Abstract

This manuscript is aimed at analyzing how operating factors may affect the durability of thermal insulation in building partitions located underground. It examines the durability of inverted insulation systems where thermal insulation is installed above the waterproofing layer and used in residential foundation slabs. The article demonstrates that, despite their popularity due to cost efficiency, the long-term success of these systems depends on thorough investigations of thermal isolation, especially considering different climate conditions. The analysis was based on an extensive literature review (2016–2024), supplemented with laboratory test results on extruded (XPS) and expanded (EPS) polystyrene boards. Additional tests examined the water penetration mechanism into insulation layers that are in direct contact with groundwater, revealing that cyclic freezing and thawing significantly increase moisture levels. The findings highlight the need for updated region-specific guidelines for the underground insulation in Central and Eastern Europe.

1. Introduction

1.1. Foundation Slabs with Inverted Insulation Layers—Operating Conditions Characteristics

The structures of underground parts of buildings significantly impact the choice of protection against atmospheric operating factors, such as ground and water pressure (which ranges from 30 to 60 MPa for every 0.3 m depth [1]), varying external temperatures, and, especially in temperate climates, frequent temperature transitions below 0 °C.

Typical construction solutions in this area can be divided into two basic groups, i.e., [2]:

- -

- foundations of buildings on footings, with floors poured on a concrete base,

- -

- building foundations that are constructed on concrete slabs.

Considering the need to ensure the required durability of underground building structures, they should be effectively protected against the effects of the above mentioned factors by both waterproof and thermal insulation. Insulation materials must reduce heat transfer through the structure in which they are installed, and waterproofing is designed to shield the building from uncontrolled humidity. The arrangement of these insulation layers can be either traditional or inverted. In traditional systems, waterproofing insulation is placed on the top of the thermal insulation to protect it from water that accumulates in the ground, while in inverted systems, waterproofing insulation is installed on the surface of the structure, shielding it from rainwater and water build-up in the soil [2,3], while thermal insulation is in this case no longer protected from such influence.

This article concentrates solely on analyzing one of the solutions mentioned above, i.e., using concrete bottom slabs in single-family buildings, combined with an inverted insulation system. While such structures provide structural simplicity and cost savings, they are increasingly examined due to their susceptibility to moisture ingress and thermal inefficiencies when not properly insulated or waterproofed. Recently, these solutions have attracted interest from private investors, but there is no scientific proof of their durability.

Such protection of underground parts of buildings should meet the utility requirements throughout their life cycle, because:

- -

- After the construction process, access to the insulation of the underground parts of buildings is very limited and often impossible,

- -

- Reproducing insulation in the area requires dismantling and/or removing protective layers, both ground and finish-surface layers.

The need to protect structures from water and moisture arises because most processes that damage building materials occur in the presence of water or moisture. Additionally, waterproofing techniques and material choice are essential. For waterproofing, various materials are used, including plastic and rubber damp-proof and basement tanking sheets, as well as bituminous membranes and coatings, cementitious and polymer coatings [4,5,6], and polymer-modified bituminous thick coatings with a thickness exceeding 3 mm [6,7,8]. Research by Hall and Hoff [9,10], and more recently by Francke et al. [11], highlights the need to combine chemical durability with mechanical integrity to ensure long-term performance. The type and number of waterproofing layers required are determined after a detailed analysis of the conditions at the building’s location and the level of its foundation [2]. However, a correct waterproofing design does not guarantee the desired level of tightness. The process and technology used for applying waterproofing are also crucial. Even the highest quality waterproofing materials will not ensure the expected tightness if they are not installed correctly or if the waterproofing is not properly executed and approved, especially at edges and sensitive areas [6]. The moisture problem in the structure can also result from ineffective horizontal damp-proofing [9,10,11,12,13,14,15,16,17,18], which provides insufficient protection for foundations against rising capillaries of moisture, as well as from inadequate vertical damp-proofing that does not sufficiently prevent groundwater penetration along the height of underground walls.

The second issue is heat transfer between structures and the surrounding ground. Insulation layers in underground parts of buildings are essential in ground frost zones to ensure proper functioning of this part of the structure. For an energy-efficient building within the habitable zone, heat loss through the floor can range from 30 to 50% [19,20,21]. Some researchers conclude that heat loss through a well-insulated residential building may be up to 25% of the total [22]. In a different study of uninsulated single-family houses in a cold, semi-arid climate, thermal losses through the floor reached 58% [23]. It has been estimated that ignoring the ground’s effect on a building’s energy efficiency can lead to errors of up to 50% [24]. A significant body of research emphasizes the importance of effective insulation in reducing thermal bridges and minimizing ground contact heat loss. Liu et al. [19] and El Saied et al. [24] found that uninsulated or poorly insulated slab-on-grade floors can contribute up to half of a building’s heat loss, especially in cold or temperate regions. Similarly, Fürtön et al. [25] used BIM simulations to model ground temperature distribution and highlight the importance of proper insulation placement. Various insulation materials are available, including synthetic options such as plastics and petroleum-based polymers like extruded polystyrene (XPS) and expanded polystyrene (EPS), as well as mineral or glass wool. Natural materials include cork, sheep wool, perlite, vermiculite, coconut, or cotton fibers. The key property of insulating materials is low thermal conductivity, and their lifespan depends on their ability to resist heat transfer. When integrated into building systems, factors such as thickness, operation, and maintenance conditions that prevent degradation or deterioration must be considered, especially protection against moisture. European standards, such as EN 13164 [26], EN 16535 [27], and ETAG 031 [28], set performance benchmarks for insulation products; however, their relevance to underground conditions remains under discussion. Despite notable progress, a gap remains in developing technical regulations specifically for inverted insulation systems in foundation slabs. While detailed guidelines exist for inverted roofing systems, applying them directly to below-grade environments is questionable due to differing moisture and load conditions.

1.2. Analysis of the Causes of Changes in the Thermal Resistance of a Building Partition

Numerous studies have explored the relationship between external temperatures and the thermal conductivity of insulation materials at temperatures above zero. These studies specifically focus on roofing and facade layers, assuming a temperature difference of 20 °C during testing and ignoring the effects of negative temperatures. Abdou and Budaiwi [29] conducted tests on fiberglass, wood wool, mineral wool, rock wool, polyethylene, polyurethane, and polystyrene at five temperatures: 4 °C, 10 °C, 24 °C, 38 °C, and 43 °C. They observed that higher operational temperatures lead to increased thermal conductivities, which may be linear in nature. These effects are more pronounced at higher temperatures, and materials like fiber insulation and polyethylene are more sensitive to changes in thermal conductivity with temperature, especially at lower densities [30,31]. Al-Ajlan [32] found that polyurethane is particularly susceptible to rising temperatures, with its thermal conductivity increasing by more than 30%, whereas polystyrene’s thermal conductivity increased by about 20% across the temperature range. Khoukhi et al. [33] reported that thermal conductivity increases linearly with temperature, with low-density samples showing a greater increase. Hay et al. and Zarr and Filliben [34,35] demonstrated that the thermal conductivity of PUR insulation is more sensitive to temperature changes than that of polystyrene, and that temperature effects outweigh density effects. Berardi and Naldi [36] showed that, within a temperature range of 20 °C to 50 °C and a 30 °C temperature difference, glass fiber, mineral wool, and XPS insulation display an almost linear relationship between thermal conductivity and average temperature. In contrast, PIR insulation shows non-linear behavior, with the lowest thermal conductivity observed between 9.4 °C and 22.9 °C. Yousefi and Tariku [37] found that the thermal conductivity and specific heat of insulation materials such as cellulose fiber, EPS, XPS, open-cell SPF, and mineral wool vary linearly with average temperatures of 5 °C, 10 °C, 21 °C, 24 °C, 35 °C, 50 °C, and 60 °C, with a temperature difference of 20 °C. An exception to this trend is PIR.

Another problem analyzed by scientists is the effect of moisture on the thermal resistance of thermal insulation material [38]. Water with high thermal conductivity fills the pores of insulation, replacing air with low conductivity, which, along with increased moisture, causes a rise in thermal conductivity [39]. The process of water penetration into the layer and the temperature conditions associated with it have proven to be important research issues and will be discussed in this manuscript.

1.3. The Purpose of the Article

This study is aimed at examining the long-term performance of inverted insulation systems in slab-on-grade foundations, integrating recent literature insights with practical observations and experimental data relevant to Central and Eastern European climates.

The article addresses an often-overlooked technical issue: the exposure of thermal insulation layers used in slab-on-grade foundations to moisture, which occurs when waterproofing does not protect these layers against operational factors. This phenomenon is examined to demonstrate its impact on the system’s durability. It has been noted that the rate of moisture penetration of thermal insulation materials is influenced not only by the soil and water conditions prevailing in the area where the building is located but also by variable operating temperatures, the impact of which is often underestimated when assessing the durability of thermal insulation materials. The article’s authors discuss an important issue that has been marginalized by other researchers to date, pointing out that the transition of operating temperatures through 0 °C significantly impacts the durability of the diffusion resistance of foundation slabs in single-family buildings located in the ground frost zone.

2. Materials and Methods

2.1. Materials

The analysis covers both the layer arrangement in the foundation slab cross-section and the thermal insulation materials that can be used in this arrangement, i.e.,:

- ➢

- Inverted insulation kits used within foundation slabs of single-family buildings—the work mechanism analyzed based on a literature review.

- ➢

- expanded and extruded polystyrene—based on randomly selected samples—was used in additional laboratory tests supporting the conclusions of the literature review.

Both groups of materials are examined in detail in Section 2.1.1 and Section 2.1.2.

2.1.1. Inverted Insulation Kits Used in Foundation Slabs of Single-Family Buildings

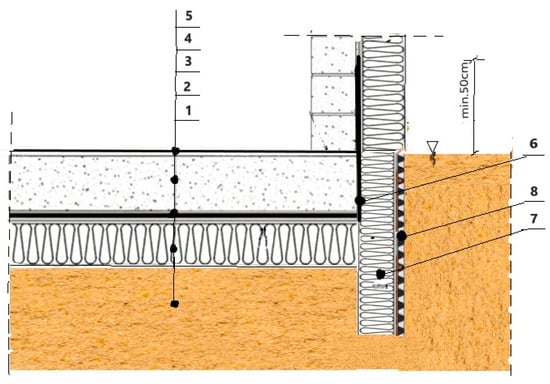

The primary goal of this study is to analyze the benchmarks that influence the durability of the reverse arrangement of insulation layers used in foundation slabs of single-family buildings, i.e., when the thermal insulation layer is placed directly on the ground and the waterproofing layer acts as a barrier between the concrete slab and the insulation material. The analyzed technical solution is shown in Figure 1.

Figure 1.

Cross-section of a foundation slab with inverted insulation layers: 1—ground layers, 2—thermal insulation, 3—horizontal waterproofing layer, 4—reinforced concrete slab, 5—additional waterproofing coating layer of the slab, 6—vertical waterproofing, 7—anti-slope layer made of thermal insulation material, 8—thermal insulation slab cover, such as made of mottled foil.

In the solution analyzed in this manuscript, the first layer laid on the ground is a thermal insulation material with low water absorption, such as XPS extruded polystyrene. The thickness of the thermal insulation layer in the discussed solutions typically ranges from 10 cm to 30 cm, depending on the planned floor layer layout. A thickness of 10 cm is assumed when an additional thermal insulation layer is to be added later on the slab or when underfloor heating is to be installed at a later stage. Thicknesses of 20 cm and 30 cm are designed to ensure thermal comfort during building use, with the 30 cm option also suitable for passive buildings. Which of these options will be most appropriate, ensuring durability from a functional perspective? The answer to this question is one of the aims of this manuscript. A layer of horizontal waterproofing is applied to the surface of the thermal insulation board, which transitions into vertical waterproofing within the wall. The type of waterproofing material is chosen based on the soil and water conditions prevailing in the building foundation. The next layer is a reinforced concrete slab, additionally protected on the surface with a layer of waterproofing coating. Around the slab, a vertical anti-flood wall is planned, made of thermal insulation material with low water absorption, buried in the ground, and featuring an additional surface cover layer.

2.1.2. Expanded and Extruded Polystyrene Boards

The study used eight randomly selected polystyrene boards, including four expanded polystyrene boards with a hydrophobized surface (compliant with EN 13163 [40]) and four extruded polystyrene boards (compliant with EN 13164 [26]), with properties specified in Table 1.

Table 1.

Properties of products used in the laboratory tests.

2.2. Methods

2.2.1. Literature Review

To achieve the goal, the analysis presented in the article, based on a literature review, is divided into the following stages:

- Stage 1—Classification of foundation slab solutions based on soil and water conditions at the site.

- Stage 2—Analysis of the impact of changing outdoor temperatures on soil and water conditions in building foundations, influencing the durability of insulation layers.

- Stage 3—Testing the durability of the performance properties of thermal insulation materials in inverted insulation layers, specifically when operating in constant moisture conditions.

Three main criteria were used to select the scientific papers for this analysis: (i) thematic scope, focusing on the reverse arrangement of insulation layers used within foundation slabs of single-family buildings; (ii) temporal scope, including papers published between 2016 and 2024, and related to the criteria mentioned above; (iii) complementation of the information obtained on the basic requirements of the topic, based on publications published previously.

Such method of selecting the analyzed publications allows for: (i) limiting the review to the most recent scientific articles, ensuring that the analysis focuses on the latest developments and current trends in the field, (ii) referencing the analyses to foundational requirements that have been in use for several years and remain relevant within the technical field. This approach emphasizes up-to-date information, offering insights that reflect the newest research findings and advancements while building on previous experience.

Stage 3 consists of two complementary parts:

- i.

- Literature review as described above.

- ii.

- Supplementary laboratory tests further supporting the arguments in the literature review. These studies examined the thermal conductivity coefficients of new products after drying to a constant mass and then after being treated with aging agents consisting of 28 days of water soaking, followed by 300 freeze–thaw cycles. The methods for conducting these tests are described below in point Section 2.2.2.

2.2.2. Additional Laboratory Tests

As part of additional laboratory tests, samples of thermal insulation products were exposed to aging conditions in the lab, and the change in their thermal conductivity coefficient before and after aging was measured. These tests were conducted following the specified research methodology.

- Aging tests, such as prolonged total immersion of the boards, followed by freezing cycles.

Water absorbability during prolonged total immersion was determined according to EN ISO 16535:2019 [27] on samples cut with a band saw, with surface dimensions of (300 × 300) mm, preserving the original thickness of the board.

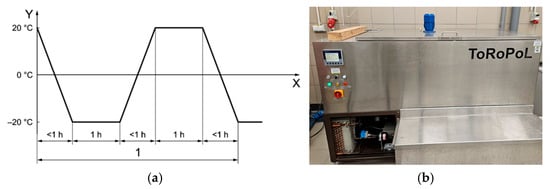

Measurements were taken after 28 days of water immersion. Following this period, the samples underwent 300 freeze–thaw cycles at −20 °C and thaw cycles in water at +20 °C, in accordance with EN ISO 16546 [41]. A single cycle process and the view of the testing chamber are available in Figure 2. Water absorbability was measured after completing 300 cycles.

Figure 2.

Freeze resistance testing: (a) course and duration of a single cycle, (b) testing chamber.

- Thermal conductivity of the boards

The thermal conductivity and thermal resistance under steady-state heat flow conditions were measured using a single–sample plate apparatus with heat flux density sensors, according to EN 12667 [42]. The thermal conductivity of the samples was tested twice for the following sample types:

- -

- Dried to a constant weight.

- -

- Damp immediately after prolonged full immersion.

The average temperature of the samples during measurement was 10 °C, the temperature difference across the sample thickness was 20 °C, and heat flowed upward. The sample thickness (L) was set to match either the target thickness of compressible samples or the actual sample dimension. The tests were conducted on samples measuring 300 × 300 mm with different thicknesses: 40 mm, 50 mm, 60 mm, 80 mm, and 100 mm.

3. Results and Discussion

3.1. Stage 1—Classification of Foundation Slab Solutions Based on Soil and Water Conditions at the Site—Literature Review

The arrangement of layers provided for use within the foundation slabs depends on [35]:

- (a)

- the degree of water tightness of the concrete provided for the slab in Poland, i.e.,:

- -

- Concretes with a water tightness degree of min. W8—without the need for additional waterproofing layers, only with sealing of sensitive areas. A water tightness degree of W8 is used in Poland to designate concrete that does not seep through at a water pressure of min. 0.8 MPa. Referring to the above values of the thickness of the actual building partition, a waterproof level of W8 indicates that the ratio of the height of the water column in meters to the thickness of the partition is at least 16–20 or higher. The numerical symbol next to the letter W, used in laboratory tests on cubic samples measuring 15 cm × 15 cm × 15 cm, should be understood as ten times the water pressure in MPa at which no seepage was observed. Differences in interpreting the water tightness of concrete according to EN 12390-8 [9] and the above classification are significant. According to EN 12390-8 [9], water permeability is evaluated based on the depth of water penetration under a pressure of 0.5 MPa over a period of 72 ± 2 h. When buildings are constructed on reinforced concrete slabs and walls made of non-permeable concrete at a water pressure of at least 0.8 MPa, the construction of underground parts is generally considered the main protection for the building against groundwater action. In such designs, it is essential to properly protect sensitive areas from water penetration through the structure, especially in locations like construction expansion joints, concrete work gaps, or installation passages.

- -

- Concretes seeping at test pressures below 0.8 MPa, requiring an additional waterproofing layer.

- (b)

- the depth of foundation of the slab-on-grade, i.e., whether it is located

- -

- In the ground frost zone, there is a need for an additional thermal insulation layer to ensure the proper functioning of the premises located on the lowest floor of the building. This option also applies to buildings without a basement, where the first floor is level 0.00.

- -

- Below the frost zone, when necessary, including a thermal insulation layer in the slab section. This case, as a rule, applies to buildings with basements, when technical rooms, storage cells, and underground garages are located within the −1 floor.

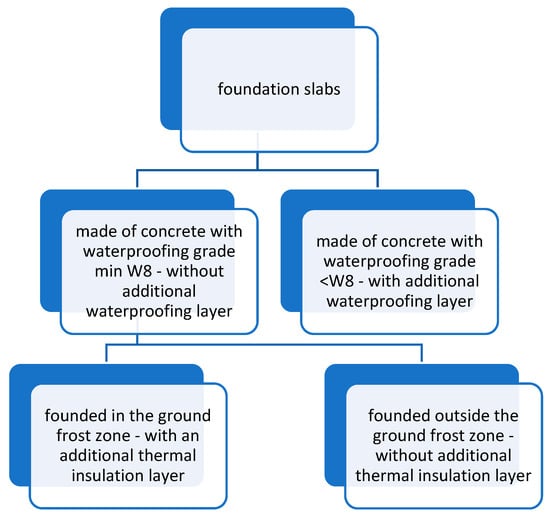

The classification is shown in Figure 3.

Figure 3.

Classification of insulation layers of foundation slabs-on-grade depending on the soil and water conditions present in their foundation zone.

The rest of the article analyses only the case of using a thermal insulation layer in the underground parts of a building operating in a ground frost zone, without additional protection by waterproofing layers.

3.2. Stage 2—The Effect of Varying Outdoor Temperatures on Soil and Water Conditions in Building Foundations—Literature Review

The main effects of projected climate change [43,44] can be summarized as:

- -

- Climate warming, recorded from the 1950s onward, with its effects on the health and life of humans and the surrounding environment.

- -

- An increase in the temperature of the Earth’s surface in the 21st century, predicted in all evaluated emissions scenarios,

- -

- An increase in the frequency of extreme rainfall events, with an increase in the frequency of heat waves and their duration.

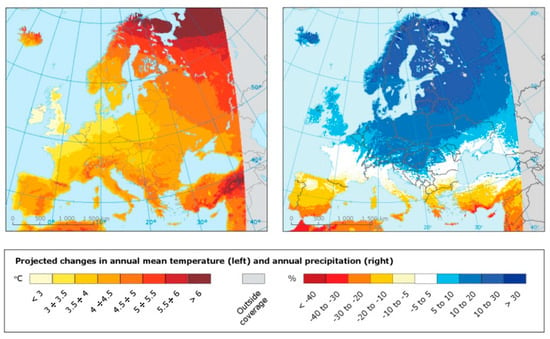

The projected increase in global average temperature in the 21st century is estimated in the range of 0.3–1.7 °C in the lowest emissions scenario and 2.6–4.8 °C in the maximum emissions scenario [45,46,47]. In Europe, the annual average land temperature is expected to rise faster than the global average temperature. According to observations, the summer temperatures in southern Europe have increased more than the winter temperatures in eastern and northern Europe [45]. Forecasts of precipitation changes show an increase in the average annual precipitation in Northern Europe and a decrease in Southern Europe, increasing the contrasts between regions that are wetter and those that are drier (Figure 4). Extreme weather events are also expected to become more frequent and intense in many areas, and sea level rise could accelerate rapidly [46]. Seasonal and geographic differences in the frequency and/or intensity of precipitation across Europe have also been noted. Between 2002 and 2011, Europe also saw a greater increase in temperature than the rest of the world, with temperatures in land areas rising an average of 1.3 °C from the previous period.

Figure 4.

Projections of temperature and precipitation distributions for 2071–2100 compared to 1971–2000 from a set of regional climate model simulations within the EUROCORDEX project [46].

The presented effects of climate change on different regions of Europe vary slightly, with the effects appearing to be less destructive for the area of northwestern Europe. According to the forecasts, summer precipitation will decrease, and extreme temperatures will increase throughout Central and Eastern Europe. In the Mediterranean region, annual precipitation will likely be lower, and temperatures will rise more than the average for all of Europe. As a result, the average groundwater level and moisture content in the soil will decrease. Studies by Pachauri et al. [43] and Tang et al. [48] emphasize that climate change is likely to raise the frequency of extreme rainfall events, elevating the risk of water infiltration and ground saturation around building foundations. Climate-related changes in soil and groundwater conditions further increase the vulnerability of insulation materials to moisture absorption and deterioration.

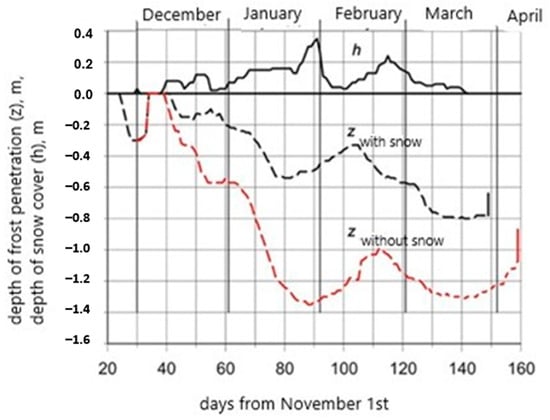

Climate warming contributes to a gradual increase in ground temperature during autumn and winter, when the outside temperature drops, often attaining values below 0 °C. Based on the data presented in [49], it was found that extreme temperatures in the central and eastern parts of Poland fall below −17 °C, while temperatures of −14 °C to −15 °C are recorded almost throughout the rest of the country. During this period, these temperatures also drop below 0 °C in the ground, therefore it is essential to determine to what depth frost can occur, since foundations in this area require additional thermal insulation, even if such temperatures occur once every few years. The phenomenon of ground freezing is a multidimensional, non-stationary process that depends on randomly variable climatic phenomena such as air temperature, precipitation (including snow cover thickness) and wind speed (affecting the formation of snow cover), as well as on the partly constant and partly random variable (under the influence of external conditions) properties of the soil, i.e., type, consistency, mineral composition, porosity, degree of saturation, and the arrangement of layers and degree of preconsolidation [49]. An example of the influence of snow cover on the depth of soil freezing is shown in Figure 5.

Figure 5.

The course of snow cover thickness (h), zero isotherm (z) under snow and without snow cover for winter in Poland [50].

Other factors that may affect the actual depth of frost penetration include the location of the groundwater table and its contamination with chemical substances, as well as conditions related to the area’s exposure, the presence and type of vegetation, the type of land use, etc. [50]. Due to the presence of water in soil at different structural levels and in different states of aggregation, frozen soil is a conventional term and refers to soil with a temperature of 0˚C or below, in which at least part of the water contained is frozen. The EN 1997 [51] standards for foundations and geotechnics do not currently include detailed provisions on the methodology for assessing frost penetration, except for the statement that the depth of the structure should be considered when designing its foundation. As we will prove in the following sections of this article, the depth of ground frost significantly impacts the durability of thermal insulation layers used in foundation slabs with an inverted insulation layer arrangement. Below, we present sample values determined based on research conducted over the last decade for the territory of Poland.

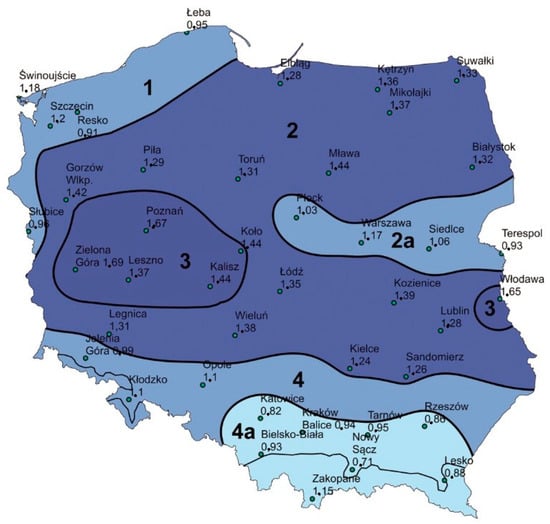

According to studies performed at the Building Research Institute [49], several frost zones shown in Figure 6 can be distinguished in Poland. This proposal was developed based on collected data, and analyses of the established position of the zero isotherm for 45 meteorological stations from a period of 30 years of observation were performed using the Gumbel distribution. The computational assumptions for determining the freezing depth assumed a homogeneous subsoil composed of gravels, coarse and medium sands [49].

Figure 6.

Proposal of a new map of ground freezing in Poland, as well as preliminary values of the depth of the zero isotherm (Zk) location and the extents of the various zones in Poland [50].

As can be seen from the above summary, in most parts of Poland, the average depth of ground frost reaches 1.3 m, and only in parts of one region called Wielkopolska it can drop to 1.5 m. In the mountainous and foothill zones, this depth depends on the height and coordinates above sea level of the area to be developed, so it should be determined individually in each case.

Other researchers compared the ground temperature distribution around a residential building, taking the measured values of an existing building in Poland as a reference [52]. A detailed simulation and a BIM model of the building were conducted, demonstrating that it is possible to apply this approach to model the temperature distribution in the ground, even with limited data. In Poland, the foundation design for passive buildings was assessed due to issues [52] related to the differences in the ground freezing depth, rainfall, and material availability.

3.3. Stage 3—Durability of Thermal Insulation Materials Working in Constant Moisture Conditions in Changing Temperatures

3.3.1. Literature Review

Another problem that needs to be evaluated is the durability of the performance of the thermal insulation layer laid within the foundation slab, especially when it is standing in an inverted arrangement. The inverted arrangement of insulation layers refers to the variant in which thermal insulation is exposed to direct contact with atmospheric agents and is not protected from this action by waterproofing (Figure 1). This is a solution increasingly used in single-family buildings, but unfortunately it is often offered with numerous technical errors. In the solutions, thermal insulation layers are exposed to constant contact with water accumulated in the ground, and in the case of foundations in the ground frost zone, also locally, to cyclic freezing and thawing. The foundation walls and the edge zone of foundation slabs are particularly exposed to such effects. Therefore, only materials with low water absorption are envisaged in the proposed solutions. According to current European standards, these include extruded polystyrene (XPS) and expanded polystyrene with reduced water absorption (EPS-P). Soggy thermal insulation successively reduces its performance, contributing to the freezing of insulated partitions.

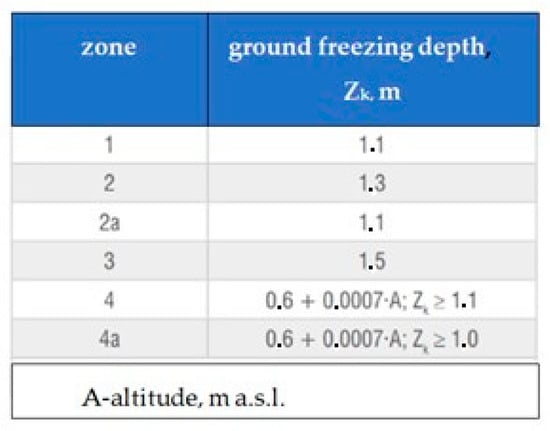

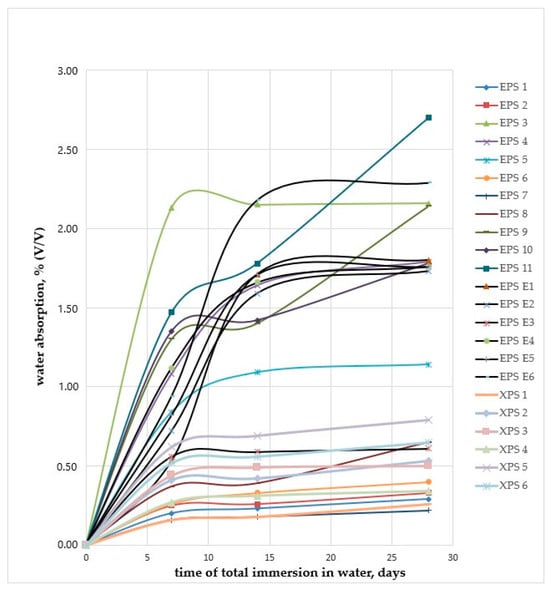

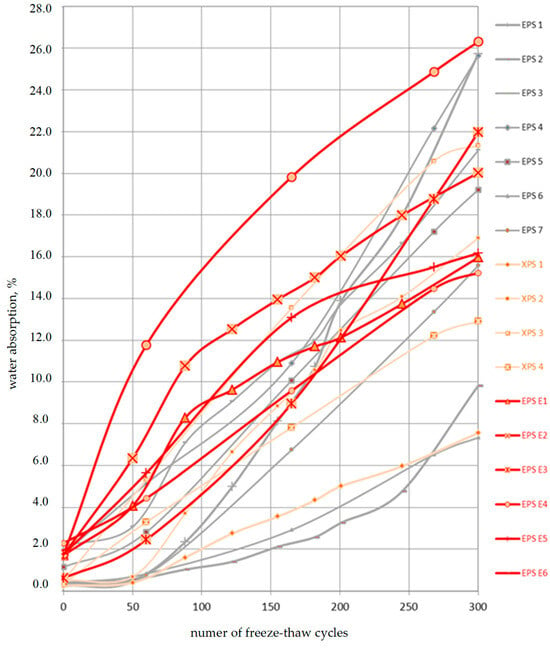

Solutions for the inverted arrangement of insulation layers for use in roof coverings are the subject of numerous studies by European scientific research bodies, and they have even lived to see the development of technical requirements for the conditions of their use. In general, most scientists agree that water soaking of the thermal insulation material occurs through water vapor diffusion [53], but temperature also has a significant impact on the rate of this phenomenon. Hedlin [54] explains that vapor pressure gradients, gravitational forces, and capillary forces can cause moisture movement in materials. There are different research positions regarding the effect of freezing and thawing cycles on the moisture content concerning thermal insulation materials with different porosity. Several studies [55,56,57,58,59] have shown that XPS is relatively resistant to the effects of freezing and thawing compared to other insulation materials, and that moisture flow caused by evaporation is the main factor contributing to moisture accumulation. In turn, [60,61] shows that variable positive and negative temperatures contribute to a significant increase in moisture in both XPS and EPS (Figure 7), while having a negligible effect on the increase in the moisture content of EPS and XPS during long-term immersion in water at positive temperatures (Figure 8). Reports in the technical literature [60,61] have already evaluated the mechanism of moisture growth of the above-mentioned thermal insulations under laboratory conditions, reflecting actual exploitation loads. The above-mentioned studies [60,61] involved subjecting several randomly selected plates of extruded polystyrene (XPS) and expanded polystyrene with reduced water absorption to total immersion in water for 28 days at a temperature of 23 ± 2 °C according to EN ISO 16535 [27] and then subjecting the soggy materials to 300 freeze–thaw cycles, according to the test methodology included in the standard according to EN ISO 16546 [41]. It has been found [60,61] that because of immersion of EPS and XPS panels in water, the essential moisture increments occur already in the first days of soaking and remain at a similar level in the following days, as can be seen in Figure 7. In contrast, alternate freezing and thawing of the panels, regardless of the amount of initial water saturation, results in a steady and significant increase in moisture content. These values are shown in Figure 8.

Figure 7.

The rate of increase in water absorption of samples over time. The number given next to the polystyrene symbol indicates the number of the sample tested [60,61].

Figure 8.

Water absorption of selected EPS and XPS samples pre-wetted because of total immersion in water for 28 days, followed by 300 freeze–thaw cycles [60,61].

Many scholars have also studied the effect of positive temperature variations on the increase in the moisture content of various materials, comparing the obtained values with the thermal conductivity of these products. Thus, Ochs et al. [62] pointed to a significant increase in the effective thermal conductivity of materials with an increase in water content from a dry state to a water-saturated state in the temperature range from 20 °C to 80 °C. Hedlin [54] assessed the effect of variable temperatures in the range of 0 °C, 2.8 °C, 11 °C, and 22 °C on the rate of moisture increase in three closed-cell materials, i.e., XPS, EPS, and PUR, and one open-cell insulation: phenolic foam. After 64 days of exposure, he found that the closed-cell insulation showed a slight increase in the moisture content of 0.1% for polystyrene and 0.4% for PUR, compared to over 20% for phenolic foam. Comparing the increase in the moisture content with the decrease in diffusion resistance of the partition, Tye and Spinney [63] found a 15% increase in thermal conductivity with only a 10% increase in the moisture content in cellulose insulation.

In the literature, the conclusions from laboratory tests were supplemented by an assessment of the problem of moisture penetration in thermal insulation materials used in inverted roof systems. Dechow and Epstein [64], assessing XPS, EPS, and PUR boards taken from roofs used for 8 years, found their moisture contents to be 1.1%, 57.9% and 17% by volume. In turn, Tougas et al. [53] confirmed that samples taken from roofs used for 11 to 38 years showed a moisture content of over 30% by volume. All these researchers confirmed also that the moisture content in inverted roofs was independent of the period of use, and that the assessment was significantly influenced by the fact that the samples were taken near roof drains exposed to a greater water accumulation, contributing to the immersion of the thermal insulation material, but also to cyclic freezing and thawing and water vapor flow caused by temperature differences in the layer [59]. A different opinion on the impact of the duration of roof covering use on the moisture content of thermal insulation made of XPS or EPS is presented in [64]. The authors state that the first significant symptoms of moisture penetration in thermal insulation, which significantly impact the durability of the diffusion resistance of the partition, are observed after 5 years of use of a roof covering with an inverted layer arrangement in a temperate climate. Based on XPS measurements taken from inverted roof systems, Dechow and Epstein [64] presented an empirical relationship between thermal conductivity and moisture content in accordance with Equation (1).

where kwet is the estimated thermal conductivity of wet insulation in W/(m⋅K).

kwet = 0.0288 + 0.00115 ∗ V

According to European technical documents, including ETAG 031 [28], only two products can be used for thermal insulation of inverted roofs, i.e.,: extruded polystyrene XPS (covered by EN 13164 +A1) [26] with or without an additional finishing layer (as sandwich panels), as well as expanded polystyrene (EPS) only with reduced water absorption, covered by EN 13163 +A2 [40]. While the performance of insulation with XPS has a tradition of several decades, in the case of EPS panels, publications signal a lack of sufficient experience in this area [60,61,65,66,67,68,69]. Additional European documents specifying the requirements for inverted roofs are EAD 040650-00-1201 [70], considering the possibility of using XPS polystyrene as a thermal insulation layer, and EAD 040773-00-1201 [71], giving requirements in this regard for EPS polystyrene. Per ETAG 031, the products mentioned above may be used in inverted roofs when their absorbability by volume does not exceed: for EPS boards, ≤1.0%, for XPS boards, ≤0.7%. The EADs mentioned above [70,71] do not have any restrictions. Since polystyrene boards also increase their moisture content during freeze/thaw cycles, ETAG 031 formulates the following limits for moisture content after freeze/thaw cycles: for EPS boards ≤ 5.0%, for XPS boards ≤ 1%. In the case of foundation slabs in their central part, the temperature transition in the ground through 0 °C is unlikely to occur, but the edges of the slab and the edge zone are exposed to such a phenomenon. Considering the above-mentioned literature reports on the negative impact of cyclic freezing-thawing on the durability of thermal insulation materials so far considered non-absorbent, one can expect successive wetting of the thermal insulation layer in this area, in case it is made of both extruded polystyrene XPS and expanded polystyrene EPS, and related loss of its functionality. Thus, during the operation of the building, there will be a successive wetting of both the thermal insulation layer and, further, the foundation slab, especially if it is made of concrete with a low degree of waterproofing, contributing to its successive degradation. The soggy thermal insulation will cease to perform the function of protecting the temperature of the concrete slab, which in the edge zone will also be exposed to work at negative temperatures in autumn and winter. It should also not be forgotten that the repair of possible foundation damage even in the above-mentioned edge zones, with a large range of repair products is very cumbersome and expensive, requires digging up the foundations, which is not always possible. The problem of repairing concrete structures is beyond the scope of this manuscript due to the extensiveness of the problem.

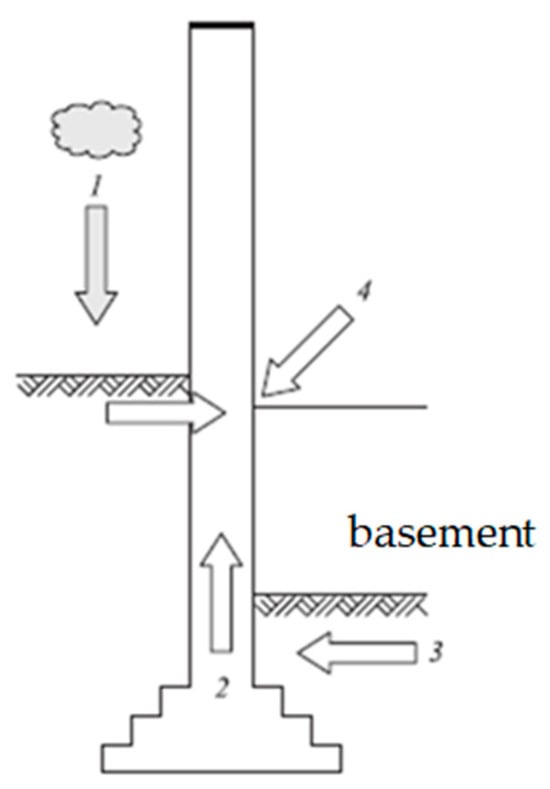

To date, no mirror-image technical requirements have been developed specifying the requirements for the durability of such solutions when used within foundation slabs, even though they are offered to private investors for implementation in single-family buildings. In both cases, thermal insulation materials used in such solutions are exposed to constant water exposure, in the case of roofs—rainwater, in the case of insulation of the underground part of the building—groundwater, rainwater, and water from failure and condensation (Figure 9).

Figure 9.

Mechanism of water penetration into structures of underground parts of buildings in the case of faulty waterproofing [6,72]; 1—rainwater and humidity, 2—capillary rise in groundwater, 3—groundwater—lateral penetration, 4—water from failure and condensation.

3.3.2. Results of Additional Laboratory Tests

In support of the arguments presented in the literature review under Section 3.3.1. the results of our additional research are presented below. The results indicating a change in the thermal conductivity coefficient of thermal insulation materials exposed to water and then exposed to negative and positive temperatures for eight randomly selected thermal insulation materials, i.e., four EPS-P boards and four XPS boards, are presented and analyzed below. The test results are presented in the tables below:

- -

- Table 2—boards in air-dry conditions,

Table 2. Results of thermal conductivity coefficient tests for thermal insulation boards: EPS-P and XPS in air-dry conditions.

Table 2. Results of thermal conductivity coefficient tests for thermal insulation boards: EPS-P and XPS in air-dry conditions. - -

- Table 3—immediately after finishing aging tests,

Table 3. Results of thermal conductivity coefficient tests for thermal insulation boards: EPS-P and XPS after completion of 28 days of total immersion in water followed by 300 freezing-thawing cycles.

Table 3. Results of thermal conductivity coefficient tests for thermal insulation boards: EPS-P and XPS after completion of 28 days of total immersion in water followed by 300 freezing-thawing cycles.

By analyzing changes in the thermal conductivity λ due to the simulating the effects of aging factors, which involved exposing pre-moistened polystyrene boards to variable temperatures below and above zero, the following patterns can be identified:

- (a)

- for XPS boards:

- -

- The results indicate a moderate increase in the λ coefficient after exposure to aging factors; at the lowest water absorption levels, the change is insignificant, within the measurement error range, without any sudden values. These changes range from 0.0021 to 0.0139 W/(m·K),

- -

- The relative percentage increase in the λ coefficient ranges from 6.6% to 35.4%, i.e., , where wp (defined by Formula (2)) is a directional coefficient characterizing the rate of increase in the coefficient λ after the action of aging factors in relation to the initial value. The differences are not high at low initial values, but at higher values, they increase faster.

where λafter is λ after completion of 28 days of total immersion in water followed by 300 freezing-thawing cycles, and λbefore is λ in the air-dry conditions,- -

- The coefficient of determination R2, confirming the correctness of the curve selection for the compared variables, is approximately 0.538, which indicates that the variability of the λ coefficient described by the above curve before and after aging is confirmed at a level of 54%,

- -

- The average increase in the λ coefficient is 0.009 W/(m·K), or approximately 23.6%.

- -

- The linear relationship between the λ coefficient before and after aging can be determined by Equation (3) shown below:

- -

- The coefficient of determination R2, confirming the correctness of the curve selection for the compared variables, is approximately 0.919. In such a case, the variability of the λ coefficient described by the above curve before and after aging indicates a strong linear relationship.

- (b)

- regarding EPS boards:

- -

- The results indicate a significant increase in the λ coefficient after freeze–thaw cycles in relation to the initial value, especially at higher water absorption values. These changes confirm even twofold increases in the above-mentioned initial values and range from 0.0213 to 0.0415 W/(m·K);

- -

- Relative percentage increases from 52.5% to 107.8%;

- -

- The average increase in the λ coefficient is 0.0272 W/(m·K), i.e., approximately 71.6%;

- -

- The linear relationship of the λ coefficient before and after aging can be determined by Equation (4) shown below:

- -

- The directional coefficient in this case can be determined by Equation (5).

- -

- The coefficient of determination R2, confirming the correctness of the curve selection for the compared variables in this case, is approximately 0.002, which indicates the lack of linear dependence between the obtained results and that the λ values after aging do not form a regular set in relation to the values obtained before aging.

Comparing the above results with reports from other researchers [53,64], the values obtained after the action of aging factors consisting of preliminary wetting of the samples, followed by freeze–thaw cycles, are like the results obtained after several to several dozen years of use of the above-mentioned products in inverted roof coverings. Unfortunately, the research currently being conducted by the authors of this article is inconsistent with the literature [38], which states that the duration of exposure to operational factors does not further increase the moisture content of thermal insulation materials. Ongoing research indicates that repeated freezing and thawing cause a further increase in the moisture content, but the cause of this phenomenon will only be determined after the research has been completed.

4. Conclusions

The article presents a literature review concerning the factors affecting the durability of thermal insulation layers used in inverted layer systems, the results of which were supported by additional results of own laboratory tests. When we talk about an inverted layer system, we mean a solution in which the waterproofing does not protect the thermal insulation from environmental factors but is placed underneath it. In the technical literature, information on the maintenance and durability of building partition solutions within which an inverted system of insulation layers has been used mainly concerns roof coverings. The results of the research included in the article allowed the extension of the existing technical knowledge in this field to inverted systems used within foundation slabs and walls. Such solutions are often used in single-family buildings. However, regarding the small population of the test objects, the presented test results cannot be generalized but should be treated as significant manifestations requiring further studies.

The article specifies the utility factors that may have the greatest impact on the reduction in thermal insulation of the building partition made in the inverted system in the underground part of the building during operation. The analyses made it possible to prove that such factor is the repeated freezing and thawing cycle. It should not be forgotten that despite the climate warming, the possibility of ground frost in the European area must be taken into account, which, with the simultaneous presence of moisture in the ground, can adversely affect the durability of the thermal insulation layer laid directly on the subsoil without a waterproofing material spacer, even if it is made of a material commonly considered non-absorbent, such as extruded polystyrene XPS.

Considering the possibility of moisture build-up in the thermal insulation laid in the cross-section of foundation slabs in single-family buildings, ensuring the durability of a building foundation slab, in addition to meeting strength requirements, requires [1,2,6,73]:

- -

- Protection against the action of water and moisture, and adaptation of these protections to the soil and water conditions prevailing in the building foundation,

- -

- Thermal insulations in the ground frost zone that are made from materials which can carry operational loads without damage.

When choosing a specific solution, you cannot uncritically rely on internet offers, as unfortunately, they often require significant adjustments during the execution of the work. Workmanship errors and the selection of insulation materials with inadequate performance properties further accelerate the degradation process of the inverted layout of the thermal insulation solution used within foundation slabs.

The most common implementation mistakes include [6]:

- -

- A complete lack of waterproofing layers separating the foundation slabs from groundwater influence.

- -

- Use of products intended only for waterproofing in areas where waterproofing is necessary.

- -

- Improper termination of waterproofing layers, e.g., their too-low elevation above the level of the adjacent ground, and improper sealing of overlaps of individual sheets of these layers.

- -

- Incorrect solutions for sealing the places of installation penetrations through slabs and foundation walls. Most often, polyurethane installation foams are used for this purpose, which, unfortunately, have little durability in conditions of continuous exposure to water or moisture.

- -

- Use of thermal insulation products that are not resistant to the action of water and moisture in the frost zone, without additional protection of their surfaces on the side of the water inflow, with an effective layer of waterproofing.

Summarizing the solutions presented in Figure 1, it seems that, from a functional point of view and certainly the most economical for investors, the safest is the option of using the thinnest thermal insulation, assuming that additional thermal insulation is applied to the surface of the board after a waterproofing layer has been applied to the surface of the board. In this case, the diffusion resistance of the thermal insulation layer under the slab is reduced because its moisture absorption due to operational factors will not adversely affect the comfort of use of rooms on the ground floor. The weakest area from the point of view of the durability of the evaluated solution is the region of the edges of the slabs and foundation walls, i.e., the area particularly exposed to the variable negative and positive temperatures.

In the process of designing and constructing building partitions with an inverted arrangement of thermal and waterproofing layers, it is advisable to:

- i.

- Maintain the water absorption properties of thermal insulation products after the freeze–thaw test at the level of:

- -

- ≤1% for XPS,

- -

- ≤5% for EPS.

- ii.

- Determine the thickness of the thermal insulation layer depending on the required value of the heat transfer coefficient of the partition. When determining this coefficient, it is necessary to consider the correction to the heat transfer coefficient of the thermal insulation system, due to the water between the thermal insulation and the waterproofing layer. This correction shall be calculated in accordance with EN ISO 6946 [74].

- iii.

- Ensure proper water drainage from the surface of the insulation layers (thermal and waterproofing), and to protect these layers from mechanical damage caused by uncontrolled impacts.

- iv.

- Ensure that the waterproofing layer has the designed thickness and be in good technical condition.

Author Contributions

Conceptualization, B.F. and E.K.; methodology, B.F. and D.K.; formal analysis, B.F., E.K. and D.K.; investigation, B.F.; resources, B.F.; data curation, B.F., E.K. and D.K.; writing—original draft preparation, B.F. and D.K.; writing—review and editing, B.F. and E.K.; visualization, B.F.; supervision, B.F. and E.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Klem, P.; Chwieduk, D.; Francke, B.; Grabarczyk, S.; Kosiorek, M.; Kubik, J.; Pogorzelski, J.A.; Szudrowicz, B.; Ściślewski, Z.; Śliwowski, L.; et al. General Construction -Building Physics; Arkady: Slupsk, Poland, 2005; Volume 2. [Google Scholar]

- Henshell, J. The Manual of Below-Grade Waterproofing, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Francke, B.; Piekarczuk, A. Experimental Investigation of Adhesion Failure between Waterproof Coatings and Terrace Tiles under Usage Loads. Buildings 2020, 10, 59. [Google Scholar] [CrossRef]

- Dong Soo, A.; Kyu Hwan, O.; Jin Sang, P.; Sang Keun, O. Viscosity and Waterproofing Performance Evaluation of Synthetic Polymerized Rubber Gel (SPRG) after Screw Mixing. Appl. Sci. 2018, 8, 1989. [Google Scholar] [CrossRef]

- Lyapidevskaya, O. Waterproofing material for protection of underground structures. In Proceedings of the XXII International Scientific Conference Construction the Formation of Living Environment (FORM-2019), E3S Web of Conferences, Tashkent, Uzbekistan, 18–21 April 2019; Volume 97, p. 02008. [Google Scholar] [CrossRef]

- Francke, B. Nowoczesne Hydroizolacje Budynków. Zeszyt 1-Zabezpieczenia Wodochronne Części Podziemnych Budynków, 1st ed.; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2021. [Google Scholar]

- EN 15814+A2; Polymer Modified Bituminous Thick Coatings for Waterproofing-Definitions and Requirements. European Committee for Standardization (CEN): Belgium, Brussels, 2014.

- Francke, B.; Wichowska, M. Influence of Groundwater pH on Water Absorption and Waterproofness of Polymer Modified Bituminous Thick Coatings. Materials 2021, 14, 2272. [Google Scholar] [CrossRef]

- EN 12390-8; Testing of concrete—Part 8: Depth of Penetration of Water Under Pressure. European Committee for Standardization (CEN): Belgium, Brussels, 2019.

- Hall, C.; Hoff, W.D. Water Transport in Brick, Stone and Concrete; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar] [CrossRef]

- Hall, C.; Hoff, W.D. Rising damp: Capillary rise dynamics in walls, Proceedings of the Royal Society A: Mathematical. Phys. Eng. Sci. 2007, 463, 1871–1884. [Google Scholar] [CrossRef]

- Franzoni, E. Rising damp removal from historical masonries: A still open challenge. Constr. Build. Mater. 2014, 54, 123–136. [Google Scholar] [CrossRef]

- Hall, C. Water movement in porous building materials—I. Unsaturated flow theory and its applications. Build. Environ. 1977, 12, 117–125. [Google Scholar] [CrossRef]

- Alfano, G.; Chiancarella, C.; Cirillo, E.; Fato, I.; Martellotta, F. Long-term performance of chemical damp-proof courses: Twelve years of laboratory testing. Build. Environ. 2006, 41, 1060–1069. [Google Scholar] [CrossRef]

- Sharpe, R.W. A mortar for rising damp studies. Build. Environ. 1978, 13, 261–265. [Google Scholar] [CrossRef]

- I’Anson, S.J.; Hoff, W.D. Chemical injection remedial treatments for rising damp—I. The interaction of damp-proofing fluids with porous building materials. Build. Environ. 1988, 23, 171–178. [Google Scholar] [CrossRef]

- Rirsch, E.; MacMullen, J.; Zhang, Z. Evaluation of mortar samples obtained from UK houses treated for rising damp. Constr. Build. Mater. 2011, 25, 2845–2850. [Google Scholar] [CrossRef]

- Francke, B.; Piekarczuk, A.; Witkowska Dobrev, J. Efficiency assessment of horizontal damp proof courses made by chemical injection in wall tests. Ain Shams Eng. J. 2024, 15, 102702. [Google Scholar] [CrossRef]

- Liu, Z.; Alterman, D.; Page, A.; Moghtaderi, B.; Chen, D. An experimental study on the thermal effects of slab-edge-insulation for slab-on-grade housing in a moderate Australian climate. Energy Build. 2021, 235, 110675. [Google Scholar] [CrossRef]

- Chen, D. Dynamic three-dimensional heat transfer calculation for uninsulated slab-on-ground constructions. Energy Build 2013, 60, 420–428. [Google Scholar] [CrossRef]

- Sau-Soto, N.; Lucero-Álvarez, J.; Borbón-Almada, A.C.; Nájera-Trejo, M.; Rodríguez-Muñoz, N.A. Structural analysis for a slab-on-grade cellular concrete foundation to reduce heat losses in temperate climate residential buildings. J. Build. Eng. 2024, 91, 109740. [Google Scholar] [CrossRef]

- Harris, D.J.; Dudek, S.J.M. Heat losses from suspended timber floors. Build. Res. Inf. 1997, 25, 226–233. [Google Scholar] [CrossRef]

- Romero-Perez, C.K.; Rodriguez-Muñoz, N.A.; Borbon-Almada, A.C.; Alpuche-Cruz, M.G.; Martin-Dominguez, I.R. Energy and Thermal Performance of Social Housing: Analysis of Heat Flow Through the Envelope and Comparison with International Schemes. J. Sol. Energy Eng. 2020, 142, 021007. [Google Scholar] [CrossRef]

- El Saied, A.; Maalouf, C.; Bejat, T.; Wurtz, E. Slab-on-grade thermal bridges: A thermal behavior and solution review. Energy Build. 2022, 257, 111770. [Google Scholar] [CrossRef]

- Fürtön, B.; Szalay, Z.; Nagy, B. BIM-based energy performance analysis of slab-on-grade constructions. In Proceedings of the 5th Central European Symposium on Building Physics 2022 (CESBP 2022), AIP Conference Proceedings, Bratislava, Slovakia, 5–7 September 2022; p. 020045. [Google Scholar] [CrossRef]

- EN 13164+A1; Thermal Insulation Products for Construction—Factory-Made Extruded Polystyrene (XPS) Products—Specifications. European Committee for Standardization (CEN): Belgium, Brussels, 2015.

- EN ISO 16535; Thermal Insulation Products for Construction—Determination of Water Absorption by Prolonged Immersion. European Committee for Standardization (CEN): Belgium, Brussels, 2019.

- Etag 031; Guideline for European Technical Approval of Inverted Roof Insulation Kits Part 1: General. European Organization for Technical Approvals: Belgium, Brussels, 2010.

- Abdou, A.; Budaiwi, I. Comparison of thermal conductivity measurements of building insulation materials under various operating temperatures. J. Build. Phys. 2005, 29, 171–184. [Google Scholar] [CrossRef]

- Daryabeigi, K.; Cunnington, G.R.; Knutson, J.R. Combined heat transfer in high-porosity high-temperature fibrous insulation: Theory and experimental validation. J. Thermophys. Heat Transf. 2011, 25, 536–546. [Google Scholar] [CrossRef]

- Koru, M. Determination of thermal conductivity of closed-cell insulation materials that depend on temperature and density. Arabian, J. Sci. Eng. 2016, 41, 4337–4346. [Google Scholar] [CrossRef]

- Al-Ajlan, S.A. Measurements of thermal properties of insulation materials by using the transient plane source technique. Appl. Therm. Eng. 2006, 26, 2184–2191. [Google Scholar] [CrossRef]

- Khoukhi, M.; Fezzioui, N.; Draoui, B.; Salah, L. The impact of changes in thermal conductivity of polystyrene insulation material under different operating temperatures on the heat transfer through the building envelope. Appl. Therm. Eng. 2016, 105, 669–674. [Google Scholar] [CrossRef]

- Hay, B.; Zarr, R.; Stacey, C.; Lira-Cortes, L.; Hammerschmidt, U.; Sokolov, N.; Zhang, J.; Filtz, J.-R.; Fleurence, N. Analysis of thermal-conductivity measurement data from international comparison of national Laboratories. Int. J. Thermophys. 2013, 34, 737–762. [Google Scholar] [CrossRef]

- Zarr, R.R.; Filliben, J.J. An International Study of Guarded Hot Plate Laboratories Using Fibrous Glass and Expanded Polystyrene Reference Materials. In American Society of Mechanical Engieers; ASTM Special Technical Publication: Philadelphia, PA, USA, 2002; Volume 1426, pp. 3–16. [Google Scholar] [CrossRef]

- Berardi, U.; Naldi, M. The impact of the temperature-dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy Build 2017, 144, 262–275. [Google Scholar] [CrossRef]

- Yousefi, Y.; Tariku, F. Thermal conductivity and specific heat capacity of insulation materials at different mean temperatures, 8th International Building Physics Conference (IBPC 2021). J. IOP Public Phys. Conf. 2021, 2069, 012090. [Google Scholar] [CrossRef]

- Tariku, F.; Shang, Y.; Molleti, S. Thermal performance of flat roof insulation materials: A review of temperature, moisture and aging effects. J. Build. Eng. 2023, 76, 107142. [Google Scholar] [CrossRef]

- Tobiasson, W.; Ricard, J. Moisture gain and its thermal consequences for common roof insulations. In Proceedings of the 5th Conference on Roofing Technology, National Institute of Standards and Technology, Gaithersburg, MD, and National Roofing Contractors Association, Rosemont, IL, USA; 1979; Volume 2, pp. 4–16. Available online: https://nrcawebstorage.blob.core.windows.net/files/TechnicalLibraryNRCA/421.pdf (accessed on 15 August 2025).

- EN 13163 + A2; Thermal Insulation Products for Construction—Factory-Made Polystyrene Foam (EPS) Products. Specifications, European Committee for Standardization (CEN): Belgium, Brussels, 2016.

- EN ISO 16546; Thermal Insulation Products in Construction—Determination of Resistance to Freezing-Thawing. European Committee for Standardization (CEN): Belgium, Brussels, 2020.

- EN 12667; Thermal Properties of Building Materials and Products—Determination of Thermal Resistance by Shielded Hotplate and Heat Flux Sensor Methods—Products with High and Medium Thermal Resistance. European Committee for Standardization (CEN): Belgium, Brussels, 2001.

- Pachauri, R.K.; Allen, M.R.; Barros, V.R.; Broome, J.; Cramer, W.; Christ, R.; Church, J.A.; Clarke, L.; Dahe, Q.; Dasgupta, P.; et al. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Koda, E.; Francke, B. Zabezpieczenia płyt fundamentowych budynków jednorodzinnych przed negatywnym wpływem oddziaływań cieplno-wilgotnościowych. In Proceedings of the XVIII Konferencja Naukowo-Techniczna, Warsztat Pracy Rzeczoznawcy Budowlanego, Kielce, Poland, 28–30 May 2025. [Google Scholar]

- Osiński, P. Wpływ Stanu Nasycenia Gruntu Wodą na Warunki Stateczności Skarp. Ph.D. Thesis, Warsaw University of Life Sciences, Warsaw, Poland, 2024. [Google Scholar]

- EEA, Climate Change Impacts and Adaptation. Available online: http://www.eea.europa.eu/soer-2015/europe/climate-change-impacts-and-adaptation. (accessed on 15 August 2025).

- Stocker, T.F.; Qin, D.; Plattner, G.K.; Tignor, M.M.B.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Box, V.; Midgley, P.M. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2013; Available online: https://assets.cambridge.org/97811070/57999/frontmatter/9781107057999_frontmatter.pdf (accessed on 25 September 2025).

- Tang, A.M.; Hughes, P.N.; Dijkstra, T.A.; Askarinejad, A.; Brenčič, M.; Cui, Y.J.; Diez, J.; Firgi, T.; Gajewska, B.; Gentile, F.; et al. Atmosphere–vegetation–soil interactions in a climate change context; impact of changing conditions on engineered transport infrastructure slopes in Europe. Q. J. Eng. Geol. Hydrogeol. 2018, 51, 156–168. [Google Scholar] [CrossRef]

- Żurański, J.A.; Godlewski, T. O Przemarzaniu Gruntu w Polsce; Building Reasearch Institute: Wrocław, Poland, 2017. [Google Scholar]

- Przemarzanie Gruntu A Projektowanie. Available online: https://inzynierbudownictwa.pl/przemarzanie-gruntu-a-projektowanie-fundamentow/ (accessed on 25 September 2025).

- EN 1997; Eurocode 7: Geotechnical Design—Part 1: General Principles. European Committee for Standardization (CEN): Belgium, Brussels, 2014.

- Godlewski, T.; Mazur, Ł.; Szlachetka, O.; Witowski, M.; Łukasik, S.; Koda, E. Design of Passive Building Foundations in the Polish Climatic Conditions. Energies 2021, 14, 7855. [Google Scholar] [CrossRef]

- Tougas, C.J.; Peer, L.B.B.; Tariku, F. Moisture accumulation in exposed extruded polystyrene insulation in western Canada. In Proceedings of the Building Envelope Technol, Sympos, Nashville, TN, USA, 16–17 November 2018; RCI, Inc.: Raleigh, NC, USA, 2018; pp. 47–60. [Google Scholar]

- Hedlin, C.P. Moisture gains by foam plastic roof insulations under controlled temperature gradients. J. Cell. Plast 1977, 313–319. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, E.; Niu, F.; Han, H.; Liu, X.; Ren, Z. Experimental investigation on performance degradation of insulation materials induced by freeze–thaw cycles and its applications. Construct. Build. Mater 2022, 350, 128844. [Google Scholar] [CrossRef]

- Niu, F.; Jiang, H.; Su, W.; Jiang, W.; He, J. Performance degradation of polymer material under freeze-thaw cycles: A case study of extruded polystyrene board. Polym.Test. 2021, 96, 107067. [Google Scholar] [CrossRef]

- Pakkala, T.A.; Lahdensivu, J. Long-term water absorption tests for frost insulation materials taking into account frost attack. Case Stud. Constr. Mater. 2014, 1, 40–45. [Google Scholar] [CrossRef]

- Iffa, E.; Tariku, F.; Simpson, W.Y. Highly insulated wall systems with exterior insulation of polyisocyanurate under different facer materials: Material characterization and long-term hygrothermal performance assessment. Materials 2020, 13, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Merkel, H. Inverted Roofs with Reduced Heat Losses Due to a Water-Repellent Separating Layer, Buildings VIII/Roof Design—Practices. 2001; pp. 1–7. Available online: https://web.ornl.gov/sci/buildings/conf-archive/2001%20B8%20papers/024_Merkel.pdf (accessed on 15 August 2025).

- Francke, B.; Geryło, R. Inverted roof insulation kits and their durability. In Proceedings of the MATEC Web of Conferences, Solo Baru, Indonesia, 11–12 July 2018; Volume 163, p. 08005. [Google Scholar] [CrossRef][Green Version]

- Runkiewicz, L.; Adamczewski, G.; Buczkowski, W.; Dzięgielewski, P.; Fiszer, P.; Fleszar, A.; Francke, B.; Garbacz, A.; Geryło, R.; Godlewski, T.; et al. Diagnostyka Obiektów Budowlanych. Badania i Oceny Elementów i Obiektów Budowlanych; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2021. [Google Scholar][Green Version]

- Ochs, F.; Heidemann, W.; Müller-Steinhagen, H. Effective thermal conductivity of moistened insulation materials as a function of temperature. Int. J. Heat Mass Tran. 2008, 51, 539–552. [Google Scholar] [CrossRef]

- Tye, R.P.; Spinney, S.C. Study of the effects of moisture vapour on the thermal transmittance characteristics of cellulose fibre thermal insulation. J. Therm. Insul. 1979, 2, 175–196. [Google Scholar] [CrossRef]

- Dechow, F.J.; Epstein, K.A. Laboratory and field investigations of moisture absorption and its effect on thermal performance of various insulations. Am. Soc. Test. Mater 1977, 660. [Google Scholar] [CrossRef]

- Francke, B.; Winker Skalna, A.; Geryło, R. The durability of inverted roof insulation kits. Arch. Civ. Eng. 2024, 70, 259–273. [Google Scholar] [CrossRef]

- Künzel, H.; Kiebl, K. Moisture Behaviour of Protected Membrane Roofs with Greenery. In Proceedings of the CIB W40 Proceedings 1, Kyoto, Japan, 1–11 December 1997. [Google Scholar]

- Künzel, H. Feuchteverhalten von Umkehrdachern Mit Massiven Deckschichten; IBP-Mitteilung: Stuttgart, Germany, 1996; Volume 295. [Google Scholar]

- Kutnar, Z. Development of flat roof assemblies—Interaction defects and failures. In Ploché Střechy; Kutnar Izolace Staveb-Expertni a Znalecka Kancelar PRAHA: Praha, Czech Republic, 2005; pp. 284–305. [Google Scholar]

- Künzel, H. Bieten Begrunte Umkehrdacher Einen Dauerhaften Warmeschutz; IBP-Mitteilung: Stuttgart, Germany, 1995; Volume 271. [Google Scholar]

- EAD 040650-00-1201; Extruded Polystyrene foam Boards as Load Bearing Layer and/or Thermal Insulation Outside the Waterproofings. European Organisation for Technical Approvals: Belgium, Brussels, 2017.

- EAD 040773-00-1201; Expanded Polystyrene Foam Boards as Load Bearing Layer and Thermal Insulation Outside the waterproofings. European Organization for Technical Approvals: Belgium, Brussels, 2018.

- Summary Report on Existing Methods Against Rising Damp, D2.1 Final Version 31.07.2014, EMERISDA, Yves Vanhellemont (Belgian Building Research Institute (BBRI). 2014. Available online: https://www.emerisda.eu/wp-content/uploads/2014/07/D-2_1.pdf (accessed on 25 September 2025).

- Francke, B. Warunki Techniczne Wykonania i Odbioru Robót Budowlanych. Część C: Zabezpieczenia i Izolacje, Zeszyt 5, Izolacje Przeciwwilgociowe i Wodochronne Części Podziemnych Budynków; Building Research Institute: Warsaw, Poland, 2019. [Google Scholar]

- ENISO 6946; Building Components and Building Components—Thermal Resistance and Heat Transfer Coefficient—Calculation Methods. European Committee for Standardization (CEN): Belgium, Brussels, 2017.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).