Numerical Study of Excavation Face Active Instability in Upward Shield Tunneling

Abstract

1. Introduction

2. Establishment of Upward Shield Tunneling Numerical Simulation Model

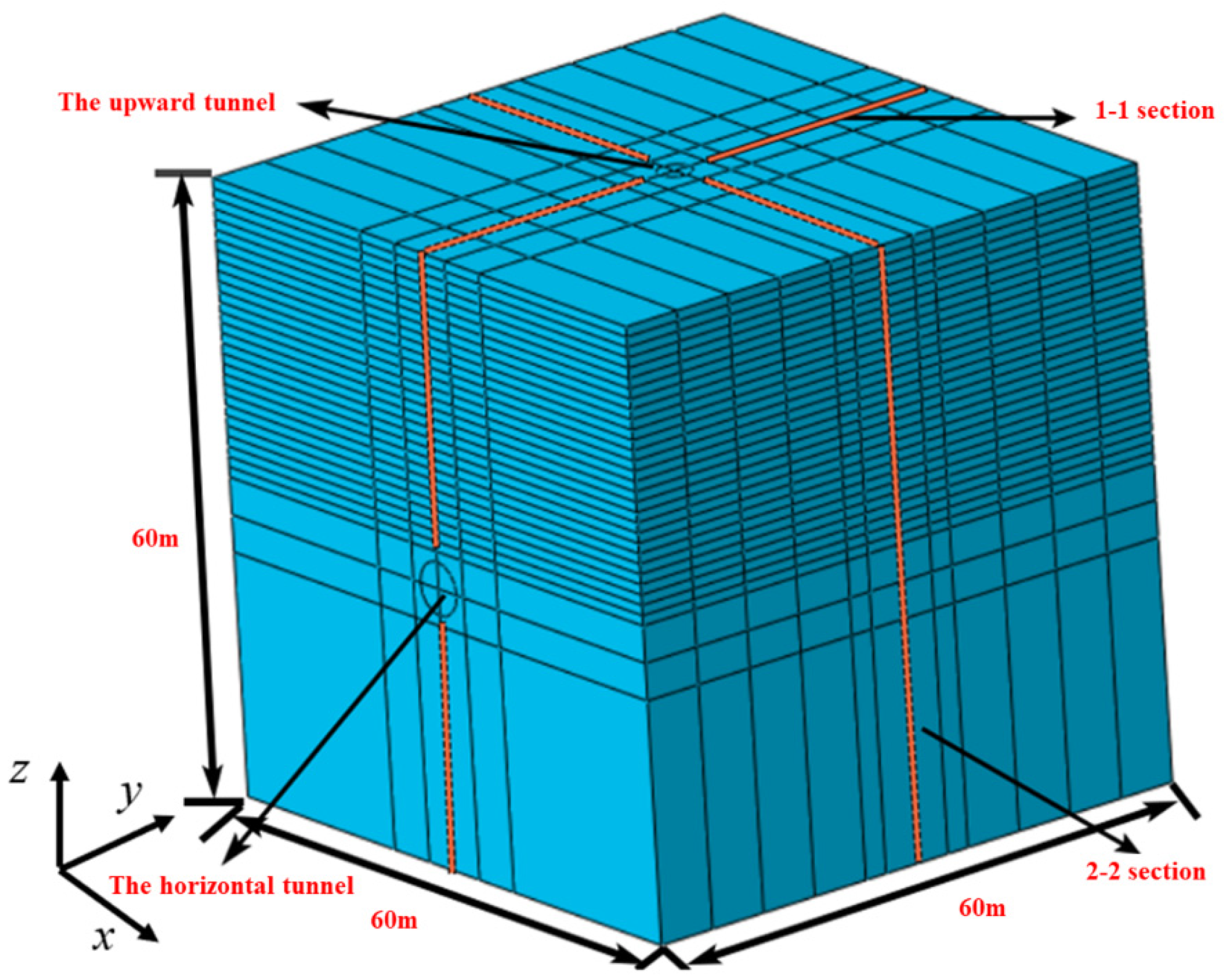

2.1. Model Size and Boundary Conditions

2.2. Material Parameters and Basic Assumptions

- (1)

- The soil is modeled as an isotropic ideal elastoplastic material, and its failure is governed by the Mohr–Coulomb criterion. Plastic strains develop when the stress state satisfies the yield condition, with progressive failure controlled via stepwise support pressure reduction.

- (2)

- It is assumed that there is no relative movement between the soil and the outer surfaces of the shield and the grout, meaning both are bonded.

- (3)

- It is assumed that an earth pressure balance method is used to counteract the soil pressure in front of the excavation face during the excavation of the horizontal shield tunnel and the upward shield tunnel.

2.3. Simulation Procedure

2.3.1. Ground Stress Equilibrium

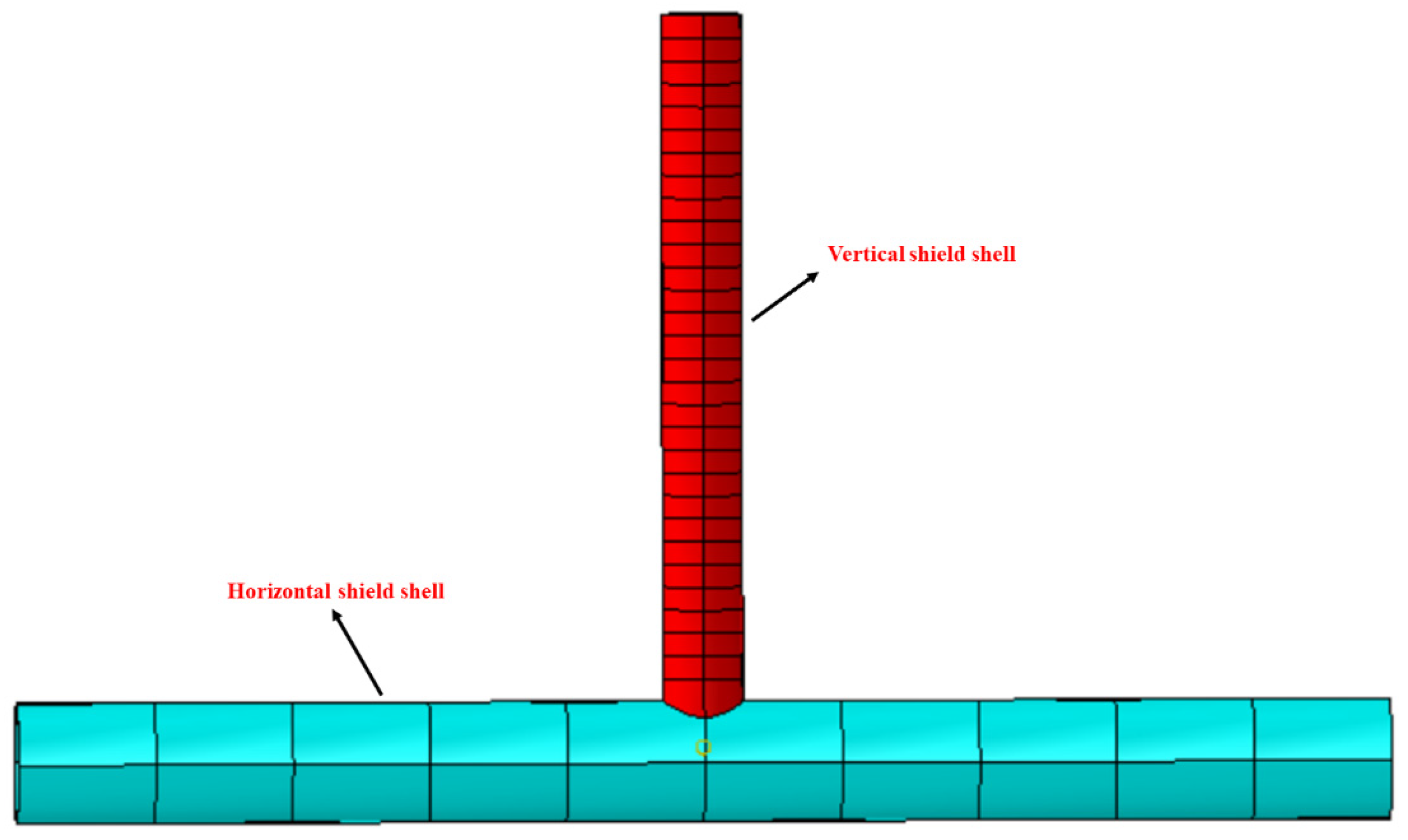

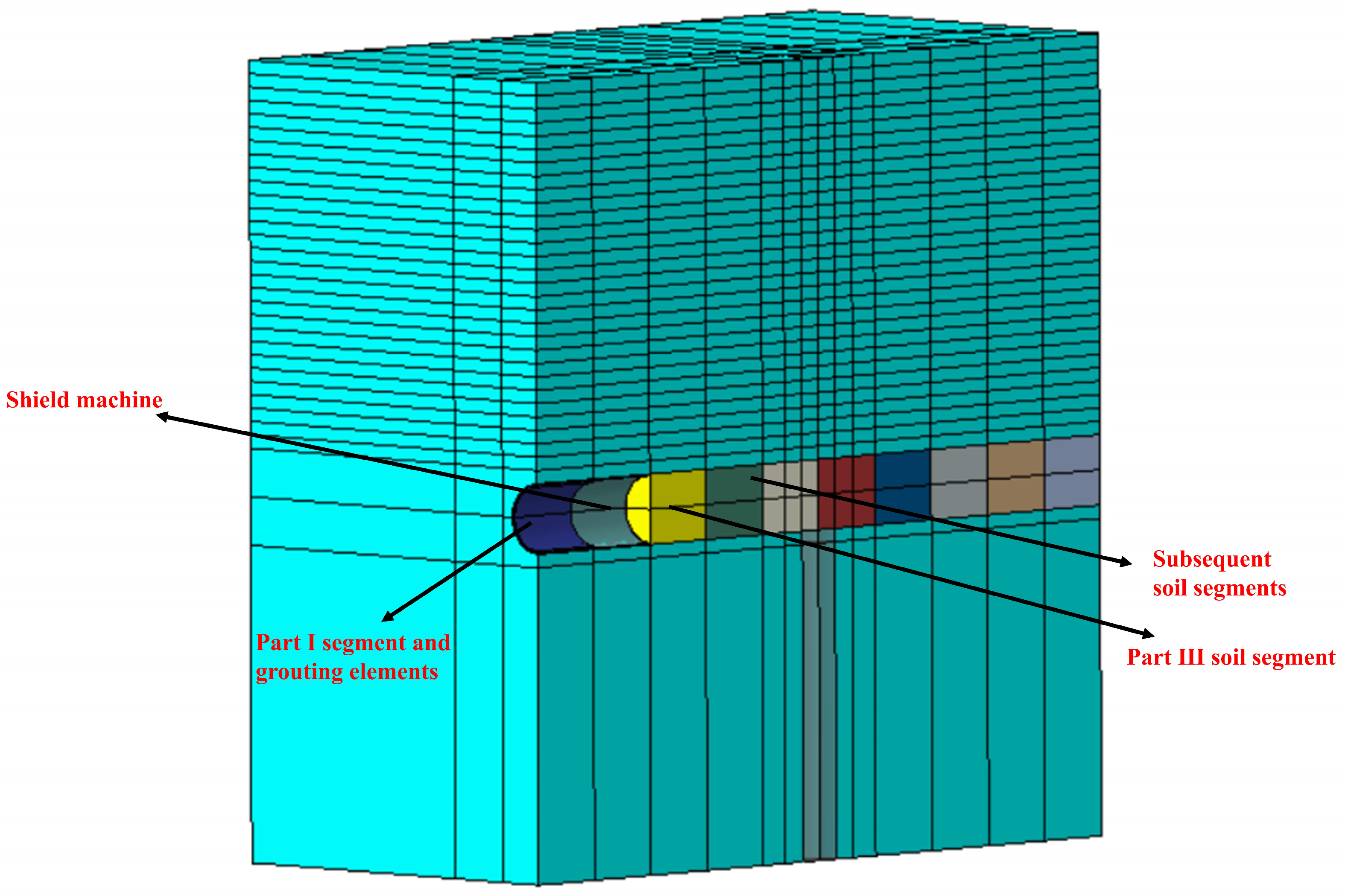

2.3.2. Construction Process of Horizontal Shield Tunnel

- (1)

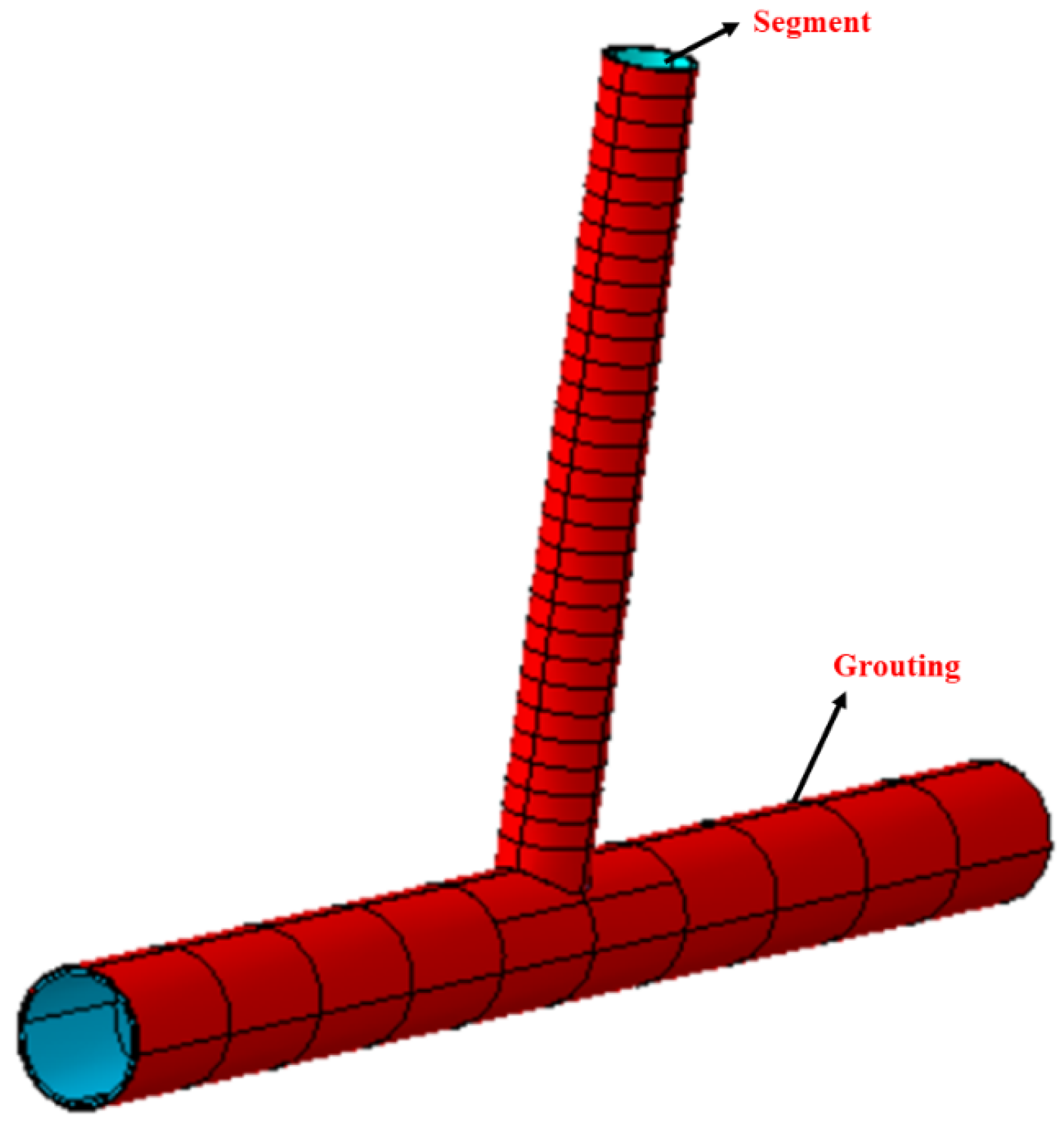

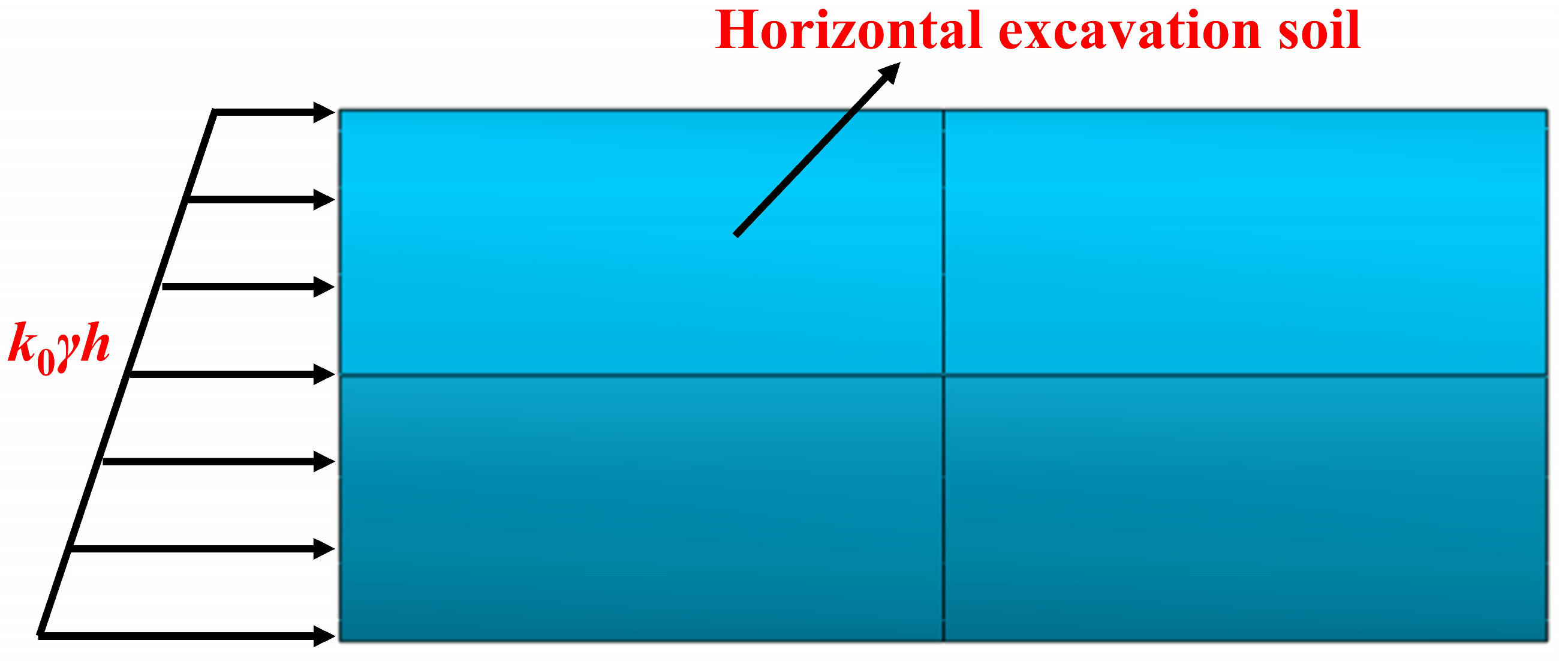

- Excavation process: The excavation soil in the horizontal tunnel is divided into 10 segments (each 6 m in length) for phased excavation, and the excavation process is simulated by activating and deactivating elements in ABAQUS. In the first analysis step, the first soil segment is deactivated. Simultaneously, the corresponding shield elements are activated, and the excavation face support pressure is applied. This support pressure has a trapezoidal distribution, as shown in Figure 5, and is calculated based on the formula k0γh, where k0 is the coefficient of earth pressure at rest (k0 = 1 − sin ϕ = 0.5 for ϕ = 30°), γ is the soil volumetric weight, and h is the distance from the soil to the ground surface. Upon moving to the next soil segment, the support pressure is removed. This process continues for the remaining nine segments in subsequent analysis steps.

- (2)

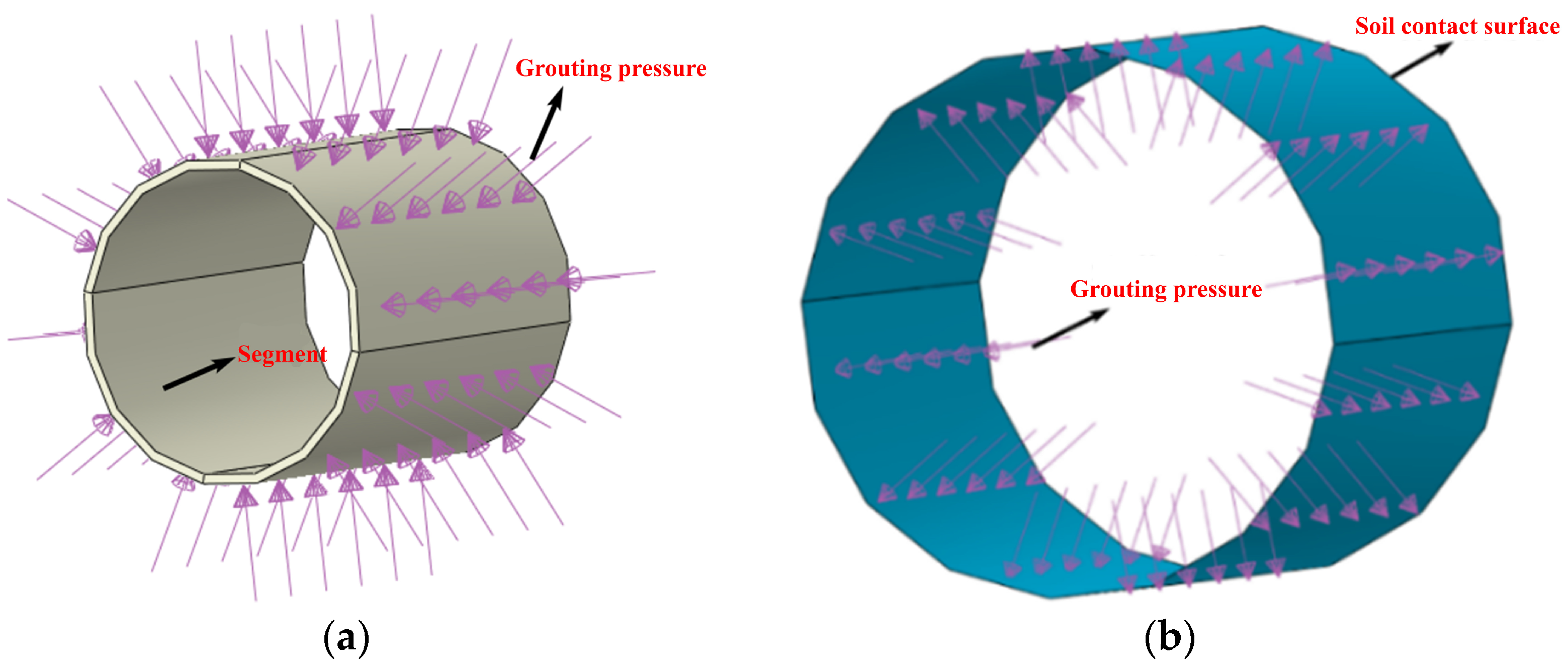

- The activation of segment and grouting elements: As the shield machine excavates the next soil segment, the shield shell parts in the previously excavated segment are deactivated and moved to the newly excavated segment to simulate the shield machine advancement. Simultaneously, the segment and grouting elements in the previously excavated segment are activated. When activating the grouting elements, grouting pressure is applied to the segments’ outer surface and the soil’s inner surface (see Figure 6). The grouting pressure is typically between 0.1 MPa and 0.3 MPa [29]; in this study, it is set at 0.15 MPa. In the following analysis steps, the remaining nine segments of the segment and grouting elements are sequentially activated.

- (3)

- Grouting hardening: The shield machine advances at a speed between 1.8 mm/min and 44 mm/min [30], with a daily advance of 12 m. Based on the standard that grouting hardens after one day [31], the grouting hardening process is simulated in the second analysis step after activating the grouting elements. From the 4th analysis step onward, the elastic modulus of the grouting in the first segment is increased to represent the hardening, and the grouting pressure on both the segment and the soil is removed. The grouting hardening for the remaining nine segments is completed in subsequent analysis steps, concluding the simulation of the horizontal tunnel construction.

2.3.3. Breaking the Top Opening of the Horizontal Tunnel Segments Part

2.3.4. Construction Process of Upward Shield Tunneling

- (1)

- Soil excavation: For instance, when the excavation depth is 15 m from the ground surface, the soil is segmented into 15 parts, each part being excavated 1 m at a time. In the initial analysis step, the first 1 m soil section is deactivated (see Figure 8). Concurrently, the upward shield machine for the first section is activated, and support pressure is applied at the excavation face, given as γh0 (see Figure 9), where h0 is the depth to the ground surface. When excavating the second section, the support pressure from the first section is removed. Subsequent analysis steps continue with the excavation of the remaining soil sections.

- (2)

- Activation of lining and grouting units, along with the grouting hardening process: The construction process of the upward shield tunnel is completed by simulating the activation of the lining and grouting units and the subsequent hardening of the grout, as detailed in Section 2.3.2.

2.3.5. The Simulation of the Active Instability During Upward Shield Tunneling

3. Numerical Analysis and Experimental Validation of Excavation Face Instability

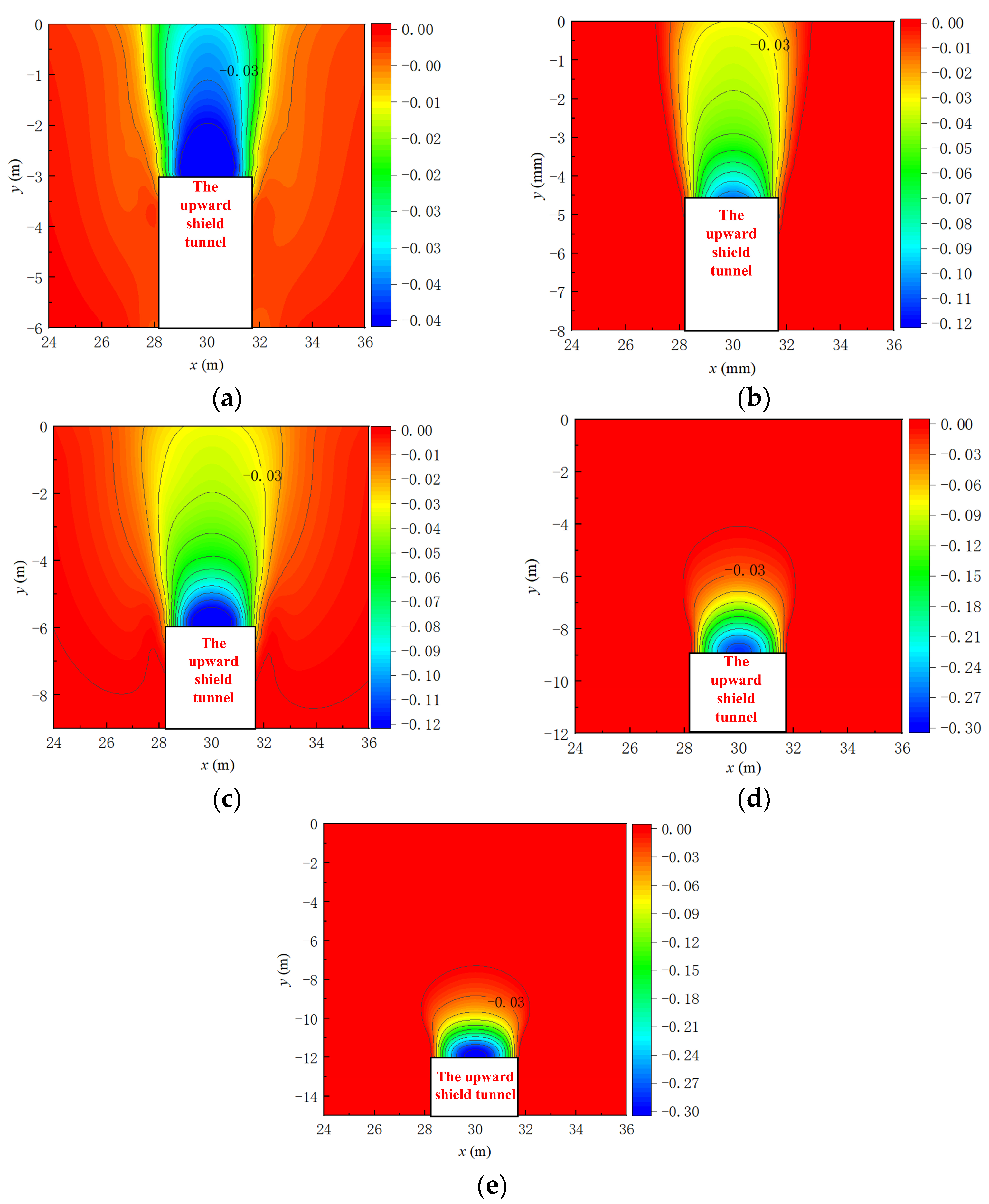

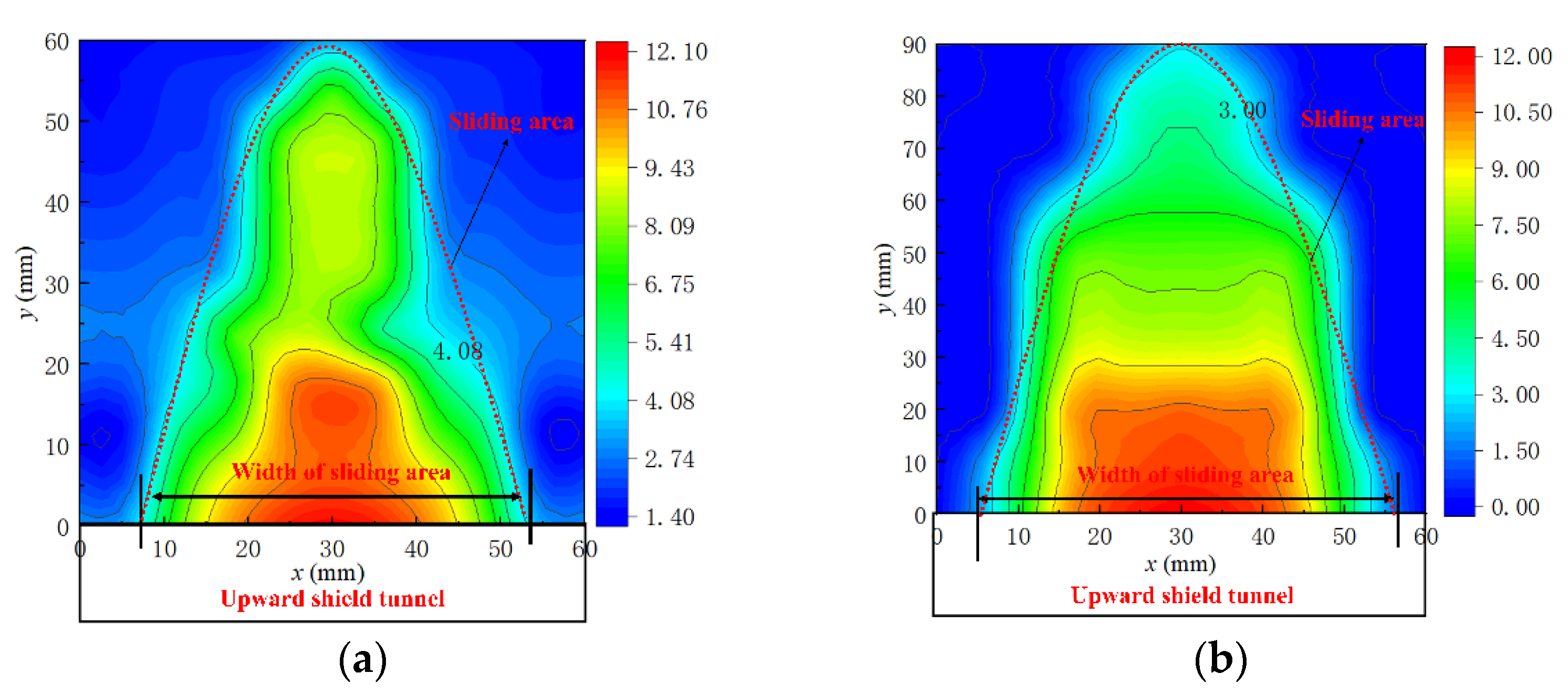

3.1. The Failure Zone of the Excavation Face Under the Active Instability State in the Numerical Model

3.2. The Variation Law of Limit Support Pressure During Active Instability of the Excavation Face in the Numerical Model

- (1)

- The initial support pressure ratio (η = P/Pinitial) was reduced from η = 1.0 (full support) to η = 0 (no support) in 20 coarse steps (each coarse step reducing η by 0.05).

- (2)

- Upon detection of a displacement acceleration point (‘knee point’) within a coarse step, the simulation backtracked to the preceding stable pressure ratio.

- (3)

- Upon detection of the knee point within a coarse step interval, the step size was immediately reduced to 0.01. The refinement process backtracked to the pressure ratio value immediately preceding the coarse step in which the knee point was detected.

- (4)

- From this preceding value, η was reduced again using the finer step size (0.01) through the region encompassing the suspected knee point. This fine-grained reduction allowed for the precise determination of ηmin corresponding to the onset of instability.

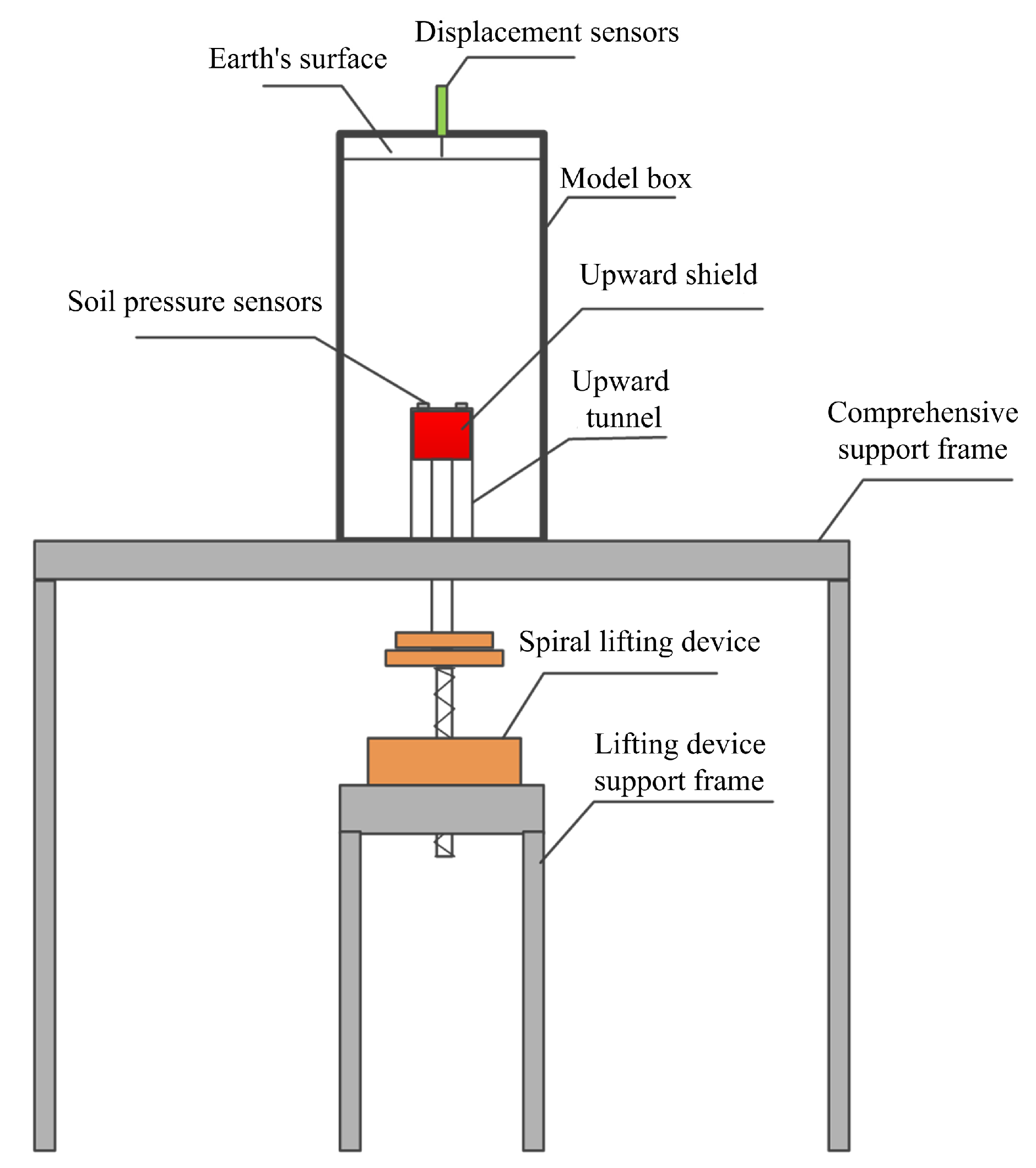

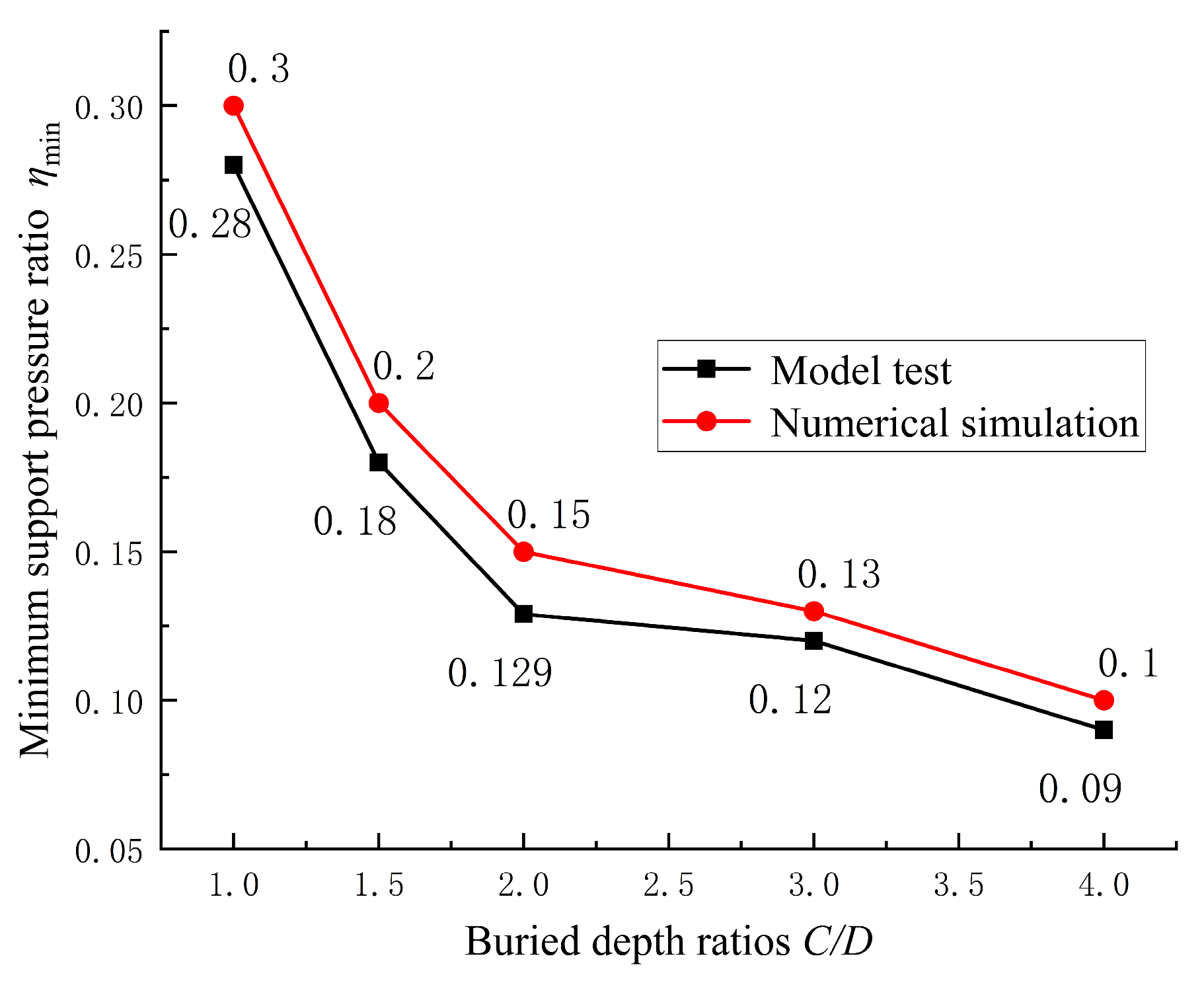

3.3. Comparison and Verification of Numerical Model and Model Test

4. Numerical Analysis of Active Instability of Upward Shield Tunneling Excavation Face

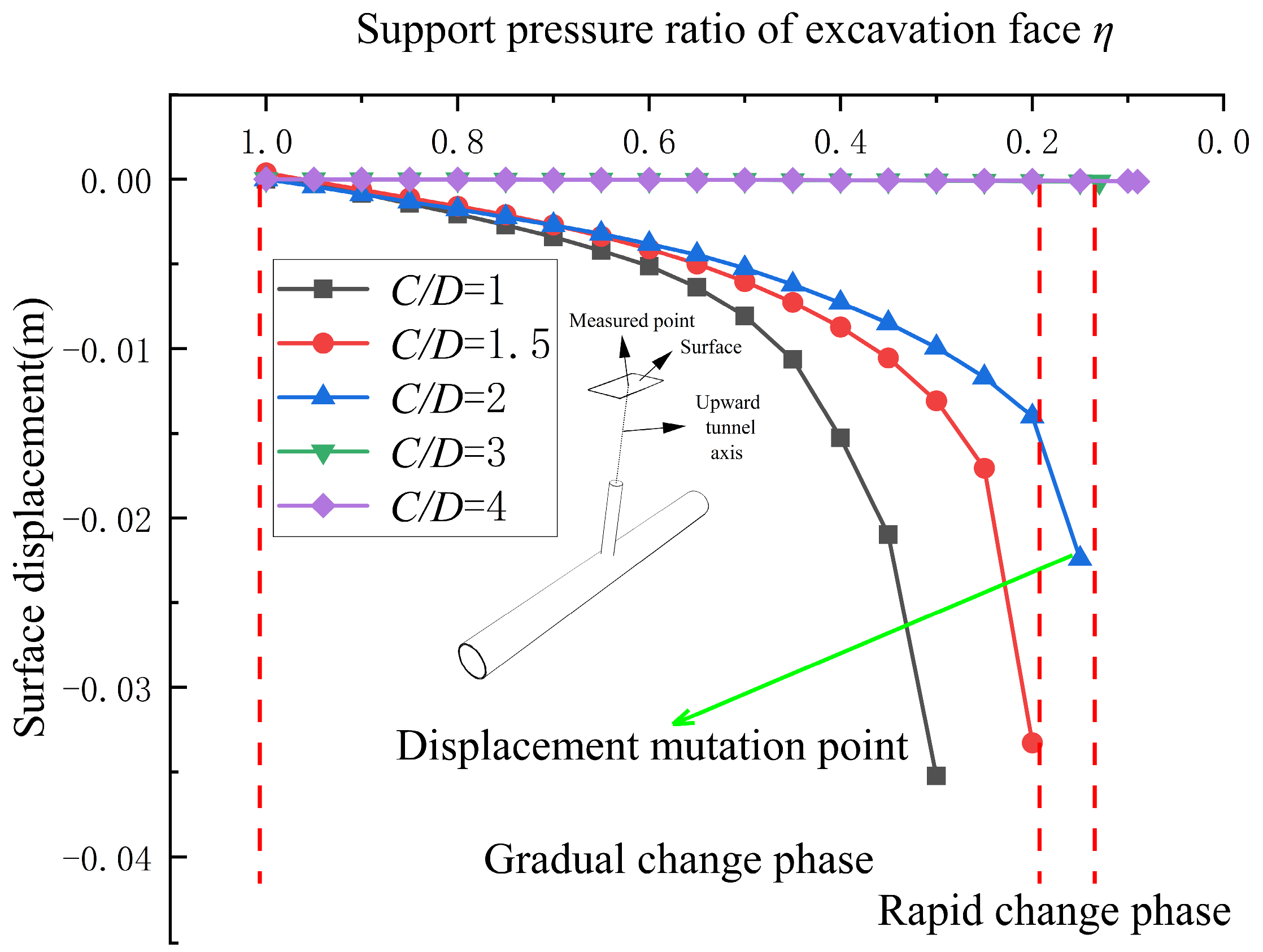

4.1. Variation in Surface Displacement Under Active Instability

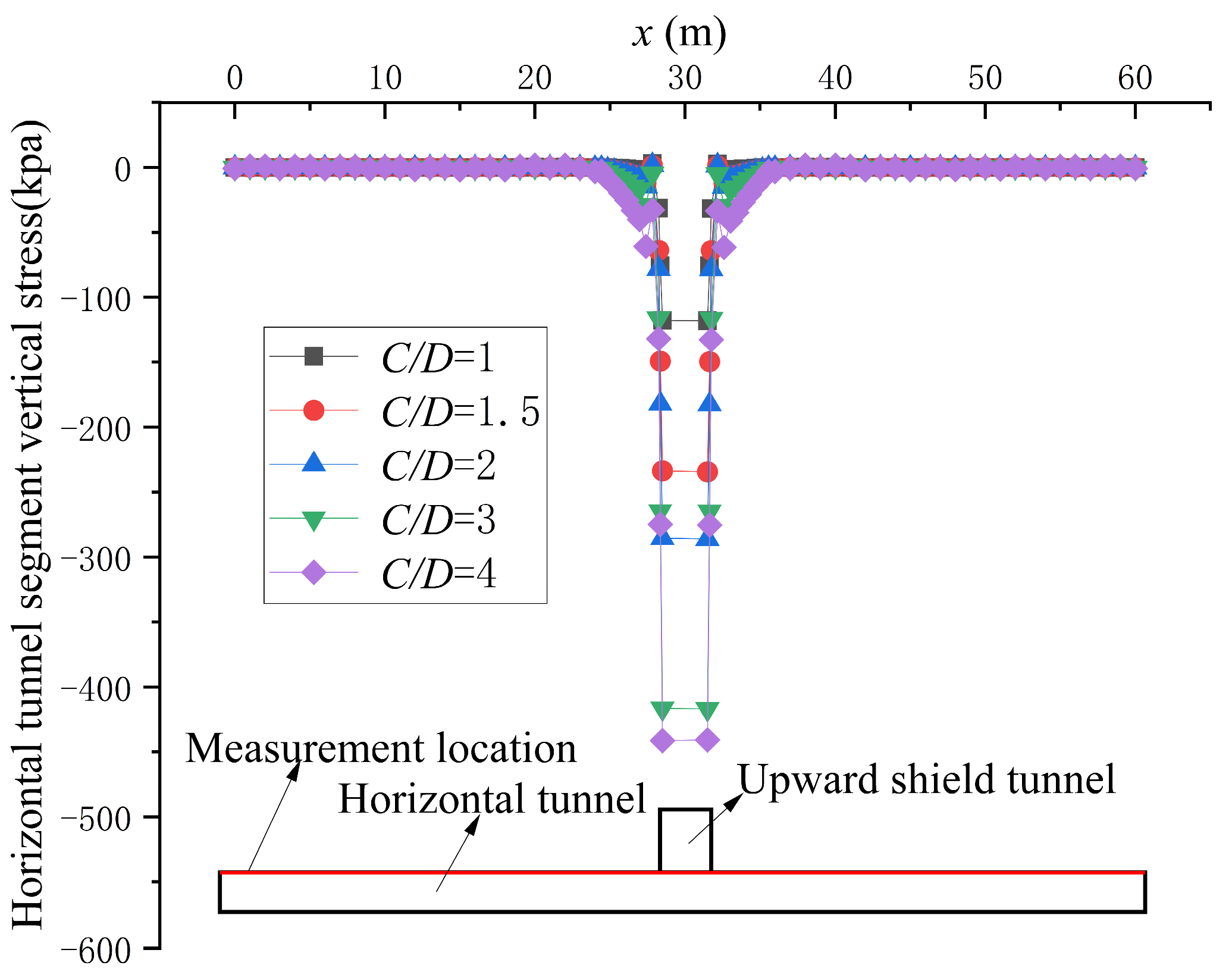

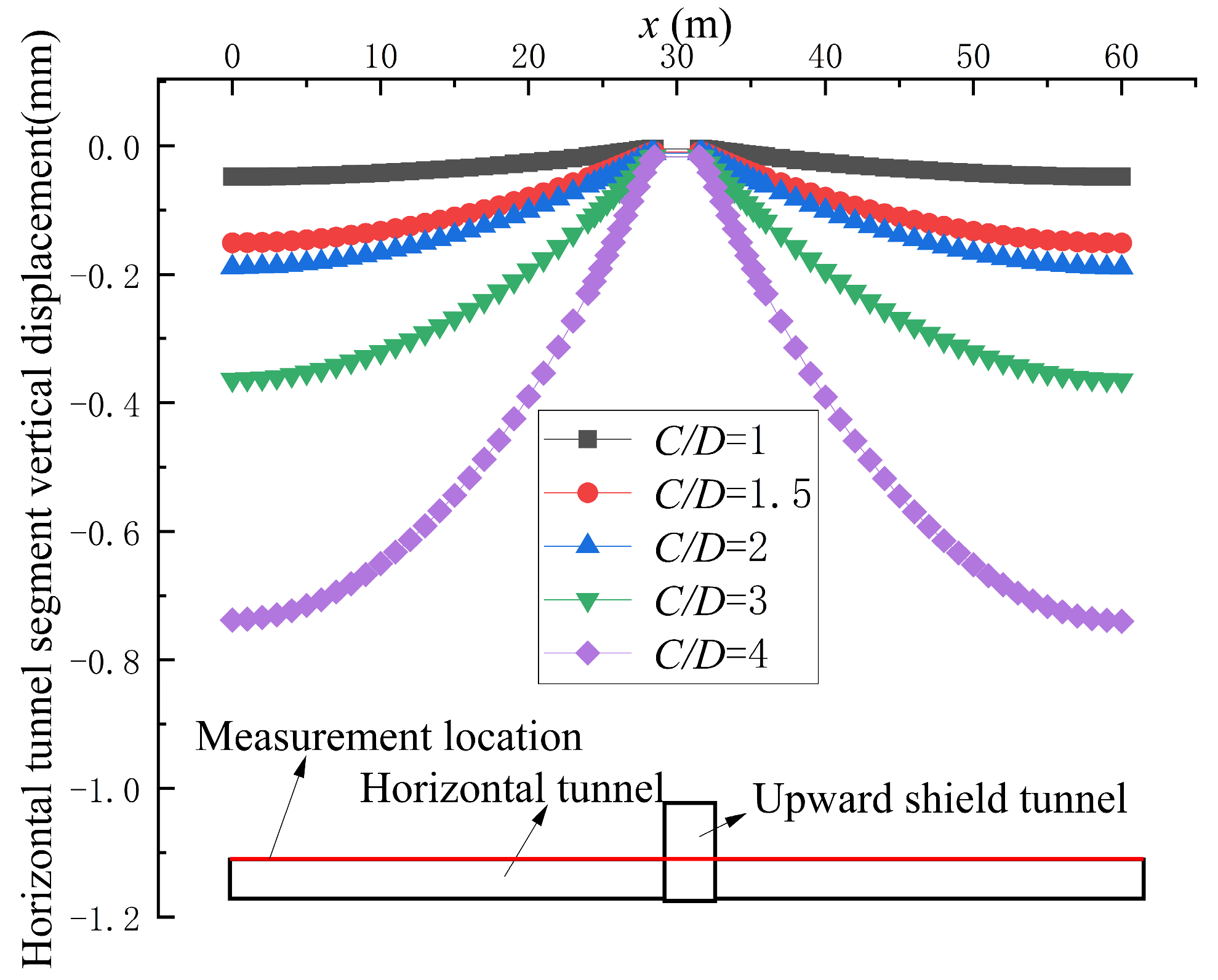

4.2. Variation in Stress and Deformation of Horizontal Tunnel Segment Under Active Instability

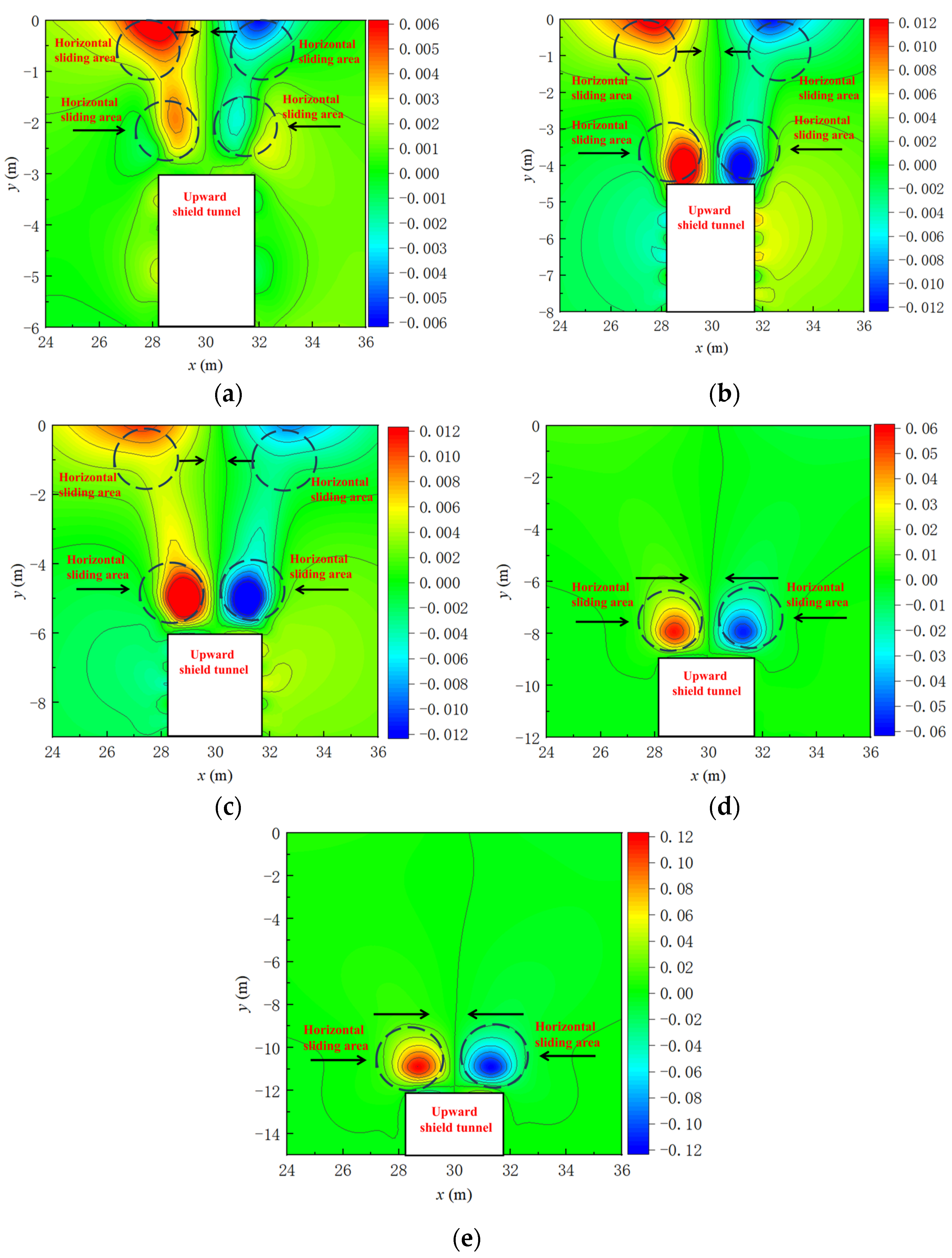

4.3. Variation in Horizontal Soil Displacement Under Active Instability

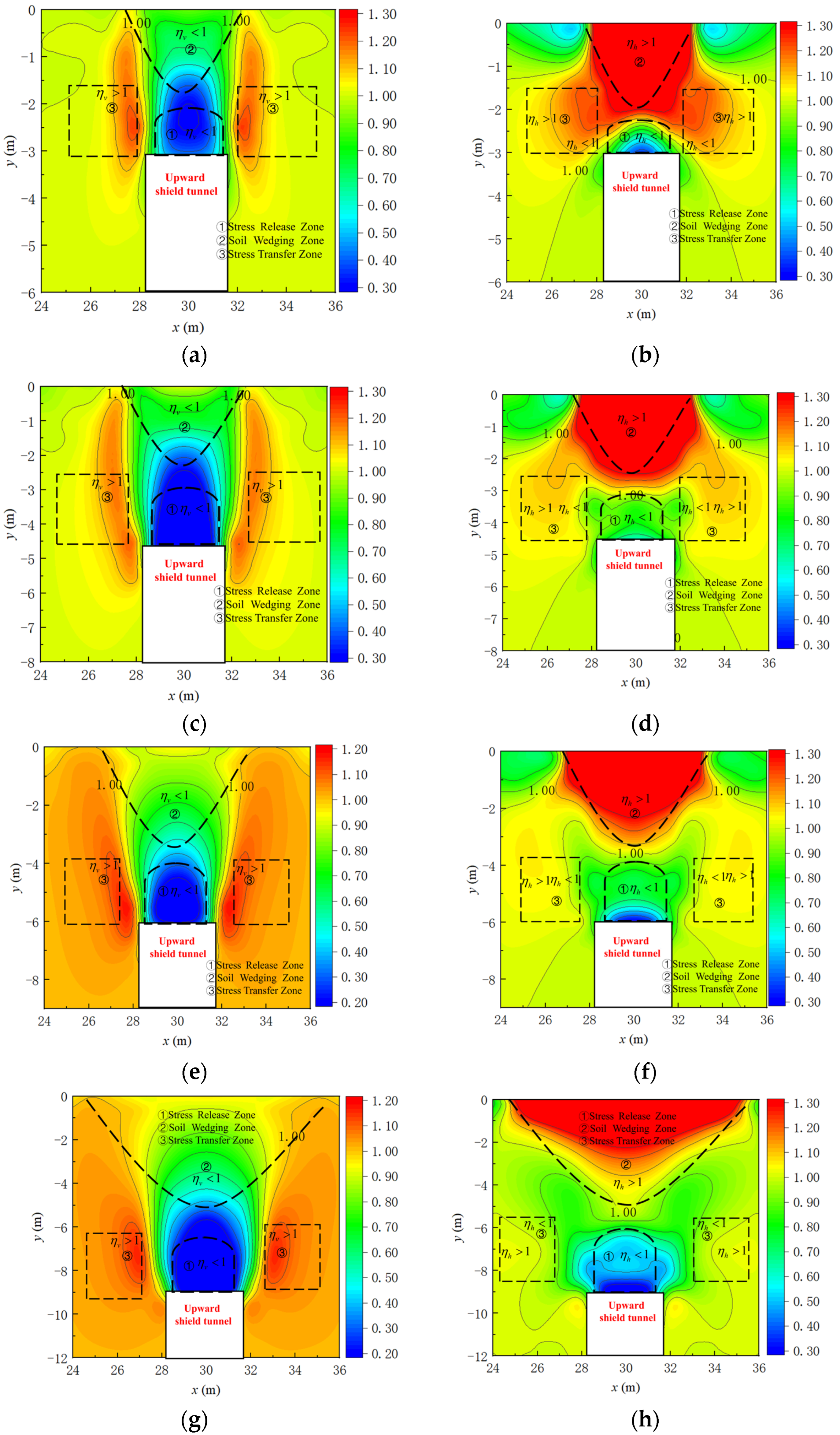

4.4. Variation in Earth Pressure Under Active Instability

- (1)

- Stress release zone

- (2)

- Soil wedging zone

- (3)

- Stress transfer zone

5. Conclusions

- (1)

- The numerical simulation results of the minimum support pressure ratio and its variation under the active instability conditions of the upward shield tunneling excavation face are close to those from model tests. As the burial depth ratio increases, the minimum support pressure ratio decreases. The failure zones of the soil at the excavation face obtained from numerical simulation align with the model test results. Under shallow burial conditions, the failure zone is an inverted cone, while in deep burial conditions, it adopts a bullet-shaped configuration. The similarity between numerical simulation results and model test results verifies the reliability of the numerical simulation results.

- (2)

- Under the active instability conditions of the upward shield tunneling excavation face, the stress at the top opening position of the horizontal tunnel segments increases. Moreover, with the increase in burial depth ratio, the stress increment becomes larger. In this state, the horizontal tunnel segments will move downward as a whole. As the support pressure ratio of the excavation face decreases, the horizontal tunnel segments at the top opening will exhibit upward displacement, eventually forming an inverted V shape. The greater the burial depth ratio, the larger the downward displacement of the horizontal tunnel segments near the top opening.

- (3)

- Under the active instability conditions of the upward shield tunneling excavation face, when the burial depth is relatively small (C/D < 3), the main horizontal failure zone of the soil above the excavation face is divided into three regions. When the burial depth is relatively large (C/D ≥ 3), the main horizontal failure zone above the excavation face consists of two regions, with the soil on both sides moving inward and interlocking. By analyzing the relationship between the displacement and stress changes in the soil above the excavation face after active instability, the stress change zones of the excavation face are classified into three categories: stress release zone, soil interlocking zone, and stress transfer zone.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Walton, G.; Kim, E.; Sinha, S.; Sturgis, G.; Berberick, D. Investigation of Shaft Stability and Anisotropic Deformation in a Deep Shaft in Idaho, United States. Int. J. Rock Mech. Min. Sci. 2018, 105, 160–171. [Google Scholar] [CrossRef]

- Wang, T.; Fang, B.; Hu, T.; Wei, L.; Dai, G. Field Study on the Application of Combined Grouting for the Super-Long Drilled Shaft. Results Eng. 2023, 19, 101366. [Google Scholar] [CrossRef]

- Feng, D.-L.; Wu, H.-N.; Chen, R.-P.; Liu, F.-X.; Yao, M. An Analytical Model to Predict the Radial Deformation of Surrounding Rock during Shaft Construction via Shaft Boring Machine. Tunn. Undergr. Space Technol. 2023, 140, 105321. [Google Scholar] [CrossRef]

- Yang, Y.-F.; Liao, S.-M.; Liu, M.-B.; Wu, D.-P.; Pan, W.-Q.; Li, H. A New Construction Method for Metro Stations in Dense Urban Areas in Shanghai Soft Ground: Open-Cut Shafts Combined with Quasi-Rectangular Jacking Boxes. Tunn. Undergr. Space Technol. 2022, 125, 104530. [Google Scholar] [CrossRef]

- Himuro, A. Upward Shield Tunneling from Deep Underground Stormwater Storage Pipes in the Central Areas. In Proceedings of the WEFTEC 2007, Water Environment Federation, San Diego, CA, USA, 13–17 October 2007; pp. 9312–9320. [Google Scholar]

- Konoha, Y.; Yamamoto, Y. Turning Simple Ideas into Reality: Development and Application of Upward Shield Tunneling Method for the Sewer Construction Project along Bandai-Hannan Line. Civ. Eng. 2003, 53–57. [Google Scholar]

- Wang, X.; Wei, X.; Wei, G.; Zhu, C.; Jin, T.; Yan, Z. Theoretical and Numerical Analysis of the Failure Mechanism and Jacking Force during Vertical Tunneling Using a CEL Approach. Tunn. Undergr. Space Technol. 2024, 148, 105765. [Google Scholar] [CrossRef]

- Zhou, Y.; Wei, G.; Wang, X.; Tao, B.; Huang, Q.; Wei, X. Analytical Solution of Soil Deformation Caused by Vertical Pipe Jacking Construction Considering Grouting Pressure. Sci. Rep. 2025, 15, 17476. [Google Scholar] [CrossRef]

- Wei, G.; Feng, F.; Huang, S.; Xu, T.; Zhu, J.; Wang, X.; Zhu, C. Full-Scale Loading Test for Shield Tunnel Segments: Load-Bearing Performance and Failure Patterns of Lining Structures. Undergr. Space 2025, 20, 197–217. [Google Scholar] [CrossRef]

- Wei, G.; Feng, W.; Wu, X.; Wu, P.; Li, H.; Zhu, Z.; Wang, Z. Research on the Combined Control of Tunnel Deformation Adjacent to the Foundation Pit by Servo Steel Strut and Capsule Grouting. Sci. Rep. 2025, 15, 23432. [Google Scholar] [CrossRef] [PubMed]

- Wei, G.; Zhou, Y.; Wang, Z.; Wang, Q.; Lu, C.; Feng, G. Deformation Control of Shield Tunnels Affected by Staged Foundation Pit Excavation: Analytical Method and Case Study. Buildings 2025, 15, 2046. [Google Scholar] [CrossRef]

- Xu, J.; Gao, M.; Wang, Y.; Yu, Z.; Zhao, J.; DeJong, M.J. Numerical Investigation of the Effects of Separated Footings on Tunnel-Soil-Structure Interaction. J. Geotech. Geoenviron. Eng. 2025, 151, 04025057. [Google Scholar] [CrossRef]

- De Buhan, P.; Cuvillier, A.; Dormieux, L.; Maghous, S. Face Stability of Shallow Circular Tunnels Driven under the Water Table: A Numerical Analysis. Int. J. Numer. Anal. Methods Geomech. 1999, 23, 79–95. [Google Scholar] [CrossRef]

- Huang, M.; Li, S.; Yu, J.; Tan, J.Q.W. Continuous Field Based Upper Bound Analysis for Three-Dimensional Tunnel Face Stability in Undrained Clay. Comput. Geotech. 2018, 94, 207–213. [Google Scholar] [CrossRef]

- Ukritchon, B.; Yingchaloenkitkhajorn, K.; Keawsawasvong, S. Three-Dimensional Undrained Tunnel Face Stability in Clay with a Linearly Increasing Shear Strength with Depth. Comput. Geotech. 2017, 88, 146–151. [Google Scholar] [CrossRef]

- Zhang, C.; Han, K.; Zhang, D. Face Stability Analysis of Shallow Circular Tunnels in Cohesive–Frictional Soils. Tunn. Undergr. Space Technol. 2015, 50, 345–357. [Google Scholar] [CrossRef]

- Vermeer, P.A.; Ruse, N.; Marcher, T. Tunnel Heading Stability in Drained Ground. Felsbau 2002, 20, 8–18. [Google Scholar]

- Kim, S.H.; Tonon, F. Face Stability and Required Support Pressure for TBM Driven Tunnels with Ideal Face Membrane–Drained Case. Tunn. Undergr. Space Technol. 2010, 25, 526–542. [Google Scholar] [CrossRef]

- Sterpi, D.; Cividini, A. A Physical and Numerical Investigation on the Stability of Shallow Tunnels in Strain Softening Media. Rock Mech. Rock Eng. 2004, 37, 277–298. [Google Scholar] [CrossRef]

- Qiao, J.-L.; Zhang, Y.-T.; Gao, J.; Li, Y.-Y. Application of Strength Reduction Method to Stability Analysis of Shield Tunnel Face. J. Tianjin Univ. (Sci. Technol.) 2010, 43, 14–20. (In Chinese) [Google Scholar]

- Lei, H.-Y.; Liu, M.; Zhong, H.-C.; Xu, Y.-G.; Yuan, D.-J. Centrifuge Model Test and Numerical Simulation of Face Instability of Shield Tunnel in Clay. J. Tianjin Univ. (Sci. Technol.) 2023, 56, 503–512. (In Chinese) [Google Scholar]

- Yan, B.-H. Numerical Simulation and Centrifugal Test Study on Stability of Shield Tunnel Excavation Surface Under Seepage Conditions. Master’s thesis, Chang’an University, Xi’an, China, 2020. (In Chinese). [Google Scholar]

- 2015 Outstanding Civil Engineering Achievement Award|Japan Society of Civil Engineers. Available online: https://www.jsce-int.org/a_t/achievement/civil/2015 (accessed on 5 August 2024).

- Liu, W.-Z.; Sun, K.; Dai, X.-Y.; Ai, G.-P.; Lei, T. Numerical simulation and field monitoring of influence of metro shield tunnel undercrossing the existing railway frame bridge by long distance. J. Railw. Sci. Eng. 2022, 19, 208–218. (In Chinese) [Google Scholar] [CrossRef]

- Zheng, G.; Lu, P.; Diao, Y. Advance Speed-Based Parametric Study of Greenfield Deformation Induced by EPBM Tunneling in Soft Ground. Comput. Geotech. 2015, 65, 220–232. [Google Scholar] [CrossRef]

- Hu, Y.; Lei, H.; Zheng, G.; Shi, L.; Zhang, T.; Shen, Z.; Jia, R. Ground Movement Induced by Triple Stacked Tunneling with Different Construction Sequences. J. Rock Mech. Geotech. Eng. 2022, 14, 1433–1446. [Google Scholar] [CrossRef]

- Cao, Y.; Lin, X.-R.; Li, Z.-L. Refined Numerical Simulation of Shallow Shield Construction in Soft Soil Stratum. Adv. Eng. Sci. 2022, 54, 149–158. (In Chinese) [Google Scholar] [CrossRef]

- Liu, Y.-N.; Lei, H.-Y.; Ma, C.-Y.; Guan, B.-H. Three-dimensional stability analysis of shied tunnel face adjacent to existing tunnels. Chin. J. Geotech. Eng. 2023, 45, 1374–1383. (In Chinese) [Google Scholar]

- Chen, K.-J. Construction Technology of Subway Engineering; China Railway Publishing House: Beijing, China, 2014. [Google Scholar]

- Cui, L.-J. Prediction of Shield Tunneling Parameters Based on Machine Learning Fusion Model. Master’s thesis, Zhejiang University, Hangzhou, China, 2022. (In Chinese). [Google Scholar]

- Liu, C.; Zhang, Z.-X.; Regueiro, R.A. Pile and Pile Group Response to Tunnelling Using a Large Diameter Slurry Shield–Case Study in Shanghai. Comput. Geotech. 2014, 59, 21–43. [Google Scholar] [CrossRef]

- Li, W. Stability Analysis of Tunnel Face in Soils Based on the Upper Bound Method of Limit Analysis. Ph.D thesis, Beijing Jiaotong University, Beijing, China, 2021. (In Chinese). [Google Scholar]

- Fei, K.; Peng, J. Detailed Explanation of ABAQUS Geotechnical Engineering Example; Posts & Telecom Press: Beijing, China, 2017. [Google Scholar]

- Cui, P.-B.; Zhu, Y.-Q.; Liu, Y.; Zhu, Z.-G.; Pan, Y.-D. Model test and particle flow numerical simulation of soil arch effect for unsaturated sandy soil tunnel. Rock Soil Mech. 2021, 42, 3451–3466. (In Chinese) [Google Scholar] [CrossRef]

| Linear Elastic Material | Elastic Modulus | Poisson Ratio |

|---|---|---|

| Segment | 25.88 GPa | 0.17 |

| Grouting material before hardening | 0.9 MPa | 0.25 |

| Grouting material after hardening | 400 MPa | 0.25 |

| Shield shell | 206 GPa | 0.3 |

| Elastic–Plastic Material | Elastic Modulus | Poisson Ratio | The Angle of Internal Friction | Cohesion | Density |

|---|---|---|---|---|---|

| Soil | 14.5 MPa | 0.32 | 30° | 0 kPa | 1500 kg/m3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Wang, X.; Wei, G.; Lin, Z.; Wei, X.; Yan, Z.; Yan, J.; Shen, X. Numerical Study of Excavation Face Active Instability in Upward Shield Tunneling. Buildings 2025, 15, 3371. https://doi.org/10.3390/buildings15183371

Li Y, Wang X, Wei G, Lin Z, Wei X, Yan Z, Yan J, Shen X. Numerical Study of Excavation Face Active Instability in Upward Shield Tunneling. Buildings. 2025; 15(18):3371. https://doi.org/10.3390/buildings15183371

Chicago/Turabian StyleLi, Yijie, Xiao Wang, Gang Wei, Zhiying Lin, Xinjiang Wei, Zihai Yan, Jiajia Yan, and Xiang Shen. 2025. "Numerical Study of Excavation Face Active Instability in Upward Shield Tunneling" Buildings 15, no. 18: 3371. https://doi.org/10.3390/buildings15183371

APA StyleLi, Y., Wang, X., Wei, G., Lin, Z., Wei, X., Yan, Z., Yan, J., & Shen, X. (2025). Numerical Study of Excavation Face Active Instability in Upward Shield Tunneling. Buildings, 15(18), 3371. https://doi.org/10.3390/buildings15183371