Mechanical Properties and Microstructure of Lightweight Aggregate Concrete Incorporating Basalt Fiber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions

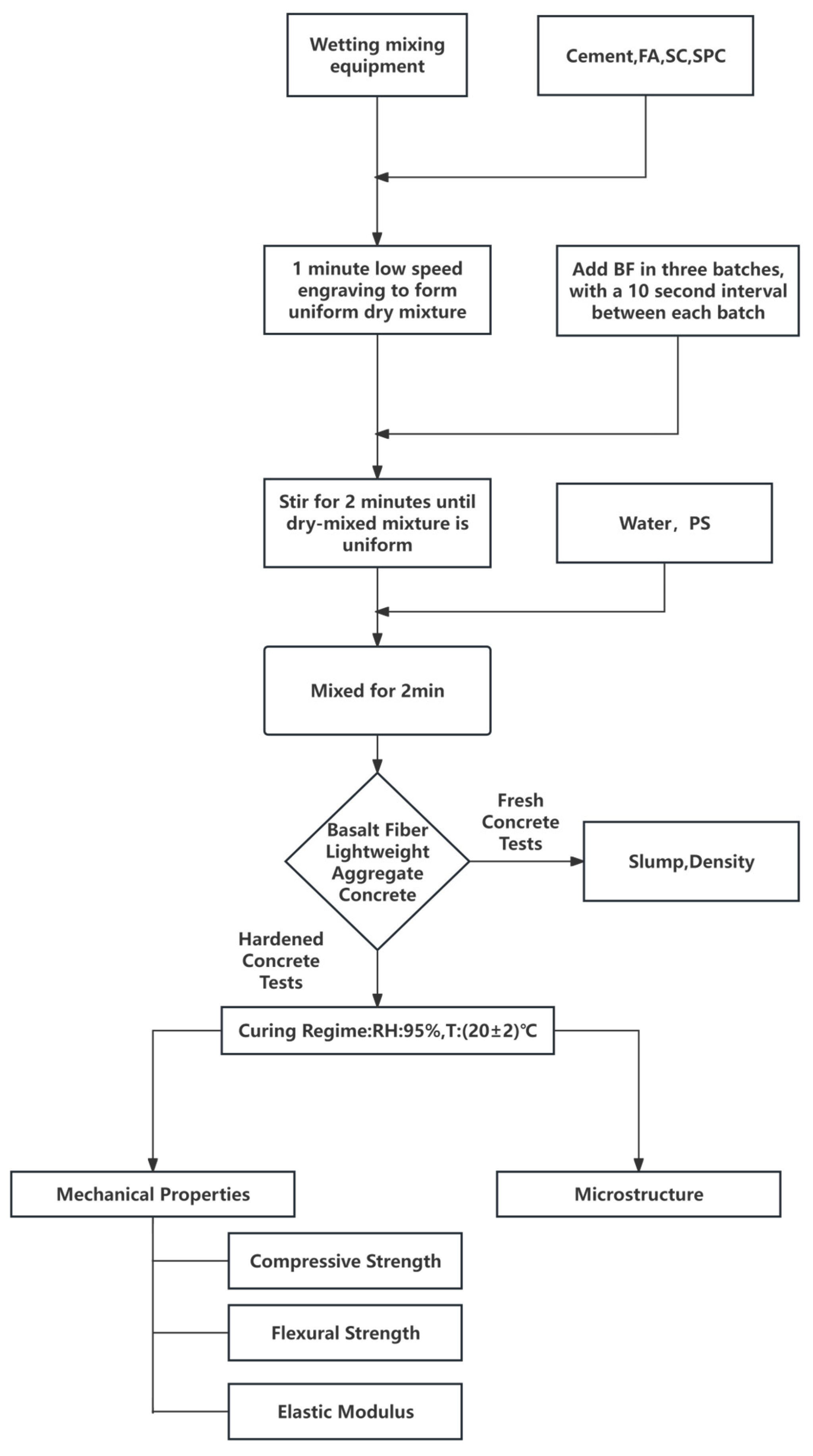

2.3. Preparation and Curing

3. Results and Discussion

3.1. Workability

3.2. Mechanical Property

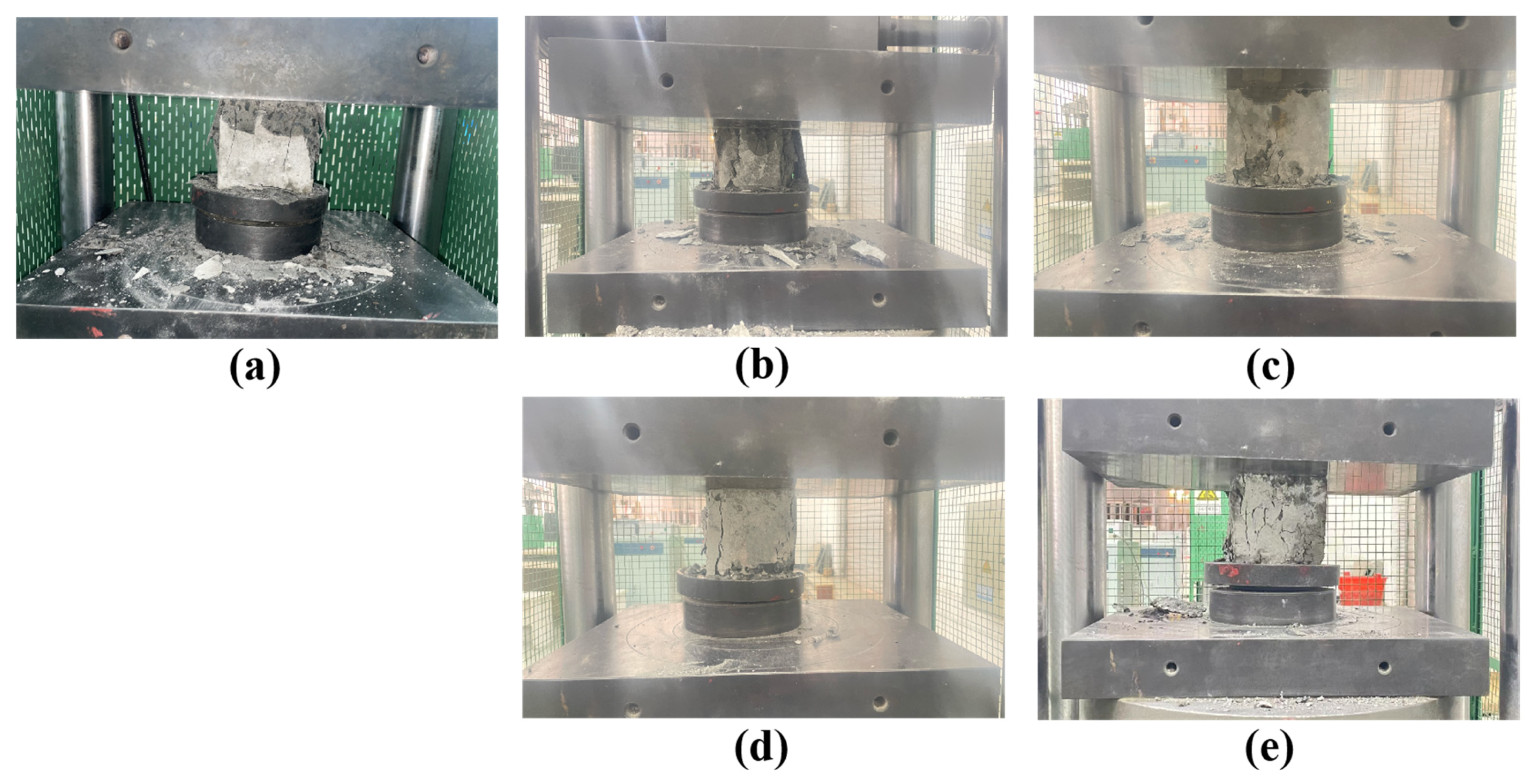

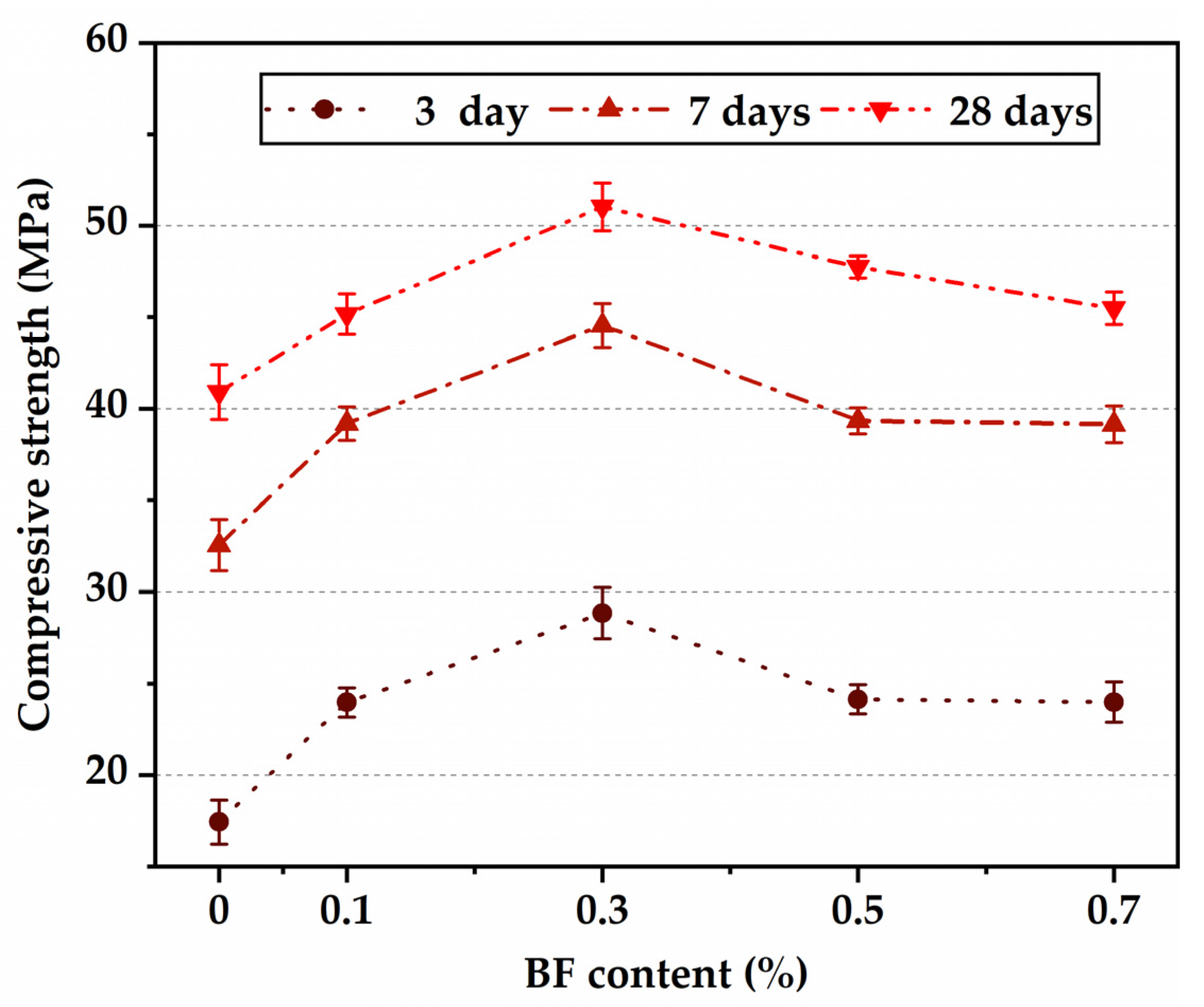

3.2.1. Compressive Strength

3.2.2. Flexural Strength

3.2.3. Elastic Modulus

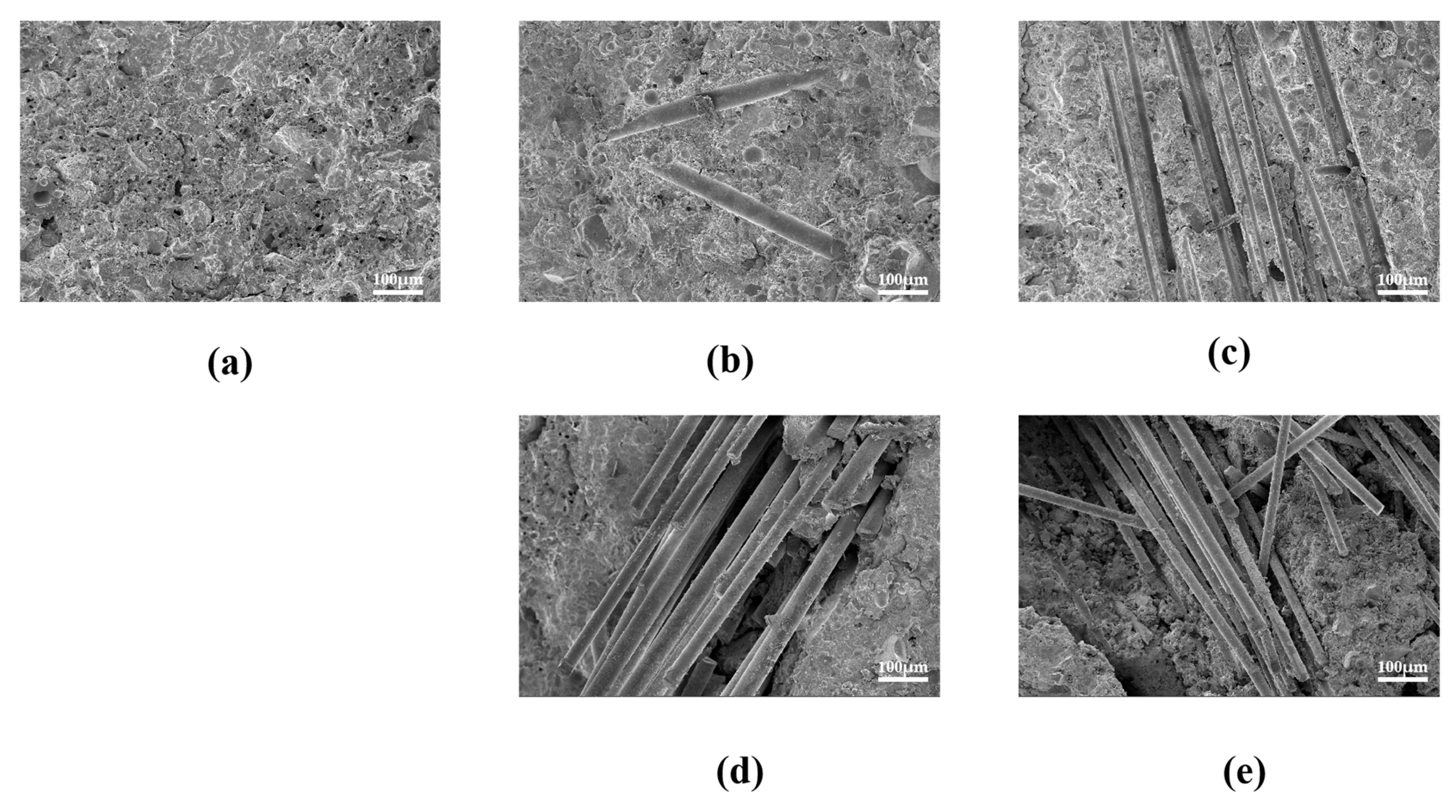

3.3. Microstructure

4. Conclusions

- The slump of the LWAC decreases with the increase in the BF due to interfacial adsorption between fibers and cement slurry. Simultaneously, the fibers within the mixture interweave with one another to establish a three-dimensional network configuration, thereby increasing the internal frictional resistance of the system and markedly diminishing the flowability of the composite mixture. The slump variation in all experimental groups ranges from 110 mm to 65 mm, meeting the requirements of JGJ 51-2002 for the workability of LWAC. The slump of 0.7% BF was 65 mm, 40.1% lower than that of BF-0. However, BF causes the slump of the LWAC to drop within a reasonable range that does not excessively affect the working performance of the LWAC mixture.

- Compared to compressive strength, the reinforcement effect of BF on the LWAC is more prominent in terms of bending and deformation resistance because the fiber forms a network structure in concrete to suppress crack propagation. After adding BF, the 28-day compressive strength, flexural strength, and elastic modulus of LWAC increased by 24.7%, 33.9%, and 38.57%, respectively. When the BF content was 0.3%, the specific strength and flexural ratio of LWAC were 30.53 kN·m/kg and 10.01%, respectively. The results also show that a basalt content of 0.3% is the best value for improving the mechanical properties of the LWAC.

- Microscopic tests show that BF penetrates through the pore structure, and its end is firmly bonded with the cement matrix. BF improves the concrete bond and fills the pores. This may help to further improve the mechanical properties of the LWAC. In subsequent research, it will be necessary to adopt microstructure characterization techniques and interfacial transition zone to further delve into the potential mechanisms for enhancing mechanical performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choi, S.-J.; Lee, J.-I.; Kim, C.-Y.; Yoon, J.-H.; Kim, K.-H. Effect of Amorphous Metallic Fibers on Thermal and Mechanical Properties of Lightweight Aggregate Cement Mortars Containing Carbon Nanotubes. Materials 2024, 17, 5449. [Google Scholar] [CrossRef]

- Song, Q.; Qin, Y.; Hou, C.; Gao, H.; Li, M. Study of the Mechanical Behavior of High-Strength Lightweight Concrete and Its Application to Bridge Pavements. Buildings 2024, 14, 2783. [Google Scholar] [CrossRef]

- Rodacka, M.; Domagała, L.; Szydłowski, R. Assessment of Properties of Structural Lightweight Concrete with Sintered Fly Ash Aggregate in Terms of Its Suitability for Use in Prestressed Members. Materials 2023, 16, 5429. [Google Scholar] [CrossRef]

- Real, S.; Gomes, M.G.; Moret Rodrigues, A.; Bogas, J.A. Contribution of Structural Lightweight Aggregate Concrete to the Reduction of Thermal Bridging Effect in Buildings. Constr. Build. Mater. 2016, 121, 460–470. [Google Scholar] [CrossRef]

- Wongkvanklom, A.; Posi, P.; Khotsopha, B.; Ketmala, C.; Pluemsud, N.; Lertnimoolchai, S.; Chindaprasirt, P. Structural Lightweight Concrete Containing Recycled Lightweight Concrete Aggregate. KSCE J. Civ. Eng. 2018, 22, 3077–3084. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. Study on Reinforced Lightweight Coconut Shell Concrete Beam Behavior under Flexure. Mater. Des. 2013, 46, 157–167. [Google Scholar] [CrossRef]

- Lo, T.Y.; Tang, W.C.; Cui, H.Z. The Effects of Aggregate Properties on Lightweight Concrete. Build. Environ. 2007, 42, 3025–3029. [Google Scholar] [CrossRef]

- Huts, A.; Konkol, J.; Marchuk, V. Granite Dust and Silica Fume as a Combined Filler of Reactive Powder Concrete. Materials 2024, 17, 6025. [Google Scholar] [CrossRef] [PubMed]

- Bogas, J.A.; Gomes, A.; Pereira, M.F.C. Self-Compacting Lightweight Concrete Produced with Expanded Clay Aggregate. Constr. Build. Mater. 2012, 35, 1013–1022. [Google Scholar] [CrossRef]

- Gu, F.; Li, C.; Wang, X.; Yang, Y.; Liu, H. Experimental Study on the Compressive Behavior of Fiber-Reinforced Ceramsite Concrete. Materials 2025, 18, 862. [Google Scholar] [CrossRef]

- He, J.; Ji, L.; Ma, H.; Ba, M.; Wang, L. Study on the Effect of Sintered Secondary Aluminum Ash Prepared Pottery Sand on the Mechanical Properties and Ecological Performance of High-Strength Cement-Based Materials. Case Stud. Constr. Mater. 2025, 22, e04700. [Google Scholar] [CrossRef]

- Qi, A.; Liu, X.; Wang, Z.; Chen, Z. Mechanical Properties of the Concrete Containing Ferronickel Slag and Blast Furnace Slag Powder. Constr. Build. Mater. 2020, 231, 117120. [Google Scholar] [CrossRef]

- Uysal, O.; Uslu, İ.; Aktaş, C.B.; Chang, B.; Yaman, İ.Ö. Physical and Mechanical Properties of Lightweight Expanded Clay Aggregate Concrete. Buildings 2024, 14, 1871. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Ahmed, S.; Lachemi, M. Lightweight Concrete Incorporating Pumice Based Blended Cement and Aggregate: Mechanical and Durability Characteristics. Constr. Build. Mater. 2011, 25, 1186–1195. [Google Scholar] [CrossRef]

- Al-sayed, S.; Wang, X.; Peng, Y. Simulation of Fracture Process of Lightweight Aggregate Concrete Based on Digital Image Processing Technology. Comput. Mater. Contin. 2024, 79, 4169–4195. [Google Scholar] [CrossRef]

- Cucuzza, R.; Aloisio, A.; Rad, M.M.; Domaneschi, M. Constructability-Based Design Approach for Steel Structures: From Truss Beams to Real-World Inspired Industrial Buildings. Autom. Constr. 2024, 166, 105630. [Google Scholar] [CrossRef]

- Khaleel Ibrahim, S.; Abbas Hadi, N.; Movahedi Rad, M. Experimental and Numerical Analysis of Steel-Polypropylene Hybrid Fibre Reinforced Concrete Deep Beams. Polymers 2023, 15, 2340. [Google Scholar] [CrossRef]

- Kawarai, T.; Komuro, M.; Kishi, N. Low-Velocity Impact-Load-Carrying Behavior of Reinforced Concrete Beams Strengthened in Flexure by Bonding a Carbon Fiber-Reinforced Polymer Sheet to the Tension-Side Surface. Buildings 2025, 15, 1713. [Google Scholar] [CrossRef]

- Hong, X.; Lee, J.C.; Ng, J.L.; Abdulkareem, M.; Yusof, Z.M.; Li, Q.; He, Q. Prediction Model and Mechanism for Drying Shrinkage of High-Strength Lightweight Concrete with Graphene Oxide. Nanomaterials 2023, 13, 1405. [Google Scholar] [CrossRef] [PubMed]

- Kytinou, V.K.; Metaxa, Z.S.; Zapris, A.G.; Kosheleva, R.I.; Prokopiou, V.D.; Alexopoulos, N.D. Exploitation of Extruded Polystyrene (XPS) Waste for Lightweight, Thermal Insulation and Rehabilitation Building Applications. Dev. Built Environ. 2024, 20, 100580. [Google Scholar] [CrossRef]

- Leão, L.S.; Spini, G.P.; De França, M.S.; Costa, E.B.C. Recycled Expanded Polystyrene (EPS) as an Eco-Friendly Alternative for Sand in Rendering Mortars. Constr. Build. Mater. 2024, 414, 135018. [Google Scholar] [CrossRef]

- Guler, S.; Yavuz, D.; Korkut, F.; Ashour, A. Strength Prediction Models for Steel, Synthetic, and Hybrid Fiber Reinforced Concretes. Struct. Concr. 2019, 20, 428–445. [Google Scholar] [CrossRef]

- Libre, N.A.; Shekarchi, M.; Mahoutian, M.; Soroushian, P. Mechanical Properties of Hybrid Fiber Reinforced Lightweight Aggregate Concrete Made with Natural Pumice. Constr. Build. Mater. 2011, 25, 2458–2464. [Google Scholar] [CrossRef]

- Zheng, R.; Pang, J.; Sun, J.; Su, Y.; Xu, G. Damage Model of Carbon-Fiber-Reinforced Concrete Based on Energy Conversion Principle. J. Compos. Sci. 2024, 8, 71. [Google Scholar] [CrossRef]

- Hong, X.; Lee, J.C.; Qian, B. Mechanical Properties and Microstructure of High-Strength Lightweight Concrete Incorporating Graphene Oxide. Nanomaterials 2022, 12, 833. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Wu, R. Using Graphene Oxide to Improve the Properties of Ultra-High-Performance Concrete with Fine Recycled Aggregate. Constr. Build. Mater. 2020, 259, 120657. [Google Scholar] [CrossRef]

- Duan, S.-J.; Feng, R.-M.; Yuan, X.-Y.; Song, L.-T.; Tong, G.-S.; Tong, J.-Z. A Review on Research Advances and Applications of Basalt Fiber-Reinforced Polymer in the Construction Industry. Buildings 2025, 15, 181. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A Short Review on Basalt Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- John, V.J.; Dharmar, B. Influence of Basalt Fibers on the Mechanical Behavior of Concrete—A Review. Struct. Concr. 2021, 22, 491–502. [Google Scholar] [CrossRef]

- Li, W.; Xu, J. Mechanical Properties of Basalt Fiber Reinforced Geopolymeric Concrete under Impact Loading. Mater. Sci. Eng. A 2009, 505, 178–186. [Google Scholar] [CrossRef]

- Jiang, H.; Luo, L.; Hou, Y.; Yang, Y. Mechanical and Microstructural Performance of UHPC with Recycled Aggregates Modified by Basalt Fiber and Nanoalumina at High Temperatures. Materials 2025, 18, 1072. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Xie, A.; Qi, Y. Experimental Study on Dynamic Mechanical Properties and Constitutive Model of Basalt Fiber Reinforced Concrete. Constr. Build. Mater. 2017, 152, 154–167. [Google Scholar] [CrossRef]

- Yin, Y.; Li, Q.; Zhang, Y.; Jiao, X.; Feng, P.; Zhang, H. Study on the Properties of Basalt Fiber-Calcined Gangue-Silty Clay Foam Concrete for Filling Undermined Goaf Areas of Highways. Materials 2025, 18, 47. [Google Scholar] [CrossRef] [PubMed]

- Abu Taqa, A.; Ebead, U.A.; Mohsen, M.O.; Aburumman, M.O.; Senouci, A.; Maherzi, W.; Qtiashat, D. Experimental Assessment of the Strength and Microstructural Properties of Fly Ash-Containing Basalt Fiber-Reinforced Self-Compacting Sustainable Concrete. J. Compos. Sci. 2025, 9, 79. [Google Scholar] [CrossRef]

- Topçuoğlu, Y.A.; Duranay, Z.B.; Gürocak, Z.; Güldemir, H. Determination of Basalt Fiber Reinforcement in Kaolin Clay: Experimental and Neural Network-Based Analysis of Liquid Limit, Plastic Limit, and Unconfined Compressive Strength. Processes 2025, 13, 377. [Google Scholar] [CrossRef]

- He, Z.; Zhao, X.; Ye, M.; Zuo, W.; Nie, X.; Zhao, J. Study on the Effect of Basalt Fiber Content and Length on Mechanical Properties and Durability of Coal Gangue Concrete. Sustainability 2024, 16, 9310. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Hanandeh, S.; Kamchoom, V.; Awoyera, P.; Avudaiappan, S. Modeling the Compressive Strength Behavior of Concrete Reinforced with Basalt Fiber. Sci. Rep. 2025, 15, 11493. [Google Scholar] [CrossRef]

- Li, J.-J.; Zhao, Z.-M. Study on Mechanical Properties of Basalt Fiber Reinforced Concrete. In Proceedings of the 2016 5th International Conference on Environment, Materials, Chemistry and Power Electronics, Zhengzhou, China, 11–12 April 2016; Atlantis Press: Xi’an, China, 2016. [Google Scholar]

- Zeng, Y.; Tang, A. Comparison of Effects of Basalt and Polyacrylonitrile Fibers on Toughness Behaviors of Lightweight Aggregate Concrete. Constr. Build. Mater. 2021, 282, 122572. [Google Scholar] [CrossRef]

- Divyah, N.; Thenmozhi, R.; Neelamegam, M.; Prakash, R. Characterization and Behavior of Basalt Fiber-reinforced Lightweight Concrete. Struct. Concr. 2021, 22, 422–430. [Google Scholar] [CrossRef]

- Xiao, L.; Li, G. Basalt Fiber for Volcanic Slag Lightweight Aggregate Concrete Research on the Impact of Performance. IOP Conf. Ser. Earth Environ. Sci. 2018, 128, 012154. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhou, X.; Tang, A.; Sun, P. Mechanical Properties of Chopped Basalt Fiber-Reinforced Lightweight Aggregate Concrete and Chopped Polyacrylonitrile Fiber Reinforced Lightweight Aggregate Concrete. Materials 2020, 13, 1715. [Google Scholar] [CrossRef]

- Wei, J.; Yang, Q.; Jiang, Q.; Li, X.; Liu, S.; Li, K.; Wang, Q. Mechanical Properties of Basalt Fiber Reinforced Ambient-Cured Lightweight Expanded Polystyrene Geopolymer Concrete. J. Build. Eng. 2023, 80, 108072. [Google Scholar] [CrossRef]

- Sun, Y.; Jia, H.; Wang, J.; Ding, Y.; Guan, Y.; Lei, D.; Li, Y. Calculation Model for the Degree of Hydration and Strength Prediction in Basalt Fiber-Reinforced Lightweight Aggregate Concrete. Buildings 2025, 15, 2699. [Google Scholar] [CrossRef]

- Zhu, Y.; He, Y.; Yuan, X.; Gao, J.; Wang, Z. Experimental Study on the Mechanical Properties of Basalt Fiber Geogrids Reinforced with Cement-Stabilized Macadam. Coatings 2024, 14, 1349. [Google Scholar] [CrossRef]

- Chen, J.; Mu, J.; Chen, A.; Long, Y.; Zhang, Y.; Zou, J. Experimental Study on the Properties of Basalt Fiber–Cement-Stabilized Expansive Soil. Sustainability 2024, 16, 7579. [Google Scholar] [CrossRef]

- Zhang, P.; Sha, D.; Li, Q.; Zhao, S.; Ling, Y. Effect of Nano Silica Particles on Impact Resistance and Durability of Concrete Containing Coal Fly Ash. Nanomaterials 2021, 11, 1296. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Liu, J. Contribution of Hybrid Fibers on the Properties of the High-Strength Lightweight Concrete Having Good Workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Dias, D.P.; Thaumaturgo, C. Fracture Toughness of Geopolymeric Concretes Reinforced with Basalt Fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Kabay, N. Abrasion Resistance and Fracture Energy of Concretes with Basalt Fiber. Constr. Build. Mater. 2014, 50, 95–101. [Google Scholar] [CrossRef]

- Kołodziejczyk, E.; Waśniewski, T. Flexural Behaviour and Internal Forces Redistribution in LWAC Double-Span Beams. Materials 2021, 14, 5614. [Google Scholar] [CrossRef] [PubMed]

- Yankelevsky, D.Z. The Uniaxial Compressive Strength of Concrete: Revisited. Mater. Struct. 2024, 57, 144. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Dai, X.; Wang, X.; Zheng, P. Microcrack Propagation of Basalt Fiber Reinforced Pavement Concrete Under Wheel Load and Freeze-Thaw Cycles Coupling. J. Test. Eval. 2025, 53, 658–673. [Google Scholar] [CrossRef]

- Liu, S.; Yang, J.; Fan, Q.; He, L.; Qin, S.; He, M. Surface Modification of Basalt Fibers with Improved Reactivity, Thermal Stability, and Tensile Strength. Fibers Polym. 2024, 25, 3403–3413. [Google Scholar] [CrossRef]

- Bao, S.; Wang, S.; Xia, H.; Liu, K.; Tang, X.; Jin, P. Enhancing the Mechanical Properties of Recycled Aggregate Concrete: A Comparative Study of Basalt- and Glass-Fiber Reinforcements. Buildings 2025, 15, 1718. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical Properties and Fracture Behavior of Basalt and Glass Fiber Reinforced Concrete: An Experimental Study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Huang, Y.; Huang, W.; Huang, Q.; Tuo, W.; Feng, Q. Study on the Axial Compressive Behavior and Constitutive Relationship of Lightweight Mixed Ceramic Concrete. Materials 2025, 18, 390. [Google Scholar] [CrossRef]

- Shafigh, P.; Chai, L.J.; Mahmud, H.B.; Nomeli, M.A. A Comparison Study of the Fresh and Hardened Properties of Normal Weight and Lightweight Aggregate Concretes. J. Build. Eng. 2018, 15, 252–260. [Google Scholar] [CrossRef]

- Hong, X.; Lee, J.C.; Ng, J.L.; Md Yusof, Z.; He, Q.; Li, Q. Effect of Graphene Oxide on the Mechanical Properties and Durability of High-Strength Lightweight Concrete Containing Shale Ceramsite. Materials 2023, 16, 2756. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of Basalt Fiber as a Strengthening Material for Concrete Structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Zhang, W. Mechanical, Chloride Resistance, and Microstructural Properties of Basalt Fiber-Reinforced Fly Ash–Silica Fume Composite Concrete. Minerals 2025, 15, 348. [Google Scholar] [CrossRef]

- Ahmed, M.; Mallick, J.; Abul Hasan, M. A Study of Factors Affecting the Flexural Tensile Strength of Concrete. J. King Saud Univ.—Eng. Sci. 2016, 28, 147–156. [Google Scholar] [CrossRef]

- Chiadighikaobi, P.C. Effects of Basalt Fiber in Lightweight Expanded Clay Concrete on Compressive Strength and Flexural Strength of Lightweight Basalt Fiber Reinforced Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012055. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, Y.; Wang, H.; Lin, S. Mechanical Properties Test and Strength Prediction on Basalt Fiber Reinforced Recycled Concrete. Adv. Civ. Eng. 2021, 2021, 6673416. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental Study on Basic Mechanical Properties of Basalt Fiber Reinforced Concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef]

- Qin, S.; Wu, L. Study on Mechanical Properties and Mechanism of New Basalt Fiber Reinforced Concrete. Case Stud. Constr. Mater. 2025, 22, e04290. [Google Scholar] [CrossRef]

- Xu, F.; Pan, H. Research on Quantitative Characterization Model of Compressive Strength or Elastic Modulus of Recycled Concrete Based on Pore Grading. Materials 2024, 18, 3. [Google Scholar] [CrossRef]

- Wu, H.; Qin, X.; Huang, X.; Kaewunruen, S. Engineering, Mechanical and Dynamic Properties of Basalt Fiber Reinforced Concrete. Materials 2023, 16, 623. [Google Scholar] [CrossRef]

- Taqa, A.A.; Mohsen, M.O.; Aburumman, M.O.; Naji, K.; Taha, R.; Senouci, A. Nano-Fly Ash and Clay for 3D-Printing Concrete Buildings: A Fundamental Study of Rheological, Mechanical and Microstructural Properties. J. Build. Eng. 2024, 92, 109718. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Aburumman, M.O.; Al Diseet, M.M.; Taha, R.; Abdel-Jaber, M.; Senouci, A.; Abu Taqa, A. Fly Ash and Natural Pozzolana Impacts on Sustainable Concrete Permeability and Mechanical Properties. Buildings 2023, 13, 1927. [Google Scholar] [CrossRef]

| No. | Aggregates for LWAC | Length of BF (mm) | Range of BF (%) | Optimal Value of BF (%) | Ref. |

|---|---|---|---|---|---|

| (1) | Industrial waste circular ceramsite | 6 | 0.5–1.5 | 1 | [39] |

| (2) | Sintered fly ash | 18 | 0–0.25 | 0.25 | [40] |

| (3) | Volcano slag | 15–17 | 0–0.4 | 0.1 | [41] |

| (4) | Lytag | 6 | 0.5–1.5 | 1.5 | [42] |

| (5) | Expanded polystyrene | 6 | 0.2–0.8 | 0.5 | [43] |

| (6) | Silica fume | 18 | 0.1–0.3 | 0.3 | [44] |

| Physical Properties | SPS | SC |

|---|---|---|

| Water absorption (24 h) (%) | 1.36 | 4.6 |

| Water absorption (3 h) (%) | 1.23 | 2.9 |

| Bulk density (kg/m3) | 974 | 835 |

| Apparent density (kg/m3) | 1638 | 1425 |

| Physical Properties | Density (kg/m3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) | Maximum Operating Temperature (℃) | Length (mm) |

|---|---|---|---|---|---|---|

| Parameter | 2940 | 3000–4800 | 91–110 | 1.5–3.2 | 650 | 6 |

| No. | Cement | BF 1 | FA 2 | SC 3 | SPS 4 | Water | PS 5 |

|---|---|---|---|---|---|---|---|

| BF-0 | 368 | 0 | 92 | 667 | 568 | 174.8 | 5.52 |

| BF-1 | 368 | 0.46 | 92 | 667 | 568 | 174.8 | 5.52 |

| BF-3 | 368 | 1.38 | 92 | 667 | 568 | 174.8 | 5.52 |

| BF-5 | 368 | 2.30 | 92 | 667 | 568 | 174.8 | 5.52 |

| BF-7 | 368 | 3.22 | 92 | 667 | 568 | 174.8 | 5.52 |

| Mix No. | BF-0 | BF-1 | BF-3 | BF-5 | BF-7 |

|---|---|---|---|---|---|

| Density (kg/m3) | 1438.4 | 1573.7 | 1668.8 | 1700.7 | 1753.6 |

| 3-day compressive strength (MPa) | 17.43 | 23.96 | 28.83 | 24.13 | 23.98 |

| 7-day compressive strength (MPa) | 32.56 | 39.19 | 44.55 | 39.34 | 39.15 |

| 28-day compressive strength (MPa) | 40.91 | 45.17 | 51.03 | 47.75 | 45.49 |

| Compressive strength growth rate (%) | - | 10.4 | 24.7 | 16.7 | 11.2 |

| C/D 1 (KN·m/kg) | 28.44 | 28.70 | 30.53 | 28.08 | 25.94 |

| Mix No. | BF-0 | BF-1 | BF-3 | BF-5 | BF-7 |

|---|---|---|---|---|---|

| Flexural strength (MPa) | 3.84 | 4.43 | 5.14 | 4.76 | 4.36 |

| Compressive strength (MPa) | 40.91 | 45.17 | 51.03 | 47.75 | 45.49 |

| Flexural strength growth rate (%) | - | 15.4 | 33.9 | 23.9 | 13.5 |

| F/C 1 (%) | 9.38 | 9.81 | 10.01 | 9.97 | 9.58 |

| Mix No. | BF-0 | BF-1 | BF-3 | BF-5 | BF-7 |

|---|---|---|---|---|---|

| 28-day elastic modulus (GPa) | 17.63 | 20.61 | 24.43 | 22.27 | 19.80 |

| Elastic modulus growth rate (%) | - | 16.90 | 38.57 | 26.32 | 12.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, X.; Song, Y.; Lee, J.C. Mechanical Properties and Microstructure of Lightweight Aggregate Concrete Incorporating Basalt Fiber. Buildings 2025, 15, 3548. https://doi.org/10.3390/buildings15193548

Hong X, Song Y, Lee JC. Mechanical Properties and Microstructure of Lightweight Aggregate Concrete Incorporating Basalt Fiber. Buildings. 2025; 15(19):3548. https://doi.org/10.3390/buildings15193548

Chicago/Turabian StyleHong, Xiaojiang, Yanqing Song, and Jin Chai Lee. 2025. "Mechanical Properties and Microstructure of Lightweight Aggregate Concrete Incorporating Basalt Fiber" Buildings 15, no. 19: 3548. https://doi.org/10.3390/buildings15193548

APA StyleHong, X., Song, Y., & Lee, J. C. (2025). Mechanical Properties and Microstructure of Lightweight Aggregate Concrete Incorporating Basalt Fiber. Buildings, 15(19), 3548. https://doi.org/10.3390/buildings15193548