Comparative Analysis of Autogenous and Microbial-Based Calcite Precipitation in Concrete: State-of-the-Art Review

Abstract

1. Introduction

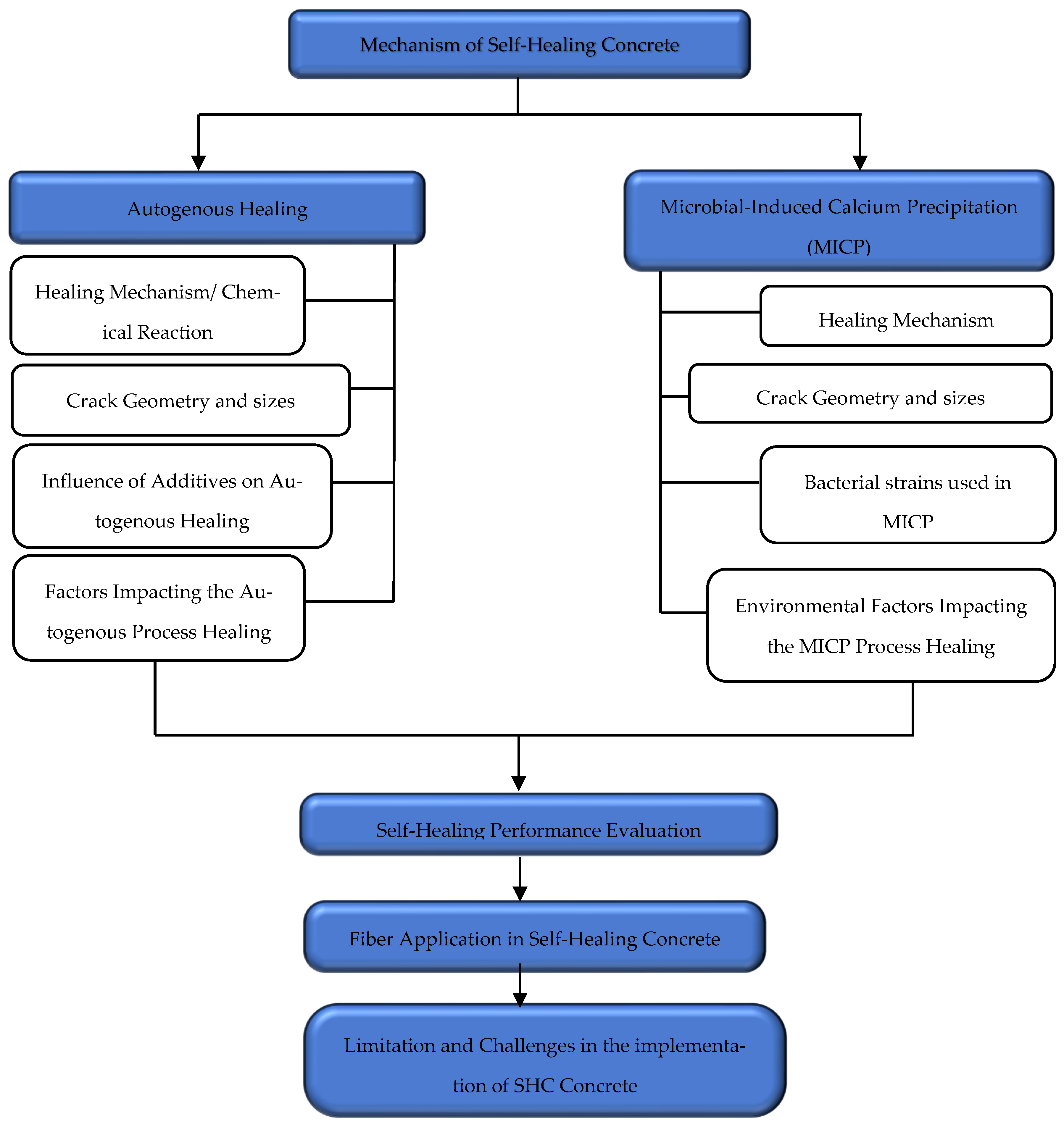

2. Review Methodology

3. Self-Healing Mechanisms in Concrete

3.1. Autogenous Healing

3.1.1. Chemical Reactions and the Healing Mechanism

- Dissolution of CO2 in water:

- Formation of calcium carbonate:

- Reaction involving bicarbonates:

3.1.2. Crack Geometry and Sizes

3.1.3. Effect of Additives on Autogenous Healing

Crystalline Admixtures

Silica Fume

Fly Ash

Magnesium Oxide (MgO)

3.1.4. Factors Impacting the Autogenous Process

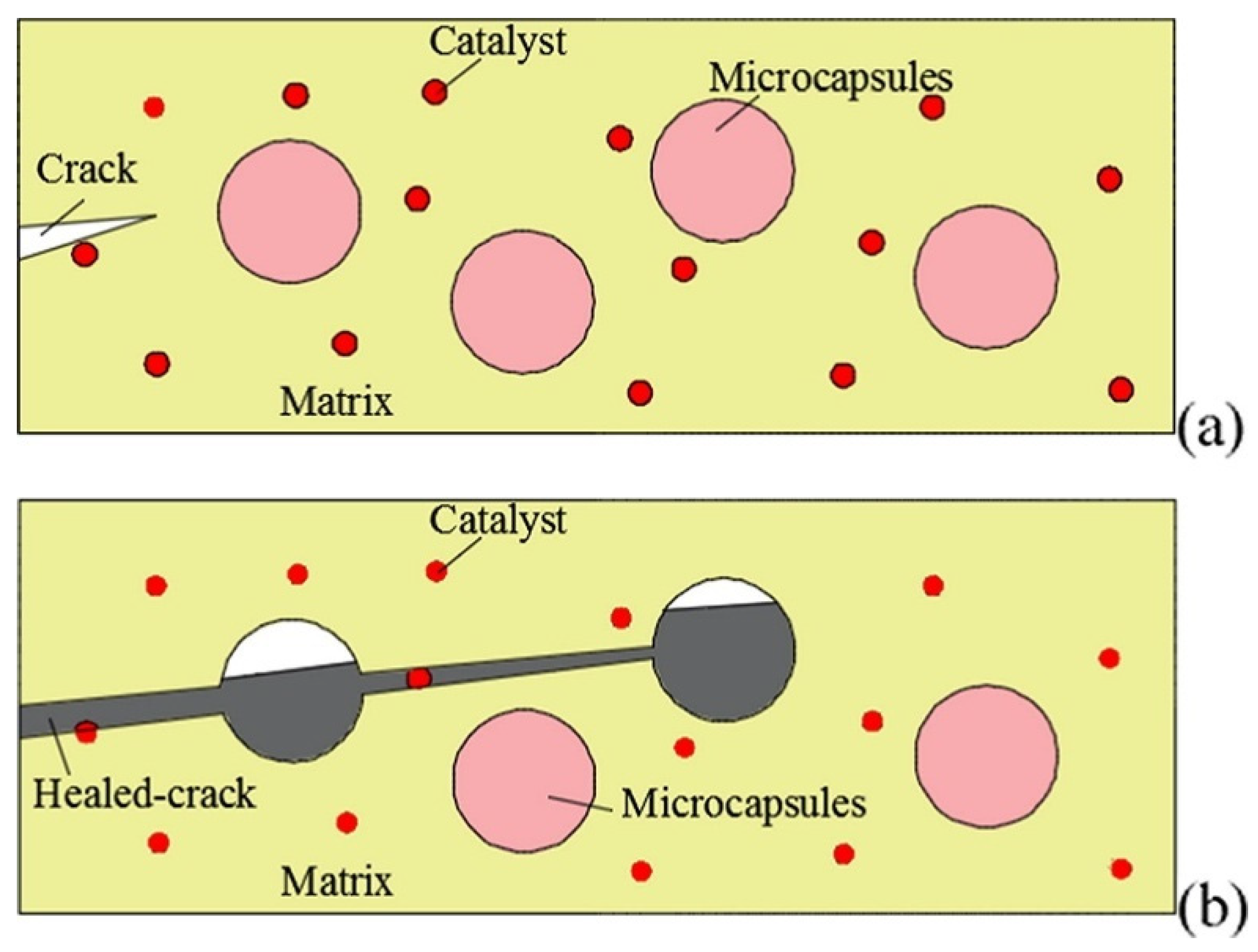

3.2. Microbial-Induced Calcium Precipitation (MICP)

3.2.1. Mechanisms of MICP

3.2.2. Crack Geometry and Sizes

3.2.3. Influencing Factors

3.2.4. Bacterial Strains Used in MICP

3.2.5. Concentrations of Bacteria Used in MICP

3.3. Bacterial Nutrients

3.4. Bacterial Carriers

3.5. Environmental Factors Influencing Microbial-Induced Self-Healing in Concrete

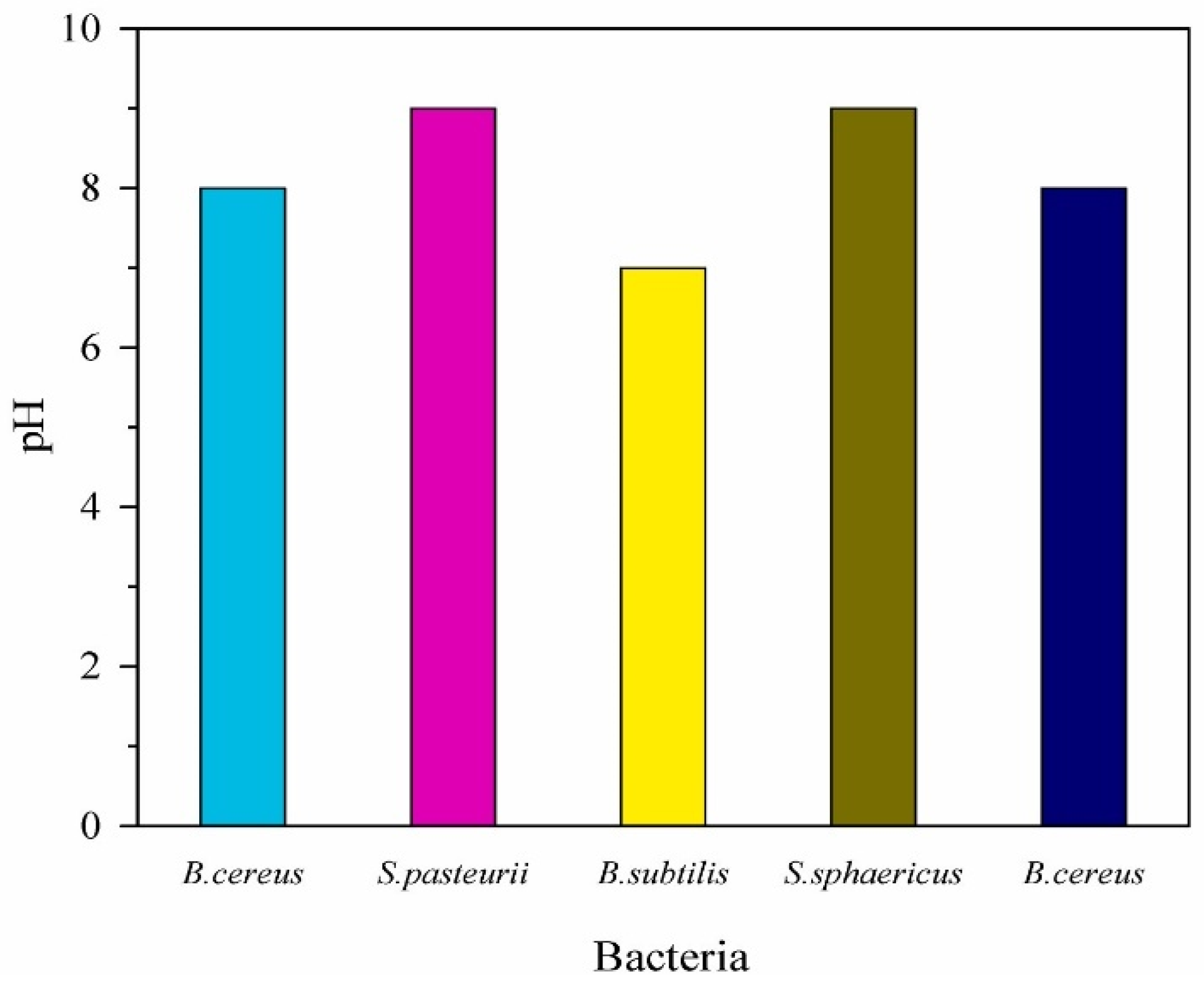

3.5.1. pH Levels

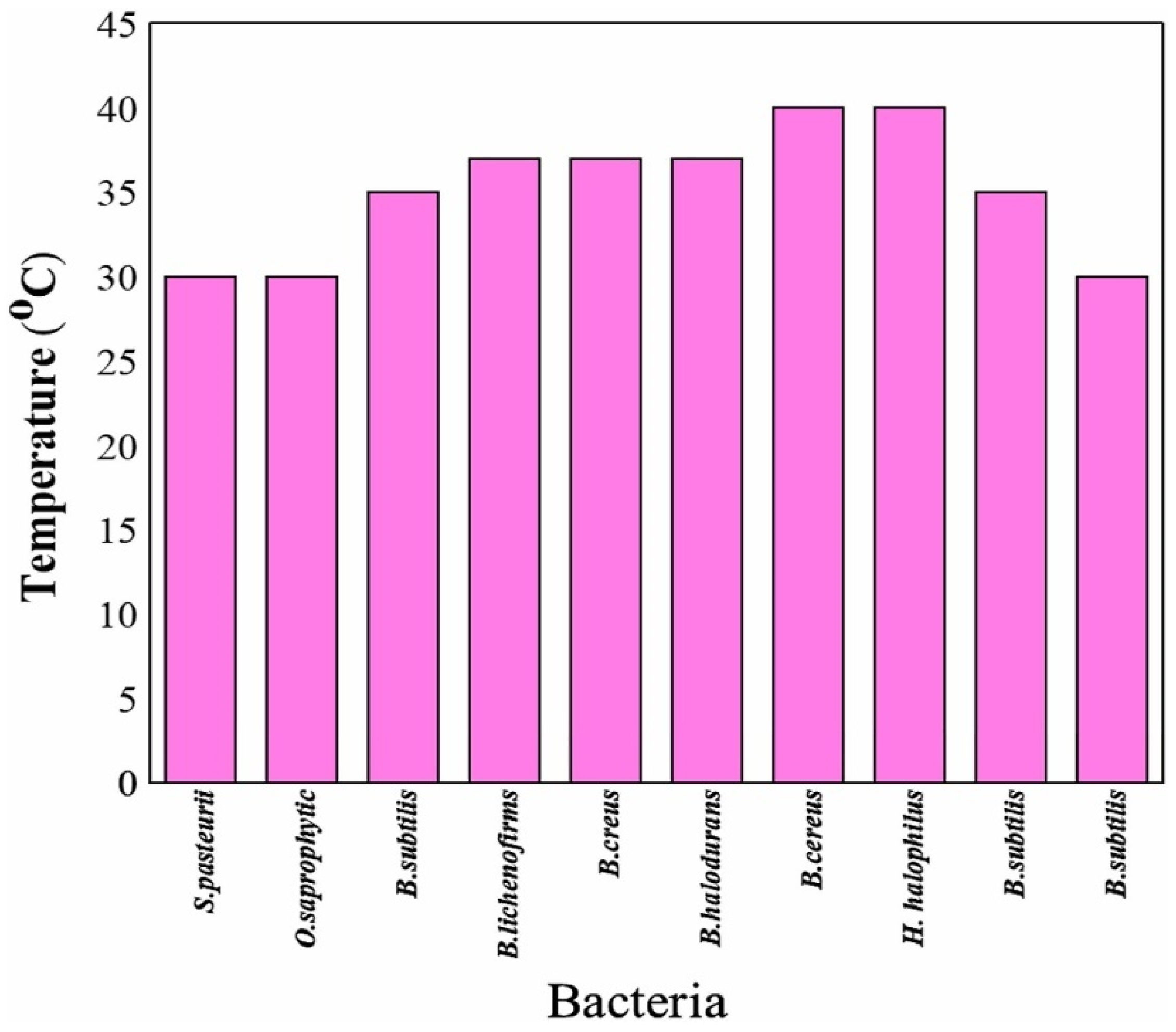

3.5.2. Temperature

3.5.3. Moisture Content and Oxygen Availability

4. Self-Healing Performance Evaluation

4.1. Pre-Cracking Test Methods for Evaluating Healing Efficiency and Mechanical Properties

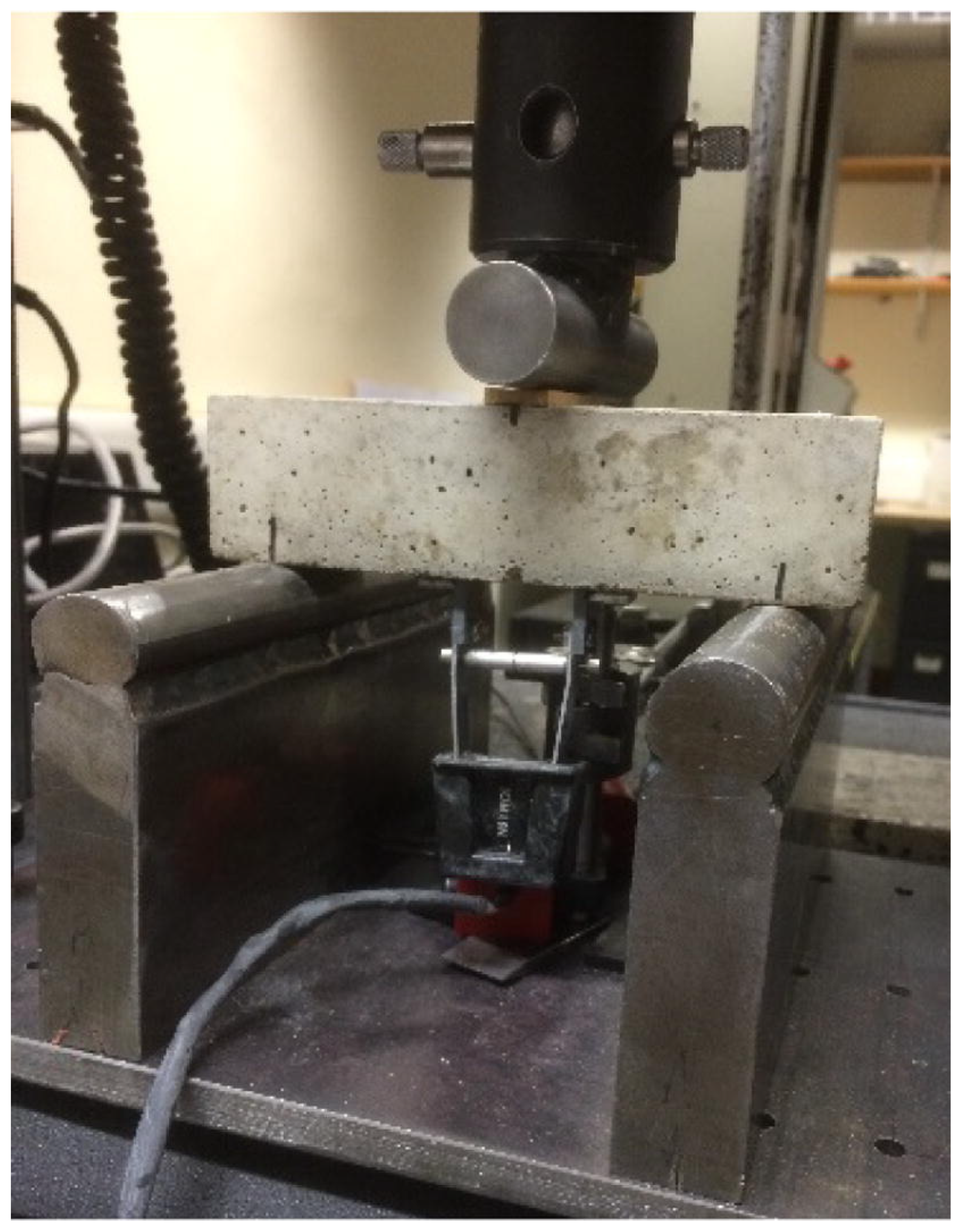

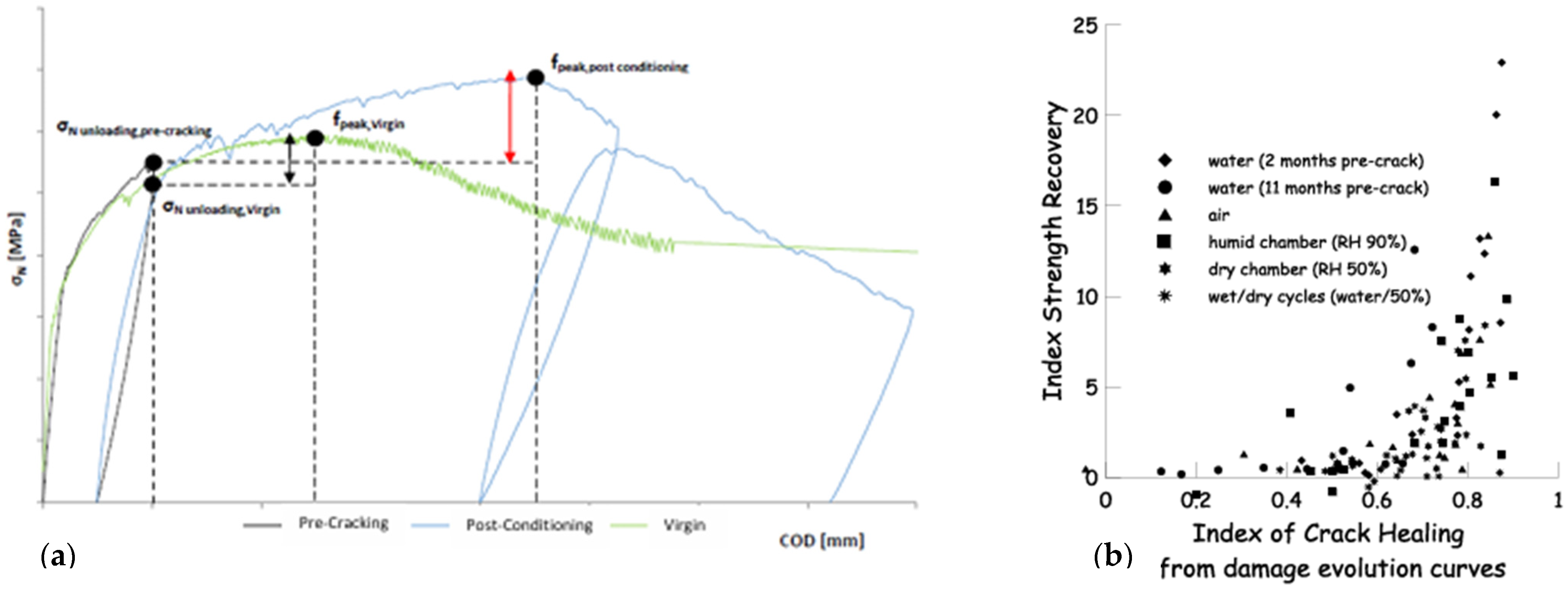

4.1.1. Flexural Bending Tests

- Index of load recovery (ILR):

- Index of damage recovery (IDR):

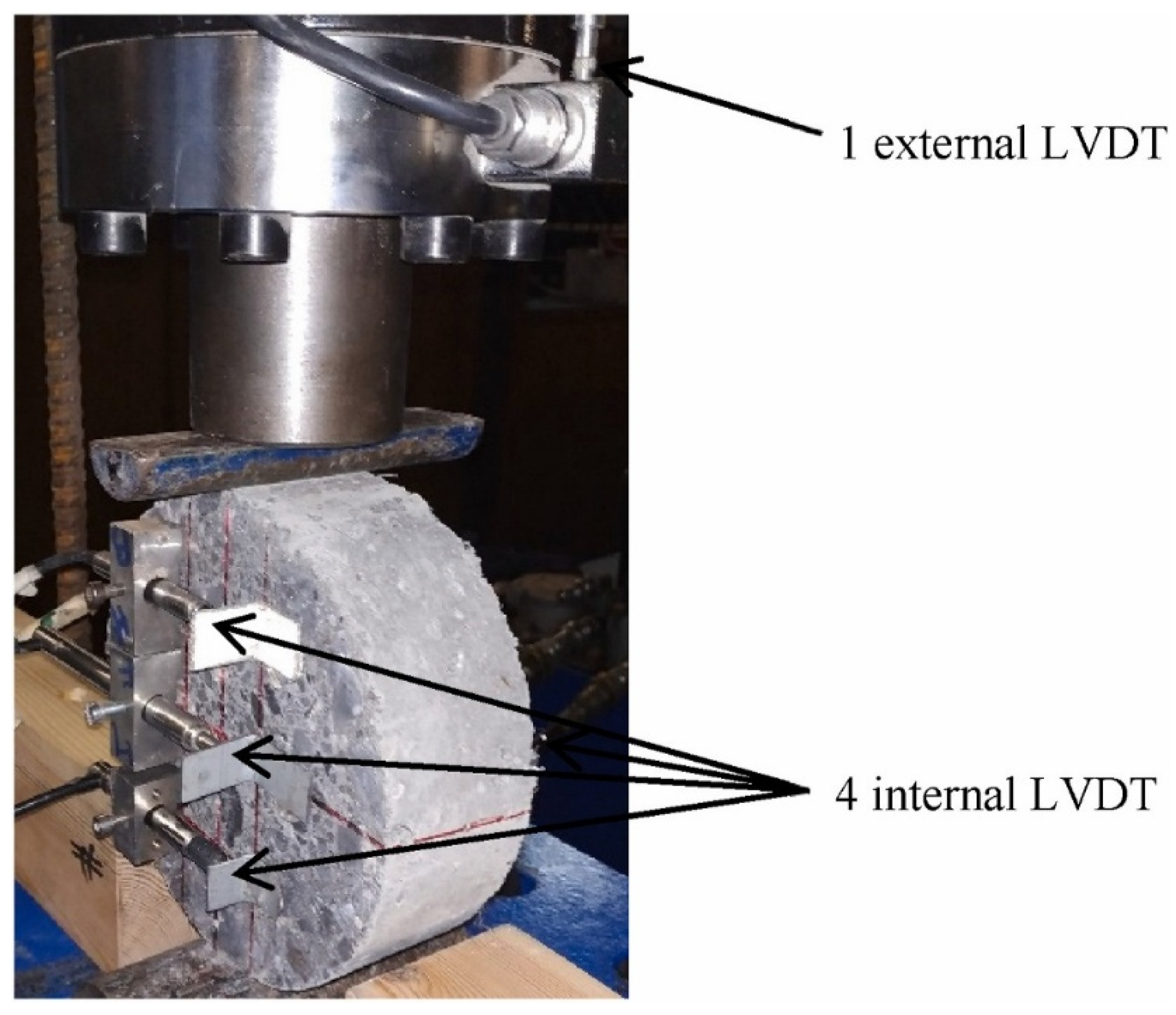

4.1.2. Splitting Tests (Indirect Tension)

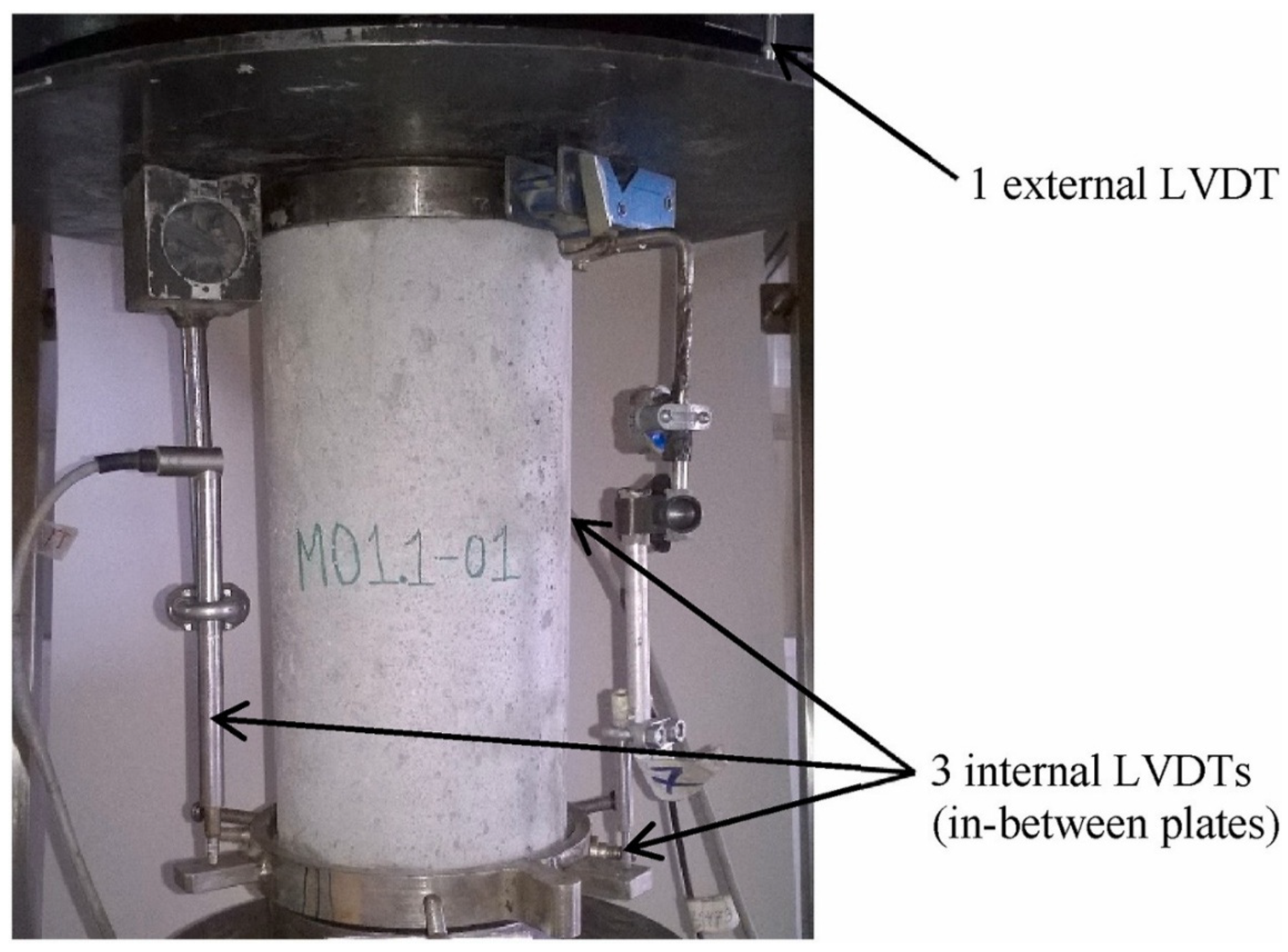

4.1.3. Compression Test

4.1.4. Uniaxial Tensile Test

4.2. Healing Efficiency, Visualization, and Determination

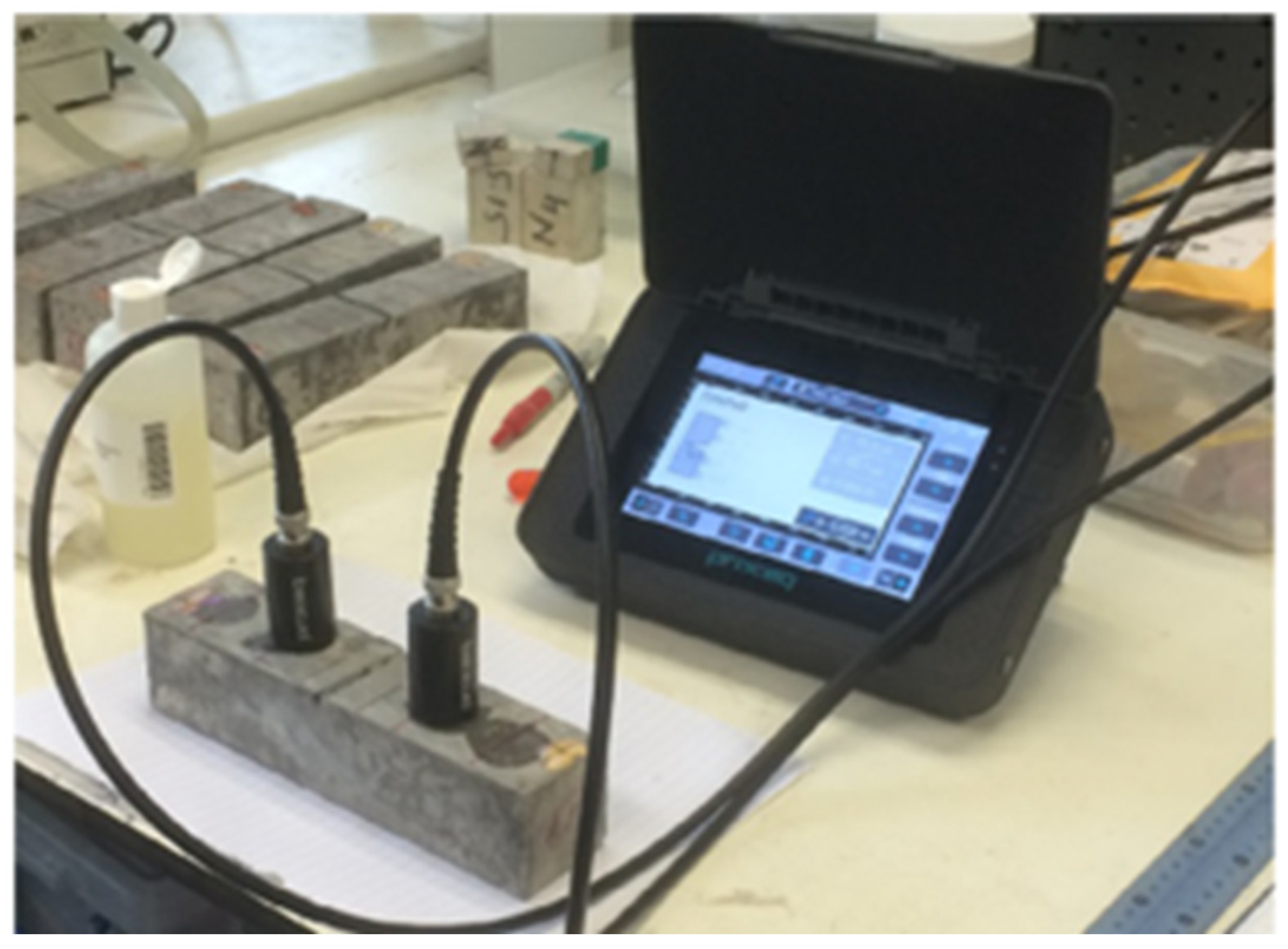

4.2.1. Ultrasonic Pulse Velocity (UPV)

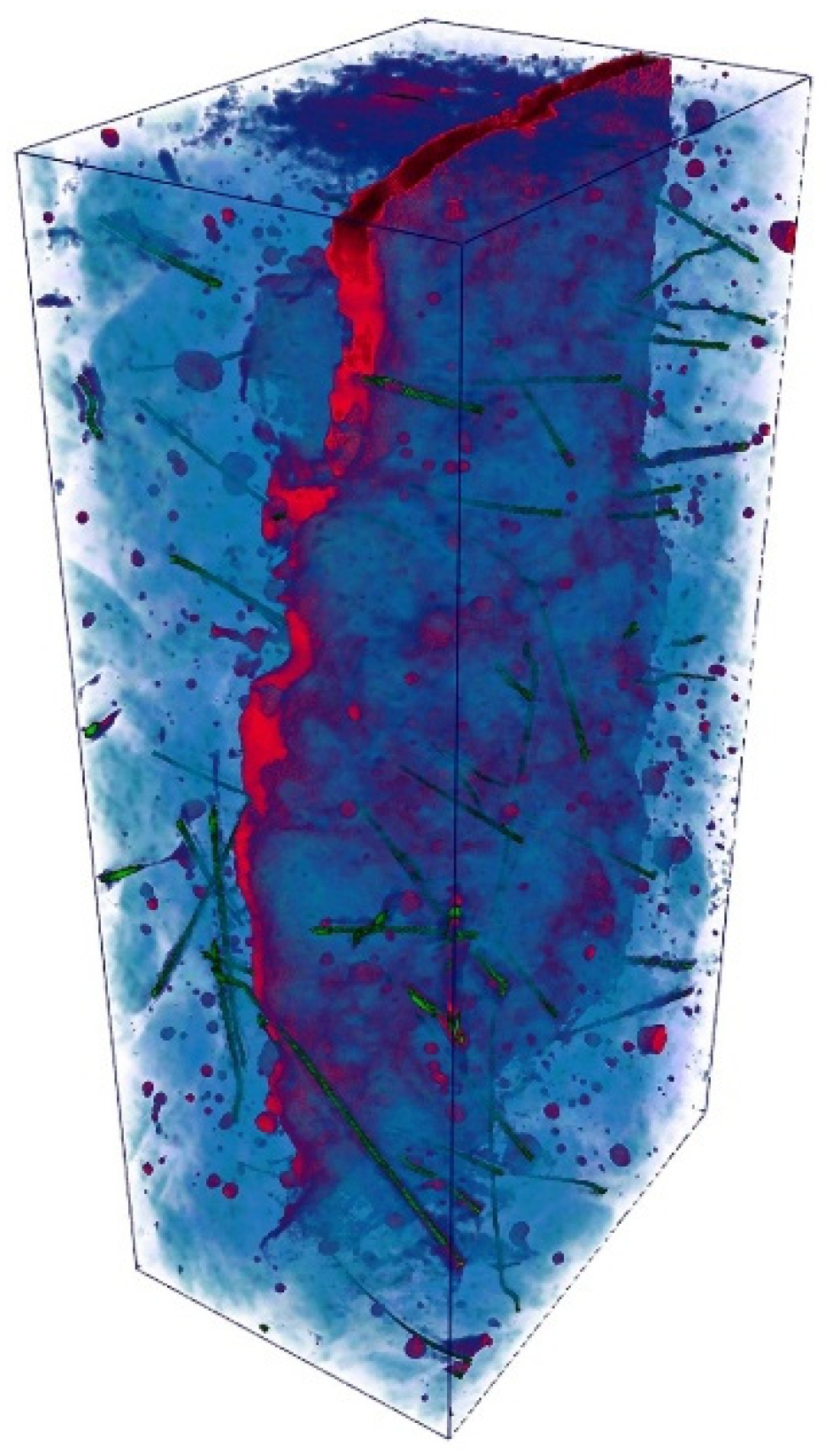

4.2.2. Imaging (BSEI, DIC, XCT, and Neutron Radiography/Tomography)

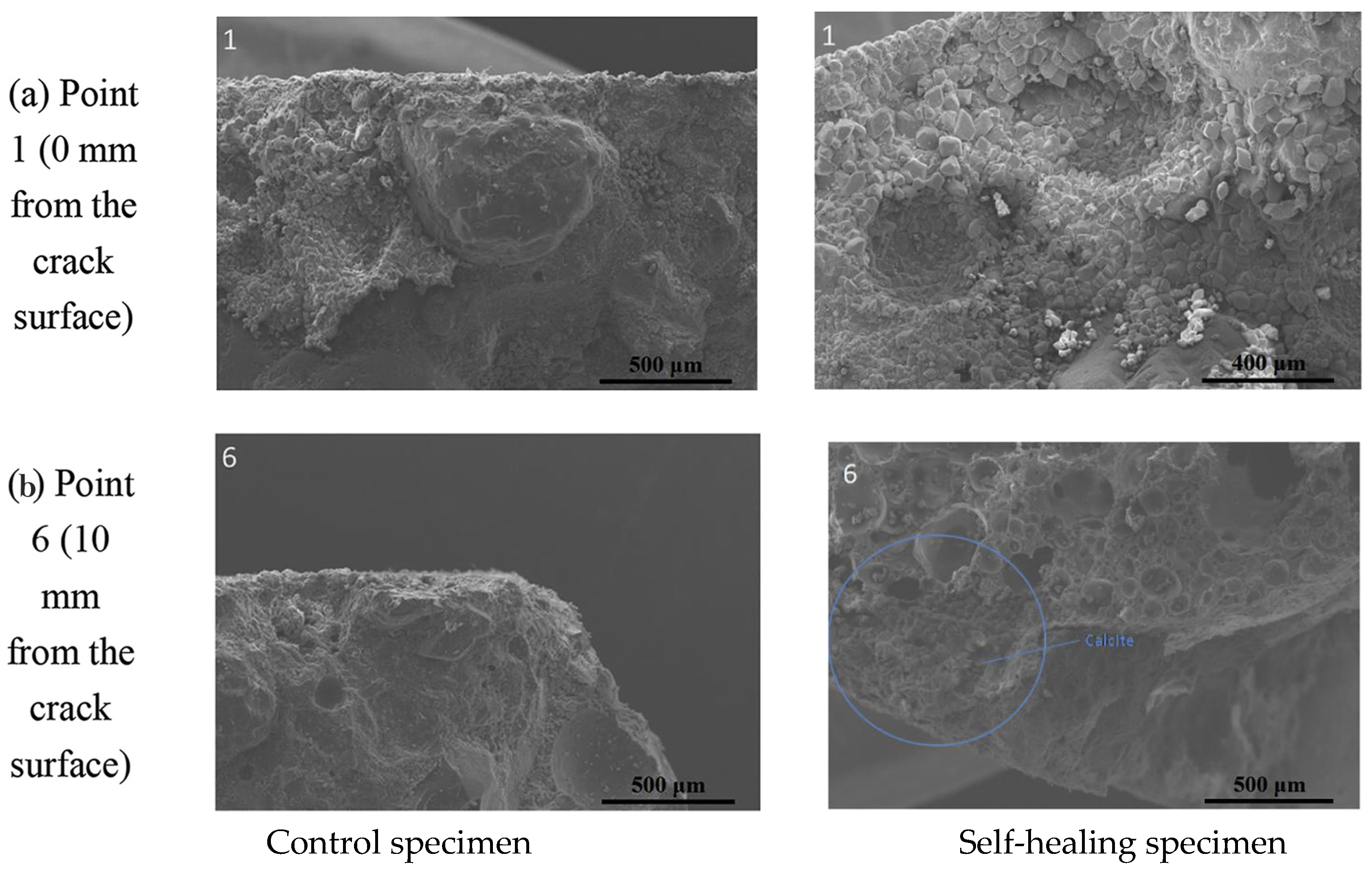

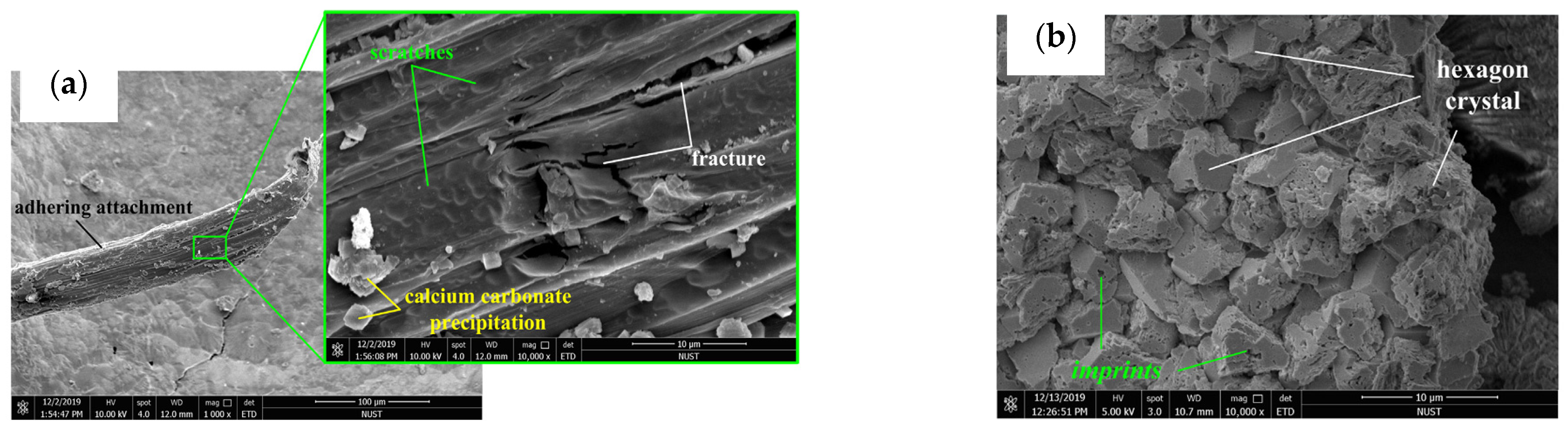

4.2.3. Microscopy (OM, SEM, and ESEM)

4.2.4. Spectroscopy and Thermoanalysis (XRD, FTIR, and TGA)

4.3. Durability Properties Testing Methods

4.3.1. Freeze–Thaw Resistance Tests

4.3.2. Chloride Ion Penetration Tests

4.3.3. Water Permeability Tests

4.3.4. Water Absorption Tests

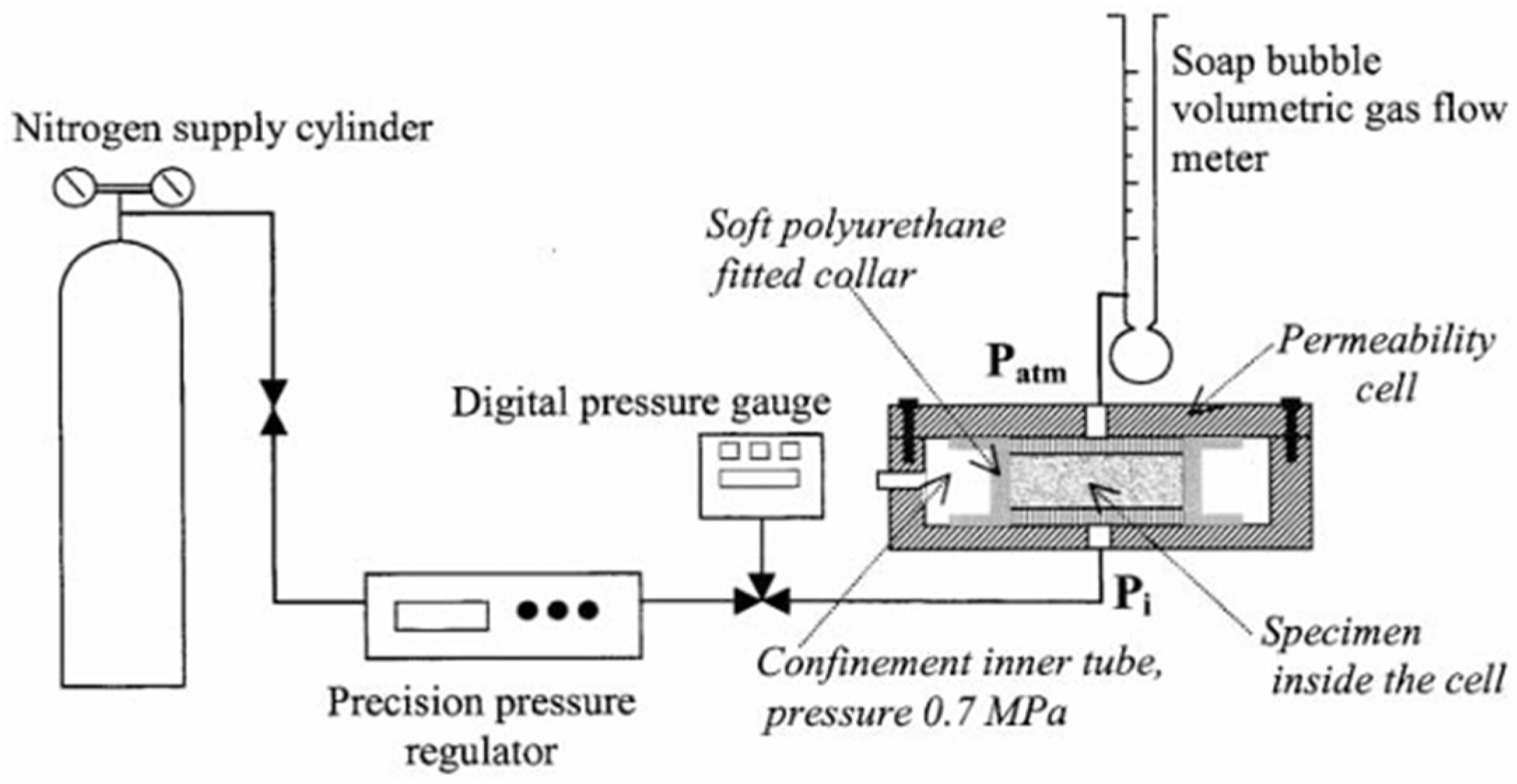

4.3.5. Gas Permeability

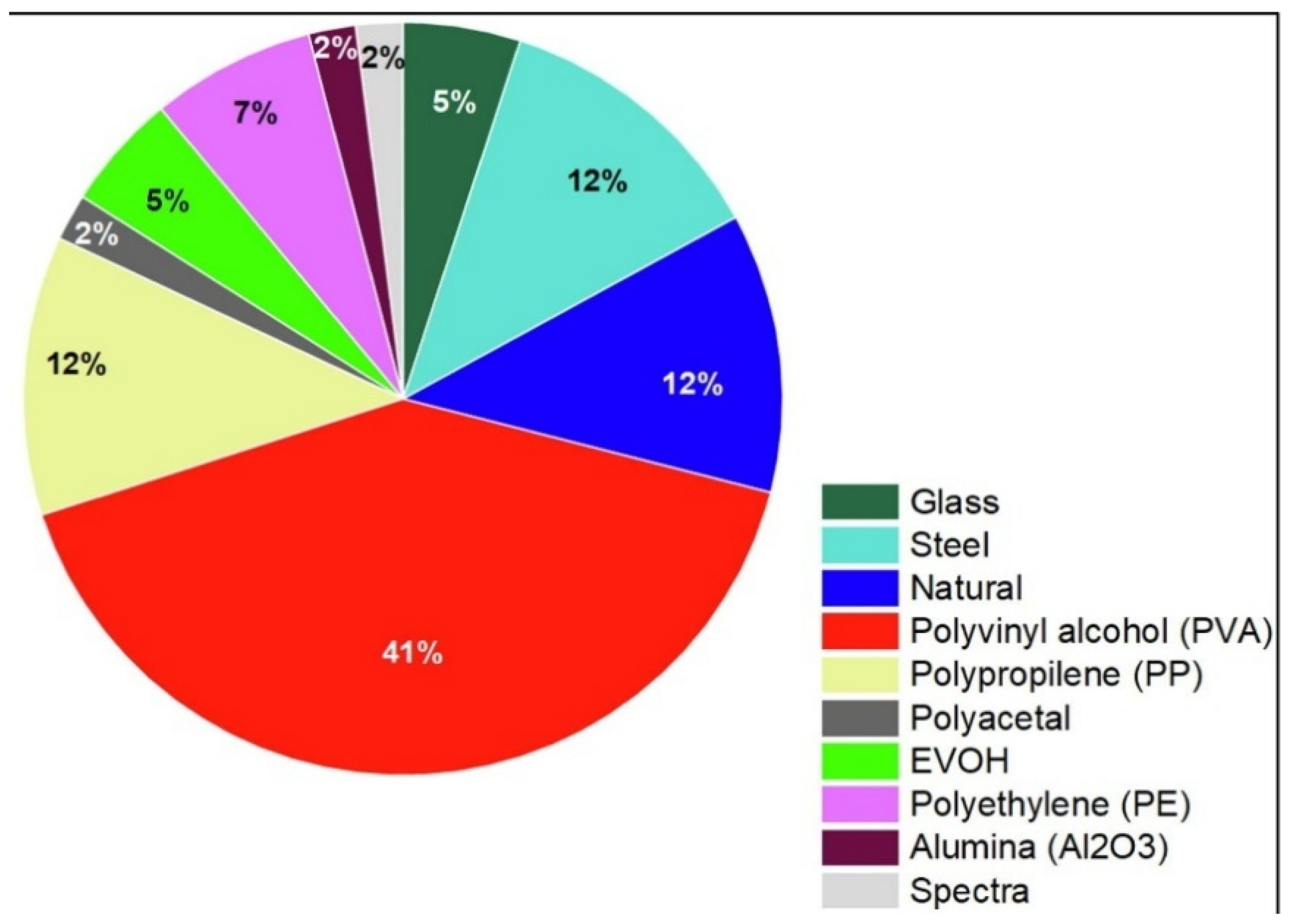

5. Fiber Application in Self-Healing Concrete

6. Limitations and Challenges

6.1. Autogenous Healing Limitation

6.2. MICP Limitations

6.2.1. Bacterial Survivability for MICP

6.2.2. Compatibility Issues

6.2.3. Scaling Challenges

6.3. Economic Parameters

7. Conclusions and Knowledge Gaps

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Talaiekhozani, A.; Keyvanfar, A.; Andalib, R.; Samadi, M.; Shafaghat, A.; Kamyab, H.; Majid, M.Z.A.; Zin, R.M.; Fulazzaky, M.A.; Lee, C.T.; et al. Application of Proteus mirabilis and Proteus vulgaris mixture to design self-healing concrete. Desalination Water Treat. 2014, 52, 3623–3630. [Google Scholar] [CrossRef]

- Samani, A.K.; Attard, M.M. Lateral strain model for concrete under compression. ACI Struct. J. 2014, 111, 441–451. [Google Scholar] [CrossRef]

- Kacker, R.; Singh, S.K.; Kasar, A.A. Understanding and Addressing Multi-faceted Failures in Building Structures. J. Fail. Anal. Prev. 2024, 24, 1542–1558. [Google Scholar] [CrossRef]

- Jiang, L.; Wu, M.; Du, F.; Chen, D.; Xiao, L.; Chen, W.; Du, W.; Ding, Q. State-of-the-Art Review of Microcapsule Self-Repairing Concrete: Principles, Applications, Test Methods, Prospects. Polymers 2024, 16, 3165. [Google Scholar] [CrossRef]

- Garg, R.; Garg, R.; Eddy, N.O. Microbial induced calcite precipitation for self-healing of concrete: A review. J. Sustain. Cem. Mater. 2023, 12, 317–330. [Google Scholar] [CrossRef]

- Ahmad, I.; Shokouhian, M.; Owolabi, D.; Jenkins, M.; McLemore, G.L. Assessment of Biogenic Healing Capability, Mechanical Properties, and Freeze–Thaw Durability of Bacterial-Based Concrete Using Bacillus subtilis, Bacillus sphaericus, and Bacillus megaterium. Buildings 2025, 15, 943. [Google Scholar] [CrossRef]

- Ahmad, I.; Shokouhian, M.; Jenkins, M.; McLemore, G.L. Quantifying the Self-Healing Efficiency of Bioconcrete Using Bacillus subtilis Immobilized in Polymer-Coated Lightweight Expanded Clay Aggregates. Buildings 2024, 14, 3916. [Google Scholar] [CrossRef]

- Ahmad, I.; Shokouhian, M.; Jenkins, M.; McLemore, G.L. Factors influencing bacterial-based precipitation, assessment of crack inducing, durability and characterization methods: A comprehensive review. Innov. Infrastruct. Solut. 2025, 10, 107. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, P.; Wang, H. Research on maintenance and strengthening strategies of concrete structures exposed to chloride environment base on state index. Adv. Eng. Technol. Res. 2022, 1, 1. [Google Scholar] [CrossRef]

- Hosoda, A.; Higuchi, T.; Eguchi, M.; Yoshida, H.; Aoki, H. Self Healing of Longitudinal Cracks in Utility Concrete Pole. J. Adv. Concr. Technol. 2012, 10, 278–284. [Google Scholar] [CrossRef]

- Amran, M.; Onaizi, A.M.; Fediuk, R.; Vatin, N.I.; Rashid, R.S.M.; Abdelgader, H.; Ozbakkaloglu, T. Self-Healing Concrete as a Prospective Construction Material: A Review. Materials 2022, 15, 3214. [Google Scholar] [CrossRef]

- Gupta, S. Comparison of improved autogenous and bio-based self-healing techniques in fiber-reinforced mortar: Effect of bacteria incorporation strategy and fiber hybridization. J. Build. Eng. 2022, 45, 103607. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Ahmad, I.; Shokouhian, M.; Jenkins, M.; McLemore, G.L.; Owolabi, D.O. Crack Healing Performance of Microbial Self-Healing Concrete Using Different Carriers. In Proceedings of the Structures Congress 2025, Phoenix, AZ, USA, 9–11 April 2025; American Society of Civil Engineers: Reston, VA, USA, 2025; pp. 362–372. [Google Scholar]

- Feng, J.; Chen, B.; Sun, W.; Wang, Y. Microbial induced calcium carbonate precipitation study using Bacillus subtilis with application to self-healing concrete preparation and characterization. Constr. Build. Mater. 2021, 280, 122460. [Google Scholar] [CrossRef]

- Rajadesingu, S.; Palani, N.; Mendonce, K.C.; Vijayakumar, P.; Monisha, P.; Ayyadurai, S. State-of-the-art review on advancements of eco-friendly bacterial-infused self-healing concrete for sustainable constructions. J. Build. Eng. 2024, 91, 109669. [Google Scholar] [CrossRef]

- Wong, P.Y.; Mal, J.; Sandak, A.; Luo, L.; Jian, J.; Pradhan, N. Advances in microbial self-healing concrete: A critical review of mechanisms, developments, and future directions. Sci. Total Environ. 2024, 947, 174553. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.-M.; Choi, Y.-C.; Park, B.; Choo, J.; Yoo, S.-W. Effect of Clinker Binder and Aggregates on Autogenous Healing in Post-Crack Flexural Behavior of Concrete Members. Materials 2020, 13, 4516. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Jaroenratanapirom, D.; Sahamitmongkol, R. Effects of Different Mineral Additives and Cracking Ages on Self-Healing Performance of Mortar. Annu. Concr. Conf. 2010, 6, 550–556. [Google Scholar]

- Rajesh, A.; Sumathi, A.; Gowdhaman, D. Strength and Durability Assessment of Self-Healing Bio-Based Composite Concrete under Different Exposure Conditions. J. Test. Eval. 2024, 52, 574–597. [Google Scholar] [CrossRef]

- Khaneghahi, M.H.; Kamireddi, D.; Rahmaninezhad, S.A.; Schauer, C.L.; Sales, C.M.; Najafi, A.; Cotton, A.; Sadighi, A.; Farnam, Y. Development of bio-inspired multi-functional polymeric-based fibers (BioFiber) for advanced delivery of bacterial-based self-healing agent in concrete. MATEC Web Conf. 2023, 378, 02001. [Google Scholar] [CrossRef]

- Su, Y.; Qian, C.; Rui, Y.; Feng, J. Exploring the coupled mechanism of fibers and bacteria on self-healing concrete from bacterial extracellular polymeric substances (EPS). Cem. Concr. Compos. 2021, 116, 103896. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-healing cement concrete composites for resilient infrastructures: A review. Compos. Part B Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Joshi, S.; Goyal, S.; Mukherjee, A.; Reddy, M.S. Microbial healing of cracks in concrete: A review. J. Ind. Microbiol. Biotechnol. 2017, 44, 1511–1525. [Google Scholar] [CrossRef]

- Xue, C.; Tapas, M.J.; Sirivivatnanon, V. Cracking and stimulated autogenous self-healing on the sustainability of cement-based materials: A review. J. Sustain. Cem. Mater. 2023, 12, 184–206. [Google Scholar] [CrossRef]

- Indhumathi, S.; Dinesh, A.; Pichumani, M. Diverse perspectives on self healing ability of Engineered Cement Composite—All-inclusive insight. Constr. Build. Mater. 2022, 323, 126473. [Google Scholar] [CrossRef]

- Saleh Salem Beshr, B.; Abdul Mohaimen, I.M.; Noor Azline, M.N.; Nor Azizi, S.; Nabilah, A.B.; Farah Nora Aznieta, A.A. Feasibility assessment on self-healing ability of cementitious composites with MgO. J. Build. Eng. 2021, 34, 101914. [Google Scholar] [CrossRef]

- Su, Y.F.; Huang, C.; Jeong, H.G.; Nantung, T.; Olek, J.; Baah, P.; Lu, N. Autogenous healing performance of internal curing agent-based self-healing cementitious composite. Cem. Concr. Compos. 2020, 114, 103825. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Moretti, F. On the use of crystalline admixtures in cement based construction materials: From porosity reducers to promoters of self healing. Smart Mater. Struct. 2016, 25, 084002. [Google Scholar] [CrossRef]

- Meraz, M.M.; Mim, N.J.; Mehedi, M.T.; Bhattacharya, B.; Aftab, M.R.; Billah, M.M.; Meraz, M.M. Self-healing concrete: Fabrication, advancement, and effectiveness for long-term integrity of concrete infrastructures. Alex. Eng. J. 2023, 73, 665–694. [Google Scholar] [CrossRef]

- De Souza, D.J.; Sanchez, L.F.M. Understanding the efficiency of autogenous and autonomous self-healing of conventional concrete mixtures through mechanical and microscopical analysis. Cem. Concr. Res. 2023, 172, 107219. [Google Scholar] [CrossRef]

- Hanna, J. Self-Healing Concrete Techniques and Technologies and Applications. Recent Prog. Mater. 2024, 6, 006. [Google Scholar] [CrossRef]

- Tian, Y.; Bao, J.; Guo, W.; Zhang, P.; Cui, Y.; Zhao, T. Autogenous self-healing of cracked concrete exposed to the marine tidal zone. Constr. Build. Mater. 2022, 357, 129336. [Google Scholar] [CrossRef]

- Lahmann, D.; Edvardsen, C.; Kessler, S. Autogenous self-healing of concrete: Experimental design and test methods—A review. Eng. Rep. 2023, 5, e12565. [Google Scholar] [CrossRef]

- Muhammad, N.Z.; Shafaghat, A.; Keyvanfar, A.; Majid, M.Z.A.; Ghoshal, S.K.; Mohammadyan Yasouj, S.E.; Ganiyu, A.A.; Samadi Kouchaksaraei, M.; Kamyab, H.; Taheri, M.M.; et al. Tests and methods of evaluating the self-healing efficiency of concrete: A review. Constr. Build. Mater. 2016, 112, 1123–1132. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Damidot, D. Characterization and quantification of self-healing behaviors of microcracks due to further hydration in cement paste. Cem. Concr. Res. 2013, 52, 71–81. [Google Scholar] [CrossRef]

- Jansen, D.; Goetz-Neunhoeffer, F.; Stabler, C.; Neubauer, J. A remastered external standard method applied to the quantification of early OPC hydration. Cem. Concr. Res. 2011, 41, 602–608. [Google Scholar] [CrossRef]

- Scrivener, K.; Ouzia, A.; Juilland, P.; Kunhi Mohamed, A. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Qian, C.; Schlangen, E. Self-healing in cementitious materials: Materials, methods and service conditions. Mater. Des. 2016, 92, 499–511. [Google Scholar] [CrossRef]

- Choi, H.; Choi, H.; Inoue, M.; Sengoku, R. Control of the Polymorphism of Calcium Carbonate Produced by Self-Healing in the Cracked Part of Cementitious Materials. Appl. Sci. 2017, 7, 546. [Google Scholar] [CrossRef]

- Javeed, Y.; Goh, Y.; Mo, K.H.; Yap, S.P.; Leo, B.F. Microbial self-healing in concrete: A comprehensive exploration of bacterial viability, implementation techniques, and mechanical properties. J. Mater. Res. Technol. 2024, 29, 2376–2395. [Google Scholar] [CrossRef]

- Amer Ali Algaifi, H.; Abu Bakar, S.; Mohd Sam, A.R.; Zainal Abidin, A.R. Crack-healing in cementitious material to improve the durability of structures: Review. MATEC Web Conf. 2018, 250, 03005. [Google Scholar] [CrossRef]

- Getnet Meharie, M. Factors Affecting the Self-Healing Efficiency of Cracked Concrete Structures. Am. J. Appl. Sci. Res. 2017, 3, 80. [Google Scholar] [CrossRef]

- Jacobsen, S.; Sellevold, E.J. Self healing of high strength concrete after deterioration by freeze/thaw. Cem. Concr. Res. 1996, 26, 55–62. [Google Scholar] [CrossRef]

- Aldea, C.-M.; Song, W.-J.; Popovics, J.S.; Shah, S.P. Extent of Healing of Cracked Normal Strength Concrete. J. Mater. Civ. Eng. 2000, 12, 92–96. [Google Scholar] [CrossRef]

- Reinhardt, H.-W.; Jooss, M. Permeability and self-healing of cracked concrete as a function of temperature and crack width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, Z.; Hou, P.; Du, P.; Zhang, L.; Xu, H. Autogenous and engineered healing mechanisms of carbonated steel slag aggregate in concrete. Constr. Build. Mater. 2016, 107, 191–202. [Google Scholar] [CrossRef]

- Kanthe, V.; Deo, S.; Murmu, M. Effect on Autogenous Healing in Concrete by Fly Ash and Rice Husk Ash. Iran. J. Energy Environ. 2019, 10, 154–158. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Chen, J.; Tang, J.; Zhou, H.; Zhou, W.; Chang, X.; Cheng, Y. Preparation and performance study of active chemicals in cementitious capillary crystalline waterproofing materials. Case Stud. Constr. Mater. 2024, 20, e02874. [Google Scholar] [CrossRef]

- Ding, Y.; Wu, Z.; Huang, Q.; Wang, Q.; Ren, Q.; Zhang, Z.; Zhang, J.; Huang, K. Research on crystalline admixtures for low carbon buildings based on the self-healing properties of concrete. Constr. Build. Mater. 2023, 409, 133932. [Google Scholar] [CrossRef]

- Hermawan, H.; Wiktor, V.; Serna, P.; Gruyaert, E. Modification of Concrete Mix Design with Crystalline Admixture for Self-healing Improvement. J. Adv. Concr. Technol. 2024, 22, 237–252. [Google Scholar] [CrossRef]

- Noor Azline, M.N.; Nabilah, A.B.; Nor Azizi, S.; Ernaleza, M.; Farah Nora Aznieta, A.A. Enhanced autogeneous self-healing of MgO blended composites incorporating with silica fume. Clean. Eng. Technol. 2023, 16, 100670. [Google Scholar] [CrossRef]

- Shetiya, R.K.; Elhadad, S.; Salem, A.; Fülöp, A.; Orban, Z. Investigation into the Effects of Crystalline Admixtures and Coatings on the Properties of Self-Healing Concrete. Materials 2024, 17, 767. [Google Scholar] [CrossRef]

- Chernykh, T.N.; Gorbachevskykh, K.A.; Kriushin, M.V.; Orlov, A.A.; Komelkova, M.V.; Platkovskii, P.O. Biomineral additives for self-healing of concrete. Vestn. MGSU 2024, 19, 569–579. [Google Scholar] [CrossRef]

- Snoeck, D.; Dewanckele, J.; Cnudde, V.; De Belie, N. X-ray computed microtomography to study autogenous healing of cementitious materials promoted by superabsorbent polymers. Cem. Concr. Compos. 2016, 65, 83–93. [Google Scholar] [CrossRef]

- Snoeck, D.; Van den Heede, P.; Van Mullem, T.; De Belie, N. Water penetration through cracks in self-healing cementitious materials with superabsorbent polymers studied by neutron radiography. Cem. Concr. Res. 2018, 113, 86–98. [Google Scholar] [CrossRef]

- Choi, Y.C.; Park, B. Enhanced autogenous healing of ground granulated blast furnace slag blended cements and mortars. J. Mater. Res. Technol. 2019, 8, 3443–3452. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.; Ding, Z. Influence of Crystalline Admixtures and Their Synergetic Combinations with Other Constituents on Autonomous Healing in Cracked Concrete—A Review. Materials 2022, 15, 440. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Li, W.; Castel, A.; Kim, T.; Huang, Y.; Wang, K. A comprehensive review on self-healing cementitious composites with crystalline admixtures: Design, performance and application. Constr. Build. Mater. 2023, 409, 134108. [Google Scholar] [CrossRef]

- Ashraf, M.; Iqbal, M.F.; Rauf, M.; Ashraf, M.U.; Ulhaq, A.; Muhammad, H.; Liu, Q. Developing a sustainable concrete incorporating bentonite clay and silica fume: Mechanical and durability performance. J. Clean. Prod. 2022, 337, 130315. [Google Scholar] [CrossRef]

- Sherir, M.A.A.; Hossain, K.M.A.; Lachemi, M. The influence of MgO-type expansive agent incorporated in self-healing system of Engineered cementitious Composites. Constr. Build. Mater. 2017, 149, 164–185. [Google Scholar] [CrossRef]

- Sherir, M.A.A.; Hossain, K.M.A.; Lachemi, M. Development and recovery of mechanical properties of self-healing cementitious composites with MgO expansive agent. Constr. Build. Mater. 2017, 148, 789–810. [Google Scholar] [CrossRef]

- Xue, C.; Li, W.; Luo, Z.; Wang, K.; Castel, A. Effect of chloride ingress on self-healing recovery of smart cementitious composite incorporating crystalline admixture and MgO expansive agent. Cem. Concr. Res. 2021, 139, 106252. [Google Scholar] [CrossRef]

- Sherir, M.A.A.; Hossain, K.M.A.; Lachemi, M. Self-healing and expansion characteristics of cementitious composites with high volume fly ash and MgO-type expansive agent. Constr. Build. Mater. 2016, 127, 80–92. [Google Scholar] [CrossRef]

- Şahmaran, M.; Keskin, S.B.; Ozerkan, G.; Yaman, I.O. Self-healing of mechanically-loaded self consolidating concretes with high volumes of fly ash. Cem. Concr. Compos. 2008, 30, 872–879. [Google Scholar] [CrossRef]

- Ahmad, I.; Khan, K.A.; Ahmad, T.; Alam, M.; Bashir, M.T. Influence of accelerated curing on the compressive strength of polymer-modified concrete. Front. Struct. Civ. Eng. 2022, 16, 589–599. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, E.-H.; Li, V.C. Autogenous healing of engineered cementitious composites at early age. Cem. Concr. Res. 2011, 41, 176–183. [Google Scholar] [CrossRef]

- Ma, H.; Herbert, E.; Ohno, M.; Li, V.C. Scale-linking model of self-healing and stiffness recovery in Engineered Cementitious Composites (ECC). Cem. Concr. Compos. 2019, 95, 1–9. [Google Scholar] [CrossRef]

- Zheng, Q.; Li, C.; Song, F.; He, B.; Li, W.; Jiang, Z. Autogenous self-healing of ultra-high-performance fiber-reinforced concrete with varying silica fume dosages: Secondary hydration and structural regeneration. Cem. Concr. Compos. 2023, 137, 104905. [Google Scholar] [CrossRef]

- Ahmad, I.; Shen, D.; Khan, K.A.; Jan, A.; Khubaib, M.; Ahmad, T.; Nasir, H. Effectiveness of Limestone Powder in Controlling the Shrinkage Behavior of Cement Based System: A Review. Silicon 2022, 14, 359–371. [Google Scholar] [CrossRef]

- Stefanoni, M.; Angst, U.; Elsener, B. The mechanism controlling corrosion of steel in carbonated cementitious materials in wetting and drying exposure. Cem. Concr. Compos. 2020, 113, 103717. [Google Scholar] [CrossRef]

- Roventi, G.; Bellezze, T.; Giuliani, G.; Conti, C. Corrosion resistance of galvanized steel reinforcements in carbonated concrete: Effect of wet–dry cycles in tap water and in chloride solution on the passivating layer. Cem. Concr. Res. 2014, 65, 76–84. [Google Scholar] [CrossRef]

- Huang, H. Thermodynamics of Autogenous Self-Healing in Cementitious Materials. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2014. [Google Scholar]

- Ahmad, I.; Shokouhian, M. Promoting Sustainable Green Infrastructure: Experimental and Numerical Investigation of Concrete Reinforced with Recycled Steel Fibers. Arch. Adv. Eng. Sci. 2024, 1–13. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Wang, Y.; Konstantinou, C. A Comprehensive Optimization Study of Microbially Induced Carbonate Precipitation for Soil Strength Enhancement: Impact of Biochemical and Environmental Factors. J. Geotech. Geoenviron. Eng. 2024, 150, 04024101. [Google Scholar] [CrossRef]

- Erdmann, N.; Schaefer, S.; Simon, T.; Becker, A.; Bröckel, U.; Strieth, D. MICP treated sand: Insights into the impact of particle size on mechanical parameters and pore network after biocementation. Discov. Mater. 2024, 4, 45. [Google Scholar] [CrossRef]

- Bang, S.S.; Galinat, J.K.; Ramakrishnan, V. Calcite precipitation induced by polyurethane-immobilized Bacillus pasteurii. Enzym. Microb. Technol. 2001, 28, 404–409. [Google Scholar] [CrossRef]

- Wang, J.Y.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Shaikh, F.U.A. A Review on the Performance Evaluation of Autonomous Self-Healing Bacterial Concrete: Mechanisms, Strength, Durability, and Microstructural Properties. J. Compos. Sci. 2022, 6, 23. [Google Scholar] [CrossRef]

- Wu, M.; Hu, X.; Zhang, Q.; Xue, D.; Zhao, Y. Growth environment optimization for inducing bacterial mineralization and its application in concrete healing. Constr. Build. Mater. 2019, 209, 631–643. [Google Scholar] [CrossRef]

- Alshalif, A.F.; Juki, M.I.; Othman, N.; Al-Gheethi, A.A.; Khalid, F.S. Improvement of mechanical properties of bio-concrete using Enterococcus faecalis and Bacillus cereus. Environ. Eng. Res. 2019, 24, 630–637. [Google Scholar] [CrossRef]

- Siddique, R.; Chahal, N.K. Effect of ureolytic bacteria on concrete properties. Constr. Build. Mater. 2011, 25, 3791–3801. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; Da Silva, F.B.; Boon, N.; Verstraete, W.; De Belie, N. Screening of bacteria and concrete compatible protection materials. Constr. Build. Mater. 2015, 88, 196–203. [Google Scholar] [CrossRef]

- Morsali, S.; Yucel Isildar, G.; Hamed Zar Gari, Z.; Tahni, A. The application of bacteria as a main factor in self-healing concrete technology. J. Build. Pathol. Rehabil. 2019, 4, 7. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Formagini, S.; Serna, P. Self-healing concrete-What Is it Good For? Mater. Constr. 2021, 71, e237. [Google Scholar] [CrossRef]

- Shaheen, N.; Khushnood, R.A.; Khaliq, W.; Murtaza, H.; Iqbal, R.; Khan, M.H. Synthesis and characterization of bio-immobilized nano/micro inert and reactive additives for feasibility investigation in self-healing concrete. Constr. Build. Mater. 2019, 226, 492–506. [Google Scholar] [CrossRef]

- Son, H.; Kim, H.; Park, S.; Lee, H. Ureolytic/Non-Ureolytic Bacteria Co-Cultured Self-Healing Agent for Cementitious Materials Crack Repair. Materials 2018, 11, 782. [Google Scholar] [CrossRef]

- Nuaklong, P.; Jongvivatsakul, P.; Phanupornprapong, V.; Intarasoontron, J.; Shahzadi, H.; Pungrasmi, W.; Thaiboonrod, S.; Likitlersuang, S. Self-repairing of shrinkage crack in mortar containing microencapsulated bacterial spores. J. Mater. Res. Technol. 2023, 23, 3441–3454. [Google Scholar] [CrossRef]

- Jiang, L.; Li, P.; Wang, W.; Zhang, Y.; Li, Z. A self-healing method for concrete cracks based on microbial-induced carbonate precipitation: Bacteria, immobilization, characterization, and application. J. Sustain. Cem. Mater. 2024, 13, 222–242. [Google Scholar] [CrossRef]

- Bang, S.S.; Lippert, J.J.; Yerra, U.; Mulukutla, S.; Ramakrishnan, V. Microbial calcite, a bio-based smart nanomaterial in concrete remediation. Int. J. Smart Nano Mater. 2010, 1, 28–39. [Google Scholar] [CrossRef]

- Abu Bakr, M.; Singh, B.K.; Hussain, A. Experimental investigations on MICP-based autonomous crack-healing recycled aggregate concrete: A sustainable approach for enhancing the strength and durability. Sustain. Resilient Infrastruct. 2024, 9, 554–581. [Google Scholar] [CrossRef]

- Hermawan, H.; Minne, P.; Serna, P.; Gruyaert, E. Understanding the Impacts of Healing Agents on the Properties of Fresh and Hardened Self-Healing Concrete: A Review. Processes 2021, 9, 2206. [Google Scholar] [CrossRef]

- Souid, A.; Esaker, M.; Elliott, D.; Hamza, O. Experimental data of bio self-healing concrete incubated in saturated natural soil. Data Brief 2019, 26, 104394. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Chen, B.; Xie, T. Experimental and theoretical analysis of bubble departure behavior in narrow rectangular channel. Prog. Nucl. Energy 2014, 77, 1–10. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X. Self-healing of concrete cracks by use of bacteria-containing low alkali cementitious material. Constr. Build. Mater. 2018, 167, 1–14. [Google Scholar] [CrossRef]

- Shanmuga Priya, T.; Ramesh, N.; Agarwal, A.; Bhusnur, S.; Chaudhary, K. Strength and durability characteristics of concrete made by micronized biomass silica and Bacteria-Bacillus sphaericus. Constr. Build. Mater. 2019, 226, 827–838. [Google Scholar] [CrossRef]

- Tan, I.S.; Ramamurthi, K.S. Spore formation in Bacillus subtilis. Environ. Microbiol. Rep. 2014, 6, 212–225. [Google Scholar] [CrossRef] [PubMed]

- Luo, M.; Qian, C.; Li, R.; Rong, H. Efficiency of concrete crack-healing based on biological carbonate precipitation. J. Wuhan Univ. Technol. Sci. Ed. 2015, 30, 1255–1259. [Google Scholar] [CrossRef]

- Chaerun, S.K.; Syarif, R.; Wattimena, R.K. Bacteria incorporated with calcium lactate pentahydrate to improve the mortar properties and self-healing occurrence. Sci. Rep. 2020, 10, 17873. [Google Scholar] [CrossRef]

- Uddin, M.N.; Tafsirojjaman, T.; Shanmugasundaram, N.; Praveenkumar, S.; Li, L. Smart self-healing bacterial concrete for sustainable goal. Innov. Infrastruct. Solut. 2023, 8, 46. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, M.B. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Andalib, R.; Abd Majid, M.Z.; Hussin, M.W.; Ponraj, M.; Keyvanfar, A.; Mirza, J.; Lee, H.-S. Optimum concentration of Bacillus megaterium for strengthening structural concrete. Constr. Build. Mater. 2016, 118, 180–193. [Google Scholar] [CrossRef]

- Dhami, N.K. Biomineralization of Calcium Carbonate Polymorphs by the Bacterial Strains Isolated from Calcareous Sites. J. Microbiol. Biotechnol. 2013, 23, 707–714. [Google Scholar] [CrossRef]

- Chen, H.-J.; Peng, C.-F.; Tang, C.-W.; Chen, Y.-T. Self-Healing Concrete by Biological Substrate. Materials 2019, 12, 4099. [Google Scholar] [CrossRef]

- Mirshahmohammad, M.; Rahmani, H.; Maleki-Kakelar, M.; Bahari, A. Performance of biological methods on self-healing and mechanical properties of concrete using S. pasteurii. Environ. Sci. Pollut. Res. 2023, 30, 2128–2144. [Google Scholar] [CrossRef] [PubMed]

- Sohail, M.G.; Al Disi, Z.; Zouari, N.; Al Nuaimi, N.; Kahraman, R.; Gencturk, B.; Rodrigues, D.F.; Yildirim, Y. Bio self-healing concrete using MICP by an indigenous Bacillus cereus strain isolated from Qatari soil. Constr. Build. Mater. 2022, 328, 126943. [Google Scholar] [CrossRef]

- Basit Ehsan Khan, M.; Dias-da-Costa, D.; Shen, L. Factors affecting the self-healing performance of bacteria-based cementitious composites: A review. Constr. Build. Mater. 2023, 384, 131271. [Google Scholar] [CrossRef]

- Tie, Y.; Ji, Y.; Zhang, H.; Jing, B.; Zeng, X.; Yang, P. Investigation on the mechanical properties of Bacillus subtilis self-healing concrete. Heliyon 2024, 10, e34131. [Google Scholar] [CrossRef]

- Amer Algaifi, H.; Abu Bakar, S.; Sam, A.R.M.; Ismail, M.; Razin Zainal Abidin, A.; Shahir, S.; Ali Hamood Altowayti, W. Insight into the role of microbial calcium carbonate and the factors involved in self-healing concrete. Constr. Build. Mater. 2020, 254, 119258. [Google Scholar] [CrossRef]

- Logeshwaran, T.; Mohan, K. Influence of Bacteria in Self-Healing Fly Ash Concrete. Int. J. Innov. Res. Adv. Eng. 2024, 11, 500–514. [Google Scholar] [CrossRef]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr. Build. Mater. 2012, 28, 351–356. [Google Scholar] [CrossRef]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of concrete incorporating silica fume. Constr. Build. Mater. 2012, 37, 645–651. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, K.; Kunal; Singh, M.; Corinaldesi, V.; Rajor, A. Properties of bacterial rice husk ash concrete. Constr. Build. Mater. 2016, 121, 112–119. [Google Scholar] [CrossRef]

- Mithanthaya, I.R.; Shet, V.B.; Mokshitha, M. Mechanism of healing, strength, and durability concepts of bacteria concrete—A review. IOP Conf. Ser. Earth Environ. Sci. 2024, 1387, 012003. [Google Scholar] [CrossRef]

- Dhami, N.K.; Reddy, M.S.; Mukherjee, A. Bacillus megaterium mediated mineralization of calcium carbonate as biogenic surface treatment of green building materials. World J. Microbiol. Biotechnol. 2013, 29, 2397–2406. [Google Scholar] [CrossRef] [PubMed]

- Achal, V.; Pan, X.; Özyurt, N. Improved strength and durability of fly ash-amended concrete by microbial calcite precipitation. Ecol. Eng. 2011, 37, 554–559. [Google Scholar] [CrossRef]

- Shen, L.; Yu, W.; Li, L.; Zhang, T.; Abshir, I.Y.; Luo, P.; Liu, Z. Microorganism, Carriers, and Immobilization Methods of the Microbial Self-Healing Cement-Based Composites: A Review. Materials 2021, 14, 5116. [Google Scholar] [CrossRef] [PubMed]

- Han, K.; Ju, J.W.; Zhang, H.; Zhu, Y.; Chang, T.-S.; Wang, Z. Mechanical response analysis of self-healing cementitious composites with microcapsules subjected to tensile loading based on a micromechanical damage-healing model. Constr. Build. Mater. 2021, 280, 122251. [Google Scholar] [CrossRef]

- De Muynck, W.; Cox, K.; De Belie, N.; Verstraete, W. Bacterial carbonate precipitation as an alternative surface treatment for concrete. Constr. Build. Mater. 2008, 22, 875–885. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Jafarnia, M.S.; Khodadad Saryazdi, M.; Moshtaghioun, S.M. Use of bacteria for repairing cracks and improving properties of concrete containing limestone powder and natural zeolite. Constr. Build. Mater. 2020, 242, 118059. [Google Scholar] [CrossRef]

- Wang, J.; Dewanckele, J.; Cnudde, V.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. X-ray computed tomography proof of bacterial-based self-healing in concrete. Cem. Concr. Compos. 2014, 53, 289–304. [Google Scholar] [CrossRef]

- Ghosh, P.; Mandal, S.; Chattopadhyay, B.D.; Pal, S. Use of microorganism to improve the strength of cement mortar. Cem. Concr. Res. 2005, 35, 1980–1983. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Wang, J.Y.; Snoeck, D.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. Application of hydrogel encapsulated carbonate precipitating bacteria for approaching a realistic self-healing in concrete. Constr. Build. Mater. 2014, 68, 110–119. [Google Scholar] [CrossRef]

- Xu, J.; Yao, W. Multiscale mechanical quantification of self-healing concrete incorporating non-ureolytic bacteria-based healing agent. Cem. Concr. Res. 2014, 64, 1–10. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Usama Salim, M. Past and present techniques of self-healing in cementitious materials: A critical review on efficiency of implemented treatments. J. Mater. Res. Technol. 2020, 9, 6883–6899. [Google Scholar] [CrossRef]

- Gauvry, E.; Mathot, A.-G.; Couvert, O.; Leguérinel, I.; Coroller, L. Effects of temperature, pH and water activity on the growth and the sporulation abilities of Bacillus subtilis BSB1. Int. J. Food Microbiol. 2021, 337, 108915. [Google Scholar] [CrossRef]

- Luhar, S.; Suthar, G.; Gourav, S. A review paper on self healing concrete. J. Civ. Eng. Res. 2015, 2015, 53–58. [Google Scholar]

- Chandra Sekhara Reddy, T.; Ravitheja, A. Macro mechanical properties of self healing concrete with crystalline admixture under different environments. Ain Shams Eng. J. 2019, 10, 23–32. [Google Scholar] [CrossRef]

- Manvith Kumar Reddy, C.; Ramesh, B.; Macrin, D. Effect of crystalline admixtures, polymers and fibers on self healing concrete—A review. Mater. Today Proc. 2020, 33, 763–770. [Google Scholar] [CrossRef]

- Sri Durga, C.S.; Ruben, N.; Sri Rama Chand, M.; Indira, M.; Venkatesh, C. Comprehensive microbiological studies on screening bacteria for self-healing concrete. Materialia 2021, 15, 101051. [Google Scholar] [CrossRef]

- dos Santos Lima, G.T.; Silvestro, L.; Tambara Júnior, L.U.D.; Cheriaf, M.; Rocha, J.C. Autonomous Self-Healing Agents in Cementitious Materials: Parameters and Impacts on Mortar Properties. Buildings 2024, 14, 2000. [Google Scholar] [CrossRef]

- Krishnapriya, S.; Venkatesh Babu, D.L.; Arulraj, G.P. Isolation and identification of bacteria to improve the strength of concrete. Microbiol. Res. 2015, 174, 48–55. [Google Scholar] [CrossRef] [PubMed]

- Albuhairi, D.; Di Sarno, L. Low-Carbon Self-Healing Concrete: State-of-the-Art, Challenges and Opportunities. Buildings 2022, 12, 1196. [Google Scholar] [CrossRef]

- Lv, L.; Yang, Z.; Chen, G.; Zhu, G.; Han, N.; Schlangen, E.; Xing, F. Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr. Build. Mater. 2016, 105, 487–495. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; Van Loo, D.; Jacobs, P. Self-healing efficiency of cementitious materials containing tubular capsules filled with healing agent. Cem. Concr. Compos. 2011, 33, 497–505. [Google Scholar] [CrossRef]

- Lv, L.; Schlangen, E.; Yang, Z.; Xing, F. Micromechanical Properties of a New Polymeric Microcapsule for Self-Healing Cementitious Materials. Materials 2016, 9, 1025. [Google Scholar] [CrossRef]

- Nodehi, M.; Ozbakkaloglu, T.; Gholampour, A. A systematic review of bacteria-based self-healing concrete: Biomineralization, mechanical, and durability properties. J. Build. Eng. 2022, 49, 104038. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-Healing in Cementitious Materials—A Review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef]

- Chu, H.; Jiang, L.; Song, Z.; Xu, Y.; Zhao, S.; Xiong, C. Repair of concrete crack by pulse electro-deposition technique. Constr. Build. Mater. 2017, 148, 241–248. [Google Scholar] [CrossRef]

- Yıldırım, G.; Khiavi, A.H.; Yeşilmen, S.; Şahmaran, M. Self-healing performance of aged cementitious composites. Cem. Concr. Compos. 2018, 87, 172–186. [Google Scholar] [CrossRef]

- Kim, D.; Kang, S.; Ahn, T.-H. Mechanical Characterization of High-Performance Steel-Fiber Reinforced Cement Composites with Self-Healing Effect. Materials 2014, 7, 508–526. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.; Inoue, M.; Kwon, S.; Choi, H.; Lim, M. Effective Crack Control of Concrete by Self-Healing of Cementitious Composites Using Synthetic Fiber. Materials 2016, 9, 248. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Li, W.; Yuan, Z. Influence of mineral additives and environmental conditions on the self-healing capabilities of cementitious materials. Cem. Concr. Compos. 2015, 57, 116–127. [Google Scholar] [CrossRef]

- Hung, C.-C.; Su, Y.-F.; Hung, H.-H. Impact of natural weathering on medium-term self-healing performance of fiber reinforced cementitious composites with intrinsic crack-width control capability. Cem. Concr. Compos. 2017, 80, 200–209. [Google Scholar] [CrossRef]

- Xu, J.; Shan, H.; Zhang, C.; Jiang, L.; Tang, L.; Xu, Y.; Xu, N. Surface coating treatment and densification of mortar by electrodeposition method. Mag. Concr. Res. 2016, 68, 69–79. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Effect of exposure conditions on self healing behavior of strain hardening cementitious composites incorporating various cementitious materials. Constr. Build. Mater. 2013, 42, 217–224. [Google Scholar] [CrossRef]

- Siad, H.; Lachemi, M.; Sahmaran, M.; Mesbah, H.A.; Hossain, K.A. Advanced engineered cementitious composites with combined self-sensing and self-healing functionalities. Constr. Build. Mater. 2018, 176, 313–322. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Al-Tabbaa, A. Self-healing of drying shrinkage cracks in cement-based materials incorporating reactive MgO. Smart Mater. Struct. 2016, 25, 084004. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; De Belie, N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Constr. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Alghamri, R.; Kanellopoulos, A.; Al-Tabbaa, A. Impregnation and encapsulation of lightweight aggregates for self-healing concrete. Constr. Build. Mater. 2016, 124, 910–921. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Qureshi, T.S.; Al-Tabbaa, A. Glass encapsulated minerals for self-healing in cement based composites. Constr. Build. Mater. 2015, 98, 780–791. [Google Scholar] [CrossRef]

- Kashif Ur Rehman, S.; Mahmood, F.; Jameel, M.; Riaz, N.; Javed, M.; Salmi, A.; Awad, Y. A Biomineralization, Mechanical and Durability Features of Bacteria-Based Self-Healing Concrete—A State of the Art Review. Crystals 2022, 12, 1222. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Tsangouri, E.; Van Hemelrijck, D.; De Belie, N. The efficiency of self-healing concrete using alternative manufacturing procedures and more realistic crack patterns. Cem. Concr. Compos. 2015, 57, 142–152. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Ding, W.; Liu, Y.; Zhang, J.; Han, N.; Xing, F. Self-healing features in cementitious material with urea–formaldehyde/epoxy microcapsules. Constr. Build. Mater. 2016, 106, 608–617. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Shui, Z. Feasibility of self-healing in cementitious materials—By using capsules or a vascular system? Constr. Build. Mater. 2014, 63, 108–118. [Google Scholar] [CrossRef]

- Maes, M.; Van Tittelboom, K.; De Belie, N. The efficiency of self-healing cementitious materials by means of encapsulated polyurethane in chloride containing environments. Constr. Build. Mater. 2014, 71, 528–537. [Google Scholar] [CrossRef]

- Ryu, J.-S.; Otsuki, N. Crack closure of reinforced concrete by electrodeposition technique. Cem. Concr. Res. 2002, 32, 159–164. [Google Scholar] [CrossRef]

- Hanna, J. Computational Modelling for the Effects of Capsular Clustering on Fracture of Encapsulation-Based Self-Healing Concrete Using XFEM and Cohesive Surface Technique. Appl. Sci. 2022, 12, 5112. [Google Scholar] [CrossRef]

- Sun, D.; Hu, J.; Zhu, X. Size optimization and self-healing evaluation of microcapsules in asphalt binder. Colloid Polym. Sci. 2015, 293, 3505–3516. [Google Scholar] [CrossRef]

- Yang, Z.; Hollar, J.; He, X.; Shi, X. A self-healing cementitious composite using oil core/silica gel shell microcapsules. Cem. Concr. Compos. 2011, 33, 506–512. [Google Scholar] [CrossRef]

- Dong, B.; Wang, Y.; Ding, W.; Li, S.; Han, N.; Xing, F.; Lu, Y. Electrochemical impedance study on steel corrosion in the simulated concrete system with a novel self-healing microcapsule. Constr. Build. Mater. 2014, 56, 1–6. [Google Scholar] [CrossRef]

- Hilloulin, B.; Van Tittelboom, K.; Gruyaert, E.; De Belie, N.; Loukili, A. Design of polymeric capsules for self-healing concrete. Cem. Concr. Compos. 2015, 55, 298–307. [Google Scholar] [CrossRef]

- Li, W.; Zhu, X.; Zhao, N.; Jiang, Z. Preparation and Properties of Melamine Urea-Formaldehyde Microcapsules for Self-Healing of Cementitious Materials. Materials 2016, 9, 152. [Google Scholar] [CrossRef]

- Li, X.; Li, M.; Song, G. Energy-dissipating and self-repairing SMA-ECC composite material system. Smart Mater. Struct. 2015, 24, 025024. [Google Scholar] [CrossRef]

- Sherif, M.M.; Khakimova, E.M.; Ozbulut, O.E.; Harris, D.K.; Ozyildirim, H.C. Behavior of mortar beams with randomly distributed superelastic shape memory alloy fibers. J. Intell. Mater. Syst. Struct. 2018, 29, 684–695. [Google Scholar] [CrossRef]

- Wang, X.F.; Yang, Z.H.; Fang, C.; Han, N.X.; Zhu, G.M.; Tang, J.N.; Xing, F. Evaluation of the mechanical performance recovery of self-healing cementitious materials—Its methods and future development: A review. Constr. Build. Mater. 2019, 212, 400–421. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Kanellopoulos, A.; Al-Tabbaa, A. Encapsulation of expansive powder minerals within a concentric glass capsule system for self-healing concrete. Constr. Build. Mater. 2016, 121, 629–643. [Google Scholar] [CrossRef]

- Teall, O.; Pilegis, M.; Davies, R.; Sweeney, J.; Jefferson, T.; Lark, R.; Gardner, D. A shape memory polymer concrete crack closure system activated by electrical current. Smart Mater. Struct. 2018, 27, 075016. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Moretti, F.; Roig Flores, M.; Serna Ros, P. Effects of autogenous healing on the recovery of mechanical performance of High Performance Fibre Reinforced Cementitious Composites (HPFRCCs): Part 1. Cem. Concr. Compos. 2017, 83, 76–100. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Moretti, F. Autogenous healing on the recovery of mechanical performance of High Performance Fibre Reinforced Cementitious Composites (HPFRCCs): Part 2—Correlation between healing of mechanical performance and crack sealing. Cem. Concr. Compos. 2016, 73, 299–315. [Google Scholar] [CrossRef]

- Siad, H.; Alyousif, A.; Keskin, O.K.; Keskin, S.B.; Lachemi, M.; Sahmaran, M.; Hossain, K.M.A. Influence of limestone powder on mechanical, physical and self-healing behavior of Engineered Cementitious Composites. Constr. Build. Mater. 2015, 99, 1–10. [Google Scholar] [CrossRef]

- Özbay, E.; Şahmaran, M.; Lachemi, M.; Yücel, H.E. Self-healing of microcracks in high-volume fly-ash-incorporated engineered cementitious composites. ACI Mater. J. 2013, 110, 33–43. [Google Scholar] [CrossRef]

- Neves, A.; Almeida, J.A.P.P.; Miranda, T.; Cunha, V.M.C.F.; Pereira, E. Self-healing assessment and variability in plain and recycled tyre fiber reinforced concrete based on tensile splitting test. J. Build. Eng. 2024, 84, 108567. [Google Scholar] [CrossRef]

- Choi, S.-G.; Wang, K.; Wen, Z.; Chu, J. Mortar crack repair using microbial induced calcite precipitation method. Cem. Concr. Compos. 2017, 83, 209–221. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Pang, S.D. Healing cement mortar by immobilization of bacteria in biochar: An integrated approach of self-healing and carbon sequestration. Cem. Concr. Compos. 2018, 86, 238–254. [Google Scholar] [CrossRef]

- Bhaskar, S.; Anwar Hossain, K.M.; Lachemi, M.; Wolfaardt, G.; Otini Kroukamp, M. Effect of self-healing on strength and durability of zeolite-immobilized bacterial cementitious mortar composites. Cem. Concr. Compos. 2017, 82, 23–33. [Google Scholar] [CrossRef]

- Bundur, Z.B.; Kirisits, M.J.; Ferron, R.D. Use of pre-wetted lightweight fine expanded shale aggregates as internal nutrient reservoirs for microorganisms in bio-mineralized mortar. Cem. Concr. Compos. 2017, 84, 167–174. [Google Scholar] [CrossRef]

- De Nardi, C.; Cecchi, A.; Ferrara, L.; Benedetti, A.; Cristofori, D. Effect of age and level of damage on the autogenous healing of lime mortars. Compos. Part B Eng. 2017, 124, 144–157. [Google Scholar] [CrossRef]

- Hung, C.-C.; Su, Y.-F. Medium-term self-healing evaluation of Engineered Cementitious Composites with varying amounts of fly ash and exposure durations. Constr. Build. Mater. 2016, 118, 194–203. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Li, V.; Su, H.; Gu, C. Durability study on engineered cementitious composites (ECC) under sulfate and chloride environment. Constr. Build. Mater. 2017, 133, 171–181. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q. Self-healing ability of Engineered Cementitious Composites (ECC) under different exposure environments. Constr. Build. Mater. 2017, 156, 142–151. [Google Scholar] [CrossRef]

- Deng, H.; Liao, G. Assessment of influence of self-healing behavior on water permeability and mechanical performance of ECC incorporating superabsorbent polymer (SAP) particles. Constr. Build. Mater. 2018, 170, 455–465. [Google Scholar] [CrossRef]

- Ranade, R.; Zhang, J.; Lynch, J.P.; Li, V.C. Influence of micro-cracking on the composite resistivity of Engineered Cementitious Composites. Cem. Concr. Res. 2014, 58, 1–12. [Google Scholar] [CrossRef]

- Ahn, E.; Kim, H.; Sim, S.-H.; Shin, S.; Shin, M. Principles and Applications of Ultrasonic-Based Nondestructive Methods for Self-Healing in Cementitious Materials. Materials 2017, 10, 278. [Google Scholar] [CrossRef] [PubMed]

- Ferrara, L.; Krelani, V.; Carsana, M. A “fracture testing” based approach to assess crack healing of concrete with and without crystalline admixtures. Constr. Build. Mater. 2014, 68, 535–551. [Google Scholar] [CrossRef]

- Fraunhofer-Gesellschaft. Speedy Analysis of Steel Fiber Reinforced Concrete. Available online: https://www.fraunhofer.de/en/press/research-news/2013/november/speedy-analysis-of-steel-fiber.html (accessed on 7 July 2025).

- Zhang, P.; Dai, Y.; Ding, X.; Zhou, C.; Xue, X.; Zhao, T. Self-healing behaviour of multiple microcracks of strain hardening cementitious composites (SHCC). Constr. Build. Mater. 2018, 169, 705–715. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; Hernandez-Sanabria, E.; Boon, N.; de Belie, N. Enhanced crack closure performance of microbial mortar through nitrate reduction. Cem. Concr. Compos. 2016, 70, 159–170. [Google Scholar] [CrossRef]

- Luo, M.; Qian, C.; Li, R. Factors affecting crack repairing capacity of bacteria-based self-healing concrete. Constr. Build. Mater. 2015, 87, 1–7. [Google Scholar] [CrossRef]

- Wang, X.; Fang, C.; Li, D.; Han, N.; Xing, F. A self-healing cementitious composite with mineral admixtures and built-in carbonate. Cem. Concr. Compos. 2018, 92, 216–229. [Google Scholar] [CrossRef]

- Rong, H.; Wei, G.; Ma, G.; Zhang, Y.; Zheng, X.; Zhang, L.; Xu, R. Influence of bacterial concentration on crack self-healing of cement-based materials. Constr. Build. Mater. 2020, 244, 118372. [Google Scholar] [CrossRef]

- Tang, W.; Kardani, O.; Cui, H. Robust evaluation of self-healing efficiency in cementitious materials—A review. Constr. Build. Mater. 2015, 81, 233–247. [Google Scholar] [CrossRef]

- Tan, L.; Ke, X.; Li, Q.; Gebhard, S.; Ferrandiz-Mas, V.; Paine, K.; Chen, W. The effects of biomineralization on the localised phase and microstructure evolutions of bacteria-based self-healing cementitious composites. Cem. Concr. Compos. 2022, 128, 104421. [Google Scholar] [CrossRef]

- Ahmad, I.; Shokouhian, M.; Cheng, H.; Radlińska, A. Enhancement of Mechanical Properties and Freeze–Thaw Durability of Recycled Aggregate Concrete using Aggregate Pretreatment. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 3605–3629. [Google Scholar] [CrossRef]

- Cheng, H.; Ahmad, I.; Shokouhian, M.; Radlińska, A. Enhancing flexural fatigue performance of recycled aggregate concrete under freeze–thaw cycles through aggregate and cement matrix modification: Effects, prediction models, and mechanisms. Constr. Build. Mater. 2025, 481, 141571. [Google Scholar] [CrossRef]

- Yan, Y.; Jia, G.; Zhang, Y.; Gao, Y.; Li, Z. The influence of expanded perlite as a bio-carrier on the freeze–thaw properties of self-healing concrete. Constr. Build. Mater. 2023, 409, 133891. [Google Scholar] [CrossRef]

- Li, S.; Wu, B.; Jiang, C.; Wu, L. Study on the damage mechanism of hydraulic concrete under the alternating action of freeze-thaw and abrasion. Constr. Build. Mater. 2024, 447, 137976. [Google Scholar] [CrossRef]

- Sharma, M.; Satyam, N.; Reddy, K.R. Effect of freeze-thaw cycles on engineering properties of biocemented sand under different treatment conditions. Eng. Geol. 2021, 284, 106022. [Google Scholar] [CrossRef]

- Oyunbileg, D.; Amgalan, J.; Batbaatar, T.; Temuujin, J. Evaluation of thermal and freeze-thaw resistances of the concretes with the silica fume addition at different water-cement ratio. Case Stud. Constr. Mater. 2023, 19, e02633. [Google Scholar] [CrossRef]

- Nosouhian, F.; Mostofinejad, D.; Hasheminejad, H. Concrete Durability Improvement in a Sulfate Environment Using Bacteria. J. Mater. Civ. Eng. 2016, 28, 04015064. [Google Scholar] [CrossRef]

- Achal, V.; Mukerjee, A.; Sudhakara Reddy, M. Biogenic treatment improves the durability and remediates the cracks of concrete structures. Constr. Build. Mater. 2013, 48, 1–5. [Google Scholar] [CrossRef]

- Xu, J.; Yao, W.; Jiang, Z. Non-Ureolytic Bacterial Carbonate Precipitation as a Surface Treatment Strategy on Cementitious Materials. J. Mater. Civ. Eng. 2014, 26, 983–991. [Google Scholar] [CrossRef]

- Phung, Q.T.; Maes, N.; De Schutter, G.; Jacques, D.; Ye, G. Determination of water permeability of cementitious materials using a controlled constant flow method. Constr. Build. Mater. 2013, 47, 1488–1496. [Google Scholar] [CrossRef]

- Siddique, R.; Nanda, V.; Kunal; Kadri, E.-H.; Iqbal Khan, M.; Singh, M.; Rajor, A. Influence of bacteria on compressive strength and permeation properties of concrete made with cement baghouse filter dust. Constr. Build. Mater. 2016, 106, 461–469. [Google Scholar] [CrossRef]

- Li, M.; Zhu, X.; Mukherjee, A.; Huang, M.; Achal, V. Biomineralization in metakaolin modified cement mortar to improve its strength with lowered cement content. J. Hazard. Mater. 2017, 329, 178–184. [Google Scholar] [CrossRef]

- Sophia, M.; Sakthieswaran, N. Synergistic effect of mineral admixture and bio-carbonate fillers on the physico-mechanical properties of gypsum plaster. Constr. Build. Mater. 2019, 204, 419–439. [Google Scholar] [CrossRef]

- Van Belleghem, B.; Montoya, R.; Dewanckele, J.; Van den Steen, N.; De Graeve, I.; Deconinck, J.; Cnudde, V.; Van Tittelboom, K.; De Belie, N. Capillary water absorption in cracked and uncracked mortar—A comparison between experimental study and finite element analysis. Constr. Build. Mater. 2016, 110, 154–162. [Google Scholar] [CrossRef]

- Wagner, C.; Villmann, B.; Slowik, V.; Mechtcherine, V. Capillary absorption of cracked strain-hardening cement-based composites. Cem. Concr. Compos. 2019, 97, 239–247. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Ghorbel, E.; Fares, H.; Cousture, A. Bacterial self-healing of concrete and durability assessment. Cem. Concr. Compos. 2019, 104, 103340. [Google Scholar] [CrossRef]

- Yildirim, G.; Sahmaran, M.; Balcikanli, M.; Ozbay, E.; Lachemi, M. Influence of cracking and healing on the gas permeability of cementitious composites. Constr. Build. Mater. 2015, 85, 217–226. [Google Scholar] [CrossRef]

- Ahmad, I.; Shokouhian, M. Enhancing Concrete Pavement Durability with Recycled Steel Fiber Extracted from Waste Tire. In Proceedings of the International Conference on Transportation and Development 2024, Atlanta, GA, USA, 15–18 June 2024; American Society of Civil Engineers: Reston, VA, USA, 2024; pp. 293–305. [Google Scholar]

- Enayati, S.M.; Riahi, F.; Azizian, H. Experimental evaluation of effect of Polypropylene fibers on the mechanical properties of fiber concrete. Int. J. Innov. Sci. Eng. Technol. 2015, 2, 112–120. [Google Scholar] [CrossRef]

- Asheghi Mehmandari, T.; Shokouhian, M.; Zakeri Josheghan, M.; Mirjafari, S.A.; Fahimifar, A.; Jahed Armaghani, D.; Tee, K.F. Flexural properties of fiber-reinforced concrete using hybrid recycled steel fibers and manufactured steel fibers. J. Build. Eng. 2024, 98, 111069. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef]

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental Investigation of the Physical and Mechanical Properties of Sisal Fiber-Reinforced Concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef]

- Castillo-Lara, J.F.; Flores-Johnson, E.A.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Carrillo, J.G.; Gonzalez-Chi, P.I.; Li, Q.M. Mechanical Properties of Natural Fiber Reinforced Foamed Concrete. Materials 2020, 13, 3060. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Mu, M.; Liu, S.; DeFlorio, W.; Hao, L.; Wang, X.; Salazar, K.S.; Taylor, M.; Castillo, A.; Cisneros-Zevallos, L.; Oh, J.K.; et al. Influence of Surface Roughness, Nanostructure, and Wetting on Bacterial Adhesion. Langmuir 2023, 39, 5426–5439. [Google Scholar] [CrossRef]

- Mamo, G.; Mattiasson, B. Alkaliphiles: The Emerging Biological Tools Enhancing Concrete Durability; Springer: Cham, Switzerland, 2019; pp. 293–342. [Google Scholar]

- Hernandez, M. Using Self-Healing Concrete for Concrete Repairs on Aging Concrete Structures. In Reclamation, Managing Water in the West; Research and Development Office: Denver, CO, USA, 2016; Volume 31. [Google Scholar]

- Jonkers, H.M. Self Healing Concrete: A Biological Approach; Springer: Dordrecht, The Netherlands, 2007; pp. 195–204. [Google Scholar]

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-mineralized self-healing recycled aggregate concrete for sustainable infrastructure. Sci. Total Environ. 2020, 703, 135007. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, F.B. Up-Scaling the Production of Bacteria for Self-Healing Concrete Application. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2015. [Google Scholar]

- Silva, F.B.; Boon, N.; De Belie, N.; Verstraete, W. Industrial application of biological self-healing concrete: Challenges and economical feasibility. J. Commer. Biotechnol. 2015, 21, 31–38. [Google Scholar] [CrossRef]

- Tziviloglou, E.; Wiktor, V.; Jonkers, H.M.; Schlangen, E. Bacteria-based self-healing concrete to increase liquid tightness of cracks. Constr. Build. Mater. 2016, 122, 118–125. [Google Scholar] [CrossRef]

| Research Objective | Mineral Additives | Specimen Size | Reinforcement | Specimen Count | Additive Ratio | Curing Method | Type of Damage Test | Crack Sealing (%)/ Time | Conclusions | References |

|---|---|---|---|---|---|---|---|---|---|---|

| Investigates the self-healing potential of mortar using CSA and CA additives. Explores hydration and CaCO3 precipitation mechanisms. | CSA, CA, Fly Ash | Not specified | Galvanized wire mesh | 6 | Not specified | Water | Splitting Tensile Test | 150 μm in 28 days (M1); 200–250 μm (M2–M5); 400 μm (M6) | M6 achieved the best sealing performance. CA and CSA improved permeability and crack closure significantly. | [19] |

| Examines MgO and silica fume for self-healing composites, focusing on strength recovery and crack closure. | MgO, Silica, Fume | 50 mm cement paste cube | None | 4 | M0 (OPC), M1 (OPC + 5% SF), M2 (OPC + 5% MgO), M3 (OPC + 5% SF + 5% MgO) | Water | Compressive Strength Test | M3: 26% (28 days); MX: 46% (56 days) | Silica fume enhances strength. MgO promotes self-healing, especially in blends. | [28] |

| Studies crack width as an indicator of healing in mortars with fly ash, silica fume, and crystalline additives. | Fly Ash, Silica Fume, CA | 50 × 50 × 50 mm | Two 10 mm deformed bars | 4 | M1 (OPC only), M2 (30% FA), M3 (10% SF), M4 (1% CA) | Water | Splitting Test | CA: 80% in 7 days; SF: complete at 19 days (cracks 0.1–0.2 mm) | CA works best for small cracks, while SF is best for wider cracks. Performance depends on cracking age and additive type. | [20] |

| Evaluates self-healing using zeolite as an internal curing agent, enhancing compressive strength and sealing efficiency. | Zeolite, Fly Ash, Sky Cement | Not specified | PVA fibers | 5 | MZ_0% Zeolite, MZ_7.5%, MZ_15%, MZ_22.5%, MZ_30% | Wet/dry cycles | Splitting Tensile Test | Not available | Zeolite enhances strength and self-healing significantly in composites under wet/dry conditions. | [29] |

| Investigates CA effects on self-healing in normal-strength and high-performance fiber-reinforced cementitious composites. | CA, Microsilica | 500 × 100 × 50 mm (NSC Size); 500 × 100 × 30 mm (HPFRCC size) | None (NSC); dispersed straight steel fibers (HPFRCC) | 4 | NCS1 (No CA), NCS2 (CA), HPFRCC1 (No CA), HPFRCC2 (CA) | Water, open air | Bending Tests | NCS (60%) under air exposure; HPFRCC showed higher recovery | CA improves sealing and mechanical recovery in both normal and high-performance composites. Fiber-CAs synergistically enhance performance. | [30] |

| Additive | Mechanism of Autogenous Healing | Effects on Concrete Properties | Effectiveness in Healing | References |

|---|---|---|---|---|

| Calcium-based minerals (e.g., calcium hydroxide, calcium carbonate, calcium sulfoaluminate) | Enhances self-healing by reacting with CO2 and water to form healing compounds (CaCO3). | Improves crack sealing, enhances durability, and reduces permeability. | Effective for healing cracks up to 0.5 mm, particularly in wet environments. | [41] |

| Crystalline admixtures (CAs) | Reacts with moisture and unhydrated cement particles to form insoluble crystals (C-S-H and CaCO3), filling cracks and reducing porosity. | Improves crack closure (up to 0.4 mm), enhances strength, reduces water permeability, and ensures long-term durability. | Effective in healing cracks up to 0.4 mm and continues healing in the presence of water. | [48,49,53,54] |

| Silica fume | Promotes the formation of additional C-S-H, refining microstructure and sealing cracks. Works well in combination with MgO. | Improves durability, reduces permeability, and enhances self-healing of small cracks (<0.3 mm). | Best for small cracks (<0.3 mm). Helps enhance matrix densification. | [50,51,55] |

| Fly ash | Rich in silica and alumina, it combines with calcium hydroxide to produce more C-S-H, which densifies the concrete matrix. | Enhances crack healing, improves durability, reduces water absorption, and supports bacterial activity for self-healing. | Moderately effective in improving long-term healing and reducing porosity. | [51,52] |

| Magnesium oxide (MgO) | Expands upon hydration, forming MgO, which fills cracks and voids. Works synergistically with silica fume and fly ash. | Improves autogenous healing, reduces shrinkage, and enhances long-term durability. However, it may slightly reduce initial strength. | Moderate to high effectiveness. Works best in moist conditions. Effective in reducing shrinkage cracks. | [50,56,57] |

| Ground granulated blast furnace slag (GGBFS) | Enhances latent hydraulic activity, contributing to crack closure. | Improves durability and sulfate resistance. | Enhances self-healing over extended periods, particularly in humid environments. | [58] |

| Superabsorbent polymers (SAPs) | Retains water to promote continuous hydration and healing. | Improves internal curing, reduces shrinkage, and enhances self-healing. | Moderate to high effectiveness. Works best in cyclic wet/dry conditions. Enhances healing of cracks up to 0.4 mm. | [56,57] |

| Bacillus Bacterial Strains | Advantages | References |

|---|---|---|

| B. cereus | Adapts to harsh environmental conditions, such as high pH and temperature. Enhances crack healing and reduces water permeability. | [51,83] |

| L. sphaericus | Precipitates CaCO3, leading to strength gain and reduced water absorption. Forms resilient endospores under extreme conditions. | [82,84,85] |

| B. subtilis | Exhibits high urease activity up to pH 9. Produces constant CaCO3 and withstands harsh environmental conditions. | [52,86] |

| S. pasteurii | Exhibits high efficiency in urea hydrolysis, making it highly effective in CaCO3 precipitation. | [77,78] |

| Bacterial Species | References |

|---|---|

| Bacillus | [15,79,98,99] |

| L. sphaericus | [86,100,101] |

| B. pasteurii | [81,102] |

| B. subtilis | [103] |

| B. megaterium | [104,105] |

| S. pasteurii | [102,106,107] |

| B. cereus | [51,83,108] |

| Bacteria Strain Used | Best Result | Concentration | References |

|---|---|---|---|

| B. subtilis | 12% improvement in compressive strength compared to controlled lightweight aggregate concrete. | 2.8 × 108 cells/mL | [103] |

| B.megaterium | Maximum strength development of 24% achieved in 50 MPa concrete. | 30 × 105 cells/mL | [104] |

| S. pasteurii and L. sphaericus | Sealed cracks and recovered compressive strength in damaged specimens. | 108 cells/mL | [111] |

| B. megaterium | Improved compressive, split tensile, and flexural strength in fly ash concrete. | 105 cells/mL | [112] |

| S. pasteurii | 35% increase in compressive strength compared to control concrete. | 105 cells/mL | [114] |

| B. aerius | Increase in compressive strength by 11.8% in bacterial concrete compared to control with 10% dosage of rice husk ash. | 105 cells/mL | [115] |

| Carrier Material | Microorganism | Crack Healing | References |

|---|---|---|---|

| Bacteria immobilized in silica gel | L. sphaericus | Crack width of 0.3 mm and depths of 10.0 and 20.0 mm | [123] |

| Spores with calcium lactate are embedded in expanded clay | B. alkalinitrilicus | Crack width ranging from 0.05 to 1.0 mm | [126] |

| Hydrogel-encapsulated spores with nutrients and calcium source | L. sphaericus | Crack width of 0.5 mm | [127] |

| Bacteria externally applied on cracked concrete structures | B. cohnii | Crack width ranging 0.1–0.4 mm | [128] |

| Spores encapsulated in microcapsules | L. sphaericus | Maximum crack width healed is 0.97 mm | [80] |

| Approaches | Test | Assessments | References |

|---|---|---|---|

| Visual Appearance | X-ray diffraction (XRD) | Chemical composition of healing substances | [48,143,144] |

| X-ray computed tomography (XCT) | 3D visualization of crack healing | [145,146] | |

| Environmental scanning electron microscopy (ESEM) | Surface morphology; microstructure of the healing substance | [147] | |

| Scanning electron microscope (SEM) | [144,148,149,150] | ||

| Image analysis and camera/optical microscope | Rate of healing and crack characterization | [144,145,150,151,152] | |

| Isothermal calorimetry | Hydration procedure | [48,153] | |

| Transmission electron microscopy (TEM) | Healing material morphology | [153] | |

| Durability Enhancement | Sorptivity test/capillary water absorption test | Water tightness | [154,155] |

| Water permeability test | Water tightness | [139,146,147,156,157] | |

| Ultrasonic pulse velocity test | Degree of damage | [96,158,159] | |

| Gas permeability | Gas tightness | [152,155] | |

| Corrosion test and chloride diffusion test | Resistance to chloride incursion | [160] | |

| Rapid chloride permeability test | [113,144,158] | ||

| Electrochemical measurements | Electrodeposition E-passivity of steel bar | [161] | |

| Electrical impedance test | Microstructural characteristics | [144] | |

| Mechanical Properties Improvement | Compression test | Fragmentation of capsules with a cracking effect Generating new cracks as opposed to reopening old ones Strength, modulus, stiffness, fracture energy, and toughness all increased in the reloaded, healed specimen | [151,158,162] |

| Impact loading test | [137] | ||

| Fatigue test | [163,164] | ||

| Nanoscale mechanical measurements | [128] | ||

| Tensile test | [145,148,165] | ||

| Three-point bending test | [153,154,166,167] | ||

| Dynamic mechanical analysis | [166] | ||

| Four-point bending test | [128,151] | ||

| Cyclic four-point bending test | [168,169] | ||

| Bond strength test | Bond strength between capsules and matrix | [166] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Owolabi, D.O.; Shokouhian, M.; Ahmad, I.; Jenkins, M.; McLemore, G.L. Comparative Analysis of Autogenous and Microbial-Based Calcite Precipitation in Concrete: State-of-the-Art Review. Buildings 2025, 15, 3289. https://doi.org/10.3390/buildings15183289

Owolabi DO, Shokouhian M, Ahmad I, Jenkins M, McLemore GL. Comparative Analysis of Autogenous and Microbial-Based Calcite Precipitation in Concrete: State-of-the-Art Review. Buildings. 2025; 15(18):3289. https://doi.org/10.3390/buildings15183289

Chicago/Turabian StyleOwolabi, David O., Mehdi Shokouhian, Izhar Ahmad, Marshell Jenkins, and Gabrielle Lynn McLemore. 2025. "Comparative Analysis of Autogenous and Microbial-Based Calcite Precipitation in Concrete: State-of-the-Art Review" Buildings 15, no. 18: 3289. https://doi.org/10.3390/buildings15183289

APA StyleOwolabi, D. O., Shokouhian, M., Ahmad, I., Jenkins, M., & McLemore, G. L. (2025). Comparative Analysis of Autogenous and Microbial-Based Calcite Precipitation in Concrete: State-of-the-Art Review. Buildings, 15(18), 3289. https://doi.org/10.3390/buildings15183289