Experimental and Theoretical Studies on Shear Performance of Corrugated Steel–Concrete Composite Arches Considering the Shear–Compression Ratio

Abstract

1. Introduction

2. Experimental Program

2.1. Specimen Design

2.2. Material Performance Testing

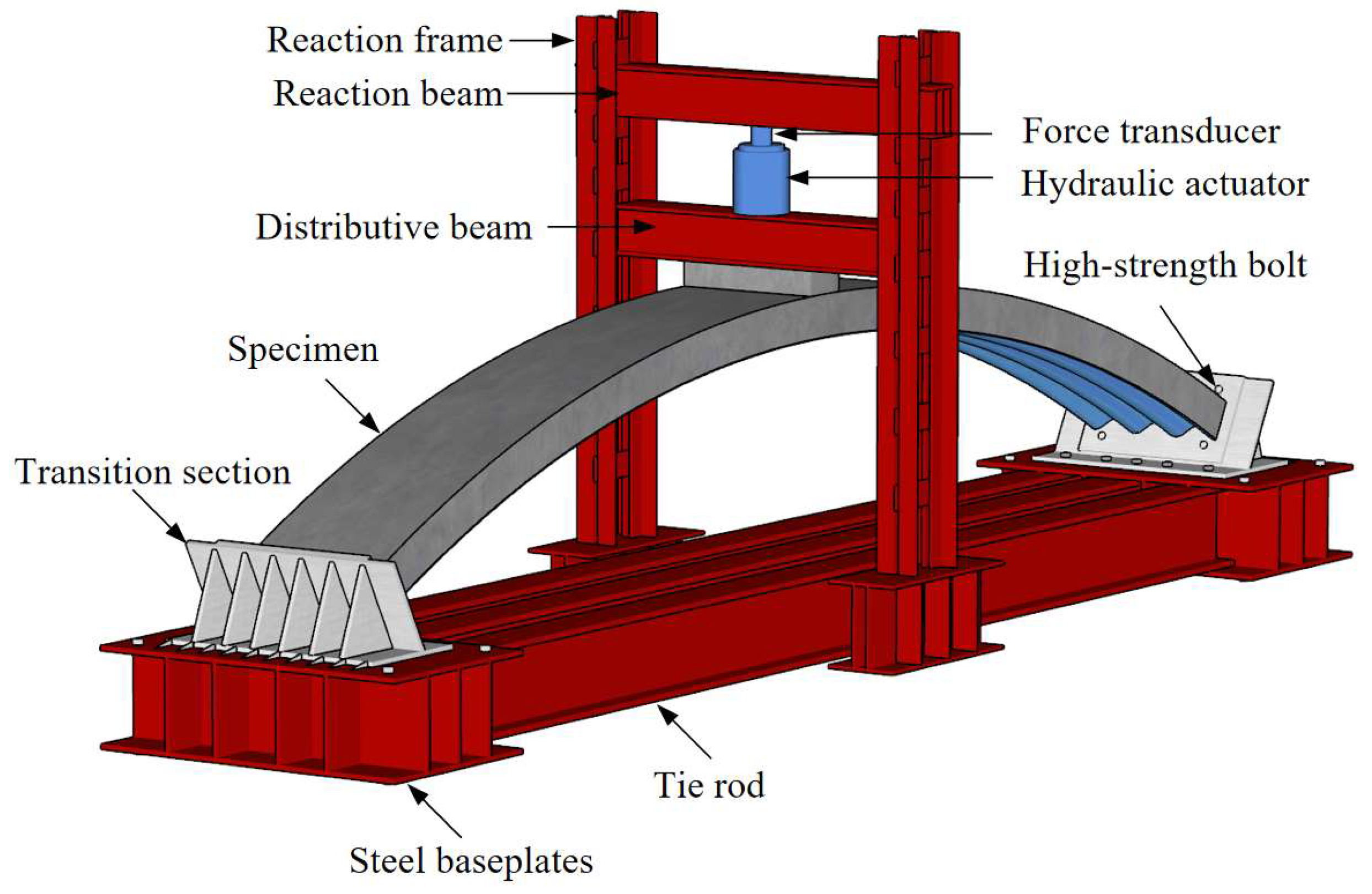

2.3. Test Setup

2.4. Measurement Arrangement

3. Experimental Results and Discussion

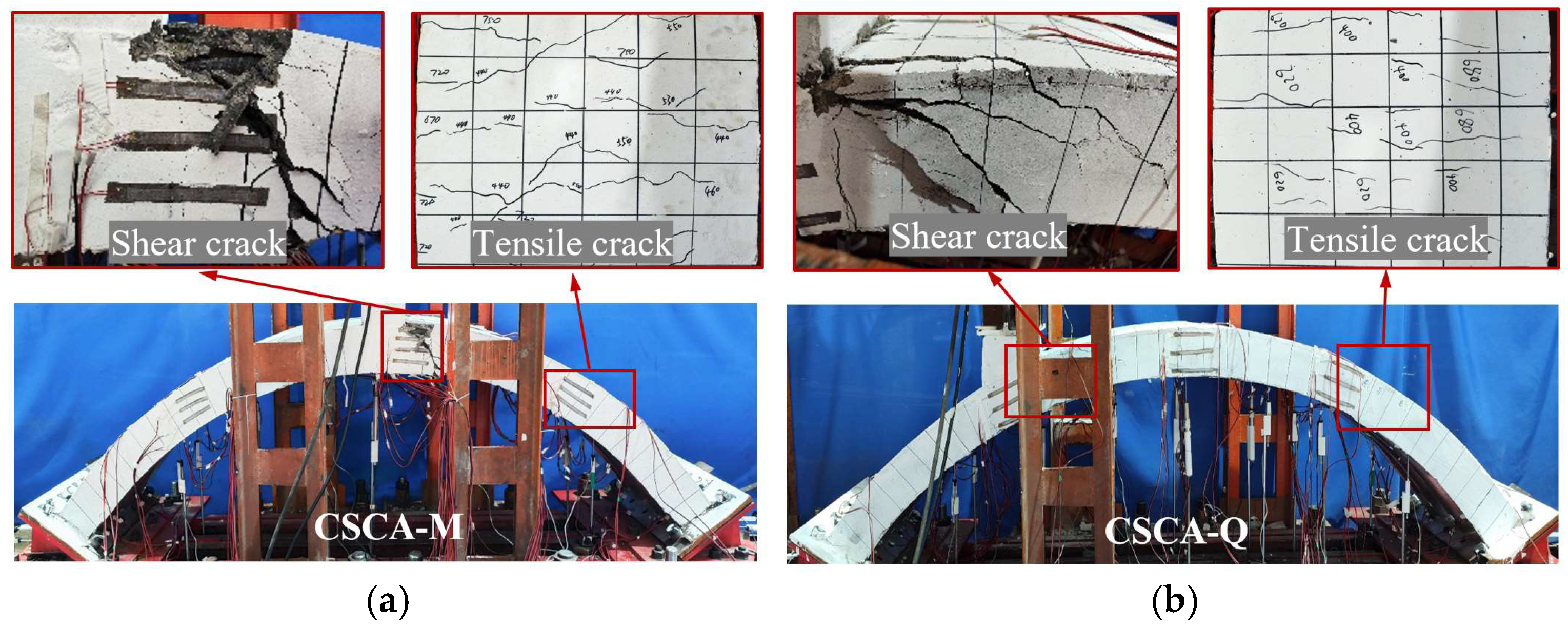

3.1. Failure Modes

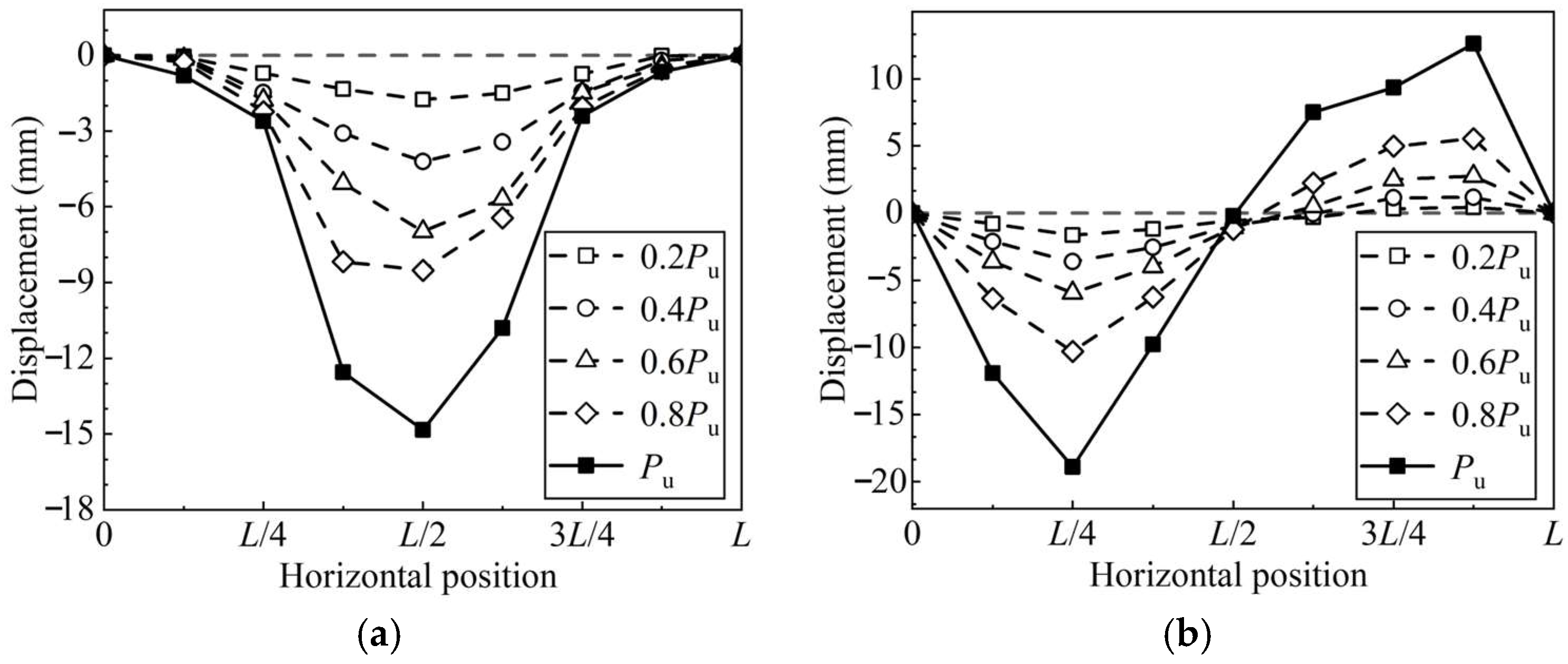

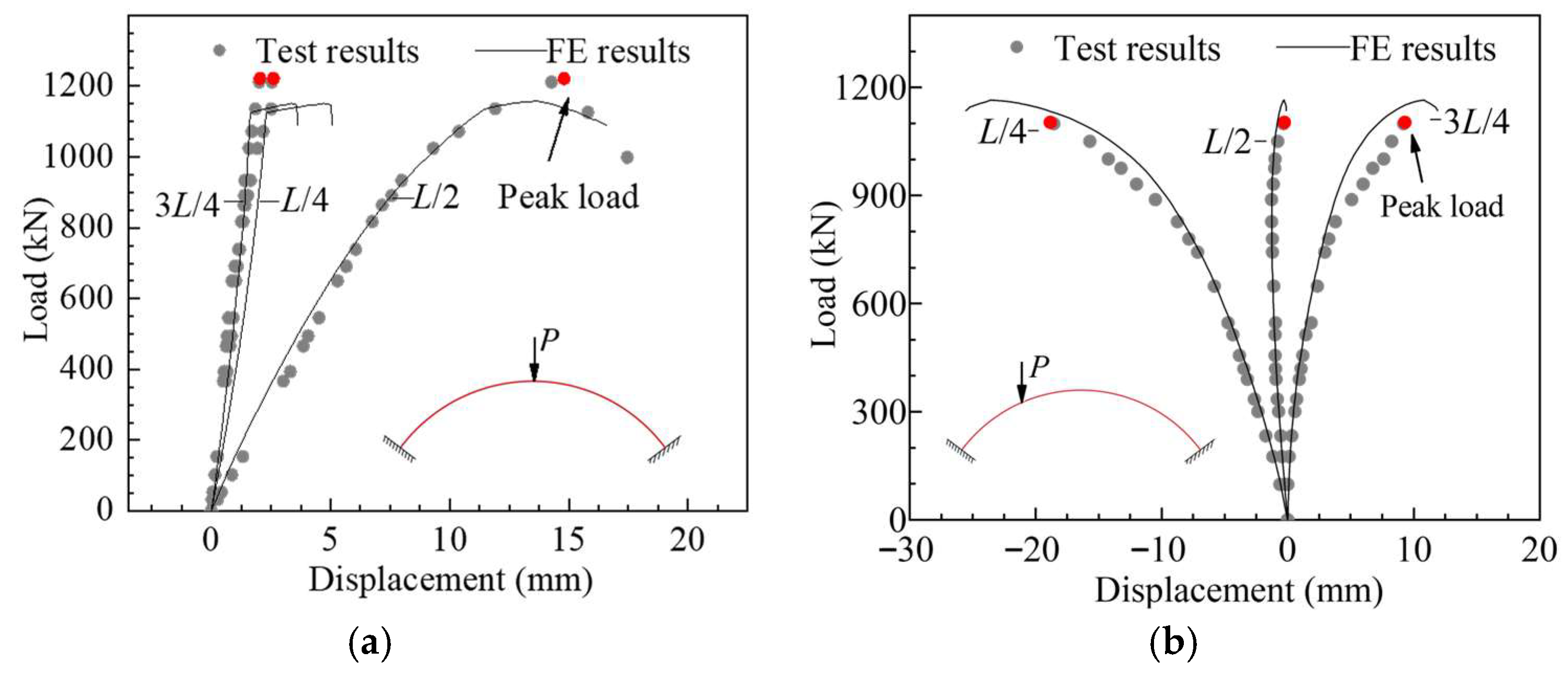

3.2. Load–Displacement Curves

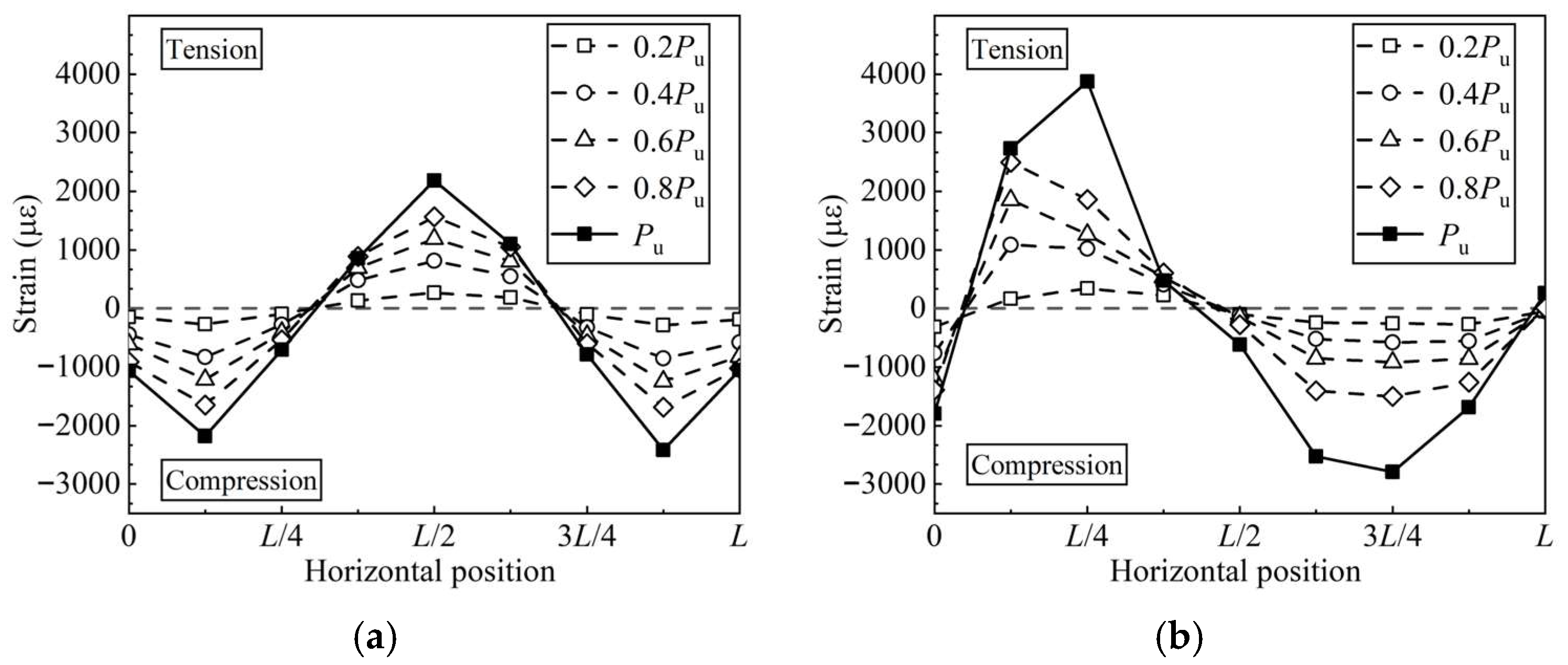

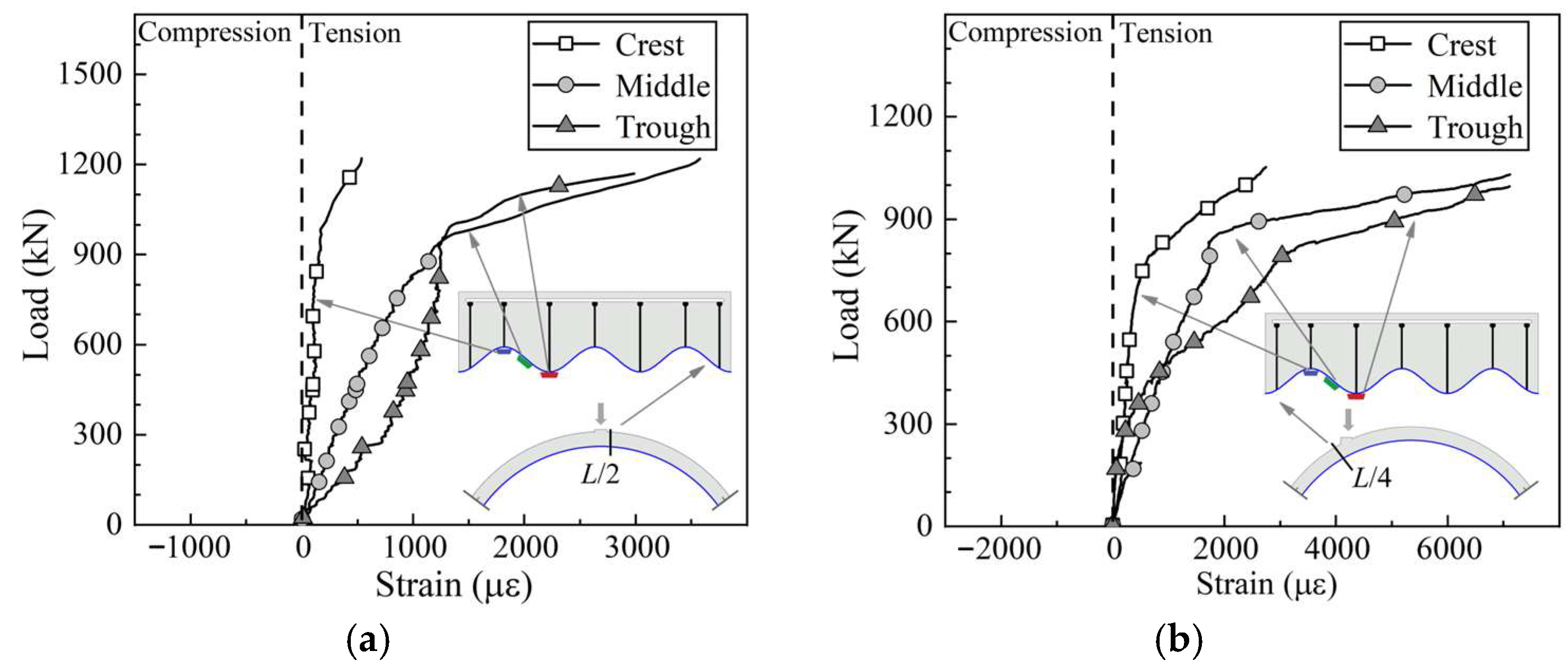

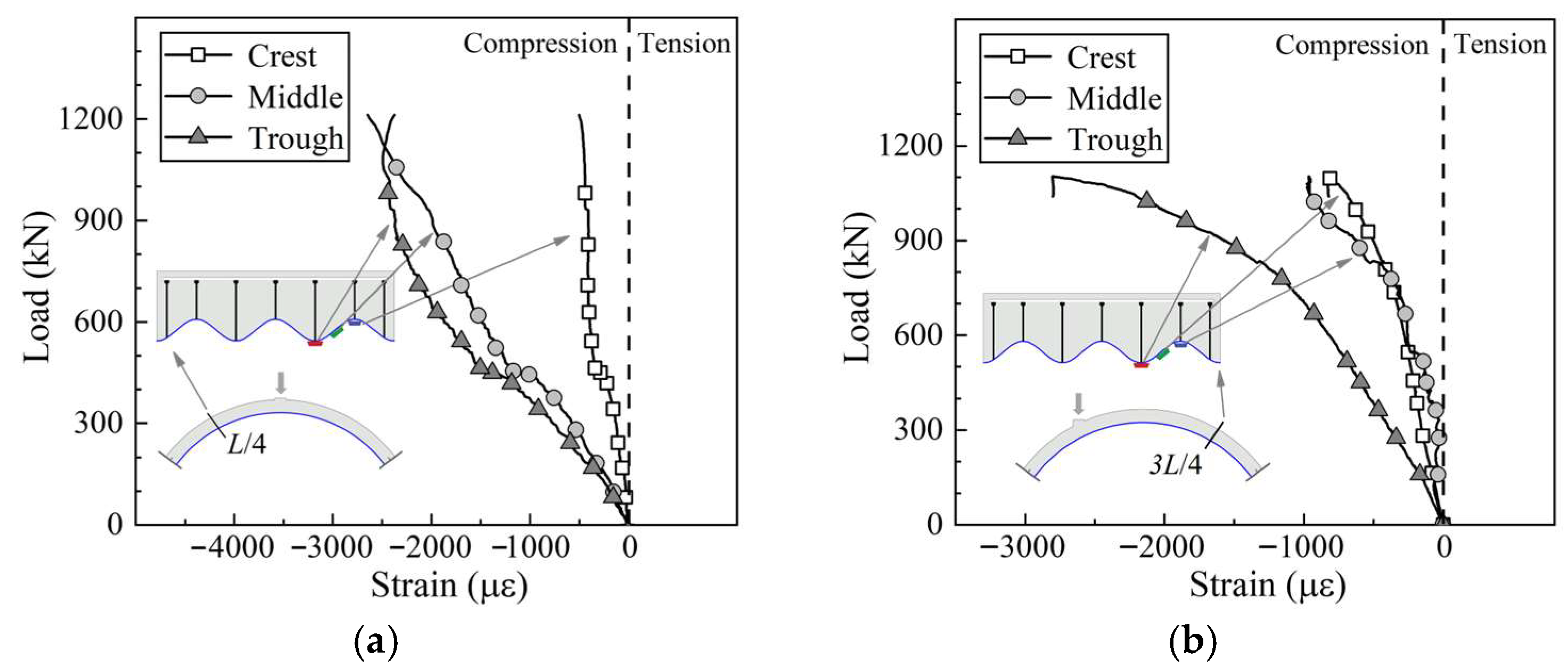

3.3. Strain Analysis of Corrugated Steel Troughs

3.4. Composite Action Analysis

4. FE Analysis

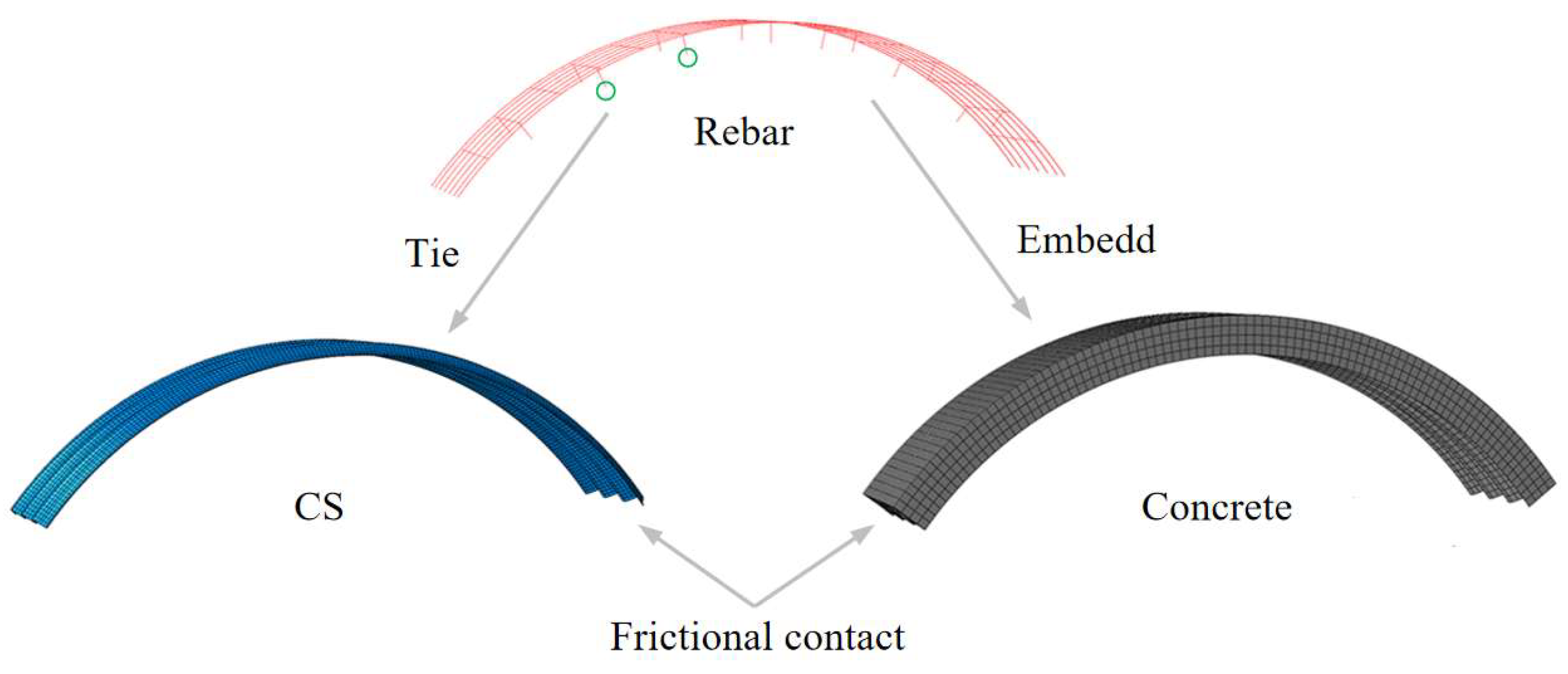

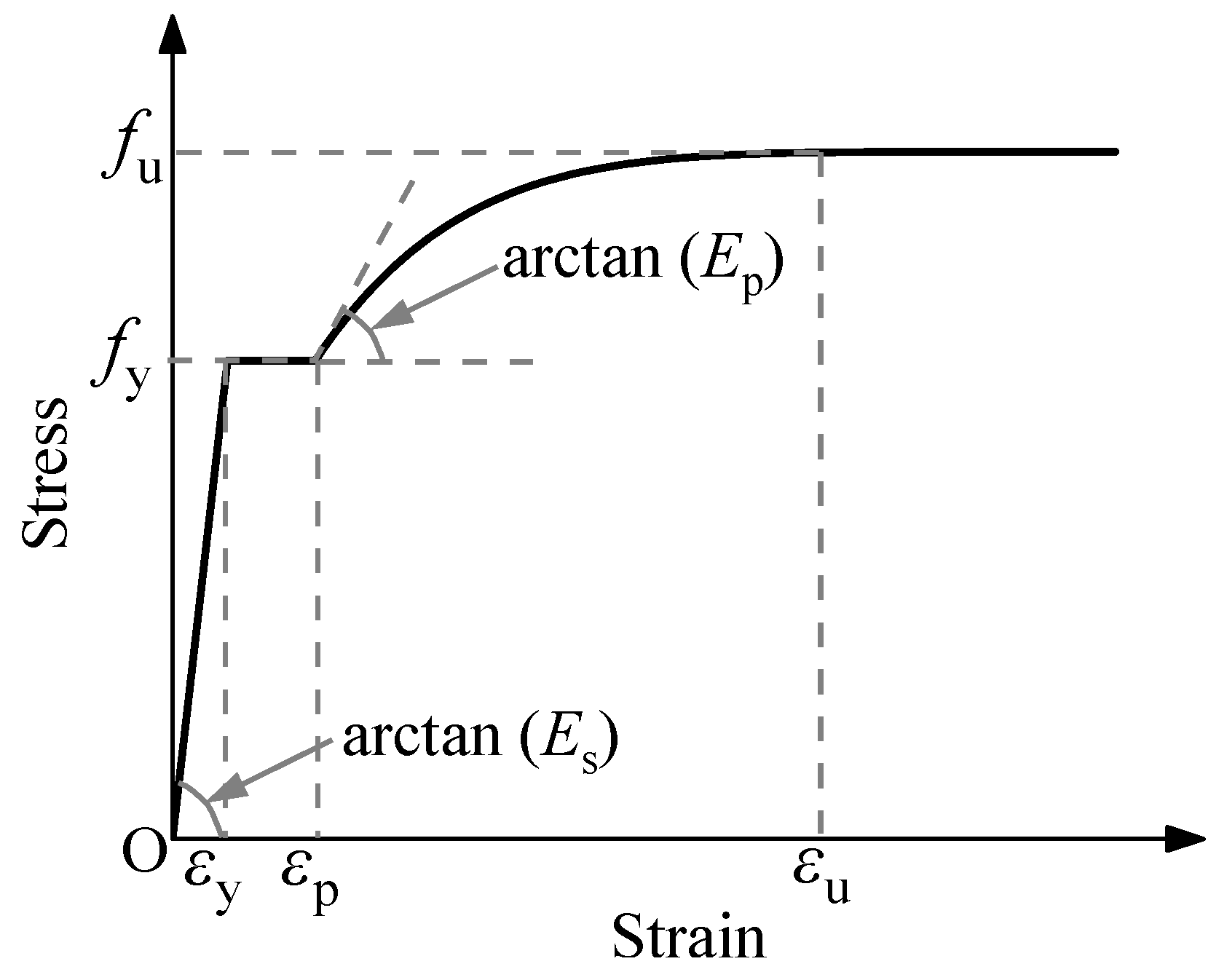

4.1. Establishment of the FE Model Based on ABAQUS

4.2. Validation of the FE Model

4.3. Parametric Analysis

4.3.1. Influence of Concrete Strength and Thickness

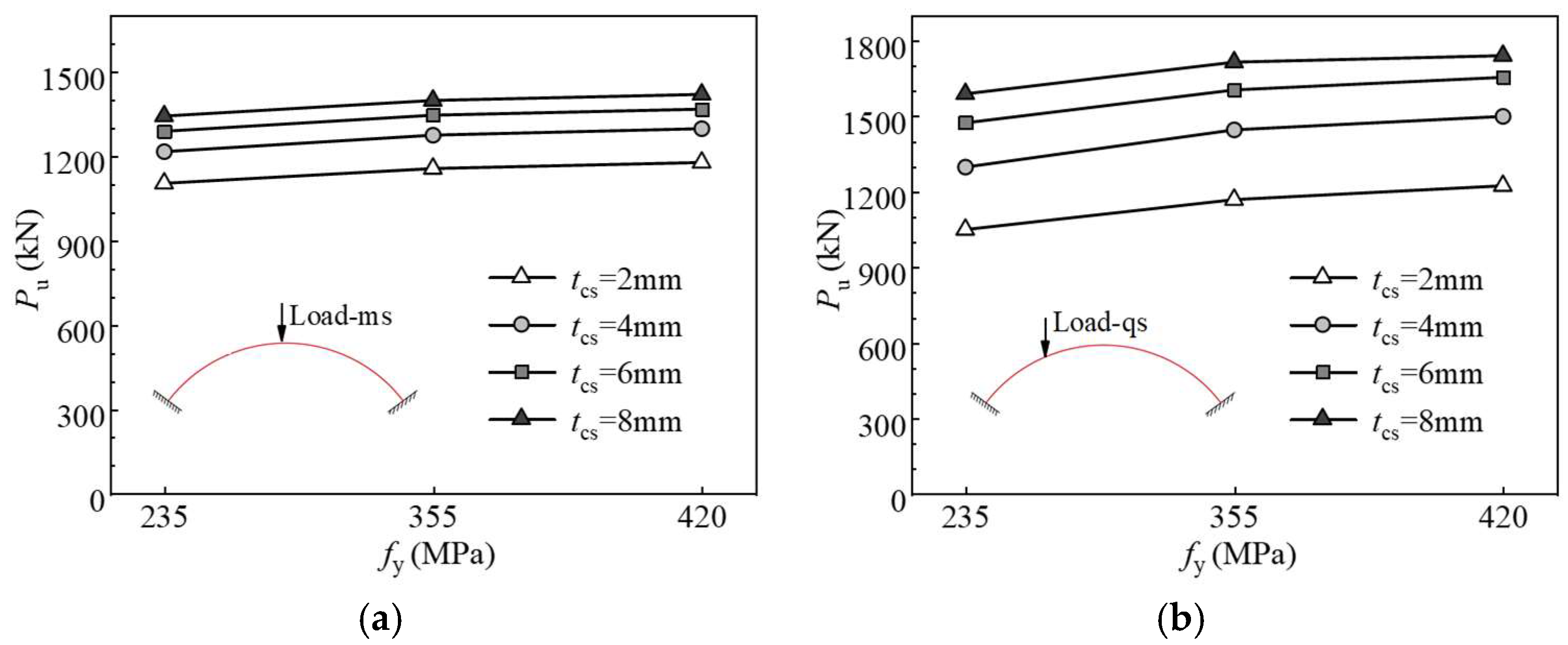

4.3.2. Influence of Corrugated Steel Strength and Thickness

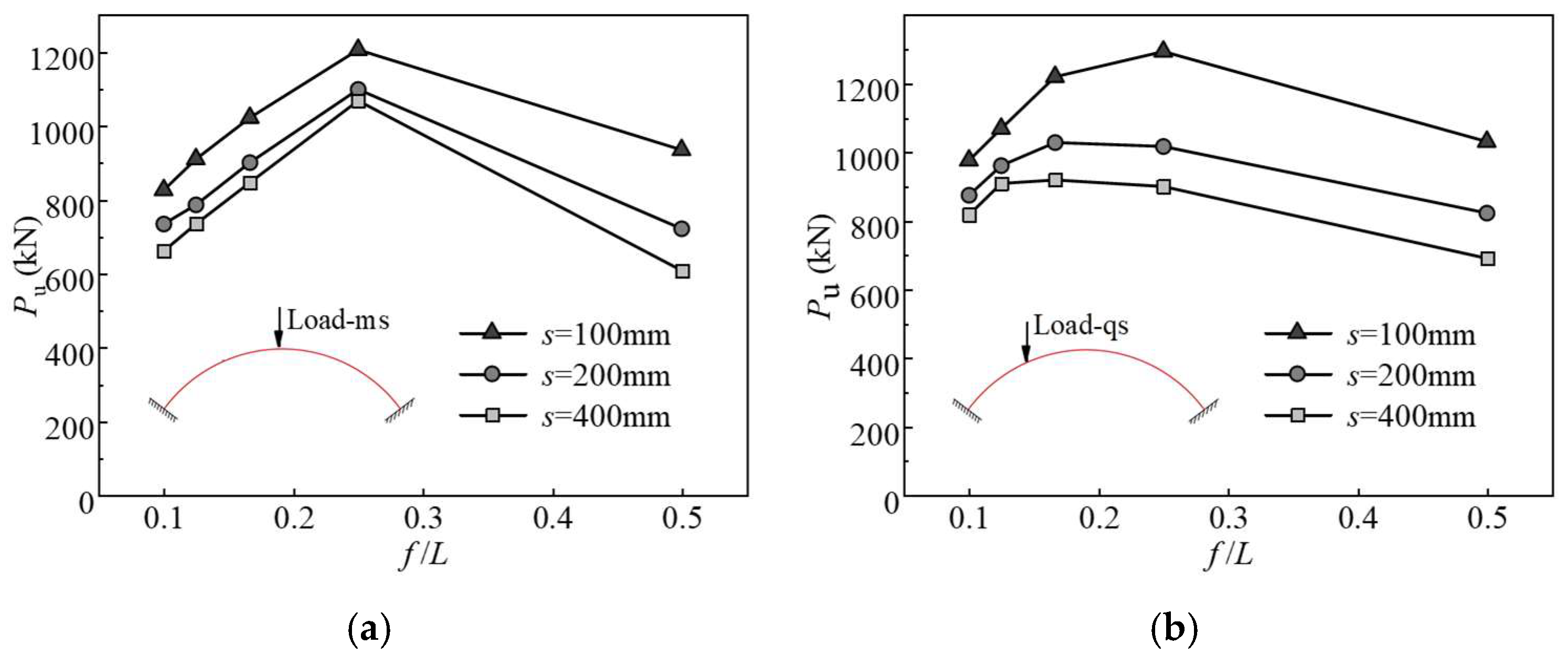

4.3.3. Influence of Rise-to-Span Ratio and Shear Connector Spacing

5. Experimental Program

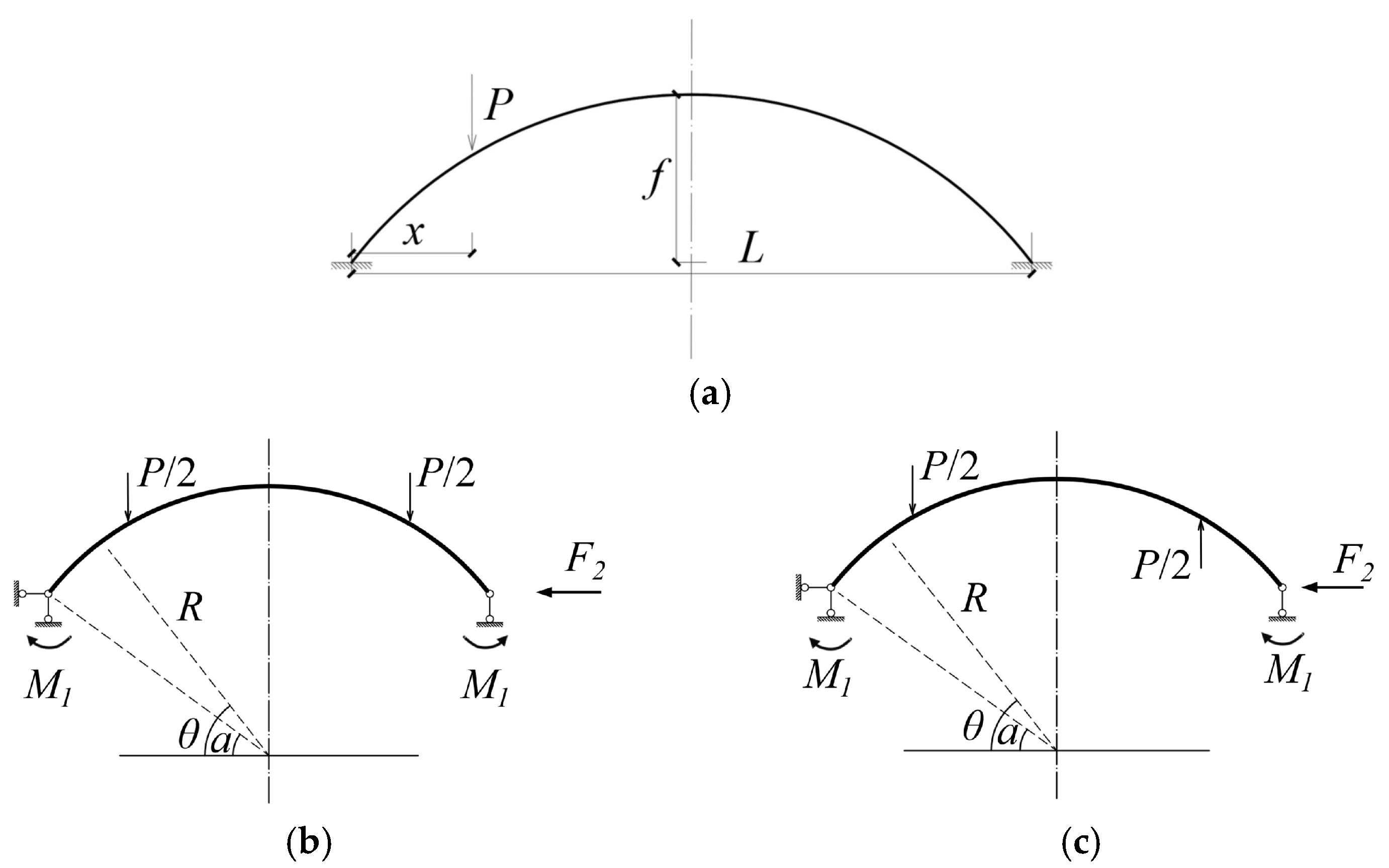

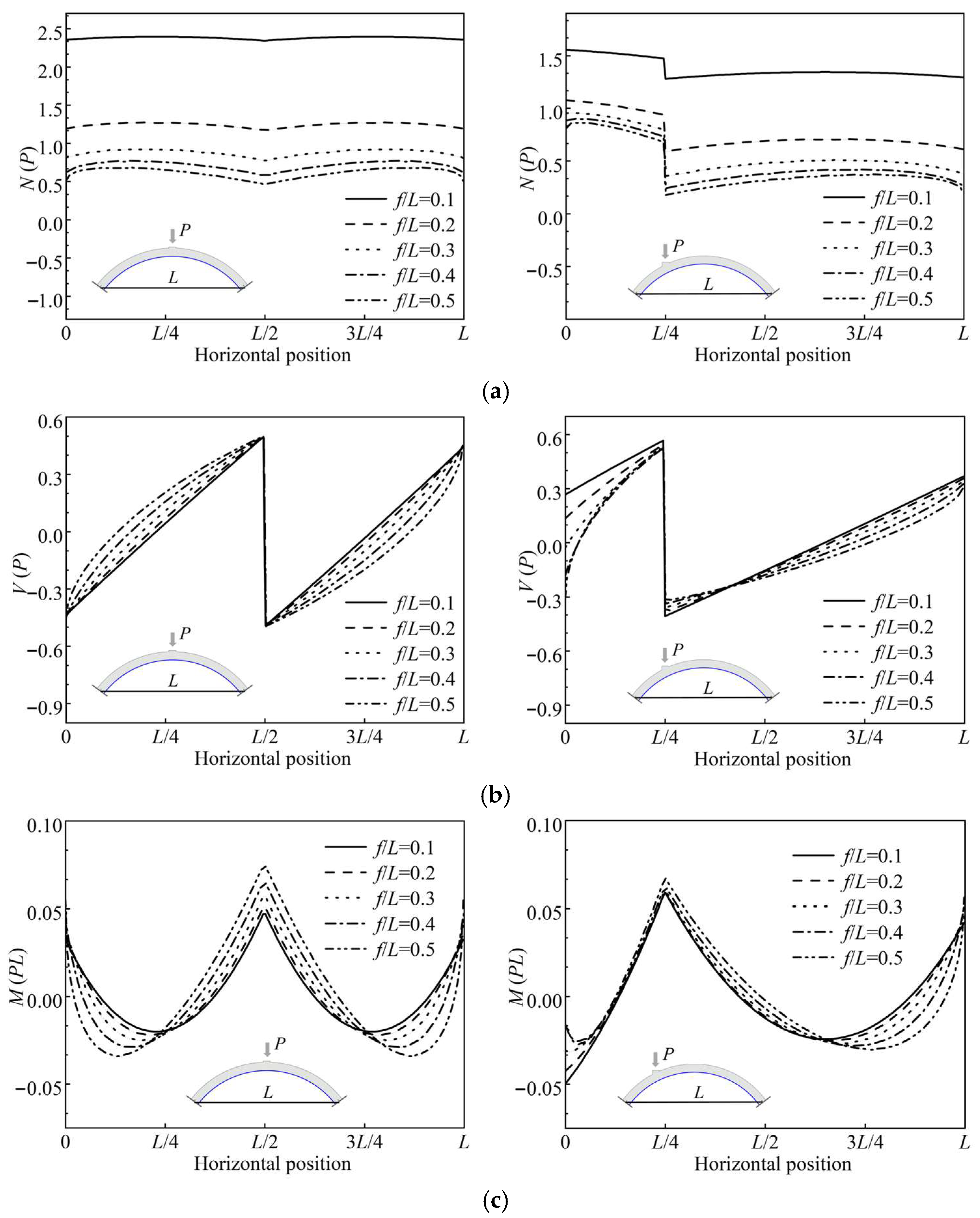

5.1. Internal Force Analysis of CSC Arches Based on Load Decomposition

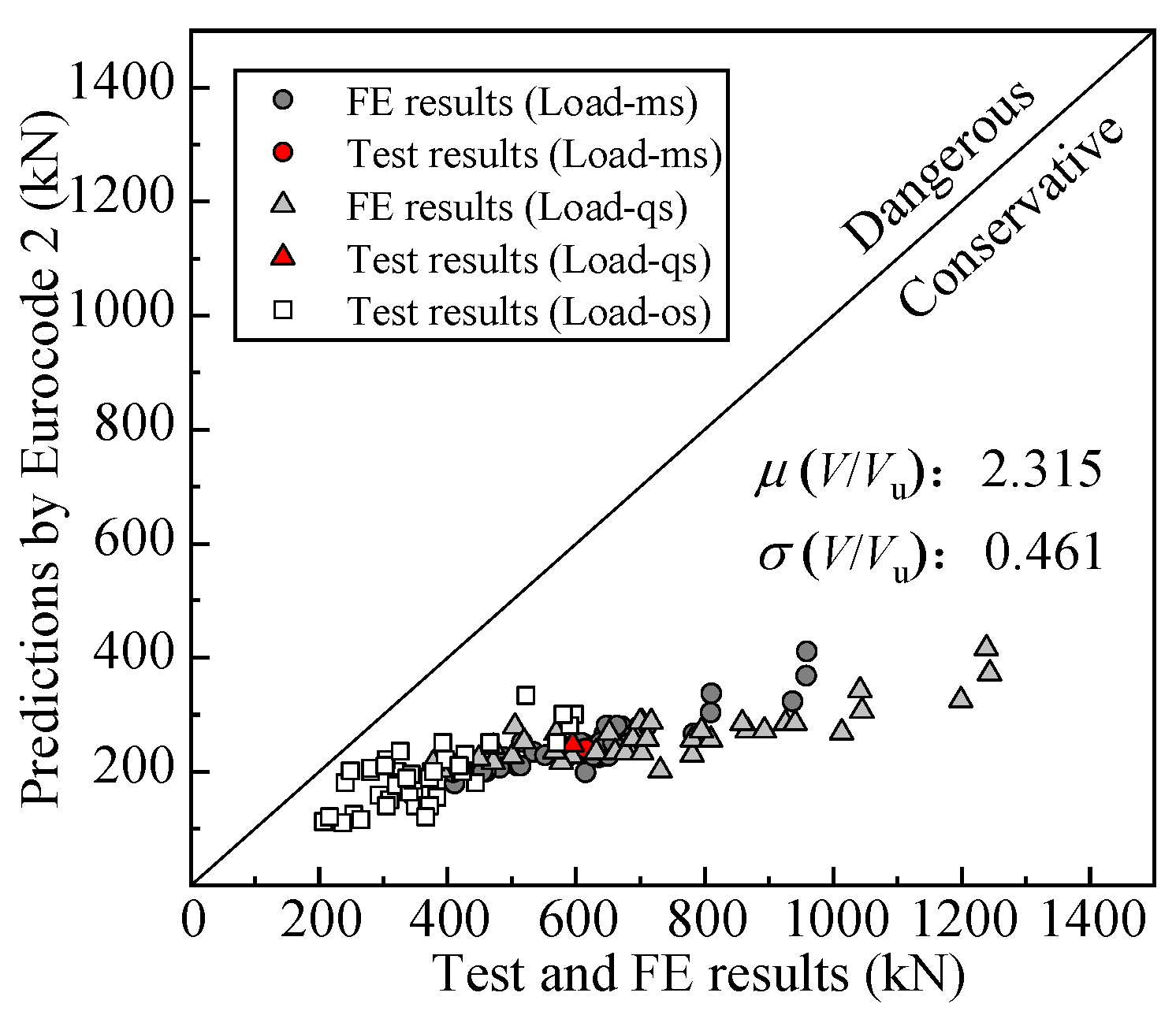

5.2. Verification of the Calculation Method for Shear Bearing Capacity

6. Discussion

6.1. Research Significance

6.2. Practical Application

6.3. Research Limitations and Future Research

7. Conclusions

- The loading location significantly influences the structural shear capacity by altering the shear–compression ratio at the failure section. Under identical sectional shear force, the mid-span loaded specimen develops a larger axial force, which restrains the formation of shear cracks and thereby increases the shear capacity of the specimen.

- Compared to mid-span loading, the shear capacity under quarter-point loading exhibits a higher sensitivity to variations in shear connector spacing and corrugated steel thickness. This behavior occurs because CSC arches under quarter-point loading are primarily bending-dominated. Changes in corrugated steel thickness and shear connector spacing significantly alter the flexural stiffness of the structure.

- The direction and location of the applied loads govern internal force discontinuities in CSC arches. Under non-radial concentrated loads, the arches exhibit discontinuities in both shear and axial forces at the loading point. In contrast, radial concentrated loads induce only a shear force discontinuity.

- Validation against results from tests and numerical simulation cases reveals that the predictive model incorporating shear–compression ratio in this study achieves excellent agreement with actual shear bearing capacities, with a mean value (μ) of 1.066 and a corresponding standard deviation (σ) of 0.071. The relative error is consistently within 15%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Theoretical Analysis for Internal Forces in CSC Arches

References

- Sun, K.; Hong, Y.; Xu, W.; Liu, H.; Zhen, Y.; Qin, J. Analysis and Prediction of the Mechanical Behavior of Corrugated Plate as Primary Support in Tunnels with Elastoplastic Constitution. Tunn. Undergr. Space Technol. 2022, 124, 104451. [Google Scholar] [CrossRef]

- Casariego, P.; Casafont, M.; Ferrer, M.; Marimon, F. Analytical Study of Flat and Curved Trapezoidal Cold Formed Steel Sheets by Means of the Yield Line Theory. Part 2: Curved Sheets with Transverse Corrugations. Thin Walled Struct. 2019, 141, 693–712. [Google Scholar] [CrossRef]

- Sun, K.; Hong, Y.; Xu, W.; Hou, Z.; Liu, X.; Yu, M.; Yuan, Z. Analysis and Prediction of Mechanical Characteristics of Corrugated Plate as Primary Support in Tunnels. Tunn. Undergr. Space Technol. 2021, 111, 103845. [Google Scholar] [CrossRef]

- Yu, S.; Wu, H.; Zhang, G.; Wang, Z.; Yao, J.; Li, H.; Liu, C. Experimental Study on Anti-Shallow-Buried-Explosion Capacity of a Corrugated Steel-Plain Concrete Composite Structure. Int. J. Impact Eng. 2023, 172, 104393. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, T.; Geng, Y.; Wang, Q.; Zhao, G.; Yang, J. Longitudinal Shear Tests and Design Methods for Corrugated Steel–Concrete Composite Slabs with Recycled Coarse Aggregate. Constr. Build. Mater. 2023, 400, 132870. [Google Scholar] [CrossRef]

- Yan, J.-B.; Fan, J.; Ding, R.; Nie, X. Steel-Concrete-Steel Sandwich Composite Structures: A Review. Eng. Struct. 2024, 302, 117449. [Google Scholar] [CrossRef]

- Yan, M.; Wang, L.; Chen, B.; He, Y. Assessment of Mid-Span Deflection of Curved Steel-Concrete-Steel Sandwich Shells under Concentrated Loading. Structures 2024, 70, 107618. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, K.; Lu, X.; Xu, G.; Chen, T. Constructional Behavior of Multi-Span Corrugated Steel Arch Culverts Stiffened by Concrete Rings. J. Constr. Steel Res. 2024, 218, 108751. [Google Scholar] [CrossRef]

- Luo, Y.; Alaghbandrad, A.; Genger, T.K.; Hammad, A. History and Recent Development of Multi-Purpose Utility Tunnels. Tunn. Undergr. Space Technol. 2020, 103, 103511. [Google Scholar] [CrossRef]

- Yan, J.-B.; Qian, X.; Liew, J.Y.R.; Zong, L. Damage Plasticity Based Numerical Analysis on Steel–Concrete–Steel Sandwich Shells Used in the Arctic Offshore Structure. Eng. Struct. 2016, 117, 542–559. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, Y.; Yang, H.; Lin, X. Experimental Behavior of Concrete-Filled Thin-Walled Corrugated Steel Tubes with Large Helical Angles under Monotonic and Cyclic Axial Compression. Thin Walled Struct. 2022, 173, 109043. [Google Scholar] [CrossRef]

- Fang, Y.; Gai, W.; Yang, H.; Lu, B. Modelling and Lock-Seam Effects on Compressive Behaviour of Concrete-Filled Helical Corrugated Steel Tubes. Structures 2023, 58, 105321. [Google Scholar] [CrossRef]

- Fang, Y.; Yang, H.; Chan, T.; Wang, Y. Experimental Investigation on Seismic Behaviour of Concrete-Filled Corrugated Steel Tubes under Cyclic Torsional Loads. Eng. Struct. 2024, 309, 118062. [Google Scholar] [CrossRef]

- Yang, G.; Wang, G.; Lu, W.; Zhao, X.; Yan, P.; Chen, M. Numerical Modeling of Surface Explosion Effects on Shallow-Buried Box Culvert Behavior during the Water Diversion. Thin Walled Struct. 2018, 133, 153–168. [Google Scholar] [CrossRef]

- Ding, W.; Huang, X.; Li, S.; Liu, W.; Zhang, Q. Flexural Stiffness Characterization of the Corrugated Steel–Concrete Composite Structure for Tunnel Projects. Undergr. Space 2023, 12, 18–30. [Google Scholar] [CrossRef]

- Guo, Y.-L.; Chen, H.; Pi, Y.-L.; Bradford, M.A. In-Plane Strength of Steel Arches with a Sinusoidal Corrugated Web under a Full-Span Uniform Vertical Load: Experimental and Numerical Investigations. Eng. Struct. 2016, 110, 105–115. [Google Scholar] [CrossRef]

- Yang, J.; Liu, F.; Chen, B.; Liu, C.; Sun, D.; Wang, Y. Compressive-Bending Behavior of Corrugated Steel-Concrete Composite Arches: Testing, Modelling and Design. Eng. Struct. 2025, 342, 120952. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, F.; Liu, C.; Yang, H.; Wang, Y.; Pei, Y. Experimental and Numerical Studies on Corrugated Steel Retrofitted Damaged Reinforced Concrete Arches. Thin Walled Struct. 2024, 205, 112386. [Google Scholar] [CrossRef]

- Yang, J.; Liu, F.; Chen, B.; Liu, C.; Sun, D.; Wang, Y. Axial Compression Behavior of Corrugated Steel-Concrete Composite Arches. J. Constr. Steel Res. 2025, 234, 109772. [Google Scholar] [CrossRef]

- Han, X.; Wei, C.; Hu, Q.; Liu, C.; Wang, Y. In-Plane Nonlinear Buckling Analysis and Design Method of Concrete-Filled Steel Tubular Catenary Arches. J. Constr. Steel Res. 2024, 214, 108485. [Google Scholar] [CrossRef]

- Sun, J.-Q.; Geng, Y.; Liew, J.Y.R.; Wang, Y.-T.; Wang, Y.-Y. Experimental and Numerical Study on Out-of-Plane Post Creep Buckling Behavior of Concrete-Filled Steel Tubular Arch. Eng. Struct. 2025, 329, 119843. [Google Scholar] [CrossRef]

- Xia, Q.; Wang, Y.; Jelovica, J.; Liu, C.; Sun, D. Experimental Study on Corrugated Steel–Concrete Composite Semicircular Arches under Midspan Loading. Structures 2022, 38, 1137–1150. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, Y.; Mei, Y.; Liu, F.; Liu, C. Static Behavior of Corrugated Steel-Shotcrete Composite Arches. Thin Walled Struct. 2024, 195, 111429. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, C.; Wang, Y.; Yang, H.; Liu, F.; Yu, Z. Experimental and Numerical Studies on the Behavior of Corrugated Steel-Sprayed ECC Composite Arches with Full-Shear-Connection. Eng. Struct. 2024, 309, 118096. [Google Scholar] [CrossRef]

- Tong, J.-Z.; Chen, Y.-L.; Li, Q.-H.; Dai, J.-B.; Wang, G.-Z.; Shen, J.-J.; Gao, W.; Xu, S.-L. Flexural Performance and Crack Width Prediction of Steel-UHTCC Composite Bridge Decks with Wet Joints. Eng. Struct. 2025, 323, 119264. [Google Scholar] [CrossRef]

- Huang, Z.; Liew, J.Y.R. Experimental and Analytical Studies of Curved Steel–Concrete–Steel Sandwich Panels under Patch Loads. Mater. Des. 2016, 93, 104–117. [Google Scholar] [CrossRef]

- Leng, Y.; Song, X. Shear Strength of Steel–Concrete–Steel Sandwich Deep Beams: A Simplified Approach. Adv. Struct. Eng. 2019, 22, 42–53. [Google Scholar] [CrossRef]

- EN 1992-2:2005; Eurocode 2: Design of Concrete Structures–Part 2: Concrete Bridges–Design and Detailing Rules. European Committee for Standardization: Brussels, Belgium, 2005.

- ACI 318-05; Building Code Requirements for Structural Concrete. American Concrete Institute: San Bernardino, CA, USA, 2005.

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2015.

- Wen, C.-B.; Zuo, J.-Q.; Zhu, B.-L.; Sun, H.-J.; Guo, Y.-L.; Zheng, W.-J.; Deng, L.-L. Shear Resistance Design of Prefabricated Corrugated Steel Plate Shear Walls with Reinforced Boundary Elements. Structures 2024, 68, 107067. [Google Scholar] [CrossRef]

- Wu, R.-M.; Tong, J.-Z. Shear Strength and Post-Ultimate Behavior of Multi-Stiffened Corrugated Steel Plate Shear Walls. J. Constr. Steel Res. 2025, 229, 109480. [Google Scholar] [CrossRef]

- Tong, J.; Zhang, J.; Yu, C.; Tong, G.; Li, Q.; Xu, S. Seismic Experiments and Shear Resistance Prediction of Multi-celled Corrugated-plate CFST Walls. Earthq. Engng Struct. Dyn. 2024, 53, 1681–1704. [Google Scholar] [CrossRef]

- Bi, Z.; Yang, G. Shear Strength of Steel-Concrete Composite I-Beams with Corrugated Steel Webs. Structures 2024, 69, 107317. [Google Scholar] [CrossRef]

- Wang, S.; He, J.; Liu, Y. Shear Behavior of Steel I-Girder with Stiffened Corrugated Web, Part I: Experimental Study. Thin Walled Struct. 2019, 140, 248–262. [Google Scholar] [CrossRef]

- Xie, Z.; Shi, L.; Peng, L.; Zhang, S.; Zhou, D.; Zhang, X.; Yu, C. Behaviour of a Cold-Formed Steel Shear Wall with Centre-Corrugated Steel Sheathing under Cyclic Loading. Eng. Struct. 2024, 318, 118650. [Google Scholar] [CrossRef]

- Yu, J.-G.; Feng, X.-T.; Carvelli, V. Hysteretic Performance of Foam-Infilled Corrugated FRP-Steel Sandwich Shear Wall. Eng. Struct. 2023, 294, 116775. [Google Scholar] [CrossRef]

- Chen, B.; Xia, X.; Liu, C.; Zhang, H.; Wang, Y. Calculation method for shear bearing capacity of corrugated steel-concrete composite arches based on experimental and theoretical studies. Eng. Struct. Under review. 2025. [Google Scholar]

- Ghali, M.K.; Said, M.; Mustafa, T.S.; El-Sayed, A.A. Behaviour of T-Shaped RC Deep Beams with Openings under Different Loading Conditions. Structures 2021, 31, 1106–1129. [Google Scholar] [CrossRef]

- Fayyadh, M.M.; Abdul Razak, H. Impact of Design Parameters and Cycles of Damage Loads on CFRP Repair Effectiveness of Shear-Deficient RC Structures. Constr. Build. Mater. 2022, 347, 128465. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Yu, Y.; Hao, N. Shear Performance of Prestressed Partially-Precast Steel Reinforced Concrete Beam: Experiments and Analyses. Structures 2024, 62, 106329. [Google Scholar] [CrossRef]

- Setiawan, A.; Cantone, R.; Fernández Ruiz, M.; Muttoni, A. Verification of Shear Failures of Cantilever Bridge Deck Slabs Subjected to Concentrated Loads. Eng. Struct. 2024, 303, 117491. [Google Scholar] [CrossRef]

- Hu, Q.; Liu, C.; Yuan, C.; Wang, Y.; Zhang, S. Experimental Investigation into In-Plane Stability of Concrete-Filled Steel Tubular Parabolic Arches Under Five-Point Concentrated Loads. Int. J. Steel Struct. 2020, 20, 2038–2050. [Google Scholar] [CrossRef]

- Yang, J.; Sun, Y.; Liu, F.; Liu, C.; Wang, Y. Dynamic Response and Energy Dissipation Mechanism of Corrugated Steel-Concrete-Corrugated Steel Sandwich Composite Arches under Impact Loading. Structures 2025, 80, 109713. [Google Scholar] [CrossRef]

- Sun, D.; Liu, C.; Wang, Y.; Xia, Q.; Liu, F. Static Performance of a New Type of Corrugated Steel-Concrete Composite Shell under Mid-Span Loading. Structures 2022, 37, 109–124. [Google Scholar] [CrossRef]

- Li, Y.; Liao, Y.; Xie, Z.; Peng, L. Stability Analysis of Curved Beams Based on First-Order Shear Deformation Theory and Moving Least-Squares Approximation. Buildings 2024, 14, 3887. [Google Scholar] [CrossRef]

- JTG D61—2005; Code for Design of Highway Masonry Bridges and Culverts. China Communications Press: Beijing, China, 2016.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- GB/T 34567-2017; Cold-Formed Corrugated Steel Pipes. Standards Press of China: Beijing, China, 2017.

| Specimen | f (mm) | L (mm) | f/L | w (mm) | tc (mm) | fck (MPa) | Load Location |

|---|---|---|---|---|---|---|---|

| CSCA-M | 750 | 3000 | 1/4 | 600 | 150 | 50 | L/2 |

| CSCA-Q | L/4 |

| Parameter | Values |

|---|---|

| s (mm) | 100, 200, 400 |

| f/L | 1/2, 1/4, 1/6, 1/8, 1/10 |

| ds (mm) | 6, 8, 10, 12 |

| fck (MPa) | 30, 40, 50 |

| hc (mm) | 150, 200, 250 |

| tcs (mm) | 2, 4, 6, 8 |

| fy (MPa) | 235, 355, 420 |

| CS size (mm) | 125 × 25, 200 × 55, 300 × 110 |

| Load location | L/2, L/4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, X.; Li, T.; Chen, B.; Yang, J.; Han, X.; Yu, Z.; Wei, C.; Zhao, H. Experimental and Theoretical Studies on Shear Performance of Corrugated Steel–Concrete Composite Arches Considering the Shear–Compression Ratio. Buildings 2025, 15, 3316. https://doi.org/10.3390/buildings15183316

Xia X, Li T, Chen B, Yang J, Han X, Yu Z, Wei C, Zhao H. Experimental and Theoretical Studies on Shear Performance of Corrugated Steel–Concrete Composite Arches Considering the Shear–Compression Ratio. Buildings. 2025; 15(18):3316. https://doi.org/10.3390/buildings15183316

Chicago/Turabian StyleXia, Xiangfei, Tianyu Li, Bowen Chen, Jinsheng Yang, Xinhao Han, Zhan Yu, Chenyang Wei, and Hongwei Zhao. 2025. "Experimental and Theoretical Studies on Shear Performance of Corrugated Steel–Concrete Composite Arches Considering the Shear–Compression Ratio" Buildings 15, no. 18: 3316. https://doi.org/10.3390/buildings15183316

APA StyleXia, X., Li, T., Chen, B., Yang, J., Han, X., Yu, Z., Wei, C., & Zhao, H. (2025). Experimental and Theoretical Studies on Shear Performance of Corrugated Steel–Concrete Composite Arches Considering the Shear–Compression Ratio. Buildings, 15(18), 3316. https://doi.org/10.3390/buildings15183316