Research on the Mechanical Properties and Micro-Evolution Characteristics of Coal Gangue-Based Composite Cementitious Materials

Abstract

1. Introduction

2. Experimental Materials and Methods

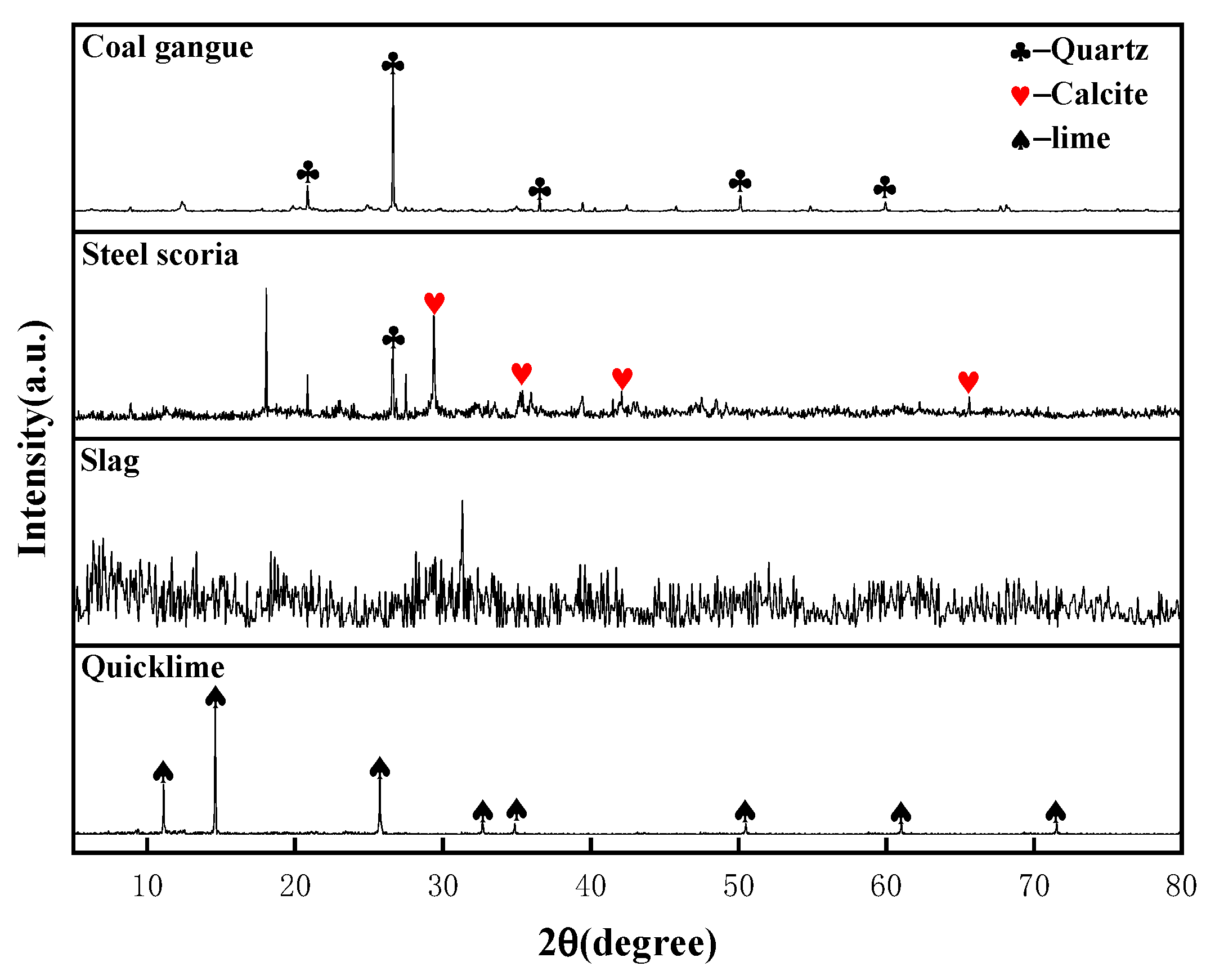

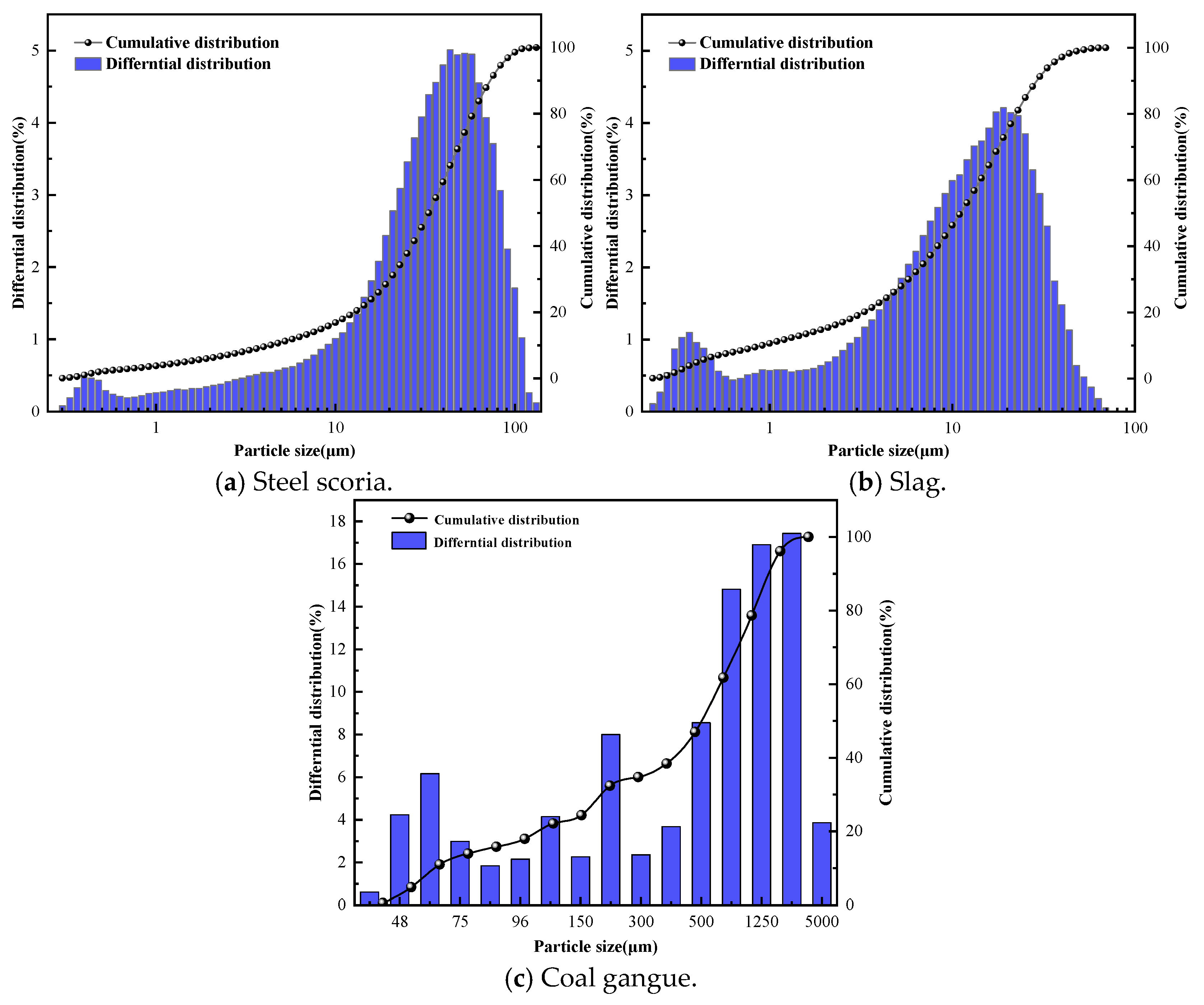

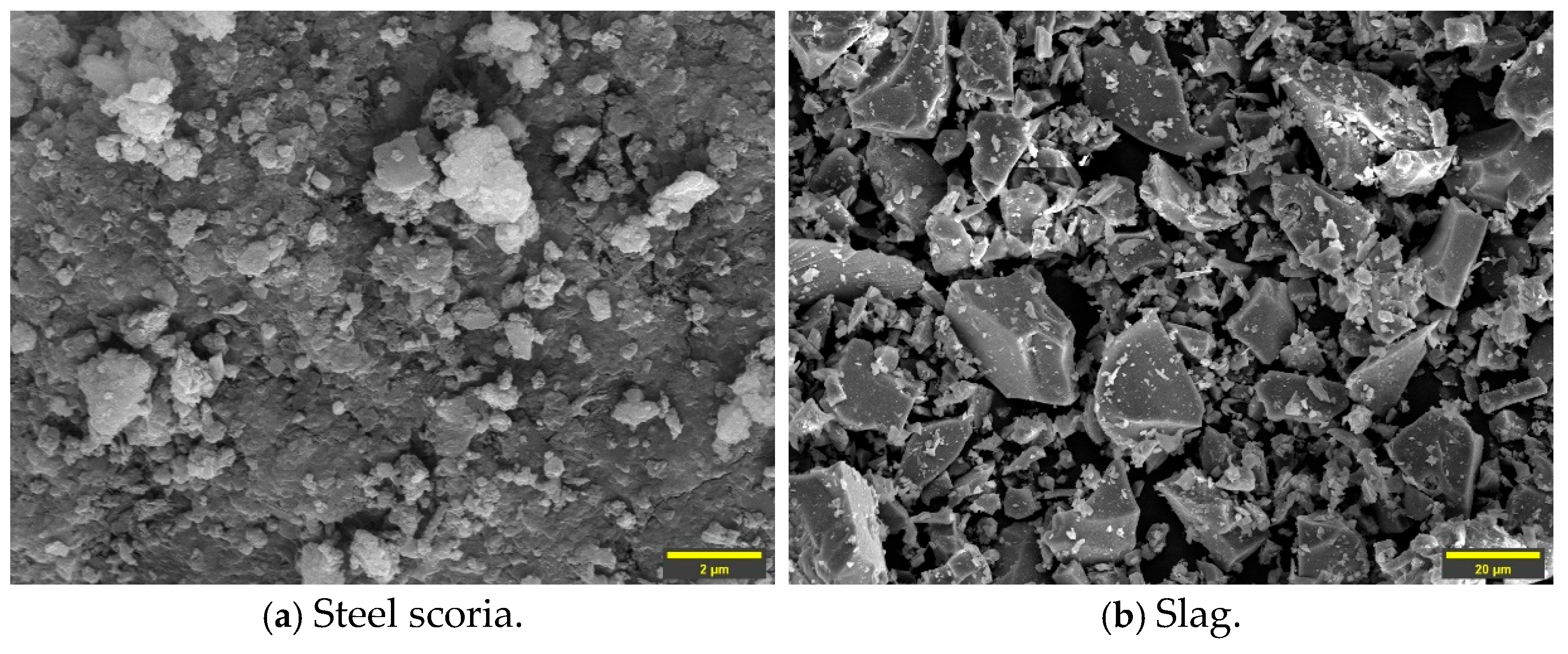

2.1. Experimental Materials

2.2. Orthogonal Design

2.3. Sample Preparation

2.4. Testing Methods

2.4.1. Setting Time

2.4.2. Flowability

2.4.3. Compressive Strength

2.4.4. Mineral Phase

2.4.5. Microstructure

3. Results and Discussion

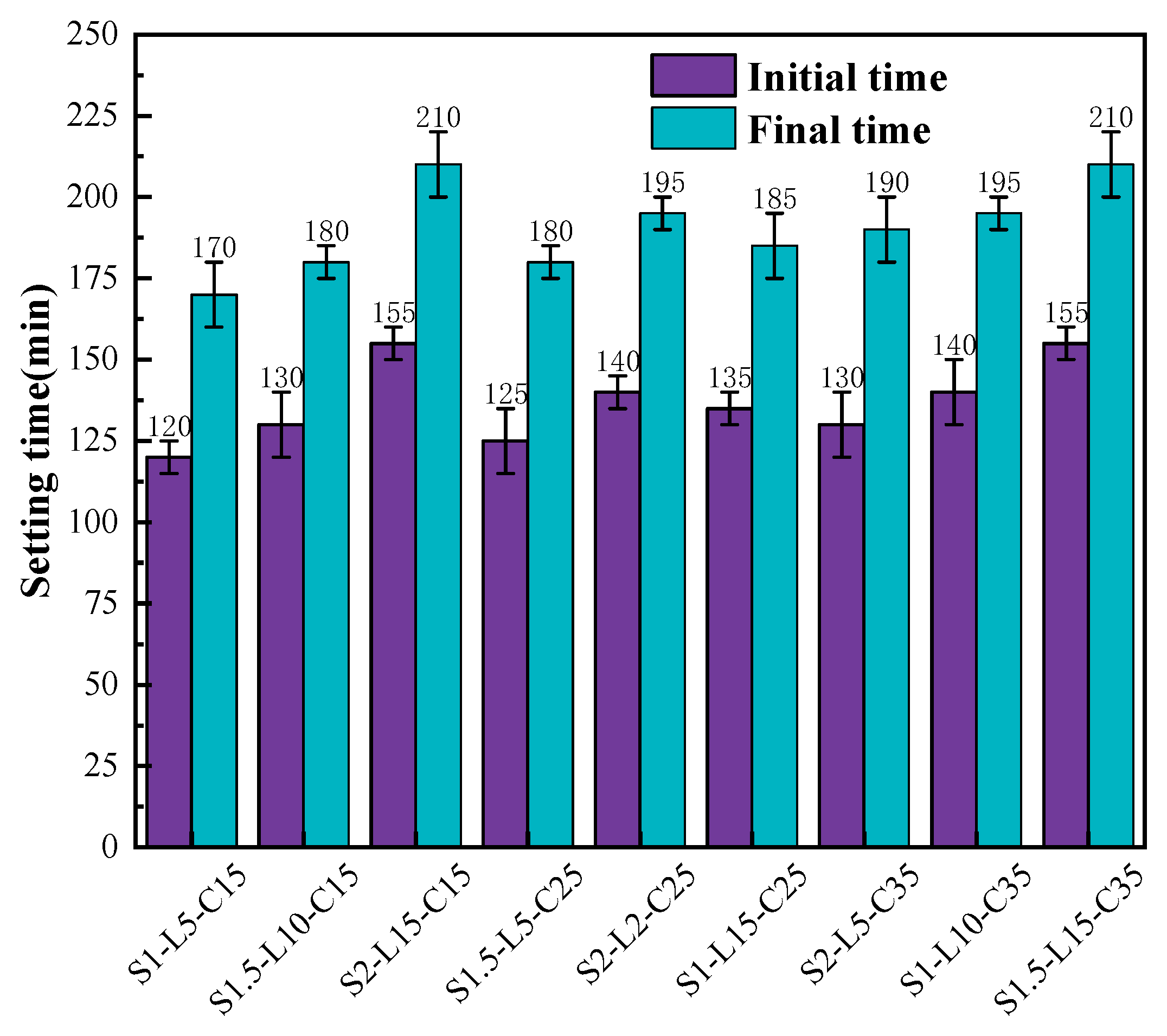

3.1. Setting Time

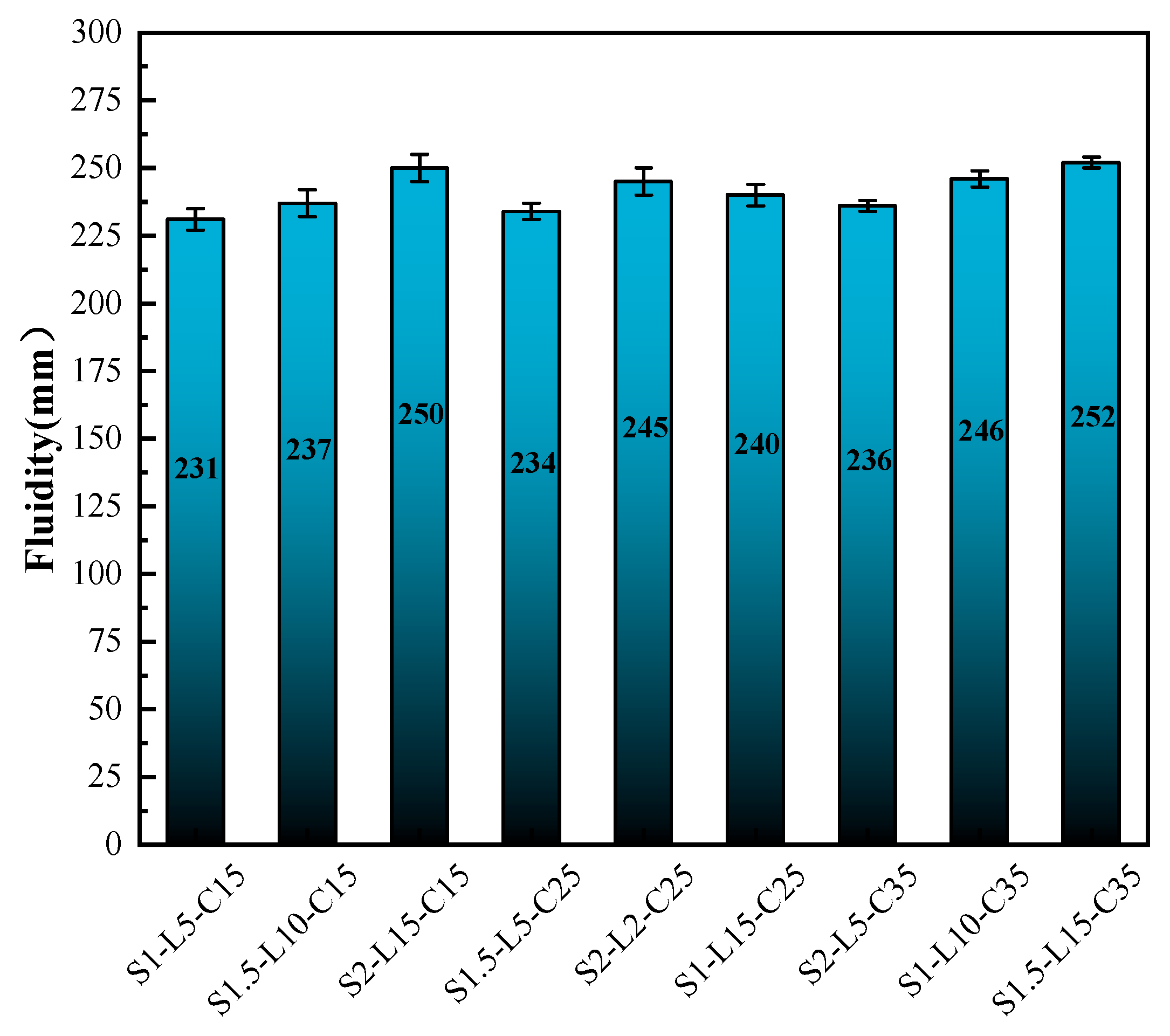

3.2. Flowability

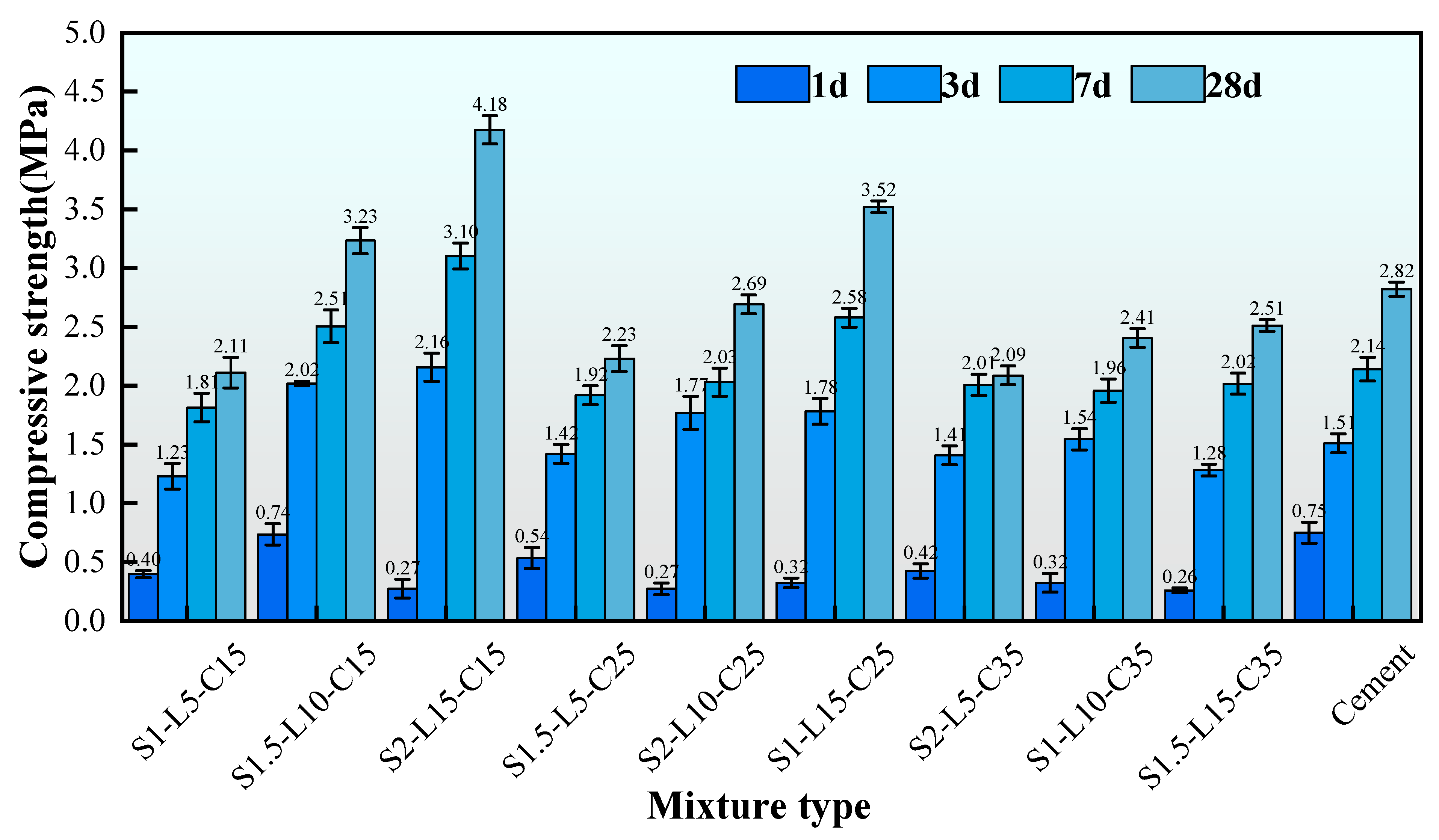

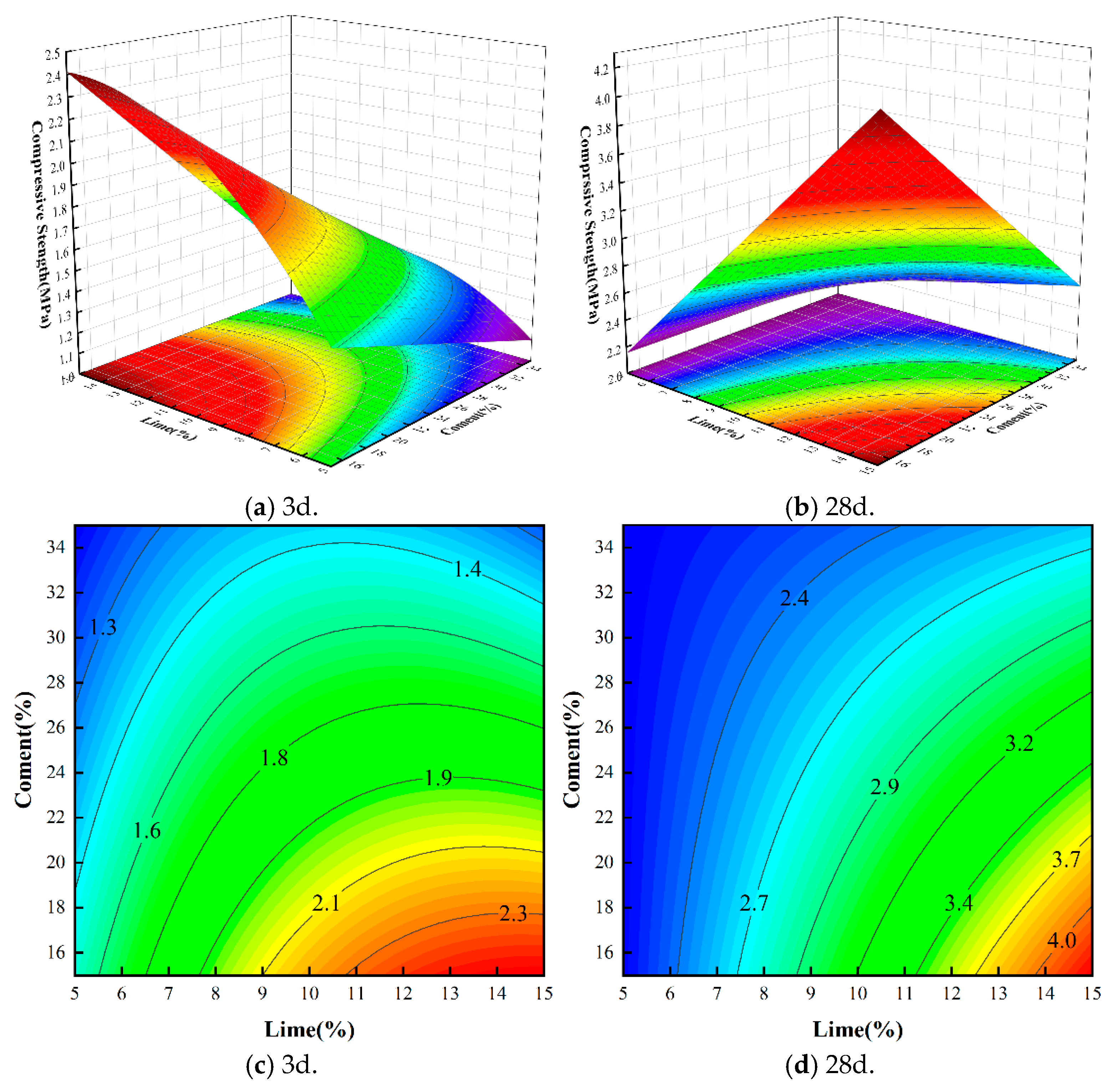

3.3. Mechanical Strength

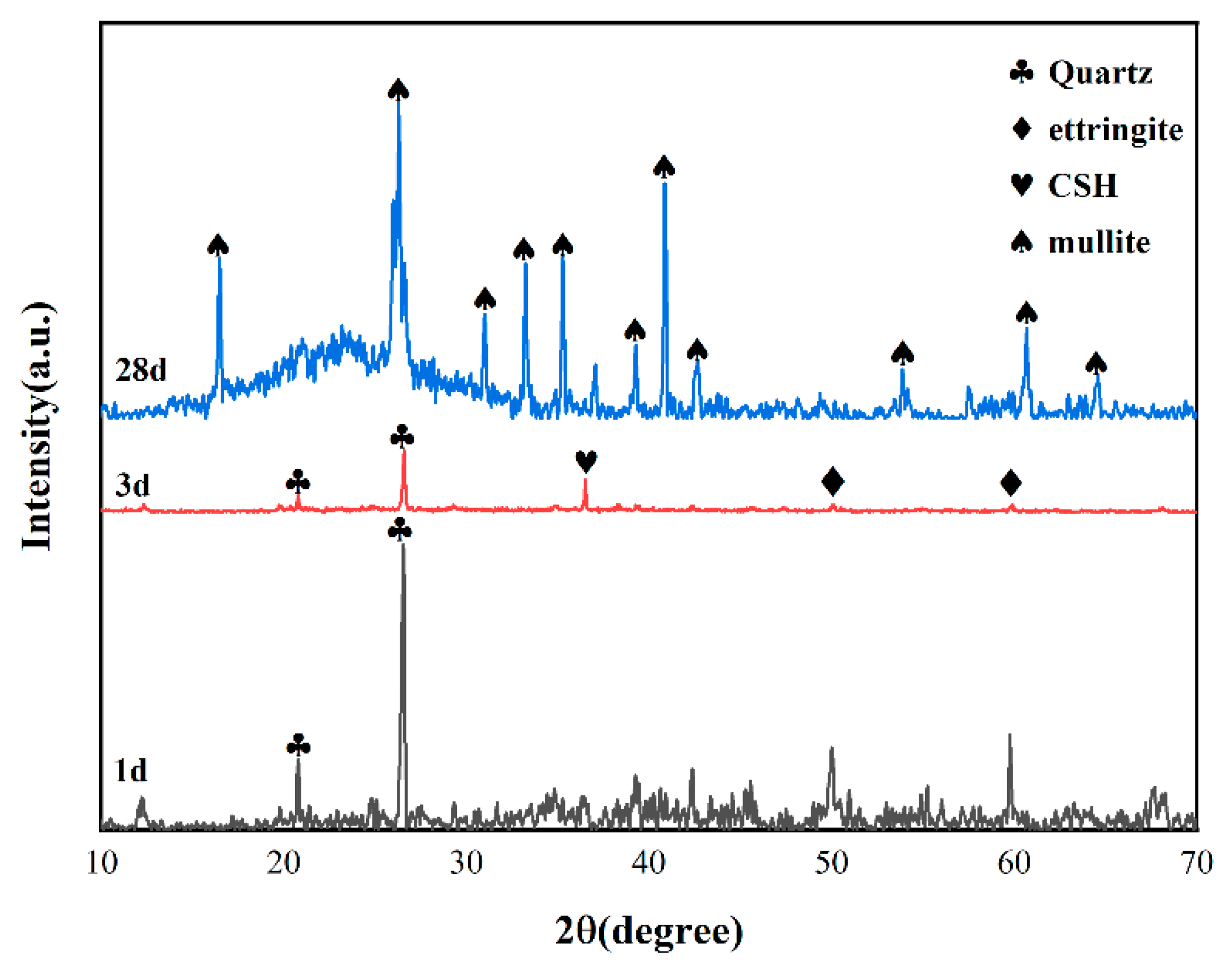

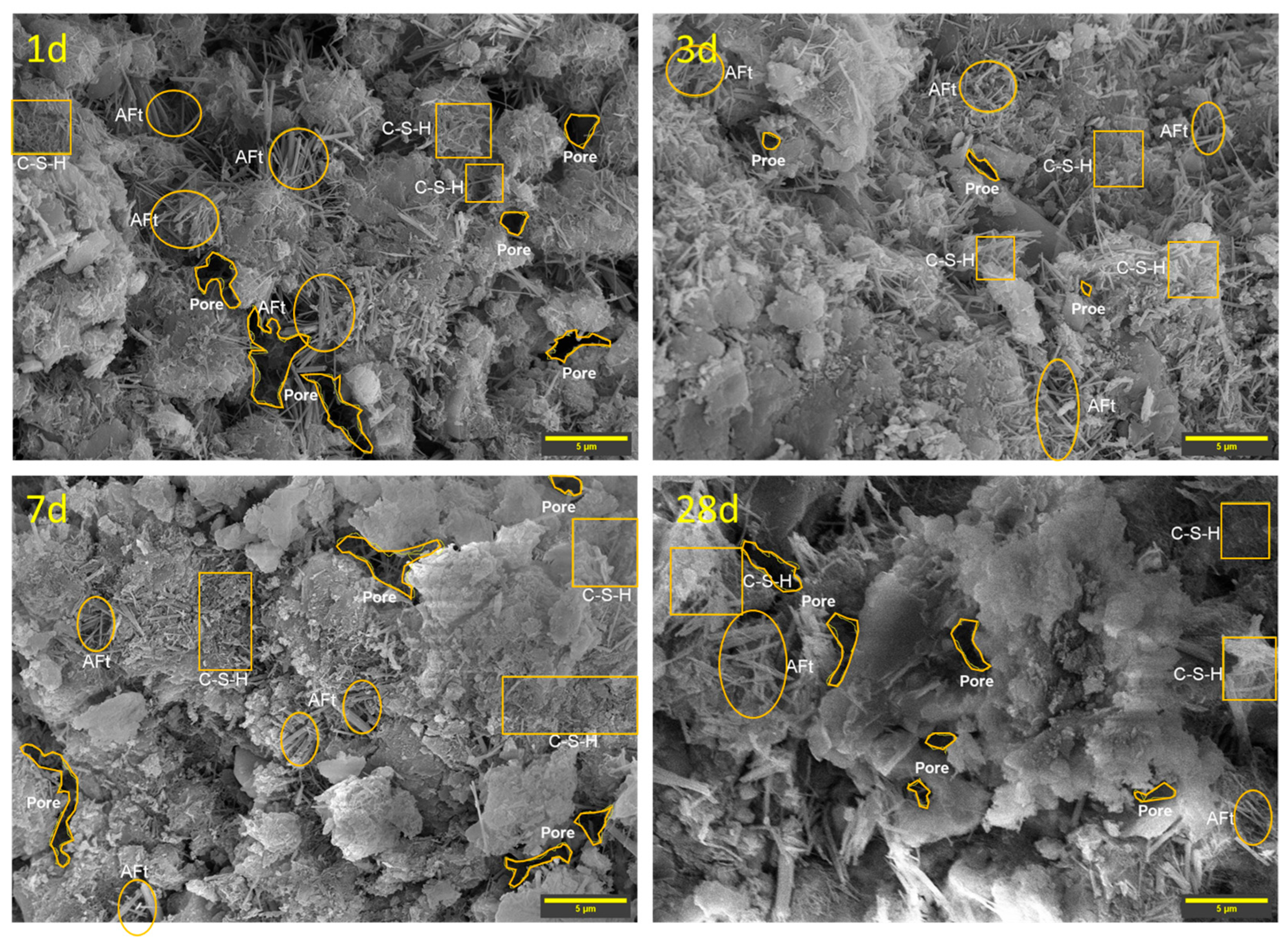

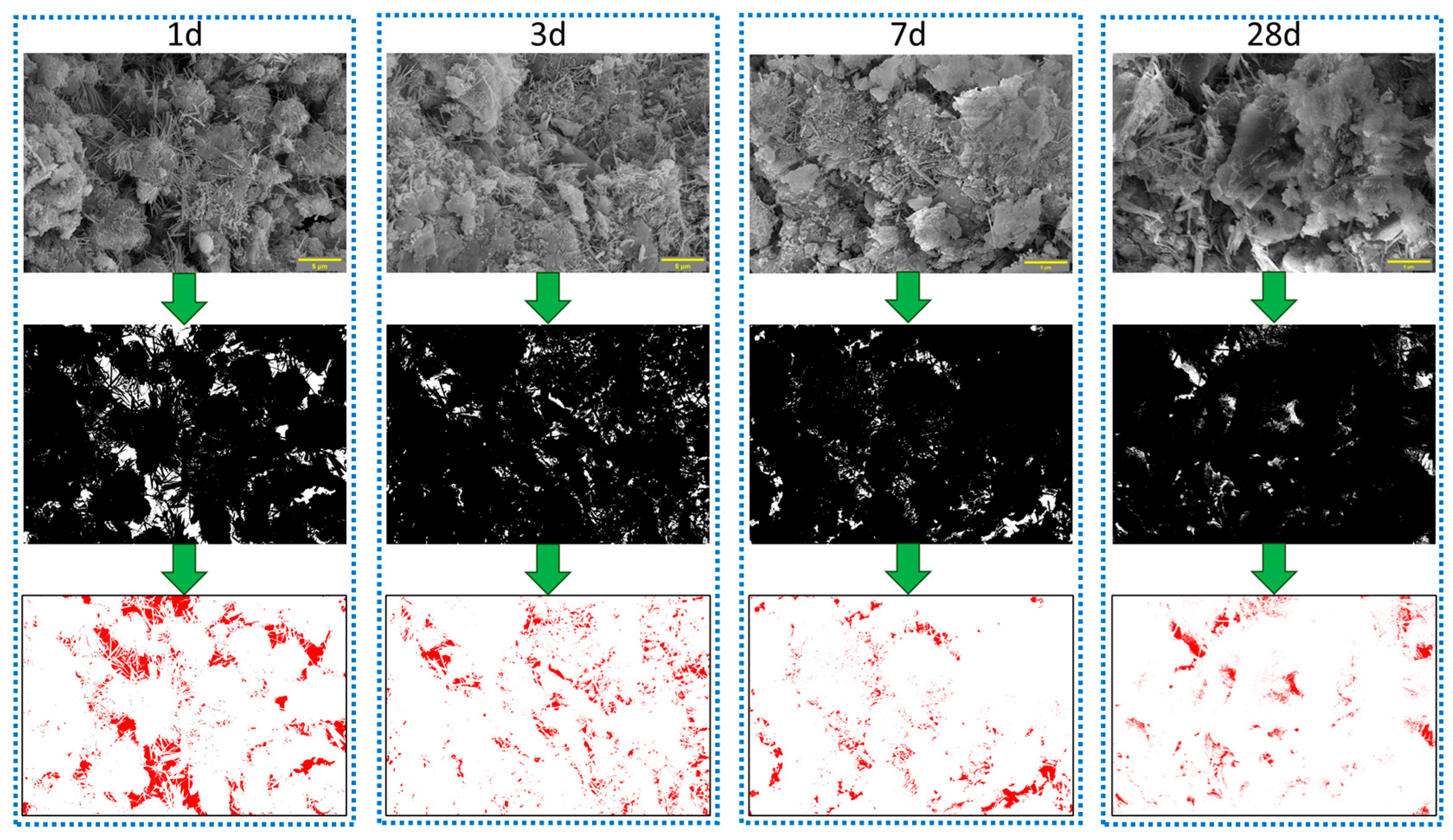

3.4. Hydration Products and Microstructure

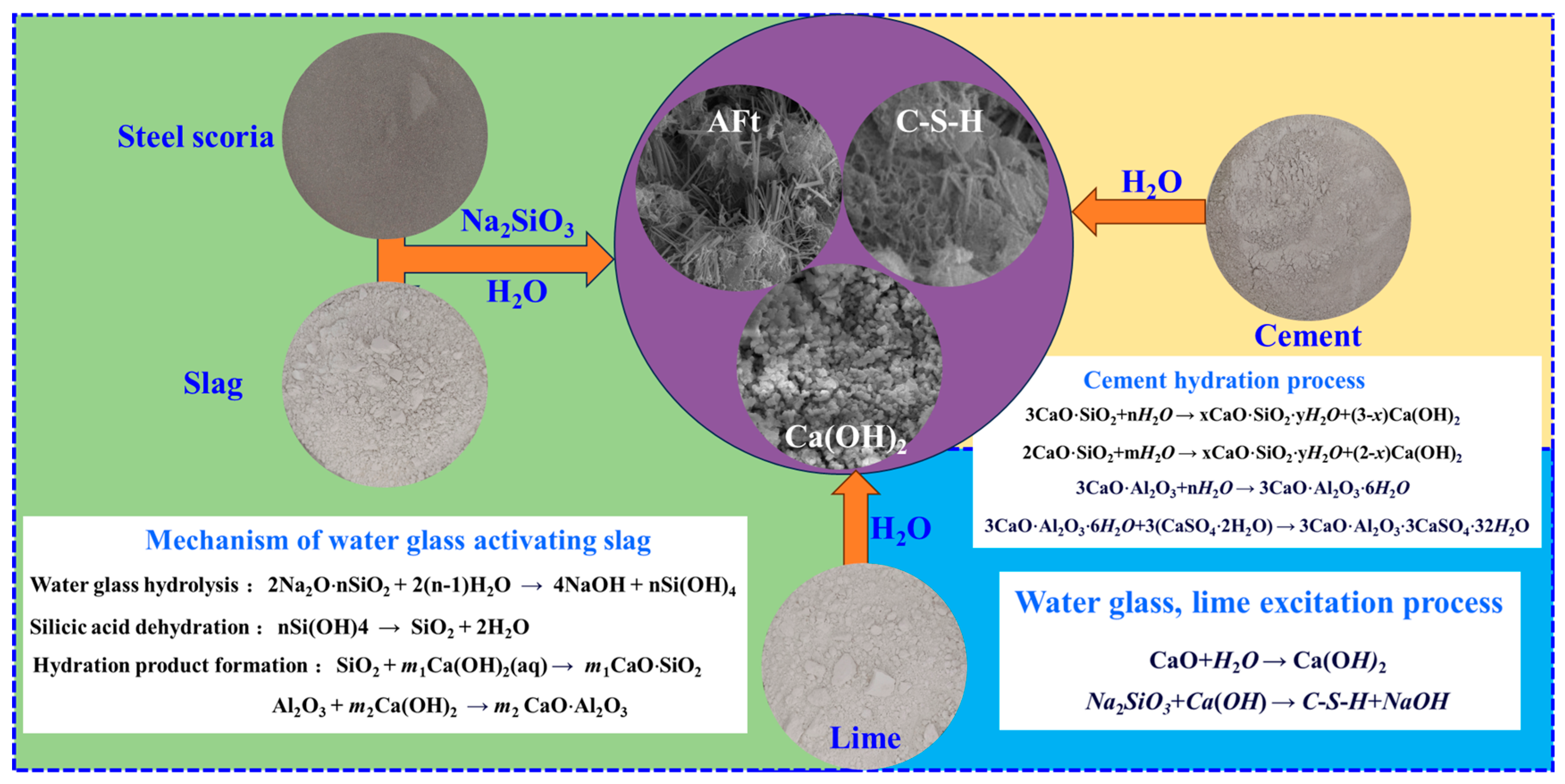

3.5. Mechanism Analysis

3.6. Environmental and Economic Benefit Analysis

4. Conclusions

- When the mass ratio of steel slag, slag, cement, water glass, and lime was 30:38:15:2:15, the CGFB achieved the largest compressive strength, good setting, and good block and flow performance. Under these mix proportions, the compressive strength of CGFB reached 2.16 MPa at 3 days and 4.18 MPa at 28 days. The initial setting time was 155 min, the final setting time was 210 min, and the slump was 250 mm.

- The high early strength of CGFB can be attributed to the hydration reaction process of cement being greatly accelerated under the stimulation of water glass, which promoted the formation of the hydration product C-S-H. Under the dual activation of water glass and lime, the potential active substances in steel slag and slag were stimulated, resulting in higher later strength in the CGFB.

- With the increase in curing age, the microstructure of the CGFB became denser, the micro-porosity gradually decreased, hydration products continued to develop, the network of C-S-H became more compact, and the length and diameter of rod-like AFt increased. Macroscopically, these changes were reflected in the performance evolution of the filling body over different curing periods.

- Based on computer image processing technology, the pore characteristics of SEM images were analyzed and compared with the macro compressive strength. The results show that as the oxidation age of the filling body increases, the porosity becomes lower and lower, and regarding the macroscopic performance, the compressive strength becomes higher and higher.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiong, Y.; Kong, D.; Song, G. Research hotspots and development trends of green coal mining: Exploring the path to sustainable development of coal mines. Resour. Policy 2024, 92, 105039. [Google Scholar] [CrossRef]

- Wang, X.-P.; Zhang, Z.-M.; Guo, Z.-H.; Su, C.; Sun, L.-H. Energy structure transformation in the context of carbon neutralization: Evolutionary game analysis based on inclusive development of coal and clean energy. J. Clean. Prod. 2023, 398, 136626. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, T.; Duan, L.; Li, J. A review of research on comprehensive treatment of mined-out areas in China. Saf. Environ. Eng. 2022, 29, 220–230. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, S.; Yu, Q.; Zhang, M.; Wang, Y.; Xu, H.; Su, F.; Li, M. Study on mechanical properties and microstructure evolution of coal gangue-based cemented backfill. Mod. Min. 2023, 39, 207–212. [Google Scholar]

- Guo, F.; Guo, Y.; Chen, L.; Jia, W.; Zhu, Y.; Li, Y.; Wang, H.; Yao, X.; Zhang, Y.; Wu, J. Multitudinous components recovery, heavy metals evolution and environmental impact of coal gasification slag: A review. Chemosphere 2023, 338, 139473. [Google Scholar] [CrossRef]

- Sun, J.; Liu, S.; Ma, Z.; Qian, H.; Wang, Y.; Al-Azzani, H.; Wang, X. Mechanical properties prediction of lightweight coal gangue shotcrete. J. Build. Eng. 2023, 80, 108088. [Google Scholar] [CrossRef]

- Behera, S.K.; Mishra, D.P.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.; Kumar, R.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, Z.; Yilmaz, E.; Han, J.; Qiu, J.; Dong, C. Effectiveness of alkali-activated slag as alternative binder on workability and early age compressive strength of cemented paste backfills. Constr. Build. Mater. 2019, 218, 689–700. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Ma, D.; Yang, S.; Yin, Q.; Feng, Y. Effect of aggregate size distribution and confining pressure on mechanical property and microstructure of cemented gangue backfill materials. Adv. Powder Technol. 2022, 33, 103686. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, J.; Wu, P.; Guo, Z.; Zhang, S.; Sun, X. Preparing a binder for cemented paste backfill using low-aluminum slag and hazardous oil shale residue and the heavy metals immobilization effects. Powder Technol. 2022, 399, 117167. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Bussière, B.; Benzaazoua, M. Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills. Cem. Concr. Compos. 2011, 33, 702–715. [Google Scholar] [CrossRef]

- Behera, S.K.; Ghosh, C.N.; Mishra, D.P.; Singh, P.; Mishra, K.; Buragohain, J.; Mandal, P.K. Strength development and microstructural investigation of lead-zinc mill tailings based paste backfill with fly ash as alternative binder. Cem. Concr. Compos. 2020, 109, 103553. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Santana-Carrillo, J.L.; Burciaga-Díaz, O.; Escalante-Garcia, J.I. Blended limestone-Portland cement binders enhanced by waste glass based and commercial sodium silicate-Effect on properties and CO2 emissions. Cem. Concr. Compos. 2022, 126, 104364. [Google Scholar] [CrossRef]

- Li, J.; Yilmaz, E.; Cao, S. Influence of industrial solid waste as filling material on mechanical and microstructural characteristics of cementitious backfills. Constr. Build. Mater. 2021, 299, 124288. [Google Scholar] [CrossRef]

- Sahoo, S.; Singh, S.P. Strength and durability properties of expansive soil treated with geopolymer and conventional stabilizers. Constr. Build. Mater. 2022, 328, 127078. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, W.B.; Zhao, R.D.; Jin, Y.F.; Yin, J.H. Solidification/stabilization treatment of Hong Kong marine deposits slurry at high water content by ISSA and GGBS. Constr. Build. Mater. 2023, 372, 130817. [Google Scholar] [CrossRef]

- Gomari, K.E.; Gomari, S.R.; Hughes, D.; Ahmed, T. Exploring the potential of steel slag waste for carbon sequestration through mineral carbonation: A comparative study of blast-furnace slag and ladle slag. J. Environ. Manag. 2024, 351, 119835. [Google Scholar] [CrossRef]

- Rungchet, A.; Chindaprasirt, P.; Wansom, S.; Pimraksa, K. Hydrothermal synthesis of calcium sulfoaluminate–belite cement from industrial waste materials. J. Clean. Prod. 2016, 115, 273–283. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, W.; Wang, S.; Liu, J.; Li, Y.; Zhuo, Y.; Xu, L.; Zhao, Y. Band application of flue gas desulfurization gypsum improves sodic soil amelioration. J. Environ. Manag. 2021, 298, 113535. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Fu, J.; Song, W. Mechanical model and strength development evolution of high content fly ash–cement grouting material. Constr. Build. Mater. 2023, 398, 132492. [Google Scholar] [CrossRef]

- Sun, M.; Ma, L.; Dai, Q.; Yang, J.; Xie, L.; Hu, Y.; Duan, L.; Yan, X.; Zhou, G.; Zeng, L.; et al. Preparation of functional geopolymers from municipal solid waste incineration fly ash: An approach combining experimental and computational simulation studies. J. Environ. Manag. 2024, 355, 120226. [Google Scholar] [CrossRef]

- Liu, J.; Liu, K.; He, B.; Liu, K.; Lu, J.; Zhou, Z.; Xu, B.; Yu, S.; Qin, G.; Wang, L.; et al. Mechanical properties and solidification mechanism of coal gangue-granulated blast furnace slag geopolymer stabilized engineering slurry. Case Stud. Constr. Mater. 2024, 21, e03660. [Google Scholar] [CrossRef]

- Jiao, H.; Ge, X.; Wang, Q.; Rong, Y.; Ruan, Z.; Li, G.; Xu, J.; Chang, X.; Lian, X.; Fang, Y. Solidification/Stabilization mechanisms of heavy metal ions in cemented paste backfill for green mine operations: A review. Int. J. Miner. Metall. Mater. 2025. [Google Scholar]

- Hao, X.; Liu, X.; Zhang, Z.; Zhang, W.; Lu, Y.; Wang, Y.; Yang, T. In-depth insight into the cementitious synergistic effect of steel slag and red mud on the properties of composite cementitious materials. J. Build. Eng. 2022, 52, 104449. [Google Scholar] [CrossRef]

- Shi, C. Characteristics and cementitious properties of ladle slag fines from steel production. Cem. Concr. Res. 2002, 32, 459–462. [Google Scholar] [CrossRef]

- Zhao, L.; Wei, W.; Bai, H.; Zhang, X.; Cang, D.-Q. Synthesis of steel slag ceramics: Chemical composition and crystalline phases of raw materials. Int. J. Miner. Metall. Mater. 2015, 22, 325–333. [Google Scholar] [CrossRef]

- Babu, T.; Thangaraj, S. A novel approach for the synthesis of eco-friendly geopolymer ternary blended mortar with GGBS, sugarcane bagasse ash, and sewage sludge ash under ambient curing conditions. KSCE J. Civ. Eng. 2023, 27, 3441–3454. [Google Scholar] [CrossRef]

- Peng, H.; Cui, C.; Liu, Z.; Cai, C.S.; Liu, Y. Synthesis and reaction mechanism of an alkali-activated metakaolin-slag composite system at room temperature. J. Mater. Civ. Eng. 2019, 31, 04018345. [Google Scholar] [CrossRef]

- Yang, X.; Wu, S.; Xu, S.; Chen, B.; Chen, D.; Wang, F.; Jiang, J.; Fan, L.; Tu, L. Effects of GBFS content and curing methods on the working performance and microstructure of ternary geopolymers based on high-content steel slag. Constr. Build. Mater. 2024, 410, 134128. [Google Scholar] [CrossRef]

- Gijbels, K.; Iacobescu, R.I.; Pontikes, Y.; Schreurs, S.; Schroeyers, W. Alkali-activated binders based on ground granulated blast furnace slag and phosphogypsum. Constr. Build. Mater. 2019, 215, 371–380. [Google Scholar] [CrossRef]

- Tian, Z.; Liu, X.; Zhang, Z.; Zhang, K.; Tang, X. Potential using of water-soluble polymer latex modified greener road geopolymeric grouts: Its preparation, characterization and mechanism. Constr. Build. Mater. 2021, 273, 121757. [Google Scholar] [CrossRef]

- Liu, S.; Liu, G.; Li, G.; Sun, Y.; Li, K.; Wang, F. The mechanism of lime regulating the early hydration of alkali-activated binder. Mine Res. Dev. 2021, 41, 48–52. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, Y.; Cui, S.; Wang, H.; Wang, W. Effect of composition and structure of blast furnace slag on its early hydration characteristics in alkaline environment. Mater. Introd. 2018, 32, 3989–3994. [Google Scholar]

- Kabir, H.; Wu, J.; Dahal, S.; Joo, T.; Garg, N. Automated estimation of cementitious sorptivity via computer vision. Nat. Commun. 2024, 15, 9935. [Google Scholar] [CrossRef] [PubMed]

- JGJ/T 70-2009; Standard for Basic Performance Test Methods of Building Mortar. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- GB/T 1346-2011; Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method. Standardization Administration of the People’s Republic of China: Beijing, China, 2011.

- GB/T 2419-2005; Cement Mortar Fluidity Determination Method. Standardization Administration of the People’s Republic of China: Beijing, China, 2005.

- Zhang, J.; He, X.; Yang, K.; Wei, Z.; Zhao, X.-Y.; Fang, J.-J. Diffusion law of coal gangue slurry and the application of fluidized filling technology of gangue in caving area. Sci. Rep. 2023, 13, 13226. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Hao, D.; Zhao, H.; Hu, Z. Study on the Flow Velocity of Safe and Energy-Saving Transportation of Light-Particle Slurry. Appl. Sci. 2024, 14, 6313. [Google Scholar] [CrossRef]

- Pan, Y.; Yuan, H.; Zhai, S.; Geng, Z.; Huo, F. Study on Slump and Compressive Strength of Gangue Based on Aggregate Size Gradation. Appl. Sci. 2024, 14, 4214. [Google Scholar] [CrossRef]

- Yang, X.; Yang, J.; Wang, X.; Yin, S.; Zhang, X.; Qi, Y.; Chen, W. Mesoscopic surface crack extension mechanism of magnesium slag-based backfill based on digital image correlation. Nondestruct. Test. Eval. 2025, 1–30. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Maciej, Z.; Linda, I.; Frank, B.; Hilbig, H.; Ben Haha, M. Mechanisms of carbonation hydration hardening in Portland cements. Cem. Concr. Res. 2022, 152, 106687. [Google Scholar] [CrossRef]

- Kang, C.; Kim, T. Influence of brine on hydration reaction of calcium sulfoaluminate and slag blended cement. Case Stud. Constr. Mater. 2023, 18, e02159. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, W.; Wu, P.; Pi, Y.; Zhang, Y. Study on preparation and strengthening mechanism of new surface treatment agent of concrete at multi-scale. Constr. Build. Mater. 2022, 346, 128404. [Google Scholar] [CrossRef]

- Lamaa, G.; Duarte, A.P.C.; Silva, R.V.; de Brito, J. Carbonation of Alkali-Activated Materials: A Review. Materials 2023, 16, 3086. [Google Scholar] [CrossRef] [PubMed]

| Material | SiO2 | Al2O3 | Fe2O3 | SO3 | K2O | CaO | MgO | TiO2 | Na2O |

|---|---|---|---|---|---|---|---|---|---|

| Coal gangue | 55.05 | 24.64 | 9.12 | 6.06 | 3.18 | 1.45 | 1.45 | 1.06 | 0.32 |

| Steel scoria | 13.5 | 4.49 | 18.8 | 0.74 | 0.26 | 25.8 | 3.82 | 0.76 | 0.29 |

| Slag | 29.6 | 16.3 | 0.34 | 2.23 | 0.42 | 40.3 | 8.2 | 1.26 | 0.52 |

| Quicklime | 5.28 | 1.54 | 0.26 | 0.23 | 0.06 | 91.1 | 1.17 | 0.08 | 0.06 |

| Sample ID | Content of SS (%) | Content of S (%) | Content of NaSiO3 (%) | Content of Q (%) | Cement (%) |

|---|---|---|---|---|---|

| S1-L5-C15 | 30 | 49 | 1 | 5 | 15 |

| S1.5-L10-C15 | 30 | 43.5 | 1.5 | 10 | 15 |

| S2-L15-C15 | 30 | 38 | 2 | 15 | 15 |

| S1.5-L5-C25 | 30 | 38.5 | 1.5 | 5 | 25 |

| S2-L10-C25 | 30 | 33 | 2 | 10 | 25 |

| S1-L15-C25 | 30 | 29 | 1 | 15 | 25 |

| S2-L5-C35 | 30 | 28 | 2 | 5 | 35 |

| S1-L10-C35 | 30 | 24 | 1 | 10 | 35 |

| S1.5-L15-C35 | 30 | 18.5 | 1.5 | 15 | 35 |

| Cement | 0 | 0 | 0 | 0 | 100 |

| Sample Number | 1 d | 3 d | 7 d | 28 d |

|---|---|---|---|---|

| Porosity/% | 10.5 | 5.6 | 4.3 | 3.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Wang, Y.; Chen, X.; Jiao, H.; Zhu, G.; Fan, Z.; Gao, M.; Xu, W.; Dong, F.; Yao, L. Research on the Mechanical Properties and Micro-Evolution Characteristics of Coal Gangue-Based Composite Cementitious Materials. Buildings 2025, 15, 3406. https://doi.org/10.3390/buildings15183406

Li G, Wang Y, Chen X, Jiao H, Zhu G, Fan Z, Gao M, Xu W, Dong F, Yao L. Research on the Mechanical Properties and Micro-Evolution Characteristics of Coal Gangue-Based Composite Cementitious Materials. Buildings. 2025; 15(18):3406. https://doi.org/10.3390/buildings15183406

Chicago/Turabian StyleLi, Gongcheng, Yuzhong Wang, Xun Chen, Huazhe Jiao, Guodong Zhu, Zongyu Fan, Mingfa Gao, Wenlong Xu, Feng Dong, and Liuyang Yao. 2025. "Research on the Mechanical Properties and Micro-Evolution Characteristics of Coal Gangue-Based Composite Cementitious Materials" Buildings 15, no. 18: 3406. https://doi.org/10.3390/buildings15183406

APA StyleLi, G., Wang, Y., Chen, X., Jiao, H., Zhu, G., Fan, Z., Gao, M., Xu, W., Dong, F., & Yao, L. (2025). Research on the Mechanical Properties and Micro-Evolution Characteristics of Coal Gangue-Based Composite Cementitious Materials. Buildings, 15(18), 3406. https://doi.org/10.3390/buildings15183406