A Comparative Experimental Study on Seismic Retrofitting Techniques for RC Frames: RC Jacketing, Steel Jacketing, and Base Isolation

Abstract

1. Introduction

2. Experimental Program

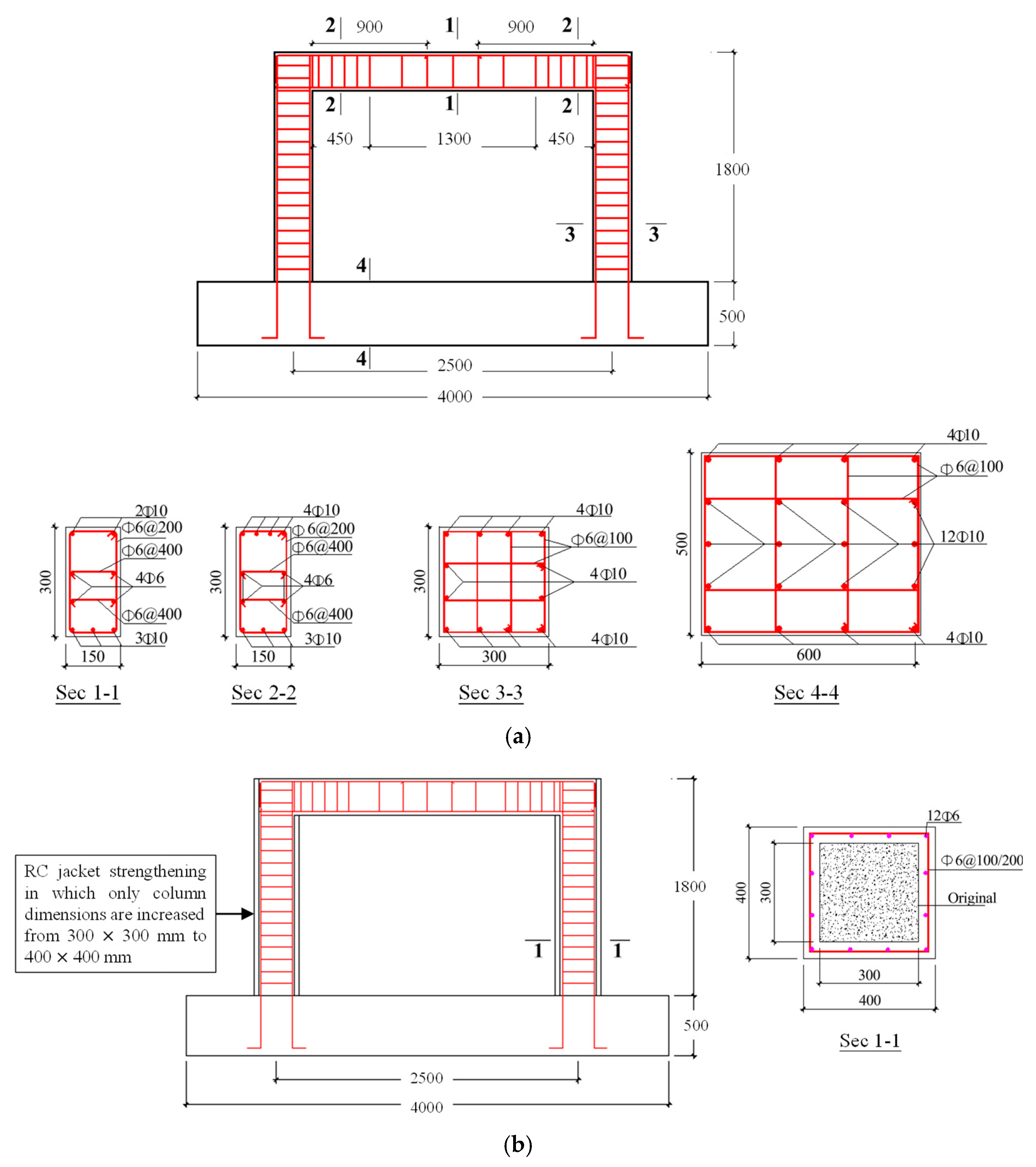

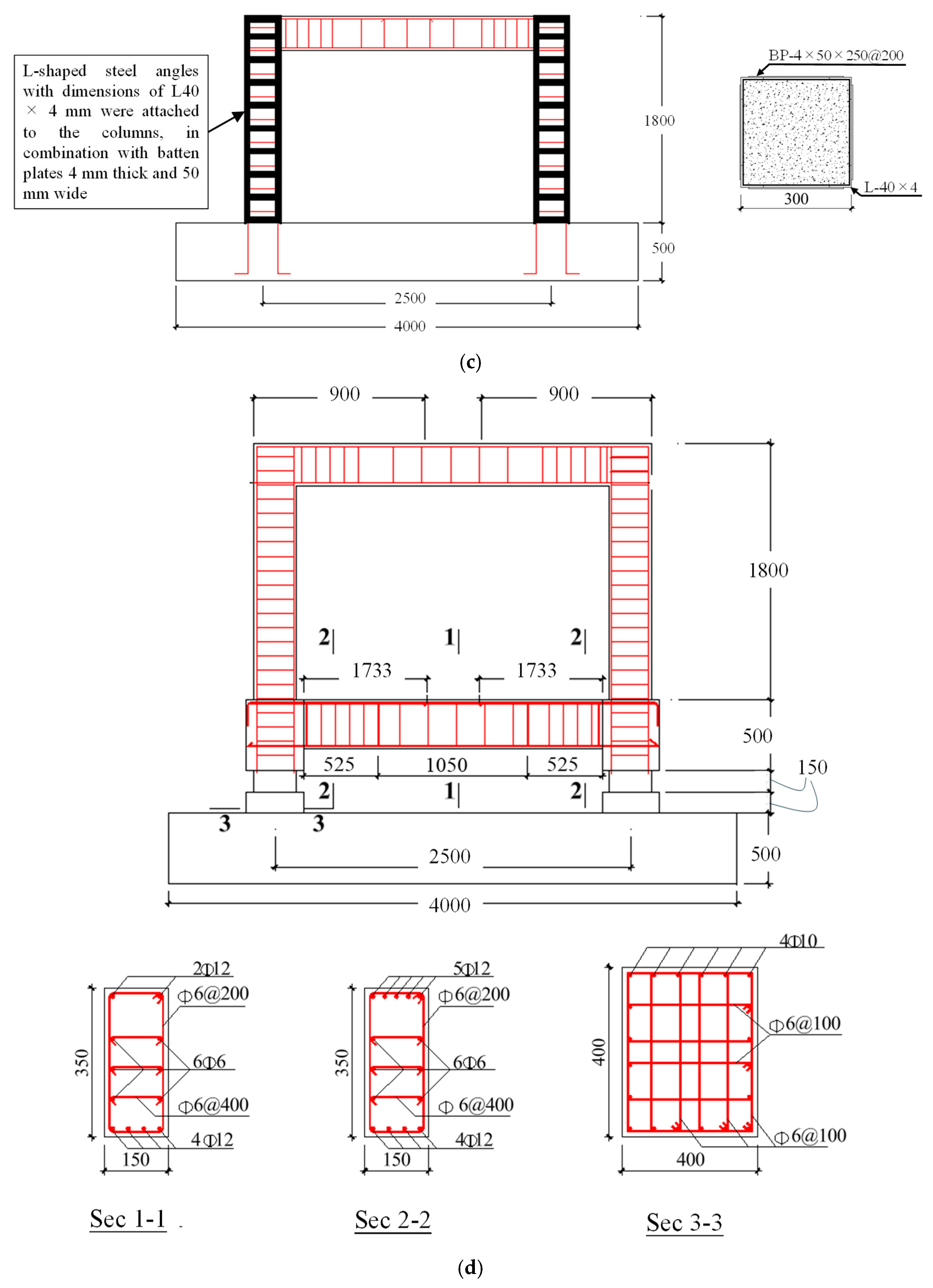

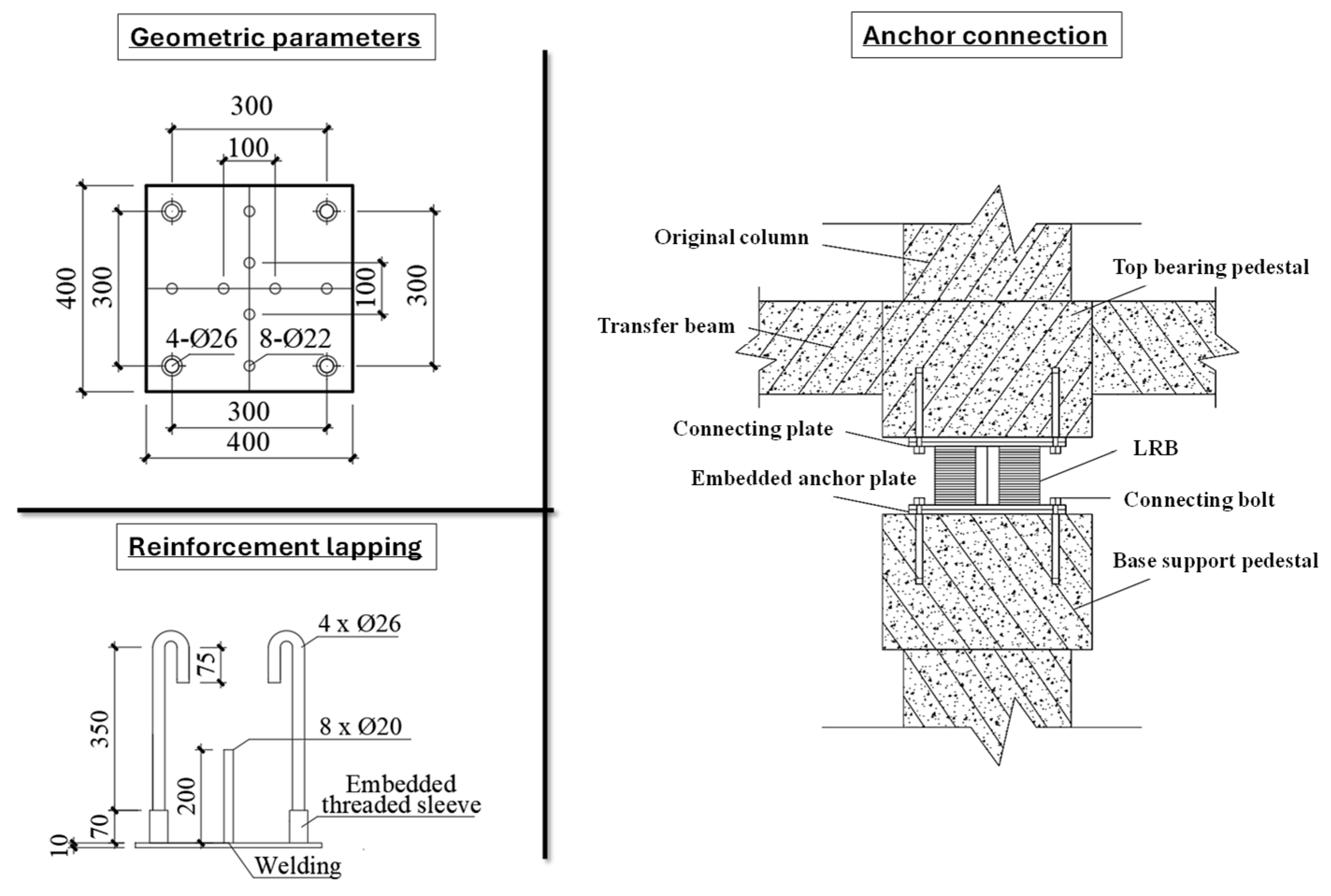

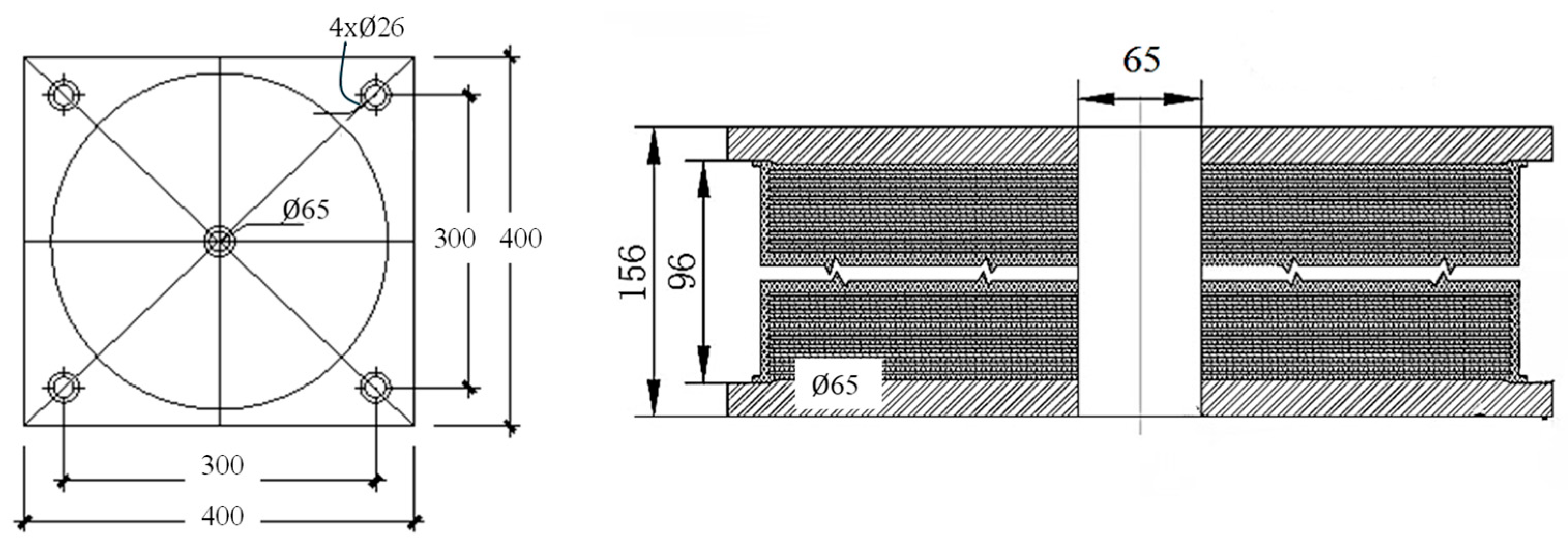

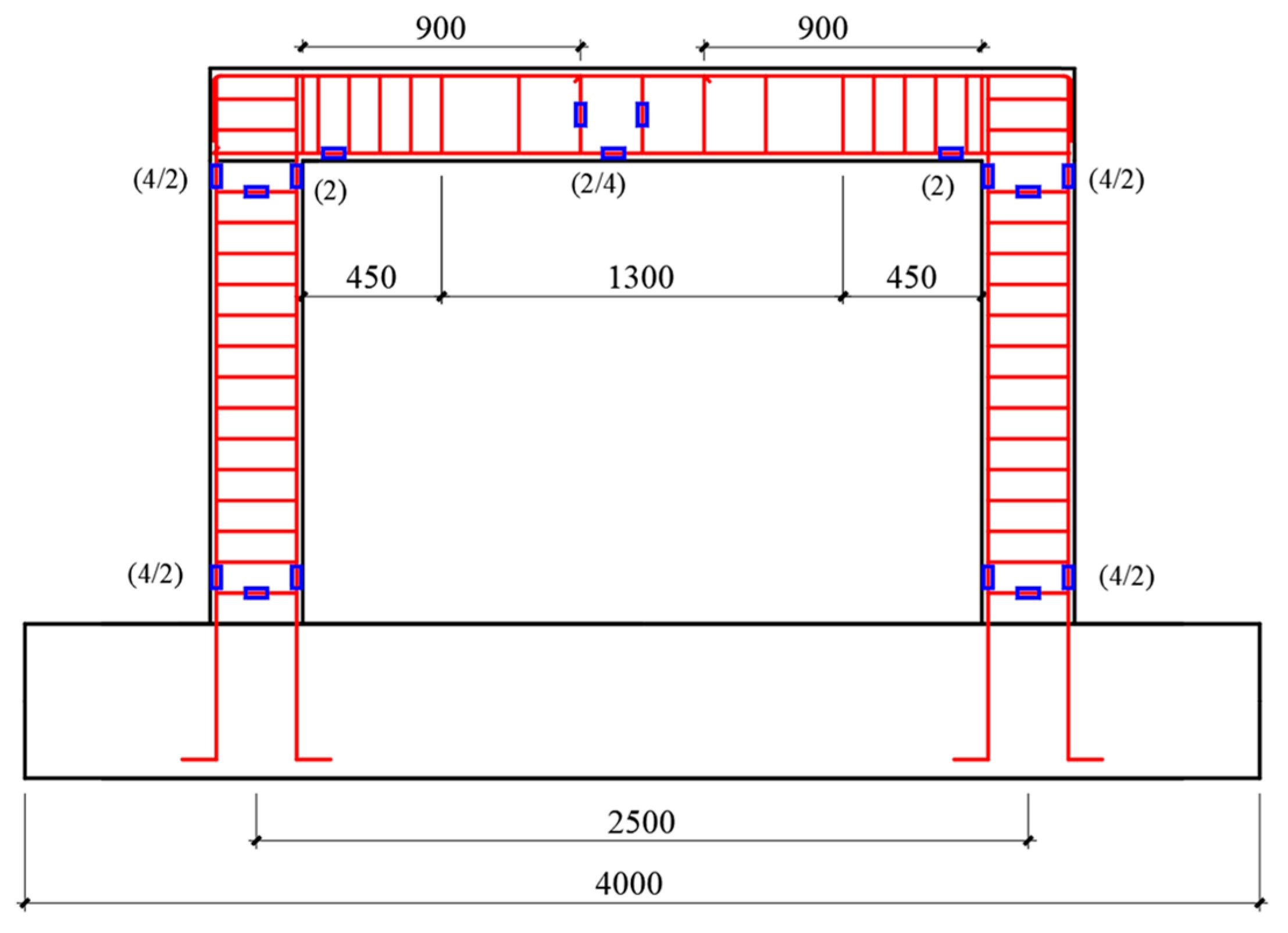

2.1. Specimen Details

2.2. Material Properties

2.3. LRB Performance Parameters

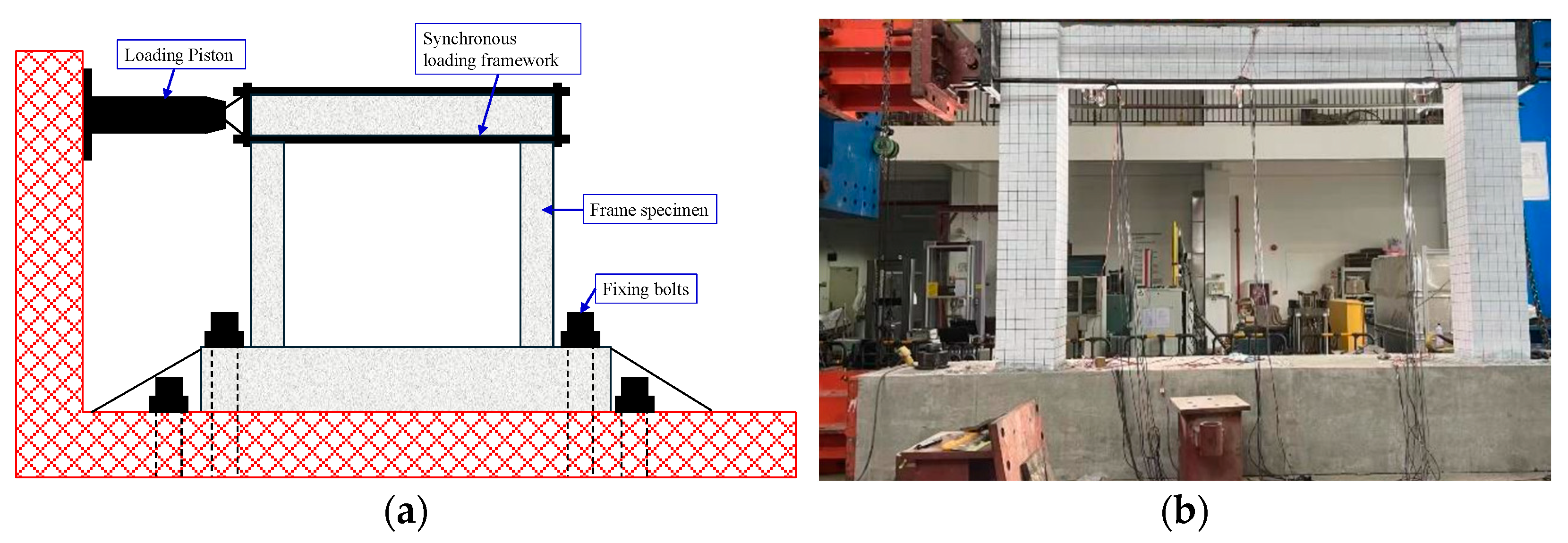

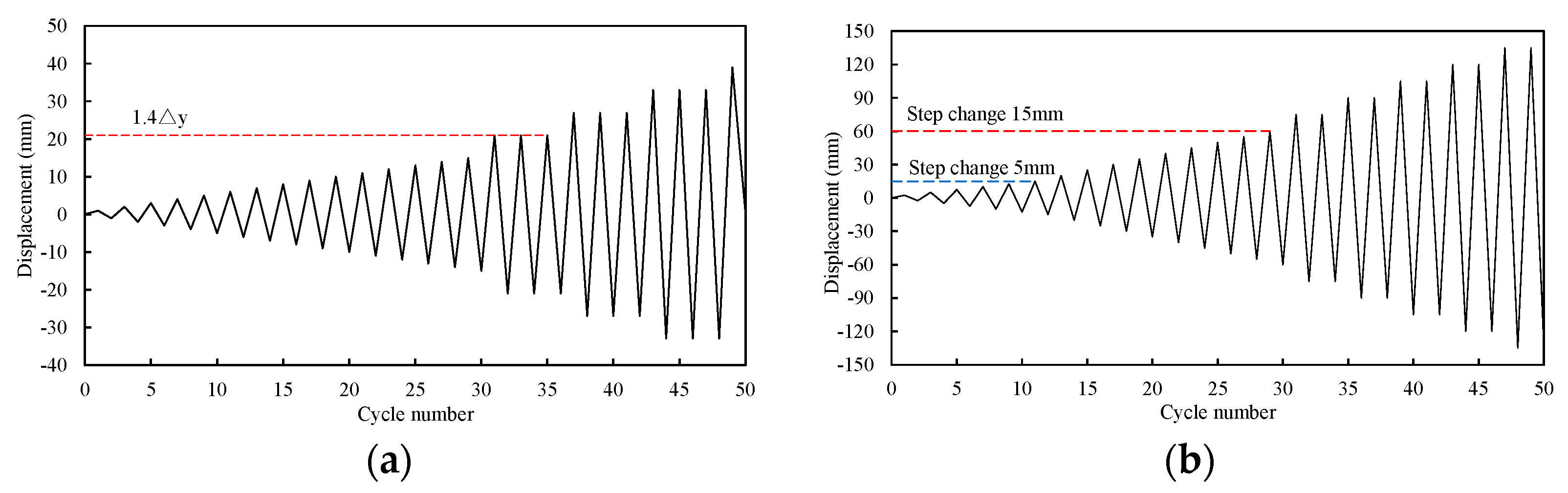

2.4. Loading Protocol

2.5. Strain Gauge Arrangement and Loading Measurement

3. Experimental Results and Discussion

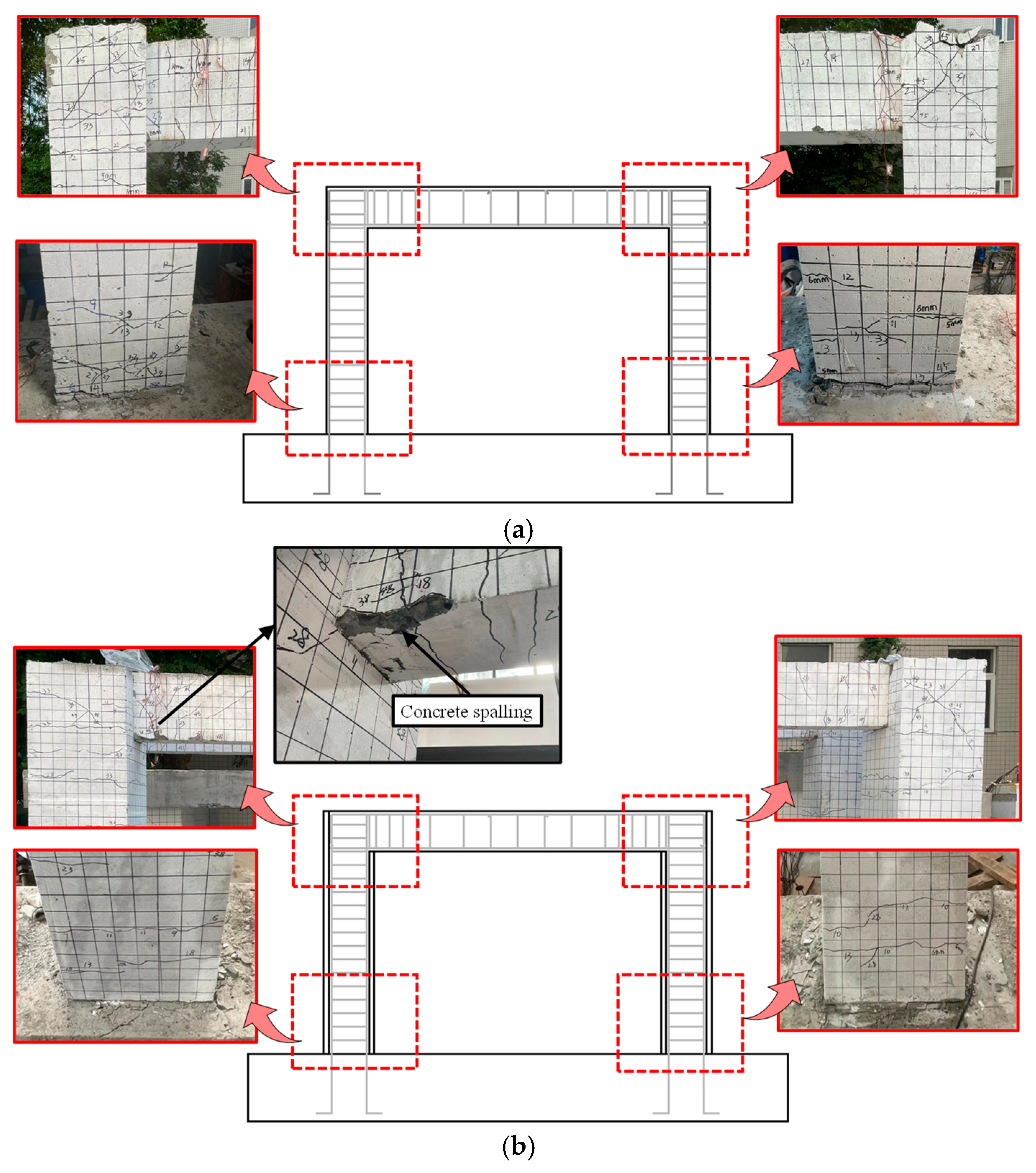

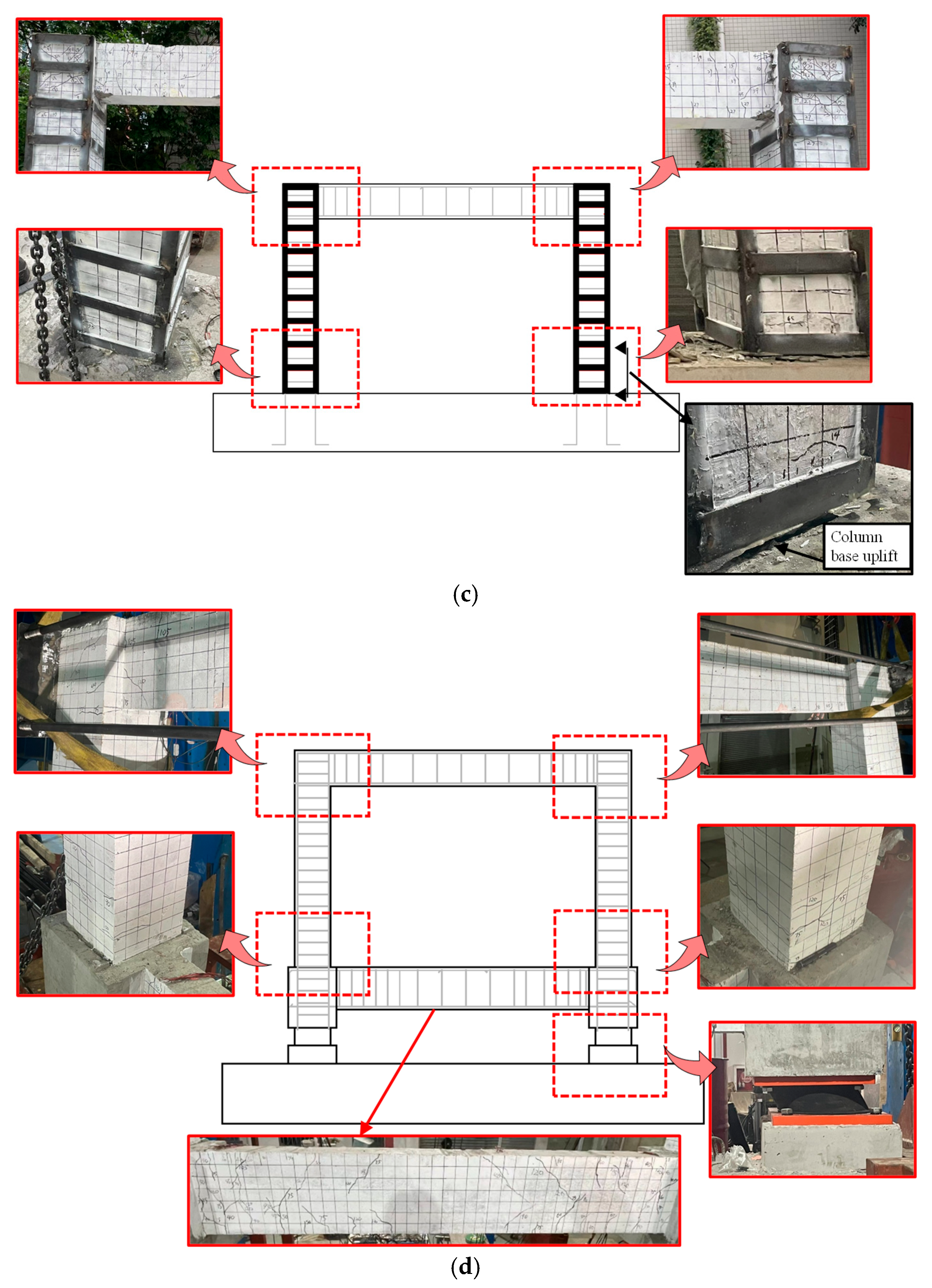

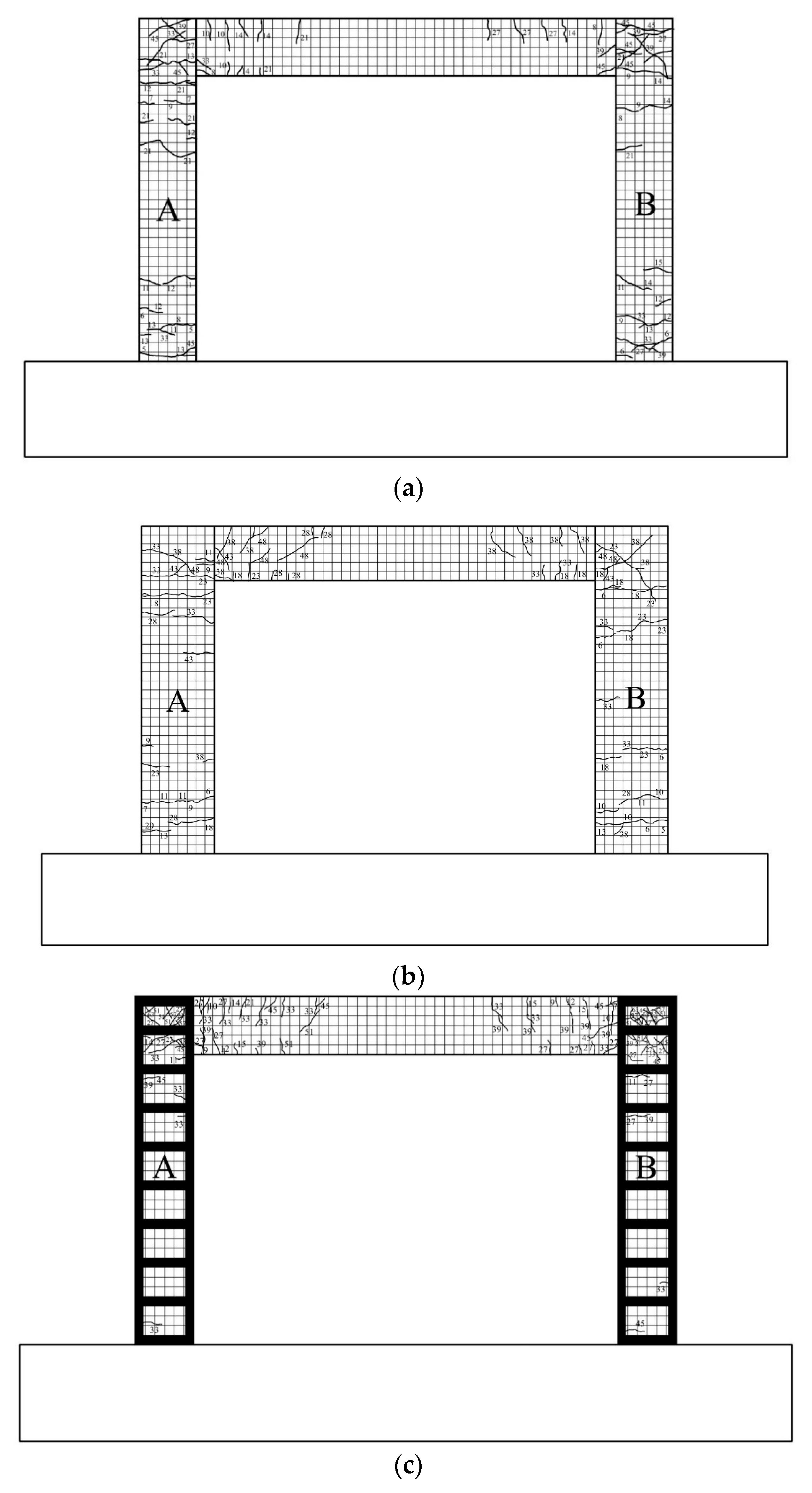

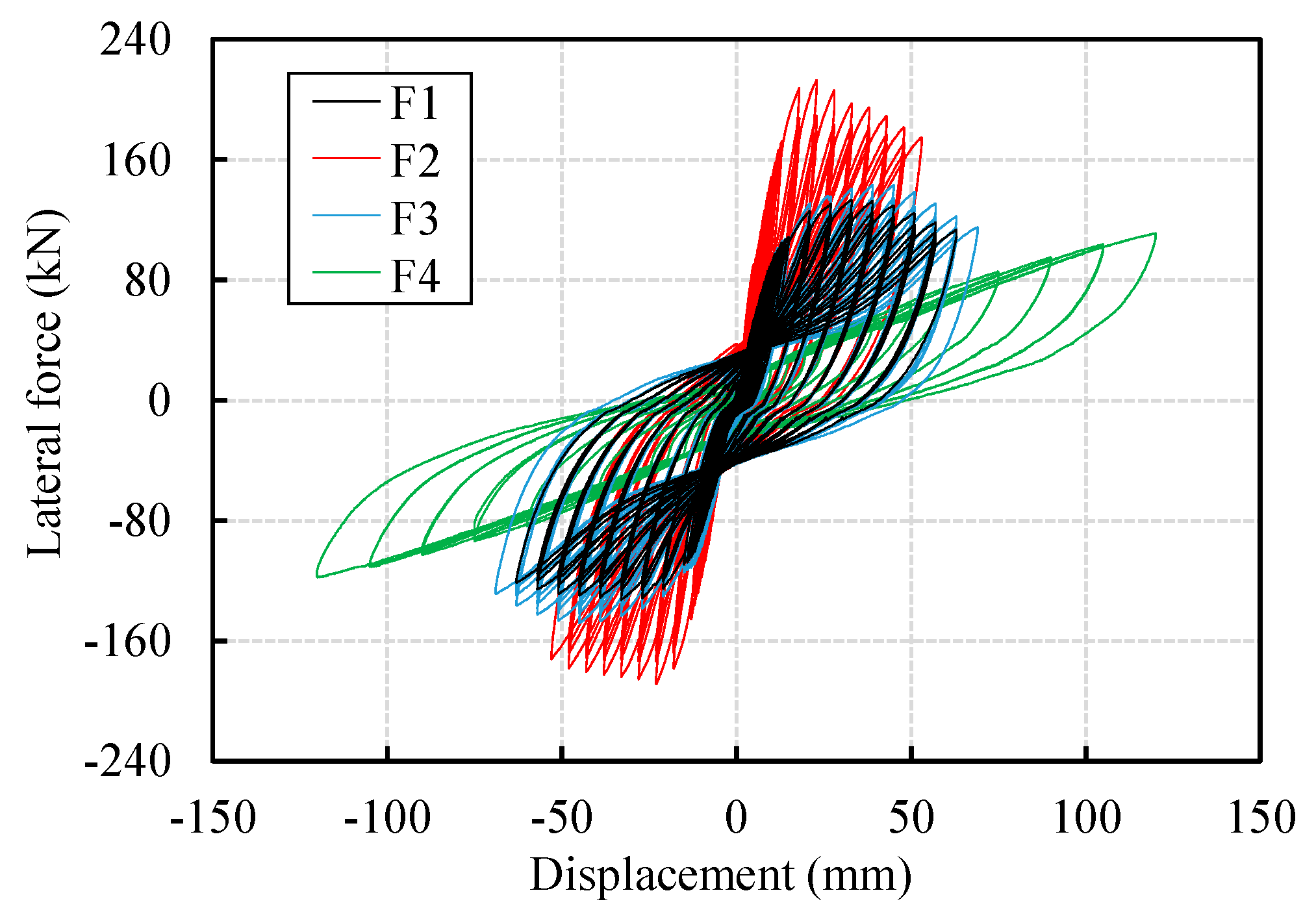

3.1. Cracking and Failure Patterns

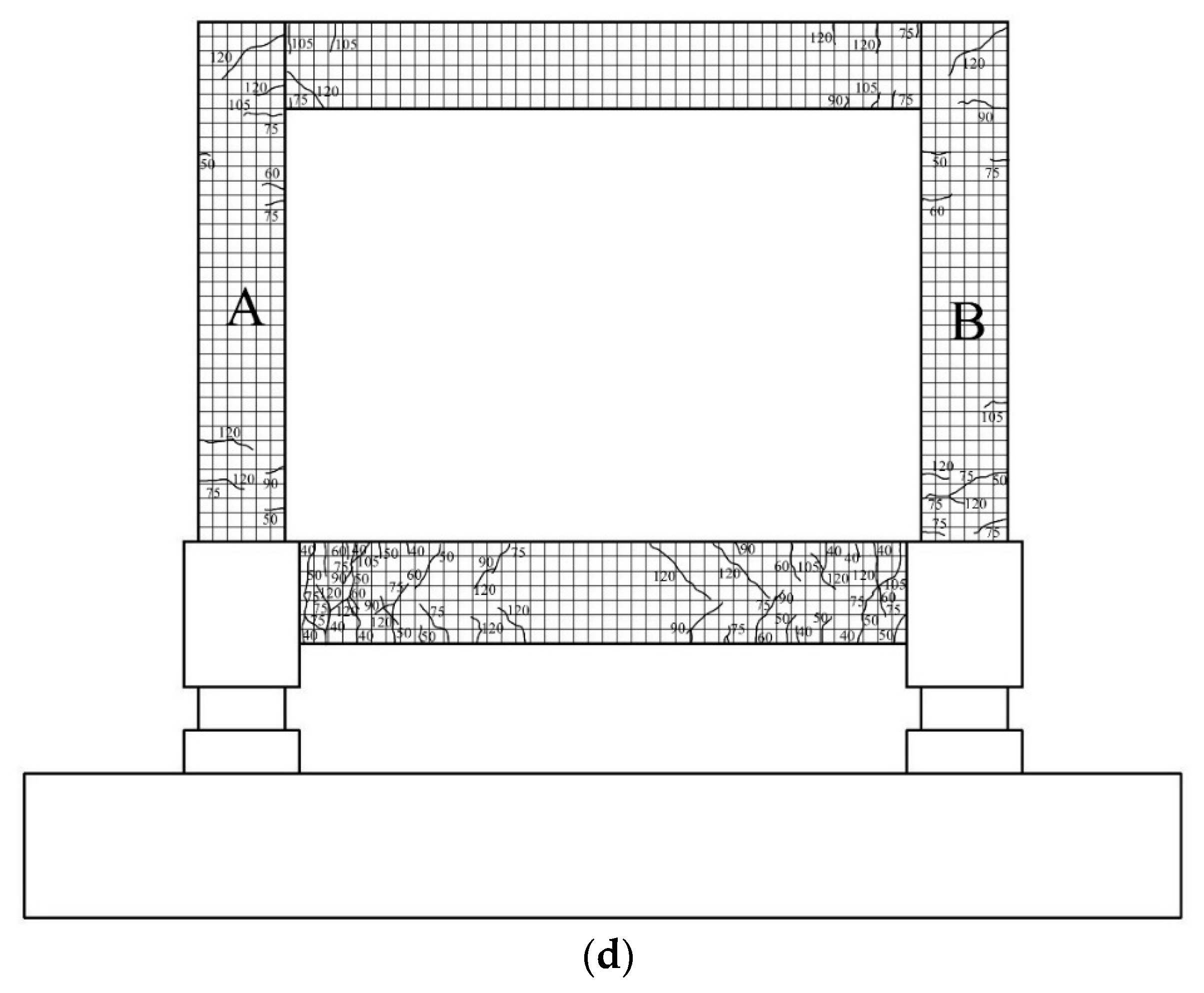

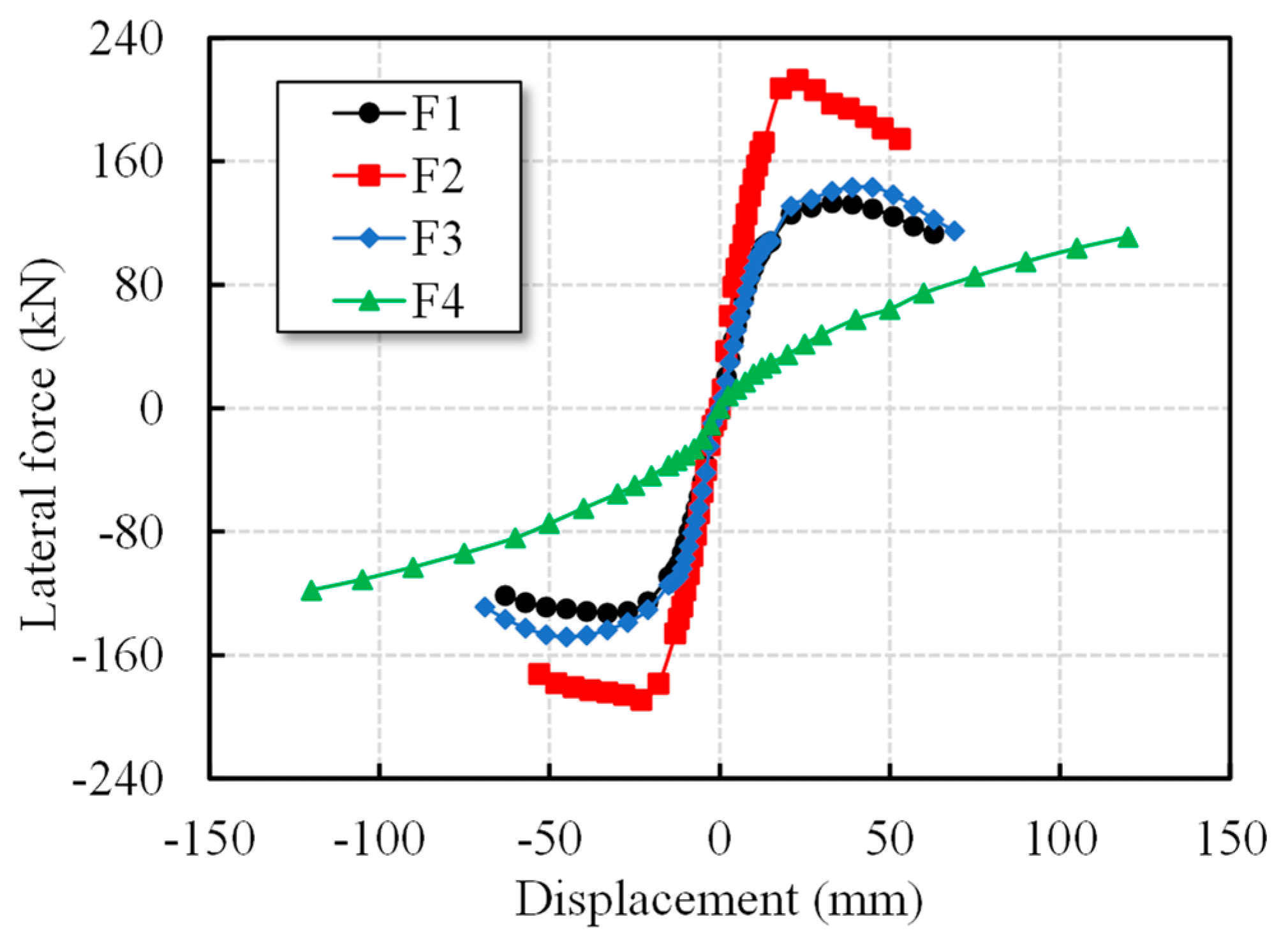

3.2. Load–Displacement Hysteretic Results

3.3. Skeleton Curve and Ductility Coefficient

3.4. Stiffness Degradation

3.5. Energy Dissipation Capacity

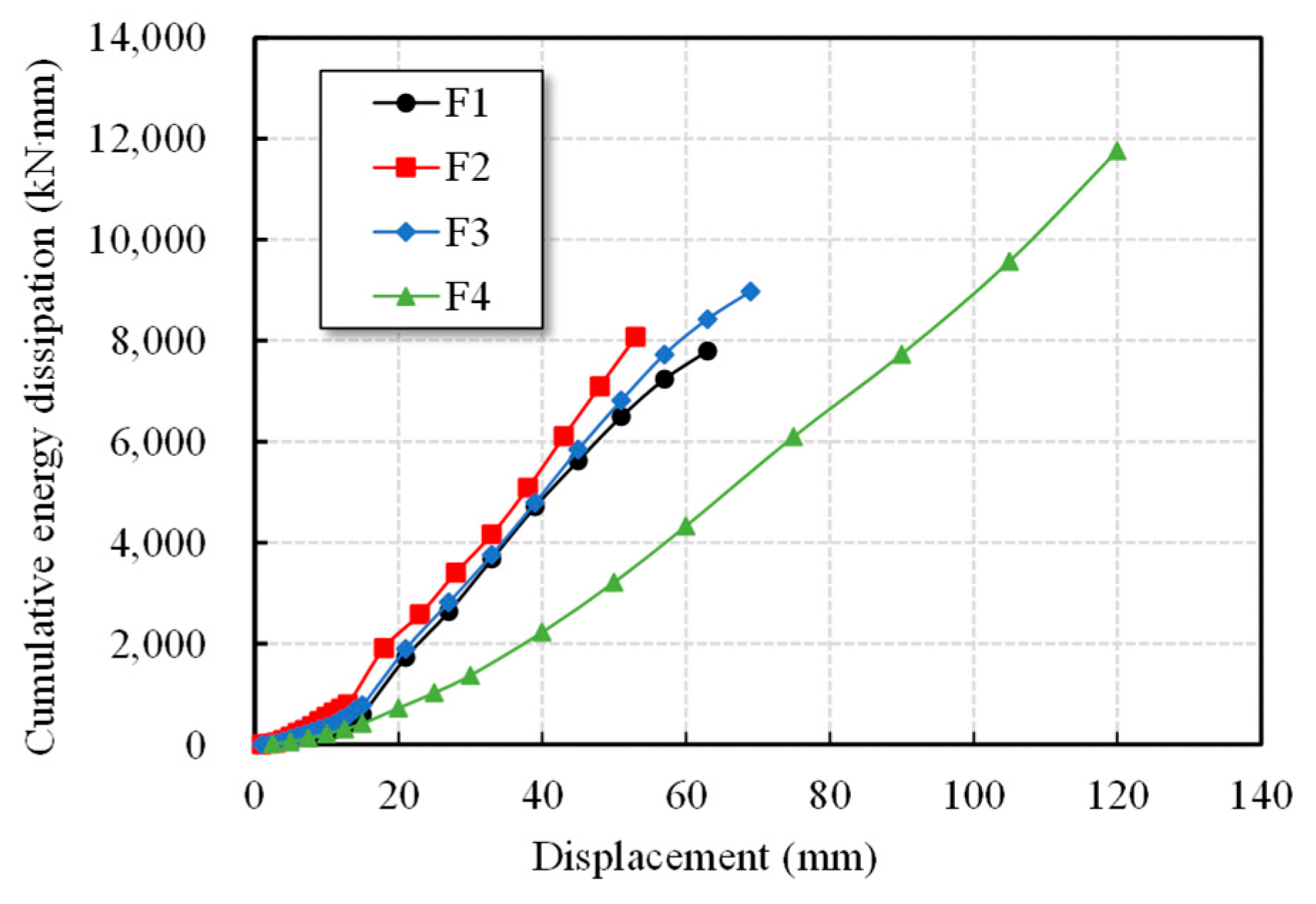

3.6. Strain Analysis

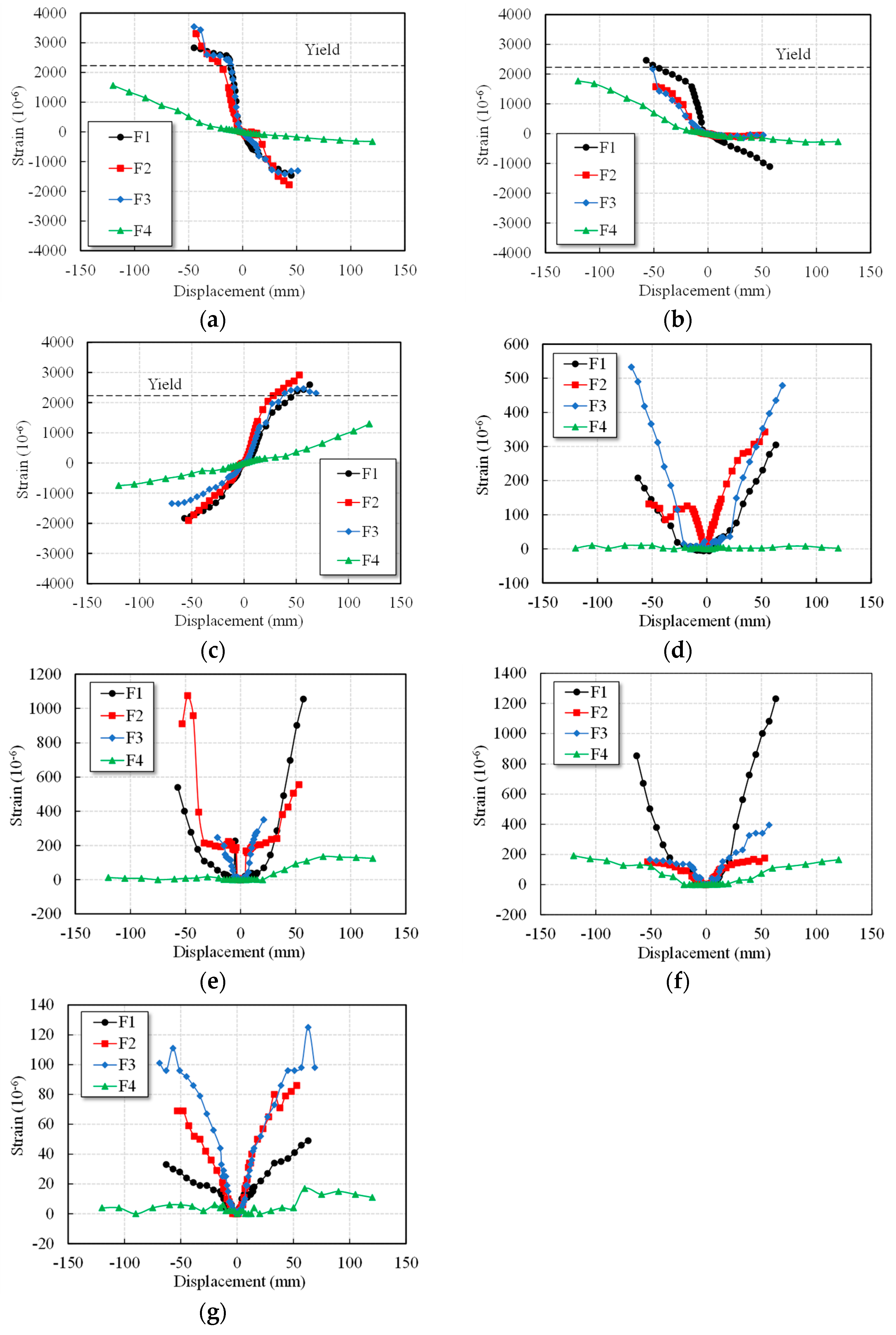

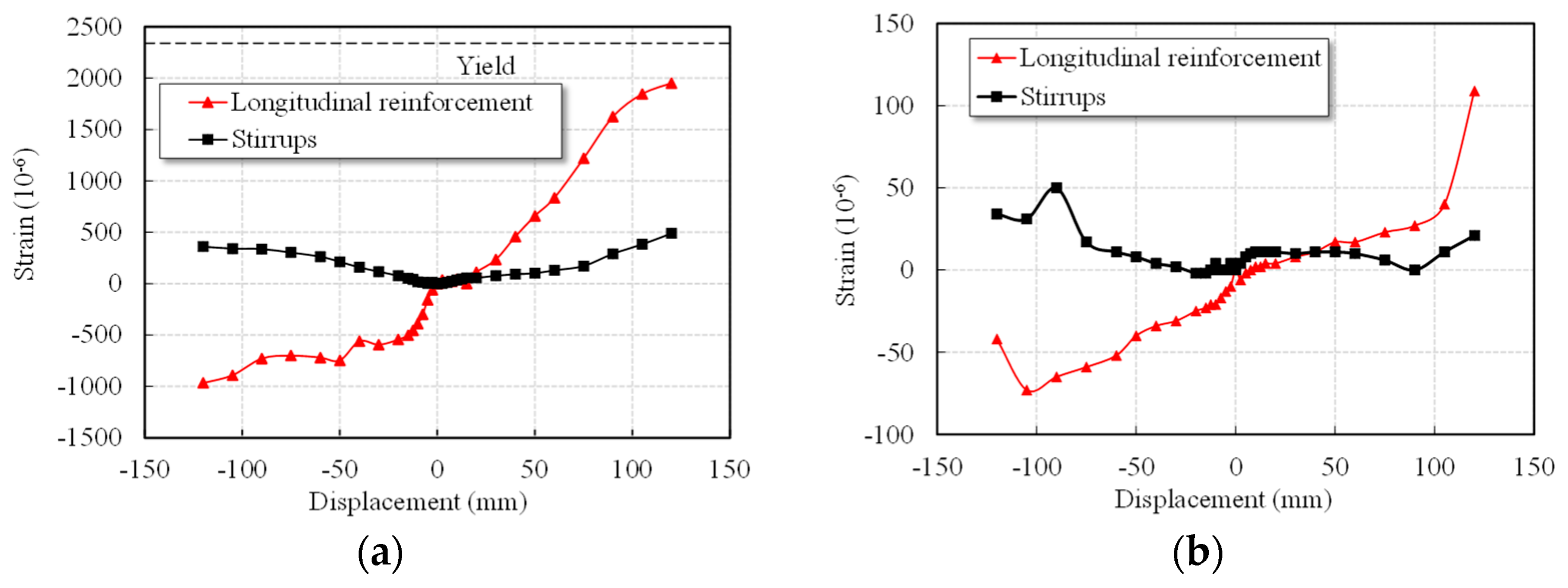

4. Conclusions

- All retrofitting methods changed the damage mechanism. RC and steel jacketing shifted the plastic hinge from the column base to the beam ends. In contrast, base isolation transferred it to the transfer beam, thereby providing better protection for the original structural elements.

- RC jacketing increased the peak lateral bearing capacity by 59.86% and the initial stiffness by 45.9% compared with the un-retrofitted specimen, while steel jacketing achieved increases of 7.5% in peak lateral bearing capacity and 2.1% increase in initial stiffness, respectively. In contrast, base isolation showed a slight decrease of 16.6% in lateral load capacity, indicating the significant reduction in the seismic force demand on the superstructure and reflecting its role in reducing seismic energy transfer rather than strengthening the superstructure.

- The ductility coefficient decreased slightly under RC jacketing by 10.4% and under steel jacketing by 10.9%, indicating restricted plastic deformation. Conversely, base isolation improved ductility significantly, extending the ultimate deformation capacity by 90.6% compared with the un-retrofitted specimen. The hysteretic energy dissipation increased by 3.5% for RC jacketing, 15.0% for steel jacketing, and 50.8% for base isolation, compared with the un-retrofitted specimen. This confirms the superior capacity of base isolation to absorb seismic energy.

- Although RC and steel jacketing enhance strength and stiffness, they slightly compromise ductility. On the other hand, base isolation achieves the best balance by significantly enhancing ductility and energy dissipation, thereby offering the most effective improvement in overall seismic performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gkournelos, P.D.; Triantafillou, T.C.; Bournas, D.A. Seismic Upgrading of Existing Reinforced Concrete Buildings: A State-of-the-Art Review. Eng. Struct. 2021, 240, 112273. [Google Scholar] [CrossRef]

- Baek, E.; Pohoryles, D.A.; Kallioras, S.; Bournas, D.A.; Choi, H.; Kim, T. Innovative Seismic and Energy Retrofitting of Wall Envelopes Using Prefabricated Textile-Reinforced Concrete Panels with an Embedded Capillary Tube System. Eng. Struct. 2022, 265, 114453. [Google Scholar] [CrossRef]

- Cosgun, T.; Sayin, B.; Gunes, B.; Mangir, A. Retrofitting Technique Effectiveness and Seismic Performance of Multi-Rise RC Buildings: A Case Study. Case Stud. Constr. Mater. 2022, 16, e00931. [Google Scholar] [CrossRef]

- Cao, X.-Y.; Shen, D.; Feng, D.-C.; Wang, C.-L.; Qu, Z.; Wu, G. Seismic Retrofitting of Existing Frame Buildings through Externally Attached Sub-Structures: State of the Art Review and Future Perspectives. J. Build. Eng. 2022, 57, 104904. [Google Scholar] [CrossRef]

- Thermou, G.E.; Elnashai, A.S. Seismic Retrofit Schemes for RC Structures and Local-global Consequences. Prog. Struct. Eng. Mater. 2006, 8, 1–15. [Google Scholar] [CrossRef]

- Hung, C.-C.; Hsiao, H.-J.; Shao, Y.; Yen, C.-H. A Comparative Study on the Seismic Performance of RC Beam-Column Joints Retrofitted by ECC, FRP, and Concrete Jacketing Methods. J. Build. Eng. 2023, 64, 105691. [Google Scholar] [CrossRef]

- Truong, G.T.; Kim, J.-C.; Choi, K.-K. Seismic Performance of Reinforced Concrete Columns Retrofitted by Various Methods. Eng. Struct. 2017, 134, 217–235. [Google Scholar] [CrossRef]

- Furtado, A.; Rodrigues, H.; Varum, H.; Costa, A. Evaluation of Different Strengthening Techniques’ Efficiency for a Soft Storey Building. Eur. J. Environ. Civ. Eng. 2017, 21, 371–388. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.-C. Properties and Applications of FRP in Strengthening RC Structures: A Review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Chang, S.-Y.; Chen, T.-W.; Tran, N.-C.; Liao, W.-I. Seismic Retroftting of RC Columns with RC Jackets and Wing Walls with Different Structural Details. Earthq. Eng. Eng. Vib. 2014, 13, 279–292. [Google Scholar] [CrossRef]

- Ma, C.-K.; Apandi, N.M.; Sofrie, C.S.Y.; Ng, J.H.; Lo, W.H.; Awang, A.Z.; Omar, W. Repair and Rehabilitation of Concrete Structures Using Confinement: A Review. Constr. Build. Mater. 2017, 133, 502–515. [Google Scholar] [CrossRef]

- Shin, J.; Jeon, J.-S. Seismic Damage Mitigation Strategy Using an FRP Column Jacketing System in Gravity-Designed Reinforced Concrete Building Frames. Compos. Struct. 2022, 279, 114700. [Google Scholar] [CrossRef]

- Kim, M.S.; Lee, Y.H. Seismic Performance of Reinforced Concrete Columns Retrofitted with Hybrid Concrete Jackets Subjected to Combined Loadings. Materials 2022, 15, 6213. [Google Scholar] [CrossRef] [PubMed]

- Olmos Navarrete, B.A.; Jara Guerrero, J.M.; Gómez Soberón, M.D.L.C.T.J.; Jara Díaz, M. Influence of RC Jacketing on the Seismic Vulnerability of RC Bridges. Eng. Struct. 2016, 123, 236–246. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, X.; Hu, B.; Sui, L.; Yuan, F. Seismic Retrofit of Nonuniformly Corroded Coastal Bridge Piers with FRP and Engineered Cementitious Composite Overlays. J. Compos. Constr. 2023, 27, 04022088. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, X.; Diao, M.; Li, Y.; Guan, H.; Sun, H. FRP Retrofit for RC Frame Substructures against Progressive Collapse: Scheme Optimisation and Resistance Calculation. Eng. Struct. 2023, 289, 116289. [Google Scholar] [CrossRef]

- Pan, J.; Wang, X.; Wu, F. Strengthening of Precast RC Frame to Mitigate Progressive Collapse by Externally Bonded CFRP Sheets Anchored with HFRP Anchors. Adv. Civ. Eng. 2018, 2018, 8098242. [Google Scholar] [CrossRef]

- Ozcan, O.; Binici, B.; Ozcebe, G. Seismic Strengthening of Rectangular Reinforced Concrete Columns Using Fiber Reinforced Polymers. Eng. Struct. 2010, 32, 964–973. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, L.; Elchalakani, M.; Cai, J. Cyclic Loading Test for Reinforced Concrete Columns Strengthened with High-Strength Engineered Cementitious Composite Jacket. Eng. Struct. 2023, 278, 115571. [Google Scholar] [CrossRef]

- Shao, Y.; Tich, K.L.; Boaro, S.B.; Billington, S.L. Impact of Fiber Distribution and Cyclic Loading on the Bond Behavior of Steel-Reinforced UHPC. Cem. Concr. Compos. 2022, 126, 104338. [Google Scholar] [CrossRef]

- Deng, M.; Zhang, Y.; Li, Q. Shear Strengthening of RC Short Columns with ECC Jacket: Cyclic Behavior Tests. Eng. Struct. 2018, 160, 535–545. [Google Scholar] [CrossRef]

- Gondaliya, K.M.; Vasanwala, S.A.; Desai, A.K.; Amin, J.A.; Bhaiya, V. Machine Learning-Based Approach for Assessing the Seismic Vulnerability of Reinforced Concrete Frame Buildings. J. Build. Eng. 2024, 97, 110785. [Google Scholar] [CrossRef]

- Kazemi, F.; Asgarkhani, N.; Jankowski, R. Machine Learning-Based Seismic Fragility and Seismic Vulnerability Assessment of Reinforced Concrete Structures. Soil Dyn. Earthq. Eng. 2023, 166, 107761. [Google Scholar] [CrossRef]

- Couto, R.; Requena-García-Cruz, M.V.; Bento, R.; Morales-Esteban, A. Seismic Vulnerability Assessment of RC Structures: Research and Practice at Building Level. In Seismic Vulnerability Assessment of RC Buildings Considering the Implications of Ageing Effects; Couto, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Samuel, M.A.; Xiong, E.; Haris, M.; Lekeufack, B.C.; Xie, Y.; Han, Y. Assessing Seismic Vulnerability Methods for RC-Frame Buildings Pre- and Post-Earthquake. Sustainability 2024, 16, 10392. [Google Scholar] [CrossRef]

- Yang, Y.; Li, T.; Dai, K.; Wu, M. Evaluation of Ground Motion Intensity Measures for Base-Isolated Steel Frame Buildings with Lead Rubber Bearings. Eng. Struct. 2025, 327, 119609. [Google Scholar] [CrossRef]

- Kanyilmaz, A.; Castiglioni, C.A. Reducing the Seismic Vulnerability of Existing Elevated Silos by Means of Base Isolation Devices. Eng. Struct. 2017, 143, 477–497. [Google Scholar] [CrossRef]

- Ghafar, W.A.; Zhong, T.; Lai, Z.; Pingle, Z.; Yang, Y.; Hasan, M.M. Seismic Isolation for Existing Structures: A Review of Retrofitting Techniques, Case Studies, and Trends. Discov. Civ. Eng. 2025, 2, 137. [Google Scholar] [CrossRef]

- Chen, P.; Lu, Y.; Wang, B.; Zhuang, P.; Dai, K. Enhancing Seismic Resilience in Base-Isolated Structures: A Performance-Based Comparison of HDRB and LRB Isolation Systems. Eng. Struct. 2025, 342, 120945. [Google Scholar] [CrossRef]

- Hu, G.-J.; Ye, K.; Tang, Z.-Y. Design and Analysis of LRB Base-Isolated Building Structure for Multilevel Performance Targets. Structures 2023, 57, 105236. [Google Scholar] [CrossRef]

- Matsagar, V.A.; Jangid, R.S. Base Isolation for Seismic Retrofitting of Structures. Pract. Period. Struct. Des. Constr. 2008, 13, 175–185. [Google Scholar] [CrossRef]

- Aghaeidoost, V.; Billah, A.H.M.M. An Advanced Rate-dependent Analytical Model of Lead Rubber Bearing. Earthq. Eng. Struct. Dyn. 2024, 53, 1961–1981. [Google Scholar] [CrossRef]

- Ziraoui, A.; Kissi, B.; Aaya, H.; Azdine, I. Seismic Behavior of Base-Isolated Building Structures with Lead Rubber Bearings (LRBs). Procedia Struct. Integr. 2024, 61, 171–179. [Google Scholar] [CrossRef]

- Fakih, M.; Hallal, J.; Darwich, H.; Damerji, H. Effect of Lead-Rubber Bearing Isolators in Reducing Seismic Damage for a High-Rise Building in Comparison with Normal Shear Wall System. Struct. Durab. Health Monit. 2021, 15, 247–260. [Google Scholar] [CrossRef]

- Mahamied, A.; Yasin, A.A.; Alzubi, Y.; Adwan, J.A.; Mahamied, I. Influence of Vertical Irregularity on the Seismic Behavior of Base Isolated RC Structures with Lead Rubber Bearings under Pulse-Like Earthquakes. Struct. Durab. Health Monit. 2023, 17, 501–519. [Google Scholar] [CrossRef]

- Faiella, D.; Calderoni, B.; Mele, E. Seismic Retrofit of Existing Masonry Buildings through Inter-Story Isolation System: A Case Study and General Design Criteria. J. Earthq. Eng. 2022, 26, 2051–2087. [Google Scholar] [CrossRef]

- Li, T.; Yang, Y.; Dai, K.; Ge, Q.; Wang, J. Influence of Ground Motion Duration on Seismic Performance of RC Frame Isolated by High Damping Rubber Bearings. Eng. Struct. 2022, 262, 114398. [Google Scholar] [CrossRef]

- Khan, B.L.; Azeem, M.; Usman, M.; Farooq, S.H.; Hanif, A.; Fawad, M. Effect of near and Far Field Earthquakes on Performance of Various Base Isolation Systems. Procedia Struct. Integr. 2019, 18, 108–118. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. China Standards Press: Beijing, China, 2021.

- GB/T 20688.1-2007; Rubber Bearings—Part 1: Seismic-Protection Isolators Test Methods. China Standards Press: Beijing, China, 2007.

- FEMA 356; Prestandard and Commentary for the Seismic Rehabilitation of Buildings. Federal Emergency Management Agency: Washington, DC, USA, 2000.

| Reinforcement Grade | d/mm | fy/MPa | fu/MPa | E × 105/MPa |

|---|---|---|---|---|

| HPB300 | 6 | 389 | 465 | 2.1 |

| 6 | 476 | 589 | ||

| HRB400 | 10 | 446 | 573 | 2.0 |

| 12 | 468 | 534 |

| Parameter | Unit | Value |

|---|---|---|

| Effective diameter | mm | 300 |

| Section area | m2 | 0.071 |

| First shape factor | / | 20.26 |

| Second shape factor | / | 5.17 |

| Vertical stiffness | kN/mm | 822 |

| Yield force | kN | 26.54 |

| Post yield stiffness | kN/mm | 0.449 |

| Horizontal equivalent stiffness | kN/mm | 0.90 |

| Total height of LRB | mm | 156 |

| Scheme | Fy (kN) | Dy (mm) | Fmax (kN) | Dmax (mm) | Fu (kN) | Du (mm) | μ |

|---|---|---|---|---|---|---|---|

| F1 | 114.64 | 17.18 | 133.19 | 33 | 113.21 | 62.95 | 3.66 |

| F2 | 184.45 | 14.73 | 212.92 | 23 | 180.98 | 48.36 | 3.28 |

| F3 | 125.17 | 19.47 | 143.26 | 45 | 121.77 | 63.43 | 3.26 |

| F4 | 32.51 | 17.93 | 111.06 | 120 | 111.06 | 120.00 | 6.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Xie, M.; Xu, Z.; Liao, J.; Abdullah, M.; Zhang, M. A Comparative Experimental Study on Seismic Retrofitting Techniques for RC Frames: RC Jacketing, Steel Jacketing, and Base Isolation. Buildings 2025, 15, 3539. https://doi.org/10.3390/buildings15193539

Wang W, Xie M, Xu Z, Liao J, Abdullah M, Zhang M. A Comparative Experimental Study on Seismic Retrofitting Techniques for RC Frames: RC Jacketing, Steel Jacketing, and Base Isolation. Buildings. 2025; 15(19):3539. https://doi.org/10.3390/buildings15193539

Chicago/Turabian StyleWang, Weilun, Mingyuan Xie, Zhiwen Xu, Jiaqi Liao, Muhammad Abdullah, and Mingyang Zhang. 2025. "A Comparative Experimental Study on Seismic Retrofitting Techniques for RC Frames: RC Jacketing, Steel Jacketing, and Base Isolation" Buildings 15, no. 19: 3539. https://doi.org/10.3390/buildings15193539

APA StyleWang, W., Xie, M., Xu, Z., Liao, J., Abdullah, M., & Zhang, M. (2025). A Comparative Experimental Study on Seismic Retrofitting Techniques for RC Frames: RC Jacketing, Steel Jacketing, and Base Isolation. Buildings, 15(19), 3539. https://doi.org/10.3390/buildings15193539