Shear Behavior of Large Keyed Dry Joints in Segmental Precast Bridges: Experiment, Numerical Modeling, and Capacity Prediction

Abstract

1. Introduction

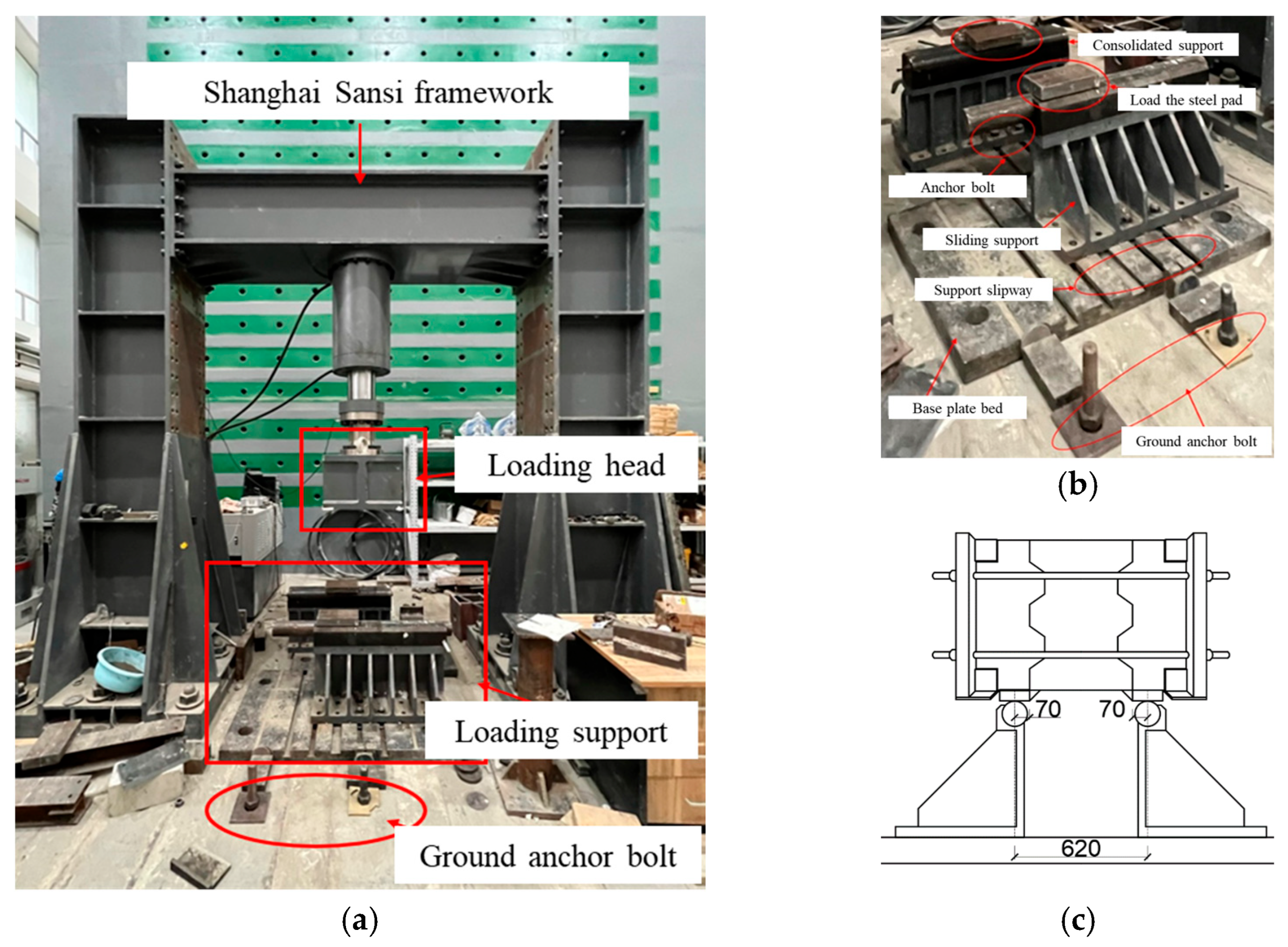

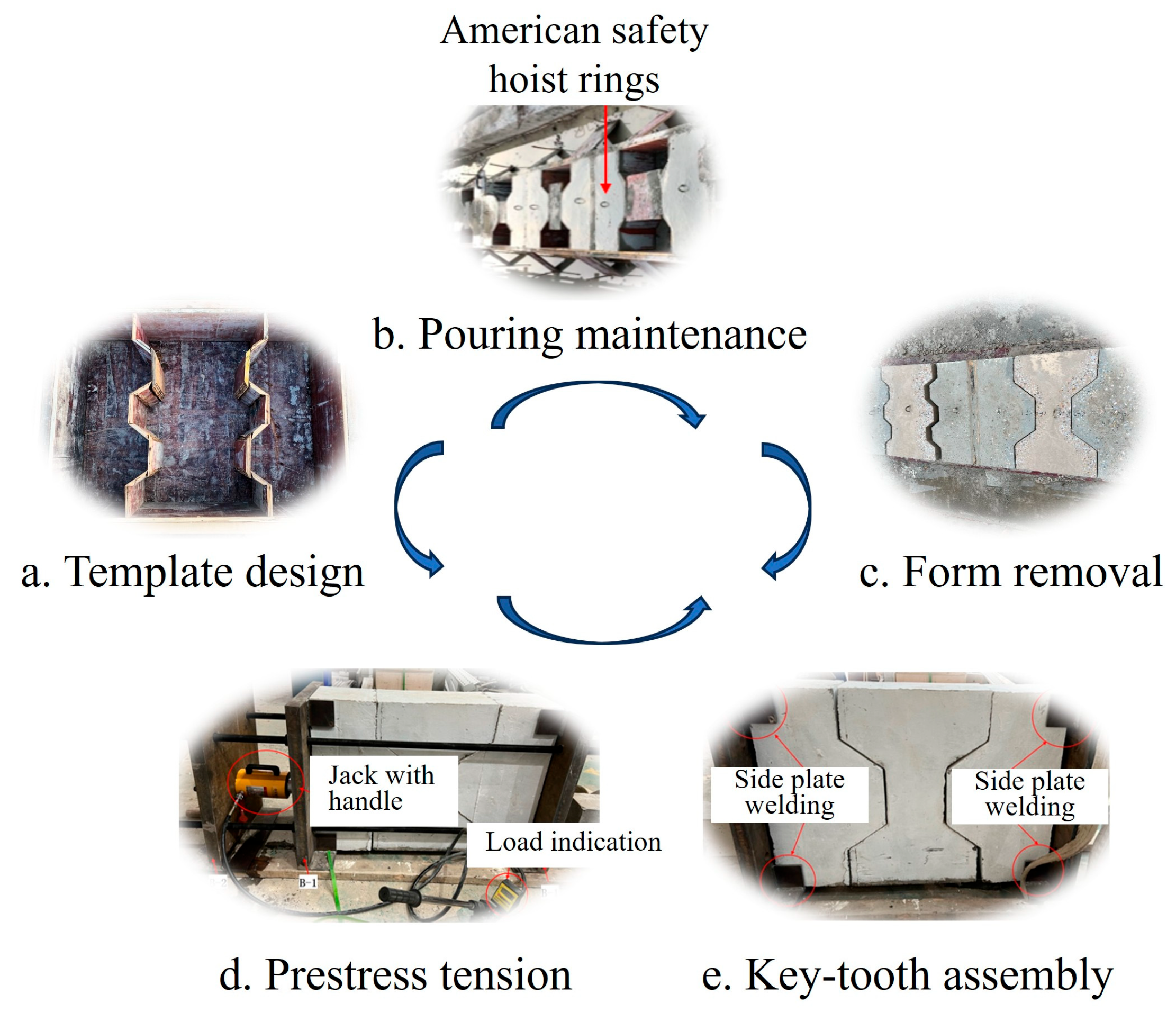

2. Experimental Program

2.1. Specimens and Parameters

2.2. Production of Key Tooth Joint Specimen

2.3. Material Property

3. Analysis and Discussion of Test Results

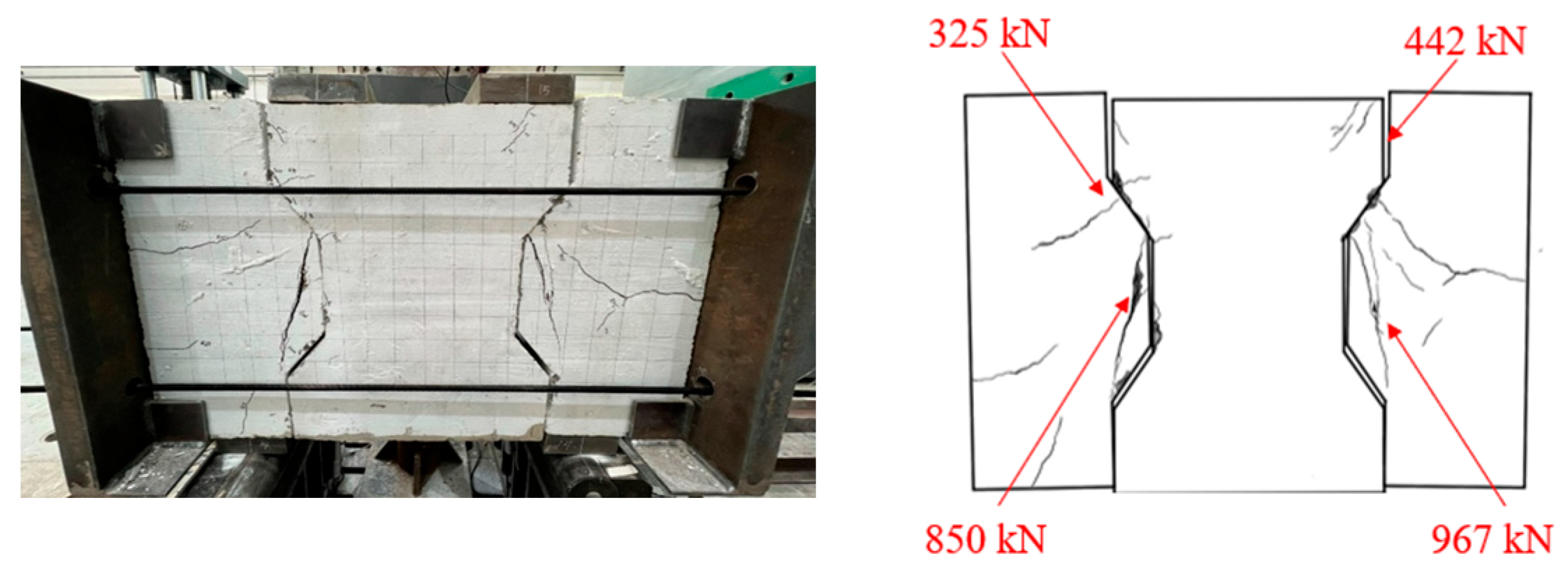

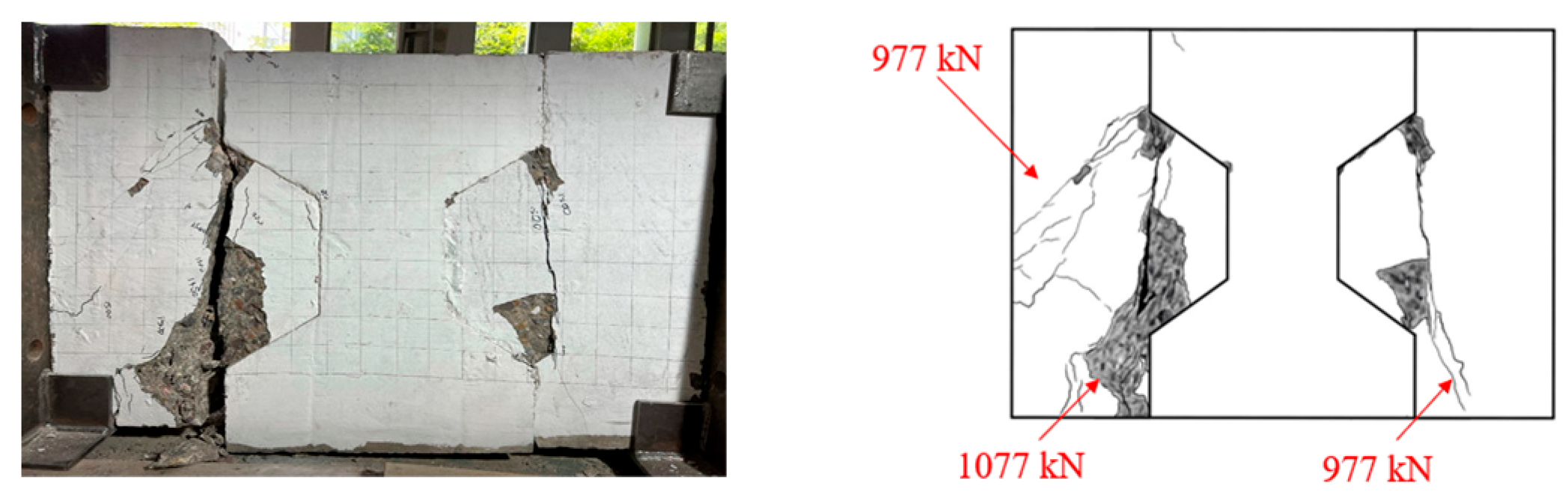

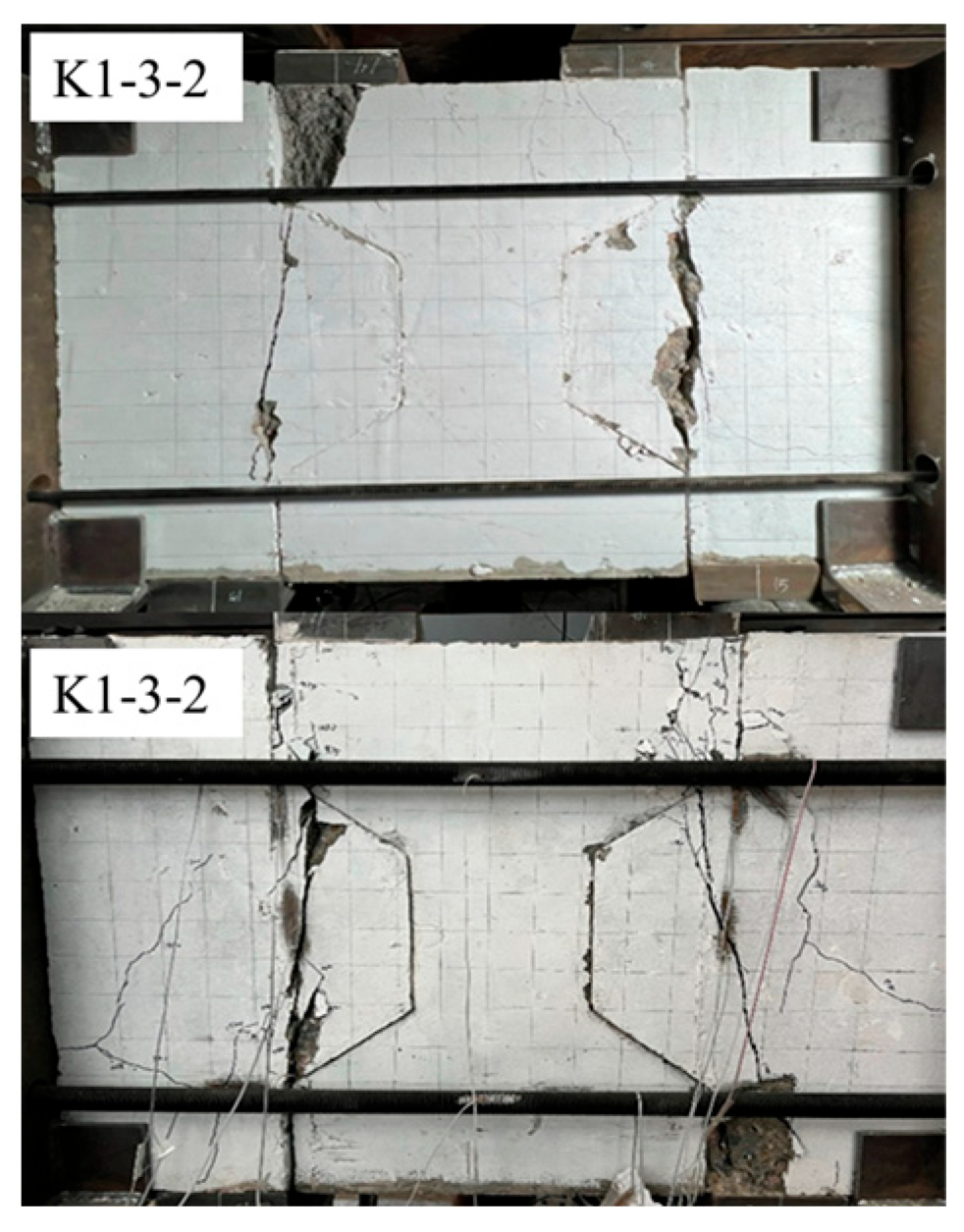

3.1. Failure Mode of Specimens

3.2. Load-Slip Curves

3.3. Analysis of Test Parameters

4. Research on Joint Flexural Shear Performance of Segmental Cap Beam

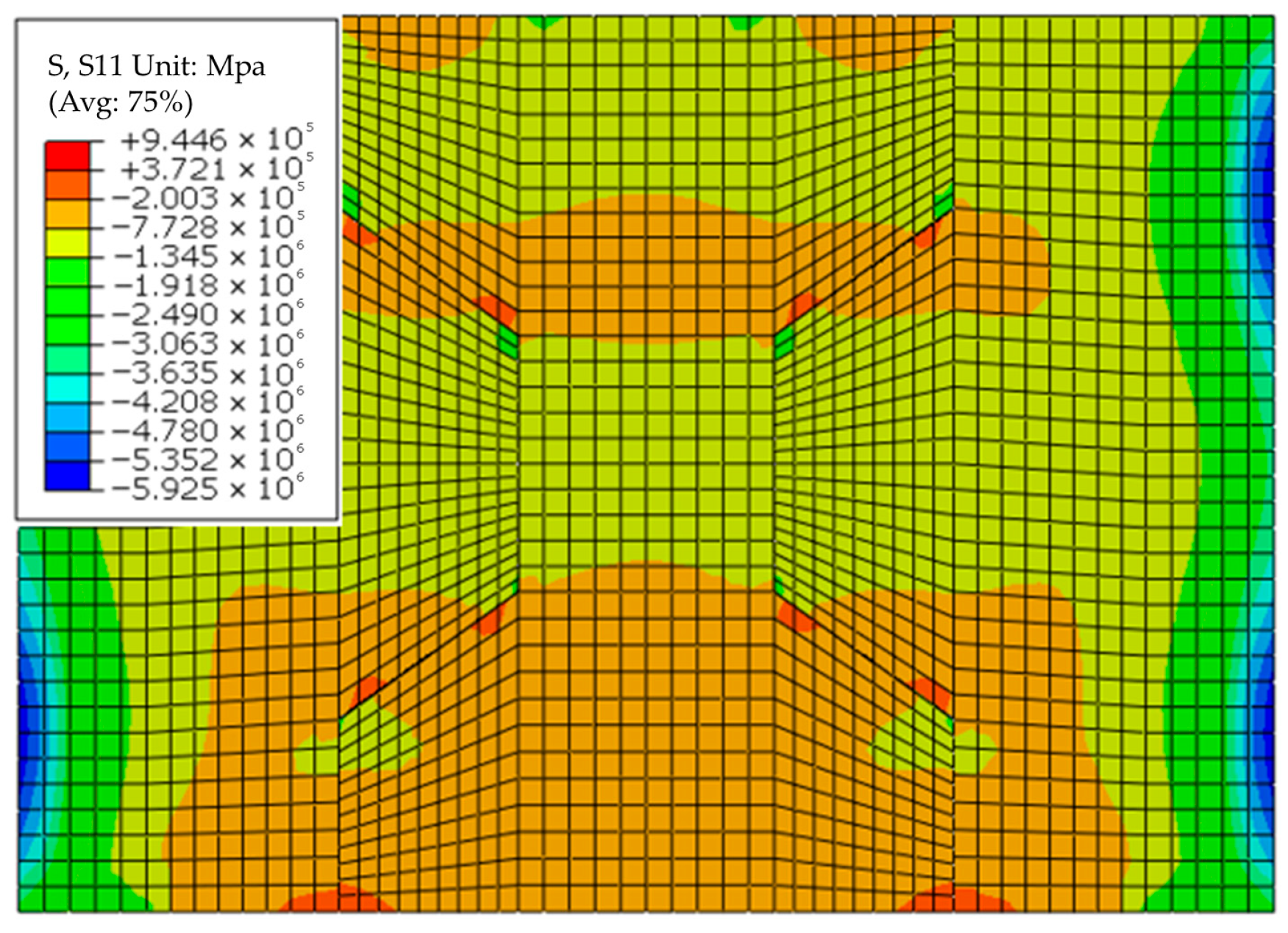

4.1. Establishment and Result Verification of Three-Segment Splicing Key Tooth Model

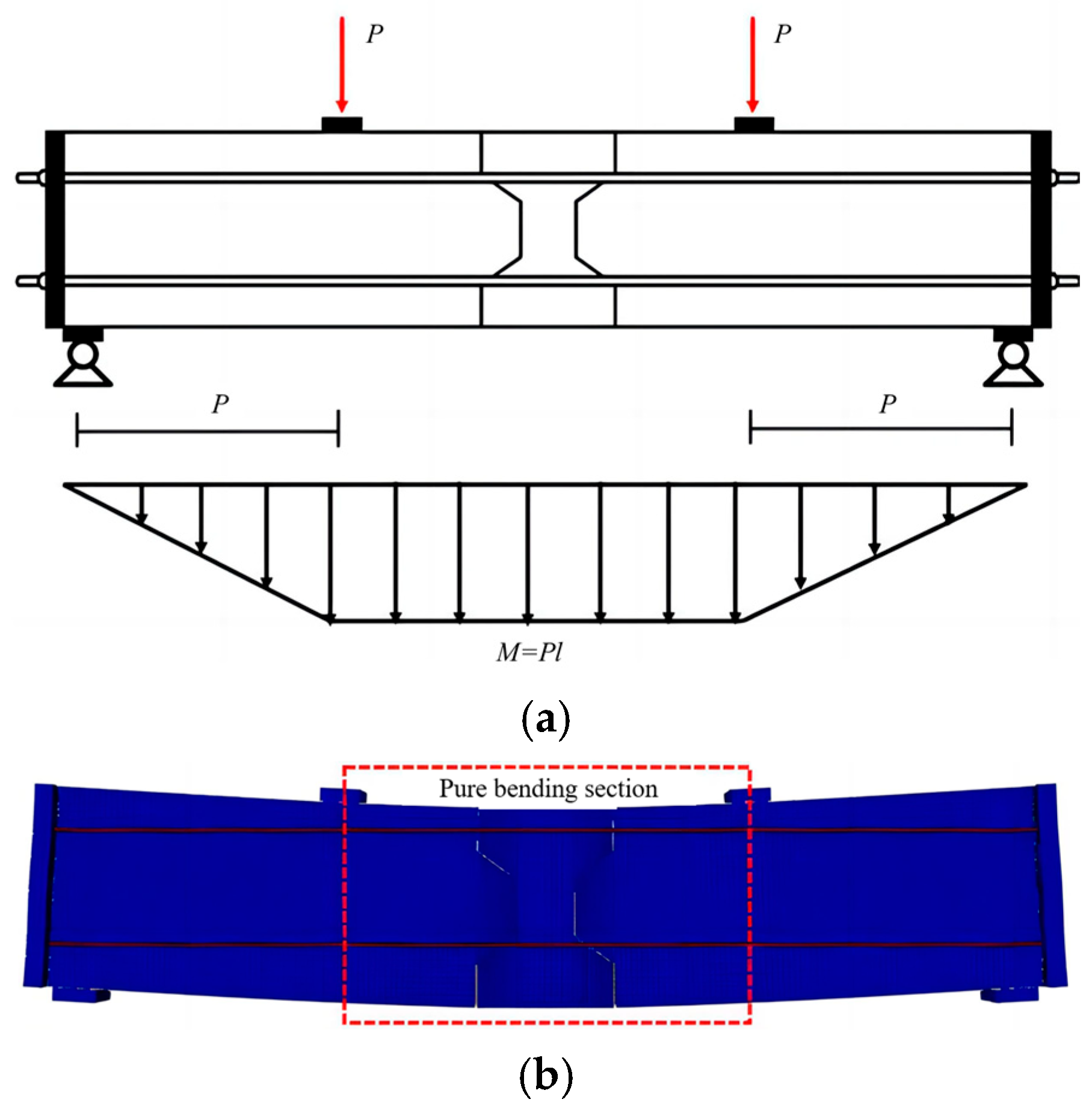

4.2. Simulation of Segmental Precast Beams

4.2.1. Finite Element Model Overview

4.2.2. Analysis of Simulation Results and Design of Shear Bearing Capacity

5. The Predicting Method for Shear Capacity of Segmental Precast Bridges

5.1. Comparison of Prediction Models

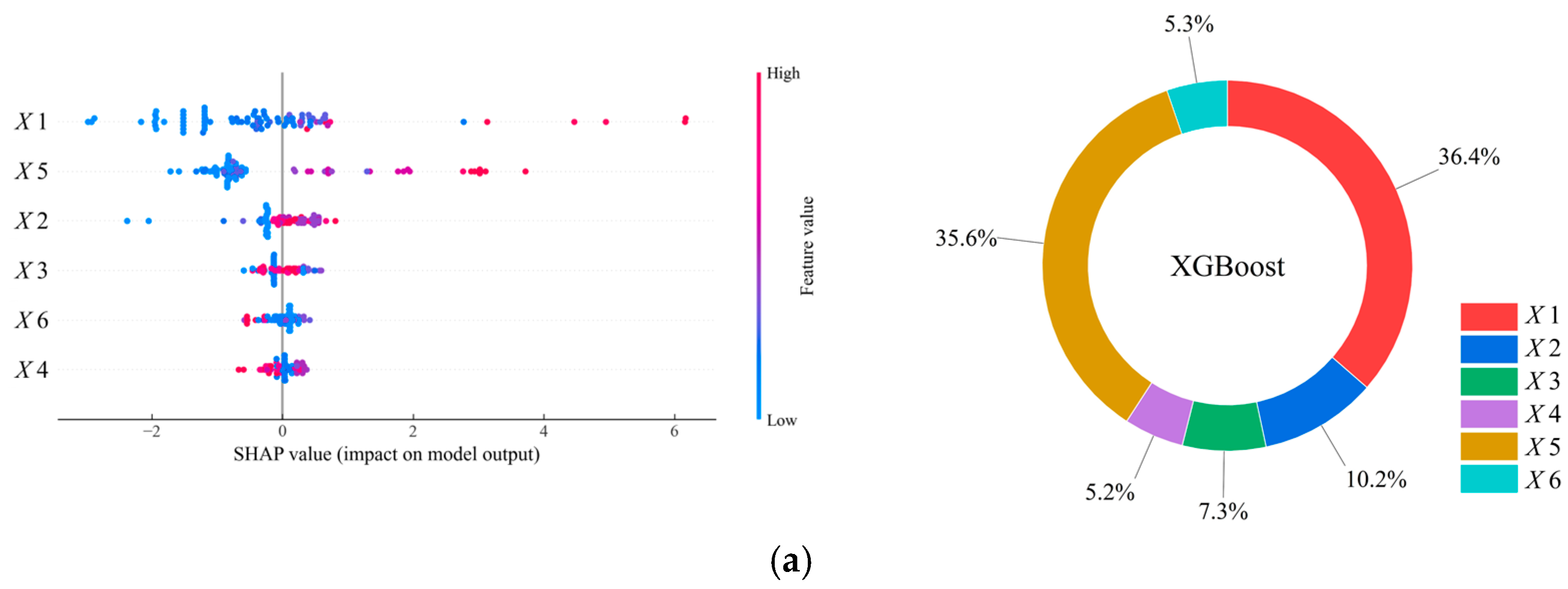

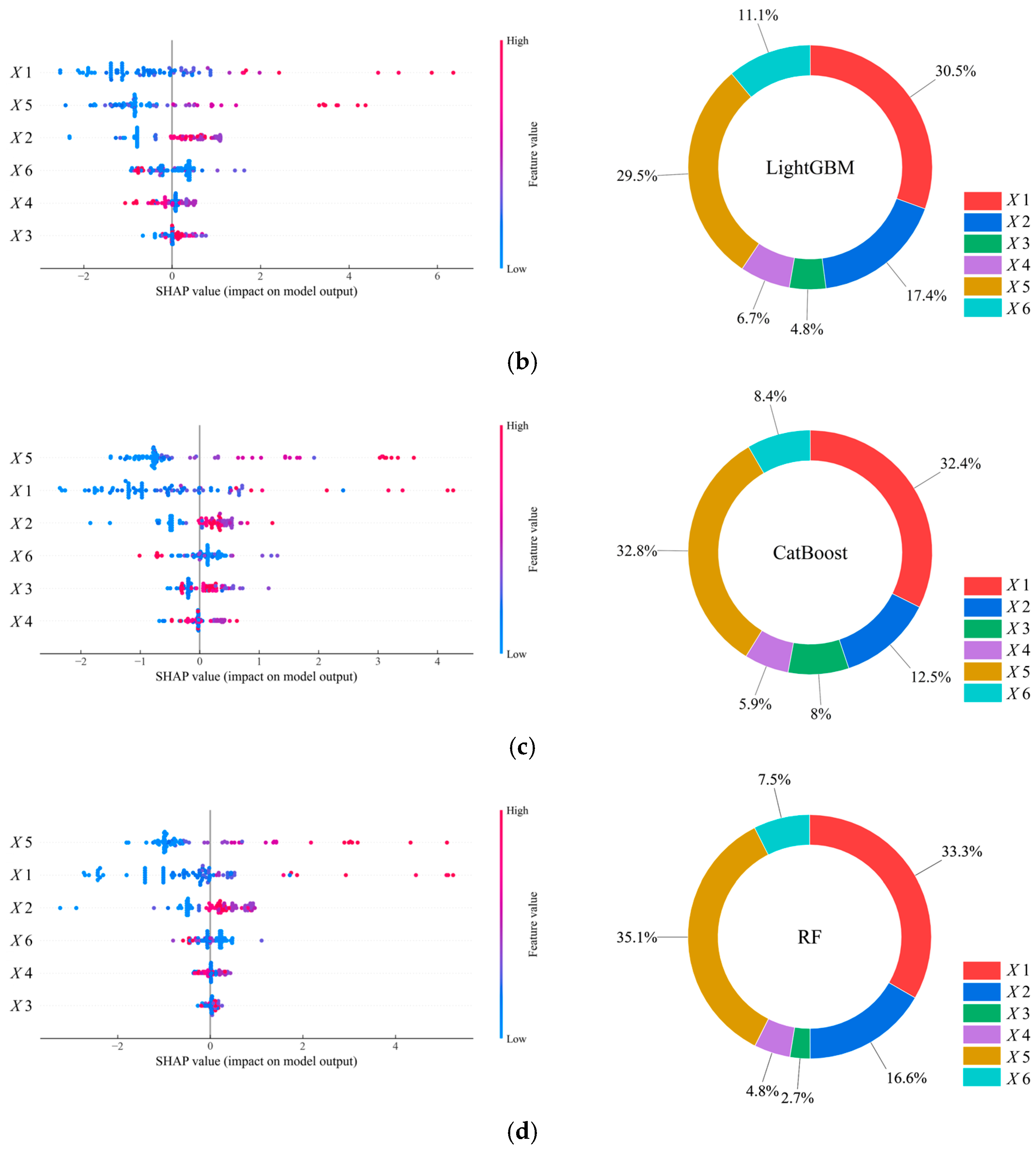

5.2. Interpretability Analysis Based on SHAP

5.3. Model Verification

6. Conclusions

- (1)

- The base height, depth-to-height ratio, and overall size of the key have an impact on the shear performance of the keyed dry joints. Increasing the overall size of the key most significantly improves its shear performance. As the base height of the key increases, the improvement in shear capacity shows a certain reduction. When the depth-to-height ratio of the key is too low, excessive relative slip may occur at the joint due to insufficient friction during shear.

- (2)

- The AASHTO specifications calculation formula for the shear capacity of keyed dry joints significantly overestimates the shear performance of the joints in beam-type structures for the given reinforcement ratios. Increasing the prestress reinforcement ratio improves both the shear capacity and displacement stiffness of the keyed dry joints. For the same joint section, a large key results in much better cracking and ultimate load capacity compared to using multiple small keys. In practical engineering, cap beams are components where cracking is not allowed, and using large keys offers better shear performance than small keys.

- (3)

- Finite element results show that the relative change in ultimate shear capacity of the segmental precast beam joint section under bending moment is less than 10% compared with the pure shear case. Moreover, the presence of bending moment slightly enhances the shear resistance of the keyed dry joint. Therefore, the shear capacity of the joint section can be reasonably designed based on its direct shear performance.

- (4)

- Comparison with experimental results reveals that the AASHTO specification formula significantly overestimates the shear strength of keyed dry joints, with the maximum error reaching 108.79%. In contrast, the machine learning models—particularly CatBoost and RF—achieve prediction errors within 10% and effectively capture nonlinear parameter interactions. Furthermore, the SHAP-based interpretability analysis identifies concrete strength and prestress level as the dominant parameters, together contributing over 60% to prediction performance. These findings confirm that ML methods not only provide higher accuracy but also deliver transparent and reliable insights, serving as a practical supplementary tool for the design and safety assessment of segmental precast bridges.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Number | X 1 | X 2 | X 3 | X 4 | X 5 | X 6 | Y |

| 1 | 56.3 | 100 | 0.50 | 0.50 | 1 | 100,000 | 8.00 |

| 2 | 56.3 | 200 | 0.57 | 0.43 | 1 | 175,000 | 8.57 |

| 3 | 44.7 | 200 | 0.57 | 0.43 | 1 | 175,000 | 8.57 |

| 4 | 56.3 | 200 | 0.57 | 0.43 | 1 | 175,000 | 7.43 |

| 5 | 68.4 | 200 | 0.57 | 0.43 | 1 | 175,000 | 7.43 |

| 6 | 56.3 | 100 | 0.57 | 0.43 | 1 | 175,000 | 6.86 |

| 7 | 60 | 50 | 0.20 | 0.80 | 2 | 75,000 | 4.88 |

| 8 | 60 | 150 | 0.60 | 0.40 | 2 | 75,000 | 6.67 |

| 9 | 60 | 150 | 0.60 | 0.40 | 2 | 75,000 | 7.44 |

| 10 | 60 | 50 | 0.60 | 0.40 | 2 | 75,000 | 6.80 |

| 11 | 63.9 | 50 | 0.60 | 0.40 | 2 | 75,000 | 6.21 |

| 12 | 63.9 | 50 | 0.20 | 0.80 | 2 | 75,000 | 4.37 |

| 13 | 63.9 | 150 | 0.60 | 0.40 | 2 | 75,000 | 8.15 |

| 14 | 29.58 | 45 | 0.56 | 0.44 | 0.05 | 115,200 | 2.45 |

| 15 | 29.58 | 45 | 0.56 | 0.44 | 0.05 | 115,200 | 2.44 |

| 16 | 29.58 | 45 | 0.56 | 0.44 | 0.05 | 115,200 | 2.35 |

| 17 | 29.58 | 45 | 0.58 | 0.42 | 0.05 | 110,880 | 2.71 |

| 18 | 29.58 | 45 | 0.58 | 0.42 | 0.05 | 110,880 | 2.69 |

| 19 | 29.58 | 45 | 0.58 | 0.42 | 0.05 | 110,880 | 2.60 |

| 20 | 49 | 35 | 0.3 | 0.5 | 1.00 | 20,000 | 4.33 |

| 21 | 49 | 35 | 0.3 | 0.5 | 2.00 | 20,000 | 5.69 |

| 22 | 48 | 25 | 0.3 | 0.5 | 1.00 | 20,000 | 4.04 |

| 23 | 48 | 50 | 0.3 | 0.5 | 1.00 | 20,000 | 4.72 |

| 24 | 55 | 35 | 0.3 | 0.5 | 1.00 | 20,000 | 5.61 |

| 25 | 49 | 35 | 0.3 | 0.6 | 1.00 | 35,000 | 4.05 |

| 26 | 49 | 35 | 0.3 | 0.6 | 2.00 | 35,000 | 5.16 |

| 27 | 41.51 | 50 | 0.50 | 0.50 | 1.00 | 20,000 | 4.48 |

| 28 | 41.51 | 50 | 0.50 | 0.50 | 2.00 | 20,000 | 5.69 |

| 29 | 40.83 | 50 | 0.50 | 0.50 | 1.00 | 20,000 | 4.04 |

| 30 | 40.83 | 50 | 0.50 | 0.50 | 1.00 | 20,000 | 4.72 |

| 31 | 41.85 | 50 | 0.57 | 0.43 | 1.00 | 35,000 | 4.05 |

| 32 | 41.85 | 50 | 0.57 | 0.43 | 2.00 | 35,000 | 5.16 |

| 33 | 42.46 | 50 | 0.57 | 0.43 | 1.00 | 35,000 | 3.93 |

| 34 | 42.46 | 50 | 0.57 | 0.43 | 1.00 | 35,000 | 3.63 |

| 35 | 41.82 | 50 | 0.60 | 0.40 | 1.00 | 50,000 | 3.63 |

| 36 | 41.82 | 50 | 0.60 | 0.40 | 2.00 | 50,000 | 4.71 |

| 37 | 50 | 35 | 0.3 | 0.6 | 1.00 | 35,000 | 3.93 |

| 38 | 50 | 35 | 0.3 | 0.6 | 1.00 | 35,000 | 3.63 |

| 39 | 49 | 35 | 0.3 | 0.6 | 1.00 | 50,000 | 3.63 |

| 40 | 49 | 35 | 0.3 | 0.6 | 2.00 | 50,000 | 4.71 |

| 41 | 50 | 30 | 0.1 | 0.4 | 0.00 | 112,500 | 6.52 |

| 42 | 50 | 30 | 0.1 | 0.4 | 0.00 | 112,500 | 6.11 |

| 43 | 50 | 30 | 0.1 | 0.4 | 0.00 | 112,500 | 5.49 |

| 44 | 58 | 30 | 0.2 | 0.2 | 0.00 | 20,000 | 6.23 |

| 45 | 58 | 30 | 0.2 | 0.2 | 0.00 | 20,000 | 6.74 |

| 46 | 58 | 30 | 0.3 | 0.3 | 0.00 | 20,000 | 6.13 |

| 47 | 58 | 30 | 0.3 | 0.3 | 0.00 | 20,000 | 5.94 |

| 48 | 58 | 30 | 0.3 | 0.3 | 0.00 | 20,000 | 7.34 |

| 49 | 58 | 30 | 0.3 | 0.3 | 0.00 | 20,000 | 6.94 |

| 50 | 58 | 30 | 0.3 | 0.3 | 0.00 | 20,000 | 8.89 |

| 51 | 58 | 30 | 0.3 | 0.3 | 0.00 | 20,000 | 9.29 |

| 52 | 58 | 30 | 0.5 | 0.5 | 0.00 | 20,000 | 7.34 |

| 53 | 58 | 30 | 0.5 | 0.5 | 0.00 | 20,000 | 7.70 |

| 54 | 42.04 | 30 | 0.3 | 0.3 | 0 | 20,000 | 5.32 |

| 55 | 42.04 | 30 | 0.3 | 0.3 | 0 | 20,000 | 6.13 |

| 56 | 42.04 | 30 | 0.5 | 0.5 | 0 | 20,000 | 6.91 |

| 57 | 42.04 | 30 | 0.5 | 0.5 | 0 | 20,000 | 7.47 |

| 58 | 42.04 | 30 | 0.3 | 0.3 | 0 | 20,000 | 5.68 |

| 59 | 42.04 | 30 | 0.3 | 0.3 | 0 | 20,000 | 7.38 |

| 60 | 42.04 | 30 | 0.5 | 0.5 | 0 | 20,000 | 7.36 |

| 61 | 42.04 | 30 | 0.5 | 0.5 | 0 | 20,000 | 7 |

| 62 | 42.04 | 30 | 0.2 | 0.2 | 0 | 20,000 | 7 |

| 63 | 42.04 | 30 | 0.2 | 0.2 | 0 | 20,000 | 7.02 |

| 64 | 42.04 | 30 | 0.3 | 0.3 | 0 | 20,000 | 7.26 |

| 65 | 42.04 | 30 | 0.3 | 0.3 | 0 | 20,000 | 7.12 |

| 66 | 42.04 | 30 | 0.3 | 0.3 | 0 | 20,000 | 7.22 |

| 67 | 42.04 | 30 | 0.3 | 0.3 | 0 | 20,000 | 8.66 |

| 68 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 6.23 |

| 69 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 6.74 |

| 70 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 6.13 |

| 71 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 5.94 |

| 72 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 7.14 |

| 73 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 7.14 |

| 74 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 8.89 |

| 75 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 9.29 |

| 76 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 7.34 |

| 77 | 54.1 | 30 | 0.0 | 0.0 | 0 | 20,000 | 7.7 |

| 78 | 74.73 | 35 | 0.3 | 0.5 | 0.5 | 20,000 | 5.88 |

| 79 | 74.73 | 35 | 0.3 | 0.5 | 1 | 20,000 | 6.94 |

| 80 | 74.73 | 35 | 0.3 | 0.5 | 2 | 20,000 | 8.37 |

| 81 | 56.84 | 35 | 0.3 | 0.5 | 0.5 | 20,000 | 6 |

| 82 | 56.84 | 35 | 0.3 | 0.5 | 1 | 20,000 | 7.36 |

| 83 | 56.84 | 35 | 0.3 | 0.5 | 2 | 20,000 | 9.3 |

| 84 | 74.73 | 35 | 0.3 | 0.6 | 0.5 | 50,000 | 4.69 |

| 85 | 74.73 | 35 | 0.3 | 0.6 | 1 | 50,000 | 5.7 |

| 86 | 74.73 | 35 | 0.3 | 0.6 | 2 | 50,000 | 7.67 |

| 87 | 52.71 | 35 | 0.3 | 0.6 | 0.5 | 50,000 | 4.56 |

| 88 | 52.71 | 35 | 0.3 | 0.6 | 1 | 50,000 | 6.43 |

| 89 | 52.71 | 35 | 0.3 | 0.6 | 2 | 50,000 | 7.99 |

| 90 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 3.87 |

| 91 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 3.87 |

| 92 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 3.87 |

| 93 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.74 |

| 94 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.74 |

| 95 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.74 |

| 96 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.76 |

| 97 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.76 |

| 98 | 27.1 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.76 |

| 99 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 5.12 |

| 100 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 5.12 |

| 101 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 5.12 |

| 102 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.13 |

| 103 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.13 |

| 104 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.13 |

| 105 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.05 |

| 106 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.05 |

| 107 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.05 |

| 108 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.13 |

| 109 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.13 |

| 110 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.13 |

| 111 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.21 |

| 112 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.21 |

| 113 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.21 |

| 114 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.59 |

| 115 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.59 |

| 116 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.59 |

| 117 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.98 |

| 118 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.98 |

| 119 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.98 |

| 120 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.21 |

| 121 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.21 |

| 122 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.21 |

| 123 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.74 |

| 124 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.74 |

| 125 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 1.74 |

| 126 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.31 |

| 127 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.31 |

| 128 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.31 |

| 129 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.44 |

| 130 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.44 |

| 131 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.44 |

| 132 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.83 |

| 133 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.83 |

| 134 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.83 |

| 135 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.97 |

| 136 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.97 |

| 137 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 6.97 |

| 138 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.78 |

| 139 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.78 |

| 140 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.78 |

| 141 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 9.13 |

| 142 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 9.13 |

| 143 | 41.9 | 10 | 0.2 | 0.2 | 0 | 10,000 | 9.13 |

| 144 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 5.47 |

| 145 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 5.47 |

| 146 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 5.47 |

| 147 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.32 |

| 148 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.32 |

| 149 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.32 |

| 150 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.27 |

| 151 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.27 |

| 152 | 33.7 | 10 | 0.2 | 0.2 | 0 | 10,000 | 8.27 |

| 153 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.47 |

| 154 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.47 |

| 155 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.47 |

| 156 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.7 |

| 157 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.7 |

| 158 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.7 |

| 159 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.23 |

| 160 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.23 |

| 161 | 36.4 | 10 | 0.2 | 0.2 | 0 | 10,000 | 2.23 |

| 162 | 82 | 30 | 0.13 | 0.4 | 0 | 112500 | 6.93 |

| 163 | 82 | 30 | 0.13 | 0.4 | 0 | 112500 | 10.91 |

| 164 | 82 | 30 | 0.13 | 0.4 | 0 | 112,500 | 7.65 |

| 165 | 82 | 30 | 0.13 | 0.4 | 0 | 112,500 | 7.73 |

| 166 | 49.9 | 30 | 0.13 | 0.4 | 0 | 112,500 | 6.92 |

| 167 | 35.5 | 60 | 0.83 | 0.83 | 0 | 18,000 | 2.18 |

| 168 | 35.5 | 60 | 0.83 | 0.83 | 0 | 18,000 | 3.48 |

| 169 | 35.5 | 60 | 0.83 | 0.83 | 0 | 18,000 | 4.12 |

| 170 | 35.5 | 60 | 0.83 | 0.83 | 0 | 18,000 | 4.99 |

| 171 | 35.5 | 60 | 0.83 | 0.83 | 0 | 18,000 | 5.28 |

| 172 | 37.5 | 60 | 0.83 | 0.83 | 0 | 18,000 | 2.18 |

| 173 | 37.5 | 60 | 0.83 | 0.83 | 0 | 18,000 | 2.92 |

| 174 | 180.2 | 5 | 0.1 | 0.1 | 0 | 20,000 | 1.46 |

| 175 | 180.2 | 5 | 0.09 | 0.1 | 0 | 20,000 | 1.93 |

| 176 | 180.2 | 5 | 0.11 | 0.1 | 0 | 20,000 | 3.01 |

| 177 | 180.2 | 5 | 0.2 | 0.2 | 0 | 20,000 | 2.03 |

| 178 | 180.2 | 5 | 0.21 | 0.2 | 0 | 20,000 | 2.34 |

| 179 | 180.2 | 10 | 0.1 | 0.1 | 0 | 20,000 | 3.18 |

| 180 | 180.2 | 10 | 0.08 | 0.1 | 0 | 20,000 | 3.98 |

| 181 | 180.2 | 10 | 0.12 | 0.1 | 0 | 20,000 | 3.6 |

| 182 | 180.2 | 10 | 0.2 | 0.2 | 0 | 20,000 | 3 |

| 183 | 180.2 | 10 | 0.18 | 0.2 | 0 | 20,000 | 3.73 |

| 184 | 180.2 | 10 | 0.22 | 0.2 | 0 | 20,000 | 3.39 |

| 185 | 180.2 | 5 | 0.3 | 0.3 | 0 | 20,000 | 3.76 |

| 186 | 180.2 | 10 | 0.4 | 0.4 | 0 | 20,000 | 3.54 |

| 187 | 61.58 | 20 | 0.5 | 0.5 | 0 | 60,000 | 4.14 |

| 188 | 61.58 | 20 | 0.5 | 0.5 | 0 | 60,000 | 4.43 |

| 189 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 5.71 |

| 190 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 6.06 |

| 191 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 8.4 |

| 192 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 9.18 |

| 193 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 7.69 |

| 194 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 7.84 |

| 195 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 7.55 |

| 196 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 7.64 |

| 197 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 8.3 |

| 198 | 128.37 | 20 | 0.5 | 0.5 | 0 | 60,000 | 9.4 |

| 199 | 120.9 | 35 | 0.25 | 0.5 | 1 | 20,000 | 11.31 |

| 200 | 120.9 | 35 | 0.25 | 0.5 | 1 | 20,000 | 12.16 |

| 201 | 120.9 | 35 | 0.25 | 0.5 | 2 | 20,000 | 13.48 |

| 202 | 120.9 | 35 | 0.25 | 0.5 | 2 | 20,000 | 13.64 |

| 203 | 114 | 35 | 0.25 | 0.5 | 1 | 20,000 | 12.72 |

| 204 | 114 | 35 | 0.25 | 0.5 | 1 | 20,000 | 12.15 |

| 205 | 114 | 35 | 0.25 | 0.5 | 2 | 20,000 | 13.88 |

| 206 | 114 | 35 | 0.25 | 0.5 | 2 | 20,000 | 14.55 |

| 207 | 120.5 | 35 | 0.3 | 0.6 | 1 | 50,000 | 10.64 |

| 208 | 120.5 | 35 | 0.3 | 0.6 | 1 | 50,000 | 10.39 |

| 209 | 120.5 | 35 | 0.3 | 0.6 | 2 | 50,000 | 14.48 |

| 210 | 120.5 | 35 | 0.3 | 0.6 | 2 | 50,000 | 14.83 |

| 211 | 121.2 | 35 | 0.3 | 0.6 | 1 | 50,000 | 11.59 |

| 212 | 121.2 | 35 | 0.3 | 0.6 | 1 | 50,000 | 11.91 |

| 213 | 121.2 | 35 | 0.3 | 0.6 | 2 | 50,000 | 14.85 |

| 214 | 121.2 | 35 | 0.3 | 0.6 | 2 | 50,000 | 15.02 |

| 215 | 152.6 | 60 | 0.33 | 0.17 | 5 | 45,000 | 17.72 |

| 216 | 152.6 | 60 | 0.33 | 0.17 | 5 | 45,000 | 20.43 |

| 217 | 152.6 | 60 | 0.33 | 0.33 | 5 | 45,000 | 21.11 |

| 218 | 152.6 | 60 | 0.33 | 0.33 | 5 | 45,000 | 18.62 |

| 219 | 152.6 | 60 | 0.33 | 0.52 | 0 | 45,000 | 19.35 |

| 220 | 152.6 | 60 | 0.33 | 0.52 | 0 | 45,000 | 19.7 |

| 221 | 152.6 | 60 | 0.33 | 0.52 | 2 | 45,000 | 11.17 |

| 222 | 152.6 | 60 | 0.33 | 0.52 | 2 | 45,000 | 11.05 |

| 223 | 152.6 | 60 | 0.33 | 0.52 | 5 | 45,000 | 16.08 |

| 224 | 152.6 | 60 | 0.33 | 0.52 | 5 | 45,000 | 16.55 |

| 225 | 152.6 | 60 | 0.33 | 0.52 | 8 | 45,000 | 22.52 |

| 226 | 152.6 | 60 | 0.33 | 0.52 | 8 | 45,000 | 23.68 |

| 227 | 152.6 | 50 | 0.33 | 0.67 | 5 | 45,000 | 15.58 |

| 228 | 152.6 | 100 | 0.33 | 0.67 | 5 | 45,000 | 15.45 |

| 229 | 152.6 | 155 | 0.33 | 0.67 | 0 | 45,000 | 8.40 |

| 230 | 152.6 | 155 | 0.33 | 0.67 | 2 | 45,000 | 12.53 |

| 231 | 152.6 | 155 | 0.33 | 0.67 | 5 | 45,000 | 16.46 |

| 232 | 152.6 | 155 | 0.33 | 0.67 | 8 | 45,000 | 19.01 |

| 233 | 109.2 | 20 | 0.05 | 0.1 | 0 | 20,000 | 3.88 |

| 234 | 109.2 | 20 | 0.07 | 0.13 | 0 | 20,000 | 4.08 |

| 235 | 109.2 | 20 | 0.1 | 0.1 | 0 | 20,000 | 2.76 |

| 236 | 109.2 | 20 | 0.13 | 0.13 | 0 | 20,000 | 3.01 |

| 237 | 109.2 | 20 | 0.15 | 0.1 | 0 | 20,000 | 4.51 |

| 238 | 109.2 | 20 | 0.18 | 0.13 | 0 | 20,000 | 4.8 |

| 239 | 109.2 | 25 | 0.06 | 0.13 | 0 | 20,000 | 4.44 |

| 240 | 109.2 | 25 | 0.03 | 0.1 | 0 | 20,000 | 4.28 |

| 241 | 109.2 | 25 | 0.13 | 0.13 | 0 | 20,000 | 3.07 |

| 242 | 109.2 | 25 | 0.1 | 0.1 | 0 | 20,000 | 2.84 |

| 243 | 109.2 | 25 | 0.17 | 0.1 | 0 | 20,000 | 4.66 |

| 244 | 109.2 | 25 | 0.19 | 0.13 | 0 | 20,000 | 4.83 |

| 245 | 109.2 | 25 | 0.38 | 0.25 | 0 | 20,000 | 6.91 |

| 246 | 109.2 | 25 | 0.58 | 0.38 | 0 | 20,000 | 7.18 |

| 247 | 109.23 | 25 | 0.03 | 0.1 | 0 | 20,000 | 3.62 |

| 248 | 109.23 | 25 | 0.06 | 0.13 | 0 | 20,000 | 5.23 |

| 249 | 109.23 | 25 | 0.1 | 0.1 | 0 | 20,000 | 3.17 |

| 250 | 109.23 | 25 | 0.13 | 0.13 | 0 | 20,000 | 4.09 |

| 251 | 109.23 | 25 | 0.17 | 0.1 | 0 | 20,000 | 5.62 |

| 252 | 109.23 | 25 | 0.19 | 0.13 | 0 | 20,000 | 5.86 |

| 253 | 109.23 | 25 | 0.06 | 0.13 | 0 | 20,000 | 5.19 |

| 254 | 109.23 | 25 | 0.03 | 0.1 | 0 | 20,000 | 4.75 |

| 255 | 109.23 | 25 | 0.13 | 0.13 | 0 | 20,000 | 5.52 |

| 256 | 109.23 | 25 | 0.1 | 0.1 | 0 | 20,000 | 5.54 |

| 257 | 109.23 | 25 | 0.17 | 0.1 | 0 | 20,000 | 5.77 |

| 258 | 109.23 | 25 | 0.19 | 0.13 | 0 | 20,000 | 4.61 |

| 259 | 24.7 | 10 | 0.11 | 0.11 | 0 | 18,000 | 1.79 |

| 260 | 24.7 | 10 | 0.11 | 0.11 | 0 | 18,000 | 1.24 |

| 261 | 24.7 | 10 | 0.11 | 0.11 | 0 | 18,000 | 1.56 |

| 262 | 24.7 | 10 | 0.17 | 0.17 | 0 | 18,000 | 1.81 |

| 263 | 24.7 | 10 | 0.17 | 0.17 | 0 | 18,000 | 1.67 |

| 264 | 24.7 | 10 | 0.17 | 0.17 | 0 | 18,000 | 1.29 |

| 265 | 24.7 | 10 | 0.22 | 0.22 | 0 | 18,000 | 1.87 |

| 266 | 24.7 | 10 | 0.22 | 0.22 | 0 | 18,000 | 2 |

| 267 | 24.7 | 10 | 0.22 | 0.22 | 0 | 18,000 | 2.21 |

| 268 | 24.7 | 10 | 0.11 | 0.11 | 0 | 18,000 | 1.79 |

| 269 | 24.7 | 10 | 0.11 | 0.11 | 0 | 18,000 | 1.8 |

| 270 | 39.81 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 6.86 |

| 271 | 39.81 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 8.25 |

| 272 | 39.81 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 8.26 |

| 273 | 39.81 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 6.86 |

| 274 | 39.81 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 8.25 |

| 275 | 39.81 | 31.8 | 0.65 | 0.35 | 2.07 | 11,614 | 8.26 |

| 276 | 41.21 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 7.25 |

| 277 | 43.66 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 7.18 |

| 278 | 43.66 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 7.18 |

| 279 | 44.35 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 6.79 |

| 280 | 44.55 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 8.87 |

| 281 | 44.55 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 10.57 |

| 282 | 44.55 | 31.8 | 0.65 | 0.35 | 2.07 | 11,614 | 8.87 |

| 283 | 44.55 | 31.8 | 0.65 | 0.35 | 3.45 | 11,614 | 10.57 |

| 284 | 45.54 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 6.10 |

| 285 | 45.54 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 6.69 |

| 286 | 45.54 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 5.99 |

| 287 | 45.54 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 6.10 |

| 288 | 45.54 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 6.69 |

| 289 | 45.54 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 5.99 |

| 290 | 45.68 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 11.29 |

| 291 | 45.68 | 31.8 | 0.65 | 0.35 | 3.45 | 11,614 | 11.29 |

| 292 | 45.82 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 10.91 |

| 293 | 45.82 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 10.55 |

| 294 | 45.82 | 31.8 | 0.65 | 0.35 | 3.45 | 11,614 | 10.91 |

| 295 | 45.82 | 31.8 | 0.65 | 0.35 | 3.45 | 11,614 | 10.55 |

| 296 | 46.14 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 10.48 |

| 297 | 46.14 | 31.8 | 0.65 | 0.35 | 3.45 | 11,614 | 10.48 |

| 298 | 46.45 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 7.34 |

| 299 | 46.45 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 8.19 |

| 300 | 46.45 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 8.74 |

| 301 | 46.45 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 7.34 |

| 302 | 46.45 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 8.19 |

| 303 | 46.45 | 31.8 | 0.65 | 0.35 | 2.07 | 11,614 | 8.74 |

| 304 | 47.50 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 5.26 |

| 305 | 47.85 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 5.34 |

| 306 | 47.85 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 9.58 |

| 307 | 48.06 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 7.85 |

| 308 | 48.06 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 8.74 |

| 309 | 48.06 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 7.85 |

| 310 | 48.06 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 8.74 |

| 311 | 48.20 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 8.64 |

| 312 | 48.2 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 8.92 |

| 313 | 48.2 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 8.92 |

| 314 | 48.34 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 9.31 |

| 315 | 48.34 | 31.8 | 0.65 | 0.35 | 2.07 | 11,614 | 9.31 |

| 316 | 49.03 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 5.64 |

| 317 | 49.75 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 5.61 |

| 318 | 50.08 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 9.57 |

| 319 | 50.29 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 10.58 |

| 320 | 50.29 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 7.65 |

| 321 | 50.29 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 9.40 |

| 322 | 50.29 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 9.40 |

| 323 | 50.29 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 7.65 |

| 324 | 50.29 | 31.8 | 0.65 | 0.35 | 2.07 | 11,614 | 9.40 |

| 325 | 50.29 | 31.8 | 0.65 | 0.35 | 2.07 | 11,614 | 9.40 |

| 326 | 50.99 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 7.31 |

| 327 | 50.99 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 7.31 |

| 328 | 53.66 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 7.68 |

| 329 | 53.66 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 8.10 |

| 330 | 53.66 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 9.22 |

| 331 | 53.66 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 7.68 |

| 332 | 53.66 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 8.10 |

| 333 | 53.66 | 31.8 | 0.65 | 0.35 | 2.07 | 11,614 | 9.22 |

| 334 | 54.34 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 9.78 |

| 335 | 55.88 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 9.30 |

| 336 | 55.88 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 11.54 |

| 337 | 55.88 | 31.8 | 0.65 | 0.35 | 1.38 | 11,614 | 9.30 |

| 338 | 55.88 | 31.8 | 0.65 | 0.35 | 3.45 | 11,614 | 11.54 |

| 339 | 56.19 | 60.0 | 0.65 | 0.35 | 1.38 | 11,614 | 6.70 |

| 340 | 56.19 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 7.29 |

| 341 | 56.58 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 7.19 |

| 342 | 56.58 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 7.19 |

| 343 | 56.86 | 60.0 | 0.65 | 0.35 | 3.45 | 11,614 | 11.18 |

| 344 | 56.86 | 31.8 | 0.65 | 0.35 | 3.45 | 11,614 | 11.18 |

| 345 | 57.07 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 5.81 |

| 346 | 69.15 | 60.0 | 0.65 | 0.35 | 2.07 | 11,614 | 11.05 |

| 347 | 69.15 | 31.8 | 0.65 | 0.35 | 2.07 | 11,614 | 11.05 |

| 348 | 69.85 | 60.0 | 0.65 | 0.35 | 0.69 | 11,614 | 9.29 |

| 349 | 69.85 | 31.8 | 0.65 | 0.35 | 0.69 | 11,614 | 9.29 |

| 350 | 38.70 | 50 | 0.50 | 0.50 | 1.00 | 50,000 | 3.86 |

| 351 | 50.00 | 50 | 0.50 | 0.50 | 1.00 | 50,000 | 4.22 |

| 352 | 56.20 | 50 | 0.50 | 0.50 | 2.00 | 50,000 | 6.70 |

| 353 | 59.60 | 50 | 0.50 | 0.50 | 2.00 | 50,000 | 6.74 |

| 354 | 80.10 | 50 | 0.50 | 0.50 | 3.00 | 50,000 | 8.96 |

| 355 | 48.80 | 50 | 0.50 | 0.50 | 3.00 | 50,000 | 7.20 |

| 356 | 37.10 | 50 | 0.50 | 0.50 | 4.00 | 50,000 | 7.08 |

| 357 | 36.60 | 50 | 0.50 | 0.50 | 4.00 | 50,000 | 7.84 |

| 358 | 37.70 | 50 | 0.50 | 0.50 | 4.50 | 50,000 | 7.50 |

| 359 | 30.20 | 50 | 0.60 | 0.40 | 0.50 | 125,000 | 2.30 |

| 360 | 53.50 | 50 | 0.60 | 0.40 | 0.50 | 125,000 | 3.14 |

| 361 | 35.70 | 50 | 0.60 | 0.40 | 1.00 | 125,000 | 3.57 |

| 362 | 35.20 | 50 | 0.60 | 0.40 | 1.00 | 125,000 | 3.50 |

| 363 | 42.20 | 50 | 0.60 | 0.40 | 1.00 | 125,000 | 3.77 |

| 364 | 59.10 | 50 | 0.60 | 0.40 | 1.50 | 125,000 | 5.29 |

| 365 | 63.70 | 50 | 0.60 | 0.40 | 2.00 | 125,000 | 5.92 |

| 366 | 42.76 | 50 | 0.68 | 0.32 | 2.00 | 70,800 | 7.06 |

| 367 | 45.82 | 50 | 0.68 | 0.32 | 3.00 | 70,800 | 7.47 |

| 368 | 43.86 | 50 | 0.68 | 0.32 | 4.00 | 70,800 | 8.26 |

| 369 | 47.35 | 50 | 0.68 | 0.32 | 2.00 | 70,800 | 7.13 |

| 370 | 46.67 | 50 | 0.68 | 0.32 | 3.00 | 70,800 | 7.47 |

| 371 | 48.54 | 50 | 0.68 | 0.32 | 4.00 | 70,800 | 8.26 |

| 372 | 41.03 | 50 | 0.50 | 0.50 | 0.50 | 20,000 | 4.10 |

| 373 | 41.03 | 50 | 0.50 | 0.50 | 1.00 | 20,000 | 4.54 |

| 374 | 41.03 | 50 | 0.50 | 0.50 | 2.00 | 20,000 | 6.35 |

| 375 | 41.03 | 50 | 0.50 | 0.50 | 0.50 | 20,000 | 4.45 |

| 376 | 41.03 | 50 | 0.50 | 0.50 | 1.00 | 20,000 | 4.68 |

| 377 | 41.03 | 50 | 0.50 | 0.50 | 2.00 | 20,000 | 6.85 |

| 378 | 44.63 | 50 | 0.50 | 0.50 | 0.50 | 30,000 | 17.00 |

| 379 | 44.63 | 50 | 0.50 | 0.50 | 1.00 | 30,000 | 5.42 |

| 380 | 44.63 | 50 | 0.50 | 0.50 | 2.00 | 30,000 | 7.37 |

| 381 | 44.63 | 50 | 0.50 | 0.50 | 0.50 | 30,000 | 4.90 |

| 382 | 44.63 | 50 | 0.50 | 0.50 | 1.00 | 30,000 | 5.84 |

| 383 | 44.63 | 50 | 0.50 | 0.50 | 2.00 | 30,000 | 7.18 |

| 384 | 45.34 | 50 | 0.50 | 0.50 | 0.50 | 40,000 | 5.59 |

| 385 | 45.34 | 50 | 0.50 | 0.50 | 1.00 | 40,000 | 5.56 |

| 386 | 45.34 | 50 | 0.50 | 0.50 | 2.00 | 40,000 | 7.67 |

| 387 | 45.34 | 50 | 0.50 | 0.50 | 0.50 | 40,000 | 3.80 |

| 388 | 45.34 | 50 | 0.50 | 0.50 | 1.00 | 40,000 | 14.55 |

| 389 | 45.34 | 50 | 0.50 | 0.50 | 2.00 | 40,000 | 7.93 |

| 390 | 44.95 | 50 | 0.50 | 0.50 | 0.50 | 20,000 | 4.07 |

| 391 | 44.95 | 50 | 0.50 | 0.50 | 1.00 | 20,000 | 5.55 |

| 392 | 44.95 | 50 | 0.50 | 0.50 | 2.00 | 20,000 | 6.92 |

| 393 | 44.95 | 50 | 0.50 | 0.50 | 0.50 | 20,000 | 4.58 |

| 394 | 44.95 | 50 | 0.50 | 0.50 | 1.00 | 20,000 | 4.53 |

| 395 | 44.95 | 50 | 0.50 | 0.50 | 2.00 | 20,000 | 6.15 |

| 396 | 46.54 | 50 | 0.50 | 0.50 | 0.50 | 30,000 | 4.59 |

| 397 | 46.54 | 50 | 0.50 | 0.50 | 1.00 | 30,000 | 5.52 |

| 398 | 46.54 | 50 | 0.50 | 0.50 | 2.00 | 30,000 | 7.02 |

| 399 | 46.54 | 50 | 0.50 | 0.50 | 0.50 | 30,000 | 5.26 |

| 400 | 46.54 | 50 | 0.50 | 0.50 | 1.00 | 30,000 | 6.12 |

| 401 | 46.54 | 50 | 0.50 | 0.50 | 2.00 | 30,000 | 7.41 |

| 402 | 46.37 | 50 | 0.50 | 0.50 | 0.50 | 40,000 | 5.43 |

| 403 | 46.37 | 50 | 0.50 | 0.50 | 1.00 | 40,000 | 4.80 |

| 404 | 46.37 | 50 | 0.50 | 0.50 | 2.00 | 40,000 | 7.08 |

| 405 | 46.37 | 50 | 0.50 | 0.50 | 0.50 | 40,000 | 4.66 |

| 406 | 46.37 | 50 | 0.50 | 0.50 | 1.00 | 40,000 | 6.25 |

| 407 | 46.37 | 50 | 0.50 | 0.50 | 2.00 | 40,000 | 7.33 |

| 408 | 50 | 40 | 0.50 | 0.50 | 0 | 32,000 | 3.39 |

| 409 | 50 | 40 | 0.50 | 0.50 | 1 | 32,000 | 4.48 |

| 410 | 50 | 40 | 0.50 | 0.50 | 2 | 32,000 | 7.51 |

| 411 | 125.6 | 130 | 0.50 | 0.50 | 0.1 | 18,000 | 5.68 |

| 412 | 130.4 | 130 | 0.50 | 0.50 | 8 | 18,000 | 11.45 |

| 413 | 129.8 | 130 | 0.50 | 0.50 | 16 | 18,000 | 18.11 |

| 414 | 148.2 | 130 | 0.50 | 0.50 | 30 | 18,000 | 32.87 |

| 415 | 121.6 | 55 | 0.50 | 0.50 | 0.1 | 18,000 | 6.62 |

| 416 | 123.1 | 55 | 0.50 | 0.50 | 8 | 18,000 | 14.67 |

| 417 | 130.4 | 55 | 0.50 | 0.50 | 16 | 18,000 | 22.61 |

| 418 | 145.3 | 55 | 0.50 | 0.50 | 30 | 18,000 | 40.03 |

| 419 | 131.7 | 120 | 0.69 | 0.31 | 2 | 78,000 | 9.23 |

| 420 | 131.7 | 40 | 0.67 | 0.33 | 2 | 54,000 | 12.16 |

| 421 | 131.7 | 40 | 0.69 | 0.31 | 2 | 78,000 | 9.03 |

| 422 | 59.9 | 120 | 0.69 | 0.31 | 2 | 78,000 | 8.30 |

| 423 | 59.9 | 40 | 0.67 | 0.33 | 2 | 54,000 | 6.76 |

| 424 | 59.9 | 40 | 0.69 | 0.31 | 2 | 78,000 | 7.12 |

| 425 | 51.4 | 120 | 0.69 | 0.31 | 2 | 78,000 | 6.61 |

| 426 | 51.4 | 40 | 0.67 | 0.33 | 2 | 54,000 | 6.26 |

| 427 | 51.4 | 40 | 0.69 | 0.31 | 2 | 78,000 | 5.94 |

| 428 | 168 | 30 | 0.20 | 0.80 | 9 | 42,000 | 27.86 |

| 429 | 168 | 30 | 0.60 | 0.40 | 9 | 42,000 | 44.64 |

| 430 | 160 | 50 | 0.50 | 0.50 | 3 | 24,000 | 25.99 |

| 431 | 141.6 | 50 | 0.49 | 0.51 | 7.5 | 41,000 | 51.71 |

| 432 | 65.19 | 75 | 0.44 | 0.56 | 1 | 136,000 | 3.51 |

| 433 | 65.19 | 75 | 0.44 | 0.56 | 2 | 136,000 | 4.74 |

| 434 | 29.58 | 45 | 0.53 | 0.47 | 0.05 | 122,400 | 2.08 |

| 435 | 29.58 | 45 | 0.53 | 0.47 | 0.05 | 122,400 | 2.07 |

| 436 | 29.58 | 45 | 0.53 | 0.47 | 0.05 | 122,400 | 2.02 |

| 437 | 29.58 | 22.5 | 0.56 | 0.44 | 0.05 | 115,200 | 2.45 |

| 438 | 29.58 | 22.5 | 0.56 | 0.44 | 0.05 | 115,200 | 2.44 |

| 439 | 29.58 | 22.5 | 0.56 | 0.44 | 0.05 | 115,200 | 2.35 |

| 440 | 29.58 | 15 | 0.58 | 0.42 | 0.05 | 110,880 | 2.71 |

| 441 | 29.58 | 15 | 0.58 | 0.42 | 0.05 | 110,880 | 2.69 |

| 442 | 29.58 | 15 | 0.58 | 0.42 | 0.05 | 110,880 | 2.60 |

References

- Ahmed, G.H.; Aziz, O.Q. Shear strength of joints in precast posttensioned segmental bridges during 1959–2019, review and analysis. Structures 2019, 20, 527–542. [Google Scholar] [CrossRef]

- Voo, Y.L.; Foster, S.J.; Voo, C.C. Ultrahigh-performance concrete segmental bridge technology: Toward sustainable bridge construction. J. Bridge Eng. 2015, 20, B5014001. [Google Scholar] [CrossRef]

- Zucca, M.; Tattoni, S.; Di Castri, M.; Simoncelli, M. On the collapse of a post-tensioned reinforced concrete truss bridge during the construction phases. Eng. Fail. Anal. 2024, 158, 107999. [Google Scholar] [CrossRef]

- Li, G.; Yang, D.; Lei, Y. Combined shear and bending behavior of joints in precast concrete segmental beams with external tendons. J. Bridge Eng. 2013, 18, 1042–1052. [Google Scholar] [CrossRef]

- Jiang, H.; Huang, C.; Mei, G.; Gao, X.; Tian, Y.; Sun, X. Experimental and numerical investigations on direct shear performance of UHPC dry joints. Eng. Struct. 2023, 283, 115872. [Google Scholar] [CrossRef]

- Yuan, A.; Yang, C.; Wang, J.; Chen, L.; Lu, R. Shear behavior of epoxy resin joints in precast concrete segmental bridges. J. Bridge Eng. 2019, 24, 04019009. [Google Scholar] [CrossRef]

- Ahmed, G.H.; Aziz, O.Q. Influence of intensity & eccentricity of posttensioning force and concrete strength on shear behavior of epoxied joints in segmental box girder bridges. Constr. Build. Mater. 2019, 197, 117–129. [Google Scholar] [CrossRef]

- Wu, J.; Liu, D.; Chen, X.; Zhang, J. Experimental study on shear performance of bond-tooth dry joints in prestressed assembled concrete beams. J. Build. Eng. 2023, 68, 106189. [Google Scholar] [CrossRef]

- Buyukozturk, O.; Bakhoum, M.M.; Michael Beattie, S. Shear behavior of joints in precast concrete segmental bridges. J. Struct. Eng. 1990, 116, 3380–3401. [Google Scholar] [CrossRef]

- Issa, M.A.; Abdalla, H.A. Structural behavior of single key joints in precast concrete segmental bridges. J. Bridge Eng. 2007, 12, 315–324. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, D. Shear behavior of steel keyed joints in precast concrete segmental bridges under direct shear loading. Struct. Concr. 2022, 23, 2710–2731. [Google Scholar] [CrossRef]

- Jiang, H.; Huang, C.; Feng, J.; Gao, X.; Wang, T.; Zhong, Z. Direct shear behavior of castellated dry RPC joints in precast concrete segmental bridges. Structures 2021, 33, 4579–4595. [Google Scholar] [CrossRef]

- Ahmed, G.H.; Aziz, O.Q. Shear behavior of dry and epoxied joints in precast concrete segmental box girder bridges under direct shear loading. Eng. Struct. 2019, 182, 89–100. [Google Scholar] [CrossRef]

- Ye, M.; Li, L.; Yoo, D.Y.; Li, H.; Shao, X.; Zhou, C. Mechanistic understanding of precast UHPC segmental beams with external tendons and epoxy joints subject to combined bending and shear. Eng. Struct. 2023, 280, 115698. [Google Scholar] [CrossRef]

- Zhan, Y.; Li, Z.; Chen, Z.; Shao, J.; Yue, F.; Liu, F.; Ma, Z.J. Experimental and numerical investigations on shear performance of key tooth joints of precast concrete segmental bridge under repeated loading. Constr. Build. Mater. 2022, 351, 128794. [Google Scholar] [CrossRef]

- Lu, W.; Li, F.; Zhu, L.; Wen, C.; Peng, W. Experimental study on the shear behavior of precast concrete segmental simply supported beam with internal tendons and glue joints. Case Stud. Constr. Mater. 2022, 17, e01545. [Google Scholar] [CrossRef]

- Bu, Z.Y.; Wu, W.Y. Inter shear transfer of unbonded prestressing precast segmental bridge column dry joints. Eng. Struct. 2018, 154, 52–65. [Google Scholar] [CrossRef]

- Zhan, Y.; Li, Z.; Chen, Z.; Shao, J.; Yue, F.; Ma, Z.J.; Zhao, S. Experimental and numerical investigations on shear behavior of large keyed tooth joints. Constr. Build. Mater. 2022, 344, 128200. [Google Scholar] [CrossRef]

- Yuan, A.; Zhao, X.; Lu, R. Experimental investigation on shear performance of fiber-reinforced high-strength concrete dry joints. Eng. Struct. 2020, 223, 111159. [Google Scholar] [CrossRef]

- Shamass, R.; Zhou, X.; Alfano, G. Finite-element analysis of shear-off failure of keyed dry joints in precast concrete segmental bridges. J. Bridge Eng. 2015, 20, 04014084. [Google Scholar] [CrossRef]

- Chen, G.; Fang, Z.; Wang, S.; Jiang, H.; Liang, H. Numerical analysis on shear behavior of joints under low confining and eccentric loads. Adv. Civ. Eng. 2019, 2019, 4589824. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, S.; Fang, Z.; Chen, G.; Li, J. Numerical analysis on the shear behavior of single-keyed dry joints in precast high-strength concrete segmental bridges. Math. Biosci. Eng. 2019, 16, 3144–3168. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, D. Experimental study on shear behavior of joints in precast concrete segmental bridges. Structures 2022, 39, 323–336. [Google Scholar] [CrossRef]

- Feng, Z.; Li, C.; Ke, L.; Yoo, D.Y. Experimental and numerical investigations on flexural performance of ultra-high-performance concrete (UHPC) beams with wet joints. Structures 2022, 45, 199–213. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Z.; Guo, J.; Wang, J. Shear strength of dry joints in precast UHPC segmental bridges: Experimental and theoretical research. J. Bridge Eng. 2019, 24, 04018100. [Google Scholar] [CrossRef]

- ACI318-14; Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary (ACI 318R-14). American Concrete Institute (ACI): Farmington Hills, MI, USA, 2014.

- Precast/Prestressed Concrete Institute. PCI Manual: PCI Design Handbook: Precast and Prestressed Concrete, 8th ed.; Precast/Prestressed Concrete Institute: Chicago, IL, USA, 2017. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD Standards: AASHTO, AASHTO LRFD Bridge Design Specifications; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2024. [Google Scholar]

- Kim, Y.J.; Chin, W.J.; Jeon, S.J. Interface Shear Strength at Various Joint Types in High-Strength Precast Concrete Structures. Materials 2020, 13, 4364. [Google Scholar] [CrossRef]

- Choi, J.S.; Lee, H.J.; Yuan, T.F.; Yoon, Y.S. Shear strength of steel fiber reinforced lightweight self-consolidating concrete joints under monotonic and cyclic loading. Constr. Build. Mater. 2023, 363, 129829. [Google Scholar] [CrossRef]

- Zhong, Z.; Zhao, S.; Xia, J.; Luo, Q.; Zhou, Q.; Yang, S.; He, F.; Yao, Y. Regression prediction model for shear strength of cold joint in concrete. Structures 2024, 68, 107168. [Google Scholar] [CrossRef]

- Billington, S.; Barnes, R.; Breen, J. A Precast Substructure Design for Standard Bridge Systems; University of Texas at Austin, Center for Transportation Research: Austin, TX, USA, 1998. [Google Scholar]

- Koseki, K.; Breen, J.E. Exploratory Study of Shear Strength of Joints for Precast Segmental Bridges; Computer Microfilm International: Houston, TX, USA, 1983. [Google Scholar]

- Jiang, H.; Chen, L.; Ma, Z.J.; Feng, W. Shear behavior of dry joints with castellated keys in precast concrete segmental bridges. J. Bridge Eng. 2015, 20, 04014062. [Google Scholar] [CrossRef]

- Gao, F. Research on the Bending Safety Performance of Large Cantilever Prefabricated and Assembled Cap Beams. Master’s Thesis, Shanghai Institute of Technology, Shanghai, China, 2019. (In Chinese). [Google Scholar]

- Marzouk, M.; Elhakeem, A.; Adel, K. Artificial neural networks applications in construction and building engineering (1991–2021): Science mapping and visualization. Appl. Soft Comput. 2024, 152, 111174. [Google Scholar] [CrossRef]

- Dikshit, A.; Pradhan, B.; Santosh, M. Artificial neural networks in drought prediction in the 21st century—A scientometric analysis. Appl. Soft Comput. 2022, 114, 108080. [Google Scholar] [CrossRef]

- Jacobsen, E.L.; Teizer, J. Deep learning in construction: Review of applications and potential avenues. J. Comput. Civ. Eng. 2022, 36, 03121001. [Google Scholar] [CrossRef]

- Ge, P.; Yang, O.; He, J.; Zhang, K.; Wu, S. A machine learning based method for predicting the shear strength of Fiber-Reinforced Concrete joints in precast segmental bridges. Eng. Struct. 2024, 302, 117324. [Google Scholar] [CrossRef]

- Freed, Y. Machine Learning-Based predictions of crack growth rates in an aeronautical aluminum alloy. Theor. Appl. Fract. Mech. 2024, 130, 104278. [Google Scholar] [CrossRef]

- Fang, X.; Wang, C.; Li, H.; Wang, X.; Zhang, S.; Luo, X.; Jia, H. Influence of mesoscopic pore characteristics on the splitting-tensile strength of cellular concrete through deep-learning based image segmentation. Constr. Build. Mater. 2022, 315, 125335. [Google Scholar] [CrossRef]

- Rabi, M.; Jweihan, Y.S.; Abarkan, I.; Ferreira, F.P.V.; Shamass, R.; Limbachiya, V.; Tsavdaridis, K.D.; Santos, L.F.P. Machine learning-driven web-post buckling resistance prediction for high-strength steel beams with elliptically-based web openings. Results Eng. 2024, 21, 101749. [Google Scholar] [CrossRef]

- Ma, C.; Chi, J.W.; Kong, F.C.; Zhou, S.H.; Lu, D.C.; Liao, W.Z. Prediction on the seismic performance limits of reinforced concrete columns based on machine learning method. Soil Dyn. Earthq. Eng. 2024, 177, 108423. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Z.; Zeng, J.; Wang, J. Machine-learning-based models to predict shear transfer strength of concrete joints. Eng. Struct. 2021, 249, 113253. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, W.; Wang, S.; Du, D.; Tang, J. Seismic response prediction of a damped structure based on data-driven machine learning methods. Eng. Struct. 2024, 301, 117264. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. China Construction Industry Press: Beijing, China, 2014.

- JTG 3362-2018; Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts. China Communications Press: Beijing, China, 2018.

- Chen, L. Research on Shear Behavior of Dry Joints in Precast Segmental Concrete Bridges. Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2013. (In Chinese). [Google Scholar]

- Zhao, Y.; Zou, R.B.; Zhang, Z.P. Experimental investigation on interface between concretes cast at different times with high strength steel bars under direct shear load. J. Build. Struct. 2015, 36, 346–353. (In Chinese) [Google Scholar]

- Fang, X. The Experimental Research on Shear Behavior of the Groove Interface with Rebar Between New and Existing Concrete (C30). Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2016. (In Chinese). [Google Scholar]

- Jiang, H.B.; Fang, X.; Guo, W.H. Experimental study on shear behavior of grooved interface between newly poured and existing concrete with reinforcement in bridge rehabilitation. J. Highw. Transp. Res. Dev. 2016, 33, 68–75. (In Chinese) [Google Scholar]

- Wei, R.B. Research on Shear Behavior of Multiple–Keyed Dry Joint of C40 SFR Concrete. Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2016. (In Chinese). [Google Scholar]

- Xiao, J.W. Experimental Study on Shear Bond Between Self Compacting Concrete and Old Concrete Z Specimen. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2017. (In Chinese). [Google Scholar]

- Zhao, Y.; Zou, R.B. Experimental investigation on interface of high strength concretes cast at different times under direct shear. J. Tongji Univ. (Nat. Sci.) 2017, 45, 962–969. (In Chinese) [Google Scholar]

- Cui, T.; He, H.X.; Yan, W.M.; Qian, Z.Z.; Zhou, D.X. Shear resistance property of ECC–existing concrete interface. J. Build. Mater. 2020, 23, 1030–1037. (In Chinese) [Google Scholar]

- Yang, J.; Zhou, J.T.; Zhang, Z.Y.; Zhano, P. Shear performance of keyway interface between UHPC and normal concrete. China J. Highw. Transp. 2021, 34, 132–144. (In Chinese) [Google Scholar]

- Qiu, L. Experimental Study on the Shear Resistance of HSC–UHPC Interfaces Cast in Different Times. Master’s Thesis, China Three Gorges University, Yichang, China, 2021. (In Chinese). [Google Scholar]

- Jiang, H.B.; Huang, C.W.; Feng, J.H.; Wang, T.; Li, P. Experimental study on direct shear behavior of dry joints of precast RPC segmental girder. J. Highw. Transp. Res. Dev. 2021, 38, 59–68. (In Chinese) [Google Scholar]

- Feng, Z.; Li, C.; Zhou, J.; Dong, C.; Ke, H.; Yoo, D.Y. Direct shear test on UHPC key–wet–joints and the unified calculation formula of direct shear capacity of UHPC wet–joints. China Civ. Eng. J. 2022, 55, 79–91. (In Chinese) [Google Scholar]

- Sun, H.C. Research on Interface Bonding Shear Characteristics of RPC–NC. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2023. (In Chinese). [Google Scholar]

- Ma, W.D. Study on the Shear Characteristics of UHPC–NC Interface. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2023. (In Chinese). [Google Scholar]

- Wang, P.; You, X.H.; Shi, Q.X.; Tao, Y. Shear behavior of rib–treated interface between ultra–high performance concrete and normal concrete. J. Civ. Environ. Eng. 2023. online first (In Chinese) [Google Scholar] [CrossRef]

- Bakhoum, M.M. Shear Behavior and Design of Joints in Precast Concrete Segmental Bridges. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1990. [Google Scholar]

- Zhou, X.; Mickleborough, N.; Li, Z. Shear strength of joints in precast concrete segmental bridges. ACI Struct. J. 2005, 102, 3. [Google Scholar] [CrossRef]

- Sun, X.S. Experimental Study on Shear Behavior of Joints in Precast Segmental Bridges. Master’s Thesis, Southeast University, Nanjing, China, 2015. (In Chinese). [Google Scholar]

- Song, S.T. Experimental Study and Theoretical Analysis in Bending and Joint Shear of High-Speed Railway Precast Segmental Concrete Box Bridges. Ph.D. Thesis, Southeast University, Nanjing, China, 2015. (In Chinese). [Google Scholar]

- Size Effect on the Shear Behavior of Single-Keyed Dry Joints in Precast Segmental Concrete Bridges. 2017. Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CPFD&dbname=CPFDLAST2017&filename=GYJZ201707001096&uniplatform=OVERSEA&v=8ZnTC3Id6dklnltboq1sa-QTVnqiDvptbmjJmR61GuF9IDzQY7IZpa0aLGPMwlBSkRTi37Bio8E%3d (accessed on 14 September 2025). (In Chinese).

- Luo, Z.; Wang, Y.; Wang, T. Shear behavior of epoxy joints in precast segmental bridges under impact loading. Eng. Struct. 2022, 269, 114641. [Google Scholar] [CrossRef]

- Zheng, H.; Cui, C.; Xuan, S.; Ma, X.; Li, Z.; Li, Y. Experimental study on direct shear performance of prefabricated splicing joints of ultrahigh-performance concrete. Case Stud. Constr. Mater. 2023, 18, e01771. [Google Scholar] [CrossRef]

- Cao, J.; Wu, F.; Fan, X.; Lei, S.; Liu, L.; Wang, X.; Peng, K. Experimental and analytical studies on direct shear performance of UHPC keyed joints. Eng. Struct. 2024, 311, 118209. [Google Scholar] [CrossRef]

- Wu, F.; Huang, L.; Liu, Z.; Cao, J.; Lei, S.; Ma, Y.; Bian, Z. Experimental investigation on shear behavior of PVA-ECC keyed joints. Eng. Struct. 2024, 309, 118071. [Google Scholar] [CrossRef]

- Zheng, F.; Jiang, J.; Li, Y.Z. Experimental Study on the Shear behavior of joints in precast segmental UHPC bridges. Highw. Eng. 2022, 47, 1–9+41. (In Chinese) [Google Scholar]

- Xu, L.Q.; Xu, Y.H.; Chen, L. Shear bearing capacity of UHPC keyed joints based on the shear-compression strength criterion. J. Southwest Jiaotong Univ. 2025, 60, 253–261. (In Chinese) [Google Scholar]

- He, F.; Zhang, Y.; Yang, J.; Qiu, J. Experimental and numerical investigation on shear performance of double-keyed epoxy UHPC joints. Railw. Constr. 2024, 64, 76–82. (In Chinese) [Google Scholar]

- Wang, H.L.; Li, B.H.; Guo, X.Y. Experimental study on shear behavior of single-keyed dry joint of precast concrete segmental bridge under combined shear and torsion. Bridge Constr. 2022, 52, 31–38. (In Chinese) [Google Scholar]

- Yuan, A.; He, Y.; Cheng, L.; Qian, S. Study on shear behavior of glued joint structure in segmental precast concrete beam. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2014, 33, 22–26+33. (In Chinese) [Google Scholar]

- Daoud, J.I. Multicollinearity and regression analysis. J. Phys. Conf. Ser. 2017, 949, 012009. [Google Scholar] [CrossRef]

- Esteghamati, M.Z.; Gernay, T.; Banerji, S. Evaluating fire resistance of timber columns using explainable machine learning models. Eng. Struct. 2023, 296, 116910. [Google Scholar] [CrossRef]

- Alabdullah, A.A.; Iqbal, M.; Zahid, M.; Khan, K.; Amin, M.N.; Jalal, F.E. Prediction of rapid chloride penetration resistance of metakaolin based high strength concrete using LightGBM and XGBoost models by incorporating SHAP analysis. Constr. Build. Mater. 2022, 345, 128296. [Google Scholar] [CrossRef]

- Suenaga, D.; Takase, Y.; Abe, T.; Orita, G.; Ando, S. Prediction accuracy of Random Forest, XGBoost, LightGBM, and artificial neural network for shear resistance of post-installed anchors. Structures 2023, 50, 1252–1263. [Google Scholar] [CrossRef]

- Nguyen-Sy, T. Optimized hybrid XGBoost-CatBoost model for enhanced prediction of concrete strength and reliability analysis using Monte Carlo simulations. Appl. Soft Comput. 2024, 167, 112490. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, G.; Huang, Y.; Aslani, F.; Nener, B. Modelling uniaxial compressive strength of lightweight self-compacting concrete using random forest regression. Constr. Build. Mater. 2019, 210, 713–719. [Google Scholar] [CrossRef]

- Liang, X. Image-based post-disaster inspection of reinforced concrete bridge systems using deep learning with Bayesian optimization. Comput.-Aided Civ. Infrastruct. Eng. 2019, 34, 415–430. [Google Scholar] [CrossRef]

- Yan, B.; Zhang, W.; Ye, Y.; Yi, W. Study on the prediction of shear capacity of new and old concrete interfaces based on explainable machine learning algorithms. Structures 2025, 71, 108065. [Google Scholar] [CrossRef]

- Liu, X.; Figueredo, G.P.; Gordon, G.S.; Thermou, G.E. Data-driven shear strength prediction of RC beams strengthened with FRCM jackets using machine learning approach. Eng. Struct. 2025, 325, 119485. [Google Scholar] [CrossRef]

- Lundberg, S. A unified approach to interpreting model predictions. arXiv 2017, arXiv:1705.07874. [Google Scholar] [CrossRef]

| Specimen Number | Thickness /mm | h/d | Concrete Grade | Prestressing Tendon Diameter/mm | Number of Tendons | Tensile Force per Tendon /kN |

|---|---|---|---|---|---|---|

| K1-1 | 250 | 0.467 | C50 | 14 | 2 | 50 |

| K1-2 | 250 | 0.253 | C50 | 14 | 4 | 43.75 |

| K1-3-1 | 250 | 0.467 | C50 | 14 | 4 | 43.75 |

| K1-3-2 | 250 | 0.467 | C50 | 20 | 4 | 43.75 |

| K1-3-3 | 250 | 0.467 | C50 | 30 | 4 | 43.75 |

| K2-1 | 250 | 0.467 | C50 | 14 | 4 | 43.75 |

| Specimen Number | Cracking Load/kN | Ultimate Load/kN | Average Shear Stress/MPa | AASHTO Calculated Values/MPa | The Ultimate Relative Slip/mm | Failure Mode |

|---|---|---|---|---|---|---|

| K1-1 | 366.47 | 571.35 | 5.71 | 9.20 | 4.74 | The key teeth are not completely broken |

| K1-2 | 602.14 | 967.43 | 5.53 | 11.55 | 12.46 | The key teeth are cut and there is large slip |

| K1-3-1 | 855.56 | 1078.90 | 6.17 | 10.36 | 6.68 | Key teeth cut |

| K1-3-2 | 905.58 | 1118.79 | 6.39 | 10.34 | 6.17 | Key teeth cut |

| K1-3-3 | 996.67 | 1186.52 | 6.78 | 10.35 | 5.58 | Key teeth cut |

| K2-1 | 453.55 | 941.78 | 5.38 | 10.35 | 7.85 | Key teeth cut |

| Specimen Number | Joint Pattern | Key Tooth Size | Prestress/MPa | Shear Span Ratio | Vertical Load/kN |

|---|---|---|---|---|---|

| M-S-1 | Single key tooth | 400 × 200 × 140 | 1 | 1.43 | 0 |

| M-S-2 | 22.075 | ||||

| M-S-3 | 45 | ||||

| M-S-4 | −22.075 |

| Specimen Number | Vertical Load/kN | Bending Moment at the Seam/kN·m | Key Tooth Limit Load/kn | Relative Displacement/mm |

|---|---|---|---|---|

| M-S-1 | 0 | 0 | 1002 | 6.60 |

| M-S-2 | 22.075 | 22.075 | 1019.63 | 6.65 |

| M-S-3 | 45 | 45 | 1058.19 | 6.83 |

| M-S-4 | −22.075 | −22.075 | 1008.29 | 6.00 |

| Model | Train | Test | ||||||

|---|---|---|---|---|---|---|---|---|

| R2 | MAE | RMSE | MAPE | R2 | MAE | RMSE | MAPE | |

| XGBoost | 0.91 | 0.69 | 1.13 | 16.16 | 0.87 | 0.93 | 1.54 | 20.34 |

| LightGBM | 0.92 | 0.59 | 1.09 | 14.56 | 0.89 | 0.94 | 1.64 | 21.91 |

| CatBoost | 0.91 | 0.71 | 1.15 | 16.57 | 0.90 | 0.88 | 1.47 | 19.56 |

| RF | 0.90 | 0.74 | 1.19 | 16.73 | 0.88 | 1.08 | 1.60 | 21.48 |

| Type | XGBoost | LightGBM | CatBoost | RF | AASHTO | Test Values /MPa | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Values /MPa | Error /% | Values /MPa | Error /% | Values /MPa | Error /% | Values /MPa | Error /% | Values /MPa | Error /% | ||

| K1-1 | 4.93 | 13.66 | 5.85 | −2.40 | 5.65 | 1.07 | 5.26 | 7.89 | 9.20 | 61.12 | 5.71 |

| K1-2 | 3.67 | 33.69 | 5.79 | −4.75 | 5.45 | 1.50 | 5.76 | −4.28 | 11.55 | 108.79 | 5.53 |

| K1-3-1 | 3.86 | 37.32 | 8.09 | −31.16 | 6.11 | 0.87 | 6.35 | −3.05 | 10.36 | 67.87 | 6.17 |

| K1-3-2 | 3.86 | 39.56 | 8.09 | −26.48 | 6.11 | 4.40 | 6.35 | 0.62 | 10.34 | 61.88 | 6.39 |

| K1-3-3 | 3.86 | 43.01 | 8.09 | −19.26 | 6.11 | 9.86 | 6.35 | 6.30 | 10.35 | 52.64 | 6.78 |

| K2-1 | 3.67 | 31.89 | 5.79 | −7.61 | 5.45 | −1.18 | 5.76 | −7.12 | 10.35 | 92.31 | 5.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Y.; Liu, D.; Qi, D.; Liu, S.; Wang, T.; Zhang, J. Shear Behavior of Large Keyed Dry Joints in Segmental Precast Bridges: Experiment, Numerical Modeling, and Capacity Prediction. Buildings 2025, 15, 3375. https://doi.org/10.3390/buildings15183375

Hou Y, Liu D, Qi D, Liu S, Wang T, Zhang J. Shear Behavior of Large Keyed Dry Joints in Segmental Precast Bridges: Experiment, Numerical Modeling, and Capacity Prediction. Buildings. 2025; 15(18):3375. https://doi.org/10.3390/buildings15183375

Chicago/Turabian StyleHou, Yongjun, Duo Liu, Di Qi, Song Liu, Tongwei Wang, and Jiandong Zhang. 2025. "Shear Behavior of Large Keyed Dry Joints in Segmental Precast Bridges: Experiment, Numerical Modeling, and Capacity Prediction" Buildings 15, no. 18: 3375. https://doi.org/10.3390/buildings15183375

APA StyleHou, Y., Liu, D., Qi, D., Liu, S., Wang, T., & Zhang, J. (2025). Shear Behavior of Large Keyed Dry Joints in Segmental Precast Bridges: Experiment, Numerical Modeling, and Capacity Prediction. Buildings, 15(18), 3375. https://doi.org/10.3390/buildings15183375