Analysis and Research on Thermal Insulation Performance of Autoclaved Aerated Concrete Sandwich Perimeter Wall in Hot-Summer and Cold-Winter Regions Under Low Temperature Environment

Abstract

1. Introduction

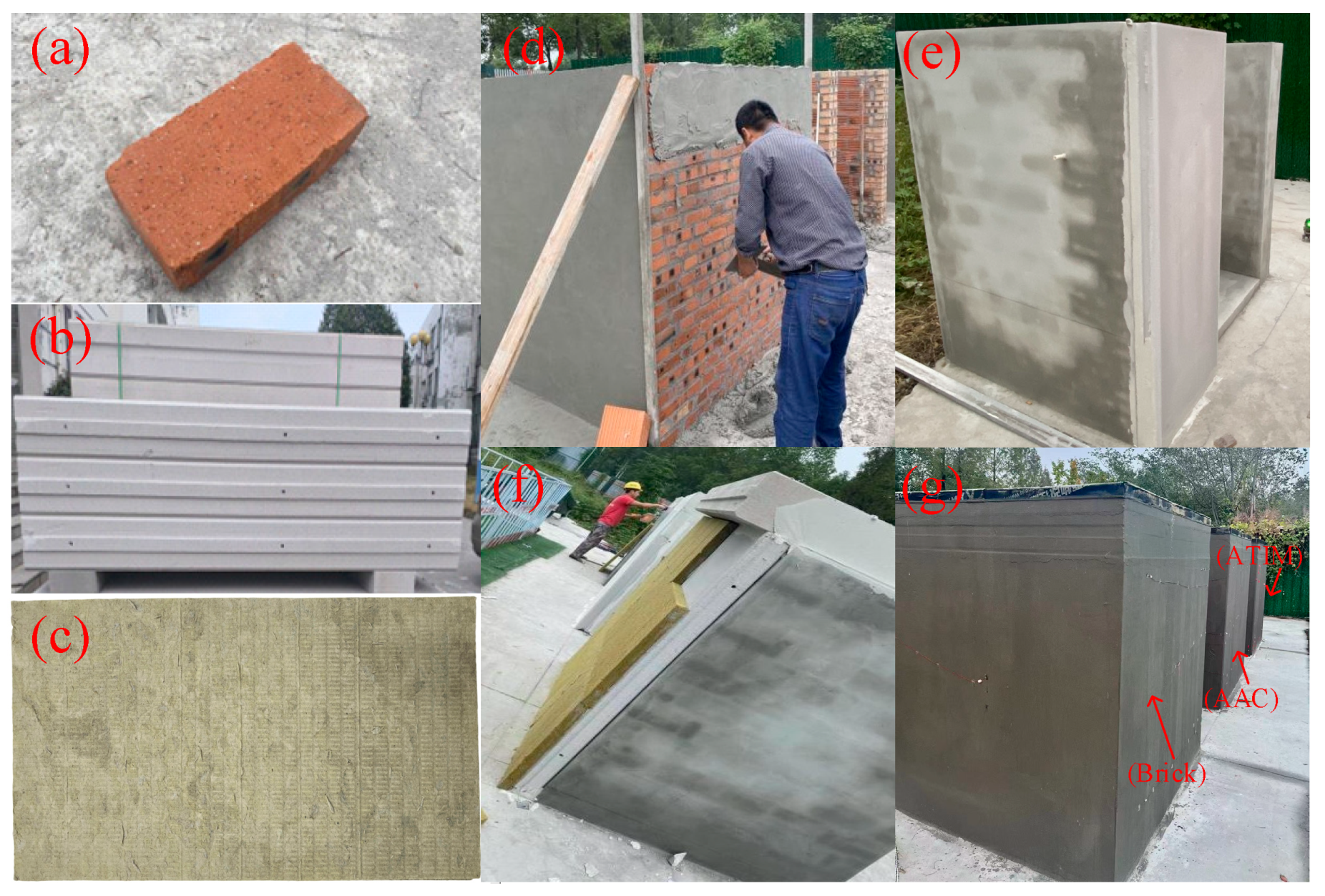

2. Materials and Methods

2.1. Material of TIM

2.2. Material of AAC

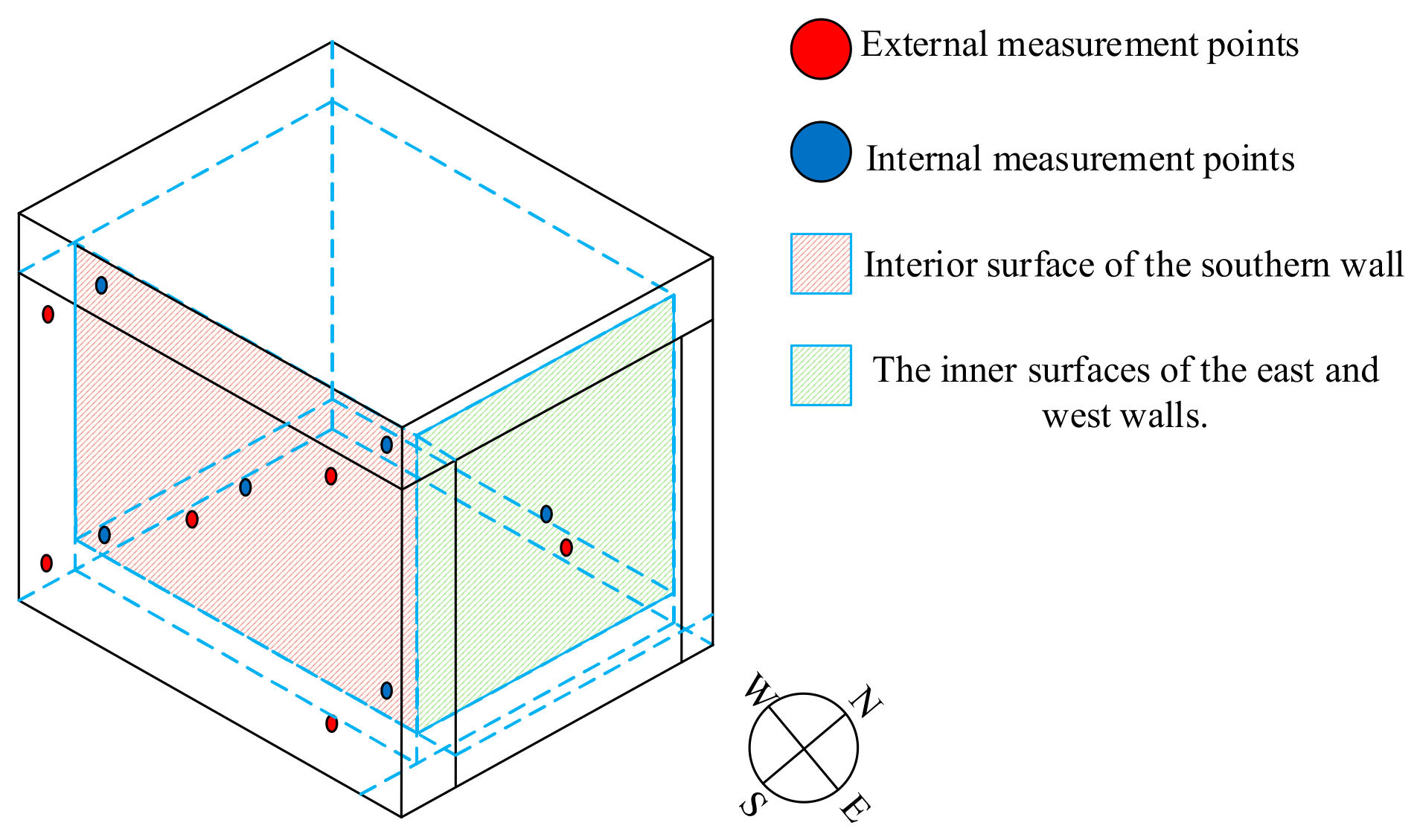

2.3. Model Introduction

3. Assessment Methods

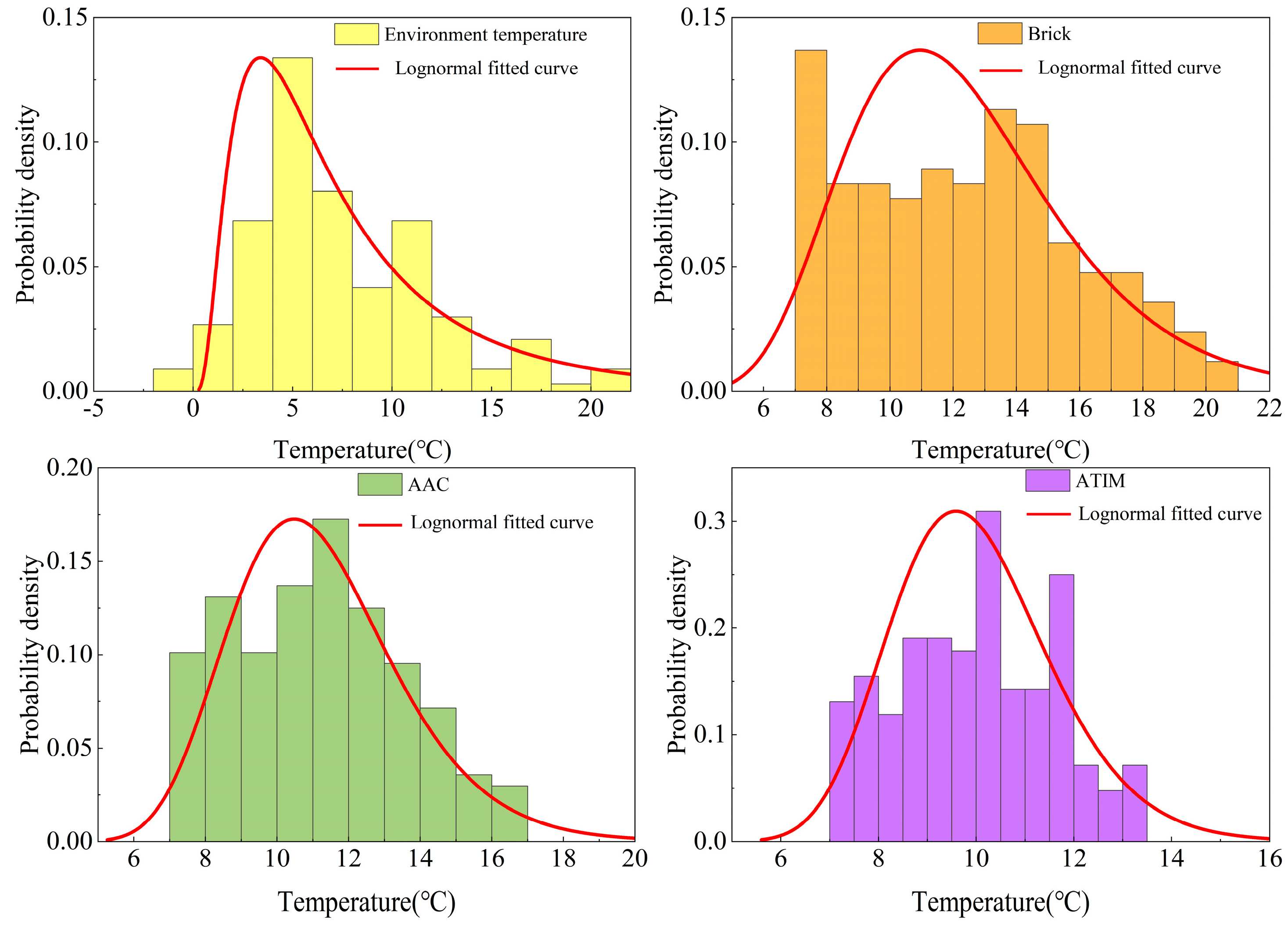

3.1. Temperature Probability Density Distribution

3.2. Evaluation of Thermal Performance

3.2.1. Heat Storage Coefficient and Thermal Inertia Index

3.2.2. Thermal Delay Time

3.2.3. Thermal Amplitude Attenuation Multiple

3.3. Heat Gain

3.4. Heat Consumption Indicator

3.5. Economic Benefits and Uncertainty

4. Results and Discussion

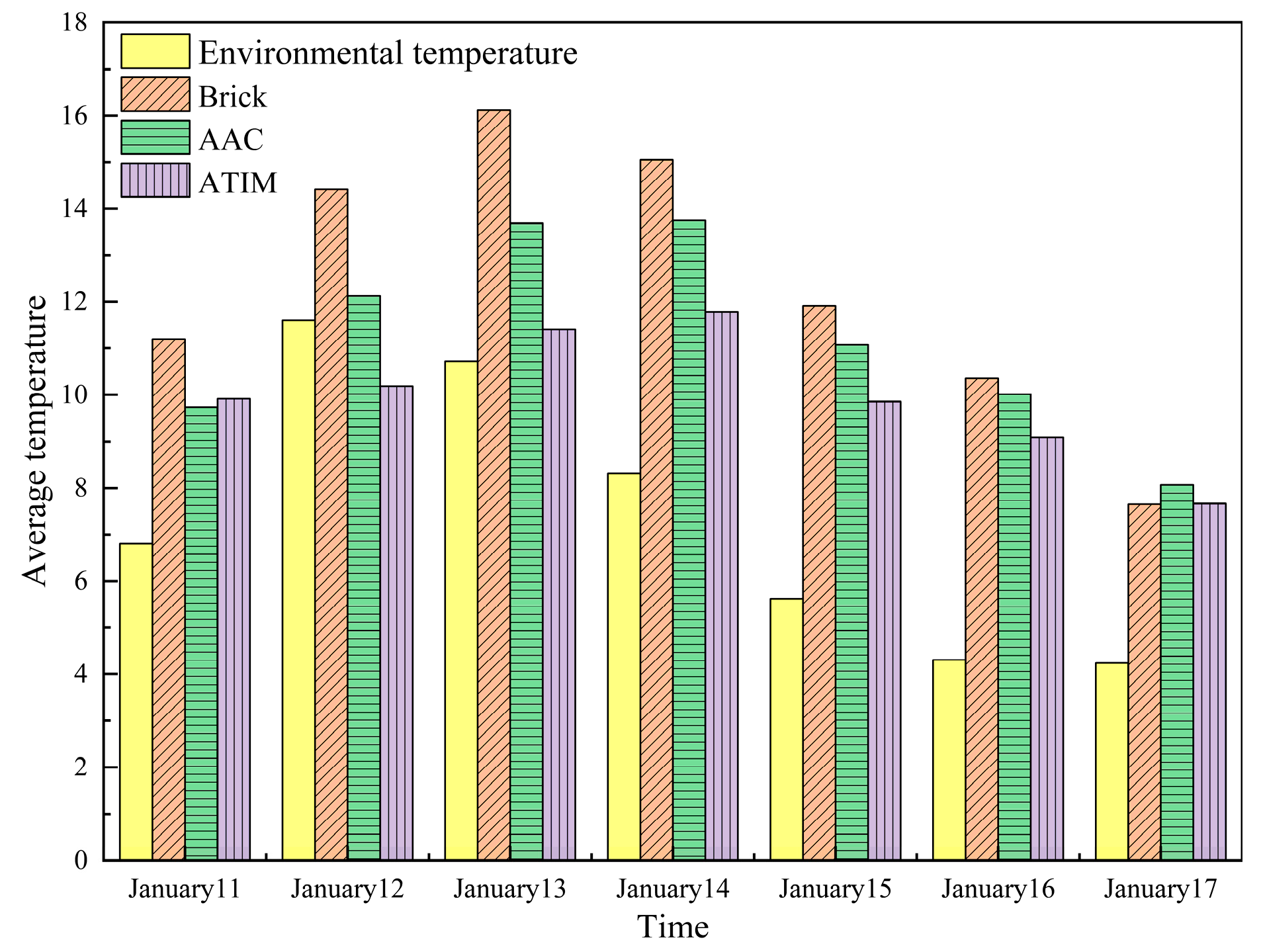

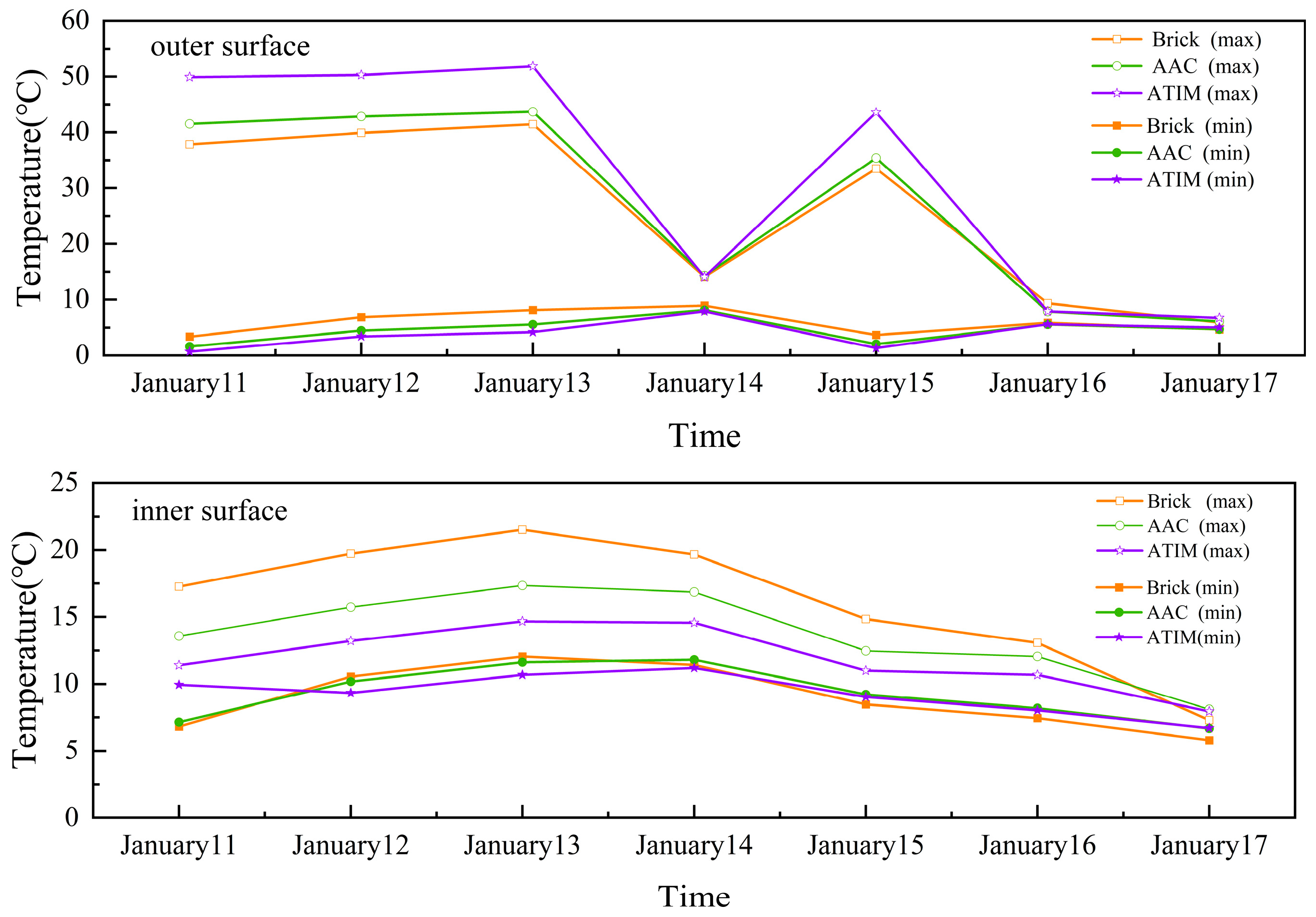

4.1. Temperature Analysis

4.2. Index of Thermal Performance

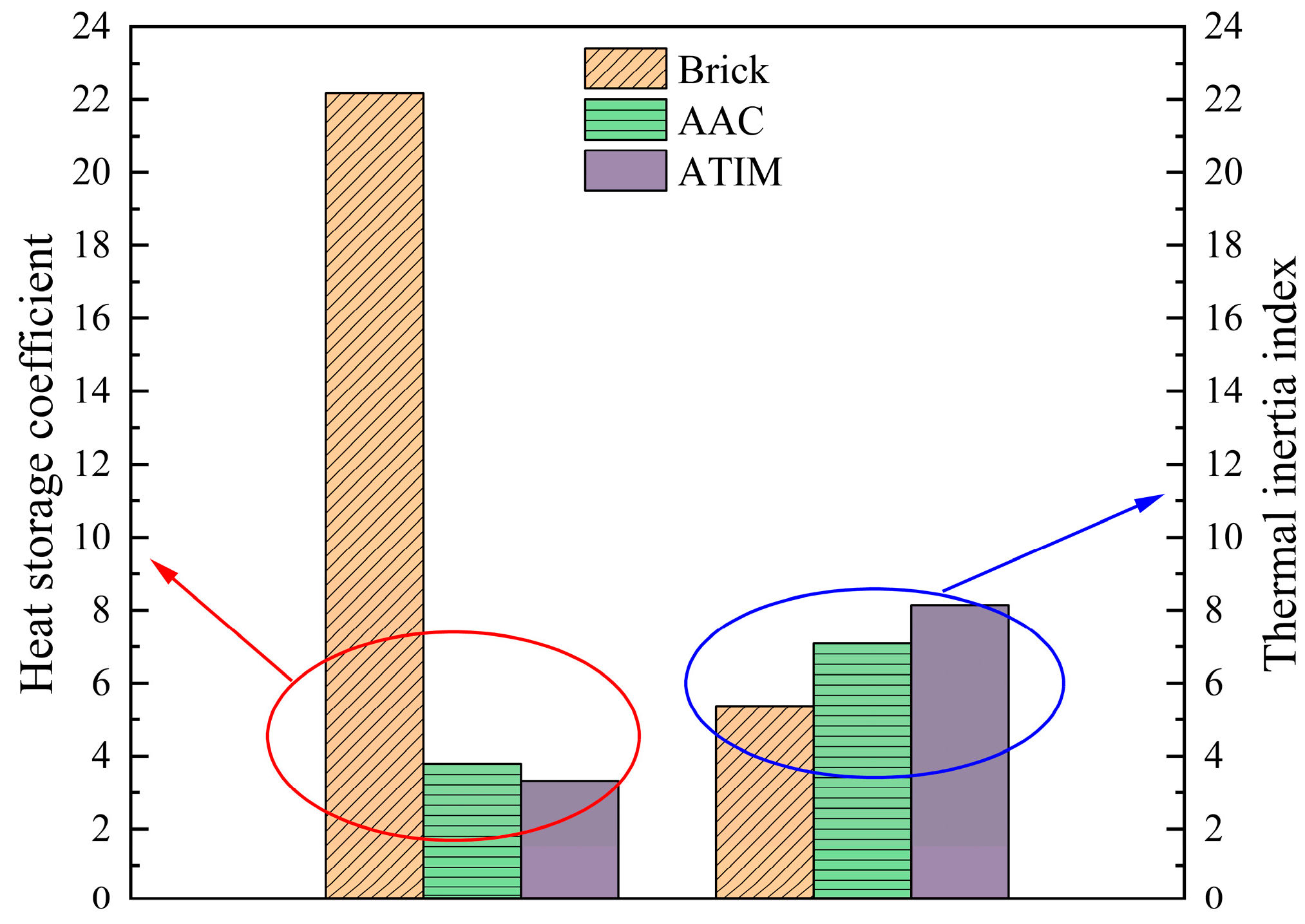

4.2.1. Heat Storage Coefficient and Thermal Inertia Index

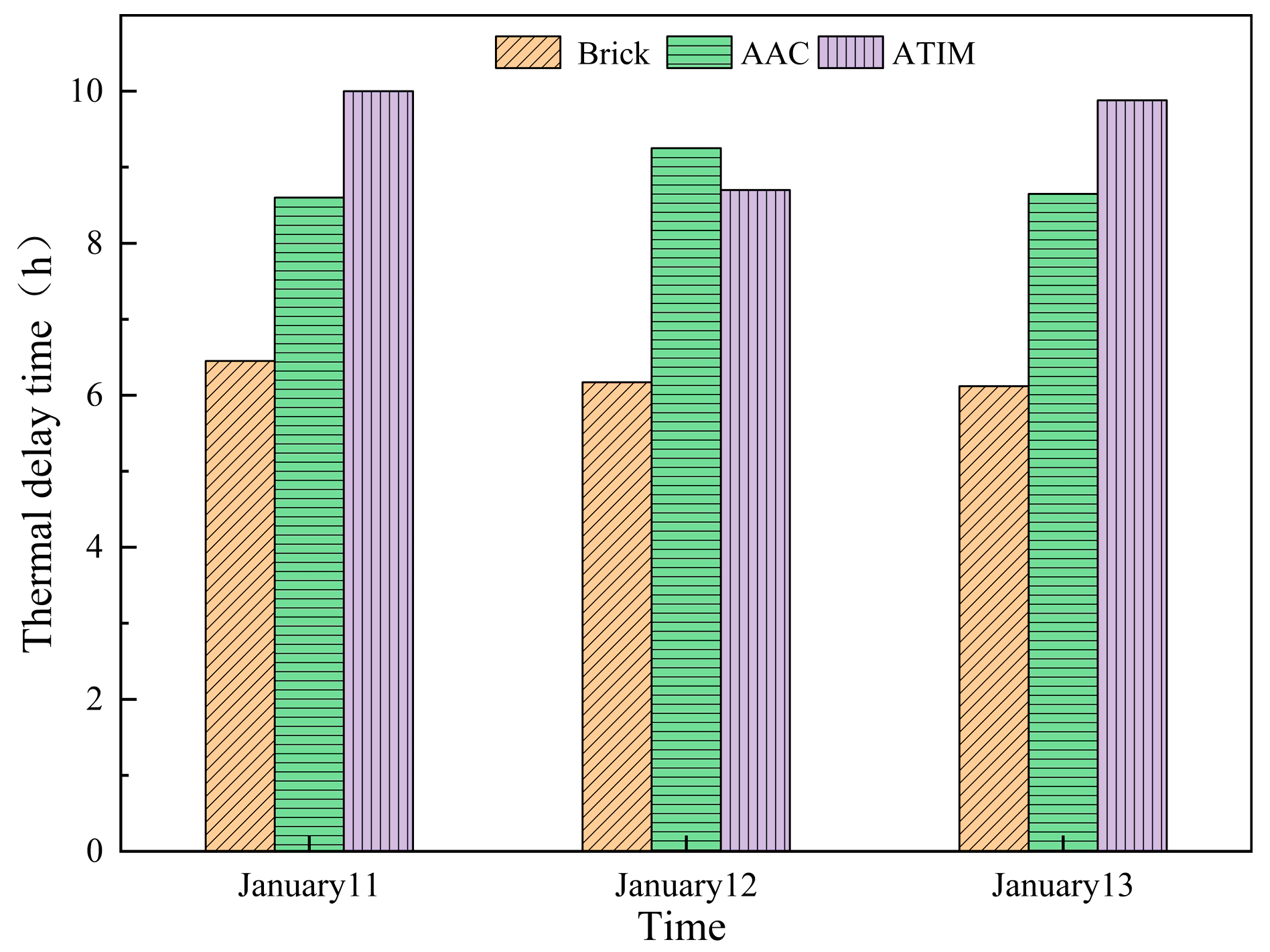

4.2.2. Thermal Delay Time

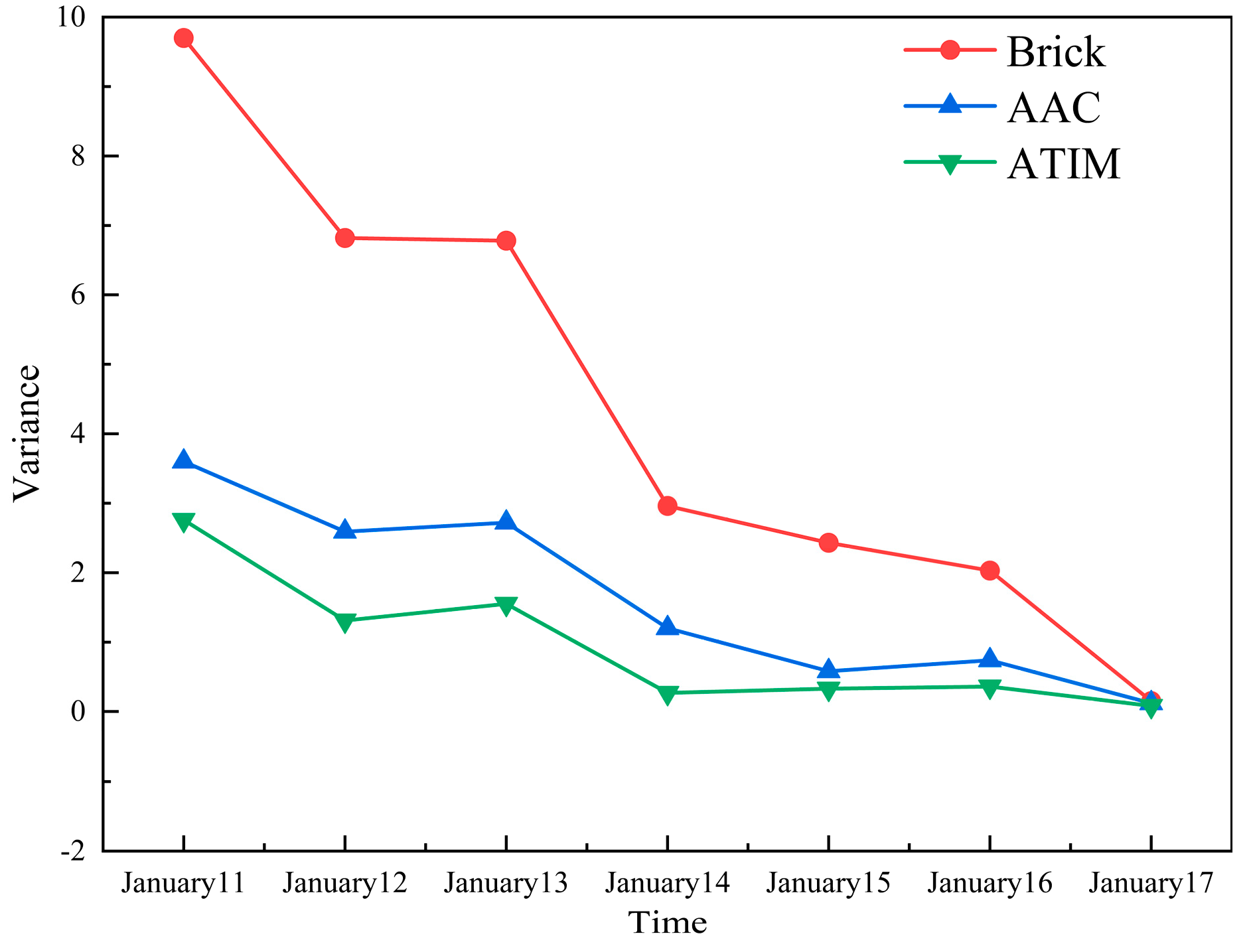

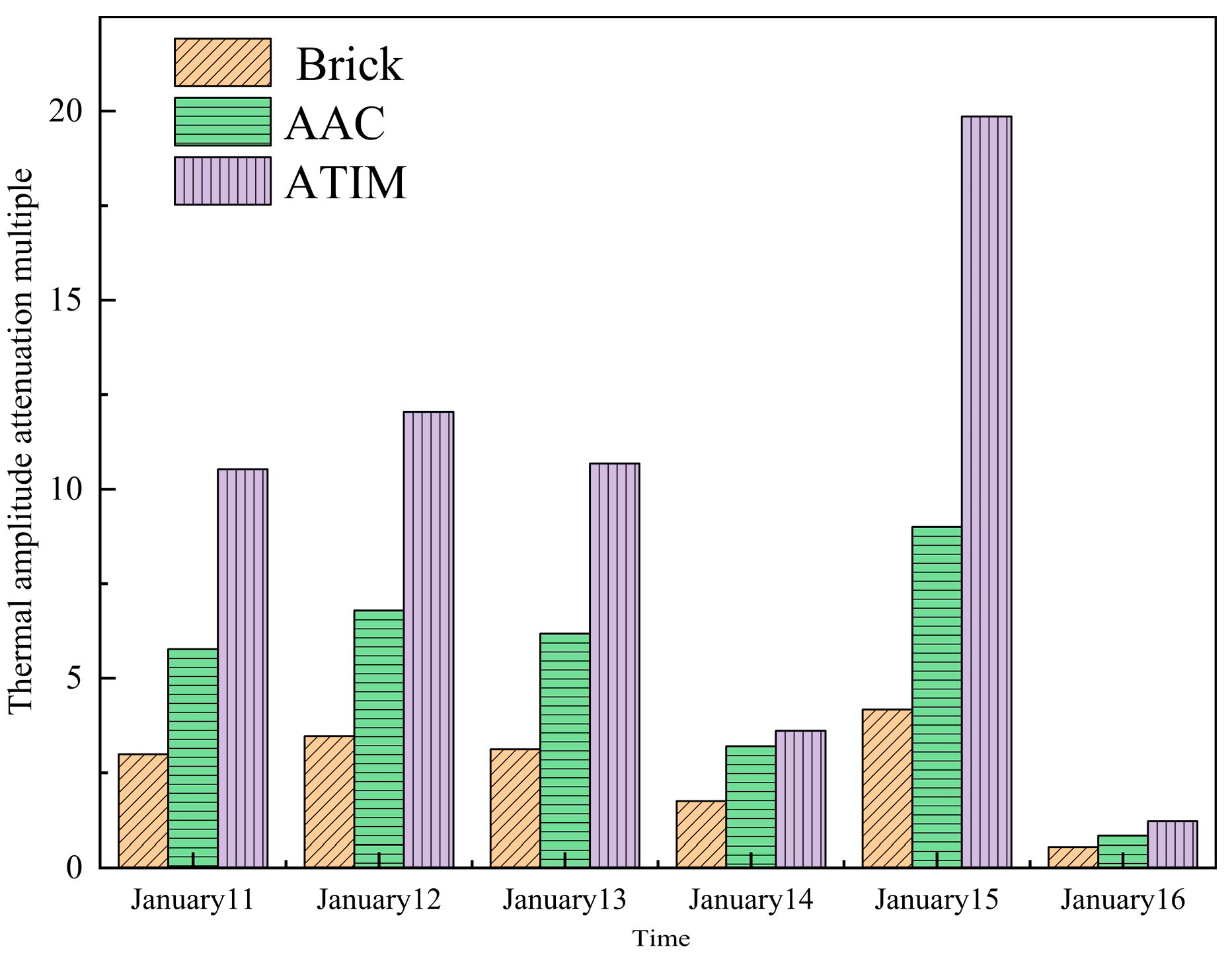

4.2.3. Thermal Amplitude Attenuation Multiple

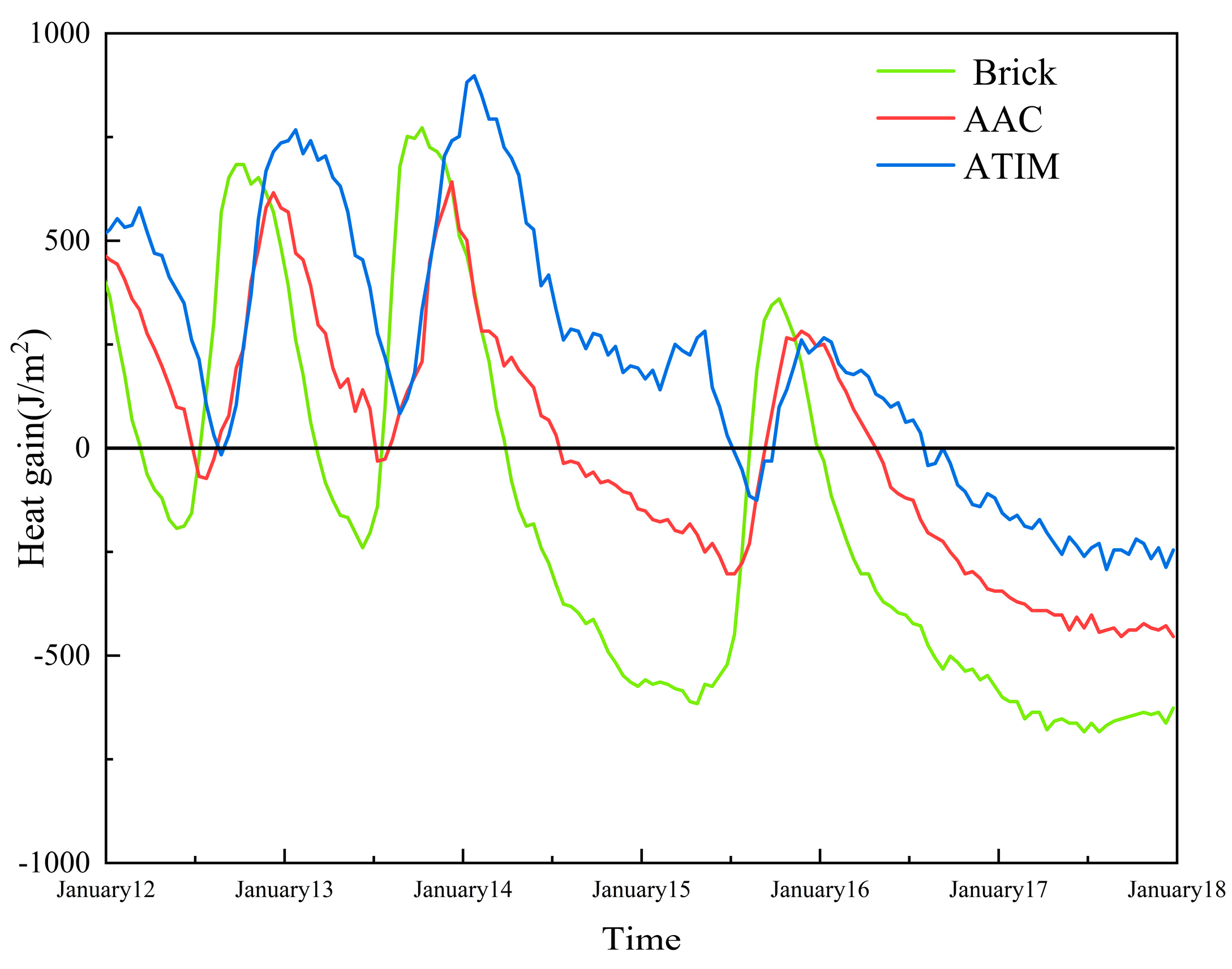

4.3. Heat Gain

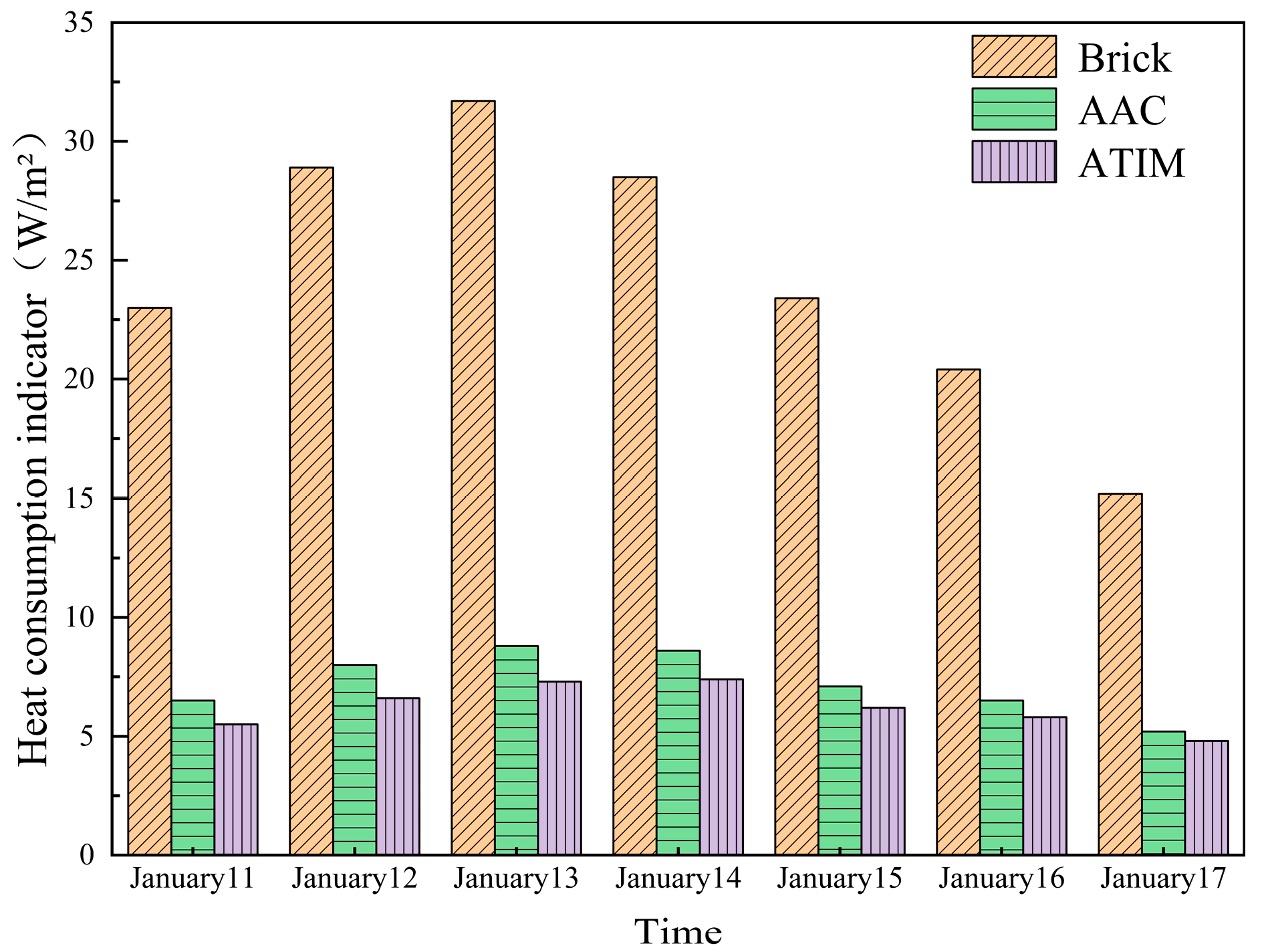

4.4. Heat Consumption

4.5. Uncertainty

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | |

| heat storage coefficient (W/(m2·K)) | |

| specific heat capacity (kJ/(kg·K)) | |

| time period (24 h) | |

| thermal resistance ((m2·K)/W) | |

| time | |

| temperature (°C) | |

| heat flux (W/m2) | |

| heat transfer coefficient (W/(m2·K)) | |

| heat transfer coefficient of the envelope structure | |

| enclosure structure area | |

| area (m2) | |

| number of air changes | |

| air change volume | |

| Greek Symbols | |

| standard deviation | |

| mean value | |

| logarithmic standard deviation | |

| logarithmic mean | |

| density (kg/m3) | |

| thermal conductivity (W/(m·K)) | |

| wall thickness (mm) | |

| heat transfer time (s) | |

| thermal delay time (h) | |

| Subscripts | |

| inter surface | |

| outer surface | |

| indoor air | |

| average indoor temperature of all rooms | |

| average outdoor temperature | |

| air | |

| Abbreviations | |

| Brick | sintered brick |

| AAC | autoclaved aerated concrete |

| ATIM | autoclaved aerated concrete–rock wool |

References

- Chen, X.; Lin, B. Towards carbon neutrality by implementing carbon emissions trading scheme: Policy evaluation in China. Energy Policy 2021, 157, 112510. [Google Scholar] [CrossRef]

- Gan, L.; Liu, Y.; Shi, Q.; Cai, W.; Ren, H. Regional inequality in the carbon emission intensity of public buildings in China. Build. Environ. 2022, 225, 109657. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, D.; Cheng, H.; Song, Y.; Yuan, K.; Du, W. Key technologies and challenges of low-carbon integrated Energy System Planning for Carbon Emission Peak and Carbon Neutrality. Autom. Electr. Power Syst. 2022, 46, 189–207. Available online: https://kns.cnki.net/nzkhtml/xmlRead/xml.html?pageType=web&fileName=DLXT202208021&tableName=CJFDTOTAL&dbCode=CJFD&fileSourceType=1&appId=KNS_BASIC_PSMC&invoice=i3Ib1gFeSpdmPGIXTkjZac+zxtHJOksFMQw1xoKJEMlJOOg0HA1j98X8wqPa/qGUy6OFfxTnODCdynZFr9RO+w4u8zh2eGbmsjL/HuQxctHQwAJiuCCtPRzGn4jwCDdFXIu7MvMwSRXhF8rr5ClcN7r4b/UpisI6tZI5Pd0QcxA= (accessed on 21 January 2022).

- Siddique, M.B.; Nielsen, P.S.; Rosendal, M.B.; Jensen, I.G.; Keles, D. Impacts of earlier natural gas phase-out & heat-saving policies on district heating and the energy system. Energy Policy 2023, 174, 113441. [Google Scholar] [CrossRef]

- Tan, Y.Y.; Awang, H.; Kaus, N.H.M. Integration of fly ash and ground granulated blast furnace slag into palm oil fuel ash based geopolymer concrete: A review. Sustain. Struct. 2024, 4, 000050. [Google Scholar] [CrossRef]

- Gómez, P.J.R.; Yero, A.M.G.; Riverón, G.C. Design and construction of houses with Guadua cane and rice husk in Ecuador as an alternative to local development. Sustain. Struct. 2024, 4, 000047. [Google Scholar] [CrossRef]

- Sathiparan, N.; Subramaniam, D.N. Optimizing fly ash and rice husk ash as cement replacements on the mechanical characteristics of pervious concrete. Sustain. Struct. 2025, 5, 000065. [Google Scholar] [CrossRef]

- Chowdhury, J.A.; Islam, S.; Islam, A.; Al Bari, A.; Debnath, A.K. Analysis of mechanical properties of fly ash and boiler slag integrated geopolymer composites. Sustain. Struct. 2025, 5, 000073. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Zuaiter, H.A.; Jawa, M.M. Carbonation and chloride penetration resistance of sustainable structural concrete with alkali-activated and ordinary Portland cement binders: A critical. Sustain. Struct. 2025, 5, 000075. [Google Scholar] [CrossRef]

- Jiang, J.; Ma, B.; Cai, Q.; Shao, Z.; Hu, Y.; Qian, B.; Wang, J.; Ma, F.; Wang, L. Utilization of ZSM-5 waste for the preparation of autoclaved aerated concrete (AAC): Mechanical properties and reaction products. Constr. Build. Mater. 2021, 297, 123821. [Google Scholar] [CrossRef]

- Kočí, V.; Maděra, J.; Černý, R. Computer aided design of interior thermal insulation system suitable for autoclaved aerated concrete structures. Appl. Therm. Eng. 2013, 58, 165–172. [Google Scholar] [CrossRef]

- Wang, C.; Xiong, D. Leaching assessment of aerated concrete made of recycled shale gas drilling cuttings: Particular pollutants, physical performance and environmental characterization. J. Clean. Prod. 2021, 282, 125099. [Google Scholar] [CrossRef]

- Feng, W.; Li, Z.; Long, Q.; Tang, S.; Zhao, Y. Study on the properties of autoclaved aerated concrete with high content concrete slurry waste. Dev. Built Environ. 2024, 17, 100338. [Google Scholar] [CrossRef]

- Ji, X.; Pan, T.; Fu, C.; Han, F.; Zhao, W.; Sha, J.; Liu, J. Hydration, microstructure and mechanical properties of cement-based materials with heat-modified autoclaved aerated concrete waste. Constr. Build. Mater. 2024, 419, 135482. [Google Scholar] [CrossRef]

- Michelini, E.; Ferretti, D.; Miccoli, L.; Parisi, F. Autoclaved aerated concrete masonry for energy efficient buildings: State of the art and future developments. Constr. Build. Mater. 2023, 402, 132996. [Google Scholar] [CrossRef]

- Liu, X.; Peng, X.; Wang, H.; Li, W.; Wang, P. Preparation and performance optimization of non-autoclaved aerated concrete based on orthogonal tests. China Powder Sci. Technol. 2024, 30, 74–84. [Google Scholar] [CrossRef]

- Miccoli, L.; Fontana, P.; Silva, N.; Klinge, A.; Cederqvist, C.; Kreft, O.; Qvaeschning, D.; Sjöström, C. Composite UHPC-AAC/CLC facade elements with modified interior plaster for new buildings and refurbishment. Materials and production technology. J. Facade Des. Eng. 2015, 3, 91–102. [Google Scholar] [CrossRef]

- Yang, R.; Zhu, J.; Wu, Z.; Wu, Z.; Li, M.; Peng, C. Thermal insulation and strength of autoclaved light concrete. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2011, 26, 132–136. [Google Scholar] [CrossRef]

- Chen, G.; Li, F.; Geng, J.; Jing, P.; Si, Z. Identification, generation of autoclaved aerated concrete pore structure and simulation of its influence on thermal conductivity. Constr. Build. Mater. 2021, 294, 123572. [Google Scholar] [CrossRef]

- Yu, C.; Shen, D.; Tu, J.; Chen, G.; Chai, L. Numerical Analysis on Thermal Behavior of Composite Wall Combined Autoclaved Aerated Concrete With Thermal Insulting Material in Summer Day. J. Therm. Sci. Eng. Appl. 2024, 16, 111002. [Google Scholar] [CrossRef]

- Stepien, A.; Dachowski, R.; Piotrowski, J.Z. Insulated Autoclaved Cellular Concretes and Improvement of Their Mechanical and Hydrothermal Properties. In Thermal Insulation and Radiation Control Technologies for Buildings; Springer International: Cham, Switzerland, 2022. [Google Scholar]

- Sharma, U.; Tariq, S.M.N. Computational Analysis of Autoclaved Aerated Concrete Block Walls for Heat Optimization-A Case Study of Frank & Debbie Islam Management Complex, Aligarh Muslim University, Aligarh, India. In International Conference on Signal, Machines, Automation, and Algorithm; Springer: Singapore, 2023. [Google Scholar]

- Sang, G. Study on Construction System of Low Energy consumption Residential Buildings in Tibet Plateau. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2009. [Google Scholar]

- Zhu, X. Research and Evaluation on Thermal Insulation Performance of the External Envelope Structure of the Fabricated Composite Wall Structure System Dwellings. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2018. [Google Scholar]

- Ma, X. Study on Optimization of Thermal Performance of Prefabricated Sandwich Wall Panels in Northwest Cold Regions. Master’s Thesis, Ningxia University, Yinchuan, China, 2021. [Google Scholar]

- Xue, W.; Xu, Y.; Zhu, Y. Development of a New Type of Precast Concrete Inorganic Insulation Sandwich Wall Panel and Study on Its Thermal Performance. China Concr. Cem. Prod. 2013, 8, 55–57. [Google Scholar]

- Liu, L. The Research on Thermal Insulation Properties and Mechanical Properties of EPS Interlayer Wall. Master’s Thesis, Yangtze University, Jingzhou, China, 2012. [Google Scholar]

- O’Hegarty, R.; Reilly, A.; West, R.; Kinnane, O. Thermal investigation of thin precast concrete sandwich panels. J. Build. Eng. 2020, 27, 100937. [Google Scholar] [CrossRef]

- Dong, X. Research on the Performance and Design of External Thermal Insulation Sandwich Wall Panels in Severe Cold Areas. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2021. [Google Scholar] [CrossRef]

- Tu, J.; Chen, G.; Yu, C. Experimental study on energy saving and thermal insulation of AAC walls and sandwich structures. Case Stud. Therm. Eng. 2024, 61, 104999. [Google Scholar] [CrossRef]

- Yang, H.; Yi, J.; Tian, G.; Tan, H. Application and performance analysis of common organic thermal insulation materials in building. Energy Conserv. 2020, 39, 18–21. [Google Scholar]

- Yan, X.; Ye, C.; Yan, Y.; Shi, B.; Qiu, Z. The design and research on a new type of inorganic insulation materials. New Build. Mater. 2014, 41, 73–76. [Google Scholar]

- GB/T 11969-2020; Test Methods of Autoclaved Aerated Concrete. China National Standardization Administration: Beijing, China, 2020.

- Zhao, J.; Li, J.; Dang, W. Quantitative mechanism of thermal inertia index on thermal stability of building envelope. J. Harbin Inst. Technol. 2018, 50, 182–188. Available online: https://link.cnki.net/urlid/23.1235.T.20181010.1630.032 (accessed on 23 July 2025).

- Zhao, J.; Dang, W. Comparative study on parameter systems of building envelope thermal storage performance. Heat. Vent. Air Cond. 2018, 48, 72–79. [Google Scholar] [CrossRef]

- Zhang, H. Study on Thermal and Energy Saving Performance of Aerogel Foamed Concrete Insulation Wall. Master’s Thesis, Guangzhou University, Guangzhou, China, 2024. Available online: https://kns.cnki.net/reader/flowpdf?invoice=DuSVJ1jZ6Hkab4DIxz10WUqTlJAdLKKVjaRUhauhwlyDe3%2FnyXq9uqFmArSgS4Z9Q2kFK4uGWwLRbpzDy%2B0695lj%2FF49etIPJUQ%2FHAEwD%2FmUUqpp8axqNbjkS7%2FDAHCORbIKMxS5O0TFAkUADJ%2F%2BUVyEfqLA1QYO5KSzP459fSw%3D&platform=NZKPT&product=CDFD&filename=1024522038.nh&tablename=cdfdlast2025&type=DISSERTATION&scope=trial&dflag=pdf&pages=&language=CHS&trial=&nonce=8606BFCC29C0439580FD1CC6D70E5249&cflag=pdf (accessed on 16 February 2025).

| Material | Density (kg/m3) | Thermal Conductivity (W/m·K) | Specific Heat Capacity (J/kg·K) |

|---|---|---|---|

| Sintered Brick | 2700 | 1.0 | 710 |

| AAC | 476.612 | 0.128 | 900 |

| Rock Wool | 120 | 0.04 | 750 |

| Raw Material | Water | Cement | Lime | Activator | Aluminum Powder |

|---|---|---|---|---|---|

| 3850 kg | 160 kg | 350 kg | 300 kg | 1.7% | 2.9% |

| Environment | 4.54 | 7.37 | 1.51 | 2.00 |

| Brick | 3.47 | 12.39 | 1.24 | 2.52 |

| AAC | 2.34 | 11.21 | 0.85 | 2.42 |

| ATIM | 1.61 | 9.99 | 0.48 | 2.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, J.; Fang, L.; Yu, C.; Chen, G.; Lan, J.; Zhang, R. Analysis and Research on Thermal Insulation Performance of Autoclaved Aerated Concrete Sandwich Perimeter Wall in Hot-Summer and Cold-Winter Regions Under Low Temperature Environment. Buildings 2025, 15, 3332. https://doi.org/10.3390/buildings15183332

Tu J, Fang L, Yu C, Chen G, Lan J, Zhang R. Analysis and Research on Thermal Insulation Performance of Autoclaved Aerated Concrete Sandwich Perimeter Wall in Hot-Summer and Cold-Winter Regions Under Low Temperature Environment. Buildings. 2025; 15(18):3332. https://doi.org/10.3390/buildings15183332

Chicago/Turabian StyleTu, Jinsong, Lintao Fang, Cairui Yu, Gulei Chen, Jing Lan, and Rui Zhang. 2025. "Analysis and Research on Thermal Insulation Performance of Autoclaved Aerated Concrete Sandwich Perimeter Wall in Hot-Summer and Cold-Winter Regions Under Low Temperature Environment" Buildings 15, no. 18: 3332. https://doi.org/10.3390/buildings15183332

APA StyleTu, J., Fang, L., Yu, C., Chen, G., Lan, J., & Zhang, R. (2025). Analysis and Research on Thermal Insulation Performance of Autoclaved Aerated Concrete Sandwich Perimeter Wall in Hot-Summer and Cold-Winter Regions Under Low Temperature Environment. Buildings, 15(18), 3332. https://doi.org/10.3390/buildings15183332