Lignocellulosic Industrial Waste as a Substitute for Virgin Hemp for a More Sustainable Hempcrete Material

Abstract

1. Introduction

2. Materials and Methods

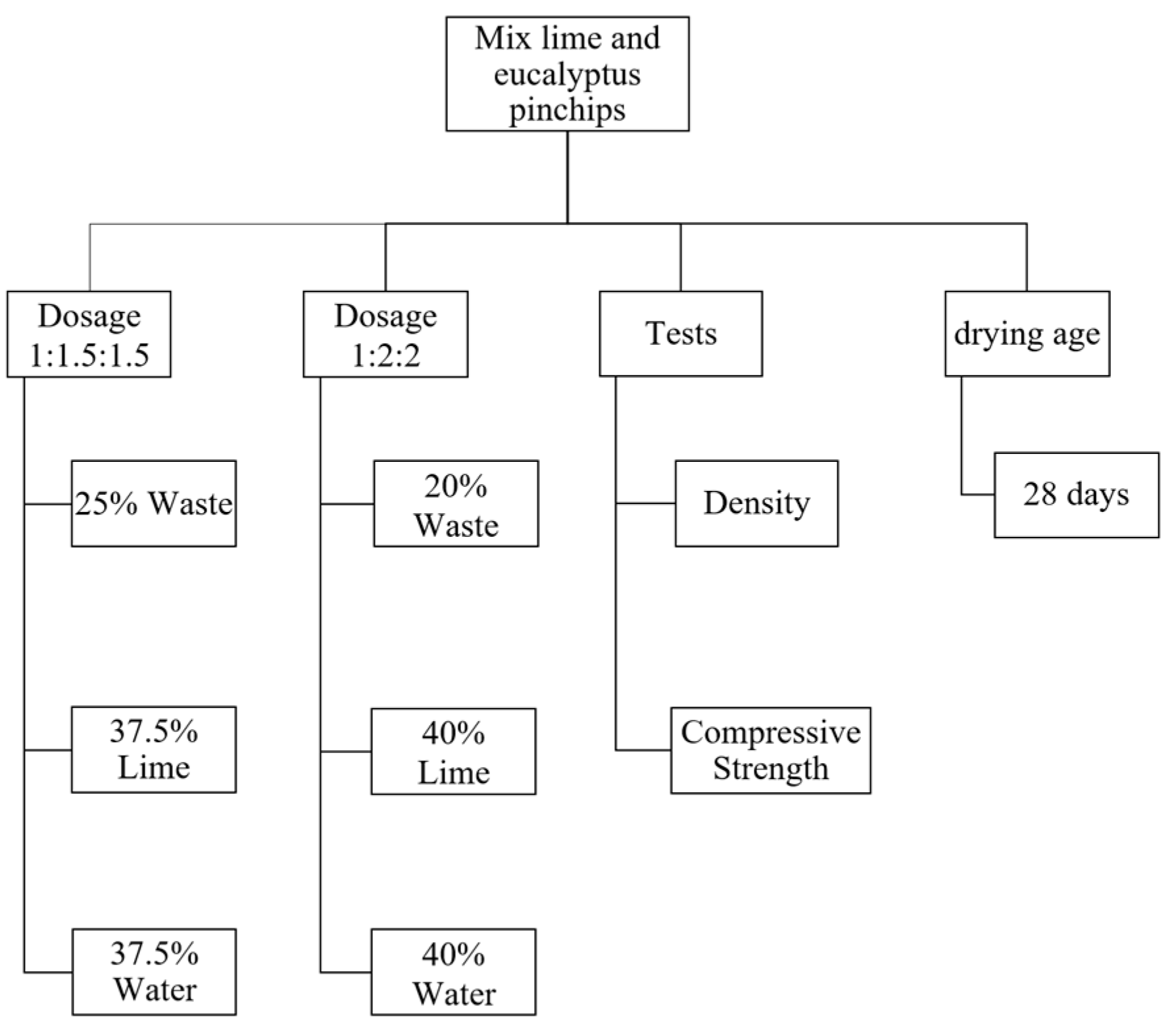

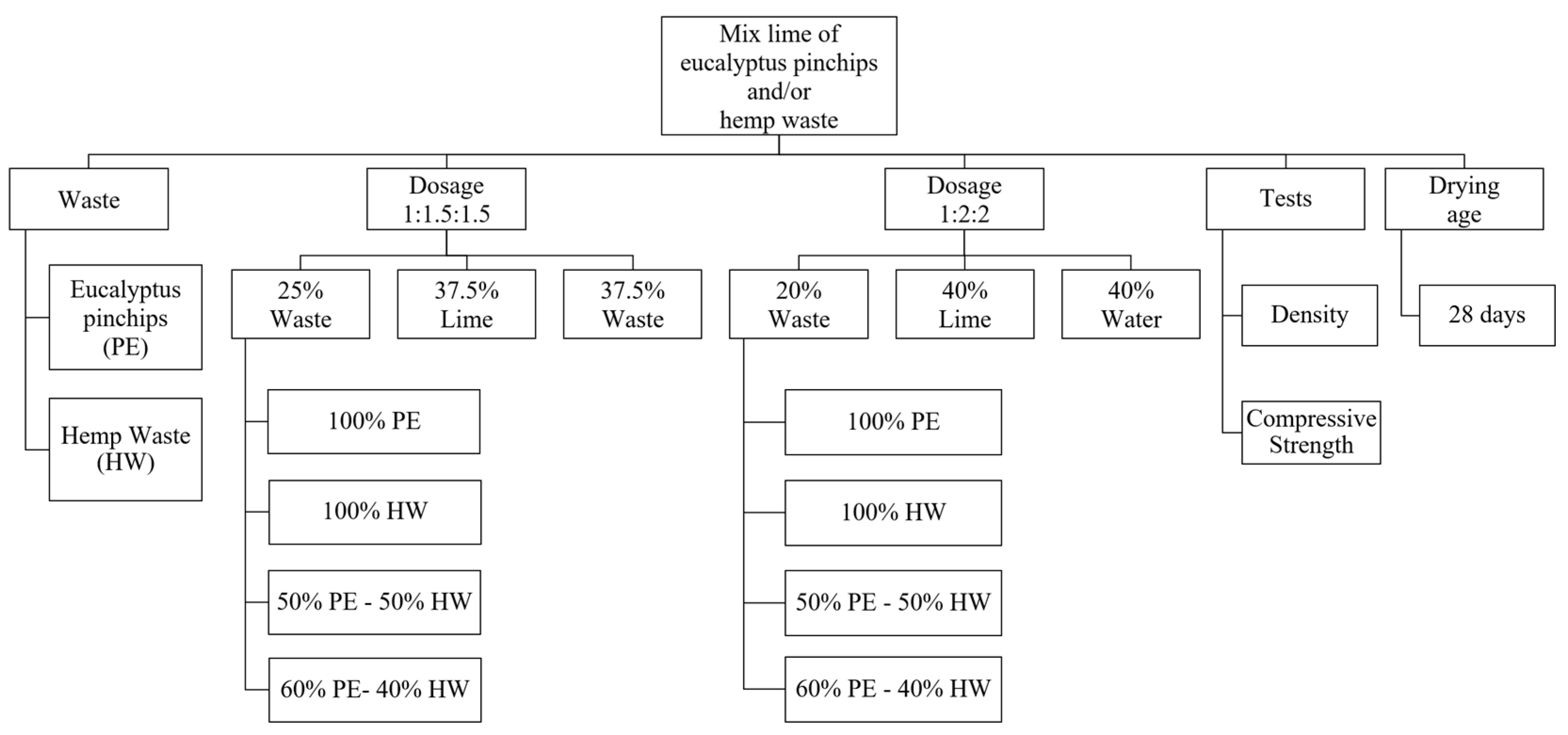

2.1. Experimental Plan

2.1.1. Stage 1

2.1.2. Stage 2

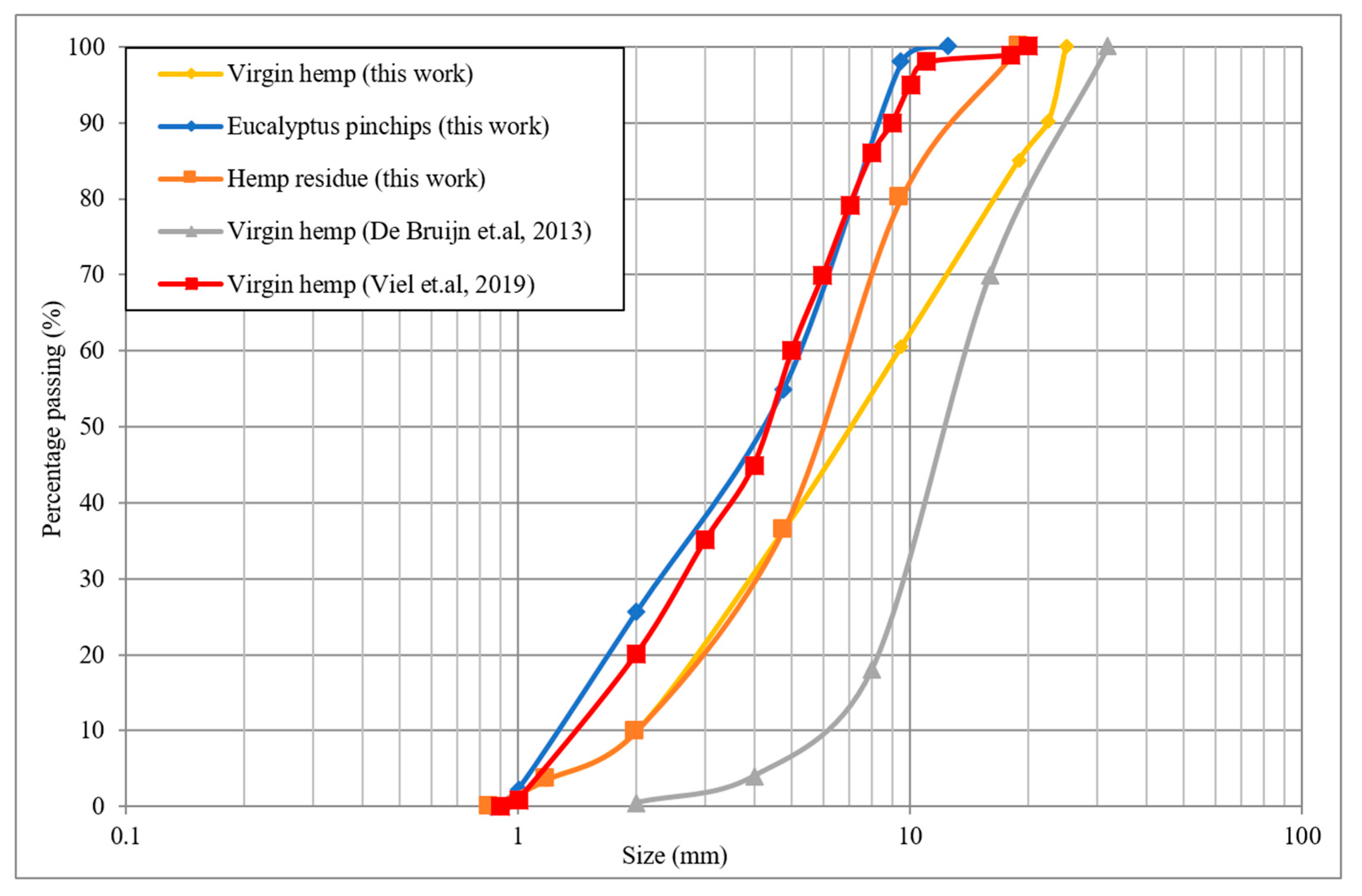

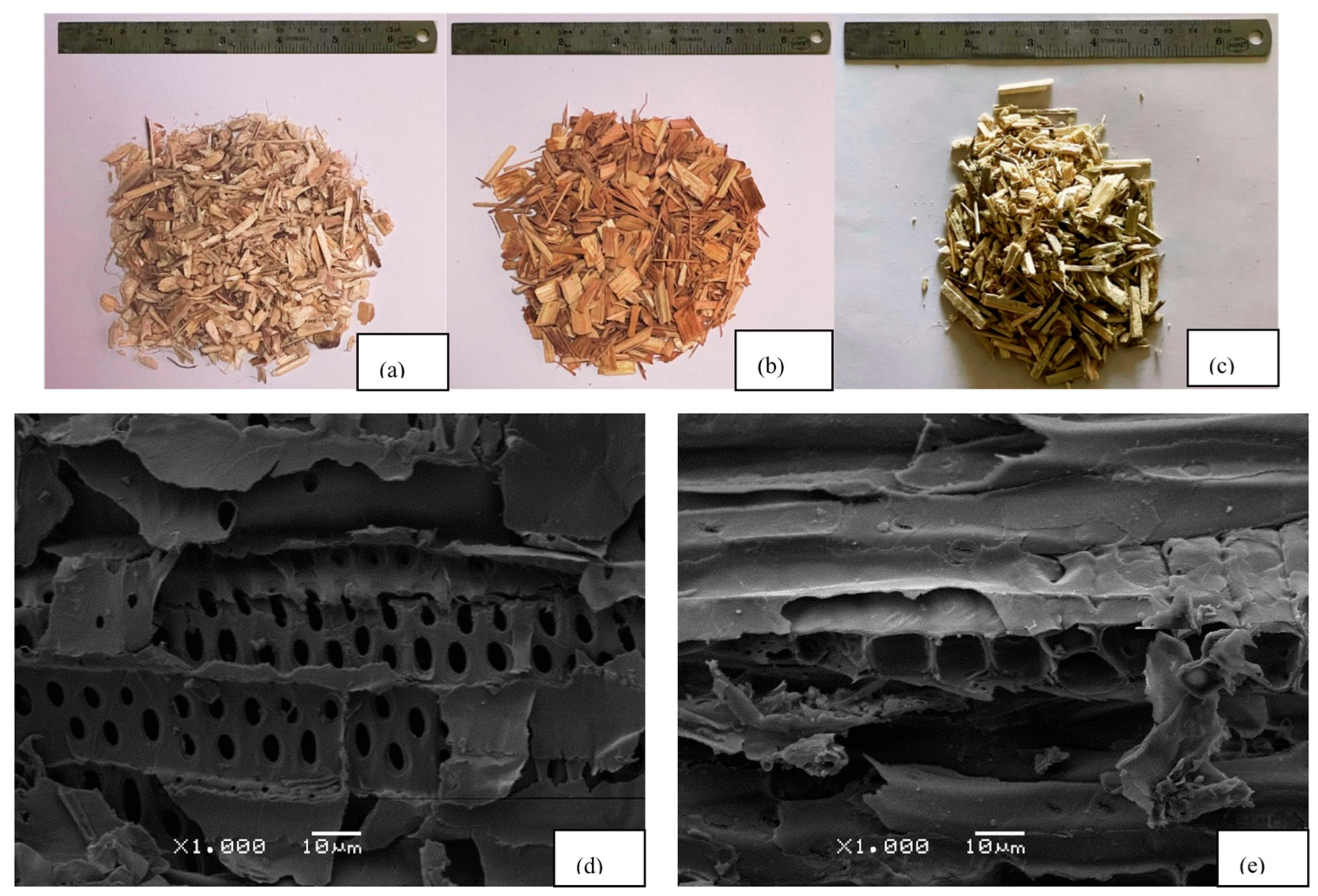

2.2. Materials

2.3. Binder

2.4. Mixture Preparation and Testing

2.5. Design of Compaction Equipment

2.6. Compressive Strength and Density Test

2.7. Life Cycle Assessment

- -

- Raw material: At this stage, eucalyptus pinchips and/or hemp residue are purchased, then dried and sieved.

- -

- Production of the material: In this stage, the mixture is differentiated, quantifying the amount of each raw material to be used, that is, the residues, binder, and water.

- -

- Manufacture of the product: In this phase, the product is manufactured in the field, with differences in density and compressive strength between the mixtures for the functional unit of 1 m3.

3. Results

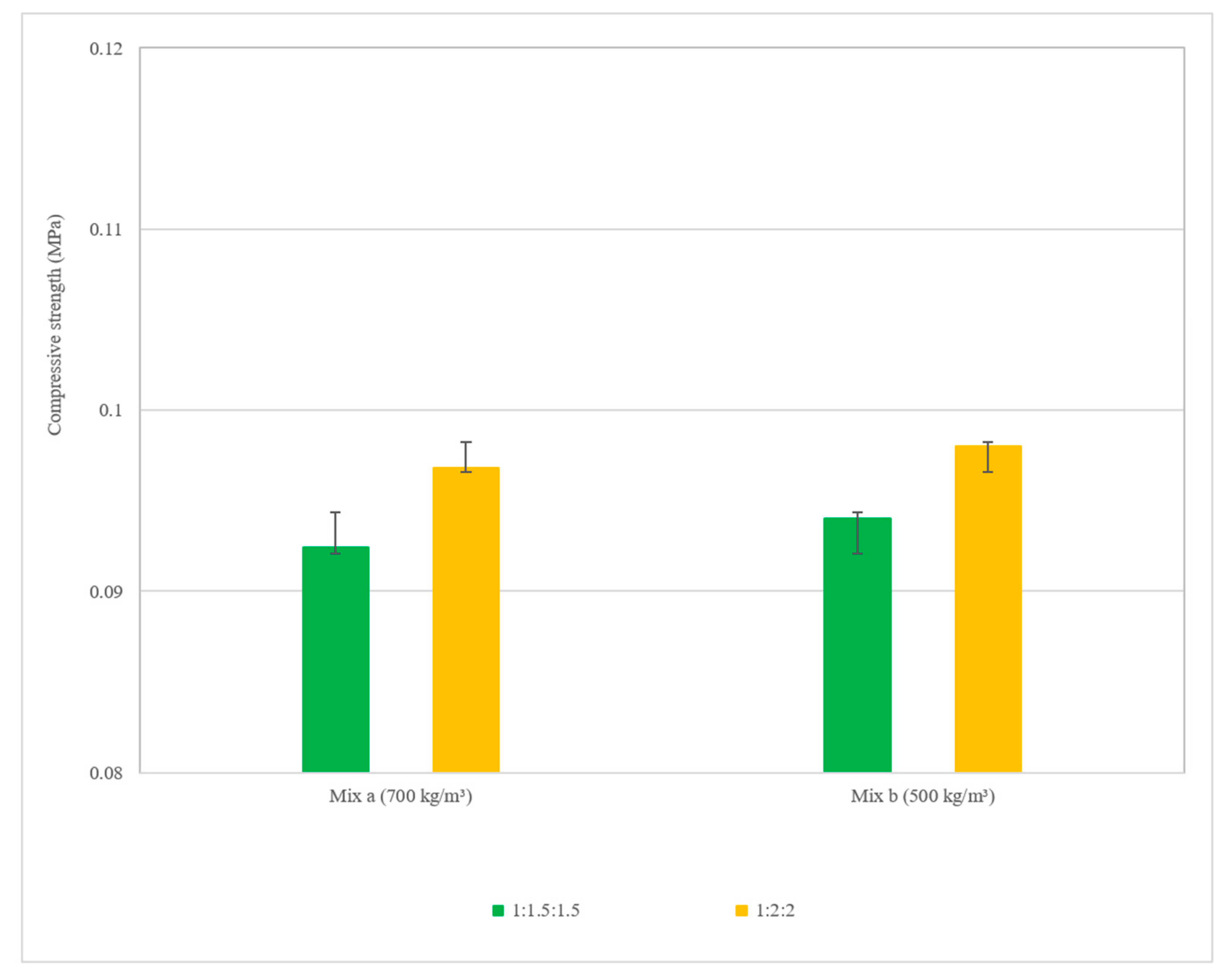

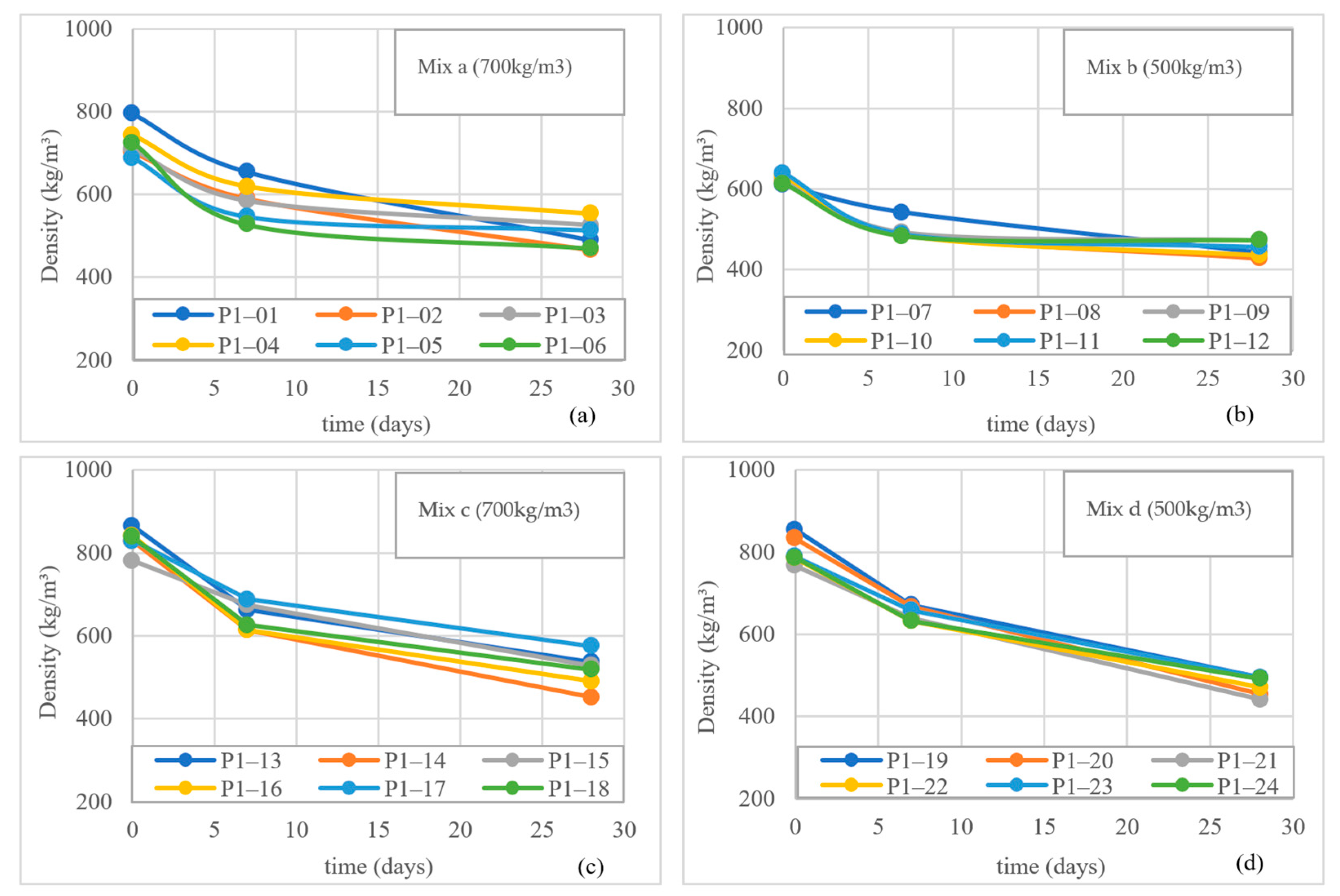

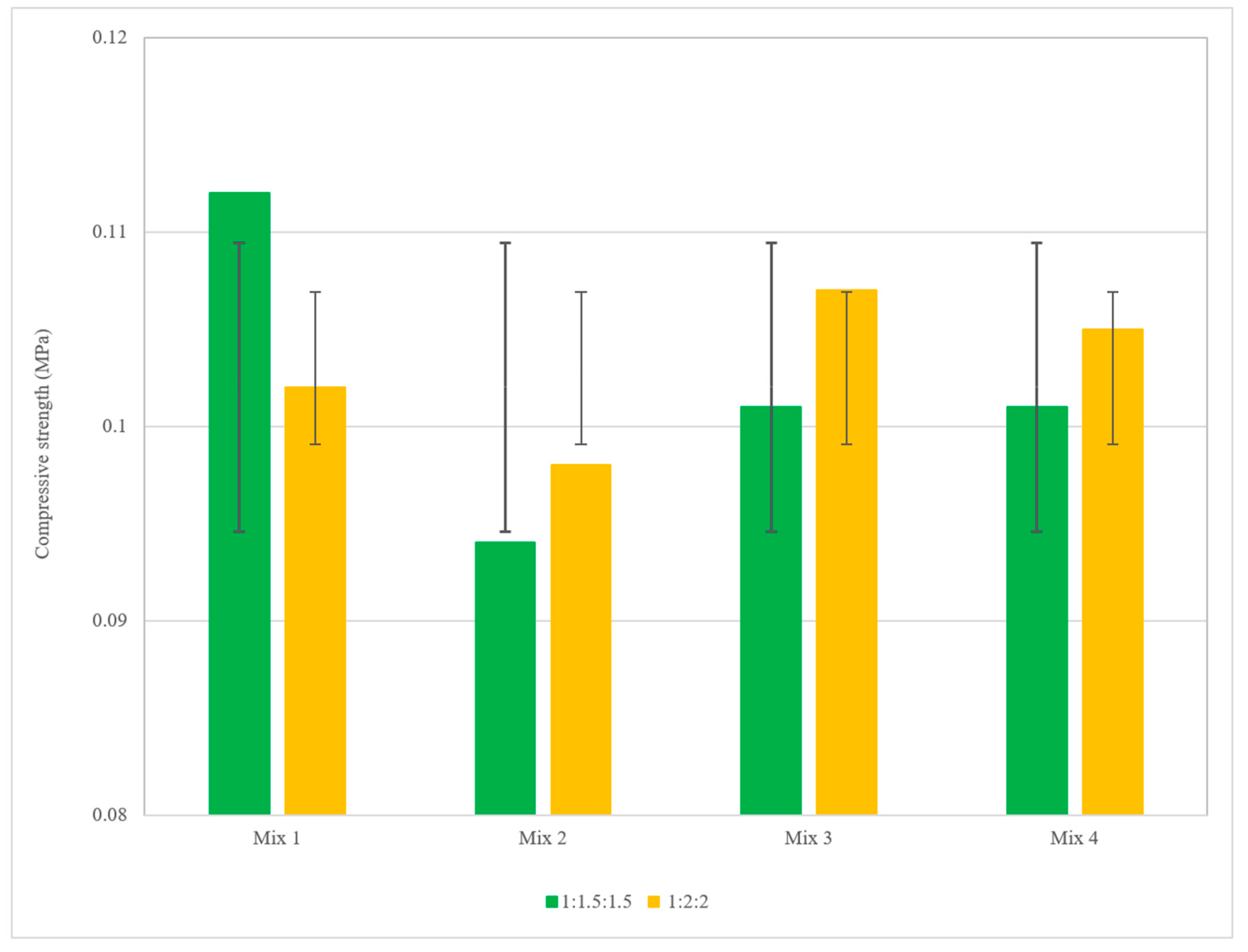

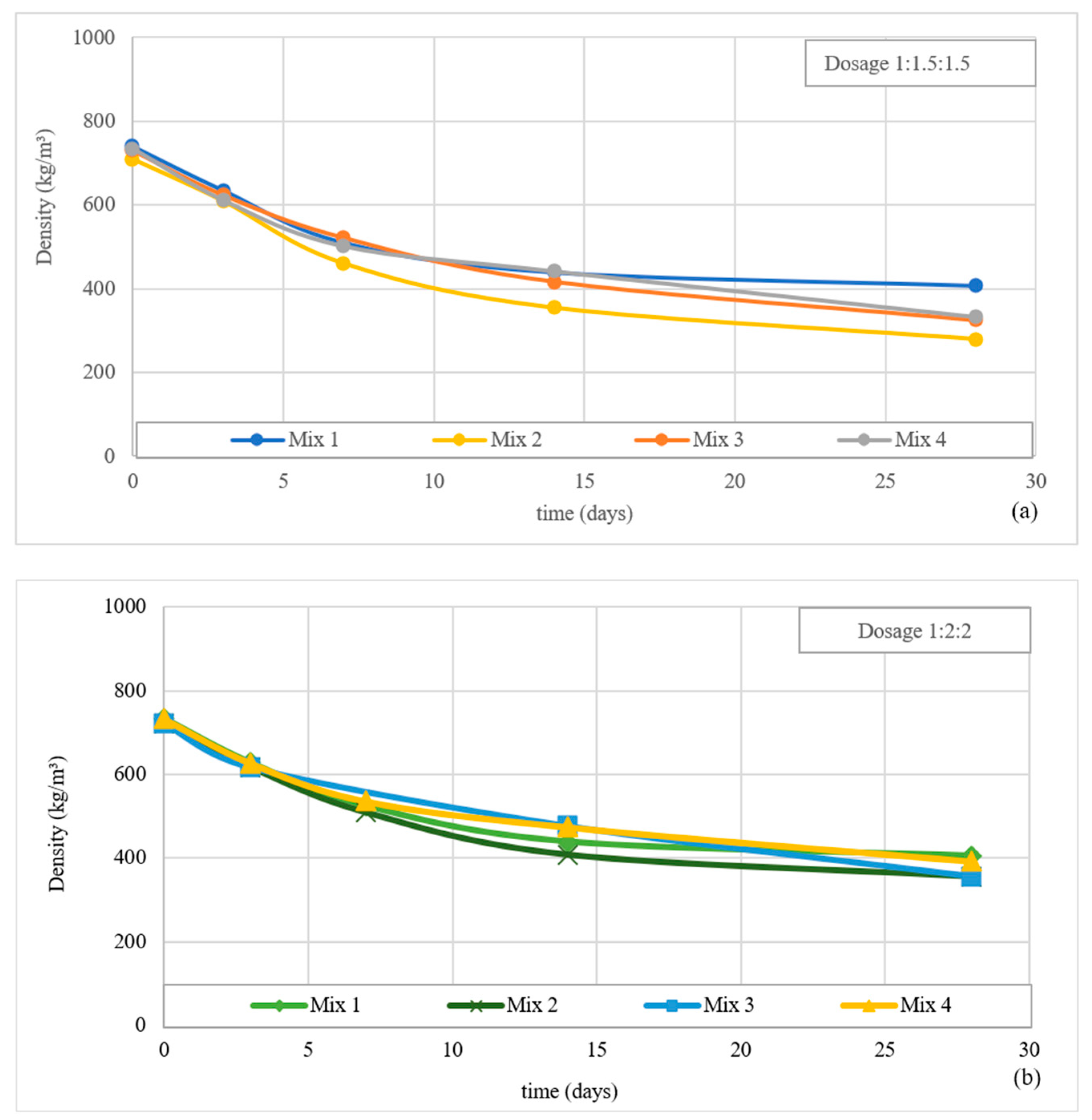

3.1. Laboratory Results

3.2. Life Cycle Assessment of Mixture

4. Discussion

5. Conclusions

- -

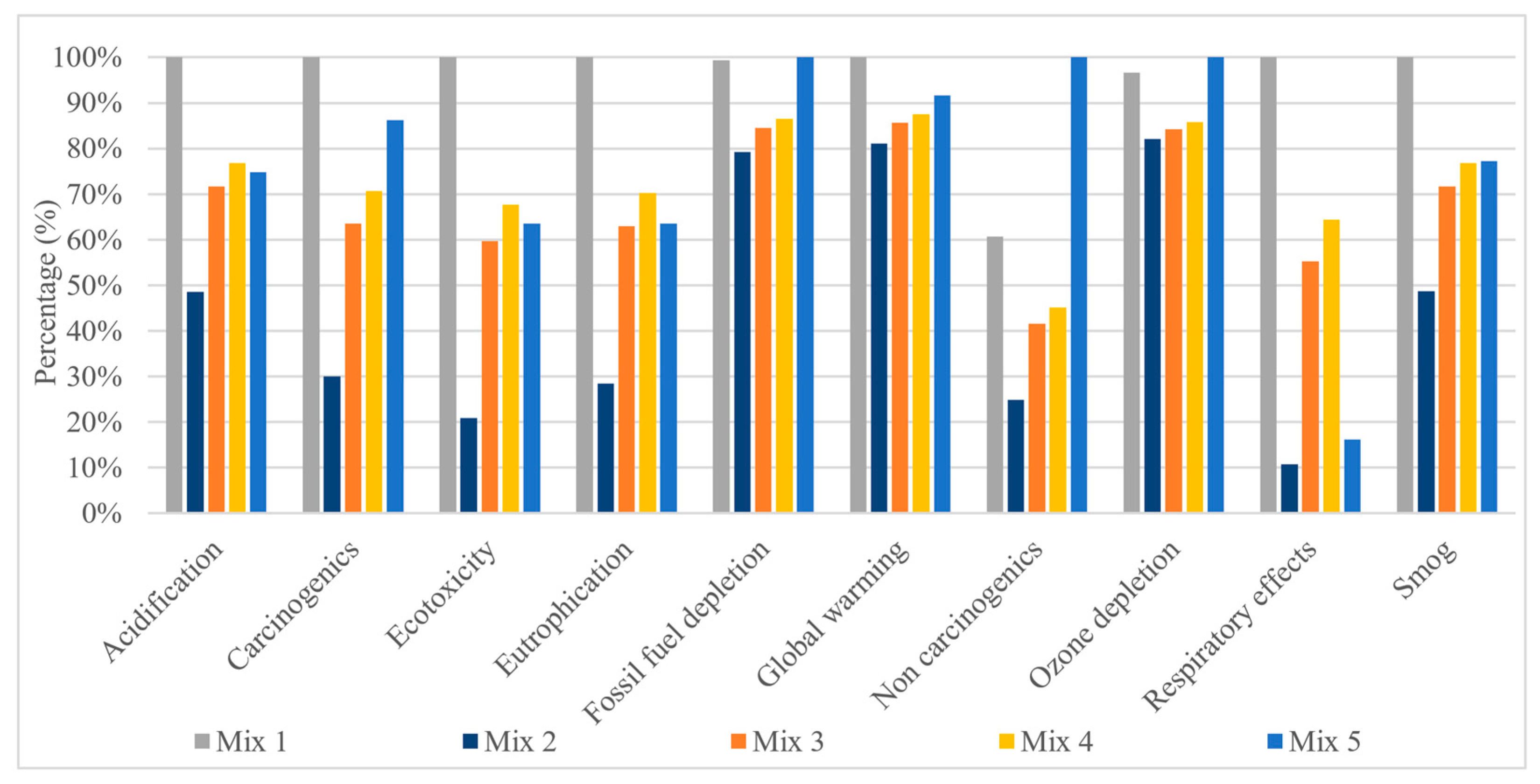

- The most promising application from a technical and environmental point of view is mixture 2. Outstanding mechanical properties were evidenced, with reductions of between 10% and 20% in emissions for respiratory and carcinogenic/non-carcinogenic effects, respectively. Then, it is a very interesting alternative for the practical use of lignocellulosic industrial waste and for reducing the environmental impacts of the hempcrete material, making it even more attractive in comparison with the conventional thermal insulation materials.

- -

- On the other hand, mix 1 proved to be the most unfavorable option in environmental terms. Environmental emissions were close to 100%, attributable to the moisture content of the by-product and their need for drying before incorporation into the mixes.

- -

- Mixes 3 and 4 presented consistent technical results in terms of density and compressive strength. However, to improve their environmental impact, it is suggested to modify the drying process of the eucalyptus pinchips, since this was identified as a critical point that generated emissions close to 40% in all the categories analyzed.

- -

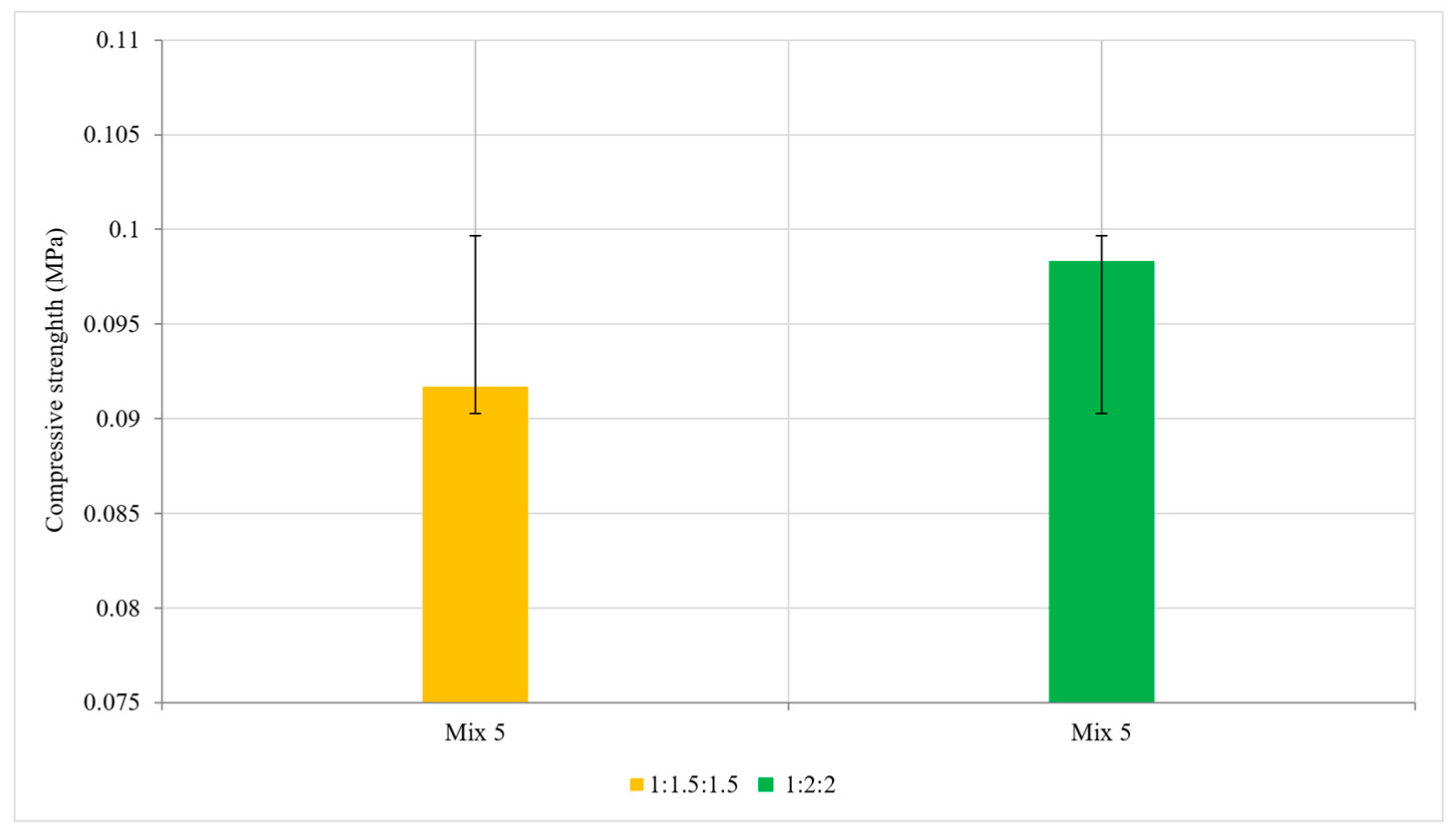

- The results of the lime-based mixes for the specimens indicate that the designed compaction system is adequate. Strengths close to the minimum are achieved and could even be better, but this is attributed to the use of a different binder than the one used in the hempcrete. In addition, the density of the mixes is within the ranges studied in the design of mixes. Therefore, the compaction equipment designed with 0.05 MPa pressure is suitable for the manufacture of lime-based mixes developed during the research.

- -

- The environmental assessment of these applications is crucial when considering the use of by-products and waste in construction. Since research into new materials involves significant costs, a practical recommendation is to determine the environmental viability even before making substantial experimental investments.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koh, C.H.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Investigation of Material Characteristics and Hygrothermal Performances of Different Bio-Based Insulation Composites. Constr. Build. Mater. 2022, 346, 128440. [Google Scholar] [CrossRef]

- Güereca, L.P.; Jato-Espino, D.; Lizasoain-Arteaga, E. Life-Cycle Assessment of Construction Materials: Analysis of Environmental Impacts and Recommendations of Eco-Efficient Management Practices. In Handbook of Environmental Materials Management; Springer International Publishing: Cham, Switzerland, 2019; pp. 2337–2372. [Google Scholar]

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life Cycle Assessment of Building Materials: Comparative Analysis of Energy and Environmental Impacts and Evaluation of the Eco-Efficiency Improvement Potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Biyada, S.; Merzouki, M.; Urbonavičius, J. New Resources for Sustainable Thermal Insulation Using Textile and Agricultural Waste in a New Circular Economy Approach: An Overview. Processes 2023, 11, 2683. [Google Scholar] [CrossRef]

- Siciliano, A.; Zhao, X.; Fedderwitz, R.; Ramakrishnan, K.; Dai, J.; Gong, A.; Zhu, J.; Kośny, J.; Hu, L. Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency. Buildings 2023, 13, 840. [Google Scholar] [CrossRef]

- Petcu, C.; Hegyi, A.; Stoian, V.; Dragomir, C.S.; Ciobanu, A.A.; Lăzărescu, A.V.; Florean, C. Research on Thermal Insulation Performance and Impact on Indoor Air Quality of Cellulose-Based Thermal Insulation Materials. Materials 2023, 16, 5458. [Google Scholar] [CrossRef]

- Liu, L.F.; Li, H.Q.; Lazzaretto, A.; Manente, G.; Tong, C.Y.; Liu, Q.B.; Li, N.P. The development history and prospects of biomass-based insulation materials for buildings. Renew. Sustain. Energy 2016, 69, 912–932. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Carabaño Rodríguez, R.; Bedoya Frutos, C.; Galván Martínez, J.; Ruiz Amador, D. La Utilización Del Corcho Como Material de Aislamiento Térmico Para Una Construcción Sostenible. In Proceedings of the Twelfth International Conference on New Directions in the Humanities, Madrid, Spain, 11–13 June 2014; Universidad Politécnica de Madrid: Madrid, Spain, 2014. [Google Scholar]

- Lanting, S. Biobased Materials in the Construction Industry: A Case Study into the Effects of Using Biobased Con-Struction Materials on Life Cycle Costs. Master’s Thesis, University of Twente, Twente, The Netherlands, 2023. [Google Scholar]

- Betts, D.; Sadeghian, P.; Fam, A. Post-Impact Residual Strength and Resilience of Sandwich Panels with Natural Fiber Composite Faces. J. Build. Eng. 2021, 38, 102184. [Google Scholar] [CrossRef]

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative Life Cycle Assessment of Bio-based Insulation Materials: Environmental and Economic Performances. GCB Bioenergy 2021, 13, 979–998. [Google Scholar] [CrossRef]

- Martínez, B.; Bernat-Maso, E.; Gil, L. Applications and Properties of Hemp Stalk-Based Insulating Biomaterials for Buildings: Review. Materials 2023, 16, 3245. [Google Scholar] [CrossRef]

- Grenon, V.; Maref, W.; Ouellet-Plamondon, C.M. Comparison of Thermal Insulation Proprieties between Glass Wool, Hemp Wool and an Experimental Material Composed of Pleurotus Ostreatus Mycelium and Ash Wood Chips. SSRN 2023. [Google Scholar] [CrossRef]

- Xu, J.; Sugawara, R.; Widyorini, R.; Han, G.; Kawai, S. Manufacture and properties of low-density binderless particleboard from kenaf core. J. Wood Sci. 2004, 50, 62–67. [Google Scholar] [CrossRef]

- Shavyrkina, N.A.; Budaeva, V.V.; Skiba, E.A.; Gismatulina, Y.A.; Sakovich, G.V. Review of Current Prospects for Using Miscanthus-Based Polymers. Polymers 2023, 15, 3097. [Google Scholar] [CrossRef]

- Khalaf, Y.; El Hage, P.; Dimitrova Mihajlova, J.; Bergeret, A.; Lacroix, P.; El Hage, R. Influence of Agricultural Fibers Size on Mechanical and Insulating Properties of Innovative Chitosan-Based Insulators. Constr. Build. Mater. 2021, 287, 123071. [Google Scholar] [CrossRef]

- Masuda, T.; Takano, K.; Hiyama, K. Sound Absorption Performance Test of Grass Compression Board to Promote Resource Circulation. E3S Web Conf. 2023, 396, 01034. [Google Scholar] [CrossRef]

- Dias, P.P.; Jayasinghe, L.B.; Waldmann, D. Investigation of Mycelium-Miscanthus Composites as Building Insulation Material. Results Mater. 2021, 10, 100189. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M.; Zainudin, E.S.; Maleque, M.A. Sugar palm tree: A versatile plant and novel source for biofibres, biomatrices, and biocomposites. Polym. Renew. Resour. 2012, 3, 61–78. [Google Scholar] [CrossRef]

- Pinto, J.; Cruz, D.; Paiva, A.; Pereira, S.; Tavares, P.; Fernandes, L.; Varum, H. Characterization of corn cob as a possible raw building material. Constr. Build. Mater. 2012, 34, 28–33. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crops Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef]

- Dong, Y.; Kong, J.; Mousavi, S.; Rismanchi, B.; Yap, P.S. Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives. Thermo 2023, 3, 38–65. [Google Scholar] [CrossRef]

- Hemmati, N.; Mirzaei, R.; Soltani, P.; Berardi, U.; Javad SheikhMozafari, M.; Edalat, H.; Rezaieyan, E.; Taban, E. Acoustic and thermal performance of wood strands-rock wool-cement composite boards as eco-friendly construction materials. Constr. Build. Mater. 2024, 445, 137935. [Google Scholar] [CrossRef]

- Amaducci, S.; Amaducci, M.T.; Benati, R.; Venturi, G. Crop yield and quality parameters of four annual fibre crops (hemp, kenaf, maize and sorghum) in the North of Italy. Ind. Crops Prod. 2000, 11, 179–186. [Google Scholar] [CrossRef]

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Cerezo, V. Propriétés Mécaniques, Thermiques et Acoustiques d’un Matériau à Base de Particules Végétales: Approche Experimentale et Modélisation Théorique. Ph.D. Thesis, Institut National des Sciences Appliquées, Lyon, France, 2005. [Google Scholar]

- De Bruijn, P.; Jeppsson, K.-H.; Sandin, K.; Nilsson, C. Mechanical properties of lime-hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar] [CrossRef]

- Hirst, E.A.J.; Walker, P.; Paine, K.A.; Yates, T. Characteristics of low-density hemp-lime building materials. Proc. Inst. Civ. Eng. Constr. Mater. 2012, 165, 15–23. [Google Scholar] [CrossRef]

- Stanwix, W.; Sparrow, A. The Hempcrete Book: Designing and Building with Hemp-Lime; Bloomsbury Publishing: New York, NY, USA, 2014. [Google Scholar]

- Komsi, J. Thermal Properties of Hempcrete, a Case Study. Bachelor’s Thesis, Helsinki Metropolia University of Applied Sciences, Helsinki, Finland, 2018. [Google Scholar]

- Balčiūnas, G.; Žvironaitė, J.; Vėjelis, S.; Jagniatinskis, A.; Gaidučis, S. Ecological, thermal and acoustical insulating composite from hemp shives and sapropel binder. Ind. Crops Prod. 2016, 91, 286–294. [Google Scholar] [CrossRef]

- Collet, F.; Pretot, S. Thermal conductivity of hemp concretes: Variation with formulation, density and water content. Constr. Build. Mater. 2014, 65, 612–619. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Effect of compaction on multi-physical properties of hemp-black liquor composites. J. Mater. Res. Technol. 2020, 2, 2487–2494. [Google Scholar] [CrossRef]

- Soto, A.D.; Pardo, V.E.; Poblete, H.P.; La Industria de Astillas 2021. Instituto Forestal. Available online: https://wef.infor.cl/?option=com_wef&task=GetFile&format=raw&id=12&f=17&n=2021 (accessed on 21 July 2025).

- Morales, R. Medios de Cultivo Líquidos para el Desarrollo de Inoculados de Hongos de Pudricion Blanca Aplicables en Biopulpaje Kraft. Bachelor’s Thesis, Universidad de Chile, Santiago, Chile, 2006. [Google Scholar]

- Bilaseca, F. Valorization of Hemp Core Residues: Impact of NaOH Treatment on the Flexural Strength of PP Composites and Intrinsic Flexural Strength of Hemp Core Fibers. Biomolecules 2020, 10, 823. [Google Scholar] [CrossRef]

- Beaugrand, J.; Nottez, M.; Konnerth, J.; Bourmaud, A. Multi-scale analysis of the structure and mechanical performance of woody hemp core and the dependence on the sampling location. Ind. Crops Prod. 2014, 60, 193–204. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties Characterization of Chemically Modified Hemp Hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef]

- Magwood, C. The Essential Guide to Hempcrete—A Strong, Versatile, Environmentally-Friendly, Energy-Efficient Natural Insulating Material; New Society Publishers: Gabriola Island, BC, Canada, 2016. [Google Scholar]

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. Advancing Standards Transforming Markets International: West Conshohocken, PA, USA, 2019.

- De Bruijn, P.; Johansson, P. Moisture fixation and thermal properties of lime–hemp concrete. Constr. Build. Mater. 2013, 47, 1235–1242. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Prétot, S.; Lanos, C. Hemp-Straw Composites: Gluing Study and Multi-Physical Characterizations. Materials 2019, 12, 1199. [Google Scholar] [CrossRef]

- Jiang, Y.; Lawrence, M.; Ansell, M.; Hussain, A. Cell wall microstructure, pore size distribution and absolute density of hemp shiv. R. Soc. Open Sci. 2018, 5, 171945. [Google Scholar] [CrossRef] [PubMed]

- UNE-EN 459-1; Building Lime—Part 1: Definitions, Specifications and Conformity Criteria. Asociacion Española de Normalizacion (UNE): Madrid, Spain, 2016.

- Chabannes, M.; Garcia-Diaz, E.; Clerc, L.; Bénézet, J.C. Studying the hardening and mechanical performances of rice husk and hemp-based building materials cured under natural and accelerated carbonation. Constr. Build. Mater. 2015, 94, 105–115. [Google Scholar] [CrossRef]

- Dhakal, U.; Berardi, U.; Gorgolewski, M.; Richman, R. Hygrothermal performance of hempcrete for Ontario (Canada) buildings. J. Clean. Prod. 2017, 142, 3655–3664. [Google Scholar] [CrossRef]

- Ip, K.; Miller, A. Life cycle greenhouse gas emissions of hemp-lime wall constructions in the UK. Resour. Conserv. Recycl. 2012, 69, 1–9. [Google Scholar] [CrossRef]

- Lupu, M.L.; Isopescu, D.N.; Baciu, I.-R.; Maxineasa, S.G.; Pruna, L.; Gheorghiu, R. Hempcrete–modern solutions for green buildings. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1242, 012021. [Google Scholar] [CrossRef]

- Somé, S.C.; Ben Fraj, A.; Pavoine, A.; Hajj Chehade, M. Modeling and experimental characterization of effective transverse thermal properties of hemp insulation concrete. Constr. Build. Mater. 2018, 189, 384–396. [Google Scholar] [CrossRef]

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. Advancing Standards Transforming Markets International: West Conshohocken, PA, USA, 2017.

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. Advancing Standards Transforming Markets International: West Conshohocken, PA, USA, 2001.

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Vogtländer, J.G. LCA. A Practical Guide for Students, Designers and Business Managers; Delft Academic Press: Oegstgeest, The Netherlands, 2023. [Google Scholar]

- OpenLCA Nexus—Databases. Available online: https://nexus.openlca.org/databases (accessed on 21 July 2025).

- Abdellatef, Y.; Khan, M.A.; Khan, A.; Alam, M.I.; Kavgic, M. Mechanical, thermal, and moisture buffering properties of novel insulating hemp-lime composite. Materials 2020, 13, 5000. [Google Scholar] [CrossRef]

- Vural Gursel, I.; Elbersen, B.; Meesters, K.P.H.; van Leeuwen, M. Defining Circular Economy Principles for Biobased Products. Sustainability 2022, 14, 12780. [Google Scholar] [CrossRef]

- Brandão, A.S.; Gonçalves, A.; Santos, J.M.R.C.A. Circular Bioeconomy Strategies: From Scientific Research to Commercially Viable Products. J. Clean. Prod. 2021, 295, 126407. [Google Scholar] [CrossRef]

- Cámara Chilena de la Construcción. Informe MACh 60 Macroeconomía y Construcción; Cámara Chilena de la Construcción: Las Condes, Chile, 2022. [Google Scholar]

- Ministerio de Vivienda y Urbanismo. Ordenanza General de Urbanismo y Construcciones; MINVU, Ed.; MINVU: Santiago, Chile, 2017. [Google Scholar]

| Density (kg/m3) | Mixtures | Eucalyptus Pinchips | Binder | Water |

|---|---|---|---|---|

| Mix a | 1:1.5:1.5 | 25% | 37.5% | 37.5% |

| (700 kg/m3) | 1:2:2 | 20% | 40% | 40% |

| Mix b | 1:1.5:1.5 | 25% | 37.5% | 37.5% |

| (500 kg/m3) | 1:2:2 | 20% | 40% | 40% |

| Dosage | Materials | Mix 1 (Eucalyptus Pinchips) | Mix 2 (Hemp Waste) | Mix 3 * | Mix 4 ** | Mix 5 (Virgin Hemp) |

|---|---|---|---|---|---|---|

| 1:1.5:1.5 | Waste | 25% | 25% | 12.5%, 12.5% | 15%, 10% | 25% |

| Binder | 37.5% | 37.5% | 37.5% | 37.5% | 37.5% | |

| Water | 37.5% | 37.5% | 37.5% | 37.5% | 37.5% | |

| 1:2:2 | Waste | 20% | 20% | 10%, 10% | 12%, 8% | 20% |

| Binder | 40% | 40% | 40% | 40% | 40% | |

| Water | 40% | 40% | 40% | 40% | 40% |

| Properties | Hemp Waste | Eucalyptus Pinchips | Traditional Hemp [26] |

|---|---|---|---|

| Bulk density (kg/m3) | 90 | 170 | 98 |

| Porosity (%) | 83 | 84 | 84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ávila-Vidal, N.; Schwarz, A.; Escribano, D.; Fuentealba, C.; Pradena-Miquel, M. Lignocellulosic Industrial Waste as a Substitute for Virgin Hemp for a More Sustainable Hempcrete Material. Buildings 2025, 15, 3446. https://doi.org/10.3390/buildings15193446

Ávila-Vidal N, Schwarz A, Escribano D, Fuentealba C, Pradena-Miquel M. Lignocellulosic Industrial Waste as a Substitute for Virgin Hemp for a More Sustainable Hempcrete Material. Buildings. 2025; 15(19):3446. https://doi.org/10.3390/buildings15193446

Chicago/Turabian StyleÁvila-Vidal, Nicole, Alex Schwarz, Daniella Escribano, Cecilia Fuentealba, and Mauricio Pradena-Miquel. 2025. "Lignocellulosic Industrial Waste as a Substitute for Virgin Hemp for a More Sustainable Hempcrete Material" Buildings 15, no. 19: 3446. https://doi.org/10.3390/buildings15193446

APA StyleÁvila-Vidal, N., Schwarz, A., Escribano, D., Fuentealba, C., & Pradena-Miquel, M. (2025). Lignocellulosic Industrial Waste as a Substitute for Virgin Hemp for a More Sustainable Hempcrete Material. Buildings, 15(19), 3446. https://doi.org/10.3390/buildings15193446