linked polyethylene foams by falling weight impact tests. J. Appl. Polym. Sci. 2021, 138, 49999. [Google Scholar] [CrossRef]

- Liu, L.; Liu, F.; Zenkert, D.; Åkermo, M.; Fagerström, M. Mesostructural origins of the anisotropic compressive properties of low-density closed-cell foams: A deeper understanding. arXiv 2025, arXiv:2503.03847. [Google Scholar] [CrossRef]

- Sathishkumar, G.; Ibrahim, M.; Mohamed Akheel, M.; Rajkumar, G.; Gopinath, B.; Karpagam, R.; Karthik, P.; Martin Charles, M.; Gautham, G.; Gowri Shankar, G. Synthesis and mechanical properties of natural fiber reinforced epoxy/polyester/polypropylene composites: A review. J. Nat. Fibers 2022, 19, 3718–3741. [Google Scholar] [CrossRef]

- Li, X.; Chua, J.W.; Yu, X.; Li, Z.; Zhao, M.; Wang, Z.; Zhai, W. 3D-printed lattice structures for sound absorption: Current progress, mechanisms and models, structural-property relationships, and future outlook. Adv. Sci. 2024, 11, 2305232. [Google Scholar] [CrossRef]

- Gwon, J.G.; Kim, S.K.; Kim, J.H. Sound absorption behavior of flexible polyurethane foams with distinct cellular structures. Mater. Des. 2016, 89, 448–454. [Google Scholar] [CrossRef]

- Lee, J.; Kim, G.H.; Ha, C.S. Sound absorption properties of polyurethane/nano-silica nanocomposite foams. J. Appl. Polym. Sci. 2012, 123, 2384–2390. [Google Scholar] [CrossRef]

- Lazzari, L.K.; Kerche, E.F.; Figueiredo, F.R.; de Albuquerque, R.F.; Bortoli, B.; Polkowski, R.D. Polyurethane Foam Coated with Organic Filers for Sound Absorption: A Briefre View; 0148-7191; SAE Technical Paper: Warrendale, PA, USA, 2024. [Google Scholar]

- Tiuc, A.E.; Nemeş, O.; Vermeşan, H.; Toma, A.C. New sound absorbent composite materials based on sawdust and polyurethane foam. Compos. Part B Eng. 2019, 165, 120–130. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, R.; Barczewski, M.; Prociak, A.; Polaczek, K. Thermal Insulation and Sound Absorption Properties of Open-Cell Polyurethane Foams Modified with Bio-Polyol Based on Used Cooking Oil. Materials 2020, 13, 5673. [Google Scholar] [CrossRef]

- Selvaraj, V.K.; Subramanian, J. Experimentation, simulation, and statistical analysis of nanofillers reinforced bio-based polyurethane foam for acoustical applications. Polym. Eng. Sci. 2023, 63, 1169–1183. [Google Scholar] [CrossRef]

- Shravage, P.; Jain, S.; Karanth, N. Effect of intrinsic parameters on sound absorption and transmission loss—A parametric study. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Lisbon, Portugal, 13–16 June 2010; International Institute of Noise Control Engineering: West Lafayette, IN, USA, 2010; pp. 664–673. [Google Scholar]

- Yilmaz, N.D.; Banks-Lee, P.; Powell, N.B.; Michielsen, S. Effects of porosity, fiber size, and layering sequence on sound absorption performance of needle-punched nonwovens. J. Appl. Polym. Sci. 2011, 121, 3056–3069. [Google Scholar] [CrossRef]

- De Salvio, D.; Fratoni, G.; D’Orazio, D.; Garai, M. Assessing human activity noise in workspaces using machine learning and numerical models. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Tokyo, Japan, 20–23 August 2023; International Institute of Noise Control Engineering: West Lafayette, IN, USA, 2023; pp. 5259–5269. [Google Scholar]

- Vardaxis, N.-G.; Bard, D. Review of acoustic comfort evaluation in dwellings: Part II—Impact sound data associated with subjective responses in laboratory tests. Build. Acoust. 2018, 25, 171–192. [Google Scholar] [CrossRef]

- Radosz, J. Pilot studies of noise annoyance in relation to time, amplitude and frequency characteristics of sound. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Washington, DC, USA, 1–5 August 2021; International Institute of Noise Control Engineering: West Lafayette, IN, USA, 2021; pp. 981–986. [Google Scholar]

- Azahari, M.S.M.; Rus, A.Z.M.; Zaliran, M.T.; Kormin, S. Improving Sound Absorption Property of Polyurethane Foams Doped with Natural Fiber; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 012009. [Google Scholar]

- Azahari, M.S.M.; Rus, A.Z.M.; Kormin, S.; Zaliran, M.T. Acoustic Properties of Polymer Foam Composites Blended with Different Percentage Loadings of Natural Fiber; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 012009. [Google Scholar]

- Hajizadeh, R.; Khavanin, A.; Barmar, M.; Jafari, A.J.; Dehghan, S.F. Improving the sound absorption properties of flexible polyurethane (PU) foam using nanofibers and nanoparticles. Sound Vib. 2019, 53, 207–222. [Google Scholar] [CrossRef]

- Bhingare, N.H.; Prakash, S. Effect of polyurethane resin addition on acoustic performance of natural coconut coir fiber. J. Nat. Fibers 2022, 19, 2902–2913. [Google Scholar] [CrossRef]

- Tsuruha, T.; Yamada, Y.; Otani, M.; Takano, Y. Effect of casing on sound absorption characteristics of fine spherical granular material. J. Acoust. Soc. Am. 2020, 147, 3418–3428. [Google Scholar] [CrossRef]

- Huang, C.; Liu, Y.; Yang, S.; Xiang, H.; Jin, Y.; Cao, S.; Chen, K. Fabrication and acoustic absorption properties of electrospun polyacrylonitrile nanofiber membranes. Phys. Scr. 2025, 100, 025902. [Google Scholar] [CrossRef]

- Železnik, A.; Čurović, L.; Prezelj, J. Sustainable sound absorption using shredded plastic particles: Adjusting low-frequency acoustic performance with particle size. J. Low Freq. Noise Vib. Act. Control 2025, 44, 1139–1150. [Google Scholar] [CrossRef]

- Suo, H.; Xu, J.; Feng, Y.; Liu, D.; Tang, P.; Feng, Y. Experimental Research and Theoretical Analysis of the Coupling Mechanism Between Microstructure and Acoustics in Porous Materials. Appl. Sci. 2025, 15, 3104. [Google Scholar] [CrossRef]

- Lashgari, M.; Taban, E.; SheikhMozafari, M.J.; Soltani, P.; Attenborough, K.; Khavanin, A. Wood chip sound absorbers: Measurements and models. Appl. Acoust. 2024, 220, 109963. [Google Scholar] [CrossRef]

- Istana, B.; Batan, I.M.; Sutikno; Khem, S.; Ubaidillah, U.; Yahya, I. Influence of Particle Size and Bulk Density on Sound Absorption Performance of Oil Palm Frond-Reinforced Composites Particleboard. Polymers 2023, 15, 510. [Google Scholar] [CrossRef]

- Kumar, R.; Saha, A.; Biswas, N.; Singh, G.; Beemkumar, N.; Kumar, A.V.; Bhowmik, A.; Bhattacharjee, B. Sound absorption properties of natural Bari bamboo composite. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2025, 14644207251313660. [Google Scholar] [CrossRef]

- Taban, E.; Soltani, P.; Berardi, U.; Putra, A.; Mousavi, S.M.; Faridan, M.; Samaei, S.E.; Khavanin, A. Measurement, modeling, and optimization of sound absorption performance of Kenaf fibers for building applications. Build. Environ. 2020, 180, 107087. [Google Scholar] [CrossRef]

- Bala, B.C.; Ayatab, Ü. A comparative study on some mechanical properties of black pine and black poplar woods. Turk. J. For. 2020, 21, 461–467. [Google Scholar] [CrossRef]

- Balboni, B.M.; Batista, A.S.; Garcia, J.N. Evaluating the potential for timber production of young forests of Eucalyptus spp. clones used for bioenergy: Wood density and mechanical properties. Aust. For. 2021, 84, 122–132. [Google Scholar] [CrossRef]

| Hybrid Composite | Key Findings | Year | Ref |

|---|---|---|---|

| Bamboo powder-filled PU foam | PU foams with 2.5% bamboo powder achieved an average SAC of 0.86 at 6300 Hz, outperforming unfilled PU foams. | 2024 | [12] |

| Areca catechu fiber-reinforced FPUF | Areca fiber reinforcement improved SAC, peaking at 0.95 at 450 Hz. Performance was influenced by fiber content, graded distribution, thickness, and air-cavity length. | 2024 | [13] |

| Lightweight RPU composite reinforced with bamboo fiber | Bamboo fiber addition improved low-frequency SAC due to enhanced pore structure and reduced density. RPU 25 composite reached SAC of 0.74 at 1250 Hz. | 2023 | [14] |

| PU composite foams reinforced with kenaf fiber | 1.2 wt% kenaf fiber (8 mm length) increased SAA to 0.65 from 0.48 (↑35.4%) compared to neat PU. | 2023 | [15] |

| Agricultural waste-reinforced PU composites | Corn silk, rice husk, and artichoke stem fillers (alkali-treated) improved SAC; corn silk achieved the highest (40.5%). | 2023 | [16] |

| Rigid/flexible PU foams with fir sawdust | 50% sawdust content improved SAC in the 420–1250 Hz range compared to 100% FPUFs. | 2022 | [17] |

| Rice plant waste-reinforced PU composites | 5% NaOH-treated rice waste improved SAC across 400–3200 Hz compared to neat PU foams. | 2021 | [9] |

| Sample No | Mesh No | Sawdust Type | Thickness (mm) | Apparent Density (kg m−3) | Flow Resistivity σ (N m−4 s) | Porosity (%) |

|---|---|---|---|---|---|---|

| 1 | 8 | Eucalyptus | 10 | 90.65 | 1030 | 91.20 |

| 2 | 30 | 70 | 2110 | 90.90 | ||

| 3 | 50 | 60.93 | 3840 | 90.60 | ||

| 4 | Poplar | 10 | 100 | 980 | 91.10 | |

| 5 | 30 | 65.14 | 1860 | 90.80 | ||

| 6 | 50 | 69.92 | 3160 | 90.40 | ||

| 7 | 10 | Eucalyptus | 10 | 78.68 | 2370 | 90.70 |

| 8 | 30 | 67.94 | 4060 | 90.50 | ||

| 9 | 50 | 58.49 | 6890 | 90.10 | ||

| 10 | Poplar | 10 | 100 | 1216 | 90.30 | |

| 11 | 30 | 67 | 2960 | 89.90 | ||

| 12 | 50 | 69.39 | 4730 | 89.70 | ||

| 13 | 16 | Eucalyptus | 10 | 66 | 2420 | 89.60 |

| 14 | 30 | 56.19 | 5690 | 90.70 | ||

| 15 | 50 | 58.95 | 9830 | 90.50 | ||

| 16 | Poplar | 10 | 67 | 1357 | 89.10 | |

| 17 | 30 | 68.71 | 3520 | 88.70 | ||

| 18 | 50 | 65.90 | 7270 | 89.20 | ||

| 19 | 20 | Eucalyptus | 10 | 76.39 | 3150 | 89.30 |

| 20 | 30 | 59.79 | 8429 | 89.10 | ||

| 21 | 50 | 58.82 | 12,530 | 88.60 | ||

| 22 | Poplar | 10 | 78.17 | 2080 | 88.90 | |

| 23 | 30 | 68.24 | 6860 | 88.50 | ||

| 24 | 50 | 67.20 | 10,902 | 88.20 | ||

| 25 | Pure foam | 10 | 47.10 | 3860 | 94.20 | |

| 26 | 30 | 44.86 | 1710 | 94.70 | ||

| 27 | 50 | 46.67 | 844 | 94.30 | ||

| Natural Fiber-Reinforced PU Foams | Keff (W/mK) | Ref |

|---|---|---|

| Eucalyptus as reinforcement | 0.044 | This study |

| Poplar as reinforcement | 0.044 | This study |

| artichoke stem waste as reinforcement | 0.049–0.051 | [47] |

| fir sawdust as reinforcement | 0.043–0.045 | [17] |

| wood fibers, bamboo fibers and rice husks as reinforcement | 0.045–0.065 | [49] |

| wheat husks as reinforcement | 0.043–0.049 | [48] |

| Hemp shives as reinforcement | 0.026–0.031 | [50] |

| Sample Type | Tensile Strength (MPa) | Elongation at Break % | Young’s Modulus (MPa) |

|---|---|---|---|

| PU foam | 0.01925 | 48.113 | 0.016677 |

| PU reinforced with Poplar sawdust | 0.06105 | 24.341 | 0.164712 |

| PU reinforced with Eucalyptus sawdust | 0.06330 | 42.009 | 0.075254 |

| Sample | NRC | SAA | Peak Frequency (α) |

|---|---|---|---|

| 1 | 0.23 | 0.22 | 2500 (0.92) |

| 2 | 0.50 | 0.50 | 800 (0.92) |

| 3 | 0.48 | 0.47 | 1000 (0.82) |

| 4 | 0.31 | 0.31 | 1600 (0.92) |

| 5 | 0.38 | 0.37 | 1250 (0.76) |

| 6 | 0.49 | 0.50 | 800 (0.96) |

| 7 | 0.26 | 0.25 | 2000 (0.84) |

| 8 | 0.39 | 0.36 | 5000 (0.79) |

| 9 | 0.59 | 0.59 | 800 (0.97) |

| 10 | 0.18 | 0.19 | 3150 (0.98) |

| 11 | 0.52 | 0.51 | 1000 (0.97) |

| 12 | 0.61 | 0.63 | 6300 (0.9) |

| 13 | 0.17 | 0.18 | 3150 (0.98) |

| 14 | 0.55 | 0.55 | 1000 (0.92) |

| 15 | 0.65 | 0.63 | 500 (0.9) |

| 16 | 0.22 | 0.22 | 2500 (0.94) |

| 17 | 0.51 | 0.52 | 800 (0.92) |

| 18 | 0.69 | 0.68 | 800 (0.96) |

| 19 | 0.25 | 0.23 | 2000 (0.73) |

| 20 | 0.48 | 0.44 | 630 (0.69) |

| 21 | 0.63 | 0.60 | 500 (0.84) |

| 22 | 0.21 | 0.22 | 2500 (0.93) |

| 23 | 0.55 | 0.52 | 800 (0.92) |

| 24 | 0.65 | 0.62 | 6300 (0.9) |

| 25 | 0.17 | 0.18 | 4000 (0.94) |

| 26 | 0.48 | 0.46 | 1000 (0.87) |

| 27 | 0.64 | 0.62 | 800 (0.89) |

| Sample | Thickness (mm) | Flow Resistivity Nm−4 s | Porosity (%) | Model | Tortuosity α∞ | Thermal Permeability | Characteristic Lengths | |

|---|---|---|---|---|---|---|---|---|

| Λ μm | Λ′ μm | |||||||

| PU foam | 10 | 3860 | 94.20 | JCAL | 2.148 | 7.44 | 28 | 345 |

| JCAL(NUPSD) | 4.1 | 287.1 | 330.4 | 2311 | ||||

| NUPSD | 4.1 | - | - | - | ||||

| 30 | 1710 | 94.70 | JCAL | 2.53 | 6.83 | 91.2 | 92.8 | |

| JCAL(NUPSD) | 6.4 | 295.3 | 378.2 | 2422 | ||||

| NUPSD | 6.4 | - | - | - | ||||

| 50 | 844 | 94.30 | JCAL | 1.1 | 48.7 | 18.3 | 677 | |

| JCAL(NUPSD) | 5.4 | 78.94 | 247 | 1335 | ||||

| NUPSD | 5.4 | - | - | - | ||||

| PU foam + Eucalyptus sawdust | 10 | 2420 | 89.60 | JCAL | 2.86 | 7.09 | 40.9 | 71.3 |

| JCAL(NUPSD) | 7 | 2871 | 330.4 | 2311 | ||||

| NUPSD | 7 | - | - | - | ||||

| 30 | 5690 | 90.70 | JCAL | 1.74 | 12.10 | 22.4 | 200.3 | |

| JCAL(NUPSD) | 7.6 | 1543 | 216.4 | 1643 | ||||

| NUPSD | 7.6 | - | - | - | ||||

| 50 | 9830 | 90.50 | JCAL | 2.53 | 10.00 | 31.3 | 500 | |

| JCAL(NUPSD) | 10.9 | 2653 | 172.5 | 1881 | ||||

| NUPSD | 10.9 | - | - | - | ||||

| PU foam + Poplar sawdust | 10 | 1357 | 89.10 | JCAL | 2.39 | 100.00 | 23.2 | 10.00 |

| JCAL(NUPSD) | 11.25 | 20,750 | 462.8 | 5201 | ||||

| NUPSD | 11.25 | - | - | - | ||||

| 30 | 3520 | 88.70 | JCAL | 2.33 | 16.00 | 27.6 | 350 | |

| JCAL(NUPSD) | 9.6 | 516.7 | 286.5 | 2752 | ||||

| NUPSD | 9.6 | - | - | - | ||||

| 50 | 7270 | 98.92 | JCAL | 1.12 | 11.00 | 19.3 | 2000 | |

| JCAL(NUPSD) | 3.75 | 13.31 | 167.8 | 6287 | ||||

| NUPSD | 3.75 | - | - | - | ||||

| Sample | Thickness mm | |||||

|---|---|---|---|---|---|---|

| wool | 30 | 534,551.1 | 11.02 | 21.72 | 48.72 | 1.02 |

| PU foam | 10 | 16,570 | 28.1 | 1.161 | 7.566 | 4.2 |

| 30 | 38,490 | 28.1 | 2.631 | 2.6773 | 4.5 | |

| 50 | 78,040 | 30.52 | 57.36 | 312.1 | 7.25 | |

| PU foam plus Eucalyptus fibers | 10 | 18,710 | 16.94 | 2.655 | 4.629 | 11.44 |

| 30 | 53,460 | 7.68 | 1.655 | 10.2 | 10.39 | |

| 50 | 89,270 | 15.33 | 1.915 | 30.586 | 14.2 | |

| PU foam plus poplar fibers | 10 | 9622 | 12.05 | 1.756 | 0.757 | 174 |

| 30 | 24,050 | 11.1 | 2.19 | 27.78 | 29.2 | |

| 50 | 53,460 | 1.06 | 2.088 | 217 | 18.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masruri, B.; Taban, E.; Khavanin, A.; Attenborough, K. Sound Absorption and Thermal Insulation by Polyurethane Foams Reinforced with Bio-Based Lignocellulosic Fillers: Data and Modeling. Buildings 2025, 15, 3590. https://doi.org/10.3390/buildings15193590

Masruri B, Taban E, Khavanin A, Attenborough K. Sound Absorption and Thermal Insulation by Polyurethane Foams Reinforced with Bio-Based Lignocellulosic Fillers: Data and Modeling. Buildings. 2025; 15(19):3590. https://doi.org/10.3390/buildings15193590

Chicago/Turabian StyleMasruri, Batol, Ebrahim Taban, Ali Khavanin, and Keith Attenborough. 2025. "Sound Absorption and Thermal Insulation by Polyurethane Foams Reinforced with Bio-Based Lignocellulosic Fillers: Data and Modeling" Buildings 15, no. 19: 3590. https://doi.org/10.3390/buildings15193590

APA StyleMasruri, B., Taban, E., Khavanin, A., & Attenborough, K. (2025). Sound Absorption and Thermal Insulation by Polyurethane Foams Reinforced with Bio-Based Lignocellulosic Fillers: Data and Modeling. Buildings, 15(19), 3590. https://doi.org/10.3390/buildings15193590