1. Introduction

The need for systematic management of structural cracks has been increasing due to factors such as building deterioration, adjacent construction activities, and earthquakes [

1]. Cracks can lead to reduced durability of concrete members, decreased load-bearing capacity caused by reinforcement corrosion, loss of water- and airtightness, and aesthetic degradation, thereby requiring thorough monitoring and management [

2]. In particular, precise monitoring is essential not only to detect the occurrence of cracks but also to assess their implications and progression in order to ensure structural safety.

Currently, most crack inspections rely on visual surveys and manual record-keeping [

3], which involve significant limitations. For instance, inspections may expose workers to hazardous environments such as ladder operations, and results can vary depending on the inspector’s subjective judgment. Moreover, manually recorded data are unsuitable for long-term monitoring and systematic analysis. Periodic inspection methods are also inefficient in terms of time and cost, while being vulnerable to missing sudden changes.

To overcome these drawbacks, automated monitoring using digital crack measurement devices has been introduced. However, most of these approaches still focus only on determining whether the absolute crack width exceeds a predefined threshold. While absolute value-based methods are useful for assessing a crack’s state at a given point in time, they cannot capture temporal variations or progressive deterioration. As a result, early-stage defects that gradually expand may not be detected in time, leading to delayed repair or reinforcement and increased maintenance costs [

4].

Cracks typically progress gradually, compromising structural durability and, if left unaddressed, potentially leading to critical failure. Therefore, even small deformations below allowable thresholds can pose risks if they accumulate over time, highlighting the importance of observing crack width variations across a temporal dimension. In aging structures especially, continuous monitoring of cracks—regardless of whether they exceed the threshold—is essential to enable early detection of potentially anomalous behavior. Traditional methods based solely on visual inspection or fixed thresholds are insufficient for identifying early-stage defects. Instead, tracking time-dependent changes is necessary for timely recognition of underlying risks.

Crack behavior is governed by nonlinear and cumulative interactions among material properties, loading histories, and environmental conditions, producing complex and evolving patterns that challenge traditional evaluation methods. Such characteristics limit the effectiveness of static threshold-based approaches, which cannot adequately capture the progressive and context-dependent nature of deterioration. This inherent complexity provides a clear rationale for employing data-driven methods capable of detecting patterns within large, heterogeneous time series datasets.

By leveraging variation-based data, it becomes possible to understand the context and flow of crack behavior over time, thereby improving the accuracy of anomaly detection [

5]. To detect subtle, progressive crack growth, a big data-based periodic analysis framework offers significant advantages. Analyzing large-scale, time series crack data enables the identification of hidden growth trends that remain within allowable limits yet signal future deterioration, thus providing a stronger basis for timely and informed maintenance decisions.

This study proposes a big data-driven framework for detecting potential crack anomalies by computing three variation metrics—long-term variation, short-term variation, and instantaneous variation—followed by normalization using a Robust Scaler and anomaly detection with the Isolation Forest algorithm. The proposed framework consists of a sequence of procedures: data transformation, normalization, and visualization during preprocessing; candidate anomaly detection during the anomaly detection stage; and redundancy-based classification of anomalies. Furthermore, by incorporating periodic analysis, the framework evaluates risk-level transitions over time, addressing the limitations of absolute value-based approaches and enabling earlier recognition of crack growth patterns. Ultimately, the framework aims to reduce labor and cost requirements for crack inspections while preventing damage caused by undetected anomalies.

The remainder of this paper is organized as follows.

Section 2 reviews prior studies on crack monitoring, big data-based anomaly detection, and the Isolation Forest algorithm.

Section 3 details the step-by-step procedures of the proposed framework.

Section 4 validates the model using both simulated and real-world datasets. Finally,

Section 5 presents the conclusions and implications of this research.

2. Literature Review

2.1. Trends in Concrete Crack Monitoring

Conventional crack inspection methods can be categorized into visual inspection, crack gauges, electronic crack meters, core sampling, and non-destructive testing (NDT), as summarized in

Table 1. Visual inspection is low-cost and quick but suffers from subjectivity, limited accessibility, and low accuracy due to reliance on human judgment [

6]. Crack gauges are simple and economical to install but are unsuitable for long-term monitoring and systematic record-keeping. Electronic crack meters allow precise displacement measurements through sensors and enable real-time monitoring; however, they require data processing and involve higher initial installation costs. Core sampling and NDT provide higher accuracy but demand costly equipment and skilled operators.

In this study, electronic crack meters were adopted because of their suitability for quantitative and long-term monitoring. These devices are attached directly to crack surfaces, measuring variations in crack width based on changes in electrical resistance, and are well-suited for large-scale data collection and long-term analysis.

Traditional crack management procedures rely on inspection–recording–observation cycles, where structural safety is assessed based on whether crack widths exceed allowable limits, followed by detailed safety evaluations when necessary. However, such approaches are highly labor-dependent, lack real-time monitoring capabilities, and are limited in cumulative data analysis. Furthermore, many monitoring devices simply determine whether an absolute threshold is exceeded, leaving sub-threshold cracks to manual inspection. Even when large datasets are collected, systematic data-driven analysis is rarely attempted.

Against this background, various studies have investigated concrete crack monitoring. Representative works from 2017 to 2024, retrieved using the keyword “concrete crack monitoring” on Google Scholar, are summarized in

Table 2. Recent research has predominantly focused on physical measurements using sensors and imaging technologies, with an emphasis on condition assessment based on observed values. Notably, vision-based deep learning approaches have demonstrated high accuracy in crack detection and classification using image data. However, while effective, most of these methods remain limited in practice because they rely heavily on large-scale labeled datasets, lack integration with long-term or real-time monitoring systems, and struggle to detect sub-threshold or gradually growing cracks that are not yet visually apparent. As a result, most existing studies provide only snapshot assessments of crack conditions at specific moments in time and rarely address predictive evaluation of progressive deterioration. In addition, prior big data-driven SHM approaches often face challenges of generalizability across different structural contexts, limited explainability of detection outcomes, and computational scalability when handling massive time series datasets. In particular, there is a scarcity of big data-based approaches that analyze time-dependent crack variations to detect early-stage risks.

In response, this study proposes a time series-based anomaly detection framework that computes and utilizes three crack variation metrics—long-term, short-term, and instantaneous—as core analytical indicators. The aim is to detect subtle or abnormal trends even when the crack width remains within allowable limits. By focusing on trend behavior rather than absolute thresholds, the proposed method complements vision-based deep learning approaches and supports continuous, real-time structural health monitoring.

2.2. Research Trends in Big Data-Based Anomaly Detection

An observation which deviates so much from other observations as to arouse suspicions that it was generated by a different mechanism is referred to as an outlier [

20]. In big data environments, anomaly detection requires the design of algorithms that are both efficient and scalable, considering the volume, variety, and velocity of the data.

Traditional statistical approaches, such as Statistical Process Control (SPC) methods—including Shewhart, EWMA, and CUSUM charts—have long been used to detect structural anomalies by monitoring deviations from predefined thresholds. These methods are widely recognized for their simplicity, interpretability, and computational efficiency. However, because they rely on assumptions of stationarity and fixed control limits, their performance is limited in complex structural health monitoring (SHM) environments, particularly in capturing subtle variations or progressive deterioration [

21,

22].

In recent years, machine learning (ML)-based anomaly detection techniques capable of handling multidimensional data and irregular distributions have been introduced. ML models have been successfully applied across various domains, including SHM benchmark datasets such as SHMnet, demonstrating improved adaptability compared to traditional control charts [

23,

24,

25]. Among these, the Isolation Forest algorithm has drawn attention for its ability to isolate anomalies by recursively partitioning the data space, offering robustness to noise and scalability to large datasets.

Deep learning (DL)-based methods, such as convolutional neural networks (CNNs), recurrent neural networks (RNNs), and autoencoders, have also achieved strong performance in anomaly detection, particularly for high-dimensional or unstructured data [

26,

27,

28]. However, these approaches are constrained in practice by their dependence on large-scale labeled datasets, high computational demands, and challenges in integration with long-term monitoring systems.

In contrast, this study applies an Isolation Forest-based anomaly detection framework that incorporates time series crack variation metrics (long-term, short-term, and instantaneous). Unlike conventional SPC methods or DL-based techniques, this framework enables early detection of potential sub-threshold anomalies without requiring extensive labeled datasets, thereby offering a practical and scalable solution for real-time structural health monitoring.

Table 3 summarizes the representative categories of outlier detection methods in big data environments, together with their advantages and limitations: statistical, distance-based, density-based, and machine learning-based approaches [

29]. Statistical methods are simple and intuitive but sensitive to distributional assumptions and threshold selection. Distance-based methods can be applied in high-dimensional data but often suffer from performance degradation as dimensionality increases. Density-based methods enable precise detection by considering data distribution, but their performance decreases when data density is uneven. Machine learning and deep learning approaches allow for complex pattern learning and advanced anomaly detection but are highly dependent on data quality and parameter tuning.

Recently, numerous studies have explored anomaly detection using big data across various industries.

Table 4 presents representative studies published since 2024, highlighting the adoption of advanced models that combine machine learning and deep learning in domains such as industry, finance, cybersecurity, and network management. However, research focusing on structural anomalies involving long-term and gradual changes, such as concrete cracks, remains limited.

In particular, cracks may continue to propagate even after their initial occurrence, making it difficult to achieve early risk recognition based solely on threshold-based evaluations at single time points. To address this gap, this study proposes a model that incorporates time-dependent crack variations (long-term, short-term, and instantaneous changes) as key variables and leverages accumulated large-scale datasets to enable relative anomaly detection and risk trend analysis. This approach allows the early identification of risk patterns even below allowable crack thresholds and supports more proactive decision-making in structural health management.

2.3. Isolation Forest-Based Approaches for Anomaly Detection

The Isolation Forest algorithm detects anomalies by generating multiple binary trees, where each tree recursively partitions the data based on randomly selected features and split values (see

Figure 1). The anomaly score is determined by the average path length required to isolate a given data point. Typically, anomalies can be isolated with fewer partitions, resulting in shorter path lengths, whereas normal data points require longer paths.

A key parameter of the algorithm, contamination, represents the expected proportion of anomalies within the dataset and influences the final decision threshold. In this study, the Isolation Forest was applied to detect anomalies in big data-based crack variation values, for the following reasons:

Performance with high-dimensional data: The model uses three crack variation metrics—long-term (relative to the initial value), instantaneous (relative to the previous value), and short-term (daily cumulative variation). These multidimensional variables can be effectively handled by Isolation Forest.

Computational efficiency: Crack data are continuously collected in real time, requiring rapid analysis of large-scale datasets. Isolation Forest requires less computational effort compared to clustering-based methods, making it suitable for large-scale monitoring.

Overcoming the limitations of absolute thresholds: Conventional crack monitoring methods rely on fixed allowable width limits, making it difficult to detect gradual growth or subtle variations. Isolation Forest, however, isolates data points based on relative separability, enabling the detection of abnormal patterns even within values below the threshold, thus allowing early identification of potential risks.

Building on these strengths, this study proposes a crack management framework that leverages temporal variation metrics to detect anomalies and assess risk at an early stage.

Isolation Forest has been widely applied in various domains of anomaly detection.

Table 5 summarizes representative studies that adopted this method. While recent works have demonstrated its effectiveness in finance, manufacturing, IoT, and infrastructure monitoring, its application to anomaly detection in crack variation data remains limited. To address this gap, the present study employs time series variation metrics to complement conventional absolute-threshold approaches, providing an early-warning framework for crack management.

3. Potential Anomaly Detection Model for Structural Cracks Based on Periodic Big Data Analysis

3.1. Overview of the Proposed Model

This study first reviewed the current status and limitations of concrete crack monitoring, the applicability of big data-based anomaly detection methods, and the characteristics of the Isolation Forest algorithm. Conventional crack monitoring has primarily focused on measuring crack width and length at specific time points, without adequately reflecting time series variability. As a result, it is difficult to identify potential risks that may occur even when cracks remain below allowable thresholds.

Big data-driven anomaly detection has been actively applied to early-warning systems across various industries; however, its application to long-term crack variation analysis remains limited. Although Isolation Forest offers strong computational efficiency and the ability to process high-dimensional data, few studies have employed it using time series crack variation metrics as primary variables.

To address this gap, this study proposes an anomaly detection model that incorporates time-dependent crack variation values and applies the Isolation Forest algorithm. The model aims to overcome the limitations of absolute-threshold monitoring by enabling early detection of potential anomalies and contributing to efficient crack data management and the development of an automated early-warning system.

This section provides an overview of the proposed anomaly detection model.

Section 3.1.1 introduces the dual framework for real-time and periodic crack monitoring.

Section 3.1.2 describes the classification scheme for crack anomalies. Finally,

Section 3.1.3 outlines the implementation and application strategies of the proposed model.

3.1.1. Real-Time and Periodic Crack Monitoring Framework

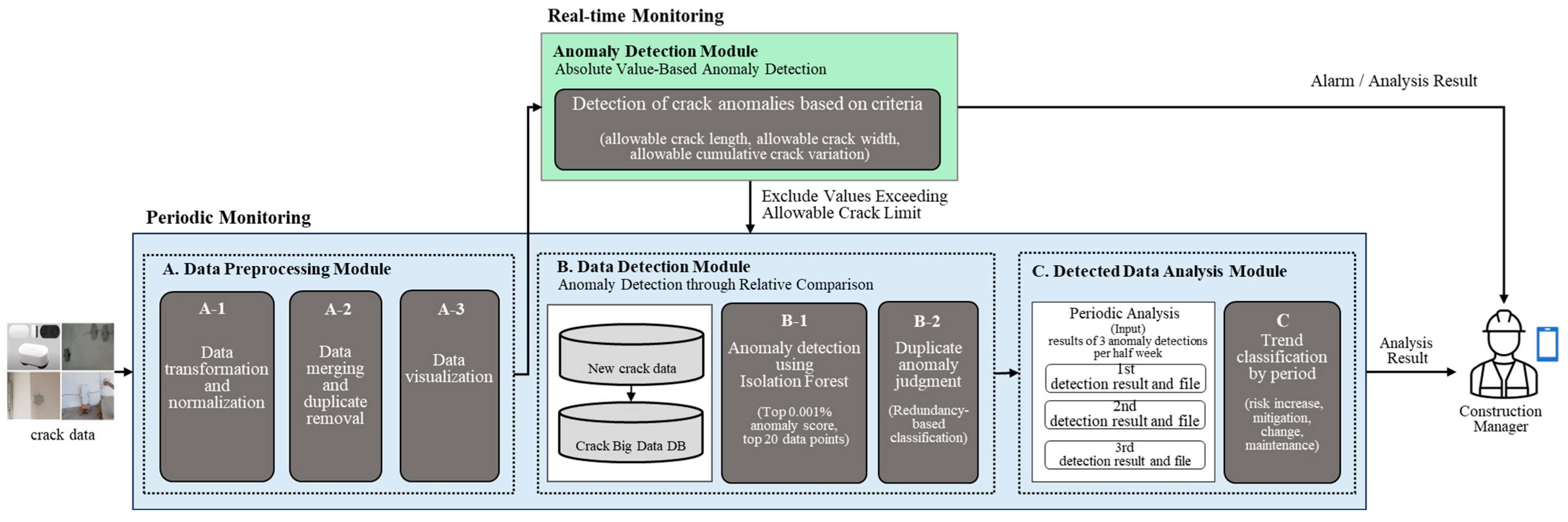

This study proposes a big data-based anomaly detection model designed to enable early detection of structural crack anomalies and long-term risk assessment (see

Figure 2). The model employs a dual framework consisting of real-time and periodic monitoring, each serving distinct purposes as summarized in

Table 6:

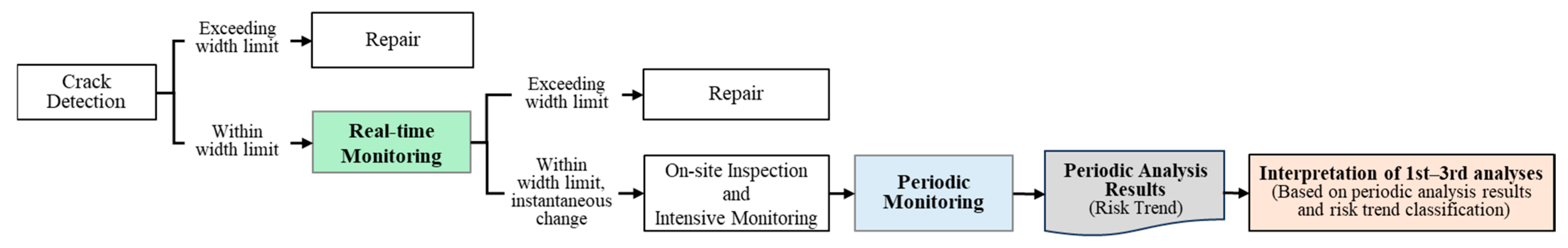

Real-time monitoring: Crack width data continuously collected from electronic sensors installed on the structure are analyzed in real time. Any data exceeding predefined allowable thresholds or exhibiting sudden fluctuations are immediately detected and flagged as anomalies.

Periodic monitoring: Accumulated time series data over a given period are analyzed to evaluate relative variability. Even if data remain within allowable thresholds, values with a high anomaly probability are identified, and long-term risk trends are assessed.

In addition,

Figure 3 illustrates the overall conceptual flow of crack management, integrating both real-time and periodic monitoring. Unlike conventional field inspection-oriented approaches, the proposed model is based on an automated data collection–analysis–decision framework. This enables the quantitative evaluation of risk trends through time series analysis, providing a more systematic and objective approach to structural crack management.

Table 7 provides a detailed comparision between conventional crack inspection methods and the proposed model.

3.1.2. Classification of Crack Anomalies

- (1)

Crack Anomaly Classification

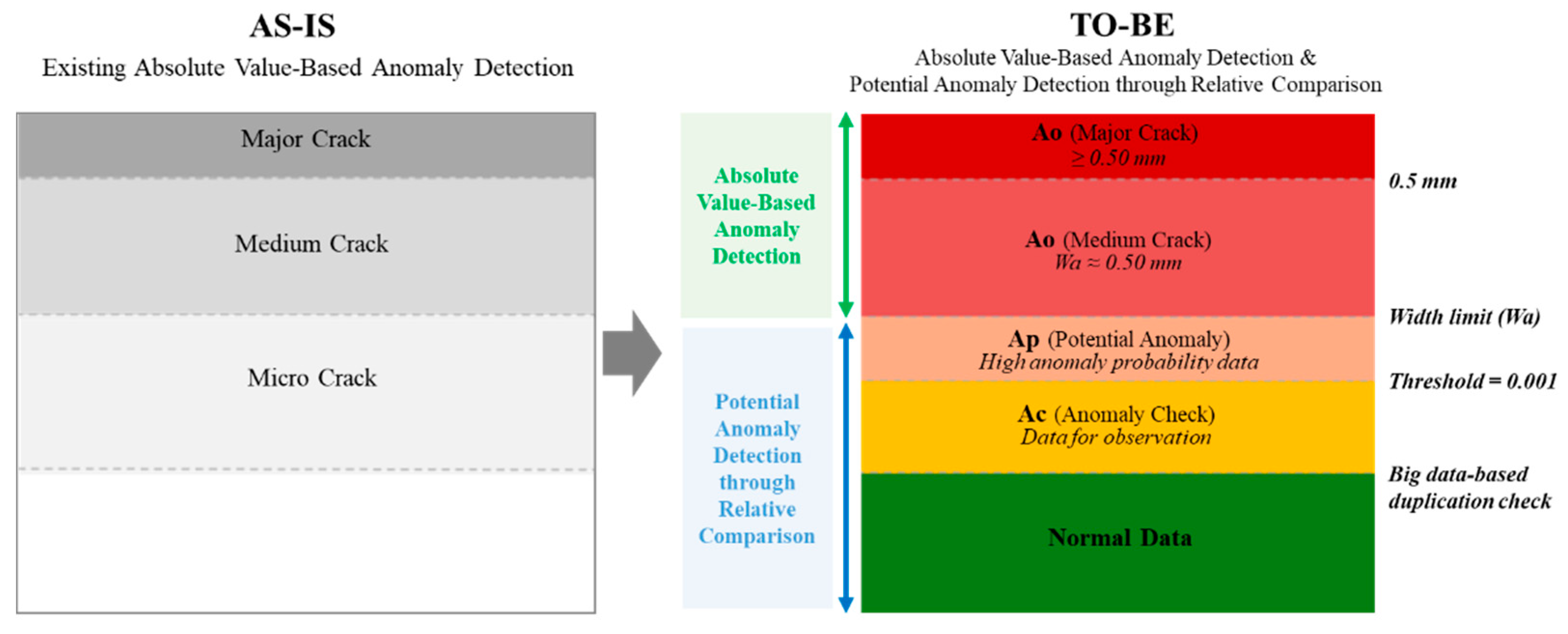

In this study, crack data were classified according to two detection approaches: absolute value criteria and relative comparison criteria, as illustrated in

Figure 4.

Absolute Value-Based Anomaly Detection: Anomalies are identified by determining whether the measured crack width exceeds the allowable crack width (Wa).

Potential Anomaly Detection through Relative Comparison: Among data within the allowable width, anomalies are identified if time series analysis reveals recurring abnormal patterns with high anomaly probability.

This classification framework enables the quantitative assessment of risks associated with cracks below the allowable limit and supports the prioritization of resources for intensive monitoring. The definitions for each category are as follows:

Ao (Anomaly Data): Data that clearly exceed or approach the structural criteria.

- -

Major Crack: Crack width ≥ 0.50 mm

- -

Medium Crack: Crack width approaching the allowable width (Wa ≈ 0.50 mm)

Ap (Potential Anomaly): Data within the allowable limit but repeatedly identified with high anomaly probability through relative comparison.

Ac (Anomaly Check): Data within the allowable limit that exhibit single-instance or low-level anomalies requiring observation.

Normal Data: Data within the threshold range without abnormal features.

- (2)

Crack Data Structure and Variation Metrics

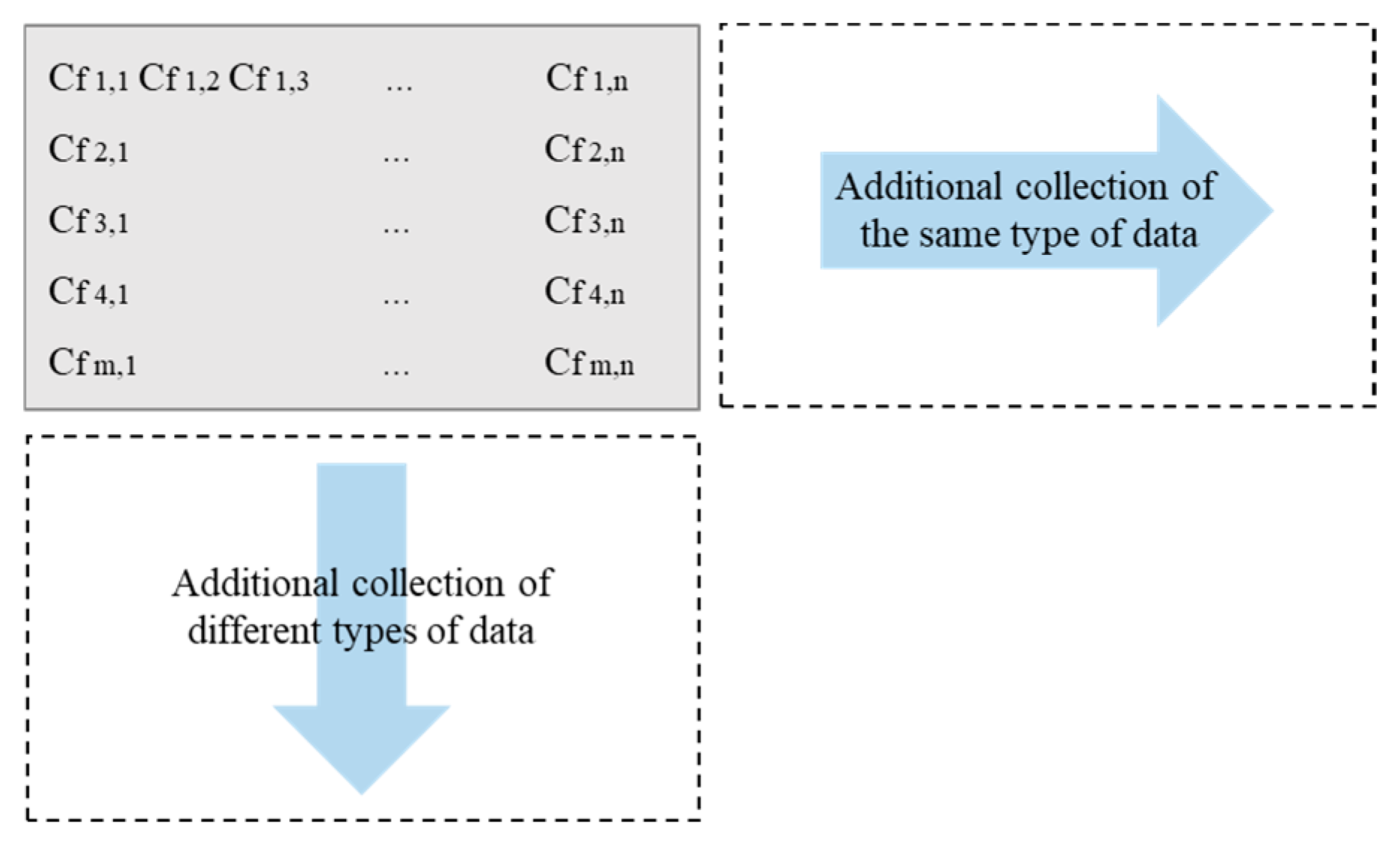

The crack data used in this study were automatically collected at fixed intervals using electronic crack monitoring devices and stored as time series information at the structural unit level. Each dataset is organized in three dimensions: facility ID (f), crack type (i), and observation time (t).

Figure 5 provides an example visualization of repeated observations (t) of multiple crack types (i) in the same facility (f). Data for the same crack type accumulates along the horizontal axis in chronological order, while data for different crack types expand along the vertical axis. This structure serves as a fundamental dataset not only for real-time monitoring but also for periodic analysis and anomaly detection.

To analyze crack progression, the following derived metrics were defined from the raw data and used as key input variables for the Isolation Forest algorithm:

3.1.3. Implementation and Application Strategy

The anomaly detection framework consists of two complementary logics: real-time and periodic analysis (see

Table 8).

Real-Time Analysis Logic: Crack width data collected from sensors are classified as anomalies (Ao) when they exceed the allowable threshold (Wa, e.g., 0.20–0.40 mm), when an abrupt fluctuation of ±0.10 mm or more occurs compared to the previous value, or when the accumulated variation surpasses the allowable threshold. In such cases, an immediate warning is triggered (see

Figure 6).

Periodic Analysis Logic: For cumulative data excluded from real-time analysis, the Isolation Forest algorithm is applied to perform anomaly detection based on relative distinctiveness. Detected data are further classified as Ap or Ac depending on redundancy checks, and time series-based risk trend analysis is then conducted to quantitatively evaluate risk levels (escalation, mitigation, fluctuation, stable).

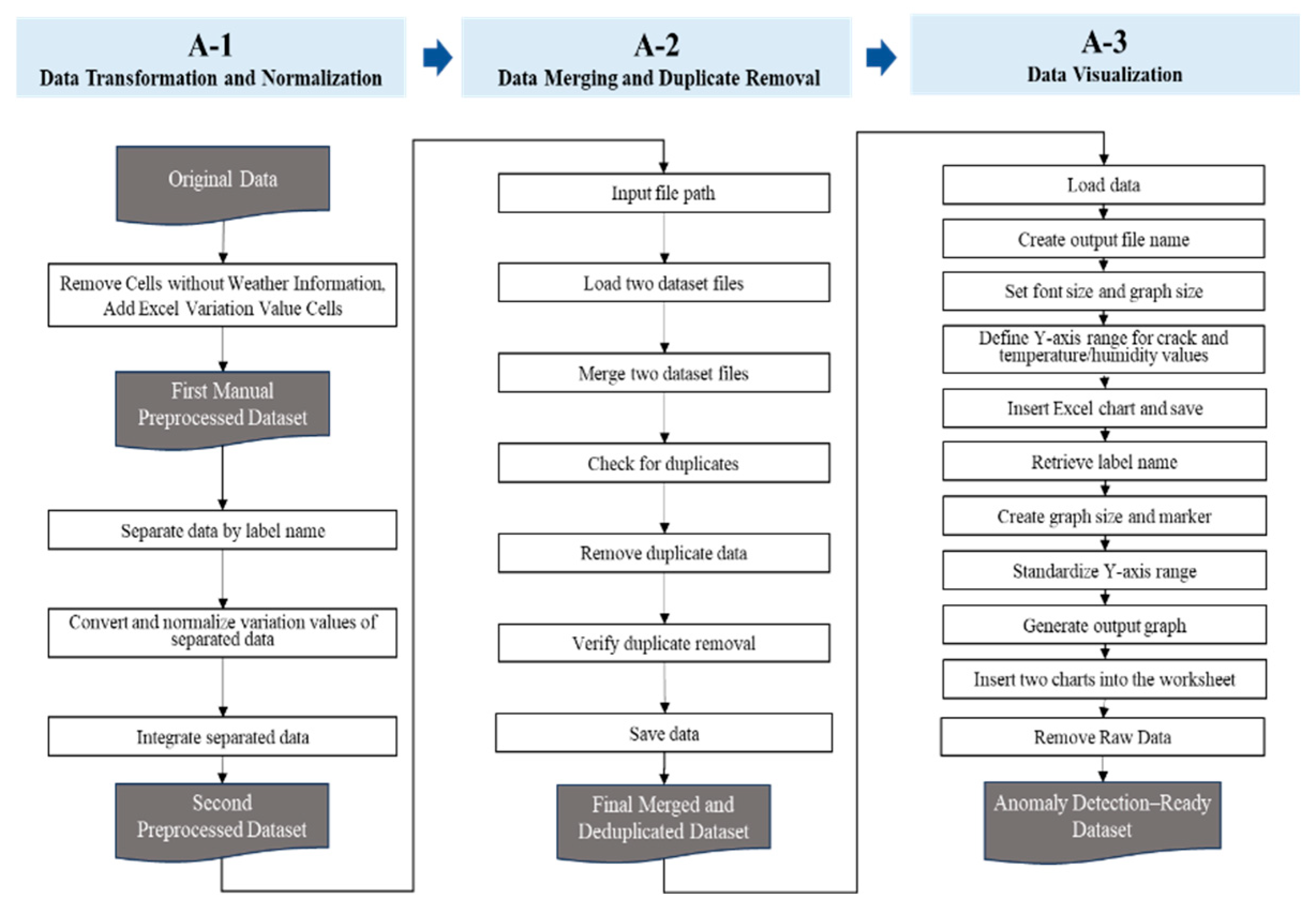

3.2. Data Preprocessing

In this study, prior to applying the Isolation Forest anomaly detection algorithm, a data preprocessing procedure was conducted to transform the raw crack data into an analysis-ready format and to ensure its quality. The procedure consisted of three stages: Data Transformation and Normalization (A-1), Data Merging and Duplicate Removal (A-2), and Data Visualization (A-3).

First, in the Data Transformation and Normalization (A-1) stage, the raw data were grouped by measurement label (label name), and difference values were calculated for crack variations as well as for environmental variables (temperature and humidity). A Robust Scaler normalization method was then applied to minimize the influence of outliers and to adjust for scale differences among variables. The normalized data were subsequently reintegrated, resulting in the second preprocessed dataset.

Second, in the Data Merging and Duplicate Removal (A-2) stage, datasets collected from different sources were merged, and duplicate entries were identified and removed. This process yielded a final integrated dataset with reduced missing values and redundancy.

Third, in the Data Visualization (A-3) stage, time series graphs of crack and environmental variables were generated with standardized Y-axis ranges based on the preprocessed dataset. Two charts were inserted into each worksheet to enable intuitive validation of data variability. This visualization step allowed researchers to confirm whether preprocessing was properly executed and whether the dataset was fully prepared for anomaly detection.

Figure 7 illustrates the entire preprocessing workflow, showing the sequential steps from raw data to the anomaly detection-ready dataset. This process enhances the reliability and reproducibility of the proposed framework.

- (1)

Data Transformation and Normalization

Because the performance of Isolation Forest depends on the input features, the raw crack data were reorganized and three variation metrics across different temporal scales were defined as the main analytical variables. These metrics capture different aspects of crack progression and enhance the accuracy of anomaly detection. These three metrics were normalized to correct for scale differences and then combined into a three-dimensional feature vector, which served as the input to the Isolation Forest model. By simultaneously incorporating variation trends across different temporal contexts, this representation enhanced the model’s ability to detect potential anomalies with greater sensitivity and interpretive precision.

- (2)

Long-Term Variation (Crack Variation Compared to Initial Value, ): Represents the change in crack width relative to the initial measurement, reflecting the long-term progression of structural cracks.

Instantaneous Variation (Crack Variation Compared to Previous Value,

): Represents the change relative to the immediately preceding observation, capturing sudden variations caused by load or environmental effects.

Short-Term Variation (Daily Cumulative Crack Variation,

): Represents the cumulative variation within a day, capturing short-term fluctuation patterns and subtle accumulations that may indicate crack growth.

To correct scale differences among variables, Robust Scaler was applied for normalization. This method uses the median and interquartile range (IQR) instead of mean and standard deviation, reducing sensitivity to outliers while improving model stability and efficiency.

- (3)

Data Merging and Duplicate Removal

Preprocessed files were consolidated, and duplicate records were eliminated to build the final dataset for analysis. This procedure followed general data processing practices rather than specialized algorithms.

- (4)

Data Visualization

To verify preprocessing quality and detect potential conversion errors, a visualization step was carried out. Signals collected by the electronic crack gauge were digitized through analog-to-digital conversion (ADC), as described in Equation (2). The corresponding crack length was then calculated using Equation (3).

where

(

).

In some cases, abnormal values were produced during the conversion process. Therefore, data points with instantaneous variations exceeding ±1 mm, or with variation values outside the range of −0.62 mm to 0.53 mm, were treated as errors and removed. This visualization process allowed intuitive identification of abnormal data and provided the basis for excluding unsuitable records from model training.

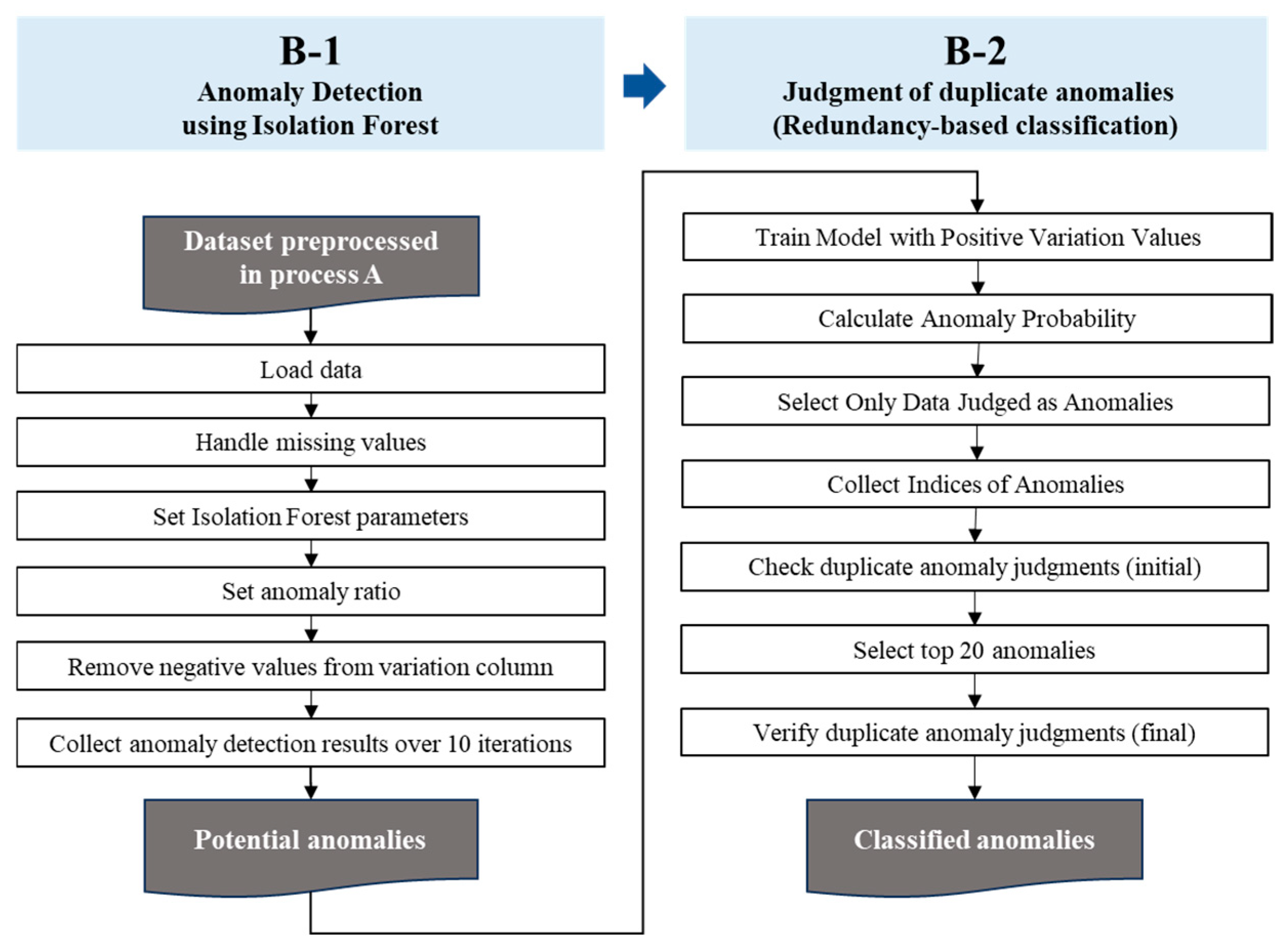

3.3. Anomaly Detection

The anomaly detection and classification process proposed in this study consists of two stages. First, potential anomalies are detected from time series crack data using the Isolation Forest algorithm. Second, the redundancy of detection results is verified to classify anomalies based on reliability.

Figure 8 presents the code implementation process of the proposed anomaly detection framework.

- (1)

Potential Anomaly Detection using Isolation Forest

This study applies the Isolation Forest algorithm to time series crack data to identify potential anomalies. Isolation Forest is well-suited for high-dimensional multivariate data, with its sensitivity influenced by the choice of input variables. In this study, the main variables are indicators that reflect crack variability across different time scales: Long-Term Variation, Instantaneous Variation, and Short-Term Accumulated Variation.

The detection process follows a dual procedure of big data-based detection and new data-based detection. First, historical crack datasets are analyzed to identify records with high relative variability, establishing a reference distribution of anomalies across the data base. Subsequently, the same algorithm is applied to newly collected data, where anomalies are detected through internal relative comparisons. This two-step process provides both a stable benchmark for evaluation and the basis for redundancy verification in the classification stage. The big data-based detection and new data-based detection in this study serve distinct but complementary purposes within the same analytical framework. Big data-based detection involves training the model on approximately 470,000 real-world crack measurements to establish a reference baseline and evaluate anomaly detection performance over long-term trends. In contrast, new data-based detection applies the same algorithm to newly incoming data to assess how reliably the model can detect potential anomalies under controlled conditions. Although both approaches rely on the Isolation Forest algorithm, their datasets and objectives differ: the big data establish the baseline, while the new data validate the model’s generalizability and robustness.

- (2)

Redundancy-Based Classification of Detected Anomalies

The results of the Isolation Forest are generated independently from big data-based detection and new data-based detection. These results are then compared to determine redundancy. If the same data point is consistently identified as an anomaly in both analyses, it is classified as Ap (Potential Anomaly), representing high potential risk and requiring prioritized monitoring. Conversely, if an anomaly is detected in only one analysis or shows low distinctiveness, it is classified as Ac (Anomaly Check), which denotes lower priority but still warrants continued observation.

This redundancy-based classification enhances the reliability and accuracy of anomaly detection results and supports the establishment of priority-based inspection strategies in structural maintenance.

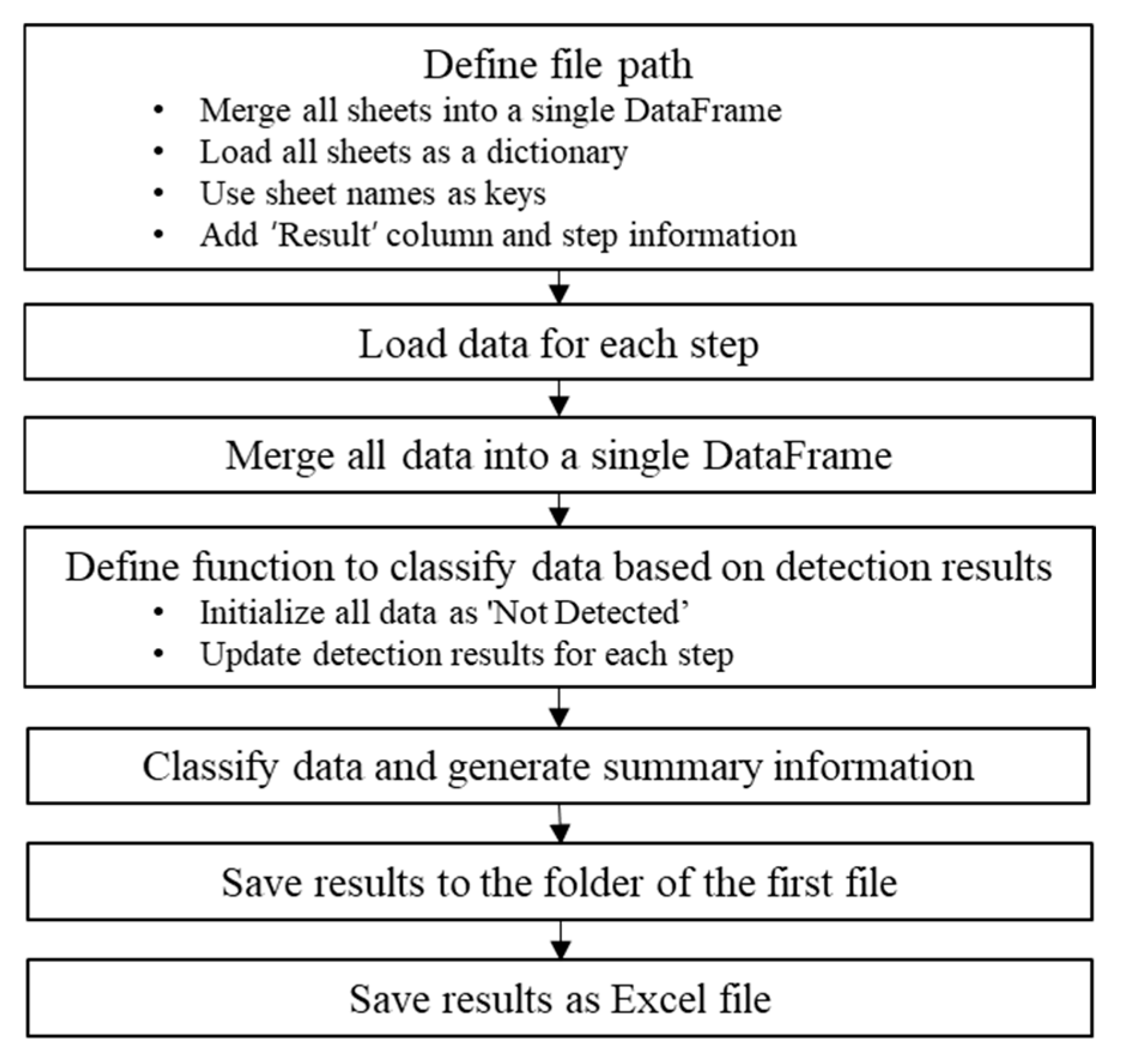

3.4. Analysis of Detected Anomalies

To evaluate the long-term risk of structural cracks, this study conducted a cumulative comparison of anomaly detection results based on periodic analysis. Periodic analyses were performed repeatedly according to a user-defined cycle, and for case validation, anomalies were detected at three intervals with a one-month gap.

Figure 9 summarizes the code implementation workflow of this periodic analysis.

The detection results were constructed from anomaly classifications at the first, second, and third cycles. Each cycle produced three categories of outcomes: data with high anomaly probability (Ap), data requiring observation (Ac), and undetected data. As shown in

Table 9, Ap refers to data identified as anomalies in both big data-based and new data-based detection, Ac denotes anomalies detected only in new data, and undetected data are those not identified as anomalies in either analysis. Risk levels were assigned to each category: Ap corresponds to risk level 3, Ac to risk level 2, and undetected data to risk level 1.

Based on this classification, risk trend transitions were derived and visualized in

Figure 10. Risk trends were divided into four categories: Mitigation, Escalation, Fluctuation, and Stable, each with further subtypes. Mitigation includes rapid mitigation, mitigation, and mitigation maintained; escalation includes rapid escalation, escalation, and escalation maintained; fluctuation is subdivided into rapid fluctuation and minor fluctuation depending on the degree of change; and stable is further classified into observation maintained or normal maintained depending on the data type (see

Table 10). This risk trend analysis quantitatively evaluates the evolution of anomalies, thereby improving diagnostic reliability for crack progression and supporting the establishment of priority-based maintenance strategies.

By combining classification results across the first, second, and third cycles, a total of 27 possible cases were generated. Each combination was mapped to one of the risk trends (Mitigation, Escalation, Fluctuation, Stable), enabling a systematic interpretation of periodic anomaly detection outcomes (see

Table 11).

4. Case Study

4.1. Overview

To evaluate the anomaly detection performance of the proposed big data-based crack variation analysis model, a simulation-based validation scenario was designed. Validation was conducted by comparing the overlap between anomalies detected from new data alone and those identified through big data-based analysis. The datasets used are summarized in

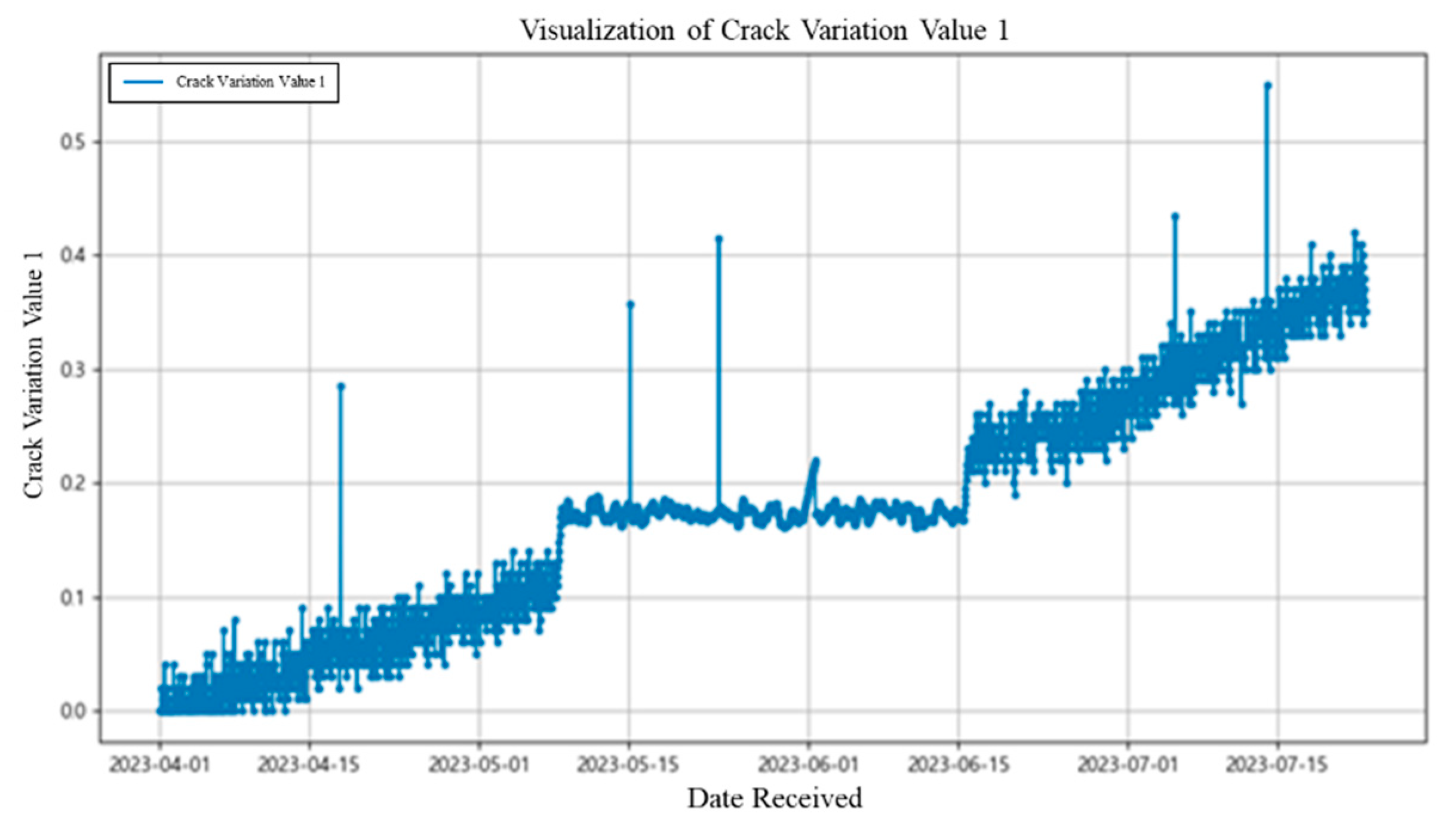

Table 12. In this study, synthetic crack data exhibiting an increase–hold–increase pattern were generated to simulate potential risk scenarios. The intention was not to prescribe fixed ground truth labels or thresholds, but rather to evaluate whether the model could correctly detect the timing and progression of anomalies with high anomaly probabilities. Because the definition of “true” anomalies is strongly dependent on threshold criteria, we deliberately created visually distinguishable data to facilitate intuitive comparison between the simulated patterns and the model’s detection results. This approach enabled straightforward validation of whether the framework can recognize anomaly-like behaviors, while future studies will focus on applying the method to real-world crack monitoring data.

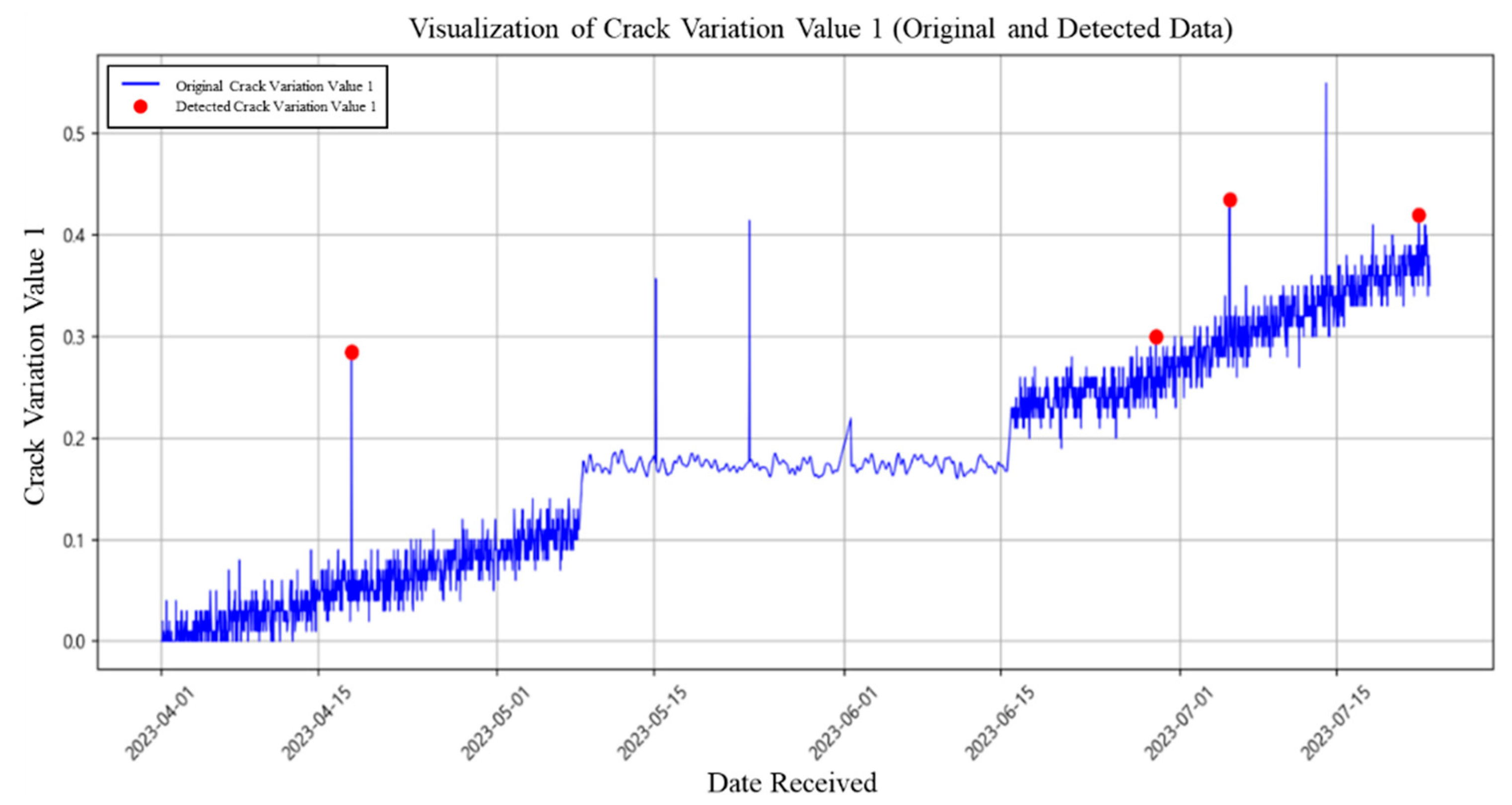

The new dataset consisted of 2720 synthetic records collected at one-hour intervals from 1 April to 23 July 2023, designed to follow an increase–hold–increase pattern (

Figure 11). This scenario reflects diverse time series variations—including long-term, short-term, and instantaneous changes—and simulates the processes of initial deformation → temporary stabilization → risk accumulation and potential sudden escalation. Its purpose was to assess whether the anomaly detection model could identify abnormal patterns beyond absolute threshold exceedance. Furthermore, periodic analysis was employed to quantify the timing and magnitude of risk evolution, thereby validating both the real-time and cumulative evaluation capabilities of the proposed model.

The big data used for validation were collected with an electronic crack monitoring device. The device is attached to crack surfaces and measures crack width precisely by detecting changes in electrical resistance (see

Figure 12). This method overcomes the subjectivity of visual inspection and the physical limitations of manual access, enabling continuous and automated collection of quantitative data.

The real dataset comprised approximately 470,000 records collected from 64 cracks across 12 sites in Seoul. Each record included crack location, width, timestamp, and environmental parameters (e.g., temperature, humidity). The detailed structure of the dataset is provided in

Appendix A.

For anomaly detection, the Isolation Forest algorithm was applied with the contamination parameter set to 0.001, reflecting the rarity of anomalies in structural crack data and ensuring higher detection sensitivity. The number of trees was maintained at the default of 100. For the dataset of ~470,000 records, preprocessing required approximately 5 min, and anomaly detection required about 10 min.

4.2. Model Validation

4.2.1. Data Preprocessing

The proposed model’s periodic anomaly detection process consists of three steps: data preprocessing → anomaly detection → risk analysis.

The collected crack data were first standardized through preprocessing, during which three variation metrics were derived: long-term variation (relative to the initial value), instantaneous variation (relative to the previous value), and short-term variation (daily cumulative change).

Table 13 presents an example of raw data after the first stage of manual preprocessing. In this stage, records with missing meteorological data were removed, and additional fields (e.g., temperature/humidity differences, variation values) were created for subsequent analysis.

The data were then transformed and normalized to produce an input format suitable for anomaly detection, as shown in

Table 14. For normalization, a Robust Scaler was applied, which scales data based on the median and interquartile range. This method is less sensitive to outliers than mean–standard deviation scaling, ensuring stability in the anomaly detection process.

4.2.2. Anomaly Detection

Based on the preprocessed data, the Isolation Forest algorithm was applied to perform anomaly detection across three monitoring cycles. At each cycle, the detected anomalies were recorded with their corresponding anomaly scores, and the results were later compared to evaluate redundancy across cycles. This redundancy formed the basis for subsequent risk trend analysis.

The validation consisted of three periodic detection cycles, with the following key findings:

1st detection result (

Table 15): In the first analysis, anomalies with scores above 0.80 were identified. Notably, the data collected on 18 April 2023 exhibited both a large long-term variation (compared to the initial value) and a significant instantaneous variation (compared to the previous value). Although the absolute crack width threshold was not exceeded, this data point showed a distinct abnormal pattern, making it a meaningful detection.

2nd detection result (

Table 16): In the second analysis, a new anomaly was detected on 28 June 2023. This record showed a high long-term variation but relatively small instantaneous and short-term variations, resulting in an anomaly score below 0.80. Meanwhile, the 18 April data was repeatedly detected in this cycle, with its anomaly score increasing compared to the first cycle. This persistence demonstrates that the abnormality remained significant despite data accumulation, indicating the need for continued observation.

3rd detection result (

Table 17): In the third analysis, the 18 April anomaly was once again detected, alongside two new anomalies identified on 5 July and 22 July 2023. Among these, the 5 July data showed the highest anomaly score across all cycles, with both long-term and instantaneous variations substantially larger than other records. This case was therefore assessed as more critical than the previously recurring April 18 anomaly, suggesting the need for prioritized on-site inspection and root-cause investigation.

4.2.3. Analysis of Detected Anomalies

The results of the three periodic detection cycles were integrated to analyze the variation patterns and risk levels of the detected anomalies. As summarized in

Table 18, one anomaly was repeatedly detected across all three cycles, one anomaly was detected in the first two cycles only, and two anomalies were newly identified in the third cycle.

Based on these detection patterns, the risk trends were categorized into three types: Stable, Fluctuation, and Escalation. An anomaly detected consistently in all three cycles was interpreted as Stable, indicating a persistent abnormal condition in the corresponding crack segment. An anomaly detected only in the first two cycles but absent in the third was classified as a case of Minor Fluctuation, suggesting that the abnormal pattern had subsided over time. In contrast, anomalies that newly appeared in the third cycle were interpreted as Escalation, indicating a worsening crack condition in those segments.

This risk trend analysis provides a quantitative interpretation of temporal changes in crack behavior and serves as a useful tool for prioritizing inspection and maintenance strategies in structural health management.

4.3. Results and Discussion

In this study, a total of four data points with high anomaly probabilities were detected. The analysis did not emphasize the absolute number of anomalies, but rather the alignment between the detection timing and the observed crack progression. To enhance interpretability, the detection threshold was intentionally set high, thereby extracting only data points with strong anomaly characteristics. This design allowed the evaluation to focus on whether the framework could effectively identify meaningful changes in crack behavior, rather than on the sheer quantity of anomalies detected.

Table 19 and

Figure 13 summarize the crack conditions and corresponding risk trends identified through periodic analysis. The dataset collected on 18 April 2023, was detected as an anomaly across all three cycles, showing a continuous increase in both long-term and instantaneous variations. This segment was therefore classified as “Stable with sustained escalation”, indicating the need for ongoing data collection and continuous monitoring.

By contrast, the dataset from 28 June 2023 was detected as an anomaly during the second cycle but not in the third. This indicates a reduced level of risk and was classified as “Mitigation with long-term observation”, suggesting that while the immediate risk has decreased, periodic monitoring remains necessary.

The datasets from 5 July and 22 July 2023, were newly identified as anomalies in the third cycle. Among these, the 5 July dataset recorded the highest anomaly score across all detections, with both long-term and instantaneous variations significantly exceeding those of other entries. These cases were classified as “Escalation”, signifying priority targets for additional inspection and management.

Overall, four anomalous crack datasets were detected, primarily influenced by long-term and instantaneous variation values. However, despite the overall increase–hold–increase trend embedded in the simulated data, abrupt anomalies within the hold phase were not detected. This outcome highlights a limitation of the Isolation Forest algorithm: as it relies on relative distributional characteristics, it may overlook subtle abnormal changes during stable intervals.

These results confirm that the proposed approach is effective for early anomaly detection during crack escalation phases, but also underscore the need to improve sensitivity during stable phases. To address this, further studies should consider optimizing algorithm parameters (e.g., contamination levels) and validating them with experimental datasets that reflect diverse distributional properties.

4.4. Limitations and Robustness Analysis

The current experiment was based on a synthetic data scenario, which imposes constraints on real-world applicability. Since cracks in actual structures often progress gradually before reaching a critical state, future research should incorporate long-term field data to enhance model validation and practical relevance. With more realistic datasets, the model could achieve more robust trend analysis and anomaly interpretation.

In addition, the robustness of the proposed framework is closely tied to the quality of data preprocessing. Since anomaly detection results can be significantly affected by noise, missing values, or duplicated entries, systematic preprocessing—such as normalization, duplicate removal, and visualization—becomes essential for ensuring reliable outcomes. In this study, preprocessing was performed under the assumption of complete and error-free data; however, in real-world applications, device-induced errors or missing data are unavoidable. Recent studies have explicitly demonstrated the critical role of preprocessing in structural health monitoring, such as handling missing monitoring data with advanced recovery models [

45] and integrating multi-source monitoring information for robust prediction [

46]. Building on these insights, future research should develop and incorporate advanced preprocessing techniques capable of distinguishing true structural anomalies from sensor-related noise, thereby further enhancing the robustness, reproducibility, and practical applicability of the proposed framework.

This study confirmed that the proposed framework can detect potential anomalies in crack progression, even when crack widths remain within allowable limits. By emphasizing trend-based interpretation rather than fixed thresholds, the framework demonstrated its capability for identifying early abnormal variations. Although validation was performed on a single dataset, the framework is model-agnostic and can be extended to other SHM datasets where time series crack variation data are available. Future research should focus on validating the framework with diverse field datasets to further demonstrate its robustness and practical applicability.

Although ground-truth labels were not available in this study, making it infeasible to evaluate false positives and false negatives in the conventional sense, the concept can be reframed in terms of anomaly probability. A false negative may correspond to the model’s failure to detect data points with high anomaly probability, whereas a false positive may involve labeling low-probability data as anomalous. Such errors could create ambiguity in anomaly interpretation and, in practice, may affect maintenance decisions. To reduce this risk, the proposed framework applies three rounds of periodic detection and integrates their outcomes, thereby focusing on consistent trend behavior rather than isolated detections. This redundancy-based strategy lowers the likelihood of both missed detections and false alarms under uncertain conditions. Nevertheless, future research should incorporate labeled datasets with confirmed structural damage events, enabling parameter optimization and a quantitative evaluation of false positives and false negatives in real-world scenarios.

Finally, expanding the framework to account for different crack types and growth patterns, and developing classification-based detection models tailored to these patterns, would enhance both the accuracy and applicability of potential anomaly detection. This study does not aim to define absolute ground-truth labels or fixed thresholds. Instead, the proposed framework focuses on analyzing the trends of detected data based on relative comparisons, providing an interpretable structure for anomaly detection. For example, in the case of the Isolation Forest algorithm, detection outcomes may vary depending on the distribution of the input data and parameter settings. Accordingly, the evaluation did not attempt to determine whether each detected point was definitively correct or incorrect, but rather whether the anomalies consistently reflected meaningful changes in crack progression trends. To enhance interpretability, the detection results were reported alongside quantitative descriptors such as anomaly count, anomaly score, and persistence. These descriptors allowed for relative comparison and provided practical insights into the model’s utility. Future research should aim to incorporate datasets with confirmed structural damage events and labeled ground truth, enabling validation through conventional metrics such as precision, recall, and F1-score.

5. Conclusions

This study proposed a periodic anomaly detection model for structural crack monitoring based on big data analysis, designed to overcome the limitations of conventional absolute threshold-based approaches. Most existing studies have focused on vision-based approaches that achieve high accuracy in detecting visible cracks, yet they remain constrained by their dependence on large-scale labeled data, the lack of validation using long-term monitoring data, and their inability to capture subtle or progressive anomalies below allowable thresholds.

In contrast, the present study does not aim to classify images at a single point in time but instead proposes an anomaly detection framework based on large-scale time series crack data. Specifically, by quantifying long-term, short-term, and instantaneous variations, the framework identifies time points with high anomaly probability, thereby enabling the early recognition of progressive crack growth patterns. Traditional monitoring methods often fail to reflect the temporal progression of crack growth, making it difficult to detect early signs of developing defects. The proposed model combines real-time anomaly detection with periodic analysis to identify both explicit anomalies and potential anomalies based on relative variations and accumulated changes, thereby enabling a more systematic assessment of structural safety.

To validate the model, approximately 2700 simulated data points following an increase–hold–increase pattern and about 470,000 field-collected crack data records were utilized. Using long-term, short-term, and instantaneous variation metrics, the model successfully detected four anomalies, demonstrating its ability to capture both sudden and cumulative risks. The results confirm that the model supports quantitative evaluation of risk trends and extends anomaly detection beyond simple threshold exceedance.

The main contributions of this study can be summarized as follows: First, the model expands analytical efficiency and applicability by utilizing large-scale crack datasets and enhances data utility through relative anomaly detection. Second, variation-based analysis enables the early detection of risks even when crack widths remain below allowable thresholds, thereby supporting preventive crack management. Third, periodic analysis facilitates the quantitative assessment of crack progression and risk levels over time, contributing to improved long-term structural stability and maintenance strategies.

Nevertheless, this study has several limitations and future research directions: First, the analysis interval was fixed at one month, and performance sensitivity to different cycle lengths was not examined. Future work should compare various intervals to establish an optimal cycle for anomaly detection. In addition, further experiments are required to ensure generalizability and statistical stability. The proposed framework could be enhanced by adjusting model parameters and defining thresholds based on real-world crack data exhibiting gradual progression, thereby improving reproducibility. Second, this study was conducted under the assumption that the collected data were input without device-related errors. However, in real-world applications, missing values or noise may occur during the preprocessing stage. Future research should focus on developing preprocessing techniques or pre-filtering models that can distinguish whether abnormal data arise from physical crack progression or from sensor malfunctions. Third, the current model focuses solely on anomaly detection and does not include predictive capabilities. Incorporating deep learning-based forecasting models could allow for the prediction of anomaly progression and risk propagation. Fourth, external environmental factors such as temperature, humidity, and vibration were not analyzed. Future frameworks should integrate multi-sensor environmental data to quantify their effects on crack occurrence and growth. Such integration would further enhance the practical applicability and robustness of the proposed framework in real-world monitoring scenarios. Fifth, anomaly detection in this study was limited to numerical crack data without considering crack shape or visual features. Combining vision-based image analysis could provide a more comprehensive assessment of crack development. Finally, the interpretation and reporting of anomaly detection results were conducted manually. Future work should employ large language models (LLMs) to automate interpretation and reporting, thereby improving accessibility and efficiency. This study confirmed that the proposed framework can detect potential anomalies in crack progression, even when crack widths remain within allowable limits. By emphasizing trend-based interpretation rather than fixed thresholds, the framework demonstrated its capability for identifying early abnormal variations. Although validated on one dataset, the framework is model-agnostic and can be applied to other SHM datasets if time series crack variation is available. Future research should extend this validation to diverse field datasets to further confirm its robustness and practical applicability.

This study proposed a data-driven framework for detecting potential crack anomalies through periodic time series analysis. The framework goes beyond simple anomaly detection by enabling quantitative assessment of crack progression and risk trends over time, thereby providing meaningful insights into structural condition. In the future, integrating this framework with sensor-based monitoring systems could facilitate real-time decision-making for structural maintenance. Moreover, there is potential to extend this approach to robotic platforms. For example, if detected anomalies are linked to robotic systems capable of conducting targeted inspections or interventions, a fully automated detection–diagnosis–response workflow could be realized. Therefore, the proposed model may serve as a core data analytics component in intelligent structural management systems. When combined with robotics, it could contribute to the development of more efficient, autonomous, and proactive maintenance solutions for buildings and civil infrastructure.

Author Contributions

Conceptualization, J.Y.; methodology, J.K.; software, J.K.; validation, J.K. and S.W.S.; investigation, J.K.; resources, J.Y.; data curation, S.W.S.; writing—original draft preparation, J.K. and S.L.; writing—review and editing, S.L.; visualization, S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by The Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport (Grant Number: RS-2024-00512799). This work is supported by the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport under the Smart Building R&D Program (Grant Number: RS-2025-02532980).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Author SeongWoong Shin was employed by the company Raycom Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Appendix A

Table A1.

Sample of Simulated New Data Used in the Experiment (Increase–Stability–Re-increase).

Table A1.

Sample of Simulated New Data Used in the Experiment (Increase–Stability–Re-increase).

| Site | Received Date | Crack Width (mm) | Temperature (°C) | Humidity (%) |

|---|

| D Site | 2023-04-01 0:00 | 0 | 22.34 | 58.58 |

| D Site | 2023-04-01 1:00 | 0 | 23.83 | 49.23 |

| D Site | 2023-04-01 2:00 | 0 | 24.57 | 46.28 |

| D Site | 2023-04-01 3:00 | 0.02 | 21.14 | 59.5 |

| D Site | 2023-04-01 4:00 | 0 | 24.17 | 55.54 |

| D Site | 2023-04-01 5:00 | 0 | 23.59 | 46.18 |

| D Site | 2023-04-01 6:00 | 0.01 | 22.71 | 52.8 |

| D Site | 2023-04-01 7:00 | 0 | 24.02 | 47.48 |

| D Site | 2023-04-01 8:00 | 0 | 21.11 | 51.1 |

| D Site | 2023-04-01 9:00 | 0 | 24.3 | 54.51 |

| D Site | 2023-04-01 10:00 | 0.01 | 21.18 | 53.97 |

| D Site | 2023-04-01 11:00 | 0.04 | 23.11 | 57.44 |

| D Site | 2023-04-01 12:00 | 0 | 24.64 | 54.01 |

| D Site | 2023-04-01 13:00 | 0 | 24.58 | 40.78 |

| D Site | 2023-04-01 14:00 | 0.01 | 23.85 | 49.97 |

| D Site | 2023-04-01 15:00 | 0 | 20.16 | 54.61 |

| D Site | 2023-04-01 16:00 | 0 | 23.84 | 53.14 |

| D Site | 2023-04-01 17:00 | 0.02 | 24.99 | 48.42 |

| D Site | 2023-04-01 18:00 | 0 | 21.85 | 41.47 |

| D Site | 2023-04-01 19:00 | 0 | 25.08 | 45.04 |

| D Site | 2023-04-01 20:00 | 0 | 24.73 | 52.06 |

| D Site | 2023-04-01 21:00 | 0 | 20.15 | 56.06 |

| D Site | 2023-04-01 22:00 | 0.01 | 20.95 | 55.11 |

| D Site | 2023-04-01 23:00 | 0 | 20.59 | 55.1 |

| D Site | 2023-04-02 0:00 | 0 | 24.61 | 57.98 |

| D Site | 2023-04-02 1:00 | 0 | 21.04 | 45.54 |

| D Site | 2023-04-02 2:00 | 0 | 20.45 | 44.82 |

| D Site | 2023-04-02 3:00 | 0 | 22.68 | 47.94 |

| D Site | 2023-04-02 4:00 | 0 | 21.61 | 59.49 |

| D Site | 2023-04-02 5:00 | 0 | 20.16 | 59.1 |

| D Site | 2023-04-02 6:00 | 0 | 20.48 | 59.72 |

| D Site | 2023-04-02 7:00 | 0.04 | 22.75 | 57.33 |

| D Site | 2023-04-02 8:00 | 0 | 24.71 | 59.51 |

| D Site | 2023-04-02 9:00 | 0.01 | 22.7 | 58.02 |

| D Site | 2023-04-02 10:00 | 0.01 | 20.55 | 51.94 |

| D Site | 2023-04-02 11:00 | 0.02 | 20.53 | 55.53 |

| D Site | 2023-04-02 12:00 | 0.01 | 22.97 | 55.18 |

| D Site | 2023-04-02 13:00 | 0 | 22.93 | 44.69 |

| D Site | 2023-04-02 14:00 | 0 | 23.41 | 56.84 |

| D Site | 2023-04-02 15:00 | 0.01 | 24.28 | 57.87 |

| D Site | 2023-04-02 16:00 | 0 | 21.68 | 47.31 |

| D Site | 2023-04-02 17:00 | 0.02 | 24.78 | 46.65 |

| D Site | 2023-04-02 18:00 | 0 | 23.97 | 49.59 |

| D Site | 2023-04-02 19:00 | 0.03 | 20.03 | 55.88 |

| D Site | 2023-04-02 20:00 | 0.03 | 21.53 | 47.56 |

| D Site | 2023-04-02 21:00 | 0 | 21.4 | 43.47 |

| D Site | 2023-04-02 22:00 | 0.01 | 24.55 | 55.82 |

| D Site | 2023-04-02 23:00 | 0.01 | 20.3 | 58.59 |

| D Site | 2023-04-03 0:00 | 0 | 23.24 | 43.78 |

| D Site | 2023-04-03 1:00 | 0.01 | 24.65 | 48.23 |

| D Site | 2023-04-03 2:00 | 0.02 | 23.05 | 51.46 |

| D Site | 2023-04-03 3:00 | 0 | 21.97 | 56.79 |

| D Site | 2023-04-03 4:00 | 0 | 24.52 | 58.69 |

| D Site | 2023-04-03 5:00 | 0.01 | 24.02 | 50.59 |

| D Site | 2023-04-03 6:00 | 0.01 | 24.5 | 42.83 |

| D Site | 2023-04-03 7:00 | 0.03 | 24.96 | 41.48 |

| D Site | 2023-04-03 8:00 | 0 | 21.83 | 47.82 |

| D Site | 2023-04-03 9:00 | 0.01 | 23.21 | 48.77 |

| D Site | 2023-04-03 10:00 | 0.01 | 24.62 | 49.65 |

| D Site | 2023-04-03 11:00 | 0 | 22.55 | 51.32 |

| D Site | 2023-04-03 12:00 | 0 | 20.61 | 50.33 |

| D Site | 2023-04-03 13:00 | 0.01 | 24.21 | 44.72 |

| D Site | 2023-04-03 14:00 | 0.01 | 21.14 | 49.22 |

| D Site | 2023-04-03 15:00 | 0.01 | 22.31 | 47.07 |

| D Site | 2023-04-03 16:00 | 0 | 23.18 | 40.05 |

| D Site | 2023-04-03 17:00 | 0.01 | 22.02 | 54.53 |

| D Site | 2023-04-03 18:00 | 0 | 23.23 | 59.67 |

| D Site | 2023-04-03 19:00 | 0 | 22.73 | 57.99 |

| D Site | 2023-04-03 20:00 | 0.02 | 21.03 | 59.95 |

| D Site | 2023-04-03 21:00 | 0.02 | 23.24 | 50.42 |

| D Site | 2023-04-03 22:00 | 0 | 23 | 56.21 |

| D Site | 2023-04-03 23:00 | 0.02 | 21.44 | 51.38 |

| D Site | 2023-04-04 0:00 | 0 | 20.51 | 50.52 |

| D Site | 2023-04-04 1:00 | 0.01 | 23.39 | 50.22 |

| D Site | 2023-04-04 2:00 | 0 | 19.86 | 41.61 |

| D Site | 2023-04-04 3:00 | 0.03 | 21.53 | 55.36 |

| D Site | 2023-04-04 4:00 | 0 | 23.48 | 42.16 |

| D Site | 2023-04-04 5:00 | 0.01 | 21.97 | 43.01 |

| D Site | 2023-04-04 6:00 | 0.02 | 20.03 | 45.87 |

| D Site | 2023-04-04 7:00 | 0 | 22.27 | 44.1 |

| D Site | 2023-04-04 8:00 | 0.01 | 21.23 | 49.01 |

| D Site | 2023-04-04 9:00 | 0.01 | 23.31 | 46.47 |

| D Site | 2023-04-04 10:00 | 0.02 | 23.13 | 58.03 |

| D Site | 2023-04-04 11:00 | 0.03 | 20.4 | 41.56 |

| D Site | 2023-04-04 12:00 | 0 | 22.79 | 59.24 |

| D Site | 2023-04-04 13:00 | 0 | 20.2 | 44.88 |

| D Site | 2023-04-04 14:00 | 0.03 | 19.97 | 39.78 |

| D Site | 2023-04-04 15:00 | 0.03 | 22.3 | 40.92 |

| D Site | 2023-04-04 16:00 | 0 | 22.29 | 49.65 |

| D Site | 2023-04-04 17:00 | 0.02 | 22.57 | 44.47 |

| D Site | 2023-04-04 18:00 | 0.02 | 24.14 | 45.94 |

| D Site | 2023-04-04 19:00 | 0.02 | 21.09 | 46.33 |

| D Site | 2023-04-04 20:00 | 0.01 | 21.56 | 58.49 |

Appendix B

Appendix B.1. Algorithm A Data Preprocessing

| Algorithm A1. Data Transformation and Normalization |

Input:

FP—input Excel file path

SHEET = “Crack Data”

COLS = {label_name, received_date, weather_date, crack_var1, temperature, humidity, ...}

Output:

D1—Second Preprocessed Dataset (per-group transformed and normalized)

Procedure:

1. Load dataset (FP, SHEET); verify required columns exist.

2. Convert received_date and weather_date to datetime; remove timezone.

3. Group data by label_name and sort by {label_name, received_date}.

4. For each group G:

a. Compute crack_var2 ← Diff(crack_var1).

b. Compute crack_var3 ← DailySum(crack_var2).

c. Compute temp_var1 ← Diff(temperature).

d. Compute hum_var1 ← Diff(humidity).

e. Normalize {crack_var1, crack_var2, crack_var3, temp_var1, hum_var1} using RobustScaler.

f. Append G to list L.

5. Concatenate groups in L → D1.

6. (Optional) Save D1 to “Preprocessed_*.xlsx”.

7. Return D1. |

| Algorithm A2. Data Merging and Duplicate Removal |

Input:

D1a, D1b—Two preprocessed datasets (optional if only one dataset available)

Output:

D2—Final Merged and Deduplicated Dataset

Procedure:

1. Merge D1a and D1b → Dm.

2. Identify duplicates based on {label_name, received_date}.

3. Remove duplicates (keep “last” entry).

4. Verify no remaining duplicates.

5. Save Dm to “Merged_Deduplicated.xlsx”.

6. Return D2. |

| Algorithm A3. Data Visualization |

Input:

D2—Deduplicated dataset

Output:

VZ—Anomaly Detection–Ready Dataset + visualization charts

Procedure:

1. Load D2.

2. Configure visualization parameters: font_size, chart_size, marker_style.

3. Define Y-axis ranges for {crack variations, temperature, humidity}.

4. Standardize X-axis by uniform time intervals.

5. Generate two plots:

a. Crack variation series {crack_var1, crack_var2, crack_var3}.

b. Environmental variation series {temp_var1, hum_var1}.

6. Insert both charts into worksheet; save as “Visualization.xlsx”.

7. Return VZ. |

Appendix B.2. Algorithm B Anomaly Detection

| Algorithm A4. Anomaly Detection using Isolation Forest |

Input:

D—preprocessed dataset from Process A

Output:

P—set of potential anomalies

Procedure:

1. Load dataset D.

2. Handle missing values (e.g., imputation or removal).

3. Set Isolation Forest parameters (n_estimators, contamination, random_state).

4. Define anomaly ratio (proportion of expected anomalies).

5. Remove negative values from variation columns, if growth-only assumption is applied.

6. For i = 1 to 10 iterations:

a. Apply Isolation Forest to D.

b. Collect anomaly scores and anomaly labels.

7. Aggregate results over iterations to form a stable set of anomaly candidates.

8. Return P (potential anomalies). |

| Algorithm A5. Judgment of Duplicate Anomalies (Redundancy-Based Classification) |

Input:

P—potential anomalies from Algorithm B-1

D_big—existing anomaly dataset (big data)

D_new—newly collected anomaly dataset

Output:

C—classified anomalies (non-redundant, final list)

Procedure:

1. Merge datasets D_big and D_new → Dm.

2. Define duplicate check keys:

{sensor_id, site_name, serial_no, label_name, received_date,

crack_var1, crack_var2, crack_var3, weather_date, temperature, humidity}.

3. Remove duplicate entries from Dm using the defined keys.

4. Train model using positive variation values to calculate anomaly probabilities.

5. Select only data points judged as anomalies.

6. Collect indices of anomaly points.

7. Perform initial duplicate check of anomaly judgments.

8. Select top 20 anomalies with highest anomaly probability.

9. Verify duplicate anomaly judgments (final).

10. Return C (classified anomalies). |

Appendix B.3. Algorithm C Analysis of Detected Anomalies

| Algorithm A6. Analyzing the dataset by applying predefined anomaly detection rules |

Input:

FP_list //list of Excel file paths containing “ProcessedData” (per step or batch)

required_cols = {label_name, received_date,

crack_var1_norm, crack_var2_norm, crack_var3_norm,

temp_var1_norm, hum_var1_norm, ...}

Output:

XLS_plots //“Plots_<basename>.xlsx” with embedded charts (per label)

XLS_summary //“Consolidated_Summary.xlsx” with consolidated table and summary sheet

Procedure:

1. Define file paths

1.1 Resolve FP_list and set output_folder: = dirname(FP_list[0]).

2. Load data for each step

2.1 For each FP ∈ FP_list:

a.D_FP ← ReadExcel(FP, sheet = “ProcessedData”); assert required_cols.

b.Add column ‘step’: = StepName(FP) //if multiple steps exist

c.Append D_FP to list L

3. Merge all data

3.1 D_all ← UnionRows(L) //align schemas; sort by key_cols.

3.2 Ensure dtypes for date/time and numeric columns are consistent.

4. Compute global Y-range (for stable visualization)

4.1 y_crack : = [min(D_all[{crack_var1_norm, crack_var2_norm, crack_var3_norm}]),

max(D_all[{crack_var1_norm, crack_var2_norm, crack_var3_norm}])]

4.2 y_env : = [min(D_all[{temp_var1_norm, hum_var1_norm}]),

max(D_all[{temp_var1_norm, hum_var1_norm}])]

5. Visualization & Export (per label)

5.1 Write D_all to new workbook “Plots_<basename(FP_list[0])>.xlsx” (sheet “ProcessedData”).

5.2 For each ℓ ∈ Unique(D_all.label_name):

a. S ← D_all where label_name == ℓ, sorted by received_date.

b. Plot-1: (S.received_date) vs. (crack_var1_norm, crack_var2_norm, crack_var3_norm); ylim:= y_crack.

c. Plot-2: (S.received_date) vs. (temp_var1_norm, hum_var1_norm); ylim := y_env.

Save PNGs “<ℓ>_crack_norm.png”, “<ℓ>_env_norm.png”; insert at anchored cells offset by row_stride.

5.3 Save workbook → XLS_plots.

6. Classify and summarize detection results

6.1 Initialize column ‘detected’:= “Not Detected” for all rows.

6.2 For each step s in StepOrder(D_all):

a.Apply detect_rules_per_step[s] to rows with step == s;

b. Update ‘detected’ := “Detected” where rule holds.

6.3 Build summary table SUM by {label_name, step}:

a.counts of Detected/Not Detected, top-k anomalies (if available),

b.first/last detection timestamps (optional).

7. Save consolidated results to Excel

7.1 WriteExcel({“Consolidated”: D_all, “Summary”: SUM},

path = output_folder/“Consolidated_Summary.xlsx”) → XLS_summary.

8. Return

8.1 Return XLS_plots, XLS_summary. |

References

- Alazmi, Y.H.; Al-Zu’bi, M.; Al-Kheetan, M.J.; Rabi, M. A Review of Robotic Applications in the Management of Structural Health Monitoring in the Saudi Arabian Construction Sector. Buildings 2025, 15, 2965. [Google Scholar] [CrossRef]

- Byeon, G.J.; Song, H.W.; Choi, U.; Woo, S.M. Crack evaluation technique and crack repair of concrete structures. Mag. Korea Concr. Inst. 2000, 12, 97–108. [Google Scholar]

- Sang-Hyuk, O.; Dae-Joong, M. Evaluation of Crack Monitoring Field Application of Self-healing Concrete Water Tank Using Image Processing Techniques. J. Korean Recycl. Constr. Resour. Inst. 2022, 10, 593–599. [Google Scholar]

- Lee, J.S.; Chang, K.H.; Hwang, J.H.; Park, H.C.; Jeon, J.T.; Kim, Y.C. Study on crack monitoring system in steel structure. J. Korean Soc. Steel Constr. 2011, 23, 159–167. [Google Scholar]

- Kang, D.-j.; Park, S.-j. Research on the development of a wind turbine anomaly detection system (ADS) for the application of virtual power plants (VPP) in a distributed energy environment. Yonsei Manag. Res. 2023, 60, 23–49. [Google Scholar] [CrossRef]

- Lee, B.Y.; Yi, S.T.; Kim, J.K. Surface crack evaluation method in concrete structures. J. Korean Soc. Nondestruct. Test. 2007, 27, 173–182. [Google Scholar]

- Arbaoui, A.; Ouahabi, A.; Jacques, S.; Hamiane, M. Concrete cracks detection and monitoring using deep learning-based multiresolution analysis. Electronics 2021, 10, 1772. [Google Scholar] [CrossRef]

- Wu, C.; Sun, K.; Xu, Y.; Zhang, S.; Huang, X.; Zeng, S. Concrete crack detection method based on optical fiber sensing network and microbending principle. Saf. Sci. 2019, 117, 299–304. [Google Scholar] [CrossRef]

- Richter, B.; Herbers, M.; Marx, S. Crack monitoring on concrete structures with distributed fiber optic sensors—Toward automated data evaluation and assessment. Struct. Concr. 2024, 25, 1465–1480. [Google Scholar] [CrossRef]

- Jung, Y.J.; Jang, S.H. Crack detection of reinforced concrete structure using smart skin. Nanomaterials 2024, 14, 632. [Google Scholar] [CrossRef]

- Yan, J.; Downey, A.; Cancelli, A.; Laflamme, S.; Chen, A.; Li, J.; Ubertini, F. Concrete crack detection and monitoring using a capacitive dense sensor array. Sensors 2019, 19, 1843. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Kang, F.; Zhang, J. Monitoring and evaluation of the repair quality of concrete cracks using piezoelectric smart aggregates. Constr. Build. Mater. 2022, 317, 125775. [Google Scholar] [CrossRef]

- Domaneschi, M.; Niccolini, G.; Lacidogna, G.; Cimellaro, G.P. Nondestructive monitoring techniques for crack detection and localization in RC elements. Appl. Sci. 2020, 10, 3248. [Google Scholar] [CrossRef]

- Chakraborty, J.; Katunin, A.; Klikowicz, P.; Salamak, M. Early crack detection of reinforced concrete structure using embedded sensors. Sensors 2019, 19, 3879. [Google Scholar] [CrossRef]

- Cha, Y.J.; Choi, W.; Büyüköztürk, O. Deep learning—Based crack damage detection using convolutional neural networks. Comput.—Aided Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. Comparison of deep convolutional neural networks and edge detectors for image-based crack detection in concrete. Constr. Build. Mater. 2018, 186, 1031–1045. [Google Scholar] [CrossRef]

- Duan, Y.; Chen, Q.; Zhang, H.; Yun, C.B.; Wu, S.; Zhu, Q. CNN-based damage identification method of tied-arch bridge using spatial-spectral information. Smart Struct. Syst. 2019, 23, 507–520. [Google Scholar]

- Ewald, V.; Groves, R.M.; Benedictus, R. DeepSHM: A deep learning approach for structural health monitoring based on guided Lamb wave technique. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2019; SPIE: Bellingham, WA, USA, 2019; Volume 10970, pp. 84–99. [Google Scholar]

- Zhang, X.; Rajan, D.; Story, B. Concrete crack detection using context—Aware deep semantic segmentation network. Comput. —Aided Civ. Infrastruct. Eng. 2019, 34, 951–971. [Google Scholar] [CrossRef]

- Wang, H.; Bah, M.J.; Hammad, M. Progress in outlier detection techniques: A survey. Ieee Access 2019, 7, 107964–108000. [Google Scholar] [CrossRef]

- Entezami, A.; Sarmadi, H.; Behkamal, B.; Mariani, S. Big data analytics and structural health monitoring: A statistical pattern recognition-based approach. Sensors 2020, 20, 2328. [Google Scholar] [CrossRef]

- Silik, A.; Noori, M.; Altabey, W.A.; Dang, J.; Ghiasi, R.; Wu, Z. Optimum wavelet selection for nonparametric analysis toward structural health monitoring for processing big data from sensor network: A comparative study. Struct. Health Monit. 2022, 21, 803–825. [Google Scholar] [CrossRef]

- Shiva, K.; Etikani, P.; Bhaskar, V.V.S.R.; Mittal, A.; Dave, A.; Thakkar, D.; Kanchetti, D.; Munirathnam, R. Anomaly detection in sensor data with machine learning: Predictive maintenance for industrial systems. J. Electr. Syst. 2024, 20, 454–462. [Google Scholar]

- Theodorakopoulos, L.; Theodoropoulou, A.; Zakka, F.; Halkiopoulos, C. Credit Card Fraud Detection with Machine Learning and Big Data Analytics: A PySpark Framework Implementation. In Data Analysis and Related Applications 5: Models, Methods and Techniques; John Wiley & Sons: Hoboken, NJ, USA, 2025; Volume 13, pp. 281–322. [Google Scholar]

- Ofoegbu, K.D.O.; Osundare, O.S.; Ike, C.S.; Fakeyede, O.G.; Ige, A.B. Real-Time Cybersecurity threat detection using machine learning and big data analytics: A comprehensive approach. Comput. Sci. IT Res. J. 2024, 4, 478–501. [Google Scholar]

- Wong, M.L.; Arjunan, T. Real-time detection of network traffic anomalies in big data environments using deep learning models. Emerg. Trends Mach. Intell. Big Data 2024, 16, 1–11. [Google Scholar]

- Wang, K.; Yan, C.; Mo, Y.; Wang, Y.; Yuan, X.; Liu, C. Anomaly detection using large-scale multimode industrial data: An integration method of nonstationary kernel and autoencoder. Eng. Appl. Artif. Intell. 2024, 131, 107839. [Google Scholar] [CrossRef]

- Song, L.; Zhang, K.; Liang, T.; Han, X.; Zhang, Y. Intelligent state of health estimation for lithium-ion battery pack based on big data analysis. J. Energy Storage 2020, 32, 101836. [Google Scholar] [CrossRef]

- Chen, H.; Ma, H.; Chu, X.; Xue, D. Anomaly detection and critical attributes identification for products with multiple operating conditions based on isolation forest. Adv. Eng. Inform. 2020, 46, 101139. [Google Scholar] [CrossRef]

- Lin, A.; Wu, H.; Liang, G.; Cardenas-Tristan, A.; Wu, X.; Zhao, C.; Li, D. A big data-driven dynamic estimation model of relief supplies demand in urban flood disaster. Int. J. Disaster Risk Reduct. 2020, 49, 101682. [Google Scholar] [CrossRef]

- Sarker, M.N.I.; Peng, Y.; Yiran, C.; Shouse, R.C. Disaster resilience through big data: Way to environmental sustainability. Int. J. Disaster Risk Reduct. 2020, 51, 101769. [Google Scholar] [CrossRef]

- Sun, L.; Shang, Z.; Xia, Y.; Bhowmick, S.; Nagarajaiah, S. Review of bridge structural health monitoring aided by big data and artificial intelligence: From condition assessment to damage detection. J. Struct. Eng. 2020, 146, 04020073. [Google Scholar] [CrossRef]

- An, W.Y.; Kim, H.J.; Kim, J.Y.; Seo, S.H. Development of a Stock Data Monitoring System Using the Isolation Forest Algorithm. In Annual Conference of KIPS; Korea Information Processing Society: Seoul, Republic of Korea, 2024; pp. 488–489. [Google Scholar]

- Xu, D.; Wang, Y.; Meng, Y.; Zhang, Z. An improved data anomaly detection method based on isolation forest. In Proceedings of the 2017 10th International Symposium On Computational Intelligence And Design (ISCID), Hangzhou, China, 9–10 December 2017; IEEE: New York, NY, USA; Volume 2, pp. 287–291. [Google Scholar]

- Kim, J.; Park, N.S.; Yun, S.; Chae, S.H.; Yoon, S. Application of isolation forest technique for outlier detection in water quality data. J. Korean Soc. Environ. Eng. 2018, 40, 473–480. [Google Scholar] [CrossRef]

- Yoo, S.; Kim, N.; Ha, Y.; Wang, J.; Jin, S. Welding process time series data anomaly detection using AutoEncoder/Isolation Forest algorithm. In Proceedings of the Spring Joint Conference of the Korean Institute of Industrial Engineers, Jeju, Republic of Korea, 2 June 2021. [Google Scholar]

- Wan, Z.; Ma, J.; Qin, N.; Zhou, Z.; Huang, D. Fault detection of air-spring devices based on GANomaly and isolated forest algorithms. In Proceedings of the 2021 IEEE 16th Conference on Industrial Electronics and Applications (ICIEA), Chengdu, China, 1–4 August 2021; IEEE: New York, NY, USA; pp. 1328–1333. [Google Scholar]

- Takanashi, M.; Ishii, Y.; Sato, S.I.; Sano, N.; Sanda, K. Road-deterioration detection using road vibration data with machine-learning approach. In Proceedings of the 2020 IEEE International Conference on Prognostics and Health Management (ICPHM), Detroit, MI, USA, 8–10 June 2020; IEEE: New York, NY, USA; pp. 1–7. [Google Scholar]

- Devi, S.K.; Thenmozhi, R.; Kumar, D.S. Self-healing IoT sensor networks with isolation forest algorithm for autonomous fault detection and recovery. In Proceedings of the 2024 International Conference on Automation and Computation (AUTOCOM), Dehradun, India, 14–16 March 2024; IEEE: New York, NY, USA; pp. 451–456. [Google Scholar]

- McKinnon, C.; Carroll, J.; McDonald, A.; Koukoura, S.; Plumley, C. Investigation of isolation forest for wind turbine pitch system condition monitoring using SCADA data. Energies 2021, 14, 6601. [Google Scholar] [CrossRef]

- Antonini, M.; Pincheira, M.; Vecchio, M.; Antonelli, F. An adaptable and unsupervised TinyML anomaly detection system for extreme industrial environments. Sensors 2023, 23, 2344. [Google Scholar] [CrossRef] [PubMed]

- Feng, B.; Zhang, L. Optimizing the Isolation Forest Algorithm for Identifying Abnormal Behaviors of Students in Education Management Big Data. J. Artif. Intell. Technol. 2024, 4, 31–39. [Google Scholar] [CrossRef]

- Yepmo, V.; Smits, G.; Lesot, M.J.; Pivert, O. CADI: Contextual Anomaly Detection using an Isolation-Forest. In Proceedings of the 39th ACM/SIGAPP Symposium on Applied Computing, Avila, Spain, 8–12 April 2024; pp. 935–944. [Google Scholar]

- Wang, J.; Li, X. Abnormal electricity detection of users based on improved canopy-kmeans and isolation forest algorithms. IEEE Access 2024, 12, 99110–99121. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, X.; Han, T.; Huang, H.; Huang, X.; Wang, L.; Wu, Z. Pipeline deformation monitoring based on long-gauge FBG sensing system: Missing data recovery and deformation calculation. J. Civ. Struct. Health Monit. 2025, 15, 2433–2453. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, X.; Han, T.; Wang, L.; Zhu, Z.; Huang, H.; Ding, J.; Wu, Z. Pipeline deformation prediction based on multi-source monitoring information and novel data-driven model. Eng. Struct. 2025, 337, 120461. [Google Scholar] [CrossRef]

Figure 1.

The isolation process in Isolation Forest.

Figure 1.

The isolation process in Isolation Forest.

Figure 2.

The proposed model combining real-time and periodic analysis for anomaly detection.

Figure 2.

The proposed model combining real-time and periodic analysis for anomaly detection.

Figure 3.

Conceptual flow of integrating real-time and periodic monitoring.

Figure 3.

Conceptual flow of integrating real-time and periodic monitoring.

Figure 4.

Classification scheme for detected crack anomalies (As-is vs. To-be).

Figure 4.

Classification scheme for detected crack anomalies (As-is vs. To-be).

Figure 5.

Data structure collected from monitoring m cracks in facility f for n times.

Figure 5.

Data structure collected from monitoring m cracks in facility f for n times.

Figure 6.

Proposed real-time anomaly decision logic.

Figure 6.

Proposed real-time anomaly decision logic.

Figure 7.

Code implementation process for data preprocessing.

Figure 7.

Code implementation process for data preprocessing.

Figure 8.

Code implementation process for anomaly detection using the Isolation Forest algorithm.

Figure 8.