Developing Critical Success Factors (CSF) for Integrating Building Information Models (BIM) into Facility Management Systems (FMS)

Abstract

1. Introduction

2. Literature Review

2.1. FM Systems (BMS) and (CAFM)

2.2. Integration of BIM-FM Systems

2.3. Employer Information Requirements (EIR)

2.4. Critical Success Factors (CSFs)

2.5. The Gap and the Selected Critical Success Factors from the Literature

3. Research Methodology

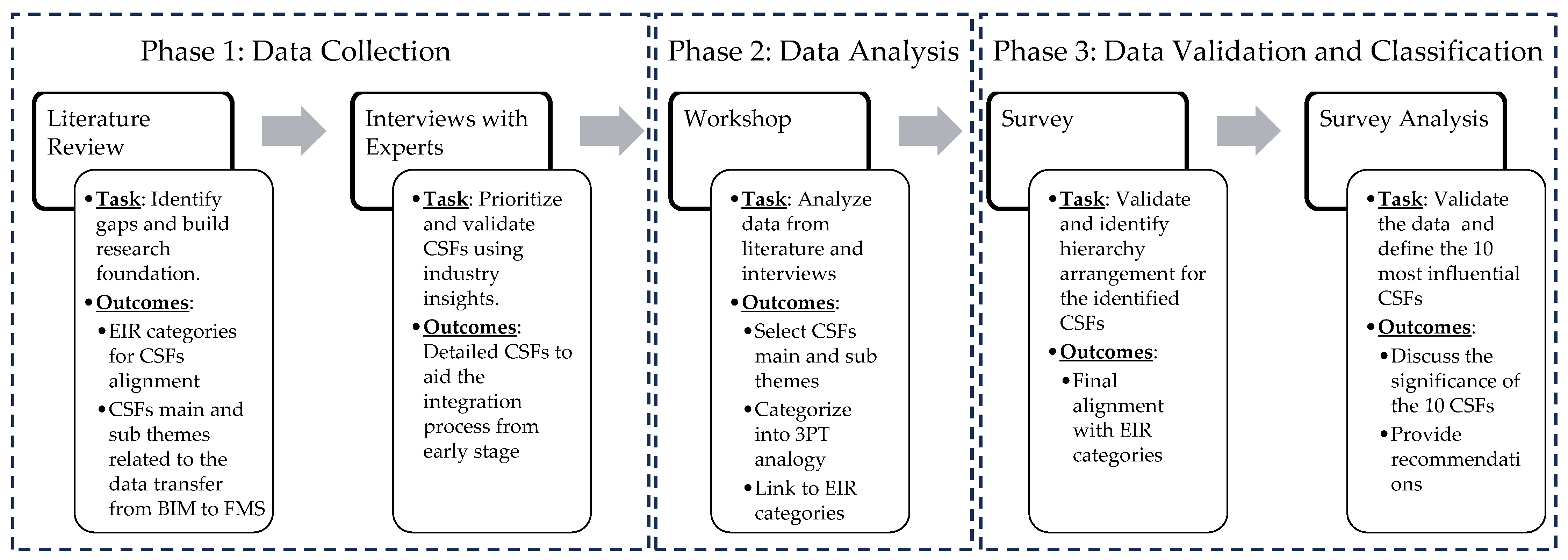

3.1. Research Literature and Study Workflow

3.2. Statistical Analysis

3.2.1. Relative Importance Index (RII)

3.2.2. Pairwise Correlation Matrix

3.2.3. Kendall Coefficient of Concordance (W)

3.2.4. Spearman’s Rank Correlation Test

4. Findings

4.1. Identified CSFs—Interviews

4.2. Identified CSFs—Workshop

4.3. Identified CSFs—Survey

4.3.1. Data Collection

4.3.2. Analysis

Relative Importance Index

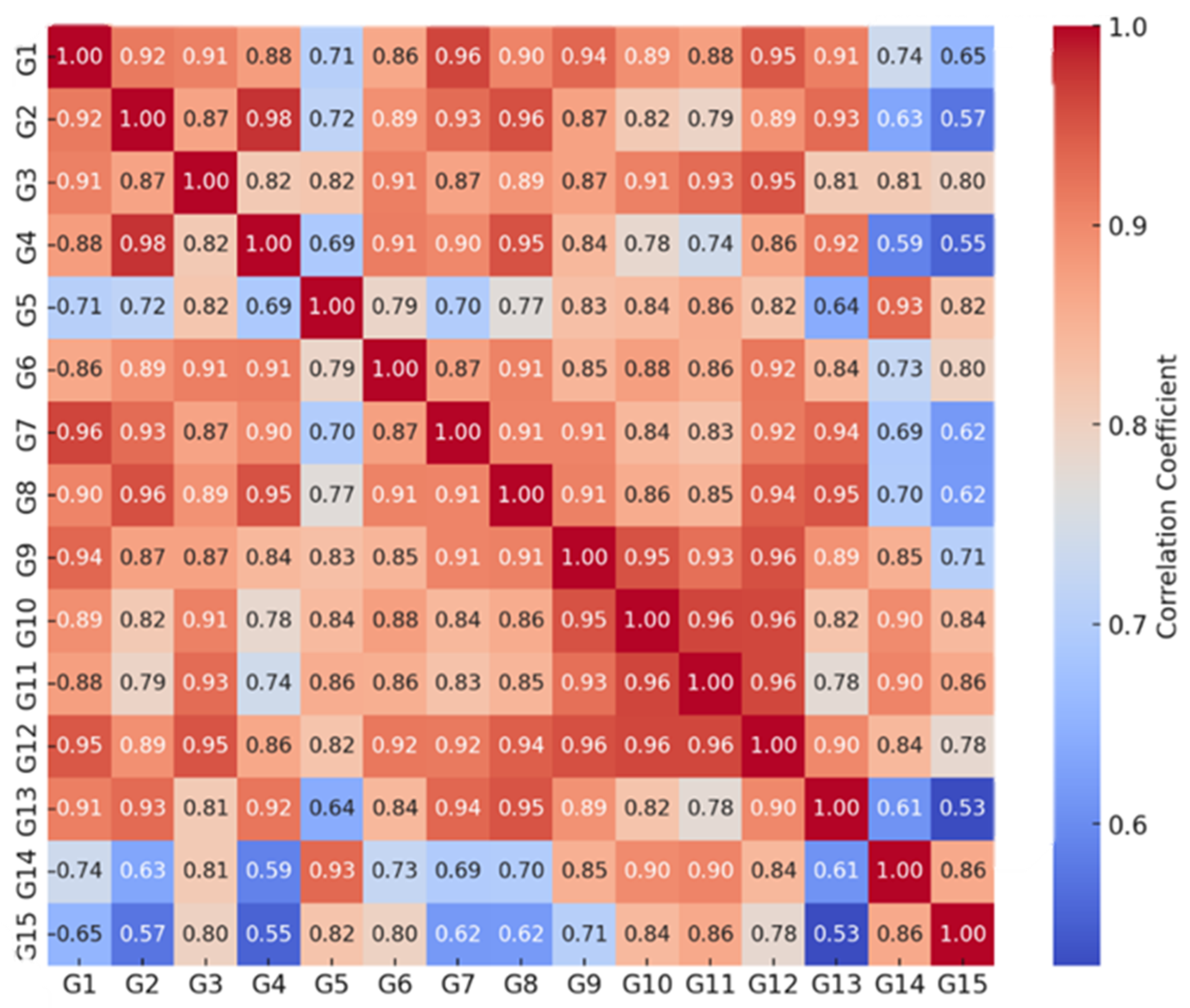

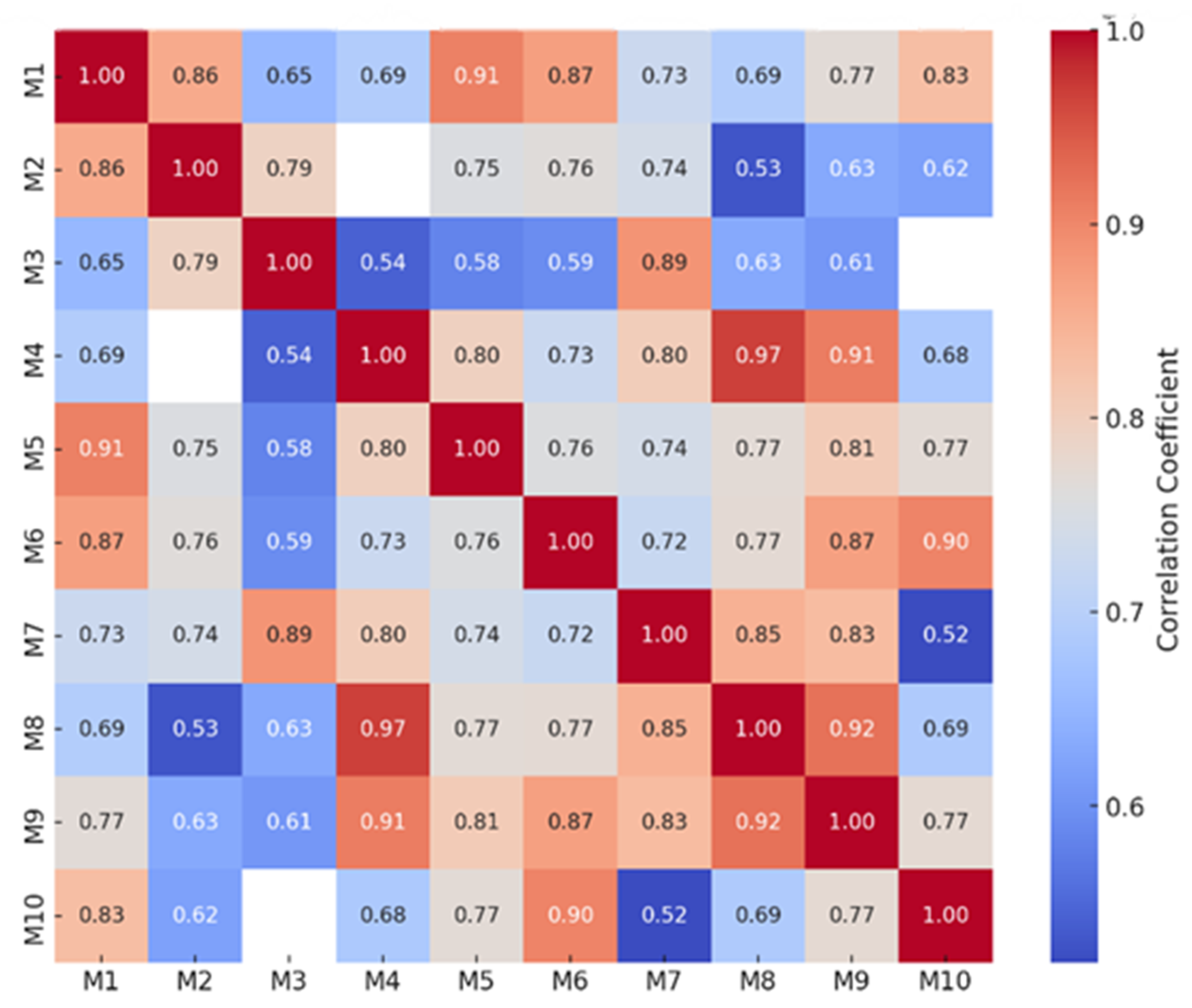

Pairwise Correlation Matrix

- The PCA (principal component analysis) on “guidance” data was performed, resulting in the following principal components (PCs) and their explained variances:

- ○

- PC1 explains 85.15% of the variance.

- ○

- PC2 explains 8.09% of the variance.

- ○

- PC3 explains 2.16% of the variance.

- ○

- PC4 explains 1.76% of the variance.

- ○

- Further components each explain less than 1% of the variance.

- ○

- All data tested significant at 5%.

- ○

- Data trends show generally a good positive correlation between the factors.

- PC1 explains 76.46% of the variance;

- PC2 explains 9.52% of the variance;

- PC3 explains 8.39% of the variance;

- PC4 explains 2.98% of the variance;

- Further components each explain less than 2% of the variance;

- Data trends generally show a good positive correlation between the factors, as shown in Figure 3.

- PC1 explains 77.57% of the variance;

- PC2 explains 13.72% of the variance;

- PC3 explains 3.76% of the variance;

- Further components each explain less than 2% of the variance.

Kendall Coefficient

Spearman’s Rank Correlation Test

5. Discussion

- Define the OIR, AIR, and FM information requirements to support the AM strategy;

- Acquire correct files, data, and formats;

- Update of information requirements during the defect liability period (DLP);

- Three-dimensional visualization of asset locations;

- Understand the link between BIM and FM management systems;

- Set realistic expectations of what BIM can deliver;

- Understand client’s IT requirements;

- The use of interoperable systems to convert 2D to 3D BIM in existing buildings;

- Upskill FM teams to leverage BIM capabilities in FM (to participate in client proposal and development;

- Adapt two versions for FM systems (pre-production and production versions).

5.1. Define the OIR, AIR, and FM Information Requirements to Support the AM Strategy

5.2. Acquire Correct Files, Data, and Formats

5.3. Update of Information Requirements During the Defect Liability Period (DLP)

5.4. Three-Dimensional Visualization of Asset Locations

5.5. Understand the Link Between BIM and FM Management Systems

5.6. Set Realistic Expectations of What BIM Can Deliver

5.7. Understand Client’s IT Requirements

5.8. The Use of Interoperable Systems to Convert 2D to 3D BIM in Existing Buildings

5.9. Upskill FM Teams to Leverage BIM Capabilities in FM (To Participate in Client Proposal and Development)

5.10. Adapt Two Versions for FM Systems (Pre-Production and Production Versions)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BIM | Building information modeling |

| FM | Facility management |

| CSF | Critical success factors |

| EIR | Employer information requirements |

| BMS | Building management systems |

| CAFM | Computer aided facility management |

| CIC BIM Protocol | Construction Industry Council BIM Standard |

| IWMS | Integrated workplace management systems |

| COBie | Construction operations building information exchange |

| QAQC | Quality assurance and quality control |

Appendix A

- SECTION 1:

- 1.

- Participant’s background information:

- 1.1

- Profession

- A.

- Architect (design)

- B.

- Engineer (implementation)

- C.

- Engineer (maintenance)

- D.

- Manager (facilities)

- E.

- Professional (enforcement)

- F.

- Other: (please specify)

- 1.2

- FM years of experience

- A.

- 1–5

- B.

- 5–10

- C.

- 10–15

- D.

- 15–20

- E.

- 20–30

- F.

- 30+

- 1.3

- BIM years of experience

- A.

- 1–5

- B.

- 5–10

- C.

- 10–15

- D.

- 15–20

- E.

- 20–30

- F.

- 30+

- 1.4

- Company name

- Text

- 1.5

- Contact email

- Text

- SECTION 2:

- 2.

- Critical success factors (CSF) hierarchy arrangement

- 2.1

- Rank the following categories according to their level of importance (1–3)

- A.

- Guidance

- B.

- Management/Planning

- C.

- Quality

- 2.2

- Kindly specify the reason for your selected ranking in the previous question[Text]

- 2.3

- Rank the following Guidance CSFs according to their level of importance (1–15) *

- A.

- Define the OIR, AIR, and FM information requirements to support the AM strategy

- B.

- Communicate FM requirements with the client (including BIM as part of the submission)

- C.

- Provide BIM standards and guidelines

- D.

- Early participation of FM

- E.

- Update of information requirements during the defect liability period (DLP)

- F.

- Identify client needs and using FM know-how to help improve BIM project outcomes

- G.

- Understand client’s IT requirements

- H.

- Understand the link between BIM and FM management systems

- I.

- Seamless data formats for the integration

- J.

- Adapt necessary plugins for adequate operations of FM systems

- K.

- Scalable file size (BIM) for better control and visibility

- L.

- Adapt systems that can be synchronized to reduce information loss

- M.

- Capacity of BIM implementation system to exchange information among different BIM and non-BIM systems without data loss

- N.

- The use of interoperable systems to convert 2D to 3D BIM in existing buildings

- O.

- Adapt two versions for FM systems (pre-production and production versions)

- 2.4

- Kindly share your views/comments on guidance in construction projects from your experience in the industry

- [Text]

- 2.5

- Rank the following management/planning CSFs according to their level of importance (1–10)

- A.

- Upskill FM teams to leverage BIM capabilities in FM (to participate in client proposal development)

- B.

- Adapt new technologies for FM systems

- C.

- Accessible BIM software vendors for FM

- D.

- Set realistic expectations of what BIM can deliver

- E.

- Stakeholders’ commitment and compliance to BIM standards and protocols

- F.

- Strong supervision from top management

- G.

- Compatible integration systems

- H.

- Plan the data transfer and quality checking process for BIM project

- I.

- Bi-directional data transfer and improvement of data handover processes and future possibilities

- J.

- Common data environment (CDE)

- 2.6

- Kindly share your views/comments on management/planning in construction projects from your experience in the industry

- [Text]

- 2.7

- Rank the following Quality CSFs according to their level of importance (1–9)

- A.

- Ensure access of good quality data from one place (BIM)

- B.

- Three-dimensional visualization of asset locations

- C.

- Acquire correct files, data, and formats

- D.

- The need for accurate scripts to identify mistakes and mismatches in the data

- E.

- Making explicit design information and making it available to stakeholders so that the design, construction, or operation intent can be easily understood and evaluated

- F.

- Effective stakeholders reviews (consultants, contractors, and FM)

- G.

- Accurate data (drawings, DDC, device IO list, asset registry, IFC IDs, automated codes, asset keys, unique codes, barcodes, etc.)

- H.

- Connected asset codes and tags in the controlling system from the asset registry (existing buildings)

- I.

- Developing a structured qualifications manual (FM and integrator’s preliminary checks)

- 2.8

- Kindly share your views/comments on quality in construction projects from your experience in the industry

- [Text]

- SECTION 3:

- 3.

- FM role (additional questions)

References

- Barki, H.; Fadli, F.; Shaat, A.; Boguslawski, P. BIM Models Generation from 2D CAD Drawings and 3D Scans: An Analysis of Challenges and Opportunities for AEC Practitioners. In Building Information Modelling (BIM) in Design; Construction and Operations: Bristol, UK, 2015. [Google Scholar]

- Naghshbandi, N. BIM for Facility Management: Challenges and Research Gaps. Civ. Eng. J. 2016, 2, 679–684. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Ge, J.; He, S.X. Digitisation in facilities management: A literature review and future research directions. Autom. Constr. 2018, 92, 312–326. [Google Scholar] [CrossRef]

- Zhang, T. Investigating the Effectiveness of BIM-BMS Integration on Managing Existing Building Facilities: A New Zealand Educational Building Case. Ph.D. Thesis, Auckland University of Technology, Auckland, New Zealand, 2019. [Google Scholar]

- Oti, A.H.; Kurul, E.; Cheung, F.K.; Tah, J.H.M. The utilization of BMS in BIM for facility management. In Proceedings of the CIB World Building Congress 2016, Tampere, Finland, 30 May–3 June 2016. [Google Scholar]

- Patacas, J.; Dawood, N.; Kassem, M. BIM for facilities management: A framework and a common data environment using open standards. Autom. Constr. 2020, 120, 103366. [Google Scholar] [CrossRef]

- Kassem, M. BIM in facilities management applications: A case study of a large university complex. Built Environ. Proj. Asset Manag. 2015, 5, 261–277. [Google Scholar] [CrossRef]

- Chan, D.D.W.; Olawumi, T.O.; Ho, A.M. Critical success factors for building information modelling (BIM) implementation in Hong Kong. Eng. Constr. Archit. Manag. 2019, 26, 1838–1854. [Google Scholar] [CrossRef]

- Joseph, J. Chapter 45—Facility Design and Process Utilities. In Biopharmaceutical Processing; Elsevier: Amsterdam, The Netherlands, 2018; p. 933. [Google Scholar]

- Puķīte, I.; Geipele, I. Different Approaches to Building Management and Maintenance Meaning Explanation. In Procedia Engineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 905–912. [Google Scholar]

- Yin, H. Building Management System to support building renovation. Boolean 2010. [Google Scholar] [CrossRef]

- Khalid, M.U.; Bashir, M.K.; Newport, D.J. Development of a Building Information Modelling (BIM)-Based Real-Time Data Integration System Using a Building Management System (BMS). In Building Information Modelling, Building Performance, Design and Smart Construction; Springer: Cham, Switzerland, 2017; pp. 93–104. [Google Scholar]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM for Owner and Facility Managers—Chapter 4. In BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Tucker, M. The rationale to integrate facilities management into the development process. Prop. Manag. 2016, 34, 332–344. [Google Scholar] [CrossRef]

- Tucker, M.; Ashworth, S. Introduction of employer information requirements (EIR) template and guidance for Facility Management. In eFMinsight; Liverpool John Moores University: Liverpool, UK, 2017. [Google Scholar]

- Ashworth, S. The Evolution of FM in the BIM Process-An Opportunity to Use CSF for Optimising Built Assets Ash. Ph.D. Thesis, Zurich University of Applied Sciences Winterthur, Winterthur, Switzerland, 2020. [Google Scholar]

- Gunduz, M.; Almuajebh, M. Critical Success Factors for Sustainable Construction Project Management. Sustainability 2020, 12, 1990. [Google Scholar] [CrossRef]

- Amuda-Yusuf, G. Critical Success Factors for Building Information Modelling Implementation. Australas. J. Constr. Econ. Build. 2018, 18, 55–73. [Google Scholar] [CrossRef]

- Babu, S.S.; Sudhakar, D. Critical Success Factors Influencing Performance of Construction Projects. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 3285–3292. [Google Scholar] [CrossRef]

- Oo, T.Z. Critical Success Factors for Application of BIM for Singapore Architectural Firms. Master’s Thesis, Heriot-Watt University, Scotland, UK, 2014. [Google Scholar]

- Chileshe, N.; Kikwasi, G.J. Critical success factors for implementation of risk assessment and management practices within the Tanza-nian construction industry. Eng. Constr. Archit. Manag. 2014, 21, 291–319. [Google Scholar] [CrossRef]

- Morlhon, R.; Pellerin, R.; Bourgault, M. Building Information Modeling Implementation through Maturity Evaluation and Critical Success Factors Management. Procedia Technol. 2014, 16, 1126–1134. [Google Scholar] [CrossRef]

- Toor, S.-U.-R.; Ogunlana, S.O. Critical COMs of success in large-scale construction projects: Evidence from Thailand construction industry. Int. J. Proj. Manag. 2008, 26, 420–430. [Google Scholar] [CrossRef]

- Sanvido, V.; Grobler, F.; Parfitt, K.; Guvenis, M.; Coyle, M. Critical Success Factors for Construction Projects. J. Constr. Eng. Manag. 1992, 118, 94–111. [Google Scholar] [CrossRef]

- Pinto, J.K.; Slevin, D.P. Critical Success Factors in R&D Projects. Res.-Technol. Manag. 1989, 32, 31–35. [Google Scholar]

- Rockart, J.F. The Changing Role of the Information Systems Executive: A Critical Success Factors Perspective. Sloan Manag. Rev. 1982, 24, 3–13. [Google Scholar]

- Bullen, C.V.; Rockart, J.F. A Primer on Critical Success Factors; Massachusetts Institute of Technology: Cambridge, MA, USA, 1981. [Google Scholar]

- Ashworth, S.; Tucker, M. FM-BIM Mobilisation Framework Critical Success Factors to Help Deliver Succesful BIM Projects Simon Ashworth. Ph.D. Thesis, Liverpool John Moores University, Liverpool, UK, 2021. [Google Scholar]

- Pinti, L.; Codinhoto, R.; Bonelli, S. A Review of Building Information Modelling (BIM) for Facility Management (FM): Implementation in Public Organisations. Appl. Sci. 2022, 15, 1540. [Google Scholar] [CrossRef]

- Oluleye, I.B.; Oyetunji, A.K.; Olukolajo, M.A.; Chan, D.W. Integrating building information modelling for improving facility management operations: A fuzzy synthetic evaluation of the critical success factors. J. Facil. Manag. 2021, 21, 201–220. [Google Scholar] [CrossRef]

- Misron, S.; Abdullah, M. Critical success factors of information modeling implementation in facilities management—An overview. Int. J. Real Estate Stud. 2018, 12, 21–32. [Google Scholar]

- Naji, K.K.; Gunduz, M.; Maki, O. Development of a Campus Facility Management Operational Framework Using a Modified Delphi Method. J. Constr. Eng. Manag. 2023, 149, 04023052. [Google Scholar] [CrossRef]

- Naji, K.K.; Gunduz, M.; Adalbi, M. Analysis of Critical Project Success Factors—Sustainable Management of the Fast-Track Construction Industry. Buildings 2023, 13, 2890. [Google Scholar] [CrossRef]

- Tholibon, D.A.; Nujid, M.M.; Mokhtar, H.; Rahim, J.A.; Aziz, N.F.A.; Tarmizi, A.A.A. Relative Importance Index (RII) in Ranking the Factors of Employer Satisfaction Towards Industrial Training Students. Int. J. Asian Educ. 2021, 2, 493–503. [Google Scholar] [CrossRef]

- Moreno, J.V.; Machete, R.; Falcão, A.P.; Gonçalves, A.B.; Bento, R. Dynamic Data Feeding into BIM for Facility Management: A Prototype Application to a University Building. Buildings 2022, 12, 645. [Google Scholar] [CrossRef]

- Wang, J.; Luo, H.; Pena-Mora, F.; Zhou, W.; Fang, W. An Integrated BIM-IoT Framework for Real-Time Quality Monitoring in Construction Site. J. Constr. Eng. Manag. 2024, 150, 05024013. [Google Scholar] [CrossRef]

- Neuville, R.; Pouliot, J.; Billen, R. Identification of the Best 3D Viewpoint within the BIM Model: Application to Visual Tasks Related to Facility Management. Buildings 2019, 9, 167. [Google Scholar] [CrossRef]

- Yalcinkaya, M.; Zibion, D.; Khan, S.A.; Singh, V.; Törmä, S. Evolution of a BIM-based facilities management solution from a monolithic BIM-centric approach to a semantically rich granular 2D and 3D visualisation. Int. J. Prod. Lifecycle Manag. 2023, 15, 89–114. [Google Scholar] [CrossRef]

- Kelly, G.; Serginson, M.; Lockley, S.; Dawood, N.; Kassem, M. BIM for facility management: A review and a case study investigating the value and challenges2. In Proceedings of the 13th International Conference on Construction Applications of Virtual Reality, London, UK, 31 October 2013. [Google Scholar]

- Zhang, C.; Zou, Y.; Dimyadi, J. A Systematic Review of Automated BIM Modelling for Existing Buildings from 2D Documentation. In Proceedings of the International Symposium on Automation and Robotics in Construction, Dubai, United Arab Emirates, 2–4 November 2021. [Google Scholar]

- Abdelalim, A.M.; Essawy, A.; Alnaser, A.A.; Shibeika, A.; Sherif, A. Digital Trio: Integration of BIM–EIR–IoT for Facilities Management of Mega Construction Projects. Sustainability 2024, 16, 6348. [Google Scholar] [CrossRef]

| No. | EIR Category | Guides |

|---|---|---|

| 1 | Management Requirements | Applicable standards and guidelines |

| CIC BIM protocol | ||

| Project roles and responsibilities | ||

| Existing client CAFM/IWMS or enterprise asset management systems | ||

| Model creation and ongoing management | ||

| 2 | Technical requirements | Software |

| IT and system performance constraints | ||

| Data exchange formats | ||

| Common coordinates system | ||

| Levels of definition | ||

| Specified model and information formats | ||

| Site information and floor and room data information | ||

| 3 | Commercial Requirements | Exchange of information in line with RIBA project stages |

| Supplier BIM assessment form | ||

| BIM tender assessment |

| No. | References | CSF Definition | Key Points | Category |

|---|---|---|---|---|

| 1 | [17] | “A limited number of areas in which results, if they are satisfactory, will ensure successful competitive performance for the individual, department or organization” | Competitive performance | Policy |

| 2 | [18] | Factors that affect the construction process | Construction process | Product Process |

| 3 | [19] | Drivers or enablers whose presence can cause success and their absence can cause failure in the implementation and adoption of building information modeling | Drivers or enablers Presence = success Absence = failure | Product |

| 4 | [20] | CSFs are the most significant factors in preventing delays in the project, increasing project performance, and ensuring success for construction projects | Prevents delay, increases project performance, and assures success | Process/E.G QA/QC |

| 5 | [21] | Factors alleged as significant for the implementation of BIM are both on organizational and project level | Significant | Product |

| 6 | [22] | Drivers or enablers for successful risk assessment and management practices by way of clarification between drivers and enablers | Drivers or enablers Successful risk assessment Management practices | Product Process Policy |

| 7 | [23] | Elements that are seen as essential and that facilitate successful implementation of new systems | Essential elements that facilitate success | Product |

| 8 | [24] | “Denotes a certain element which significantly contributes to and is remarkably vital for the achievement of a project” | Significant contribution | Product |

| 9 | [25] | “Elements that foreseen achievement instead of simply the unadulterated survival of a construction project” | Foreseen achievement | Product |

| 10 | [26] | CSF can be defined as certain rules, executive procedures, and environmental conditions that are felt to have an important impact on whether or not a project will succeed | Certain rules Executive procedures Environmental conditions | Policy Process |

| 11 | [27] | CSFs are objects or agendas to be put in place for an organization or project to succeed | Objects or agendas | Process |

| 12 | [28] | CSFs have been defined as foundations that determined the successful performance of an individual, department, or organization [28]; the identification of CSFs is needed to enhance project performance and organization performance | Foundation | Policy |

| Main Theme (MT) | Category | Reference | Sub-Categories | 3PT Category |

|---|---|---|---|---|

| MT-3 | Addressing and overcoming perceived barriers and challenges to the adoption and use of BIM | [29] | Upskilling FM teams to empower them for successful engagement in BIM projects | Policy |

| Setting realistic expectations of what BIM can deliver | Policy | |||

| Understanding the link between BIM, CAFM, and FM management | Technology | |||

| MT-4 | Making the benefits of BIM to FM transparent, realistic, and achievable | [29] | Planning realistic timelines for the realization of benefits | Policy |

| Ensure access to good quality data from one place | Product/policy | |||

| Improving the handover from construction to operation | Process | |||

| BIM investment and organization readiness for change | [31] | Organizational re-engineering for BIM | Policy | |

| Adequate investment in BIM | Policy | |||

| FM leaders and staff commitment to BIM | [31] | Early involvement of in-house FM project teams | Policy | |

| Availability of competent staff | Policy | |||

| MT-7 | Clarifying the role and tasks of FMs in the BIM process | [29] | Defining the EIR, OIR, AIR, and FM information requirements to support the AM strategy | Policy |

| Writing key BIM documents and guiding clients | Product | |||

| Identifying client needs and using FM know-how to help improve BIM project outcomes | Process | |||

| BIM policy | [32] | Governments need to establish a specific policy for adopting BIM on all projects | Policy | |

| Specific government departments are responsible for setting BIM policy | Policy | |||

| Specific organizations are to take responsibility for BIM implementation in the country | Policy | |||

| MT-8 | Acquiring essential knowledge of key BIM standards/guidance documents for practical use in a BIM project | [29] | Using BIM standards and guidance in projects to achieve better outcomes for all stakeholders | Process/policy |

| Other useful BIM guidance documents | Product | |||

| MT-9 | Ensuring people have adequate BIM training and competency skills for successful engagement in BIM projects | [29] | Acquiring essential knowledge about BIM standards and guidance documents | Policy |

| Sources for EIR guidance, BIM books and BIM training courses | Policy/product | |||

| Accessible BIM hardware and software packages | [31] | BIM hardware and software availability | Technology | |

| Accessible BIM software vendors for FM | Technology | |||

| MT10 | Ensuring the “successful transfer and on-going management” of “3D models, alphanumeric data, and documents for CAFM/FM systems” | [29] | Planning the data transfer and quality checking process for BIM projects | Process |

| Planning what data to collect and how to transfer it into FM management systems | Process | |||

| Using standards and specific classification systems to ensure data are well-structured to enable easy transfer from BIM models using COBie/IFC | Technology | |||

| Bi-directional data transfer and improving data handover processes and future possibilities | Process | |||

| Product information sharing | [32] | Capacity of the BIM implementation system to exchange information among different BIM and non-BIM systems without data loss | Technology | |

| Make explicit design information available to stakeholders so they can easily understand and evaluate the design, construction, or operation intent. | Product |

| No. | Interviewees | Participants | No. of Interviews |

|---|---|---|---|

| I-1 | University’s Facility Management team—Doha | 1 FM Manager | 1 |

| I-2 | A Smart City Facility Management team—Doha |

| 4 |

| I-3 | Facility Management Consultants—Doha |

| 2 |

| I-4 | Public Transportations Facility Management—Doha |

| 1 |

| I-5 | Sport Venues Facility Management team—Doha |

| 1 |

| I-6 | Research Associate with FM experience—UK |

| 1 |

| Total | 16 Participants | 10 Interviews |

| W | Interpretation |

|---|---|

| 0 | No agreement |

| 0.10 | Weak agreement |

| 0.30 | Moderate agreement |

| 0.60 | Strong agreement |

| 1 | Perfect agreement |

| Value of the Spearman’s Coefficient |Absolute Value| | Strength of Correlation |

|---|---|

| 0.00–0.19 | Very weak |

| 0.20–0.39 | Weak |

| 0.40–0.59 | Moderate |

| 0.60–0.79 | Strong |

| 0.80–1.00 | Very strong |

| No. | Critical Success Factors (CSFs) | BMS | CAFM | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I-1 | I-2 | I-3 | I-4 | I-5 | I-6 | I-1 | I-2 | I-3 | I-4 | I-5 | I-6 | ||

| 1 | Asking for BIM from the start of the project | ● | ● | ● | - | ● | - | ● | |||||

| 2 | Providing BIM as part of the as-built submission in the handover | ● | ● | ● | - | ● | - | ● | |||||

| 3 | Adding guidelines for data usage in COBie in the specifications—preliminary stages | ● | ● | ● | - | ● | - | ● | |||||

| 4 | Issuing information capturing guidelines and how to transfer them into CAFM from the start of the project + asset information code language | ● | - | - | ● | - | ● | ||||||

| 5 | Successful communication of FM requirements with the client | ● | - | - | ● | ||||||||

| 6 | Planning ahead to avoid conflicts and issues between stakeholders | ● | ● | - | ● | - | ● | ||||||

| 7 | Including BIM in the FM requirements in early stages | ● | ● | ● | - | ● | - | ● | |||||

| 8 | Acquiring correct files data and format—QAQC | ● | ● | - | ● | - | ● | ||||||

| 9 | Organization and coordination leading to standardized data collection | ● | ● | - | ● | - | ● | ||||||

| 10 | Stakeholders’ commitment to protocols | ● | - | - | ● | ||||||||

| 11 | Client working closely with IT team (FM integrator) to know how to accomplish what is needed | ● | - | - | ● | ||||||||

| 12 | Proper and synchronized working of the system and the model (BIM viewer, not opening in CAFM application—external plugin) | ● | - | - | ● | ||||||||

| 13 | Visualization of asset location | ● | ● | ● | ● | ● | - | ● | ● | - | ● | ||

| 14 | The smaller the BIM model size, the more efficient | ● | ● | ● | ● | ● | - | ● | ● | - | ● | ||

| 15 | Automatic scheduling for the equipment—FM maintenance | ● | ● | - | - | ||||||||

| 16 | Faster integrating process with the 2D to CAFM/BMS—reduced file size | ● | ● | - | ● | - | |||||||

| 17 | The need for accurate scripts to identify mistakes and mismatches in the data—QAQC | - | ● | ● | - | ● | ● | - | ● | ||||

| 18 | Adjoined work, automated registry (easy search of assets, accuracy)—QAQC | ● | ● | - | ● | - | ● | ||||||

| 19 | Centralized command station/center (reducing manpower, increasing efficiency in operation, better response time, and smart operations) | ● | ● | ● | - | ● | - | ● | |||||

| 20 | Interfacing all systems into a centralized platform | ● | ● | ● | - | ● | ● | - | ● | ||||

| 21 | Adapting the asset registry by the MC (accurate asset keys, unique codes, barcodes, etc.)—QAQC | ● | ● | - | ● | - | ● | ||||||

| 22 | Consultants’ reviews—QAQC | ● | ● | ● | ● | - | ● | - | ● | ||||

| 23 | Strong supervision from top management | ● | ● | - | ● | - | ● | ||||||

| 24 | Correct set of information in the handover (drawings, DDC, device IO list, and asset registry)—QAQC | ● | ● | - | ● | - | ● | ||||||

| 25 | FM and integrator’s preliminary checks—QAQC | ● | ● | ● | - | ● | - | ● | |||||

| 26 | FM reviews—QAQC | ● | ● | ● | ● | - | ● | ● | - | ● | |||

| 27 | Adapting new technologies by FM (e.g., BIM) | ● | ● | ● | - | ● | ● | - | ● | ||||

| 28 | Collaborating with system integrators for easy conversion of 2D to 3D GIS software and 3D models | ● | - | ● | - | ||||||||

| 29 | Confirming 2D CAD drawings have assigned points from asset registry—QAQC | ● | ● | ● | - | ● | ● | - | ● | ||||

| 30 | Developing two platform versions—pre-production version (testing) and integrated platform production version (operation) | ● | - | ● | - | ||||||||

| 31 | Accurate IFC IDs and automated codes—QAQC | ● | ● | - | ● | ● | - | ||||||

| 32 | Separate but compatible controlling and maintenance systems—BACS/SCADA and MMS | ● | - | - | |||||||||

| 33 | Connected asset codes and tags in the controlling system—QAQC | ● | ● | - | ● | - | |||||||

| 34 | Responsible stakeholder to fix all hand over data during the defect liability period | ● | ● | ● | - | ● | - | ● | |||||

| 35 | Breaking down the data into a more structured qualification manual for everyone to use | ● | ● | - | ● | - | |||||||

| Category | Sub-Categories | CSFs | Link to EIR | 3PT | Source |

|---|---|---|---|---|---|

| Guidance ST 0.1 | FM Requirements ST 0.1.1 | Define the OIR, AIR, and FM information requirements to support the AM strategy | Commercial

| Policy | Literature |

| Communicate FM requirements with the client (including BIM as part of the submission) | Management

| Process | Interviews | ||

| Provide BIM standards and guidelines | Management

| Product | Interviews | ||

| Early participation of FM | Management | ||||

| Policy | Literature Interviews | |||

| Update of information requirements during the defect liability period (DLP) | Management

| Process | Interviews | ||

| Client needs ST 0.1.2 | Identify client needs and using FM know-how to help improve BIM project outcomes | Commercial

| Process | Literature | |

| Understand client’s IT requirements | Commercial - Client strategic purpose Management

| Technology | Interviews | ||

| Technical: Link between BIM-FM systems ST 0.1.3 | Understand the link between BIM and FM management systems | Technical

| Technology | Literature | |

| Seamless data formats for the integration | Technical

| Product Technology | Interviews | ||

| Adapt necessary plugins for adequate operations of FM systems | Management

| Technology | Interviews | ||

| Scalable file size (BIM) for better control and visibility | Management

| Product | Interviews | ||

| Adapt systems that can be synchronized to reduce information loss | Technical

| Technology | Interviews | ||

| Capacity of BIM implementation system to exchange information among different BIM and non-BIM systems without data loss | Technical

| Technology | Literature | ||

| The use of interoperable systems to convert 2D to 3D BIM in existing buildings | Management

| Technology | Interviews | ||

| Adapt two versions for FM systems (pre-production and production versions) | Management

| Product | Interviews | ||

| Planning/Management ST 0.2 | Skills ST 0.2.1 | Upskill FM teams to leverage BIM capabilities in FM (to participate in client proposal development) | Technical

| Policy | Literature Interviews |

| Adopt new technologies for FM systems | Technical

| Product/Technology | Interviews | ||

| Accessible BIM software vendors for FM | Technical

| Technology | Literature | ||

| Expectations 0.2.2 | Set realistic expectations of what BIM can deliver | Commercial

| Policy | Literature | |

| Stakeholders’ commitment and compliance to BIM standards and protocols | Management

| Policy | Literature Interviews | ||

| Strong supervision from top management | Management

| Policy | Interviews | ||

| Compatible integration systems | Technical

| Technology | Interviews | ||

| Data ST 0.2.3 | Plan the data transfer and quality checking process for BIM project | Management

| Process | Literature | |

| Bi-directional data transfer and improvement of data handover processes and future possibilities | Management

| Process | Literature | ||

| Common data environment (CDE) | Management

| Product | Interviews | ||

| Quality ST 0.3 | QA/QC 0.3.1 | Ensure access of good quality data from one place (BIM) | Management

| Product Policy | Literature |

| Three-dimensional visualization of asset locations | Management

| Technology Product | Interviews | ||

| Acquire correct files data and format | Management

| Policy Product | Interviews | ||

| The need for accurate scripts to identify mistakes and mismatches in the data | Management

| Product Process | Interviews | ||

| Making explicit design information and making it available to stakeholders so that the design, construction, or operation intent can be easily understood and evaluated | Management

| Product | Literature | ||

| Effective stakeholders reviews (consultants, contractors, and FM) | Management

| Policy | Interviews | ||

| Accurate data (drawings, DDC, device IO list, asset registry, IFC IDs, automated codes, asset keys, unique codes, barcodes, etc.) | Management

| Product | Interviews | ||

| Connected asset codes and tags in the controlling system from the asset registry (existing buildings) | Management

| Product | Interviews | ||

| Developing a structured qualifications manual (FM and integrator’s preliminary checks) | Management

| Process | Interviews |

| No. | Position | FM Years of Exp. | BIM Years of Exp. |

|---|---|---|---|

| 1 | Facilities Manager | 1–5 | 1–5 |

| 2 | Facilities Manager | 21+ | 6–10 |

| 3 | Academic (Researcher in BIM-FM) | 1–5 | 1–5 |

| 4 | Engineer (Maintenance) | 6–10 | 1–5 |

| 5 | Facilities Manager | 21+ | 21+ |

| 6 | Researcher in IT for construction | 1–5 | 6–10 |

| 7 | Quantity Surveyor | 11–15 | 1–5 |

| 8 | Academic (Researcher in BIM-FM) | 11–15 | 6–10 |

| 9 | Academic (Researcher in BIM-FM) | 1–5 | 6–10 |

| 10 | Engineer | 1–5 | 1–5 |

| 11 | Academic (Researcher in BIM-FM) | 6–10 | 16–20 |

| 12 | Academic (Researcher in BIM-FM) | 1–5 | 11–15 |

| 13 | Facilities Manager | 11–15 | 11–15 |

| 14 | Academic (Researcher in BIM-FM) | 11–15 | 11–15 |

| 15 | Engineer (Implementation) | 6–10 | 1–5 |

| Factor | RII | RII Ranking | ||

|---|---|---|---|---|

| Guidance | A | Define the OIR, AIR, and FM information requirements to support the AM strategy | 0.28 | 1 |

| B | Communicate FM requirements with the client (including BIM as part of the submission) | 1.32 | 32 | |

| C | Provide BIM standards and guidelines | 1.4 | 34 | |

| D | Early participation of FM | 1.133333 | 27 | |

| E | Update of information requirements during the defect liability period (DLP) | 0.6 | 3 | |

| F | Identify client needs and use FM know-how to help improve BIM project outcomes | 0.92 | 12 | |

| G | Understand client’s IT | 0.826667 | 7 | |

| H | Understand the link between BIM and FM management systems | 0.666667 | 5 | |

| I | Seamless data formats for the integration | 1.133333 | 27 | |

| J | Adapt necessary plugins for adequate operations of FM systems | 1.053333 | 24 | |

| K | Scalable file size (BIM) for better control and visibility | 1.013333 | 20 | |

| L | Adapt systems that can be synchronized to reduce information loss | 1.013333 | 20 | |

| M | Capacity of BIM implementation system to exchange information among different BIM and non-BIM systems without data loss | 1.133333 | 27 | |

| N | The use of interoperable systems to convert 2D to 3D BIM in existing buildings | 0.866667 | 8 | |

| O | Adapt two versions for FM systems (pre-production and production versions) | 0.893333 | 10 | |

| Planning and Management | A | Upskill FM teams to leverage BIM capabilities in FM (to participate in client proposal and development | 0.866667 | 8 |

| B | Adopt new technologies for FM systems | 0.986667 | 17 | |

| C | Accessible BIM software vendors for FM | 0.906667 | 11 | |

| D | Set realistic expectations of what BIM can deliver | 0.8 | 6 | |

| E | Stakeholders’ commitment and compliance to BIM standards and protocols | 1.493333 | 35 | |

| F | Strong supervision from top management | 0.973333 | 14 | |

| G | Compatible integration systems | 0.973333 | 14 | |

| H | Plan the data transfer and quality checking process for the BIM project | 1.093333 | 25 | |

| I | Bi-directional data transfer and improvement of data handover processes and future possibilities | 1.013333 | 20 | |

| J | Common data environment (CDE) | 1 | 18 | |

| Quality | A | Ensure access of good quality data from one place (BIM) | 1.32 | 32 |

| B | Three-dimensional visualization of asset locations | 0.626667 | 4 | |

| C | Acquire correct files, data and formats | 0.586667 | 2 | |

| D | The need for accurate scripts to identify mistakes and mismatches in the data | 1.146667 | 30 | |

| E | Making explicit design information and making it available to stakeholders so that the design, construction, or operation intent can be easily understood and evaluated | 1.093333 | 25 | |

| F | Effective stakeholder reviews (consultants, contractors, and FM) | 1.013333 | 20 | |

| G | Accurate data (drawings, DDC, device IO list, asset registry, IFC IDs, automated codes, asset keys, unique codes, barcodes, etc.) | 1 | 18 | |

| H | Connected asset codes and tags in the controlling system from the asset registry (existing buildings) | 1.213333 | 31 | |

| I | Developing a structured qualifications manual (FM and integrator’s preliminary checks) | 0.973333 | 14 | |

| J | Centralizing data access to ensure consistency and reduce the risk of working with outdated or inaccurate information | 0.933333 | 13 | |

| Pearson’s r | G1 | G2 | G3 | G4 | G5 | G6 | G7 | G9 | G10 | G11 | G12 | G13 | G14 | G15 |

| G1 | - | 0.916 | 0.908 | 0.877 | 0.705 | 0.864 | 0.964 | 0.935 | 0.895 | 0.876 | 0.947 | 0.912 | 0.737 | 0.655 |

| G2 | 0.916 | - | 0.870 | 0.977 | 0.715 | 0.892 | 0.928 | 0.872 | 0.815 | 0.793 | 0.893 | 0.930 | 0.633 | 0.574 |

| G3 | 0.908 | 0.870 | - | 0.815 | 0.820 | 0.910 | 0.870 | 0.872 | 0.909 | 0.929 | 0.952 | 0.812 | 0.813 | 0.798 |

| G4 | 0.877 | 0.977 | 0.815 | - | 0.690 | 0.913 | 0.901 | 0.842 | 0.784 | 0.742 | 0.864 | 0.921 | 0.588 | 0.553 |

| G5 | 0.705 | 0.715 | 0.820 | 0.690 | - | 0.791 | 0.697 | 0.832 | 0.838 | 0.858 | 0.825 | 0.642 | 0.933 | 0.824 |

| G6 | 0.864 | 0.892 | 0.910 | 0.913 | 0.791 | - | 0.873 | 0.847 | 0.876 | 0.856 | 0.919 | 0.842 | 0.725 | 0.797 |

| G7 | 0.964 | 0.928 | 0.870 | 0.901 | 0.697 | 0.873 | - | 0.905 | 0.844 | 0.825 | 0.916 | 0.935 | 0.695 | 0.617 |

| G9 | 0.935 | 0.872 | 0.872 | 0.842 | 0.832 | 0.847 | 0.905 | - | 0.954 | 0.926 | 0.955 | 0.891 | 0.854 | 0.705 |

| G10 | 0.895 | 0.815 | 0.909 | 0.784 | 0.838 | 0.876 | 0.844 | 0.954 | - | 0.965 | 0.962 | 0.824 | 0.898 | 0.841 |

| G11 | 0.876 | 0.793 | 0.929 | 0.742 | 0.858 | 0.856 | 0.825 | 0.926 | 0.965 | - | 0.963 | 0.777 | 0.905 | 0.862 |

| G12 | 0.947 | 0.893 | 0.952 | 0.864 | 0.825 | 0.919 | 0.916 | 0.955 | 0.962 | 0.963 | - | 0.901 | 0.842 | 0.782 |

| G13 | 0.912 | 0.930 | 0.812 | 0.921 | 0.642 | 0.842 | 0.935 | 0.891 | 0.824 | 0.777 | 0.901 | - | 0.610 | 0.529 |

| G14 | 0.737 | 0.633 | 0.813 | 0.588 | 0.933 | 0.725 | 0.695 | 0.854 | 0.898 | 0.905 | 0.842 | 0.610 | - | 0.863 |

| G15 | 0.655 | 0.574 | 0.798 | 0.553 | 0.824 | 0.797 | 0.617 | 0.705 | 0.841 | 0.862 | 0.782 | 0.529 | 0.863 | - |

| Pearson’s r | M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | M9 | M10 |

| M1 | - | 0.858 | 0.653 | 0.691 | 0.908 | 0.873 | 0.729 | 0.692 | 0.768 | 0.830 |

| M2 | 0.858 | - | 0.792 | 0.448 | 0.755 | 0.764 | 0.741 | 0.530 | 0.630 | 0.619 |

| M3 | 0.653 | 0.792 | - | 0.544 | 0.582 | 0.593 | 0.886 | 0.631 | 0.607 | 0.374 |

| M4 | 0.691 | 0.448 | 0.544 | - | 0.797 | 0.727 | 0.805 | 0.967 | 0.911 | 0.684 |

| M5 | 0.908 | 0.755 | 0.582 | 0.797 | - | 0.756 | 0.742 | 0.769 | 0.807 | 0.770 |

| M6 | 0.873 | 0.764 | 0.593 | 0.727 | 0.756 | - | 0.724 | 0.771 | 0.871 | 0.904 |

| M7 | 0.729 | 0.741 | 0.886 | 0.805 | 0.742 | 0.724 | - | 0.848 | 0.835 | 0.519 |

| M8 | 0.692 | 0.530 | 0.631 | 0.967 | 0.769 | 0.771 | 0.848 | - | 0.921 | 0.687 |

| M9 | 0.768 | 0.630 | 0.607 | 0.911 | 0.807 | 0.871 | 0.835 | 0.921 | - | 0.774 |

| M10 | 0.830 | 0.619 | 0.374 | 0.684 | 0.770 | 0.904 | 0.519 | 0.687 | 0.774 | - |

| Pearson’s r | Q1 | Q2 | Q3 | Q4 | Q5 | Q6 | Q7 | Q8 | Q9 |

| Q1 | - | 0.675 | 0.966 | 0.811 | 0.554 | 0.781 | 0.926 | 0.815 | 0.729 |

| Q2 | 0.675 | - | 0.571 | 0.874 | 0.860 | 0.840 | 0.443 | 0.695 | 0.920 |

| Q3 | 0.966 | 0.571 | - | 0.751 | 0.477 | 0.738 | 0.945 | 0.810 | 0.633 |

| Q4 | 0.811 | 0.874 | 0.751 | - | 0.807 | 0.882 | 0.612 | 0.708 | 0.857 |

| Q5 | 0.554 | 0.860 | 0.477 | 0.807 | - | 0.782 | 0.408 | 0.724 | 0.852 |

| Q6 | 0.781 | 0.840 | 0.738 | 0.882 | 0.782 | - | 0.655 | 0.715 | 0.888 |

| Q7 | 0.926 | 0.443 | 0.945 | 0.612 | 0.408 | 0.655 | - | 0.810 | 0.586 |

| Q8 | 0.815 | 0.695 | 0.810 | 0.708 | 0.724 | 0.715 | 0.810 | - | 0.743 |

| Q9 | 0.729 | 0.920 | 0.633 | 0.857 | 0.852 | 0.888 | 0.586 | 0.743 | - |

| Category | Kendall Coefficient | Interpretation |

|---|---|---|

| Guidance | 0.695 | Strong |

| Management and planning | 0.587 | Moderate to strong |

| Quality | 0.625 | Strong |

| Category | Kendall Coefficient | Interpretation |

|---|---|---|

| Guidance | 0.822 | Very strong |

| Management and planning | 0.716 | Strong |

| Quality | 0.727 | Strong |

| Rank | Critical Success Factor | Group | Recommendation |

|---|---|---|---|

| 1 | Define the OIR, AIR, and FM information requirements to support the AM strategy | Guidance | Define clear information requirements early in the project to effectively support asset management (AM) strategies, ensuring seamless integration and operational efficiency |

| 2 | Acquire correct files, data, and formats | Quality | Standardize data formats and structures across the BIM project to enhance consistency and interoperability |

| 3 | Update of information requirements during the defect liability period (DLP) | Guidance | Establish protocols for regularly updating the BIM model during the defect liability period (DLP) to incorporate modifications and maintain accurate asset information |

| 4 | Three-dimensional visualization of asset locations | Quality | Utilize 3D visualization tools within BIM to enhance asset tracking and management for facility managers |

| 5 | Understand the link between BIM and FM management systems | Guidance | Provide training for FM teams on BIM functionalities, emphasizing data flow, interoperability, and improved decision making within an integrated BIM-FM system |

| 6 | Set realistic expectations of what BIM can deliver | Planning and Management | Set realistic expectations regarding BIM’s capabilities and limitations in facility management to align project objectives and prevent scope misalignment |

| 7 | Understand IT requirements by the client | Guidance | Collaborate with clients to assess IT requirements and ensure seamless compatibility between BIM and existing systems |

| 8 | The use of interoperable systems to convert 2D to 3D BIM in existing buildings | Guidance | Use interoperable solutions to convert 2D drawings into 3D BIM models, particularly for retrofitting older buildings |

| 9 | Upskill FM teams to leverage BIM capabilities in FM (to participate in client proposal and development | Planning and Management | Continuously upskill FM teams in the latest BIM technologies, enabling them to contribute to client proposals and integrate FM needs from design to operation |

| 10 | Adapt two versions for FM systems (pre-production and production versions) | Guidance | Maintain both pre-production and production versions of the FM system to test and refine updates before full implementation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, A.M.; Abdelkarim, S.B.; Adalbi, M.; Elnahhas, R.; Naji, K. Developing Critical Success Factors (CSF) for Integrating Building Information Models (BIM) into Facility Management Systems (FMS). Buildings 2025, 15, 3434. https://doi.org/10.3390/buildings15193434

Ahmad AM, Abdelkarim SB, Adalbi M, Elnahhas R, Naji K. Developing Critical Success Factors (CSF) for Integrating Building Information Models (BIM) into Facility Management Systems (FMS). Buildings. 2025; 15(19):3434. https://doi.org/10.3390/buildings15193434

Chicago/Turabian StyleAhmad, Ahmad Mohammad, Shimaa Basheir Abdelkarim, Mohamed Adalbi, Rowaida Elnahhas, and Khalid Naji. 2025. "Developing Critical Success Factors (CSF) for Integrating Building Information Models (BIM) into Facility Management Systems (FMS)" Buildings 15, no. 19: 3434. https://doi.org/10.3390/buildings15193434

APA StyleAhmad, A. M., Abdelkarim, S. B., Adalbi, M., Elnahhas, R., & Naji, K. (2025). Developing Critical Success Factors (CSF) for Integrating Building Information Models (BIM) into Facility Management Systems (FMS). Buildings, 15(19), 3434. https://doi.org/10.3390/buildings15193434

_Hou.png)