Research and Application of Assembled SC Coal Gangue External Wallboard

Abstract

1. Introduction

2. SC Gangue

2.1. Selection and Use Principles

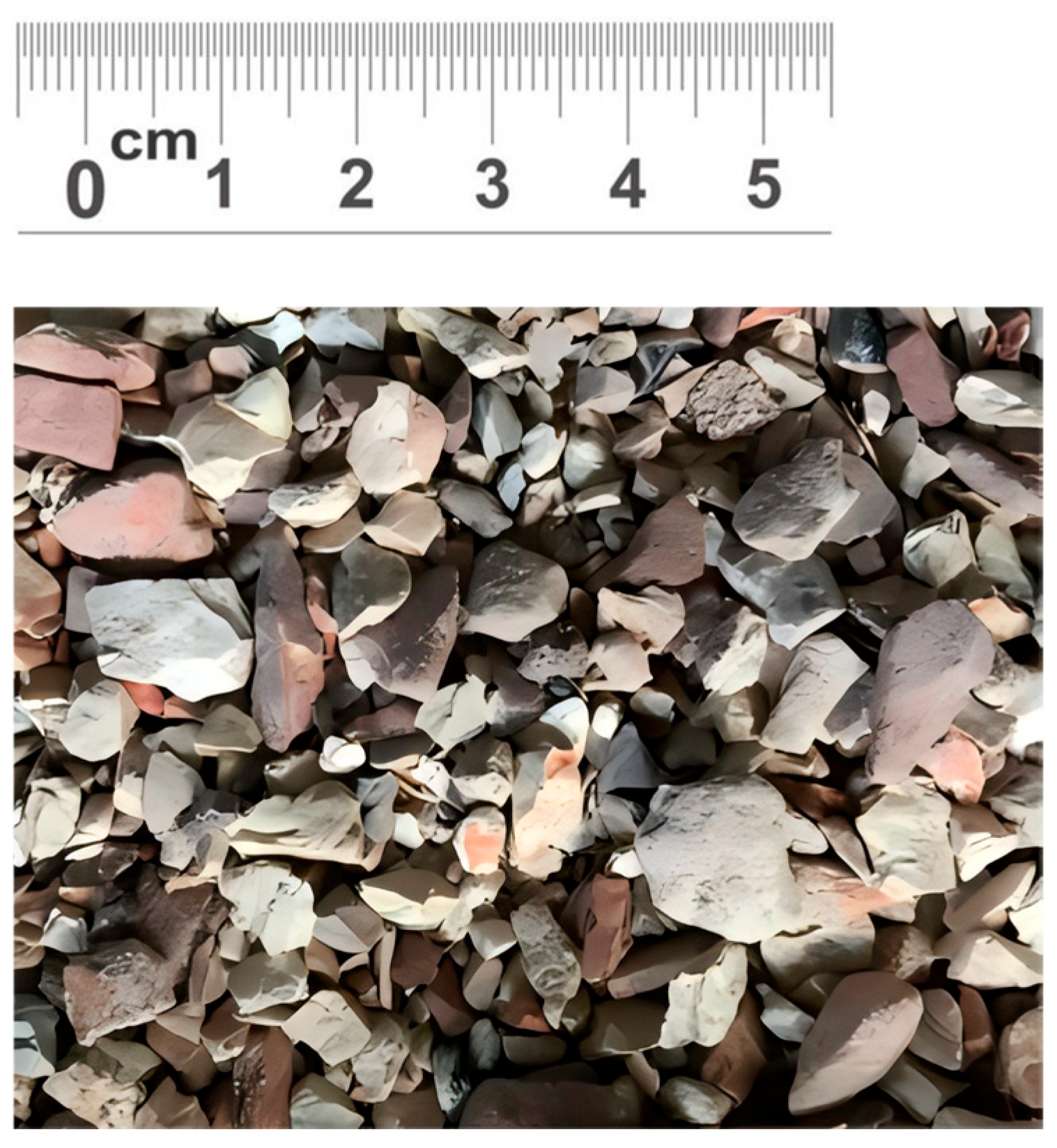

2.2. Crushing and Screening

2.3. Basic Performance

3. SC Coal Gangue Fine-Stone Concrete

3.1. Basic Requirements of Fine-Stone Concrete

3.2. Raw Materials of Fine-Stone Concrete

3.3. Mix Proportion of Fine-Stone Concrete

3.3.1. Preparation Strength

3.3.2. Water–Binder Ratio

3.3.3. Water Consumption

3.3.4. Ement Amount

3.3.5. Sand Rate

3.3.6. Aggregate Dosage

3.4. Performance of Fine-Stone Concrete

3.4.1. Mechanical Properties

- Compressive strength

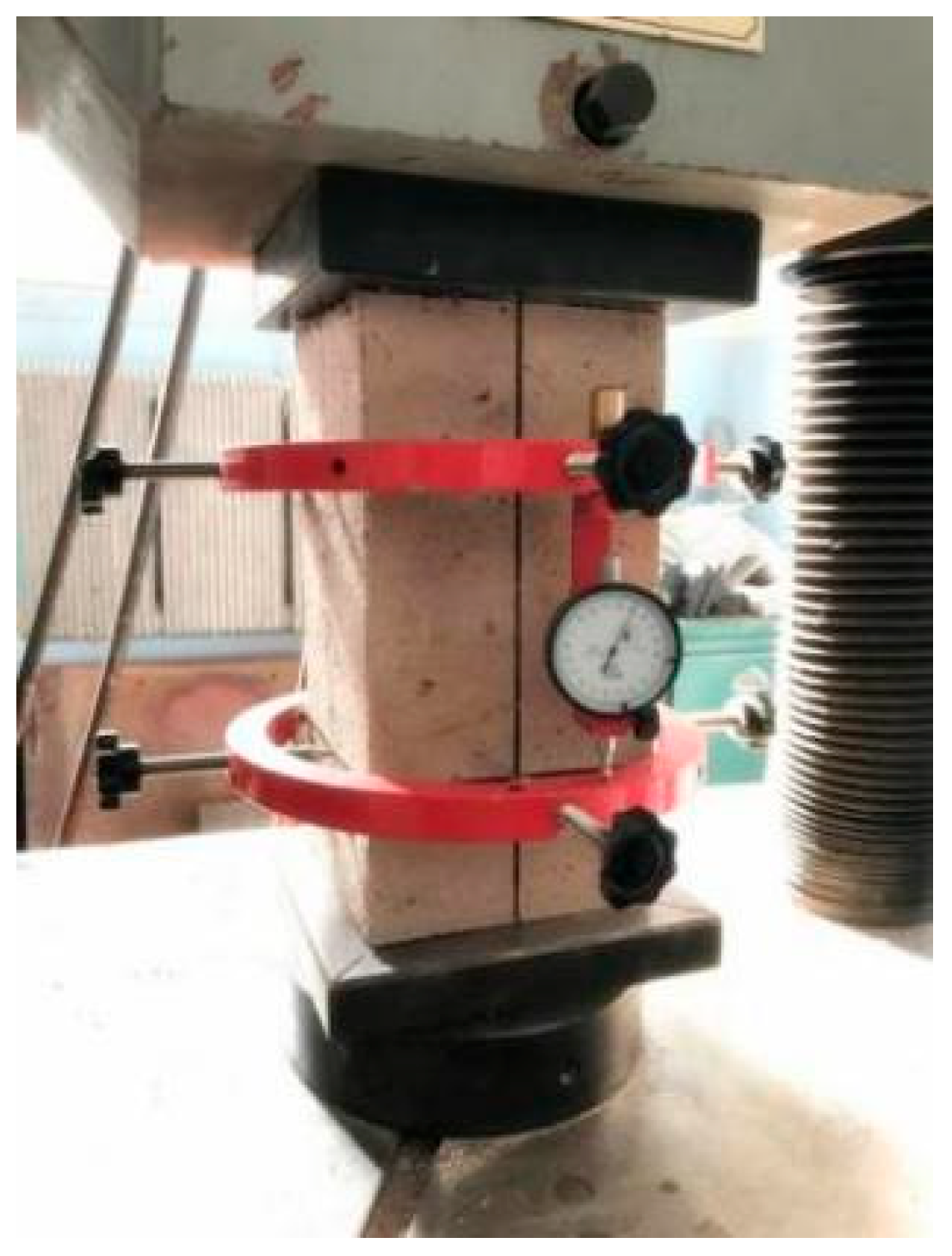

- Axial compressive strength and elastic modulus

- Splitting tensile strength

- Flexural strength

3.4.2. Freeze–Thaw Test

3.4.3. Carbonization Test

4. SC Coal Gangue Board

4.1. Design and Maintenance

4.1.1. Reinforcement

4.1.2. Anti-Cracking Measures

4.1.3. Panel Fixation

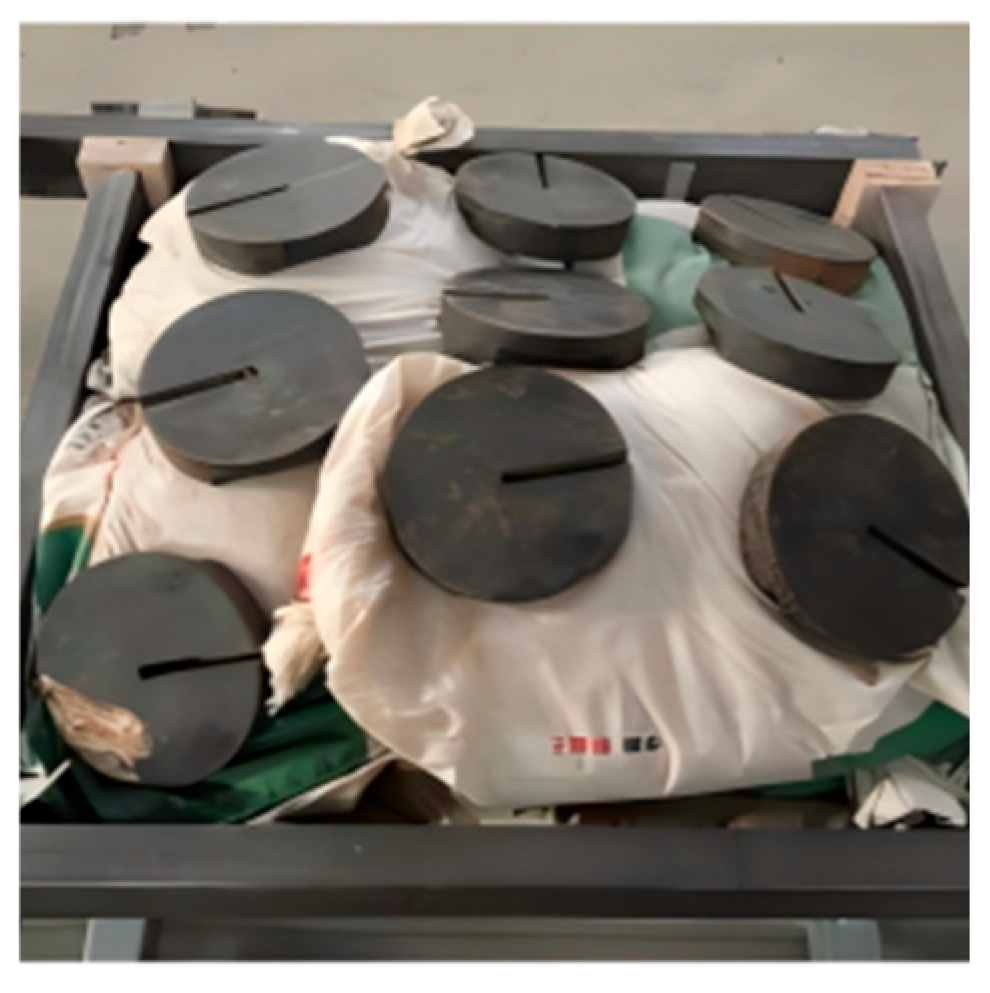

4.1.4. Maintenance

4.2. Performance Test

4.2.1. Surcharge Test

4.2.2. Impact Test

4.2.3. Impermeability Test

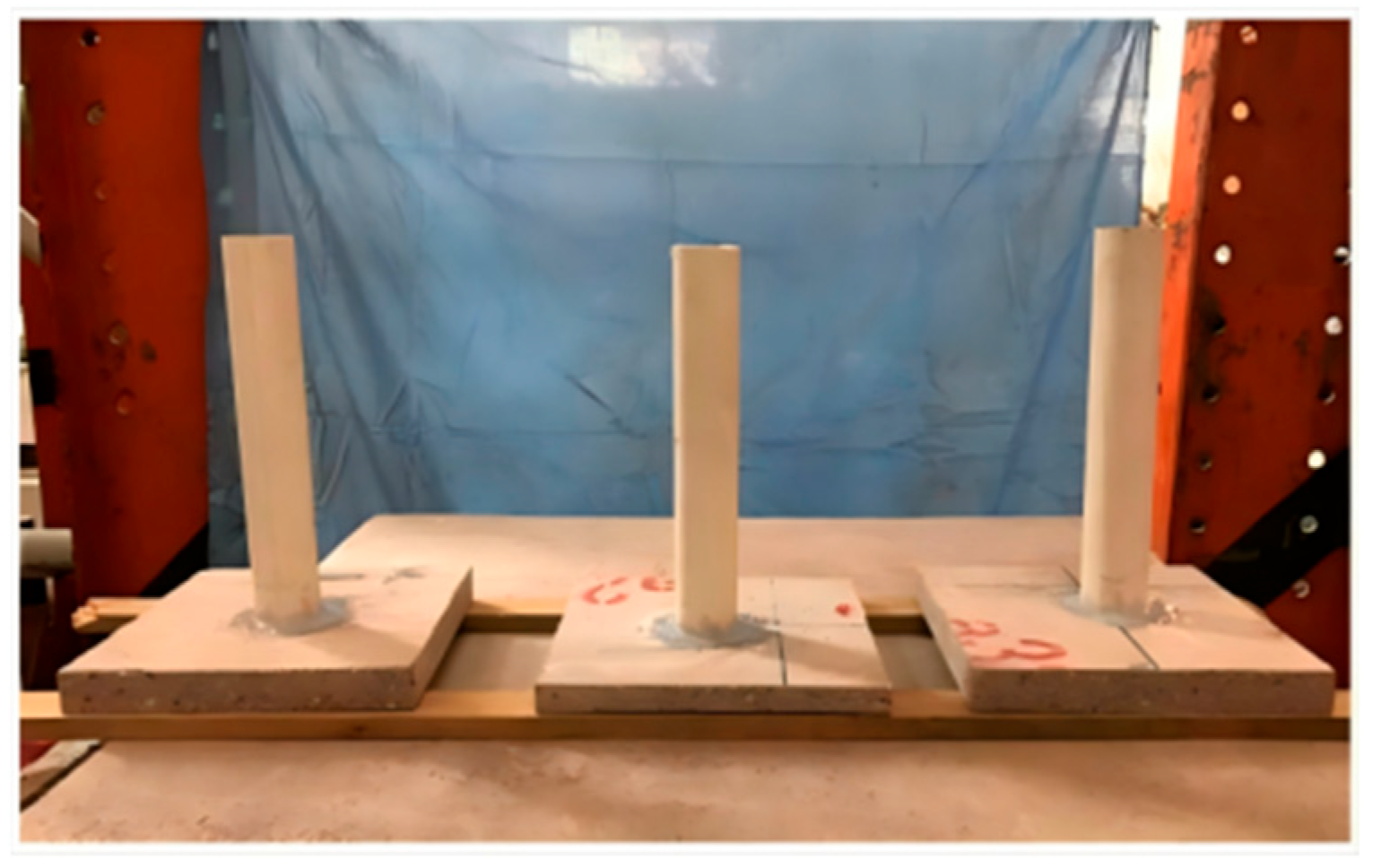

4.2.4. Hanging Test

5. Application of SC Coal Gangue Composite Exterior Wallboard

5.1. Segmentation of Exterior Wall

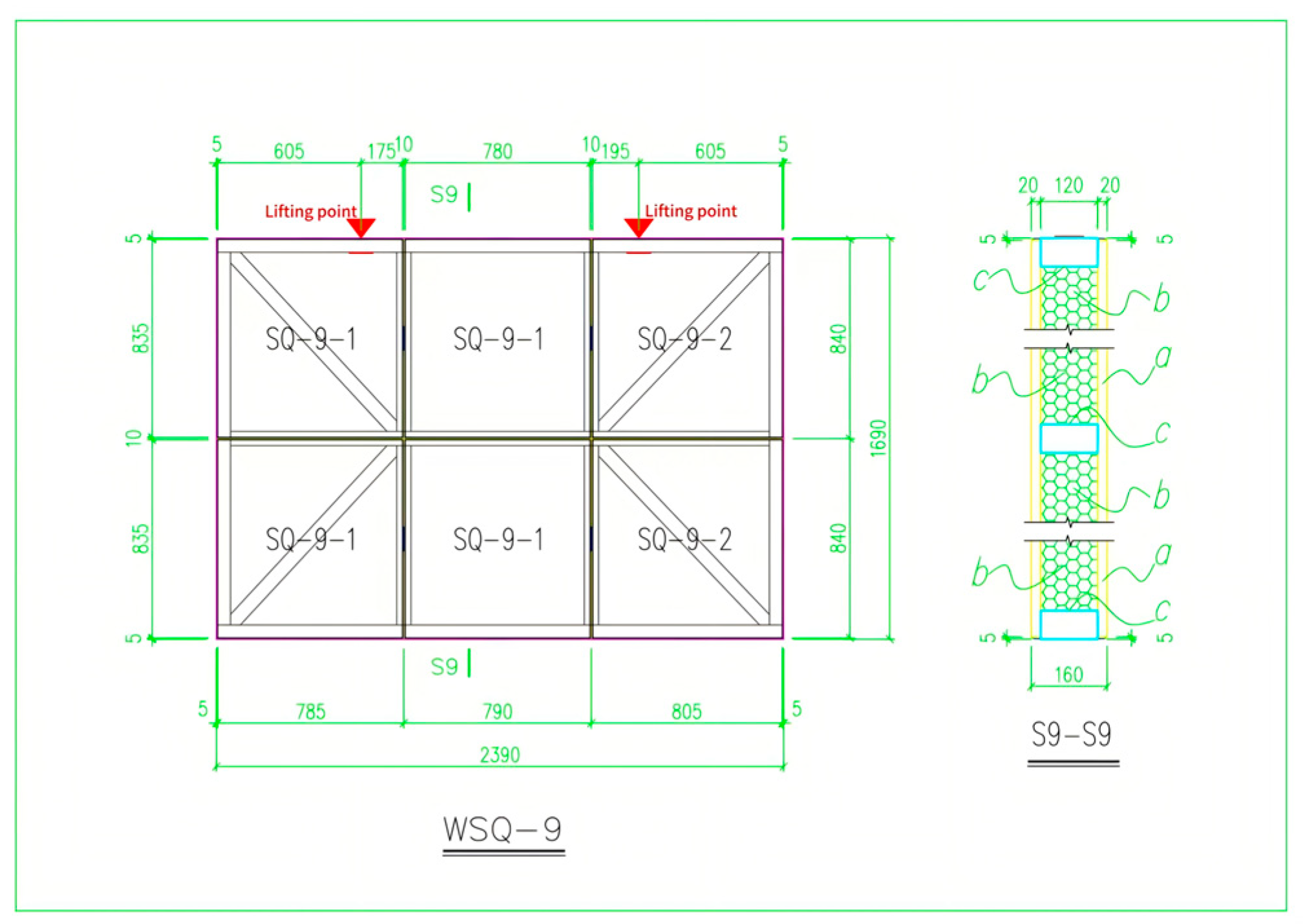

5.2. SC Coal Gangue Composite Wallboard

5.3. On-Site Installation

6. Conclusions

- (1)

- SC coal gangue was selected as an aggregate, and SC coal gangue concrete of strength grade C20 was obtained.

- (2)

- Using the SC coal gangue concrete, 20 mm thick SC coal gangue panels were designed and manufactured. Through the experimental tests, the properties of the board were found to meet the requirements of the relevant standards of building wallboard.

- (3)

- Through experiments, the anchorage, shear, and tensile bearing capacity of the SC coal gangue panel were obtained, which provided a basis for the fixation and application of the wallboard.

- (4)

- The SC coal gangue composite wallboard was obtained by using the SC coal gangue panel, keel and rock wool. Its heat transfer coefficient was reduced from 0.47 to 0.31, a decrease of 34.0%, air sound insulation was provided, and the self-weight of the external wallboard was reduced by 37.5%, meaning that the related performance was better than the requirements of the current standard.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, L.; Gu, W.Z.; He, Z.W.; Liu, C.Y.; Zhao, M.Y. Current situation of comprehensive utilization of coal gangue and exploration of ways of high-value utilization:A case study of china national coal group corporation. Coal Sci. Technol. 2025, 53, 104–124. [Google Scholar]

- Liu, X.P.; Wu, S.W.; Zhang, C. Activation of Se-enriched coal gangue and the efficient use of coal gangue Se fertilizer. J. Plant Nutr. Fertil. 2020, 26, 1526–1535. [Google Scholar]

- Wang, A.G.; Liu, P.; Sun, D.S.; Liu, K.W.; Fang, L.A. Research progress in activity evaluation methods of calcined coal gangue powder materials. Mater. Rep. 2018, 32, 1903–1909. [Google Scholar]

- Zhang, J.J.; Song, H.P.; Feng, Z.J.; Munkhbat, B.; Jin, D.P.; Wei, J.J. Study on the effect of coal gangue particle size and ratio on desertified soil improvement. J. Environ. Eng. Technol. 2025, 15, 780–787. [Google Scholar]

- Yang, Y.; Hu, A.P.; Zhang, X.Y.; Gao, T.; Wang, S.J. Experimental study on compressive properties of modified raw soil mixed with coal gangue powder and mineral powder. Build. Struct. 2022, 52, 2202–2206. [Google Scholar] [CrossRef]

- Liu, H. Study on aerated concrete block preparation used with fly ash and coal gangue of fuxin. Bull. Chin. Ceram. Soc. 2013, 32, 1932–1935. [Google Scholar] [CrossRef]

- Yi, Q.; Gu, J.; Chen, W.J.; Xiang, H.; Guo, Z.H. Effect of coal gangue fine aggregate modification treatment on mortar performance. Bull. Chin. Ceram. Soc. 2025, 44, 2193–2200. [Google Scholar] [CrossRef]

- Mao, M.J.; Huang, B.; Chen, H.X.; Zhang, D.S. Research on damage of unburned coal gangue coarse aggregate concrete after high temperature. Build. Struct. 2022, 52, 1566–1570. [Google Scholar] [CrossRef]

- Sun, Z.H.; WANG, Y.B.; Ma, S.X.; Li, M. Energy storage modification of coal gangue and its application inhigh-specific-energy batteries. Coal Sci. Technol. 2025, 53, 318–326. [Google Scholar]

- Zhao, Z.; Wu, W.F.; Han, Y.Q.; Hou, X.J.; Li, S.P.; Zhang, J.B.; Li, H.Q.; Feng, L.L. Preparation of gallium oxide by hydrolyzing dilute gallium sulfate from galli-um enriched mother liquor of coal gangue. Clean Coal Technol. 2024, 30, 99–108. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Zhai, H.B.; Zhang, J.W.; Yan, K.Z.; Yang, F.L. Mineral occurrence and acid leaching characteristic of aluminum forcoal gangue in shanxi province. Coal Sci. Technol. 2025, 53, 434–444. [Google Scholar]

- Li, G.M.; Su, N.J.; Zhu, B.S.; Liang, L.P.; Tian, Y.M. Fe3O4 and Fe loaded composites as microwave absorbents by recycling of gangue. Bull. Chin. Ceram. Soc. 2021, 40, 2998–3004. [Google Scholar] [CrossRef]

- Wu, X.G.; Tao, X.K.; Yu, S.Y.; Li, S.S.; Zhang, R.H. Research progress on the application of high-performance composite sandwich exterior wall panels. Build. Struct. 2020, 50, 611–616. [Google Scholar] [CrossRef]

- Zhang, J.H.; Meng, F.H.; Wang, L.N.; Dai, L.F.; Yao, L.F. Preparation and properties of coal gangue-based foamed ceramics. Bull. Chin. Ceram. Soc. 2023, 42, 960–969. [Google Scholar] [CrossRef]

- GB 6566-2010; Limits of Radionuclides in Building Materials. China Standards Press: Beijing, China, 2010.

- GB 8624-2012; Classification for Burning Behavior of Building Materials and Products. China Standards Press: Beijing, China, 2012.

- GB/T 14685-2022; Pebble and Crushed Stone for Construction. China Standards Press: Beijing, China, 2022.

- GB 55037-2022; General Code for Fire Protection of Buildings and Congstructions. China Planning Press: Beijing, China, 2022.

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011.

- GB/T 50010-2010 (Year 2024 Edition); Standard for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2024.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Building Industry Press: Beijing, China, 2019.

- GB/T50082-2024; Standard for Test Methods of Long-Term Performanceand Durability of Concrete. China Building Industry Press: Beijing, China, 2024.

- GB/T 30100-2013; Test Methods for Building Wallboard. China Standards Press: Beijing, China, 2013.

- GB 50189-2015; Design Standard for Energy Efficiency of Public Buildings. China Building Industry Press: Beijing, China, 2015.

| Detection Project | Radioactivity Specific Activity (Bq/kg) | Internal Exposure | External Exposure | Standard | ||

|---|---|---|---|---|---|---|

| Ra-226 | Th-232 | K-40 | ||||

| Index | 94.23 | 71.56 | 509.74 | 0.45 | 0.61 | Ir < 1.0 |

| Essential Component | Al2O3 | SiO2 | CaO | Fe2O3 | MgO | K2O | Others |

|---|---|---|---|---|---|---|---|

| Content (%) | 14.8 | 54.1 | 14.2 | 12.4 | 2.4 | 1.1 | 1.0 |

| Square Hole Sieve Size (mm) | Screen Oversize (kg) | Retained (%) | Cumulative Retained (%) |

|---|---|---|---|

| 16.0 | 0 | / | / |

| 9.5 | 0.05 | 2.8 | 2.8 |

| 4.75 | 1.03 | 54.3 | 57.1 |

| 2.36 | 0.79 | 38.7 | 95.8 |

| Square Hole Sieve Size | Screen Oversize (g) | Retained (%) | Cumulative Retained (%) | Standard (%) |

|---|---|---|---|---|

| 4.75 mm | 0 | 0 | 0 | 10~0 |

| 2.36 mm | 23.0 | 4.6 | 4.6 | 25~0 |

| 1.18 mm | 123.0 | 24.6 | 29.2 | 50~10 |

| 600 μm | 120.0 | 24.0 | 53.2 | 70~41 |

| 300 μm | 12.0 | 18.4 | 71.6 | 92~70 |

| 150 μm | 52.0 | 10.4 | 82.0 | 94~80 |

| Physical Indicator | Grain Size (mm) | Molded Cylinder Compressive Strength (MPa) | Apparent Density (kg·m−3) | Bulk Density (kg·m−3) | Water Absorption (%) |

|---|---|---|---|---|---|

| Coarse aggregate | 5~10 | 2.5 | 2440 | 1132 | 9.6 |

| Physical Indicators | Apparent Density (kg·m−3) | Aggregate Size (mm) | Bulk Density (kg·m−3) | Fineness Modulus | Type |

|---|---|---|---|---|---|

| Fine aggregate | 2441 | <3.00 | 1209 | 2.41 | Medium sand |

| Cement | Fine Aggregate | Coarse Aggregate | Fly Ash | Water-Reducing Admixture | Water | Short Fibers |

|---|---|---|---|---|---|---|

| 280 | 326 | 1525 | 31 | 4.5 | 338 | 2.0 |

| Age (d) | 3 | 7 | 14 | 28 | |

|---|---|---|---|---|---|

| Compressive strength Measured value (MPa) | 1 | 7.0 | 13.7 | 16.9 | 21.7 |

| 2 | 6.6 | 13.4 | 16.8 | 20.8 | |

| 3 | 6.5 | 12.8 | 15.9 | 20.5 | |

| Average value | 6.7 | 13.3 | 16.5 | 21.0 | |

| Relative deviation | −3.0%~4.5% | −3.8%~3.0% | −3.6%~2.4% | −2.4%~3.3% | |

| Test Group | Number of Specimens | Before Freeze–Thaw Cycle | Number of Cycles | After Freeze–Thaw Cycle | Average Mass Loss Rate (%) | Average Dynamic Elastic Modulus Loss Rate (%) | ||

|---|---|---|---|---|---|---|---|---|

| Quality Mean (kg) | Mean Value of Dynamic Elastic Modulus (GPa) | Quality Mean (kg) | Mean Value of Dynamic Elastic Modulus (GPa) | |||||

| Ⅰ | 3 | 8.20 | 16.65 | 25 | 7.56 | 11.83 | 7 | 30 |

| Ⅱ | 3 | 8.28 | 17.40 | 28 | 7.56 | 10.85 | 8 | 37 |

| Ⅲ | 3 | 8.14 | 17.33 | 29 | 7.35 | 10.72 | 9 | 38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Yang, J.; Wu, J.; Yang, L.; Zhao, Q.; Wang, P. Research and Application of Assembled SC Coal Gangue External Wallboard. Buildings 2025, 15, 3545. https://doi.org/10.3390/buildings15193545

Yan Y, Yang J, Wu J, Yang L, Zhao Q, Wang P. Research and Application of Assembled SC Coal Gangue External Wallboard. Buildings. 2025; 15(19):3545. https://doi.org/10.3390/buildings15193545

Chicago/Turabian StyleYan, Yajie, Jisen Yang, Jinhui Wu, Le Yang, Qiang Zhao, and Peipeng Wang. 2025. "Research and Application of Assembled SC Coal Gangue External Wallboard" Buildings 15, no. 19: 3545. https://doi.org/10.3390/buildings15193545

APA StyleYan, Y., Yang, J., Wu, J., Yang, L., Zhao, Q., & Wang, P. (2025). Research and Application of Assembled SC Coal Gangue External Wallboard. Buildings, 15(19), 3545. https://doi.org/10.3390/buildings15193545