Advancing Low-Carbon Construction: A Systematic Literature Review of Carbon Emissions of Prefabricated Construction

Abstract

1. Introduction

2. Methodology

2.1. Data Collection

- Step 1:

- Identification. The literature in the PC management field was initially searched using keywords. Given the affix interchangeability of PC [21], we developed a comprehensive search algorithm to capture all literature related to carbon emissions of PC. The Web of Science was selected as the primary database due to its comprehensive disciplinary coverage, rigorous quality standards, and user-friendly interactive interface, which offer straightforward tools for data manipulation, extraction, and visualization [27]. Integrated with multiple influential databases such as SCI, SSCI, and A&HCI, Web of Science enables searches by topic, article type (e.g., reviews, highly cited), and boasts robust features for citation tracking, journal evaluation, and subject categorization. Data collection commenced with searching the titles, abstracts, and keywords of publications in Web of Science using appropriate keywords. The main search algorithm was defined as follows:

| TS = ((“emission*”) |

| AND |

| (“prefabrication” OR “prefabricated building” OR “prefabricated housing” OR “prefabricated construction” OR “precast concrete” OR “precast fabrication” OR “off*site construction” OR “off*site manufactur*” OR “off*site production” OR “modular construction” OR “modular building” OR “industriali?ed construction” OR “industriali?ed building*” OR “industriali?ed housing” OR “modern method* of construction”)) |

- Step 2:

- Screening. Using the above search algorithm, we first retrieved 309 articles. However, this initial set included non-English language papers and non-peer-reviewed articles, among others. Therefore, the following criteria for literature data screening were applied in the Web of Science: (1) a time frame from the initial retrieval date to 1 May 2024; (2) the selected papers should be published in peer-reviewed journals in English; (3) retention of research articles and review papers only.

- Step 3:

- Eligibility assessment. To ensure the literature aligns with the scope of this study, a two-step manual qualification procedure was implemented: (1) Exclude literature that is not relevant to the construction industry; (2) The selected literature should be closely related to both PC and carbon emissions. This process resulted in 149 eligible articles.

- Step 4:

- We read the full text of each remaining article to further narrow the literature to the field of carbon emissions of PC. Some studies focused primarily on cost-effectiveness, building efficiency, and mechanical performance were excluded. Finally, 114 articles were included in the review database on carbon emissions of PC.

2.2. Scientometric Analysis

2.3. Qualitative Analysis

3. Results of Scientometric Analysis

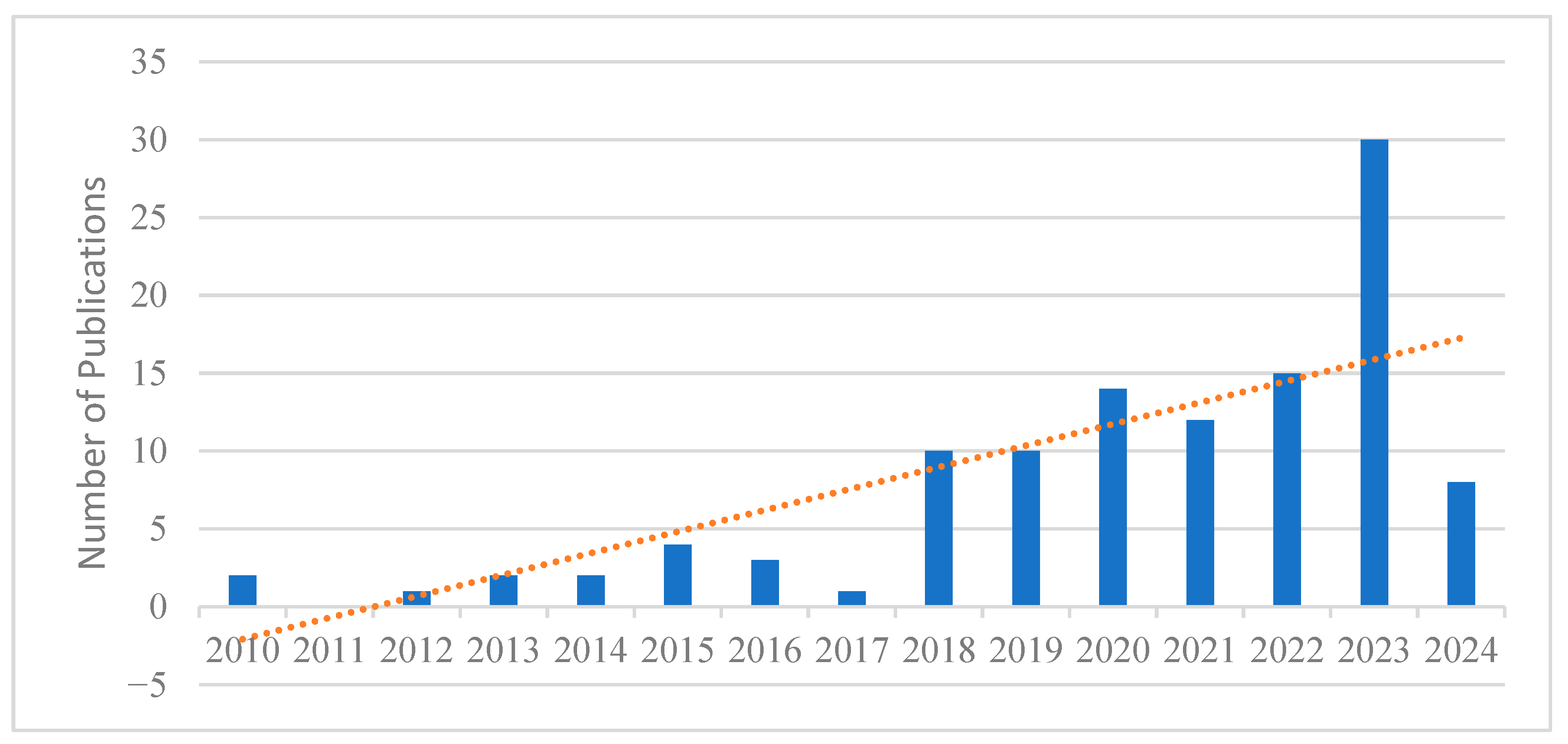

3.1. An Overview of the Literature Sample

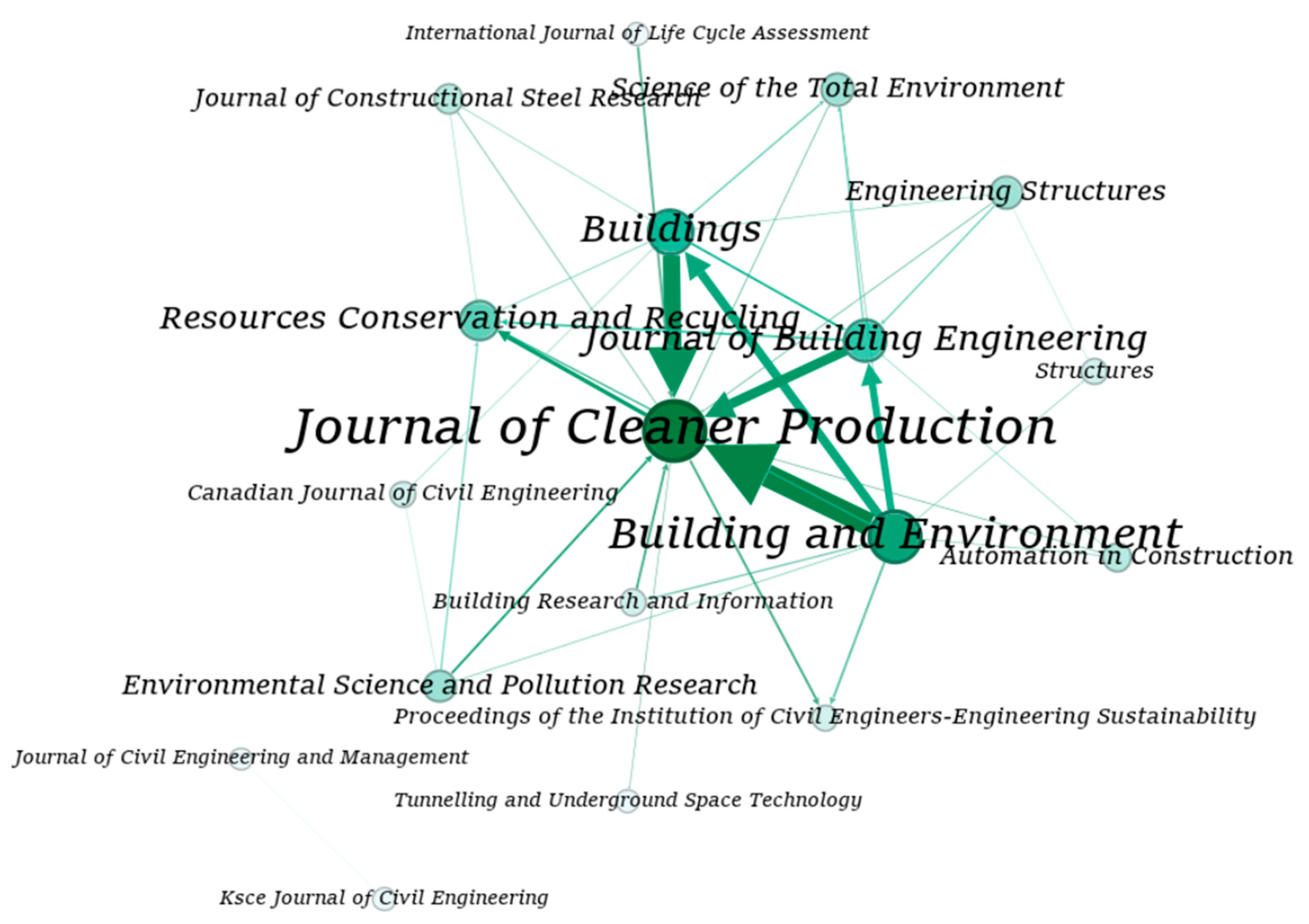

3.2. Citation Analysis of Journal Sources

3.3. Citation of Articles

| Author | Title | Citations | Norm. Citations |

|---|---|---|---|

| Yang et al. (2013) [31] | Assessment of CO2 reduction in alkali-activated concrete | 415 | 2.64 |

| Jaillon and Poon (2014) [32] | Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong | 182 | 1.70 |

| Hong et al. (2016) [33] | Life-cycle energy analysis of prefabricated building components: an input-output-based hybrid model | 169 | 2.05 |

| Jiang et al. (2018) [34] | A SWOT analysis for promoting off-site construction under the backdrop of China’s new urbanization | 129 | 2.11 |

| Teng et al. (2018) [35] | Reducing building life cycle carbon emissions through prefabrication: Evidence from and gaps in empirical studies | 121 | 1.98 |

| Hao et al. (2020) [36] | Carbon emission reduction in prefabrication construction during materialization stage: A BIM-based life-cycle assessment approach | 116 | 2.72 |

| Ataei et al. (2016) [38] | Experimental study of composite beams having a precast geopolymer concrete slab and deconstructable bolted shear connectors | 114 | 1.38 |

| Dong et al. (2015) [37] | A life cycle assessment model for evaluating the environmental impacts of building construction in Hong Kong | 111 | 1.03 |

| Yepes et al. (2015) [40] | Cost and CO2 emission optimization of precast-prestressed concrete U-beam road bridges by a hybrid glowworm swarm algorithm | 104 | 0.96 |

| Minunno et al. (2018) [39] | Strategies for Applying the Circular Economy to Prefabricated Buildings | 102 | 1.67 |

3.4. Countries Active in Carbon Emissions of PC

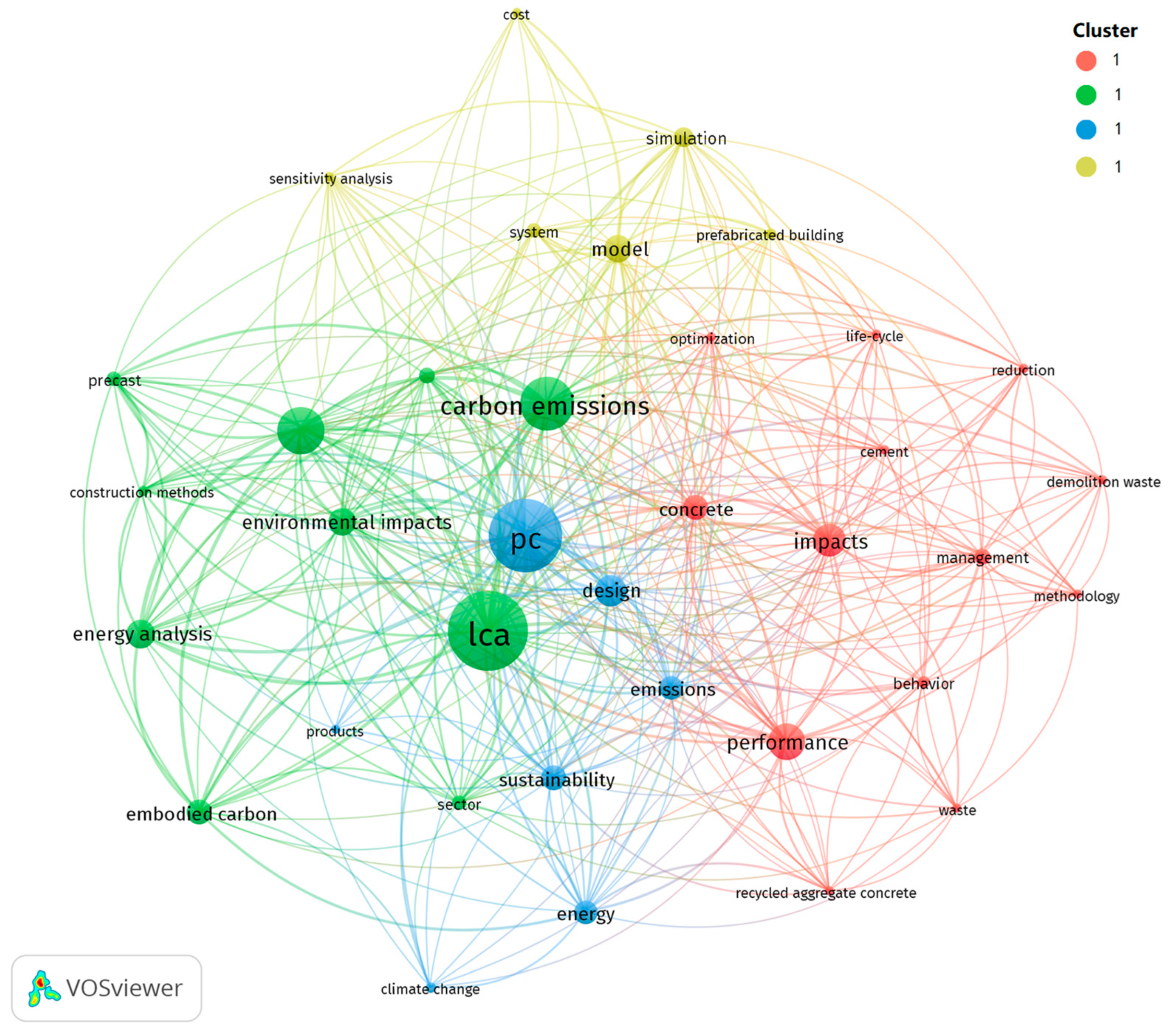

3.5. Co-Occurrence of Keywords

4. Qualitative Analysis and Discussion

4.1. Research Hotspots

- LCA:LCA is a methodology used to evaluate the environmental impacts and resource consumption of a product or service throughout its entire life cycle, from raw material extraction to production, use, disposal, and recycling [44,45]. In the literature on carbon emissions from PC, frequent references to LCA not only highlight the core methodological status of this approach but also demonstrate researchers’ intense focus on comprehending and assessing the full life-cycle carbon emissions and environmental impacts of PC [42].

- Performance and Energy Analysis:The performance and energy usage of PC are crucial factors in assessing their carbon emissions and environmental impacts. Energy analysis quantifies the main carbon emission sources of buildings, and is an indispensable core analytical method for assessing the overall carbon performance and optimizing the design to reduce operational carbon emissions. It focuses on the type and amount of energy used in the production and operation of PC and their impact on the environment [46,47,48]. Reasonable performance and energy analysis can help researchers optimize design and material selection to enhance building performance, reduce energy consumption, and minimize carbon emissions to the greatest extent [49]. Energy analysis is also used as a tool to quantify energy consumption and carbon emissions during the operational phase of buildings.

- Assessment of Environmental Impacts:The environmental impacts of PC, including their potential effects on climate, ecosystems, and human health, are a significant concern for researchers. Various methods and indicators are used to evaluate these impacts, and researchers explore ways to mitigate negative effects through design, construction, and management measures.

- Optimization of Design:Design is a crucial stage in the life cycle of PC, and it plays a significant role in reducing carbon emissions and environmental impacts. Researchers are likely to focus on optimizing design to reduce energy consumption, improve material utilization, and minimize waste generation. This may involve the adoption of green building technologies, modular design, and the use of prefabricated components.

4.2. Current Research Trend

- Theme 1: Material optimization and Waste management (Red cluster)This theme focuses on the use of materials, waste management, performance optimization, and environmental impact throughout the life cycle of PC. It covers the whole process from the selection and use of building materials to building demolition and waste disposal, aiming to reduce carbon emissions and improve building performance by optimizing material use and waste management strategies.For example, Some scholars have utilized life cycle assessment (LCA) to evaluate the environmental performance of concrete, considering carbon emissions, resource consumption, and energy use, while also assessing trade-offs with mechanical performance such as compressive strength, and exploring strategies to optimize both sustainability and structural efficiency [50,51]. In order to promote the recycling of hazardous waste and reduce carbon emissions from PC, a suitable steam curing regime was combined with a suitable coal gangue content to realize green concrete with good durability, low cost, and significant environmental benefits [52]. The reutilization of construction waste as a means to mitigate the carbon footprint of PC has emerged as a pivotal area of research. Current investigations have solidified the environmental sustainability and technical viability of transforming prefabricated concrete waste into concrete blocks, particularly highlighting the superior performance exhibited by blocks with a 20% waste substitution ratio [16]. This finding underscores the potential of such practices to contribute significantly to the Low-carbon transition within the construction sector.The cluster of studies has strengthened the theoretical framework of low-carbon construction by advancing LCA methods, integrating circular economy principles, and promoting green design. Practical case studies show how material optimization and waste management can achieve low-carbon goals, offering feasible solutions for the industry. While material optimization and waste management have advanced, current research often concentrates on specific materials (e.g., basalt concrete) without considering regional production variations and their carbon emissions. Recycling concrete waste offers environmental benefits, but challenges related to feasibility and cost persist. Although modular construction helps reduce emissions, the environmental advantages of alternative materials remain unclear. Future research should focus on regional differences, enhance waste recovery methods, and investigate alternative materials for more effective low-carbon solutions.

- Theme 2: Carbon emission assessment and energy efficiency analysis of PC (Green cluster)This theme focuses on quantitative analysis of carbon emissions, covering several topics such as assessment methods, energy consumption analysis, carbon emissions calculation, construction methods and so on. The carbon emission assessment of PC in the existing research includes: carbon emission assessment in the building materialization stage of buildings [8], carbon emission assessment using LCA [53] and real-time carbon emission assessment [1]. Scholars have worked diligently to use quantitative analysis tools to assess the environmental impact of buildings over their life cycle and explores the potential of PC as a possible solution to reduce carbon emissions and improve building efficiency [13,50,54,55,56].The Energy analysis topic focuses on the type and amount of energy used in the production and operation of PC and their impact on the environment [48,57]. This includes the analysis of energy consumption in the production of building materials, component prefabrication, on-site construction and building operations, with the aim of identifying ways to reduce energy consumption and carbon emissions [42,47,57].In the aforementioned studies, the tools used to calculate carbon emissions became a key discussion point. Previous studies mainly used four methods: statistical, process-based, input–output, and hybrid analyses. Statistical analysis, an effective and rapid approach, fundamentally relies on extensive, coherent, rigorous, and adequately detailed public statistical data [46]. However, in the context of PC, a field that is currently in its infancy in many countries, the acquisition of carbon emission data is arduous. As a result, the utilization of statistical analysis in the majority of research endeavors focusing on PC is fraught with difficulties and constraints. Pervez et al., (2021) [2] conducted a comprehensive review of GHG emissions quantification methods, distinguishing and analyzing two main methods are used, i.e., process-based and input-output method, and affirms the benefits of the process-based method. Process-based analysis is a bottom-up approach that assesses the environmental impact of products and services based on their production process [2]. Every activity involved in the building construction process entails the use of materials and energy, with the resource consumption of each activity being identified and the corresponding carbon emissions being calculated [46,58]. Input-output analysis is an economic analysis tool in carbon emissions research, which uses a top-down approach to assess the resource and pollution embodiments in products and services on a macroeconomic scale, especially for quantitative analysis of GHG emissions [2]. The method considers the whole economy as a system and takes into account the interdependence between different industrial sectors, and tracks the source and path of resource flows and pollution emissions by constructing input-output tables [59]. In addition, upon analyzing the statistics of carbon emission calculation methodologies documented in the literature, it is evident that the carbon emission factor method enjoys widespread utilization [8,60,61].The studies in this cluster offer a range of perspectives on carbon emission assessment in PC, particularly in the application of assessment methods and energy efficiency analysis. However, the literature still faces challenges such as methodological discrepancies (Process-based analysis focuses on carbon emissions at the specific construction stage, emphasizing precise, activity-level data, while input-output analysis considers resource flows and pollution emissions within the broader economic system, with potential discrepancies in the results), overlooked regional variations, and difficulties in data acquisition. Future research should focus on integrating diverse methods, addressing regional research gaps, and advancing the practical implementation of low-carbon technologies. These efforts will further contribute to the global reduction of carbon emissions and the enhancement of energy efficiency in PC.

- Theme 3: Sustainable design for lower carbon emissions and energy consumption (Blue cluster)This theme closely integrates climate change with sustainable building design, explores how to effectively address the challenges posed by climate change in the building design process, and promotes the practice of sustainable building technologies and concepts. It emphasizes the integration of Sustainable design concept into the design to achieve a harmonious coexistence between buildings and the environment [49,57].Numerous researchers have been devoting sustained efforts to design optimization to advance building energy efficiency and curtail carbon emissions [49,57,62]. Fings suggests that decarbonizing the design phase—achieved through selecting materials with low embodied carbon and optimizing structural systems—yields greater lifecycle benefits than post-construction interventions [63]. To achieve balanced environmental objectives for PC, Ji et al. (2024) developed an optimized framework that rapidly determines the optimal energy-saving design, guiding designers in selecting prefabricated envelopes, orientations, and photovoltaic systems for effective energy-efficient design [49]. Some scholars found that in deep foundation projects using concrete, the design decision of using a higher proportion of prefabricated components can reduce GHG emissions by 44% compared to fully cast-in-place construction [64].To advance low-carbon construction, integrating building demolition planning and material reuse considerations at the design stage has become an innovative solution. This propelled the exploration of DfD—a novel construction methodology that enables direct repurposing of materials from old buildings into new projects, thereby reducing: ① waste processing emissions, ② carbon footprint from new material fabrication, and ③ recycling-associated carbon emissions [57]. Standardized and modular PC technology provides an ideal implementation platform for the DfD strategy. Their integration delivers innovative pathways toward more low-carbon and sustainable construction practices.This cluster underscores the potential of embedding sustainable design principles into the architectural process, with a focus on fostering a harmonious relationship between buildings and the environment. Scholars are increasingly investigating how low-carbon objectives can be integrated at the design stage, particularly through the selection of materials and structural optimization, which not only reduces carbon emissions but also enhances lifecycle benefits. While the decarbonization of the design phase is widely recognized for its long-term environmental advantages, existing research also highlights the necessity of post-construction interventions to optimize energy efficiency and further reduce carbon emissions. The challenge of balancing early-stage design optimization with subsequent interventions remains a critical issue for future studies. Additionally, although standardized and modular technologies offer an ideal platform for implementing DfD, their successful deployment across diverse regions and project scales, especially in less-developed areas, presents significant challenges. Addressing these obstacles is vital to advancing the broader adoption of low-carbon building practices.

- Theme 4: Carbon emission simulation (Yellow cluster)Research on this theme uses dynamic system modeling (e.g., system dynamics, BIM integration), multi-objective optimization algorithms (genetic algorithms, particle swarm optimization) to achieve dynamic tradeoffs and optimal decisions among multiple dimensions such as carbon emissions, costs, construction efficiency, and resource constraints. The emergence of costs indicates that cost–benefit analysis is one of the important goals of the optimization policy for construction projects.At the system modeling level, a dynamic simulation approach utilizing system dynamics methodology was adopted to investigate evolving carbon emission profiles of power construction projects, with explicit consideration of PC technology level and R&D investment dynamics, thereby overcoming constraints inherent in traditional static LCAs [8]. Tushar et al. (2022) further advanced the integration of BIM and LCA frameworks by deploying Monte Carlo simulations to probabilistically assess critical design parameters (e.g., insulation material thickness, fly ash replacement ratios) in prefabricated sandwich panels, thereby catalyzing a fundamental transition from conventional trial-and-error design methodologies to sophisticated probabilistic optimization strategies [45]. In conjunction with simulation models, sensitivity analysis is often employed to analyze and optimize the model’s output in order to identify the key factors influencing the sustainability of construction projects. For example, sensitivity analysis was used to identify the key factors that affect the life cycle of PC and optimize the design to cope with different environmental and climate change conditions [65].At the multi-objective optimization level, Guo et al. (2023) employed an enhanced genetic algorithm to investigate the trade-off dynamics between prefabrication costs and carbon emissions under resource constraints, revealing a significant threshold effect at a 35–40% prefabrication rate—a critical juncture that not only signifies the apex of marginal emission reduction efficiency but also embodies the dynamic equilibrium between market maturity and technological innovation [66]. Jeong et al. (2017) developed an integrated simulation framework leveraging the Web-CYCLONE tool to concurrently evaluate construction efficiency, cost implications, and carbon emissions, thereby quantifiably demonstrating the conflicting relationship between the operational efficiency benefits and environmental costs inherently associated with PC technology [67].This cluster introduces dynamic simulation and multi-objective optimization methods, overcoming the limitations of traditional static LCA methods. These methods enable dynamic evaluation of carbon emissions throughout the building process, offering a more comprehensive understanding of emissions at each stage and providing valuable decision-making support for low-carbon construction. While these approaches show great potential, challenges remain in balancing carbon emissions, costs, and construction efficiency, as well as adapting algorithms to different real-world scenarios. Future research should focus on refining algorithms, fostering interdisciplinary collaboration, and incorporating long-term benefit analysis to guide more sustainable and low-carbon building practices.

4.3. Research Gaps and Future Needs

- (1)

- The absence of empirical data, along with the lack of real-time monitoring systems for carbon emissions in PC remains a significant gap. Earlier implementation of real-time monitoring will be helpful for the formulation of an emission reduction plan, process control, and post-analysis. However, the one-off, unique, and complex nature of construction projects presents significant challenges for the long-term monitoring and data collection of carbon emissions. Despite research on real-time carbon emission monitoring has made significant progress, most studies still primarily focus on traditional construction methods [68,69]. Some new studies using Digital Twin technology are also in the early stages [23,24]. Several studies conducted on the real-time monitoring of GHG emissions of PC have primarily focuses on a limited range of construction machinery and does not explore a broader set of equipment or materials [69] and others are difficult to implement widely in practice due to the high cost and installation challenges [1]. Additionally, although these studies propose innovative data collection methods, challenges remain in terms of system scalability and practical deployment, particularly regarding sensor stability and cost-effectiveness for large-scale applications.Given the above challenges, Future research should focus on developing low-cost, efficient real-time carbon emission monitoring systems. These systems need to be highly scalable to support large-scale construction projects while ensuring long-term stability and data reliability. Smart monitoring systems based on Internet of Things (IoT) technology can integrate with cloud computing platforms to centrally process data, enabling dynamic monitoring and analysis throughout the entire construction process. Additionally, data integration and innovative analytical methods should be prioritized. Researchers should also investigate how to integrate big data analytics with Life Cycle Management Systems (LCMS) and BIM, utilizing the simulation and optimization capabilities of digital twins to improve the precision of carbon emission control decisions. Moreover, efforts should address the system’s accessibility and deployment, ensuring that it can be widely applied across projects of various sizes and in different regions. In the future, practitioners should prioritize developing cost-effective, easy-to-deploy carbon emission monitoring systems that integrate seamlessly with construction workflows. It is also essential to provide training and support to ensure workers and managers can use these systems effectively. Policymakers should establish clear regulations and offer financial incentives, like subsidies and tax breaks, to encourage the adoption of real-time monitoring. Promoting industry standards for carbon tracking and fostering collaboration between researchers, industry, and government will help speed up the development and implementation of these technologies.

- (2)

- The inconsistency in carbon emission assessment methodologies across different studies is a key issue. Existing studies on quantifying carbon emissions from PC exhibit significant methodological differences, and a widely accepted, standardized evaluation framework has yet to be established. Key issues include inconsistent system boundaries, varying data sources and quality, and an incomplete emission factor database specific to PC [8]. For example, most studies focus on the “production-construction” stages, with insufficient attention given to carbon emissions during the demolition and recycling stages [46,57]. Mo et al. (2023) argued that the component recovery rate during the demolition phase of buildings using PC technology can reach 18%, and the carbon emission in this stage should be fully considered in the assessment [56]. Although some studies have used the LCA method, it is difficult to achieve an evaluation covering the full life cycle. This is because a full life cycle carbon evaluation requires data from the operational (decades-long), maintenance, and demolition stages, which is challenging to obtain, and the data quality is hard to guarantee. Therefore, although Zhou et al. (2023) divides the full life cycle into five stages—“material production, transportation, construction, operation, and demolition”—in actual assessments, due to the difficulty in obtaining data for the demolition stage, carbon emissions during this phase are often estimated proportionally, with the core analysis still focused on the construction phase [53]. Li et al. (2023) states that a unified carbon emission factor database for buildings has not been established, and regional differences in energy structures and production processes cause significant fluctuations in emission factors, affecting accounting accuracy [8].Based on the aforementioned review, the need for standardized carbon emission assessment frameworks is essential to advance the field, particularly through improving data collection at each stage of the life cycle and developing a comprehensive carbon emission factor database. Future research should focus on establishing a unified carbon emission assessment framework, to address this issue, researchers should aim to cover the entire life cycle of buildings, with particular attention to the carbon emissions during the demolition and recycling stages. Developing standardized carbon emission assessment methods will facilitate the comparison and integration of various research findings, providing more reliable evidence for policymaking and industry practices. Practitioners should adopt a life-cycle approach starting from the design and construction phases, collaborating with environmental consultants to ensure that carbon emissions during the demolition and recycling stages are fully considered. At the same time, the construction industry should invest more in sustainable materials and low-carbon technologies to enhance resource efficiency. Policymakers should establish regulatory frameworks to ensure carbon emission assessments cover the entire life cycle of buildings, implement incentives to promote sustainable practices, and support the comparison and integration of research findings through standardized databases and tools.

- (3)

- There has been no comprehensive, unified approach that integrates the various carbon reduction strategies—such as material optimization, waste management, energy efficiency, and sustainable design—into a cohesive framework for practical application. While individual strategies have been thoroughly researched and shown to be effective in reducing carbon emissions, they are often examined in isolation, with little consideration of how they can be combined or coordinated to maximize their collective environmental benefits. This fragmented approach fails to address the complexity of real-world construction projects, where multiple factors need to be considered simultaneously. Furthermore, most studies focus on one or two aspects of carbon reduction, such as energy efficiency during construction [48,65] or the use of sustainable materials [50,52], but neglect how these strategies can be harmonized across the entire lifecycle of a building. Industry practitioners often lack clear, actionable guidance on how to effectively implement these carbon reduction strategies, which may hinder the widespread adoption of low-carbon construction practices.Future research should prioritize the development of an integrated approach that seamlessly combines material selection, energy analysis, waste reduction, and design optimization in a way that aligns with both industry needs and regulatory requirements. A unified framework would not only streamline the decision-making process but also amplify the environmental benefits of PC. By addressing this gap, researchers can provide the construction industry with a valuable tool that facilitates the transition to more sustainable, carbon-neutral building practices. For policymakers, in addition to the incentives mentioned earlier, the government should also foster greater interdepartmental collaboration to ensure alignment across various policy areas—such as environmental protection, urban planning, and building codes—thereby supporting the construction industry’s overall progress toward carbon reduction goals.

5. Conclusions

- (1)

- Drawing on a systematically curated database of 114 journal articles, the review demonstrates a sharp rise in research on PC-related carbon emissions since 2010, reflecting growing global attention to decarbonizing construction. The top journals and top articles were also presented herein. Countries active show that China dominates in the research scale, while Australia leads in terms of quality and impact. Regional collaboration is characterized by two primary citation clusters: one connecting Asia, and the other linking Europe and North America. Moreover, emerging countries like Sri Lanka has demonstrated growing influence in recent years.

- (2)

- The top 5 items with the highest occurrence frequency highlight four key research hotspots: LCA, Performance and Energy Analysis, Assessment of Environmental Impacts, and Optimization of Design. Combining the results from keyword co-occurrence clustering and content analysis, research on carbon emissions in PC converged into four dominant thematic categories: Material optimization and waste management, Carbon emission assessment and energy efficiency analysis, Sustainable design for low-carbon outcomes and Carbon emission simulation.

- (3)

- LCA emerged as the most prevalent methodology for quantifying carbon emissions of PC. This centrality is evidenced by its application across all research themes—from material optimization to design strategies—establishing LCA as the foundational framework for holistic carbon footprint evaluation in PC studies.

- (4)

- An in-depth qualitative analysis revealed three critical gaps that demand urgent attention: the absence of real-time carbon monitoring systems for PC, with current methods being limited to traditional construction and facing significant high-cost deployment barriers; inconsistency in carbon assessment methodologies, characterized by varying system boundaries and the lack of standardized emission factors; and the fragmentation of carbon reduction strategies, where material optimization, energy analysis, and sustainable design are often studied in isolation without integrated implementation frameworks.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PC | Prefabricated Construction |

| LCA | life Cycle Assessment |

| GHG | Greenhouse Gas |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| DfD | Design for Deconstruction |

| IFD | Industrialized Flexible and Demountable |

| BIM | Building Information Modeling |

| LCMS | Life Cycle Management Systems |

| EMoC | Environmental Model of Construction |

References

- Liu, G.; Chen, R.; Xu, P.; Fu, Y.; Mao, C.; Hong, J. Real-Time Carbon Emission Monitoring in Prefabricated Construction. Autom. Constr. 2020, 110, 102945. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Petrillo, A. A Quantitative Assessment of Greenhouse Gas (GHG) Emissions from Conventional and Modular Construction: A Case of Developing Country. J. Clean. Prod. 2021, 294, 126210. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Ning, X.; Li, L. Gauging the Impacts of Urbanization on CO2 Emissions from the Construction Industry: Evidence from China. J. Environ. Manag. 2021, 288, 112440. [Google Scholar] [CrossRef]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in Off-Site Manufacturing for Buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef]

- Yuan, M.; Li, Z.; Li, X.; Li, L.; Zhang, S.; Luo, X. How to Promote the Sustainable Development of Prefabricated Residential Buildings in China: A Tripartite Evolutionary Game Analysis. J. Clean. Prod. 2022, 349, 131423. [Google Scholar] [CrossRef]

- Wu, P.; Low, S.P.; Jin, X. Identification of Non-Value Adding (NVA) Activities in Precast Concrete Installation Sites to Achieve Low-Carbon Installation. Resour. Conserv. Recycl. 2013, 81, 60–70. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus Conventional Construction: Comparing Life-Cycle Impacts of Alternative Structural Materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Li, X.; Xie, W.; Yang, T.; Lin, C.; Jim, C.Y. Carbon Emission Evaluation of Prefabricated Concrete Composite Plates during the Building Materialization Stage. Build. Environ. 2023, 232, 110045. [Google Scholar] [CrossRef]

- Goodier, C.; Gibb, A. Future Opportunities for Offsite in the UK. Constr. Manag. Econ. 2007, 25, 585–595. [Google Scholar] [CrossRef]

- He, R.; Li, M.; Gan, V.J.L.; Ma, J. BIM-Enabled Computerized Design and Digital Fabrication of Industrialized Buildings: A Case Study. J. Clean. Prod. 2020, 278, 123505. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Li, T.; Yuan, M. A Holistic Literature Review of Building Information Modeling for Prefabricated Construction. J. Civ. Eng. Manag. 2021, 27, 485–499. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.S. The Hindrance to Using Prefabrication in Hong Kong’s Building Industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A Comparative Study of Environmental Performance between Prefabricated and Traditional Residential Buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Du, Q.; Bao, T.; Li, Y.; Huang, Y.; Shao, L. Impact of Prefabrication Technology on the Cradle-to-Site CO2 Emissions of Residential Buildings. Clean Technol. Environ. Policy 2019, 21, 1499–1514. [Google Scholar] [CrossRef]

- Hu, R.; Chen, K.; Fang, W.; Zheng, L.; Xu, J. The Technology-Environment Relationship Revisited: Evidence from the Impact of Prefabrication on Reducing Construction Waste. J. Clean. Prod. 2022, 341, 130883. [Google Scholar] [CrossRef]

- Galvín, A.P.; Sabrina, S.; Auxi, B.; Peña, A.; López-Uceda, A. Leaching Performance of Concrete Eco-Blocks: Towards Zero-Waste in Precast Concrete Plants. J. Environ. Manag. 2023, 344, 118409. [Google Scholar] [CrossRef] [PubMed]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring Embodied Carbon Dioxide Equivalent of Buildings: A Review and Critique of Current Industry Practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Lu, W.; Tam, V.W.Y.; Chen, H.; Du, L. A Holistic Review of Research on Carbon Emissions of Green Building Construction Industry. Eng. Constr. Archit. Manag. 2020, 27, 1065–1092. [Google Scholar] [CrossRef]

- Joseph, V.R.; Mustaffa, N.K. Carbon Emissions Management in Construction Operations: A Systematic Review. Eng. Constr. Archit. Manag. 2023, 30, 1271–1299. [Google Scholar] [CrossRef]

- Jin, R.; Hong, J.; Zuo, J. Environmental Performance of Off-Site Constructed Facilities: A Critical Review. Energy Build. 2020, 207, 109567. [Google Scholar] [CrossRef]

- Li, L.; Luan, H.; Yin, X.; Dou, Y.; Yuan, M.; Li, Z. Understanding Sustainability in Off-Site Construction Management: State of the Art and Future Directions. J. Constr. Eng. Manag. 2022, 148, 03122008. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, Y.; Feng, W.; Fang, Y.; Feng, A. Factors That Influence the Quantification of the Embodied Carbon Emission of Prefabricated Buildings: A Systematic. Buildings 2022, 12, 1265. [Google Scholar] [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Oti-Sarpong, K.; Wuni, I.Y.; Tetteh, M.O. Systematic Review on the Integration of Building Information Modelling and Prefabrication Construction for Low-Carbon Building Delivery. Build. Res. Inf. 2022, 51, 279–300. [Google Scholar] [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Sepasgozar, S.M.E.; Kamat, V.R. Digital Twin-Enabled Prefabrication Supply Chain for Smart Construction and Carbon Emissions Evaluation in Building Projects. J. Build. Eng. 2023, 78, 107598. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science Mapping Approach to Assisting the Review of Construction and Demolition Waste Management Research Published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A Holistic Review of Off-Site Construction Literature Published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Liu, W. The Data Source of This Study Is Web of Science Core Collection? Not Enough. Scientometrics 2019, 121, 1815–1824. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Oraee, M.; Hosseini, M.R.; Papadonikolaki, E.; Palliyaguru, R.; Arashpour, M. Collaboration in BIM-Based Construction Networks: A Bibliometric-Qualitative Literature Review. Int. J. Proj. Manag. 2017, 35, 1288–1301. [Google Scholar] [CrossRef]

- Monkman, S.; Shao, Y. Integration of Carbon Sequestration into Curing Process of Precast Concrete. Can. J. Civ. Eng. 2010, 37, 302–310. [Google Scholar] [CrossRef]

- Yang, K.; Song, J.; Song, K. Assessment of CO2 Reduction of Alkali-Activated Concrete. J. Clean. Prod. 2013, 39, 265–272. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life Cycle Design and Prefabrication in Buildings: A Review and Case Studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-Cycle Energy Analysis of Prefabricated Building Components: An Input-Output-Based Hybrid Model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Jiang, R.; Mao, C.; Hou, L.; Wu, C.; Tan, J. A SWOT Analysis for Promoting Off-Site Construction under the Backdrop of China’s New Urbanisation. J. Clean. Prod. 2018, 173, 225–234. [Google Scholar] [CrossRef]

- Teng, Y.; Li, K.; Pan, W.; Ng, T. Reducing Building Life Cycle Carbon Emissions through Prefabrication: Evidence from and Gaps in Empirical Studies. Build. Environ. 2018, 132, 125–136. [Google Scholar] [CrossRef]

- Hao, J.L.; Cheng, B.; Lu, W.; Xu, J.; Wang, J.; Bu, W.; Guo, Z. Carbon Emission Reduction in Prefabrication Construction during Materialization Stage: A BIM-Based Life-Cycle Assessment Approach. Sci. Total Environ. 2020, 723, 137870. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.H.; Ng, S.T. A Life Cycle Assessment Model for Evaluating the Environmental Impacts of Building Construction in Hong Kong. Build. Environ. 2015, 89, 183–191. [Google Scholar] [CrossRef]

- Ataei, A.; Bradford, M.A.; Liu, X. Experimental Study of Composite Beams Having a Precast Geopolymer Concrete Slab and Deconstructable Bolted Shear Connectors. Eng. Struct. 2016, 114, 1–13. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Yepes, V.; Martí, J.V.; García-Segura, T. Cost and CO2 Emission Optimization of Precast-Prestressed Concrete U-Beam Road Bridges by a Hybrid Glowworm Swarm Algorithm. Autom. Constr. 2015, 49, 123–134. [Google Scholar] [CrossRef]

- Munmulla, T.; Hidallana-Gamage, H.D.; Navaratnam, S.; Ponnampalam, T.; Zhang, G.; Jayasinghe, T. Suitability of Modular Technology for House Construction in Sri Lanka: A Survey and a Case Study. Buildings 2023, 13, 2592. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Jayasinghe, J.A.S.C.; Kulatunga, A.K.; Zhang, G. A Comparative Life Cycle Assessment of Prefabricated and Traditional Construction—A Case of a Developing Country. J. Build. Eng. 2023, 72, 106550. [Google Scholar] [CrossRef]

- Munmulla, T.; Navaratnam, S.; Hidallana-Gamage, H.D.; Tushar, Q.; Ponnampalam, T.; Zhang, G.; Jayasinghe, M.T.R. Sustainable Approaches to Improve the Resilience of Modular Buildings under Wind Loads. J. Constr. Steel Res. 2023, 211, 108124. [Google Scholar] [CrossRef]

- Dong, L.; Wang, Y.; Li, H.X.; Jiang, B.; Al-Hussein, M. Carbon Reduction Measures-Based LCA of Prefabricated Temporary Housing with Renewable Energy Systems. Sustain. 2018, 10, 718. [Google Scholar] [CrossRef]

- Tushar, Q.; Zhang, G.; Bhuiyan, M.A.; Navaratnam, S.; Giustozzi, F.; Hou, L. Retrofit of Building Façade Using Precast Sandwich Panel: An Integrated Thermal and Environmental Assessment on BIM-Based LCA. Buildings 2022, 12, 2098. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative Study of Greenhouse Gas Emissions between Off-Site Prefabrication and Conventional Construction Methods: Two Case Studies of Residential Projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Sebaibi, N.; Boutouil, M. Reducing Energy Consumption of Prefabricated Building Elements and Lowering the Environmental Impact of Concrete. Eng. Struct. 2020, 213, 110594. [Google Scholar] [CrossRef]

- Ismail, F.H.; Shahrestani, M.; Vahdati, M.; Boyd, P.; Donyavi, S. Climate Change and the Energy Performance of Buildings in the Future—A Case Study for Prefabricated Buildings in the UK. J. Build. Eng. 2021, 39, 102285. [Google Scholar] [CrossRef]

- Ji, Y.; Lv, J.; Li, H.X.; Liu, Y.; Yao, F.; Liu, X.; Wang, S. Improving the Performance of Prefabricated Houses through Multi-Objective Optimization Design. J. Build. Eng. 2024, 84, 108579. [Google Scholar] [CrossRef]

- Ingrao, C.; Lo Giudice, A.; Tricase, C.; Mbohwa, C.; Rana, R. The Use of Basalt Aggregates in the Production of Concrete for the Prefabrication Industry: Environmental Impact Assessment, Interpretation and Improvement. J. Clean. Prod. 2014, 75, 195–204. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Mahdi, H.A.; Riofrio, A.; Eidgahee, D.R.; Baykara, H.; Soleymani, A.; Kontoni, D.P.N.; Shakeri, J.; Jahangir, H. Optimal Compressive Strength of RHA Ultra-High-Performance Lightweight Concrete (UHPLC) and Its Environmental Performance Using Life Cycle Assessment. Civ. Eng. J. 2022, 8, 2391–2410. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, T.; Gao, X. Incorporation of Self-Ignited Coal Gangue in Steam Cured Precast Concrete. J. Clean. Prod. 2021, 292, 126004. [Google Scholar] [CrossRef]

- Zhou, F.; Ning, Y.; Guo, X.; Guo, S. Analyze Differences in Carbon Emissions from Traditional and Prefabricated Buildings Combining the Life Cycle. Buildings 2023, 13, 874. [Google Scholar] [CrossRef]

- Kim, T.; Chae, C.U. Evaluation Analysis of the CO2 Emission and Absorption Life Cycle for Precast Concrete in Korea. Sustainability 2016, 8, 663. [Google Scholar] [CrossRef]

- Luna-Tintos, J.F.; Cobreros, C.; López-Escamilla, Á.; Herrera-Limones, R.; Torres-García, M. Methodology to Evaluate the Embodied Primary Energy and CO2 Production at Each Stage of the Life Cycle of Prefabricated Structural Systems: The Case of the Solar Decathlon Competition. Energies 2020, 13, 4311. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, T.; Qu, J.; Cai, G.; Cao, Z.; Jiang, W. An Empirical Study of Carbon Emission Calculation in the Production and Construction Phase of A Prefabricated Office Building from Zhejiang, China. Buildings 2023, 13, 53. [Google Scholar] [CrossRef]

- Eckelman, M.J.; Brown, C.; Troup, L.N.; Wang, L.; Webster, M.D.; Hajjar, J.F. Life Cycle Energy and Environmental Benefits of Novel Design-for-Deconstruction Structural Systems in Steel Buildings. Build. Environ. 2018, 143, 421–430. [Google Scholar] [CrossRef]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction Matters Comparing Environmental Impacts of Building Modular and Conventional Homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Sharrard, A.L.; Matthews, H.S.; Ries, R.J. Estimating Construction Project Environmental Effects Using an Input-Output-Based Hybrid Life-Cycle Assessment Model. J. Infrastruct. Syst. 2008, 14, 327–336. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, Y.; Qian, X.; Ming, Z.; Nie, R. Urbanization and CO2 Emissions in Resource-exhausted Cities: Evidence from Xuzhou City, China. Nat. Hazards 2019, 99, 807–826. [Google Scholar] [CrossRef]

- Wang, J.; Song, X.; Chen, K. Which Influencing Factors Cause CO2 Emissions Differences in China’s Provincial Construction Industry: Empirical Analysis from a Quantile Regression Model. Pol. J. Environ. Stud. 2020, 29, 331–347. [Google Scholar] [CrossRef]

- Stevanović, S. Optimization of Passive Solar Design Strategies: A Review. Renew. Sustain. Energy Rev. 2013, 25, 177–196. [Google Scholar] [CrossRef]

- Chesné, L.; Duforestel, T.; Roux, J.J.; Rusaouën, G. Energy Saving and Environmental Resources Potentials: Toward New Methods of Building Design. Build. Environ. 2012, 58, 199–207. [Google Scholar] [CrossRef]

- Pujadas-Gispert, E.; Sanjuan-Delmás, D.; de la Fuente, A.; Moonen, S.P.G.F.; Josa, A. Environmental Analysis of Concrete Deep Foundations: Influence of Prefabrication, Concrete Strength, and Design Codes. J. Clean. Prod. 2020, 244, 118751. [Google Scholar] [CrossRef]

- Satola, D.; Kristiansen, A.B.; Houlihan-Wiberg, A.; Gustavsen, A.; Ma, T.; Wang, R.Z. Comparative Life Cycle Assessment of Various Energy Efficiency Designs of a Container-Based Housing Unit in China: A Case Study. Build. Environ. 2020, 186, 107358. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, Y.; Chang, C.; Yu, Y. Carbon Emissions of Assembly Buildings Constrained by Flexible Resource: A Study on Cost Optimization. Buildings 2023, 13, 90. [Google Scholar] [CrossRef]

- Jeong, J.; Hong, T.; Ji, C.; Kim, J.; Lee, M.; Jeong, K.; Lee, S. An Integrated Evaluation of Productivity, Cost and CO2 Emission between Prefabricated and Conventional Columns. J. Clean. Prod. 2017, 142, 2393–2406. [Google Scholar] [CrossRef]

- Seo, M.S.; Kim, T.; Hong, G.; Kim, H. On-Site Measurements of CO2 Emissions during the Construction Phase of a Building Complex. Energies 2016, 9, 599. [Google Scholar] [CrossRef]

- Liu, G.; Yang, H.; Fu, Y.; Mao, C.; Xu, P.; Hong, J.; Li, R. Cyber-Physical System-Based Real-Time Monitoring and Visualization of Greenhouse Gas Emissions of Prefabricated Construction. J. Clean. Prod. 2020, 246, 119059. [Google Scholar] [CrossRef]

| Journal | Total Link Strength | Number of Articles | Total Citations | Avg. Citations | Avg. Norm. Citations |

|---|---|---|---|---|---|

| Journal of Cleaner Production | 83 | 36 | 1639 | 46 | 1.07 |

| Building and Environment | 59 | 13 | 584 | 45 | 1.20 |

| Engineering Structures | 5 | 4 | 229 | 57 | 0.73 |

| Buildings | 41 | 20 | 182 | 9 | 0.70 |

| Resources Conservation and Recycling | 14 | 4 | 141 | 35 | 1.05 |

| Automation in Construction | 3 | 2 | 140 | 70 | 1.10 |

| Journal of Building Engineering | 32 | 11 | 139 | 13 | 1.28 |

| Science of the Total Environment | 6 | 1 | 123 | 123 | 2.98 |

| Canadian Journal of Civil Engineering | 2 | 2 | 68 | 34 | 0.79 |

| Building Research and Information | 5 | 3 | 49 | 16 | 1.59 |

| Fresenius Environmental Bulletin | 0 | 1 | 32 | 32 | 0.78 |

| Environmental Science and Pollution Research | 7 | 1 | 30 | 30 | 0.73 |

| Ksce Journal of Civil Engineering | 1 | 1 | 26 | 26 | 0.34 |

| Structural Design of Tall and Special Buildings | 0 | 1 | 21 | 21 | 0.54 |

| Proceedings of the Institution of Civil Engineers-Engineering Sustainability | 6 | 2 | 17 | 9 | 0.25 |

| International Journal of Life Cycle Assessment | 3 | 1 | 14 | 14 | 0.45 |

| Journal of Civil Engineering and Management | 1 | 1 | 14 | 14 | 0.49 |

| Pci Journal | 0 | 1 | 9 | 9 | 0.12 |

| Tunnelling and Underground Space Technology | 1 | 1 | 5 | 5 | 1.61 |

| Journal of Environmental Management | 0 | 2 | 4 | 2 | 1.98 |

| Building Services Engineering Research & Technology | 0 | 1 | 1 | 1 | 0.32 |

| European Journal of Environmental And Civil Engineering | 0 | 1 | 1 | 1 | 3.00 |

| Journal of Constructional Steel Research | 3 | 1 | 1 | 1 | 0.32 |

| Advances in Civil Engineering | 0 | 2 | 0 | 0 | 0.00 |

| Structures | 2 | 1 | 0 | 0 | 0.00 |

| Country | Total Link Strength | Number of Articals | Number of Ciations | Avg. Pub. Year | Avg. Citations | Avg. Norm. Citations |

|---|---|---|---|---|---|---|

| China | 102 | 57 | 1826 | 2021 | 32.04 | 1.10 |

| Australia | 66 | 21 | 973 | 2019 | 46.33 | 1.15 |

| South Korea | 18 | 9 | 205 | 2019 | 22.78 | 0.71 |

| USA | 25 | 10 | 162 | 2020 | 16.20 | 0.82 |

| Portugal | 28 | 6 | 140 | 2021 | 23.33 | 1.18 |

| Spain | 0 | 4 | 135 | 2019 | 33.75 | 0.70 |

| Germany | 3 | 4 | 112 | 2020 | 28.00 | 0.70 |

| Italy | 12 | 3 | 94 | 2019 | 31.33 | 1.01 |

| Malaysia | 12 | 4 | 92 | 2020 | 23.00 | 0.55 |

| UK | 17 | 8 | 81 | 2021 | 10.13 | 0.71 |

| Singapore | 12 | 4 | 60 | 2020 | 15.00 | 0.91 |

| Sri Lanka | 19 | 3 | 24 | 2022 | 8.00 | 1.61 |

| № | Original Keywords | Normalized Keywords |

|---|---|---|

| 1 | life cycle assessment | lca |

| 2 | life-cycle assessment | lca |

| 3 | life cycle assessment (lca) | lca |

| 4 | co2 emissions | carbon emissions |

| 5 | co2 emission | carbon emissions |

| 6 | carbon emission | carbon emissions |

| 7 | prefabrication | pc |

| 8 | offsite construction | pc |

| 9 | precast concrete | pc |

| 10 | modular construction | pc |

| Label | Total Link Strength | Occurrences | Avg. Pub. Year | Avg. Citations | Avg. Norm. Citations | Cluster |

|---|---|---|---|---|---|---|

| behavior | 19 | 7 | 2018 | 42.57 | 0.67 | 1 |

| carbon emissions | 120 | 29 | 2021 | 21.48 | 1.14 | 2 |

| cement | 22 | 5 | 2020 | 33.40 | 1.59 | 1 |

| climate change | 17 | 6 | 2022 | 18.17 | 0.61 | 3 |

| concrete | 47 | 14 | 2020 | 52.93 | 0.91 | 1 |

| construction methods | 40 | 6 | 2020 | 45.17 | 1.26 | 2 |

| cost | 14 | 5 | 2021 | 18.00 | 0.65 | 4 |

| demolition waste | 24 | 5 | 2021 | 60.20 | 1.89 | 1 |

| design | 70 | 17 | 2021 | 36.61 | 1.04 | 3 |

| embodied carbon | 60 | 14 | 2021 | 28.07 | 0.86 | 2 |

| embodied energy | 47 | 9 | 2020 | 55.44 | 1.47 | 2 |

| emissions | 45 | 13 | 2020 | 44.75 | 1.22 | 3 |

| energy | 46 | 13 | 2020 | 18.38 | 0.83 | 3 |

| energy analysis | 76 | 16 | 2020 | 36.27 | 1.21 | 2 |

| environmental impacts | 85 | 15 | 2020 | 35.93 | 1.18 | 2 |

| greenhouse-gas emissions | 120 | 26 | 2020 | 36.35 | 1.12 | 2 |

| impacts | 68 | 18 | 2020 | 46.00 | 1.18 | 1 |

| lca | 178 | 43 | 2021 | 29.55 | 1.11 | 2 |

| life-cycle | 22 | 5 | 2019 | 37.60 | 0.72 | 1 |

| management | 37 | 9 | 2021 | 25.00 | 1.12 | 1 |

| methodology | 19 | 5 | 2021 | 36.60 | 1.59 | 1 |

| model | 53 | 15 | 2021 | 17.07 | 0.85 | 4 |

| optimization | 24 | 5 | 2021 | 27.17 | 0.64 | 1 |

| pc | 158 | 40 | 2020 | 41.33 | 1.21 | 3 |

| performance | 79 | 20 | 2022 | 22.80 | 1.18 | 1 |

| precast | 46 | 8 | 2020 | 39.92 | 0.94 | 2 |

| prefabricated building | 25 | 6 | 2023 | 10.33 | 1.23 | 4 |

| products | 11 | 5 | 2017 | 42.60 | 1.22 | 3 |

| recycled aggregate concrete | 22 | 5 | 2022 | 20.40 | 1.37 | 1 |

| reduction | 22 | 5 | 2021 | 28.60 | 0.92 | 1 |

| sector | 40 | 8 | 2022 | 20.88 | 1.19 | 2 |

| sensitivity analysis | 29 | 5 | 2021 | 20.00 | 0.49 | 4 |

| simulation | 44 | 11 | 2021 | 31.50 | 0.50 | 4 |

| sustainability | 54 | 14 | 2020 | 31.15 | 0.97 | 3 |

| system | 27 | 8 | 2021 | 25.94 | 0.67 | 4 |

| waste | 20 | 5 | 2020 | 40.60 | 0.72 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Zhao, Y.; Fang, X.; Liu, Y.; Bai, W.; Ma, S. Advancing Low-Carbon Construction: A Systematic Literature Review of Carbon Emissions of Prefabricated Construction. Buildings 2025, 15, 3578. https://doi.org/10.3390/buildings15193578

Zhang S, Zhao Y, Fang X, Liu Y, Bai W, Ma S. Advancing Low-Carbon Construction: A Systematic Literature Review of Carbon Emissions of Prefabricated Construction. Buildings. 2025; 15(19):3578. https://doi.org/10.3390/buildings15193578

Chicago/Turabian StyleZhang, Shengxi, Yinghao Zhao, Xianhua Fang, Yan Liu, Wenhao Bai, and Shengbin Ma. 2025. "Advancing Low-Carbon Construction: A Systematic Literature Review of Carbon Emissions of Prefabricated Construction" Buildings 15, no. 19: 3578. https://doi.org/10.3390/buildings15193578

APA StyleZhang, S., Zhao, Y., Fang, X., Liu, Y., Bai, W., & Ma, S. (2025). Advancing Low-Carbon Construction: A Systematic Literature Review of Carbon Emissions of Prefabricated Construction. Buildings, 15(19), 3578. https://doi.org/10.3390/buildings15193578