Prediction on Dynamic Yield Stress and Plastic Viscosity of Recycled Coarse Aggregate Concrete Using Machine Learning Algorithms

Abstract

1. Introduction

2. Database and Models

2.1. Data Collection, Processing, and Partition

2.2. Model Development

2.2.1. Artificial Neural Network (ANN)

2.2.2. Random Forest (RF)

2.2.3. Extreme Gradient Boosting (XGBoost)

2.2.4. Light Gradient Boosting Machine (LightGBM)

2.2.5. Support Vector Machine (SVM)

2.2.6. Decision Tree (DT)

2.2.7. Hyperparameter Tuning for Machine Learning Models

3. Results and Discussion

3.1. Data Analysis

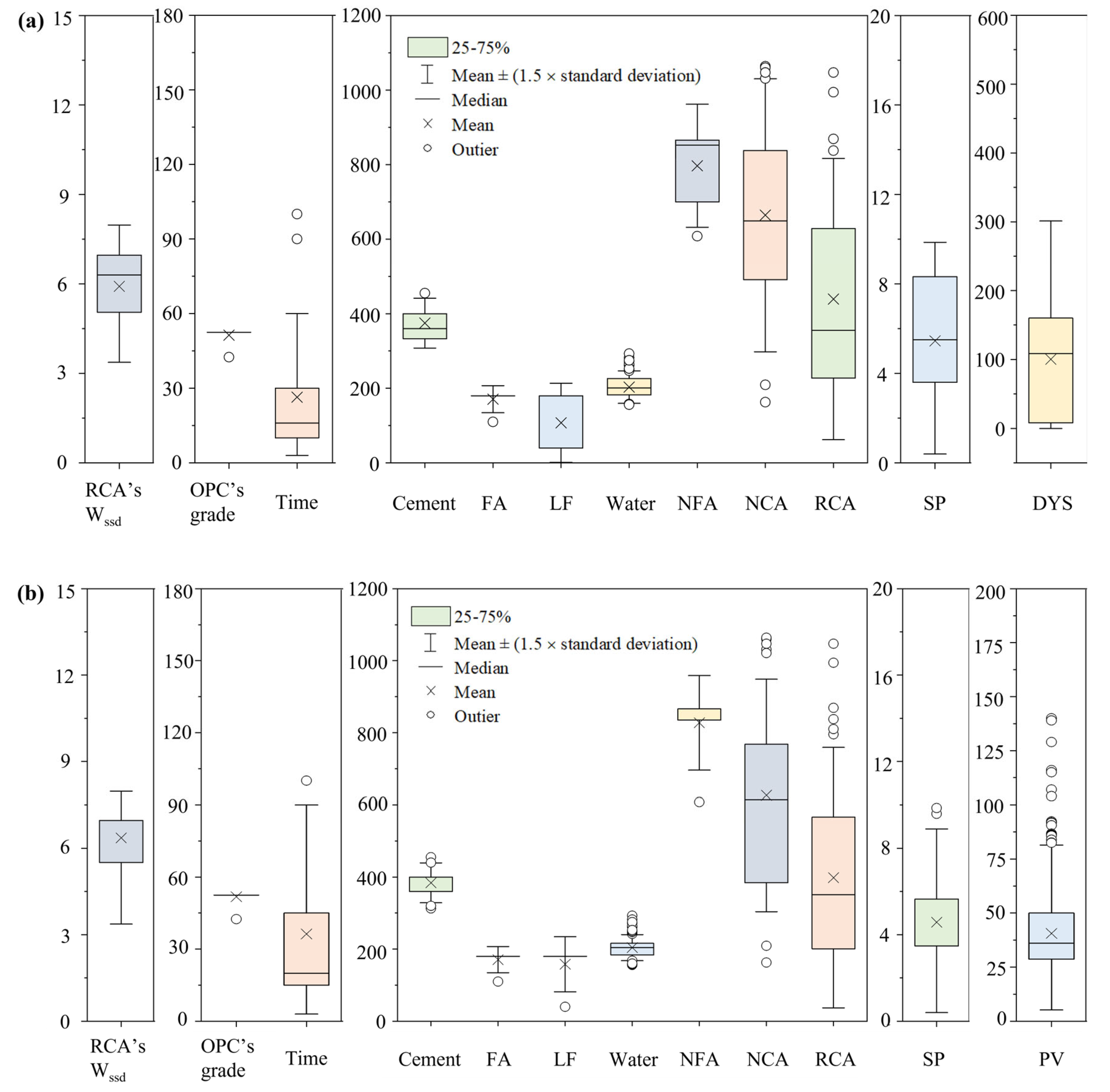

3.1.1. Statistical Analysis

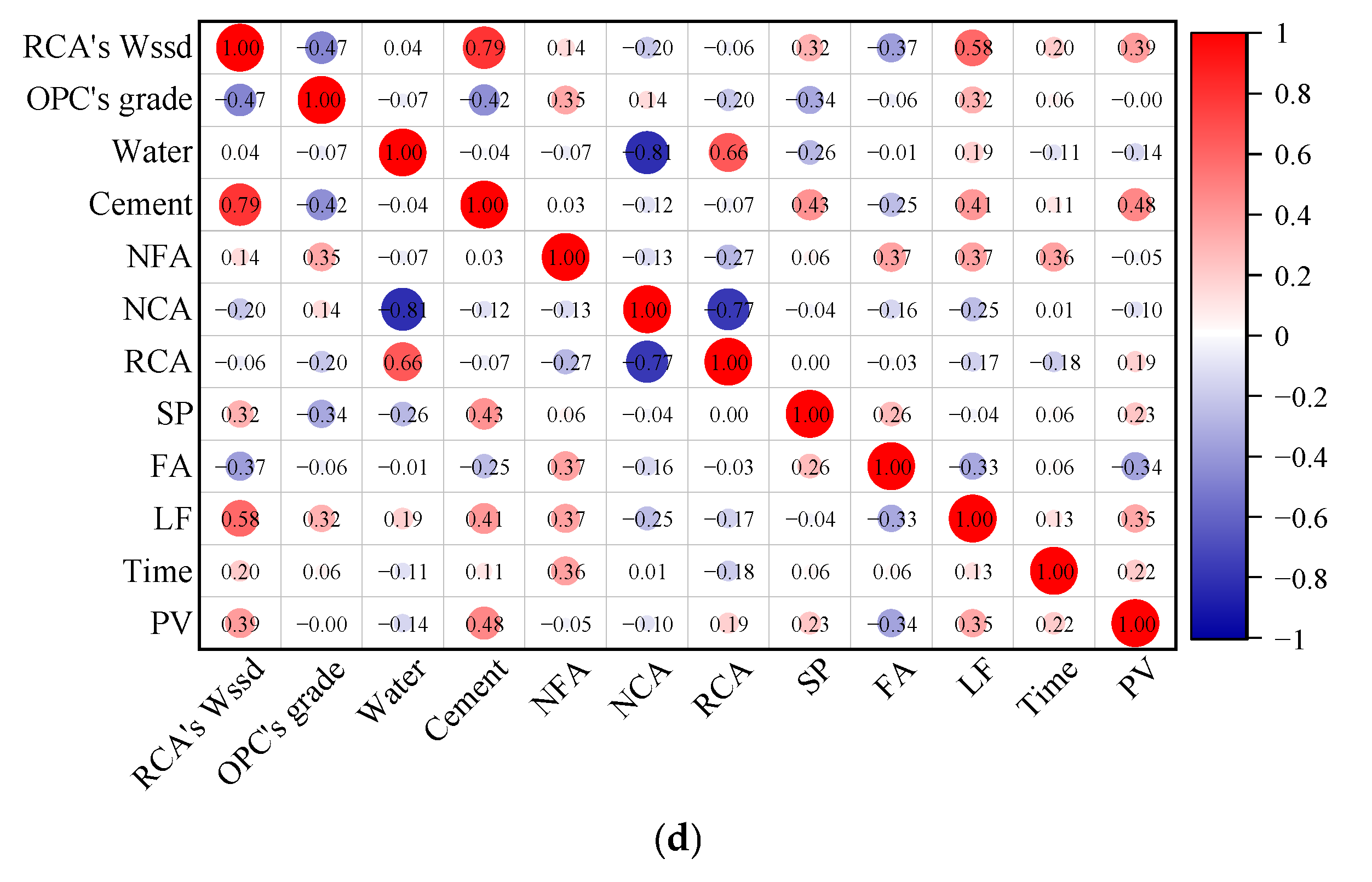

3.1.2. Pearson and Spearman Analyses

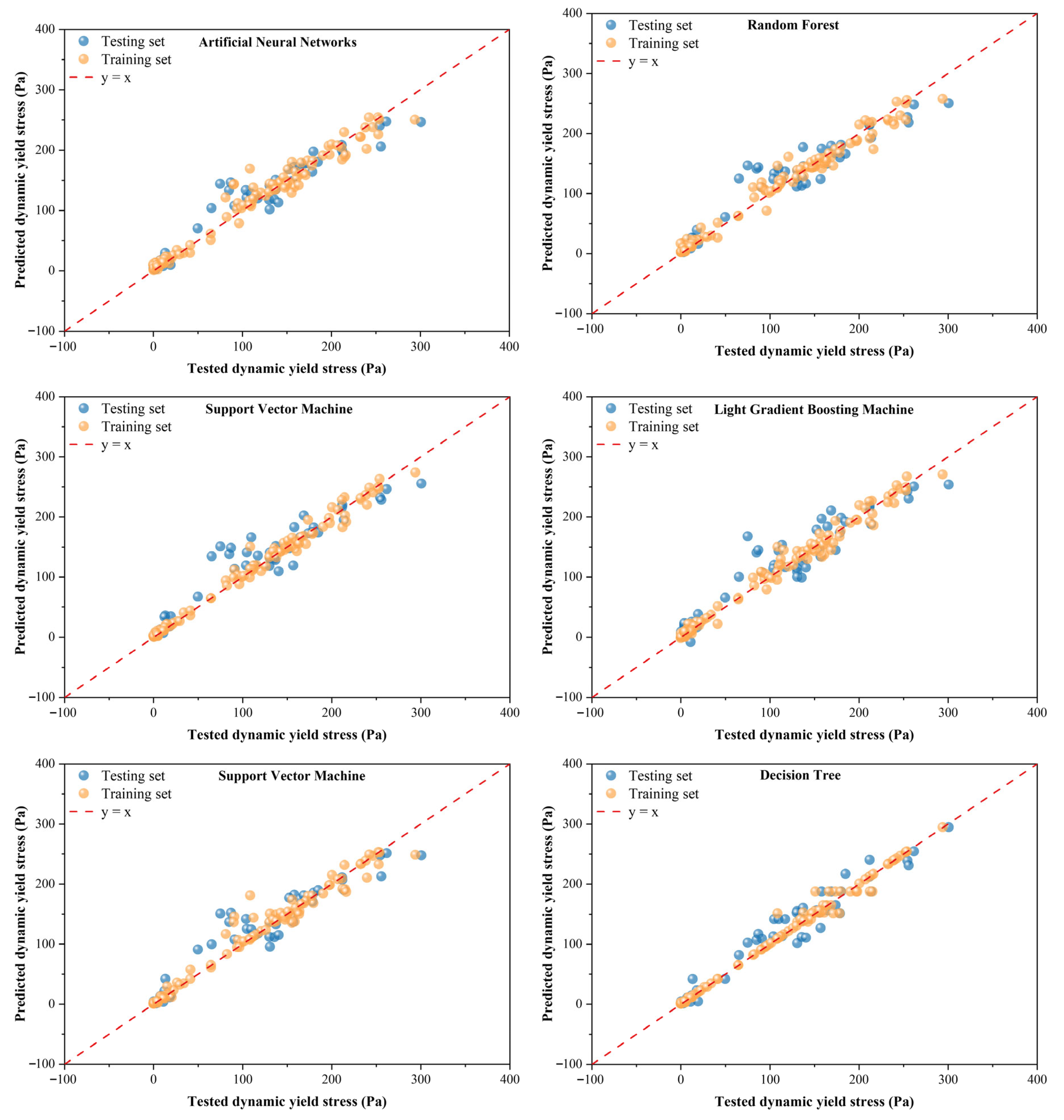

3.2. Dynamic Yield Stress: Model Evaluation and Accuracy Assessment

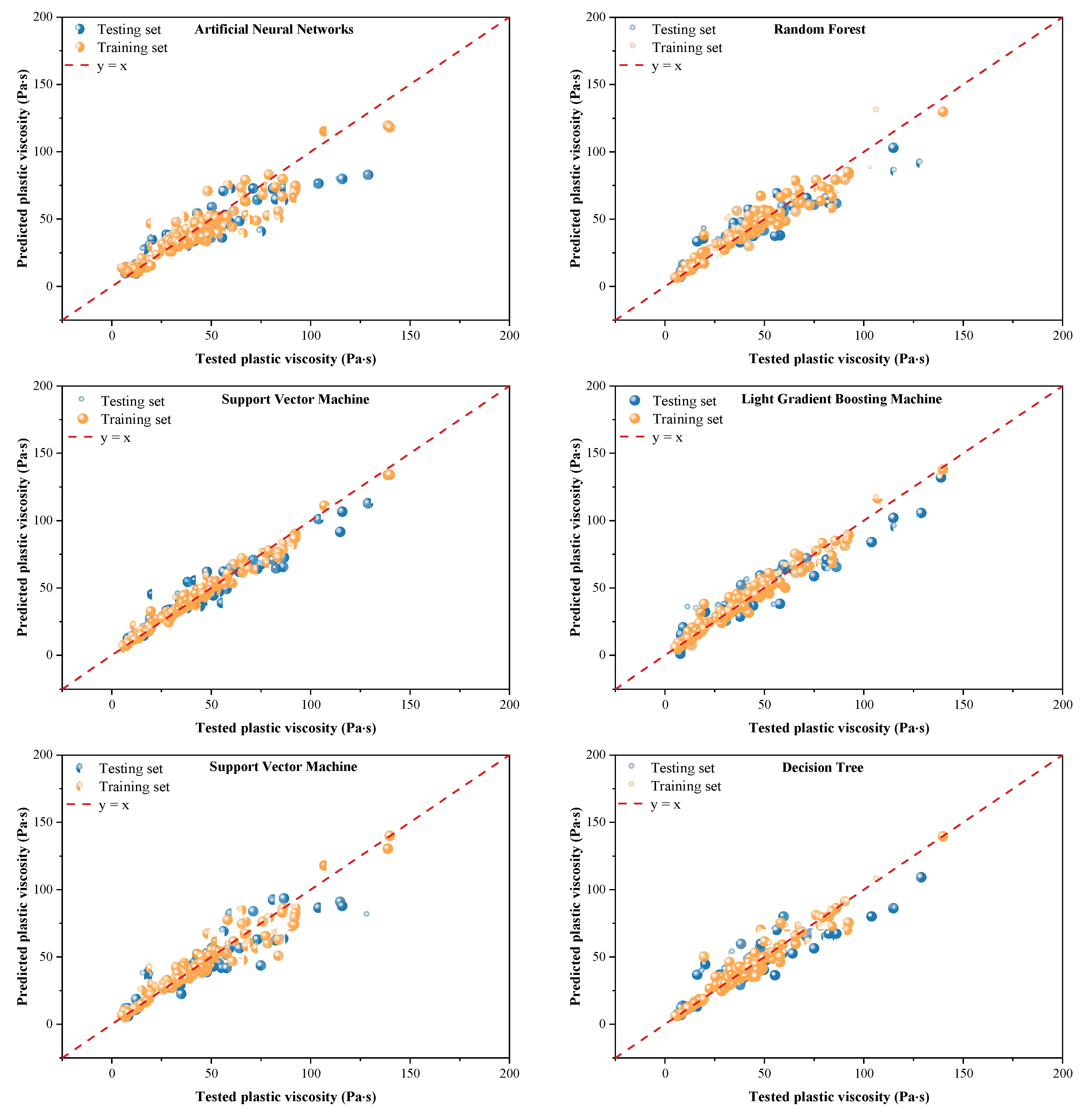

3.3. Plastic Viscosity: Model Evaluation and Accuracy Assessment

3.4. Sensitivity/Significance/Importance Analysis

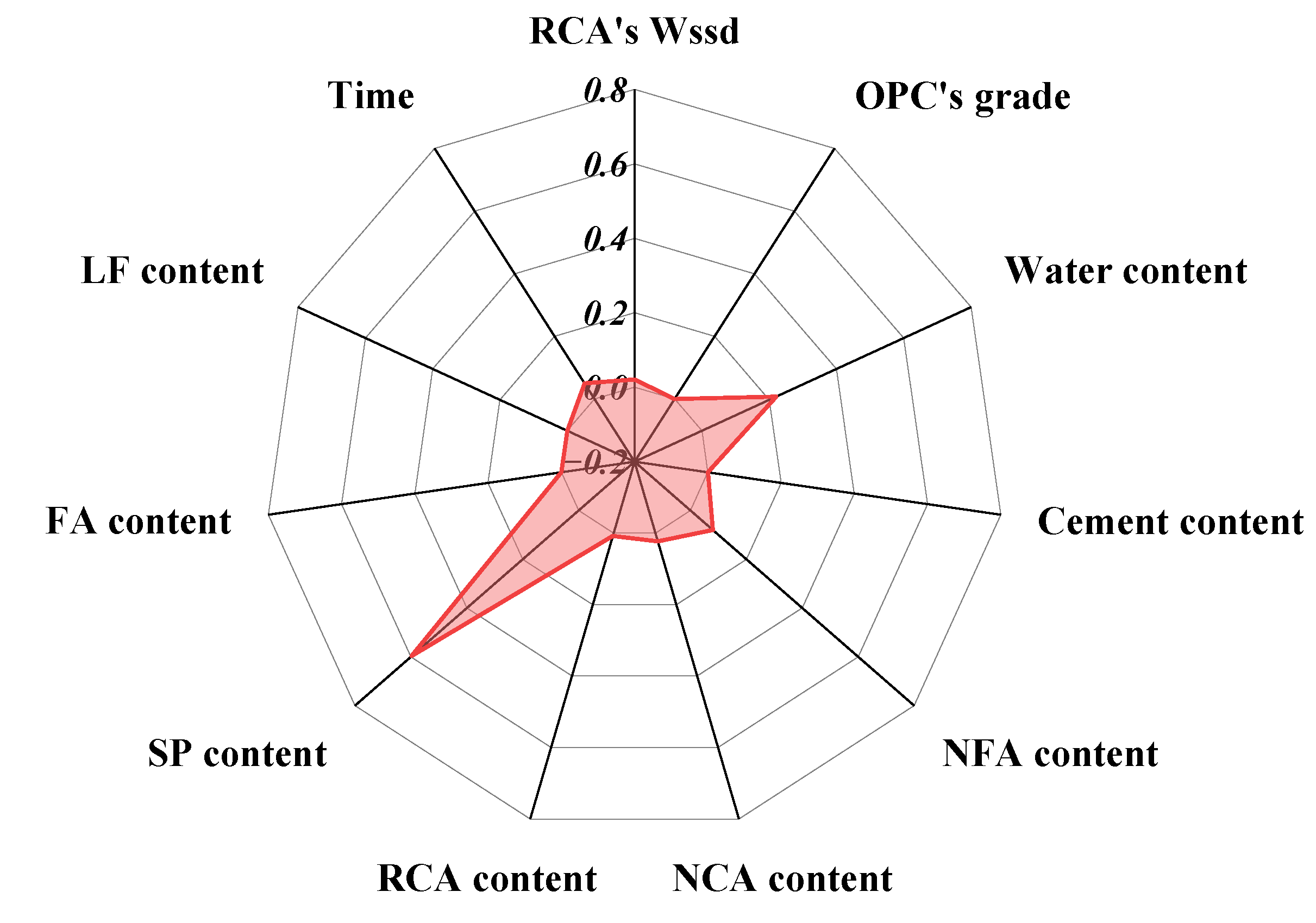

3.4.1. Importance Analysis for DYS

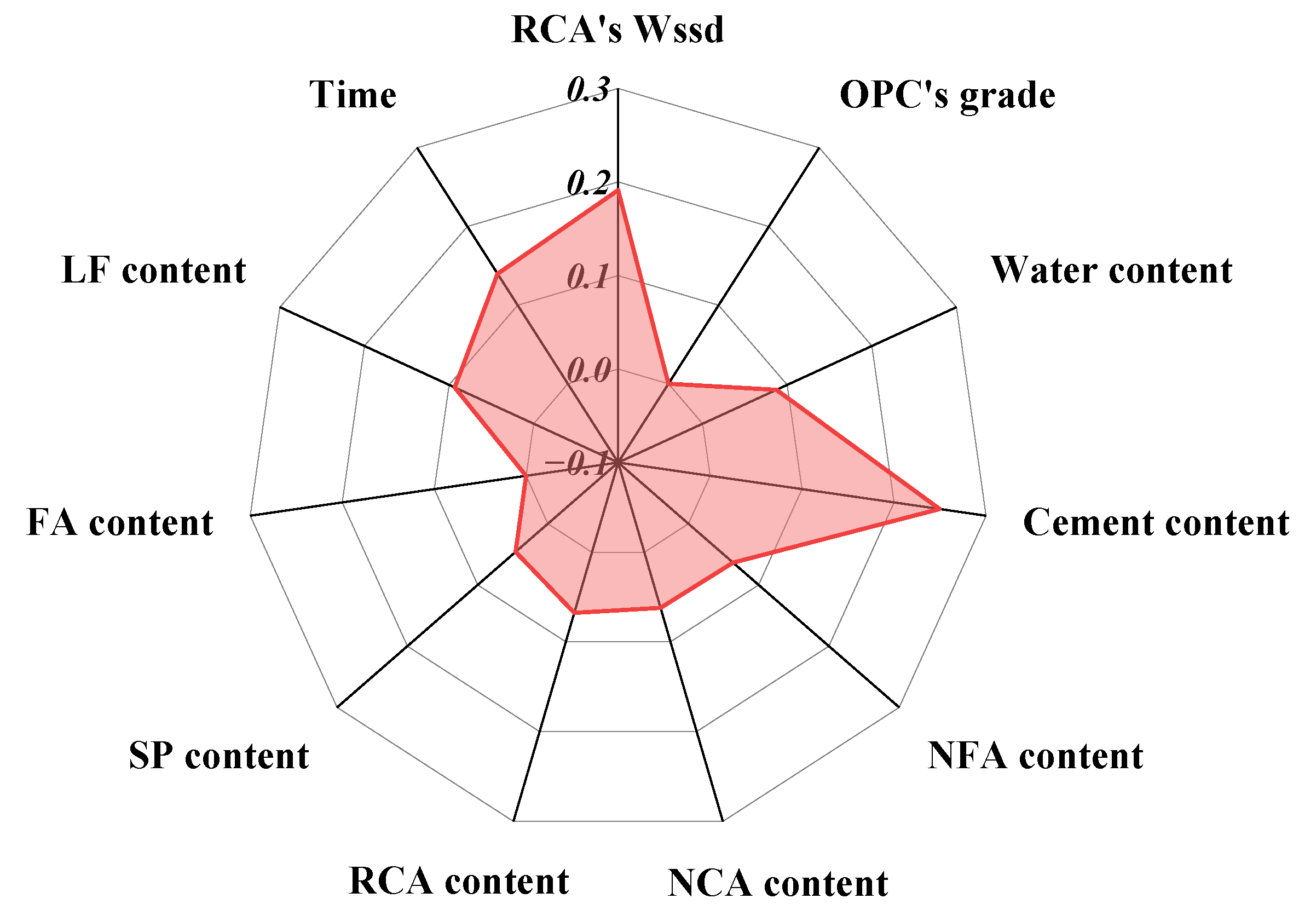

3.4.2. Importance Analysis for PV

4. Conclusions

- (1)

- The DT model demonstrated the best predictive performance for DYS, achieving the highest testing R2 of 0.9506. Accordingly, DT is the preferred model for DYS on small datasets, leveraging the full dataset while capturing hierarchical and nonlinear interactions with minimal overfitting. The ANN model ranked second with a testing R2 of 0.9285. SVM and ensemble models, including RF, XGBoost, and LightGBM, exhibited moderate to strong performance, with testing R2 values ranging from 0.8990 to 0.9173.

- (2)

- The XGBoost model excelled in predicting RCAC’s PV, achieving the highest testing R2 of 0.9298. Therefore, XGBoost is the recommended choice for PV, reflecting superior capture of multiple paste-level interactions that govern viscosity. LightGBM also performed well, with a testing R2 of 0.8935. Simpler models, including DT and RF, achieved moderate predictive accuracy, with testing R2 values of 0.8577 and 0.8665, respectively. SVM and ANN showed lower predictive capabilities, with testing R2 values falling below 0.85.

- (3)

- As identified by the DT model, SP content and water content (i.e., w/b ratios) are the most influential factors for RCAC’s DYS. Thus, adjusting SP content and w/b ratio is the most effective lever for controlling DYS. For PV, cement content and RCA’s Wssd emerged as the dominant parameters in the XGBoost model, confirming that cement content and RCA absorption govern paste lubrication and viscosity. These conclusions are corroborated by the Pearson and Spearman coefficient analyses. The observed time-dependent effect on PV confirms the dynamic nature of RCAC rheology as indicated by feature importance.

- (4)

- Future research should focus on expanding the database, particularly for predicting DYS, to improve model generalization and reliability. The apparently small effects of FA, LF, and cement strength grade likely reflect data limitations rather than intrinsic irrelevance. Current samples are limited and unevenly distributed, with missing intermediate levels. Addressing these limitations by incorporating more samples with evenly distributed parameter values could better capture their true influence on RCAC’s rheological properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maglad, A.M.; Mansour, W.; Tayeh, B.A.; Elmasry, M.; Yosri, A.M.; Fayed, S. Experimental and analytical investigation of fracture characteristics of steel fiber-reinforced recycled aggregate concrete. Int. J. Concr. Struct. Mater. 2023, 17, 74. [Google Scholar] [CrossRef]

- Mansour, W.; Li, W.; Wang, P.; Badawi, M. Experimental and numerical evaluations of the shear performance of recycled aggregate RC beams strengthened using CFRP sheets. Eng. Struct. 2024, 301, 117368. [Google Scholar] [CrossRef]

- Wu, Y.W.; Liu, C.; Liu, H.W.; Zhang, Z.Z.; He, C.H.; Liu, S.H.; Zhang, R.F.; Wang, Y.Q.; Bai, G.L. Study on the rheology and buildability of 3D printed concrete with recycled coarse aggregates. J. Build. Eng. 2021, 42, 103030. [Google Scholar] [CrossRef]

- Zou, S.; Xiao, J.Z.; Duan, Z.H.; Ding, T.; Hou, S.D. On rheology of mortar with recycled fine aggregate for 3D printing. Constr. Build. Mater. 2021, 311, 125312. [Google Scholar] [CrossRef]

- Hou, S.D.; Duan, Z.H.; Xiao, J.Z.; Li, L.; Bai, Y.H. Effect of moisture condition and brick content in recycled coarse aggregate on rheological properties of fresh concrete. J. Build. Eng. 2021, 35, 102075. [Google Scholar] [CrossRef]

- Singh, R.B.; Singh, B. Rheology of High-Volume Fly Ash Self-Compacting Recycled Aggregate Concrete. J. Mater. Civil. Eng. 2021, 33, 04021280. [Google Scholar] [CrossRef]

- González-Taboada, I.; González-Fonteboa, B.; Martínez-Abella, F.; Roussel, N. Robustness of self-compacting recycled concrete: Analysis of sensitivity parameters. Mater. Struct. 2018, 51, 537–546. [Google Scholar] [CrossRef]

- Iris, G.T.; Belén, G.F.; Fernando, M.A.; Diego, C.L. Self-compacting recycled concrete: Relationships between empirical and rheological parameters and proposal of a workability box. Constr. Build. Mater. 2017, 143, 537–546. [Google Scholar] [CrossRef]

- Safhi, A.E.; Dabiri, H.; Soliman, A.; Khayat, K.H. Prediction of self-consolidating concrete properties using XGBoost machine learning algorithm: Rheological properties. Powder Technol. 2024, 438, 119623. [Google Scholar] [CrossRef]

- Miao, Y.; Lau, S.S.Y.; Lo, K.K.N.; Song, Y.; Lai, H.; Zhang, J.; Tao, Y.; Fan, Y. Harnessing climate variables for predicting PV power output: A backpropagation neural network analysis in a subtropical climate region. Sol. Energy 2023, 264, 111979. [Google Scholar] [CrossRef]

- Miao, Y.; Liu, P.; Fu, I.C.S.; Lei, Q.; Lau, S.S.Y.; Tao, Y. The study of architectural geometry and shape in the energy balance of glazed roofs. Buildings 2022, 12, 1550. [Google Scholar] [CrossRef]

- Bu, L.T.; Du, G.Q.; Hou, Q. Prediction of the Compressive Strength of Recycled Aggregate Concrete Based on Artificial Neural Network. Materials 2021, 14, 3921. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.H.; Zou, C.Y.; Zhang, X.C.; Yan, J.C. Innovative prediction models for the frost durability of recycled aggregate concrete using soft computing methods. J. Build. Eng. 2021, 34, 101822. [Google Scholar] [CrossRef]

- Liu, K.H.; Alam, M.S.; Zhu, J.; Zheng, J.K.; Chi, L. Prediction of carbonation depth for recycled aggregate concrete using ANN hybridized with swarm intelligence algorithms. Constr. Build. Mater. 2021, 301, 124382. [Google Scholar] [CrossRef]

- Jin, L.B.; Dong, T.Y.; Fan, T.; Duan, J.; Yu, H.L.; Jiao, P.F.; Zhang, W.B. Prediction of the chloride diffusivity of recycled aggregate concrete using artificial neural network. Mater. Today Commun. 2022, 32, 104137. [Google Scholar] [CrossRef]

- Liu, K.H.; Zheng, J.K.; Pacheco-Torgal, F.; Zhao, X.Y. Innovative modeling framework of chloride resistance of recycled aggregate concrete using ensemble-machine-learning methods. Constr. Build. Mater. 2022, 337, 127613. [Google Scholar] [CrossRef]

- Liu, K.H.; Dai, Z.H.; Zhang, R.B.; Zheng, J.K.; Zhu, J.; Yang, X.C. Prediction of the sulfate resistance for recycled aggregate concrete based on ensemble learning algorithms. Constr. Build. Mater. 2022, 317, 125917. [Google Scholar] [CrossRef]

- Deng, Q.; Xiao, J.Z.; Duan, Z.H.; Li, L.; Guan, X.S. An intelligent mix design system for sustainable concrete containing multi-source recycled aggregate. J. Build. Eng. 2024, 96, 110566. [Google Scholar] [CrossRef]

- Duan, Z.H.; Zhao, W.J.; Ye, T.H.; Zhang, Y.H.; Zhang, C.C. Measurement of Water Absorption of Recycled Aggregate. Materials 2022, 15, 5141. [Google Scholar] [CrossRef]

- González-Taboada, I.; González-Fonteboa, B.; Martínez-Abella, F.; Carro-López, D. Study of recycled concrete aggregate quality and its relationship with recycled concrete compressive strength using database analysis. Mater. Construc. 2016, 66, 323. [Google Scholar] [CrossRef]

- Miao, Y.; Chau, K.W.; Lau, S.S.Y.; Ye, T. A novel thermal comfort model modified by time scale and habitual trajectory. Renew. Sustain. Energy Rev. 2025, 207, 114903. [Google Scholar] [CrossRef]

- Du, Z.; Liu, Y.; Zhang, Z. Spatiotemporal analysis of influencing factors of carbon emission in public buildings in China. Buildings 2022, 12, 424. [Google Scholar] [CrossRef]

- Amario, M.; Pepe, M.; Martinelli, E.; Toledo, R.D. Rheological Behavior at Fresh State of Structural Recycled Aggregate Concrete. High. Tech. Concr. Where Technol. Eng. Meet. 2018, 215–223. [Google Scholar]

- Amario, M.; Pepe, M.; Rangel, C.S.; Toledo, R.D. Analytical tool for assessment of the rheological behavior of recycled aggregate concrete. Constr. Build. Mater. 2021, 309, 125166. [Google Scholar] [CrossRef]

- Amer, A.A.M.; Ezziane, K.; Bougara, A.; Adjoudj, M. Rheological and mechanical behavior of concrete made with pre-saturated and dried recycled concrete aggregates. Constr. Build. Mater. 2016, 123, 300–308. [Google Scholar] [CrossRef]

- Bizinotto, M.B.; Faleschini, F.; Fernández, C.G.J.; Hernández, D.F.A. Effects of chemical admixtures on the rheology of fresh recycled aggregate concretes. Constr. Build. Mater. 2017, 151, 353–362. [Google Scholar] [CrossRef]

- Faleschini, F.; Jiménez, C.; Barra, M.; Aponte, D.; Vázquez, E.; Pellegrino, C. Rheology of fresh concretes with recycled aggregates. Constr. Build. Mater. 2014, 73, 407–416. [Google Scholar] [CrossRef]

- González-Taboada, I.; González-Fonteboa, B.; Eiras-López, J.; Rojo-López, G. Tools for the study of self-compacting recycled concrete fresh behaviour: Workability and rheology. J. Clean. Prod. 2017, 156, 1–18. [Google Scholar] [CrossRef]

- González-Taboada, I.; González-Fonteboa, B.; Martínez-Abella, F.; Seara-Paz, S. Analysis of rheological behaviour of self-compacting concrete made with recycled aggregates. Constr. Build. Mater. 2017, 157, 18–25. [Google Scholar] [CrossRef]

- González-Taboada, I.; González-Fonteboa, B.; Martínez-Abella, F.; Seara-Paz, S. Evaluation of self-compacting recycled concrete robustness by statistical approach. Constr. Build. Mater. 2018, 176, 720–736. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoglu, M.; Algin, Z.; Yazici, H. Rheological and fresh properties of self-compacting concretes containing coarse and fine recycled concrete aggregates. Constr. Build. Mater. 2016, 113, 622–630. [Google Scholar] [CrossRef]

- Mandal, R.; Panda, S.K.; Nayak, S. Evaluation of rheological properties of sustainable self-compacting recycled aggregate concrete produced by two-stage mixing approach. J. Build. Eng. 2024, 87, 109126. [Google Scholar] [CrossRef]

- Tahar, Z.E.A.; Benabed, B.; Kadri, E.; Ngo, T.T.; Bouvet, A. Rheology and strength of concrete made with recycled concrete aggregates as replacement of natural aggregates. Epitoanyag 2020, 72, 48–58. [Google Scholar] [CrossRef]

- Duan, Z.; Jiang, S.; Xiao, J.; Hou, S.; Chen, X. Effect of Moisture Condition of Recycled Coarse Aggregate on the Properties of Concrete (in Chinese). J. Build. Mater. 2021, 24, 545–550. [Google Scholar]

- Yang, L.; Shami, A. On hyperparameter optimization of machine learning algorithms: Theory and practice. Neurocomputing 2020, 415, 295–316. [Google Scholar] [CrossRef]

- Bischl, B.; Binder, M.; Lang, M.; Pielok, T.; Richter, J.; Coors, S.; Thomas, J.; Ullmann, T.; Becker, M.; Boulesteix, A.L.; et al. Hyperparameter optimization: Foundations, algorithms, best practices, and open challenges. Wires Data Min. Knowl. 2023, 13, e1484. [Google Scholar] [CrossRef]

- Feng, H.; Feng, Z.; Wang, W.; Deng, Z.; Zheng, B. Impact of polycarboxylate superplasticizers (PCEs) with novel molecular structures on fluidity, rheological behavior and adsorption properties of cement mortar. Constr. Build. Mater. 2021, 292, 123285. [Google Scholar] [CrossRef]

- Xie, J.; Cui, X.; Guo, N.; Liu, G. Influence of mix proportions on rheological properties, air content of wet shotcrete—A case study. Appl. Sci. 2021, 11, 3550. [Google Scholar] [CrossRef]

| Model | Hyperparameter | DYS | PV |

|---|---|---|---|

| ANN | Learning rate | 0.001 | 0.001 |

| Activation | ‘relu’ | ‘relu’ | |

| Hidden_layer_sizes | [32, 16] | [32, 16] | |

| RF | n_estimators | 149 | 247 |

| Max_depth | 45 | 12 | |

| Min_samples_split | 4 | 6 | |

| Min_samples_leaf | 1 | 1 | |

| XGBoost | Learning rate | 0.14 | 0.02 |

| Max_depth | 3 | 32 | |

| Gamma | 4 | 5 | |

| n_estimators | 84 | 266 | |

| subsample | 0.99 | 0.5 | |

| LightGBM | Learning rate | 0.19 | 0.16 |

| max_depth | 40 | 11 | |

| n_estimators | 257 | 335 | |

| subsample | 1 | 0.93 | |

| SVM | degree | 3 | 4 |

| epsilon | 0.1 | 0.001 | |

| gamma | ‘scale’ | ‘scale’ | |

| C | 1000 | 100 | |

| Kernel | ‘rbf’ | ‘poly’ | |

| DT | max_depth | 9 | 10 |

| min_samples_split | 2 | 3 | |

| min_samples_leaf | 1 | 3 |

| Parameter | Sample Size | Mean | Min. | Median | Max. | P10 | P90 | |

|---|---|---|---|---|---|---|---|---|

| Inputs | RCA’s Wssd | 147 | 5.91 | 3.37 | 6.30 | 7.97 | 3.37 | 7.00 |

| OPC’s grade | 171 | 51.3 | 42.5 | 52.5 | 52.5 | 42.5 | 52.5 | |

| Water | 171 | 203.3 | 156.0 | 200.7 | 292.9 | 168.0 | 240.0 | |

| Cement | 171 | 374.6 | 313.0 | 360.0 | 455.0 | 320.0 | 440.0 | |

| NFA | 171 | 796.9 | 608.0 | 852.0 | 944.0 | 608.0 | 944.0 | |

| NCA | 138 | 664.1 | 163.0 | 649.0 | 1064.0 | 327.0 | 1021.0 | |

| RCA | 147 | 439.3 | 121.9 | 355.0 | 1047.0 | 140.4 | 868.8 | |

| SP | 162 | 5.45 | 0.40 | 5.50 | 9.86 | 1.34 | 9.86 | |

| FA | 23 | 170.9 | 110.0 | 180.0 | 180.0 | 110.0 | 180.0 | |

| LF | 60 | 107.7 | 40.0 | 40.0 | 180.0 | 40.0 | 180.0 | |

| Time | 171 | 26 | 3 | 16 | 100 | 10 | 60 | |

| Outputs | DYS | 171 | 100.31 | 0 | 108.48 | 301.20 | 4.09 | 214.00 |

| Parameter | Sample Size | Mean | Min. | Median | Max. | P10 | P90 | |

|---|---|---|---|---|---|---|---|---|

| Inputs | RCA’s Wssd | 268 | 6.36 | 3.37 | 6.96 | 7.97 | 5.05 | 6.96 |

| OPC’s grade | 325 | 51.8 | 42.5 | 52.5 | 52.5 | 52.5 | 52.5 | |

| Water | 325 | 204.3 | 156.0 | 204.2 | 292.9 | 178.5 | 232.1 | |

| Cement | 325 | 383.8 | 313.0 | 400.0 | 455.0 | 320.0 | 440.0 | |

| NFA | 325 | 827.6 | 608.0 | 866.0 | 944.0 | 700.0 | 880.0 | |

| NCA | 266 | 626.3 | 163.0 | 614.4 | 1064.0 | 384.0 | 887.0 | |

| RCA | 268 | 398.1 | 121.9 | 351.0 | 1047.0 | 138.3 | 795.3 | |

| SP | 316 | 4.58 | 0.40 | 3.48 | 9.86 | 1.60 | 9.86 | |

| FA | 23 | 170.9 | 110.0 | 180.0 | 180.0 | 110.0 | 180.0 | |

| LF | 199 | 158.2 | 40.0 | 180.0 | 180.0 | 40.0 | 180.0 | |

| Time | 325 | 36 | 3 | 20 | 100 | 10 | 90 | |

| Outputs | PV | 325 | 40.59 | 5.23 | 36.10 | 140.00 | 11.58 | 72.60 |

| Model | Dataset | R2 | RMSE | MAE |

|---|---|---|---|---|

| ANN | Training | 0.9702 | 14.50 | 9.26 |

| Testing | 0.9285 | 21.97 | 15.40 | |

| RF | Training | 0.9792 | 7.97 | 7.87 |

| Testing | 0.9142 | 12.14 | 16.78 | |

| XGBoost | Training | 0.9892 | 8.73 | 5.57 |

| Testing | 0.9067 | 25.09 | 16.62 | |

| LightGBM | Training | 0.9845 | 10.47 | 7.01 |

| Testing | 0.8990 | 26.10 | 19.50 | |

| SVM | Training | 0.9740 | 13.55 | 6.44 |

| Testing | 0.9173 | 23.62 | 15.58 | |

| DT | Training | 0.9914 | 7.80 | 3.03 |

| Testing | 0.9506 | 18.25 | 13.99 |

| Model | Dataset | R2 | RMSE | MAE |

|---|---|---|---|---|

| ANN | Training | 0.8750 | 8.59 | 5.76 |

| Testing | 0.8230 | 11.20 | 7.51 | |

| RF | Training | 0.9417 | 5.87 | 3.81 |

| Testing | 0.8665 | 9.73 | 6.48 | |

| XGBoost | Training | 0.9840 | 3.08 | 1.97 |

| Testing | 0.9298 | 7.06 | 4.58 | |

| LightGBM | Training | 0.9709 | 4.15 | 2.79 |

| Testing | 0.8935 | 8.69 | 6.06 | |

| SVM | Training | 0.9348 | 6.21 | 3.27 |

| Testing | 0.8487 | 10.36 | 6.60 | |

| DT | Training | 0.9503 | 5.42 | 3.04 |

| Testing | 0.8577 | 10.05 | 7.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Liu, W.; Ye, T. Prediction on Dynamic Yield Stress and Plastic Viscosity of Recycled Coarse Aggregate Concrete Using Machine Learning Algorithms. Buildings 2025, 15, 3353. https://doi.org/10.3390/buildings15183353

Chen H, Liu W, Ye T. Prediction on Dynamic Yield Stress and Plastic Viscosity of Recycled Coarse Aggregate Concrete Using Machine Learning Algorithms. Buildings. 2025; 15(18):3353. https://doi.org/10.3390/buildings15183353

Chicago/Turabian StyleChen, Haoxi, Wenlin Liu, and Taohua Ye. 2025. "Prediction on Dynamic Yield Stress and Plastic Viscosity of Recycled Coarse Aggregate Concrete Using Machine Learning Algorithms" Buildings 15, no. 18: 3353. https://doi.org/10.3390/buildings15183353

APA StyleChen, H., Liu, W., & Ye, T. (2025). Prediction on Dynamic Yield Stress and Plastic Viscosity of Recycled Coarse Aggregate Concrete Using Machine Learning Algorithms. Buildings, 15(18), 3353. https://doi.org/10.3390/buildings15183353