Influence and Bearing Mechanisms of Thorn Shape on Compressive Characteristics of Thorn Piles

Abstract

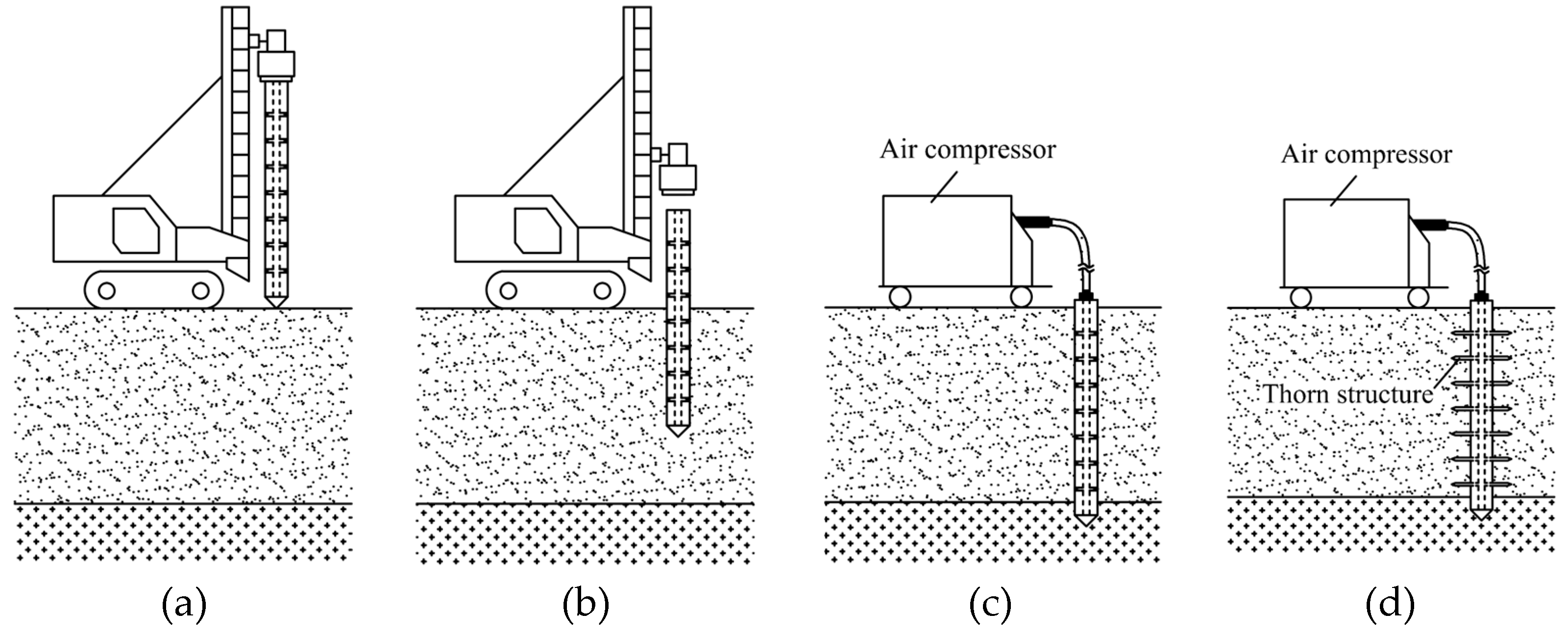

1. Introduction

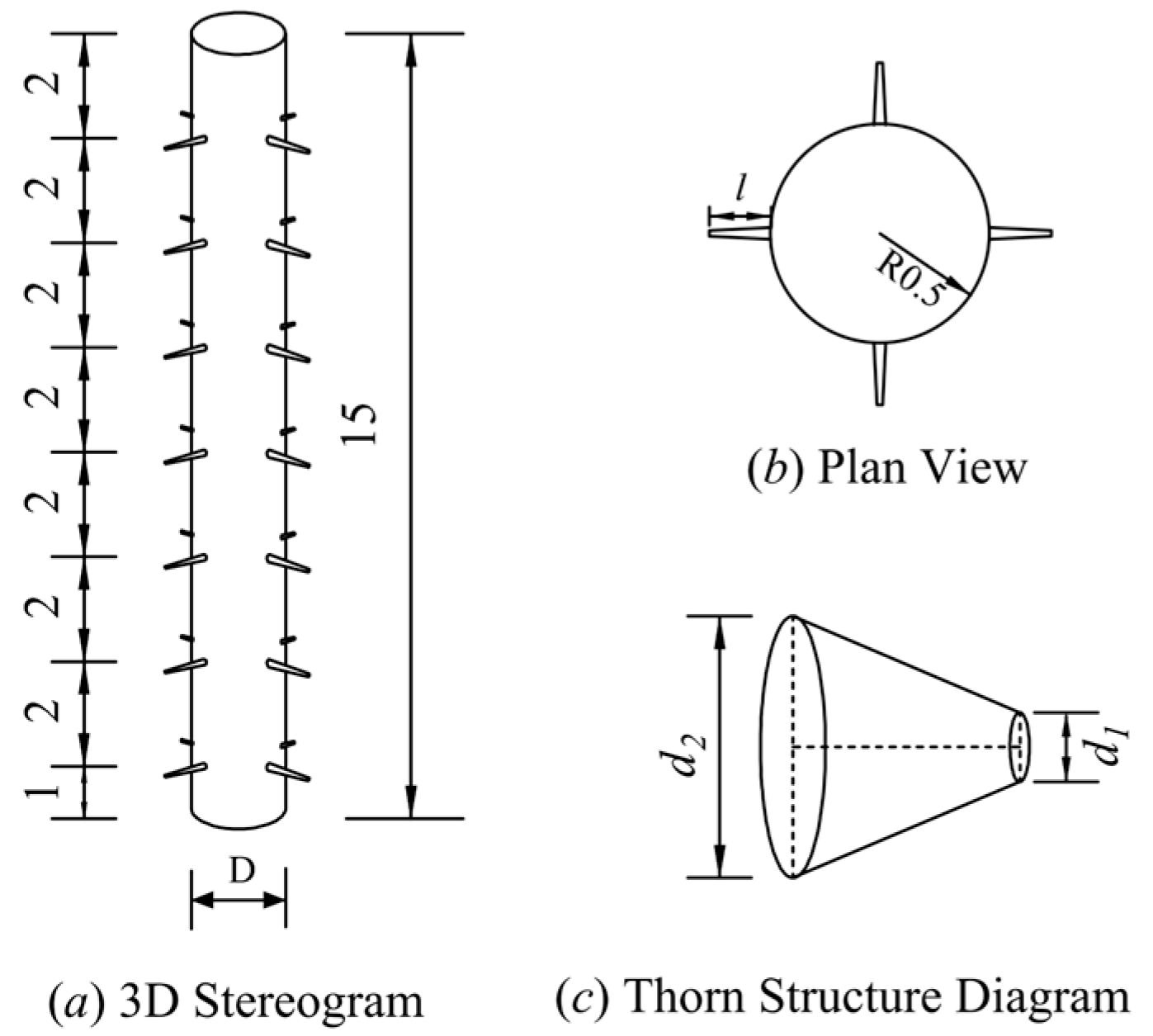

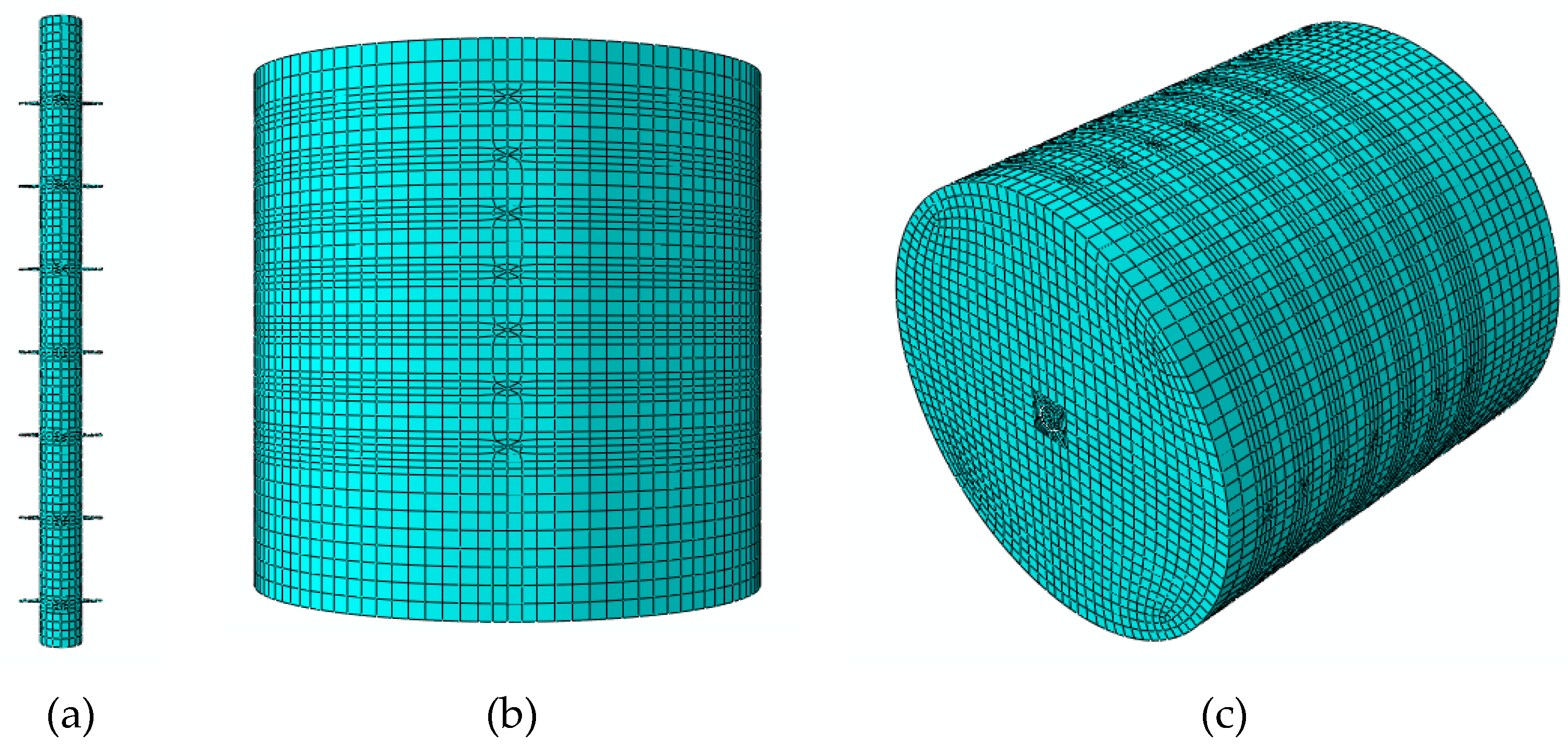

2. Numerical Simulation

2.1. Numerical Model

2.2. Material Parameters

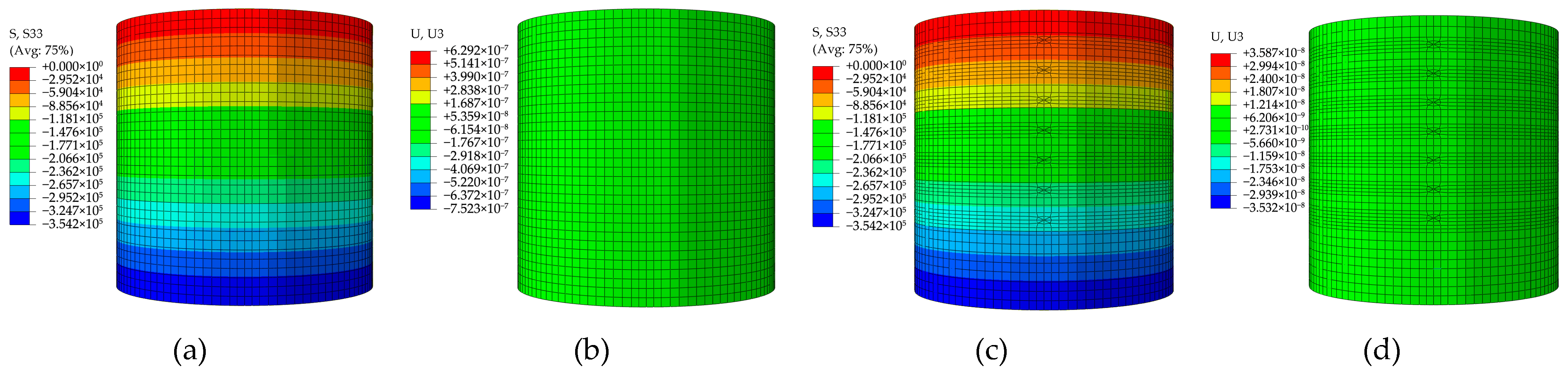

2.3. Numerical Analysis

2.4. Model Verification

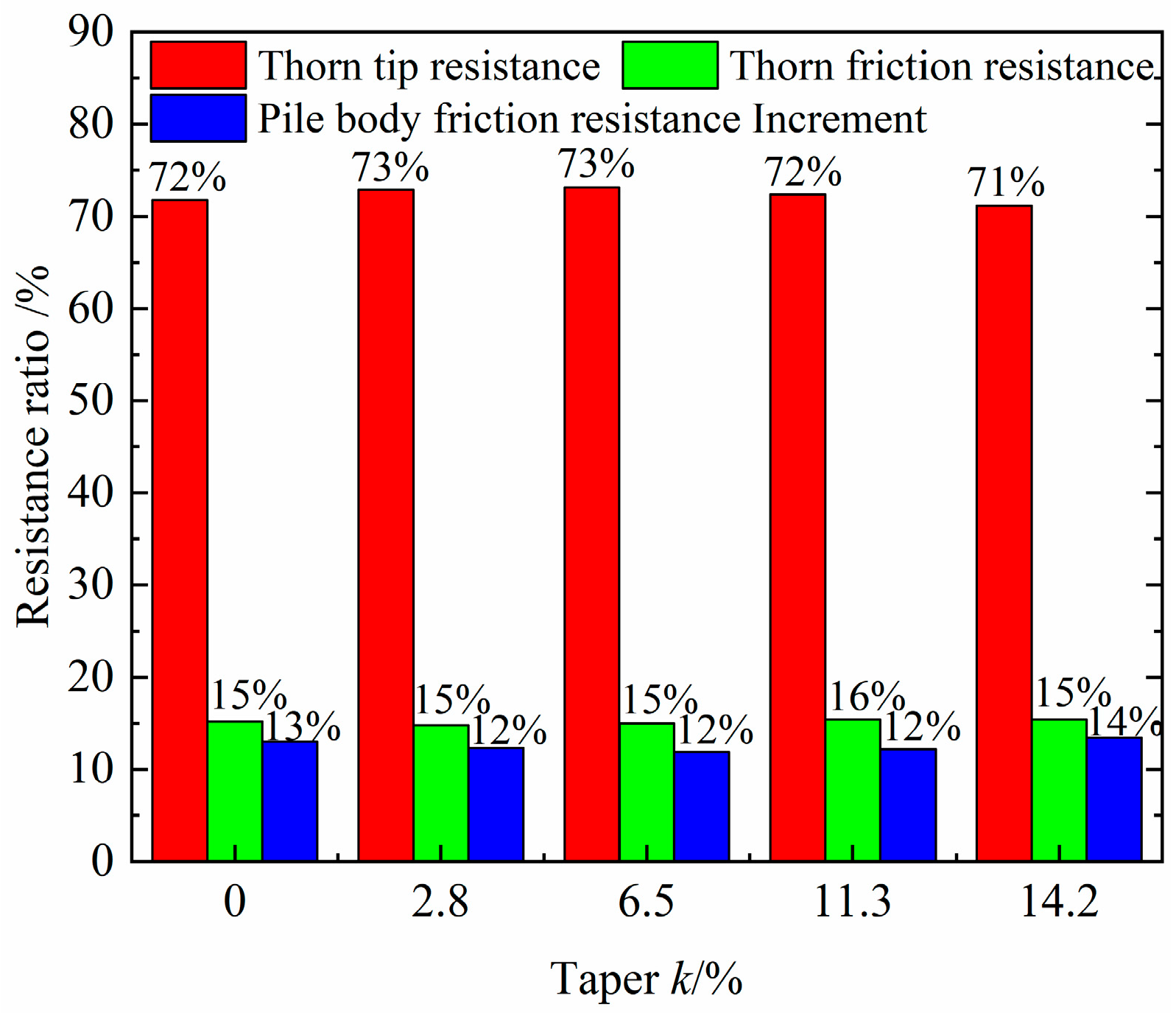

3. Analysis of Results

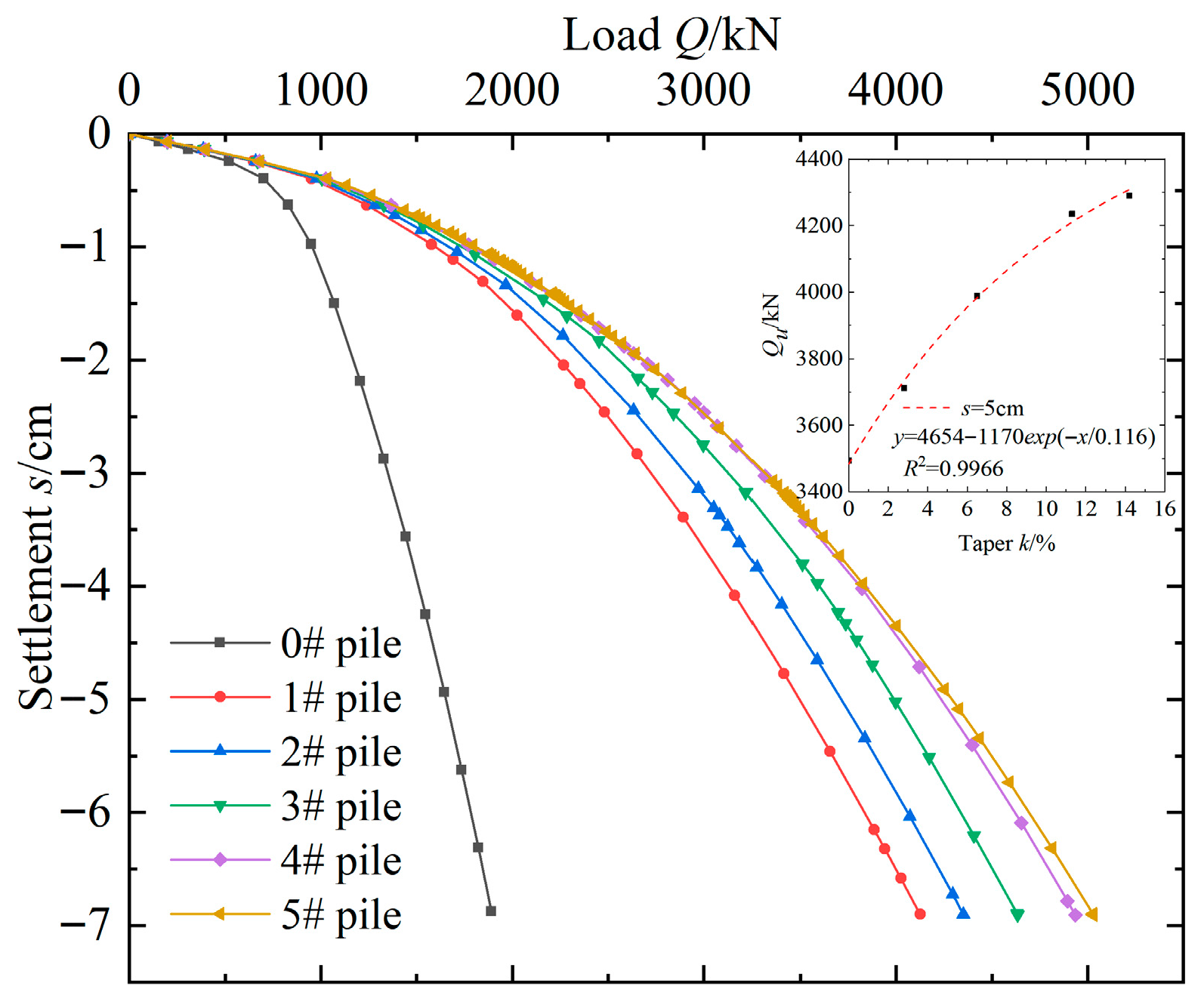

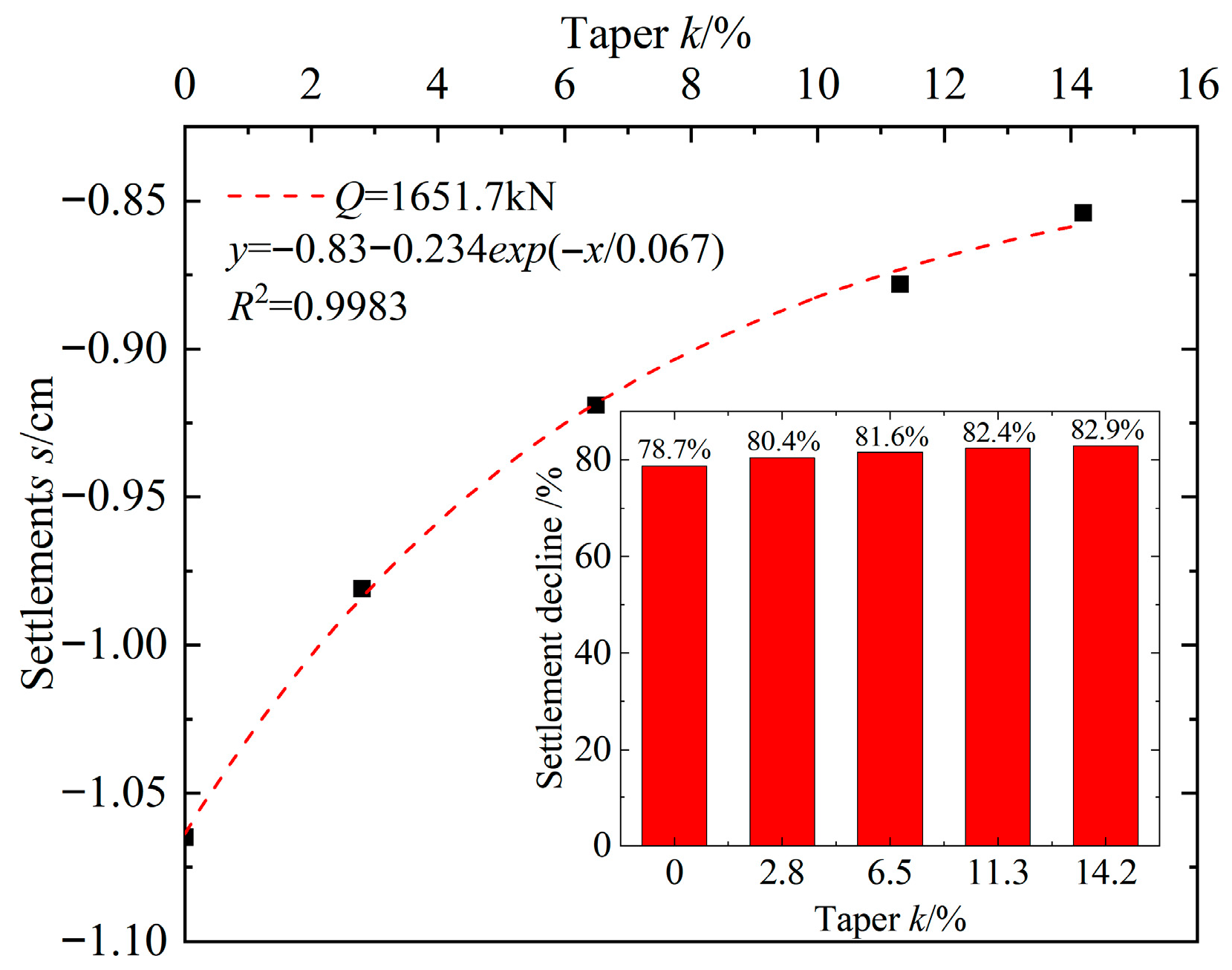

3.1. Load-Settlement Analysis

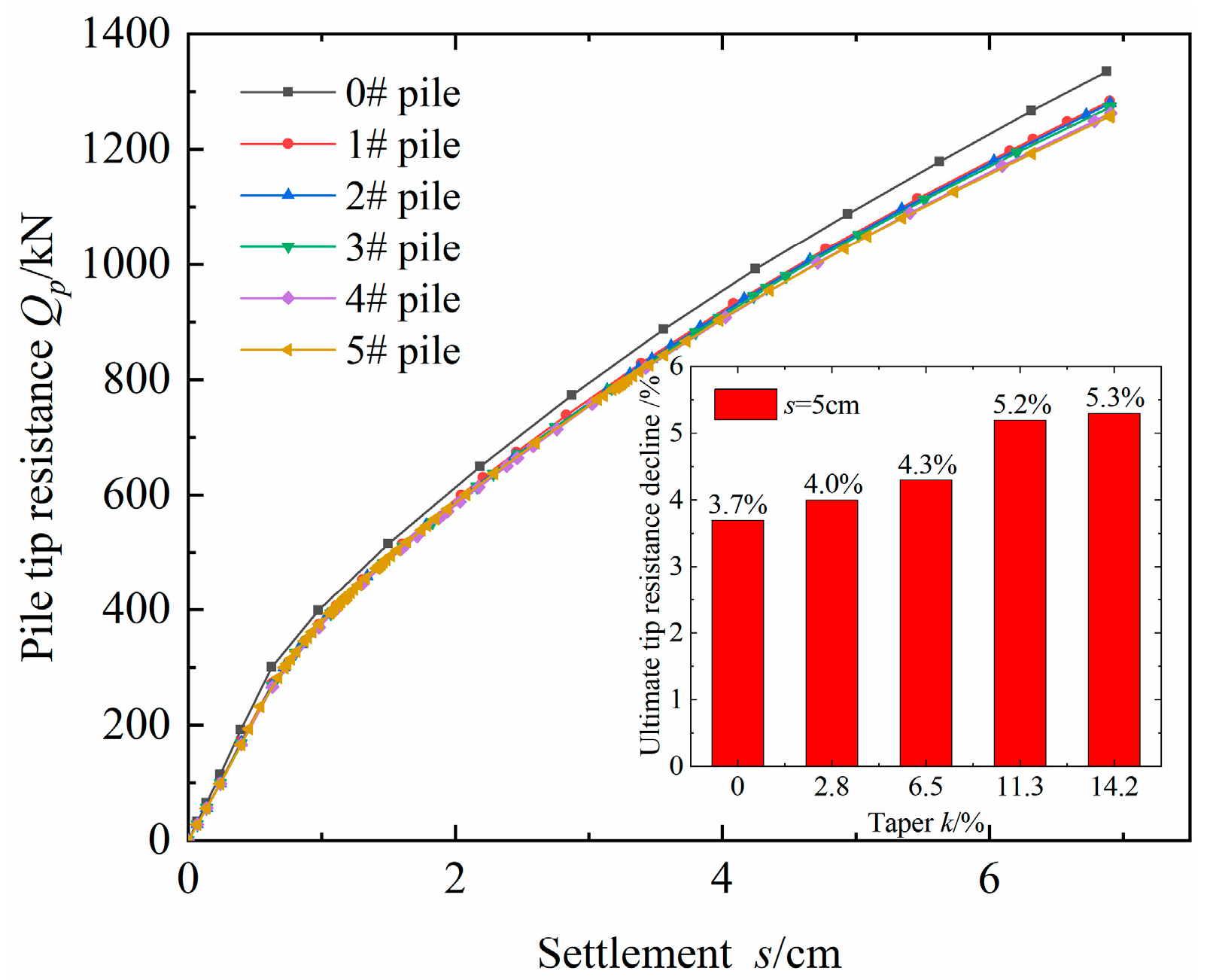

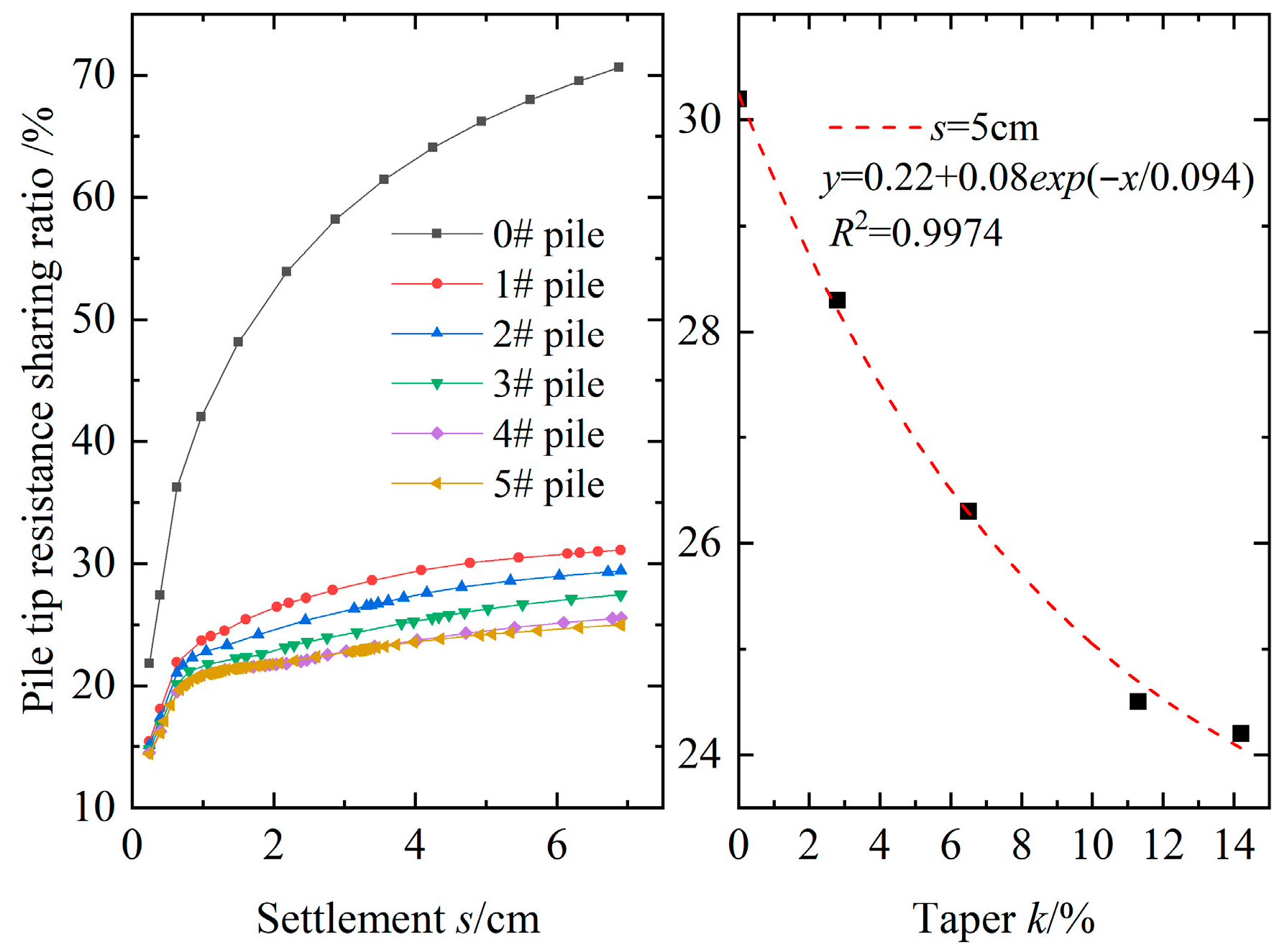

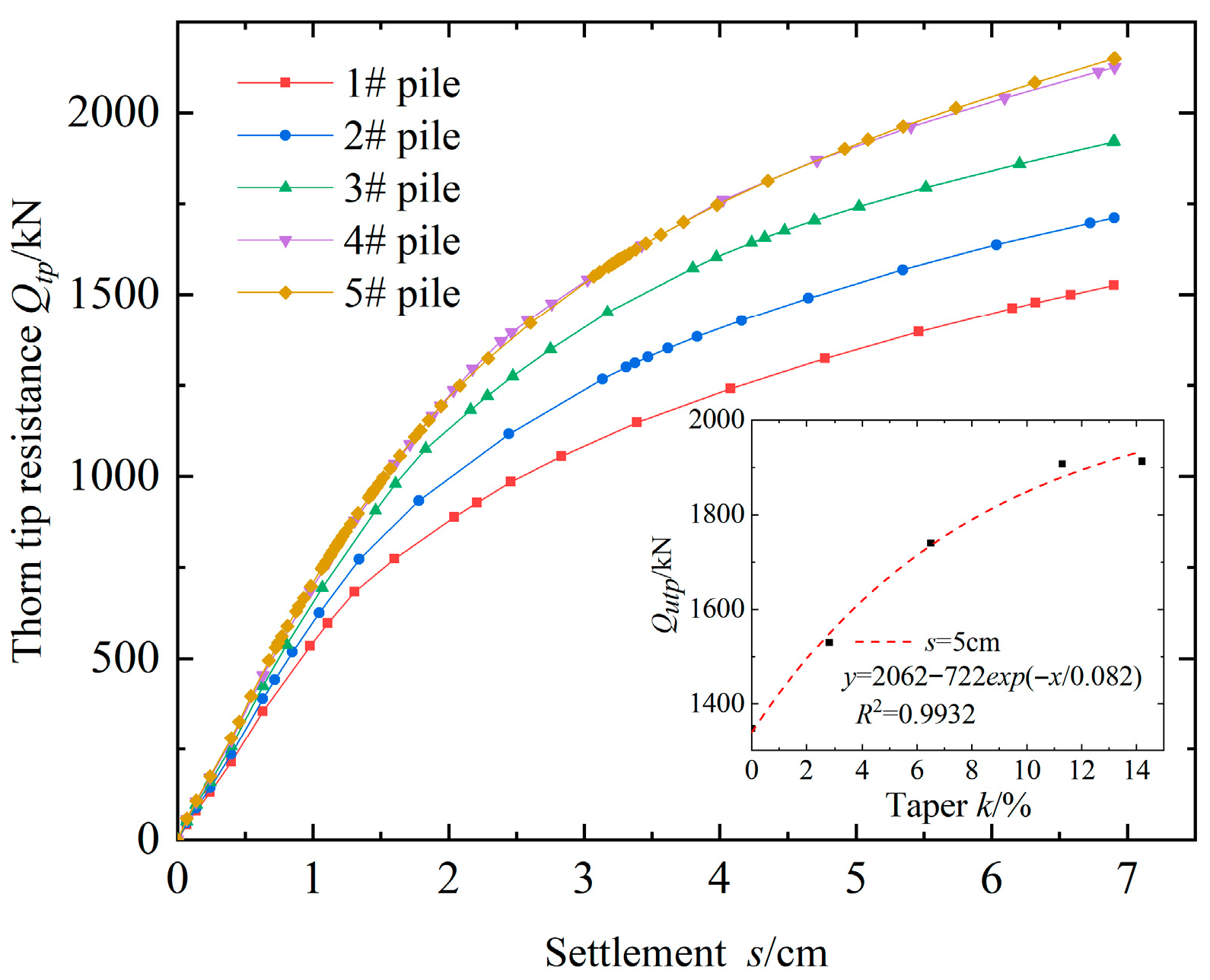

3.2. Influence of Thorn Shape on Pile Tip Resistance

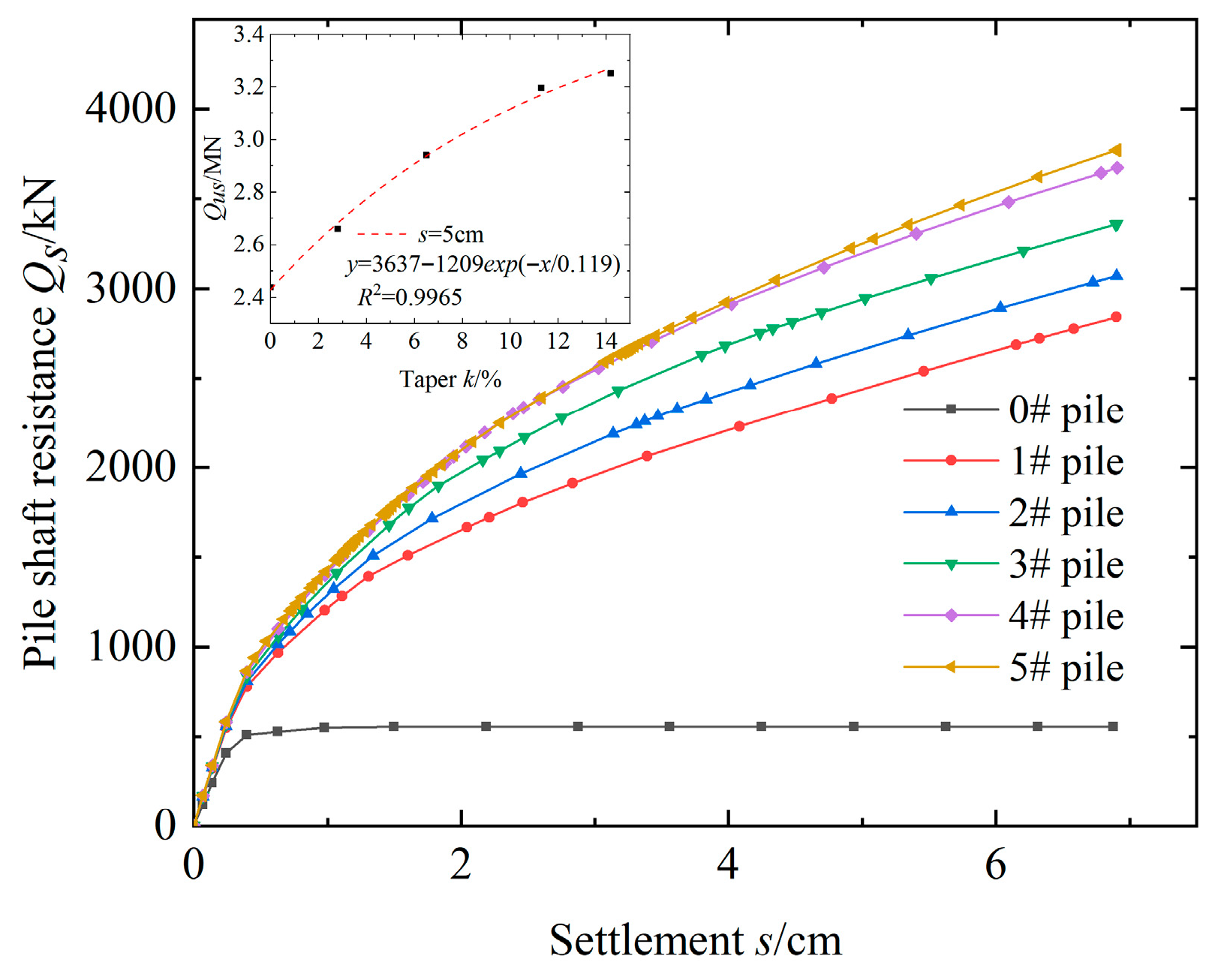

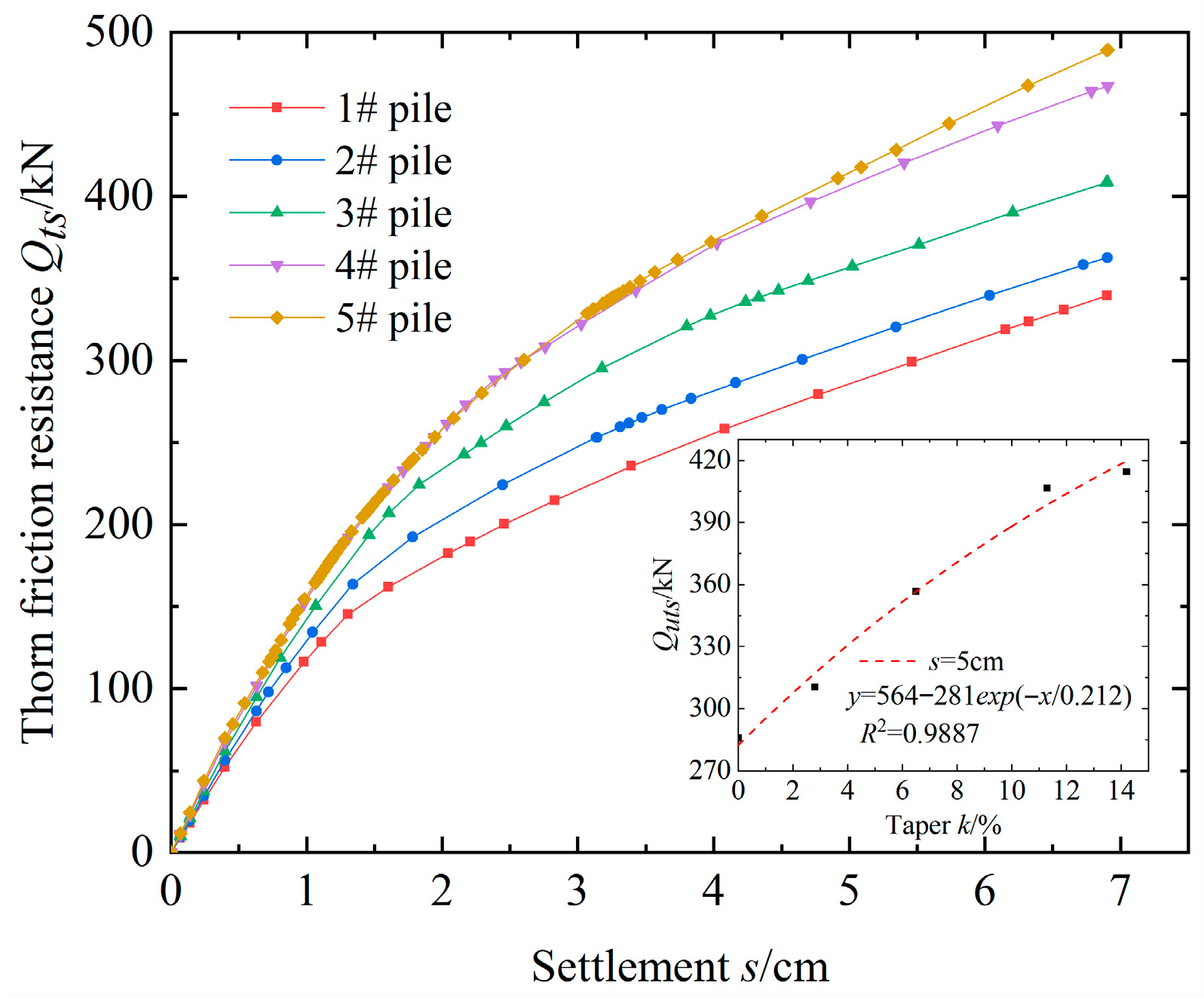

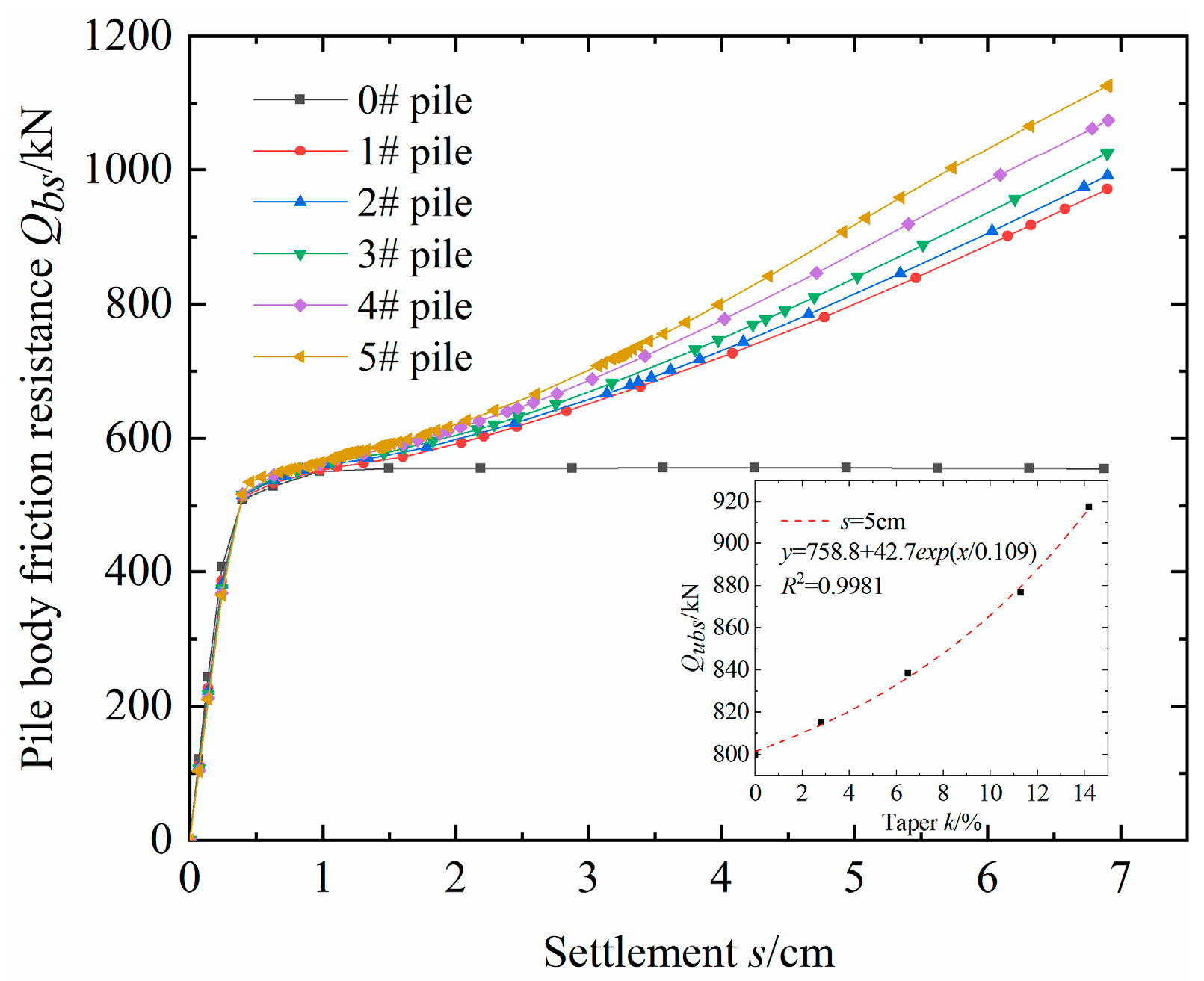

3.3. Influence of Thorn Shape on Pile Shaft Resistance

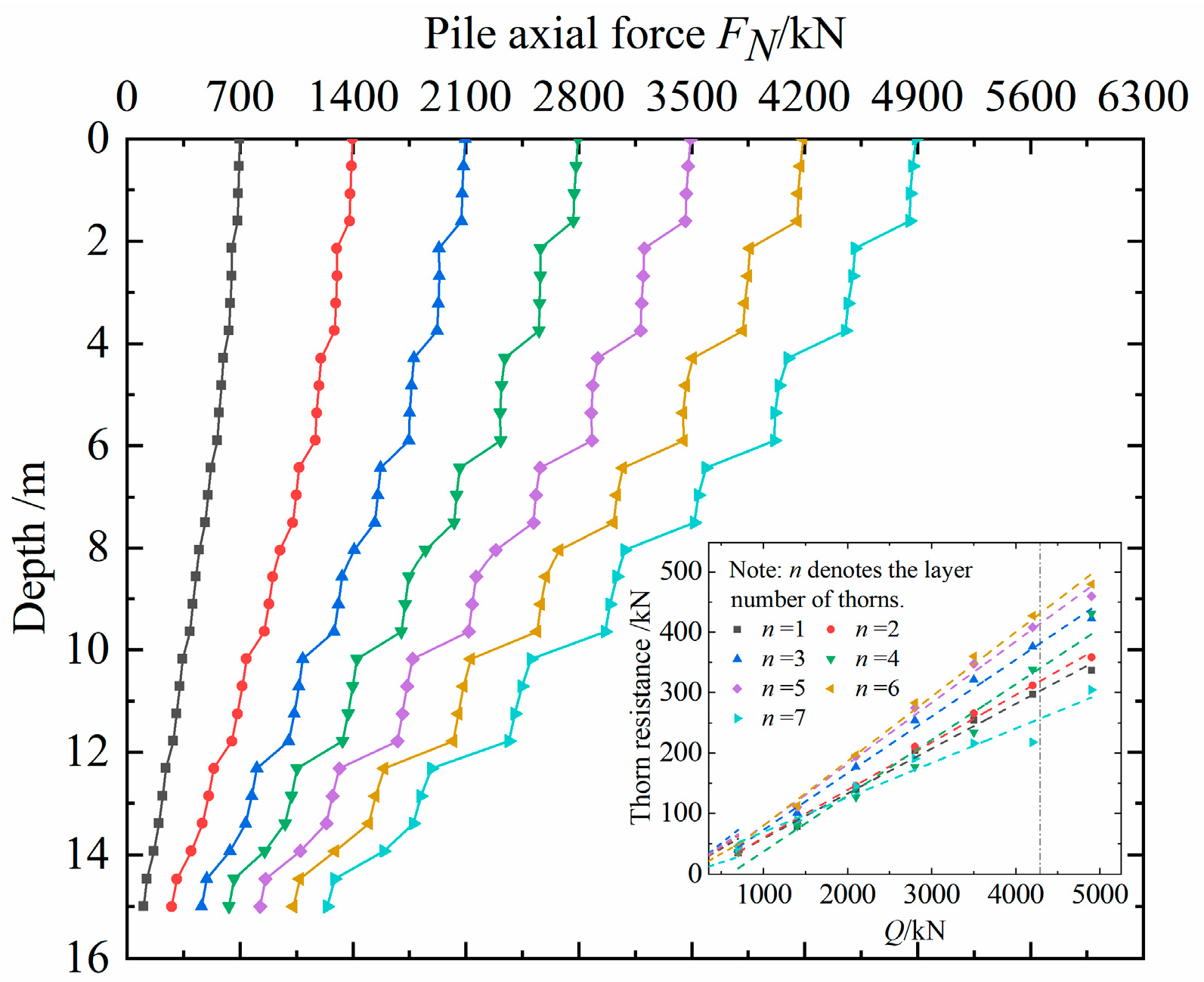

3.4. Influence of Thorn Shape on Pile Axial Force

4. Discussion

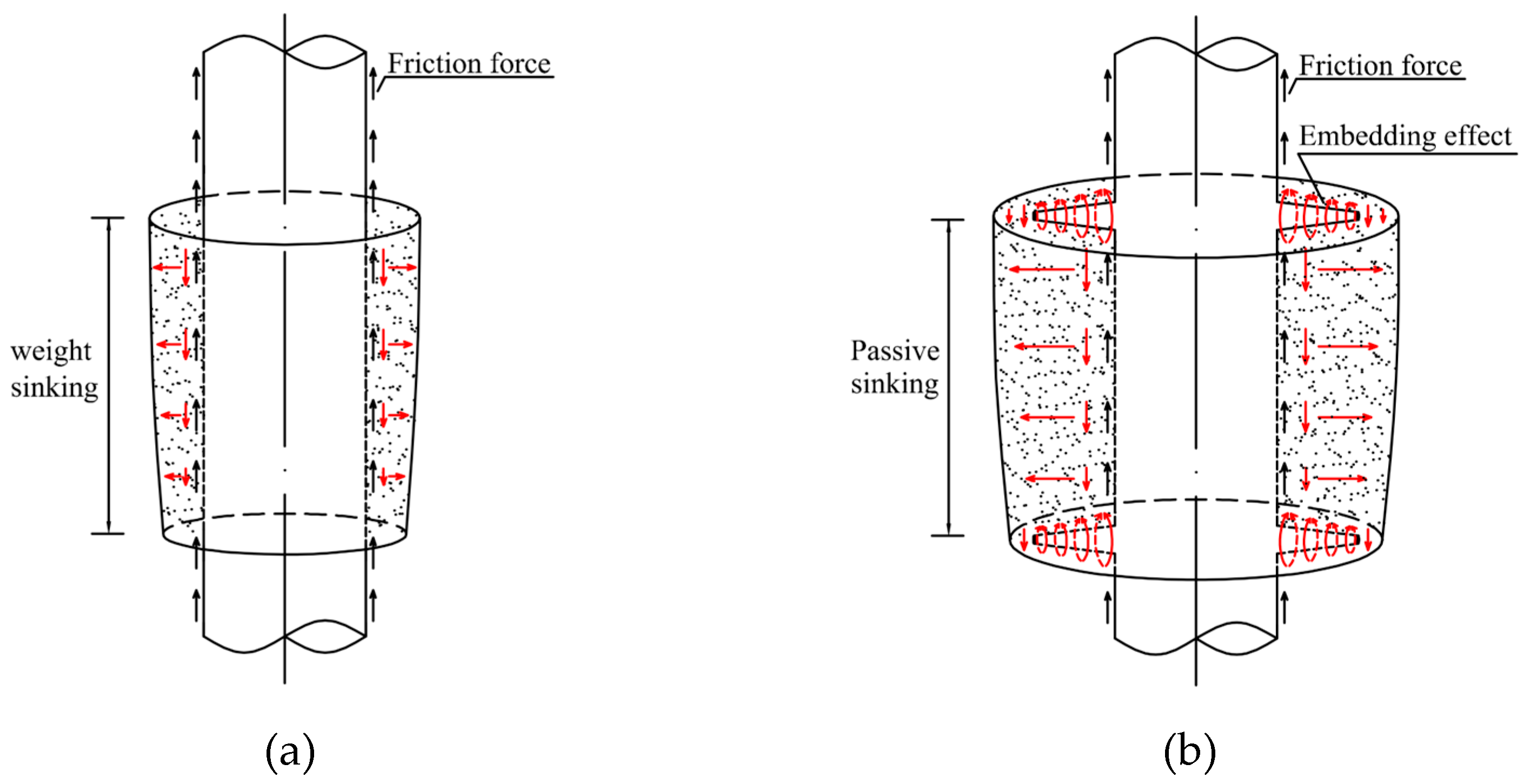

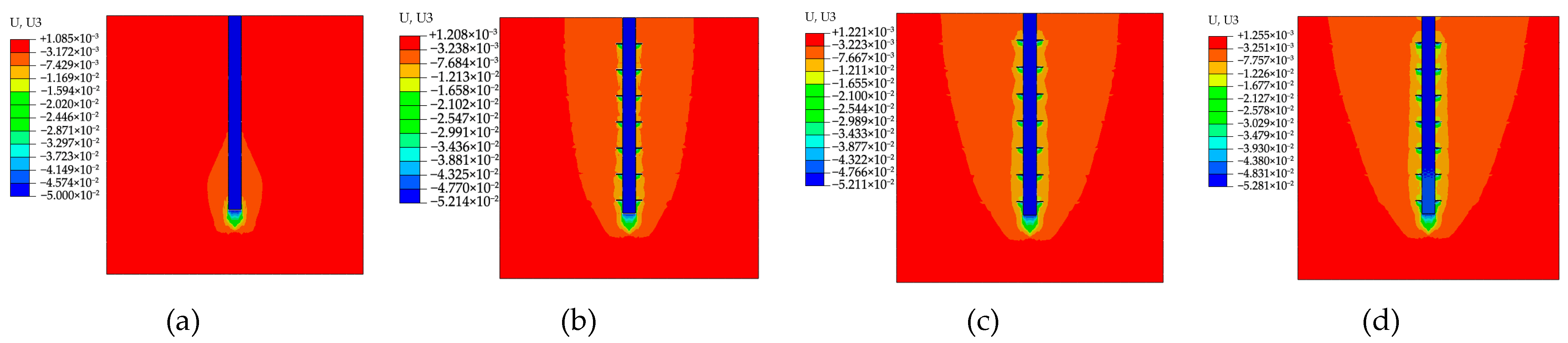

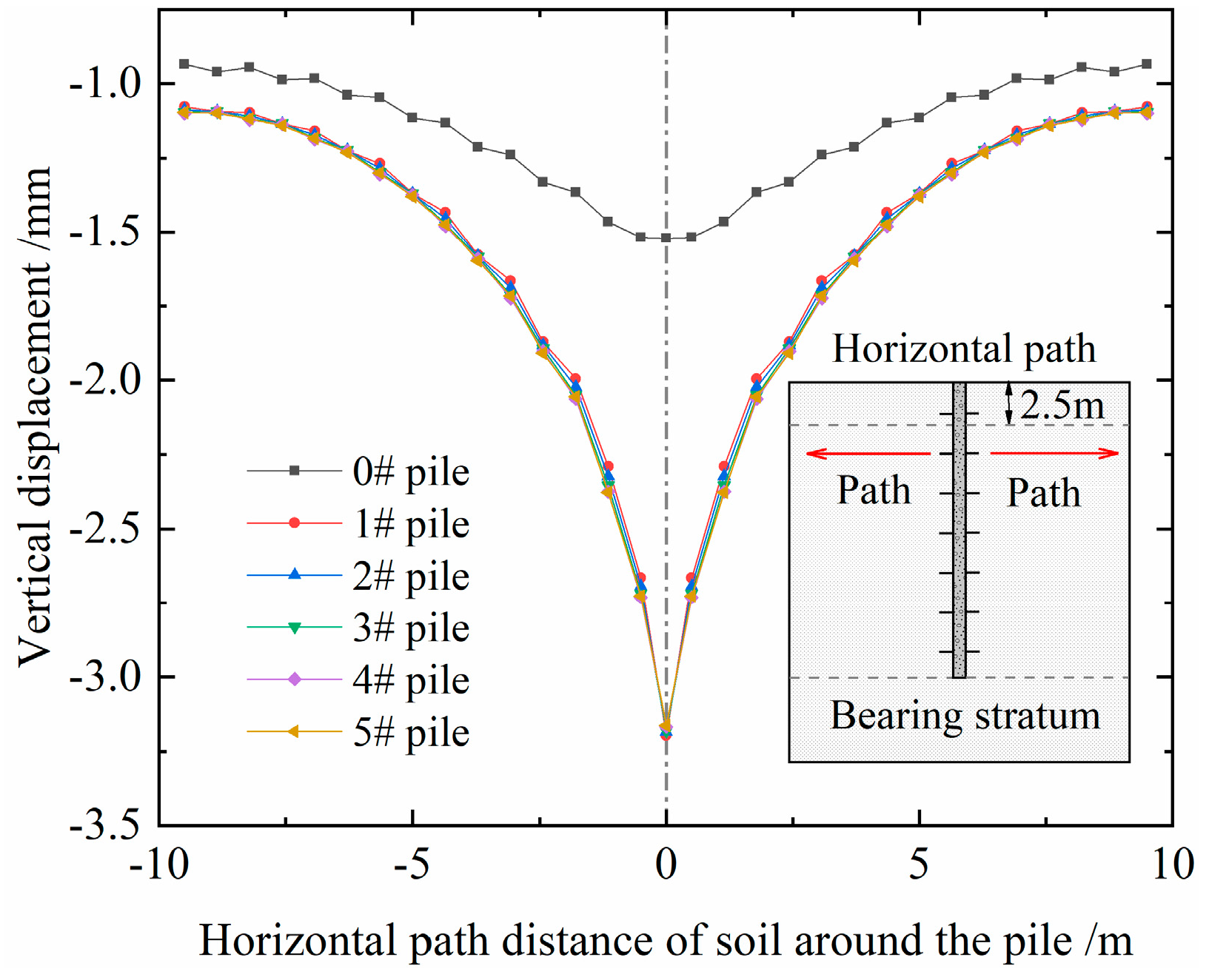

4.1. Pile and Soil Interaction Mechanism

4.2. Analysis of Influencing Factors

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, Y.; Zhang, Y.; Li, G.; Xie, S.; Shi, J. Experimental study on characteristics of tooth pile under vertical load. Yangtze River 2020, 51, 184–190. [Google Scholar]

- Fu, Y.; Du, P.; Zhang, Y.; Li, G.; Cao, Z.; Liu, X. Model Test on Pullout Resistance Characteristics of Multi-tooth Pile in Sand. J. Yangtze Riv. Sci. Res. Inst. 2021, 38, 121–126. [Google Scholar]

- Du, P.; Fu, Y.; Liu, X.; Li, G. Model Test Study on the Load-bearing Behaviour of Multi-tooth Piles under Different Bearing Layers. KSCE J. Civ. Eng. 2023, 27, 955–965. [Google Scholar] [CrossRef]

- Xiong, H.; Niu, Z.; Jang, Y.; Yang, J.; Zhou, Z. Experimental study of bearing characteristics of new ribbed prestressed pipe piles. China Concr. Cem. Prod. 2009, 32–35. [Google Scholar] [CrossRef]

- Fang, P.; Qi, J.; Zhou, Z. Comparative study on bearing capacity of enhanced pretensioned spun concrete piles and conventional pipe piles. Chin. J. Geotech. Eng. 2013, 35 (Suppl. S2), 1020–1023. [Google Scholar]

- Guo, Z.; Wei, L.; Feng, S.; He, Q. Load-settlement behavior and simulation analysis of enhanced prestressed pipe piles. Build. Struct. 2014, 44, 77–81. [Google Scholar]

- Wang, Z.; Fang, P.; Xie, X.; Wang, K.; Wang, W.; Li, J. Analysis of effected factors for vertical compressive bearing capacity of ribbed bamboo joint pile. Rock. Soil. Mech. 2018, 39, 381–388. [Google Scholar] [CrossRef]

- Gao, X.; Wang, J.; Zhu, X. Static load test and load transfer mechanism study of squeezed branch and plate pile in collapsible loess foundation. J. Zhejiang Univ. Sci. A 2007, 8, 1110–1117. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, P.; Cui, W.; Gao, Y. Bearing behavior and failure mechanism of squeezed branch piles. J. Rock. Mech. Geotech. Eng. 2018, 10, 935–946. [Google Scholar] [CrossRef]

- Ma, H.; Wu, Y.; Tong, Y.; Jiang, X. Research on bearing theory of squeezed branch pile. Adv. Civ. Eng. 2020, 2020, 6637261. [Google Scholar] [CrossRef]

- Shi, D.; Xiao, J.; Yang, C.; Liu, B. Research on the Plate Cavity Geometry of the Squeezed Branch Pile. Procedia Eng. 2014, 73, 29–34. [Google Scholar] [CrossRef][Green Version]

- Chen, Y.; Deng, A.; Lu, F.; Sun, H. Failure mechanism and bearing capacity of vertically loaded pile with partially-screwed shaft: Experiment and simulations. Comput. Geotech. 2020, 118, 103337. [Google Scholar] [CrossRef]

- Shao, K.; Su, Q.; Liu, J.; Liu, K.; Xiong, Z.; Wang, T. Optimization of inter-helix spacing for helical piles in sand. J. Rock. Mech. Geotech. Eng. 2022, 14, 936–952. [Google Scholar] [CrossRef]

- Ma, J.; Wang, R.; Hu, Z.; Mu, T.; Liu, A.; Olusegun, V.T. Limit equilibrium theory in calculating screw pile bearing capacity under compression. Proc. Inst. Civ. Eng.-Geotech. Eng. 2023, 177, 468–481. [Google Scholar] [CrossRef]

- Meng, Z.; Chen, J.; Wang, J. Numerical analysis of bearing capacity of drilled displacement piles with a screw-shaped shaft in sand. Mar. Georesources Geotechnol. 2017, 35, 661–669. [Google Scholar] [CrossRef]

- Ma, H.; Liu, L.; Wang, P.; Yuan, S.; He, Q.; Yang, X. Calculation method and mechanism of ultimate side resistance of screw pile. Mar. Georesources Geotechnol. 2023, 41, 99–113. [Google Scholar] [CrossRef]

- Dou, D.; Gao, Q. Research on Influential Factors and Vertical Bearing Capacity of Screw Piles. Port. Eng. Technol. 2020, 57, 55–58. [Google Scholar]

- Ma, J.; Luo, L.; Mu, T.; Guo, H.; Tang, Y. Experimental study on characteristics of pile-soil interaction in screw piles. Buildings 2022, 12, 2091. [Google Scholar] [CrossRef]

- Yang, T.; Zheng, W.; Xie, Y.; Zhang, H.; Yue, X. Evaluating screw-shaft pile composite foundations in round Gravelly soil: A study using model tests and numerical simulations. Heliyon 2023, 9, e20887. [Google Scholar] [CrossRef] [PubMed]

- Khidri, M.; Deng, L. Field axial cyclic loading tests of screw micropiles in cohesionless soil. Soil Dyn. Earthq. Eng. 2021, 143, 106601. [Google Scholar] [CrossRef]

- Khidri, M.; Deng, L. Field axial loading tests of screw micropiles in sand. Can. Geotech. J. 2022, 59, 458–472. [Google Scholar] [CrossRef]

- Sanzeni, A.; Danesi, E.G. Field tests and interpretation of screw micropiles subjected to axial loading in cohesive soil. Int. J. Geotech. Eng. 2022, 16, 391–399. [Google Scholar] [CrossRef]

- Fang, C.; Zhang, X.; Peng, G. Discussion on the Bearing Force Characteristic and the Failure Behavior of a New Kind Half-screwed Filling Pile. Geotech. Eng. Techn. 2006, 20, 316–319. [Google Scholar]

- Wang, S.; Feng, Z.; Tang, J.; Zhao, Z. Experimental study on bearing mechanism of screw cast-in-place piles under vertical loads. Chin. J. Geotech. Eng. 2021, 43, 383–389. [Google Scholar]

- Chen, Y.; Yu, Y.; Dong, Y.; Sun, H.; Gong, C. Experimental Study on Working Behavior of Vertically Loaded Screw-shaft Pile. Chin. J. Undergr. Sp. Eng. 2022, 18, 860–867. [Google Scholar]

- Wei, J.; El Naggar, M.H. Experimental study of axial behaviour of tapered piles. Can. Geotech. J. 1998, 35, 641–654. [Google Scholar] [CrossRef]

- El Naggar, M.H.; Wei, J. Axial capacity of tapered piles established from model tests. Can. Geotech. J. 1999, 36, 1185–1194. [Google Scholar] [CrossRef]

- He, J. Behavior Characteristics Research on TaperedPile in Soft Clay Foundation. Master’s Thesis, Hunan University of Technology, Hunan, China, 2008. [Google Scholar]

- Liu, J.; He, J.; Min, C. Contrast research of bearing characteristic for composite foundation with tapered piles and cylindrical piles. In Proceedings of the 18th East Asia-Pacific Conference on Structural Engineering and Construction, Guangzhou, China, 28 November 2009; School of Civil Engineering and Architecture, Hunan University of Technology: Zhuzhou, China, 2009; pp. 301–307. [Google Scholar]

- Wang, N.; Le, Y.; Hu, W.; Fang, T.; Zhu, B.; Geng, D.; Xu, C. New interaction model for the annular zone of stepped piles with respect to their vertical dynamic characteristics. Comput. Geotech. 2020, 117, 103256. [Google Scholar] [CrossRef]

- Jiang, S.; Huang, M.; Fang, T.; Chen, W.; Xing, S. A new large step-tapered hollow pile and its bearing capacity. Proc. Inst. Civ. Eng.-Geotech. Eng. 2020, 173, 191–206. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Yang, Z.; Gong, X.; Xu, R. Analytical solutions for laterally loaded step-tapered piles by state space method. Chin. J. Geotech. Eng. 2023, 45, 1944–1952. [Google Scholar]

- Fang, T. Study on Deformation and Load-Bearing Characteristics of Segmentally Variable Cross-Section Pile. Ph.D. Thesis, Chongqing University, Chongqing, China, 2012. [Google Scholar]

- Dickin, E.A.; Leung, C.F. The influence of foundation geometry on the uplift behaviour of piles with enlarged bases. Can. Geotech. J. 1992, 29, 498–505. [Google Scholar] [CrossRef]

- Chae, D.; Cho, W.; Na, H.Y. Uplift capacity of belled pile in weathered sandstones. Int. J. Offshore Polar 2012, 22, 297–305. [Google Scholar]

- Yang, Y.; Qiu, L. MPM simulation of uplift resistance of enlarged base piles in sand. Soils Found 2020, 60, 1322–1330. [Google Scholar] [CrossRef]

- Schafer, M.; Madabhushi, S. Uplift resistance of enlarged base pile foundations. Indian Geotech. J. 2020, 50, 426–441. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, J.; Mengke, T. Uplift Tests and Calculations of Under-reamed Piles. Ind. Constr. 2003, 33, 42–45. [Google Scholar]

- Majumder, M.; Chakraborty, D. Uplift capacity and failure mechanism of under-reamed piles in clay based on lower bound finite element limit analysis. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2021, 92, 647–658. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Cheng, X.; Huang, H. Load transfer method for squeezed and branch piles considering cavity ex-pansion theory. Chin. J. Highw. Transp. 2018, 31, 20–29. [Google Scholar]

- Du, P.; Liu, X.; Zhou, D.; Huang, Z. Pneumatic Thorn Pile. Patent CN202222633702.6, 3 February 2023. [Google Scholar]

- Du, P.; Zhou, D.; Liu, X.; Hai, J. Pneumatic Temperature Controlled Thorn Pile. Patent CN202211210972.4, 31 October 2023. [Google Scholar]

- Wu, W.; Wu, X. Construction technology of thorn-shaped-cast-in-situ pile and its form squeezing machine. Constr. Mach. 2007, 94–98. [Google Scholar]

- Cao, X. Design and Research of Forming Machine for Thorn-shaped Cast-in-situ Pile. Mech. Eng. Autom. 2012, 95–96+99. [Google Scholar]

- Gou, J.; Liu, Y. Mechanical Analysis and Stability Design of Extrusion Forming Machine of Thorn Pile. J. Shanxi Datong Univ. Nat. Sci. 2013, 29, 49–51. [Google Scholar]

- Yin, Y.; Sun, D.; Gong, W. Experiment and numerical simulation of the bearing characteristics of root foundations. Chin. Civ. Eng. J. 2009, 42, 162–169. [Google Scholar]

- Gong, W.; Yang, C.; Dai, G.; Yin, Y. In-situ test on vertical compressive bearing characteristic of rooted caisson with grouting at caisson side. J. Build. Struct. 2018, 39, 164–173. [Google Scholar]

- Wang, L.; Gong, W.; Yin, Y.; Tong, X. Field experimental study on vertical bearing capacity of root-caisson foundation. Adv. Soil Dyn. Found. Eng. 2014, 274–283. [Google Scholar]

- Dai, G.; Gong, W. Application of bi-directional static loading test to deep foundations. J. Rock Mech. Geotech. Eng. 2012, 4, 269–275. [Google Scholar] [CrossRef]

- Wang, Z. Field Test and Numerical Simulation of Vertical Bearing Capacity of Root Foundation. J. Civ. Eng. Manag. 2021, 38, 119–125+139. [Google Scholar]

- Sun, Y.; Ge, N.; Hou, C.; Zhu, D. Model test study on vertical bearing capacity of root foundation. J. Hefei Univ. Technol. (Nat. Sci.) 2019, 42, 1251–1257. [Google Scholar]

- Sun, Y. Experimental Study and Numerical Simulation of Vertical Foundation Bearing Behavior of Foot Foundations. Master’s Thesis, Hefei University of Technology, Hefei, China, 2018. [Google Scholar]

- Feng, X. Experimental Study on the Uplift Bearing Characteristics of Roots Foundation Based on Transparent Soil Technology. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2021. [Google Scholar]

- Liu, Z.; Zhu, D.; Yin, Y.; Zou, B.; Hou, C. Model Test Study on Vertical Load Action of Root Foundation. J. Anhui Jianzhu Univ. 2019, 27, 29–35. [Google Scholar]

- Ji, H.; Yu, Y.; Ren, W.; Yin, Y. Influence of roots arrangement on vertical bearing capacity of root piles. J. Hefei Univ. Technol. (Nat. Sci.) 2023, 46, 204–211. [Google Scholar]

- Wei, L.; Yang, F.; Yan, R.; Duan, L. Study on the whole process true stress-strain relationship of structural steels. Eng. Mech. 2025, 42, 216–225+272. [Google Scholar]

- Wang, J.; Wang, B.; Gao, Y. Study onload transfermechanism of bored piles. J. Hohai Univ. (Nat. Sci.) 2007, 35, 430–433. [Google Scholar]

- Fei, K.; Zhang, J. Application of ABAQUS in Geotechnical Engineering; China Water & Power Press: Beijing, China, 2010; pp. 282–286. [Google Scholar]

- Li, J.; Xing, Y.; Cui, W.; Fang, K. Bearing Characteristics of Single Pile Under Vertical Load in Karst Area. J. Jinan Univ. (Sci. Technol.) 2020, 34, 417–422. [Google Scholar]

- JGJ94-2008; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Code for Building Pile Foundations. China Architecture & Building Press: Beijing, China, 2008.

- JGJ106-2014; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Code for Testing of Building Foundation Piles. China Architecture & Building Press: Beijing, China, 2014.

- Bagheri, M.; Jamkhaneh, M.E.; Samali, B. Effect of seismic soil–pile–structure interaction on mid-and high-rise steel buildings resting on a group of pile foundations. Int. J. Geomech. 2018, 18, 04018103. [Google Scholar] [CrossRef]

- Asgari, A.; Bagheri, M.; Hadizadeh, M. Advanced seismic analysis of soil-foundation-structure interaction for shallow and pile foundations in saturated and dry deposits: Insights from 3D parallel finite element modeling. Structures 2024, 69, 107503. [Google Scholar] [CrossRef]

- Asgari, A.; Ranjbar, F.; Bagheri, M. Seismic resilience of pile groups to lateral spreading in liquefiable soils: 3D parallel finite element modeling. Structures 2025, 74, 108578. [Google Scholar] [CrossRef]

| Type | Pile Diameter D (mm) | Thorn Length l (mm) | d2 (mm) | d1 (mm) | d2/d1 | Taper k = (d2 − d1)/l | Number |

|---|---|---|---|---|---|---|---|

| Smooth pile | 1000 | / | / | / | / | / | 0# pile |

| Thorn pile | 500 | 50.00 | 50.00 | 1 | 0.0% | 1# pile | |

| 56.95 | 42.71 | 0.75 | 2.8% | 2# pile | |||

| 65.46 | 32.73 | 0.5 | 6.5% | 3# pile | |||

| 75.59 | 18.90 | 0.25 | 11.3% | 4# pile | |||

| 81.09 | 10.14 | 0.125 | 14.2% | 5# pile |

| Type | Elastic Modulus (Pa) | Poisson’s Ratio | Density (kg/m3) | Cohesion (Pa) | Internal Friction Angle (φ°) | Dilation Angle (°) |

|---|---|---|---|---|---|---|

| Silt | 3.6 × 107 | 0.25 | 1800 | 1600 | 25 | 8 |

| Pile body | 3.0 × 1010 | 0.2 | 2500 | / | / | / |

| Pile thorn | 2.1 × 1011 | 0.3 | 7850 | / | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, P.; Liu, X.; Zhou, D.; Feng, C. Influence and Bearing Mechanisms of Thorn Shape on Compressive Characteristics of Thorn Piles. Buildings 2025, 15, 3328. https://doi.org/10.3390/buildings15183328

Du P, Liu X, Zhou D, Feng C. Influence and Bearing Mechanisms of Thorn Shape on Compressive Characteristics of Thorn Piles. Buildings. 2025; 15(18):3328. https://doi.org/10.3390/buildings15183328

Chicago/Turabian StyleDu, Peng, Xiaoling Liu, Dequan Zhou, and Chenxi Feng. 2025. "Influence and Bearing Mechanisms of Thorn Shape on Compressive Characteristics of Thorn Piles" Buildings 15, no. 18: 3328. https://doi.org/10.3390/buildings15183328

APA StyleDu, P., Liu, X., Zhou, D., & Feng, C. (2025). Influence and Bearing Mechanisms of Thorn Shape on Compressive Characteristics of Thorn Piles. Buildings, 15(18), 3328. https://doi.org/10.3390/buildings15183328