1. Introduction

Adobe construction is increasingly valued for its low environmental footprint, affordability, and compatibility with vernacular building traditions, particularly in rural or low-income contexts [

1]. Adobe materials offer significant environmental advantages, with CO

2 emissions of 22 kg/ton compared to the 143 kg/ton of concrete blocks [

1]. Recent studies have emphasized the role of circular economy strategies in adobe construction, demonstrating how waste valorization contributes to reducing embodied emissions [

2]. However, conventional adobe bricks are limited by their structural and thermal properties, with compressive strength values significantly varying between manufacturers and manufacturing techniques [

3,

4]. Hence, additional enhancements are required for adobe bricks to become suitable for modern energy-efficient applications.

Efforts to enhance the performance of Adobe bricks have focused on the incorporation of organic fibers and natural clay minerals. Natural fiber reinforcement has demonstrated significant potential across diverse geographical contexts, with various plant-based fibers achieving substantial mechanical improvements [

5,

6,

7]. Parallel advances in geopolymer and fiber-reinforced bricks further illustrate how natural fibers and alternative binders can enhance both thermal and mechanical performance [

8]. For instance, studies on seagrass fibers (Posidonia Oceanica) have shown superior performance to straw, confirming the potential of alternative natural fibers [

9].

Rice husk, a widely available agricultural by-product in Thailand, containing 45% cellulose, 19% hemicelluloses, 19.5% lignin, and 15% silica by weight [

10], has been shown to improve adobe brick properties when incorporated into mixtures, though the effects vary with soil composition and require optimization [

11]. Research in Thailand has demonstrated that while the addition of rice husk significantly improves shrinkage resistance and provides important reinforcement benefits, it can reduce compressive strength [

11]. Other studies have found considerable improvements in the properties of adobe composites reinforced with other natural fibers. An example is the palm-fiber reinforcement, which is linked to a 59% increase in compressive strength of adobe bricks [

12]; sisal-fiber reinforcement shows a 240% increase in compressive strength at optimal concentrations [

6]. Recent studies have shown that date-palm waste can reduce thermal conductivity by 49% in earth bricks [

13], whilst others report that the addition of pine needles can lead to up to ~24% higher compressive strength compared to straw reinforcement [

5], with measured strengths of ~3.2–3.3 MPa versus ~2.7 MPa for straw. Organic waste has been validated as a means of reinforcing adobe. The residues from the paper and pulp industry, for example, have yielded up to 190% gains in compressive strength and a 30% decrease in thermal conductivity [

14]. Furthermore, hemp-shiv reinforcement has been studied to increase flexural strength by 39% [

15]. Additionally, bunho and junco fibers attain 20% enhancement in thermal insulation properties [

16], and the use of fonio straw has been found to reduce thermal conductivity by up to ~67% at 1 wt% [

17]. Mechanical performance peaks at ~0.2–0.4 wt% and may decline at higher dosages, indicating that the optimum level balances insulation gains with strength. Comparative studies of several types of fibers have also shown that wheat straw offers a good compromise between mechanical properties and water resistance [

18].

In addition to fiber reinforcement, mineral additives such as bentonite have proven beneficial in enhancing cohesion, water resistance, and plasticity of earth-based materials. These properties are encouraged by the fine-grained alumino-silicate content of bentonite [

19]. There is also the promise of bio-stabilization strategies, which use natural additives. Cow dung, for example, provides a 40% increase in mechanical strength stemming from synergistic organic-mineral interactions [

20]. Dynamic compaction methods have also been shown to increase the compressive strength by 79% in combination with proper clay content [

21].

While these enhancement approaches show significant promise, limited research has systematically compared additive performance across different soil mineralogies or examined how compositional parameters such as silica-to-alumina ratios correlate with mechanical and thermal outcomes. Additionally, the integration of disaster waste materials into adobe construction represents an underexplored opportunity for circular economy applications.

Dredged sediments and similar materials reused in construction have attracted significant international interest, thereby setting a precedent in other similar projects [

22]. Adobe bricks have also been successfully integrated with construction waste materials; recycled powder demonstrates significant performance improvements and contributes to the circular economy [

23]. Various industrial waste materials such as ash and limestone sludge have also been effectively incorporated in the composition of adobe bricks as a means of sustainable waste-management [

24].

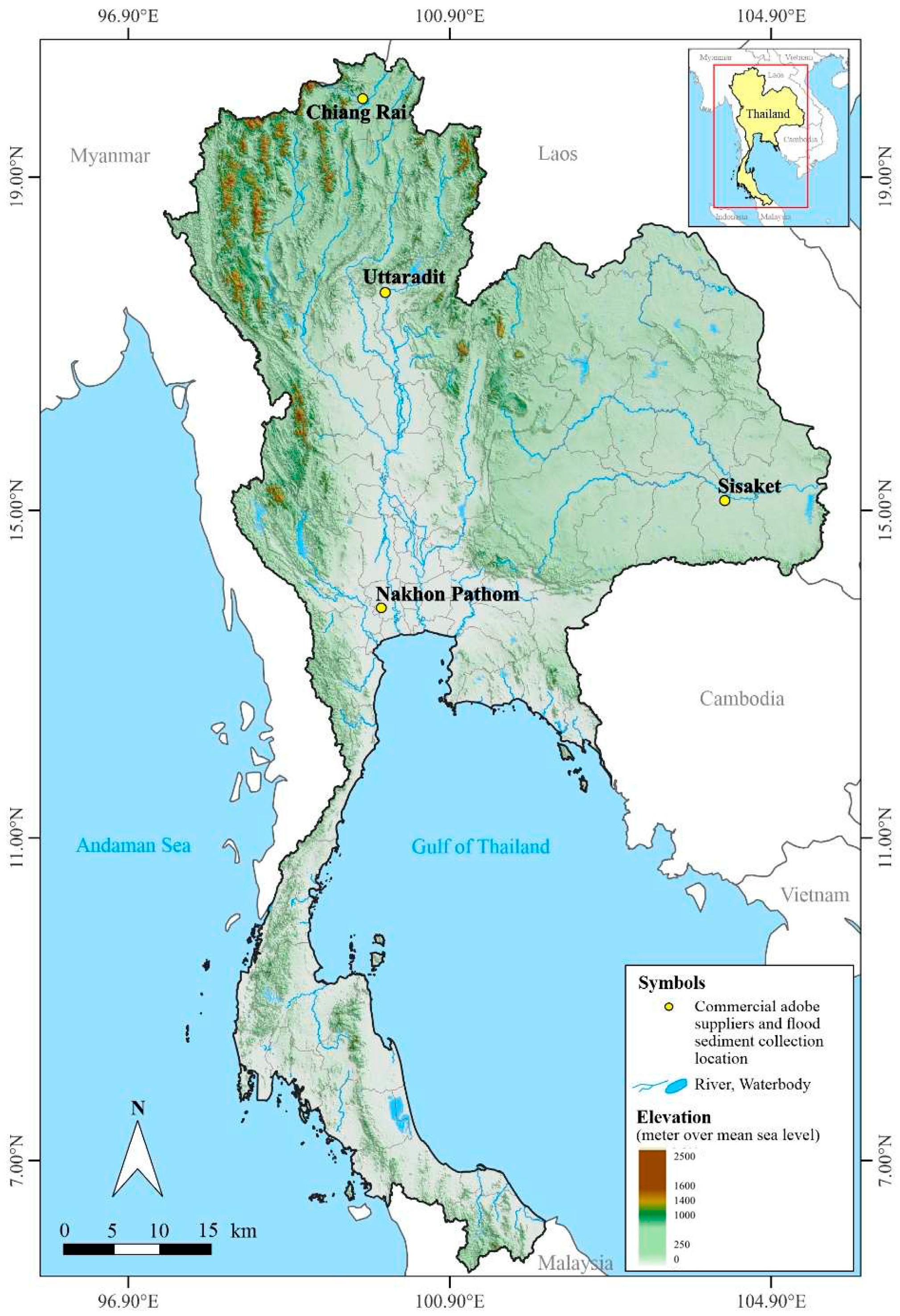

In September 2024, Chiang Rai province was hit by extreme flooding that left sediments over 2 m high in the areas it affected, especially the Mae Sai district (

Figure 1). These flood-derived sediments represent a major disposal problem as they are of large volume and can lead to unintended consequences if not properly disposed of. This paper thus investigates the possibility of recycling these deposits into a usable construction material by assessing their suitability to be made into adobe bricks. In order to create a control group, the soils used to make three commercially available adobe bricks were used as references, namely Nakhon Pathom (NPT), Sisaket (SSK), and Uttaradit (UTT), which represents established regional adobe production practices with the addition of natural fibers being common. More recent systematic research has established baseline ranges of mechanical properties of traditional adobe construction, with strong regional variations [

25]. Rice husk was added to the Chiang Rai flood sediment (CRI) to enable comparability. Initial findings, nevertheless, showed that they were not strong enough when used alone. Therefore, bentonite was added as a second stabilizer to see whether rice husk, bentonite or the mixture of both could convert the sediment to a construction grade material.

Although the research of natural fibers and mineral additives has advanced, there are still a number of critical knowledge gaps that have not been filled. The majority of research has assessed additives individually and in a single-soil environment, and little focus has been made on the effects of various soil mineralogies on the performance of additives. Also, thermal performance is commonly underreported even though it is applicable in tropical climates [

16], and no research has been performed linking adobe development with the reuse of sediment waste in circular construction plans. On the same note, experiments on non-traditional additives, like Bakelite, have demonstrated a decrease in compressive strength and a considerable enhancement in thermal insulation, which underscores thermal-mechanical trade-offs [

26].

This research fills these knowledge gaps by using three main innovations: (1) systematic research on the relationships between soil mineralogy and additive effectiveness in various Thai soils, which form predictive frameworks, depending on the soil composition and plasticity properties; (2) dual-additive optimization between rice husk and sodium bentonite in gradual concentrations (5, 10, 15) to apply to the specific performance of flood sediments; and (3) comprehensive valorization of September 2024 Chiang Rai flood sediments as construction materials, investigating the potential for disaster waste transformation into functional building components.

3. Results

A total of twelve adobe formulations were developed to evaluate the influence of soil origin and additive combination on the mechanical and thermal performance of adobe bricks. The results are structured in three phases that reflect the material development pathway: initial evaluation of regional soil performance and reinforcement using rice husk and optimization of flood-sediment adobe bricks with bentonite. Each stage includes detailed assessments of compressive strength, flexural strength, and thermal conductivity.

3.1. Baseline Performance of Regional Soils

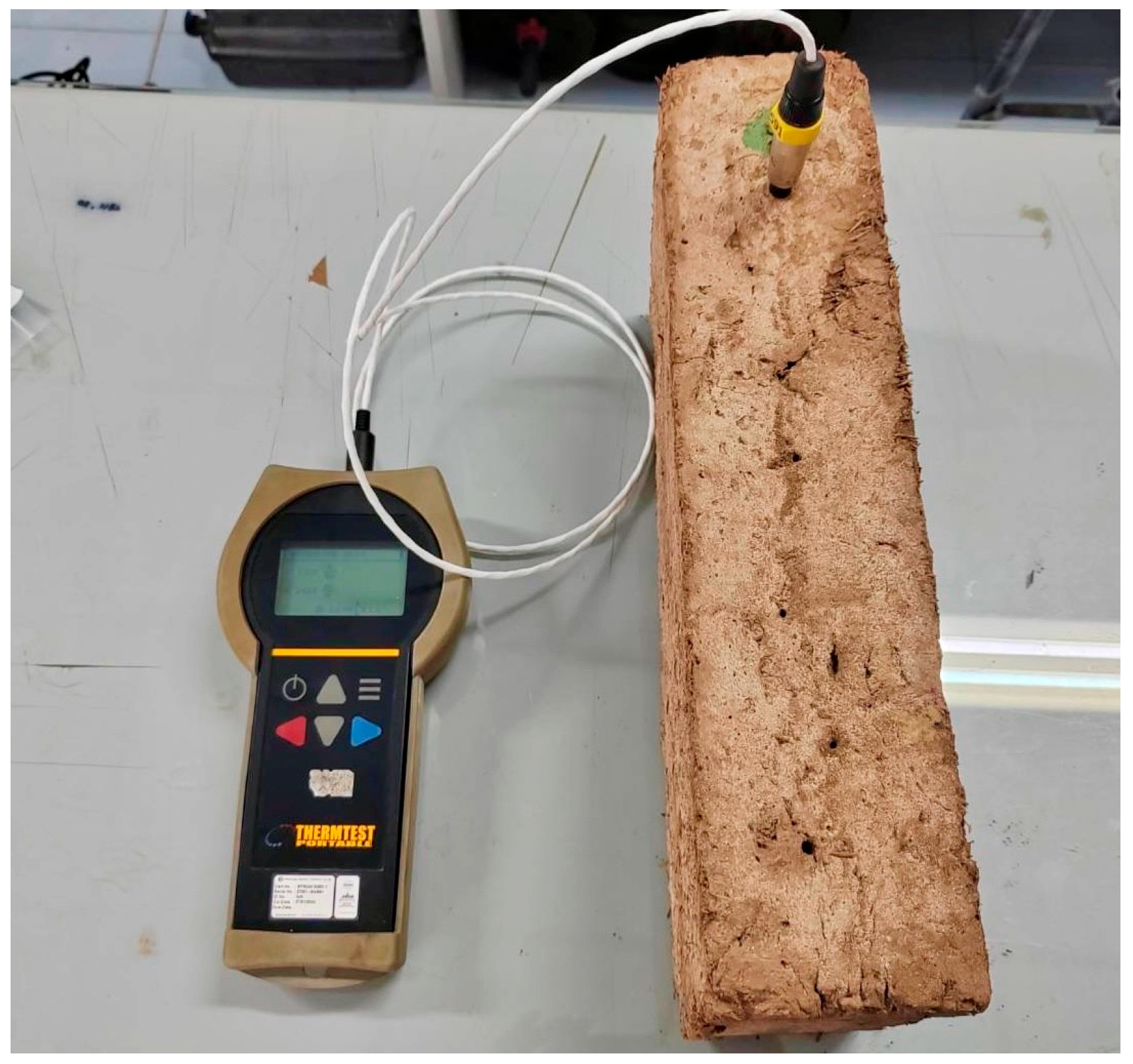

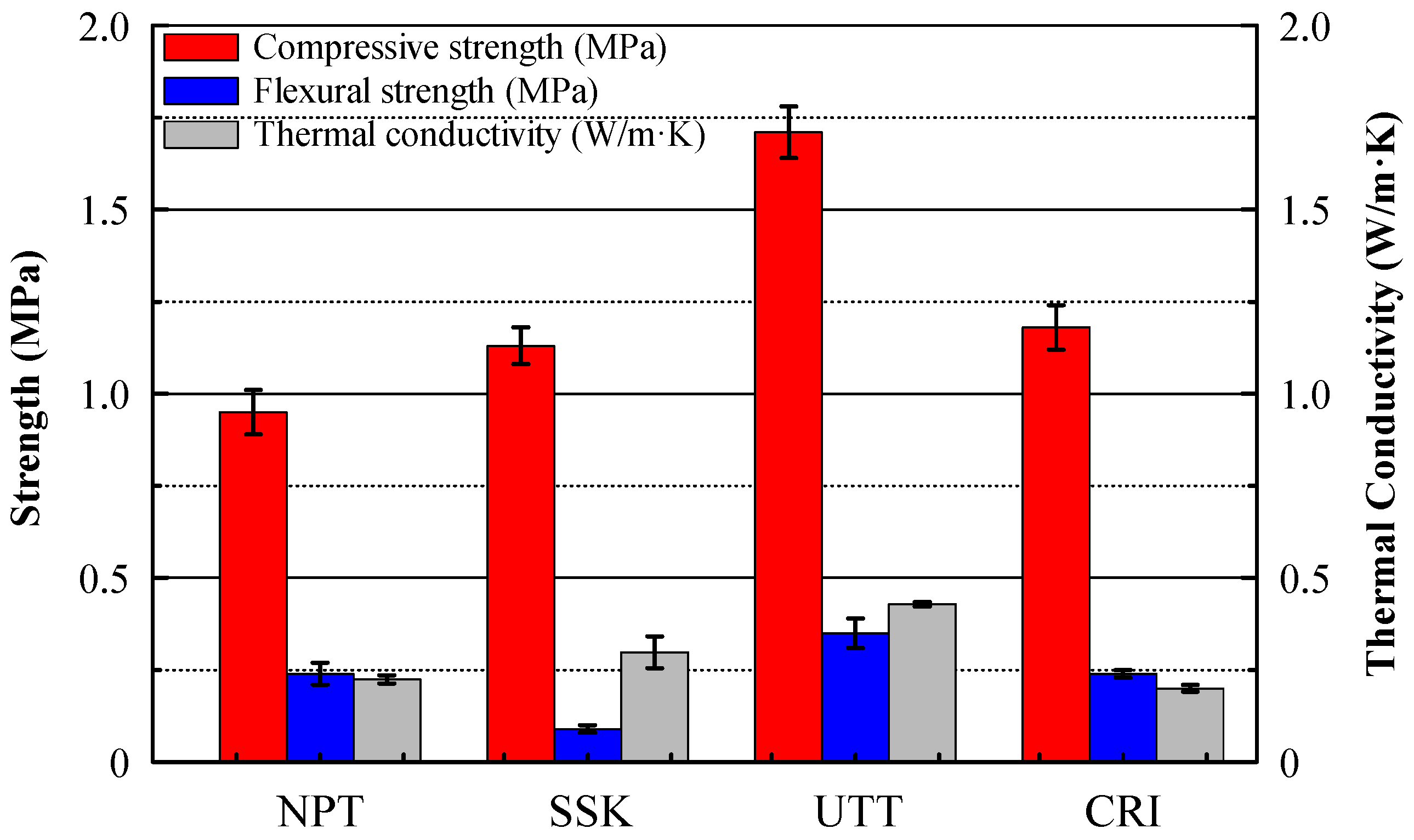

Adobe performance varied across the four soil types, with distinct mechanical and thermal characteristics observed for each formulation (

Figure 10). Uttaradit soil achieved the highest mechanical properties among all tested materials, with compressive strength of 1.71 ± 0.07 MPa and flexural strength of 0.35 ± 0.04 MPa. However, this superior mechanical performance corresponded with the highest thermal conductivity of 0.428 ± 0.006 W/m·K.

Chiang Rai flood sediment demonstrated moderate compressive strength (1.18 ± 0.06 MPa) and flexural strength of (0.24 ± 0.01 MPa) among all formulations. Notably, this material exhibited the lowest thermal conductivity (0.200 ± 0.009 W/m·K), indicating superior thermal insulation properties.

Nakhon Pathom and Sisaket soils showed compressive strengths of 0.95 ± 0.06 and 1.13 ± 0.05 MPa, respectively, with contrasting flexural behaviors: NPT achieved 0.24 ± 0.03 MPa while SSK reached 0.09 ± 0.01 MPa. Thermal conductivities were 0.224 ± 0.011 W/m·K for NPT and 0.298 ± 0.043 W/m·K for SSK.

The results reveal an inverse relationship between mechanical strength and thermal insulation performance: UTT provided optimal mechanical properties but limited thermal benefits, while CRI offered superior insulation with moderate structural capacity. NPT and SSK exhibited intermediate performance across both mechanical and thermal metrics, establishing distinct baseline characteristics for subsequent additive optimization studies.

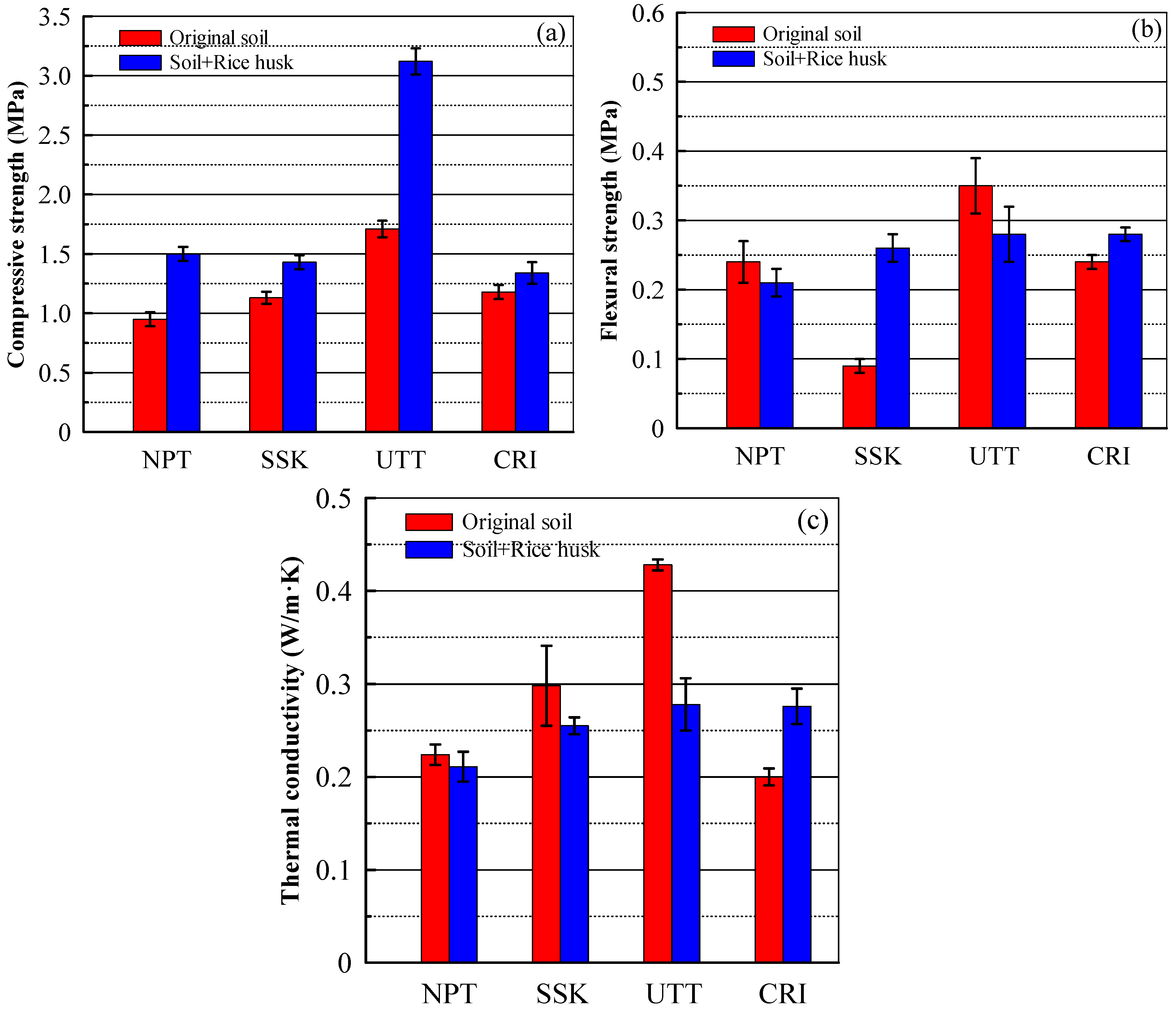

3.2. Effects of Rice Husk Reinforcement

Rice husk incorporation produced systematic mechanical and thermal property modifications across all soil matrices, with enhancement magnitude correlating with mineralogical composition and baseline matrix characteristics (

Figure 11).

The compressive strength increased significantly across the soil types. The highest increase was observed in UTT, where 1.71 ± 0.07 MPa improved to 3.12 ± 0.11 MPa (82.5% increased). This was succeeded by NPT (57.9% increase to 1.50 ± 0.06 MPa), SSK (26.5% increase to 1.43 ± 0.06 MPa), and CRI (13.6% increase to 1.34 ± 0.09 MPa). The silica to alumina ratio can be used to rationalize the observed ranking, with UTT, which has a balanced composition (42.1% SiO2 and 40.4% Al2O3), exhibiting optimal performance, and CRI, which has a more heterogeneous composition (15.3% SiO2, 16.8% Al2O3), having limited enhancement efficacy.

The responses of flexural strength showed opposite trends. CRI experienced a significant positive change, with a 16.7% increase from 0.24 ± 0.01 to 0.28 ± 0.01 MPa, whilst the other soils exhibited decreases of between 4.5% in NPT and 34.9% in UTT, suggesting that the reinforcement behaviors were different in the various matrices.

All formulations showed an improvement in thermal conductivity with the following ranking of performance: NPT + RH (0.211 ± 0.016 W/m·K) < SSK + RH (0.255 ± 0.009 W/m·K) < CRI + RH (0.276 ± 0.019 W/m·K) < UTT + RH (0.278 ± 0.028 W/m·K). This shows that rice husk is a good renewable insulation additive. The trade-offs between density and porosity are reflected in the inverse correlation between mechanical strength and thermal insulation capacity, with high compressive performance and low insulation capacity.

Measurement variability varies across formulations. UTT + RH produced very similar results (relative coefficient of variation, CV = 3.56%), but CRI + RH was more variable (CV = 6.65%), as flood sediment deposits are heterogeneous. NPT + RH and SSK + RH exhibited intermediate variability, with CVs of 4.01% and 4.18%, respectively. These findings support the idea that mineralogical composition is the major factor that determines the effectiveness of reinforcement of rice husk, but the exact mechanisms that underlie soil-specific responses are not yet well understood without the in-depth micro-structural analysis.

3.3. Optimization of Flood Sediment with Bentonite

Complex material interactions and trade-offs in performance were evident in the systematic addition of bentonite to CRI flood sediment (

Figure 12). The results of individual additives were opposite: the addition of rice husk (CRI+RH) resulted in an optimal compressive strength of 1.34 ± 0.09 MPa along with a thermal conductivity of 0.276 ± 0.019 W/m·K, and the addition of bentonite (CRI + B5) enhanced flexural strength to 0.40 ± 0.04 MPa, but decreased compressive strength to 0.85 ± 0.07 MPa and increased thermal conductivity to 0.404 ± 0.010 W/m·K. Dual-additive systems allowed balancing between the mechanical and thermal spectrum: CRI + RH + B5 had intermediate properties (0.82 ± 0.07 MPa compressive, 0.26 ± 0.01 MPa flexural, 0.263 ± 0.008 W/m·K thermal conductivity); CRI + RH + B10 had balanced properties (0.99 ± 0.02 MPa compressive, 0.23 ± 0.01 MPa flexural, 0.232 ± 0.013 W/m·K).

These data support systematic trade-offs which allow application-specific optimization: compressive strength is maximized by rice husk addition, moderate concentrations of bentonite (5–10%) balance mechanical and thermal properties, and high concentrations of bentonite (15%) maximize thermal insulation at the expense of structural capacity. In this way, formulation strategies may be customized: maximum compressive strength with addition of sole rice husk, balanced properties with moderate addition of bentonite, or increased thermal properties with high addition of bentonite.

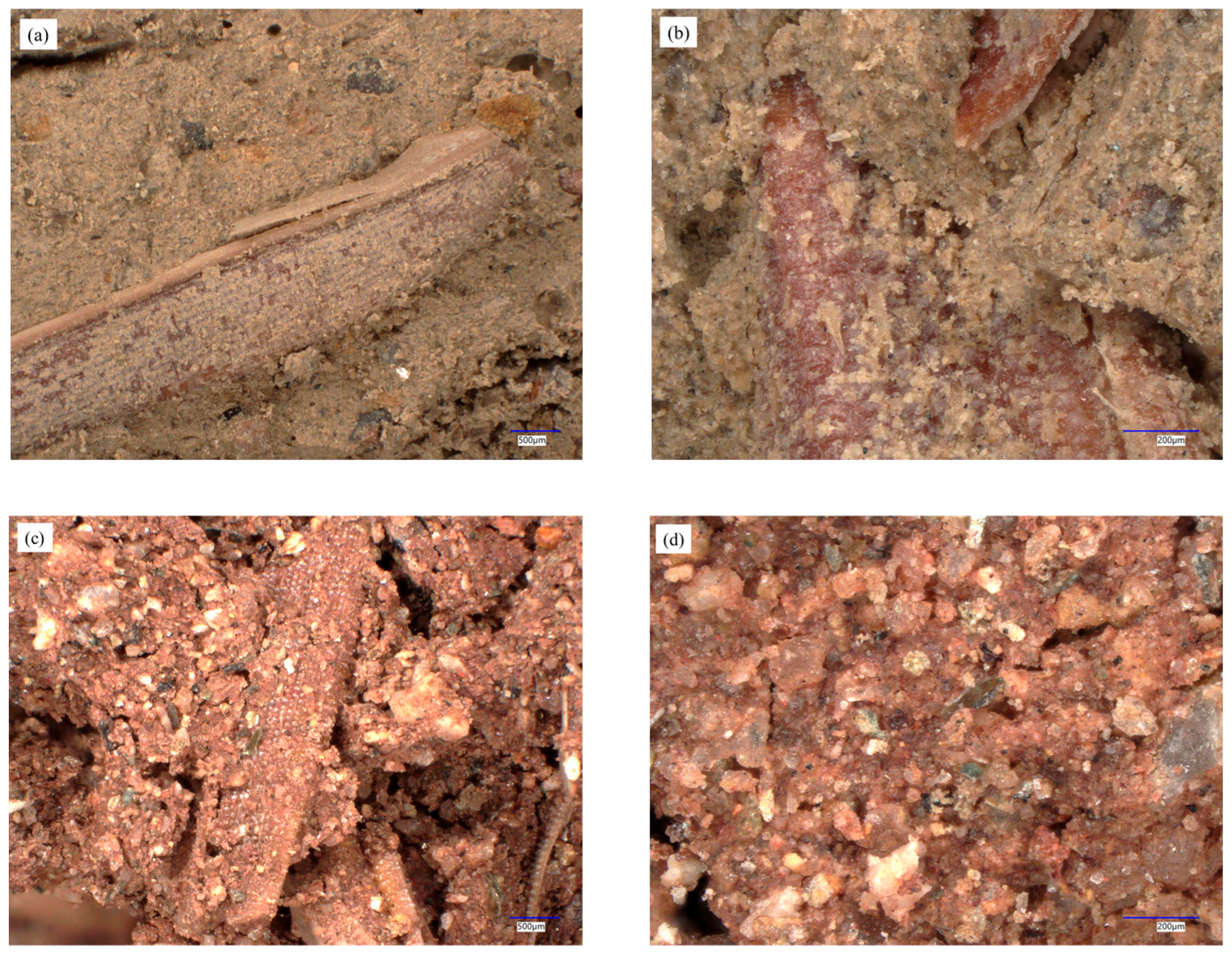

3.4. Microstructural Analysis

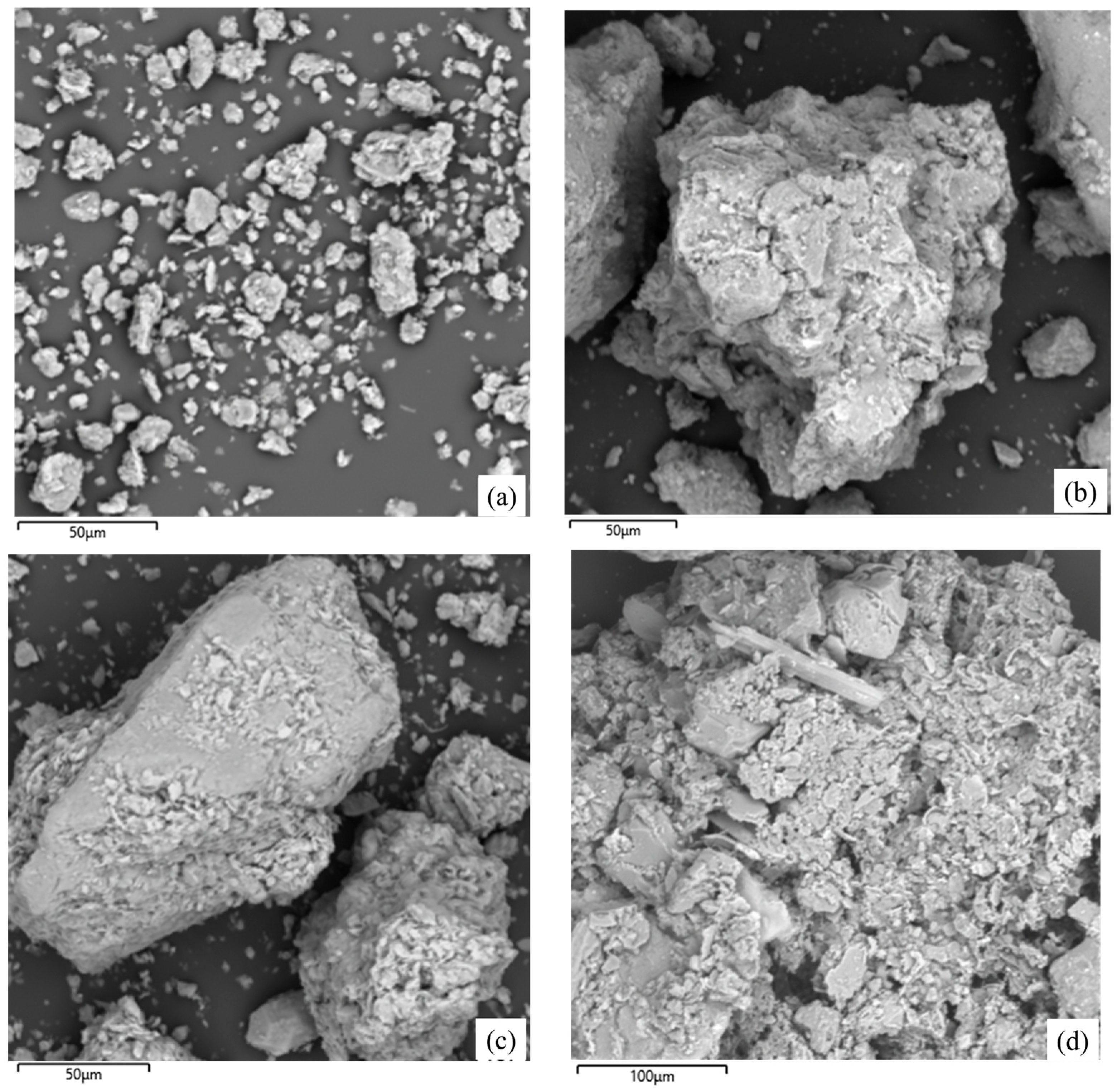

Optical microscopy with polarized light (OM-LIBs) was performed on selected formulations to understand the underlying mechanisms governing the observed mechanical and thermal performance variations. CRI + RH and CRI + RH + B10 were chosen for detailed microstructural examination as they represent contrasting optimization strategies: CRI + RH maximizes compressive strength (1.34 ± 0.09 MPa) while CRI + RH + B10 prioritizes thermal insulation (0.199 ± 0.015 W/m·K) with significantly reduced mechanical performance (0.39 ± 0.03 MPa).

CRI + RH formulations revealed rice husk fibers distributed heterogeneously throughout the flood sediment matrix with highly variable interfacial bonding characteristics (

Figure 13a,b). The rice husk particles, ranging from 0.15 to 4.0 mm in length, formed a three-dimensional reinforcing network within the soil matrix. However, substantial void spaces were observed between matrix particles, and fiber-matrix adhesion varied significantly across the sample. Poor interfacial bonding in several regions correlates directly with the modest 13.6% compressive strength improvement compared to other soil types, while the abundant air voids explain the moderate thermal conductivity reduction to 0.276 ± 0.019 W/m·K.

In contrast, CRI + RH + B10 formulations exhibited fundamentally altered microstructural characteristics due to bentonite’s binding and void-filling effects (

Figure 13c,d). The fine bentonite particles (97.29% passing 0.075 mm) effectively filled interparticle voids and created a significantly more continuous, dense matrix structure. This enhanced matrix continuity eliminated most air voids and improved particle packing efficiency, resulting in superior thermal insulation properties (0.199 ± 0.015 W/m·K). However, the increased density and reduced porosity contributed to matrix brittleness, explaining the substantial reduction in compressive strength to 0.39 ± 0.03 MPa.

The microstructural analysis reveals that rice husk provides mechanical reinforcement through fiber bridging in the heterogeneous CRI matrix, while bentonite addition fundamentally transforms the composite from a fiber-reinforced system to a dense, thermally optimized material. This microstructural understanding validates the observed trade-offs between mechanical and thermal performance in the dual-additive systems.

3.5. Rice Husk Reinforcement Mechanisms

The systematic change in rice husk performance in various soil matrices can be explained by a certain physicochemical interaction between the silica-rich rice husk (87.3% SiO2) and the different soil mineral compositions. The reinforcement mechanisms act based on the chemical compatibility and physical interlocking effects.

UTT soil showed the best incorporation of rice husk because of the balanced ratio of SiO2/Al2O3 (42.1%:40.4%), which gives the best silica-silica bonding and still has enough alumina phases to hold the matrix together. This chemical compatibility coupled with good load transfer mechanisms led to the maximum increase in compressive strength (82.5% improvement to 3.12 ± 0.11 MPa).

NPT soil, though rich in silica (67.0% SiO2), was moderately enhanced (57.9% to 1.50 ± 0.06 MPa) because of the low alumina phases (22.0% Al2O3) to bind the matrix. SSK demonstrated a moderate performance (26.5% to 1.43 ± 0.06 MPa) that was associated with moderate alumina content (25.5% Al2O3), which validated the significance of balanced mineralogy in terms of the optimum fiber-matrix interaction.

CRI flood sediment is a special situation in which heterogeneous composition (15.3% SiO2, 16.8% Al2O3) results in changing local bonding conditions. Although this reduces compressive enhancement (13.6% to 1.34 ± 0.09 MPa), it is the only matrix that enhances flexural strength (40% increase to 0.28 ± 0.01 MPa) by distributed fiber network effects. This mechanism is supported by the microstructural evidence in the form of three-dimensional fiber distribution that increases the resistance of cracks to bending loads.

The enhancement in thermal conductivity of all rice husk formulations (0.211–0.278 W/m·K range) is due to the induction of organic porosity and the low thermal conductivity of rice husk fibers (approximately 0.05–0.08 W/m·K) which forms effective insulation channels irrespective of the type of soil matrix.

4. Discussion

This section interprets the results presented earlier, shedding light on the material behavior, additive interactions, and underlying mechanisms that govern the performance of the studied adobe formulations. Three core findings emerge: the influence of soil mineral composition on baseline properties, the role of rice husk in enhancing mechanical and thermal properties, and the viability of bentonite for stabilizing flood-derived sediment. These insights contribute to a broader understanding of optimized material design for sustainable earthen construction.

4.1. Influence of Mineral Composition on Adobe Behavior

It was found that the mineralogical diversity of the soils under study had a strong impact on the adobe performance characteristics as it was shown in

Table 6 and confirmed by XRD analysis (

Figure 4;

Table 3). The correlation between the soil structure and performance shows some particular behaviors related to the prevalent mineral phases.

The Uttaradit soil, which had a balanced composition of silica-alumina (42.1% SiO2, 40.4% Al2O3), had the best mechanical performance of all the soils tested with compressive strength of 1.71 ± 0.07 MPa and flexural strength of 0.35 ± 0.04 MPa. Nevertheless, the high thermal conductivity (0.428 ± 0.006 W/m·K) that comes with the high strength of UTT meant that the material had low insulation ability.

Although it is heterogeneous (15.3% SiO2, 16.8% Al2O3), Chiang Rai flood sediment exhibited significant compressive strength (1.18 ± 0.06 MPa) and the highest insulation performance with the lowest thermal conductivity (0.200 ± 0.009 W/m·K). The correlation between the depositional source of the material and thermal performance needs further microstructural studies to be able to establish causative processes.

The soil of Nakhon Pathom with high silica content (67.0% SiO

2), had moderate mechanical (0.95 ± 0.06 MPa compressive, 0.24 ± 0.03 MPa flexural) and thermal (0.224 ± 0.011 W/m·K) behavior. These findings are in line with the findings in the Champagne region, which indicated that the quartz-dominated soils exhibit different yet moderate performance properties, which underscores the effects of mineralogical dominance on adobe performance [

29].

Sisaket soil had similar compressive strength (1.13 ± 0.05 MPa) and intermediate flexural resistance (0.09 ± 0.01 MPa) and intermediate thermal conductivity (0.298 ± 0.043 W/m·K). The reported TiO

2 content of SSK (55.5%) is deemed to be an artifact of relative peak dominance and was not used in the interpretation of the properties (see

Section 2.2). The intermediate flexural performance is associated with the small amount of alumina-bearing phases. This finding is consistent with the results that mineral composition influences mechanical behavior in earthen materials [

33].

These findings define clear performance characteristics of the tested materials: UTT was found to have the best mechanical properties with balanced mineralogy, CRI was found to have the best thermal insulation with heterogeneous composition, and NPT and SSK were found to have intermediate properties. The overall inverse correlation of mechanical strength and thermal insulation of all soils in this study indicates material trade-offs, which should be considered in application-specific optimization strategies.

4.2. Mechanism of Rice Husk Reinforcement

Rice husk addition significantly enhanced adobe performance across all soil types, with the magnitude of improvement correlating with soil mineralogy and baseline material characteristics (

Table 7). The reinforcement effectiveness varied systematically among different soil matrices, as observed in this study, with underlying mechanisms revealed through microstructural analysis.

Uttaradit soil demonstrated the most substantial improvements with rice husk addition, achieving compressive strength increases of 82.5% (from 1.71 ± 0.07 to 3.12 ± 0.11 MPa) while experiencing flexural strength reduction of 20.0% (from 0.35 ± 0.04 to 0.28 ± 0.04 MPa). This performance profile indicates complex interactions between the fiber additive and UTT’s balanced mineralogy (42.1% SiO2, 40.4% Al2O3), though detailed interfacial analysis would be necessary to elucidate specific mechanisms.

Nakhon Pathom soil exhibited substantial improvements with rice husk incorporation, achieving compressive strength enhancement of 57.9% to 1.50 ± 0.06 MPa and flexural strength reduction of 12.5% to 0.21 ± 0.02 MPa. The quartz-dominated composition (67.0% SiO2) correlates with this balanced enhancement pattern, though the relationship requires microstructural investigation to establish causative factors.

Sisaket soil showed moderate compressive strength improvements of 26.5% to 1.43 ± 0.06 MPa with flexural strength increases of 189% to 0.26 ± 0.02 MPa. Chiang Rai sediment demonstrated contrasting behavior with modest compressive gains of 13.6% to 1.34 ± 0.09 MPa but exceptional flexural enhancement of 16.7% to 0.28 ± 0.01 MPa. This unique flexural response, where both CRI and SSK improved while NPT and UTT decreased, reflects the different reinforcement mechanisms across soil matrices and suggests that heterogeneous compositions can enable alternative fiber-matrix interaction pathways.

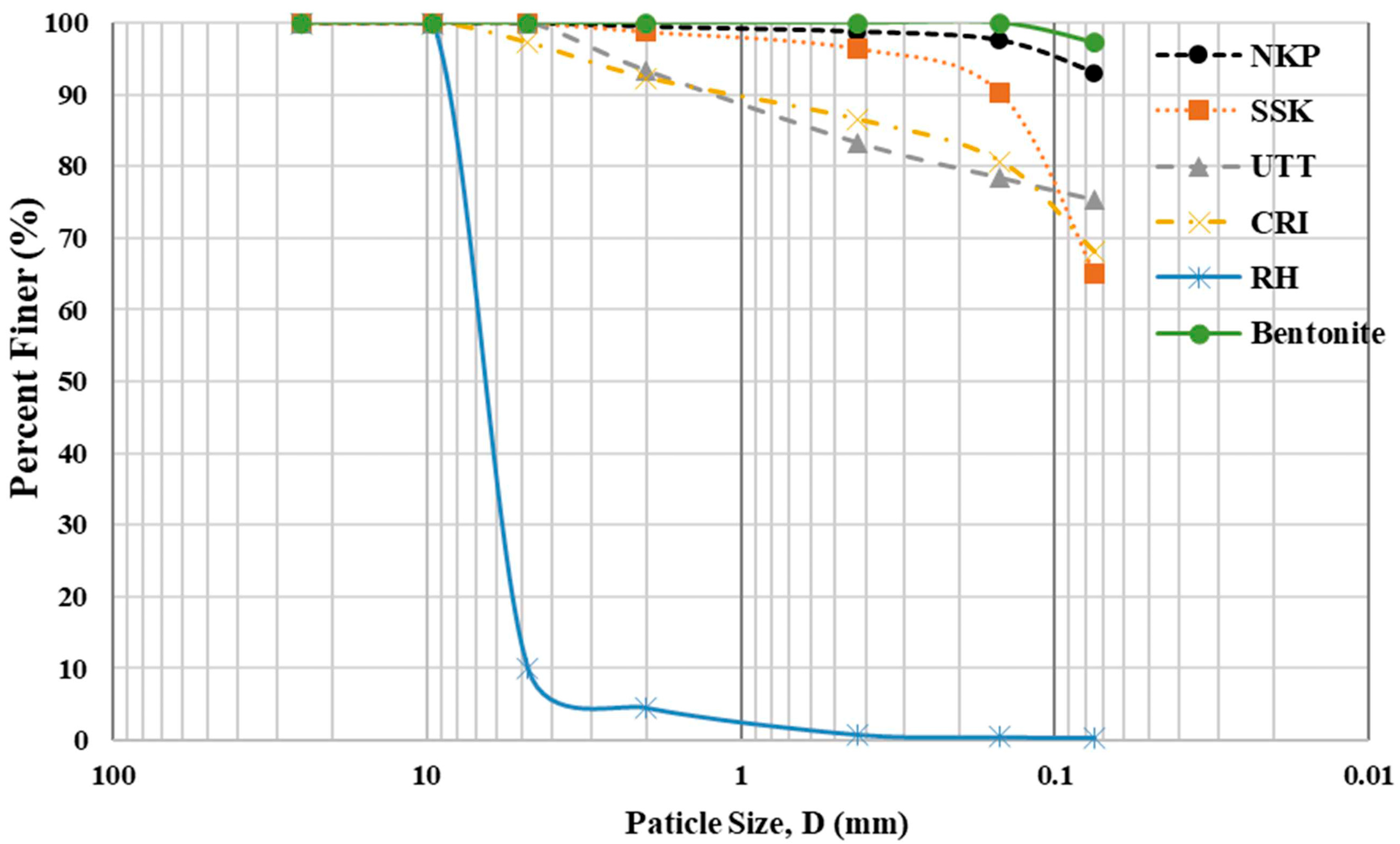

The particle size analysis reveals that rice husk exhibits predominantly coarse particles, with 89.98% retained above 4.75 mm sieve size, providing fibrous reinforcement within the adobe matrix. The moisture content during casting varies significantly among formulations: CRI + RH (49.93%), NPT + RH (38.29%), SSK + RH (22.56%), and UTT + RH (17.26%), indicating different water absorption characteristics that may influence bonding behavior.

Microstructural analysis using optical microscopy with polarized light (OM-LIBs) reveals distinct characteristics between CRI + RH and CRI + RH + B10 systems. The CRI + RH samples show individual rice husk fibers appearing as elongated, light brown to tan colored tubular structures embedded within the darker brown soil matrix. The fibers display a hollow, cellular structure typical of plant cellulose with visible void spaces around the fiber-matrix interfaces. The matrix appears heterogeneous with variable particle sizes and colors, creating a loose, porous microstructure that explains both the modest compressive improvement (13.6%) and the unique flexural enhancement (16.7%) observed in CRI formulations.

In contrast, the CRI + RH + B10 samples exhibit a fundamentally different microstructure, characterized by a much denser, more uniform reddish-brown matrix. The fine bentonite particles appear to have filled the void spaces and created a more continuous matrix structure. The overall microstructure is significantly denser and more homogeneous compared to the CRI + RH system, with reduced porosity. Measurement analysis indicates that rice husk fibers in this system maintain lengths over 1200 μm, but they are more intimately bonded within the denser bentonite-enhanced matrix. This denser microstructure correlates with the superior thermal insulation properties (0.199 ± 0.015 W/m·K) but reduced mechanical performance (0.39 ± 0.03 MPa compressive) of the CRI + RH + B10 formulation.

The microstructural comparison reveals that rice husk has been shown to reinforce by physical fiber bridging in the loose CRI matrix, and addition of bentonite fundamentally changes the composite behavior by forming a dense, thermally optimized material by filling in the voids and densifying the matrix. The apparent disparity in porosity and matrix continuity between the two systems confirms the apparent trade-offs between mechanical strength and thermal performance.

The enhancement of thermal conductivity was observed in all rice husk formulations and the thermal conductivity varied between 0.211 ± 0.016 W/m·K (NPT+RH) to 0.278 ± 0.028 W/m·K (UTT+RH). The thermal improvement is negatively proportional to mechanical per-performance, which means that there are material trade-offs affecting application-specific optimization strategies. These thermal gains indicate that rice husk can be an effective renewable additive to enhance insulation and this is probably because it introduces air pores around the fibers as well as because the organic fiber material itself has low thermal conductivity.

4.3. Optimization of Flood Sediment Using Bentonite

Systematic optimization of CRI flood sediment with bentonite demonstrated viable pathways for converting disaster waste into functional building materials, as evidenced by the comprehensive performance evaluation shown in

Table 8. The dual additive approach addressed the inherent limitations of heterogeneous flood sediment while maintaining its superior thermal characteristics.

Single additive systems revealed distinct enhancement mechanisms. Rice husk addition alone (CRI+RH) achieved the highest compressive strength of 1.34 ± 0.09 MPa, representing a 13.6% improvement over the untreated CRI baseline (1.18 ± 0.06 MPa). This enhancement also improved flexural performance from 0.24 ± 0.01 to 0.28 ± 0.01 MPa (16.7% increase). Conversely, bentonite addition alone (CRI + B5) demonstrated contrasting behavior with reduced compressive strength (0.85 ± 0.07 MPa) but improved flexural strength (0.40 ± 0.04 MPa) and increased thermal conductivity to 0.404 ± 0.010 W/m·K, indicating reduced insulation performance.

Dual additive systems enabled systematic property customization to suit specific application requirements. The CRI + RH + B5, CRI + RH + B10 and CRI + RH + B10 formulations demonstrated that increasing bentonite content alters material behavior in predictable patterns: CRI + RH + B5 achieved 0.82 ± 0.07 MPa compressive strength and 0.26 ± 0.01 MPa flexural strength with moderate thermal conductivity (0.263 ± 0.008 W/m·K); CRI + RH + B10 provided balanced properties with 0.99 ± 0.02 MPa compressive strength and 0.23 ± 0.01 MPa flexural strength while maintaining good thermal conductivity (0.232 ± 0.013 W/m·K). Higher bentonite content (CRI + RH + B10) resulted in reduced mechanical performance (0.39 ± 0.03 MPa compressive, 0.20 ± 0.01 MPa flexural) but achieved superior thermal insulation (0.199 ± 0.015 W/m·K).

The microstructural examination shows the basic variations in composite behavior.

Figure 13c,d indicate that CRI + RH + B10 formulations had significantly changed microstructural properties as a result of the binding and void-filling properties of bentonite. The small curved particles of bentonite (97.29% through 0.075 mm) were effective in filling interparticle voids and forming a much more continuous, dense matrix structure. This increased continuity of the matrix and removed the majority of air pores and increased the efficiency of particle packing leading to excellent thermal insulation. Nevertheless, the higher density and the lower porosity were the factors that enhanced the brittleness of the matrix, which is why the compressive strength had decreased significantly.

These findings define definite optimization directions: rice husk is the best material to maximize compressive properties, moderate levels of bentonite (5–10%) are the best to balance mechanical and thermal properties, and high levels of bentonite (15%) are the best to maximize thermal insulation at the cost of structural capacity. Although the effects of bentonite differ greatly across material systems [

38], the observed systematic trade-offs in this work make it possible to design adobe structures using application-specific material. The results offer quantitative advice to the valorization of flood sediment in construction projects, but the practical application of the results must consider the economic factors, processing scalability, and long-term durability performance that were not studied in the present study.

4.4. Strategic Implications for Sustainable Construction

This research establishes a systematic framework for adobe optimization based on local soil mineralogy and available waste streams, supporting both circular economy principles and climate-responsive building strategies. The experimental findings demonstrate practical pathways for material optimization that align with regional resource availability.

The integration of rice husk, a readily available agricultural by-product in Thailand, with commercially available bentonite creates a circular material protocol consistent with waste valorization approaches documented in construction materials research [

23,

38]. The superior performance achieved with UTT-based formulations (3.12 ± 0.11 MPa compressive strength) and the successful enhancement of CRI flood sediment (thermal conductivity improved to 0.276 ± 0.019 W/m·K) demonstrate that additive effectiveness correlates with soil chemistry, though the specific mechanisms require further investigation.

The systematic enhancement of flood sediment demonstrates potential pathways for disaster waste utilization in construction applications. CRI formulations achieved compressive strengths up to 1.34 ± 0.09 MPa and flexural strengths up to 0.40 ± 0.04 MPa with bentonite addition, indicating suitability for non-structural applications such as interior partitions and thermal insulation systems. These performance levels provide alternatives for post-disaster reconstruction while addressing waste management challenges. While Thailand lacks formal standards for unburnt adobe bricks, preliminary quality guidelines suggest minimum compressive strength of 2.07 MPa. Among the tested formulations, UTT + RH (3.12 ± 0.11 MPa) significantly exceeds this benchmark, while most CRI-based formulations remain suitable for non-structural applications.

The integration of local waste streams with regional soil resources offers potential benefits through reduced material transportation requirements and waste valorization. Consistent thermal performance improvements across all rice husk formulations (0.211–0.278 W/m·K range) compared to baseline soil performance (0.200–0.428 W/m·K range) demonstrate enhanced insulation characteristics suitable for tropical building applications where thermal comfort is paramount.

This research contributes to broader waste-to-construction-material development, supported by parallel investigations of paper and pulp residues [

14] and other organic waste applications in earthen construction. This approach aligns with Thailand’s Bio-Circular-Green economic development framework through agricultural residue utilization, disaster waste reuse, and low-carbon construction alternatives. However, successful implementation requires addressing scaling considerations, economic feasibility analysis, and regulatory compliance that extend beyond the current laboratory-scale investigation.

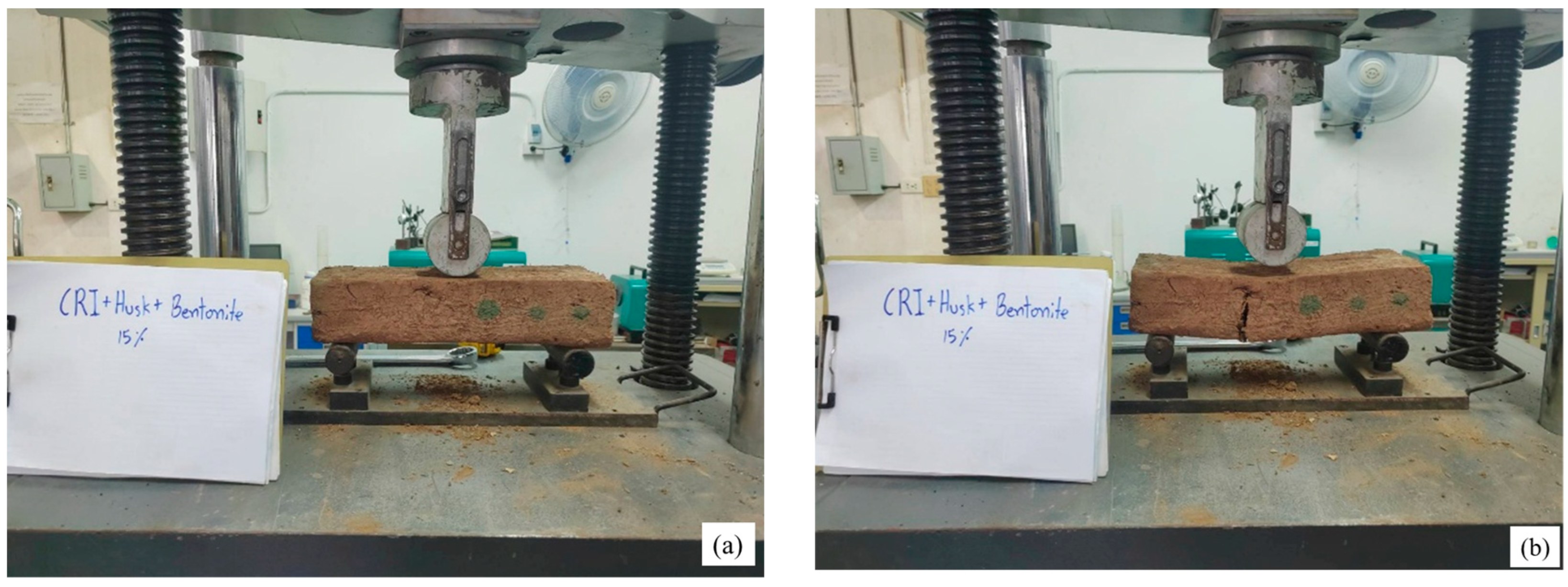

Figure 14 demonstrates practical implementation of adobe construction techniques in Thailand, showing the feasibility of earthen building applications in real-world contexts.

4.5. Sustainability Assessment and Implementation Implications

Adobe construction shows great environmental benefits with its significantly lower embodied carbon compared to traditional masonry material. Life-cycle analyses approximate embodied carbon of 0.00175–0.01250 kg CO

2eq/kg for adobe systems [

39], compared to about 0.24 kg CO

2eq/kg of fired clay bricks and 0.23 kg CO

2eq/kg of concrete blocks [

40]. The main cause of this order-of-magnitude difference is the removal of energy-intensive firing processes and the use of solar drying methodologies.

Environmental value goes beyond material production by using localized sourcing strategies. The locally sourced soil and agricultural residues are normally used in Adobe production, thus significantly lowering the transportation-related emissions [

39]. Such a localized strategy is consistent with the principles of circular construction as it incorporates the waste streams regionally and reduces the impact of supply chains. Also, the thermal mass characteristics of adobe lead to less operational energy use, as it requires less mechanical cooling, which also provides environmental and occupant comfort advantages.

The environmental case is backed by economic analysis in terms of life-cycle cost benefits. The cost benefits are based on the fact that there is less material transportation, less maintenance needs, and no industrial processing [

41]. Local material integration and simplified production techniques opens economic opportunities and minimize capital investment requirements.

This combination of environmental and economic considerations makes the use of adobe construction a feasible low-carbon alternative that promotes sustainable building practices due to its low environmental impact and higher economic accessibility. This research contributes to broader waste-to-construction-material development, supported by parallel investigations of paper and pulp residues [

14] and other organic waste applications in earthen construction. This approach aligns with Thailand’s Bio-Circular-Green economic development framework through agricultural residue utilization, disaster waste reuse, and low-carbon construction alternatives.

5. Conclusions

This study systematically evaluated the mechanical and thermal characteristics of adobe bricks produced using four types of Thai soils, namely Nakhon Pathom (NPT), Sisaket (SSK), Uttaradit (UTT), and flood-derived sediment in Chiang Rai (CRI) with the addition of rice husk and sodium bentonite. The findings establish quantitative relationships between soil mineralogy and material performance while demonstrating viable pathways for disaster waste valorization through innovative dual-additive optimization.

The mineral composition of soil definitively influences adobe performance characteristics. Uttaradit soil with balanced SiO2/Al2O3 ratios (42.1%:40.4%) achieved optimal mechanical properties (3.12 ± 0.11 MPa compressive strength with rice husk addition), while Chiang Rai flood sediment with heterogeneous composition (15.3% SiO2, 16.8% Al2O3) demonstrated superior thermal insulation (0.200 ± 0.009 W/m·K). These findings provide predictive frameworks for material selection based on mineralogical characteristics.

Rice husk reinforcement systematically increased compressive strength in all soil matrices (13.6–82.5% improvement) and consistently increased thermal performance (0.211–0.278 W/m·K). The magnitude of the enhancement was directly proportional to the soil mineralogy, UTT recorded the highest absolute strength enhancement (82.5% to 3.12 ± 0.11 MPa), although the flexural strength declined by 34.9%. Microstructural examination showed that rice husk could reinforce mechanically by forming three-dimensional fiber networks and provide desirable porosity to act as thermal insulation.

Dual-additive strategies of flood sediment optimization allowed customization of materials according to application. CRI + RH gave the best compressive strength (1.34 ± 0.09 MPa), CRI + RH + B10 balanced (0.99 ± 0.02 MPa compressive, 0.232 ± 0.013 W/m·K thermal) and CRI + RH + B10 gave the best thermal insulation (0.199 ± 0.015 W/m·K) where non-structural applications are needed. This is a systematic trade-off that enables adobe bricks to be customized to suit construction requirements.

This study defines the material selection principles into practical use: UTT-based formulations are applicable to high-strength structural projects, NPT and SSK formulations are applicable in general construction projects, and CRI-based systems are applicable in thermal insulation and post-disaster reconstruction projects. Flood sediment valorization aligns with the Bio-Circular-Green economic development model of Thailand, which helps in sustainable building practices and the principles of the circular economy.

There are several limitations that should be taken into consideration to fully implement it. The ongoing experiment is on laboratory scale specimens of two-week curing time, which might not be a complete reflection of long-term durability in the field. The characteristics of weathering resistance, freeze–thaw cycling, and moisture absorption demand specific research to be thoroughly evaluated in terms of performance. The shift in the laboratory mixing to industrial production presents the issues of quality control, homogeneity maintenance, and economic optimization that need pilot-scale studies.

While the OM-LIBs analysis reveals fundamental mechanisms, quantitative image analysis and additional characterization techniques would strengthen the mechanistic understanding. This study does not include analysis of dimensional stability, creep behavior, or bond strength with mortar systems relevant for practical construction applications. Implementation requires consideration of technical standardization, quality control procedures, and compatibility with current building regulations. Comprehensive economic analysis should consider quality control costs, skill development requirements, and regulatory compliance expenses.

These results advance adobe material science by establishing quantitative relationships between soil composition and performance while demonstrating practical pathways for disaster waste utilization. The low processing requirements and utilization of locally accessible raw materials make adoption feasible in resource-limited settings, contributing to waste management solutions and affordable housing development.