Experimental Study on Performance of High-Performance Concrete Based on Different Fine Aggregate Systems

Abstract

1. Introduction

2. Test Profile

2.1. Raw Materials

2.2. Proportioning Design

2.3. Specimen Making and Test Method

2.3.1. Specimen Making

2.3.2. Test Method

3. Result and Discussion

3.1. Workability

3.1.1. Slump

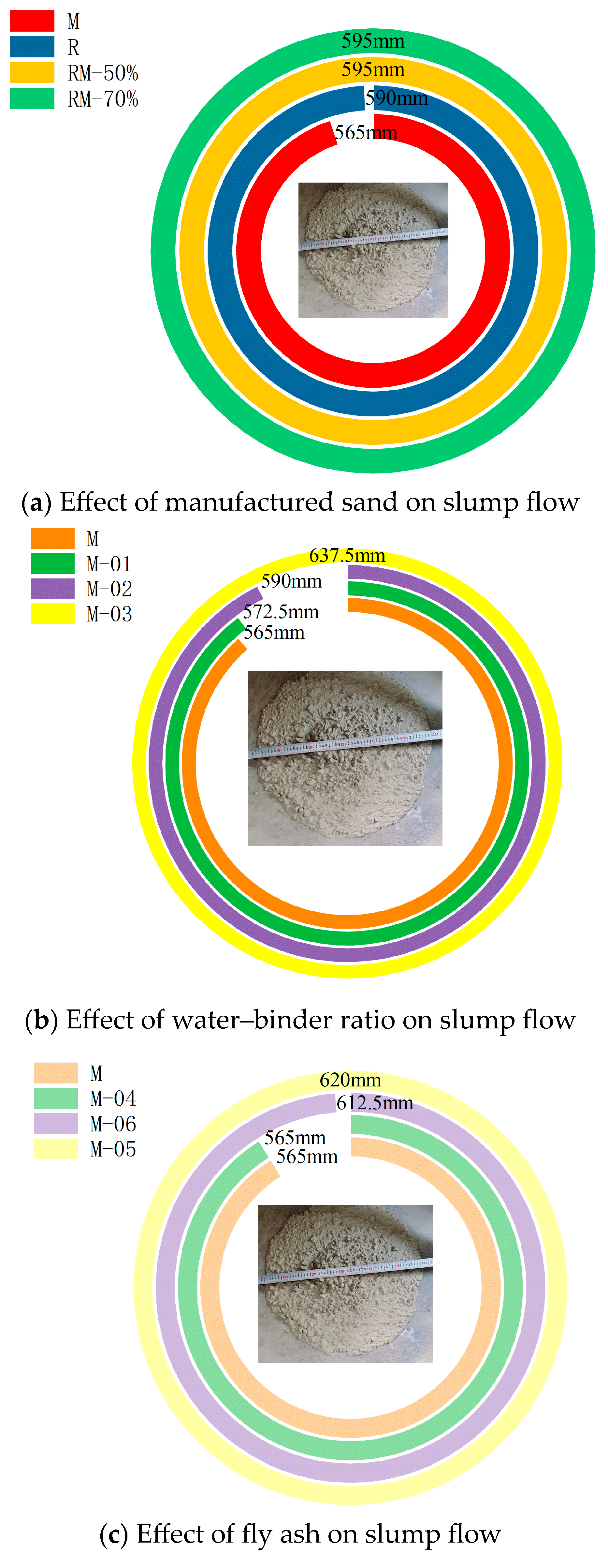

3.1.2. Slump Flow

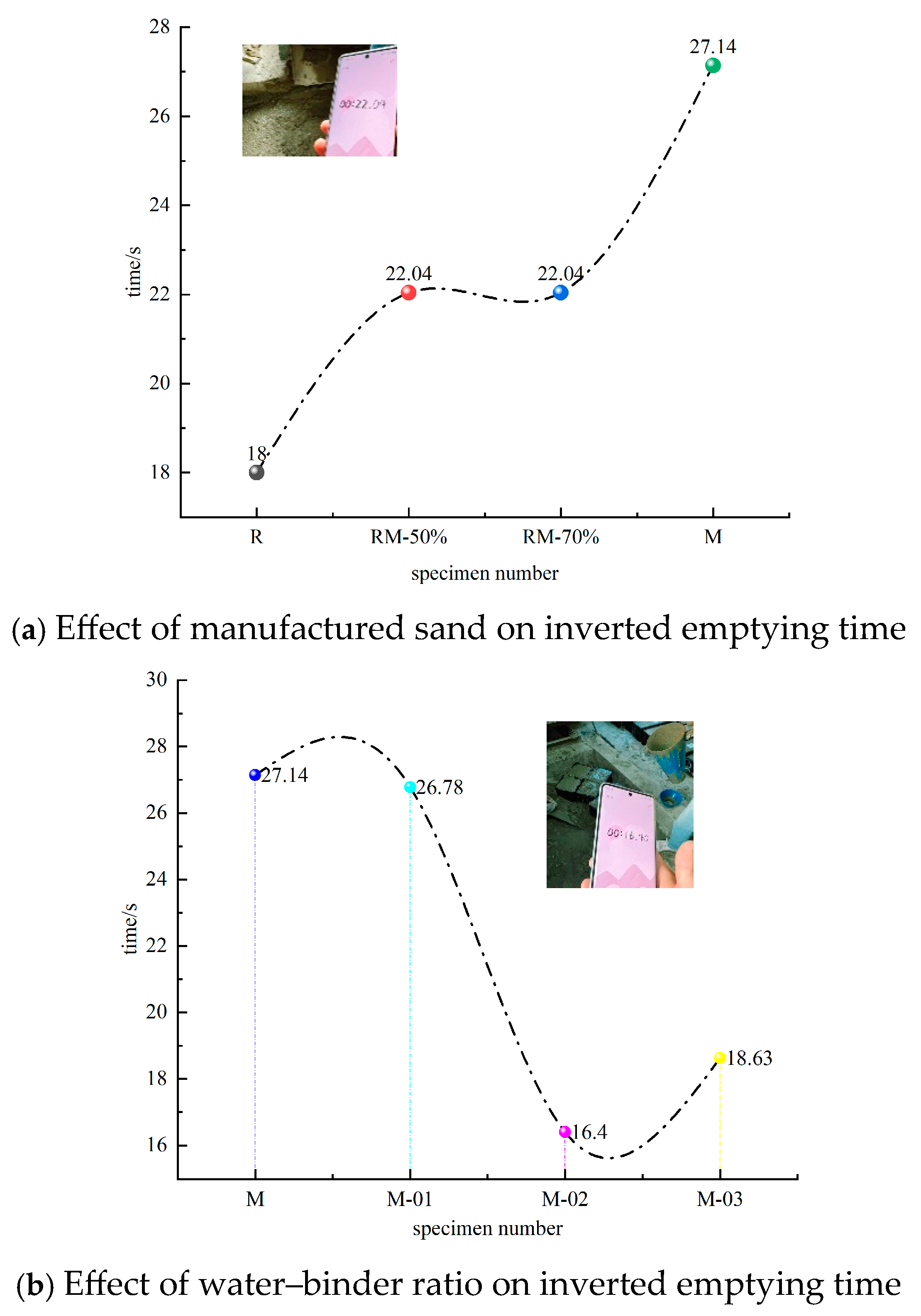

3.1.3. Inverted Emptying Time

3.2. Mechanical Property

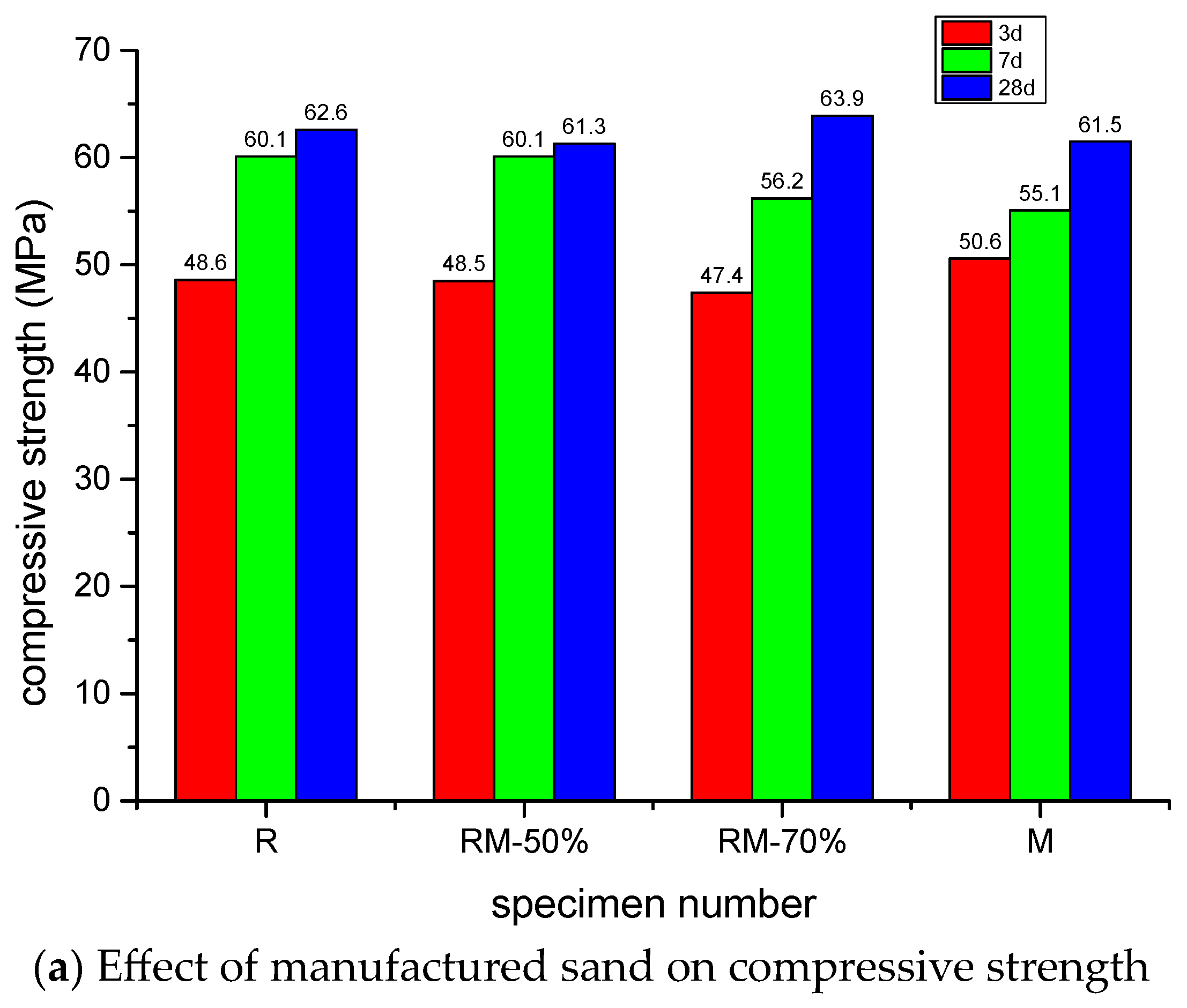

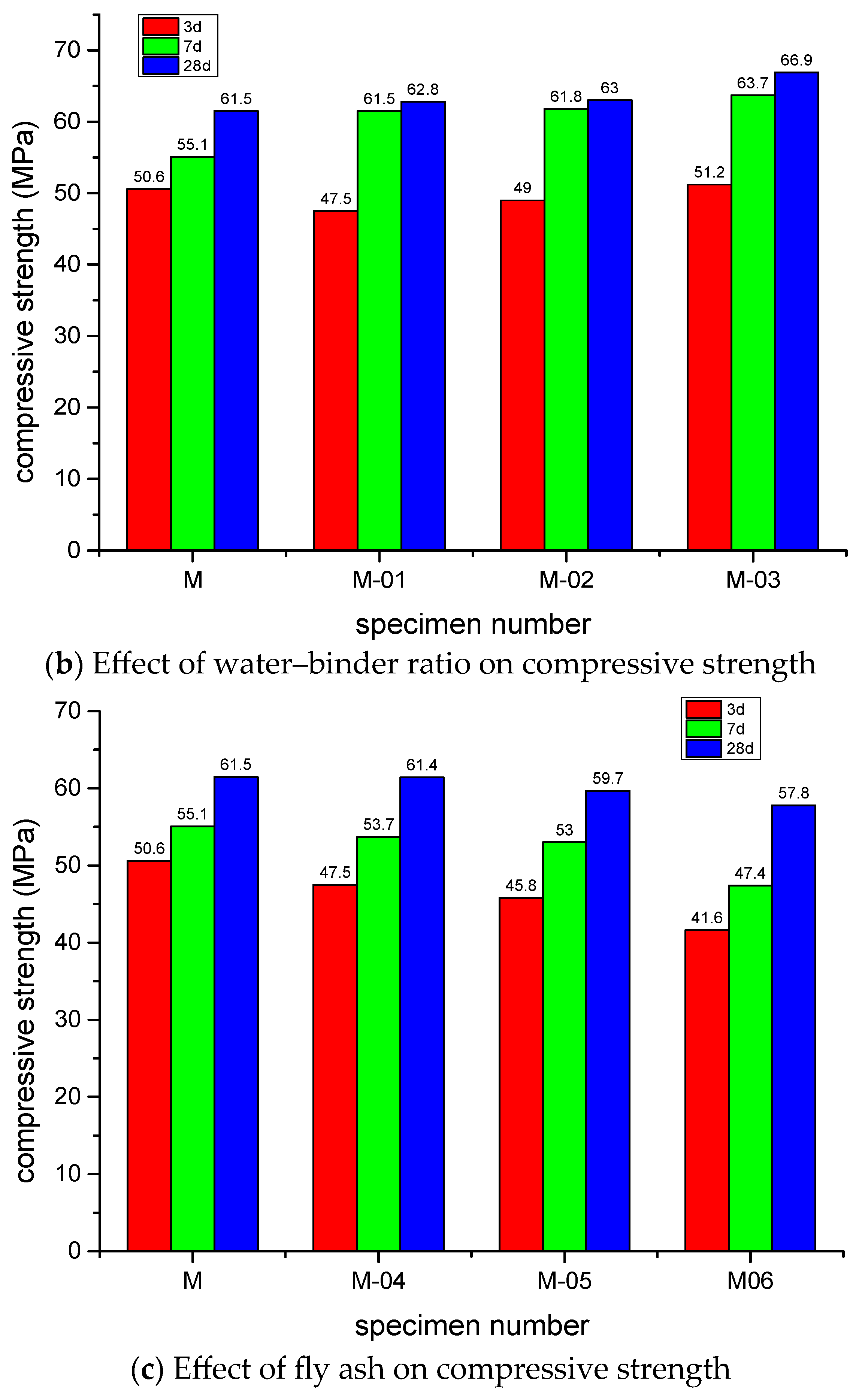

3.2.1. Compressive Strength

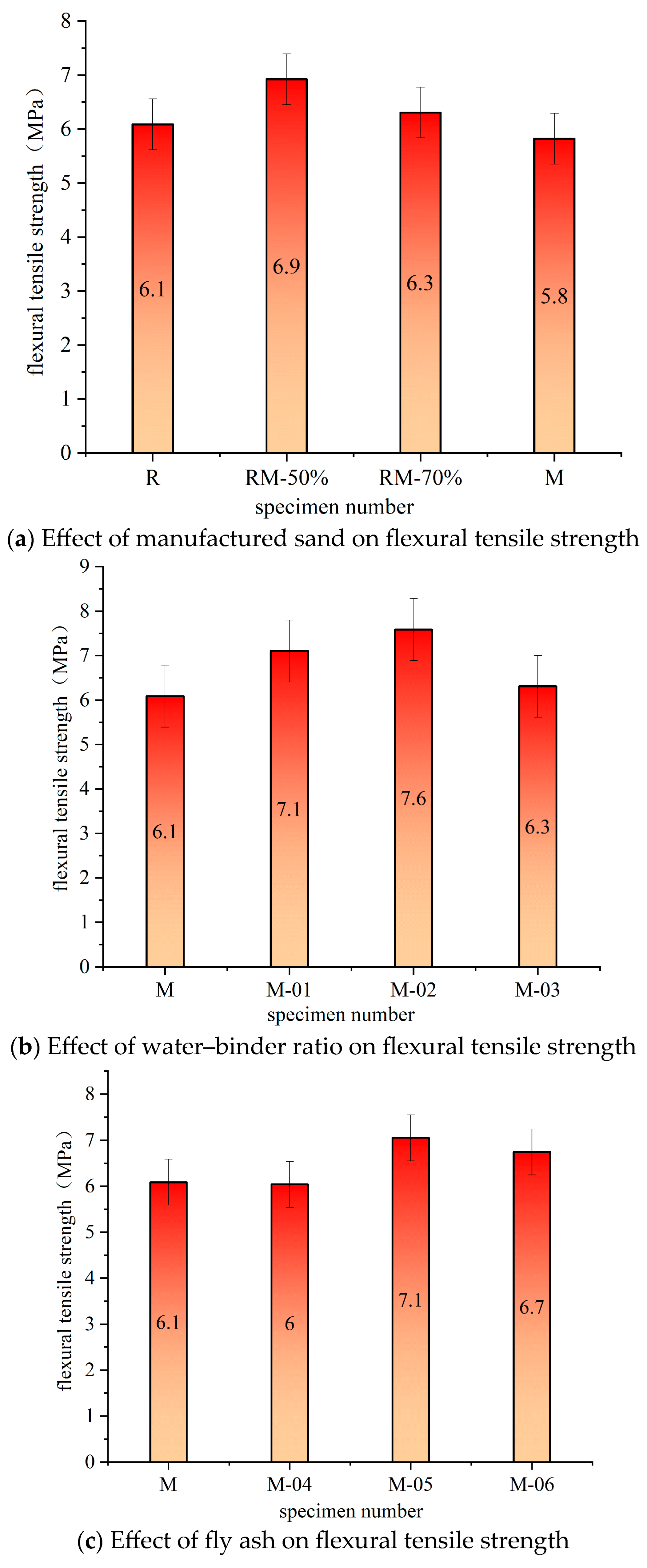

3.2.2. Flexural Tensile Strength

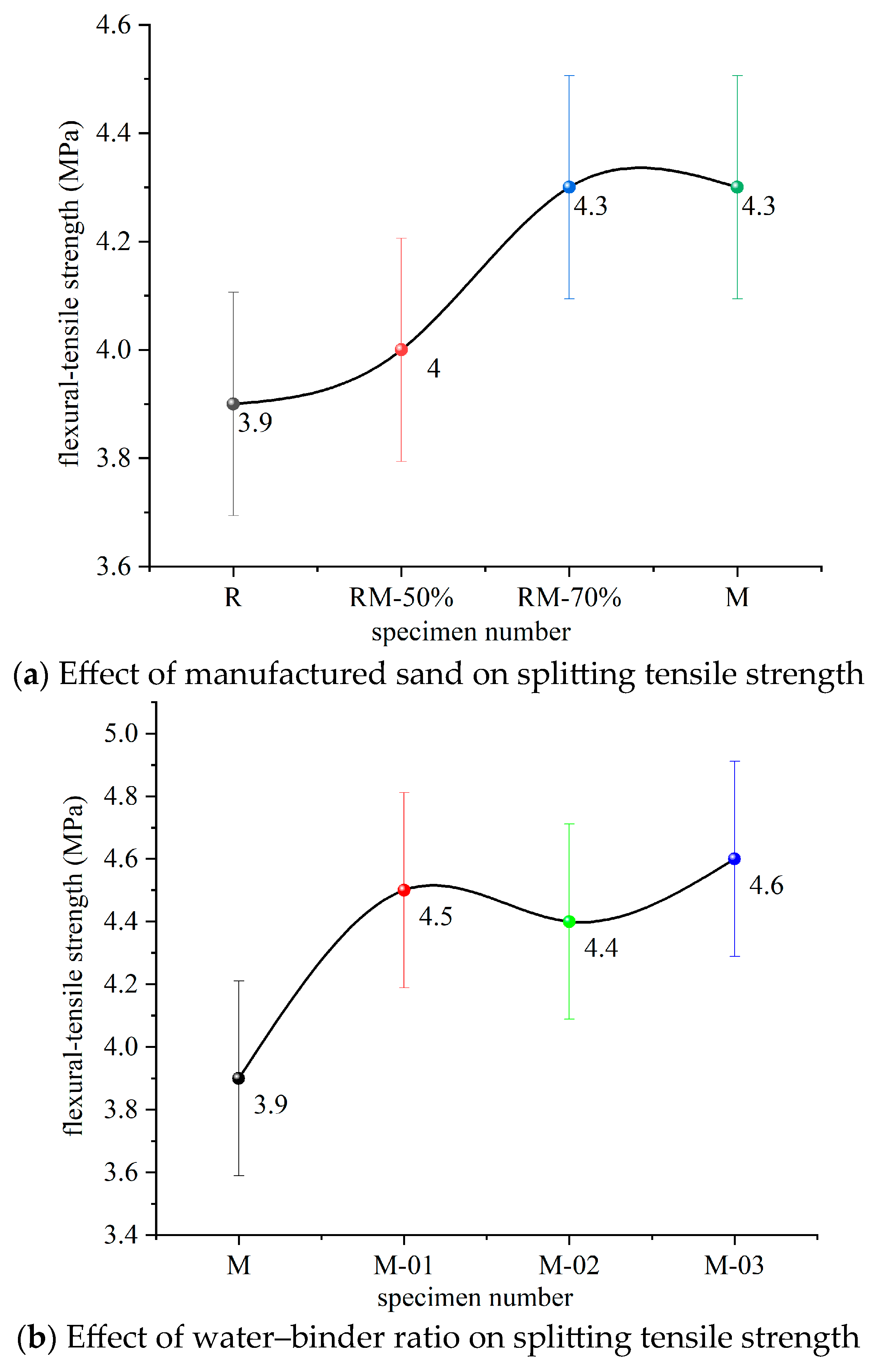

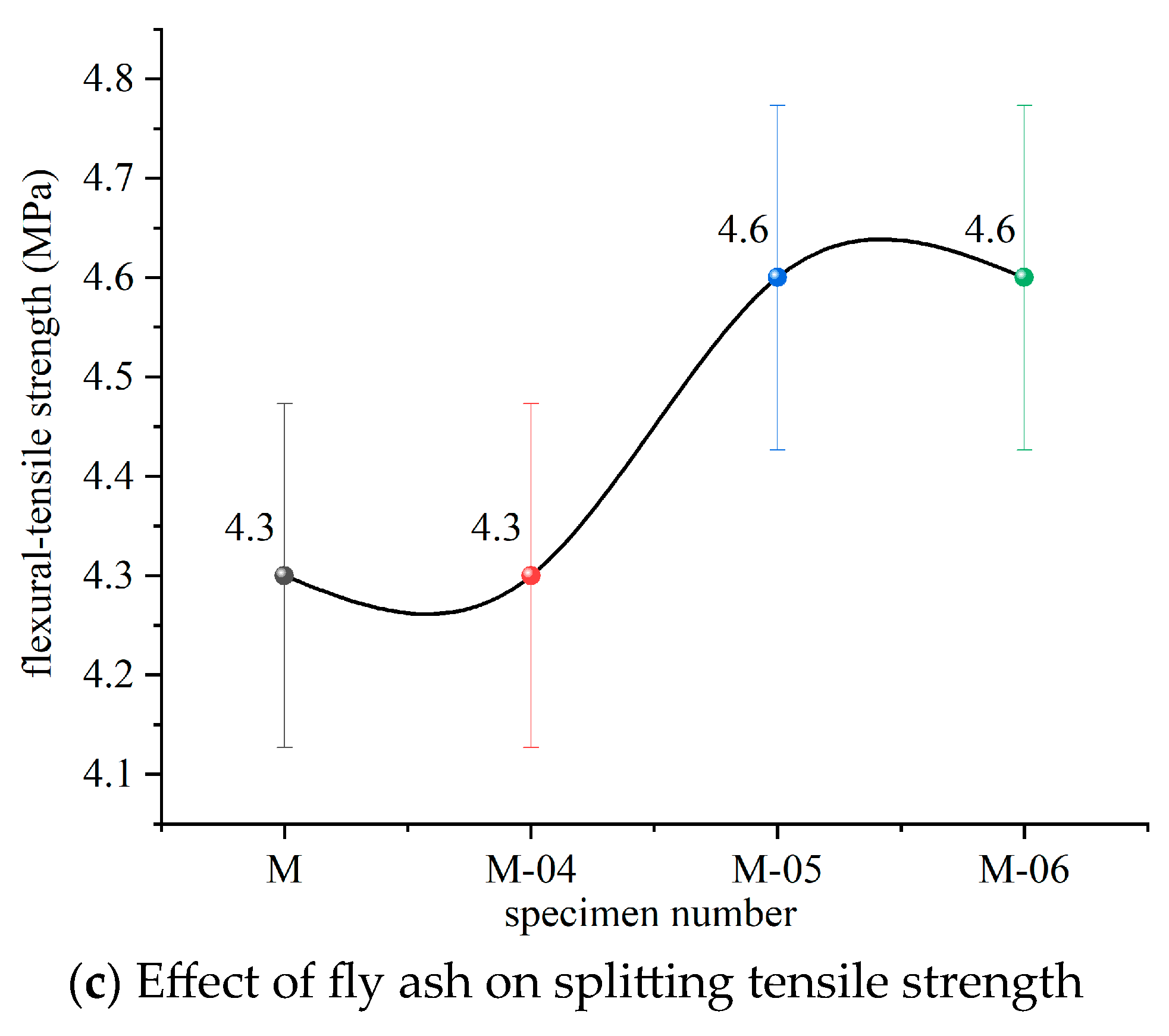

3.2.3. Splitting Tensile Strength

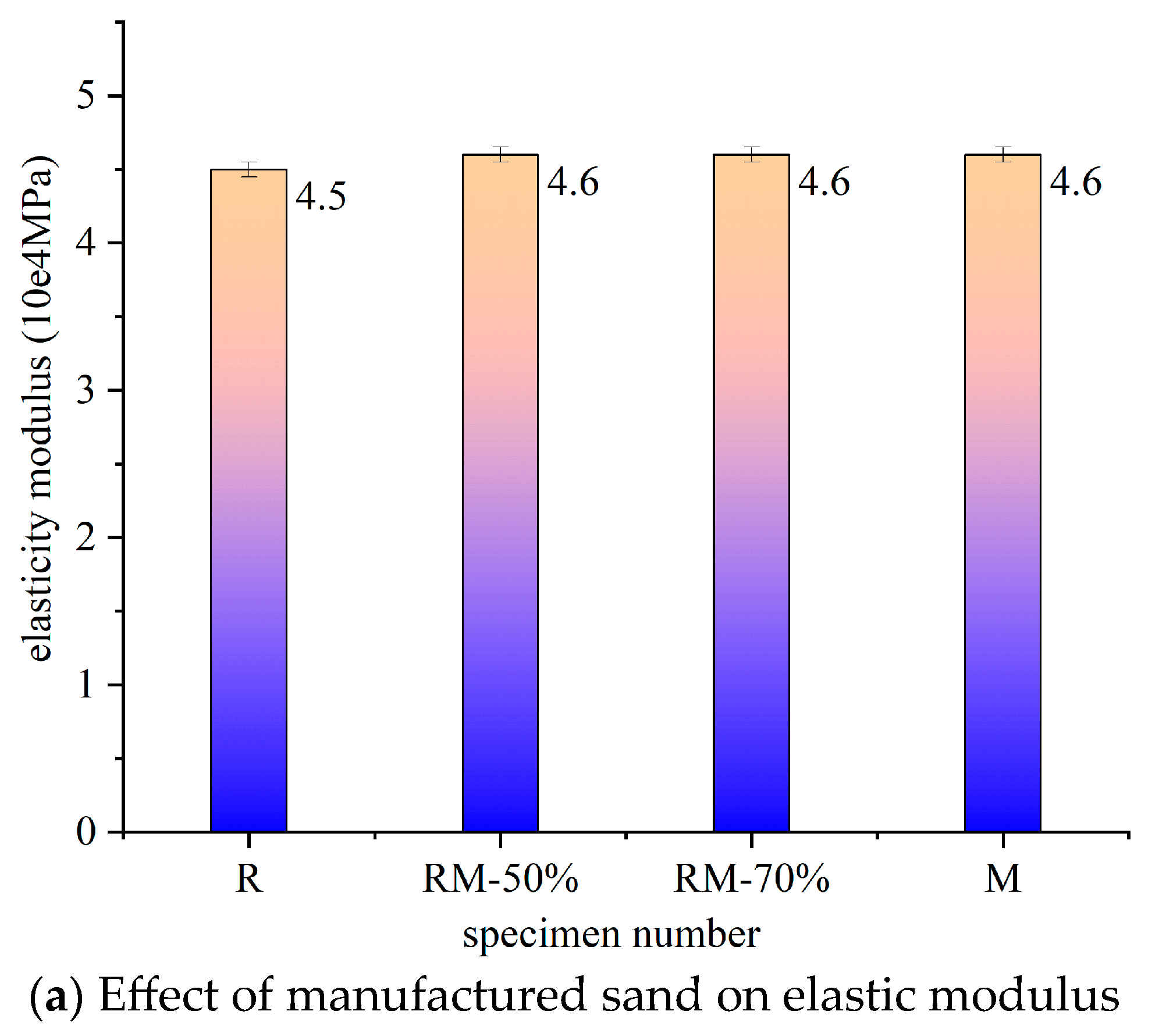

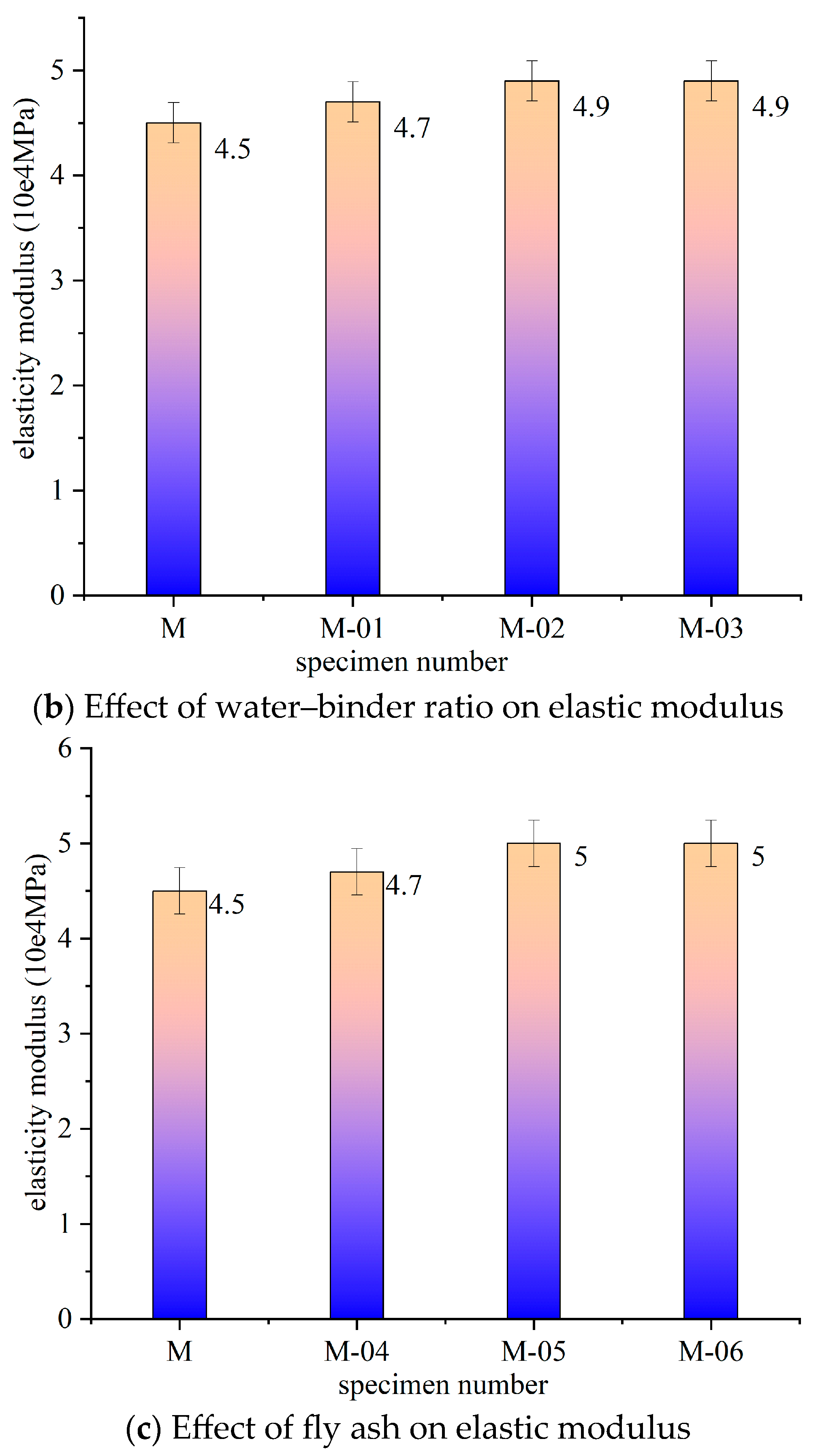

3.2.4. Modulus of Elasticity

4. Microstructural Analysis

5. Conclusions

- (1)

- An increase in manufactured sand content led to a reduction in concrete slump. Complete replacement of river sand (100%) resulted in a 4.0% decrease in slump. In contrast, the spread flow of concrete improved with elevated levels of manufactured sand and fly ash. Specifically, at a water-to-binder ratio of 0.3, a 9.7% increase in spread flow was observed.

- (2)

- The incorporation of manufactured sand contributed to an enhancement in the compressive strength of concrete, with the 28-day strength peaking at 63.9 MPa under a 70% replacement ratio. A reduction in the water-to-binder ratio further improved compressive performance, yielding a strength of 66.9 MPa at a ratio of 0.3. Conversely, an increase in fly ash content resulted in a decline in compressive strength, which measured 57.8 MPa at a 25% incorporation rate.

- (3)

- The 28-day flexural strength of concrete reached an optimal value of 6.9 MPa with a 50% replacement of manufactured sand. A lower water-to-binder ratio further enhanced the flexural performance, achieving a peak strength of 7.6 MPa at a ratio of 0.31. Additionally, the maximum 28-day flexural strength observed with 20% fly ash content was 7.1 MPa.

- (4)

- The splitting tensile strength of concrete exhibited a positive correlation with the content of manufactured sand, peaking at 4.3 MPa with a 70% replacement rate. At a water-to-binder ratio of 0.3, the tensile strength reached its maximum value of 4.6 MPa. Furthermore, higher fly ash content also contributed to enhanced tensile performance, achieving a peak strength of 4.6 MPa at a 25% incorporation rate.

- (5)

- The elastic modulus exhibited an increasing trend with higher manufactured sand replacement rates, lower water-to-binder ratios, and greater fly ash content. Nevertheless, the influence of the manufactured sand replacement rate on the elastic modulus was relatively minor. In comparison, both a reduced water-to-binder ratio and an elevated fly ash content significantly improved the elastic modulus, which reached a maximum 28-day value of 5.0 × 104 MPa.

- (6)

- Microstructural analysis revealed that both blended sand and manufactured sand concrete exhibited a denser internal matrix. It should be noted, however, that the stone powder in manufactured sand may undergo carbonation during hydration, forming calcium carbonate and consequently affecting concrete performance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Y.; Zhang, L. Application and Effect Analysis of Ultrafine Mineral Powder in Performance Improvement of Manufactured Sand Concrete. Concrete 2023, 11, 181–184+205. [Google Scholar]

- Hao, Z.J.; Zhang, Y.L. Effect of Compound Blending High-Performance Mineral Powder on Mechanical Properties of High-Strength Manufactured Sand Concrete. Met. Mine 2023, 2, 260–265. [Google Scholar]

- Huang, Z.G.; Xu, Z.H.; Li, B.X.; Lv, D.X.; Huang, A. Influence of Flaky Particles in Manufactured Sand on Properties and Microstructure of Mortar and Concrete. Bull. Chin. Ceram. Soc. 2022, 41, 1981–1989. [Google Scholar]

- Liu, C.J.; Wang, Q.C.; Zhou, Y.J.; Xu, W.B.; Zan, W.; Chen, L. Effect of Gradation of Manufactured Sand on Properties of Ultra-High-Performance Concrete. Concrete 2022, 1, 131–134. [Google Scholar]

- Sun, J.T.; Wu, D.L.; Cao, L.H.; Shen, W.G.; Lu, Z.L.; Ji, X.L. Study on Properties of High-Strength High-Performance Concrete with Blended Sand. Concrete 2019, 9, 146–149. [Google Scholar]

- Wang, C.Q.; Gao, H.L. Experimental Study on Application of Ultra-High Pumping Manufactured Sand Concrete. Concrete 2019, 6, 112–114. [Google Scholar]

- Rathore, Y.; Raheem, J. Sustainable Concrete Advancements: Exploring Deccan Basalt Manufactured Sand as A River Sand Alternative. Natl. Acad. Sci. Lett. 2025, 1–7. [Google Scholar] [CrossRef]

- Rathore, Y.; Raheem, J. The Evolution, Characteristics, and Potential of Manufactured Sand in Concrete: A Short Review. Natl. Acad. Sci. Lett. 2025. [Google Scholar] [CrossRef]

- Rathore, Y.; Raheem, J. Experimental Investigation of Concrete Performance Incorporating Deccan Basalt Manufactured Sand and Rice Husk Ash. Natl. Acad. Sci. Lett. 2025. [Google Scholar] [CrossRef]

- Chintada Chandrasekhar, G.D.; Ransinchung, R.N. Assessment of interface characteristics and durability aspects of manufactured sand (M-sand) in engineered cementitious composites. J. Build. Eng. 2024, 91, 109705. [Google Scholar] [CrossRef]

- Sathvik, S.; Oyebisi, S.; Kumar, R.; Shakor, P.; Adejonwo, O.; Tantri, A.; Suma, V. Analyzing the influence of manufactured sand and fly ash on concrete strength through experimental and machine learning methods. Sci. Rep. 2025, 15, 4978. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Li, S.; Zhao, H. Influence of Mica Content in Manufactured Sand on Mechanical and Durability Properties of C50 Concrete. Highway 2025, 70, 350–354. [Google Scholar]

- Zhang, T.; Li, K.; Tan, K.; Chang, Z.; Tan, Y.; Tang, L.; Yang, D.; Zeng, S. Mix Design and Performance Optimization of Concrete with High Stone Powder Content Manufactured Sand. J. South China Univ. Technol. (Nat. Sci. Ed.) 2025, 53, 123–53136. [Google Scholar]

- Yao, Z.; Gao, M.; Wang, H. Mechanical Properties and Multi-Condition Durability of Concrete with Different Fine Aggregates. J. Beijing Univ. Technol. 2025, 51, 595–603. [Google Scholar]

- Wang, J.; Fan, H.; Zhang, Q.; Wang, X. Effect of Stone Powder Content in Limestone Manufactured Sand on Salt-Freezing Resistance of Concrete. J. Build. Mater. 2025, 28, 671–677. [Google Scholar]

- Bian, L.; Ding, L.; Bian, J.; Li, F.; Bai, Z. Evaluation Method for Particle Shape of Natural Sand Manufactured Sand Based on, D.I.P. J. Build. Mater. 2025, 28, 693–28700. [Google Scholar]

- Peng, X.; Li, G.; Zhang, J.; Zhang, C.; You, D.; Pei, M.; Zhang, L. Experimental Study on Optimization of Particle Shape and Gradation of Manufactured Sand. Min. Metall. Eng. 2024, 44, 207–211. [Google Scholar]

- Li, W.; Cheng, L.; Liu, H.; Mu, J.; Zhang, K.; Ren, Q.; Jiang, Z. Influence of Limestone Powder as Mineral Admixture on Mechanical Properties and Durability of Manufactured Sand Concrete. Concrete 2024, 7, 94–98. [Google Scholar]

- Xia, Y.; Zhang, Y.; Zhang, Y.; Zhu, W.; Zhu, W. Study on Mechanical Properties of Manufactured Sand Concrete Prepared with Ground Tuff. Mater. Rep. 2025, 39, 71–77. [Google Scholar]

- Chen, F.; Liu, J.; Jiao, H.; Yang, L.; Niu, H.; Shen, H.; Xu, Y. Effect of Stone Powder Content on Mixing Performance and Mechanical Properties of Manufactured Sand Concrete. Concrete 2025, 3, 177–180. [Google Scholar]

- An, W.H. Research and Application of Blended Sand Concrete in Fujiang River Third Bridge. Concrete 2006, 8, 41–43. [Google Scholar]

- Chen, J.; Gu, X.B.; Gao, H.L. Experimental Study and Application of High-Lift Pumping Manufactured Sand Concrete. New Build. Mater. 2019, 46, 25–28. [Google Scholar]

- Ye, X.L.; Yue, X.X.; Jiang, G.R.; Liu, S.; Ye, X.S.; Zhou, B. Effect of Stone Powder on Early Volume Stability of High-Performance Concrete with Blended Sand. Concrete 2017, 4, 95–98. [Google Scholar]

- Zhai, W. Research on Design Method of Mix Ratio of Manufactured Sand Concrete; Beijing University of Civil Engineering and Architecture: Beijing, China, 2025; Volume 202, pp. 1–5. [Google Scholar]

- Yan, Y.; Tao, S.; Zhuang, Z.; Cui, Z. Optimization design and experiment of mixing ratio of sand concrete with pumping mechanism. Concrete 2022, 2, 121–126. [Google Scholar]

- Song, S.; Zhang, Z.; Zhuang, K. Study on the influence of limestone sand gradation on the performance of flow concrete. Concrete 2021, 11, 108–111+116. [Google Scholar]

- Zhang, S.; Yang, X.; Zhou, J.; Qin, Q. Mix ratio design and microstructure analysis of high-strength self-compacting-mortar with manufactured sand. Concrete 2022, 2, 140–144+154. [Google Scholar]

- GB/T 14684-2022; Sand for Construction. China Academy of Building Research: Beijing, China, 2022.

- JGJ52-2006; Standard for Quality and Inspection Methods of Sand and Stone for Ordinary Concrete. China Academy of Building Research: Beijing, China, 2006.

- JGJ55-2011; Specification for Mix Proportion Design of Ordinary Concrete. China Academy of Building Research: Beijing, China, 2011.

- GB/T50081-2019; Standard for Test Methods of Mechanical Properties of Ordinary Concrete. China Academy of Building Research: Beijing, China, 2019.

- GB/T 50080-2016; Standard for Performance Test Methods of Ordinary Concrete Mixes. China Academy of Building Research: Beijing, China, 2016.

| No. | Kind of Material | Information or Remark |

|---|---|---|

| 1 | Cement | P.O 52.5 ordinary Portland cement |

| 2 | Fly Ash | Grade II fly ash |

| 3 | Fine Aggregate | mechanism sand (0.75–4.75 mm)—Qiubei, Yunnan |

| river sand (0.75–4.75 mm)—Honghe, Yunnan | ||

| 4 | Coarse Aggregate | mechanism sand (5.0–20.00 mm) |

| 5 | Admixture | HY-PI high-performance water reducer with a water reduction rate of 27.5% |

| 6 | water | tap water (pH ≈ 7) |

| Chemical Components (g/kg) | |||||||

|---|---|---|---|---|---|---|---|

| Ca | Si | Al | S | Fe | Mg | K | Ti |

| 314.3 | 43.4 | 5.9 | 16.7 | 0.0 | 0.0 | 7.3 | 1.3 |

| Chemical Components (g/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|

| fly ash | Ca | Si | Al | S | Fe | Mg | K | Ti |

| 7.5 | 58.8 | 14.0 | 2.1 | 65.1 | 0.0 | 13.6 | 9.8 | |

| ID | Water–Binder Ratio | Total Cementitious Materials Content (kg/m3) | Cement | Fly Ash (kg/m3) | Manufactured Sand (kg/m3) | River Sand (kg/m3) | Coarse Aggregate (kg/m3) | Water (kg/m3) | Water Reducer (kg/m3) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.75–4.75 mm | 0.75–4.75 mm | 5–10 mm | 10–20 mm | |||||||

| R | 0.33 | 480.0 | 432.0 | 48.0 | 0.0 | 839.7 | 308.8 | 926.5 | 158.0 | 5.9 |

| RM-50% | 0.33 | 480.0 | 432.0 | 48.0 | 419.8 | 419.8 | 308.8 | 926.5 | 158.0 | 5.9 |

| RM-70% | 0.33 | 480.0 | 432.0 | 48.0 | 586.7 | 253.0 | 308.8 | 926.5 | 158.0 | 5.9 |

| M | 0.33 | 480.0 | 432.0 | 48.0 | 839.7 | 0.0 | 308.8 | 926.5 | 158.0 | 5.9 |

| M-01 | 0.32 | 495.0 | 445.5 | 49.5 | 581.9 | 251.0 | 306.3 | 918.9 | 158.0 | 6.5 |

| M-02 | 0.31 | 510.0 | 459.0 | 51.0 | 577.0 | 249.0 | 303.7 | 911.2 | 158.0 | 7.0 |

| M-03 | 0.30 | 525.0 | 472.5 | 52.5 | 572.2 | 247.0 | 301.2 | 903.6 | 158.0 | 7.3 |

| M-04 | 0.33 | 480.0 | 384.0 | 96.0 | 839.7 | 0.0 | 308.8 | 926.5 | 158.0 | 5.9 |

| M-05 | 0.33 | 480.0 | 360.0 | 120.0 | 839.7 | 0.0 | 308.8 | 926.5 | 158.0 | 5.9 |

| M-06 | 0.33 | 480.0 | 336.0 | 144.0 | 839.7 | 0.0 | 308.8 | 926.5 | 158.0 | 5.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, X.; Zhu, E.; Zhang, M.; Wu, L.; Li, P. Experimental Study on Performance of High-Performance Concrete Based on Different Fine Aggregate Systems. Buildings 2025, 15, 3386. https://doi.org/10.3390/buildings15183386

He X, Zhu E, Zhang M, Wu L, Li P. Experimental Study on Performance of High-Performance Concrete Based on Different Fine Aggregate Systems. Buildings. 2025; 15(18):3386. https://doi.org/10.3390/buildings15183386

Chicago/Turabian StyleHe, Xiaojun, Enjin Zhu, Mingxiang Zhang, Liao Wu, and Peiguo Li. 2025. "Experimental Study on Performance of High-Performance Concrete Based on Different Fine Aggregate Systems" Buildings 15, no. 18: 3386. https://doi.org/10.3390/buildings15183386

APA StyleHe, X., Zhu, E., Zhang, M., Wu, L., & Li, P. (2025). Experimental Study on Performance of High-Performance Concrete Based on Different Fine Aggregate Systems. Buildings, 15(18), 3386. https://doi.org/10.3390/buildings15183386