1. Introduction

The rapid expansion of urban rail transit has made subway construction a key driver in advancing urbanization and improving the efficiency of public transportation systems. However, traditional cast-in-place subway stations have revealed limitations in practical applications, such as long construction periods, severe environmental pollution, and difficulties in quality control [

1]. Prefabricated and assembled subway stations, leveraging the advantages of high industrialization, standardization, and green construction, have gradually become a research highlight and development direction in underground engineering construction. As the design theory and construction technology of prefabricated concrete structures continue to improve, various forms of prefabricated subway stations, including assembled splicing structures and assembled integral structures, have been successfully applied in multiple urban rail transit projects both domestically and internationally. Among them, the assembled splicing subway station, as an innovative structural system, involves the standardized prefabrication of certain components in factories, followed by high-precision lifting and rapid splicing on-site. Key joint areas are combined with cast-in-place concrete layers to form an integrated structure where prefabrication and cast-in-place forces collaboratively work together. This technology not only enhances construction efficiency and reduces ecological damage but also significantly improves the construction quality of engineering projects, offering a more efficient, environmentally friendly, and sustainable solution for subway station construction [

2]. The construction site is illustrated in

Figure 1. Nevertheless, as urban underground space development extends to deeper and more complex geological conditions, coupled with increasingly frequent seismic activities globally, subway stations, as key hubs and densely populated areas in urban lifeline projects, are attracting widespread attention regarding structural safety, stability, and integrity under extreme disasters such as strong earthquakes and explosions [

3,

4]. Especially in unfavorable geological and environmental conditions such as soft soil and high-intensity earthquake zones, the dynamic soil-structure interaction is complex, and the structure is prone to adverse responses such as large deformation, joint opening, and slippage, posing severe challenges to the connection reliability and overall seismic resistance of prefabricated structures [

5,

6].

The mechanical properties of joints have a decisive impact on the seismic performance of prefabricated underground structures, and different types of joints exhibit varying seismic responses. Yang et al. [

7,

8,

9] systematically investigated the mechanical behavior of grouted mortise-and-tenon joints in prefabricated subway structures through four-point pure shear tests and numerical simulations, revealing the influence of key geometric parameters on bending stiffness and deformation, and proposed an improved shear key method for predicting shear capacity under various loading conditions, which was validated for safety and reliability in the application of Changchun Metro Line 2. Lin et al. [

10], based on the full-process monitoring data of prefabricated stations on Changchun Metro Line 2, systematically studied the mechanical behavior and deformation characteristics of double-tenon joints at the crown and single-tenon joints at the foot under high bending moments through on-site monitoring and numerical simulation comparisons. Xiong [

11] proposed and verified a new tenon-bolt-type prefabricated column end joint through experiments and numerical simulations, revealing its seismic advantages of high ductility and good energy dissipation under different axial compression ratios. In addition, Liu et al. [

12,

13] conducted quasi-static loading tests on large-diameter grouted sleeve-connected beam–plate–column, column–plate, and side wall–plate joints, revealing that while these prefabricated joints exhibit comparable bearing and deformation capacities to cast-in-place monolithic joints, they differ significantly in ductility and ultimate failure modes. Qiu et al. [

14] systematically investigated the mechanical behavior of prefabricated double-wall integrated underground diaphragm wall assembly joints through full-scale pure bending tests and mechanical modeling, revealing the role of axial force in crack suppression, non-planar deformation mechanisms, and the critical contribution of fasteners, and confirmed that the joint outperforms cast-in-place sections in bearing capacity and stiffness degradation while demonstrating high safety and low-carbon advantages in the Shenzhen Metro Line 8 application. Liu et al. [

15,

16] experimentally demonstrated that Y-shaped joints with embedded steel plates outperform those with embedded connectors in mechanical stability, strength, stiffness, energy dissipation, and ductility, while wall–beam–column joints connected by welded steel plates exhibit superior energy dissipation and ductility compared to mechanical connector joints, despite similar ultimate bearing capacities.

The influence of soil-structure interaction on the seismic response of underground structures has garnered increasing attention. Particularly, the adverse effects caused by large deformations and weak bearing capacity in soft soil are more pronounced, making it a crucial issue that cannot be overlooked in the performance-based seismic design of underground engineering. Zhu et al. [

17,

18] conducted centrifuge shaking table tests in Sendai, revealing that the superstructure, through soil-structure interaction, significantly amplifies near-field soil acceleration and excess pore water pressure accumulation, thereby intensifying foundation lateral deformation and dynamic loading on underground structures, leading to joint cracking, internal force redistribution, and overall response deterioration. Yan et al. [

19] demonstrated through centrifuge shaking table tests that in soft soil areas, soil-structure interaction significantly influences subway station seismic response, where liquefiable interlayers or fully liquefied sites reduce soil stiffness and seismic energy transmission, producing a natural isolation effect that results in less damage compared to stiffer but less deformation-compatible clay sites. Li et al. [

20] investigated the seismic performance of cross-transfer subway stations in soft soil under horizontal seismic action, showing that soil-structure interaction significantly influences their response, with superior cooperative deformation compared to single stations, but increased reinforcement stiffness in the overlapping soil layer alters the dynamic coupling, intensifying the seismic response of both upper and lower stations. Miao et al. [

21] developed an automatic modeling system incorporating soft soil nonlinearity through shaking table tests and validated simulations, revealing the mechanism by which surface structure-soil-substructure interaction influences subway station seismic response. Wu et al. [

22] combined shaking table tests with calibrated nonlinear finite element simulations to systematically study the seismic performance of a typical two-story, three-span Shanghai subway station in soft soil, revealing the scale effect on deformation and bending moment, identifying the bottom column base as the weakest part, and confirming the recurrence risk of the Daikai station failure mode in soft soil. Hashash [

23] pointed out that seismic loads on underground structures are primarily manifested as the restraint from surrounding ground deformation, rather than inertial forces as in surface structures, and reviewed various soil-structure interaction analysis methods, ranging from free-field deformation to dynamic numerical simulations. Wang [

24] simulated the seismic response of a double-walled subway station in soft soil using a discrete-finite element method, revealing soil-structure and structure-structure interface contact and collision behaviors, and found that high-pulse ground motions may cause disproportionate amplification of structural deformation and cracking. Wang et al. [

25] systematically investigated the dynamic soil-structure-structure interaction between an underground station and adjacent pile foundations under vertical S-waves using frequency-domain numerical analysis with enhanced ANSYS 14.5 software, revealing the influence of structural layout, earthquake direction, spacing, soil parameters, and superstructure characteristics on system response. Zhuang et al. [

26,

27] found through numerical analysis that large underground structures significantly alter the liquefaction potential of the surrounding soil in liquefiable soil layers and recommended the use of elastic sliding supports to reduce the risk of seismic damage. Tamari et al. [

28], Wang et al. [

29], and Ma et al. [

30] systematically studied the seismic behavior of underground structures and their interaction with soil, revealing the important role of soil-structure interaction in the stress, deformation, and failure mechanisms of structures.

Practical engineering applications have shown that prefabricated construction technology not only effectively addresses complex construction challenges but also exhibits irreplaceable comprehensive advantages in improving project quality, construction efficiency, operational safety, and environmental protection [

31,

32]. Prefabricated subway stations have been widely studied and promoted for application in multiple cities in China, primarily utilizing two construction modes. One is the “fully prefabricated structure”, where all main structural components are prefabricated in the factory and assembled on-site. The other is the “assembled splicing structure”, where some key components of the station, such as the roof, floor, side walls, columns, or beams, are prefabricated and then assembled to form an overall structural system through stacking or connection. The connection and assembly technology of prefabricated structures is crucial for achieving efficient and safe application. Currently, it mainly includes prestressed tendon connections [

33,

34,

35], bolt connections [

36,

37], cast-in-place concrete connections [

38], and grouted splicing connections. These technologies have been widely applied in various structural forms such as bridges, buildings, and underground engineering. Among them, prestressed tendon connections and bolt connections belong to “dry connections”, which are characterized by the elimination of on-site wet concrete pouring, fast construction speed, minimal environmental impact, and good recoverability and deformation capacity. Their mechanical behavior is mainly controlled by nonlinear mechanisms such as opening, sliding, and retraction of the joint interface during loading. However, dry connections have relatively limited integrity and energy dissipation capacity [

39]. In contrast, cast-in-place concrete connections and various grouted splicing connections are classified as “wet connections”, which achieve rigid connections between components through post-cast concrete or high-strength grouting materials. They exhibit higher integrity and stiffness, and their structural performance can approach or even reach the level of cast-in-place monolithic structures. Such connection methods are particularly suitable for key parts with high requirements for bearing capacity, stiffness, and durability, and they facilitate quality control and on-site construction organization.

Given the frequent occurrence of earthquakes worldwide, as an important component of urban rail transit, the seismic performance of subway stations has become a key research area in civil engineering and a crucial topic in engineering practice [

40,

41,

42]. Huo et al. [

43] studied the load transfer mechanism of underground structures through dynamic numerical analysis, revealing that the relative stiffness and interfacial friction characteristics of the structure are key factors affecting seismic response. Wang et al. [

44] investigated the shock absorption effect of different seismic isolation measures on underground station structures, finding that the lower the stiffness of the flexible seismic isolation layer, the more significant the shock absorption effect. Wu et al. [

45] proposed a new partially prefabricated structure with prefabricated arched roof panels, which showed less column damage, more uniform force distribution, and better inter-story deformation capacity compared to monolithic structures. Gao et al. [

46] revealed the impact of assembly technology and construction sequence on structures through full-process construction simulation and seismic response analysis. Qin et al. [

47] studied the optimal seismic demand parameters for prefabricated subway stations at different burial depths and, based on the optimized intensity measure (IM), developed seismic fragility curves that enhance the accuracy of seismic vulnerability assessment for underground infrastructure. Ding et al. [

48] systematically investigated the mechanical response of prefabricated subway stations under horizontal seismic action in a single-ring configuration, demonstrating that the structure exhibits high safety and stability during seismic loading. Chen et al. [

49] pointed out that the potential failure modes of prefabricated columns are relatively minor, but both structures exhibited a failure mode of column failure before wall failure, with the most unfavorable seismic location located at the bottom of the lower column. Cheng et al. [

50] established a numerical model using OpenSees 2.3.0 and found that the burial depth of the structure significantly affects its seismic performance and failure mechanism. Other studies have shown that the dynamic response characteristics of prefabricated structures under seismic action are significantly different from those of cast-in-place monolithic structures [

51,

52,

53].

Based on the assembly methods of prefabricated components, prefabricated structures can be divided into wet connection (requiring the casting of grout or concrete) and dry connection (using methods such as bolts and welding that do not require wet operations). Traditionally, prefabricated underground structures have predominantly adopted the dry connection method, and related research has mainly focused on the seismic performance of prefabricated monolithic subway stations with dry connections or cast-in-place subway stations. However, this work introduces a novel subway station structure that combines wet and dry connections. Taking the actual subway station project of Shenzhen Metro Line 15 in Guangdong Province as the research object, the nonlinear static-dynamic coupled refined finite element model considering soil-structure interaction was established. Three types of underground structures with the same proportional dimensions (CIP, ASS, and AMS) were comparatively analyzed to systematically evaluate the seismic performance of different types of underground structures. By comparing the displacement response, internal force characteristics, and structural damage distribution of these three types of structural forms under seismic action, the differences in the seismic performance were comprehensively explored. In particular, the impact of the characteristics of splicing interfaces at different locations on the seismic response of the ASS was also investigated. This research provides new ideas and technical support for the safe construction of urban rail transit infrastructure, thereby promoting the development of the construction industry towards a more sustainable direction.

3. Seismic Response of Structures

3.1. Inter-Story Drift Ratio

To systematically evaluate the dynamic response differences between prefabricated and cast-in-place subway station structures under seismic action, this study selected two typical prefabricated structural forms, namely ASS and AMS, and compared them with traditional CIP. For three types of subway station models under the same site conditions, nonlinear dynamic time-history analysis was conducted under seismic input of different intensity levels.

To visually compare the deformation capacity differences between prefabricated structures and traditional CIP, the inter-story drift ratio (IDR) can be adopted as the key evaluation indicator. IDR is defined as the ratio of the horizontal relative displacement generated between adjacent floors during the seismic response process to the story height, which can effectively reflect the degree of lateral deformation and the quality of seismic performance of the structure. The IDR can be expressed as follows:

where

u1 is the displacement of Floor 1 (middle slab to bottom slab),

u2 is the displacement of Floor 2 (top slab to middle slab), and

hc is the floor height.

From

Figure 8, it can be observed that a comparison of the IDR of the station structures under different ground motions reveals that the Loma Prieta ground motion induces the largest IDR, while the Chi-Chi ground motion results in the smallest IDR, indicating the significant impact of ground motion spectral characteristics on structural response. Therefore, seismic ground motions with low-frequency characteristics have the most significant adverse effects on structures, followed by those with medium-frequency characteristics, while the effects of high-frequency seismic ground motions are relatively minor. As the PGA increases from 0.2 g to 1.0 g, the overall IDR of the structure shows an upward trend, consistent with the basic law of nonlinear dynamic response. When PGA = 0.2 g, the IDR of all three types of structures is at a relatively low level with insignificant differences, indicating that under low-intensity seismic motion, prefabricated and cast-in-place structures exhibit comparable deformation control capabilities, with good structural integrity and mechanical behavior in the joint area approaching ideal rigid connections. However, as the seismic intensity increases, the discontinuity and nonlinear characteristics of the joint connection area gradually emerge, becoming a key factor affecting overall performance. In this context, although the IDR of the AMS remains relatively low, it is slightly higher than that of the CIP under high PGA conditions, indicating that its splicing interface may experience slight slippage or local damage under strong earthquakes, but it still exhibits good deformation coordination capability. In contrast, the IDR of the ASS is higher than that of both CIP and AMS under all ground motion inputs, and the gap further widens as PGA increases. This phenomenon indicates that the joints of the ASS may possess significant flexibility, making them prone to accumulating inelastic deformation under seismic action, thereby exacerbating IDR. Especially under strong seismic action, the joint area may evolve into the deformation concentration zone, leading to stiffness degradation and internal force redistribution, ultimately weakening the structural integrity and seismic stability. Therefore, optimizing the joint construction details and enhancing connection stiffness and energy dissipation capacity are key to improving the seismic performance of prefabricated subway stations.

In addition, under the same structural conditions, as PGA increases from 0.2 g to 0.4 g, IDR of all three structures shows a significant increasing trend. The IDR of the ASS growth rate is about 55%. However, as PGA continued to increase to 0.8 g, the growth rate of IDR significantly slowed down, only increasing by about 13%. The trend of change is mainly due to the nonlinear dynamic response mechanism in soil structure interaction. The subway station in this work is shallowly buried in soft soil, and the dynamic response characteristics are highly dependent on the physical and mechanical properties of the foundation soil. When the seismic intensity reaches a certain level, the foundation soil begins to exhibit obvious strain-softening characteristics. The nonlinear behavior causes the soil to attenuate seismic energy during the earthquake process, achieving a natural isolation effect and thus suppressing further growth of the IDR for the structure to some degree. When PGA increases from 0.8 g to 1.0 g, the IDR of the three structures increases significantly. The structure and foundation soil have entered a more serious nonlinear deformation stage. Under such extreme conditions, even if there is a certain soil softening effect, it cannot completely inhibit the sharp rise in the IDR of the structure, which reflects the non-negligible destructive force of high-intensity ground motions on the structure.

When designing prefabricated structures, the matching relationship between the seismic spectrum and the natural vibration characteristics of the structure should be fully considered to avoid resonance in the low-frequency dominant region. At the same time, excessive reliance on the passive energy dissipation of soil should be avoided, and active optimization of joint construction should be implemented to enhance connection stiffness and ductility. In particular, technologies such as high-strength grouted sleeves, shear connectors, or prestressed splicing should be adopted on key force transfer paths to enhance the deformation coordination capacity and energy dissipation mechanism of the joints. While ensuring the integrity of the structure, inter-story drift should be reasonably controlled to prevent the formation of weak hinges or instability mechanisms under strong earthquakes.

3.2. Internal Force Response

To evaluate the mechanical performance differences in various structural forms under seismic action, detailed observations and comparative analyses were conducted on the internal force responses of key components such as the sidewalls and middle columns of CIPs, AMSs, and ASSs.

Figure 9 shows that multiple monitoring sections are set up at key structural stress-bearing areas, including the middle column (M), the left sidewall (L), and the right sidewall (R), to record in real-time the changes in axial force, shear force, and bending moment of each component during the seismic excitation process.

Figure 10 shows the maximum internal forces sustained by the middle columns and sidewalls of each structural form at the monitoring sections when PGA = 1.0 g.

As can be seen from

Figure 10, the internal force of the sidewalls of the three structural forms, CIP, AMS, and ASS, are highly consistent overall, and the internal force curves are basically superimposed, indicating similar overall stress patterns. And the trends of internal force changes corresponding to the three types of seismic motions are basically similar. It is worth noting that the internal force values of the left sidewall are generally higher than those of the right sidewall. This phenomenon is mainly attributed to the asymmetric layout design of the structure, which results in the left sidewall bearing greater vertical soil load and structural self-weight and generating the larger internal force response. In addition, due to the eccentricity of the structural center of gravity, the uneven distribution of seismic inertial force further increases the stress on the left sidewall. As can be seen from

Figure 10c, the internal force of the middle column in the CIP is the largest, especially at the two key sections of the column top and bottom, where the internal force is significantly higher than that in AMS and ASS. This is consistent with its characteristics of high integrity, large stiffness, and direct internal force transfer paths. In contrast, the internal force of the AMS at the column top is close to that of the CIP, indicating that the upper connection joints have good stiffness and force transfer capabilities. However, in the bottom of the column area, the internal force of the AMS is significantly lower than that of the CIP. This phenomenon may stem from the design of using grouting sleeves for connection at the column base. The prefabricated column is connected to the structure with high-strength connections through embedded sleeves, effectively enhancing the stiffness and ductility of local sections. For the ASS, the internal force of the middle column is significantly lower than that of the CIP and AMS throughout the entire height range, exhibiting the lowest level of internal force. This indicates that the assembly splicing structure has a certain internal force weakening effect under seismic action; that is, due to the existence of the splicing interface, the overall stiffness of the structure is reduced, and the concentrated transmission of seismic force to the central column is partially suppressed, and internal force tends to be dispersed and transmitted through multiple paths. This characteristic can be seen to some extent as the passive “isolation” or “energy dissipation” mechanism, which helps alleviate the stress state of key components but may also be accompanied by greater overall deformation. In addition,

Figure 10 also shows that the maximum internal force of both the sidewalls and the middle columns occurs at the bottom section of the lower floor, which is the most unfavorable stress position of the structure and the key control section in seismic design.

In summary, the distribution characteristics of internal force reveal that although the overall stress patterns of CIP, AMS, and ASS structural forms are similar, there are significant differences in the forces acting on key parts, reflecting the profound impact of different connection methods on structural mechanical behavior. The asymmetric layout of the structure leads to uneven stress distribution on the side walls, with the left side wall bearing higher internal forces under seismic action. In seismic design, symmetry should be optimized to reduce the eccentric effect. As the main load-bearing component, the middle column experiences concentrated internal force at the top and bottom areas, with the lowermost part being the most unfavorable section, requiring special attention to enhance its bearing capacity and ductility construction. The CIP, with good integrity and high stiffness, transfers internal forces directly and concentrically. The internal force at the top of the column in the AMS is close to that in the CIP, indicating that the upper connections have good force transfer performance. However, the lower internal force at the column base may be related to the characteristics of the grouted sleeve connections, requiring attention to the stiffness matching and construction quality of the connection area. In contrast, the internal force in the middle column of the ASS is significantly lower, indicating that the introduction of flexibility into the splicing interface reduces the overall stiffness, weakens the concentrated transfer of seismic forces to the core components, and leads to a passive redistribution of forces or energy dissipation mechanism, which can help alleviate stress in key parts but may also be accompanied by a greater deformation response. In seismic design, the mindset should shift from “equivalent to cast-in-place” to performance-based design, making rational use of the flexibility characteristics of prefabricated joints to achieve redistribution of internal forces, balance structural stiffness and energy dissipation capacity, and ensure the safety of key parts while enhancing the seismic robustness and recoverability of the structure.

3.3. Damage Analysis

Figure 11 shows the seismic damage to the station structures (under Loma Prieta motion with PGA = 1.0 g).

Figure 12 shows the tension damage contour plots for three types of subway station structures under three types of ground motions when PGA = 1.0 g. The three subway station structures in

Figure 11 and

Figure 12 are labeled as CIP, AMS, and ASS, respectively. If the tension damage coefficient (DAMAGET) is greater than 0, it indicates that the concrete begins to show slight damage under tension. When the coefficient approaches 1.0, it indicates that the concrete is close to complete tensile failure. If the compression damage coefficient (DAMAGEC) exceeds 0, the concrete begins to show slight compressive damage under compressive stress. As the coefficient approaches 1.0, the concrete approaches complete compressive failure. The default average threshold for stress calculation at element nodes is 75%.

From

Figure 11, it can be seen that when PGA = 1.0 g, the compression damage of the three structural forms (CIP, AMS, and ASS) is generally at a low level, indicating that the structure is not in a severe compression damage state. Compression damage is mainly concentrated in key joint areas, with the most significant being the connection between the middle column and the bottom slab. The area is prone to compression damage due to the combined effects of significant axial pressure and bending moment. Secondly, there is also a certain degree of compression damage at the intersection of the top slab and the middle column, as well as at the intersection of the top slab and the sidewalls, which is mainly due to the local stress concentration of the top slab under the combined action of soil cover load and seismic inertial force. However, the extent of the damage in these areas is generally small, and the damage variables are far from reaching a completely destroyed state, indicating that the concrete still maintains good bearing capacity, and the impact of compression damage on the overall structural performance is relatively limited. It is worth noting that compared with the CIP, the compression damage distribution of the AMS shows a significant upward movement of damage; that is, the damage area originally concentrated at the bottom of the column in the CIP is transferred to the upper part of the column in the AMS. The phenomenon may be attributed to the structural measure of the AMS using a grouting sleeve connection at the bottom of the column, which significantly enhances the local stiffness and restraint ability of the column base area, effectively suppressing the crushing and microcrack development of concrete in this area, thereby redistributing some of the stress and damage originally concentrated at the bottom of the column to the unreinforced area above it. The damage transfer mechanism to some extent protects the key column bottom joints and avoids the premature brittle collapse. In contrast, the distribution of compressive damage in ASS is more dispersed, which is related to the coordination of slip and deformation allowed by the splicing interfaces, resulting in a decrease in stress concentration. The findings are consistent with the observations reported by Chen et al. [

64], further validating the reliability of the results obtained in this study. To sum up, under strong seismic actions the prefabricated structures can effectively regulate the damage development path through reasonable joint design, effectively utilize the stiffness gradient and deformation capacity of prefabricated joints, and achieve protection of key parts and optimization of damage mechanisms, thereby enhancing the repairability and seismic robustness of the structure while ensuring safety.

From

Figure 12, it can be seen that all three types of station structures exhibit extensive tensile damage to the cross-section at the joint connections. It can be inferred that there is severe cracking damage to the concrete at these locations. By further comparing the tensile damage of the structures, it can be observed that the overall tension damage distribution area of AMSs and CIPs is basically equivalent, indicating that under high seismic excitation, although the AMS adopts grouting sleeves, the development degree of tension damage is similar to CIPs, and the two have similar mechanical response characteristics. Tension damage is mainly concentrated in the key stress joints of the structure, such as the boundary between the slab and column and the junction between the sidewall and the slab, which become high-risk areas for concrete tension damage. In contrast, the tension damage of ASSs exhibits significantly different distribution characteristics. The damage area in the joint area is significantly reduced, especially in the complex joint area where the slab and column intersect, with the smaller damage range and lower damage degree. This phenomenon is mainly attributed to the widely used non-rigid splicing joint design in ASSs. The types of nodes allow for a certain degree of relative rotation and slight slippage between components, thereby weakening rigid constraints and reducing the efficiency of direct transmission of internal force. The connection mechanism plays a role in passive energy dissipation and internal force redistribution to a certain extent, reducing the concentration of tensile stress in key components, effectively protecting the core load-bearing system of the structure, and improving the overall seismic resilience. However, due to the fact that the splicing joint itself becomes a key part of deformation coordination, its repeated tension and closure under earthquake action can easily cause local stress concentration in the sidewall joint area, resulting in more obvious tensile damage to the sidewall concrete near the joint. This indicates that although the ASS performs well in reducing damage to the middle column, the seismic performance of the sidewall joints needs to be given special attention in design to prevent premature local failure under strong earthquakes.

To further examine and contrast the damage evolution patterns of the three structures,

Figure 13 shows the changing trends of compression and tension damage factors in key areas of each structure under Loma Prieta motion with the increase in PGA.

As shown in

Figure 13a, under varying seismic intensities, the compression damage factors (DAMAGEC) of the key parts of the three structures show certain differences. For CIP, the DAMAGEC values at the bottom of the central column and the bottom of the side walls are relatively high and continue to increase with the increase in PGA, indicating that these areas are typical stress concentration sites under seismic action and are prone to concrete compression damage. AMSs and CIPs have similar overall compression damage development patterns, and the trend of the maximum DAMAGEC increasing with PGA is basically consistent with CIPs. In contrast, ASSs exhibit a unique damage distribution pattern. As PGA increases from 0.2 g to 1.0 g, the DAMAGEC value of the ASS at the bottom of the sidewall is significantly higher than that of the CIP and AMS, indicating that the joint interface is prone to non-coordinated deformation in the joint area under high stress conditions, leading to increased damage in that area. However, it is worth noting that the compression damage level of the ASS middle column is significantly lower than that of the CIP and AMS, especially under high PGA conditions, where the advantage is more prominent. This indicates that non-rigid joints effectively regulate the distribution of internal force by allowing a certain degree of relative slip, reducing the concentrated transmission of load to the middle column, and thus improving the compressive performance of the middle column area. According to the development curve of the tension damage factors (DAMAGET) shown in

Figure 13b, under low PGA conditions, the tensile damage development at the top and bottom of the upper column in the ASS is gradual, with damage values considerably lower than those observed in the CIP and AMS, reflecting the good integrity and damage control ability under small earthquakes. However, the DAMAGET values at the top and bottom of the sidewalls are significantly higher than the other two structures, reflecting that the joint area is more prone to local peeling under tensile stress, becoming the potential weak link. As PGA further increases to 1.0 g, the rapid development of DAMAGET in all three structures approaches 1.0. Overall, under the action of small earthquakes, the damage of the ASS on key load-bearing components such as middle columns is significantly lower than that of the CIP and AMS, demonstrating superior damage control capabilities. But as the intensity of the earthquake increases, the damage development of the lateral joint interface accelerates, and the damage is concentrated in the joint area of the sidewalls.

In the design of prefabricated structures, by reasonably designing the stiffness, strength, and deformation capacity of joints, damage is actively guided to occur in non-critical areas that are easy to detect and repair and do not affect overall stability, achieving the seismic strategy of “strong columns and weak joints” or “damage isolation”. At the same time, structural measures must be strengthened in the joint area, such as setting up tensile anchors, interfacial shear keys, or elastic sealing materials, to improve the durability and impermeability, ensuring that the structure still has the necessary safety reserves and recoverable functions after strong earthquakes.

3.4. Response of Splicing Interface

To obtain the maximum deformation response of the assembly joint interface, and acknowledging that the left sidewall typically bears a heavier load than the right under seismic action, this study established multiple monitoring sections at critical joints within the ASS under intense earthquake conditions featuring a PGA of 1.0 g. Specifically, the monitoring sections encompass the left sidewall (L) and the middle column (C), as illustrated in

Figure 14.

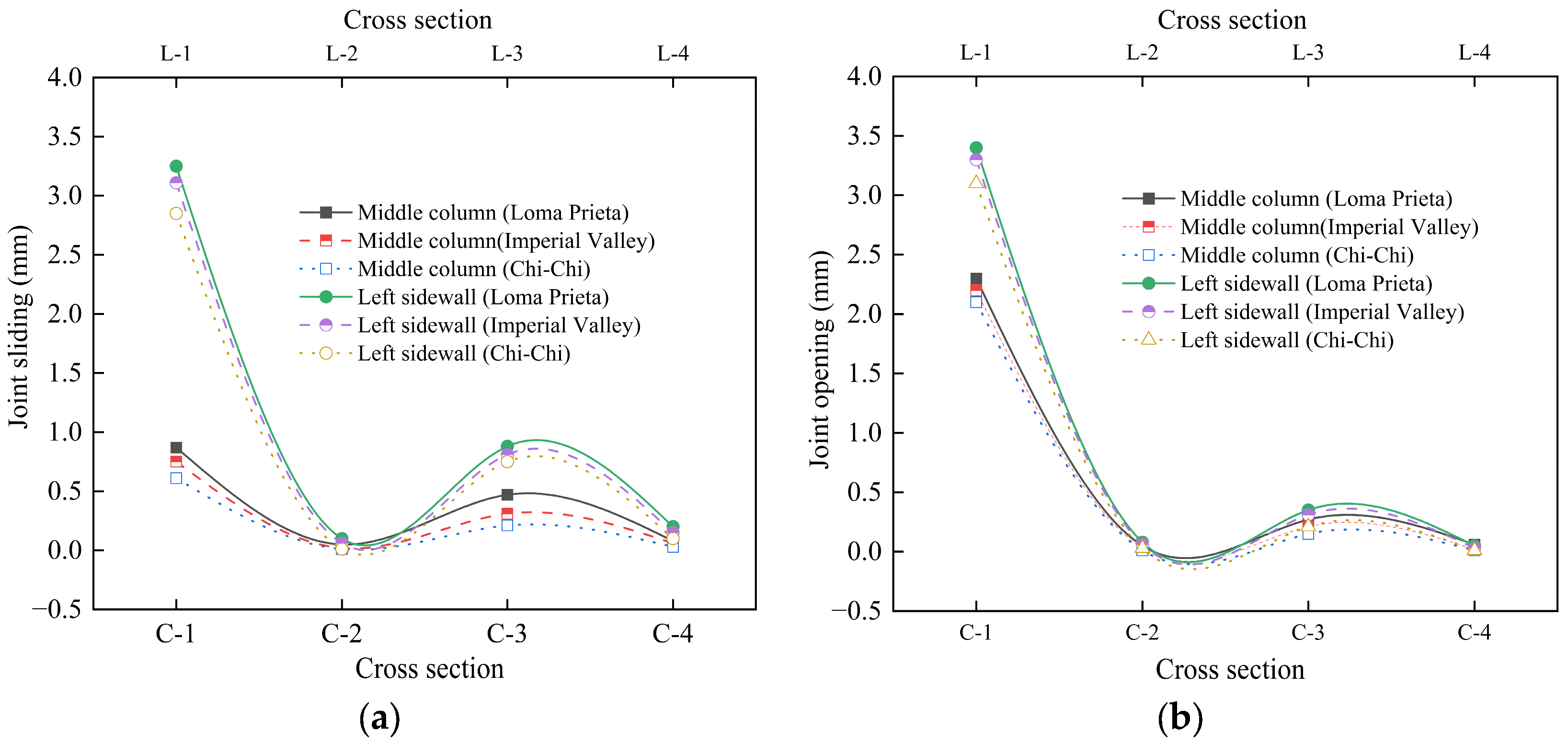

Figure 15 illustrates the maximum deformation response at the splicing interface of the monitoring sections with respect to the distribution characteristics of both horizontal sliding distance and vertical opening width. As depicted in

Figure 15a, during intense seismic activity, the horizontal relative displacement at the top monitoring section (L-1) on the left sidewall attains a maximum value of 3.25 mm, markedly exceeding that of other monitored zones, thereby emerging as the most prominent deformation area among joints. This observation suggests that the top of the left sidewall undergoes substantial bending moment and shear force. Given that the area typically resides at the junction of prefabricated wall panels, it experiences weaker boundary constraints and possesses lower connection stiffness compared to CIP, leading to enhanced lateral deformation capacity and susceptibility to cumulative slip, demonstrating typical flexible joint behavior. Furthermore, the horizontal sliding distance of the monitoring section (C-1) at the top of the middle column measures just 0.87 mm, significantly less than that at the top of the sidewall. This indicates that the connection joint between the middle column and the top slab exhibits greater connection stiffness and enhanced lateral displacement resistance. This is primarily attributed to the superior structural integrity and more comprehensive restraint conditions of the middle column, which facilitates the effective transmission of horizontal shear force. The horizontal sliding in the remaining monitoring areas is confined to within 0.45 mm, with some areas approaching zero, which demonstrates the exceptional deformation coordination capabilities, free from any noticeable sliding or detachment. Further analysis reveals that the non-uniform distribution of joint slip underscores the stress redistribution process within the structure during intense earthquakes and also emphasizes the localized areas of structural weakness. As the pivotal lateral load-resisting element, excessive slip at the top of the sidewall could result in deteriorated joint sealing performance and compromised waterproof layers and potentially impact the support conditions of the roof, ultimately jeopardizing the overall structural safety. Consequently, this area serves as the critical control part for seismic performance. Upon examining the distribution of joint opening width depicted in

Figure 15b, it becomes evident that the top of the left sidewall exhibits not only pronounced horizontal sliding but also the relatively significant vertical opening width, further confirming the nonlinear response characteristics of the joint under complex loading conditions. Consequently, in seismic design, it is imperative to implement reinforcement measures for such crucial connection sections to enhance the long-term serviceability. Therefore, in the design of prefabricated structures, attention should not only be paid to the overall load-bearing capacity but also to the refined design of the joint. For areas with high deformation requirements, such as the top of the sidewall, joint constructions with good ductility, adaptive deformation capacity, and reliable waterproof performance should be adopted, such as setting shear keys, pre-compressed springs, elastic filler material, or slidable energy dissipation devices to coordinate large displacements, alleviate stress concentration, and maintain sealing function. For key force transmission paths such as the central column, high-rigidity connections should be maintained to ensure efficient force flow transmission.

4. The Impact of Splicing Interface on Seismic Response

The splicing interface, as a key connecting part between prefabricated components, constitutes a critical link in the structural force transmission system, and the mechanical behavior directly determines the seismic performance of the structure. In order to further explore the influence mechanism of the splicing interface under seismic action, this study adopted two contact modeling strategies, namely “Surface to Surface Contact” and “Tie Contact”, to more accurately reflect the sliding, opening, and force transmission characteristics of the interface. The study systematically regulated the contact conditions of key joint interfaces, with a focus on analyzing the effects on the deformation modes and internal force redistribution of underground structures when PGA = 1.0 g. The component splicing interface is shown in

Figure 16. Where TW represents the splicing interface at the top of the sidewall, BW represents the splicing interface at the bottom of the sidewall, CP represents the splicing interface in the assembly area between cast-in-place and prefabricated components, and MC represents the splicing interface at the end of the middle column. Six different cases of splicing interface configurations were designed. The results are summarized in

Table 4. Where “T” represents “Tie Contact”, “S” represents “Surface to Surface Contact”, and “A” represents that all splicing interfaces are uniformly set to the same contact type. In addition,

η is defined as the ratio of the IDR under each case to that of the T-A case.

From

Table 4, it can be seen that the splicing interface CP between cast-in-place components and prefabricated components exerts the greatest influence on the IDR of the subway station structure and is the dominant factor controlling the overall deformation characteristics. The splicing interface TW between the top of the sidewall and the top slab also exhibits strong sensitivity, and the quality of the connection performance directly affects the deformation response. If the bonding strength between the two key splicing interfaces is insufficient, interface sliding or opening is prone to occur under seismic action, resulting in stiffness degradation in the joint area, thereby reducing the structure’s overall lateral stiffness and even localized deformation concentration, seriously weakening the seismic performance. In contrast, the connection strength of splicing interface MC has a relatively small impact on deformation response and is a non-critical influencing factor. This phenomenon indicates that although the middle column bears the main vertical load, the variation in the joint connection stiffness has limited control over the overall horizontal deformation, and the lateral deformation response depends more on the integrity and collaborative working ability of the sidewalls. However, it is worth noting that when the splicing interface BW between the bottom of the sidewall and the bottom slab connection area is set with “Tie Contact”, the IDR of the structure is significantly reduced. This indicates that a good connection in this area can effectively enhance the lateral constraint capability at the bottom of the structure.

Figure 17 presents a comparison of the maximum internal force response of the middle column and two sidewalls for six distinct joint splicing interface cases under Loma Prieta motion when PGA = 1.0 g. From

Figure 17, it can be observed that the T-CP case exhibits the lowest internal force response level, closely matching the internal force values of the T-A case, both of which fall within the lower bound of the overall internal force response range. This suggests that achieving the rigid connection at the CP interface significantly enhances structural integrity and facilitates more efficient load transfer pathways, thereby effectively mitigating stress concentrations in critical components and improving the structural collaborative performance. In contrast, the internal force response curves for the T-TW, T-BW, and T-MC cases nearly overlap with the results from the S-A case, all reaching the upper limit of internal force response. This observation indicates that even when the critical joint splicing interfaces between the prefabricated components are idealized as rigid connections, the contribution to improving overall structural force redistribution remains minimal.

The joint splicing interface CP between cast-in-place and prefabricated components is the core controlling factor that determines the seismic performance of the structure. The area is located at a critical joint for structural stress conversion and plays an important role in coordinating vertical load transmission and horizontal forces. If the splicing interface connection is weak, it is highly likely to form weak hinges, leading to sudden stiffness changes and imbalanced redistribution of internal force, and even causing local failure to evolve into overall instability. In contrast, splicing interfaces such as TW, BW, and MC have less impact on the distribution of internal force in the main structure due to the secondary path or relatively uniform force distribution in the overall force transmission system. In the design and construction of prefabricated subway station structures, emphasis should be placed on ensuring the connection quality of the joint splicing interface CP between the cast-in-place and the prefabricated components, ensuring that it has sufficient rigidity and ductility.

In the design of prefabricated structures, emphasis should be placed on the design of joint stiffness and strength, especially at key joints where stress concentration and high deformation demands occur. The joint constructions with high stiffness, high strength, and good ductility should be adopted to ensure efficient and stable force flow transmission while avoiding problems such as sudden changes in stiffness and uneven distribution of internal forces caused by joint weakening. For non-critical areas, flexible joints can be appropriately used to distribute stress and increase the overall toughness of the structure. However, factors such as joint durability, waterproof performance, and maintenance costs need to be comprehensively considered during design to ensure the safety, reliability, and functional integrity of the structure throughout the life cycle.