Recycled Waste Materials Utilised in 3D Concrete Printing for Construction Applications: A Scientometric Review

Abstract

1. Introduction

- 1-

- Can a bibliometric analysis provide an understanding of the current state of recycled materials utilised in 3D concrete printing as per the experimental work conducted in previous studies?

- 2-

- Which recycled waste materials are being used in 3D concrete printing, how are they sourced, and what are their characteristics in terms of morphology, chemical composition, and physical properties?

- 3-

- What are the effects of incorporating these recycled materials in terms of rheology (flowability, extrudability, and buildability) as well as mechanical performance (strength and anisotropy)?

- 4-

- What are the environmental and economic implications of using recycled materials in 3D concrete printing compared to conventional construction methods?

Contribution and Significance of This Study

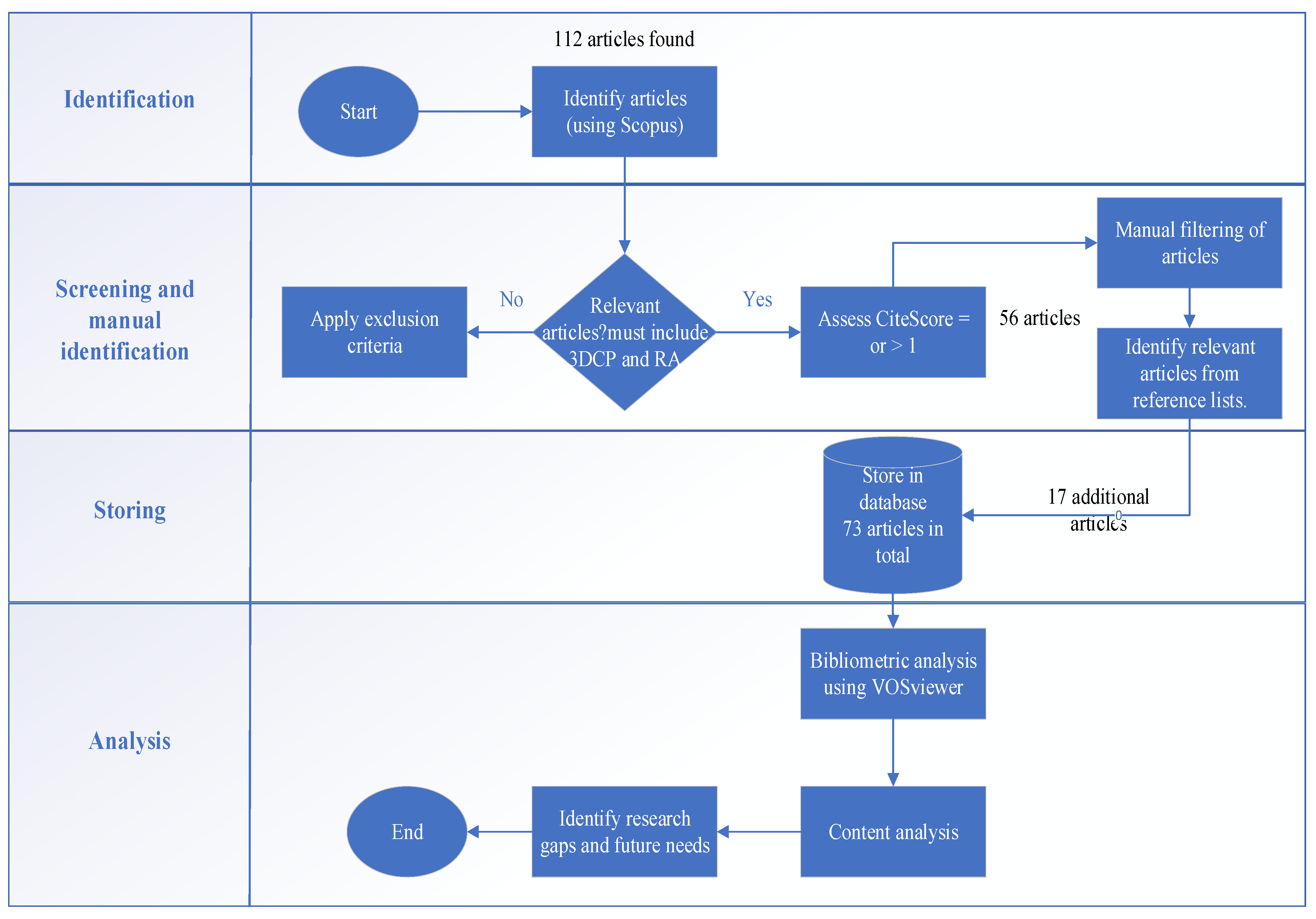

2. Bibliometric Analysis Methodology

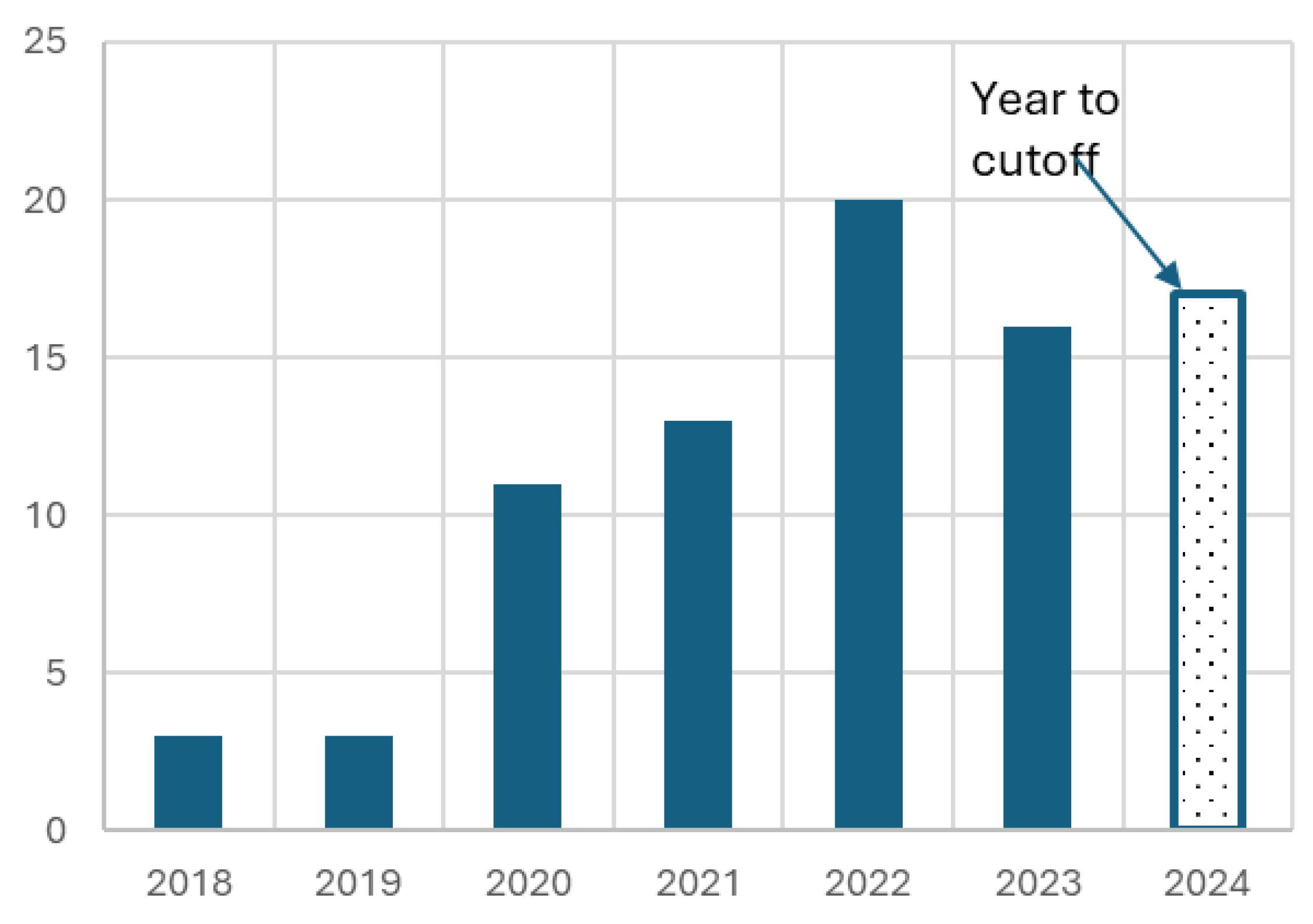

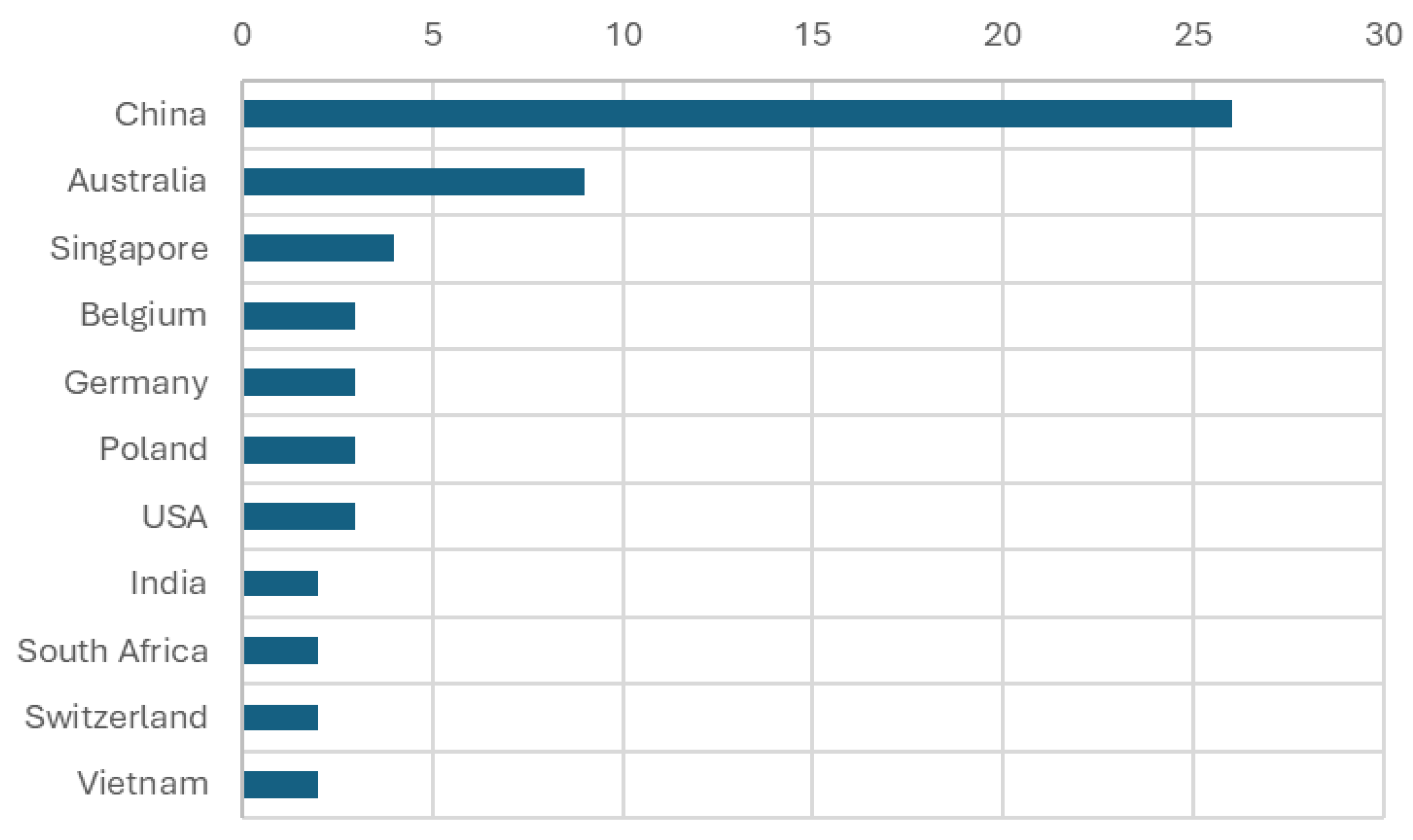

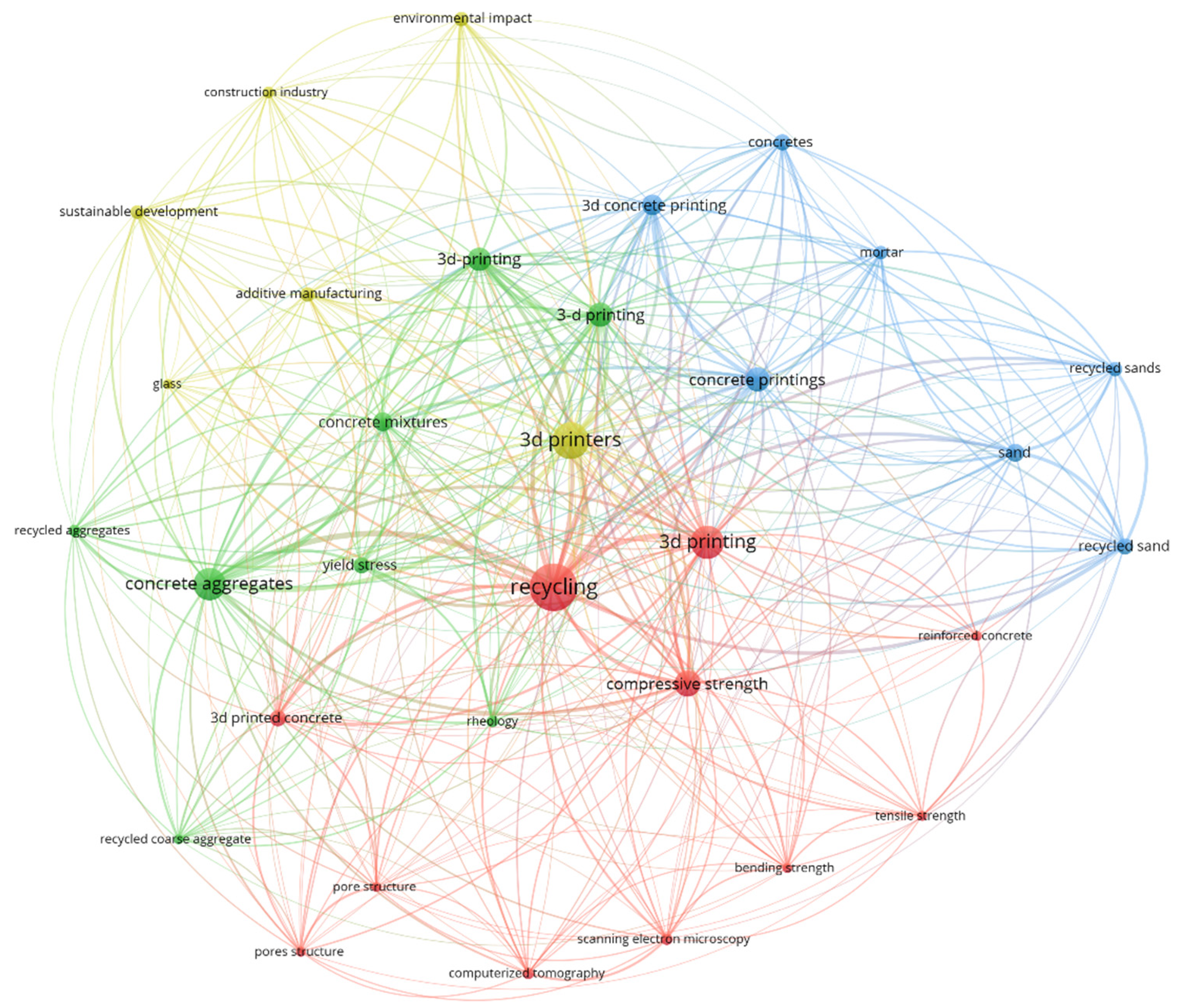

3. Bibliometric Analysis Results

4. Content Analysis Results

4.1. Category 1: Recycled Materials in 3D Concrete Printing

4.1.1. Overview of Recycled Materials

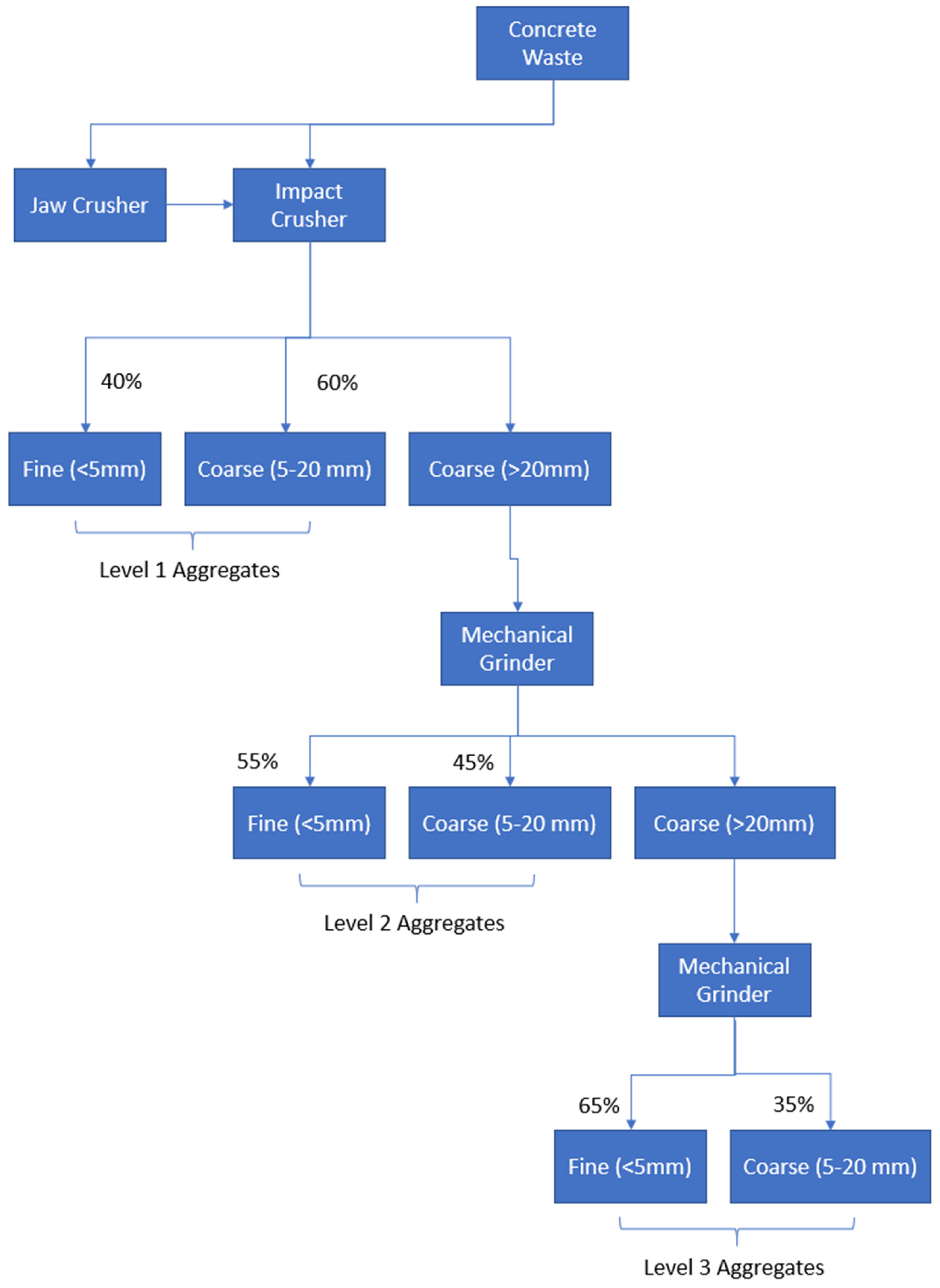

Recycled Material Recovery Process

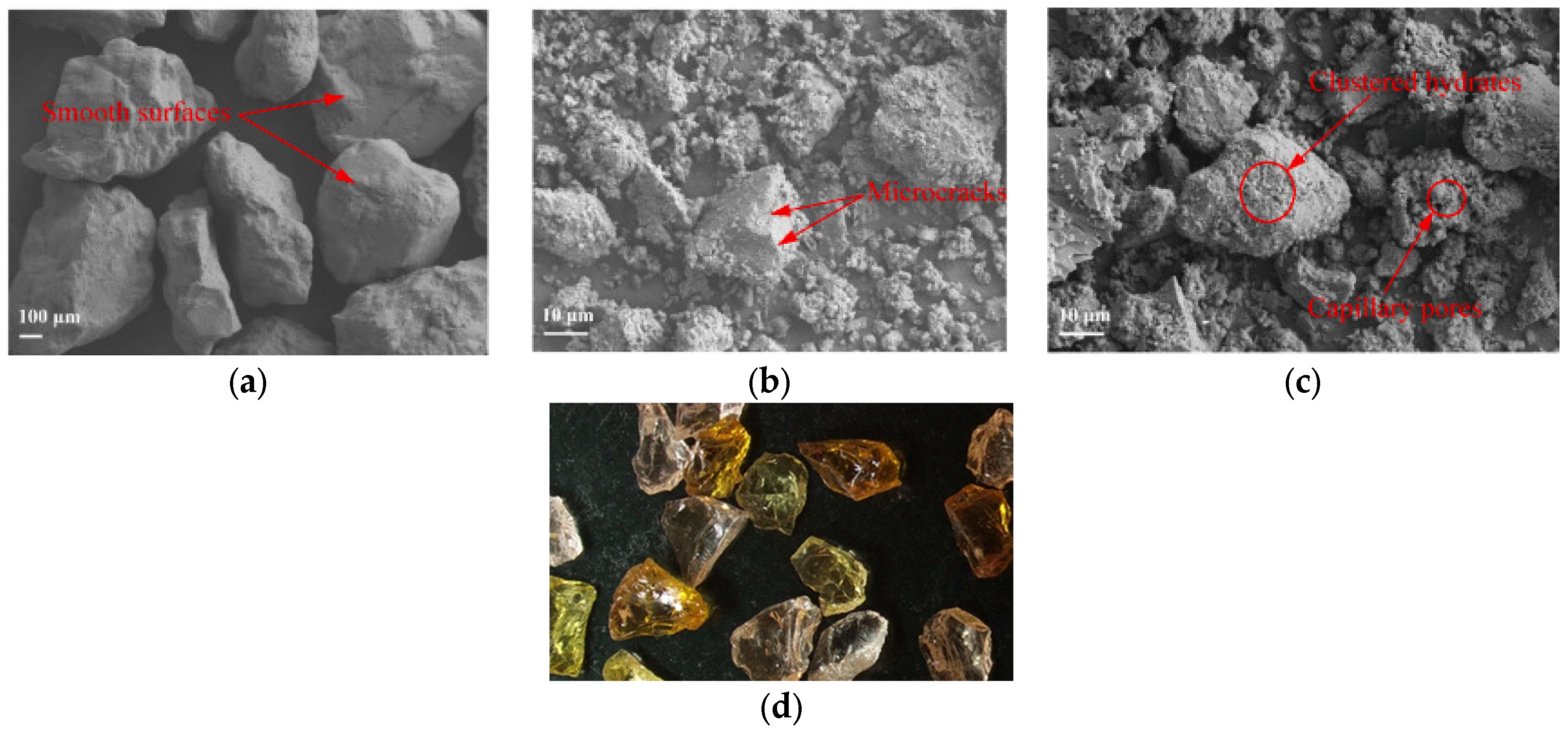

Material Morphology

Chemical Composition

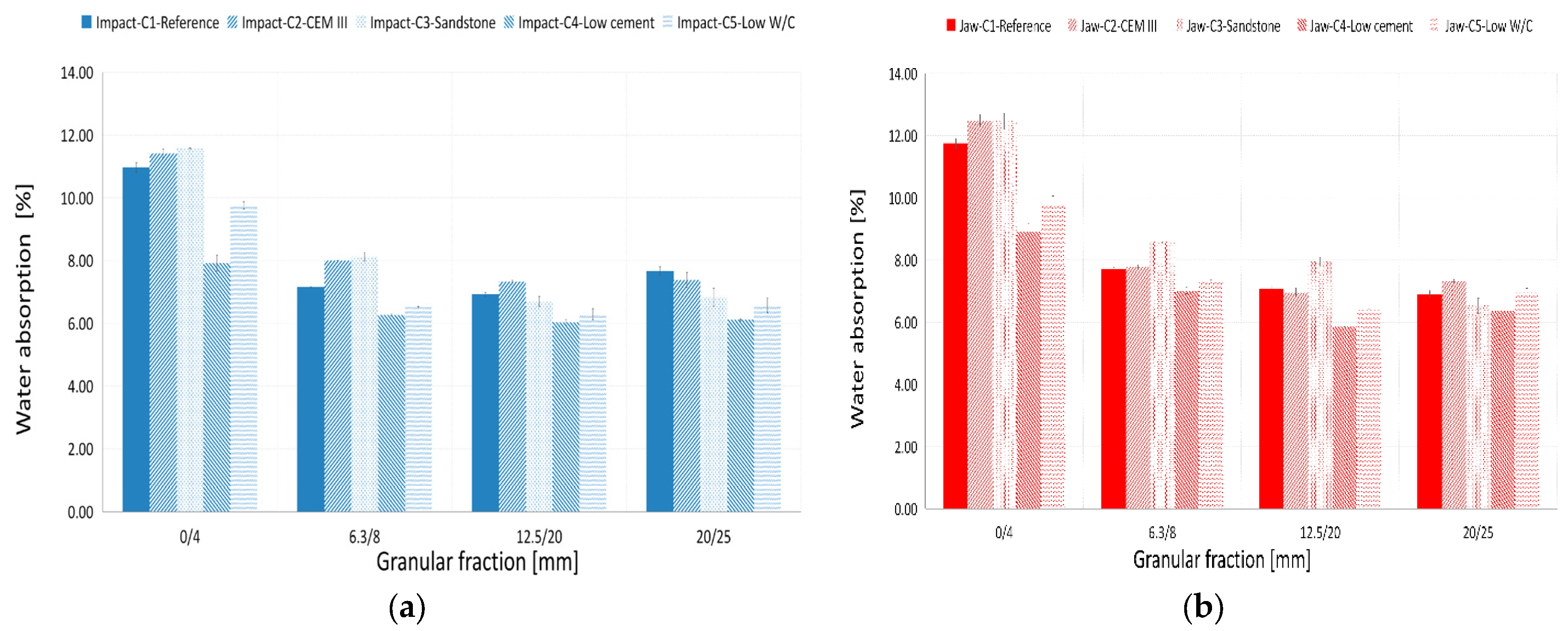

Material Basic Properties

4.2. Category 2: Printability and Performance of 3D-Printed Concrete

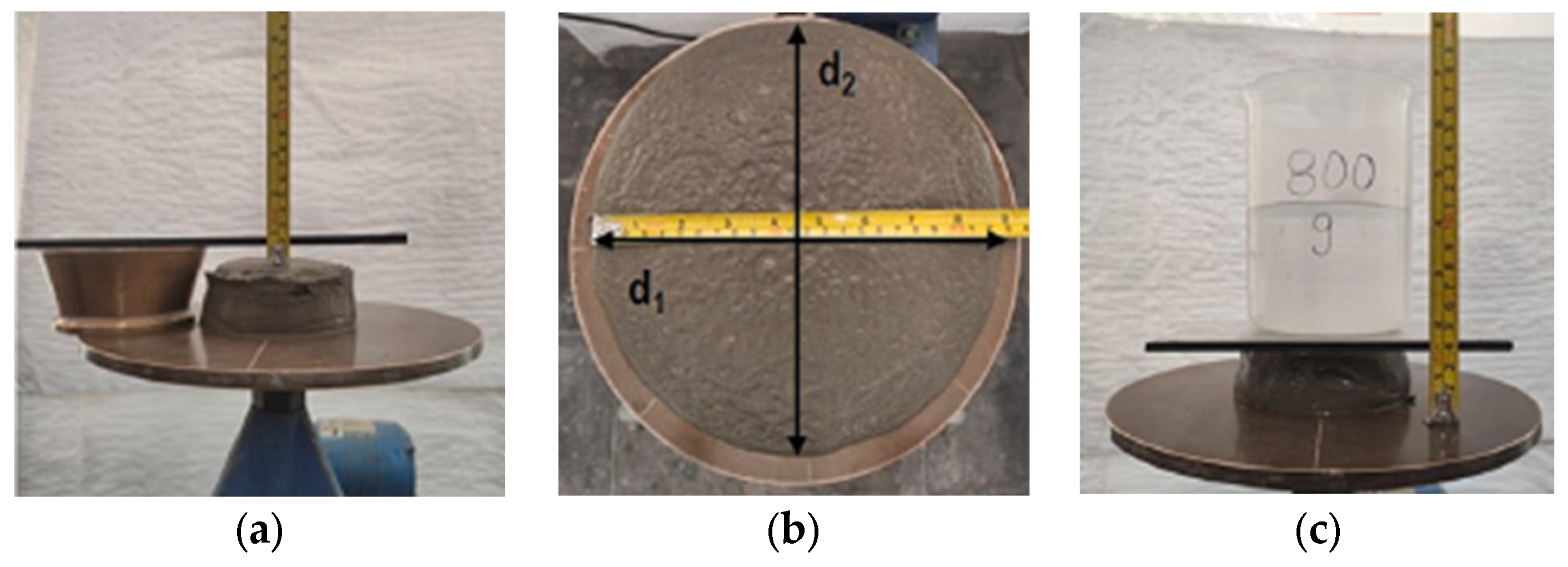

4.2.1. Printability Parameters of 3DCP Using Recycled Aggregates

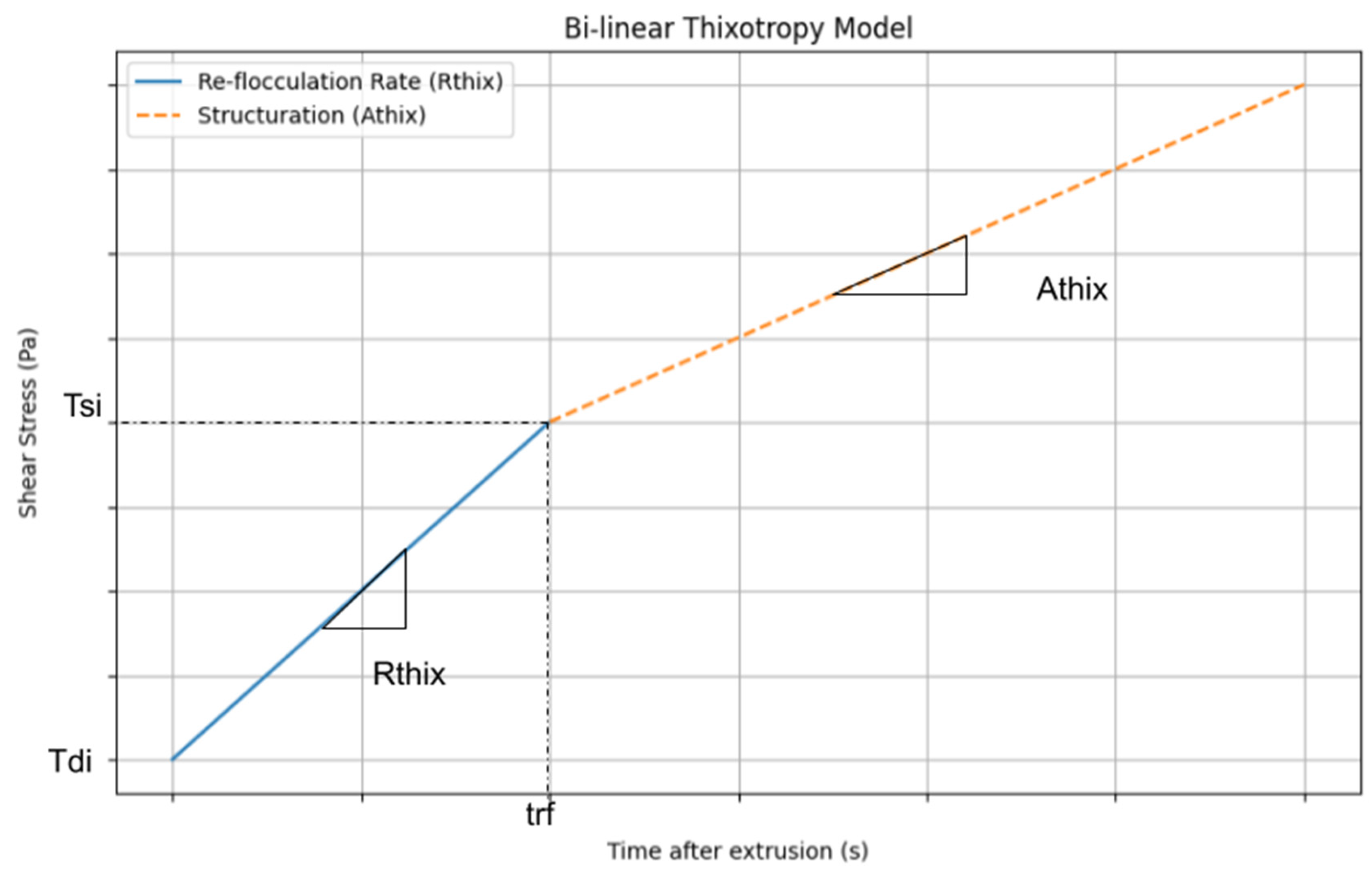

- is the short-term re-flocculation rate measured in Pa/s.

- is the structuration rate measured in Pa/s.

- is the re-flocculation time measured in s.

- is the initial static yield stress measured in Pa.

- is the initial dynamic yield stress measured in Pa.

- is the static yield shear stress post extrusion measured in Pa.

- t is the time since extrusion measured in s.

| Aggregate Replacement (%) | Avg. τ_si (Pa) | Std. Dev. (pa) | Avg. τ_di (Pa) | Std. Dev. (pa) | Avg Rthix (Pa/s) | Std Dev. (Pa/s) | Avg trf (s) | Std. Dev (s) |

|---|---|---|---|---|---|---|---|---|

| 0 | 678.80 | 66.42 | 544.60 | 26.50 | 3.65 | 1.10 | 40.70 | 23.25 |

| 25 | 828.40 | 98.37 | 606.20 | 28.27 | 4.18 | 1.87 | 70.00 | 58.20 |

| 50 | 1066.10 | 140.66 | 682.30 | 67.03 | 4.05 | 0.86 | 97.10 | 22.84 |

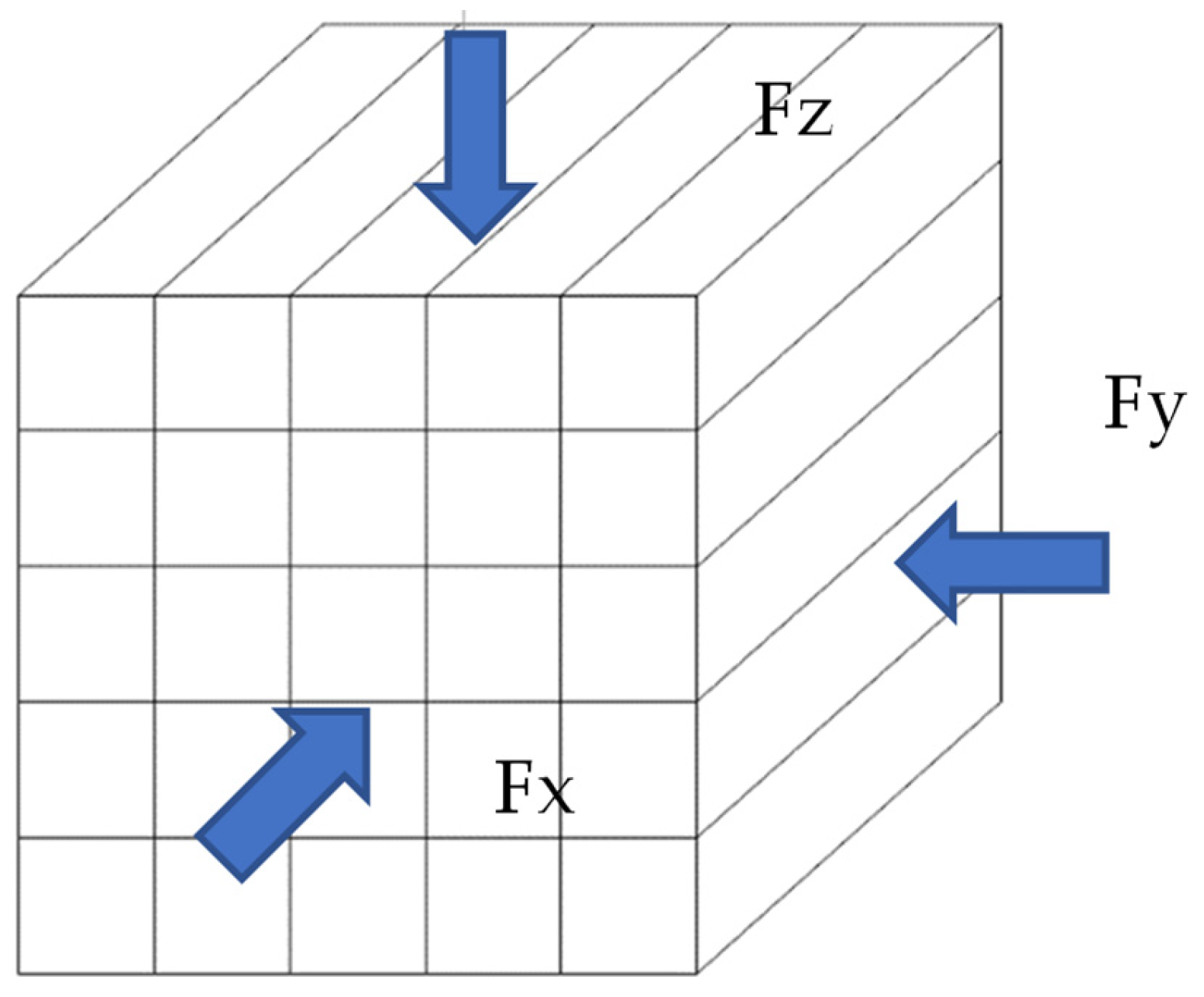

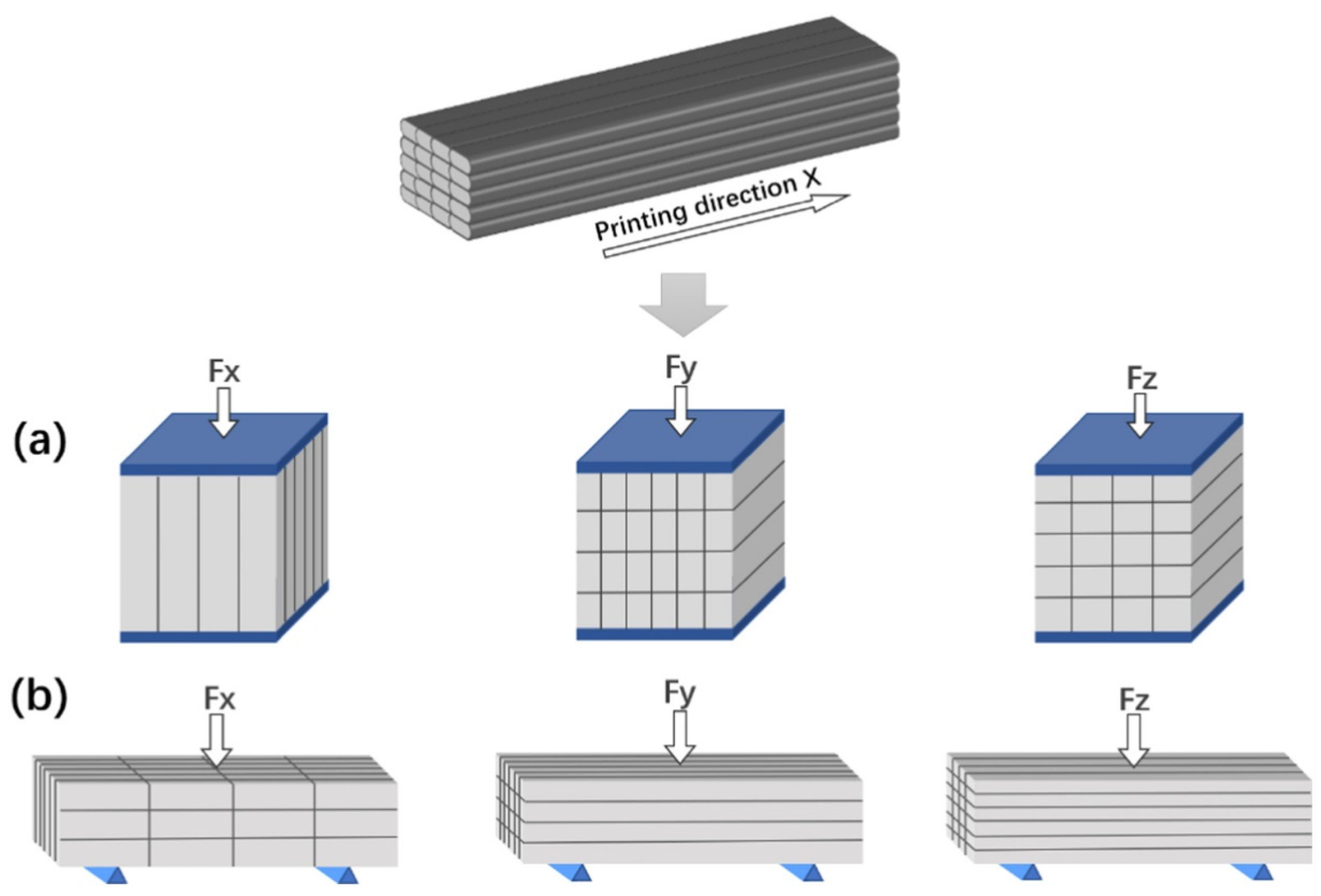

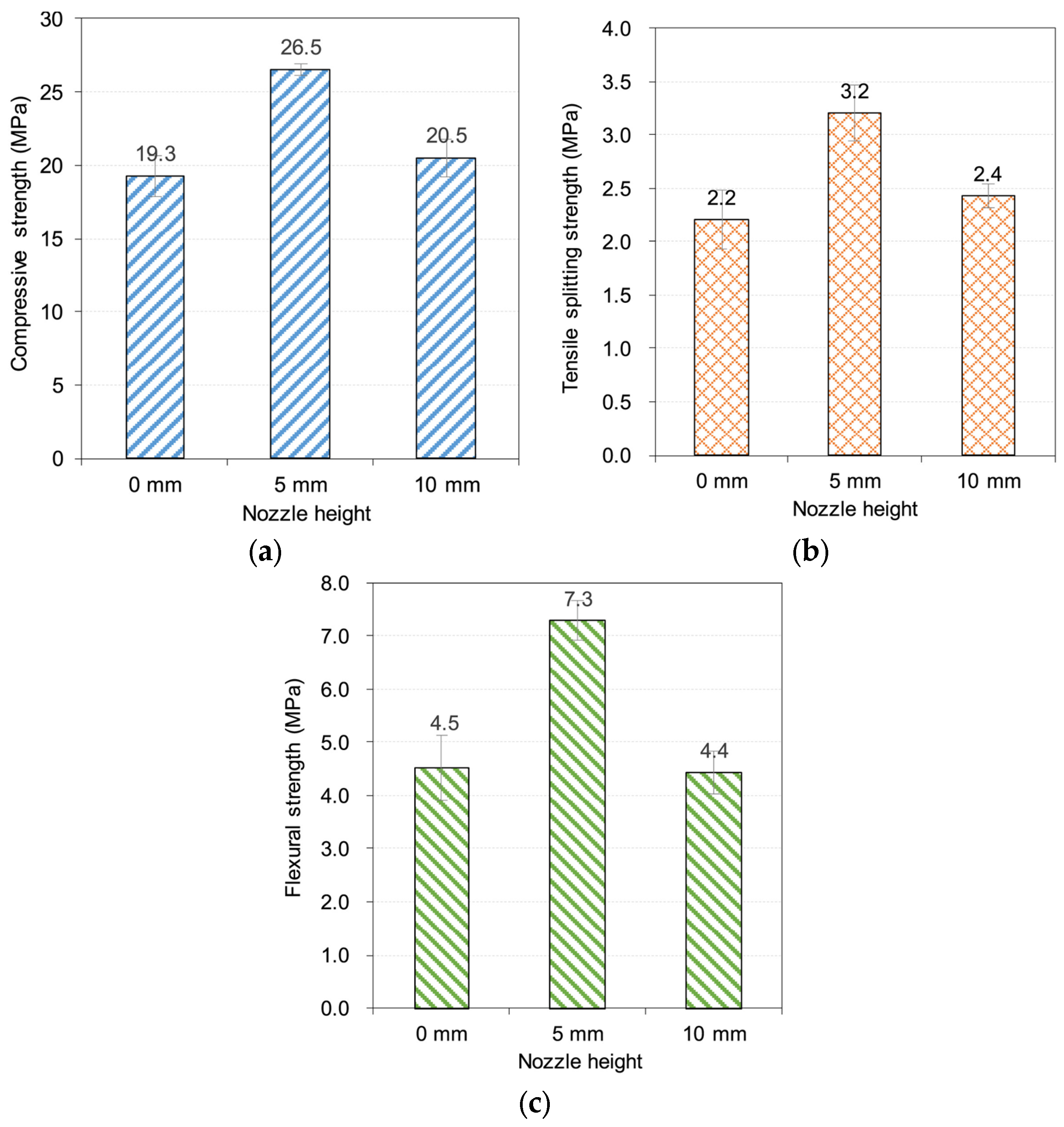

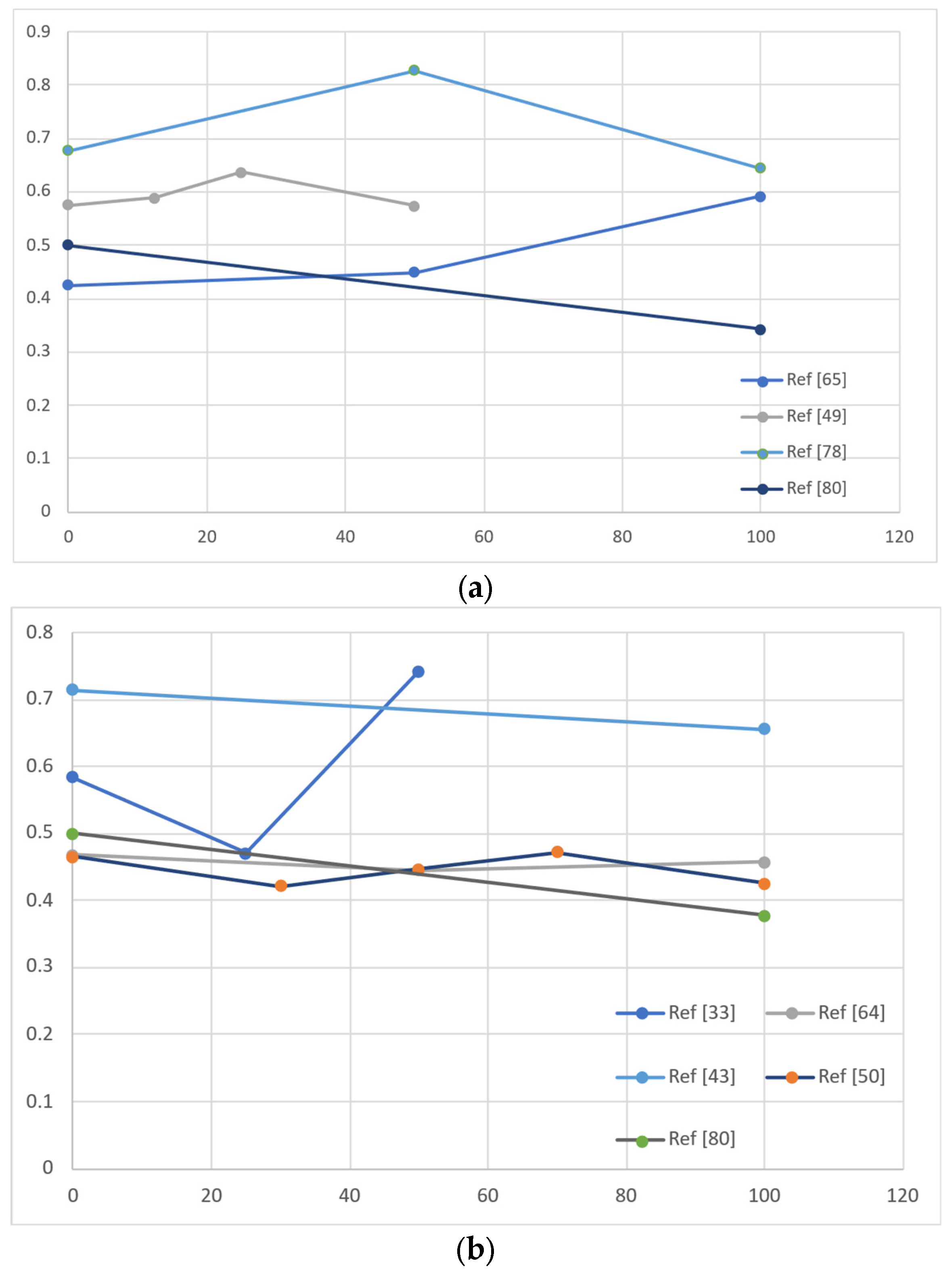

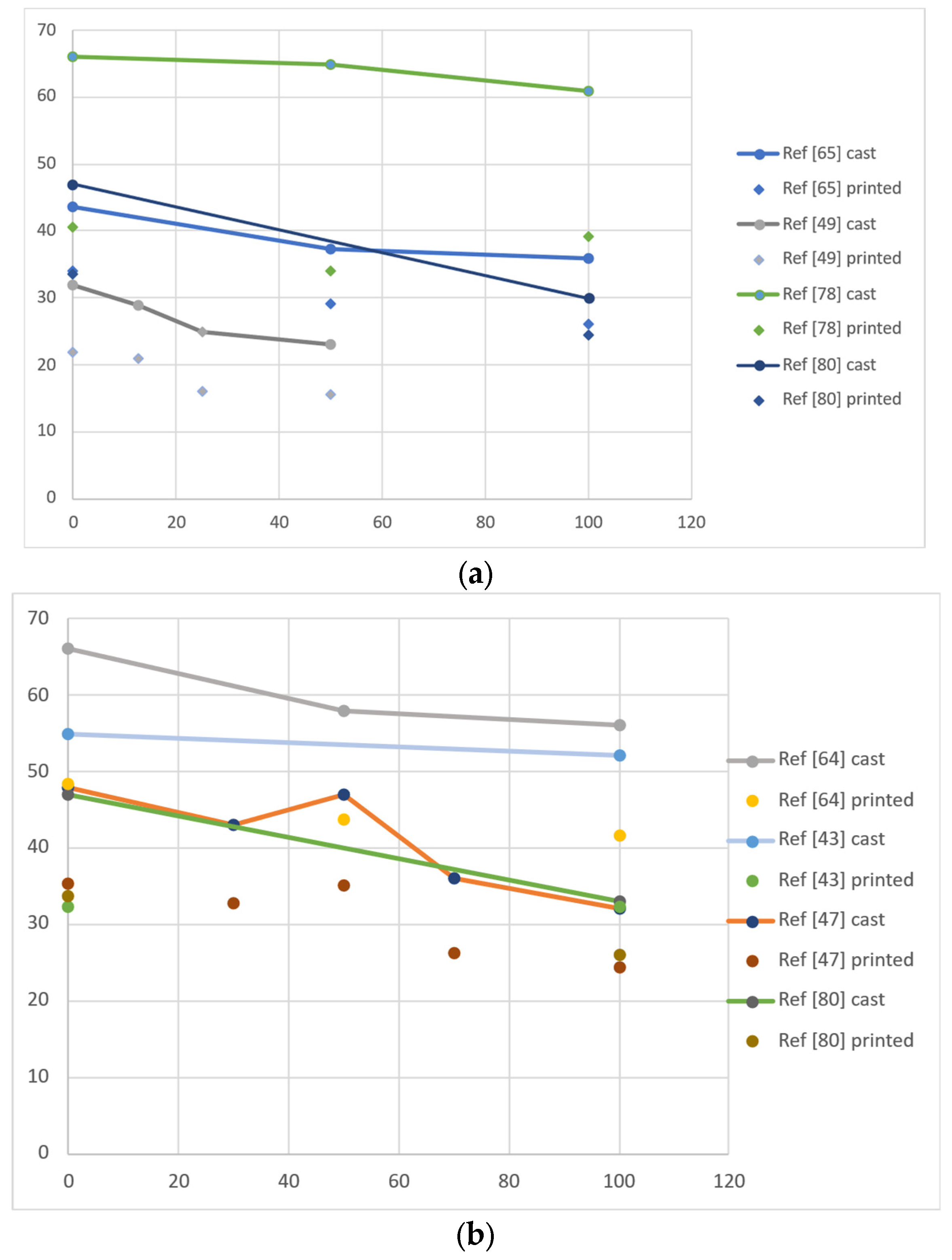

4.2.2. Mechanical Properties of 3DCP with Recycled Materials

Mechanical Strength

- is the anisotropic coefficient.

- : compressive strength in the X direction.

- : compressive strength in the Y direction.

- : compressive strength in the Z direction.

- : compressive strength of the casted samples

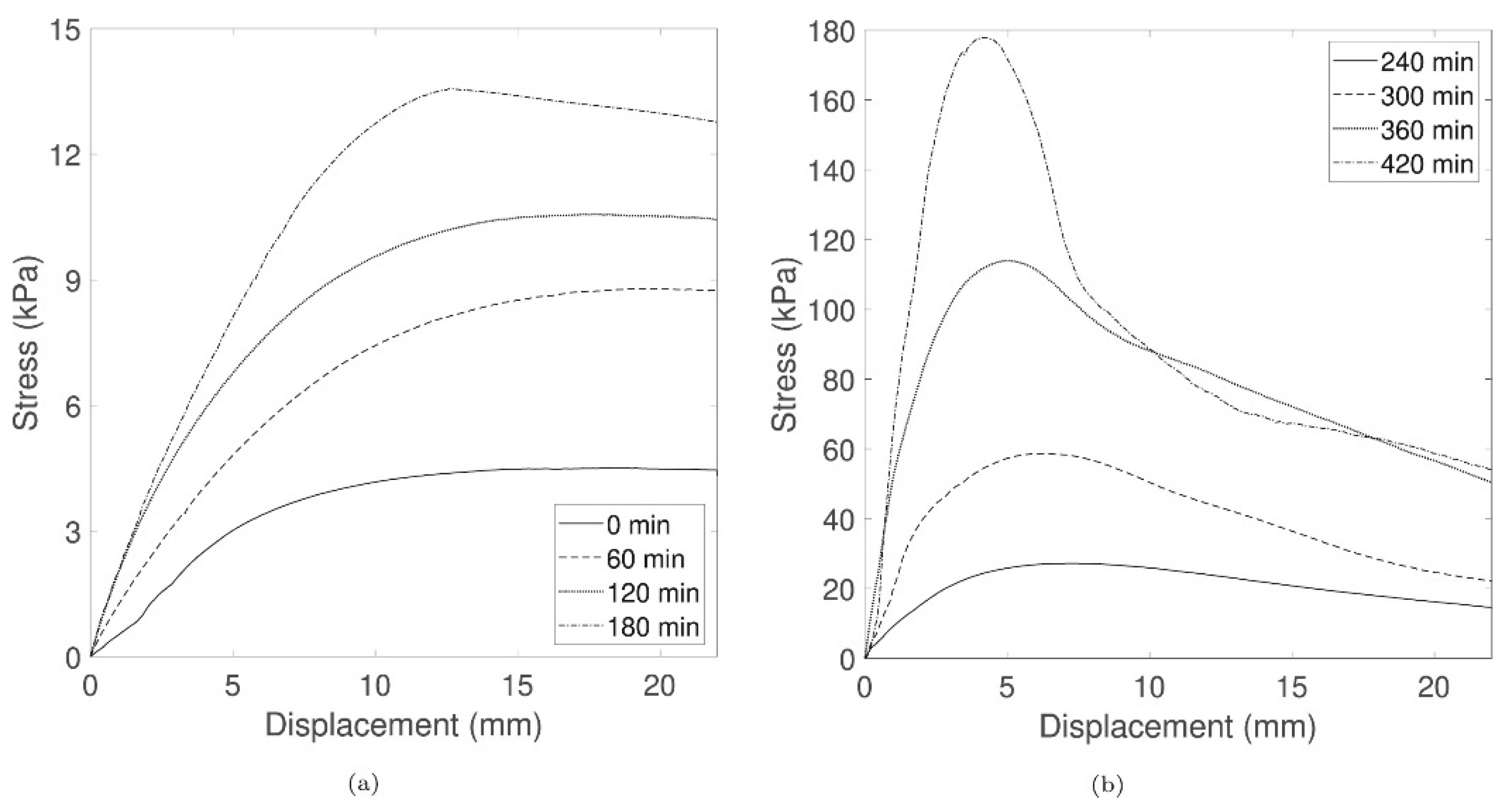

Freeze–Thaw and Permeability for 3DCP with Recycled Aggregates

4.3. Category 3: Innovation in 3D Printing Techniques and Materials

4.4. Category 4: Environmental Impact Performance and Economic Aspects of 3DCP

4.5. Category 5: Challenges and Future Directions

4.5.1. Material Properties and Consistency

4.5.2. Regulatory Barriers in 3DCP with Recycled Aggregates

5. Conclusions and Future Research Needs

- -

- Due to the nature of the printability process being sensitive to both the method and material used, future studies should aim to standardise the set of metrics measured, such as the static/dynamic yield stress, plastic viscosity, interlayer time gaps, and nozzle standoff height, and ensuring that strengths are assessed in all three directions (X, Y, and Z). This will allow for a transparent and more standardised reporting of the various results across recycled materials and printing setups. Future studies should also introduce acceptance or tolerance limits to these parameters to accelerate the adaptation of such procedures in the industry.

- -

- Future studies can focus on presenting a more holistic image by assessment of the long-term durability parameters such as chloride ingress, carbonation, freeze–thaw, shrinkage, and creep. These parameters have been less focused on in the previous works analysed in this study (up to the cutoff date), but are important for presenting the scalability of the process.

- -

- In structural applications, future studies can focus on assessing the bonding between the printed mortar with steel reinforcement to assess the behaviour of thermal and impact resistance.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Cement | Fly Ash | Silica Fume | Slag | Recycled Powder | Fine Aggregates (<4 mm) | Recycled Powder Type | W/B | Superplasticiser | HPMC | Polypropylene Fibre (PP) | Slump | Compressive Strength |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [89] | ||||||||||||

| 1000 | - | 100 | - | - | 990 | Recycled ceramic powder | 0.32 | 2 | 1.28 | 2 | 155 | |

| 1000 | 100 | - | - | - | 990 | 0.32 | 2 | 1.28 | 2 | 166 | ||

| 1000 | - | - | - | 100 | 990 | 0.32 | 2 | 1.28 | 2 | 155 | ||

| 900 | - | 100 | - | 100 | 990 | 0.32 | 2 | 1.28 | 2 | 157.5 | ||

| 800 | - | 100 | - | 200 | 990 | 0.32 | 2 | 1.28 | 2 | 146.5 | ||

| 700 | - | 100 | - | 300 | 990 | 0.32 | 2 | 1.28 | 2 | 136 | ||

| [90] | ||||||||||||

| 560 | 160 | 80 | - | - | 1266 | Recycled 3D concrete waste | 0.28 | 2.2 | - | - | 168 | |

| 504 | 160 | 80 | - | 44 | 1266 | 0.3 | 2.2 | - | - | 165 | ||

| 448 | 160 | 80 | - | 88 | 1266 | 0.33 | 2.2 | - | - | 162 | ||

| 392 | 160 | 80 | - | 132 | 1266 | 0.36 | 2.2 | - | - | 152 | ||

| 336 | 160 | 80 | - | 176 | 1266 | 0.39 | 2.2 | - | - | 141 | ||

| 280 | 160 | 80 | - | 220 | 1266 | 0.43 | 2.2 | - | - | 135 | ||

| [91] | ||||||||||||

| 800 | - | 8 | - | 0 | 1290 | Recycled clay brick aggregate | - | 0.6 | - | - | - | |

| 720 | - | 8 | - | 80 | 1290 | - | 0.6 | - | - | - | ||

| 640 | - | 8 | - | 160 | 1290 | - | 0.6 | - | - | - | ||

| 560 | - | 8 | - | 240 | 1290 | - | 0.6 | - | - | - | ||

| 560 | - | 8 | - | 240 | 1290 | - | 0.6 | - | - | - | ||

| 560 | - | 8 | - | 240 | 1290 | - | 0.6 | - | - | - | ||

| 560 | - | 8 | - | 240 | 1290 | - | 0.6 | - | - | - | ||

| 560 | - | 8 | - | 240 | 1290 | - | 0.45 | - | - | - | ||

| 560 | - | 8 | - | 240 | 1290 | - | 0.5 | - | - | - | ||

| Cement | Fly Ash | Silica Fume | NA (<4 mm) | RFA (<4 mm) | W/B | Early Strengthening Agent (ESA) | Superplasticiser | HPMC | Sodium Gluconate | Nanoclay | PVA Fibres | PE Fibres (%) | Added Water | Slump |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [73] | ||||||||||||||

| 1000 | - | - | 1000 | - | 0.35 | - | 2.13 | 1.28 | 0.7 | 5 | - | - | - | 164 |

| 1000 | - | - | 875 | 125 | 0.35 | - | 1.03 | 1.28 | 0.7 | 5 | - | - | 17.1 | 165 |

| 1000 | - | - | 750 | 250 | 0.35 | - | 1.68 | 1.28 | 0.7 | 5 | - | - | 34.2 | 161 |

| 1000 | - | - | 500 | 500 | 0.35 | - | 1.84 | 1.28 | 0.7 | 5 | - | - | 68.5 | 160 |

| 1000 | - | - | 875 | 125 | 0.35 | - | 1.03 | 1.28 | 0.7 | 5 | - | - | - | 160 |

| 1000 | - | - | 750 | 250 | 0.35 | - | 1.68 | 1.28 | 0.7 | 5 | - | - | - | 155 |

| 1000 | - | - | 500 | 500 | 0.35 | - | 1.84 | 1.28 | 0.7 | 5 | - | - | - | 153 |

| [29] | ||||||||||||||

| 1000 | - | - | 1000 | - | 0.35 | - | 0.71 | 1.25 | - | 5.63 | - | - | - | - |

| 1000 | - | - | 750 | 250 | 0.39 | - | 0.74 | 1.26 | - | 5.63 | - | - | - | - |

| 1000 | - | - | 500 | 500 | 0.42 | - | 0.86 | 1.28 | - | 5.63 | - | - | - | - |

| [65] | ||||||||||||||

| 605.2 | 60.9 | 30.5 | 1210.7 | - | 0.3 | 60.5 | 14.3 | 1.5 | - | - | 0.5 | - | - | - |

| 605.2 | 60.9 | 30.5 | 605.35 | 605.35 | 0.3 | 60.5 | 14.3 | 1.5 | - | - | 0.5 | - | - | - |

| 605.2 | 60.9 | 30.5 | - | 1210.7 | 0.3 | 60.5 | 14.3 | 1.5 | - | - | 0.5 | - | - | - |

| [31] | ||||||||||||||

| 1000 | - | - | 1000 | - | 0.35 | - | 0.83 | 1.28 | - | - | - | - | - | - |

| 1000 | - | - | 500 | 500 | 0.42 | - | 0.83 | 1.28 | - | - | - | - | - | - |

| 1000 | - | - | - | 1000 | 0.49 | - | 0.83 | 1.28 | - | - | - | - | - | - |

| 1000 | - | - | - | 1000 | 0.49 | - | 0.83 | 1.28 | 0.6 | - | - | - | - | - |

| 1000 | - | - | - | 1000 | 0.49 | - | 0.83 | 1.28 | 1.2 | - | - | - | - | - |

| [48] | ||||||||||||||

| 1000 | - | - | 1000 | - | 0.35 | - | 0.83 | 1.28 | - | - | - | - | - | - |

| 1000 | - | - | - | 1000 | 0.49 | - | 0.83 | 1.28 | - | - | - | - | - | - |

| 1000 | - | - | - | 1000 | 0.49 | - | 0.83 | 1.28 | 0.3 | - | - | - | - | - |

| 1000 | - | - | - | 1000 | 0.49 | - | 0.83 | 1.28 | 0.6 | - | - | - | - | - |

| 1000 | - | - | - | 1000 | 0.49 | - | 0.83 | 1.28 | 1.2 | - | - | - | - | - |

| [69] | ||||||||||||||

| 1000 | - | - | 1000 | - | 0.35 | - | 0.71 | 1.28 | - | - | - | 0.25 | - | - |

| 1000 | - | - | 1000 | - | 0.35 | - | 0.73 | 1.28 | - | - | - | 0.50 | - | - |

| 1000 | - | - | 1000 | - | 0.35 | - | 1.12 | 1.28 | - | - | - | 1.00 | - | - |

| 1000 | - | - | 1000 | - | 0.35 | - | 1.98 | 1.28 | - | - | - | 1.40 | - | - |

| 1000 | - | - | 500 | 500 | 0.42 | - | 0.86 | 1.28 | - | - | - | 0.25 | - | - |

| 1000 | - | - | 500 | 500 | 0.42 | - | 1 | 1.28 | - | - | - | 0.50 | - | - |

| 1000 | - | - | 500 | 500 | 0.42 | - | 1.24 | 1.28 | - | - | - | 1.00 | - | - |

| 1000 | - | - | 500 | 500 | 0.42 | - | 2.18 | 1.28 | - | - | - | 1.40 | - | - |

| [77] | ||||||||||||||

| 800 | - | - | 1135.61 | - | 0.37 | - | 2.50 | - | - | - | - | - | - | - |

| 800 | 567.80 | 488.31 | 0.50 | - | 5.00 | - | - | - | - | - | - | - | ||

| 800 | - | - | - | 770.00 | 0.475 | - | 5.00 | - | - | - | - | - | - | - |

| Cement | Fly Ash | Silica Fume | Slag | NA (<4 mm) | NCA (<10 mm) | RFA (<4 mm) | RCA (<10 mm) | W/B | Superplasticiser | HPMC | VMA | PVA Fibres |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [51] | ||||||||||||

| 376.3 | - | - | 376.3 | - | - | - | 1279.3 | 0.35 | 5.27 | - | 0.75 | - |

| 374.2 | - | - | 374.2 | 371.5 | - | - | 900.8 | 0.35 | 5.24 | - | 0.75 | - |

| 370.8 | - | - | 370.8 | - | - | 351.5 | 909.4 | 0.35 | 5.19 | - | 0.74 | - |

| 374.2 | - | - | 374.2 | 371.5 | - | - | 900.8 | 0.35 | 3.74 | - | 0.75 | - |

| 370.8 | - | - | 370.8 | - | - | 351.5 | 909.4 | 0.35 | 3.34 | - | 0.74 | - |

| [52] | ||||||||||||

| 1000 | 101 | 50 | - | 2009 | - | - | - | 0.3 | 7 | 1 | - | 1 |

| 1000 | 101 | 50 | - | 999 | 1499 | - | - | 0.3 | 8 | 2 | - | 1 |

| 1000 | 101 | 50 | - | 999 | 749 | - | 749 | 0.3 | 10 | 2 | - | 1 |

| 1000 | 101 | 50 | - | 999 | - | - | 1499 | 0.3 | 11 | 2 | - | 1 |

| [32] | ||||||||||||

| 1124.2 | 113.3 | 56.6 | - | - | - | - | - | 0.3 | 7.8 | 114.1 | - | 0.9 |

| 605.2 | 60.9 | 30.5 | - | 1210.7 | - | - | - | 0.3 | 4.3 | 0.6 | - | 0.5 |

| 605.2 | 60.9 | 30.5 | - | 604.7 | 907 | - | - | 0.3 | 5.1 | 1.1 | - | 0.5 |

| 605.2 | 60.9 | 30.5 | - | 604.7 | 453.5 | - | 453.5 | 0.3 | 6 | 1 | - | 0.5 |

| 605.2 | 60.9 | 30.5 | - | 604.7 | - | - | 907 | 0.3 | 6.9 | 0.9 | - | 0.5 |

| Test Type | References | Standards Requirements |

|---|---|---|

| Compression | [53] | ASTM C109 |

| [34] | ASTM C109 | |

| [47] | ASTM C109 | |

| [92] | EN 196-1 | |

| [48] | ASTM D2166 | |

| [28] | ASTM C109 | |

| [93] | DIN EN 12390-3:2019-10 | |

| [74] | EN 197 | |

| [94] | Unspecified | |

| [27] | GB 50081 | |

| [54] | EN 1015-11:2020 | |

| [73] | GB/T17671-2021 | |

| [64] | ASTM D2166 | |

| [68] | AS 1012.9 | |

| [95] | GB 50081 | |

| [92] | GB/T17671-2021 | |

| [33] | GB 50081 | |

| [96] | ASTM C642 | |

| [71] | GB 50081 | |

| [65] | GB 50081 | |

| [97] | GB 50081 | |

| [93] | GB 50081 | |

| [78] | GB 50081 | |

| [98] | GB 50081 | |

| [50] | GB 50081 | |

| [41] | UNE-EN 1015 | |

| [99] | EN 1015-11:2020 | |

| [15] | GB 50081 | |

| [67] | GB 50081 | |

| Tensile | [53] | NEN-EN 12390–6 |

| [49] | NEN-EN 12390–6 | |

| [47] | NEN-EN 12390–6 | |

| [50] | GB 50081 | |

| [71] | GB 50081 | |

| [96] | ASTM C642 | |

| [78] | GB 50081 | |

| [54] | GB 50081 | |

| Flexural | [50] | ASTM C78 |

| [44] | ASTM C78 | |

| [74] | EN 196-1 | |

| [100] | CSN EN 14617 | |

| [69] | ASTM C1609 | |

| [74] | EN 197 | |

| [39] | GB 50081 | |

| [54] | EN 1015-11:2020 | |

| [64] | ASTM D2166 | |

| [33] | GB 50081 | |

| [96] | ASTM C642 | |

| [71] | GB 50081 | |

| [78] | GB 50081 | |

| [54] | GB 50081 | |

| [44] | UNE-EN 1015 | |

| [99] | EN 1015-11:2020 | |

| [15] | GB 50081 | |

| [67] | GB 50081 | |

| [70] | GB 50081 | |

| Freeze–thaw | [54] | EN 1015-11:2020 |

| Thermal Conductivity | [73] | GB/T17671 |

| Interlayer bonding | [64] | GB 50081 |

| [96] | ASTM C642 | |

| [15] | GB 50081 |

| Recycled Aggregate (%) | Recycled Aggregate Type | Recycled Powder (%) | Recycled Powder Type | Reported Strength at 28 Days (MPa) | Direction | Anisotropy Coefficient | Reference |

|---|---|---|---|---|---|---|---|

| 0-cast | Fine | 43.60 | NA | [65] | |||

| 0 | 38.530 | X | 0.43 | ||||

| 0 | 36.60 | Y | |||||

| 0 | 27.25 | Z | |||||

| 50-cast | 37.20 | NA | |||||

| 50 | 36.05 | X | 0.45 | ||||

| 50 | 28.55 | Y | |||||

| 50 | 22.95 | Z | |||||

| 100-cast | 35.95 | NA | |||||

| 100 | 35.80 | X | 0.59 | ||||

| 100 | 24.80 | Y | |||||

| 100 | 17.83 | Z | |||||

| 0-cast | Fine | 32 | NA | [49] | |||

| 0 | 22 | X | 0.57 | ||||

| 0 | 18 | Y | |||||

| 0 | 25.5 | Z | |||||

| 12.5-cast | 29 | NA | |||||

| 12.5 | 21 | X | 0.59 | ||||

| 12.5 | 14 | Y | |||||

| 12.5 | 27.5 | Z | |||||

| 25-cast | 24.9 | NA | |||||

| 25 | 17 | X | 0.64 | ||||

| 25 | 13 | Y | |||||

| 18 | Z | ||||||

| 50-cast | 23 | NA | |||||

| 50 | 16 | X | 0.57 | ||||

| 50 | 13 | Y | |||||

| 50 | 18 | Z | |||||

| 0-cast | Fine | 66 | NA | [78] | |||

| 0 | 44 | X | 0.68 | ||||

| 0 | 35 | Y | |||||

| 0 | 42.5 | Z | |||||

| 50-cast | 65 | NA | |||||

| 50 | 36 | X | 0.82 | ||||

| 50 | 32 | Y | |||||

| 50 | 34 | Z | |||||

| 100-cast | 61 | NA | |||||

| 100 | 46 | X | 0.64 | ||||

| 100 | 31 | Y | |||||

| 100 | 40.5 | Z | |||||

| 0-cast | Coarse | 12 | Recycled CDW | 39.8 | NA | [33] | |

| 0 | 12 | 27 | X | 0.58 | |||

| 0 | 12 | 24.4 | Y | ||||

| 0 | 12 | 28 | Z | ||||

| 25-cast | 12 | 35.6 | NA | ||||

| 25 | 12 | 26.6 | X | 0.47 | |||

| 25 | 12 | 24 | Y | ||||

| 25 | 12 | 27.5 | Z | ||||

| 50-cast | 12 | 32.5 | NA | ||||

| 50 | 12 | 18 | X | 0.74 | |||

| 50 | 12 | 17 | Y | ||||

| 50 | 12 | 21 | Z | ||||

| 0-cast | Coarse | 66 | NA | [64] | |||

| 0 | 52 | X | 0.47 | ||||

| 0 | 47 | Y | |||||

| 0 | 46 | Z | |||||

| 50-cast | 58 | NA | |||||

| 50 | 48 | X | 0.45 | ||||

| 50 | 45 | Y | |||||

| 50 | 38 | Z | |||||

| 100-cast | 56 | NA | |||||

| 100 | 46 | X | 0.46 | ||||

| 100 | 42 | Y | |||||

| 100 | 37 | Z | |||||

| 0-cast | Fine—Recycled Glass | 48 | NA | [53] | |||

| 0 | 45 | X | 0.15 | ||||

| 0 | 44 | Y | |||||

| 0 | 42.5 | Z | |||||

| 25-cast | 46 | NA | |||||

| 25 | 44 | X | 0.13 | ||||

| 25 | 42.5 | Y | |||||

| 25 | 41.5 | Z | |||||

| 50-cast | 43 | NA | |||||

| 50 | 39.5 | X | 0.18 | ||||

| 50 | 39 | Y | |||||

| 50 | 37.5 | Z | |||||

| 75-cast | 42 | NA | |||||

| 75 | 38.5 | X | 0.18 | ||||

| 75 | 37 | Y | |||||

| 75 | 37.5 | Z | |||||

| 100-cast | 36.5 | NA | |||||

| 100 | 32.5 | X | 0.15 | ||||

| 100 | 33.5 | Y | |||||

| 100 | 34 | Z | |||||

| 15-Cast | Fine -untreated rubber | 29.4 | |||||

| 15 | 29.4 | Y | [68] | ||||

| 15 | 30.4 | Z | |||||

| 15 | 0.25 cement treated rubber | 30.9 | |||||

| 15 | 30.4 | Y | |||||

| 15 | 31.1 | Z | |||||

| 15 | 0.4 cement treated rubber | 33.2 | |||||

| 15 | 37 | Y | |||||

| 15 | 34.6 | Z | |||||

| 15 | 0.55 cement treated rubber | 32.9 | |||||

| 15 | 36.4 | Y | |||||

| 15 | 35.3 | Z | |||||

| 0-cast | Coarse | 48 | NA | [50] | |||

| 0 | 38 | X | 0.47 | ||||

| 0 | 36 | Y | |||||

| 0 | 32 | Z | |||||

| 30-cast | 43 | NA | |||||

| 30 | 35 | X | 0.42 | ||||

| 30 | 32 | Y | |||||

| 30 | 31 | Z | |||||

| 50-cast | 47 | NA | |||||

| 50 | 37 | X | 0.45 | ||||

| 50 | 35 | Y | |||||

| 50 | 33 | Z | |||||

| 70-cast | 36 | NA | |||||

| 70 | 28 | X | 0.47 | ||||

| 70 | 27 | Y | |||||

| 70 | 24 | Z | |||||

| 100-cast | 32 | NA | |||||

| 100 | 26 | X | 0.43 | ||||

| 100 | 25 | Y | |||||

| 100 | 22 | Z |

References

- Guerra, B.C.; Leite, F. Circular Economy in the Construction Industry: An Overview of United States Stakeholders’ Awareness, Major Challenges, and Enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Lima, L.; Trindade, E.; Alencar, L.; Alencar, M.; Silva, L. Sustainability in the Construction Industry: A Systematic Review of the Literature. J. Clean. Prod. 2021, 289, 125730. [Google Scholar] [CrossRef]

- Goel, A.; Ganesh, L.S.; Kaur, A. Sustainability Integration in the Management of Construction Projects: A Morphological Analysis of over Two Decades’ Research Literature. J. Clean. Prod. 2019, 236, 117676. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D Printing with Concrete—Technical, Economic and Environmental Potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D Printing Using Concrete Extrusion: A Roadmap for Research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An Evaluation of the Recycled Aggregate Characteristics and the Recycled Aggregate Concrete Mechanical Properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Duan, Z.; Hou, S.; Xiao, J.; Singh, A. Rheological Properties of Mortar Containing Recycled Powders from Construction and Demolition Wastes. Constr. Build. Mater. 2020, 237, 117622. [Google Scholar] [CrossRef]

- Han, Y.; Yang, Z.; Ding, T.; Xiao, J.; Evangelista, L.; De Brito, J.; Saruhan, V.; Keskinateş, M.; Felekoğlu, B.; Panda, B.; et al. Comparative Economic, Environmental and Productivity Assessment of a Concrete Bathroom Unit Fabricated through 3D Printing and a Precast Approach. Constr. Build. Mater. 2021, 211, 348–351. [Google Scholar] [CrossRef]

- Zhang, B.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A Scientometric Analysis Approach to Analyze the Present Research on Recycled Aggregate Concrete. J. Build. Eng. 2022, 46, 103679. [Google Scholar] [CrossRef]

- Tu, H.; Wei, Z.; Bahrami, A.; Ben Kahla, N.; Ahmad, A.; Özkılıç, Y.O. Recent Advancements and Future Trends in 3D Concrete Printing Using Waste Materials. Dev. Built Environ. 2023, 16, 100187. [Google Scholar] [CrossRef]

- Chougan, M.; Skibicki, S.; Al-Noaimat, Y.A.; Federowicz, K.; Hoffmann, M.; Sibera, D.; Cendrowski, K.; Techman, M.; Nuno Pacheco, J.; Ghaffar, S.H.; et al. Comparative Analysis of Ternary Blended Cement with Clay and Engineering Brick Aggregate for High-Performance 3D Printing. Dev. Built Environ. 2024, 20, 100529. [Google Scholar] [CrossRef]

- Liu, Q.; Tang, H.; Chen, K.; Peng, B.; Sun, C.; Singh, A.; Li, J. Utilizing CO2 to Improve Plastic Shrinkage and Mechanical Properties of 3D Printed Mortar Made with Recycled Fine Aggregates. Constr. Build. Mater. 2024, 433, 136546. [Google Scholar] [CrossRef]

- Cuevas, K.; Chung, S.Y.; Sikora, P.; Stephan, D. Performance of Normal-Weight and Lightweight 3D Printed Cementitious Composites with Recycled Glass: Sorption and Microstructural Perspective. J. Build. Eng. 2024, 97, 110880. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, X.; Xiao, J.; Ji, G.; Zhang, S.; Hsu, S.C.; Poon, C.S. Comparative Eco-Efficiency Assessment of 3D-Printed Recycled Aggregate Concrete Structure for Mid-Rise Residential Buildings. J. Build. Eng. 2024, 95, 110349. [Google Scholar] [CrossRef]

- Li, Z.; Liu, H.; Nie, P.; Cheng, X.; Zheng, G.; Jin, W.; Xiong, B. Mechanical Properties of Concrete Reinforced with High-Performance Microparticles for 3D Concrete Printing. Constr. Build. Mater. 2024, 411, 134676. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, M.; Ma, G. An Experimental Study on 3D Printed Concrete Reinforced with Fibers Recycled from Wind Turbine Blades. J. Build. Eng. 2024, 91, 109578. [Google Scholar] [CrossRef]

- Bodur, B.; Mecit Işık, M.A.; Benli, A.; Bayrak, B.; Öz, A.; Bayraktar, O.Y.; Kaplan, G.; Aydın, A.C. Durability of Green Rubberized 3D Printed Lightweight Cement Composites Reinforced with Micro Attapulgite and Micro Steel Fibers: Printability and Environmental Perspective. J. Build. Eng. 2024, 90, 109447. [Google Scholar] [CrossRef]

- Matarneh, S.T.; Danso-Amoako, M.; Al-Bizri, S.; Gaterell, M.; Matarneh, R. Building Information Modeling for Facilities Management: A Literature Review and Future Research Directions. J. Build. Eng. 2019, 24, 100755. [Google Scholar] [CrossRef]

- Ellegaard, O.; Wallin, J.A. The Bibliometric Analysis of Scholarly Production: How Great Is the Impact? Scientometrics 2015, 105, 1809–1831. [Google Scholar] [CrossRef] [PubMed]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to Conduct a Bibliometric Analysis: An Overview and Guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Butler, L. Explaining Australia’s Increased Share of ISI Publications—The Effects of a Funding Formula Based on Publication Counts. Res. Policy 2003, 32, 143–155. [Google Scholar] [CrossRef]

- Krippendorff, K. Content Analysis: An Introduction to Its Methodology; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2019. [Google Scholar]

- Rhodes, O.; Rostami, A.; Khodadadyan, A.; Dunne, S. Response Strategies of UK Construction Contractors to COVID-19 in the Consideration of New Projects. Buildings 2022, 12, 946. [Google Scholar] [CrossRef]

- Hou, S.; Duan, Z.; Xiao, J.; Ye, J. A Review of 3D Printed Concrete: Performance Requirements, Testing Measurements and Mix Design. Constr. Build. Mater. 2021, 273, 121745. [Google Scholar] [CrossRef]

- Şahin, H.G.; Mardani-Aghabaglou, A. Assessment of Materials, Design Parameters and Some Properties of 3D Printing Concrete Mixtures; a State-of-the-Art Review. Constr. Build. Mater. 2022, 316, 125865. [Google Scholar] [CrossRef]

- de Brito, J.; Kurda, R. The Past and Future of Sustainable Concrete: A Critical Review and New Strategies on Cement-Based Materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- Andrew Ting, G.H.G.H.; Noel Quah, T.K.T.K.; Lim, J.H.J.H.; Daniel Tay, Y.W.Y.W.; Tan, M.J.M.J. Extrudable Region Parametrical Study of 3D Printable Concrete Using Recycled Glass Concrete. J. Build. Eng. 2022, 50, 104091. [Google Scholar] [CrossRef]

- Bai, G.; Wang, L.; Ma, G.; Sanjayan, J.; Bai, M. 3D Printing Eco-Friendly Concrete Containing under-Utilised and Waste Solids as Aggregates. Cem. Concr. Compos. 2021, 120, 104037. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Qin, F.; Duan, Z. Mechanical Behavior of 3D Printed Mortar with Recycled Sand at Early Ages. Constr. Build. Mater. 2020, 248, 118654. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, B.; Liu, S.; He, J.; Hernandez, A.G. Role of Recycled Concrete Powder as Sand Replacement in the Properties of Cement Mortar. J. Clean. Prod. 2022, 371, 133424. [Google Scholar] [CrossRef]

- Zou, S.; Xiao, J.; Duan, Z.; Ding, T.; Hou, S. On Rheology of Mortar with Recycled Fine Aggregate for 3D Printing. Constr. Build. Mater. 2021, 311, 125312. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, C.; Liu, H.; Zhang, Z.; He, C.; Liu, S.; Zhang, R.; Wang, Y.; Bai, G. Study on the Rheology and Buildability of 3D Printed Concrete with Recycled Coarse Aggregates. J. Build. Eng. 2021, 42, 103030. [Google Scholar] [CrossRef]

- Xiao, J.; Hou, S.; Duan, Z.; Zou, S. Rheology of 3D Printable Concrete Prepared by Secondary Mixing of Ready-Mix Concrete. Cem. Concr. Compos. 2023, 138, 104958. [Google Scholar] [CrossRef]

- Ting, G.H.A.; Tay, Y.W.D.; Qian, Y.; Tan, M.J. Utilization of Recycled Glass for 3D Concrete Printing: Rheological and Mechanical Properties. J. Mater. Cycles Waste Manag. 2019, 21, 994–1003. [Google Scholar] [CrossRef]

- Chen, Y.; Chaves Figueiredo, S.; Li, Z.; Chang, Z.; Jansen, K.; Çopuroğlu, O.; Schlangen, E. Improving Printability of Limestone-Calcined Clay-Based Cementitious Materials by Using Viscosity-Modifying Admixture. Cem. Concr. Res. 2020, 132, 106040. [Google Scholar] [CrossRef]

- De Vlieger, J.; Boehme, L.; Blaakmeer, J.; Li, J. Buildability Assessment of Mortar with Fine Recycled Aggregates for 3D Printing. Constr. Build. Mater. 2023, 367, 130313. [Google Scholar] [CrossRef]

- Ji, G.; Xiao, J.; Zhi, P.; Wu, Y.C.; Han, N. Effects of Extrusion Parameters on Properties of 3D Printing Concrete with Coarse Aggregates. Constr. Build. Mater. 2022, 325, 126740. [Google Scholar] [CrossRef]

- Liu, C.; Wang, X.; Chen, Y.; Zhang, C.; Ma, L.; Deng, Z.; Chen, C.; Zhang, Y.; Pan, J.; Banthia, N. Influence of Hydroxypropyl Methylcellulose and Silica Fume on Stability, Rheological Properties, and Printability of 3D Printing Foam Concrete. Cem. Concr. Compos. 2021, 122, 104158. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Gunasekara, C.; Fox, K.; Tran, P. 3D-Printed Concrete with Recycled Glass: Effect of Glass Gradation on Flexural Strength and Microstructure. Constr. Build. Mater. 2022, 314, 125561. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M. Evaluating the Printability of Concretes Containing Lightweight Coarse Aggregates. Cem. Concr. Compos. 2020, 109, 103570. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Vargas, A.; Martínez, F.; Mejía de Gutiérrez, R. Utilization of Powders and Fine Aggregates from the Recycling of Construction and Demolition Waste in the 3D Printing of Portland-Based Cementitious Materials. Clean. Mater. 2024, 11, 100234. [Google Scholar] [CrossRef]

- Hack, N.; Dörfler, K.; Walzer, A.N.; Wangler, T.; Mata-Falcón, J.; Kumar, N.; Buchli, J.; Kaufmann, W.; Flatt, R.J.; Gramazio, F.; et al. Structural Stay-in-Place Formwork for Robotic in Situ Fabrication of Non-Standard Concrete Structures: A Real Scale Architectural Demonstrator. Autom. Constr. 2020, 115, 103197. [Google Scholar] [CrossRef]

- Han, Y.; Yang, Z.; Ding, T.; Xiao, J. Environmental and Economic Assessment on 3D Printed Buildings with Recycled Concrete. J. Clean. Prod. 2021, 278, 123884. [Google Scholar] [CrossRef]

- Khan, S.A.; Koç, M.; Al-Ghamdi, S.G. Sustainability Assessment, Potentials and Challenges of 3D Printed Concrete Structures: A Systematic Review for Built Environmental Applications. J. Clean. Prod. 2021, 303, 127027. [Google Scholar] [CrossRef]

- Tinoco, M.P.M.P.; de Mendonça, É.M.É.M.; Fernandez, L.I.C.L.I.C.; Caldas, L.R.L.R.; Reales, O.A.M.O.A.M.; Toledo Filho, R.D.R.D. Life Cycle Assessment (LCA) and Environmental Sustainability of Cementitious Materials for 3D Concrete Printing: A Systematic Literature Review. J. Build. Eng. 2022, 52, 104456. [Google Scholar] [CrossRef]

- Sormunen, P.; Kärki, T. Recycled Construction and Demolition Waste as a Possible Source of Materials for Composite Manufacturing. J. Build. Eng. 2019, 24, 100742. [Google Scholar] [CrossRef]

- Xiao, J.; Zou, S.; Yu, Y.; Wang, Y.; Ding, T.; Zhu, Y.; Yu, J.; Li, S.; Duan, Z.; Wu, Y.; et al. 3D Recycled Mortar Printing: System Development, Process Design, Material Properties and on-Site Printing. J. Build. Eng. 2020, 32, 101779. [Google Scholar] [CrossRef]

- Zou, S.; Xiao, J.; Ding, T.; Duan, Z.; Zhang, Q. Printability and Advantages of 3D Printing Mortar with 100% Recycled Sand. Constr. Build. Mater. 2021, 273, 121699. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Wang, Y. Hardened Properties of Layered 3D Printed Concrete with Recycled Sand. Cem. Concr. Compos. 2020, 113, 103724. [Google Scholar] [CrossRef]

- Tong, J.; Ding, Y.; Lv, X.; Ning, W. Effect of Carbonated Recycled Coarse Aggregates on the Mechanical Properties of 3D Printed Recycled Concrete. J. Build. Eng. 2023, 80, 107959. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; van Dam, B.; Zeidan, T.; De Schutter, G.; Van Tittelboom, K. Performance Criteria, Environmental Impact and Cost Assessment for 3D Printable Concrete Mixtures. Resour. Conserv. Recycl. 2022, 181, 106255. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Wu, Y.; Bai, G.; He, C.; Yao, Y.; Zhang, R.; Wang, Y. 3D Printing Concrete with Recycled Coarse Aggregates: The Influence of Pore Structure on Interlayer Adhesion. Cem. Concr. Compos. 2022, 134, 104742. [Google Scholar] [CrossRef]

- Ting, G.H.A.; Tay, Y.W.D.; Tan, M.J. Experimental Measurement on the Effects of Recycled Glass Cullets as Aggregates for Construction 3D Printing. J. Clean. Prod. 2021, 300, 126919. [Google Scholar] [CrossRef]

- Skibicki, S.; Pułtorak, M.; Kaszyńska, M.; Hoffmann, M.; Ekiert, E.; Sibera, D. The Effect of Using Recycled PET Aggregates on Mechanical and Durability Properties of 3D Printed Mortar. Constr. Build. Mater. 2022, 335, 127443. [Google Scholar] [CrossRef]

- Munir, Q.; Afshariantorghabeh, S.; Kärki, T. Industrial Waste Pretreatment Approach for 3D Printing of Sustainable Building Materials. Urban Sci. 2022, 6, 50. [Google Scholar] [CrossRef]

- Singh, A.; Miao, X.; Zhou, X.; Deng, Q.; Li, J.; Zou, S.; Duan, Z. Use of Recycled Fine Aggregates and Recycled Powders in Sustainable Recycled Concrete. J. Build. Eng. 2023, 77, 107370. [Google Scholar] [CrossRef]

- Mahmood, A.; Nanos, N.; Begg, D. An Evaluation of the Strength for Recycled Fine Aggregate Replacement in Cementitious Mortars. Buildings 2024, 14, 470. [Google Scholar] [CrossRef]

- Vegas, I.; Azkarate, I.; Juarrero, A.; Frías, M. Diseño y Prestaciones de Morteros de Albañilería Elaborados Con Áridos Reciclados Procedentes de Escombro de Hormigón. Mater. Constr. 2009, 59, 5–18. [Google Scholar] [CrossRef]

- Morón, A.; Ferrández, D.; Saiz, P.; Morón, C. Experimental Study with Cement Mortars Made with Recycled Concrete Aggregate and Reinforced with Aramid Fibers. Appl. Sci. 2021, 11, 7791. [Google Scholar] [CrossRef]

- Hubert, J.; Zhao, Z.; Michel, F.; Courard, L. Effect of Crushing Method on the Properties of Produced Recycled Concrete Aggregates. Buildings 2023, 13, 2217. [Google Scholar] [CrossRef]

- Gokce, A.; Nagataki, S.; Saeki, T.; Hisada, M. Identification of Frost-Susceptible Recycled Concrete Aggregates for Durability of Concrete. Constr. Build. Mater. 2011, 25, 2426–2431. [Google Scholar] [CrossRef]

- Park, S.-S.; Kim, S.-J.; Chen, K.; Lee, Y.-J.; Lee, S.-B. Crushing Characteristics of a Recycled Aggregate from Waste Concrete. Constr. Build. Mater. 2018, 160, 100–105. [Google Scholar] [CrossRef]

- Beltrán, M.G.; Barbudo, A.; Agrela, F.; Galvín, A.P.; Jiménez, J.R. Effect of Cement Addition on the Properties of Recycled Concretes to Reach Control Concretes Strengths. J. Clean. Prod. 2014, 79, 124–133. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Wu, Y.; Bai, G.; He, C.; Zhang, R.; Wang, Y. Hardened Properties of 3D Printed Concrete with Recycled Coarse Aggregate. Cem. Concr. Res. 2022, 159, 106868. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Z.; Wu, Y.; Liu, H.; Zhang, T.; Wang, X.; Zhang, W. 3D Printing Concrete with Recycled Sand: The Influence Mechanism of Extruded Pore Defects on Constitutive Relationship. J. Build. Eng. 2023, 68, 106169. [Google Scholar] [CrossRef]

- Li, J.; Zhan, B.; Gao, P.; Hu, L.; Qiao, M.; Sha, H.; Yu, Q. Effects of Recycled Concrete Powders on the Rheology, Setting and Early Age Strength of Cement Paste. Constr. Build. Mater. 2023, 401, 132899. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, H.; Anand, K.; Singh, A.; Xie, Y.M. Sustainable Use of Ultrafine Recycled Glass in Additive Manufactured (3D Printed) Reactive Powder Concrete. Constr. Build. Mater. 2024, 419, 135556. [Google Scholar] [CrossRef]

- Liu, J.; Setunge, S.; Tran, P. 3D Concrete Printing with Cement-Coated Recycled Crumb Rubber: Compressive and Microstructural Properties. Constr. Build. Mater. 2022, 347, 128507. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Yu, J. Flexural Properties of 3D Printed Fibre-Reinforced Concrete with Recycled Sand. Constr. Build. Mater. 2021, 288, 123077. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, S.; Liu, Q.; Xu, M.; Wang, S.; Lan, T. Closed-Form Fracture Model for Evaluating Crack Resistance of 3D Printed Fiber-Reinforced Alkali-Activated Slag/Fly Ash Recycled Sand Concrete. J. Build. Eng. 2024, 86, 108964. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, J.; Ding, T. Flexural Performance of 3D-Printed Composite Beams with ECC and Recycled Fine Aggregate Concrete: Experimental and Numerical Analysis. Eng. Struct. 2023, 283, 115865. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. 3D Concrete Printing: A Lower Bound Analytical Model for Buildability Performance Quantification. Autom. Constr. 2019, 106, 102904. [Google Scholar] [CrossRef]

- Hao, L.; Xiao, J.; Sun, J.; Xia, B.; Cao, W. Thermal Conductivity of 3D Printed Concrete with Recycled Fine Aggregate Composite Phase Change Materials. J. Clean. Prod. 2022, 364, 132598. [Google Scholar] [CrossRef]

- Rahul, A.V.; Mohan, M.K.; De Schutter, G.; Van Tittelboom, K. 3D Printable Concrete with Natural and Recycled Coarse Aggregates: Rheological, Mechanical and Shrinkage Behaviour. Cem. Concr. Compos. 2022, 125, 104311. [Google Scholar] [CrossRef]

- Pan, Z.; Si, D.; Tao, J.; Xiao, J. Compressive Behavior of 3D Printed Concrete with Different Printing Paths and Concrete Ages. Case Stud. Constr. Mater. 2023, 18, e01949. [Google Scholar] [CrossRef]

- Federowicz, K.; Cendrowski, K.; Sikora, P. Low Carbon Cementious Composite Incorporated with Biochar and Recycled Fines Suitable for 3d Printing Applications. Fract. Struct. Integr. 2025, 71, 91–107. [Google Scholar]

- Pepe, M.; Lombardi, R.; Lima, C.; Paolillo, B.; Martinelli, E. Experimental Evidence on the Possible Use of Fine Concrete and Brick Recycled Aggregates for 3D Printed Cement-Based Mixtures. Materials 2025, 18, 583. [Google Scholar] [CrossRef]

- Bai, M.; Wu, Y.; Xiao, J.; Ding, T.; Yu, K. Workability and Hardened Properties of 3D Printed Engineered Cementitious Composites Incorporating Recycled Sand and PE Fibers. J. Build. Eng. 2023, 71, 106477. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened Properties of 3D Printed Concrete: The Influence of Process Parameters on Interlayer Adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Xiao, J.; Lv, Z.; Duan, Z.; Hou, S. Study on Preparation and Mechanical Properties of 3D Printed Concrete with Different Aggregate Combinations. J. Build. Eng. 2022, 51, 104282. [Google Scholar] [CrossRef]

- Sun, H.Q.; Zeng, J.J.; Hong, G.Y.; Zhuge, Y.; Liu, Y.; Zhang, Y. 3D-Printed Functionally Graded Concrete Plates: Concept and Bending Behavior. Eng. Struct. 2025, 327, 119551. [Google Scholar] [CrossRef]

- Charrier, M.; Ouellet-Plamondon, C.M. Artificial Neural Network for the Prediction of the Fresh Properties of Cementitious Materials. Cem. Concr. Res. 2022, 156, 106761. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, D.; Lu, Y. A Navier–Stokes-Informed Neural Network for Simulating the Flow Behavior of Flowable Cement Paste in 3D Concrete Printing. Buildings 2025, 15, 275. [Google Scholar] [CrossRef]

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A Comprehensive Review on the Use of Recycled Concrete Aggregate for Pavement Construction: Properties, Performance, and Sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Fonseca, M.; Matos, A.M. 3D Construction Printing Standing for Sustainability and Circularity: Material-Level Opportunities. Materials 2023, 16, 2458. [Google Scholar] [CrossRef]

- BS EN 8500-1:2019; Concrete—Complementary British Standard to BS EN 206—Part 1: Method of Specifying and Guidance for the Specifier. British Standards Institution (BSI): London, UK, 2019.

- BS EN 8500-2:2019; Concrete—Complementary British Standard to BS EN 206—Part 2: Specification for Constituent Materials and Concrete. British Standards Institution (BSI): London, UK, 2019.

- BS EN 12620:2013; Aggregates for Concrete. British Standards Institution (BSI): London, UK, 2013.

- Yang, C.; Xu, X.; Lei, Z.; Sun, J.; Wang, Y.; Luo, G.; Yao, H.; Mei, Y. Enhancing Mechanical Properties of Three-Dimensional Concrete at Elevated Temperatures through Recycled Ceramic Powder Treatment Methods. J. Mater. Res. Technol. 2024, 31, 434–446. [Google Scholar] [CrossRef]

- Skibicki, S.; Federowicz, K.; Hoffmann, M.; Chougan, M.; Sibera, D.; Cendrowski, K.; Techman, M.; Pacheco, J.N.; Liard, M.; Sikora, P. Potential of Reusing 3D Printed Concrete (3DPC) Fine Recycled Aggregates as a Strategy towards Decreasing Cement Content in 3DPC. Materials 2024, 17, 2580. [Google Scholar] [CrossRef]

- Zhang, C.; Jia, Z.; Luo, Z.; Deng, Z.; Wang, Z.; Chen, C.; Zhang, Y. Printability and Pore Structure of 3D Printing Low Carbon Concrete Using Recycled Clay Brick Powder with Various Particle Features. J. Sustain. Cem.-Based Mater. 2023, 12, 808–817. [Google Scholar] [CrossRef]

- Ly, O.; Yoris-Nobile, A.I.; Sebaibi, N.; Blanco-Fernandez, E.; Boutouil, M.; Castro-Fresno, D.; Hall, A.E.; Herbert, R.J.H.; Deboucha, W.; Reis, B.; et al. Optimisation of 3D Printed Concrete for Artificial Reefs: Biofouling and Mechanical Analysis. Constr. Build. Mater. 2021, 272, 121649. [Google Scholar] [CrossRef]

- Mai, I.; Brohmann, L.; Freund, N.; Gantner, S.; Kloft, H.; Lowke, D.; Hack, N. Large Particle 3d Concrete Printing—A Green and Viable Solution. Materials 2021, 14, 6125. [Google Scholar] [CrossRef] [PubMed]

- Skibicki, S.; Jakubowska, P.; Kaszyńska, M.; Sibera, D.; Cendrowski, K.; Hoffmann, M. Early-Age Mechanical Properties of 3d-Printed Mortar with Spent Garnet. Materials 2022, 15, 100. [Google Scholar] [CrossRef] [PubMed]

- Qian, H.; Hua, S.; Yue, H.; Feng, G.; Qian, L.; Jiang, W.; Zhang, L. Utilization of Recycled Construction Powder in 3D Concrete Printable Materials through Particle Packing Optimization. J. Build. Eng. 2022, 61, 105236. [Google Scholar] [CrossRef]

- Rajeev, P.; Ramesh, A.; Navaratnam, S.; Sanjayan, J. Using Fibre Recovered from Face Mask Waste to Improve Printability in 3D Concrete Printing. Cem. Concr. Compos. 2023, 139, 105047. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, Y.; Chen, G.; Li, S.; Singh, A.; Luo, X.; Liu, C.; Gao, J.; Du, H. Development of Low-Carbon Materials from GGBS and Clay Brick Powder for 3D Concrete Printing. Constr. Build. Mater. 2023, 383, 131232. [Google Scholar] [CrossRef]

- Lv, Z.; Xiao, J.; Duan, Z.; Tang, Y. Time-Dependent Evolution and Strength Modulation of 3D Printed Concrete Pore Structure Based on Microbial Remediation. J. Build. Eng. 2023, 79, 107830. [Google Scholar] [CrossRef]

- Daniel Oosthuizen, J.; John Babafemi, A.; Shaun Walls, R. 3D-Printed Recycled Plastic Eco-Aggregate (Resin8) Concrete. Constr. Build. Mater. 2023, 408, 133712. [Google Scholar] [CrossRef]

- Krčma, M.; Škaroupka, D.; Vosynek, P.; Zikmund, T.; Kaiser, J.; Palousek, D. Use of Polymer Concrete for Large-Scale 3D Printing. Rapid Prototyp. J. 2021, 27, 465–474. [Google Scholar] [CrossRef]

| Methodology | Research Areas Concerned | Article |

|---|---|---|

| Critical Review | 3DCP and concrete materials: durability, performance, mix design, and testing requirements. | [24] |

| Critical Review | 3DCP advantages, disadvantages, materials used, and performance requirements. | [25] |

| Critical Review | Sustainable materials manufacturing techniques durability and uses in construction. | [26] |

| Critical Review | 3DCP and recycled materials: manufacturing, techniques, material types, performance requirements and applications | [10] |

| Journal | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 (to Date) | Total |

|---|---|---|---|---|---|---|---|---|

| Construction and Building Materials | 4 | 4 | 5 | 3 | 3 | 19 | ||

| Journal of Building Engineering | 1 | 1 | 1 | 4 | 4 | 2 | 13 | |

| Cement and Concrete Composites | 2 | 3 | 2 | 2 | 9 | |||

| Journal of Cleaner Production | 3 | 2 | 2 | 7 | ||||

| Materials | 1 | 1 | 1 | 1 | 4 | |||

| Cement and Concrete Research | 1 | 2 | 1 | 4 | ||||

| Automation in Construction | 1 | 1 | 2 | |||||

| Resources Conservation and Recycling | 1 | 1 | 2 | |||||

| Acta Geotechnica | 1 | 1 | ||||||

| Buildings | 1 | 1 | ||||||

| Case Studies in Construction Materials | 1 | 1 | ||||||

| Cleaner Materials | 1 | 1 | ||||||

| Construction Innovation | 1 | 1 | ||||||

| Engineering Structures | 1 | 1 | ||||||

| Journal of Material Cycles and Waste Management | 1 | 1 | ||||||

| Journal of Sustainable Cement Based Materials | 1 | 1 | ||||||

| Rapid Prototyping Journal | 1 | 1 | ||||||

| Smart and Sustainable Built Environment | 1 | 1 | ||||||

| Technology Architecture and Design | 1 | 1 | ||||||

| Urban Science | 1 | 1 | ||||||

| Virtual and Physical Prototyping | 1 | 1 |

| Category | Description | Notable Publications |

|---|---|---|

| Recycled materials in 3D printing | Explores the feasibility, extraction process, morphology, chemical composition, and physical properties of recycled materials in 3D printing. | [6,7,27,28,29,30,31,32,33,34] |

| Printability and Performance of 3DCP | Investigates the mechanical properties such as workability, extrudability, and structural integrity of concrete mixes designed for 3D printing applications. | [35,36,37,38,39] |

| Innovation in 3D Printing Techniques and Materials | Explores innovative techniques and material formulations. This includes studies on novel printing processes, material enhancements, and the development of mixtures with improved properties for printing. | [4,40,41,42] |

| Environmental and Economic Sustainability | Research into the environmental and economic implications of adopting 3D printing technology in construction, with a focus on the sustainability of using recycled materials and the potential of waste reduction and emissions. | [43,44,45] |

| Challenges and Future Directions | Identifies the current challenges in the field of 3D concrete printing and proposes future directions for research and development. This includes addressing issues related to material properties, printing processes, scalability, and adoption barriers. | [46,47] |

| Material | SiO2 | Al2O3 | B2O3 | Na2O | K2O | CaO | MgO | Fe2O3 | TiO2 | SO3 | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete Waste Powder | 36.10–43.00 | 8.30–12.00 | - | 0.60–1.00 | 0.60–2.80 | 28.70 -31.00 | 1.90–2.80 | 4.00–6.80 | 0.00–0.20 | 0.00–0.50 | [7,41] |

| Ceramic Waste Powder | 59.30 | 16.10 | - | 0.50 | 1.60 | 9.80 | 0.80 | 5.50 | - | - | |

| Clay Brick Waste Powder | 59.00–68.00 | 17.00–18.40 | - | 1.10–2.50 | 1.50–3.00 | 3.00–5.40 | 2.00–2.40 | 7.00–7.80 | 0.00–1.00 | 0.00–0.30 | |

| Mixed Brick Powder | 45.00 | 15.00 | 1.00 | 3.00 | 22.00 | 3.00 | 6.00 | 0.80 | 2.00 | [7] | |

| Ultra Fine Glass Powder | 64.94 | 1.81 | 9.16 | 0.44 | 10.48 | 3.12 | 1.97 | 0.09 | [67] | ||

| Recycled Powder from Construction waste | 47.70 | 16.70 | - | - | - | 23.20 | 2.90 | 7.10 | - | 2.40 | [33] |

| Cement (ordinary 42.5) | 19.29–23 | 1.42–9.00 | 0.09–0.38 | 0.34–1.00 | 57.00–66.02 | 1.27–2.10 | 2.86–4.44 | 0.10–0.25 | 2.30–3.29 | [7,34,39,63,65,68] | |

| Fly Ash | 51.10–55.00 | 27.20–28.80 | - | 0.30–1.28 | 0.70–1.20 | 3.50–5.80 | 1.10–1.30 | 3.40–9.20 | 1.49–2.50 | 0.11–1.10 | |

| Silica Fumes | 86.62–98.37 | 0.19–0.51 | 0.12 | 0.20–0.56 | 0.23–2.03 | 0.30–1.02 | 0.15–2.77 | 0.08–1.52 | - | 0.58–0.83 | |

| Ground Slag | 37.54 | 10.49 | - | - | 0.31 | 39.87 | 0.46 | 0.31 | 0.46 | 0.10 |

| Type | Fineness Modulus | Crush Index | Max Particle Size (mm) | Apparent Density (kg/m3) | Loose Density (kg/m3) | Dense Packing Density (kg/m3) | Moisture Content (%) | Water Absorption (%) | Reference |

|---|---|---|---|---|---|---|---|---|---|

| Natural Fine Aggregates | 1.62 | - | 0.90 | 2586.50 | 1399.00 | 1491.00 | 0.20 | 4.50 | [29,31,32,33,36,48,65,69,70] |

| 1.62 | - | 0.90 | 2586.50 | 1399.00 | 1491.00 | 0.20 | 1.00 | ||

| 2.11 | 1.80 | - | - | - | 1425.00 | - | 2.90 | ||

| 3.50 | 22.00 | - | 2580.00 | 1364.00 | 1510.00 | - | 1.20 | ||

| 2.69 | - | - | 2617.00 | - | - | - | - | ||

| 2.23 | 2.23 | 2940.00 | 3.20 | ||||||

| Natural Coarse Aggregates | - | - | - | 2712.00 | - | - | - | 1.10 | [32,33,64] |

| - | 14.90 | - | - | - | 1331.00 | - | 1.10 | ||

| - | - | - | 2964.00 | - | - | 0.70 | 1.16 | ||

| Recycled Fine Aggregates | 1.53 | - | 0.90 | 2410.70 | 1014.00 | 1070.00 | 0.60 | 13.50 | [31,48,49,69,70] |

| 1.53 | - | 0.90 | 2410.70 | 1014.00 | 1070.00 | 0.60 | 15.00 | ||

| 3.20 | 28.00 | - | 2605.00 | 1280.00 | 1411.00 | - | 8.90 | ||

| - | - | - | 2623.00 | - | - | - | 8.26 | ||

| 3.00 | 3.18 | 2680.00 | 8.80 | ||||||

| Recycled coarse Aggregates | - | - | - | 2538.00 | - | - | - | 7.29 | [33,63,64] |

| - | 23.32 | - | - | - | 1329.00 | - | 7.29 | ||

| - | - | - | 2634.00 | - | - | 6.96 |

| Construction Technique | ||||||

|---|---|---|---|---|---|---|

| Impact Category | 3D Printing—0% RA | 3D Printing—50% RA | 3D Printing—100% RA | Conventional Construction—0% RA | Conventional Construction—50% RA | Conventional Construction—100% RA |

| Global warming (carbon dioxide CO2-eq) | 5737.58 | 5666.92 | 5595.50 | 4449.00 | 4496.90 | 4523.80 |

| Acidification (sulphur dioxide SO2-eq) | 27.54 | 26.73 | 25.92 | 22.34 | 22.06 | 21.54 |

| Photochemical pollution (ethylene C2H4-eq) | 0.16 | 0.12 | 0.10 | 0.18 | 0.15 | 0.130 |

| Eutrophication (Nitrogen Oxide NOx-eq) | 17.55 | 16.42 | 15.27 | 15.71 | 14.85 | 13.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, A.; Nanos, N.; Begg, D.; Dhakal, H.N. Recycled Waste Materials Utilised in 3D Concrete Printing for Construction Applications: A Scientometric Review. Buildings 2025, 15, 3572. https://doi.org/10.3390/buildings15193572

Mahmood A, Nanos N, Begg D, Dhakal HN. Recycled Waste Materials Utilised in 3D Concrete Printing for Construction Applications: A Scientometric Review. Buildings. 2025; 15(19):3572. https://doi.org/10.3390/buildings15193572

Chicago/Turabian StyleMahmood, Ali, Nikos Nanos, David Begg, and Hom Nath Dhakal. 2025. "Recycled Waste Materials Utilised in 3D Concrete Printing for Construction Applications: A Scientometric Review" Buildings 15, no. 19: 3572. https://doi.org/10.3390/buildings15193572

APA StyleMahmood, A., Nanos, N., Begg, D., & Dhakal, H. N. (2025). Recycled Waste Materials Utilised in 3D Concrete Printing for Construction Applications: A Scientometric Review. Buildings, 15(19), 3572. https://doi.org/10.3390/buildings15193572